Truvox Multiwash MW240, Multiwash MW 340, Multiwash MW 340/PUMP, Multiwash MW440/PUMP, Battery Multiwash 340/Pump User Manual

...

1

ORIGINAL INSTRUCTIONS

CAUTION – READ THESE INSTRUCTIONS BEFORE USING

THE MACHINE

Multiwash

MW240, MW 340, MW 340/PUMP,

MW440/PUMP

USER MANUAL EN

MANUEL D'UTILISATION FR

GEBRAUCHSANLEITUNG DE

03-5977-0000 Issue 3 01-15

2

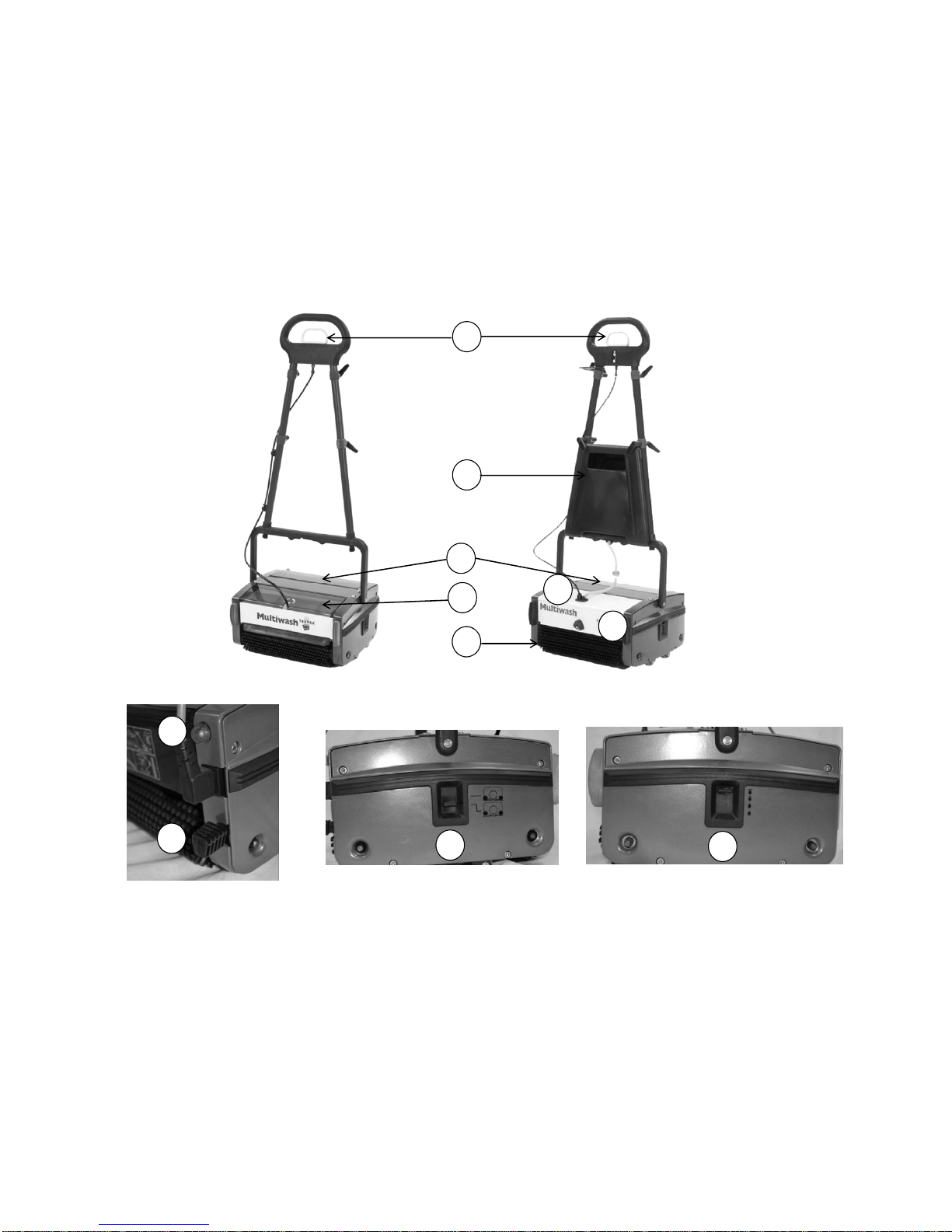

7 8 9 10

1

4 3 5 6 2

2

IMPORTANT

BEFORE USE READ THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCE

Introduction

The following instructions contain important information

about the machine and safety advice for the operator.

Equipment must be operated, serviced and maintained in

accordance with the manufacturer’s instructions. If in doubt

contact the supplier of your machine.

Read all instructions before using

the machine

Product information

The Multiwash floor cleaning machines are designed for use

on smooth, even floors in indoor areas. They can be used on

most floor surfaces including short-pile carpet, wood, PVC,

rubber and stone. They should not be used on rough uneven

surfaces. This machine is for indoor use only. The machine

is intended for commercial use, for example in hotels,

schools, hospitals, factories, shops, offices, rental

businesses and other than normal housekeeping purposes.

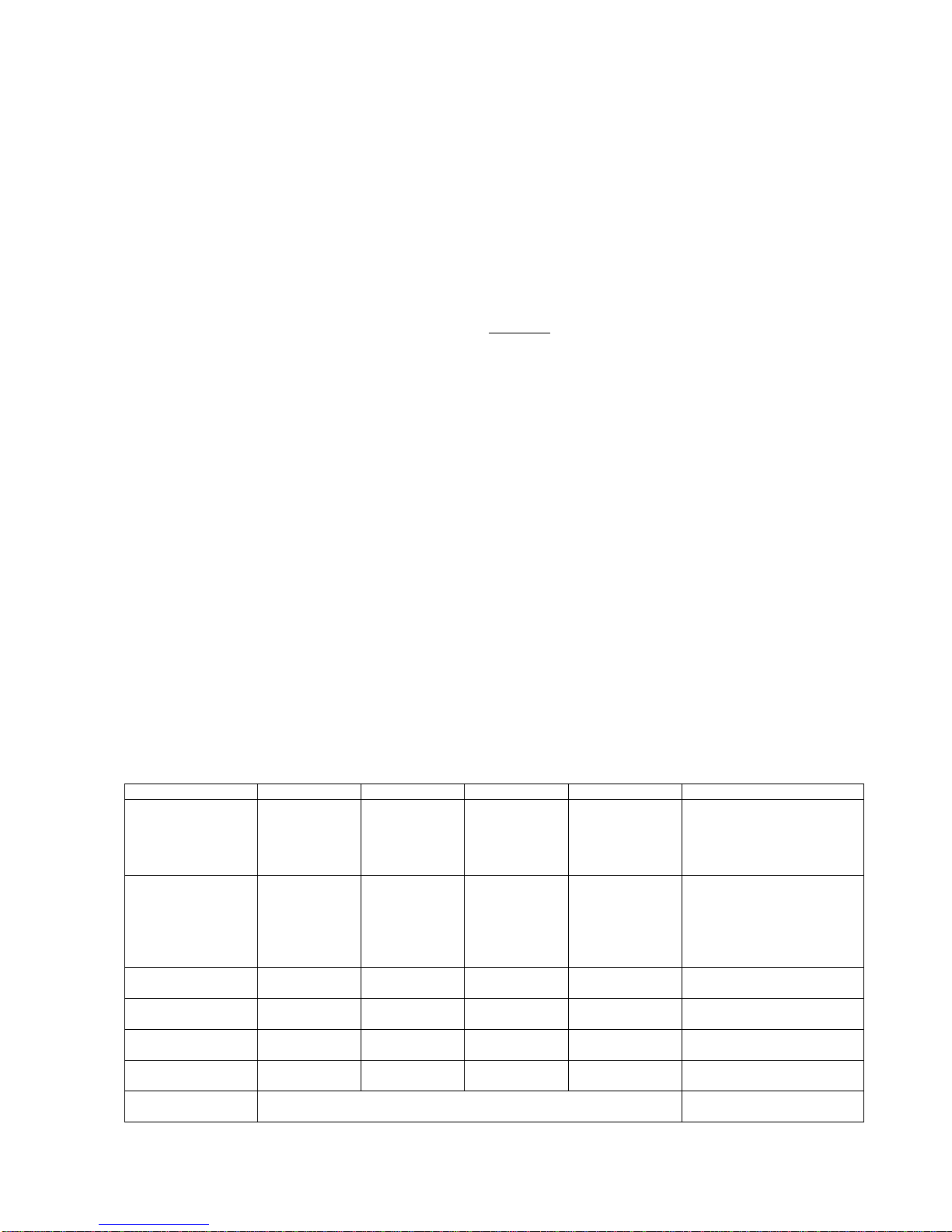

Technical Specifications

Model

Multiwash 240 Multiwash 340

Multiwash 340

(Pump)

Multiwash 440

(Pump)

Product Code

MW240 MW340 MW340/PUMP MW440/PUMP

Voltage AC (~)/ Frequency V/ Hz 230/ 50 230/ 50 230/ 50 230/ 50

Motor power (+ pump) W 400 600 600 + 26 1000 + 26

Productivity rate m²/h 650 930 930 1150

Solution tank capacity l 1.2 1.7 4 4

Brush width cm 24 34 34 44

Brush speed rpm 650 650 650 650

Brush pressure g/cm² 250 250 250 250

Sound pressure level dB(A) 68 69 69 71

Dimensions (L x W x H) cm 37.8 x 34 x 111.8 37.8 x 44 x 111.8 37.8 x 44 x 111.8 37.8 x 54 x 111.8

Weight kg 20 23 25 28

Cable length m 12 12 12 12

Warranty 1 year

•

Noise levels measured at a distance of 1 meter from machine and 1.6 metres above floor, when washing a hard floor.

Measurements recorded using a hand held meter.

• Handle vibration does not exceed 2.5 m/s², when operating on a smooth hard surface.

• Above dimensions are approx. Since the company’s policy is to continuously improve the product, there could be changes without

prior notice.

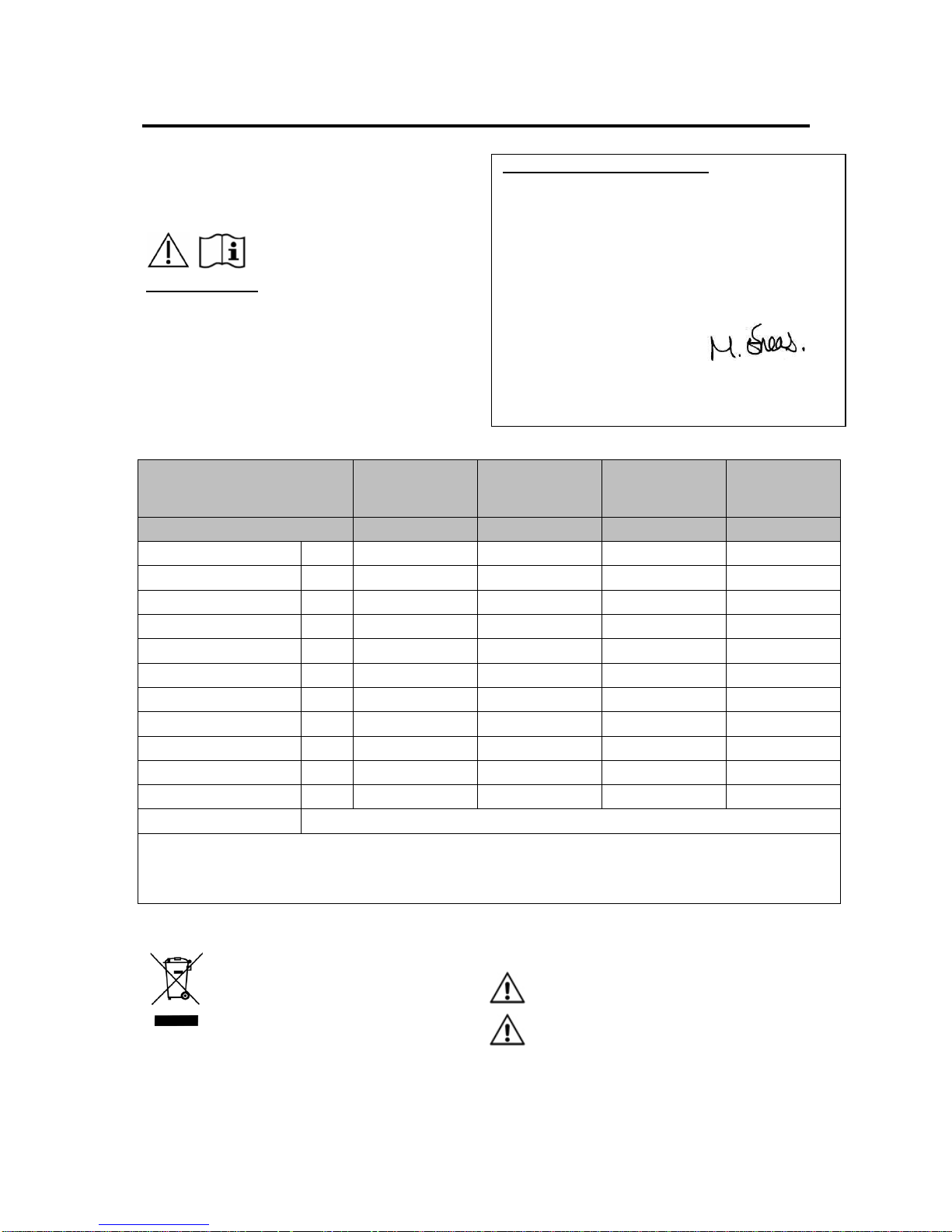

Waste Electrical & Electronic Equipment

(WEEE)

Do not dispose of this device with unsorted

waste. Improper disposal may be harmful to

the environment and human health. Please

refer to your local waste authority for

information on return and collection systems in

your area.

IMPORTANT SAFETY ADVICE

The safety information described in this manual provides

basic precautions and supplements standards in force in the

country where the machine is used.

This symbol warns the operator of hazards and

unsafe practices which could result in severe

personal injury or death.

WARNING – to reduce the risk of injury, electric

shock or fire.

1. This machine must only be used for the manufacturer’s

approved application as described in this manual.

2. The machine must be unpacked and assembled in

accordance with these instructions before connecting to

the electrical supply.

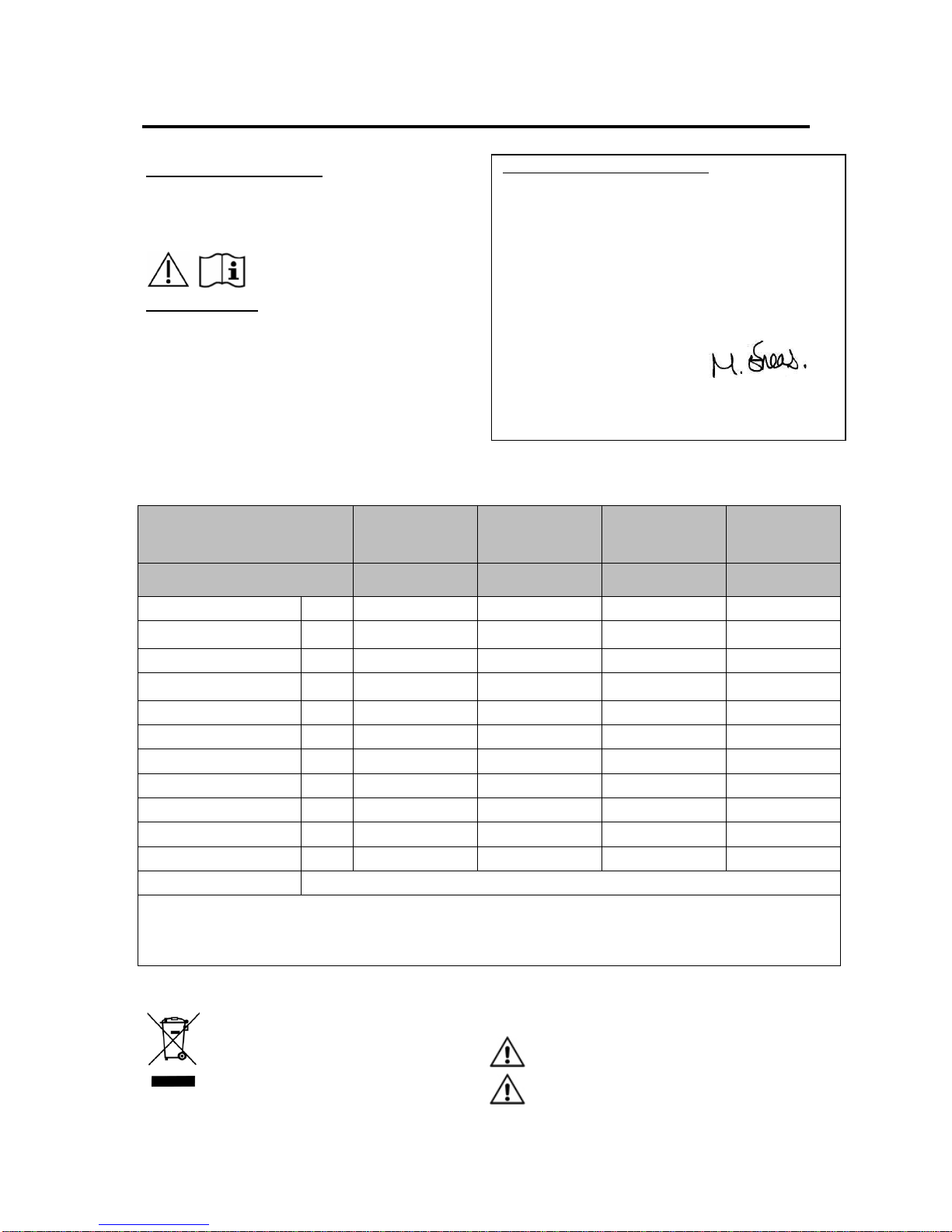

EC DECLA

RATION OF CONFORMITY

Machine Type: Floor Cleaning Machine

Model: MW240…, MW340…, MW340/PUMP…,

MW440/PUMP…

This machine is in conformity with the following EU directives:

• Machinery Directive: 2006/42/EC

• The EMC Directive: 2004/108/EC

Applied harmonised standards:

EN60335-1, EN60335-2-72, EN55014-1, EN55014-2,

EN61000-3-2, EN61000-3-3, EN62233

Truvox International Limited

Unit C (East), Hamilton Business Park,

Manaton Way, Botley Road, Malcolm Eneas

Hedge End, Southampton, Operations Manager

SO30 2JR, UK Southampton, 22/01/2015

3

3. Operators must be fully trained in the use of the machine

in accordance with these instructions, able to perform

regular user maintenance and the correct selection of

accessories.

4. Operators should be physically capable to manoeuvre,

transport and operate the machines.

5. Operators should be able to recognise unusual operation

of the machine and report any problems.

6. Only genuine accessories and spare parts provided with

the machine or those approved by the manufacturer

should be used. All repairs must be performed by a

qualified service agent.

7. Do not use without filters in place.

8. Do not modify the machine from its original design.

9. Only use the machine on firm level surfaces. DO NOT

use on a gradient or more than 2% slopes.

10. DO NOT use on rough uneven surfaces e.g. industrial or

coarse concrete surfaces.

11. DO NOT use outdoors e.g. on patios, decks or rough

surface.

12. WARNING Do not fill machines with water hotter than

40ºC

13. DO NOT use diesel/petrol or corrosive detergents to

wash floors, even if diluted.

14. This machine is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the machine by a person responsible

for their safety.

15. Keep children and unauthorised persons away from the

machine when in use. Do not use as a toy.

16. The machine must be kept clean and in good condition

with regular inspections of the battery charging lead and

plug for signs of any damage. If any parts are damaged

they shall only be replaced by an approved part by the

manufacturer, its service agent or a similar qualified

person in order to avoid a hazard.

ELECTRICAL HAZARD

17. CAUTION - This machine is for dry indoor use only and

should not be used or stored outdoors in wet conditions.

18. DO NOT use where hazardous dust is present.

19. DO NOT use in an explosive atmosphere.

20. DO NOT pick up or use near flammable or combustible

fluids, hazardous dusts or vapours.

21. CAUTION - If it is suspected that there is hazardous dust

or flammable materials stop cleaning the area

immediately and consult your superior.

22. DO NOT use to clean up any burning or lighted materials

such as cigarettes, matches, ashes or other combustible

objects.

23. Take care when using a machine near the top of stairs to

avoid overbalancing.

24. DO NOT put any object into openings. DO NOT use with

any opening blocked; keep free of dust, debris and

anything that may reduce airflow.

25. DO NOT cover the machine when in use.

26. Keep hair, loose clothing, hands, feet and all other parts

of the body away from openings and moving parts.

27. DO NOT use if it has been damaged, left outdoors or

dropped in water.

28. DO NOT run the machine dry, as this could damage the

floor surface or the machine itself.

29. Never use excessive foaming or highly corrosive

cleaning solutions.

30. Do not operate the machine with a damaged supply lead

or plug, or after the machine malfunctions or is damaged

in any way. Contact an authorised Service Agent for

repair or adjustment.

31. Only replace the supply cord with the type specified in

the instruction manual.

32. This machine should always be connected to a fully

earthed power supply of the right voltage and frequency.

33. DO NOT leave machine running unattended.

34. Do not leave the machine connected to the electricity

supply when not in use, always remove the plug from the

socket-outlet.

35. Switch off the machine before removing the plug.

36. When unplugging, pull the plug, not the supply cord.

37. The machine shall be disconnected from its power

source when not in use and before commencing cleaning

of the machine or maintenance and when replacing parts

or accessories, by removing the plug from the socketoutlet.

38. DO NOT pull or carry by the supply cord. DO NOT use

cord as a handle, close door on cord or pull cord around

sharp edges or corners.

39. WARNING: Keep the supply cord clear of moving parts.

40. DO NOT kink or twist the supply cord and keep cord

away from heated surfaces.

41. DO NOT operate switches or touch the mains plug with

wet hands as this may cause electric shock.

42. The power supply cord plus any extension leads should

not exceed 30 metres in total. The cross section of an

extension cable wiring must be at least 2.5mm².

CONTROLS ON THE MACHINE

The operating controls are located on the handle and on the

side of the machine. Please refer to page 1.

1. Solution discharge handle 6. Main brush

2. Solution tank 7. Motor overload button

3. Recovery tank 8. Pedal

4. Lid cap 9. Transport/working mode

5. Nozzle 10. Brush pressure

Transporting the machine

Incorrect lifting techniques may result in personal injury. We

advise that the manual handling regulations are followed. Do

not expose the machine to rain or moisture.

When transporting the machine ensure that all components,

tanks and removable parts are securely fastened, and that

the supply cord and plug are not trailing.

When transporting the machine the handle should be locked

in the upright position.

Take extreme care when moving the machine up or down

steps or stairs.

Brush Identification

Red, Blue, White and Yellow brush buttons are packed with

the machine. Simply plug the buttons into the hole in the

brush as shown. Clear identification, by colour coding, helps

prevent cross contamination.

Storage

• Always switch off, empty, wipe down and dry the machine

after use.

• Both the solution and recovery tanks should be emptied

and flushed out with clean water to ensure the seals and

pumps are free from any cleaning detergents.

• Wrap the supply cord around the cable winder ensuring

that the plug is not trailing on the floor.

• Store the machine in a dry indoor area only.

Maintenance

W

ARNING - Before undertaking maintenance

operations or adjustments switch off machine

and unplug from the electricity supply.

IMPORTANT – All other servicing and repairs should only be

performed by a Truvox engineer or Authorised Service

Agent. IMPORTANT – Should the machine fail to operate

please refer to the fault diagnosis section in the back of this

instruction manual. If the problem / remedy is not listed

4

please contact Truvox Customer Service Department for

rapid attention.

The machine requires minimum maintenance apart from the

following checks by the operator prior to use:

• DO NOT use aggressive detergents, acid, lye etc. during

cleaning and washing and take particular care with

electrical parts.

• Supply cord - Regularly inspect sheath, plug and cord

anchorage for damage or loose connection. Only replace

the supply cord with the type specified in these

instructions.

• Brushes - For maximum life, wash the brushes regularly.

Ensure machine is in Transport mode when not in use.

Store additional brushes in a vertical position to avoid

bending of bristles. Check for permanent bending of

bristles in a particular direction. This may occur if the

machine is operated for several days without removing the

brushes, which is not recommended. If this occurs, reverse

the brush so that the bent bristles are automatically

straightened.

• Wiper Blade - After years of use the wiper blade may

wear. If this occurs the water collection performance will

decrease. It should be replaced by an authorised service

agent.

• Solution tank filter (Standard) - The filter prevents

clogging of the drip holes in the tank. Periodically clean the

filter to ensure uniform discharge of liquid. In case of nonuniform discharge from the drip holes, back flush the tank

in running water. Clean the drip holes using wire or a blunt

pin.

• Solution feed filter (Pump) - The filter prevents clogging

of the spray nozzle and should be periodically cleaned.

Use pressurised air/water for cleaning.

• Nozzle maintenance (Pump) - If the spray of the nozzle

becomes blocked, slide the nozzle cover off and remove

nozzle wash in clean water and clean using a pin and refit.

After sales service

Truvox machines are high quality machines that have been

tested for safety by authorised technicians. It is always

apparent that after longer working periods, electrical and

mechanical components will show signs of wear and tear or

ageing. To maintain operational safety and reliability the

following service interval has been defined: Every year or

after 250 hours. Under extreme or specialised conditions

and/or insufficient maintenance, shorter maintenance

intervals are necessary. Use only original Truvox spare

parts. Use of other spare parts will invalidate all warranty and

liability claims. Should you require after sales service please

contact the supplier from whom you purchased the machine,

who will arrange service. Repairs and servicing of Truvox

products should only be performed by trained staff. Improper

repairs can cause considerable danger to the user.

Guarantee

Your product is guaranteed for one year from the date of

original purchase, or hire purchase, against defects in

materials or workmanship during manufacture. Within the

guarantee period we undertake at our discretion, to repair or

replace free of charge to the purchaser, any part found to be

defective, subject to the following conditions:

C

ONDITIONS

1. Claims made under the terms of the guarantee must be

supported by the original invoice/bill of sale issued at the

time of sale, or the machine Serial No.

2. For claims under this guarantee contact the supplier from

whom you purchased the product who will arrange the

appropriate action. Do not initially return the product as

this could result in transit damage.

3. Neither Truvox nor its distributor shall be liable for any

incidental or consequential loss.

4. This guarantee is governed by the laws of England.

5. This guarantee does not cover any of the following:

• Periodic maintenance, and repair or replacement

of parts due to normal wear and tear.

• Damage caused by accident, misuse or neglect, or

the fitting of other than genuine Truvox parts.

• Defects in other than genuine Truvox parts, or

repairs, modifications or adjustments performed by

other than a Truvox service engineer or authorised

service agent.

• Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

• Consumable items such as, brushes, drive discs,

filters and vacuum skirts.

This guarantee does not affect your statutory rights, or

your rights against the supplier arising from their sales or

purchase contract. Truvox International Limited policy is

one of continual product development and we reserve the

right to alter specifications without prior notice.

Recommended Spares & Accessories

Item MW240

MW340

MW340/Pump

MW440/Pump

Usage

Standard brush –

black (2 required)

90-0127-0000 90-0130-0000 90-0130-0000 90-0387-0000

All natural stone floors,

ceramic, mosaic, wood,

profiled rubber, vinyl, PVC

(First time cleaning);

smooth concrete

Soft brush – grey

(2 required)

90-0133-0000 90-0131-0000 90-0131-0000 90-0388-0000

All natural stone floors,

ceramic, mosaic, wood,

profiled rubber, vinyl, PVC

(Maintenance cleaning);

short pile carpet, marble

granite

Side brush –

black (1 required)

90-0134-0000 90-0132-0000 90-0132-0000 90-0385-0000 For up-to-the-edge cleaning

Hard brush –

blue (2 required)

- 90-0089-0000 90-0089-0000 -

To suit individual floor

conditions, smooth concrete

Escalator brush –

blue (2 required)

- 90-0090-0000 90-0090-0000 90-0469-0000 For use on escalators

4 litre tank

- - 90-0307-0000 90-0103-0000

Trolley

(for all models)

05-3395-0500 For easier transport

5

Fault diagnosis

The following simple checks may be performed by the operator:

Trouble

Reason

Remedy

Machine fails to

start – no power

• Transport working knob is in

bottom position

• Motor overload protector has

tripped

• Micro switches are faulty open

circuit

• Change to operating position (Fig 3)

• Reset the protector button after a

minimum of 30 seconds from tripping

by pressing the over load protector

manually and continue working (7 on

page 2)

• Check mains cable

• Check plug top fuse

Machine fails to pick

up water from the

floor

• Worn brushes

• Damaged lip on recovery tank

• Broken lugs on recovery tank

• Drum not revolving

• Bridge fitted wrong way on

machine or springs broken

• Replace brush, lip, lugs or springs

• Fit bridge the correct way

Machine fails to

spray solution onto

the floor

(MW340/Pump &

MW440/Pump only)

• Blocked jet

• Blocked inline filter

• Faulty pump

• Blocked filter or faulty valve in

solution tank

• Faulty pump micro switches

• Damaged or broken pull cable

• Clean jet or inline filter

Machine only sprays

when handle in

upright position

• Loose lower handle bolts • Tighten lower handle bolts

Drum is turning, but

brushes are not

• If one or both brushes are not

turning, stripped gears in gear

box

Machine fails to let

solution onto the

floor (MW240 &

MW340 only)

• Damaged or broken pull cable

• Adjustment on pull cable

• Dirty filter in clean water tank

• Blocked holes in outlet channel

• Empty clean water tank and fill up

with clean water

• Clean holes

Drum not turning

• Plastic gear inside rim of drum

sheared

• Drum sprocket bearing seized

• Build up of dirty hair etc. around

bridge springs

• Plastic gears in gear box stripped

• Drum rubber sleeve loose on

drum

• Clean drum and bearings and remove

dirt and build up

Motor makes a

humming noise but

does not turn

• Motor capacitor faulty

• Motor seized up

• Faulty motor windings

• Contact service agent

* If the fuse blows several times, the machine should be checked by an authorised Service Agent

6

AVERTISSEMENT – LISEZ ATENTIVEMENT CETTE NOTICE AVANT D'UTILISER LA MACHINE

ET CONSERVEZ-LA POUR VOUS Y RÉFÉRER ULTÉRIEUREMENT

Informations sur le produit

La notice suivante contient des informations importantes sur

les machines et des avis de sécurité pour l’opérateur.

L’équipement doit être utilisé et entretenu conformément aux

instructions du fabricant. En cas de doute, contactez votre

fournisseur.

Lire attentivement toutes les

instructions avant toute utilisation.

Product information

Les machines de nettoyage des sols Multiwash sont

conçues pour une utilisation sur sols lisses et réguliers en

intérieur. Elles peuvent être utilisées sur la plupart des sols,

y compris les moquettes à poils courts, le bois, le PVC, le

caoutchouc et la pierre. Elles ne doivent pas être utilisées

sur des surfaces rugueuses irrégulières. Cette machine est

prévue pour une utilisation commerciale, par exemple dans

des hôtels, des écoles, des hôpitaux, des usines, des

boutiques, des bureaux, des entreprises de location ainsi

que pour les utilisations plus intensives qu'un ménage

classique.

Spécifications Techniques

Modèle

Multiwash 240 Multiwash 340

Multiwash 340

(Pump)

Multiwash 440

(Pump)

Code produit

MW240 MW340 MW340/PUMP MW440/PUMP

Tension CA (~) / Fréquence V/ Hz 230/ 50 230/ 50 230/ 50 230/ 50

Puissance moteur (+

pompe)

W 400 600 600 + 26 1000 + 26

Taux de productivité m²/h 650 930 930 1150

Capacité du réservoir de

solution

l 1.2 1.7 4 4

Largeur de la brosse cm 24 34 34 44

Vitesse de la brosse rpm 650 650 650 650

Pression de la brosse g/cm² 250 250 250 250

Niveau de pression sonore dB(A) 68 69 69 71

Dimensions (L x l x H) cm 37.8 x 34 x 111.8 37.8 x 44 x 111.8 37.8 x 44 x 111.8 37.8 x 54 x 111.8

Poids kg 20 23 25 28

Longueur du câble

d'alimentation

m 12 12 12 12

Garantie 1 an

•

Les niveaux sonores sont mesurés à une distance d’1 mètre par rapport à la machine et de 1,6 mètres au-dessus du sol

pendant le lavage d'un revêtement dur. Les mesures sont enregistrées par un appareil portatif.

• La vibration du manche ne dépasse pas 2,5 m/s² lors d'une utilisation sur une surface dure et lisse.

• Les dimensions ci-dessus sont approximatives. Truvox poursuivant une politique d'amélioration continue, des changements

peuvent être apportés sans avis préalable.

Déchets d'Equipements Electriques et Electroniques

(DEEE)

Ne pas jeter cet appareil avec les déchets non

recyclables. Toute élimination inappropriée peut

être nocive pour l’environnement et la santé

humaine.

S’adresser aux agences locales de traitement

des déchets pour obtenir des informations sur

les systèmes de retour et de collecte dans votre secteur.

IMPORTANTES CONSIGNES DE SECURITE

Les consignes de sécurité décrites dans ce manuel

proviennent des consignes de sécurité standards en vigueur

dans le pays où l’appareil est utilisé.

Ce symbole alerte l’utilisateur sur les dangers

éventuels et les pratiques imprudentes pouvant

entraîner des blessures graves voire la mort.

ATTENTION – Afin de réduire le risqué d’incendie,

electrocution ou de blessure:

DÉCLARATION DE CONFORMITÉ CE

Type de machine : Nettoyeuse de sol

Modèle MW240…, MW340…, MW340/PUMP…,

MW440/PUMP…

Cette machine est conforme aux directives de l’Union

européenne suivantes :

• Directive sur les machines 2006/42/EC

• Directive CME 2004/108/EC

Normes harmonisées appliquées

EN60335-1, EN60335-2-72, EN55014-1, EN55014-2,

EN61000-3-2, EN61000-3-3, EN62233

Truvox International Limited

Unit C (East), Hamilton Business Park,

Manaton Way, Botley Road, Malcolm Eneas

Hedge End, Southampton, Operations Manager

SO30 2JR, UK Southampton, 22/01/2015

Loading...

Loading...