Page 1

T-23

TRUE FOOD SERVICE EQUIPMENT, INC.

2001 East Terra Lane • O’Fallon, Missouri 63366-4434

(636)-240-2400 • FAX (636)272-2408 • INT’L FAX (636)272-7546 • (800)325-6152

Parts Department (800)424-TRUE • Parts Department FAX# (636)272-9471

INSTALLATION MANUAL FOR T-SERIES FREEZER /

REFRIGERATOR (SWING AND SLIDE DOOR)

TABLE OF CONTENTS

Safety Information

Safety Precautions 1

TSD Do’s and Don’ts 2

Proper Disposal 3

Connecting Electricity 4

Adapter Plugs 4

Installation / Operation Instructions

Ownership 5

Required Tools 5

Uncrating 5

Leveling Cabinet 6

Installation of Castors or Optional Legs 7

Installing Optional Castors on a T-12FG 8

Slide Door Operation Instructions 9

Wire Gauge Chart 10

Sealing Cabinet to Floor & Electrical Inst. 11

T-35

Start-up 12

Shelving Install/Operation & Light Switches 13

Grasslin Defrost Timer (Freezer Units Only) 14

Field Troubleshooting (Freezer Units Only) 15-16

Light Cover Install for T-12FG 17

Maintenance, Care & Cleaning

Cleaning Condenser Coil 18-19

Temperature Control Adjustment 20

TSD-47G

TSD-69

Stainless Steel Equipment Care & Cleaning 21-22

Light Bulb Replacement 22

Warranty (U.S.A. & CANADA ONLY!) 23

*Spanish, German, French, Dutch, and Arabic versions included.

CONGRATULATIONS!

You have just purchased the finest commercial

freezer / refrigerator available. You can expect many

years of trouble-free operation.

T-SERIES

FREEZER / REFRIGERATOR SWING

& SLIDE DOOR

............ www.truemfg.com ............

4/30/10 -500 SB #897001

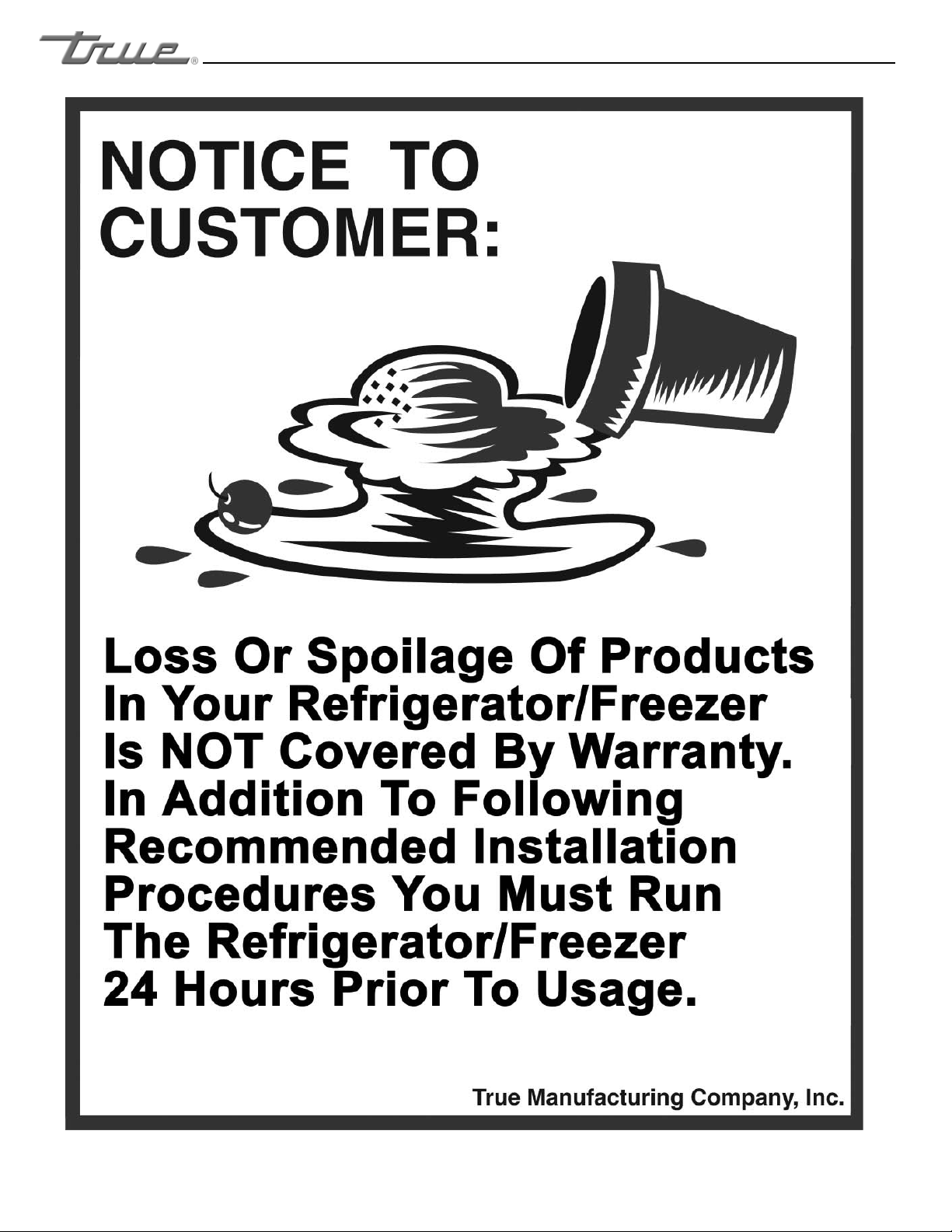

Page 2

True Food Service Equipment, Inc.

............ www.truemfg.com ............

Page 3

True Food Service Equipment, Inc.

SAFETY INFORMATION

How to Maintain Your Freezer

/ Refrigerator to Receive the Most

Efficient and Successful Operation

You have selected one of the nest commercial refrigeration units made.

It is manufactured under strict quality controls with only the best quality

materials available. Your TRUE cooler when properly maintained will give

you many years of trouble-free service.

WARNING!

Use this appliance for its intended purpose as described

in this Owner Manual.

This cabinet contains fluorinated greenhouse gas covered by the Kyoto Protocol

(please refer to cabinet’s inner label for type and volume,

GWP of 134a= 1,300. R404a= 3,800).

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

This refrigerator must be properly installed and

located in accordance with the Installation

Instructions before it is used.

Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

Do not touch the cold surfaces in the freezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

NOTE: We strongly recommend that any

servicing be performed by a quali ed

individual.

Unplug the refrigerator before cleaning and

making repairs.

Setting temperature controls to the 0 position

does not remove power to the light circuit,

perimeter heaters, or evaporator fans.

Keep fingers out of the “pinch point” areas;

clearances between the doors and between the

doors and cabinet are necessarily small; be

careful closing doors when children are in the

area.

1

1

............ www.truemfg.com ............

............ www.truemfg.com ............

1

1

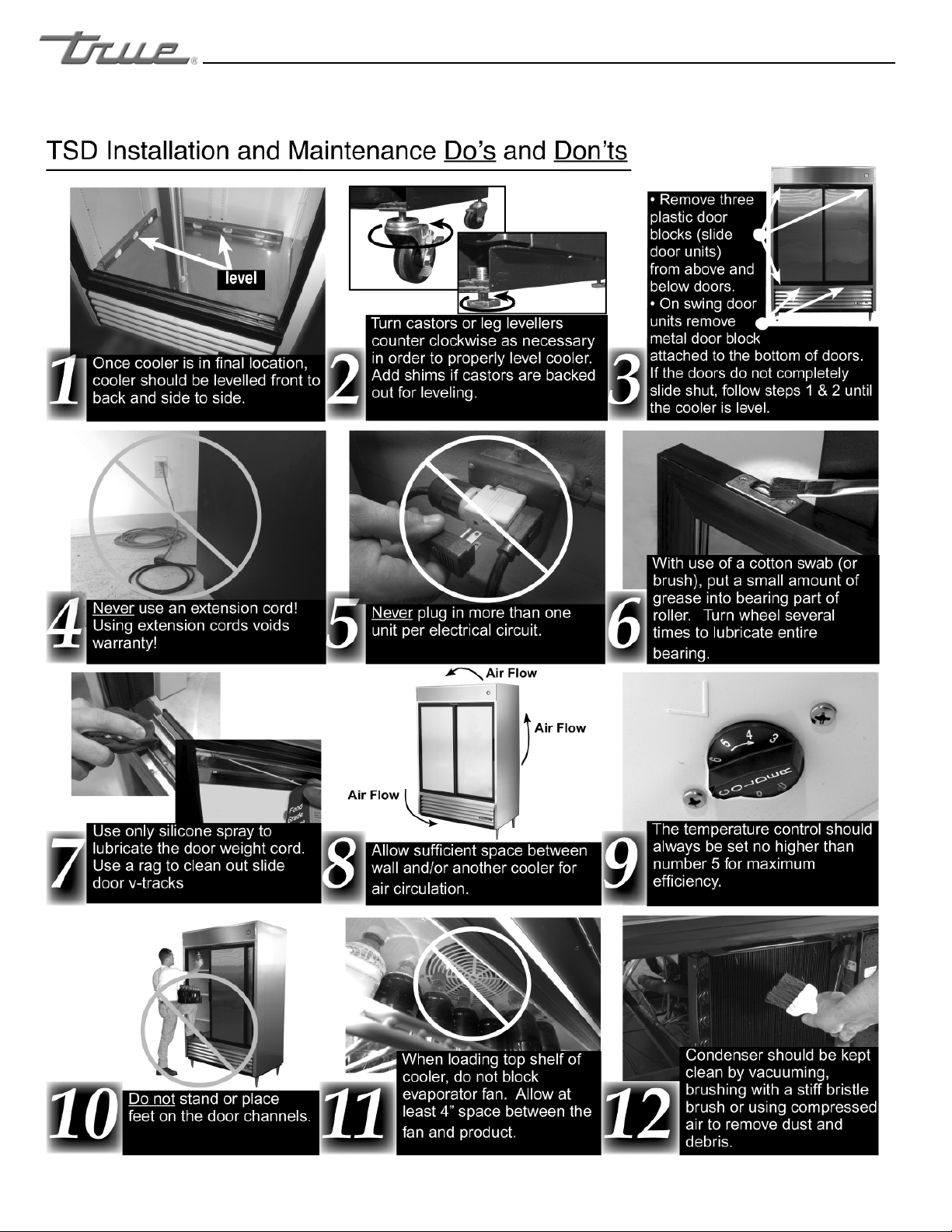

Page 4

True Food Service Equipment, Inc.

2 2

............ www.truemfg.com ............

Page 5

True Food Service Equipment, Inc.

SAFETY INFORMATION

DANGER!

RISK OF CHILD ENTRAPMENT

PROPER DISPOSAL OF THE FREEZER /

REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous… even if they will sit for “just a few

days.” If you are getting rid of your old refrigerator,

please follow the instructions below to help

prevent accidents.

Before You Throw Away Your Old Refrigerator

or Freezer:

Take off the doors.

Leave the shelves in place so that children may

not easily climb inside.

Refrigerant Disposal

Your old refrigerator may have a cooling system

that uses “Ozone Depleting ” chemicals. If you are

throwing away your old refrigerator, make sure the

refrigerant is removed for proper disposal by a

qualified service technician. If you intentionally

release any refrigerants you can be subject to

fines and imprisonment under provisions of the

environmental regulations.

USE OF EXTENSION CORDS

NEVER USE AN EXTENSION CORD! TRUE will not warranty any refrigerator that has been

connected to an extension cord.

3

............ www.truemfg.com ............

3

Page 6

True Food Service Equipment, Inc.

SAFETY INFORMATION

WARNING!

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall outlet to minimize the possibility

of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your personal

responsibility and obligation to have it replaced with the

properly grounded 3-prong wall outlet.

The refrigerator should always be plugged into it’s own

individual electrical circuit, which has a voltage rating

that matches the rating plate.

This provides the best performance and also prevents

overloading building wiring circuits which could cause

a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the power

cord. Always grip plug firmly and pull straight out from

the outlet.

Repair or replace immediately all power cords that have

become frayed or otherwise damaged. Do not use a cord

that shows cracks or abrasion damage along its length

or at either end.

When removing the refrigerator away from the wall, be

careful not to roll over or damage the power cord.

USE OF ADAPTER PLUGS

NEVER USE AN ADAPTER PLUG! Because of potential safety hazards under certain conditions,

we strongly recommend against the use of an adapter plug.

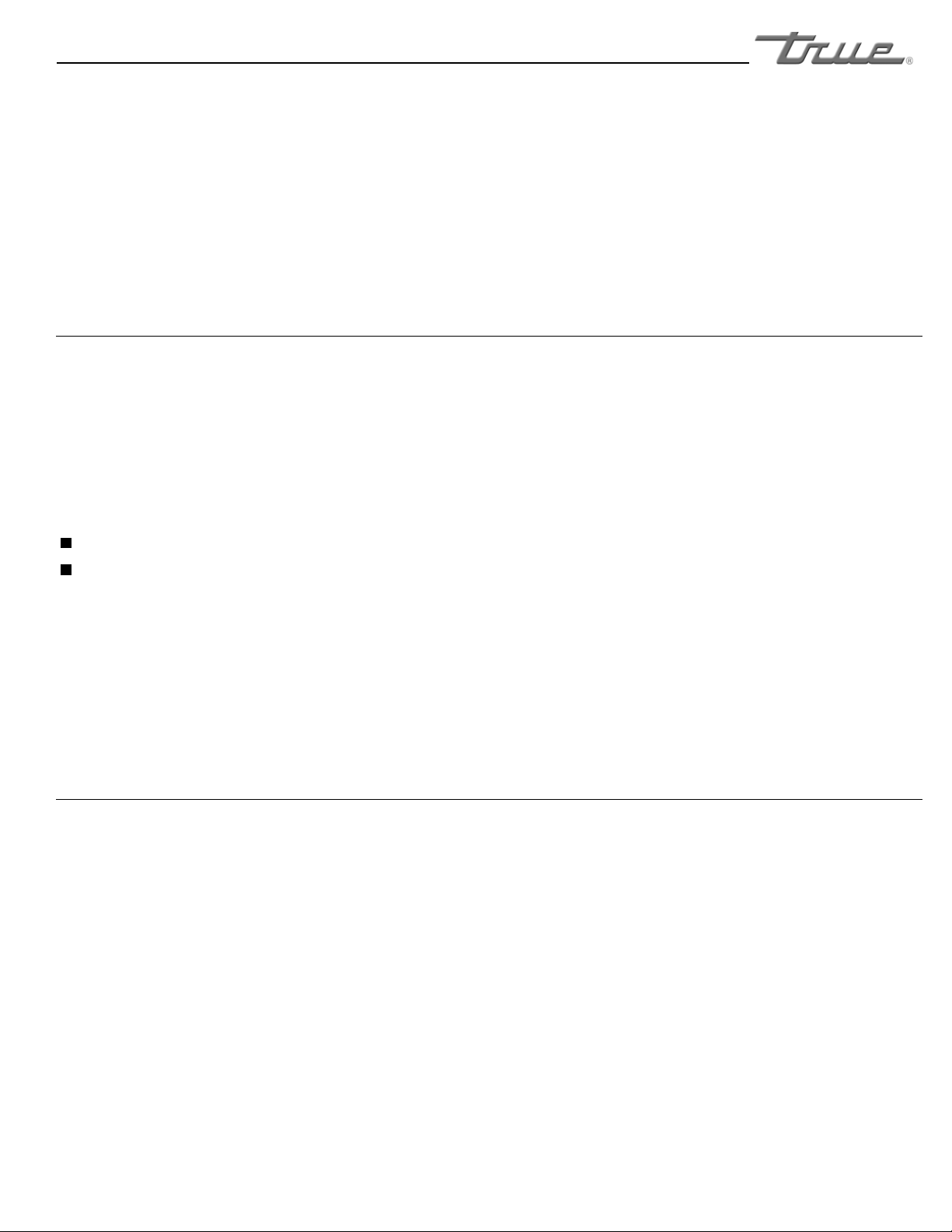

(North America Use Only!)

NEMA plugs

TRUE uses these types of plugs. If you do

not have the right outlet have a certified

electrician install the correct power source.

T-72F WIRING CHANGES (110V Application Only)

Previous design: 4 prong plug NEMA 14-20R - 4 wire circuit (see image 1).

Current design: 3 prong plug NEMA 5-20R - 3 wire circuit (see image 2).

WIRING CONVERSION

At Receptacle Box

1. Turn breaker off

2. Disconnect all wires from receptacle

3. Insulate red wire (tape or wire nut)

4. Connect black, white, and green wires

to 3 prong plug NEMA 5-20R per

instructions on receptacle

At Breaker Panel

1. With breaker turned off, remove wires

1 2

NOTE: It is the customer’s responsibility to make sure receptacle

wiring meets all local electrical codes. TRUE recommends hiring

a licensed quali ed electrician to make this change.

4 4

............ www.truemfg.com ............

2. Remove double pole breaker

3. Install single pole breaker

4. Connect black wire to breaker

5. Insulate red wire

6. Turn breaker back on

Page 7

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

INSTALLATION / OPERATION INSTRUCTIONS

OWNERSHIP

To insure that your unit works properly from the

first day, it must be installed properly. We highly

recommend a trained refrigeration mechanic and

electrician install your True equipment. The cost

of a professional installation is money well spent.

Before you start to install your True unit,

carefully inspect it for freight damage. If damage

is discovered, immediately file a claim with the

delivery freight carrier.

True is not responsible for damage incurred

during shipment.

REQUIRED TOOLS

Adjustable Wrench

Phillips Head Screwdriver

Level

UNCRATING

NOTE:

Units with a solar thermometer will experience a 15

second delay after exposed to light before it reads

the proper temperature.

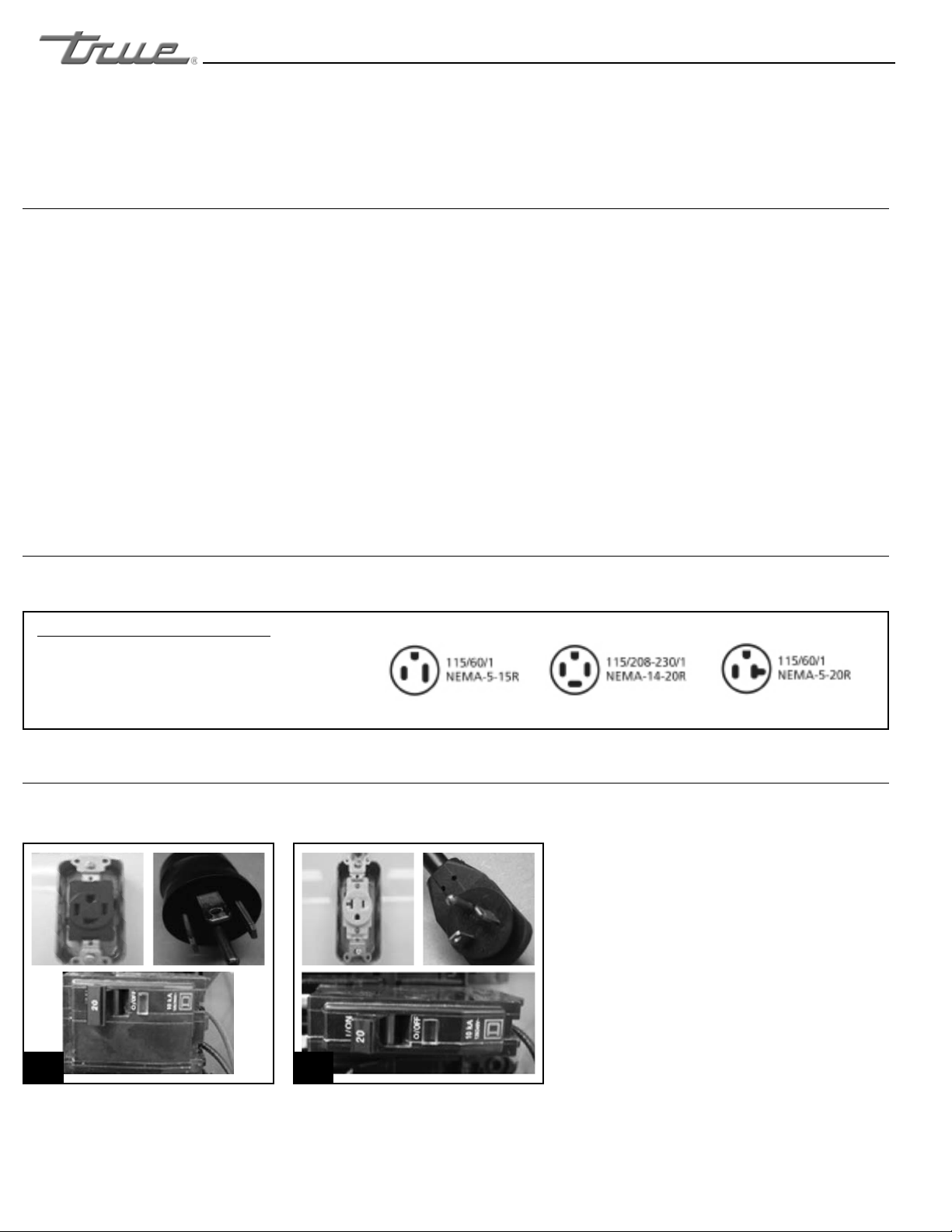

The following procedure is recommended for uncrating

the unit:

A. Remove the outer packaging, (cardboard and

bubbles or styrofoam corners and clear plastic).

Inspect for concealed damage. Again, immediately

file a claim with the freight carrier if there is

damage.

B. Move your unit as close to the final location as

possible before removing the wooden skid.

C. Remove door bracket on swinging glass door models

(see image 1-2). Sliding glass door models contain

shipping blocks (three for each door). Remove

the two styrofoam blocks taped to the top of the

door tracks (see image 3). The shipping blocks

are orange in color and by opening the door a little

the blocks can be removed (see images 4-6). Do

not throw the bracket or blocks away. For future

cabinet movement the bracket and blocks will need

to be installed so the glass door does not receive any

damage. (See image for bracket and shipping block

removal)

Note: Keys for coolers with door locks are located in

warranty packets

.

1 2 3

4

5

............ www.truemfg.com ............

5

6

5

Page 8

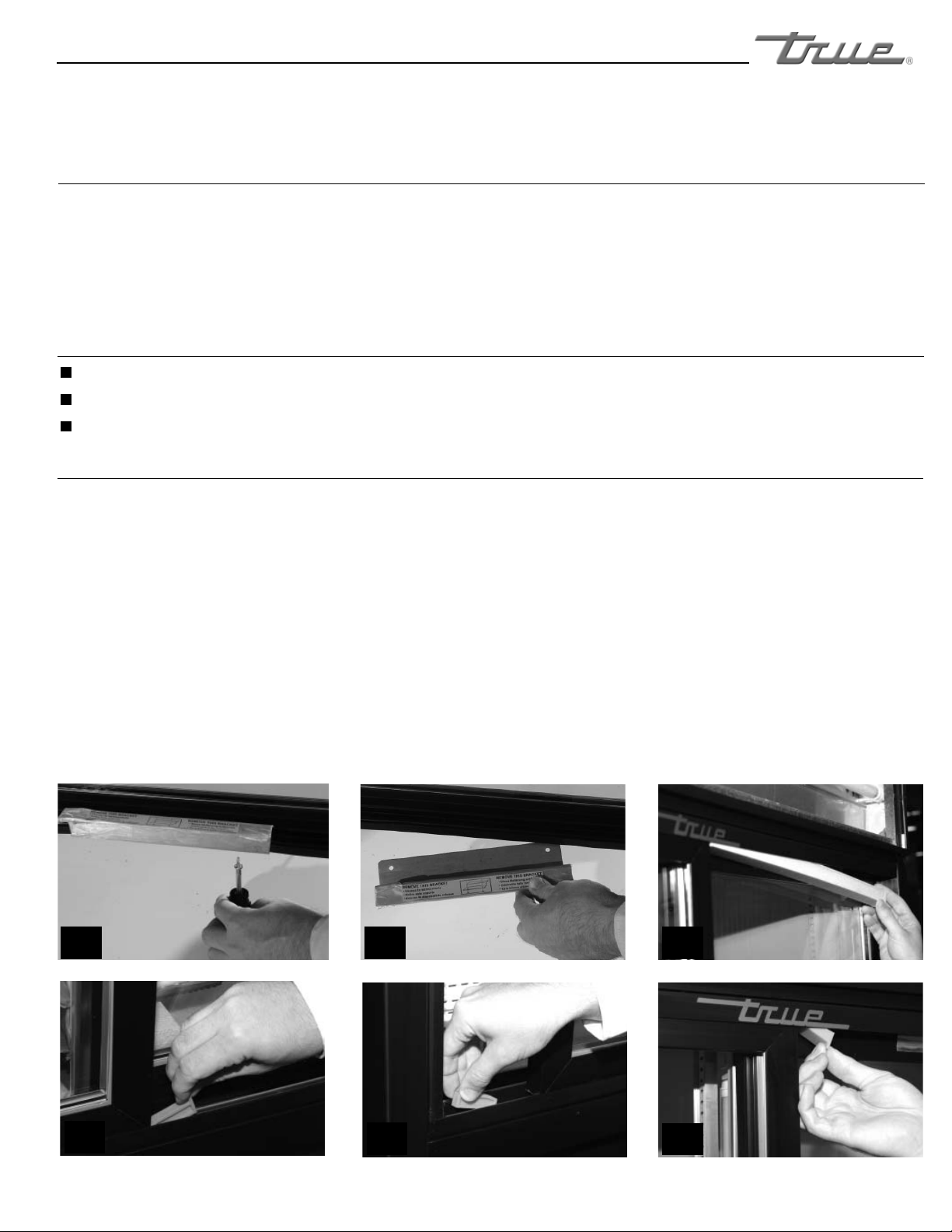

LOCATING

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

A. Remove louver from the front of cabinet (see page

17 for louver grill removal / reinstallation) and

backguard (if applicable) from rear of cabinet.

B. Skid bolts are located in each of 4 corners inside

cabinet bottom. (See photo A).

C. Remove skid bolts. (See photo B).

D. Cut straps if applicable. (See photo C).

E. Carefully lift cabinet off of skid.

LEVELING

A. Set unit in its final location. Be sure there is

adequate ventilation in your room. Under extreme heat

conditions, (100°F+, 38°C+), you may want to install an

exhaust fan.

Warning

Warranty is void if ventilation is insufficient.

B. Proper leveling of your True cooler is critical to

operating success (for non-mobile models). Effective

condensate removal and door operation will be effected

by leveling.

C. The cooler should be leveled front to back and side

to side with a level.

D. Ensure that the drain hose or hoses are positioned in

the pan.

E. Free plug and cord from inside the lower rear of the

cooler (do not plug in).

F. The unit should be placed close enough to the

electrical supply so that extension cords are never used.

A

Removing skid from

bottom of cabinet.

Warning

Compressor warranties are void if the unit is

more than 7 ft. (2.1m) from plug-in connection.

P

B

C

REMOTE UNITS (This section applies to

remotes only!)

• Remote cabinets must be ordered as remote.

We do not recommend converting from a

standard self contained to remote system.

• All remote cabinets must be hard wired.

• No castors available.

• All remote cabinets come standard using 404A

refrigerant.

• All remote units come standard with expansion

valve, liquid line solenoid, heated condensate

pan, and defrost timer when applicable.

6 6

............ www.truemfg.com ............

• Contact True Technical Service for BTU

requirements.

• No wiring necessary between cabinet and

condensing unit.

• All remote condensing units purchased from

True are 208/230 volts single phase.

If you have any questions regarding this

section, please call True at 1-(800)-325-6152.

Page 9

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

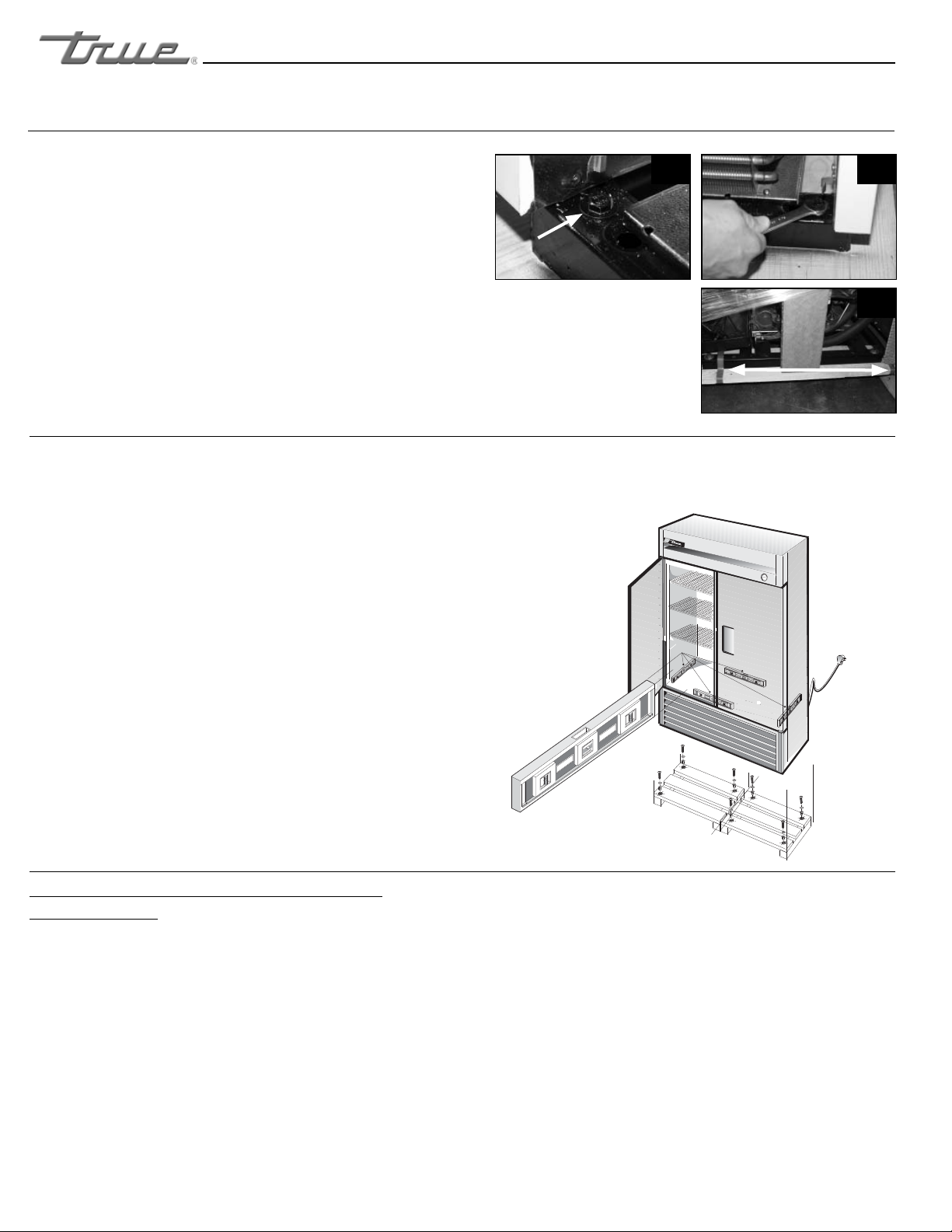

INSTALLATION OF CASTORS OR OPTIONAL LEGS

Important Safeguard for installation of leg/castor (Images 1-5 demonstrate procedure)

Securing Castors and Legs

To obtain maximum strength and stability of the

unit, it is important that you make sure each castor

is secure. Optional legs are hand-tightened securely

against the lower rail assembly see image 4-5. The

bearing race on the castor or the top edge of the

leg must make firm contact with the rail.

Unit leveling

Four leveling shims have been provided for

leveling castored units positioned on uneven

oors. Shims must be positioned between rail

end and bearing race.

A. Turn the bearing race counter-clockwise until

the cabinet is level. Level front to back and side to

side. (diagonally)

B. Install the desired number of shims, making sure

the slot of the shim is in contact with the threaded

stem of the castor. (See image 2)

C. If more than one shim is used, turn the slot at a

90° angle so they are not in line.

D. Turn the bearing race clockwise to tighten

and secure the castor by tightening the anchoring

bolt with a 3/4 inch open-end wrench or the tool

provided. (See image 3)

CAUTION

To avoid damage to lower rail assembly,

slowly raise unit to upright position.

Note: Open holes located on the cross members of the

frame rail should be plugged before unit is in use.

1

Thread castor into the underside of

cabinet frame rail.

5

The end of the leg is adjustable

to easy leveling.

7

2

For leveling, insert the shim between the

castor and frame rail.

Lower Rail

Assembly

Rail End

Snug Fit

Here

3

Use the tool provided to tighten

the castor into place.

Lower Rail Assembly

Rail End

Leveling Shim

CastorLeg

............ www.truemfg.com ............

4

Thread leg into cabinet bottom

frame rail.

Snug Fit

Here

Bearing

Race

7

Page 10

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

INSTALLING OPTIONAL CASTORS ON A T-12FG

Final Location

A. Place styrofoam corners behind cooler for cushion

and carefully tilt unit on it’s back.

B. Remove the louvered grill by removing four

phillips-head screws.

C. Remove the four bolts from the skid with an

adjustable wrench, and locate the four castors. Castors

are placed inside cooler, within the bubble wrap.

D. Install one castor in each of the four female threaded

areas as indicated.

NOTE: Two out of the four castors are designated

with an “F” for front. These are provided with

hand-brakes. Position these castors in FRONT of

the unit.

E. When all castors have been threaded fully, replace

grill and lift unit; positioning it into its final location.

F. Ensure that the two front castors are positioned

FORWARD as illustrated and locked down with the

hand-brakes.

K. Proper leveling of your TRUE cooler is critical to

operating success. Effective condensate removal and

door operation will be effected by leveling. Adjust

castors or add shims.

WARNING:

Unit may tip forward if procedure “F” is not

strictly followed.

G. Units final location should be adequately ventilated.

Conditions where heat exceeds 100ºF require an

exhaust fan.

H. Ensure that the drain hose for hoses are positioned

in the pan.

I. Free plug and cord from inside the lower rear of the

cooler (Do Not Plug In.)

WARNING:

Warranty is VOID if ventilation is insufficient.

J. The unit should be placed close enough to the

electrical supply so that extension cords are NEVER

used.

WARNING:

Compressor warranties are void if the unit is more

than 6 1/2ft. (1.98m) from plug-in connection.

POSITIONING OF THE

CASTOR IS CRITICAL. ORIENT

THE CASTOR IN THE FORWARD

POSITION AS SHOWN

8 8

............ www.truemfg.com ............

Page 11

True Food Service Equipment, Inc.

CENTER DOOR

CENTERED DOOR

INSTALLATION / OPERATION INSTRUCTIONS

SLIDE DOORS

STEP 1

Before removing slide door do not use the side

latch. Tension on the door cord is needed to

execute these operation instructions. Doors

can not be removed unless placed in specific

locations stated in these instructions.

STEP 2

Two Doo r Un its : Slide the front door so it is

centered on the cabinet. The door can not be

removed unless it is centered. See image 1

for door channel openings and image 2 for

centering door.

Three Door Units: Slide the middle door to

the right side so the glass is centered with the

left edge of the right side door. See image 3.

Image 1 (Two Door Units ONLY)

CENTERED DOOR

Gasket fasten to door bottom assures door

will remain in track when unit is placed on

uneven surface.

STEP 3

After centering the door lift it up and tilt top of

door towards the back of the unit so the rollers

are out of the top channel. Swing the bottom

of the door out of the bottom channel. Then

remove the door and set it down. See image 4.

(TWO DOOR UNITS SKIP TO STEP 6)

STEP 4

Slide right door to the left so left edge lines

up with the left edge of True Logo located

above the door. See image 5. Then lift door

out of track same way as image 4.

Image 4

True Logo

True Logo

Image 6 (Three Door Units ONLY)

Image 7

STEP 7

Let the door cord slowly retract back into

the door side channel. The knot tied at the

end of the door cord will keep the cord

from retracting all the way back into the

door channel. See image 9.

Image 8

Image 2 (Two Door Units ONLY)

CENTER DOOR

Image 3 (Three Door Units ONLY)

9

Door Cord

Knot

Image 9

STEP 1

After cabinet is installed in a final location

and correctly leveled check for any openings

when the slide doors are completely closed.

If there are any gaps/openings between

the closed doors and cabinet, the doors

will need to be adjusted.

Image 5 (Three Door Units ONLY)

STEP 5

Slide left door to the right so right edge lines

up with the end of the True Logo located at

the top of the door frame. See image 6. Then

lift door out of track same way as image 4.

STEP 6

Remove door cord from roller bracket. The

black plastic tab holding the door cord slides

out the back. See images 7 & 8.

STEP 2

Using a 7/16” wrench or adjustable wrench

and 1/8” allen wrench loosen roller and

move along slotted hole. After adjustment

has been made

tighten the

roller into

place. See

image 10.

............ www.truemfg.com ............

P-Clip keeps cord

in-place (prevents

cord damage).

TO ADJUST SLIDE DOOR

Image 10

9

Page 12

INSTALLATION / OPERATION INSTRUCTIONS

CONDUCTORS AND CIRCUITS

Wire Gauge for 2% Voltage Drop in Supply Circuits

115 Volt Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

2 14 14 14 14 14 14 14 14 14 14 14 14

3 14 14 14 14 14 14 14 14 14 14 14 12

4 14 14 14 14 14 14 14 14 14 12 12 12

5 14 14 14 14 14 14 14 12 12 12 10 10

6 14 14 14 14 14 14 12 12 12 10 10 10

7 14 14 14 14 14 12 12 12 10 10 10 8

8 14 14 14 14 12 12 12 10 10 10 8 8

9 14 14 14 12 12 12 10 10 10 8 8 8

10 14 14 14 12 12 10 10 10 10 8 8 8

12 14 14 12 12 10 10 10 8 8 8 8 6

14 14 14 12 10 10 10 8 8 8 6 6 6

16 14 12 12 10 10 8 8 8 8 6 6 6

18 14 12 10 10 8 8 8 8 8 8 8 5

20 14 12 10 10 8 8 8 6 6 6 5 5

25 12 10 10 8 8 6 6 6 6 5 4 4

True Food Service Equipment, Inc.

30 12 10 8 8 6 6 6 6 5 4 4 3

35 10 10 8 6 6 6 5 5 4 4 3 2

40 10 8 8 6 6 5 5 4 4 3 2 2

45 10 8 6 6 6 5 4 4 3 3 2 1

50 10 8 6 6 5 4 4 3 3 2 1 1

Wire Gauge for 2% Voltage Drop in Supply Circuits

230 Volts Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

5 14 14 14 14 14 14 14 14 14 14 14 14

6 14 14 14 14 14 14 14 14 14 14 14 12

7 14 14 14 14 14 14 14 14 14 14 12 12

8 14 14 14 14 14 14 14 14 14 12 12 12

9 14 14 14 14 14 14 14 14 12 12 12 10

10 14 14 14 14 14 14 14 12 12 12 10 10

12 14 14 14 14 14 14 12 12 12 10 10 10

14 14 14 14 14 14 12 12 12 10 10 10 8

16 14 14 14 14 12 12 12 10 10 10 8 8

18 14 14 14 12 12 12 10 10 10 8 8 8

20 14 14 14 12 10 10 10 10 10 8 8 8

25 14 14 12 12 10 10 10 10 8 8 6 6

30 14 12 12 10 10 10 8 8 8 6 6 6

35 14 12 10 10 10 8 8 8 8 6 6 5

40 14 12 10 10 8 8 8 6 6 6 5 5

50 12 10 10 8 6 6 6 6 6 5 4 4

60 12 10 8 6 6 6 6 6 5 4 4 3

70 10 10 8 6 6 6 5 5 4 4 2 2

80 10 8 8 6 6 5 5 4 4 3 2 2

90 10 8 6 6 5 5 4 4 3 3 1 1

100 10 8 6 6 5 4 4 3 3 2 1 1

10 10

............ www.truemfg.com ............

Page 13

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

ELECTRICAL INSTRUCTIONS

A. Before your new unit is connected to a

power supply, check the incoming voltage with a

voltmeter. If anything less than 100% of the rated

voltage for operation is noted, correct immediately.

B. All units are equipped with a 7 ft. (2.1m) service

cord, and must be powered at proper operating

voltage at all times. Refer to cabinet data plate for

this voltage.

True requires that a sole use circuit be dedicated

for the unit. Failure to do so voids warranty.

WARNING

Compressor warranties are void if compressor

burns out due to low voltage.

WARNING

Power supply cord ground should not be

removed!

NOTE

To reference wiring diagram - Remove front

louvered grill, wiring diagram is positioned on the

inside cabinet wall.

SEALING CABINET TO FLOOR

Step 1 - Position Cabinet

Allow one inch between the wall and rear of

the refrigerator to assure proper ventilation. For

freezers 3 inches between the wall and rear of the

cabinet will assure proper ventilation.

Step 2 - Level Cabinet

Cabinet should be level, side to side and front to

back. Place a carpenter’s level in the interior floor

in four places:

A. Position level in the inside floor of the unit near

the doors. (Level should be parallel to cabinet

front). Level cabinet.

B. Position level at the inside rear of cabinet.

(Again level should be placed parallel to cabinet

back).

C. Perform similar procedures to steps a & b by

placing the level on inside floor (left and right

sides - parallel to the depth of the cooler). Level

cabinet.

Step 3

Draw an outline on the base on the floor.

Step 4

Raise and block the front side of the cabinet.

Step 5

Apply a bead of “NSF Approved Sealant”, (see list

below), To floor on half inch inside the outline

drawn. The bead must be heavy enough to seal

the entire cabinet surface when it is down on the

sealant.

Step 6

Raise and block the rear of the cabinet

Step 7

Apply sealant on floor as outline in Step 5. on other

three sides.

Step 8

Examine to see that cabinet is sealed to floor

around entire perimeter.

Asphalt floors are very susceptible to chemical

attack. A layer of tape on the floor prior to

applying the sealant will protect the floor.

NSF Approved Sealants:

1. Minnesota Mining #ECU800 Caulk

2. Minnesota Mining #ECU2185 Caulk

3. Minnesota Mining #ECU1055 Bead

4. Minnesota Mining #ECU1202 Bead

5. Armstrong Cork - Rubber Caulk

6. Products Research Co. #5000 Rubber Caulk

7. G.E. Silicone Sealer

8. Dow Corning Silicone Sealer

Note:

11

............ www.truemfg.com ............

11

Page 14

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

FREEZERS ONLY! (COMPRESSOR BAND REMOVAL)

PLEASE CHECK YOUR COMPRESSOR. IF THERE IS A SHIPPING BAND, PLEASE REMOVE.

WARNING:

COMPRESSOR BAND MUST BE REMOVED

BEFORE UNIT IS CONNECTED TO POWER

SUPPLY.

The metal band can be reached from the rear of

the unit. A pair of tin snips will cut through the

band. Once the band is located and removed. You

may proceed with the installation of your new

equipment. (See image to the right).

Cutting band that is around compressor

STARTUP

A. The compressor is ready to operate. Plug in the

cooler.

B. Temperature control set at No. 4 position gives

refrigerators an approximate temperature of 35°F.

Allow unit to function several hours, completely

cooling cabinet before changing the control setting.

C. Excessive tampering with the control could

lead to service difficulties. Should it ever become

necessary to replace temperature control, be sure it

is ordered from your True dealer or recommended

service agent.

D. Good air flow in your True unit is critical. Be

careful to load product so that it neither presses

against the back wall, nor comes within four inches

of the evaporator housing. Refrigerated air off the

coil must circulate down the back wall.

NOTE

If the cooler is disconnected or shut off, wait ve

minutes before starting again.

RECOMMENDATION

Before loading product we recommend you

run your True unit empty for two to three days.

This allows you to be sure electrical wiring and

installation are correct and no shipping damage

has occurred. Remember, our factory warranty

does not cover product loss!

REPLACEMENT PARTS

TRUE maintains a record of the cabinet serial

number for your cooler. If at any time during

the life of your cooler, a part is needed, you

may obtain this part by furnishing the model

number and serial number to the company from

whom you purchased the cooler. Call Toll-Free:

(800)-424-TRUE (Direct to Parts Department).

(800)-325-6152 (U.S.A. & Canada only) or call:

(636)-240-2400.

12 12

............ www.truemfg.com ............

Page 15

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

SHELVING INSTALLATION / OPERATION &

LIGHT SWITCH LOCATION

SHELF & ORGANIZER INSTALLATION:

Step 1

A. Hook shelf clips onto shelf standards.

(see illustration).

B. Position all four shelf clips equal in distance

from the floor for flat shelves.

T-Series

& GDM-5

WIRE SHELVES:

Wire shelves are oriented so that cross support bars

are facing down.

Airflow

Guard

NOTE:

T-Series models include an airflow guard on the rear

of shelves to maintain an air space at the rear of the

cabinet. (see illustration).

Step 2

Place shelves on shelf clips making sure all corners

are seated properly.

Shelf

Shelf

Shelf

Clip

Pillaster

LIGHT SWITCH LOCATION:

Light switch location depends upon the T-Series model.

Most T-Series models will have the light switch located

inside the unit on the right side of the ceiling. Most

instances the switch is located next to the temperature

control. Some models have the switch located on the

right side of the evaporator housing along the interior

ceiling.

13

............ www.truemfg.com ............

13

Page 16

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

FREEZERS DEFROST TIME CLOCK OPERATION

T-19F, T-19FZ, T-23F

Defrost System!

This defrost system is time initiated

/ time terminated. The refrigeration

system does not restart until the

defrost cycle has timed out.

REQUIRED TOOLS:

• Phillips Screwdriver

• 1/4” Nut Driver or Socket

Locating The Defrost Timer:

See page 2 for removing louver grill instructions.

* T-23F-2 / T-23DT Grill must be

reattached correctly for proper

operation.

Single Door Models:

Defrost timer is located in the lower right corner

behind the louvered grill (inside galvanized

electrical box).

Outer most dial. White tabs represent 15 minutes of defrost time.

ALL OTHER UNITS.

Defrost System!

This defrost system is temperature

terminated, however the time clock

has been designed with a time

termination back-up.

REQUIRED TOOLS:

• Phillips Screwdriver

• 1/4” Nut Driver or Socket

Locating The Defrost Timer:

See page 2 for removing louver grill

instructions.

Two Door Models:

Defrost timer is located in the middle of the

cabinet, behind the louvered grill. Timer

is mounted to the left of the centered ballast

box (Inside of gray timer box).

Three Door Models:

Defrost timer is located on the left upright

post behind the louvered grill (Inside of

gray timer box).

Outer most dial. White

tabs represent 15

minutes of defrost time.

Time of day.

Inner most dial.

Setting the timer:

(UNPLUG UNIT FROM

POWER SUPPLY!)

DO NOT SET THE TIME BY

ROTATING THE “OUTER” DIAL.

Turn the minute hand clockwise until the

time of day on the outer dial is aligned with

the triangle marker on the inner dial (two

o’clock position).

Factory setting 2 am, 8 am, 2 pm, 8 pm.

15 minutes in length. True recommends

maximum 15 minute defrost cycles &

minimum 4 defrost periods per day.

Setting the timer:

(UNPLUG UNIT FROM

POWER SUPPLY!)

DO NOT SET THE TIME BY

ROTATING THE “OUTER” DIAL.

Turn the minute hand clockwise until the time of

day on the outer dial is aligned with the triangle

marker on the inner dial (two o’clock position).

The following procedure may be

followed to customize your needs.

STEP 1

In order to program the time to begin the defrost

cycle, flip the white tabs out to set the defrost

time. To eliminate a defrost time flip the white

tabs back toward the center of the Defrost Timer.

14 14

............ www.truemfg.com ............

The following procedure may be

followed to customize your needs.

STEP 1

In order to program the time to begin the

defrost cycle, flip the white tabs out to set

the defrost time. To eliminate a defrost

time flip the white tabs back toward the

center of the Defrost Timer.

NOTE:

True recommends a minimum 30

minute (2 tabs) defrost cycle three

times per day.

(Except T-19F/19FZ/23F).

The white tabs located on the outmost area

of the time clock have been factory set

for (6:00 a.m., 2:00 p.m., and 10:00 p.m.).

Each tab represents 15 minutes of defrost

time. Notice that at each defrost time two

white tabs are set for 15 minutes each for a

total of 30 minutes of defrost.

High usage, high temperature,

Defrost Timer Box Image 1

All models except T-19F, T-19FZ, T-23F.

WARNING:

and high humidity may

require additional defrost

settings per day. Once clock

is set & grill is correctly

reinstalled cabinet can be

plugged in.

Page 17

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

IF THE COMPRESSOR WILL

NOT RUN

1. If there is no voltage at the

compressor terminals, follow the

wiring diagram and check back from

compressor to the power supply to find

where the circuit is interrupted.

2. If power is available at the

compressor terminals, and the

compressor does not run, check the

voltage at the compressor terminals

while attempting to start the

compressor.

If voltage at the compressor terminals is

below 90% of the nameplate voltage, it

is possible the motor may not develop

sufficient torque to start. Check to

determine if wire sizes are adequate,

electrical connections are loose, the

circuit is overloaded, or if the power

supply is inadequate.

3. On single phase compressors,

a defective capacitor or relay may

prevent the compressor starting. If

the compressor attempts to start but

is unable to do so, or if there is a

humming sound, check the relay to

see if the relay contacts are damaged

or fused. The relay points should be

closed during the initial starting cycle,

but should open as the compressor

comes up to speed.

Remove the wires from the starting

relay and capacitors. Use a high

voltage ohmmeter to check for

continuity throughout the relay

coil. Replace the relay if there is not

continuity. Use an ohmmeter to check

across the relay contacts. Potential

relay contacts are normally closed when

the relay is not energized, current relay

contacts are normally open. If either

gives an incorrect reading, replace the

relay.

Any capacitor found to be bulging,

leaking, or damaged should be

replaced.

15

............ www.truemfg.com ............

Make sure capacitors are discharged

before checking. Check for continuity

between each capacitor terminal and the

case. Continuity indicates a short, and

the capacitor should be replaced.

Substitute a “known to be good” start

capacitor if available. If compressor

then starts and runs properly, replace

the original start capacitor.

If a capacitor tester is not available, an

ohmmeter may be used to check run

and start capacitors for shorts or open

circuits. Use an ohmmeter set to its

highest resistance scale, and connect

prods to capacitor terminals.

a) With a good capacitor, the

indicator should first move zero, and

then gradually increase to infinity.

b) If there is no movement of the

ohmmeter indicator, an open circuit is

indicated.

c) If the ohmmeter indicator

moves to zero, and remains there or on

a low resistance reading, a short circuit

is indicated. Defective capacitors

should be replaced.

4. If the correct voltage is available

at the compressor terminals, and no

current is drawn, remove all wires from

the terminals and check for continuity

through the motor windings. On single

phase motor compressors, check for

continuity from terminals C to R, and C

to S. On compressors with line break

inherent protectors, an open overload

protector can cause a lack of continuity.

If the compressor is warm, wait one

hour for the compressor to cool and

recheck. If continuity cannot be

established through all motor windings,

the compressor should be replaced.

Check the motor for ground by means

of a continuity check between the

common terminal and the compressor

shell. If there is a ground, replace the

compressor.

5. If the compressor has an external

protector, check for continuity through

the protector or protectors. All external

inherent protectors on compressors can

be replaced in the field.

IF THE MOTOR COMPRESSOR

STARTS BUT TRIPS

REPEATEDLY ON THE

OVERLOAD PROTECTOR

1. Check the compressor suction

and discharge pressures while the

compressor is operating. Be sure the

pressures are within the limitations

of the compressor. If pressures are

excessive it may be necessary to clean

the condenser, purge air from the

system, replace crankcase pressure

regulating valve.

An excessively low suction pressure

may indicate a loss of charge.

On units with no service gauge parts

where pressures can be checked, check

condenser to be sure it is clean and fan

is running. Excessive temperatures on

suction and discharge line may also

indicate abnormal operating conditions.

2. Check the line voltage at the motor

terminals while the compressor is

operating. The voltage should be

within 10% of the nameplate voltage

rating. If outside those limits, the

voltage supply must be brought

within the proper range, or a motor

compressor with different electrical

characteristics must be used.

3. Check the amperage drawn while

the compressor is operating. Under

normal operating conditions, the

amperage drawn will seldom exceed

110% of the nameplate amperage.

High amperage can be caused by low

voltage, defective running capacitors,

or a defective starting relay.

Continued on next page

15

Page 18

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

4. If all operating conditions are

normal, the voltage supply at the

compressor terminals balanced and

within limits, the compressor crankcase

temperature within normal limits,

and the amperage drawn within the

specified range, the motor protector

may be defective, and should be

replaced.

If the operating conditions are normal

and the compressor is running

excessively hot for no observable

reason, or if the amperage drawn is

above the normal range and sufficient

to repeatedly trip the protector, the

compressor has internal damage and

should be replaced.

IF THE COMPRESSOR RUNS

BUT WILL NOT REFRIGERATE

1. Check the refrigerant charge.

Check the evaporator surface

to determine if it is evenly cold

throughout, or if partially starved. A

lack of charge may be indicated by

light, fluffy frost at the evaporator inlet.

Add refrigerant if necessary.

2. Check the compressor suction

pressure. An abnormally low pressure

may indicate a loss of refrigerant

charge, a malfunctioning capillary tube,

a lack of evaporator capacity possibly

due to icing or low air flow, or a

restriction in the system.

Often a restriction in a drier or strainer

can be identified by frost or a decrease

in temperature across the restriction due

to the pressure drop in the line. This

will be true only if liquid refrigerant

is in the line at the restricted point,

since any temperature change due to

restriction would be caused by the

flashing of liquid into vapor as the

pressure changes.

Any abnormal restriction in the system

must be corrected.

3. Check the compressor discharge

pressure. An abnormally high

discharge pressure can cause a loss of

capacity, and can be caused by a dirty

condenser, a malfunctioning condenser

fan, or air in the system.

4. If the suction pressure is high,

and the evaporator and condenser

are functioning normally, check the

compressor amperage draw. An

amperage draw near or above the

nameplate rating indicates normal

compressor or unit may have damaged

valves.

An amperage draw considerably below

the nameplate rating may indicate a

broken suction reed or broken

connecting rod in the compressor.

DIAGNOSIS AND

REPLACEMENT OF FREEZER

CABINET COMPONENTS

1. Defrost Time Clock

A. Check timer motor to be sure

it runs.

B. Check contacts on the defrost

timer.

C. Check solenoid windings for

continuity to ensure contact

switching.

D. Check to be sure defrost

actuator pins are in proper

position.

E. Check all wires in the timer for

tightness to terminals and

broken wires.

2. Defrost Control On The

Evaporator Drain Pan

A. If the defrost time is always

35 minutes (or whatever duration

the elapsed time adjustment is set

at) and the fan motors do not delay

after a defrost cycle and it has been

determined that the solenoid in the

defrost clock is functioning, change

the defrost control in the evaporator

compartment in the top of the

freezer. This control is attached to the

evaporator drain pan.

3. Coil Defrost Heater

A. Lower the evaporator cover.

Disconnect the coil heater by removing

the wire nuts at the point where the

heater joins the electrical circuit of the

freezer in the evaporator compartment.

Check heater for continuity with an

ohmmeter. If the heater is defective,

cut the bale wires holding the heater

to the coil and remove the heater.

Replace with a new heater using bale

wires provided.

4. Drain Tube Heater

A. Lower the evaporator cover.

Disconnect the drain tube heater by

removing the wire nuts at the point

where the heater joins the electrical

circuit of the freezer in the evaporator

compartment. Check the drain tube

heater with an ohmmeter.

B. If the drain tube heater is

defective, disconnect the drain tube

from the rigid plastic drain, bend the

tabs that hold the evaporator drain pan

to the evaporator cover and raise the

drain pan so that the flexible heater is

visible, pull heater out of the plastic

drain tube and replace. Connect heater

to the electrical circuit in the evaporator

compartment.

5. Cabinet Temperature

Control

A. Remove the two screws on the

right side of the evaporator housing

that holds the control mounting plate.

Reach behind the evaporator housing

on the control side of the cabinet

and pull the control bulb out of the

receptacle in the roof of the cabinet.

Disconnect the wires from the control.

Check control for continuity, replace if

defective.

16 16

............ www.truemfg.com ............

Page 19

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

Light Cover Installation for T-12FG

REQUIRED TOOLS

• none

- IMPORTANT -

- IMPORTANT -

Before replacing light cover

Before installing lamp cover

turn cabinet on and wait until it

turn cabinet on and allow it to

reaches temperature.

reach temperature.

STEP 1

Locate rubber gasket behind lamp holder

mounted to evaporator housing. (See

Image 1).

STEP 2

Fit the bottom edge of the lamp cover

into the bottom groove of the rubber

gasket and rotate upwards while

working the edges into the rest of the

rectangular groove. (See Images 2-3).

(slide fingers underneath top edges of

rubber gasket and push rubber over the

top lip of the lamp shield)

1

Rubber Gasket

Lamp Holder

2

STEP 3

Be sure lamp cover is seated properly in

rubber gasket.

- NOTE -

- IMPORTANT -

If cabinet is turned off and

interior allowed to warm up

Before replacing light cover

turn cabinet on and wait until it

lamp cover may become loose

reaches temperature.

and require reinstallation.

Follow directions above.

17

............ www.truemfg.com ............

Lamp Cover

3

17

Page 20

True Food Service Equipment, Inc.

MAINTENANCE, CARE & CLEANING

MAINTENANCE, CARE & CLEANING

CLEANING THE CONDENSER COIL

When using electrical appliances, basic safety precautions should be followed, including the following:

REQUIRED TOOLS:

• Phillips Screwdriver

• Stiff Bristle Brush

• Adjustable Wrench

• Air Tank or CO2 Tank

• Vacuum Cleaner

Step 1

Disconnect power to unit.

Step 2

SLIDE DOOR MODELS: (See Image 1)

Take off lower grill assembly by removing two (2)

screws in lower corners. (older models may have snap

lock tabs instead of screws).

Loosen screws holding the top pivot pins. Swing grill

up and remove frame hooks from pivot pins at top of

louver.

SWING DOOR MODELS: (See Image 2)

Take off lower grill assembly by opening the door and

removing screws from the top of the louver grill. Some

models have a door light switch. Please use caution

when removing the grill on these models. Do not pinch

wires. For reinstall, reattach the grill to the magnets on

front of the cabinet and reinstall the screws on top of

the grill.

Step 3

Remove bolts anchoring compressor assembly

to frame rails and carefully slide out. (tube

connections are flexible)

Step 4

Clean off accumulated dirt from the condenser coil and

the fan with a stiff bristle brush.

Step 5

Lift cardboard cover above fan at plastic plugs and

carefully clean condenser coil and fan blades.

Step 6

INDOOR LOCATION:

After brushing condenser coil vacuum dirt from coil,

and interior floor.

OUTDOOR LOCATION:

(GDM-33, GDM-47, and GDM-49 only) After brushing

condenser coil blow CO

side to fan. (See Image 4.)

through condenser from fin

2

Step 7

Replace cardboard cover. Carefully slide compressor

assembly back into position and replace bolts.

Step 8

Reinstall louver assembly onto unit with appropriate

fastener and clips. Tighten all screws.

Step 9

Connect unit to power and check to see if compressor

is running.

Image 1. Slide

Door Models

Image 2. Swing Door Models

P

Image 3.

REMOVE COVER MAKE POWER CONNECTION

E. McCabe

1227-5

NEPCO/CENTRALAB

Image 4.

18 18

............ www.truemfg.com ............

Page 21

True Food Service Equipment, Inc.

MAINTENANCE, CARE & CLEANING

IMPORTANT WARRANTY INFORMATION

Condensers accumulate dirt and require cleaning every 30 days. Dirty condensers result in compressor

failure, product loss, and lost sales... which are not covered by warranty.

If you keep the Condenser clean you will minimize your service expense and lower your electrical costs.

The Condenser requires scheduled cleaning every thirty days or as needed.

Air is pulled through the Condenser continuously, along with dust, lint, grease, etc.

A dirty Condenser can result in NON-WARRANTEED part & Compressor Failures, Product Loss, and Lost

Sales.

Proper cleaning involves removing dust from the Condenser. By using a soft brush, or vacuuming the

Condenser with a shop vac, or using CO2, nitrogen, or pressurized air.

If you cannot remove the dirt adequately, please call your refrigeration service company.

On most of the units the condenser is accessible in the rear of the unit. You must remove the cabinet grill

to expose the Condenser.

The Condenser looks like a group of vertical ns. You need to be able to see through the condenser for

the unit to function at maximum capacity. Do not place lter material in front of condensing coil. This

material blocks air- ow to the coil similar to having a dirty coil.

THE CLEANING OF THE CONDENSER IS NOT

COVERED BY THE WARRANTY!

HOW TO CLEAN THE CONDENSER:

1. Disconnect the electrical power to the unit.

2. Remove the louvered grill.

3. Vacuum or brush the dirt, lint, or debris from the nned condenser coil.

4. If you have a signi cant dirt build up you can blow out the condenser with compressed air. (CAUTION

MUST BE USED to avoid eye injury. Eye protection is recommended.)

5. When nished be sure to replace the louvered grill. The grill protects the condenser.

6. Reconnect the electrical power to the unit.

If you have any questions, please call True Manufacturing at 636-240-2400 or 800-325-6152 and ask for the

Service Department. Service Department Availability Monday-Friday 7:30 a.m. to 5:30p.m.

and Saturday 8:00 a.m. to 12:00 a.m. CST.

19

............ www.truemfg.com ............

19

Page 22

True Food Service Equipment, Inc.

MAINTENANCE, CARE & CLEANING

TEMPERATURE CONTROL ADJUSTMENT FOR

HIGH ALTITUDE ONLY!

TERMS:

__________ STEP 4 ___________

Cut-out - Temperature sensed

by the controller that shuts the

compressor off.

Cut-in - Temperature sensed

by the controller that turns the

compressor on.

REQUIRED TOOLS

• Phillips Head Screwdriver

• 5/64” or 2 mm Allen Wrench

• T-7 Torx Wrench

For high elevation installations,

it may be necessary to

“warm-up” the set points. To

make the adjustment, insert

the appropriate tool in each

adjustment screw and turn 1/4

of a revolution clockwise (to

the right). This procedure will

adjust both the cut-in and cut-out

about 2°F warmer.

__________ STEP 5 ___________

__________ STEP 1 ___________

Unplug the cooler.

__________ STEP 2 ___________

Remove the screws that secure

the temperature control to the

inset box lower left side of the

cabinet (when facing the front of

the cabinet).

__________ STEP 3 ___________

Pull out gently from cabinet.

NOTE:

Mechanical temperature

controllers are affected when

functioning at high altitude.

The cut-in and cut-out

temperatures will be colder

than when the controller

functions closer to sea level.

Make sure to reconnect the pink

wire to the proper spade

terminal when reinstalling.

Danfoss Temperature Control (High Altitude Only!)

Cut-out Adjustment Screw Allen

(5/64” or 2 mm) (clockwise for

warmer)

Cut-in Adjustment Screw Torx (T-7)

(clockwise for warmer)

Compressor Connection (pink)

Compressor Connection (pink)

20 20

............ www.truemfg.com ............

Page 23

True Food Service Equipment, Inc.

MAINTENANCE, CARE & CLEANING

Stainless Steel Equipment Care and Cleaning

CAUTION: Do not use any steel wool, abrasive or chlorine based products to clean stainless

steel surfaces.

Stainless Steel Opponents

There are three basic things which can break down your stainless steel’s passivity layer and allow

corrosion to rear its ugly head.

1) Scratches from wire brushes, scrapers, and steel pads are just a few examples of items that can be

abrasive to stainless steel’s surface.

2) Deposits left on your stainless steel can leave spots. You may have hard or soft water depending on

what part of the country you live in. Hard water can leave spots. Hard water that is heated can

leave deposits if left to sit too long. These deposits can cause the passive layer to break down and

rust your stainless steel. All deposits left from food prep or service should be removed as soon as

possible.

3) Chlorides are present in table salt, food, and water. Household and industrial cleaners are the worst

type of chlorides to use.

8 steps that can help prevent rust on stainless steel:

1. Using the correct cleaning tools

Use non-abrasive tools when cleaning your stainless steel products. The stainless steel’s passive

layer will not be harmed by soft cloths and plastic scouring pads. Step 2 tells you how to find the

polishing marks.

2. Cleaning along the polish lines

Polishing lines or “grain” are visible on some stainless steels. Always scrub parallel to visible lines

on some stainless steels. Use a plastic scouring pad or soft cloth when you cannot see the grain.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners

While many traditional cleaners are loaded with chlorides, the industry is providing an ever

increasing choice of non-chloride cleaners. If you are not sure of your cleaner’s chloride content

contact your cleaner supplier. If they tell you that your present cleaner contains chlorides, ask if

they have an alternative. Avoid cleaners containing quaternary salts as they can attack stainless

steel, causing pitting and rusting.

4. Water Treatment

To reduce deposits, soften the hard water when possible. Installation of certain filters can remove

corrosive and distasteful elements. Salts in a properly maintained water softener can be to your

advantage. Contact a treatment specialist if you are not sure of the proper water treatment.

5. Maintaining the cleanliness of your food equipment

Use cleaners at recommended strength (alkaline, alkaline chlorinated or non-chloride). Avoid

build-up of hard stains by cleaning frequently. When boiling water with your stainless steel

equipment, the single most likely cause of damage is chlorides in the water. Heating any cleaners

containing chlorides will have the same damaging effects.

6. Rinse

When using chlorinated cleaners you must rinse and wipe dry immediately. It is better to wipe

standing cleaning agents and water as soon as possible. Allow the stainless steel equipment to air

dry. Oxygen helps maintain the passivity film on stainless steel.

7. Hydrochloric acid (muriatic acid) should never be used on stainless steel

8. Regularly restore/passivate stainless steel

21

............ www.truemfg.com ............

21

Page 24

True Food Service Equipment, Inc.

MAINTENANCE, CARE & CLEANING

Stainless Steel Equipment Care and Cleaning

Recommended cleaners for certain situations / environments of stainless steel

A) Soap, ammonia and detergent medallion applied with a cloth or sponge can be used for routine

cleaning.

B) Arcal 20, Lac-O-Nu Ecoshine applied provides barrier film for fingerprints and smears.

C) Cameo, Talc, Zud First Impression is applied by rubbing in the direction of the polished lines for

stubborn stains and discoloring.

D) Easy-off and De-Grease It oven aid are excellent for removals on all finishes for grease-fatty acids,

blood and burnt-on foods.

E) Any good commercial detergent can be applied with a sponge or cloth to remove grease and oil.

F) Benefit, Super Sheen, Sheila Shine are good for restoration / passivation.

NOTE:

The use of stainless steel cleaners or other such solvents is not

recommended on plastic parts. Warm soap and water will suffice.

LIGHT BULB REPLACEMENT

IDL (Integrated Door Lighting)

WARNING:

Disconnect power to cabinet before

replacing light bulbs.

INTERIOR LIGHTS:

Simply unscrew the light bulb(See Image 1 & 2).

IDL (INTEGRATED DOOR LIGHTING):

Squeeze the plastic lampshield together and pull

away from the door (See Image 3).

Push the bulb down while pulling the spring

activated lampholder up. This will give you

enough clearance to take the bulb out

(See Image 4).

1

Interior Light

2

Interior Light

22 22

............ www.truemfg.com ............

3

IDL (Integrated Door Lighting) IDL (Integrated Door Lighting)

4

Page 25

T

RUE

R

EFRIGERATION

®

MADE IN

U.S.A.

SINCE 1945

TRUE warrants to the original purchaser of every new TRUE refrigerated unit, the cabinet and all parts thereof, to be free from defects in material or

workmanship, under normal and proper use and maintenance service as specified by TRUE and upon proper installation and start-up in accordance with

the instruction packet supplied with each TRUE unit. TRUE’s obligation under this warranty is limited to a period of one (1) year from the date of original

installation or 15 months after shipment date from TRUE, whichever occurs first.

Any part covered under this warranty that are determined by TRUE to have been defective within one (1) year of original installation or fifteen (15)

months after shipment date from manufacturer, whichever occurs first, is limited to the repair or replacement, including labor charges, of defective parts or

assemblies. The labor warranty shall include standard straight time labor charges only and reasonable travel time, as determined by TRUE.

In addition to the one (1) year warranty stated above, TRUE warrants its hermetically and semi-hermetically sealed compressor to be free from defects

in both material and workmanship under normal and proper use and maintenance service for a period of four (4) additional years from the date of original

installation but not to exceed five (5) years and three (3) months after shipment from the manufacturer.

Compressors determined by TRUE to have been defective within this extended time period will, at TRUE’s option, be either repaired or replaced with a

compressor or compressor parts of similar design and capacity.

The four (4) year extended compressor warranty applies only to hermetically and semi-hermetically sealed parts of the compressor and does not apply

to any other parts or components, including, but not limited to, cabinet, paint finish, temperature control, refrigerant, metering device, driers, motor starting

equipment, fan assembly or any other electrical component, etcetera.

The four year compressor warranty detailed above will be voided if the following procedure is not carefully adhered to:

1. This system contains R404A or R134A refrigerant and polyol ester lubricant. The polyol ester lubricant has rapid moisture absorbing qualities. If long

exposure to the ambient conditions occur, the lubricant must be removed and replaced with new. For oil amounts and specifications please call True

technical service department (800-325-6152). Failure to comply with recommended lubricant specification will void the compressor warranty.

2. Drier replacement is very important and must be changed when a system is opened for servicing. A drier using XH-7 desiccant or an exact

replacement solid core drier must be used. The new drier must also be the same capacity as the drier being replaced.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must be obtained.

All claims for labor or parts must be made directly through TRUE. All claims should include: model number of the unit, the serial number of the cabinet,

proof of purchase, date of installation, and all pertinent information supporting the existence of the alleged defect.

In case of warranty compressor, the compressor model tag must be returned to TRUE along with above listed information.

Any action or breach of these warranty provisions must be commenced within one (1) year after that cause of action has occurred.

TRUE’s sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional limitations below. This warranty

neither assumes nor authorizes any person to assume obligations other than those expressly covered by this warranty.

NO CONSEQUENTIAL DAMAGES. TRUE IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS; OR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

INCLUDING WITHOUT LIMITATION, LOSSES OR DAMAGES ARISING FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT ON ACCOUNT OF

REFRIGERATION FAILURE.

WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original purchaser/user to whom delivered. ANY SUCH

ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANTIES HEREIN MADE AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

IMPROPER USAGE. TRUE ASSUMES NO LIABILITY FOR PARTS OR LABOR COVERAGE FOR COMPONENT FAILURE OR OTHER DAMAGES RESULTING FROM

IMPROPER USAGE OR INSTALLATION OR FAILURE TO CLEAN AND/OR MAINTAIN PRODUCT AS SET FORTH IN THE WARRANTY PACKET PROVIDED WITH THE UNIT.

RESIDENTIAL APPLICATIONS: True assumes no liability for parts or labor coverage for component failure or other damages resulting from installation in

non-commercial or residential applications.

ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE, FLOOD, ACTS OF GOD. TRUE is not responsible for

the repair or replacement of any parts that TRUE determines have been subjected after the date of manufacture to alteration, neglect, abuse, misuse,

accident, damage during transit or installation, fire, flood, or act of God.

IMPROPER ELECTRICAL CONNECTIONS. TRUE IS NOT RESPONSIBLE FOR THE REPAIR OR REPLACEMENT OF FAILED OR DAMAGED COMPONENTS RESULTING

FROM ELECTRICAL POWER FAILURE, THE USE OF EXTENSION CORDS, LOW VOLTAGE, OR VOLTAGE DROPS TO THE UNIT.

NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE: THERE ARE NO OTHER WARRANTIES, EXPRESSED, IMPLIED OR

STATUTORY, EXCEPT THE ONE (1) YEAR PARTS & LABOR WARRANTY AND THE ADDITIONAL FOUR (4) YEAR COMPRESSOR WARRANTY AS DESCRIBED ABOVE.

THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY AND MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

OUTSIDE U.S./Canada: This warranty does not apply to, and TRUE is not responsible for, any warranty claims made on products sold or used outside the

United States or Canada.

WARRANTY INFORMATION (U.S.A & CANADA ONLY!)

ONE YEAR PARTS & LABOR WARRANTY

ADDITIONAL FOUR YEAR COMPRESSOR WARRANTY

404A/134A COMPRESSOR WARRANTY

WARRANTY CLAIMS

WHAT IS NOT COVERED BY THIS WARRANTY

23

............ www.truemfg.com ............

23

Loading...

Loading...