True Fitness Service

Manual

Elliptical Trainers

750E

750EA

600EA

True fitness technology, Inc. makes no representations or warranties regarding the

contents of this manual. We reserve the right to revise this document at any time or

to make changes to the product described within it without notice or obligation to

notify any person of such revisions or changes.

© 2004, True Fitness, Inc. All rights reserved. Printed in the United States of

America.

865 Hoff Road. O’Fallon, MO 63366. 1-800-426-6570. Fax 636-272-3026.

www.truefitness.com

Revision 9/2004

Recommended Tool List

Technicians will need at minimum the tools listed below to work on the True Fitness

equipment covered by these procedures.

Electrical Tools

A multi meter capable of testing voltage, amperage, resistance and continuity.

Outlet tester with a grounding indicator.

Wire stripper, cutter and crimper.

Flashlight

Mechanical Tools

Screwdrivers:

#1 Phillips, #2 Phillips, large flat blade, small flat blade, short handled flat blade.

Metric hex-key (Allen wrench) set.

Metric socket set and ratchet with 6mm to 19mm sizes and 21mm and 34mm sizes.

Metric combination wrenches with 4mm to 21mm sizes and a 27mm El crank.

Snap ring pliers, both internal and external.

True Fitness Elliptical 2 19/32 Wrench pn: 90361501

Rubber mallet.

Channel lock pliers or standard pliers with a jaw opening of 2 9/16” for use in removing

and tightening sleeve nuts.

Needle nose pliers.

Crescent wrench

Special Tool

Bicycle crank puller

Park Tool USA CCP-2

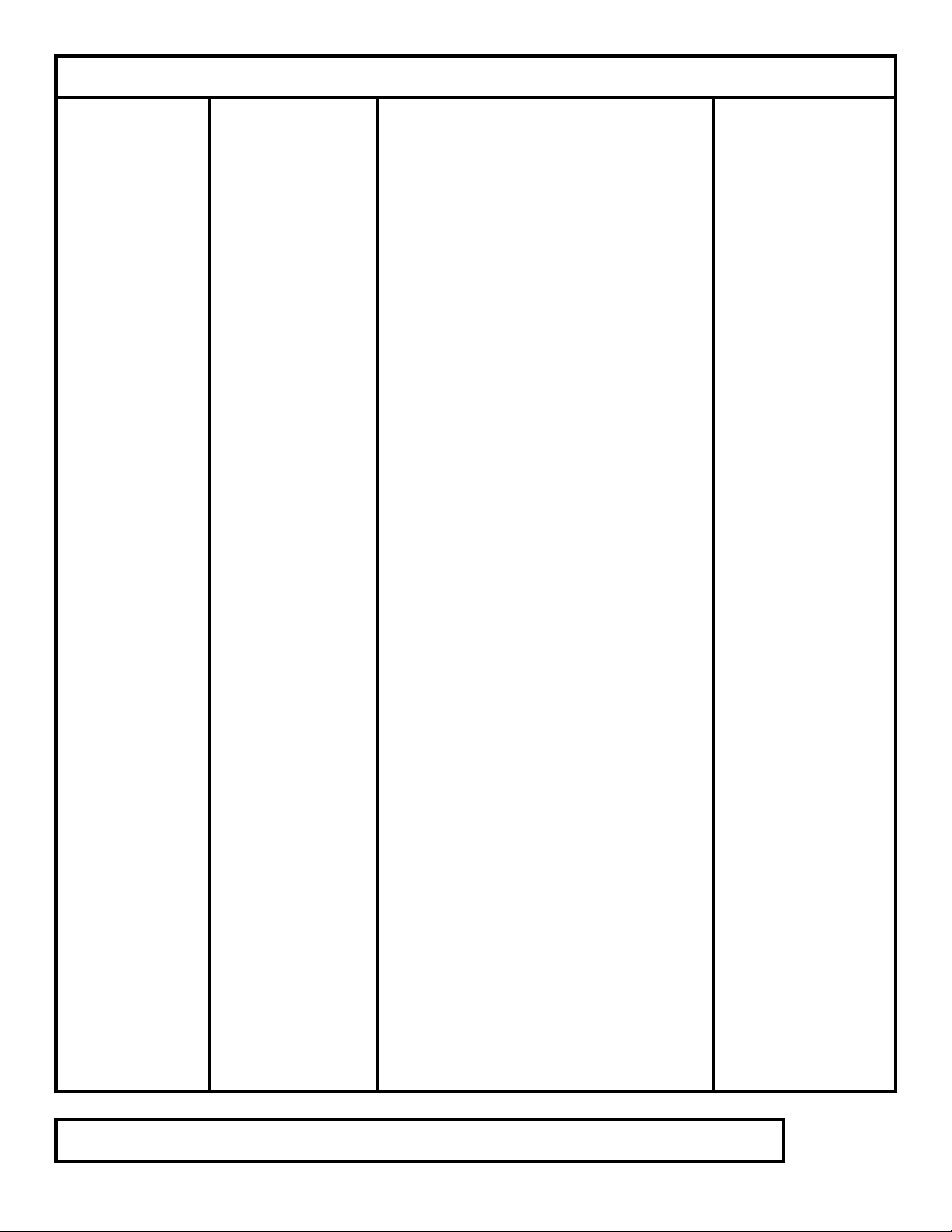

True Fitness

Elliptical

Service Manual

START

Symptom guide

Wiring Diagrams

Parts Manual

Removal and Replacement Procedures

Page 1

Test Mode *750 ONLY Procedure

•

D

I

A

G

N

O

S

T

I

C

S

To Enter Diagnostic

Mode

Console / Display

Output

RPM

Console Key Input

Contact Heart Rate

DA (Resistance)

Exit Diagnostics

Press and hold the “Start” key as you

begin pedaling.

• Continue pedaling throughout the test.

-------

• Press “Enter” key – initiates the second

LED function test.

• Press “Enter” key again –all LED’s

should be on.

--------

• Press “Enter” key – RPM’s displayed in

the far right window.

--------

• Press “Enter” key –A beep should sound

when each key is pressed.

--------

• Press “Enter” key. Hold both handle

pick-ups. Heart symbol will flash and

readout will display.

-------

• Press “Enter” key – Press + to increase

resistance and – to decrease resistance.

• To quit diagnostics press “Enter” key or

stop pedaling and the unit will reset.

Page 2

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

SYMPTOM GUIDE

600EA

Resistance Malfunction . . . . . . . . . . . . . . . . . . . Page 13

No Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

No Speed Reading. . . . . . . . . . . . . . . . . . . . . . . . Page 15

750E,750EA

No Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Heavy Resistance . . . . . . . . . . . . . . . . . . . . . . . . Page 6

No Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

All Models

No Contact Heart Rate . . . . . . . . . . . . . . . . . . . . Page 8

No Polar Heart Rate . . . . . . . . . . . . . . . . . . . . . . Page 9

Vibration from Drive Train . . . . . . . . . . . . . . . . . . . Page 10

Knocking in Rhythm of Pedaling . . . . . . . . . . . . . Page 11

Squealing / Screeching from

Aluminum Extrusion Tubes . . . . . . . . . . . . . . . . . Page 12

Page 3

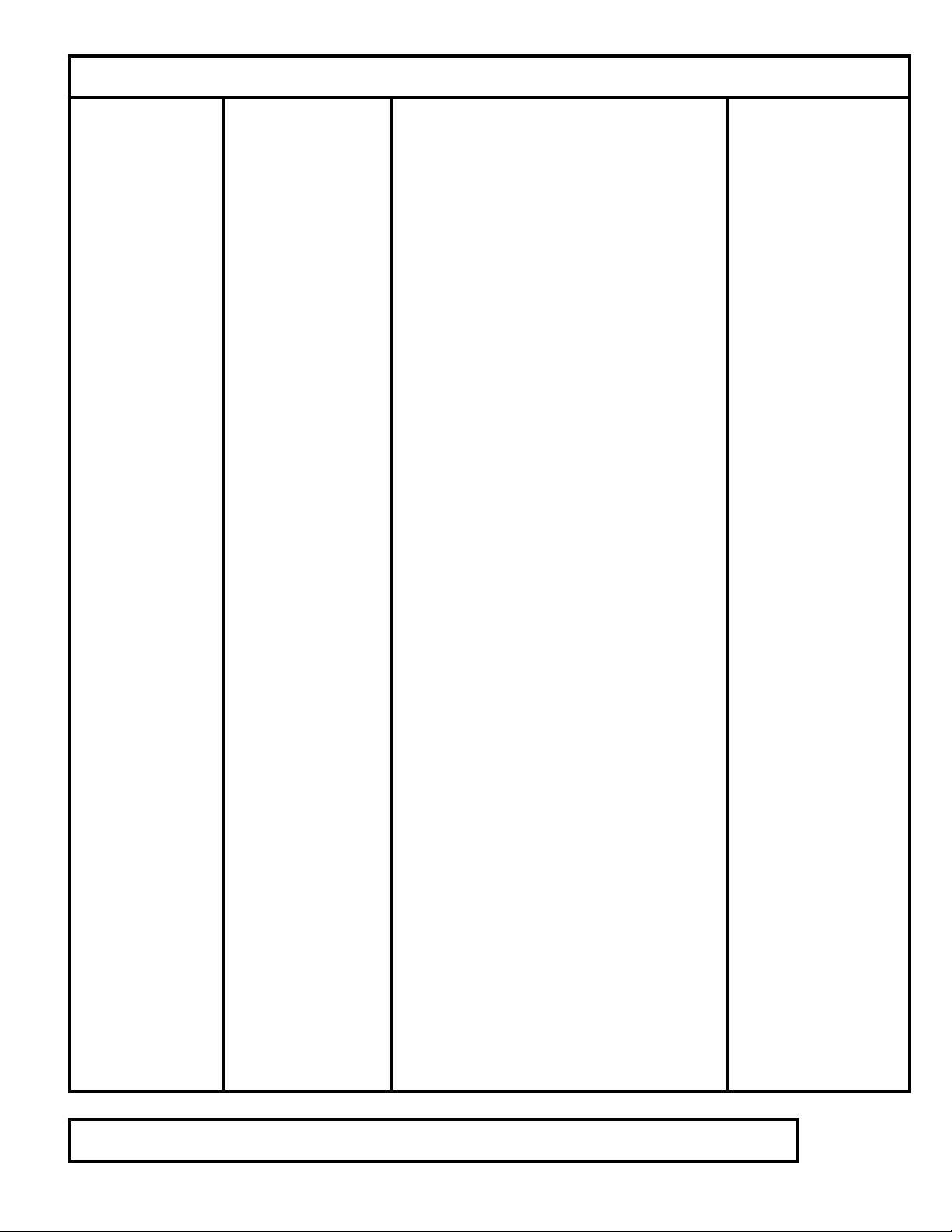

Symptom Probable Cause Corrective Action Recommended Tools

NO RESISTANCE

Page 4

750E, 750EA

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Console Set

Defective Cables

Power Resistance

• Remove console bolts to access 7-pin

connector. Do not disconnect console

set.

• Enter DA (resistance) test mode.

(Page 3).

• Press + key to force .7 VDC out of

panel.

• Set meter for DC Volts. Measure

between #2 pin and #4 pin at 7- pin

connector.

• Is .7 VDC present? No- replace console

set. If present, continue on.

--------

• Remove right mast cover and handlebar.

• Measure between the #2and #4 wires at

the 7 –pin connector on

• Is .7 VDC present? No- replace cable

for console. If present, continue on.

--------

• DO NOT PEDAL.

• Set meter for resistance. Disconnect 3-

pin connector at the lower control board.

Measure resistance between #1 pin and

#3 pin.

• Resistance should be 10 ohms, +/- 1

ohm.

• If less than 10 Ohms- replace power

resistance. If resistance checks OK,

continue on.

--------

• DO NOT PEDAL.

• Remove main body cover, set meter for

continuity.

• Disconnect brake cable from brake and

lower board.

• Check continuity of all wires in cable.

• Check for cross continuity- this would

indicate multiple shorts in the cable.

• No continuity? Replace Brake cable.

• Yes continuity? Replace lower board.

the lower board.

Note:

You must pedal at least

30 RPM when

performing any voltage

test. You may require the

assistance of another

person when performing

voltage checks.

Multi-meter

Symptom Probable Cause Corrective Action Recommended Tools

HEAVY

RESISTANCE

750E, 750EA

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Foreign Objects

Console Set

Defective Cables

Lower control

Board/ Brake

• Check for foreign objects causing

mechanical binding.

• Remove foreign objects.

--------

• Remove the console set.

• Disconnect the 7-pin connector from the

back of the console set.

• Pedal.

• Resistance normal? Replace console set.

--------

• Remove right side handle bar assembly

and mast cover.

• Disconnect 7- pin connector from the

lower control board.

• Pedal.

• If resistance is normal- replace cable for

console.

--------

• Remove main body cover.

• Disconnect 3- pin connector from the

brake.

• Resistance still heavy- Replace brake.

• Resistance normal

• Check brake cables for cross continuity.

• Replace lower control board.

Multi-meter

Page 5

Symptom Probable Cause Corrective Action Recommended Tools

p

p

750E, 750EA

Page 6

No Display

Console Set

Brake

Defective Cable

Console Cable/

Lower Control

Board

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

• Remove console set bolts. Verify good

connection at the back of the console

set. Set meter for DC volts

• Pedal.

• Measure between #1 and #4 wires for

5.5 – 7.5 VDC.

• Is required voltage present?

• If yes- replace console set. If not,

continue on.

--------

• Remove right side bar assembly, right

mast cover and main body cover.

• Disconnect 3- wire connector at brake.

• Set meter for AC volts.

• Pedal.

• The voltage should increase as pedaling

increases.

• Is minimum voltage 9 VAC @ 30

RPM?

• If No- replace Brake. If yes, continue

on.

--------

• Remove right side bar assembly, right

mast cover and main body cover.

• Disconnect 3- wire cable from brake and

lower control board.

• Set meter for continuity.

• Check all 3 wires in cable for continuity.

• No continuity? Replace cable

----------

• Set meter for DC volts. Reconnect

cable to brake and lower control board.

• Pedal.

• Measure for 5.5 – 7.5 VDC between #1

and #4 wires on 7- pin cable for the

console at the lower control board.

• Voltage is present? Replace cable for

console.

• Voltage not present? Replace lower

control board.

Note:

You mus t pedal at least

30 RPM when

erforming any voltage

test. You may require the

assist ance of another

erso n w h en perf ormin g

voltage check s.

Multi-meter

Symptom Probable Cause Corrective Action Recommended Tools

p

p

•

NO CONTACT

HEART RATE

750E, 750EA

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Wire Connections

Dirty Sensors

Console Set/

Wiring

Verify hand pulse sensors are clean.

--------

• Set meter for continuity.

• Remove Console set.

• Check for continuity in both sets of

hand pulse sensors between the console

set and hand pulse sensor plates.

• If continuity is OK – Replace Console

set. If no- continue on.

--------

• Check wire connections @ handlebar

console mast joint

• Check connections of wires to hand

pulse sensor by removing hand pulse

sensor plates.

• To remove hand pulse sensor plates

carefully pry under one end to free them

from the plastic handgrips.

• Bad connections? - Reconnect/ Replace

bad wires.

• Recheck continuity.

Note:

You mus t pedal at least

30 RPM when

erforming any voltage

test. You may require the

assist ance of another

erso n w h en perf ormin g

voltage check s.

Multi-meter

Double sided tape

Page 7

600EA.

p

p

g

Control Panel

Defective Cables

• Attach heart rate simulator around chest

or use Polar simulator.

• Do not touch the hand pulse sensors.

• Start pedaling

• Check display for heart rate.

--------

• Does console display heart rate with

chest strap?

• Does console display heart rate with HR

simulator?

• If unit responds with simulator and not

chest strap then replace chest strap.

• If unit does not respond with strap or

simulator then replace Console set.

Note:

You must pedal at le ast

30 RPM when

erforming any voltage

test. You may require the

assistan ce of another

erson when performing

volta

e checks.

Polar Heart Rate

Simulator

Excessive radio,

electromagnetic or

audible noise can

cause poor heart rate

reception.

Symptom Probable Cause Corrective Action Recommended Tools

NO POLAR

HEART RATE

750E, 750EA

Page 8

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

VIBRATION

FROM DRIVE

750E, 750EA

TRAIN

600EA.

Belt Tension

Brake Vibration

Wobbling Pulleys

Shaft Vibrations

Vibrating Bearings

• Remove main body cover.

• Check poly V- belt for bumps- if bump

exists, replace the belt.

• Check for proper belt tension. Belt

should be very tight, grasp belt in the

middle and twist, you should only be

able to twist it 90 degrees.

--------

• Pedal.

• Very carefully check brake for

vibration, use caution

arms cross in front of the brake.

• If vibration is found- tighten bolts and

/or replace brake.

--------

• Does pulley of either poly V- wheel

wobble? If so then tighten bolts.

• If tightening does not resolve- replace

damaged poly-v- wheels.

--------

• Check shaft assemblies. Check for

endplay on shaft assemblies.

• Check for vibration in shaft assemblies

by applying screwdriver to frame at

shaft bearings.

• If vibration is found- replace shaft

assembly.

Caution:

When

as the moving

checking for vibrations

take care to not get

caught by the pulleys,

belts and moving parts.

--------

• Check belt tensioned.

• Use screwdriver method to check

bearings on wheel shaft.

• Replace tension wheel assembly.

Long handled

screwdriver

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 9

Symptom Probable Cause Corrective Action Recommended Tools

KNOCKING IN

RHYTHM OF

PEDALING

Crank and Shaft

Swing Arm Bearings

• Remove main body cover.

• Check crank arm nuts for tightness.

• Is noise coming from the crank area

• If yes – remove crank, check shaft and

crank for damage.

• Replace parts as needed.

--------

• Check the moving arm bearing for

noise.

• Tighten nut and check for noise.

• If noise continues – replace moving arm

assembly.

Multi-meter

14mm socket

21mm socket

27mm socket

Page 10

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

SQUEALING /

SCREECHING

FROM

ALUMINUM

EXTRUSION

TUBES

750E, 750EA,

600EA.

Cleaning Aluminum

Extrusion Tubes

Checking Rollers

Moving Arm Travel

• Remove aluminum extrusion tubes.

• Clean tracks with general purpose

cleaner. DO NOT USE PETROLIUM

BASED CLEANERS – it will degrade

the rollers.

• Clean roller.

-------

• Check rollers for bumps and flat spots.

• Do rollers spin freely?

• If rollers do not spin freely – replace

rollers.

--------

• Do the moving arms run straight down

the aluminum extrusion tubes?

• If no – loosen nut on cubic joint.

• If no help – replace moving arm

assembly.

Non- petroleum based

cleaner. (For example:

Simple Green)

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 11

Symptom Probable Cause Corrective Action Recommended Tools

p

p

g

600EA

RESISTANCE

MALFUNCTION

Console Set

Lower Board / Brake

Cable

Brake Coil

Console Cable

• Remove console bolts to access 7-pin

connector. Do not disconnect console

set. Set meter for DC Volts. Measure

between pin 1(red) and pin 5(blue) at 7pin connector.

• Enter DA (resistance) test mode. Page

SG-1.

• Press + key to force .9 VDC out of

panel.

• Press + to check voltage at all levels. Is

voltage displayed on meter

approximately the same as voltage

displayed in heart rate window? Noreplace console set. Yes, continue on.

--------

• Remove main body cover & locate the

cable connecting the brake and the

lower control board. Set meter to DC

volts.

• Check DC voltage between pins 2 and 4

of the power supply

• Is voltage is same as shown in heart rate

window?

• If NO – go to console cable.

• Check voltage at the 2-pin connector at

the brake. Press + to increase resistance

and voltage.

• Does the voltage start at 3.7 and

increase to 30 VDC? If no- check

continuity of cable. If cable is broken

replace it, if cable is good – replace the

lower board.

--------

• Set meter to resistance and check the

coil. Coil resistance should be 15 ohms,

+ or – 2 Ohms. If not then replace the

coil.

--------

• Set meter to resistance; perform

continuity check on wire harness.

• Check for cross continuity.

• Broken wires? Replace cable.

Note:

You mus t pedal at least

30 RPM when

erforming any voltage

test. You may require the

assist ance of another

erson when performing

volta

e checks.

Multi-meter

Page 12

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

NO DISPLAY

600EA

Power Issues

Control Panel

Power Supply

Cables

• Set meter to AC voltage and test wall

outlet to 120 VAC.

• Turn power switch on

• Does power switch lamp come on?

• Yes – go to control panel.

• No- remove rear cover.

• Check voltage input to switch, is it 120

VAC? If yes – replace switch. If no –

continue on.

• Check voltage at end of power cord.

• No voltage? Replace cord.

• Check fuse in power inlet.

• Replace fuse or replace power inlet and

wires.

--------

• Check connection to the display.

• Reseat connection.

• Set meter to DC volts, unplug display

and check voltage between pin 1and pin

2.

• If 12VDC is present – replace control

panel.

--------

• Check voltage between pin 2and pin 3at

the power supply.

• If 12 VDC present – replace power

supply.

--------

• Perform a continuity check on the cables

leading to the control panel.

• Replaced damaged cables.

Multi-meter

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 13

Symptom Probable Cause Corrective Action Recommended Tools

NO SPEED

READING

600EA

Console Assembly

RPM Sensor

Defective ECB

Control Board

• Remove monitor bolts. Move the swing

arms until the magnet is in front of the

sensor.

• Set meter for DC volts. Check voltage

between pin 3 and pin 1 at console

assembly with cable connected.

• Move swing arms. When magnet is

over the pickup the voltage should be 0

VDC. When the magnet is not over the

pickup, the voltage should be 5 VDC.

• Does the voltage alternate between 0

VDC and 5 VDC? If yes – replace

console assembly.

--------

• Turn power off, remove rear cover

• Disconnect the sensor connector. Set

meter for resistance.

• Check resistance at the 2 pins of the

connector. Slowly move the swing arms

to rotate the wheel.

• Does the meter show continuity when

the magnet is over the pickup? If no –

replace the sensor.

--------

• Perform a continuity and contact check

on the console wire.

• Replace defective wire.

Multi-meter

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

WIRING DIAGRAMS

TAE 600 Page 16

TAE 750 Page 17

TE 750 Page 18

Page 15

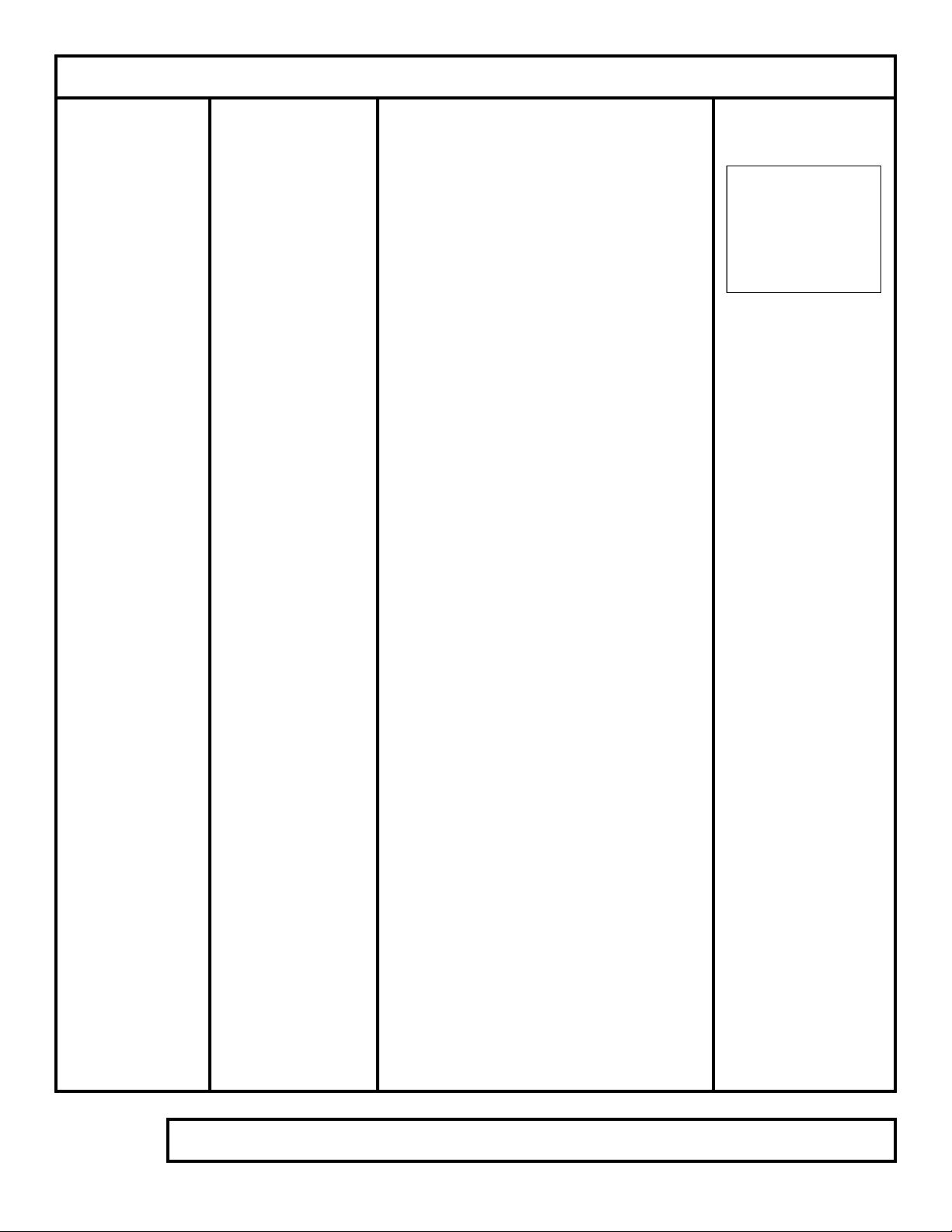

TRUE TAE 600

WIRING DIAGRAM

Page 16

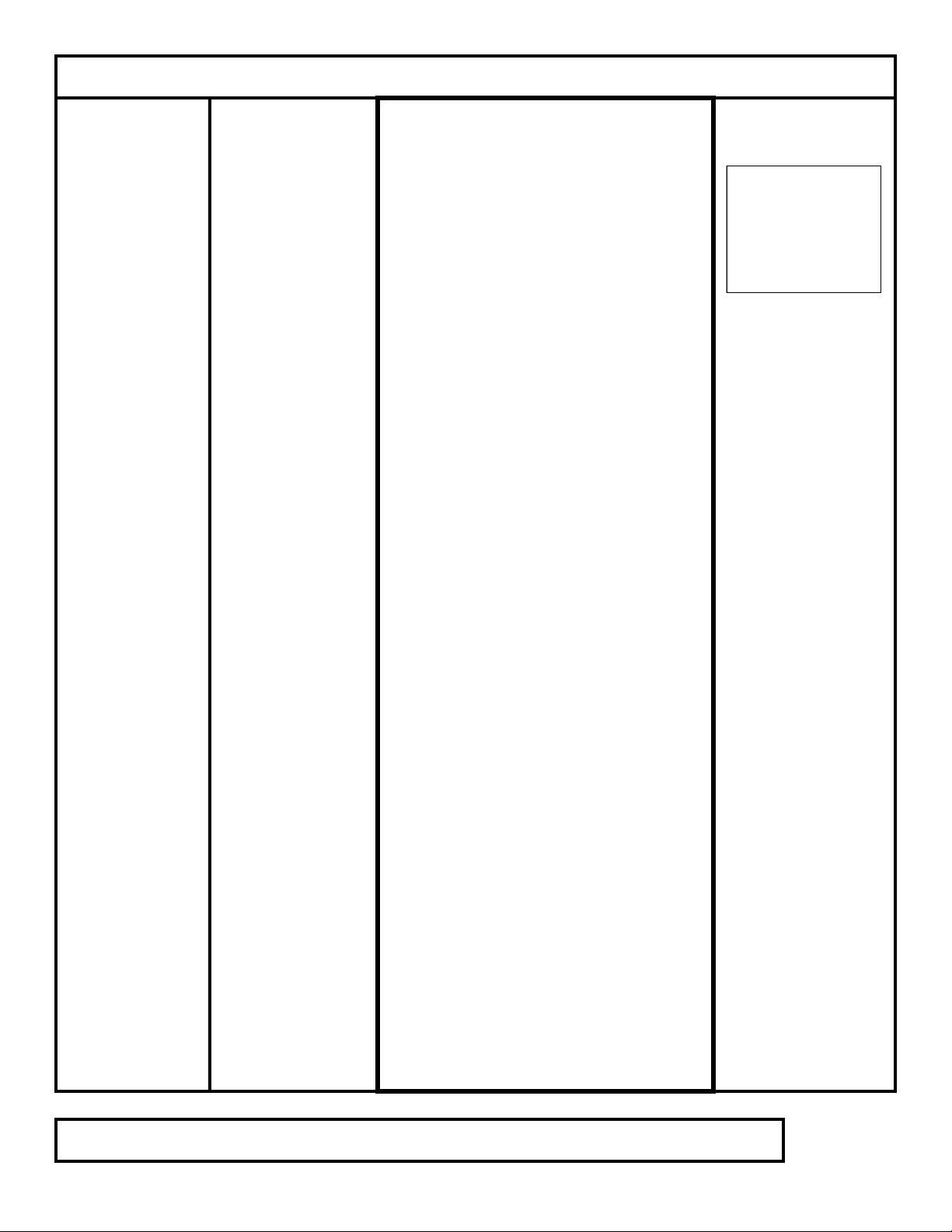

TRUE TAE 750

WIRING DIAGRAM

Page 17

WIRING DIAGRAM

TRUE TE 750

Page 18

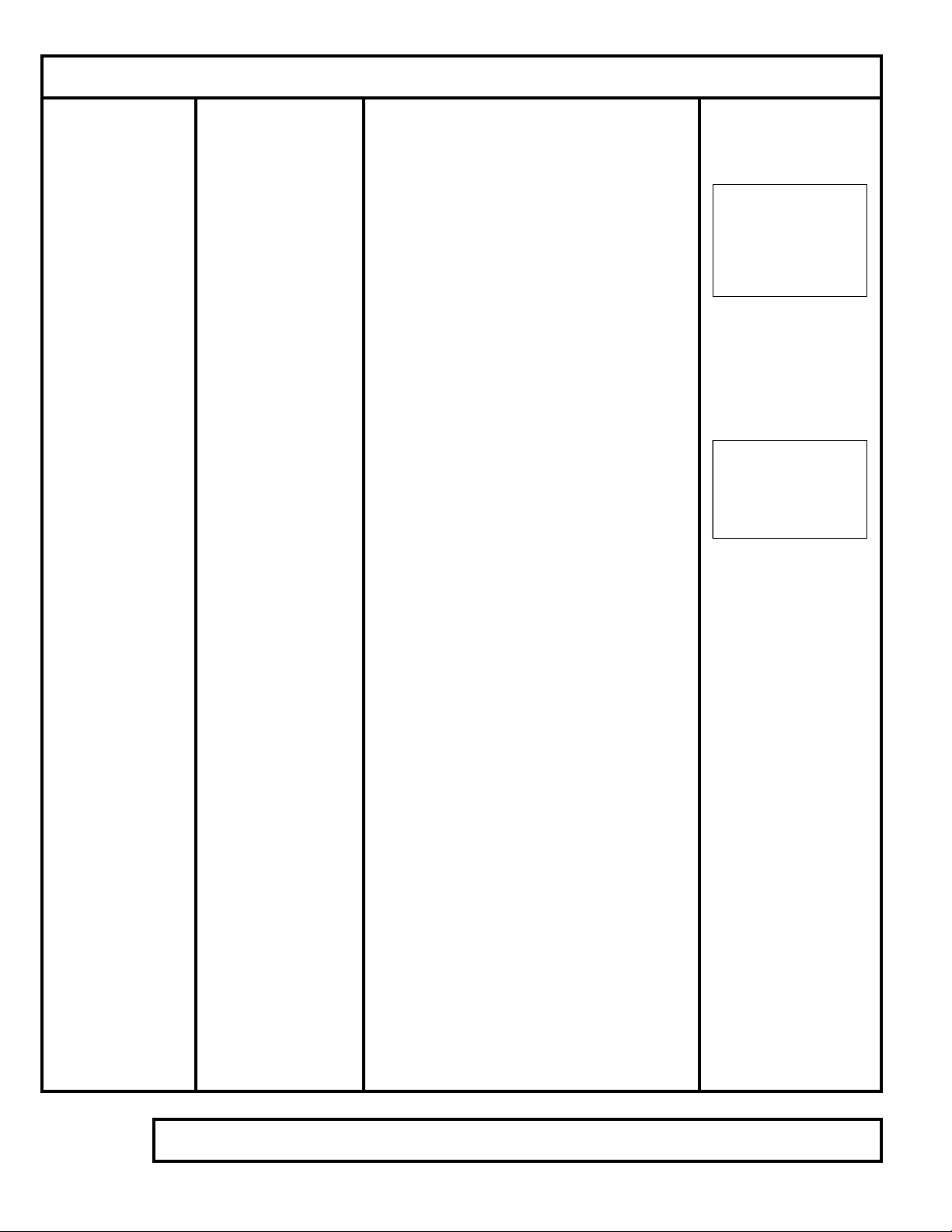

True Armed

Elliptical 600B

Exploded Diagram Page 20

Parts List Page 21

Page 19

TRUE TAE 600

Page 20

TAE 600B

REF # PART# DESCRIPTION QTY

AC1 7TSZEP42CSM CONSOLE MAST ASSY 1

AE1 7TSZEP17PAM-6R1 RIGHT ARM ASSY 1

AE2 7TSZEP17PAM-6L1 LEFT ARM ASSY 1

AE3 7TSW0306011A MVG ARM PIVOT 2

AG1 7TSZEP25HDB-R HANDLEBAR ASSY RH 1

AG2 7TSZEP25HDB-L HANDLEBAR ASSY LH 1

AJ1 7TSZEP07FST FRNT STBL ASSY 1

AN1 7TS12325001 CONSOLE ASSY 1

AS1 7TMD0208010C BRAKE ECB SET 1

AT1 7TS08317001 CRANK ARM 2

B28 7TMB0301002 FOOT PAD WASHER 2

B29 7TMJ1390003E VERTCL SPT PLATE 1

B30 7TMJ1390004 UPPER SPT PLATE 1

B31 7TMB0302002 FOOT PAD 2

B51 7TME0102021 SCREW CVR SPT 6

C53 4

C54 4

C55 4

C56 7TMB0401050A STATIONARY BAR 2

E05 7TMB0609025 STABILIZER BAR 2

E07 7TSZEP25RAL ARM TRACK 1

E08 7TMB0674006 RUBBER PLATE TRK 2

E10 7TME0112024 OVAL HEX SKT TRK 8

E12 7TMB0206002C FOOT PLATE 2

E14 7TMB0304011 FOOT PLATE INSERT 2

E18 7TME0502027 FLAT WASHER 8

E19 7TME0501007 SPRING WASHER 8

E52 7TME0102027 SCREW FOOTPLATE 8

E54 7TME0505037 TEFLON WASHER 2

E55 7TME0204026 NYLON NUT 2

E56 7TME0505020 TEFLON WASHER 2

E57 7TME0502006 FLAT WASHER 2

E60 7TMB0609063B MVG ARM JOINT 2

G08 7TMB0678005A END CAP SWING A RM 2

AC1 7TSP0302022A CONSOLE MAST 1

G51 7TMB0401058A FOAM GRIP UPPER H/BAR 2

G55 7TME0104057 SCREW RND HEX 8

G57 7TMB0609018 HNDLBR END CAP 4

G61 7TMD0508001 CONNECTOR ARM A 1

G62 7TMD0508002 CONNECTOR ARM B 1

G63 7TME0101042 CONNECTOR ARM NUT 1

G64 7TME0204007 NYLON NUT 4

G65 7TME0506013 WAVE WASHER 8

G66 7TME0508011 WASHER CONNECTOR ARM 8

J02 7TMB0304006 FT LEVELER 2

J04 7TME0112024 SCREW FT STABILIZER 2

J06 7TMB0609035 END CAP STABILIZER

J07 7TMJ3344001 RAIL CVR ANCHOR 22

L02 7TMB0103002 MOVING WHEEL 2

2

Page 21

Page 22

L51 7TME0204005 NYLON NUT 2

L52 7TME0502030 FLAT WASHER 2

M01 7TS11317001 WHEEL ASSY MVG ARM 1

M52 7TME0502026 FLAT WASHER 4

M53 7TME0112074 SCREW OVAL HEX SCKT 4

N05 7TME0104055 SCREW CNTRL PNL 4

P01 7TMC0501045D CONSOLE WIRE UPPER 1

P02 7TMJ1802001 SENSOR BRKT 1

P03 7TMC0522004 CONSOLE WIRE LOWE R 1

P04 7TMC0510039B RPM SENSOR W/WIRE 1

P06 7TMC0203006B CONTROL BOARD 1

P07 7TMC0504042 POWER CORD 1

P08 7TMC0703019A POWER SOCKET 1

P09 7TMC0701002 POWER SWITCH 1

P51 7TME0102021 RPM SENSOR SCREW 1

P53 7TME0108004 SCREW OVAL TAPPING 2

Q01 7TMB0202036A PEDESTAL SIDE CVR 2

Q02 7TMB0601005 WATER BTL HLDR 1

Q03 7TMB0222005A MAIN CVR 1

Q06 7TMB0246001 RAIL CVR LH 1

AC1 7TSP0302022A CONSOLE MAST 1

Q07 7TMB0246002 RAIL CVR RH 1

Q08 7TME0121005 MAIN CVR 19

Q09 7TME0107030 PEDESTAL CVR 14

Q10 7TME0107013 MAIN CVR 6

Q11 7TME0701001 C CLIP MAIN CVR 2

Q14 7TMB0627006B CORROSION CVR 1

Q15 7TMB0613010A RND PLUG RT SIDE CVR 2

Q16 7TMB0678018A RECTANGULER PLUG 1

R05 7TMJ3305016A POLY V WHEEL 1

R06 7TME0208006 NUT HEX HEAD 2

R09 7TME0104047 FLYWHEEL 6

R17 7TMD0603005 POLY V BELT 1

R20 7TME0504006 WASHER 6

R22 7TME0508004 WASHER 4

S01 7TMJ1374012A ECB CONNECTION PLATE 1

S05 7TME0110002 EYE-BOLT 2

S51 7TME0201012 AXLE NUT 2

S53 7TMJ1245001 BELT ADJ 2

S54 7TME0204010 BELT ADJ 2

S55 7TME0502054 AXLE NUT 2

S56 7TME0102021 BRAKE BRKT 2

S57 7TME0107013 CONTROL BOARD 5

T51 7TME0902015 CRANK PIN 2

T52 7TME0506012 CRANK PIN 2

V01 7TMG0102057B REAR CVR 2

7TME0606037C ASSEMBLY 1

True Armed

Elliptical 750

Exploded Diagram Page 24

Parts lists Page 25

Page 23

TRUE TAE 750

Page 24

REF. # PART # DESCRIPTION QTY

AC1 7TSZEP17CSM PEDESTAL ASSY-WITH PIVOT BEARING BLOCK ASSY 1

AE1 7TSZEP17PAM-7R1 PEDAL ARM ASSY-RH 1

AE2 7TSZEP17PAM-7L1 PEDAL ARM ASSY-LH 1

AG2 7TSZEP17HDB-R HANDLEBAR ASSY-RH(TALL) 1

AG2 7TSZEP17HDB-R1 HANDLEBAR ASSY-RH(SHORT) 1

AG3 7TSZEP17HDB-L HANDLEBAR ASSY-LH(TALL) 1

AG3 7TSZEP17HDB-L1 HANDLEBAR ASSY-LH(SHORT) 1

AJ1 7TSZEP07FST STABILIZER ASSY-FRONT 1

AN1 7TS12317001 CONTROL PANEL 1

AS1 7TMZD0208007 BRAKE ASSY 1

AS1 7TMD0208016B BRAKE ASSY-AFTER SERIAL # 02-EA-1102K 1

AT1 7TSZW0306007 CRANK ARM ASSY 2

AU1 7TSM0325001 BELT TENSIONER ASSY-PRIMARY 1

B07 7TME0102021 SCREW-FRAME SUPPORT 6

B15 7TMB0301002 LEVELER LOCK NUT-REAR 4

B16 7TMB0302002 LEVELER-REAR 4

B18 7TMJ1390001 COVER LOWER SUPPORT-REAR 1

B19 7TMJ1390004 COVER UPPER SUPPORT-REAR 1

C15 7TME0104165 BOLT-PEDESTAL MOUNTING 4

C16 7TME0502019 WASHER-PEDESTAL MOUNTING 4

C17 7TME0501007 SPRING WASHER-PEDESTAL MOUNTING 4

C56 7TMB0401050A GRIP-FIXED HANDLEBAR 2

E04 7TMB0206002C PEDAL PLATE (PLASTIC) 2

E05 7TMB0609025 END CAP-PEDAL ARM 2

E07 7TSZEP25RAL PEDAL ARM TRACK 2

E08 7TMB0674006 RUBBER PAD-PEDAL ARM TRACK 2

E10 7TME0112024 SCREW-TRACK MOUNTING 8

E12 7TME0102027 SCREW-PEDAL PLATE 8

E15 7TMB0304011 PEDAL PLATE COVER (RUBBER) 2

E18 7TME0502027 FLAT WASHER-TRACK MOUNTING 8

E19 7TME0501007 SPRING WASHER-TRACK MOUNTING 8

G04 7TMB06A7001 BRACKET-PULSE SENSOR 2

G05 7TME0102069 SCREW-PULSE BRACKET 4

G06 7TMJ1278001 SENSOR PLATE-PULSE 2

G07 7TME0201028 NUT-PULSE BRACKET 4

G08 7TMB0678005A END CAP-SWING ARM PIVOT 2

G51 7TMB0401059A GRIP-UPPER BODY HANDLEBAR 2

G61 7TMD0508001 SWIVAL JOINT 2

G62 7TMD0508002 SWIVAL JOINT 2

G64 7TME0204007 NYLON NUT-SWIVAL JOINT 4

G66 7TME0508011 CONE WASHER-SWIVAL JOINT 8

J02 7TMB0304006 LEVELER-FRONT 2

J04 7TME0112024 SCREW-FRONT STABILIZER 2

J06 7TMB0609035 END CAP-FT STABILIZER 2

J07 7TMJ3344001 RETAINER-RAIL COVER 2

P01 7TMC0501027 CABLE-DISPLAY

P02 7TMC0516021B CABLE-REMOTE SWITCH(H/BAR END) 2

P03 7TMC0535004 CABLE-BRAKE (LOWER BOARD END) 1

TAE 750

1

Page 25

P04 7TMC0516022B CABLE-REMOTE SWITCH(LH CONSOLE END) 1

P05 7TMC0516023C CABLE-REMOTE SWITCH(RH CONS OLE END) 1

P06 7TMC0535005 CABLE-BRAKE (BRAKE END) 1

P06 7TMC0712019B SWITCH-RH HANDLEBAR REMOTE

P07 7TME0204003 NYLON NUT-REISTOR MOUNTING 4

P08 7TME0102027 SCREW-RESISTOR MOUNT 7

P08 7TMC0712020B SWITCH-LH HANDLEBAR REMOTE

P09 7TME0502082 WASHER-RESISTOR MOUNT 4

P11 7TMC0203004 CONTROL BOARD 1

P12 7TMC0736002 RESISTOR 1

P17 7TMB06B8001 MOUNT-CONTROL BOARD 1

P18 7TMJ1393003 BRACKET-RESISTOR 1

P20 7TME0107037 SCREW-RESISTOR MOUNT 11

Q01 7TMB0202036A SIDE COVER SET-LEFT & RIGHT 1

Q02 7TMB0601005 BOTTLE HOLDER 1

Q03 7tszep07Fcv COVER-REAR 1

Q06 7TMB0246001 COVER-LEFT RAIL 1

Q06 7TMB0246002 COVER-RIGHT RAIL 1

Q08 7TME0102053 SCREW-REAR COVER 10

Q09 7TME0107030 SCREW-SIDE COVERS 12

Q10 7TME0107013 SCREW-REAR COVER 2

Q11 7TME0701001 C CLAMP-REAR COVER 2

Q14 7TMB0627006B COVER-CENTER FRAME MEMBER 1

Q15 7TMB0613010A PLUG-ROUND-SIDE COVER 2

Q16 7TMB0678018A PLUG-SQUARE-SIDE COVER 1

R01 7TSM0330001 SHAFT ASSY-PEDAL CRANK 1

R02 7TSM0330002 SHAFT ASSY-SECONDARY DRIVE W/SMALL POLY V WHEEL 1

R09 7TMD0604001 POLY V BELT-PRIMARY DRIVE 1

R10 7TMD0601014 POLY V BELT-SECONDARY DRIVE 1

R16 7TME0208008 NUT-CRANK ARM 2

R21 7TME0112024 SCREW-TENSIONER MOUNTING 1

R22 7TME0502035 WASHER-TENSIONER MOUNTING 1

R26 7TSZEP17CPS PIVOT-PEDAL ARM 2

R27 7TS11317001 WHEEL-PEDAL ARM 4

R28 7TME0502026 WASHER-PEDAL ARM WHEEL 4

R29 7TME0112074 SCREW-PEDAL ARM WASHER 4

S02 7TME0202012 NUT-BRAKE AXLE NUT 2

S03 7TMJ1245001 BRACKET-BRAKE BELT ADJUSTER 2

S04 7TME0204010 NYLON NUT-BRAKE BELT ADJUSTER 2

S05 7TME0110015 BOLT-BRAKE BELT ADJUSTER 2

U08 7TME0110009 BOLT-PRIMARY BELT ADJUSTER 2

U09 7TME0102010 SCREW-PRIMARY BELT ADJUSTER 1

U10 7TME0204009 NYLON NUT-PRIMARY BELT ADJUSTER 1

U11 7TME0502098 WASHER-PRIMARY BELT ADJUSTER 1

7TMG0102032 DECAL-REAR COVER(WHITE) 2

7TMG0102096D DECAL-REAR COVER(SILVER) 2

Page 26

7TME0606037C HARWARE KIT-ASSEMBLY 1

True Elliptical 750

Prior to Serial # 00-EL2253L

(Non-Cartridge Bearing)

Exploded diagram Page 28

Parts lists Page 29

After Serial # 00-EL2253L

(Cartridge Bearing)

Exploded diagram Page 31

Parts lists Page 32

Page 27

(Non-Cartridge Bearings)

TRUE TE 750

PARTS DIAGRAM

Page 28

TE 750 PRIOR TO SERIAL # 00-

REF. # PART # DESCRIPTION QTY

AC1 7TSP0302010 PEDESTAL 1

AE1 7TSZ03307001R PEDAL ARM ASSY-RH 1

AE2 7TSZ03307001L PEDAL ARM ASSY-LH 1

AG2 7TSZEP07HDB-R HANDLEBAR ASSY-RH 1

AG3 7TSZEP07HDB-L HANDLEBAR ASSY-LH 1

AJ1 7TSZEP07FST STABILIZER ASSY-FRONT 1

AN1 7TSZM0307002 CONTROL PANEL 1

AS1 7TMZD0208007 BRAKE ASSY 1

AS1 7TMD0208016B BRAKE ASSY-AFTER SERIAL # 02-EL0541J 1

AT1 7TSZW0306007 CRANK ARM ASSY 2

AU1 7TSM0325001 BELT TENSIONER ASSY-PRIMARY 1

B07 7TME0102021 SCREW-FRAME SUPPORT 6

B15 7TMB0301002 LEVELER LOCK NUT-REAR 4

B16 7TMB0302002 LEVELER-REAR 4

B18 7TMJ1390001 COVER LOWER SUPPORT-REAR 1

B19 7TMJ1390004 COVER UPPER SUPPORT-REAR 1

C14 7TME0112029 SCREW-HANDLEBAR MOUNTING 6

C15 7TME0104165 BOLT-PEDESTAL MOUNTING 4

C16 7TME0502019 WASHER-PEDESTAL MOUNTING 4

C17 7TME0501007 SPRING WASHER-PEDESTAL MOUNTING 4

E04 7TMB0206002C PEDAL PLATE (PLASTIC) 2

E05 7TMB0609025 END CAP-PEDAL ARM 2

E07 7TSZEP25RAL PEDAL ARM TRACK 2

E08 7TMB0674006 RUBBER PAD-PEDAL ARM TRACK 2

E10 7TME0112024 SCREW-TRACK MOUNTING 8

E12 7TME0102027 SCREW-PEDAL PLATE 8

E15 7TMB0304011 PEDAL PLATE COVER (RUBBER) 2

E18 7TME0502027 FLAT WASHER-TRACK MOUNTING 8

E19 7TME0501007 SPRING WASHER-TRACK MOUNTING 8

G04 7TMB06A7001 BRACKET-PULSE SENSOR 2

G05 7TME0102069 SCREW-PULSE BRACKET 4

G06 7TMJ1278001 SENSOR PLATE-PULSE 2

G07 7TME0201028 NUT-PULSE BRACKET 4

J02 7TMB0304006 LEVELER-FRONT 2

J04 7TME0112024 SCREW-FRONT STABILIZER 2

J06 7TMB0609035 END CAP-FT STABILIZER 2

J07 7TMJ3344001 RETAINER-RAIL COVER 2

P01 7TMC0501027 CABLE-DISPLAY 1

P02 7TMC0516005 CABLE-HRC PEDESTAL END 2

P03 7TMC0535004 CABLE-BRAKE (LOWER BOARD END) 1

P05 7TMC0539003 CABLE-HRC HANDLEBAR END 2

P06 7TMC0535005 CABLE-BRAKE (BRAKE END) 1

P07 7TME0204003 NYLON NUT-REISTOR MOUNTING

P08 7TME0102027 SCREW-RESISTOR MOUNT 7

EL2253L

(Non- Cartridge Bearings)

4

Page 29

P09 7TME0502082 WASHER-RESISTOR MOUNT 4

P11 7TMC0203004 CONTROL BOARD 1

P12 7TMC0736002 RESISTOR 1

P17 7TMB06B8001 MOUNT-CONTROL BOARD 1

P18 7TMJ1393003 BRACKET-RESISTOR 1

P20 7TME0107037 SCREW-RESISTOR MOUNT 11

Q01L 7TMB020202A SIDE COVER-LEFT FRONT 1

Q01R 7TMB020202R SIDE COVER-RIGHT FRONT 1

Q02 7TMB0601005 BOTTLE HOLDER 1

Q03 7TMB0222003 COVER-REAR 1

Q06 7TMB0246001 COVER-LEFT RAIL 1

Q06 7TMB0246002 COVER-RIGHT RAIL 1

Q08 7TME0102053 SCREW-REAR COVER 10

Q09 7TME0107030 SCREW-SIDE COVERS 12

Q10 7TME0107013 SCREW-REAR COVER 2

Q11 7TME0701001 C CLAMP-REAR COVER 2

Q14 7TMB0627006B COVER-CENTER FRAME MEMBER 1

R01 7TSZEP07DAX SHAFT ASSY-PEDAL CRANK 1

R02 7TSZEP07PUL SHAFT ASSY-SECONDARY DRIVE 1

R05 7TMZD0112013 POLY V WHEEL-SMALL 1

R09 7TMD0604001 POLY V BELT-PRIMARY DRIVE 1

R10 7TMD0601014 POLY V BELT-SECONDARY DRIVE 1

R16 7TME0208008 NUT-CRANK ARM 2

R21 7TME0112024 SCREW-TENSIONER MOUNTING 1

R22 7TME0502035 WASHER-TENSIONER MOUNTING 1

R26 7TSZEP17CPS PIVOT-PEDAL ARM 2

R27 7TS11317001 WHEEL-PEDAL ARM 4

R28 7TME0502026 WASHER-PEDAL ARM WHEEL 4

R29 7TME0112074 SCREW-PEDAL ARM WASHER 4

S02 7TME0202012 NUT-BRAKE AXLE NUT 2

S03 7TMJ1245001 BRACKET-BRAKE BELT ADJUSTER 2

S04 7TME0204010 NYLON NUT-BRAKE BELT ADJUSTER 2

S05 7TME0110015 BOLT-BRAKE BELT ADJUSTER 2

U08 7TME0110009 BOLT-PRIMARY BELT ADJUSTER 2

U09 7TME0102010 SCREW-PRIMARY BELT ADJUSTER 1

U10 7TME0204009 NYLON NUT-PRIMARY BELT ADJUSTER 1

U11 7TME0502098 WASHER-PRIMARY BELT ADJUSTER 1

7TMG0102032 DECAL-REAR COVER(WHITE) 2

7TME0606020 HARWARE KIT-ASSEMBLY 1

Page 30

TRUE TE 750

PARTS DIAGRAM

(Cartridge Bearings)

Page 31

Page 32

REF. # PART # DESCRIPTION QTY

AC1 7TSP0302010 PEDESTAL 1

AE1 7TSZ03307001R PEDAL ARM ASSY-RH 1

AE2 7TSZ03307001L PEDAL ARM ASSY-LH 1

AG2 7TSZEP07HDB-R HANDLEBAR ASSY-RH 1

AG3 7TSZEP07HDB-L HANDLEBAR ASSY-LH 1

AJ1 7TSZEP07FST STABILIZER ASSY-FRONT 1

AN1 7TSZM0307002 CONTROL PANEL 1

AS1 7TMZD0208007 BRAKE ASSY 1

AS1 7TMD0208016B BRAKE ASSY-AFTER SERIAL # 02-EA-1102K 1

AT1 7TSZW0306007 CRANK ARM ASSY 2

AU1 7TSM0325001 BELT TENSIONER ASSY-PRIMARY 1

B07 7TME0102021 SCREW-FRAME SUPPORT 6

B15 7TMB0301002 LEVELER LOCK NUT-REAR 4

B16 7TMB0302002 LEVELER-REAR 4

B18 7TMJ1390001 COVER LOWER SUPPORT-REAR 1

B19 7TMJ1390004 COVER UPPER SUPPORT-REAR 1

C14 7TME0112029 SCREW-HANDLEBAR MOUNTING 6

C15 7TME0104165 BOLT-PEDESTAL MOUNTING 4

C16 7TME0502019 WASHER-PEDESTAL MOUNTING 4

C17 7TME0501007 SPRING WASHER-PEDESTAL MOUNTING 4

E04 7TMB0206002C PEDAL PLATE (PLASTIC) 2

E05 7TMB0609025 END CAP-PEDAL ARM 2

E07 7TSZEP25RAL PEDAL ARM TRACK 2

E08 7TMB0674006 RUBBER PAD-PEDAL ARM TRACK 2

E10 7TME0112024 SCREW-TRACK MOUNTING 8

E12 7TME0102027 SCREW-PEDAL PLATE 8

E15 7TMB0304011 PEDAL PLATE COVER (RUBBER) 2

E18 7TME0502027 FLAT WASHER-TRACK MOUNTING 8

E19 7TME0501007 SPRING WASHER-TRACK MOUNTING 8

G04 7TMB06A7001 BRACKET-PULSE SENSOR 2

G05 7TME0102069 SCREW-PULSE BRACKET 4

G06 7TMJ1278001 SENSOR PLATE-PULSE 2

G07 7TME0201028 NUT-PULSE BRACKET 4

J02 7TMB0304006 LEVELER-FRONT 2

J04 7TME0112024 SCREW-FRONT STABILIZER 2

J06 7TMB0609035 END CAP-FT STABILIZER 2

J07 7TMJ3344001 RETAINER-RAIL COVER 2

P01 7TMC0501027 CABLE-DISPLAY 1

P02 7TMC0516005 CABLE-HRC PEDESTAL END 2

P03 7TMC0535004 CABLE-BRAKE (LOWER BOARD END) 1

P05 7TMC0539003 CABLE-HRC HANDLEBAR END 2

P06 7TMC0535005 CABLE-BRAKE (BRAKE END) 1

P07 7TME0204003 NYLON NUT-REISTOR MOUNTING 4

P08 7TME0102027 SCREW-RESISTOR MOUNT 7

P09

P11 7TMC0203004 CONTROL BOARD 1

P12 7TMC0736002 RESISTOR 1

TE 750 AFTER SERIAL # 00-EL2253L

CARTRIDGE BEARING TYPE

7TME0502082 WASHER-RESISTOR MOUNT 4

P17 7TMB06B8001 MOUNT-CONTROL BOARD 1

P18 7TMJ1393003 BRACKET-RESISTOR 1

P20 7TME0107037 SCREW-RESISTOR MOUNT 11

Q01L 7TMB020202A SIDE COVER-LEFT FRONT 1

Q01R 7TMB020202R SIDE COVER-RIGHT FRONT 1

Q02 7TMB0601005 BOTTLE HOLDER 1

Q03 7TMB0222003 COVER-REAR 1

Q06 7TMB0246001 COVER-LEFT RAIL 1

Q06 7TMB0246002 COVER-RIGHT RAIL 1

Q08 7TME0102053 SCREW-REAR COVER 10

Q09 7TME0107030 SCREW-SIDE COVERS 12

Q10 7TME0107013 SCREW-REAR COVER 2

Q11 7TME0701001 C CLAMP-REAR COVER 2

Q14 7TMB0627006B COVER-CENTER FRAME MEMBER 1

R01 7TSM0330001 SHAFT ASSY-PEDAL CRANK 1

R02 7TSM0330002 SHAFT ASSY-SECONDARY DRIVE 1

R05 7TMZD0112013 POLY V WHEEL-SMALL 1

R09 7TMD0604001 POLY V BELT-PRIMARY DRIVE 1

R10 7TMD0601014 POLY V BELT-SECONDARY DRIVE 1

R16 7TME0208008 NUT-CRANK ARM 2

R21 7TME0112024 SCREW-TENSIONER MOUNTING 1

R22 7TME0502035 WASHER-TENSIONER MOUNTING 1

R26 7TSZEP17CPS PIVOT-PEDAL ARM 2

R27 7TS11317001 WHEEL-PEDAL ARM 4

R28 7TME0502026 WASHER-PEDAL ARM WHEEL 4

R29 7TME0112074 SCREW-PEDAL ARM WASHER 4

S02 7TME0202012 NUT-BRAKE AXLE NUT 2

S03 7TMJ1245001 BRACKET-BRAKE BELT ADJUSTER 2

S04 7TME0204010 NYLON NUT-BRAKE BELT ADJUSTER 2

S05 7TME0110015 BOLT-BRAKE BELT ADJUSTER 2

U08 7TME0110009 BOLT-PRIMARY BELT ADJUSTER 2

U09 7TME0102010 SCREW-PRIMARY BELT ADJUSTER 1

U10 7TME0204009 NYLON NUT-PRIMARY BELT ADJUSTER 1

U11 7TME0502098 WASHER-PRIMARY BELT ADJUSTER 1

7TMG0102032 DECAL-REAR COVER(WHITE) 2

7TME0606020 HARWARE KIT-ASSEMBLY 1

Page 33

Page 34

True Fitness

Removal &

Replacement

500R

500U

600U

600R

Page 35

600 Series Elliptical

Remove Crank Page 37

Remove Belt Wheel Page 38

Remove Brake Page 40

750E & 750EA Series Elliptical

Remove Belt & Tensioner Assembly Page 43

Remove Small Poly-V Pulley Page 44

Remove Crank & .235 Diameter Poly-V Pulley Page 46

Page 36

Remove Hub Assembly Page 47

Removal and Replacement

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

TABLE OF CONTENTS

Removal & Replacement 600

Remove Crank

Tools Required:

Crank Puller

Crescent Wrench

Block of wood

Step 1.

Place block of wood under moving

Arm assembly to prebvent counterclockwise rotation. Note position of

block of wood to the left of the tray.

Step 2.

Place 15mm socket end of crank

Puller over axle nut. Loosen the axle

Nut by turning the crank puller counterClockwise with a crescent wrench.

Step 3.

Remove crank assembly from hub.

Step 1. Wood Block Placement.

Step 2. Axel Nut Removal.

Step 3. Remove Crank Assembly from Hub.

Copyright 2001 True Fitness Technology, Inc.

Page 37

Removal & Replacement 600

Remove Belt Wheel

Tools Required:

15mm Socket nd Ratchet

11mm Box End Wrench

5mm Hex Wrench

Phillips Screw Driver

Step 1.

Loosen belt-tensioning nuts on bolts

Attached to brake axel on both sides.

Step 1. Loosen Belt Tensioning Nuts.

Step 2.

Loosen and remove axel nuts on

Brake, both sides.

Step 3.

Push belt over edge and off of wheel.

Step 2. Remove Axel Nuts.

Step 3. Remove Belt from Wheel.

Page 38

Copyright 2001 True Fitness Technology, Inc.

Removal & Replacement 600

Remove Belt Wheel (Continued)

Step 4.

Remove 5mm hex screws from

Bearing fixtures on both sides of belt

Wheel axel

.

Step 4. Remove screws from Bearing Fixtures.

Step 5.

Lift belt wheel assembly from bearing

Fixtures.

Copyright 2001 True Fitness Technology, Inc.

Step 5. Lift belt wheel assembly from bearing Fixtures.

Page 39

Removal & Replacement 600

Remove Brake

Tools Required:

Phillips Screw Driver

Step 1.

Remove screw holding the nagnet

Brake bracket located under the rear

Brake with Phillips head screw driver.

Step 2.

Disconnect electrical terminal at

Brake.

Step 1. Brake Bracket Removal.

Step 2. Disconnect Electrical Terminal at Brake.

Page 40

Step 3.

Disconnect electrical terminal from

The console set at the control box

Located above the brake.

Copyright 2001 True Fitness Technology, Inc.

Step 3. Disconnect Cable from Control Box.

Removal & Replacement 600

Remove Brake (Continued)

Step 4.

Remove Phillips head scrwes

Holding control box above the brake

To the frame. Remove control box..

Step 4. Control Box Removal.

Step 5.

Pull backwards on the brake and

Magnet assembly to free it from

Slotted axle flanges. Lift brake

Out.

Step 5. Lift Brake & Magnet Assembly Out.

Copyright 2001 True Fitness Technology, Inc.

Page 41

Removal & Replacement 600

Remove Brake (Continued)

Step 6.

Remove Phillips head screws

From brackets on both sides of

Brake.

Step 6. Remove Screws from Bracket.

Step 7.

Remove brackets to free belt.

Step 7. Remove Brake Brackets & Belt.

Page 42

Copyright 2001 True Fitness Technology, Inc.

Removal & Replacement 750E & 750EA

Remove Belt & Tensioner Assembly

Tools Required:

11mm Box Wrench

5mm Hex Wrench

Step 1.

Use 11mm box wrench to remove

Nut and washer from belt tensioning

screw.

Step 1. Remove Nut.

Step 2.

Remove belt from belt tensioner

Assembly and wheels.

Step 3.

Use 5mm hex wrench to remove

Button head screw and washer

Attaching belt tensioner assembly to

Frame..

Step 2. Remove Belt.

Step 3. Remove Tensioner.

Copyright 2001 True Fitness Technology, Inc.

Page 43

Removal & Replacement 750E & 750EA

Remove Small Poly-V Pulley

Tools Required:

3mm Hex Wrench

4mm Hex Wrench

Bicycle Crank Puller

Hammer Handle

Adjustable Wrench

Step 1.

Use 3mm hex wrench to loosen set

Screw in pulley.

Step 1. Loosen Set Screw.

Page 44

Step 2.

Use Hammer Handle to prevent

Rotation of large wheel when

Removing pulley.

Copyright 2001 True Fitness Technology, Inc.

Step 2. Prevent Rotation of Fly Wheel.

Removal & Replacement 750E & 750EA

Remove Small Poly-V Pulley (Continued)

Step 3.

Use 4mm hex wrench to remove

Screw and washer holding the

Small Poly- V wheel on.

Step 3. Remove Center Screw.

Step 4.

Remove Poly-V wheel using bicycle

Crank puller and adjustable wrench

Remove key from shaft.

Step 4. Use Puller to Remove.

Copyright 2001 True Fitness Technology, Inc.

Page 45

Removal & Replacement 750E & 750EA

Remove Crank & .235 Diameter Poly-V Pulley

Tools Required:

Block of Wood to Block Crank

21mm Socket & Ratchet

Metric Cotter-less Crank Puller

10mm Hex Wrench

Step 1.

Place block of wood under crank at

Left to prevent counter-clockwise

Rotation.

Page 46

Step 2.

Remove center nut using 21mm

socket & ratchet.

Copyright 2001 True Fitness Technology, Inc.

Step 1. Block to Prevent Rotation.

Step 2. Prevent Rotation of Fly Wheel.

Removal & Replacement 750E & 750EA

Remove Crank & .235 Diameter Poly-V Pulley (Continued)

Step 3.

Move block of wood to right of

Crank to prevent clockwise rotation.

Step 3. Block to Prevent Rotation.

Step 4.

Place metric cotter-less crank puller

Over end of crank shaft.

Turn puller clock-wise with 10mm

Hex wrench to remove crank.

Step 4. Pull Crank.

Step 5.

Pull crank arm off of crank shaft

And set moving arm aside.

Copyright 2001 True Fitness Technology, Inc.

Step 5. Move Arm Aside.

Page 47

emoval & Replacement 750E & 750EA

r

Remove Hub Assemblies

Tools Required:

Elliptical Wrench (pn: 90361501)

Channel Lock Pliers

Flat Blade Screwdrive

Step 1.

Use elliptical wrench or pliers to

Remove large hex nuts holding hub

Assembly in place.

Step 1. Remove Large Hex Nut.

Step 2.

Remove retainer clip with flat-blade

Screwdriver

To remove wheel from frame, slip

Shaft through bearing.

Step 3.

Pull wheel and hub assembly out as

A unit. Bearings and axle cannot be

Field serviced.

Step 2. Remove Clip.

Page 48

Step 3. Pull Assembly Out.

Copyright 2001 True Fitness Technology, Inc.

Loading...

Loading...