INSTALLATION, OPERATION

AND SERVICE MANUAL

WARNINGS

SALAMANDER

S86

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR DEATH. THE INSTRUCTION

MANUAL MUST BE READ CAREFULLY BEFORE

INSTALLING, OPERATING OR SERVICING THIS

EQUIPMENT

TO BE INSTALLED ONLY BY AN AUTHORISED PERSON

IN ACCORDANCE WITH AS 5601, LOCAL AUTHORITY,

GAS, ELECTRICITY , ANY APPLICABLE ST ATUTORY

REGULA TIONS AND MANUF ACTURER

REQUIREMENTS.

Salamander Manual Page 1 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

THIS EQUIPMENT IS DESIGNED FOR COMMERCIAL

CATERING PURPOSES AND WILL GENERATE

SIGNIFICANT HEAT. HOT SURFACES WILL CAUSE

BURNS. A HAZARD AND RISK ASSESSMENT MUST BE

UNDERTAKEN BY OWNERS AND ALL OPERATORS

MADE AWARE OF THESE.

DO NOT STORE OR USE FLAMMABLE LIQUIDS NEAR

THIS APPLIANCE.

DO NOT SPRAY AEROSOLS NEAR THIS APPLIANCE

WHILE IT IS IN OPERATION.

INSTALLATION CLEARANCES AS SPECIFIED MUST BE

OBSERVED.

IF YOU SMELL GAS, TURN THE UNIT OFF AND THE

MAIN GAS SUPPLY VALVE TO THE UNIT. CONTACT

YOUR GAS SUPPLIER OR AN AUTHORISED PERSON.

BEFORE TURNING ON THE MAIN GAS SUPPLY, CHECK

THE UNIT TO BE CERTAIN THAT ALL THE VALVES ARE

IN THE “OFF” POSITION.

PLEASE KEEP THIS MANUAL FOR FUTURE

REFERENCE AND REFERENCE BY ALL OPERATORS.

Salamander Manual Page 2 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

CONGRATULATIONS

Comcater thanks you for choosing this product and welcomes you to the

ever-growing Comcater customer circle. This product has been specifically

designed by Comcater to meet a wide rage of applications and represents the

best quality and highest value equipment.

Please read the instruction manual carefully to ensure the safe and reliable

operation and performance of your equipment.

Should you ever require service, you will be supported by Comcater’s trained

and qualified service network – the largest available.

Comcater assures you of every support and wishes you every business

success.

Michael Wood

Managing Director

Comcater

Salamander Manual Page 3 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

TABLE OF CONTENTS

INTRODUCTION .............................................................................................5

GENERAL.................................................................................................5

WARRANTY .............................................................................................5

GENERAL INFORMATION .............................................................................6

INSPECTION............................................................................................6

OPERATOR MANUAL ..............................................................................6

INSTALLATION.........................................................................................6

GAS CONNECTION .................................................................................6

GAS PRESSURE .....................................................................................6

COMMISSIONING....................................................................................6

SPECIFICATIONS...........................................................................................7

INSTALLATION.........................................................................................7

GAS SUPPLY PRESSURE.......................................................................9

NOMINAL GAS CONSUMPTION .............................................................9

TEST POINT PRESSURE........................................................................9

VENTILATION AND AIR SUPPLY.............................................................9

GENERAL SPECIFICATIONS ................................................................10

OPERATING INSTRUCTIONS......................................................................11

LIGHTING INSTRUCTIONS ................................................................... 11

SALAMANDER BURNERS.....................................................................12

SALAMANDER BURNER IGNITION ......................................................12

OPERATOR MAINTENANCE .......................................................................15

CLEANING STAINLESS STEEL.............................................................16

SERVICE.......................................................................................................17

RECOMMENDED SERVICE ..................................................................17

SERVICE INFORMATION ......................................................................17

BURNER ADJUSTMENTS .....................................................................18

CONVERSION INSTRUCTIONS............................................................19

SPARE PARTS .......................................................................................20

TROUBLE SHOOTING .................................................................................21

ALL BURNERS.......................................................................................21

SALAMANDER – MAJOR PARTS IDENTIFICATION ..................................22

SALAMANDER – EXPLODED VIEWS AND

BILL OF MATERIALS ...................................................................................25

DRA WINGS...................................................................................................27

Salamander Manual Page 4 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

INTRODUCTION

GENERAL

This equipment is designed for commercial catering purposes and

incorporates a wide range of design features to benefit the customer. This

versatility will satisfy a wide range of customer needs.

WARRANTY

This product is warranted for 12 months parts and labour and is subject to the

correct installation, operation, maintenance and care of the equipment.

Warranty does not extend to:

• Damages caused in shipment.

• Damage as a result of incorrect installation.

• Damage as a result of incorrect operation.

• Damages caused by unauthorised service and use of non-original parts.

• Gas supply issues to the equipment.

• Failure resulting from improper maintenance.

• Failure as a result of tampering with, removal of, or changing any preset

control or safety device.

• Service ‘After hours’.

• Conditions as defined in Comcater terms and condition of sale.

For all warranty work, authorized service and genuine and authorized

spare parts, please contact Comcater Service 03 8369 4600.

Please ensure you quote the Model and Serial Number of the unit. The

Model and Serial Number of the unit is recorded on the sales invoice.

Alternatively, the information is recorded on the front of the unit and on the data

plate located behind the front panel.

Salamander Manual Page 5 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

GENERAL INFORMATION

INSPECTION

Please inspect the unit on receipt. If the unit is damaged, contact the carrier

immediately and file a damage claim with them. Save all packing materials

when filing a claim. Freight damage claims are the responsibility of the

purchaser and are not covered under warranty.

OPERATOR MANUAL

This manual contains important information for your safety and the

installation, operation, maintenance and service of this equipment.

Please read the manual carefully and ensure all operators of the

equipment are aware of the contents and safety requirements.

Warning: You must assess all hazards and risks associated with the

operation of the equipment in your environment and advise all operators

of these.

INSTALLATION

This equipment must be installed by an authorized person in accordance

with AS 5601, local authority, gas, electricity, any applicable statutory

regulations and manufacturer requirements.

GAS CONNECTION

The appliance must be connected by an authorized person to the gas type

specified on the unit. The gas type is shown adjacent to the rear gas

connection point on the back panel and on the data plate. Connect to and use

only the correct type of gas.

GAS PRESSURE

The authorized person installing this equipment must ensure that the gas

operating pressure is the same as shown on the rating plate, the test point

pressure is correct (refer page 9) and that there is sufficient gas volume.

COMMISSIONING

The authorized person installing this equipment must commission the

equipment in accordance with AS 5601 - gas leakage, operational checking,

adjustments and instructing the owner on use of the equipment are prescribed

requirements.

Salamander Manual Page 6 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

SPECIFICATIONS

INSTALLATION

THIS EQUIPMENT MUST BE INSTALLED BY AN

AUTHORIZED PERSON IN ACCORDANCE WITH AS 5601,

LOCAL AUTHORITY, GAS, ELECTRICITY, ANY APPLICABLE

STATUTORY REGULATIONS AND MANUFACTURER

REQUIREMENTS.

NOTE: INSTALLATION IS THE RESPONSIBILITY OF THE OWNER

Gas Inlet Connection: ½” BSP Female.

Gas Connection Point: The gas connection point is located at the rear of

the unit (300 mm from the right hand side and

45mm above the base of the unit)

Details are shown in the drawing at the rear of this

manual.

Gas Connection: The appliance must be connected by an

authorized person to the gas type specified on the

unit. The gas type is shown adjacent to the gas

connection point and on the data plate. Connect

to and use only the correct type of gas.

The authorized person installing this equipment

must comply with AS 5601 requirements.

Prescribed requirements include, commission the

equipment, gas leakage testing, operational

checking and adjustments.

All units are tested and adjusted at the factory; however, burners and pilots

must be checked at the installed location and adjusted if necessary.

Salamander Manual Page 7 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Data Plate: The data plate is located behind the front panel.

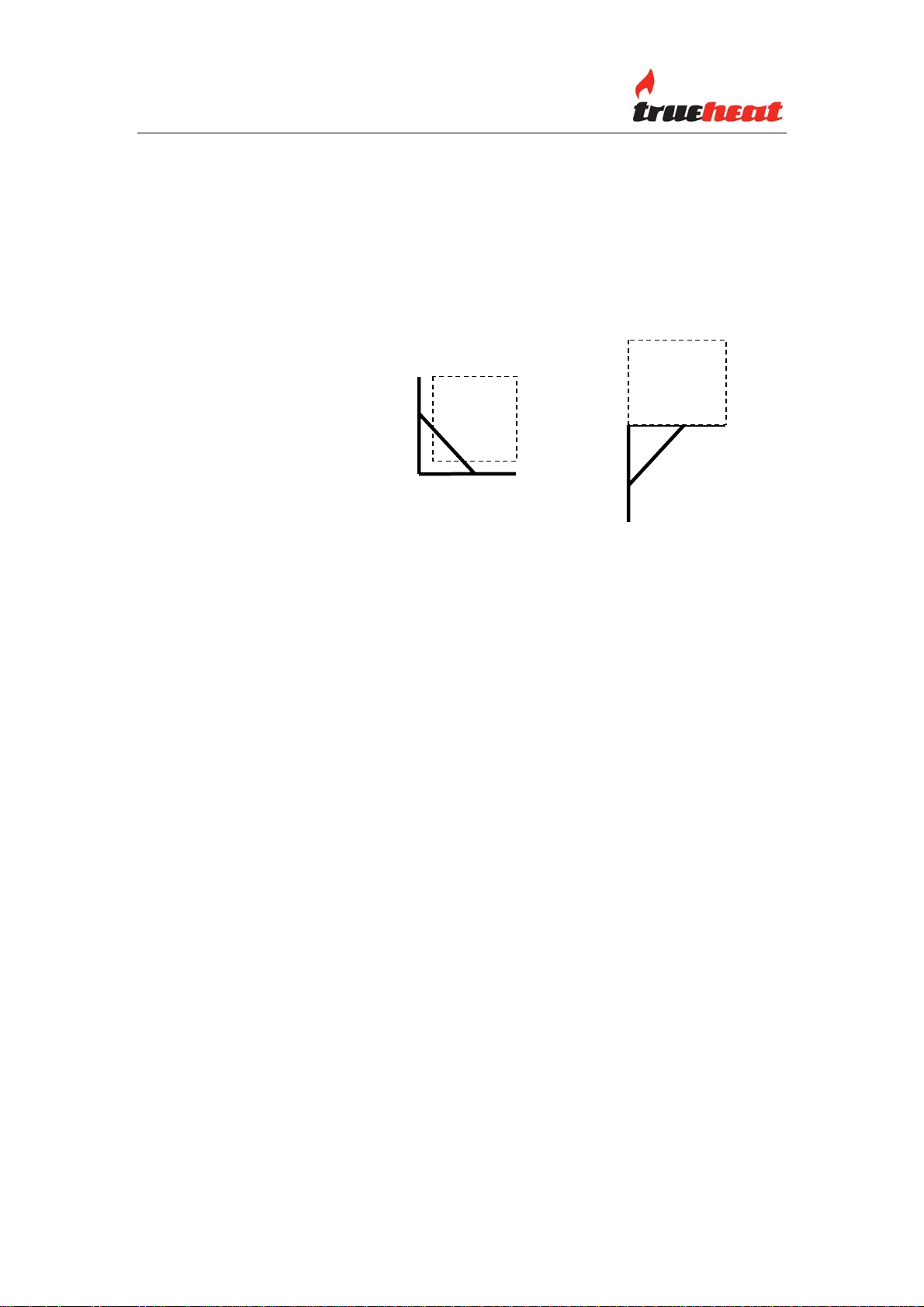

Installation: The Salamander is provided with two mounting

brackets. The brackets may be fitted in two ways

as follows:

Select a suitable location and fix the mounting

brackets in position (Refer ‘Installation Clearances’

below). The brackets must be securely mounted.

Mount the Salamander to the brackets by inserting

the four M10 mounting bolts (supplied) from the

underside of the bracket into the Salamander.

Warning: The Salamander mounting bolt s must

be inserted and secured.

Warning: The Salamander should never be

installed and operated as a counter top unit.

Installation Clearances: The MINIMUM clearances from combustible

surfaces are:

Sides: 300mm (Note: the sides of the Salamander

are removable and adequate clearance must be

provided for safe handling large products.

Rear: 100mm

Adequate clearance must also be provided for

service.

Salamander Manual Page 8 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

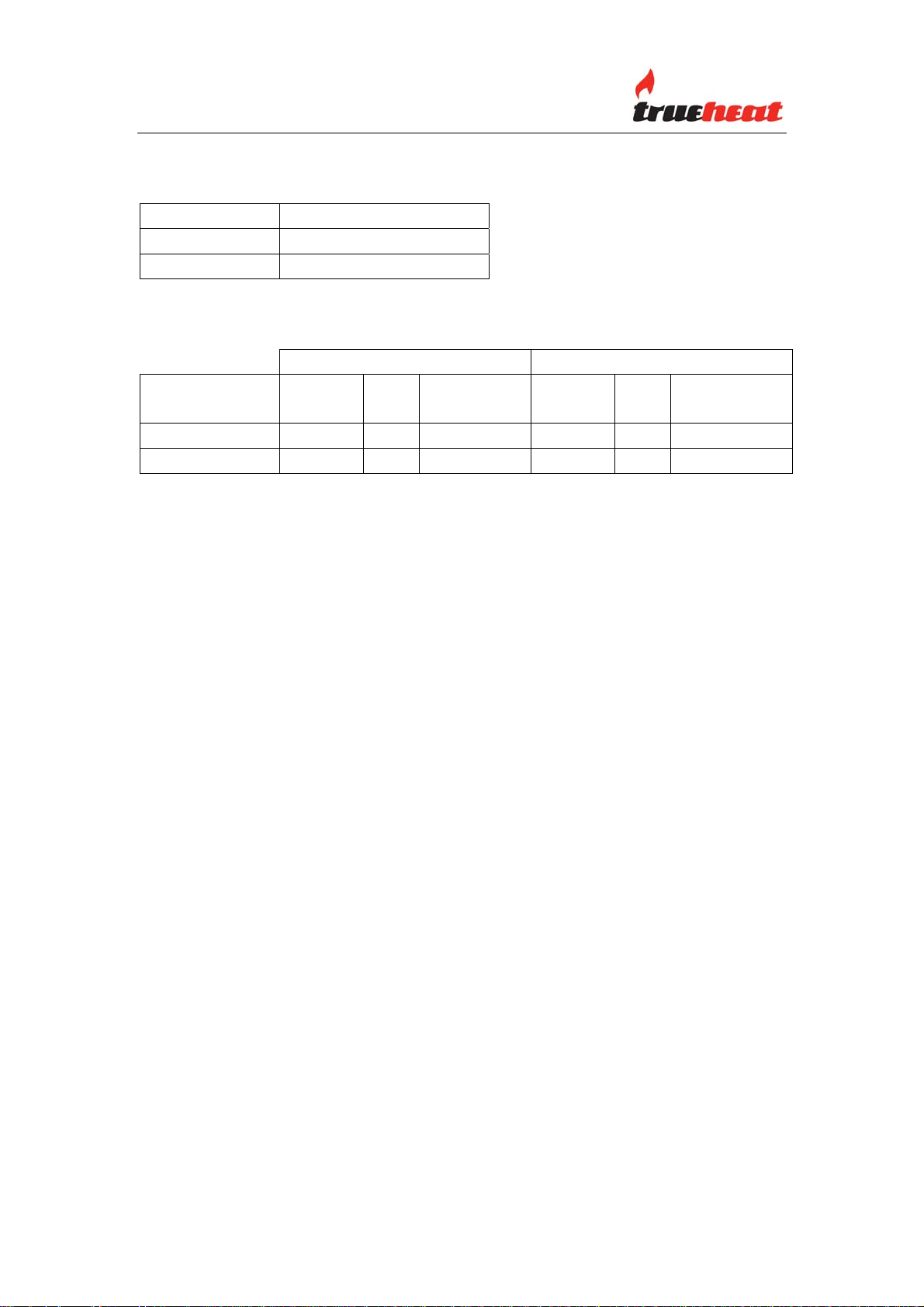

MINIMUM GAS SUPPLY INLET PRESSURE

Gas Type Gas Pressure

Natural Gas 1.13 kPa

LP Gas 2.75 kPa

NOMINAL GAS CONSUMPTION

BURNER

(EACH)

SALAMANDER 1.70mm 14 1.0 kPa 1.00mm 13 2.60 kPa

TOTAL

ORIFICE

NATURAL GAS PROPANE GAS

MJ/h TEST POINT

(mm)

28 26

PRESSURE

ORIFICE

(mm)

MJ/h TEST POINT

PRESSURE

Note: Pressure test point is located on the gas manifold (refer also ‘Test Point

Pressure’ below).

Turndown Setting

Natural Gas 5 turns out from fully in

Propane Gas 3 turns out from fully in

TEST POINT PRESSURE

The gas pressure test point is located on the gas manifold and is accessed by

removing the gas valve control knobs, piezzo igniter leads and the front panel.

The test point pressure is shown in the Nominal Gas Consumption Table

above and is set with the two burners operating at maximum setting.

VENTILA TION AND AIR SUPPL Y

All gas burners and pilots require sufficient air to operate. For optimum

performance and for your safety, it is ESSENTIAL that the equipment, in the

installed position, has the proper air and ventilation and the correct

exhaust/canopy and air balance. The correct installation and compliance with

all regulatory and other requirements is the responsibility of the

purchaser/owner.

Please note that a strong exhaust canopy will create a vacuum if there is

insufficient replacement air. The amount of air exhausted must be replaced by

an equal amount of air.

Airflow to the appliance must not be blocked or restricted (e.g. large objects

should not be placed in front of the appliance).

Salamander Manual Page 9 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

GENERAL SPECIFICATIONS

OVERALL DIMENSIONS AND WEIGHT

MODEL DEPTH

(mm)

SALAMANDER

CCE S86

WIDTH

(mm)

HEIGHT

(mm)

WEIGHT

(Kg)

Assembled 515 860 440 63

Shipping 635 980 560 81

Detailed dimensional specifications are shown at the rear of this manual.

Salamander Manual Page 10 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

OPERATING INSTRUCTIONS

LIGHTING INSTRUCTIONS

DO NOT OPERATE THE UNIT UNLESS IT HAS BEEN

INST ALLED AND COMMISSIONED BY AN AUTHORIZED

PERSON.

BEFORE TURNING ON THE MAIN GAS SUPPLY, CHECK AND

ENSURE THAT ALL THE VALVES ARE IN THE “OFF”

POSITION.

THIS EQUIPMENT IS DESIGNED FOR COMMERCIAL

CATERING PURPOSES AND WILL GENERATE SIGNIFICANT

HEAT. HO T SURFACES WILL CAUSE BURNS. A HAZARD

AND RISK ASSESSMENT MUST BE UNDERTAKEN BY

OWNERS AND ALL OPERATORS MADE AWARE OF THESE.

THE TOP OF THE SALAMANDER HAS FLUE OUTLETS AND

IS VERY HOT – THE FLUE OUTLETS MUST NEVER BE

COVERED OR RESTRICTED IN ANY WAY AND STAFF MUST

BE INSTRUCTED NOT TO TOUCH THE TOP SURFACE.

NOTE: For your safety, all burners are controlled by a flame failure sensing

device. If the device does not sense a flame, gas supply to the burner

will be cut.

Salamander Manual Page 11 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

SALAMANDER BURNERS

Salamander Burner Control

WARNING: Ensure there are no objects placed on top of the unit and that

there are no restrictions to the flue passages.

NOTE: Ensure the gas supply to the equipment is turned ON

SALAMANDER BURNER IGNITION

Starting from the OFF ● position, turn the control knob to the LEVEL 1 position.

Fully depress the control knob and then press the piezzo igniter to ignite the

burner – repeat until the burner ignites. Keep the knob fully depressed for 15

seconds after the burner lights. When the automatic valve senses that the

BURNER is alight, the gas flow to the burner will continue when the knob is

released. The equipment may then be operated between LEVEL 1 position

(highest heat) and LEVEL 2 (lowest heat).

NOTE: When the equipment is cold, the gas properties are such that it is

likely to be easier to light the burner (at the front or the side) with a gas

torch rather than the piezzo igniter as per the above process.

WARNING: NEVER PLACE YOUR HAND UNDER THE BURNER.

Shut Down

Turn the control knob to the OFF ● position.

NOTE: If the burner flame were accidentally extinguished, the flame failure

safety device would operate and cut the gas flow to the main burner. It would

then be necessary to re-light the burners by following the above procedure.

Salamander Manual Page 12 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Cooking Shelf

The cooking shelf holds the cooking tray and grease drawer and slides in and

out for ease of loading and removing product. A lock is provided to prevent

accidental complete removal of the cooking shelf. To completely remove the

cooking shelf, lift the handle upwards and carefully remove.

Warning: Hot surfaces – use appropriate safe handling techniques and

protective clothing.

Cooking Shelf Assembly

Cooking Shelf Height

The cooking shelf height is adjustable. To adjust the height, lift the height

adjustment control arm and move laterally until the desired height is reached

and then lower the control arm into the desired slot.

In the highest position, the

cooking tray is 45mm from the burner. In the lowest position, the cooking tray

is 125mm from the burner.

Warning: Ensure the height adjustment control arm is always locked in a

position.

Warning: Hot surfaces – use appropriate safe handling techniques and

protective clothing.

End Covers/Sides

The end covers/sides of the Salamander are removable – either or both may

be removed as required. The covers are removed by pulling outwards.

Warning: Hot surfaces – use appropriate safe handling techniques and

protective clothing.

Salamander Manual Page 13 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Cooking

Many factors will determine the best cooking height for your product. As a

general guide:

• If your product is burning on top and the internal temperature is low,

the cooking tray may be too close to the burner and should be

lowered.

• If the product is not browning or cooking fast enough, raise the

cooking tray.

Warning: Hot surfaces – use appropriate safe handling techniques and

protective clothing.

Salamander Manual Page 14 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

OPERATOR MAINTENANCE

USE ONLY SUITABLE CHEMICALS AND OBSERVE ALL

MANUFACTURER SAFETY REQUIREMENTS FOR SAFE

HANDLING AND USE.

Note: The equipment must be kept clean to ensure safe and reliable

operation and performance.

Warning: Empty the grease drawer as necessary and clean. Excessive

deposits in the grease drawer may cause flare-ups.

Warning: Hot surfaces – use appropriate safe handling techniques and

protective clothing.

The following procedures are recommended – the amount of cleaning will

depend on the equipment usage and the products being cooked.

After each use: Ensure the cooking tray and grease draw are clean.

Excessive deposits in the grease drawer may cause flare-ups (Refer ‘Cleaning

Stainless Steel’ below).

Daily: The cooking shelf and grease tray should be removed and cleaned with

hot water and detergent. Wipe and clean all exterior surfaces (Refer ‘Cleaning

Stainless Steel’ below).

Weekly: Inspect all surfaces of the cooking chamber, including burners, and

clean as necessary. More frequent cleaning may be necessary based on

equipment usage.

Burners: The burners may be removed and cleaned as necessary by undoing

the burner retaining screw, removing the piezzo ignition lead, releasing the

thermocouple from the ignition block (held by spring force), lifting up the burner

and pulling forward – after cleaning, ensure the burner is dry and replaced in

reverse order in the correct position.

Warning: If your burners require cleaning and you are not confident in

performing this task, please call for service.

Salamander Manual Page 15 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Lifting Mechanism: It may be necessary to lubricate the lifting mechanism on

occasions. If required, use industry approved, heat resistant, food safe grease

on the chain and sprockets. These are accessed by removing the protective

cover.

CLEANING STAINLESS STEEL

Regularly wipe surfaces with hot water and detergent (use non-abrasive

cleaning aids as necessary). Rinse the washed area with a wet sponge and

clean water and wipe the area dry to prevent streaking. Follow this process

and wash a small area at a time to prevent chemical residue and streaking.

Stainless steel may discolour if overheated. These stains can usually be

removed using an appropriate powder/paste. To scrape off heavy deposits of

grease and oil, use only wood or plastic tools as necessary.

Note: Never use steel wool to clean stainless steel.

Note: Damage may occur if chemicals not suitable for stainless steel are

used.

Note: Use non-abrasive cleaning aids (Brushes/Pads).

Salamander Manual Page 16 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

SERVICE

FOR YOUR SAFETY, ALL SERVICE WORK MUST BE

CARRIED OUT BY AN AUTHORISED PERSON AND USE

ONLY ORIGINAL SUPPLIED AND SPECIFIED PARTS.

TEST ALL FITTINGS, PIPES AND PIPE CONNECTIONS FOR

LEAKS IN ACCORDANCE WITH APPROVED GAS LEAK TEST

PROCESSES AND METHODS. DO NOT USE A FLAME.

Note: When checking gas test point pressure, ensure that all other

equipment on the same line is turned ‘ON’ and operating.

RECOMMENDED SERVICE

It is recommended that an authorized person service your appliance every 12

months. This period is for guidance purpose only and may vary based on

usage of the equipment and operator care. Prescribed service tasks include;

• Functional test of all components and clean, lubricate and adjust as

necessary.

• Inspect and clean all gas valves and lubricate with an industry approved

lubricant.

• Inspect all gas piping.

• Check and adjust specified gas pressures.

• Leak test.

• Full operational, performance and safety test.

SERVICE INFORMATION

• To access gas valves, remove control knobs and the front panel.

• To remove a gas valve, disconnect the gas valve at the manifold tee

spigot connection and remove the valve.

• To access thermocouples, release the thermocouple from the ignition

block (spring clip) or remove the top of the unit.

• To access burners, remove the top panel, undo the retaining screw,

remove the piezzo ignition lead, release the thermocouple from the

ignition block (held by spring force), lift up the burner and pull forward –

re-assemble in reverse order.

Salamander Manual Page 17 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

BURNER ADJUSTMENTS

Leak Test

• Ensure that all valves are in the OFF position.

• Turn on the main gas supply valve.

• Light the burners.

• Leak test all valves and fittings using approved methods.

• Correct any leaks as required and re-check.

• Shut off all valves and set controls to the “OFF” position.

Test Point Pressure

The test point is located on the gas manifold. The gas manifold and pressure

test point is accessed by removing the gas valve control knobs and the front

panel. The test point pressure is shown in the Nominal Gas Consumption

Table and is set with the two burners operating at maximum setting.

Burner Adjustment

The burner orifices are fixed as specified and cannot be adjusted. The

specified gas rate will be achieved if the gas supply pressure and test point

pressure is correct and all gas components are clean and free of blockages.

The turndown (low flame) setting can be adjusted by adjusting the screw on

the gas valve.

A distinct blue flame over the entire port area of the burner will be achieved at

full rate when the air supply is correct.

If the flame is yellow and wavy, the cause needs to be established.

WARNING: If you are not competent in performing any service task or require

assistance, please contact Comcater Service 03 8369 4600.

Salamander Manual Page 18 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

CONVERSION INSTRUCTIONS

TO BE COMPLETED BY AN AUTHORISED PERSON

ENSURE GAS IS ISOLATED WHILST PERFORMING

CONVERSION WORK. PERFORM A LEAK TEST BEFORE

IGNITING AND MAKING BURNER AND PILOT

ADJUSTMENTS.

TO PROPANE GAS

Regulator Change regulator to PROPANE gas configuration

and adjust as necessary.

Burner Injectors Access and change the injectors to PROPANE Gas

injectors (refer Nominal Gas Consumption

Table).

LEAK TEST IN ACCORDANCE WITH APPROVED METHODS

Ignite burners and adjust.

AMEND DATA PLATE AND APPLY ‘PROPANE’ GAS LABEL

TO NATURAL GAS (NG)

Regulator Change regulator to NG gas configuration and

adjust as necessary.

Burner Injectors Access and change the injectors to NG Injectors

(refer Nominal Gas Consumption Table).

LEAK TEST IN ACCORDANCE WITH APPROVED METHODS

Ignite burners and adjust.

AMEND DATA PLATE AND APPLY ‘NATURAL GAS’ LABEL.

Salamander Manual Page 19 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

SPARE PARTS

A list of major spare part items is shown at the end of this manual.

These parts and all other parts used in the Comcater Salamander are available

from Comcater.

Warning: Use only genuine spare parts.

Warning: Use of non-authorised parts voids warranty and equipment

approval.

Salamander Manual Page 20 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

TROUBLE SHOOTING

ALL SERVICE WORK TO BE COMPLETED BY AN

AUTHORISED PERSON.

ALL BURNERS

CONDITION CHECK

Yellow burner flame. Primary air

Check air supply and ventilation

Flame lifting off burner ports. Primary air

Check air supply and ventilation

‘Popping’ after turning off. Primary air

Air shutter

Burner flame too large. Gas pressure

Piezzo will not spark. Igniter lead, igniter and electrode

Flame burns back to orifice. Primary air

Salamander Manual Page 21 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

MAJOR PARTS IDENTIFICATION

IDENTIFICATION PART NUMBER ITEM NAME

CCE KB-BTW20 Burner Infra-Red Large (Salamander)

CCE KB-F60N

Flame Failure Gas Valve F60N with 3/8” Nut and

Olive (Salamander)

CCE KB-99301/270

CCE KB-99301/DG Decal Knob – Grill (Range/Barbeque/Salamander)

Knob Black – Suit F60P/F60N

(Range/Barbeque/Salamander)

CCE KB-99301/E Escutcheon – F60N (Salamander)

CCE KB-C7931 Ignition Block to Suit CCE KB-BTW20 (Salamander)

CCE KG-200090 Thermocouple 900XM9XUnif/Sleeve

CCE KB-301170

CCE KB-301100

Injector 1/8" BSP Salamander Burners (NG 1.70mm)

Injector 1/8" BSP Salamander Burners (LPG

1.00mm)

Salamander Manual Page 22 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

CCE KB-23700 Injector Holder

CCE KG-073964 Piezzo Igniter and Nut – Red Button

CCE KG-HT1000 Lead Ignition H/T 1000 mm (Salamander)

CCE Q01011D Cooking Tray

CCE Q01011E Grease Drawer

CCE Q01011O Salamander Mounting Bracket (Universal L/R)

CCE KB-WMT Manifold Tee ¼” BSP Male

Salamander Manual Page 23 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

CCE KB-WMT/TP

Manifold Tee ¼” BSP Male Complete With Pressure

Test Point

CCE KB-AT952-15 3/8” (10mm) Aluminium Tube

CCE KB-RV47LM

CCE

MAXITROL GAS REGULATOR ½" BSP NG

MAXITROL CONVERSION KIT LPG

Source File: PARTSIDENTIFICATION SALAMANDER 13 Sep 07

Salamander Manual Page 24 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Salamander Manual Page 25 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Salamander Manual Page 26 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Salamander Manual Page 27 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

N o t e s

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Salamander Manual Page 28 Revision: 13 Sep 07

OPERATOR MANUAL S86 130907.doc

Loading...

Loading...