Truvox Multiwash 240, Multiwash 340, Multiwash 440 User Manual

USER MANUAL

EN

2

BEDIENUNGSANLEITUNG

DE 10

MANUEL D'UTILISATION

FR 20

MANUAL DEL USUARIO

ES

29

03-5977-0000 05/12 V.1

www.truvox.com

1

2

MULTIWASH

The following manual contains important information

about the machine and safety advice for the operator.

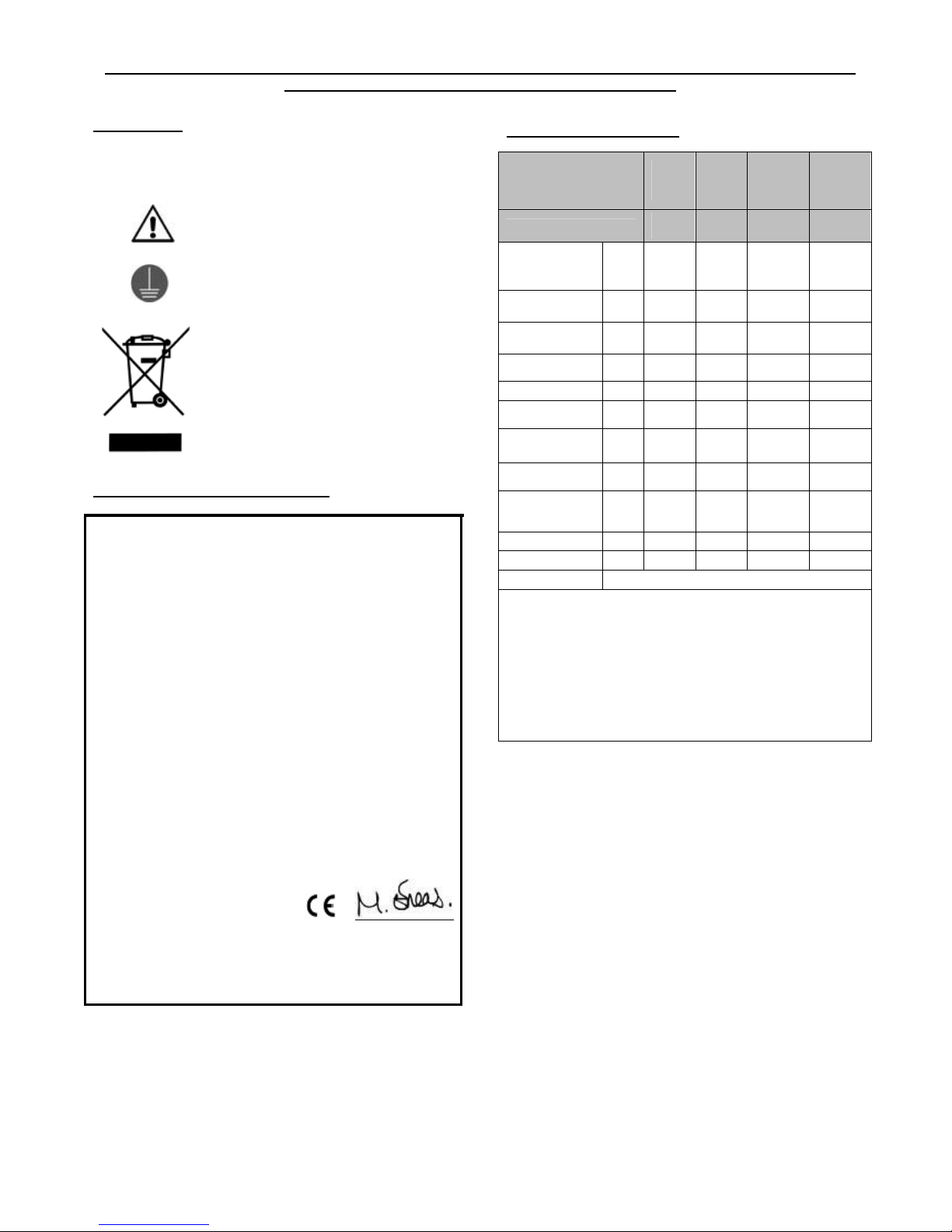

WARNING

Earth Ground Symbol

Waste Electrical & Electronic

Equipment (WEEE)

Do not dispose of this device with

unsorted waste. Improper disposal

may be harmful to the environment

and human health. Please refer to

your local waste authority for

information on return and collection

systems in your area.

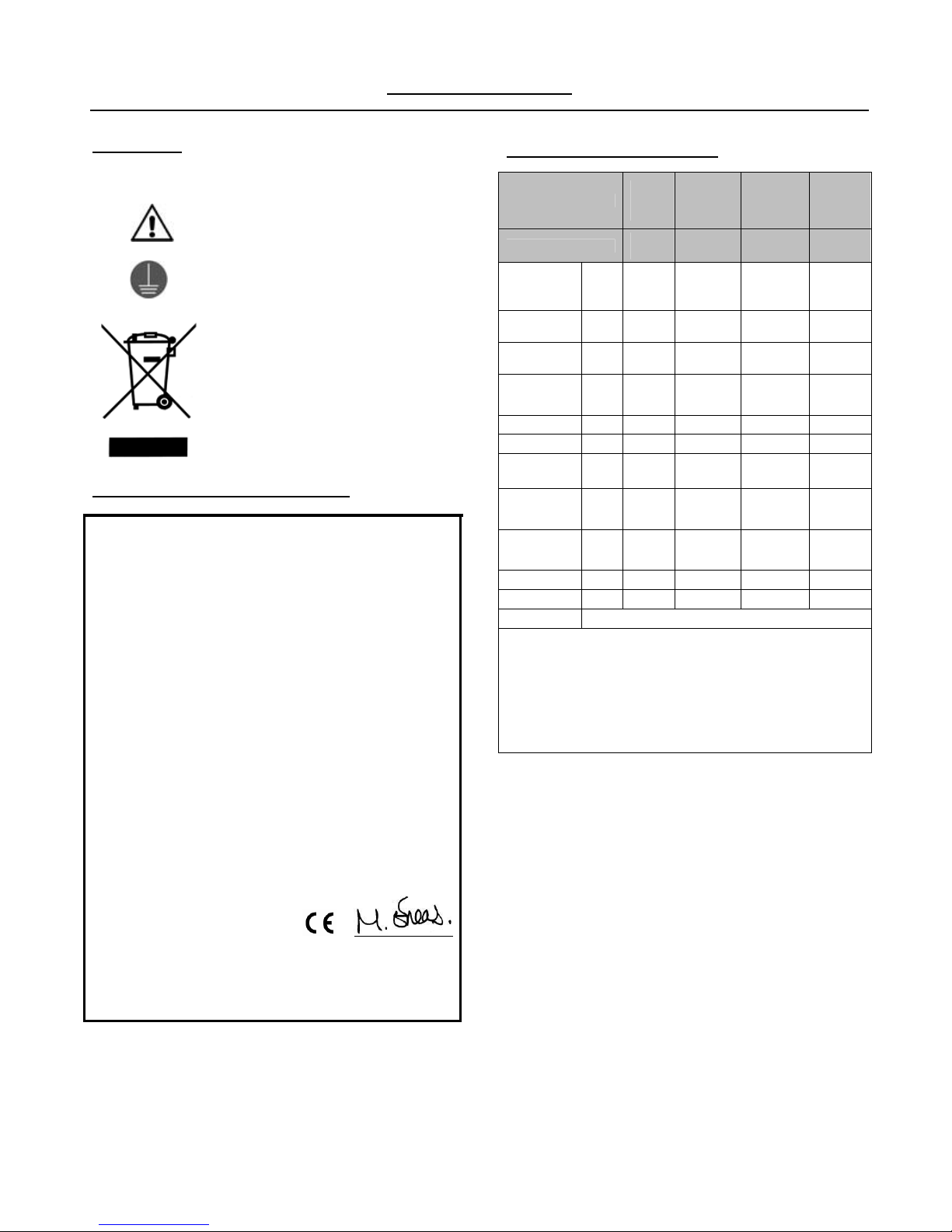

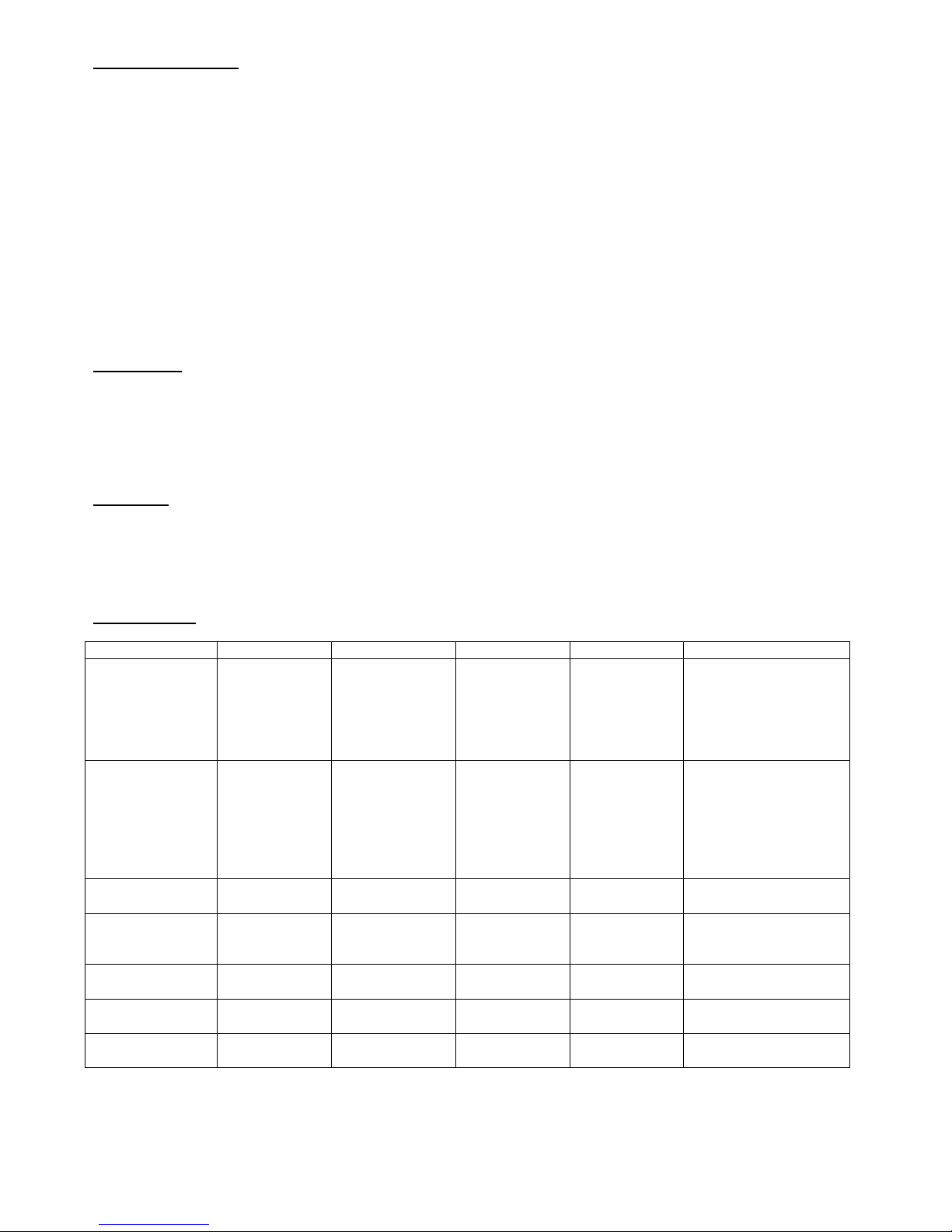

TECHNICAL SPECIFICATIONS

Model

Multi

wash

240

Multi

wash

340

Multi

wash

340

(Pump)

Multi

wash

440

(Pump)

Product Code

MW

240

MW

340

MW340/

PUMP

MW440/

PUMP

Voltage AC

(~)/

Frequency

V/

Hz

230/

50

230/

50

230/

50

230/

50

Motor power

(+ pump)

W 400 600

600 +

26

1000 +

26

Productivity

rate

m²/h 650 930 - 1150

Solution

tank

capacity

l 1.2 1.7 4 4

Brush width cm 24 34 34 44

Brush speed rpm 650 650 650 650

Brush

pressure

g/cm

²

250 250 250 250

Sound

pressure

level

dB(

A)

68 69 69 71

Dimensions

(L x W x H)

cm

37.8x

34 x

111.8

37.8 x

44 x

111.8

37.8 x

44 x

111.8

37.8 x

54 x

111.8

Weight kg 20 23 25 28

Cable length m 12 12 12 12

Warranty 1 year

• Noise levels measured at a distance of 1 meter from machine and

1.6 metres above floor, when washing a hard floor. Measurements

recorded using a hand held meter.

• Handle vibration does not exceed 2.5 m/s², when operating on a

smooth hard surface.

• Above dimensions are approx. Since the company’s policy is to

continuously improve the product, there could be changes without

prior notice.

If you have any queries or questions, please contact

the supplier who you purchased the machine from or

Truvox International.

Truvox International Limited

Third Avenue, Millbrook, Southampton, Hampshire,

SO15 0LE, United Kingdom; Tel.: +44 (0) 23 8070 6600,

Fax: +44 (0) 23 8070 5001; Email: sales@truvox.com;

Web: www.truvox.com

EC DECLARATION OF CONFORMITY

Machine Type: Floor cleaning machine

Type: Multiwash

Model: MW240…,

MW340…,

MW340/Pump…,

MW440/Pump…

This machine is in conformity with the following EU

directives:

2006/42/EC

2004/108/EC

Applied

harmonised

standards

Machinery Directive

The EMC Directive

EN60335-1, EN60335-2-72,

EN55014-1, EN55014-2,

EN610003-2, EN610003-3,

EN62233

Truvox International

Malcolm Eneas

Third Avenue, Millbrook

Operations Manager

SO15 0LE, Southampton

Hampshire, England

Southampton, 01-11-2008

ORIGINAL INSTRUCTIONS

WARNING - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE & RETAIN FOR FUTURE REFERENCE

3

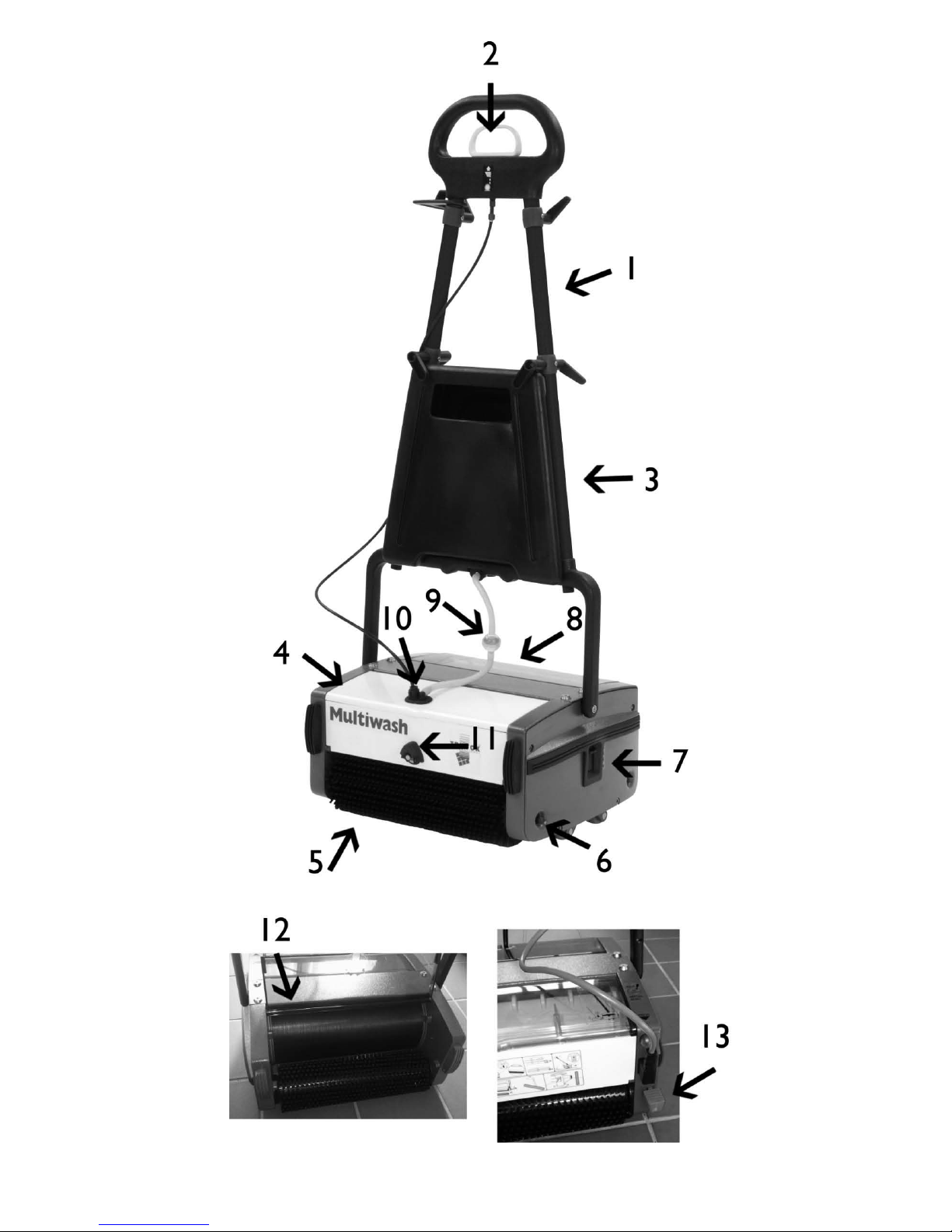

Please refer to machine pictures on page 1

1

2

3

4

5

6

Top handle

Liquid discharge

control handle

Solution tank

(optional)

Boot

Main brush

Brush shaft

7

8

9

10

11

12

13

Transport/ working

knob

Recovery tank

Filter

Lid cap

Nozzle

Conveyor drum

Pedal

1. Product information

The Multiwash floor cleaning machines are designed for

use on smooth, even floors in indoor areas. They can be

used on most floor surfaces including short-pile carpet,

wood, PVC, rubber and stone. They should not be used

on rough uneven surfaces. The machine is intended for

commercial use, for example in hotels, schools, hospitals,

factories, shops, offices, rental businesses and other than

normal housekeeping purposes.

The following instructions contain important information

about the machines and safety advice for the operator.

These instructions are valid for the following models:

Multiwash - MW240…, MW340…, MW340/Pump…,

MW440/Pump…

Equipment must be operated, serviced and maintained in

accordance with the manufacturer’s instructions. If in

doubt contact the supplier of your machine.

1.1 Important safety advice

When using this machine, basic safety

precautions should be followed, including the

following:

• This machine must only be used for the manufacturer’s

approved application as described in this manual.

• Please note that the safety information described in the

manual supplements and does not replace standards in

force in the country in which the machine is used.

• WARNING - Only use accessories and spare parts

provided with the machine or those approved by the

manufacturer. The use of other spare parts or

accessories may impair the safety of the machine.

• CAUTION - This machine is for dry indoor use only and

should not be used or stored outdoors in wet conditions.

• All parts are to be positioned as indicated in the

instructions before using the machine.

• The machine must be unpacked and assembled in

accordance with these instructions before connecting to

the electrical supply.

• DO NOT use where hazardous dust is present.

• DO NOT use in an explosive atmosphere.

• DO NOT pick up or use near flammable fluids, dusts or

vapours.

• DO NOT use to clean up any burning or lighted

materials such as cigarettes, matches, ashes or other

combustible objects.

• Take care when using a machine near the top of stairs

to avoid overbalancing.

• Only use the machine on firm level surfaces. DO NOT

use on a gradient or more than 2% slopes.

• DO NOT operate this machine on rough uneven

surfaces e.g. industrial concrete floors.

• DO NOT use on coarse concrete surfaces.

• DO NOT use outdoors e.g. on patios, decks or rough

surfaces.

• DO NOT sweep over wet surfaces.

• WARNING – Do not fill machines with water hotter than

50°C.

• DO NOT use diesel/petrol or corrosive detergents to

wash floors.

• DO NOT wash and vacuum corrosive, flammable and/

or explosive liquids, even if diluted.

• DO NOT put any object into openings. DO NOT use

with any opening blocked; keep free of dust, debris and

anything that may reduce airflow.

• DO NOT cover machine when in use.

•

DO N

OT lea

ve the machine connected to the electricity

supply when not in use; always remove the plug from

the socket outlet.

• DO NOT leave machine running unattended.

• This machine should always be connected to a fully

earthed power supply of the right voltage and frequency.

• The machine shall be disconnected from its power

source during its cleaning or maintenance and when

replacing parts or accessories, by removing the plug

from the socket-outlet.

• DO NOT use if it has been damaged, left outdoors or

dropped into water.

• DO NOT operate switches or touch the mains plug with

wet hands as this may cause electric shock.

• WARNING - Keep the power supply cord clear of

moving parts (and/or rotating brushes). During operation

hazard may occur when running the machine over the

power supply cord.

• DO NOT operate the machine with a damaged supply

cord or plug, or after the machine malfunctions or is

damaged in any way. Contact an authorised Service

Agent for repair or adjustment.

• DO NOT pull or carry by the supply cord. DO NOT use

cord as a handle, close door on cord or pull cord around

sharp edges or corners.

• The plug of the power supply cord must be removed

from the socket-outlet before commencing cleaning of

the machine or undertaking maintenance operations.

• DO NOT kink or twist the power cord and keep cord

away from heated surfaces.

• When unplugging, pull the plug, not the supply cord.

• The power supply cord must be regularly inspected for

signs of damage. If the power supply cord is damaged,

it shall only be replaced by a suitable cord by the

manufacturer, its service agent or a similar qualified

person in order to avoid a hazard.

• The battery charging lead is to be regularly inspected for

signs of damage. If the lead is damaged, it shall only be

4

replaced by the manufacturer, its service agent or a

similar qualified person in order to avoid a hazard.

• When recharging ensure area is sufficiently ventilated.

• DO NOT run the machine dry, as this could damage the

floor surface or the machine itself.

• Never use excessive foaming or highly corrosive

cleaning solutions.

1.2 Guidelines for the operator

• This machine is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the machine by a

person responsible for their safety.

• Operators must be fully trained in the use of the

machine in accordance with these instructions, able to

perform user maintenance and the correct selection of

accessories.

• Operators should be physically capable to manoeuvre,

transport and operate the machines.

• Operators should be able to recognise unusual

operation of the machine and report any problems.

• Keep children and unauthorised persons away from

the machine when in use.

• Keep cleaning solutions away from children and pets

at all times.

• CAUTION - This machine is for dry indoor use only

and should not be used or stored outdoors in wet

conditions.

• DO NOT clean the machine using water sprays or jets.

• Keep hair, loose clothing, hands, feet and all other

parts of the body away from openings and moving

parts.

• Keep machine clean and in good operating condition.

• Let the machine do the work. Grip the handle as lightly

as possible.

• Stand with feet slightly apart to maintain good balance.

Avoid twisting the body more than 45 degrees.

• Wear suitable footwear to avoid slipping.

• Wear suitable clothing to keep dry and warm.

• Where possible implement job rotation and adequate

rest periods to avoid continuous use of the same

muscles.

• DO NOT smoke when using the machine.

1.3 Transporting the machine

CAUTION - THIS MACHINE IS HEAVY

Do not attempt to lift the machine without assistance.

Incorrect lifting techniques may result in personal injury.

We advise that the manual handling regulations are

followed. Please refer to the technical table for details on

weight of machine. The machine can be moved to the

area to be cleaned by pushing the pedal down, pulling the

handle backwards and then pushing the machine. When

transporting the machine ensure that all components,

tanks and removable parts are securely fastened. When

transporting the machine the handle should be locked in

the upright position. Take extreme care when moving the

machine up or down steps or stairs. CAUTION – Bumping

over thresholds, kerbs and similar obstacles can damage

the machine. Small obstacles can be overcome by pulling

the machine backwards.

2. Preparing for use

2.1 Electrical connection

Before connecting the machine to the power supply,

check that your supply voltage corresponds with that

marked on the rating label on the machine.

2.2 Unpacking the machine

1. Bottom handle 8. Screws & washers

2. Machine body 9. Cable retainer

3. Pump Housing (Pump) 10. Power cord

4. Auxiliary Tank (Pump) 11. Recovery tank

5. Top handle & pull cable 12. Hook

6. Handle LH & RH 13. Knob

7. Brush shafts (2)

Fig.1

1. To save packing space and to ensure the safety of the

machine during transportation, the Multiwash comes to

you with its handle dismantled. Ensure that the listed

parts are present as shown and identify them in order

to understand the assembly instructions.

2. Remove the hook which holds the bottom handle with

the machine body while holding the bottom handle.

UK only

The supply cord for 230v models is fitted with a plug

containing a 13 amp fuse. Should the fuse require

replacement it must only be replaced by a 13 amp

fuse conforming to BS1362, and the fuse cover must

be refitted. If the fuse cover is lost the plug must not

be used until the correct replacement cover is fitted.

Should an extension cord be used, ensure cord rating

is adequate for the equipment. Do not use extension

cord in coiled condition as this could result in

overheating of the cord. The power supply cord plus

any extension leads should not exceed 30 m in total.

The cross-section of any extension cable wiring must

be at least 2, 5 mm².

WARNING – THIS APPLIANCE MUST BE

EARTHED.

5

WARNING - Since the bottom handle is spring loaded,

care must be taken when removing the hook to avoid

sudden springing back leading to possible injury to

personnel.

2.3 Setting up the machine

1. Insert the two tubular handles into the bottom handle

and secure them using knob (2 off) by tightening

lightly. Ensure that the handles are assembled

according to their marked position and the cable

holding hooks are pointing towards the rear.

2. Slide the electric cable retainer into the top portion of

RH handle.

3. Fit the top handle over the tubular handles and secure

them with washer and screw (2 sets).Ensure that the

label on the top handle is facing the front of the

machine. Now tighten firmly both the knobs and

screws alternately. Insert the dummy caps provided to

cover the screws (2 off) in the top handle.

4. Pass the free end of the pull cable through the plastic

guide in RH Handle. Press and twist clockwise to firmly

secure the cable end to the fresh water tank

(Standard).

5. Fix the auxiliary tank firmly into the bottom handle by

holding the top handle.

6. Rotate the knob to hold the auxiliary tank.

7. The brushes are only loosely packed in the machine

for transit, therefore the brush shafts must be fitted

before operating the machine. Push the shafts through

the brushes from the side of the machine. To remove

brushes, push the brush shaft out from the side of the

machine using the fingers and withdraw the shaft.

Normally the standard brush will be supplied with the

machine. Brushes should be selected according to the

type of floor surface to be cleaned, and the degree of

dirt to be removed, please refer Brush Selection Guide.

8. The machine is now ready for use.

2.4 Working principle

1. Cleaning liquid in the solution tank is applied to the

floor by either gravity (Standard) or Spray (Pump).

2. The counter rotating brushes scrub the floor and also

throw the dirty water on the conveyor drum. The front

brush does most of the scrubbing and drying. The rear

brush completes the scrubbing and collects the

remaining water off the floor.

3. A blade fitted to the dirty water tank wipes the drum

and collects the dirty water.

Fig. 2

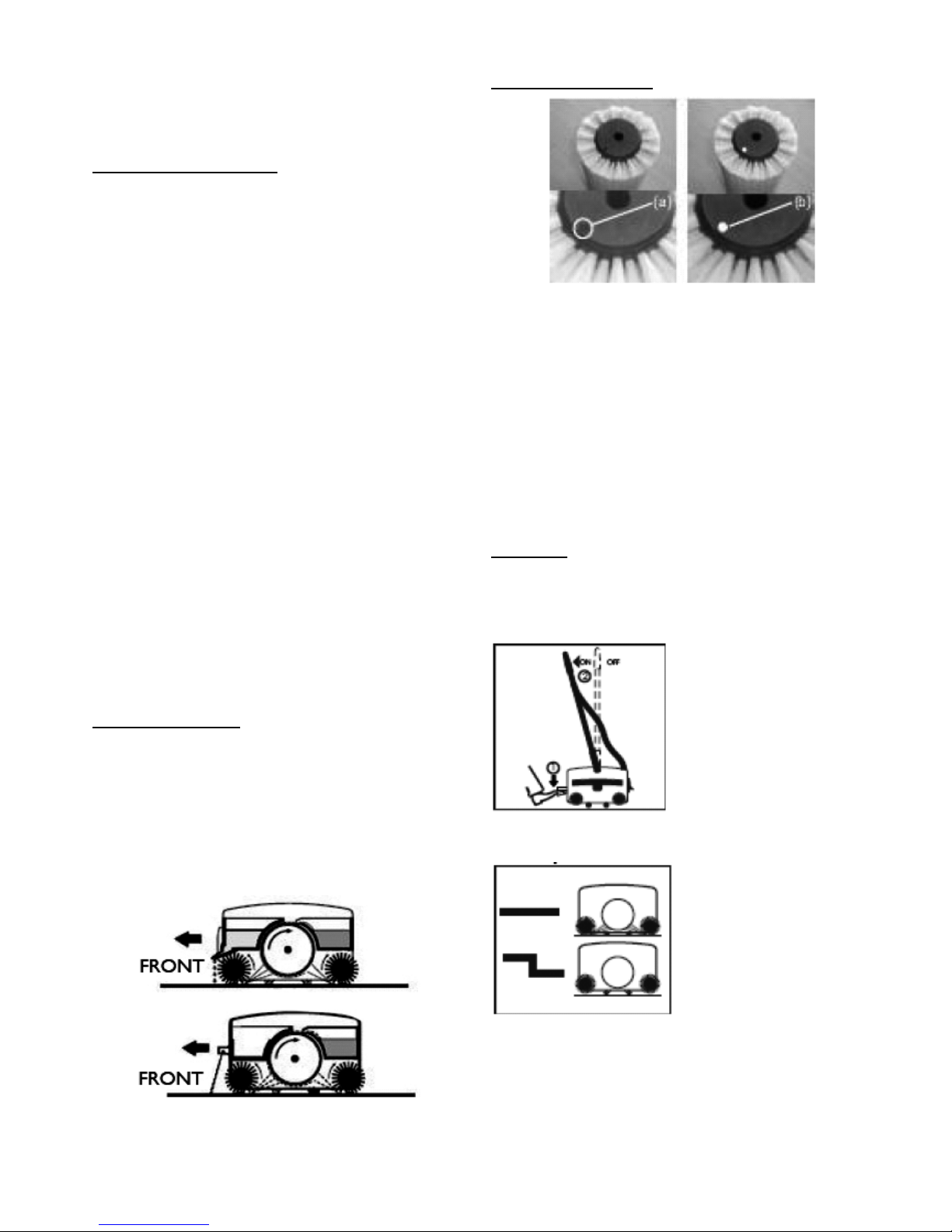

2.5 Brush identification

Fig. 3

(a) Hole provided for plugging button

(b) Brush with button plugged

This is applicable when the customer has more than one

set of brushes of same type. Distinct colour coding make it

easy to separate tools into their correct areas of use.

Washroom tools are kept in the restroom; kitchen tools

are kept in the kitchen - reducing bacteria crosscontamination between high and low-risk areas. Red,

Blue, White and Yellow brush buttons are packed with the

machine. Simply plug the buttons into the hole in the

brush as shown. Clear identification, by colour coding,

helps to prevent cross contamination.

3. Controls

The operating controls are located on the handle (1) and

on the side of the machine. Please refer to page 1.

On/Off Control

By pressing the pedal lightly

with your foot, pull back the

handle a little to start the

motor. The brushes and the

drum starts rotating. Pulling

the handle further without

pressing the pedal, lowers

the machine and engages

the rotating brushes onto

the floor. To stop working,

take the handle to the

vertical position.

Transport/Working Mode Control

Slide this knob to TOP

position (Working Mode) to

operate the machine. Slide

this knob to BOTTOM

position to move the

machine and park the

machine.

WARNING- Keeping the knob in the top position (working

mode) and moving the machine will damage the brushes.

6

Brush Contact Control

Brush contact with the floor

is adjustable in 4 steps,

contact is MINIMUM when

the knob is fully down and

MAXIMUM when it is fully

raised. This helps you to

compensate for the wear of

brushes and also to control

the scrubbing effect. If the

machine does not move

when the handle is lowered, slide the transport/working

mode knob up one step.

Cleaning Liquid Discharge Control

By pulling, the liquid

discharge control handle

up, the cleaning solution is

dispensed on the floor. The

solution stops once the

liquid discharge control

handle is released.

Pull cable connect / disconnect control

Insert the free end of pull

cable into the valve body

fitted in the fresh water

tank. Press and twist

clockwise to secure the

cable end. Similarly, press

and twist anti clockwise to

disconnect the cable end.

Motor Overload Protector

In the event of motor

getting overloaded due to

improper power supply or

unexpected obstruction to

the brush/drum rotation,

the over load protector

trips and protects the

motor from damage. If this

happens, identify the

cause, correct it and, reset

the protector button after minimum of 30 seconds from

tripping by pressing the over load protector manually and

continue working.

IMPORTANT - Should the machine fail to operate, contact

the supplier from whom you purchased the machine.

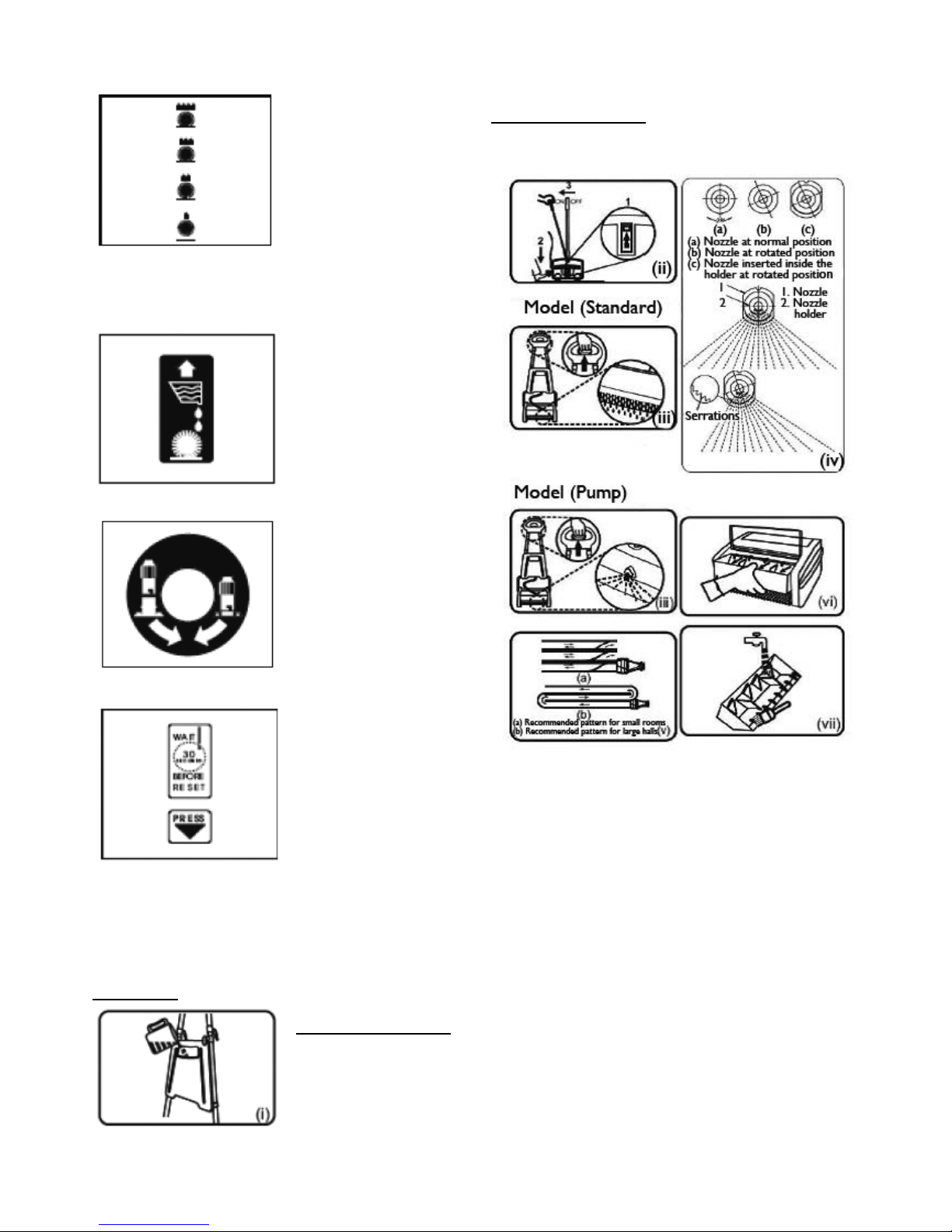

4. Operation

4.1 Checks before use

• Ensure that the brushes

are fitted properly

• Fill fresh water tank with

cleaning solution

• Insert the plug into mains socket

4.2 Using the machine

WARNING - Never start the machine without a brush or

pad fitted.

Recommended washing sequence

1. Start the machine by pressing the pedal and pulling the

handle back (Fig-ii).

2. Move forward, while sparingly pulling the liquid

discharge control handle (Fig-iii). This handle should

not be kept pulled all the time. The duration and

frequency of pulling and releasing has to be adjusted

to match with the type of floor, extent of dirt. etc. For

tiled or stone floors, apply very little water. The spray

pattern of the Multiwash can be adjusted by the user.

Adjust the spray to prevent solution being dispensed

onto areas that already have been cleaned. The spray

pattern is adjusted by using the serrations in the spray

nozzle and holder. Each serration allows a 4 degree

change (Fig-i v).

3. Stop the liquid discharge approximately 30 cm before

the end of forward motion, continue to move forward

up to the wall without pulling the pull handle.

4. Pull the machine backwards in the same track, but

without discharging any liquid. When you reach the

starting point, change the track and repeat steps 2

through

7

5. When you are changing the track allow some overlap

with the cleaned area. In case of large halls take a Uturn and move forward. If quick drying is required,

move on the same track, without discharging the liquid

(Fig-v)

6. Clean the blades and push the tank into its place.

WARNING- Pre-sweep the floor to remove debris before

using the Multiwash. WARNING- Avoid touching the sharp

edge of dirty water tank, it may cause injury to hands.

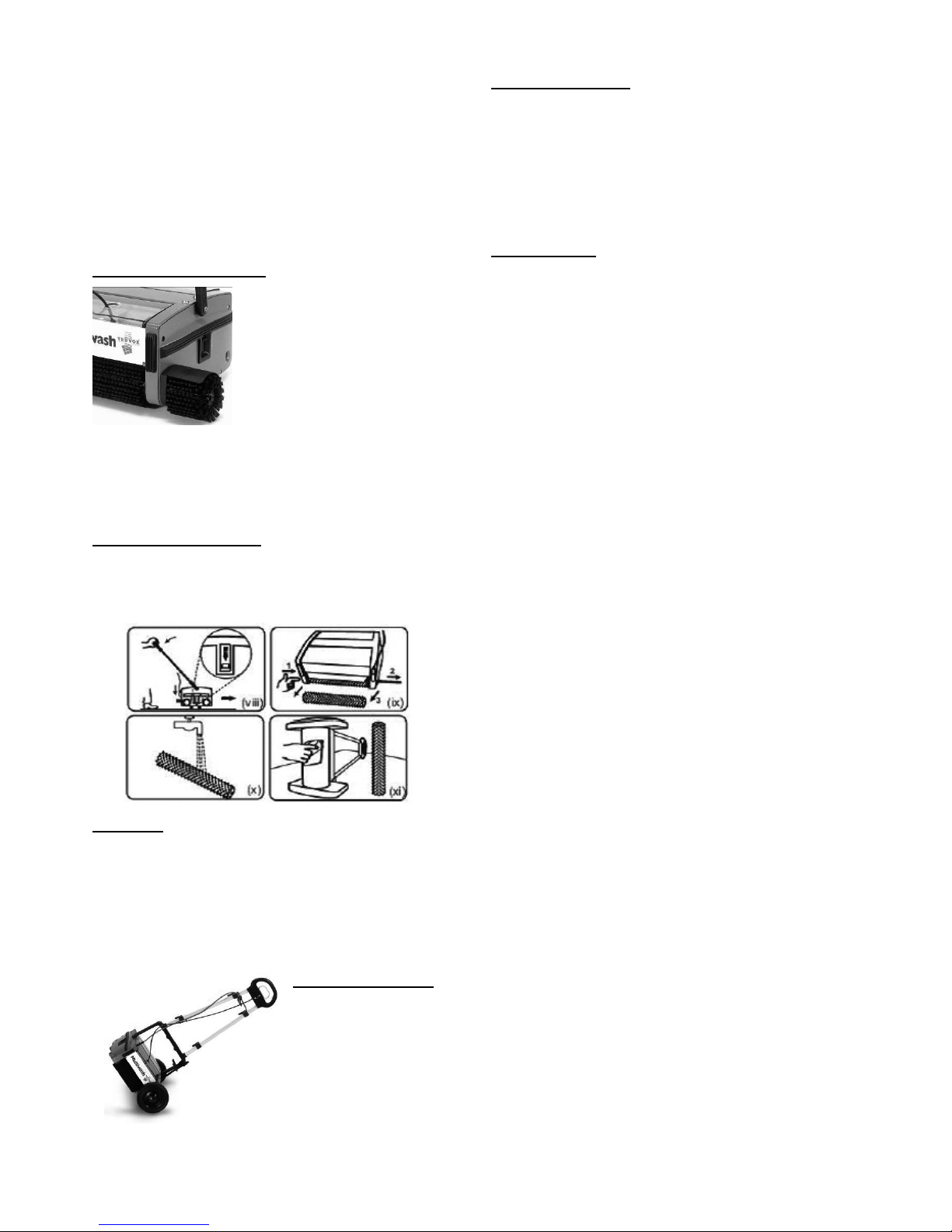

4.3 Fitting the side brush

To clean up to walls, the side

brush can be used. Switch off and

unplug the machine before fitting

the side brush.

WARNING - Do not use side

brush in a room with no wall

skirting, otherwise, the wall may

get dirty.

1. Remove the front brush and brush shaft.

2. Fix the shield assembly on the side plate.

3. Insert the side brush through the shield and main

brush.

4.4 Using the side brush

1. Tilt the machine at an angle move forward. This way,

the dirty water thrown by the side brush will be

collected by the rear brush.

2. Use side brush only for washing the edges.

5. Storage

• Always switch off, empty, wipe down and dry the

machine after use.

• The tank should be emptied and flushed out with clean

water.

• Wrap the supply cord around the cable winder ensuring

that the plug is not trailing on the floor.

• Store the machine in a dry indoor area only.

5.1 Transport trolley

The simply fitted trolley

provides for ease of

movement when

transporting the machine.

WARNING - Empty all

liquid from the machine

before using the

transporter.

5.2 Using the trolley

1. With the machine handle in the upright position place

the trolley centrally alongside the machine.

2. By holding the machine firmly, strap the Velcro with the

machine to fix the transporter.

3. Ensure that the Velcro strap is securely wrapped

around the bottom handle.

4. Now the trolley is ready to use. The machine can then

be manoeuvred easily whilst holding the top handle.

6. Maintenance

WARNING - Before undertaking maintenance operations

or adjustments switch off machine and unplug from the

electricity supply. IMPORTANT – All other servicing and

repairs should only be performed by a Truvox engineer or

Authorised Service Agent. IMPORTANT – Should the

machine fail to operate please refer to the fault diagnosis

section in the back of this instruction manual. If the

problem / remedy is not listed please contact Truvox

Customer Service Department for rapid attention.

The machine requires minimum maintenance apart from

the following checks by the operator prior to use:

• DO NOT use aggressive detergents, acid, lye etc.

during cleaning and washing and take particular care

with electrical parts.

• Supply cord - Regularly inspect sheath, plug and cord

anchorage for damage or loose connection. Only

replace the supply cord with the type specified in these

instructions.

• Brushes - For maximum life, wash the brushes

regularly. Ensure machine is in Transport mode when

not in use. Store additional brushes in a vertical position

to avoid bending of bristles. Check for permanent

bending of bristles in a particular direction. This may

occur if the machine is operated for several days without

removing the brushes, which is not recommended. If

this occurs, reverse the brush so that the bent bristles

are automatically straightened.

• Wiper Blade - After years of use the wiper blade may

wear. If this occurs the water collection performance will

decrease. It should be replaced by an authorised

service agent.

• Solution tank filter (Standard) - The filter prevents

clogging of the drip holes in the tank. Periodically clean

the filter to ensure uniform discharge of liquid. In case of

non-uniform discharge from the drip holes, back flush

the tank in running

water. Clean the drip holes using

wire or a blunt pin.

• Solution feed filter (Pump) - The filter prevents clogging

of the spray nozzle and should be periodically cleaned.

Use pressurised air/water for cleaning.

• Nozzle maintenance (Pump) - If the spray of the nozzle

becomes blocked, slide the nozzle cover off and remove

nozzle wash in clean water and clean using a pin and

refit.

8

7. After sales service

Truvox machines are high quality machines that have

been tested for safety by authorised technicians. It is

always apparent that after longer working periods,

electrical and mechanical components will show signs of

wear and tear or ageing. To maintain operational safety

and reliability the following service interval has been

defined: Every year or after 250 hours. Under extreme or

specialised conditions and/or insufficient maintenance,

shorter maintenance intervals are necessary. Use only

original Truvox spare parts. Use of other spare parts will

invalidate all warranty and liability claims. Should you

require after sales service please contact the supplier from

whom you purchased the machine, who will arrange

service. Repairs and servicing of Truvox products should

only be performed by trained staff. Improper repairs can

cause considerable danger to the user.

8. Guarantee

Your product is guaranteed for one year from the date of

original purchase, or hire purchase, against defects in

materials or workmanship during manufacture. Within the

guarantee period we undertake at our discretion, to repair

or replace free of charge to the purchaser, any part found

to be defective, subject to the following conditions:

C

ONDITIONS

1. Claims made under the terms of the guarantee must be

supported by the original invoice/bill of sale issued at

the time of sale, or the machine Serial No.

2. For claims under this guarantee contact the supplier

from whom you purchased the product who will

arrange the appropriate action. Do not initially return

the product as this could result in transit damage.

3. Neither Truvox nor its distributor shall be liable for

any incidental or consequential loss.

4. This guarantee is governed by the laws of England.

5. This guarantee does not cover any of the following:

• Periodic maintenance, and repair or

replacement of parts due to normal wear and

tear.

• Damage caused by accident, misuse or neglect,

or the fitting of other than genuine Truvox parts.

• Defects in other than genuine Truvox parts, or

repairs, modifications or adjustments performed

by other than a Truvox service engineer or

authorised service agent.

• Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

• Consumable items such as, brushes, drive

discs, filters and vacuum skirts.

• This guarantee does not affect your statutory

rights, or your rights against the supplier arising

from their sales or purchase contract. Truvox

International Limited policy is one of continual

product development and we reserve the right to

alter specifications without prior notice.

9. Accessories

Item MW240 MW340 MW340/Pump MW440/Pump Usage

Standard brush –

black (2 required)

90-0127-0000 90-0130-0000 90-0130-0000 90-0387-0000

All natural stone floors,

ceramic, mosaic,

wood, profiled rubber,

vinyl, PVC (First time

cleaning); smooth

concrete

Soft brush – grey

(2 required)

90-0133-0000 90-0131-0000 90-0131-0000 90-0388-0000

All natural stone floors,

ceramic, mosaic,

wood, profiled rubber,

vinyl, PVC

(Maintenance

cleaning); short pile

carpet, marble granite

Side brush –

black (1 required)

90-0134-0000 90-0132-0000 90-0132-0000 90-0385-0000

For up-to-the-edge

cleaning

Hard brush –

blue (2 required)

- 90-0089-0000 90-0089-0000 -

To suit individual floor

conditions, smooth

concrete

Escalator brush –

blue (2 required)

- 90-0090-0000 90-0090-0000 90-0469-0000 For use on escalators

4 litre tank

- - 90-0307-0000 90-0103-0000

Trolley

(for all models)

05-3395-0000 05-3395-0000 05-3395-0000 05-3395-0000 For easier transport

9

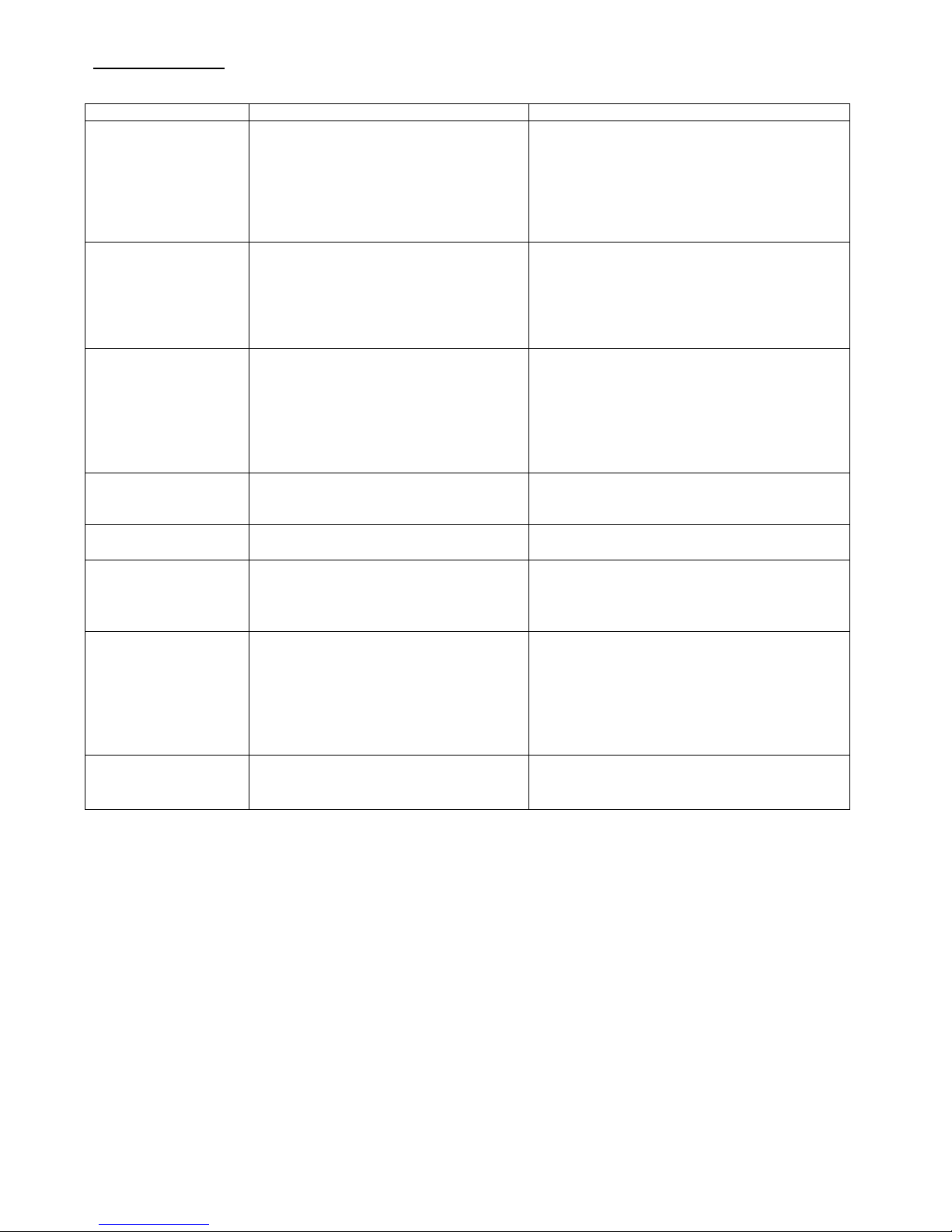

10. Fault diagnosis

The following simple checks may be performed by the operator:

Trouble Reason Remedy

Machine fails to start

– no power

• Transport working knob is in bottom

position

• Motor overload protector has tripped

• Micro switches are faulty open circuit

•

Check mains cable

• Check plug top fuse

• When handle is lowered transport wheels

move allowing brushes to touch the floor, if

transport wheels don’t move when handle is

lowered remove wheels and shafts and

clean.

Machine fails to pick

up water from the

floor

• Worn brushes

• Damaged lip on recovery tank

• Broken lugs on recovery tank

• Drum not revolving

• Bridge fitted wrong way on machine or

springs broken

•

Replace brush, lip, lugs or springs

• Fit bridge the correct way

Machine fails to

spray solution onto

the floor

(MW340/Pump &

MW440/Pump only)

• Blocked jet

• Blocked inline filter

• Faulty pump

• Blocked filter or faulty valve in solution

tank

• Faulty pump micro switches

• Damaged or broken pull cable

•

Clean jet or inline filter

Machine only sprays

when handle in

upright position

• Loose lower handle bolts

•

Tighten lower handle bolts

Drum is turning, but

brushes are not

• If one or both brushes are not turning,

stripped gears in gear box

Machine fails to let

solution onto the

floor (MW240 &

MW340 only)

• Damaged or broken pull cable

• Adjustment on pull cable

• Dirty filter in clean water tank

• Blocked holes in outlet channel

•

Empty clean water tank and fill up with clean

water

• Clean holes

Drum not turning

• Plastic gear inside rim of drum

sheared

• Drum sprocket bearing seized

• Build up of dirty hair etc. around bridge

springs

• Plastic gears in gear box stripped

• Drum rubber sleeve loose on drum

•

Clean drum and bearings and remove dirt

and build up

Motor makes a

humming noise but

does not turn

• Motor capacitor faulty

• Motor seized up

• Faulty motor windings

•

Contact service agent

* If the fuse blows several times, the machine should be checked by an authorised Service Agent.

10

MULTIWASH

Diese Bedienungsanleitung enthält wichtige

Informationen zu diesem Gerät sowie

Sicherheitsanweisungen für den Benutzer.

ACHTUNG

Erdungssymbol

Elektro- und Elektronik-Altgeräte

(WEEE)

Entsorgen Sie dieses Gerät nicht im

Hausmüll. Eine unsachgemäße

Entsorgung kann die Umwelt und

die Gesundheit schädigen. Wenden

Sie sich für Informationen über die

Abgabe- und Sammelsysteme in

Ihrer Region an die lokale

Entsorgungsstelle.

TECHNISCHE ANGABEN

Modell

Multi

wash

240

Multi

wash

340

Multi

wash

340

(Pumpe)

Multi

wash

440

(Pumpe)

Produktnummer

MW

240

MW

340

MW340/

PUMPE

MW440/

PUMPE

Spannung AC

(~)/ Frequenz

V/

Hz

230/

50

230/

50

230/

50

230/

50

Motorleistung (+

Pumpe)

W 400 600

600 +

26

1000 +

26

Arbeitsleistung m²/h 650 930 - 1150

Füllmenge

Laugentank

l 1.2 1.7 4 4

Bürstenbreite cm 24 34 34 44

Bürstendrehzahl

U/

min

650 650 650 650

Bürstendruck

g/cm

²

250 250 250 250

Geräuschpegel

dB

(A)

68 69 69 71

Abmessungen

(H x B x L)

cm

37,8 x

34 x

111,8

37,8 x

44 x

111,8

37,8 x

44 x

111,8

37,8 x

54 x

111,8

Gewicht kg 20 23 25 28

Kabellänge m 12 12 12 12

Gewährleistung 1 Jahr

• Die Geräuschentwicklung wurde im Abstand von 1 Meter von der

Maschine und 1,6 Metern über dem Boden beim Reinigen von

Hartboden gemessen. Die Messungen wurden mit einem

Handmessgerät durchgeführt.

• Die Griffvibration übersteigt 2,5 m/s² im Betrieb auf einer ebenen,

harten Fläche nicht.

• Die obenstehenden Abmessungen sind Richtwerte. Da sich unser

Unternehmen der ununterbrochenen Weiterentwicklung seiner

Produkte verschrieben hat, können die Daten ohne Ankündigung

geändert werden.

Wenn Sie Probleme oder Fragen haben, wenden Sie

sich an den Fachhändler, bei dem Sie die Maschine

erworben haben, oder an Truvox International.

Truvox International Limited

Third Avenue, Millbrook, Southampton, Hampshire,

SO15 0LE, Großbritannien; Tel.: +44 (0) 23 8070 6600,

Fax: +44 (0) 23 8070 5001; E-Mail: sales@truvox.com;

Web: www.truvox.com

EU-KONFORMITÄTSERKLÄRUNG

Gerätetyp: Bodenreinigungsmaschine

Typ: Multiwash

Modell: MW240…,

MW340…,

MW340/Pumpe…,

MW440/Pumpe…

Dieses Gerät entspricht den folgenden EU-Richtlinien:

2006/42/EG

2004/108/EG

Angewendete

harmonisierte

Normen

Machinenrichtlinie

EMV-Richtlinie

EN60335-1, EN60335-2-72,

EN55014-1, EN55014-2,

EN610003-2, EN610003-3,

EN62233

Truvox International

Malcolm Eneas

Third Avenue, Millbrook

Operations Manager

SO15 0LE, Southampton

Hampshire, England

Southampton, 01-11-2008

ACHTUNG – LESEN SIE DIESE ANLEITUNG VOR DER VERWENDUNG DES GERÄTES SORGFÄLTIG DURCH

UND BEWAHREN SIE SIE FÜR REFERENZZWECKE AUF

11

Beachten Sie die Geräteabbildungen auf Seite 1

1

2

3

4

5

6

Oberer Griff

Steuergriff für

Flüssigkeitsabgabe

Laugentank

(optional)

Abdeckung

Hauptbürste

Bürstenwelle

7

8

9

10

11

12

13

Transport/Arbeitsknopf

Sammelbehälter

Filter

Deckelkappe

Düse

Trommel

Pedal

1. Produktinformationen

Die Multiwash-Bodenreinigungsmaschinen sind für den

Einsatz auf glatten, ebenen Böden in Innenräumen

bestimmt. Sie können auf den meisten Bodenbelägen wie

kurzflorigem Teppich, Holz, PVC, Gummi und Stein

verwendet werden. Sie sollten nicht auf rauen, unebenen

Flächen verwendet werden. Das Gerät ist für die

gewerbliche Nutzung, zum Beispiel in Hotels, Schulen,

Krankenhäusern, Fabriken, Ladengeschäften, Büros,

Vermietungsunternehmen und andere Zwecke außer der

normalen Haushaltsreinigung vorgesehen.

Diese Bedienungsanleitung enthält wichtige Informationen

zu den Geräten sowie Sicherheitsanweisungen für den

Benutzer. Diese Bedienungsanleitung gilt für folgende

Modelle:

Multiwash - MW240…, MW340…, MW340/Pumpe…,

MW440/Pumpe…

Das Gerät muss im Einklang mit den Anweisungen des

Herstellers bedient, instand gehalten und gewartet

werden. Wenden Sie sich im Zweifelsfall an Ihren

Fachhändler.

1.1 Wichtiger Sicherheitshinweis

Bei der Verwendung dieses Geräts sollten die

grundlegenden Sicherheitsvorkehrungen

eingehalten werden, unter anderem die

folgenden:

• Das Gerät darf nur für den vom Hersteller vorgesehenen

Verwendungszweck, wie in dieser Anleitung

beschrieben, verwendet werden.

• Beachten Sie, dass die Sicherheitshinweise in den

Ergänzungen zur Bedienungsanleitung keinen Vorrang

vor den Normen in dem Land, in dem das Gerät benutzt

wird, haben.

• ACHTUNG - Verwenden Sie nur Zubehör- und

Ersatzteile, die mit der Maschine geliefert werden oder

vom Hersteller zugelassen sind. Durch die Verwendung

anderer Ersatz- oder Zubehörteile kann die Sicherheit

der Maschine beeinträchtigt werden.

• HINWEIS - Diese Maschine ist nur für die Verwendung

in trockenen Innenräumen vorgesehen und darf nicht im

Freien bei feuchtem Wetter verwendet oder gelagert

werden.

• Alle Teile müssen vor der Benutzung des Gerätes wie in

der Anleitung angegeben positioniert werden.

• Das Gerät muss vor seinem Anschluss an die

Stromversorgung entsprechend dieser Anleitung

ausgepackt und montiert werden.

• Verwenden Sie das Gerät NICHT in Räumen mit

gefährlichem Staub.

• Verwenden Sie das Gerät NICHT in explosionsfähigen

Atmosphären.

• Starten oder verwenden Sie das Gerät NICHT in der

Nähe entzündlicher Flüssigkeiten, Stäube oder

Dämpfe.

• Verwenden Sie das Gerät NICHT, um damit

brennende oder glimmende Materialien wie Zigaretten,

Streichhölzer, Asche oder andere entzündliche

Gegenstände aufzunehmen.

• Verwenden Sie das Gerät am oberen Ende von

Treppen mit Vorsicht, um Unfälle durch

Gleichgewichtsverlust zu vermeiden.

• Nutzen Sie das Gerät nur auf festen, ebenen

Oberflächen. Verwenden Sie das Gerät NICHT auf

schrägen Flächen und bei einem Gefälle von mehr als

2 %.

• Benutzen Sie das Gerät NICHT auf rauen, unebenen

Flächen wie industriellen Betonböden.

• Verwenden Sie das Gerät NICHT auf groben

Betonoberflächen.

• Verwenden Sie das Gerät NICHT in Außenbereichen

wie z.Bsp. Innenhöfen oder Terrassen oder auf rauen

Oberflächen.

• Verwenden Sie das Gerät NICHT auf nassen Flächen.

• ACHTUNG – Befüllen Sie die Maschinen nicht mit

Wasser, das wärmer ist als 50 °C.

• Verwenden Sie NIEMALS Diesel/Benzin oder ätzende

Reinigungsmittel auf den Böden.

• Wischen und saugen Sie NIEMALS ätzende,

entflamm-bare und/oder explosive Flüssigkeiten, auch

nicht in Verdünnung.

• Stecken Sie KEINE Gegenstände in die Öffnungen

des Geräts. Verwenden Sie das Gerät NICHT, wenn

Öffnungen versperrt sind. Entfernen Sie Staub, Unrat

und alles, was zu einer Beeinträchtigung des

Luftstroms führen könnte.

• Decken Sie das Gerät während der Benutzung N

I

CHT

ab.

• Ziehen Sie den Stecker der Maschine IMMER nach

der Verwendung aus der Steckdose; lassen Sie das

Gerät nie an die Stromversorgung angeschlossen.

• Lassen Sie das Gerät NICHT unbeaufsichtigt laufen.

• Die Maschine sollte immer mit einem ordnungsgemäß

geerdeten Stromanschluss mit der richtigen Spannung

und Frequenz verbunden werden.

• Wenn es gereinigt oder gewartet wird oder wenn Teile

oder Zubehör ausgetauscht werden, sollte das Gerät

immer durch Abziehen des Steckers aus der

Steckdose von der Stromversorgung getrennt werden.

• Benutzen Sie das Gerät NICHT, wenn es beschädigt,

draußen stehen gelassen oder in Wasser eingetaucht

wurde.

• Betätigen Sie die Schalter und berühren Sie den

Netzstecker NICHT mit nassen Händen, da Sie dabei

einen elektrischen Schlag bekommen können.

• ACHTUNG - Halten Sie das Stromkabel von sich

bewegenden Teilen (und/oder rotierenden Bürsten)

Loading...

Loading...