True Fitness 600U, 750U, 500U, 600R, 500R User Manual

...

True Fitness Service

Manual

Exercise Bicycles

500R, 500U

600R, 600U

750R, 750U

True fitness technology, Inc. makes no representations or warranties regarding the

contents of this manual. We reserve the right to revise this document at any time or

to make changes to the product described within it without notice or obligation to

notify any person of such revisions or changes.

© 2004, True Fitness, Inc. All rights reserved. Printed in the United States of

America.

865 Hoff Road. O’Fallon, MO 63366. 1-800-426-6570. Fax 636-272-3026.

www.truefitness.com

Revision 9/2004

Recommended Tool List

Technicians will need at minimum the tools listed below to work on the True Fitness

equipment covered by these procedures.

Electrical Tools

A multi meter capable of testing voltage, amperage, resistance and continuity.

Outlet tester with a grounding indicator.

Wire stripper, cutter and crimper.

Flashlight

Mechanical Tools

Screwdrivers:

#1 Phillips, #2 Phillips, large flat blade, small flat blade, short handled flat blade.

Metric hex-key (Allen wrench) set.

Metric socket set and ratchet with 6mm to 19mm sizes and 21mm and 34mm sizes.

Metric combination wrenches with 4mm to 21mm sizes and a 27mm El crank.

Snap ring pliers, both internal and external.

Rubber mallet.

Channel lock pliers or standard pliers with a jaw opening of 2 9/16” for use in removing

and tightening sleeve nuts.

Needle nose pliers.

Crescent wrench

Special Tool

Bicycle crank puller

Park Tool USA CCP-2

True Fitness Bicycle

Service Manual

START

Symptom guide

Wiring Diagrams

Parts Manual

Removal and Replacement Procedures

Page 1

Test Mode *750 ONLY Procedure

•

Page 2

D

I

A

G

N

O

S

T

I

C

S

To Enter Diagnostic

Mode

Console / Display

Output

RPM

Console Key Input

Contact Heart Rate

Press and hold the “Start” key as you

• Continue pedaling throughout the test.

• Press “Enter” key – initiates the second

• Press “Enter” key again –all LED’s

• Press “Enter” key – RPM’s displayed in

• Press “Enter” key –A beep should sound

• Press “Enter” key. Hold both handle

DA (Resistance)

Exit Diagnostics

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

• Press “Enter” key – Press + to increase

• To quit diagnostics press “Enter” key or

begin pedaling.

-------

LED function test.

should be on.

--------

the far right window.

--------

when each key is pressed.

--------

pick-ups. Heart symbol will flash and

readout will display.

-------

resistance and – to decrease resistance.

stop pedaling and the unit will reset.

SYMPTOM GUIDE

500U, 500R

ECB Malfunction . . . . . . . . . . . . . . . . . . . . . . . Page 4

Irregular or No Display . . . . . . . . . . . . . . . . . . Page 5

No RPM Reading . . . . . . . . . . . . . . . . . . . . . . . . Page 6

No Polar Heart Rate . . . . . . . . . . . . . . . . . . . . . . Page 7

600U, 600R

Irregular or No Display . . . . . . . . . . . . . . . . . . . Page 8

No RPM Reading . . . . . . . . . . . . . . . . . . . . . . . . Page 9

No Contact Heart Rate . . . . . . . . . . . . . . . . . . . . Page 10

Handle Bar Buttons

Do Not Function . . . . . . . . . . . . . . . . . . . . . . . . .

Page 11

750U, 750R

No Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Heavy Resistance . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Irregular or No Display . . . . . . . . . . . . . . . . . . . Page 14

No Contact Heart Rate . . . . . . . . . . . . . . . . . . . . Page 15

No Polar Heart Rate . . . . . . . . . . . . . . . . . . . . . . Page 16

Page 3

g

Symptom Probable Cause Corrective Action

•

ECB

MALFUNCTION

500R, 500U

Control Panel

Defective Cables

Defective ECB

Control Board

Optical Sensor

DC Motor

ECB Limit Switch

Loud Continuous

Tone from lower

board (ECB board)

Power on unit. Check for 5VDC between pins 1 and 2. (Page 18)

• No 5VDC? Replace control panel.

• Check for 6VDC or more between pins 5 and 6 of 6PA while issuing

a resistance command.

• No 6VDC or more? Replace control panel.

• Perform continuity check on upper section and lower section cables.

• Replace broken cables.

• If cables test OK and voltage is correct on 5 &6 pins – replace ECB

board

• If ECB does not fix- connect 6PA and 6PB.

• Check DC volts between pins 2 and 3. Rotate blades of the motor

shaft, voltage should shift from 0 VDC and 5VDC. If voltage does

not shift- replace EC B Board

• Check for 6 VDC or more between pins 5&6 on 6 pin PBA @ ECB

board connection. If >6 VDC exists but motor doesn’t rotate, replace

motor.

• Check continuity between pins 2 and 4 of 6PB. Press lower limit

switch.

• If no continuity shift- replace ECB limit switch assembly.

• The loud continuous tone is a safety feature designed to protect the

ECB motor. If the motor binds and cannot move the ECB board will

divert the power from the motor to a speaker that emits this tone. If

you have the continuous tone check to see if the motor is bound.

Check the front pivot point

bolt to allow for the motor to freely move the magnet bar.

Note: If motor has been bound and then

freed the motor may have been weakened. If

components now move freely but the motor

is laborin

– replace the motor.

Page 4

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

--------

--------

--------

--------

---------

for the magnet bar and loosen the

Symptom Probable Cause Corrective Action Recommended Tools

IRREGULAR OR

NO DISPLAY

500R, 500U

DC Adaptor

Adapter Plug or

Jack

Control Panel

Cables

• Connect DC Adapter to 110 VAC power

supply.

• Look for printed output on adapters

label. If greater than 9 VDC computer

board may be damaged.

• Test for 9VDC output. If not 9 VDC

then replace adaptor.

--------

• Connect DC plug to Bike. Does it seat

into the socket properly? If not- replace

adapter or jack.

--------

• Check DC voltage between pins 2 and 4

for 9 VDC on 5PB. (Page 18)

• If 9 VDC is found replace the Control

Panel.

--------

• Perform continuity checks on all upper

and lower cables.

• Replace defective cables.

• If cables OK- replace DC Jack.

Multi-meter

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 5

Symptom Probable Cause Corrective Action Recommended Tools

NO RPM

READING

500R, 500U

Control Panel/ RPM

Sensor

Defective Cables

Defective RPM

Sensor Set

• Disconnect 5PA from 5PB. Set meter to

check continuity between 2 and 5 of

5PB. (See Page 18)

• Turn pedals slowly, check continuity

between 2 and 5 of 5PB.

• Does continuity change from off to on?

• If yes – cables and sensor are good –

Replace Control Panel.

• If no – Go to Defective RPM Set.

When the sensor is over the

pickup, continuity will exist.

When sensor is not over pickup,

cicuit will be open.

--------

• Perform continuity checks on all upper

and lower cables.

• Replace defective cables.

--------

• If cables OK- Replace RPM sensor set.

Multi-meter

Page 6

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

NO POLAR

HEART RATE

500R, 500U

Control Panel

Heart Rate Chest

Strap

External

Interference

• Attach a known good heart rate

transmitter around chest or use polar

simulator.

• If control panel does not display a heart

rate – replace Control Panel.

--------

• If heart rate registers with use of HR

simulator but not chest strap – replace

chest strap.

--------

• If erroneous readings continue, check

for and eliminate external interference.

• Locate RF sources and use process of

elimination. Common sources of RF

interference are: Invisible fences for

pets; wireless networks; cordless

phones, Cell phones, radios, home

security sensors, etc.

Heart Rate Simulator

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 7

Symptom Probable Cause Corrective Action Recommended Tools

IRREGULAR OR

NO DISPLAY

600R, 600U

Control Panel

Control Board

Cables

AC Voltage Output

Generator Output

Cable

• Probe leads between pin 1 and 2 of 5PB.

(Page 19-20)

• Pedal unit up to at least 30 RPM.

• Is voltage 5 VDC?

• If not 5 VDC – replace Control Panel.

--------

• Disconnect 6PG from 6PH.

• Pedal.

• Check DC voltage between pins 2 and 3

for 5 VDC.

• No 5 VDC? – Replace Control Board.

-------

• Perform continuity checks on all upper

and lower cables.

• Replace defective cables

--------

• Check for AC Voltage between pins 1

and 2 of 3PB, and pins 2 and 3 of 3PB.

• Is there AC voltage output in both

places?

• If yes – replace Control Board.

• Check for AC Voltage between pins 1

and 2 of 3PD, and pins 2 and 3 of 3PD.

• Is there AC voltage output in both

places?

• If no – replace Generator.

------

• Perform a continuity check on the

generator output cable.

• If no continuity – replace cable

Multi-meter

Page 8

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

NO RPM

READING

600R, 600U

Control Panel

Defective Cables

Defective RPM

Sensor Set

• Disconnect 5PA from 5PB. (Page 19-

20).

• Set meter to check continuity between

pins 2 and 5 of 5PB

• Turn crank and align the magnet with

the sensor

• Is there continuity? If Yes – Replace

Control Panel. If No- continue to next

step.

--------

• Check continuity of RPM Sensor, when

magnet is in alignment with the sensor

there should be continuity, when not

aligned- no continuity. If it does not

respond properly- replace the sensor.

• Check gap on RPM Sensor

• Perform a continuity check on all upper

and lower cables.

• No continuity? – Replace defective

cable.

• Continuity? – Replace RPM Sensor Set.

Multi-meter

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 9

Symptom Probable Cause Corrective Action Recommended Tools

NO CONTACT

HEART RATE

600R, 600U

Page 10

Control Panel

Defective Cables

Defective Handles

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

• Disconnect 7P6A and 7P6B from

control panel. 600U (Page 19) 600R

(Page 20). Check continuity between

7P6B and handle mounted heart rate

sensor plates of the following:

HRRR and pin 6 of 7P6B

HRRL and pin 5 of 7P6B

HRLR and pin 2 of 7P6B

HRLL and pin 1 of 7P6B

• Is there continuity?

• If yes – replace computer.

• If No- continue to the next step

--------

• Perform a contact and continuity check

on cable 600 12P, 600 12P coils upper

cables and the handle cables.

• Are cables OK? If No- Replace

defective cables. If Yes- continue on to

the next step.

--------

• Remove and carefully check all

connections to the contact plates.

• Reconnect loose connections.

• If connections OK – Replace handles.

Multi-meter

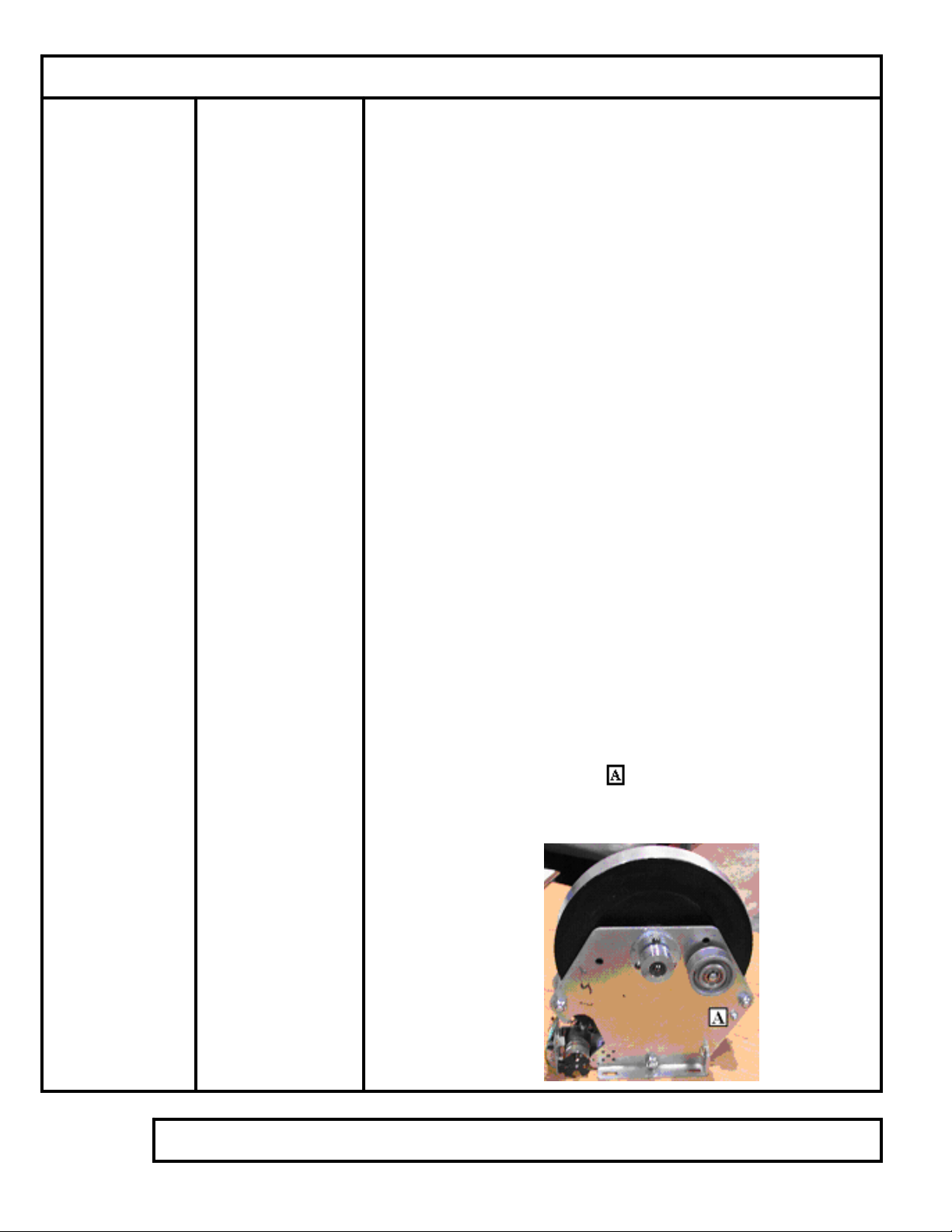

Symptom Probable Cause Corrective Action Recommended Tools

HANDLEBAR

BUTTONS DO

NOT FUNCTION

600R

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

“Cruise Control”

“Start” Button

“Shift” Button

“_“ Button

“Select” Button

“+” Button

• Remove console-mounting screws.

Locate 10P7B (Page 20).

• Check for continuity between pin 7 and

pin 1 at 10P7B. Press Cruise control

button.

(A)

• No continuity? Perform a continuity

check on the appropriate cable.

• Replace cable or if cable good – replace

handlebar assembly.

--------

• Check for continuity between pin 7 and

pin 2 at 10P7B. Press Start button. See

(A) above.

--------

• Check for continuity between pin 7 and

pin 3 at 10P7B. Press Shift button. See

(A) above.

--------

• Check for continuity between pin 7 and

pin 4 at 10P7B. Press _ button. See (A)

above.

--------

• Check for continuity between pin 7 and

pin 5 at 10P7B. Press Select button. See

(A) above.

--------

• Check for continuity between pin 7 and

pin 6 at 10P7B. Press + button. See (A)

above.

--------

• If all have continuity and problem

persists – replace Console

Multi-meter

Page 11

Symptom Probable Cause Corrective Action Recommended Tools

•

p

p

g

NO RESISTANCE

750U, 750R

Console Set

Defective Cables

Power Resistance

Brake Harness/

Lower Board

Remove console bolts to access 7-pin

connector. Do not disconnect console

set.

• Enter DA (resistance) test mode.

(Page 2).

• Press + key to force .7 VDC out of

panel.

• Set meter for DC Volts. Measure

between #2 pin and #4 pin at 7- pin

connector.

• Is .7 VDC present? No- replace console

set. If present, continue on.

--------

• Remove right mast cover and handlebar.

• Measure between the #2and #4 wires at

the 7 –pin connector on

• Is .7 VDC present? No- replace cable

for console. If present, continue on.

--------

• DO NOT PEDAL.

• Set meter for resistance. Disconnect 3-

pin connector at the lower control board.

Measure resistance between #1 pin and

#3 pin.

• Resistance should be 10 ohms, +/- 1

ohm.

• If less than 10 Ohms- replace power

resistance. If resistance checks OK,

continue on.

--------

• DO NOT PEDAL.

• Remove main body cover, set meter for

continuity.

• Disconnect brake cable from brake and

lower board.

• Check continuity of all wires in cable.

• Check for cross continuity- this would

indicate multiple shorts in the cable.

• No continuity? Replace Brake cable.

• Yes continuity? Replace lower board.

the lower board.

Note:

You mus t pedal at least

30 RPM when

erforming any voltage

test. You may require the

assist ance of another

erson when performing

volta

e checks.

Multi-meter

Page 12

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

HEAVY

RESISTANCE

750U, 750R

Console Set

Defective Cables

Lower control

Board/Brake

• Remove the console set.

• Disconnect the 7 pin connector from the

back of the console set.

• Pedal.

• Resistance normal? Replace console set.

--------

• Remove pedal and if 3 piece crank

remove crank arm.

• Remove right side cover assembly.

• Disconnect 7- pin connector from the

lower control board.

• Pedal.

• If resistance is normal- replace cable for

console.

--------

• Disconnect 3- pin connector from the

brake.

• Resistance still heavy- Replace brake.

• Resistance normal

• Check brake cables for cross continuity.

• Replace lower control board.

Multi-meter

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 13

Symptom Probable Cause Corrective Action Recommended Tools

p

p

g

No Display

750U, 750R

Console Set

Brake

Defective Cable

Console Cable/

Lower Control

Board

• Remove console set bolts. Verify good

connection at the back of the console

set. Set meter for DC volts

• Pedal.

• Measure between #1 and #4 wires (Page

21) for 5.5 – 7.5 VDC.

• Is required voltage present?

• If yes- replace console set. If not,

continue on.

--------

• Remove pedal and if 3 piece crank

remove crank arm.

• Remove right side cover.

• Disconnect 3- wire connector at brake.

• Set meter for AC volts.

• Pedal.

• The voltage should increase as pedaling

increases.

• Is minimum voltage 9 VAC @ 30

RPM?

• If No- replace Brake. If yes, continue

on.

--------

• Remove pedal and if 3 piece crank

remove crank arm.

• Remove right side cover.

• Disconnect 3- wire cable from brake and

lower control board.

• Set meter for continuity.

• Check all 3 wires in cable for continuity.

• No continuity? Replace cable

----------

• Set meter for DC volts. Reconnect

cable to brake and lower control board.

• Pedal.

• Measure for 5.5 – 7.5 VDC between #1

and #4 wires on 7- pin cable for the

console at the lower control board.

• Voltage is present? Replace cable for

console.

• Voltage not present? Replace lower

control board.

Note:

You must pedal at le ast

30 RPM when

erforming any voltage

test. You may require the

assistan ce of another

erson when performing

e checks.

volta

Multi-meter

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

p

p

g

NO CONTACT

HEART RATE

750U, 750R

Dirty Sensors

Console Set/

Wiring

Wire Connections

• Verify hand pulse sensors are clean.

--------

• Set meter for continuity.

• Remove Console set.

• Check for continuity in both sets of

hand pulse sensors between the console

set and hand pulse sensor plates.

• If continuity is OK – Replace Console

set. If no- continue on.

--------

• Check wire connections @ handlebar

console mast joint

• Check connections of wires to hand

pulse sensor by removing hand pulse

sensor plates.

• To remove hand pulse sensor plates

carefully pry under one end to free them

from the plastic handgrips.

• Bad connections? - Reconnect/ Replace

bad wires.

• Recheck continuity.

Note:

You must pedal at le ast

30 RPM when

erforming any voltage

test. You may require the

assistan ce of another

erson when performing

e checks.

volta

Multi-meter

Double sided tape

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 15

Symptom Probable Cause Corrective Action Recommended Tools

p

p

g

NO POLAR

HEART RATE

750U, 750R

Control Panel

Defective Cables

Defective ECB

Control Board

• Attach known good heart rate

transmitter around chest or use Polar

simulator.

• Do not touch the hand pulse sensors.

• Start pedaling

• Check display for heart rate.

--------

• Does console display heart rate with

chest strap?

• Does console display heart rate with HR

simulator?

• If unit responds with simulator and not

chest strap then replace chest strap.

• If unit does not respond with strap or

simulator then replace Console set.

Note:

You must pedal at le ast

30 RPM when

erforming any voltage

test. You may require the

assistan ce of another

erson when performing

e checks.

volta

Polar Heart Rate

Simulator

Page 16

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

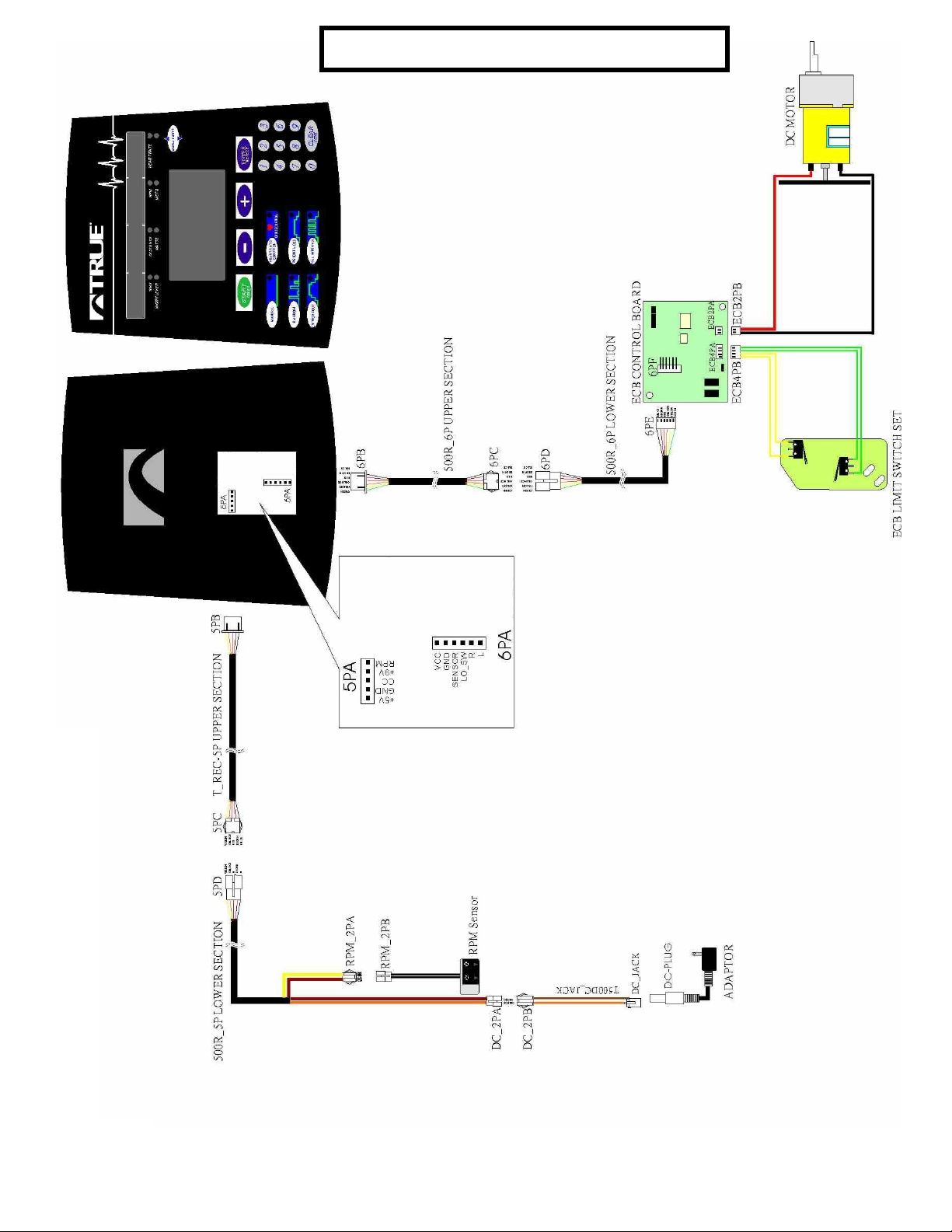

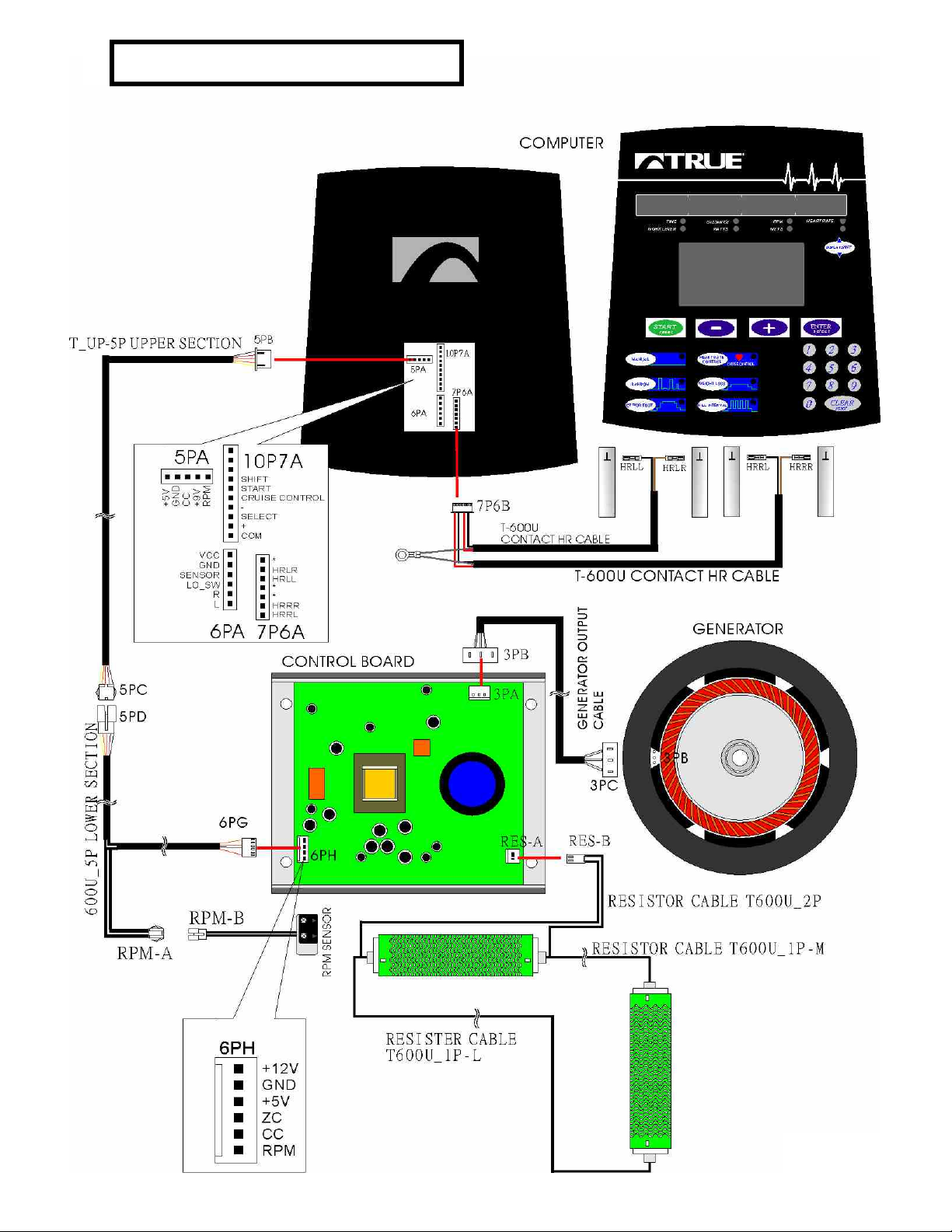

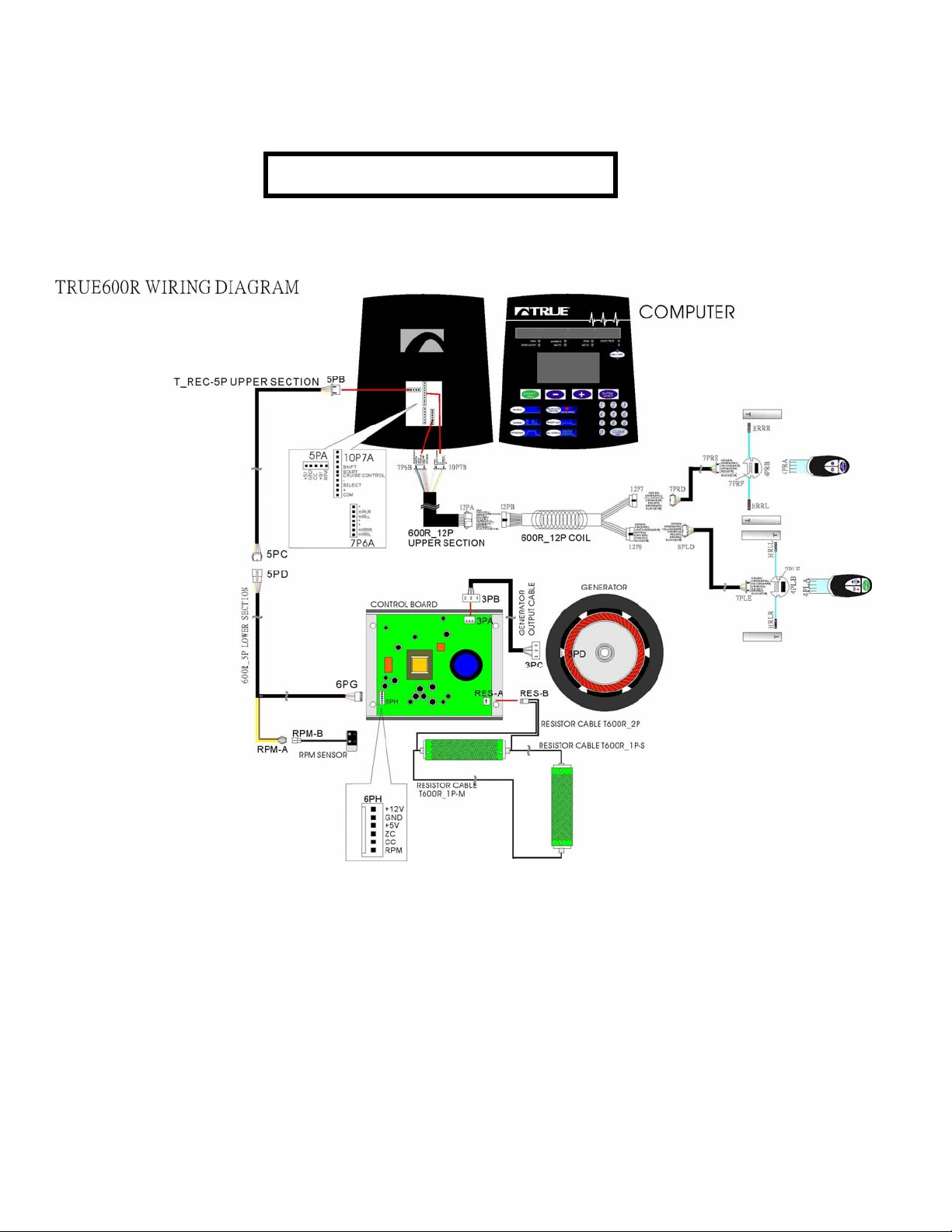

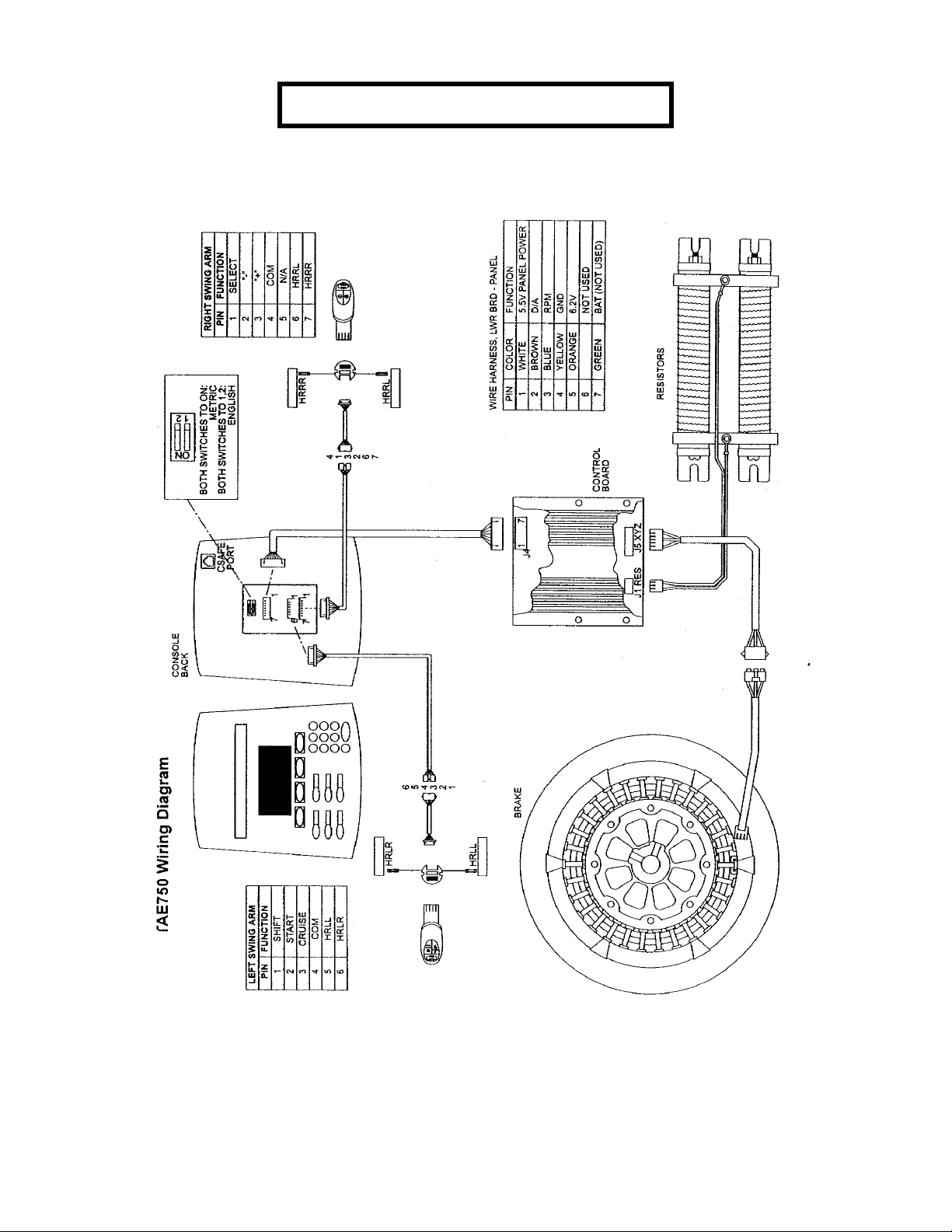

WIRING DIAGRAMS

TR / TU 500 Page 18

600 U Page 19

600 R Page 20

TR/TU 750 Page 21

Page 17

Page 18

TR/ TU 500 WIRING DIAGRAM

TU 600 WIRING DIAGRAM

Page 19

Page 20

TR 600 WIRING DIAGRAM

TR/ TU 750 WIRING DIAGRAM

Page 21

Page 22

True Upright Bike

500

True Recumbent

Bike 500

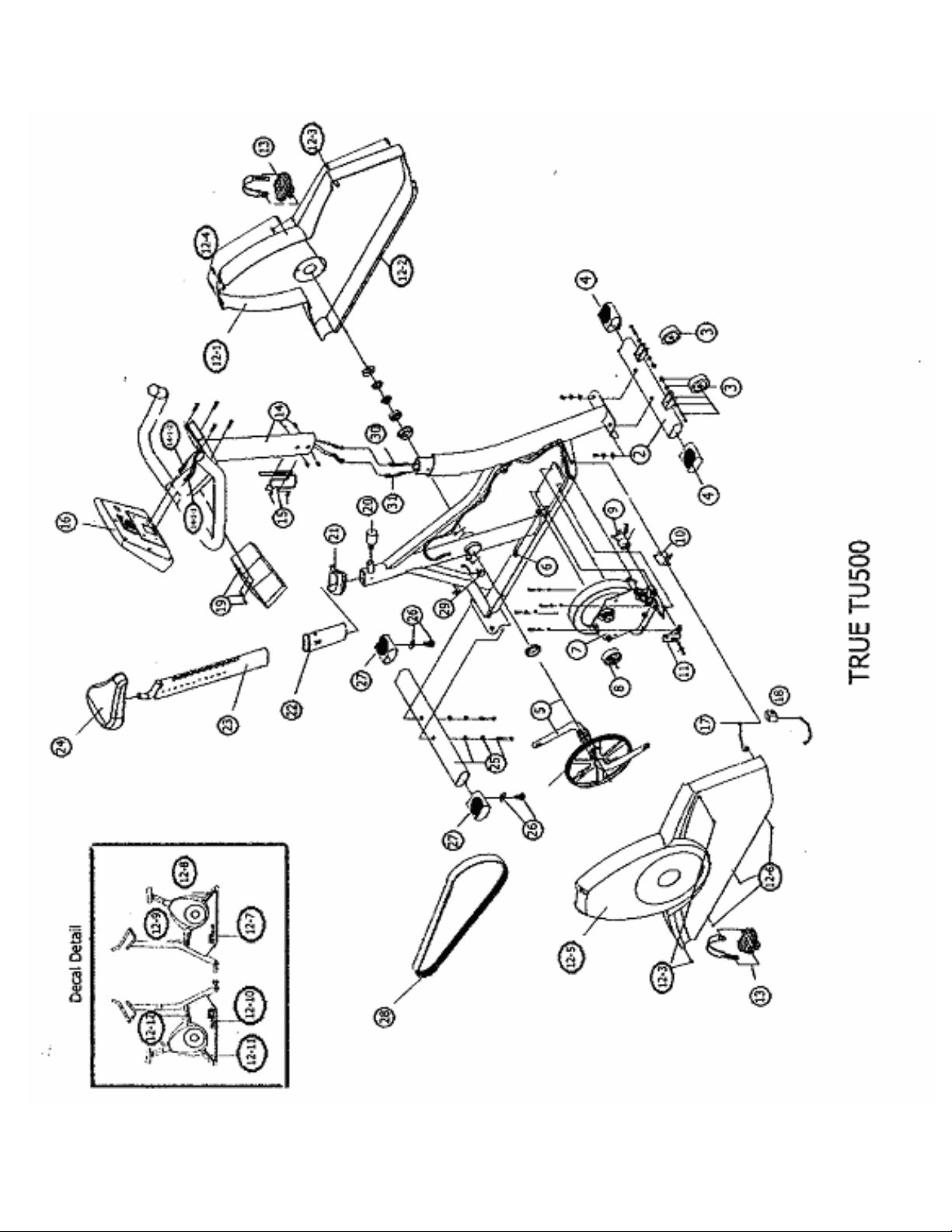

TU 500 Exploded Diagram Pg 22

TU 500 Parts List Pg 23

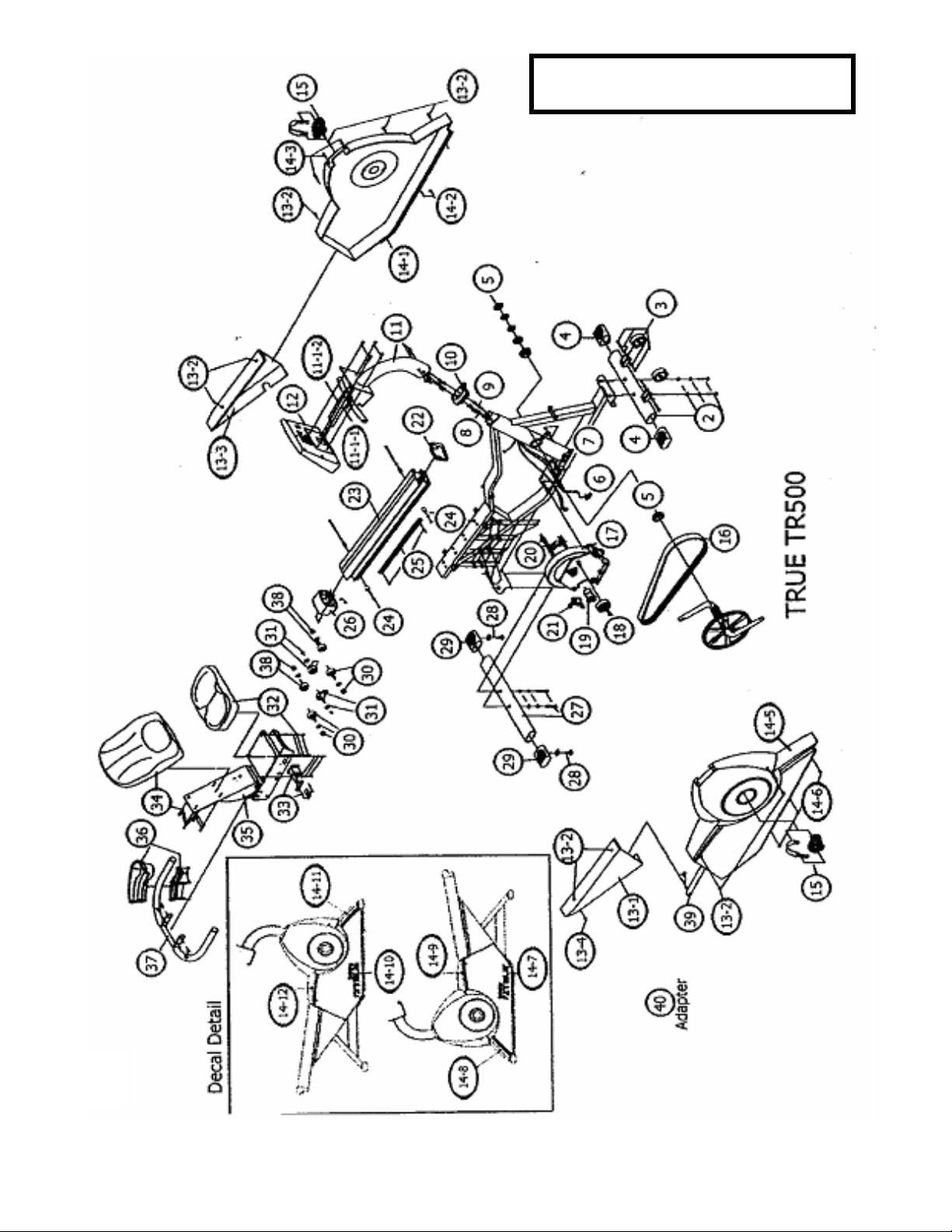

TR 500 Exploded Diagram Pg 25

TR 500 Parts List Pg 26

Page 23

Page 24

TU 500 EXERCISE BIKE

REF.

PART # DESCRIPTION QTY

#

2 7T010800 FRONT STABILIZER WITH BOLTS 1 SET

3 7T000200 TRANSPORTATION WHEEL HIT 1 SET

4 7T000300 FTONT STABILIZER END CAP 2 PCS

5 7T000400 CRANK PULLEY WITH CAPS AND BEARINGS 1 SET

6 7T000600 BOLT BELT TENSION 1 PC

7 7T010900 BRAKE ASSY 1 SET

8 7T001700 ALUMINUM IDLER ASSY 1 SET

9 7T001800 ECB DC MOTOR WITN SCREWS 1 SET

10 7T002000 ECB CONTROL BOARD WITH SCREWS 1 SET

11 7T001900 ECB LIMIT SWITCH WTH SCREWS 1 SET

^12-

7T011000 LEFT SHROUD WITH DECALS 1 SET

1

^12-

2 7T001302 SCREW 1 PC

^12-

3 7T001202 SCREW 6 PCS.

^12-

7T001303 SCREW 3 PCS.

4

^12-

7T011100 RIGHT SHROUD WITH DECAL 1 SET

5

^12-

7T001306 HEX NUT SIDE COVER 3 PCS.

6

^12-

7 7T011200 DECAL---WHITE----RIGHT 1 PC

^12-

8 7T001311 SHROUD DECAL B WHITE 1 PC

^12-

7T001312 SHROUD DECAL D WHITE 1 PC

9

^12-

7T011300 DECAL---WHITE----LEFT 1 PC

10

^12-

7T001308 SHROUD DECAL-A WHITE 1 PC

11

^12-

7T001309 SHROUD DECAL C WHITE 1 PC

12

13 7T001400 PEDALSET WITH STRAPS 1 SET

14 7T004000 HANDLE BAR 6 PIN WITH BOLTS 1 SET

141-1 7T004001 CABLE ASSY 6 PIN UPPER 1 PC.

14-

7T004002 CABEL ASSY 5 PIN UPPPER 1 PC.

1-2

15 7T004100 BOTTLE CAGE WITH SCREWS 1 SET

16 7T001100 COMPUTER WITH SCREWS 1 SET

17 7T003800 DC JACK 1 PC

18 7T003900 ADAPTER 9VDC 1.2A 1 PC

19 7T004200 CD PLAYER HOLDER WITH SCREWS 1 SET

20 7T004300 SEAT ADJUSTING KNOB 1 PC

21 7T000900 SHROUD TRIM CAP 1 PC

22 7T004400 SEAT POST SLEAVE 1 PC

23 7T004500 SEAT POST

24 7T004600 SADDDLE WITH CLAMP 1 PC

1 PC

Page 25

Page 26

25 7T002600 REAR STABILIZER WITH BOLTS 1 SET

26 7T002700 ADJUSTING STAND KIT 1 SET

27 7T002800 REAR STABILIZER END CAP 2 PCS

28 7T012700 POLY V BELT 1 PC

29 7T005800 RPM SENSOR WITH WIRE AND NUT 1 SET

30 7T004700 CABLE ASSY 5 PIN LOWER SPEED SENSE 1 PC

31 7T004800 CABLE ASSY 6 PIN LOWER SECTION 1 PC

7T013000 MODEL DECAL SILVER 1 SET

7T012901 DECAL A SILVER 1 PC

7T012902 DECAL B SILVER 1 PC

7T012903 DECAL C SILVER 1 PC

7T012904 DECAL D SILVER 1 PC

7TU50100 ASSY HDW. KIT 1 SET

7TU50200 COMPUTER SCREW KIT 1 SET

7TU60200 FRONT STABILIZER HDW. KIT 1 SET

7TU60500 HANDLE BAR HDW. KIT 1 SET

7TU60600 CD HOLDER HDW. KIT 1 SET

7TU60700 TOOL KIT 1 SET

7TU60300 REAR STABILIZER HDW KIT 1 SET

TR 500 Exercise Bike

Page 27

REF # PART# DESCRIPTION QTY.

02 7T000100 Front Stabilizer w/Bolts 1 SET

03 7T000200 Transportation Wheel Kit 1 SET

04 7T000300 Front Stabilizer End Cap 2 PCS

05 7T000400 Crank Pulley w/E Caps & Bearings 1 SET

06 7T005800 RPM Sensor w/Wire & Nut 1 SET

07 7T000600 Bolt - Belt Tension 1 PC

08 7T000700 Cable Assembly - 6 Pin Lower 1 PC

09 7T000800 Cable Assembly - 5 Pin Lower 1 PC

10 7T000900 Shroud Trim Cap 1 PC

11 7T001000 Console Mast Set 1 SET

11-1-1 7T001001 Cable Assy, 6 Pin Upper 1 PC

11-1-2 7T004700 Cable Assy, 5 Pin Upper 1 PC

12 7T001100 Computer Set 1 SET

13-1 7T001201 Rear Shroud - Right 1 PC

13-2 7T001202 Screw, Sidecover 10 PCS

13-3 7T001203 Rear Shroud - Left 1 PC

13-4 7T001204 Screw, Rear Cover 1 PC

14-1 7T001301 500R Shroud - Left Complete w/ Model Decal and Shroud Decals 1 SET

14-2 7T001302 Screw - Side Cover 1 PC

14-3 7T001303 Screw 3 PCS

TR 500

Page 28

14-5 7T001305 500R Shroud - Right Complete w/ Model Decal and Shroud Decals 1 PC

14-6 7T001306 Hex Nut - Side Cover 3 PCS

14-7 7T001307 Model Decal for 500R - Left (Wht) 1 PC

14-8 7T001308 Shroud Decal - A (Wht) 1 PC

14-9 7T001309 Shroud Decal - C (Wht) 1 PC

14-10 7T001310 Model Decal for 500R - Right (Wht) 1 PC

14-11 7T001311 Shroud Decal - B (Wht) 1 PC

14-12 7T001312 Shroud Decal - D (Wht) 1 PC

15 7T001400 Pedal Set w/Straps 1 SET

16 7T001500 Poly-v Belt 1 PC

17 7T010700 TR500 Brake Assy 1 SET

18 7T001700 Aluminum Idler Assembly 1 SET

19 7T001800 ECB DC Motor w/Screws 1 SET

20 7T001900 ECB Limit Switch w/Screws 1 SET

21 7T002000 ECB Control Board w/Screws 1 SET

22 7T002100 Aluminum Rail Trim Cap 1 PC

23 7T002200 Aluminum Rail w/Bolts 1 SET

24 7T002300 Stopper Kit 1 SET

25

7T002400 Fore and Aft Adjusting Rack w/Bolts 1 SET

Loading...

Loading...