DR-10 CUTSHEET

AND OPERATING

MANUAL

1 — Last update: 2019/09/24

TruSteel

Copyright © 2019 TruSteel

Table of Contents

1. DR-10 OVERVIEW .............................................................................................................................. 1

2. IMPORTANT: READ THIS BEFORE PROCEEDING........................................................................... 2

3. PRE-INSTALLATION OVERVIEW ...................................................................................................... 3

4. DR-10 SETUP ILLUSTRATION........................................................................................................... 4

4.1. 1. DR-10 Vessel ......................................................................................................................... 5

4.2. 2. Mixer...................................................................................................................................... 6

4.3. 3. VFD (Variable Frequency Drive)............................................................................................. 7

4.4. 4. Chiller .................................................................................................................................... 8

4.5. 5. Vacuum Pump...................................................................................................................... 11

4.6. 6. Heater .................................................................................................................................. 13

5. ANCILLARY EQUIPMENT SPECIFICATION SHEET ........................................................................ 16

6. OPERATION & MAINTENANCE ....................................................................................................... 19

6.1. OPERATING PROCEDURE ..................................................................................................... 20

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

1. DR-10 OVERVIEW

The DR-10 Decarboxylation Reactor is capable of devolatizing

and decarbing up to 10 gallons of material per run.

Material is heated and mixed while under a low vacuum. Non-desirables

will evaporate and exit from the exchanger “arm”.

The jacketed vessel is heated with an oil heater which pumps hot

transfer oil through the vessel jacket. The crude material is mixed by the

motor/shaft/prop set on top of the vessel.

The condenser arm is cooled by a chiller unit. The system is under

vacuum.

Parts of the DR-10

1. Vessel w/ condenser arm

2. Mixer; controlled by a Variable Drive w/remote

3. Hot Oil Heater

Stainless steel braided hoses included with fittings; (1) 48” hose, (1) 72” hose

4. Chiller Unit (hoses included)

5. Vaccum Pump (hose included)

6. Kevlar heat protection jacket and a protective Kevlar glove

Page 1 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

2. IMPORTANT: READ THIS BEFORE PROCEEDING

TruSteel maintains this packet to provide general guidance to our customers. The recommendations

expressed herein represent the views only of our professional staff. They have not been reviewed or

approved by any organization that developed the local electrical, fire, and plumbing codes or standards.

These recommendations are based upon the best available information at the time they were written and

are not intended to and do not constitute professional electrician or plumbing advice or official

interpretations of any code or code provision.

Local building, fire, and energy codes govern legal requirements at the state, county, and municipal

levels. They vary widely from jurisdiction to jurisdiction and can change frequently. Those local codes

take precedence over TruSteel floor plans. Please consult the applicable edition of your local codes.

TruSteel expressly disclaims any liability resulting from reliance upon the recommendations or opinions

expressed in this packet and makes no representations, warranties, or claims of any kind concerning the

accuracy or completeness of the information presented in this packet.

Page 2 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

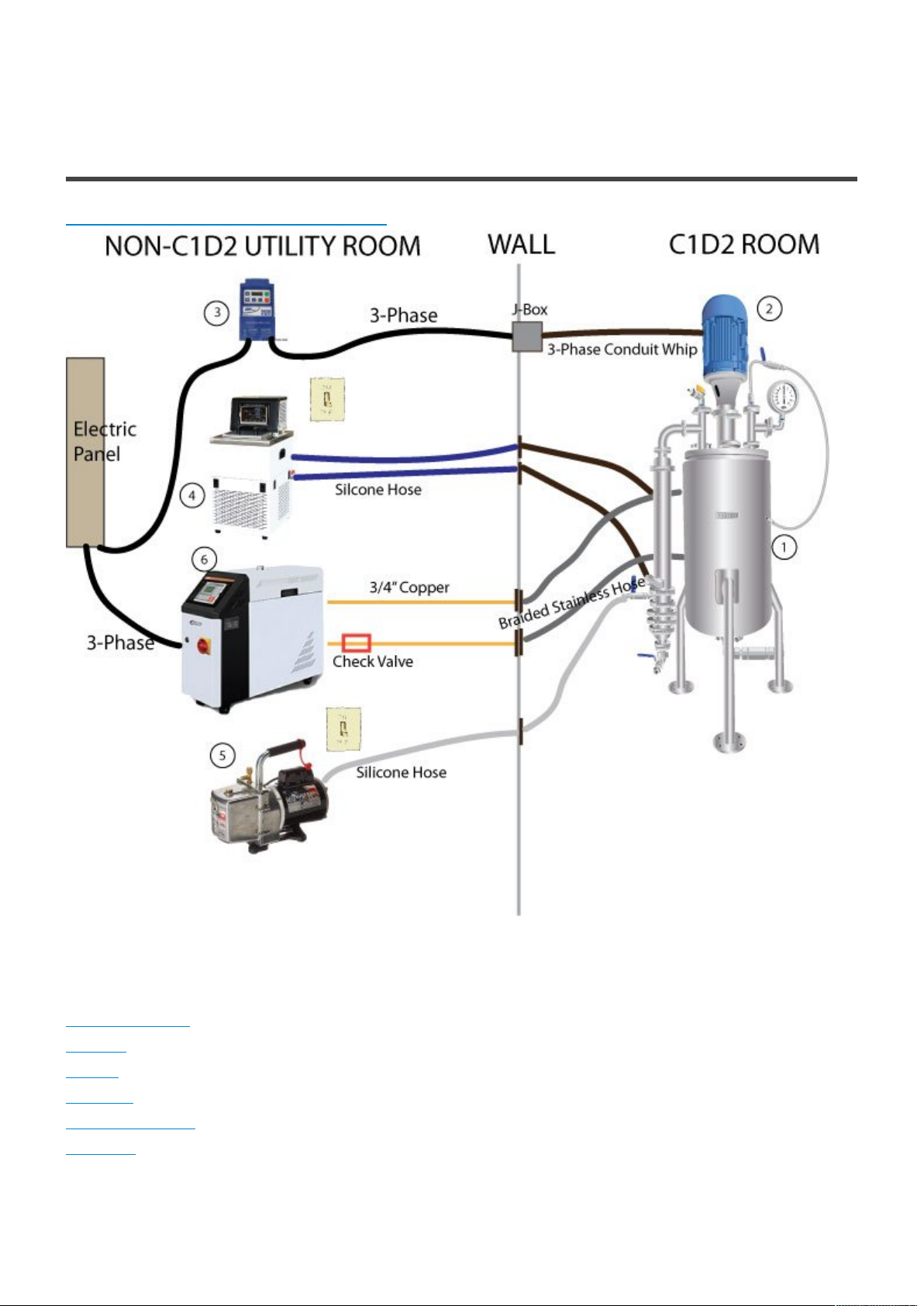

3. PRE-INSTALLATION OVERVIEW

This Pre-Installation Guide describes the requirements for preparing for your TruSteel DR-10 installation.

This information in this manual serves as a recommended guide to help you and your contractors

successfully install all required electrical and plumbing for the ancillary equipment.

This guide covers all electrical and plumbing specifications for the chiller, heater, drive panel, and

vacuum pump. This guide does not describe the installation of the DR-10 itself as it is highly

recommended you hire a TruSteel certified installation contractor.

The following portion describes the steps to completing your pre-installation and setting up your DR-10

installation date:

1. Full Payment Recieved

2. DR-10 Shipped (includes all equipment) Note: there may be a case where some parts must be

shipped separate.

3. TruSteel requires the client to properly install (electric) all equipment according to code.

Note: For C1D2 compliancy, all ancillary equipment shall be placed outside the room that the

DR-10 will be run.

The DR-10 vessel and the Mixer Motor are C1D2 compliant.

The hot oil heater and the mixer require 3-phase electrical hookups. The chiller and vacuum pump

require 115V switches.

4. An installation date is determined.

A TruSteel Certied installation technician will contact you to oversee the pre-installation

requirements. A target date can be set for the install. As long as all requirements are met, the

install date will be confirmed.

5. The DR-10 will be installed with training.

The DR-10 installation will be signed off by the client with 100% satisfaction and a 1 year

warranty.

Page 3 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4. DR-10 SETUP ILLUSTRATION

CLICK HERE FOR PRINTABLE VERSION

Table of Contents for Each Part

1. DR-10 Vessel

2. Mixer

3. VFD

4. Chiller

5. Vacuum Pump

6. Heater

Page 4 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.1. 1. DR-10 Vessel

This is the DR-10 vessel with the condenser “arm”. All parts of this vessel are supplied by TruSteel.

Parts List

1. 13-gallon vessel with legs

2. Condenser arm with all clamps and valves (vacuum valve, discharge valve)

3. Feed hose (60“ long 1/2” diameter stainless steel braided hose with 1/2” Swagelok tube adaptor/stub)

– Customer is responsible to adpat this hose to their feed vessel

4. Discharge – the discharge can be adapted two different ways. The standard setup is a 1/2” tube

“spiket” that can be discharged into a bucket or jar. The second option is to use the 48” long 1/2”

diameter stainless steel braided hose with a 1/2” Swagelok tube adaptor/stub that the customer can use

with a collection vessel.

5. Compression adapator – used to apply pressure to discharge material from system. Air/N2

compressor NOT supplied by TruSteel.

6. Pressure/Vacuum Gauge

7. Kevlar jacket for vessel

8. Cover for condenser arm

Setup Required by Customer

There is essentially no setup required. You should have a dedicated space for the DR-10 that is next to

the wall separating your C1D2 Room and your Non-C1D2 Utility Room.

Page 5 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.2. 2. Mixer

This is the C1D2/C1D1 Compliant Mixer that sits on top of the DR-10 vessel.

Parts List

1. Mixer Motor

2. Shaft

3. (2) Props

Setup Required by Customer

You do not need to place the mixer at this point. You will need an electrician available at the installation

to tie in the electrical wires (conduit). The conduit can be setup without being landed, before the install

date.

Page 6 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.3. 3. VFD (Variable Frequency Drive)

The VFD (Variable Frequency Drive) supplies power to, and controls, the mixer motor.

The VFD requires single phase wiring from your electrical panel to the VFD, then 3 phase wiring from the

VFD to the mixer motor. TruSteel suggests placing a J-Box when contining the 3 phase wiring conduit

through the wall.

Parts List

1. Lenze VFD

2. Remote Control (includes 8 feet of CAT5)

Setup Required by Customer

1. Mount VFD to wall inside NON-C1D2 room

2. Run single phase electric into the VFD.

3. Run 3 phase electric to a j-box on the wall

4. Continue 3 phase electric from j-box to where mixer will “live”

5. On day of install, electrician will be required to land wires to mixer motor

Page 7 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.4. 4. Chiller

The chiller unit is used to cool the condenser “arm”.

Parts List

1. Chiller Unit

2. Connection tubing included (1/2” silicone)

Not Included:

1 gallon of glycol

10 feet of 1/2” silicone tubing (for plumbing inside room)

Insulation for silicone tubing

All copper plumbing and 1/2” hose barbs

Setup Required by Customer

1. Have either a plug, or a 110V wall switch (recommended)

to power the chiller

2. Run copper plumbing to the 1/2” hose barbs

3. Make sure you have enough silicone hose inside the

room to reach your DR-10 unit

Note: The chiller run inside the room should not be more than 5 feet.

Page 8 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

Helpful Images

Plumbing from chiller to the wall. 1/2” silicone tubing to copper plumbing securely mounted to wall.

Page 9 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

Plumbing inside wall of DR-10 room. Copper plumbing to 1/2” hose barb. Each run has about 5 feet of

insulated silicon tubing.

Page 10 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.5. 5. Vacuum Pump

The Vacuum pump should be placed OUTSIDE your C1D2 room, along with your other ancillary

equipment.

Parts List

1. Vacuum Pump

2. Vacuum Pump Oil (in vacuum pump box)

3. 10 feet of 1/2” braided silicone hose

Not Included:

Copper plumbing and hose barbs to go through the wall.

Setup Required by Customer

1. Have either a plug, or a 110V wall switch (recommended)

to power the vacuum pump

2. Run copper plumbing to the 1/2” hose barbs

Helpful Images

Page 11 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

A top view of the vacuum pump with braided silicone hose going to a hose barb on the wall.

Vacuum pump hose( 1/2” braided silicone hose) coming into DR-10 room

Page 12 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

4.6. 6. Heater

The heater is a hot mineral oil heater.

Parts List

1. Oil Heater

2. 10 gallons of Mineral Oil

3. 3/4” inline Check Valve

4. (1) 72” long 3/4” diameter braided stainless steel hose with fittings and valves

5. (1) 48” long 3/4” diameter braided stainless steel hose with fittings and valves

Setup Required by Customer

1. Determine the placement of the heater unit. Note: With the check valve used in the outlet line, the unit

can sit on the floor. Without the check valve, the unit will need to sit on a table about 3-4 feet high.

2. Plumbing setup from heater to the wall. Use 3/4” copper with NO FLUX and NO PIPE DOPE. Place

the Check Valve supplied on the outlet run of the copper plumbing. See images below for a better view

of the plumbing.

3. Run the 3 phase electric required to the heater.

NOTE: The DR-10 unit should close enough to the wall so that the supplied braided stainless hoses

reach the unit from the wall. Please do not try to extend these hoses.

Page 13 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

Helpful Images

This is a front view look at the hot mineral oil heater. Note that it is placed very close to the wall.

Page 14 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

This is the view of the plumbing on the back of the heater. Note the check valve on the outlet side of the

heater.

This is the view of the plumbing coming into the DR-10 room. The valves and braided stainless lines are

provided by TruSteel.

Page 15 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

5. ANCILLARY EQUIPMENT SPECIFICATION SHEET

DR-10 Tank w/Condenser Arm

FOOTPRINT

36“W x 36“D x 55“H

Mixer

MODEL ELECTRICAL

MXTCMTSDR10 208-230/460V, 3Phase

Variable Drive for Mixer

MODEL ELECTRICAL DIMENSIONS

ESV751NO2YXC 200/240V – 1 or 3Ø Input (3Ø Output) – 4.2A 3.4”H x 2.2”W x .72”D

ESV751N04TXB 400/480V – 3Ø Input (3Ø Output) – 2A 3.4”H x 2.2”W x .72”D

Technical Documents

Drive

• AC Tech Lenze SMVector NEMA 4X

Flyer

• AC Tech Lenze SMVector Brochure

• AC Tech Lenze SMVector Datasheet

• AC Tech Lenze SMVector Wiring

Tutorial

• Lenze SMV Frequency Inverter

Operating Instructions

• AC Tech Lenze SMVector 1HP CAD Drawing

• AC Tech Lenze Keypad Installation Instructions

• AC Tech Lenze SMVector EMP Programmer Operating Instructions

Page 16 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

Remote

• SMVector Remote Keypad Installation Guide

• SMVector Flyer

• SMVector Instruction Manual

• SMVector Manual

Heater

MODEL ELECTRICAL DIMENSIONS

STM-907-HT 3-Phase 230V/23A or 460V/12A 27”H X 10”W X 29”D

STM-1220-UL 3-Phase 460V/15A 29.7”H X 12.6”W X 35.4”D

NOTE: Heater model may vary due to stock/lead times.

Technical Documents

• CutSheet

• User Manual

Chiller

MODEL ELECTRICAL DIMENSIONS DOCUMENT DOCUMENT

AI C20 115V/1-Phase/9.5A 26”h x 12”w x 15.5“d

Page 17 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

Technical Documents

• User Manual

• CutSheet

Vacuum Pump

MODAL ELECTRICAL DIMENSIONS DOCUMENT

DV-4E-250 115V/1-Phase/4A 12 × 9 × 9 inches

Technical Documents

• Product Brochure

Page 18 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

6. OPERATION & MAINTENANCE

DISCLAIMER AND SAFETY GUIDELINES

Read the DR-10 user manual to become familiar with the features of this product before operating.

Failure to operate the product correctly can result in damage to the product, personal property, and

cause serious injury.

This product must be operate with caution and common sense and requires some basic mechanical

ability. Also note that material used in the DR-10 may vary and parameters based on customer

preference for final product may vary.

This product is not intended for use by children. Do not use with incompatible components or alter this

product in any way outside of the documents provided by TruSteel.

This Operating Procedure is a recommendation from TruSteel. Temperatures and running time may vary

based on customer preference.

Page 19 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

6.1. OPERATING PROCEDURE

Step 1: Solvent Recovery

The DR10 is NOT intended to be a solvent recovery solution, however, you will be able to purge the

small percentage left from your falling film evaporator. The more solvent you have left from your falling

film, the longer this step will take and the more risk you have of over working the condenser.

This process can take anywhere from 1-3 hours.

The Operating procedure TruSteel suggests is as follows:

1. Set the heater to 70 Celsius (158F)

2. Set the chiller to -10 Celcius (14F)

3. Load material into the DR10

This can either be done from a pressurized vessel or through a funnel via one of the ports on the lid.

The maximum amount of material is 10 gallons (approx. 38 Liters)

NOTE: The more solvent you have in your material, the less amount you should load into the DR10. If

you feel your material has a lot of solvent, try 6-7 gallons (23-26 Liters)

4. Set mixer at a speed where the material is being whipped without spraying up onto the lid. A nice,

consistent vortex should form.

5. As the temperature begins to rise to around 50C (Temperature of material read from the

thermocouple), begin to pull vacuum.

NOTE: Gauge your vacuum depending on the amount of “froth” that is forming on top of the material.

Use the vacuum adjustment knob. You do not want this froth to pull over into the condenser.

TIP: Lower vacuum if the material is frothing up toward the lid. Continue adjusting vacuum throughout

this process.

6. As you feel the material is purging of solvent, you can try to raise the heater temperature to 80C

(176F) Continue to gauge how much vacuum you can pull at this higher temperature.

7. Repeat step 6, by raising the heater to 90C (194F) By this time you should have most of your solvent

purged.

Page 20 of 21

TruSteel DR-10 CUTSHEET AND OPERATING MANUAL - 1

8. Throughout this process, monitor the condenser sightglass and discharge recovered solvent.

Step 2: Decarboxylation

1. Increase heater temperature to 140C (284F) The thermocouple reading of your material should be

123C (253F) As the heater reaches 140C (284F), check the temperature of your material. Make sure you

maintain between 123C (253F) and 130C (266F).

WARNING: Do not put the set point of the heater over 140C (284F) in order to speed up the heating

process. You can damage your material by raising it too high.

2. Continue to monitor the mixer and the material with vacuum. You should have a nice, even vortex and

your material should appear thicker than when started. You may need to increase your mixer speed to

compensate for the thicker material.

3. Monitor the condenser sight glass and discharge as needed.

4. Pull a mild vacuum and increase as you feel necessary. Be careful not to pull too much as “bumping”

may occur (material can pass over into the condenser)

5. Monitor the solution for excessive bumping. A mild boil is the desired outcome

6. Decarb times may vary, a good starting point is 30 minutes as soon as the solution hits 123 C, test

your results as this may not be enough or too much time at temp

7. After timer is done, close vacuum valve and release the vacuum in the system.

8. Using N2 or dried compressed air, charge the system to 5 psi.

9. Drain solution into desired vessel, we recommend filtering it before moving to your next step

10. It is important to drain the solution immediately after decarboxylation is complete to avoid

isomerizing your material

11. Clean system by boiling ethanol or isopropyl, followed by water.

Page 21 of 21

Loading...

Loading...