Truvox Orbis OB431500, Orbis OB501500 User Instructions

1

User instructions

Orbis - OB431500, OB501500

Mains powered floor burnishers

03-8229-0000 Iss.1

CAUTION

–

READ THESE INSTRUCTIONS BEFORE USING THE MACHINE

ORIGINAL INSTRUCTIONS

2

Contents

Diagrams...........................................................................................................................................3

1 Product Information....................................................................................................................4

1.1 Important Safety Advice...................................................................................................4

1.2 Guidelines for the operator...............................................................................................4

1.3 Transporting the machine................................................................................................5

1.4 Symbols & Markings........................................................................................................5

2 Preparing for use.......................................................................................................................5

2.1 Electrical connection........................................................................................................5

3 Preparing for use.......................................................................................................................6

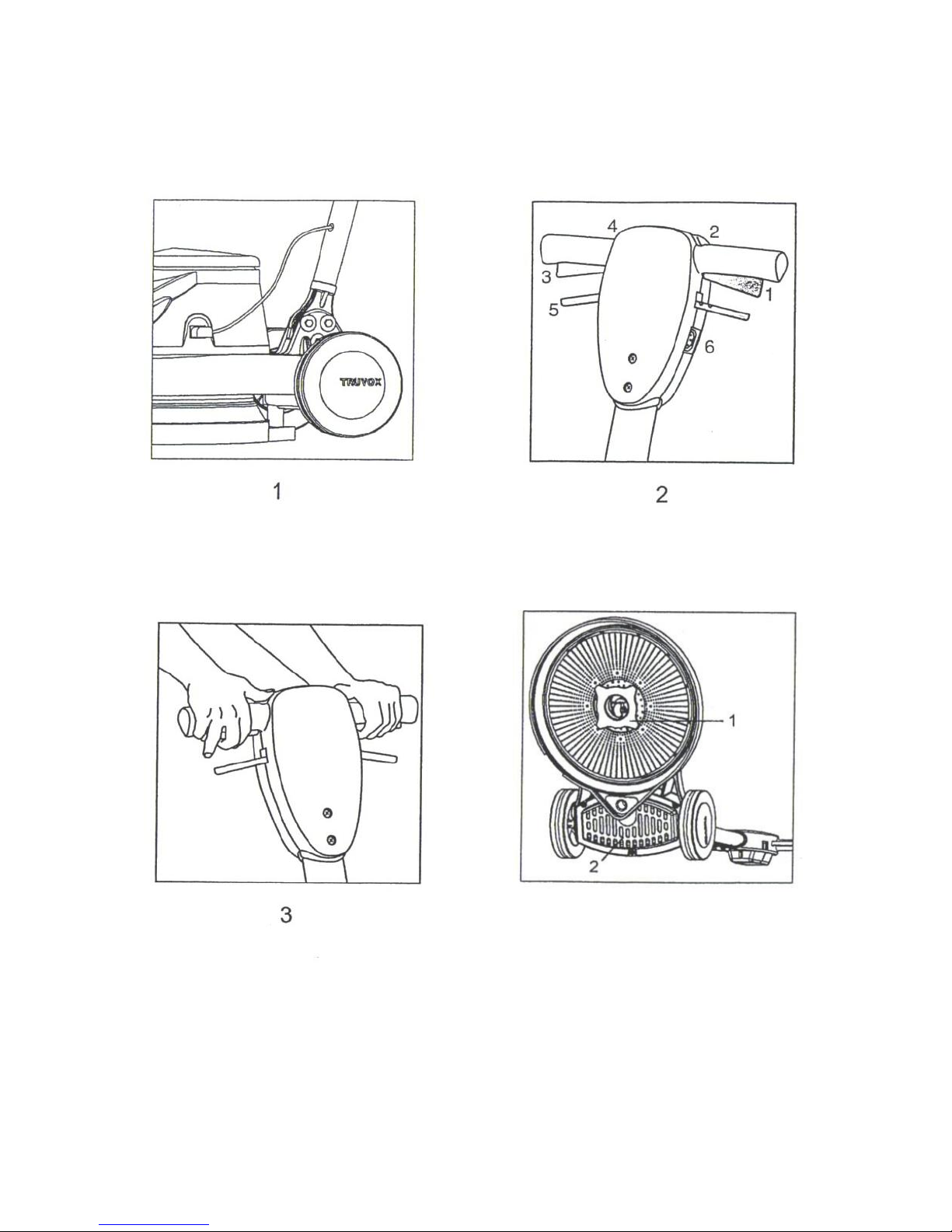

3.1 Fitting the handle.............................................................................................................6

4 Controls.....................................................................................................................................6

5 Fitting pads................................................................................................................................6

6 Adjusting the handle height........................................................................................................6

7 Operation...................................................................................................................................6

7.1 Starting the machine........................................................................................................6

7.2 Polishing..........................................................................................................................6

8 Storage......................................................................................................................................7

9 Maintenance..............................................................................................................................7

10 After Sales Service....................................................................................................................7

11 Guarantee.................................................................................................................................7

12 Waste Electrical & Electronic Equipment (WEEE)......................................................................7

13 Technical specification...............................................................................................................8

14 Accessories...............................................................................................................................8

15 Fault diagnosis...........................................................................................................................9

16 Parts Lists & Diagrams.............................................................................................................10

17 Base wiring diagram................................................................................................................21

18 Handle wiring diagram.............................................................................................................22

19 Declaration of Conformity.........................................................................................................23

3

Diagrams

4

4

IMPORTANT

BEFORE USE READ THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCE

1 Product Information

These commercial floor treatment machines are

designed for the high speed polishing and

burnishing of hard floors in indoor areas. A

passive dust control system is supplied as

standard with each model.

This machine must only be used for the

manufacturer’s approved application. Do not

use the machine where it is suspected that the

carpet, floor or upholstery contains health

endangering dust or debris such as asbestos or

chemical waste. If this is suspected do not

proceed, contact your supervisor, supplier or

Truvox International for advice.

The following instructions contain important

information about the machine and safety advice

for the operator.

Equipment must be operated, serviced and

maintained in accordance with the

manufacturer’s instructions. If in doubt contact

the supplier of your machine.

NOTE - To protect the machine from possible

damage during transit, the machine base and

handle are packed seperately. Ensure that both

items are present and follow the simple assembly

instructions to bring the machine into service.

These instructions are valid for the following

models:

OB431500, OB501500

1.1 Important Safety Advice

When using electrical equipment basic safety

precautions should be followed including the

following.

• Read all instructions carefully before use.

• This appliance is suitable for commercial use,

for example in hotels, schools, hospitals,

factories, shops, offices and rental businesses.

• This machine is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the machine by a person

responsible for their safety.

• Keep children and unauthorised persons away

from the machine when in use.

• Before using the appliance, check that the

mains power voltage corresponds with the

voltage shown on the rating plate.

• All parts are to be positioned as indicated in the

instructions before using the machine.

• Do not operate the machine if it malfunctions or

is damaged in any way. Contact an authorised

service agent for repair or adjustment.

• Do not operate switches or touch the mains

plug with wet hands as this may cause electric

shock.

• When unplugging pull the plug, not the supply

cord.

• Do not pull or carry by cord, use cord as a

handle, close a door on cord, or pull around

sharp edges or corners.

• Keep hair, loose clothing, fingers and all parts

of body away from openings and moving parts.

• Keep cord away from heated surfaces.

• Do not use where hazardous dust is present.

• Do not use in an explosive atmosphere.

• Do not pick up oil or other flammable material.

• Do not use to pick up moisture or any liquids.

• Do not leave the machine connected to the

electricity supply when not in use, always

remove the plug from the socket-outlet.

• Switch off the machine before removing the

plug.

• Keep the power supply cord clear of moving

parts. During operation hazard may occur

when running the machine over the power

supply cord.

• The power supply cord must be regularly

inspected for signs of damage. If the power

supply cord is damaged, it shall only be

replaced by the manufacturer, its service agent

or a similar qualified person in order to avoid a

hazard.

• Only replace the supply cord with the type

specified in the instruction manual.

• Do not operate the machine with a damaged

supply cord or plug, or after the machine

malfunctions or is damaged in any way.

Contact an authorised Service Agent for repair

or adjustment.

• The plug of the power supply cord must be

removed from the socket-outlet before

commencing cleaning of the machine or

undertaking maintenance operations.

• Do not kink or twist the power cord.

• Take care when using a machine near the top

of stairs to avoid overbalancing.

1.2 Guidelines for the operator

WARNING

Operators must be fully trained in the use

of the machine in accordance with these

instructions, able to perform user maintenance

and the correct selection of accessories.

• Operators should be physically capable to

manoeuvre, transport and operate the

machine.

5

• Operators should be able to recognise unusual

operation of the machine and report any

problems.

• Only use the machine on firm level surfaces.

• Wear suitable footwear to avoid slipping.

• Wear suitable clothing to keep dry and warm.

• Where possible implement job rotation and

adequate rest periods to avoid continuous use

of the same muscles.

• Do not leave machine running unattended

• Do not smoke when using the machine.

• Do not put any objects into openings. Do not

use with any opening blocked: keep free of

dust, debris, hair, or anything that may reduce

air flow.

WARNING This machine is for dry use

only.

CAUTION - This machine is for indoor

use only and should not be used or

stored outdoors or in wet conditions.

CAUTION - If it is suspected that there is

hazardous dust or flammable materials

stop cleaning the area immediately and

consult your superior.

WARNING Only use accessories and

spare parts provided with the machine or

those approved by the manufacturer.

The use of other accessories may impair

the safety of the machine.

• Ensure the machine is switched off before

adding or changing accessories.

1.3 Transporting the machine

CAUTION – Incorrect lifting techniques

may result in personal injury, where

applicable do not lift large and heavy

machines without assistance. We advise that the

manual handling regulations are followed.

Please refer to the technical table for details on

weight of machine.

When transporting the machine ensure that all

components, tanks and removable parts are

securely fastened, and that the supply cord and

plug are not trailing. Detach hose and wand from

machine where applicable.

Take extreme care when moving the machine up

or down steps or stairs.

1.4 Symbols & Markings

WARNING

WARNING – READ THESE

INSTRUCTIONS BEFORE

USING MACHINE

Earth symbol

2 Preparing for use

2.1 Electrical connection

Before connecting the machine to the power

supply, check that your supply voltage

corresponds with that marked on the rating label.

The power supply cord plus any extension leads

should not exceed 30m in total, otherwise you

may experience problems starting up the

machine. The cross-section of any extension

cable wiring must be at least 2,5 mm².

Should an extension cord be used, ensure cord

rating is adequate for the equipment. Do not use

extension cord in coiled condition as this could

result in overheating of the cord.

UK only

The supply cord for 230v models is fitted with a

plug containing a 13 amp fuse. Should the fuse

require replacement it must only be replaced by a

13 amp fuse conforming to BS1362, and the fuse

cover must be refitted. If the fuse cover is lost the

plug must not be used until the correct

replacement cover is fitted.

IMPORTANT - If the supply cord is damaged, it

must only be replaced by a special cord available

from the manufacturer or an authorised service

agent.

WARNING – THIS APPLIANCE MUST BE

EARTHED

6

3 Preparing for use

3.1 Fitting the handle

1. Carefully remove the machine base and

handle from their respective packaging.

2. Check that the following items are present with

the base:-

- Vacuum skirt

- Dust bag

- M8 x 70 Bolt (3)

- Nyloc Hex. nut (3)

- Plain washer (6)

- Spanner (2)

3. Take handle and remove tie from the knuckle

pivot, ensuring that toothed gear does not fall

out of housing when tie is removed.

4. With the handle held vertically and cable

winder to the rear, lower pivot between the

raised flanges on the machine base.

5. Align holes in pivot with those on the base and

fit the three M8 bolts, washers and nuts, and

tighten using the spanner and Allen key

supplied (Fig.1).

6. Connect supply lead from handle to socket on

side of motor housing.

4 Controls

The operating controls for all models are located

on the handle (Fig 2 ).

1 - Switch trigger, left hand

Used to switch motor ON and OFF. Can only

be operated with handle in working position,

and if left hand interlock button (2) has

previously been depressed

2 - Interlock button, left hand

This must be depressed initially to enable left

hand switch trigger to switch motor on.

3 - Switch trigger, right hand

Used to switch motor ON and OFF. Can only

be operated with handle in working position,

and if right hand interlock button (4) has

previously been depressed.

4 - Interlock button, right hand

This must be depressed initially to enable

right hand switch trigger to switch motor on.

5 - Handle adjustment lever

Used to adjust handle to comfortable working

height. Note: For safety reasons the machine

cannot be operated unless the handle is

moved to a working height.

Cable winder

Used to hold supply cord in place on handle

when machine is not in use.

Neon indicator (on handle)

• Lights when the machine is connected to the

power supply.

5 Fitting pads

WARNING - This appliance has been

designed for use with the pads

specified by the manufacturer. The

fitting of other pads may affect its

performance and safety.

Always ensure machine is unplugged before

fitting or removing parts.

• Raise cleaning head by pulling handle

backwards to rest on the floor.

• Unscrew central pad lock and remove with

washer.

• Press cleaning pad onto drive disc, refit

washer and pad lock and tighten (Fig 4).

• Return machine to upright position.

• IMPORTANT - Never allow the cleaning

head to rest on the pad when not in use.

6 Adjusting the handle height

Select the most comfortable handle height using

the adjustment lever as previously described (see

Controls) and lock in position.

7 Operation

7.1 Starting the machine

• Fully unwind the supply cord from the handle

and plug in to a convenient socket outlet. The

neon indicator on the handle should light

showing that power is available.

• With the handle set at a convenient working

height and with both left and right hands on the

handle, depress both interlock buttons with the

thumbs and squeeze both switch triggers to

start the machine (Fig 3).

• WARNING - Never start the machine

without pads fitted.

• Once the machine has started the push

buttons should be released. The machine will

operate with either or both of the switch

triggers held.

• To stop the machine release both switch

triggers.

• Normal movement of the machine is in a

forward and backward direction.

7.2 Polishing

• Fit pads suitable for the speed of the machine

and the surface to be polished.

• Apply polish to the floor in accordance with the

manufacturers instructions.

• Do not keep the machine rotating on one

spot for more than 5-10 seconds, as this

could cause overheating and damage the

floor surface.

7

8 Storage

• Always unplug the machine after use.

• Wrap the supply cord around the handlebar

and cable winder ensuring that the plug is not

trailing on the floor.

• The machine should normally be stored with

the handle in the fully upright position.

• Never store the machine with a pad fitted as

this causes distortion, and results in instability

during operation.

• Store the machine in a dry indoor area only.

9 Maintenance

WARNING - Before undertaking

maintenance operations or

adjustments switch off machine and

unplug from the electricity supply.

The machine requires minimum maintenance

apart from the following checks by a trained

operator.

• Supply cord - Regularly inspect sheath, plug

and cord anchorage for damage or loose

connection. Only replace the supply cord with

the type specified in these instructions.

• Passive vacuum unit - All dust bags must be

changed regularly, and hose checked for

blockage to avoid unsatisfactory results.

10 After Sales Service

Truvox machines are high quality machines that

have been tested for safety by authorised

technicians. It is always apparent that after longer

working periods, electrical and mechanical

components will show signs of wear and tear or

ageing.

Under extreme or specialised conditions and/or

insufficient maintenance, shorter maintenance

intervals are necessary. Use only original Truvox

spare parts. Use of other spare parts will

invalidate all warranty and liability claims.

Should you require after sales service please

contact the supplier from whom you purchased

the machine, who will arrange service. Repairs

and servicing of Truvox products should only be

performed by trained staff. Improper repairs can

cause considerable dangers to the user.

11 Guarantee

Your product is guaranteed for two year from the

date of original purchase, or hire purchase,

against defects in materials or workmanship

during manufacture. Within the guarantee period

we undertake at our discretion, to repair or

replace free of charge to the purchaser, any part

found to be defective, subject to the following

conditions.

CONDITIONS

1. Claims made under the terms of the

guarantee must be supported by the original

invoice/bill of sale issued at the time of sale,

or the machine Serial Number.

2. For claims under this guarantee contact the

supplier from whom you purchased the

product who will arrange the appropriate

action. Do not initially return the product as

this could result in transit damage.

3. Neither Truvox nor its distributors shall be

liable for any incidental or consequential loss.

4. This guarantee is governed by the laws of

England. This guarantee does not cover any

of the following: Periodic maintenance, and

repair or replacement of parts due to normal

wear and tear.

5. This guarantee is governed by the laws of

England. This guarantee does not cover any

of the following: Periodic maintenance, and

repair or replacement of parts due to normal

wear and tear.

• Damage caused by accident, misuse or

neglect, or the fitting of other than genuine

Truvox parts.

• Defects in other than genuine Truvox

parts, or repairs, modifications or

adjustments performed by other than a

Truvox service engineer or authorised

service agent.

• Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

• Consumable items and wear parts such as

drive belts.

This guarantee does not affect your statutory

rights, nor your rights against the supplier arising

from their sales or purchase contract.

12 Waste Electrical & Electronic Equipment

(WEEE)

Do not dispose of this device

with unsorted waste. Improper

disposal may be harmful to the

environment and human health.

Please refer to your local waste

authority for information on

return and collection systems in

your area.

8

13 Technical specification

All models : Class I construction. Enclosure to IPX0. Fitted with 20m supply cord type H05VVF 3x1.0mm² (10A), and non rewireable plug.

Model OB431500 OB501500

Working width cm 43 50

Pad diameter cm 43 50

Pad pressure gm/cm² 5.5 4

Voltage a.c. - 50Hz V 230 230

Voltage d.c. - 50/60Hz V

• •

Motor speed rpm 1500 1500

Motor rating W 1100 1100

Handle height cm 125 125

Weight kg 34 34.5

Noise level (Passive vacuum) (see note 1)

dB(A) 65 65

Handle vibration (see note 2)

m/s²

< 2.5 < 2.5

Vacuum bag capacity ltr 1 1

1 Noise levels measured at a distance of 0.25 metre from machine and 1,5 metres above

floor, when scrubbing a hard floor. Measurements recorded using a hand held meter.

2 Handle vibration does not exceed 2,5 m/s², when operating on any surface with brush or

pads.

Measurements recorded by an independent test laboratory

14 Accessories

Item

Part No.

OB431500

Part No.

OB501500

Part No.

OB502000

Vacuum skirt 05-3766-0000 05-3767-0000 05-3767-0000

Paper bag (5 pack) (passive system) 06-0207-0000

Micro filter cloth bag (passive system) 03-6703-0000

Dust collection box 03-6705-0000

IMPORTANT : Genuine accessories are only available from authorised Service Agents or

Truvox Customer Service Deptartment.

Loading...

Loading...