Page 1

INSTALLATION AND OPERATION

MANUAL

RANGE SERIES

WARNINGS

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR DEATH. THE INSTRUCTION

MANUAL MUST BE READ CAREFULLY BEFORE

INSTALLING, OPERATING OR SERVICING THIS

EQUIPMENT

TO BE INSTALLED ONLY BY AN AUTHORISED PERSON

IN ACCORDANCE WITH AS 5601, LOCAL AUTHORITY,

GAS, ELECTRICITY , ANY APPLICABLE ST ATUTORY

REGULA TIONS AND MANUFACTURER

REQUIREMENTS.

Range Manual Page 1 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 2

THIS EQUIPMENT IS DESIGNED FOR COMMERCIAL

CATERING PURPOSES AND WILL GENERATE

SIGNIFICANT HEAT. HOT SURFACES WILL CAUSE

BURNS. A HAZARD AND RISK ASSESSMENT MUST BE

UNDERTAKEN BY OWNERS AND ALL OPERATORS

MADE AWARE OF THESE.

DO NOT STORE OR USE FLAMMABLE LIQUIDS NEAR

THIS APPLIANCE.

DO NOT SPRAY AEROSOLS NEAR THIS APPLIANCE

WHILE IT IS IN OPERATION.

INSTALLATION CLEARANCES AS SPECIFIED MUST BE

OBSERVED.

IF YOU SMELL GAS, TURN THE UNIT OFF AND THE

MAIN GAS SUPPLY VALVE TO THE UNIT. CONTACT

YOUR GAS SUPPLIER OR AN AUTHORISED PERSON.

BEFORE TURNING ON THE MAIN GAS SUPPLY, CHECK

THE UNIT TO BE CERTAIN THAT ALL THE VALVES ARE

IN THE “OFF” POSITION.

PLEASE KEEP THIS MANUAL FOR FUTURE

REFERENCE AND REFERENCE BY ALL OPERATORS.

Range Manual Page 2 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 3

CONGRATULATIONS

Comcater thanks you for choosing this product and welcomes you to the

ever-growing Comcater customer circle. This product has been specifically

designed by Comcater to meet a wide rage of applications and represents the

best quality and highest value equipment.

Please read the instruction manual carefully to ensure the safe and reliable

operation and performance of your equipment.

Should you ever require service, you will be supported by Comcater’s trained

and qualified service network – the largest available.

Comcater assures you of every support and wishes you every business

success.

Michael Wood

Managing Director

Comcater

Range Manual Page 3 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 4

TABLE OF CONTENTS

INTRODUCTION----------------------------------------------------------------------------------------------6

GENERAL ------------------------------------------------------------------------------------------------6

WARRANTY ---------------------------------------------------------------------------------------------6

GENERAL INFORMATION--------------------------------------------------------------------------------7

INSPECTION --------------------------------------------------------------------------------------------7

OPERATOR MANUAL---------------------------------------------------------------------------------7

INSTALLATION------------------------------------------------------------------------------------------7

GAS CONNECTION -----------------------------------------------------------------------------------7

GAS PRESSURE---------------------------------------------------------------------------------------7

COMMISSIONING -------------------------------------------------------------------------------------7

SPECIFICATIONS--------------------------------------------------------------------------------------------8

INSTALLATION------------------------------------------------------------------------------------------8

GAS INPUT INFORMATION----------------------------------------------------------------------- 10

GAS SUPPLY PRESSURE ------------------------------------------------------------------------ 10

NOMINAL GAS CONSUMPTION ----------------------------------------------------------------10

TEST POINT PRESSURE-------------------------------------------------------------------------- 10

VENTILATION & AIR SUPPLY -------------------------------------------------------------------- 11

MODEL OPTIONS------------------------------------------------------------------------------------ 12

GENERAL SPECIFICATIONS--------------------------------------------------------------------- 12

OPERATING INSTRUCTIONS ------------------------------------------------------------------------- 13

LIGHTING INSTRUCTIONS ----------------------------------------------------------------------- 13

OPEN TOP BURNERS------------------------------------------------------------------------------ 14

GRILL BURNER(S) ---------------------------------------------------------------------------------- 15

OVEN BURNER -------------------------------------------------------------------------------------- 16

OPERATOR MAINTENANCE--------------------------------------------------------------------------- 18

SEASONING THE GRILL -------------------------------------------------------------------------- 18

CLEANING STAINLESS STEEL------------------------------------------------------------------ 19

OVEN INTERIOR (Enamel)------------------------------------------------------------------------ 19

OPEN TOP BURNERS------------------------------------------------------------------------------ 19

ENAMELLED TRIVETS----------------------------------------------------------------------------- 20

Range Manual Page 4 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 5

TABLE OF CONTENTS (continued)

SERVICE........................................................................................................................21

RECOMMENDED SERVICE ...................................................................................21

SERVICE INFORMATION .......................................................................................21

OPEN AND GRILL BURNER ADJUSTMENTS........................................................ 22

OVEN CONTROL SETTINGS AND ADJUSTMENTS.............................................. 23

CONVERSION INSTRUCTIONS ............................................................................. 25

SPARE PARTS ........................................................................................................26

TROUBLE SHOOTING...................................................................................................27

ALL BURNERS ........................................................................................................ 27

OVEN....................................................................................................................... 28

RANGE OPTIONS.....................................................................................................29-30

MAJOR PARTS IDENTIFICATION............................................................................31-34

EXPLODED VIEWS AND BILL OF MATERIALS......................................................35-45

DRAWINGS ...............................................................................................................46-59

Range Manual Page 5 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 6

INTRODUCTION

GENERAL

This equipment is designed for commercial catering purposes and

incorporates a wide range of design features. It is available in various

configurations for open burners, grill sections and oven and as a top only unit.

This versatility will satisfy a wide range of customer needs.

WARRANTY

This product is warranted for 12 months parts and labour and is subject to the

correct installation, operation, maintenance and care of the equipment.

Warranty does not extend to:

• Damages caused in shipment

• Damage as a result of incorrect installation

• Damage as a result of incorrect operation

• Damages caused by unauthorised service and use of non original parts

• Gas supply issues to the equipment

• Failure resulting from improper maintenance

• Failure as a result of tampering with, removal of, or changing any preset

control or safety device

• Service ‘After hours’

• Conditions as defined in Comcater terms and condition of sale

For all warranty work, authorized service and genuine and authorized

spare parts, please contact Comcater Service 03 8369 4600.

Please ensure you quote the Model and Serial Number of the unit. The

Model and Serial Number of the unit is recorded on the sales invoice.

Alternatively:

For ranges with ovens - the information is recorded on the data plate behind

the oven control panel. Please refer to the SPECIFICATION (Installation)

section to access the data plate. Please ensure you locate and replace the

outer oven control knob correctly.

For Top only units – the information is recorded on the data plate located at

the rear of the unit.

Range Manual Page 6 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 7

GENERAL INFORMATION

Inspection.

Please inspect the unit on receipt. If the unit is damaged, contact the carrier

immediately and file a damage claim with them. Save all packing materials

when filing a claim. Freight damage claims are the responsibility of the

purchaser and are not covered under warranty.

Operator Manual.

This manual contains important information for your safety and the

installation, operation, maintenance and service of this equipment.

Please read the manual carefully and ensure all operators of the

equipment are aware of the contents and safety requirements. You must

also assess all hazards and risks associated with the operation of the

equipment in your environment and advise all operators of these.

Installation.

This equipment must be installed by an authorized person in accordance

with AS 5601, local authority, gas, electricity, any applicable statutory

regulations and manufacturer requirements.

Gas Connection.

The appliance must be connected by an authorized person to the gas type

specified on the unit. The gas type is shown adjacent to the rear gas

connection point and on the data plate. Connect to and use only the correct

type of gas.

Gas Pressure.

The authorized person installing this equipment must ensure that the gas

operating pressure is the same as shown on the rating plate and that there is

sufficient gas volume.

Commissioning.

The authorized person installing this equipment must commission the

equipment in accordance with AS 5601 - gas leakage, operational checking,

adjustments and instructing the owner on use of the equipment are prescribed

requirements.

Range Manual Page 7 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 8

SPECIFICATIONS

INSTALLATION

THIS EQUIPMENT MUST BE INSTALLED BY AN

AUTHORIZED PERSON IN ACCORDANCE WITH AS 5601,

LOCAL AUTHORITY, GAS, ELECTRICITY , ANY APPLICABLE

STATUTORY REGULATIONS AND MANUFACTURER

REQUIREMENTS.

NOTE: INSTALLATION IS THE RESPONSIBILITY OF THE OWNER

Gas Inlet Connection: 3/4” BSP Female.

Gas Connection Point: For Range units, the gas connection point is

located at the rear of the unit (600 mm above the

floor and 85 mm from the right hand side)

For Top only units, the gas connection point is

located at the rear of the unit (85mm above the

base and 85mm from the right hand side)

Details are shown in the drawings at the rear of

this manual.

Gas Connection: The appliance must be connected by an

authorized person to the gas type specified on the

unit. The gas type is shown adjacent to the rear

gas connection point and on the data plate.

Connect to and use only the correct type of

gas.

The authorized person installing this equipment

must comply with AS 5601 requirements.

Prescribed requirements include, commission the

equipment, gas leakage testing, operational

checking and adjustments.

All units are tested and adjusted at the factory; however, burners and pilots

must be checked at the installed location and adjusted if necessary.

Range Manual Page 8 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 9

Data Plate: For ranges with ovens, the data plate is located

behind the oven control panel. For Top only units,

the data plate is located at the rear of the unit.

Data Plate Access: To access the data plate on a Range unit:

• turn the oven thermostat control knob to the

OFF position

OFF

• remove the oven thermostat control knob by

gently pulling (a smaller knob remains and

is not to be removed),

• undo the screw at the top of the panel and

open the panel

• carefully remove the lead from the piezzo

igniter and then fully open the panel.

To close the panel, follow the above procedures in

reverse. Ensure the piezzo igniter is re connected.

After re inserting the screw, ensure that the inner

knob is in the OFF position and then align the

outer oven thermostat control knob with the OFF

position and gently push the knob back on.

Clearances Oven Base: When the unit is installed and the legs are

adjusted so that the top of the front rail is 910mm

above the floor, the unit may be installed on a

non-combustible surface (the unit is set at 910mm

ex factory). If the height from the floor to the top of

the front rail is less than 910mm, the unit must be

installed on a fireproof base. Legs on floor

models must not be removed – the space under

the unit is a primary source of air for the oven

burner combustion.

Range Manual Page 9 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 10

Installation Clearances: The MINIMUM clearance from combustible

surfaces is 150 mm (Sides and Rear). Adequate

clearance must also be provided for service.

Levelling: Refer also to ‘Clearances Oven Base’ above.

To adjust the legs to level the unit to the floor

and/or to slightly adjust the height of the unit, raise

the front of the unit and adjust the legs (ensure

safe work practices). Similarly, raise the back and

adjust the legs. DO NOT LAY THE UNIT ON ITS

BACK. ENSURE THE UNIT IS LEVEL.

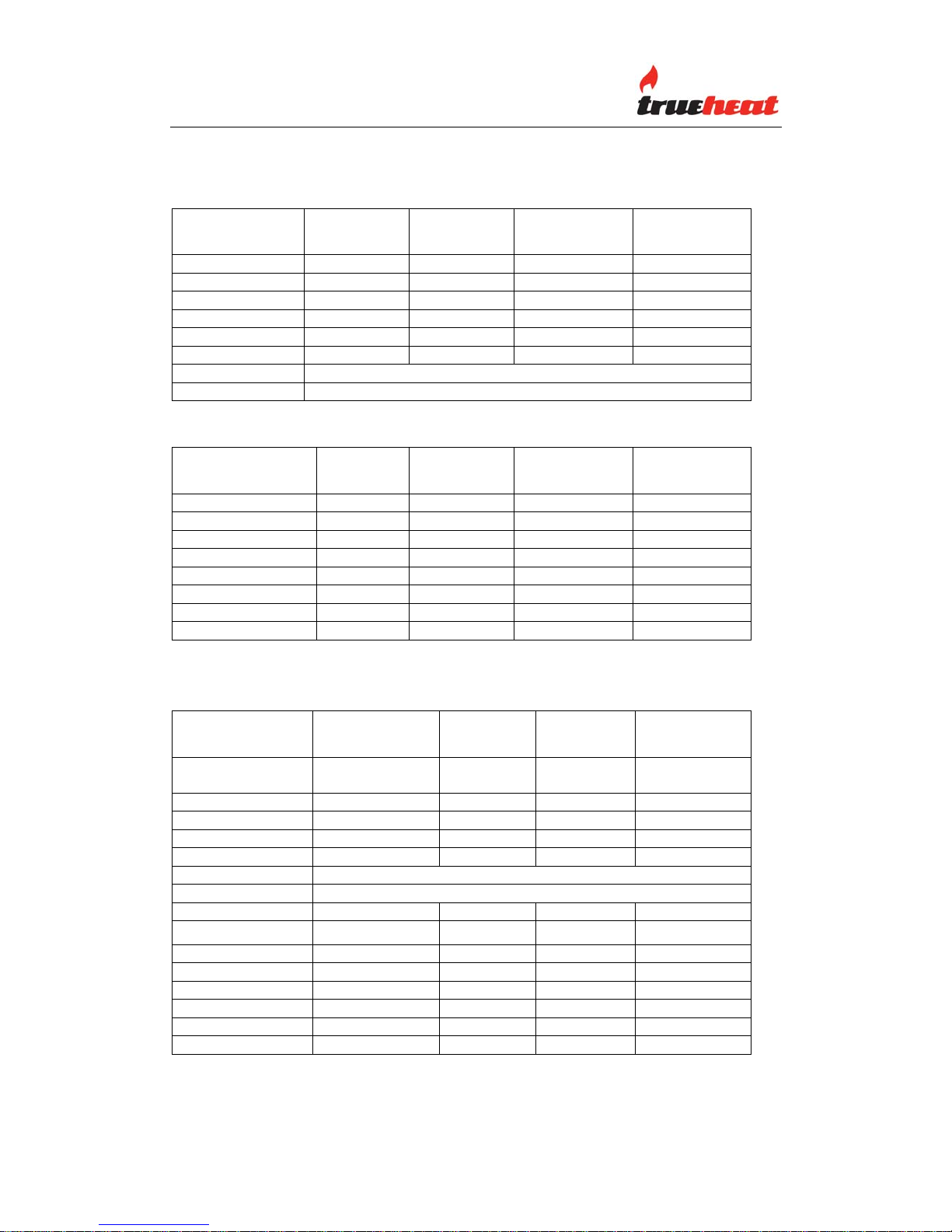

GAS INPUT INFORMATION

MINIMUM GAS SUPPLY INLET PRESSURE

Gas Type Gas Pressure

Natural Gas 1.13 kPa

LP Gas 2.75 kPa

NOMINAL GAS CONSUMPTION

NATURAL GAS PROPANE GAS

BURNER

(EACH)

ORIFICE

(mm)

MJ/h TEST POINT

PRESSURE

ORIFICE

(mm)

MJ/h TEST POINT

PRESSURE

OPEN (Each) 2.30 24 1.0 kPa 1.40 23 2.50 kPa

GRILL (Each) 2.20 22.5 1.0 kPa 1.30 19.5 2.50 kPa

OVEN (Each) 2.60 30 .85 kPa 1.50 26 2.45 kPa

PILOT (Each) .20 .50 1.0 kPa .20 .50 2.50 kPa

Note: Pressure test points are located as follows (refer also ‘Test Point

Pressure’ below);

a. open top and grill burners - gas manifold, and

b. oven burner – located on the EUROSIT 630 Thermostat

TEST POINT PRESSURE

The open top and grill gas pressure test point is located on the gas manifold.

The gas manifold and pressure test point is accessed by removing the gas

valve control knobs and the front panel. The test point pressure is shown in the

Nominal Gas Consumption Table above and is set with two open top

burners operating at maximum setting.

Range Manual Page 10 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 11

The oven burner pressure test point is located on the EUROSIT 630

thermostat. To access and make adjustments – refer to the SERVICE section

of this manual. The test point pressure is shown in the Nominal Gas

Consumption Table above and set to the specified pressure AFTER the gas

manifold pressure has been set.

VENTILA TION AND AIR SUPPL Y

All gas burners and pilots require sufficient air to operate. For optimum

performance and for your safety, it is ESSENTIAL that the equipment, in the

installed position, has the proper air and ventilation and the correct

exhaust/canopy and air balance. The correct installation and compliance with

all regulatory and other requirements is the responsibility of the

purchaser/owner.

Please note that a strong exhaust canopy will create a vacuum if there is

insufficient replacement air. The amount of air exhausted must be replaced by

an equal amount of air.

Airflow to the appliance must not be blocked or restricted (e.g. large objects

should not be placed in front of the appliance). The flue must never be covered

or restricted in any way.

Range Manual Page 11 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 12

MODEL OPTIONS

RANGE OPTIONS COMPLETE WITH OVEN

Model

Open

Burners

Width of

Grill (mm)

Grill

Position

Oven

R90-6 6 0 Yes

R90-4-30GL 4 300 Left Yes

R90-4-30GR 4 300 Right Yes

R90-2-60GL 2 600 Left Yes

R90-2-60GR 2 600 Right Yes

R90-0-90G 0 900 Yes

R60-4 To be developed

R60-0-60G To be developed

RANGE OPTIONS TOP ONLY

Model

Open

Burners

Width of

Grill (mm)

Grill

Position

Oven

T90-6 6 0 No

T90-4-30GL 4 300 Left No

T90-4-30GR 4 300 Right No

T90-2-60GL 2 600 Left No

T90-2-60GR 2 600 Right No

T90-0-90G 0 900 No

T60-4 4 0 No

T60-0-60G 0 600 No

GENERAL SPECIFICATIONS

OVERALL DIMENSIONS AND WEIGHT

MODEL HEIGHT

(mm)

WIDTH

(mm)

DEPTH

(mm)

WEIGHT

(Kg)

RANGE

COMPLETE

R90-6 1115mm 900mm 803mm 180Kg

R90-0-90G 1115mm 900mm 803mm 174Kg

R90-2-60G 1115mm 900mm 803mm 162Kg

R90-4-30G 1115mm 900mm 803mm 179Kg

R60-4 To be developed

R60-0-60G To be developed

TOP ONLY

T90-6 385mm 900mm 803mm 90Kg

T90-0-90G 385mm 900mm 803mm 84Kg

T90-2-60G 385mm 900mm 803mm 72Kg

T90-4-30G 385mm 900mm 803mm 89Kg

T60-4 385mm 600mm 803mm 60Kg

T60-0-60G 385mm 600mm 803mm 56Kg

Detailed dimensional specifications are shown at the rear of this manual.

Range Manual Page 12 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 13

OPERATING INSTRUCTIONS

LIGHTING INSTRUCTIONS

DO NOT OPERATE THE UNIT UNLESS IT HAS BEEN

INST ALLED AND COMMISSIONED BY AN AUTHORIZED

PERSON.

BEFORE TURNING ON THE MAIN GAS SUPPLY, CHECK AND

ENSURE THAT ALL THE VALVES ARE IN THE “OFF”

POSITION.

THIS EQUIPMENT IS DESIGNED FOR COMMERCIAL

CATERING PURPOSES AND WILL GENERATE SIGNIFICANT

HEA T. HOT SURF ACES WILL CAUSE BURNS. A HAZARD AND

RISK ASSESSMENT MUST BE UNDERTAKEN BY OWNERS

AND ALL OPERATORS MADE AWARE OF THESE.

NOTE: Ensure the gas supply to the equipment is turned ON.

NOTE: For your safety, all burners are controlled by a flame failure

sensing device. If the device does not sense a flame, gas

supply to the burner will be cut.

WARNING: When open top burners adjacent to the backgaurd or the side

of a grill plate are operated at high heat and covered by large

cooking vessels (i.e. pots, pans etc), dispersing heat may

cause discolouration and or distortion of the adjacent metal

surface.

Range Manual Page 13 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 14

OPEN TOP BURNERS

Open/Grill Burner Control

Pilot Flame Ignition

Starting from the OFF● position, press the control knob and rotate to the

PILOT ★ position.

Press the knob and ignite the pilot flame with a taper - keep the knob fully

depressed for 15 seconds after the pilot lights.

Release the knob and check the pilot flame stays alight. If the pilot flame did

not stay alight, repeat the ignition procedure.

Open Burner Ignition

Slightly depress the control knob and rotate to LEVEL 1 or LEVEL 2.

When the automatic valve senses that the pilot is alight, the gas flow to the

main burner is opened.

Pilot Standby Position

To turn the main burner off and keep the pilot ON, slightly depress the control

knob and rotate to the PILOT ★ position.

Shut Down/Pilot OFF

Slightly depress the control knob and rotate to the OFF ● position.

Range Manual Page 14 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 15

NOTE: If the pilot flame were accidentally extinguished, the flame failure safety

device would operate and cut the gas flow to the main burner. It would then be

necessary to re light the pilot by following the above procedure.

GRILL BURNER(S)

NOTE: Ensure the gas supply to the equipment is turned ON

Pilot Flame Ignition

Starting from the OFF ● position, press the control knob and rotate to the

PILOT ★ position.

Press the control knob and then press the piezzo igniter to ignite the pilot flame

– repeat until the pilot ignites (the pilot flame can be viewed through the front

panel). Keep the knob fully depressed for 15 seconds after the pilot lights.

Release the knob and check the pilot flame stays alight. If the pilot flame did

not stay alight, repeat the ignition procedure.

Grill Burner Ignition

Slightly depress the control knob and rotate to the LEVEL 1 or LEVEL 2

position.

When the automatic valve senses that the pilot is alight, the gas flow to the

main burner is opened.

Pilot Standby Position

To turn the main burner off and keep the pilot ON, slightly depress the control

knob and rotate to the PILOT ★ position.

Shut Down/Pilot OFF

Slightly depress the control knob and rotate to the OFF ● position.

NOTE: If the pilot flame were accidentally extinguished, the flame failure safety

device would operate and cut the gas flow to the main burner. It would then be

necessary to re light the pilot by following the above procedure.

Range Manual Page 15 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 16

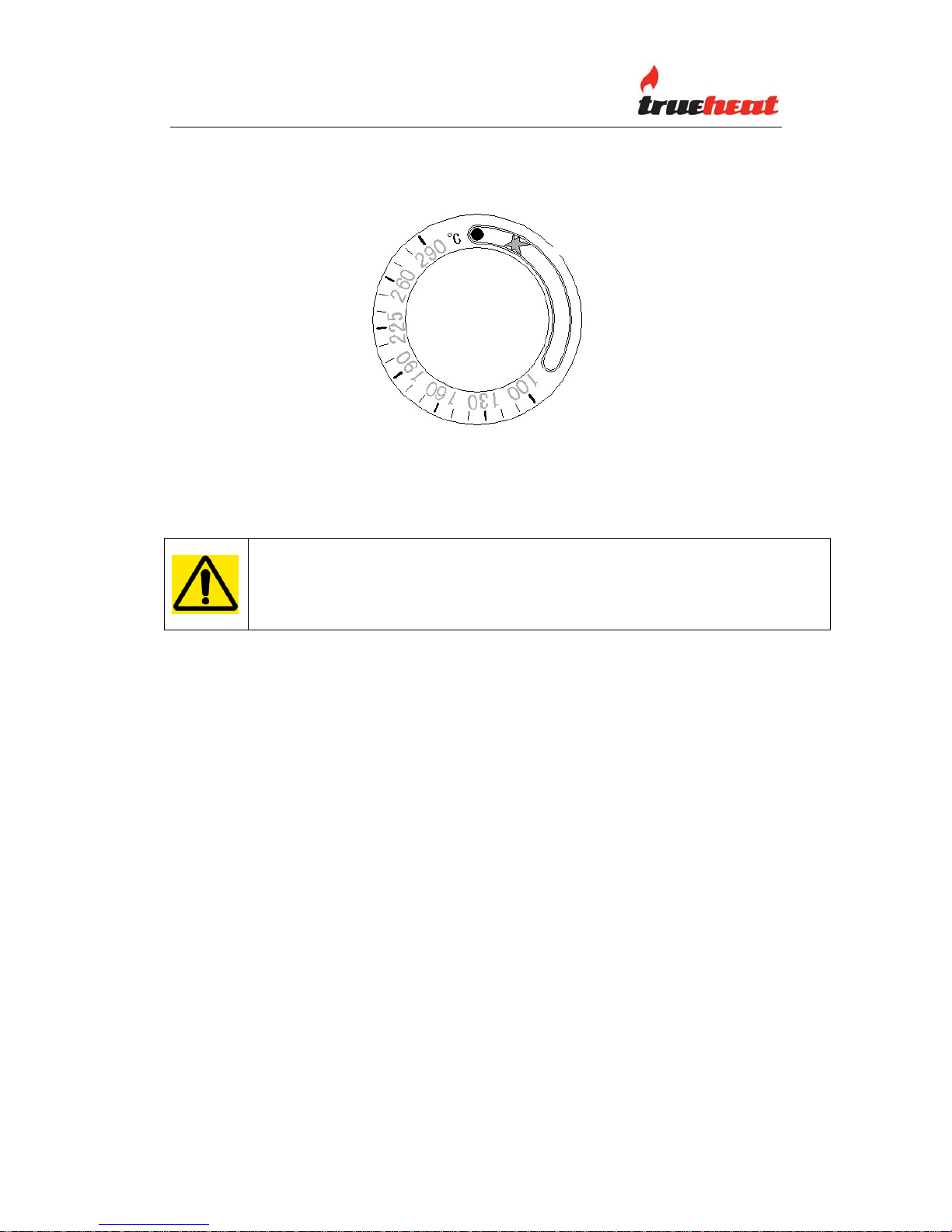

OVEN BURNER

OFF ●

PILOT ★

Oven Burner Control

Pilot Flame Ignition

WARNING: OPEN THE OVEN DOOR WHEN LIGHTING THE OVEN

PILOT. ENSURE THE PILOT IS ESTABLISHED BEFORE CLOSING

THE OVEN DOOR. THE PILOT FLAME CAN BE SEEN THROUGH

THE VIEWING HOLE.

Starting from the OFF position ●, press and turn the knob to the PILOT

position ★.

Press the control knob and then press the piezzo igniter – repeat until the pilot

lights. After the pilot lights, keep the control knob depressed for 15 seconds.

Release the knob and check that the pilot flame continues to burn. If the pilot

goes out, repeat the pilot lighting operation.

Temperature Selection

Turn the oven control knob to the desired temperature.

Pilot Standby Position

To turn the main burner off and keep the pilot ON, slightly depress the control

knob and rotate to the PILOT ★ position.

Range Manual Page 16 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 17

Shut Down/Pilot OFF

Slightly depress the control knob and rotate to the OFF ● position.

NOTE: If the pilot flame were accidentally extinguished, the flame failure

safety device would operate and cut the gas flow to the main burner. It would

then be necessary to re light the pilot by following the above procedure.

Range Manual Page 17 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 18

OPERATOR MAINTENANCE OPERATOR MAINTENANCE

USE ONLY SUITABL E CHEMICALS AND OBSERVE ALL

MANUFACTURER SAFETY REQUIREMENTS FOR SAFE

HANDLING AND USE.

SEASONING THE GRILL

NOTE: The grill surface has protective coating applied at manufacture.

Remove this by washing with hot water and a mild detergent until clean.

Season the grill by applying a thin coat of cooking oil with a cloth to the entire

grill surface. Remove any excess oil with a cloth.

Light the grill burner(s) and set at the lowest level (LEVEL 2). Operate the grill

for about 20 minutes and then wipe away the oil. Repeat this procedure three

times.

IMPORTANT: Only use low heat (LEVEL 2) when seasoning the grill.

NOTE: The grill surface will discolour from heat. Discolouring will not affect the

grill surface function and does not render the grill surface defective.

The grill surface should be cleaned with hot water and detergent.

Normally, if maintained properly, the grill will not need to be seasoned again. If

however, the grill has been overheated and product sticks to the grill surface, it

may be necessary to season the grill again.

Carbon and grease will affect the cooking performance and should be

removed as follows:

After each use, clean the grill thoroughly with a sharp grill scraper and wipe

off any excess debris.

NOTE: Empty the grease drawer as necessary and clean.

Weekly, clean the grill surface thoroughly with a grill pad while the surface is

Range Manual Page 18 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 19

still warm (not hot). After cleaning, ensure any detergent/chemical is

thoroughly removed. The grill surface should be covered with a thin film of

cooking oil to prevent rusting.

Note: The grill plate is made of steel and can be easily scored or dented by

careless use of scrapers and spatulas.

CLEANING STAINLESS STEEL

Regularly wipe the surface with hot water and detergent. Rinse the washed

area with a wet sponge and clean water and wipe the area dry to prevent

streaking. Follow this process and wash a small area at a time to prevent

chemical residue and streaking.

Stainless steel may discolour if overheated. These stains can usually be

removed using an appropriate powder/paste. To scrape off heavy deposits of

grease and oil, use only wood or plastic tools as necessary.

Note: Never use steel wool to clean stainless steel.

Note: Damage may occur if chemicals not suitable for stainless steel are used.

OVEN INTERIOR (Enamel)

Note: Remove all oven racks and guides and clean these separately with a

suitable detergent and warm water.

The enamelled oven interior surface should be cleaned regularly with a

suitable oven cleaner.

OPEN TOP BURNERS

Note: Spillage is the major cause of problems to the performance of open top

and pilot burners. Spillage can block gas ports, which then causes burners to

operate inefficiently or, in bad cases, not at all. Clean any spillages as they

occur.

Note: The burner caps are enamelled – do not use abrasive cleaners.

To clean the burners, remove the burner cap and clean with a suitable

detergent and warm water. If the burner ports are blocked, clean these with a

stiff brush. Place the burner cap back on the burner, ignite and check that the

flame is even and comes from all ports (this dries the burner cap).

Range Manual Page 19 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 20

If any ports remain clogged, remove the burner cap and complete burner and

clean thoroughly with a suitable detergent and hot water. Dry thoroughly,

ensure the air shutter is fully open, reinstall (ensure the injector is located in

the burner venturi), ignite and check the flame pattern.

Note: The burner flame should be uniformly blue. If yellow flames are present,

this may indicate that grease and dirt are present in the burner throat. Remove

and clean the burner per the above.

ENAMELLED TRIVETS

The enamelled trivets should be removed from the appliance before cleaning.

To clean the trivets, wash with warm water and a suitable detergent using a

soft cloth and then dry.

Note: Do not use abrasives pads or chemicals – these will damage the

enamelling.

For heavily soiled trivets, use a suitable oven cleaner and non-abrasive pad or

brush.

Range Manual Page 20 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 21

SERVICE

FOR YOUR SAFETY, ALL SERVICE WORK MUST BE

CARRIED OUT BY AN AUTHORISED PERSON AND USE

ONLY ORIGINAL SUPPLIED AND SPECIFIED PARTS.

TEST ALL FITTINGS, PIPES AND PIPE CONNECTIONS FOR

LEAKS IN ACCORDANCE WITH APPROVED GAS LEAK

TEST PROCESSES AND METHODS. DO NOT USE A

FLAME.

Note: When checking gas pressure, ensure that all other equipment on

the same line is turned “ON”.

RECOMMENDED SERVICE

It is recommended that your appliance be serviced by an authorized person

every 12 months. This period is for guidance purpose only and may vary based

on usage of the equipment and operator care. Prescribed service tasks

include;

• Functional test of all components and clean and adjust as necessary.

• Inspect and clean all gas valves and lubricate with an industry approved

lubricant.

• Inspect all gas piping.

• Check and adjust specified gas pressures.

• Leak test.

• Full operational, performance and safety test.

SERVICE INFORMAT ION

To access gas valves, remove control knobs and the front panel.

To remove a gas valve, disconnect the gas valve at the manifold tee spigot

connection and remove the valve.

To access the oven thermostat, refer SPECIFICATIONS ‘Data Plate Access’.

To access open burner thermocouples/pilots, remove trivets.

To access grill burner thermocouples/pilots/igniters, remove grill plate.

To access oven burner thermocouples/pilots/igniters, remove oven base.

Range Manual Page 21 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 22

OPEN AND GRILL BURNER ADJUSTMENTS

Leak Test

Ensure that all valves are in the OFF position.

Turn on the main gas supply valve.

Light all pilots.

Leak test all valves and fittings using approved methods.

Correct any leaks as required and re-check.

Shut off all valves and set thermostat dials to “OFF” position.

Test Point Pressure

The open top and grill gas pressure test point is located on the gas manifold.

The gas manifold and pressure test point is accessed by removing the gas

valve control knobs and the front panel. The test point pressure is shown in the

Nominal Gas Consumption Table and is set with two open top burners

operating at maximum setting.

Pilot Burner Adjustment

Set all pilots so that the flame envelops the tip of the thermocouple by

adjusting the pilot flame adjusting screw within the pilot - clockwise to

decrease, or anti-clockwise to increase.

Service adjustment should not be necessary unless changing the gas valve or

performing gas conversion.

Burner Adjustment

The open top, grill and oven burner orifices are fixed as specified and cannot

be adjusted. The specified gas rate will be achieved if the gas supply

pressure and test point pressure is correct.

The turndown (low flame) setting can be adjusted by adjusting the screw on

the gas valve.

A distinct blue flame over the entire port area of the burner will be achieved at

full rate when the air supply is correct and the air shutter is properly adjusted.

If the flame is yellow and wavy, the cause needs to be established.

WARNING: If you are not competent in performing any service task or require

assistance, please contact Comcater Service 03 8369 4600.

Range Manual Page 22 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 23

OVEN CONTROL SETTINGS AND ADJUSTMENTS

Test Point Pressure

The oven burner pressure test point is located on the EUROSIT 630

thermostat. The test point pressure is shown in the Nominal Gas Consumption

Table and is set to the specified pressure AFTER the gas manifold pressure

has been set.

(Reference: SIT Manual 630 EUROSIT Manual – ensure current copy)

Extract from SIT manual – contact manufacturer (SIT) for any updates

All adjustments must be made based on the specific characteristics of the

appliance. Check inlet and outlet pressure using the pressure test points (6

and 7) provided. After testing, carefully seal test points with the provided

screws. Recommended torque: 2.5 Nm.

Adjustment of Maximum and Minimum Outlet Flows

These adjustments must be carried out with the thermostat bulb cold.

Range Manual Page 23 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 24

Maximum Flow

Turn the knob to position 7.

Turn the setting screw (2) fully in.

Turn the setting screw anticlockwise to increase gas flow.

CAUTION: The setting screw should not be unscrewed more than 2 turns from

the fully in position.

Minimum Flow

Starting from position 7, turn the knob slowly clockwise to the minimum flow

position (just before the cut-off click).

Turn the screw (3) clockwise to reduce flow.

It is possible to use screws with calibrated bores (available on request) to

replace the maximum by-pass flow setting screw. In this, it is necessary to

screw the calibrated screw fully in with 7 Nm torque.

Adjustment of gas flow to the pilot burner.

Turn the screw (5) clockwise to reduce flow.

IMPORTANT: At the end of all setting and adjustment operations, check gas

seals and the efficiency of the appliance.

After carrying out all adjustments, fit the provided seals and/or block the setting

screw with paint.

Maintenance

The only maintenance operation permitted by SIT Group is replacement of the

thermocouple. This must be carried out by a qualified person according to the

instructions provided with the spare parts.

The above instructions are an extract from ‘SIT Manual 630 EUROSIT

Manual’.

Ensure you contact the manufacturer (SIT Group) for any updates.

Range Manual Page 24 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 25

CONVERSION INSTRUCTIONS

TO BE COMPLETED BY AN AUTHORISED PERSON

ENSURE GAS IS ISOLATED WHILST PERFORMING

CONVERSION WORK. PERFORM A LEAK TEST BEFORE

IGNITING AND CALIBRATING BURNER AND PILOT

ADJUSTMENTS.

TO PROPANE GAS

Regulator Change regulator to PROPANE gas configuration

and adjust as necessary

Open Burner/Grill Burner Access and change the injectors to PROPANE Gas

injectors (refer Nominal Gas Consumption

Table)

Oven Burner Access and change the injector to a PROPANE

Gas Injector (refer Nominal Gas Consumption

Table)

LEAK TEST IN ACCORDANCE WITH APPROVED METHODS

Ignite burners and adjust.

AMEND DATA PLATE AND APPLY ‘PROPANE’ GAS LABEL

TO NATURAL GAS (NG)

Regulator Change regulator to NG gas configuration and

adjust as necessary

Open Burner/Grill Burner Access and change the injectors to a NG Injectors

(refer Nominal Gas Consumption Table)

Oven Burner Access and change the injector to a NG Injector

(refer Nominal Gas Consumption Table)

Range Manual Page 25 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 26

LEAK TEST IN ACCORDANCE WITH APPROVED METHODS

Ignite burners and adjust

AMEND DATA PLATE AND APPLY ‘NATURAL GAS’ LABEL

SPARE PARTS

A list of major spare part items is shown at the end of this manual.

These parts and all other parts used in the Comcater range are available from

Comcater.

Range Manual Page 26 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 27

TROUBLE SHOOTING

ALL SERVICE WORK TO BE COMPLETED BY AN

AUTHORISED PERSON.

ALL BURNERS

CONDITION CHECK

Pilot will not light. Gas supply is on and gas pressure is correct

Blocked pilots

Pilot adjusting screw

Pilot repeatedly goes out. Pilot flame size and position

Thermocouple

Flame safety device

Yellow Burner Flame. Primary air and adjust air shutter

Flame lifting off burner ports. Primary air

Air shutter

‘Popping’ after turning off. Primary air

Air shutter

Burner flame too large. Gas pressure

Delayed ignition. Pilot flame

Burner and ports clean

Air shutter

Gas pressure

Piezzo will not spark. Igniter lead, igniter and electrode

Flame burns back to orifice Primary air

Air shutter

Range Manual Page 27 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 28

OVEN

Incorrect oven temperature Oven thermostat and control dial position

Burner shuts off at set Thermostat/by-pass

temperature

Range Manual Page 28 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 29

RANGE OPTIONS - TOP ONLY

MODEL T90-6

MODEL T90-0-90G

MODEL T90-4-30GR

MODEL T90-4-30GL

MODEL T90-2-60GL

MODEL T90-2-60GR

MODEL T60-0-60G

MODEL T60-4

File Name: Range Option 1(130907)

Range Manual Page 29 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 30

RANGES COMPLETE WITH OVEN

MODEL R90-0-90G

MODEL R90-6

MODEL R90-4-30GL MODELR90-4-30GR

MODELR90-2-60GL

MODEL R90-2-60GR

File Name: Range Option 2 (130907)

Range Manual Page 30 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 31

MAJOR PARTS IDENTIFICATION

IDENTIFICATION PART NUMBER ITEM NAME

CCE KB-F60P Flame Failure Gas Valve F60P

CCE KB-99301/270 Knob Black – Suit F60P (Open Top and Grill Burners)

CCE KB-99301/DF

CCE KB-99301/DR

CCE KB-99301/DG

Decal Knob - Front

Decal Knob - Rear

Decal Knob - Grill

CCE KB-99301/EP Escutcheon – Knob/Pilot Position

CCE B21002 Oven Thermostat Knob

CCE KB-100.017 Pilot 1FX2H (Open Burners)

CCE KB-100.011

CCE KG-915036

Pilot 3FX3H (Grill/Oven Burners With Igniter Holder)

Electrode Pilot/Bunsen (Bent Electrode)

Range Manual Page 31 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 32

CCE KB-6402 Manifold Plug 1/4" BSP

CCE KB-WRB/E Rear Burner Complete (Enamelled Cap)

CCE KB-WFB/E Front Burner Complete (Enamelled Cap)

CCE KB-WTB/E Trivet (Enamelled)

CCE KB-WPS Pot Stand (Stainless Steel)

CCE KB-WOB Oven Burner

CCE KB-WGB Grill Burner

CCE KB-WMB Manifold Bush ¼” BSP Female

CCE KB-WMT Manifold Tee ¼” BSP Male

Range Manual Page 32 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 33

CCE KB-WMT/TP

Manifold Tee ¼” BSP Male Complete With Pressure

Test Point

CCE KB-WIH/L Injector Holder Left Hand Aluminium

CCE KB-WIH/R Injector Holder Right Hand Aluminium

CCE KG-AT63503C Aluminium Tube 1/4" (6.35mm) 3 Metres

CCE KG-200090 Thermocouple 900XM9XUnif/Sleeve

CCE KG-200021 Thermocouple 1500XM9XUnif/Sleeve

CCE KG-200255 Thermocouple 320XM9XUnif/Sleeve

CCE KG - 348130

CCE KG - 348140

CCE KG – 348220

CCE KG - 348230

Injector 1/8" BSP Grill Burners (LPG 1.30mm)

Injector 1/8" BSP Open Burners (LPG 1.40mm)

Injector 1/8" BSP Grill Burners ((NG 2.20mm)

Injector 1/8" BSP Open Burners (NG 2.30mm)

CCE KG - 72150

CCE KG - 72260

Injector RBA C/W Nut & Olive 3/8" Tube (Oven)

(LPG 1.50mm)

Injector RBA C/W Nut & Olive 3/8" Tube (Oven)

(NG 2.60mm Orifice )

Range Manual Page 33 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 34

CCE Q26004

Oven Shelf

CCE Q26100 Oven Rack Guide (Left Hand)

CCE Q26101 Oven Rack Guide (Right Hand)

CCE B21001 Oven Handle Bracket

CCE KG-073964 Piezzo Igniter and Nut – Red Button

CCE KG - HT1500

CCE KG - HT250

Lead Ignition H/T 1500 mm (OVEN)

Lead Ignition H/T

250 mm (GRILL)

CCE KB-RV48LM-66

CCE

MAXITROL GAS REGULATOR 3/4" BSP NG

MAXITROL CONVERSION KIT LPG

Source File: PARTSIDENTIFICATION 130907

Range Manual Page 34 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 35

Range Manual Page 35 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 36

Range Manual Page 36 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 37

Range Manual Page 37 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 38

Range Manual Page 38 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 39

Range Manual Page 39 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 40

Range Manual Page 40 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 41

Range Manual Page 41 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 42

Range Manual Page 42 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 43

Range Manual Page 43 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 44

Range Manual Page 44 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 45

Range Manual Page 45 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 46

Range Manual Page 46 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 47

Range Manual Page 47 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 48

Range Manual Page 48 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 49

Range Manual Page 49 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 50

Range Manual Page 50 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 51

Range Manual Page 51 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 52

Range Manual Page 52 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 53

Range Manual Page 53 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 54

Range Manual Page 54 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 55

Range Manual Page 55 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 56

Range Manual Page 56 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 57

Range Manual Page 57 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 58

Range Manual Page 58 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 59

Range Manual Page 59 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Page 60

N o t e s

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Range Manual Page 60 Revision: 13 Sep 07

OPERATOR MANUAL 130907.doc

Loading...

Loading...