Page 1

TRUE RESIDENTIAL

THE TRUE 42 / 48

INSTALLATION GUIDE

®

PRESERVE THE MOMENT

TM

Page 2

THANK YOU

FOR YOUR PURCHASE

Page 3

INDE X

OWNERSHIP 1

SAFETY PRECAUTIONS 1

DISPOSAL OF OLD REFRIGERATOR 1

CFC DISPOSAL 1

SITE PREPARATION 3

ELECTRICAL REQUIREMENTS 3

SPECIFICATIONS 7

ANTI-TIP BRACKET INSTALLATION 11

LEVELING THE UNIT 11

BASIC ELECTRONIC CONTROL OPERATIONS 15

SHELVING 23

REMOVING THE DOORS 23

KICK PLATE INSTALLATION 23

GENERAL MAINTENANCE 27

STAINLESS STEEL CLEANING AND MAINTENANCE 27

CONTACT INFORMATION

WARRANTY GUIDE

NOTE:

AS WE STRIVE FOR CONTINUOUS IMPROVEMENTS, FEATURES AND SPECIFICATIONS ARE SUBJECT

TO CHANGE WITHOUT NOTICE.

Page 4

THE TRUE 42 / 48

TR-42SBS-SS-B

R-48SBS-SS-B

T

Commercial refrigeration refined for the home, envied in the industry,

and crafted—gorgeously—in America.

Page 5

O w n e r s h i p

1 - 2

s a f e t y p r e c a u t i O n s

D i s p O s a l O f t h e O l D r e f r i g e r a t O r

c f c D i s p O s a l

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

1

Page 6

OWNERSHIP

TO INSURE THAT YOUR UNIT WORKS PROPERLY

FROM THE FIRST DAY, IT MUST BE INSTALLED

PROPERLY.

NOTE: WE HIGHLY RECOMMEND A TRAINED

REFRIGERATION MECHANIC AND ELECTRICIAN

®

INSTALL YOUR TRUE RESIDENTIAL

THE COST OF A PROFESSIONAL INSTALLATION

IS MONEY WELL SPENT.

Before you start to install your True Residential®

Cabinet, carefully inspect it for freight damage. If

damage is discovered, immediately file a claim with

the delivery freight carrier. True is not responsible for

damage incurred during shipment.

Any questions about the installation please

contact your True dealer or True Technical Service

Department at 844-746-9423. Please have your

model and serial numbers available when you call our

Service Department.

CA B INE T.

NOTE: WE STRONGLY RECOMMEND THAT ANY

SERVICING BE PERFORMED BY A QUALIFIED

INDIVIDUAL.

PROPER DISPOSAL OF THE OLD

REFRIGERATOR

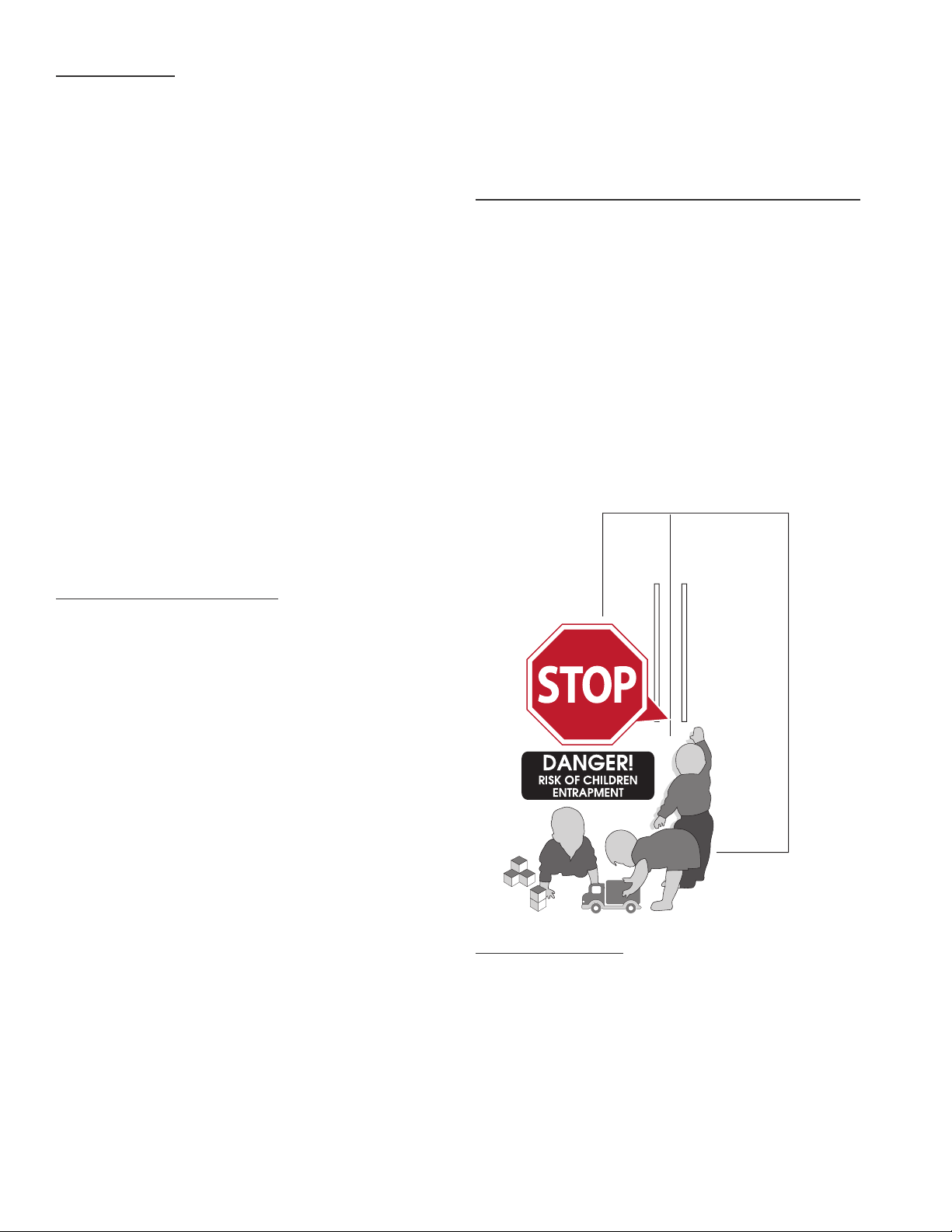

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous...Even if they will sit for “just a few

days”. If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

BEFORE YOU THROW AWAY YOUR OLD

REFRIGERATOR OR FREEZER:

• Take off the doors.

• Leave the shelves in place so that children may

not easily climb inside.

SAFETY PRECAUTIONS

• This refrigerator must be properly installed and

located in accordance with the installation

instructions before it is used.

• Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

seriously injure themselves or damage the

refrigerator.

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

• Keep hands away from the “pinch point” areas

(gaps between the doors and between the doors

and cabinet). Small areas are not necessarily safe.

• Unplug the refrigerator before cleaning and

making repairs.

• Setting temperature control to OFF only removes

power from the refrigeration system, it does not

remove power from other circuits. For example,

temperature control and lights.

CFC DISPOSAL

Your old refrigerator may have a cooling system that

used CFCs (chlorofluorocarbons). CFCs are believed

to harm stratospheric ozone. If you are throwing away

your old refrigerator, make sure the CFC refrigerant

is removed for proper disposal by a qualified service.

If you intentionally release this CFC refrigerant you

can be subject to fines and imprisonment under

provisions of the environment legislation.

TRUE RESIDENTIAL

2

®

Page 7

3 - 6

s i t e p r e p a r a t i O n

e l e c t r i c a l r e q u i r e m e n t s

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

3

Page 8

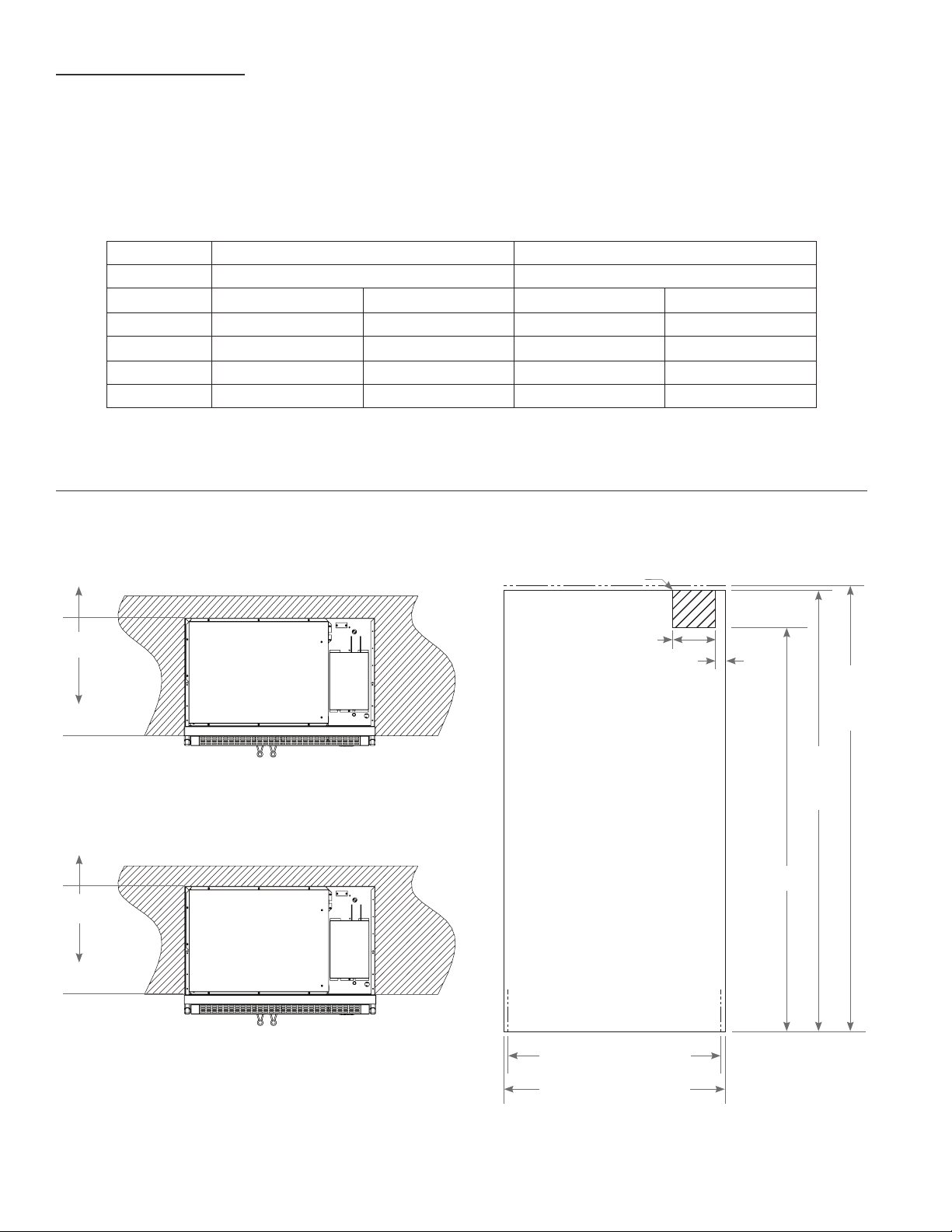

SITE PREPARATION

• Rough Opening dimensions. (See figure 1 and 2)

• For FLUSH installations the front face of the unit will be flush with the surrounding cabinets. (See figure 3)

• For PROUD (Standard) installations, the front face of the unit will extend beyond cabinets. (See figure 4)

MEASUREMENTS & WEIGHT

TR-42 TR-48

FLUSH PROUD FLUSH PROUD

WIDTH

42

DEPTH 26

HEIGHT

84

¼

”

”

¼

”

41

24

84

¾

”

”

”

48

84

26

1/4

”

”

¼

”

47

24

84

3/4

”

”

”

WEIGHT* 720 Lbs 720 Lbs 820 Lbs 820 Lbs

Cord Length 8 feet 8 feet 8 feet 8 feet

* Because of the weight of this unit, it is recommended to consult a ooring expert prior to installation. The ooring

beneath the unit should be rated to support at least 150 pounds per square foot.

TR-42

" MINIMUM

26

FLUSH INSTALL

" MINIMUM

24

PROUD INSTALL

TOP VIEW

FIGURE 1 - ROUGH OPENING

FLUSH INSTALL

FRONT VIEW

FIGURE 2 - ROUGH OPENING

Electrical located in

this area

"

8

"

2

84

¼

"

FLUSH

INSTALL

"

84

PROUD

INSTALL

"

77

TRUE RESIDENTIAL

4

PROUD INSTALL

®

¾

" PROUD INSTALL

41

¼

" FLUSH INSTALL

42

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

Page 9

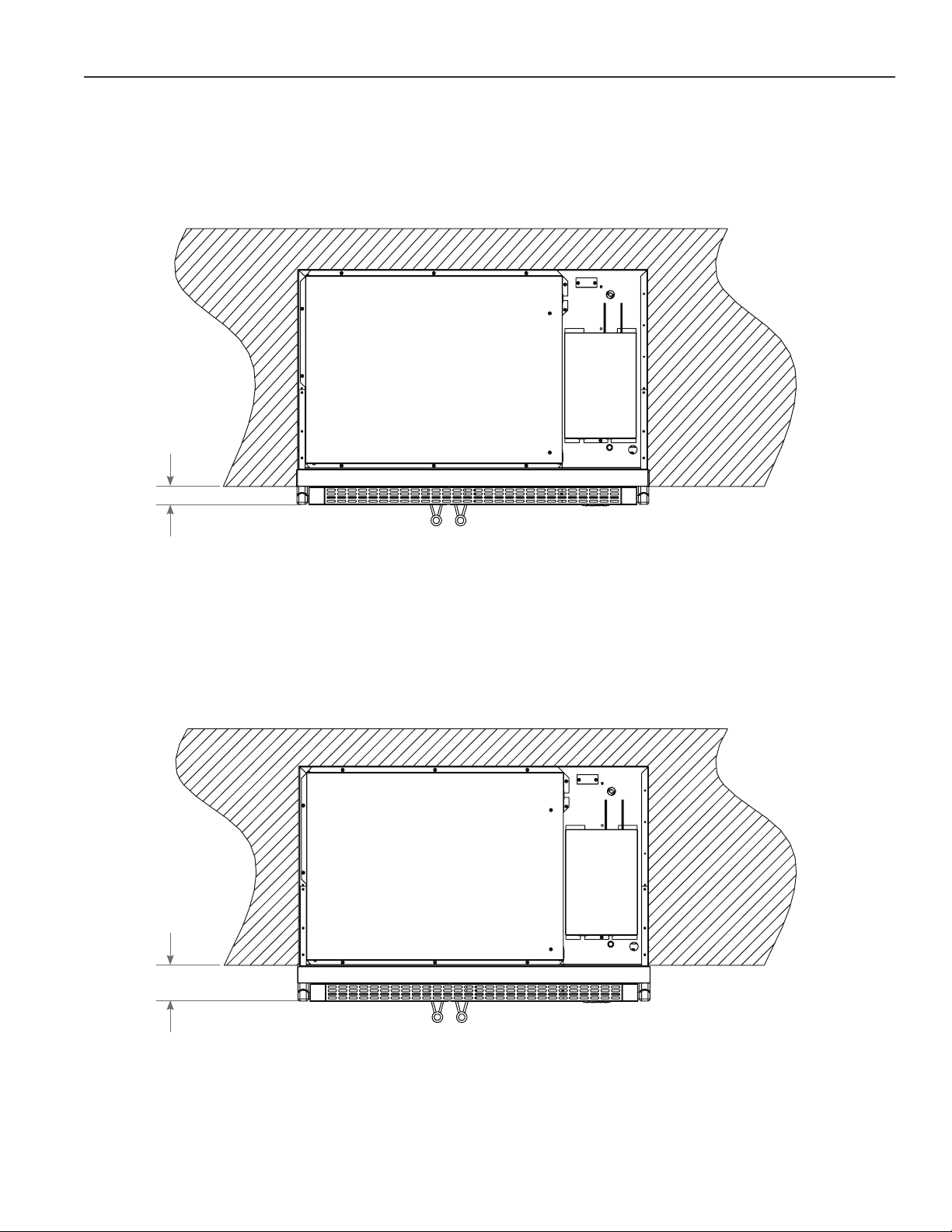

TR-42

TOP VIEW

FIGURE 3 - FLUSH INSTALLATION

3/16

"

2

TOP VIEW

FIGURE 4 - PROUD INSTALLATION

3/16

"

4

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

THE TRUE 42 / 48

5

Page 10

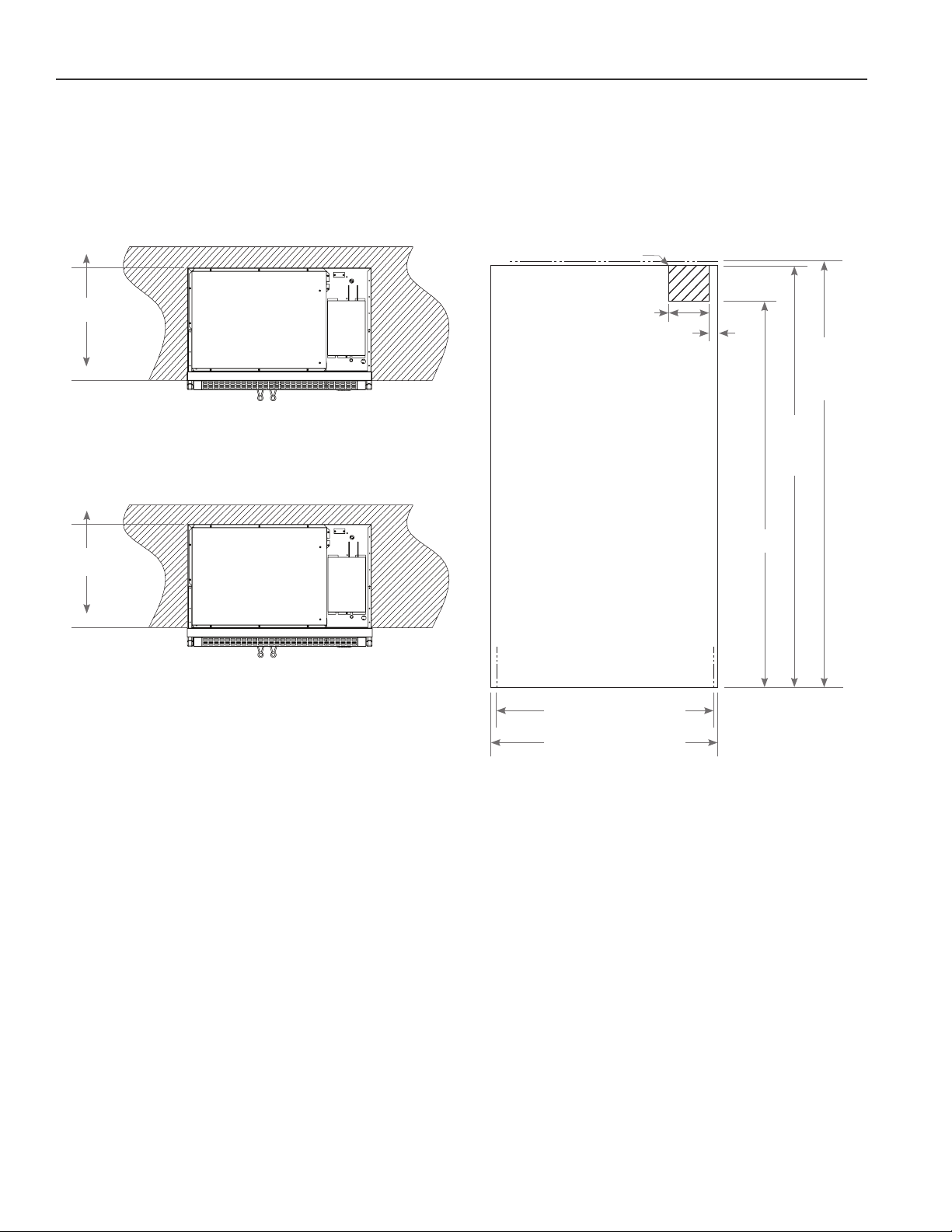

TR-48

" MINIMUM

26

FLUSH INSTALL

" MINIMUM

24

PROUD INSTALL

TOP VIEW

FIGURE 1 - ROUGH OPENING

FLUSH INSTALL

FRONT VIEW

FIGURE 2 - ROUGH OPENING

Electrical located in

this area

"

8

"

2

PROUD

INSTALL

"

77

84

FLUSH

INSTALL

"

84

¼

"

PROUD INSTALL

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

¾

" PROUD INSTALL

47

¼

" FLUSH INSTALL

48

TRUE RESIDENTIAL

6

®

Page 11

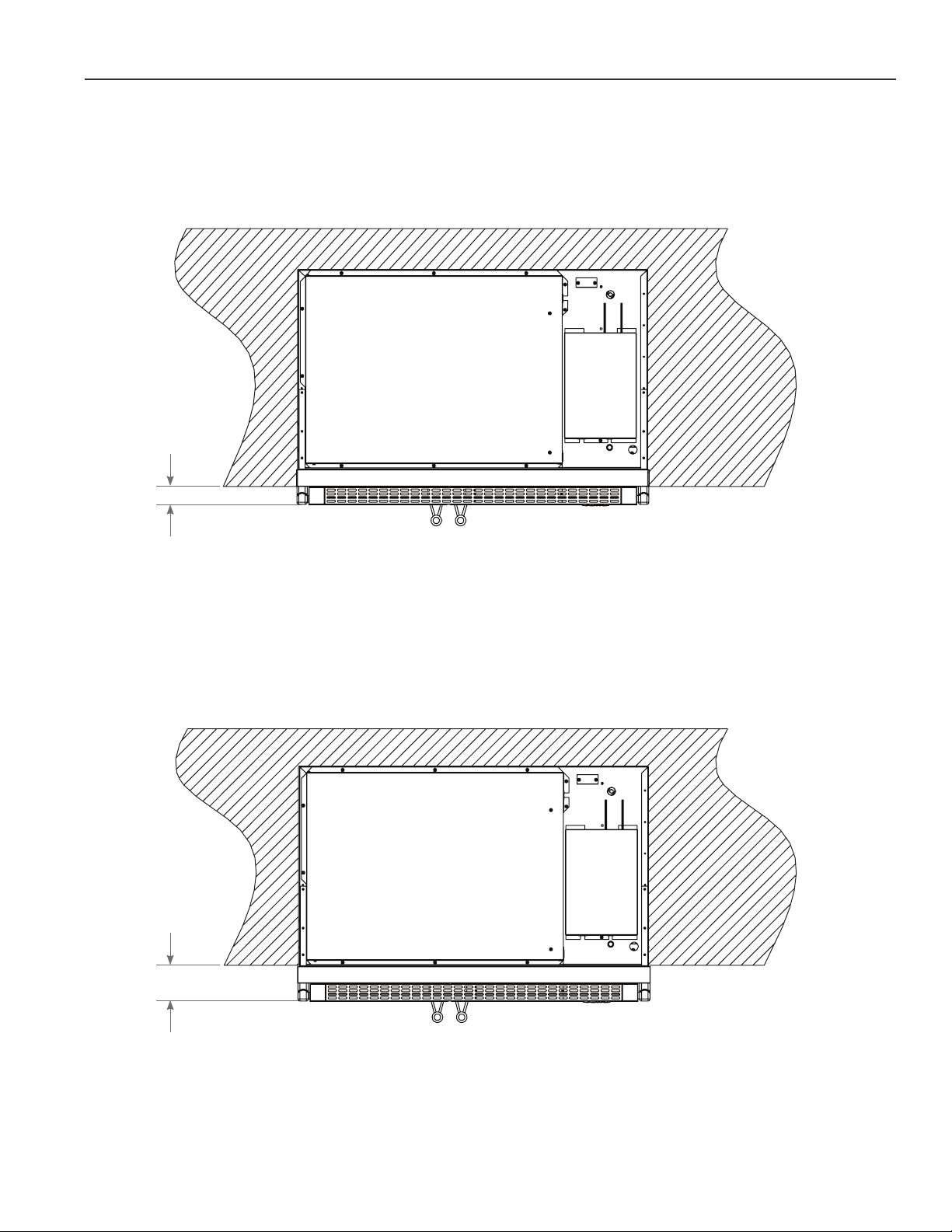

TR-48

TOP VIEW

FIGURE 3 - FLUSH INSTALLATION

3/16

"

2

TOP VIEW

FIGURE 4 - PROUD INSTALLATION

3/16

"

4

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

THE TRUE 42 / 48

7

Page 12

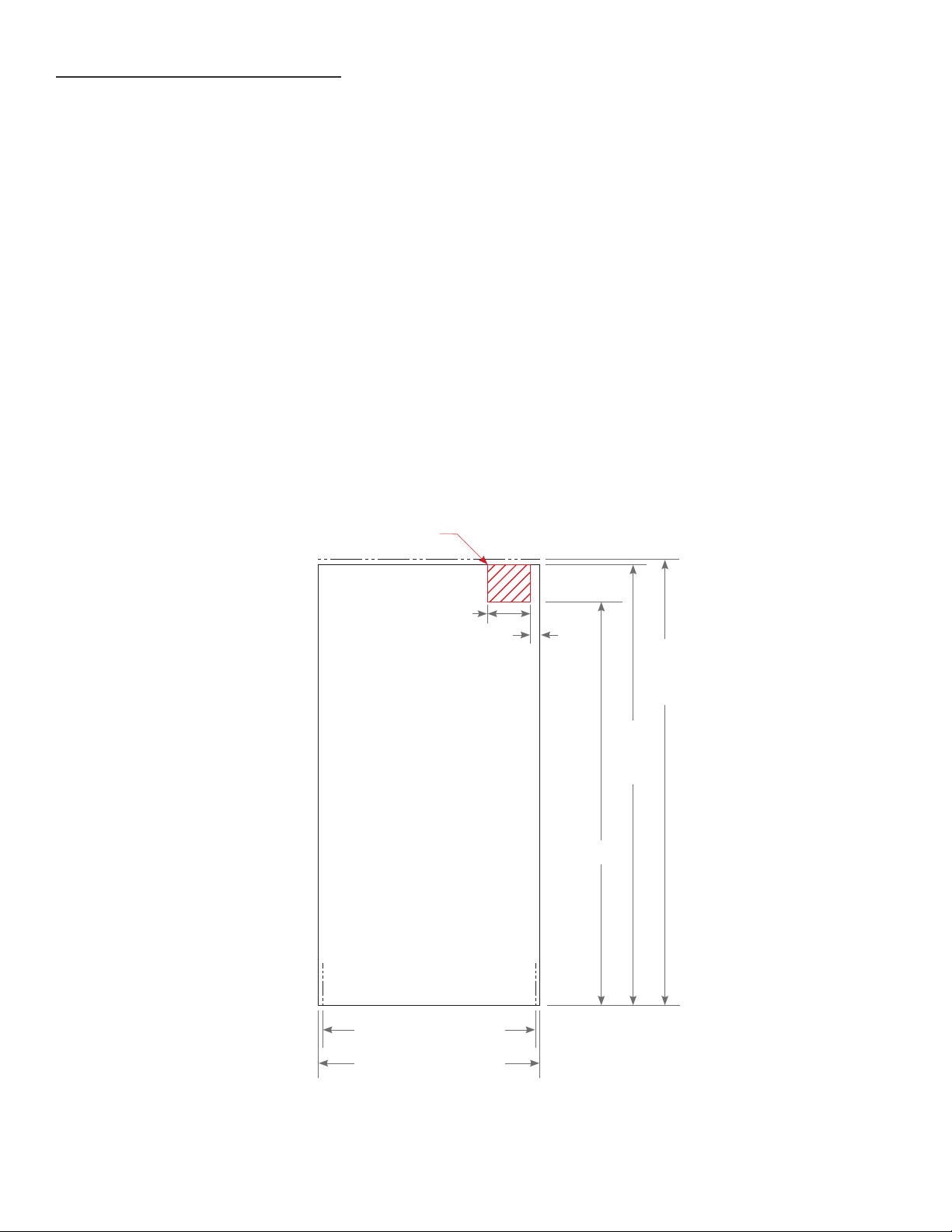

ELECTRICAL REQUIREMENTS

For all built-in models, the electrical supply should be located within the shaded area shown in the

illustration (See Figure 5). Follow the National Electrical Code and local codes and ordinances when

installing the receptacle. A separate circuit, servicing only this appliance is required. A ground fault

circuit interrupter (GFCI) is not recommended and may cause interruption of operation.

• POWER SUPPLY 115 V AC, 60 HZ

• CIRCUIT BREAKER 15 AMP

• RECEPTACLE 3-PRONG GROUNDING-TYPE

NOTES:

• THE OUTLET MUST BE CHECKED BY A QUALIFIED ELECTRICIAN TO BE

SURE THAT IT IS WIRED WITH THE CORRECT POLARITY.

• VERIFY THAT THE OUTLET IS PROPERLY GROUNDED.

FRONT VIEW

FIGURE 5 - ROUGH OPENING

Electrical located

in this area

"

8

"

2

84

¼

"

FLUSH

INSTALL

"

84

PROUD

INSTALL

"

77

TRUE RESIDENTIAL

8

¾

" PROUD INSTALL

41

¼

" FLUSH INSTALL

42

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

®

Page 13

7 - 11

s p e c i f i c a t i O n s

TR-42 / TR-48

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

9

Page 14

OVERALL DIMENSIONS - TR-42

½

"

2

TOP VIEW

9/16

"

41

CABINET WIDTH

DOORS OPEN 90º

23

25/32

"

20

13/16

"

5/8

"

26

DOORS OPEN 135º

TRUE RESIDENTIAL

10

1/32

"

13

®

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

17

5/32

"

Page 15

83

31/32

FRONT VIEW

"

29/32

"

72

21/32

"

67

DOOR

HEIGHT

30

27

25

15/32

29/32

25/32

"

"

"

¾

"

83

CABINET

HEIGHT

15/16

"

3

SIDE VIEW

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

THE TRUE 42 / 48

11

Page 16

OVERALL DIMENSIONS - TR-48

½

"

2

TOP VIEW

9/16

"

47

CABINET WIDTH

DOORS OPEN 90º

23

25/32

"

20

13/16

"

5/8

"

32

DOORS OPEN 135º

TRUE RESIDENTIAL

12

1/16

"

13

®

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

21

7/16

"

Page 17

83

31/32

"

72

21/32

FRONT VIEW

29/32

"

67

DOOR

HEIGHT

"

30

27

25

15/32

29/32

25/32

"

"

"

15/16

"

3

SIDE VIEW

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

THE TRUE 42 / 48

13

Page 18

n O t e s

TRUE RESIDENTIAL

14

®

Page 19

11 - 14

a n t i - t i p B r a c k e t i n s t a l l a t i O n

l e v e l i n g t h e u n i t

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

15

Page 20

ANTI-TIP KIT INSTALLATION

ANTI-TIP BRACKET KIT:

• One (1) anti-tip bracket (Figure 1.1)

• Four (4) masonry 3/16" screws

• Eight (8) wood #12 – 2" screws

• Twelve (12) 1/4" washers

FOR ALL FULL SIZE RESIDENTIAL MODELS, THE ANTITIP BRACKET ENGAGES WITH THE REAR LEVELING

LEGS TO SECURE THE UNIT. FOLLOW THESE STEPS

TO SECURE THE BRACKET BEFORE MOVING THE

UNIT INTO FINAL OPERATING POSITION.

1. Determine final location of the unit. For a FLUSH

install, measure back 24-31/32" (Dimension A)

from the surrounding cabinetry. For a PROUD

install, measure back 22-31/32" (Dimension B)

from the surrounding cabinetry. For either type of

install, place the anti-tip bracket centered in the

rough opening.

25/32

"

20

2. Using the bracket as a guide, drill pilot holes into

the floor and wall. It is recommended to secure the

bracket to as many floor joists and wall studs as

possible.

3. Using the provided screws and washers, secure the

bracket to the wall/floor. Adjust the rear rollers to

just above their lowest position and move the unit to

its final position. Raise the rear rollers a minimum

of 1/8" to engage the bracket.

FIGURE 1.1 - ANTI-TIP BRACKET

DIMENSION A

Flush Install

31/32

"

24

NOTES:

Dimensions may vary by ± 1/8”

DIMENSION B

Proud Install

31/32

"

22

• BECAUSE OF THE WEIGHT OF THIS UNIT (720 LBS), IT IS RECOMMENDED TO CONSULT A

FLOORING EXPERT PRIOR TO INSTALLATION. THE FLOORING BENEATH THE UNIT SHOULD BE

RATED TO SUPPORT AT LEAST 150 POUNDS PER SQUARE FOOT.

• EIGHT (8) ¼-20 X 1" LAG BOLTS SECURING THE UNIT TO THE SKID DURING SHIPPING MAY

ALSO BE USED ON THE INSTALLATION OF THE ANTI-TIP BRACKET.

!

WARNING

TIP OVER HAZARD

A child or adult could tip the refrigerator resulting in property damage or bodily harm. Follow these instructions

to properly install the anti-tip device. If the unit is moved, verify the device is properly engaged before normal

usage of unit commences.

1

/8”

TRUE RESIDENTIAL

16

®

NOTE: DIMENSIONS MAY VARY BY ±

Page 21

LEVELING THE UNIT

It is very important that the refrigerator sits level. This will insure that the doors will align and seal properly

and that the drain pans will not spill over.

TO LEVEL THE UNIT:

1. PLACE A LEVEL ON THE INTERIOR FLOOR. CHECK AND ADJUST FOR LEVEL FROM FRONT

TO BACK, ALSO CHECK AND ADJUST FOR LEVEL FROM RIGHT TO LEFT.

2. ADJUST THE FRONTS USING A SET OF PLIERS OR A WRENCH. (SEE FIGURE 6)

3. ADJUST THE REAR USING A 7/16" SOCKET AND RATCHET. (SEE FIGURE 6) TURN CLOCK-

WISE TO RAISE THE REAR OF THE UNIT.

FIGURE 6 - LEG ADJUSTMENTS

REAR LEG

ADJUSTMENT

FRONT LEG

ADJUSTMENT

NOTE: DIMENSIONS MAY VARY BY ± 1/8”

THE TRUE 42 / 48

17

Page 22

n O t e s

TRUE RESIDENTIAL

18

®

Page 23

15 - 22

B a s i c e l e c t r O n i c c O n t r O l O p e r a t i O n s

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

19

Page 24

BASIC ELECTRONIC CONTROL OPERATIONS

The following pages describe the basic input operations performed at the control panel;

• Switching unit ON and OFF

• Adjusting set-point (temperature adjustment)

• Enabling and disabling door ajar alarm feature

• Switching accent lighting systems ON and OFF

PLEASE NOTE THAT THOUGH POSSIBLE TO DISPLAY TEMPERATURES IN FAHRENHEIT OR

CELSIUS, IN MOST CASES FAHRENHEIT READINGS ARE SHOWN IN THIS MANUAL.

UNIT ON/OFF

All units are shipped in ON Mode. When electricity is supplied to the appliance, a short power up

diagnostics test is initiated followed by one audible beep, the lights energizing and temperature readings

appearing in the LCD.

NOTES:

• WHENEVER THE UNIT IS SWITCHED OFF USING THE POWER KEY, THE WORD “OFF”

WILL BE VISIBLE IN THE LCD (SEE FIGURE 7) AS LONG AS THERE IS ELECTRICITY

SUPPLIED TO THE APPLIANCE.

• WHENEVER THE UNIT IS SWITCHED ON USING THE POWER KEY, THE UNIT EMITS ONE

AUDIBLE BEEP, AND THEN TEMPERATURE READINGS WILL APPEAR IN THE LCD.

(SEE FIGURE 8).

• IF THE UNIT EXPERIENCES ANY PROBLEMS DURING THE POWER UP DIAGNOSTIC TEST,

THEN THE APPROPRIATE FAULT CODES WILL BE DISPLAYED.

(SEE PAGE 21, FIGURE 13 - NOTIFICATION ALERTS).

WARNING!

!

WHEN IN “OFF” MODE, AC LINE VOLTAGE IS STILL PRESENT AT MAIN CONTROL BOARD!

FIGURE 7 - CONTROL PANEL OFF

OFF

FIGURE 8 - CONTROL PANEL ON

TRUE RESIDENTIAL

20

34°F

-4°F

®

Page 25

ZONE NAVIGATION (TEMPERATURE ADJUSTMENT)

To adjust set-points, press ZONE for the appropriate compartment, then DOWN or UP key on control panel

in multiple key strokes until the desired set-point is achieved (See Figure 9). Each key stroke equals a one

degree change and is accompanied by an audible beep. When the desired set-point is reached press the

ZONE key until you reach the “HOME” screen, where the current zone temperatures will be displayed.

NOTES:

• THE TEMPERATURE RANGE IN A FREEZER ZONE IS -4°F (-20°C) TO +4°F (-16°C).

• THE TEMPERATURE RANGE IN A REFRIGERATOR ZONE IS +34°F (+1°C) TO +42°F (+6°C).

• INITIAL FACTORY SET-POINTS ARE 0°F (-18°C) IN A FREEZER ZONE AND 38°F (3°C) IN A

REFRIGERATOR ZONE.

• THE INITIAL STROKE OF THE UP OR DOWN KEY WILL CHANGE THE PREVIOUS SET-POINT BY

ONE DEGREE.

FIGURE 9 - ADJUSTING SET-POINTS

ZONE

NAVIGATION

NOTIFICATION

(SEE NOTIFICATION ALERTS)

AREA

ZONE

-4°F

REFRIGERATOR

34°F

34°F

ZONE

ZONE

FREEZER

-4°F

THE TRUE 42 / 48

21

Page 26

MODE NAVIGATION

The following pages illustrate unique customer input operations performed at the control panel. The input

operations described are:

TEMPERATURE UNIT SELECTION MODE, VACATION MODE, AND HOLIDAY MODE.

(SEE FIGURE 10).

NOTES: (HOLIDAY MODE)

• SET-POINTS CANNOT BE CHANGED AND MANUAL DEFROST CANNOT BE INITIATED.

• THE FOLLOWING HOLDS TRUE IN ACCORDANCE WITH STAR-K REQUIREMENTS:

- Freezer defrosting functions will convert to a fixed time base sequence.

- The compartment/zone thermistors will still detect cut-in and cut-out, which is the determining factor to

start/stop the cooling process, but there will be a random sixteen (16) to twenty-one (21) second delay

before cooling begins/ends.

- The phrase “HOLIDAY MODE ACTIVE” in the LCD remains energized when the door is closed.

FIGURE 10 - MODE NAVIGATION

MODE

NAVIGATION

-4°F

MODE

Activate Holiday Mode

Te mperatureºf

Vacation Mode

Activate Holiday Mode

Te mperature ºf

Vacation Mode

34°F

MODE

MODE

Holiday Mode Active

press any key to

exit

Te mperature Is

Celcius

press any key to exit

Te mperature Is

Fahrenheit

press any key to exit

TRUE RESIDENTIAL

22

Activate Holiday Mode

Te mperatureºf

Vacation Mode

®

MODE

Vacation Mode

Active

press any key to exit

Page 27

ACCENT LIGHTING SYSTEM

All models are equipped with an accent lighting system in the refrigerator and or freezer compartment(s). To

energize the accent lighting system, press the LIGHT key, and navigate to the corresponding compartment,

DOOR or ON will appear in the LCD indicating the accent lights are enabled (See Figure 11). With the accent

lighting system ON, the LED’s will be energized and stay illuminated when the door is closed, in the DOOR

position the lighting system will only be energized with the door opening.

NOTE:

• WHEN LIGHTS ARE PLACED IN “ON” MODE, LIGHTS WILL NOT FADE-UP WHEN DOOR OPENS.

FIGURE 11 - ACCENT LIGHTS ON/DOOR

LIGHT

LIGHT

BACK TO HOME SCREEN

REFRIGERATOR LIGHT DOOR

FREEZER LIGHT DOOR

Exit

NAVIGATION

-4°F

34°F

LIGHT

REFRIGERATOR LIGHT ON

FREEZER LIGHT DOOR

Exit

REFRIGERATOR LIGHT DOOR

FREEZER LIGHT DOOR

Exit

FREEZER LIGHT DOOR

REFRIGERATOR LIGHT DOOR

Exit

LIGHT

REFRIGERATOR LIGHT DOOR

FREEZER LIGHT ON

Exit

THE TRUE 42 / 48

23

Page 28

ALARM NAVIGATION (DOOR AJAR ALARM FEATURE ON/OFF)

All Residential Series units are equipped with a door ajar alarm feature. To enable the door ajar alarm, press

the ALARM key on the control panel and “DOOR AJAR ALARM ON” will appear in the LCD indicating the alarm

is enabled (See Figure 12). With the alarm enabled, the notification icons will appear and an audible alarm will

beep continuously whenever a door is left open for more than 5 minutes. To disable the door ajar alarm, press

the ALARM key again and “DOOR AJAR ALARM OFF” will appear in the LCD.

FIGURE 12 - ALARM NAVIGATION

AL ARM

BACK TO MAIN SCREEN

NAVIGATION

-4°F

refrigerator

door ajar

freezer

drawer ajar

Door Alarm On

Exit

34°F

TRUE RESIDENTIAL

24

ALARM

®

ALARM

Door Alarm Off

exit

Door Alarm Off

Exit

ALARM

TO STOP ALARM BUZZER PRESS

Page 29

NOTIFICATION ALERTS

NOTIFICATION ALERTS

MAIN SCREEN C

C

The diagrams on these pages illustrate what a customer may see in the LCD if the appliance needs attention

(See Figure 13).

FIGURE 13 - NOTIFICATION ALERTS

service

required

freezer

door ajar

refrigerator

door ajar

refrigerator

high temp

freezer

high temp

-4°F

34°F

showroom

mode

OULD SHOW THE FOLLOWING

OMMUNICATION ERROR:

Communication Error

call for service

THE TRUE 42 / 48

25

Page 30

n O t e s

TRUE RESIDENTIAL

26

®

Page 31

23 - 26

s h e l v i n g

r e m O v i n g t h e D O O r s

k i c k p l a t e i n s t a l l a t i O n

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

27

Page 32

SHELVING

All shelving and door bins come

packaged inside the unit.

(See Figure 14)

FIGURE 14

REFRIGERATOR STORAGE

GLASS SHELVES

Remove the top foam piece holding the glass shelves. Carefully remove shelves and set aside. (See Figure 15).

Remove all other packing material. To install, insert glass shelf into the shelf standards on the back wall, with

the front tilted upward, and then lower the front until it stops. (See Figure 16). To remove or adjust a glass

shelf, tilt up, and then lift up and out.

FIGURE 15 FIGURE 16

Final Glass Shelf Installation

DOOR BINS

The door bins are located in the bottom drawer of the refrigerator. (See Figure 17). To install, push tabs into the

slots in the door and slide downward unit it stops. (See Figure 18). To remove or adjust a door bin, lift up and

away from door back.

NOTE: BE CAUTIOUS OF PLACING TALL ITEMS IN TOP DOOR BIN, AS ITEMS MIGHT INTERFERE

WITH UI CONTROL PANEL.

FIGURE 17 FIGURE 18 Final Door Bin Installation

TRUE RESIDENTIAL

28

®

Page 33

DRAWERS

To remove a drawer, pull drawer forward until it stops. Use a Phillips screw driver to remove the two (2) screws

securing the drawer to the slides, then lift the drawer up and out of unit. (See Figure 19). To reinstall, pull drawer

slides all the way forward on unit, and then slide the drawer onto the slides until the hook on the back of the

slide is over top of the drawer, reinstall the screws using the Phillips screw driver.

Figure 19

FREEZER STORAGE

WIRE SHELVES

Remove the top foam piece holding the wire shelves. Carefully remove shelves and set aside. (See Figure 20).

Remove all other packing material. To install, insert wire shelf into the shelf standards on the back wall, with the

front tilted upward, and then lower the front until it stops. (See Figure 21). To remove or adjust a wire shelf, tilt

up, and then lift up and out.

FIGURE 20 FIGURE 21 Final Wire Shelf Installation

WIRE BASKETS

To remove a basket, pull drawer forward until it stops. Use a Phillips

screw driver to remove the two (2) screws securing the basket to the

slides, then lift the basket up and out of unit. To reinstall, pull drawer

slides all the way forward on unit, and then slide the basket onto the

slides until the hook on the back of the slide is over top of the rails,

reinstall the screws using the Phillips screw driver. (See Figure 22).

Figure 22

THE TRUE 42 / 48

29

Page 34

REMOVING THE DOORS

REMOVING THE DOORS

Open the door to 90 degrees. (See Image 23). Lift the door straight up and out of the hinges. (See Image 24).

To re-install, hold the door 90 degrees to the opening and align hinge posts to the hinges. Lower the door into

place.

FIGURE 23 FIGURE 24

KICK PLATE INSTALLATION

KICK PLATE

The kick plate is shipped with the unit but not attached to allow access to level the unit (See Image 25). Once

the unit is level, the kick plate attaches to the front, bottom of the unit with magnets located on the left and

right. (See Image 26).

FIGURE 25 FIGURE 26 - Magnets Installed Kick Plate

TRUE RESIDENTIAL

30

®

Page 35

s t a i n l e s s s t e e l e q u i p m e n t c a r e a n D c l e a n i n g

g e n e r a l m a i n t e n a n c e

27-28

w a r r a n t y

c O n t a c t i n f O r m a t i O n

PRESERVE THE MOMENT

TM

THE TRUE 42 / 48

31

Page 36

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

CAUTION: DO NOT USE ANY STEEL WOOL,

ABRASIVE OR CHLORINE BASED PRODUCTS TO

CLEAN STAINLESS STEEL SURFACES.

STAINLESS STEEL OPPONENTS

There are three basic things which can break down

your stainless steel’s passivity layer and allow

corrosion to rear its ugly head.

1. Scratches from wire brushes, scrapers, and steel

pads are just a few examples of items that can be

abrasive to stainless steel’s surface.

2. Deposits left on your stainless steel can leave

spots. You may have hard or soft water depending

on what part of the country you live in. Hard water

can leave spots. Hard water that is heated can

leave deposits if left to sit too long. These deposits

can cause the passive layer to break down and

rust your stainless steel.

All deposits left from food prep or service should

be removed as soon as possible.

3. Chlorides are present in table salt, food, and

water. Household and industrial cleaners are the

worst type of chlorides

to use.

RECOMMENDED CLEANERS FOR CERTAIN SITUATIONS /

ENVIRONMENTS OF STAINLESS STEEL

A. Soap, ammonia and detergent medallion applied

with a cloth or sponge can be used for routine

cleaning.

NOTE: THE USE OF STAINLESS STEEL

CLEANERS OR OTHER SUCH SOLVENTS IS NOT

RECOMMENDED ON PLASTIC PARTS. WARM

SOAP AND WATER WILL SUFFICE.

8 STEPS THAT CAN HELP PREVENT RUST ON STAINLESS STEEL:

1. USING THE CORRECT CLEANING TOOLS

Use non-abrasive tools when cleaning your stainless steel

products. The stainless steel’s passive layer will not be

harmed by soft cloths and plastic scouring pads. Step 2

tells you how to find the polishing marks.

2. CLEANING ALONG THE POLISH LINES

Polishing lines or “grain” are visible on some stainless

steels. Always scrub parallel to visible lines on some

stainless steels. Use a plastic scouring pad or soft cloth

when you cannot see the grain.

3. USE ALK ALINE, ALKALINE CHLORINATED OR NON-

CHLORIDE CONTAINING CLEANERS

While many traditional cleaners are loaded with chlorides,

the industry is providing an ever increasing choice of nonchloride cleaners. If you are not sure of your cleaner’s

chloride content contact your cleaner supplier. If they

tell you that your present cleaner contains chlorides,

ask if they have an alternative. Avoid cleaners containing

quaternary salts as they can attack stainless steel, causing

pitting and rusting.

4. WATER TREATMENT

To reduce deposits, soften the hard water when possible.

Installation of cer tain f ilters can remove corrosive and

distasteful elements. Salts in a properly maintained water

softener can be to your advantage. Contact a treatment

specialist if you are not sure of the proper water

treatment.

B. Arcal 20, Lac-O-Nu Ecoshine applied provides

barrier film for fingerprints and smears.

C. Cameo, Talc, Zud First Impression is applied by

rubbing in the direction of the polished lines for

stubborn stains and discoloring.

D. Easy-off and De-Grease It oven aid are excellent

for removals on all finishes for grease-fatty acids,

blood and burnt-on foods.

E. Any good commercial detergent can be applied

with a sponge or cloth to remove grease and oil.

F. Benefit, Super Sheen, Sheila Shine are good for

restoration / passivation.

TRUE RESIDENTIAL

32

®

5. MAINTAINING THE CLEANLINESS OF YOUR FOOD

EQUIPMENT

Use cleaners at the recommended strength (alkaline

chlorinated or non-chloride). Avoid build-up of hard

stains by cleaning frequently. When boiling water with

your stainless steel equipment, the single most likely cause

of damage is chlorides in the water. Heating any cleaners

containing chlorides will have the same damaging effects.

6. RINSE

When using chlorinated cleaners you must rinse and wipe

dry immediately. It is better to wipe standing cleaning

agents and water as soon as possible. Allow the stainless

steel equipment to air dry. Oxygen helps maintain the

passivity film on stainless steel.

7. HYDROCHLORIC ACID (MURIATIC ACID) SHOULD NEVER

BE USED ON STAINLESS STEEL

8. REGULARLY RESTORE/PASSIVATE STAINLESS STEEL

Page 37

GENERAL MAINTENANCE

Keeping the condenser coil clean will minimize required service and lower electrical cost. The condenser coil is

accessible from the front. (See Figure 27).

The condenser coil should be cleaned by removing dust and other build-up from the tube assembly with

vacuum or a cleaning rag.

When properly cleaned you should be able to see through the tube assembly.

Warranty does not cover cleaning the condenser coil.

FIGURE 27

THE TRUE 42 / 48

33

Page 38

WARRANTY

LIMITED 30 DAY COSMETIC WARRANTY

Stainless steel doors, handles, and shelves are warranted to be free from defective materials or workmanship for a period

of thirty (30) days from the date of original retail purchase. Any defects must be reported to the selling dealer within thirty

(30) days from the date of original retail purchase. This limited warranty excludes any type of freight / concealed damage.

THREE-YEAR PARTS & LABOR WARRANTY *For units purchased after Feb. 1, 2013.

TRUE warrants to the original purchaser of every new TRUE refrigerated unit, the cabinet and all parts thereof, to be free

from defects in material or workmanship under normal and proper use and maintenance as specified by TRUE and upon

proper installation and start-up in accordance with the instruction packet supplied with each TRUE unit. TRUE’s obligation

under this warranty is limited to a period of three (3) years from the date of original installation or thirty nine (39) months

after shipment date from TRUE, whichever occurs first.

SIX-YEAR SEALED SYSTEM WARRANTY - PARTS & LABOR *For units purchased after Feb. 1, 2013.

TRUE warrants its hermetically sealed system: compressor, evaporator coil, condenser coil, drier, metering device

and connecting tubing to be free from defects in both material and workmanship under normal and proper use and

maintenance service for a period of six (6) years from the date of original installation but not to exceed six (6) years and

three (3) months after shipment from the manufacturer, whichever occurs first.

TERMS APPLICABLE TO EACH WARRANTY

Any part covered under the above warranties that is determined by TRUE to have been defective within the time frame is

limited to the repair or replacement, including labor charges, of defective parts or assemblies. The labor warranty shall

include standard straight time labor charges only and reasonable travel time, as determined by TRUE.

WARRANTY CLAIMS

All claims for labor or parts must be made directly through TRUE. All claims should include: model number and serial

number of cabinet, proof of purchase, and date of installation. In case of warranted compressor, the compressor model

tag must be returned to TRUE along with the above listed information.

WHAT IS NOT COVERED BY THIS WARRANTY

TRUE’s sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional

limitations below. This warranty neither assumes nor authorizes any person to assume obligations other than those

expressly covered by this warranty.

NO CONSEQUENTIAL DAMAGES. TRUE is not responsible for economic loss, profit loss; or special, indirect or

consequential damages, including without limitation, losses or damages arising from food or product spoilage claims

whether or not on account or refrigeration failure.

WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original purchaser/

user to whom delivered. Any such assignment or transfer shall void the warranties herein made and shall void all

warranties, express or implied, including any warranty or merchantability or fitness for a particular purpose.

IMPROPER USAGE. TRUE assumes no liability for parts or labor coverage for component failure or other damages

resulting from improper usage or installation or failure to clean and/or maintain product as set forth in the warranty packet

provided with the unit.

ALTERATION OR NEGLECT. TRUE is not responsible for the repair or replacement of any parts that TRUE determines have

been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or

installation, fire, flood, or act of God.

IMPROPER ELECTRICAL CONNECTIONS. TRUE is not responsible for the repair or replacement of failed or damaged

components resulting from electrical power failure, high or low voltage, use of extension cords, or improper grounding of

the unit.

NO IMPLIED WARRANTY. There are no other warranties, expressed, implied or statutory except the 30 day cosmetic,

3-year parts and labor and 6-year sealed system warranty as described above. These warranties are exclusive and in lieu

of all other warranties, including implied warranty and merchantability or fitness for a particular purpose. There are no

warranties which extend beyond the description on the face hereof.

Some states do not allow the exclusion or limitation of consequential damages or a limitation on how long an implied

warranty lasts, so the above exclusion or limitation may not apply to you. This warranty gives you specific legal rights and

you may have other rights that vary from state to state.

OUTSIDE U.S./CANADA. This warranty does not apply to, and TRUE is not responsible for, any warranty claims made on

products sold or used outside the United States or Canada.

TRUE RESIDENTIAL

34

®

Page 39

CONTACT INFORMATION

Please have your serial # on hand so we can better assist you. The serial # is a 7-digit number located on the

left hand side wall by the pull out wire basket located in the freezer section of your unit.

Customer Service

P# 888 - 616-878 3

Website – www.true-residential.com

Warranty Department

P# - 844-849-6179

Website – trueresidentialwarranty@truemfg.com

Service Department

P# 844-746-9423

Website - service@truemfg.com

THE TRUE 42 / 48

35

Page 40

TRUE RESIDENTIAL

36

®

Page 41

Page 42

CONTACT US

www.true-residential.com

toll free (888)616-8783

AC 8/16 # MISC_18 39

Loading...

Loading...