True Manufacturing Company TBB-3G-S, TD-50-18-S-LT, TBB-2, TDD-4, TDB-24-48-1-G-1 User Manual

TRUE FOOD SERVICE EQUIPMENT, INC.

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366

(636)-240-2400 • FAX (636)272-2408 • INT’L FAX (636)272-7546 • (800)325-6152

Parts Department (800)424-TRUE • Parts Department FAX# (636)272-9471

INSTALLATION MANUAL FOR

BAR EQUIPMENT AND GLASS CHILLERS

TDD-4

TD-50-18-S-LT

TBB-2

TABLE OF CONTENTS

Safety Information

Safety Precautions 1

Proper Disposal 2

Connecting Electricity 3

Adapter Plugs 3

Installation / Operation Instructions

Ownership 4

Required Tools 4

Uncrating 4

Location 5

Leveling Cabinet 5

Wire Gauge Cart 6

Sealing Cabinet to the floor 7

Electrical Instructions 8

Beer Dispensers 8-9

Start-up and Light Switch Location 9

Shelving & Bin Divider Installation 10

Storage & Handling 10

Temperature/Pressure/Tapping 11

Draft Beer Problems 12

TBB-3G-S

TDB-24-48-1-G-1

Maintenance, Care & Cleaning

Temperature Control Adjustment 13

Changing CO

Cleaning Bar System 15

Cleaning the Condenser 16

Important Warranty Information 17

Stainless Steel Equipment Care & Cleaning 18-19

Lightbulb Replacement 20

Warranty (U.S.A. and Canada ONLY!) 21

*Spanish, German, French, and Dutch versions included.

Gas Cylinder 14

2

CONGRATULATIONS!

You have just purchased the finest commercial

refrigerator available. You can expect many years of

trouble-free operation.

BAR EQUIPMENT AND

GLASS CHILLERS

............ www.truemfg.com ............

9/8/08-18K SB #894417

True Food Service Equipment, Inc.

............ www.truemfg.com ............

True Food Service Equipment, Inc.

SAFETY INFORMATION

How to Maintain Your lkkkfdls

Unit to Receive the Most Efficient and

Successful Operation

You have selected one of the finest commercial refrigeration units made. It is manufactured under

strict quality controls with only the best quality materials available. Your TRUE cooler when

properly maintained will give you many years of trouble-free service.

WARNING!

Use this appliance for its intended purpose as described in this Owner Manual.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

• This refrigerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

• Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

• Do not touch the cold surfaces in the freezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

• Keep fingers out of the “pinch point” areas;

clearances between the doors and between

the doors and cabinet are necessarily small; be

careful closing doors when children are in the

area.

NOTE: We strongly recommend that any

servicing be preformed by a qualified

individual.

• Unplug the refrigerator before cleaning and

making repairs.

• Setting temperature controls to the 0 position

does not remove power to the light circuit,

perimeter heaters, or evaporator fans.

1

............ www.truemfg.com ............

1

True Food Service Equipment, Inc.

SAFETY INFORMATION

DANGER!

RISK OF CHILD ENTRAPMENT

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous… even if they will sit for “just a few

days.” If you are getting rid of your old refrigerator,

please follow the instructions below to help

prevent accidents.

Before You Throw Away Your Old Refrigerator or

Freezer:

• Take off the doors.

• Leave the shelves in place so that children may

not easily climb inside.

Refrigerant Disposal

Your old refrigerator may have a cooling system

that uses “Ozone Depleting ” chemicals. If you are

throwing away your old refrigerator, make sure

the refrigerant is removed for proper disposal by

a qualified service technician. If you intentionally

release any refrigerants you can be subject to

fines and imprisonment under provisions of the

environmental regulations.

USE OF EXTENSION CORDS

NEVER USE AN EXTENSION CORD! TRUE will not warranty any refrigerator that has been connected to an

extension cord.

2 2

............ www.truemfg.com ............

True Food Service Equipment, Inc.

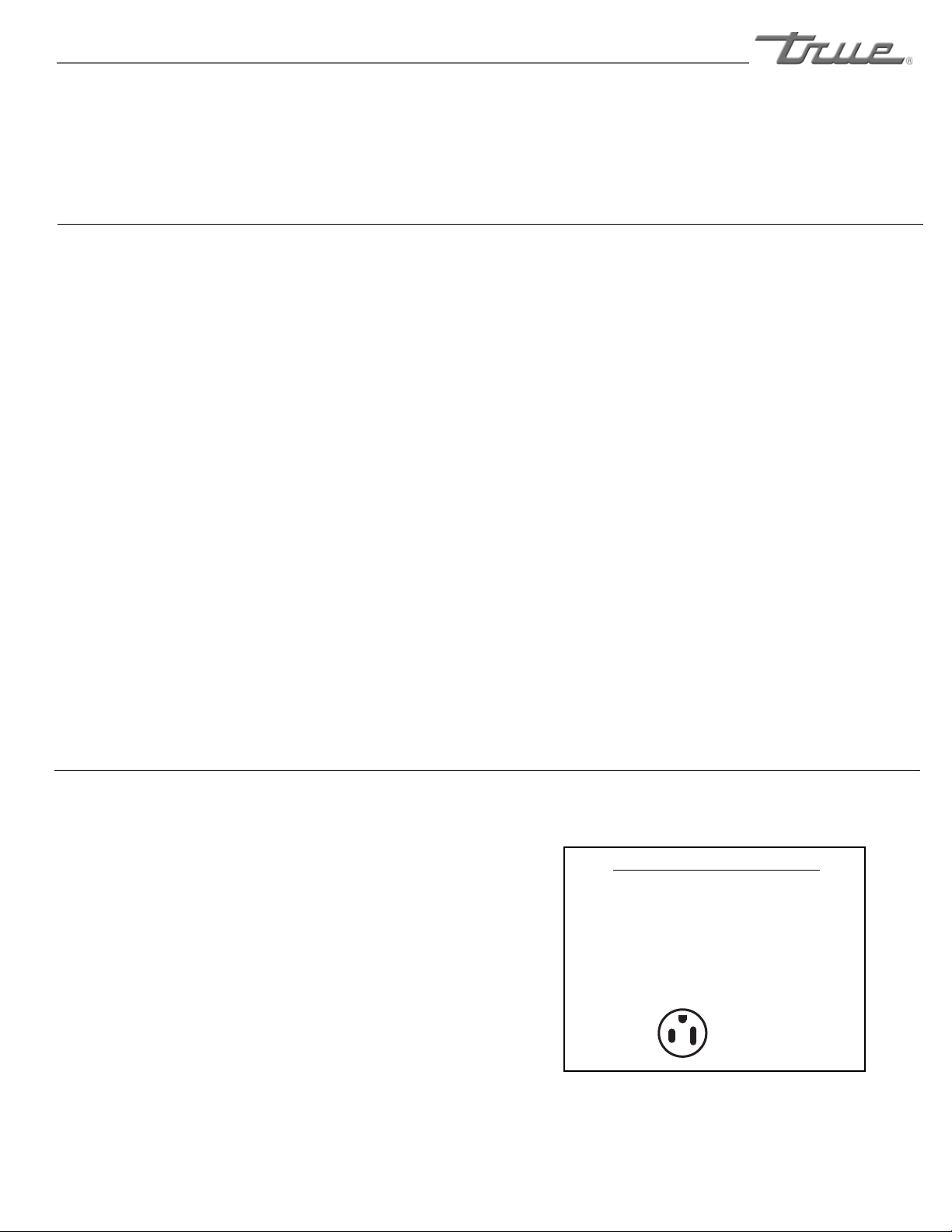

115/60/1

NEMA-5-15R

SAFETY INFORMATION

WARNING!

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped

with a 3-prong (grounding) plug which mates

with a standard 3-prong (grounding) wall outlet to

minimize the possibility of electric shock hazard

from this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

If the outlet is a standard 2-prong outlet, it is your

personal responsibility and obligation to have it

replaced with the properly grounded 3-prong wall

outlet.

The refrigerator should always be plugged into

it’s own individual electrical circuit, which has a

voltage rating that matches the rating plate.

This provides the best performance and also

prevents overloading building wiring circuits which

could cause a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

When removing the refrigerator away from the wall,

be careful not to roll over or damage the power

cord.

USE OF ADAPTER PLUGS

NEVER USE AN ADAPTER PLUG! Because of potential safety hazards under certain conditions, we strongly

recommend against the use of an adapter plug.

(North America Use Only!)

NEMA plugs

TRUE uses these types of plugs.

If you do not have the right outlet

have a certified electrician install

the correct power source.

3

............ www.truemfg.com ............

3

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

INSTALLATION / OPERATION INSTRUCTIONS

OWNERSHIP

To insure that your unit works properly from the

first day, it must be installed properly. We highly

recommend a trained refrigeration mechanic and

electrician install your True equipment. The cost of

a professional installation is money well spent.

REQUIRED TOOLS

• Adjustable Wrench

• Phillips Head Screwdriver

• Level

UNCRATING

Step 1

The following procedure is recommended for

uncrating the unit:

A. Remove the outer packaging, (cardboard

and bubbles or styrofoam corners and clear

plastic). Inspect for concealed damage. Again,

immediately file a claim with the freight carrier

if there is damage.

Before you start to install your True unit, carefully

inspect it for freight damage. If damage is

discovered, immediately file a claim with the

delivery freight carrier.

True is not responsible for damage incurred during

shipment.

1

B. Move your unit as close to the final location as

possible before removing the wooden skid.

C. Remove door bracket on swinging glass door

models (see image 1-2).

Note: Keys for coolers with door locks are located in

warranty packets.

REMOTE UNITS (This section applies to remotes

only!)

• Remote cabinets must be ordered as remote.

We do not recommend converting for a

standard self contained to remote system.

• All remote cabinets must be hard wired.

• No castors available.

• All remote cabinets come standard using 404A

refrigerant.

• All remote units come standard with expansion

valve, liquid line solenoid, heated condensate

pan, and defrost timer when applicable.

2

• Contact True Technical Service for BTU

requirements.

• No wiring necessary between cabinet and

condensing unit.

• All remote condensing units purchased from

True are 208/230 volts single phase.

If you have any questions regarding this section,

please call True at 1-(800)-325-6152.

4 4

............ www.truemfg.com ............

True Food Service Equipment, Inc.

INSTALLATION / OPERATION INSTRUCTIONS

LOCATING

TOOLS REQUIRED:

• Phillips screw driver

• 3/8” socket or 3/8” wrench

Step 2

A. Use a phillips screw diver and remove four

screws from the L-bracket connected the unit

to the wood skid (see image 1). Then use a 3/8”

socket or wrench and remove the L-bracket

from the unit (see image 2).

When lifting unit do not use the countertop as

a lifting point. Also remember to leave cabinet

upright for 24 hours before plugging

into power source.

B. Remove skid by unscrewing all base rail anchor

brackets. Place skid to the side.

C. Carefully upright cabinet.

(Image 1)

Removing

bracket from

skid.

(Image 2)

Removing

bracket from

cabinet.

LEVELING

Step 3

A. Set unit in its final location. Be sure there is

adequate ventilation in your room. Under extreme

heat conditions, (100°F+, 38°C+), you may want to

install an exhaust fan.

Warning

Warranty is void if ventilation is insufficient.

B. Proper leveling of your True cooler is critical to

operating success (for non-mobile models). Effective

condensate removal and door operation will be

effected by leveling.

C. The cooler should be leveled front to back and

side to side with a level.

D. Ensure that the drain hose or hoses are

positioned in the pan.

E. Free plug and cord from inside the lower rear of

the cooler (do not plug in).

F. The unit should be placed close enough to the

electrical supply so that extension cords are never

used.

Warning

Compressor warranties are void if the unit is more than

7 ft. (2.1m) from plug-in connection or an extension

cord is used to connect unit to a power supply.

5

............ www.truemfg.com ............

5

Loading...

Loading...