True Fitness Service

Manual

455 Pediatric

Treadmill

True fitness technology, Inc. makes no representations or warranties regarding the

contents of this manual. We reserve the right to revise this document at any time or

to make changes to the product described within it without notice or obligation to

notify any person of such revisions or changes.

© 2004, True Fitness, Inc. All rights reserved. Printed in the United States of

America.

865 Hoff Road. O’Fallon, MO 63366. 1-800-426-6570. Fax 636-272-3026.

www.truefitness.com

Revision 9/2004

Treadmill Preventative Maintenance

Checklist

Run calibration or run a manual program and

watch and listen for anything out of the ordinary.

Perform a push off test (page T-7) to check for

proper lubrication. If excessive friction is found

and lubrication doesn’t correct the problem

perform the amp draw test (page T1-2)

Inspect the belt surfaces, topside should still have

texture for grip, bottom should be porous fabric-

not glazed, smooth or hard.

Inspect deck surface, should be free of scratches,

abrasions or blistering.

Listen for excessive bearing noise, from a

standing position, in the front and rear roller and

motor.

Check for front roller/belt slippage and belt

tension adjustment. Look for slippage on drive

pulley.

Inspect/ adjust tracking of belt.

Vacuum out motor area, being careful not to

damage PWM.

Inspect drive belt for wear and cracking.

Wipe down machine- leave it in better condition

than you found it.

True Fitness

Treadmill Service

Manual

START

Symptom guide

Calibration Procedures

Diagnostic Procedures

Test Procedures

Wiring Diagrams

Part Manuals

Page 1

Page 2

SYMPTOM GUIDE

Error Code Definitions . . . . . . . . . . . . . . . . . . . . . . . . Page 3, 4

No Belt Movement . . . . . . . . . . . . . . . . . . . . . . . . Page 5, 6

Tread Belt Stops During Workout . . . . . . . . . . . . . . . . Page 7

Heart Rate Not Working / Erratic Readings . . . . . . . . Page 8

Elevation Not Functional . . . . . . . . . . . . . . . . . . . . .. . Page 9

Speed Fluctuation: E2 Cal . . . . . . . . . . . . . . . . . . . . . . Page 10

Speed Fluctuation: S4, E5, E2

E3: EPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

No Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Circuit Breaker Trips at Start Up . . . . . . . . . . . . . .. . Page 13

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . Page 14

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. Page 15

Page 11

Symptom Probable Cause Corrective Action Recommended Tools

ERROR

MESSAGES:

S1 L LUBE

S2 C CLEAN

S3 M MOTOR

E5 S SPEED

E1 S STALL

E1 I INCLINE

E1 R RANGE

SENSOR

Indicates that the

accumulated distance

is such that the deck

needs to be lubed

Indicates that the

accumulated distance

is such that the

machine needs to be

cleaned.

Indicates that the

accumulated time on

the treadmill is such

that the motor brushes

need to be

changed/checked.

Cannot read speed

sensor

Incline reading not

changing when

commanded

Incline reading has

changed without the

incline being

commanded.

Maximum or

minimum elevation

out of calibrated

ranges

• Lube deck with True Fitness liquid

silicone lubricant. Inspect wax bar

assembly on commercial models, if

worn to less that ¼ inch in thicknessreplace wax bar.

• Remove motor cover and vacuum dust

from area. Wipe down the exposed area

of the deck beside the straddle covers

with a clean, dry cloth.

• Check/Replace motor brushes as

needed.

• Reset timer.

• Perform Speed Sensor Test page 21

• See Elevation Not Functional page 9.

• See Elevation Not Functional page 9.

• See Elevation Not Functional page 9.

Liquid silicone single

use pack

Liquid Silicone

Applicator.

Vacuum

Shop towel

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 3

Symptom Probable Cause Corrective Action Recommended Tools

E2 O

ERROR

MESSAGES:

(cont’d)

OVERSPEED

E2 C

CALIBRATE

E3 E EEPROM

E2 R

RECALIBRATE

Belt speed ramping

too fast.

Micro-controller

cannot adjust belt

speed to target.

Software error during

treadmill startup

diagnostics.

Treadmill has lost

calibration settings.

Perform Amp Draw Test – Page

Perform Belt / Deck Wear Test – Page 21.

Calibrate Treadmill – Page 14.

See appropriate Symptom Guide – pages 10-11.

Restart Treadmill, if error persists- replace

control panel.

Recalibrate Treadmill – Page 14.

(If unit loses programs- replace control panel)

17.

Multi-meter

Phillips head

screwdriver

Page 4

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

MOVEMENT

NO BELT

Treadmill in need of

calibration.

Missing command to

PWM.

Missing/incorrect

voltage to motor.

Damaged motor.

• Run calibration. (page 14)

--------

• Is PWM light blinking/ illuminated

when fast button is pushed?

NO- Check continuity on wire harness, if

harness has continuity breaks replace the

harness. If harness has continuity- replace

the upper panel. Refer to wiring harness

diagram for your model.

YES- move on to next step, wire harness and

control panel are OK.

--------

• With treadmill in calibration mode

(page 14)

• Set speed at 4 MPH

• Check VDC across MTR 1 and MTR 2

with the motor leads connected to the

motor the voltage should measure 10

VDC for every 1 MPH.

• If voltage is missing or low- Replace

PWM.

• If voltage is greater than 20 VDC/MPH

motor may have open windings.

--------

• With PWM LED Blinking/ Illuminated-

move the tread belt with your foot to see

if motor begins to move on its own.

• If motor begins to move, inspect the

condition of the brushes and the

commutator.

• If brushes are bad- replace brushes

• If motor doesn’t turn or has a damaged

com segment- replace motor.

Continue on next page…

Multi-meter

PWM / Motor test

cables

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 16

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 5

Symptom Probable Cause Corrective Action Recommended Tools

NO BELT

MOVEMENT

(cont’d)

Motor turns but belt

does not.

• Check belt tension.

• Set belt tension to 1/8-inch deflection or

correct tension can be verified by

twisting the belt almost to a 90-degree

position.

Note:

All trouble

shooting should

be performed in

calibration

mode.

Pa ge 14

Belt cannot be

moved manually-

foreign object under

belt.

--------

• Remove foreign object.

Perform the Amp Draw Test (page 17) to check

for excessive amp draw damage

Page 6

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

TREADBELT

STOPS

DURING

WORKOUT

Error Code

displays:

Go to page 3 &

Page 4.

Loose safety key

connection

Belt movement issue

Worn Deck / Belt

Occurs when making

changes to speed or

elevation

Overloaded house

circuit

Continuity,

connection to motor

Tread belt not

centered or

obstructed

• Check safety key to ensure that it is

seating properly.

• Check connection sensitivity.

--------

• If treadmill will not reset with cycling

the power go to NO BELT

MOVEMENT (pages 5 & 6)

--------

• Perform Belt / Deck Wear Test

(page 21).

• Perform Amp Draw Test (page 17).

• Apply silicone.

• Replace Deck and Belt.

--------

• May be related to electro static

discharge. Contact Technical support

for assistance.

--------

• Verify the treadmill is on a dedicated

circuit with at least a 15 amp breaker

• Have customer supply a dedicated

circuit

--------

• Reconnect or replace motor wires or

connectors

--------

• Tension tread belt (page 19)

• Center tread belt

• Remove obstruction

Liquid silicone

single use pack

Liquid silicone

Applicator

Multi-meter

Socket set

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 7

•

Symptom Probable Cause Corrective Action Recommended Tools

NOT

HEART RATE

WORKING /

ERRATIC

READINGS

Incorrect power

source

Improper treadmill

grounding

Improper heart rate

receiver mount

Defective Chest

Strap

Defective receiver

Radio Frequency

Interference

Verify that the treadmill is connected to

a dedicated line, 15-amp circuit, and not

on an extension cord.

• Move to proper outlet.

• Test 110 VAC outlet for proper ground

--------

• Proper grounding is vitally important.

• Ensure that the pedestal wire harness

ground lead is secure

--------

• Ensure that the HR receiver is not

touching metal and is mounted with the

wires in a vertical position with the blue

receiver facing the runner

--------

• Does the receiver pick up a signal from

the HR simulator?

• If yes, replace chest strap

--------

• Does the heart rate LED on the control

panel blink? If not then replace the

receiver.

--------

• Locate RF sources and use process of

elimination. Common sources of RF

interference are: Invisible fences for

pets; wireless networks; cordless

phones, Cell phones, radios, home

security sensors, etc.

Multi-meter

Double sided tape

Heart rate simulator

Note:

All trouble

shooting should

be performed in

calibration

mode.

Pa ge 14

Page 8

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

•

Symptom Probable Cause Corrective Action Recommended Tools

ELEVATION

FUNCTIONAL

( E1 ERROR)

NOT

Improper grounding

/ Calibration

(May

cause unit to

drift up & down

without command)

Unit is stuck at full

incline

Defective Start

Capacitor

Defective PWM

Test 110VAC outlet for proper

grounding

• If unit has not been calibrated –

calibrate

• Ensure that incline cables are secure on

PWM

--------

• Verify the lower limit switch is properly

connected to the PWM

• Remove the LLS wire from the PWM

and short the two posts of the connector

together with an alligator clip. Cycle the

power. If the treadmill lowers itself

then replace the lower limit switch.

• Perform Incline potentiometer

calibration procedure (page 20)

• If incline nut is stripped- replace incline

nut

--------

• Do Up/Down command LED’s light?

• If No- skip to defective PWM section.

• If yes- does motor hum with no

movement?

• If yes- check the leads to the capacitor

for breaks, if no breaks- replace

capacitor.

• If No- replace PWM.

--------

• If no Up/Down LED’s light check

continuity on data cables.

• If cables are good- replace Upper Panel.

• If cables bad- Replace data cables.

Multi-meter

Alligator clip

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 9

Symptom Probable Cause Corrective Action Recommended Tools

SPEED

FLUCTUATION

E2: CAL

Speed Fluctuation

(Due to high friction)

Speed Fluctuation

(Due to Voltage

fluctuation)

Bad Data Feedback

Incorrect Speed

Sensor Gap

• Perform Push Off Test (page 21)

• Perform Amp Draw Test (page 17)

--------

• Check Line voltage for fluctuations.

• Have customer take corrective action.

--------

• Verify tach feedback accuracy through

out the speed range.

• If inaccurate perform speed sensor test

(page 18)

--------

• Verify correct Speed sensor Gap.

• Gap should be equal to the thickness of

(3) credit cards pressed together

(approximately 1/8 to ¼ inch)

------

Multi-meter

Socket Set

Silicone Lubrication

Packet

Silicone Lubrication

Applicator

Note: All

trouble shooting

shou ld be

performed in

C alibration

M ode :

See Page 14

Page 10

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

SPEED

FLUCTUATION

S4: Sensor

E5: Speed Sensor

E3: EPROM Error

E2: Overspeed

No Belt Movement

No/Intermittent

Tach Feedback

Overspeed Error

E3: EPROM Error

Software error

during treadmill

startup

• Go to page 5, 6.

--------

• Enter Calibration mode (page 14)

• Verify speed feedback in speed display

through out the speed range. [Speed

display should never show 0 mph when

belt is moving]

• If no tach feedback is available perform

speed sensor test (page 18).

• Check continuity of tach feedback

portion of the data cable (To identify

tach feed back lines see wiring diagram

section for specific model).

--------

• Check/Adjust tread belt tension (page

20)

• Perform speed sensor test (page 18) If

speed sensor fails adjust gap, if still

fails-replace speed sensor.

• Perform belt / deck wear test (page 21)

If badly worn, replace belt and deck.

• Replace PWM

--------

• Restart unit- if error persists, replace

control panel.

Multi-meter

Socket Set

Silicone Lubrication

Packet

Silicone Lubrication

Applicator

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Page 11

•

Symptom Probable Cause Corrective Action Recommended Tools

NO DISPLAY

No power at the 110

VAC outlet.

No power to the

treadmill.

No power to the

control panel.

Check home circuit breaker. Reset as

necessary.

• Test for 110 VAC at outlet.

• Identify if outlet is a GFI.

Note: Some brands of GFI

outlets are too sensitive for

treadmill use. Call the help

line if encountering GFI

issues.

--------

• Check for AC light on PWM.

(See diagram pages 23)

• Check for 110 VAC at power cord.

Replace if no power.

• If Yes- Check for 110 VAC at tread

power switch. Replace if no power.

• If Yes-Check for 110 VAC at tread

circuit breaker. Replace/ reset if

necessary.

• If Yes- Check for 110 VAC at PWM

across AC1 & AC2.

• If Yes- Replace PWM.

--------

• Check status LED +11 VDC on PWM

(See diagram pages 23). If not remove

fuses and check continuity as replace as

needed.

• If Yes- Check wire harness connections

at PWM and Control Panel. Reconnect

as needed.

• If Yes- Check voltage on harness at

panel. Refer to wiring diagram for your

machine type in wiring diagram section.

If voltage is present– replace panel and

recalibrate (page 14). If voltage is

present check voltage at PWM. If

voltage is present at PWM replace

pedestal wire harness.

replace PWM and recalibrate (page 14).

If 0 VDC

not

Allen Key set.

Phillips head

screwdriver.

Multi-meter.

Note:

All trouble

shooting should

be performed in

calibration

mode.

Pa ge 14

Page 12

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Symptom Probable Cause Corrective Action Recommended Tools

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

CIRCUIT

BREAKER

TRIPS

Possible short in

treadmill wiring.

Motor issues.

Incline motor

drawing treadmill

down

Bad PWM

Too much tension

on belt or

obstruction

Weakened circuit

breaker or High

belt/deck friction

under

belt.

• Power off the treadmill and inspect all

wiring for shorts or burned areas.

• Secure all connectors.

--------

• Disconnect motor leads from the PWM.

Power on treadmill, press start. If the

breaker does not trip check the motor

brushes and perform the motor test

procedure (page 19).

• Reconnect motor to the PWM, if the

breaker trips- replace the motor.

--------

• Unplug incline motor.

• Power on treadmill, if breaker does not

trip- replace incline motor.

--------

• Unplug PWM, power on machine. If

breaker doesn’t

• Check for correct tension adjustment

(page 20)

• Check for obstruction- remove

obstruction.

• Perform AC Amp Draw Test (page 17)

at circuit breaker.

• If draw is less than 15 amps

continuously - replace breaker.

• Perform Amp Draw test (page 17) If

Amp draw is higher than recommended

try push test (page 21) procedure.

trip- replace PWM.

--------

--------

Allen Key set

Needle nose pliers

Socket set

Multi-meter

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 14

Page 13

455 Calibration

Enter Calibration Mode by holding the Up and Down keys while inserting the safety key

In message center window displayed: Press Start to Calibrate

NOTE: In Calibration mode, it is possible to check if the speed sensor is reading all the front roller

magnets: the Met light will light when a magnet is in front of the sensor. Speed must be less than 1 mph.

Press Start/Reset to begin calibration

Treadmill will elevate and speed up/slow down. Wait for belt to stop.

Message center window will display: Successful, or will indicate error area.

Remove and re-insert safety key. Check operation of treadmill.

Page 14

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

Calibration Procedures

To enter diagnostic mode, press and hold the FAST and SLOW buttons while pushing in the safety key.

The control panel will show “Diagnostics”.

Press the UP button: Total Hours (in whole hours)

Press the UP button: Distance (in miles, two digits past decimal point)

Press the UP button: Average Speed (in mph)

Error List (This is an error log, but just a list of errors possible on the unit.)

S1: Lube

S2: Clean

S3: Motor

S4: Sensor

E1: Minimum

E2: Overspeed

E2: Cal

E3: EPROM

Remove Safety Key to exit Diagnostics

Page 15

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

DIAGNOSTICS

TEST PROCEDURES

Grounded Outlet Test Page 17

Amp Draw Test Page 17

Speed Sensor Test Page 18

Voltage to Drive Motor Test Page 18

Drive Motor Test Page 19

Drive Belt Tension Test Page 19

Tread belt Tension Test Page 19

Incline Potentiometer Calibration Test Page 20

Voltage to Incline Motor Test Page 20

Belt / Deck Wear Test (Push Off Test) Page 21

Page 16

GROUNDED OUTLET TEST

This test is very important for optimal HRC and incline operation.

Set voltmeter for Volts AC

Place 1 lead in the right side of the outlet (hot)

AMP DRAW TEST

This test is a good indicator of the wear condition of the belt and deck, and the need for lubrication.

The treadmill circuit breaker will trip at 15 amps, so be sure the voltmeter you are using is rated for at least

15 amps when you are load testing the treadmill. This test can be performed either on one of the AC power

cord leads or on one of the DC motor leads from the PWM to the motor. Testing the amp draw at certain

speeds without load and with load will signal whether higher than normal amp draw is a result of PWM

failure or increased friction from belt and deck wear.

AC AMP DRAW PROCEDURE

DC AMP DRAW PROCEDURE

Page 17

Place 1 lead in the ground plug

A properly grounded outlet will read 110 VAC

This procedure requires an AC clamp-on ammeter. Place the clamp around either of the power cord

leads, black or white. Load test requires a person to walk on the tread belt for 5-10 minutes.

2.5 mph w/out load 2.0-2.5 AMPS AC

2.5 mph with load 2.75-3.75 AMPS AC

4.0 mph w/out load 3.5-4.0 AMPS AC

4.0 mph with load 5.0-7.0 AMPS AC

This procedure can be performed with an ordinary voltmeter. (Note: Be sure the voltmeter is rated

to handle 15 DC amps.) Disconnect the red motor lead from MTR1 on the PWM. Connect the

voltmeter to MTR 1 on the PWM and the other voltmeter lead to the red motor lead so that the

voltmeter completes the connection of the PWM to the motor.

2.5 mph w/out load 4.5-5.0 AMPS DC

2.5 mph with load 7.0-8.0 AMPS DC

4.0 mph w/out load 5.0-5.5 AMPS DC

4.0 mph with load 8.5-9.0 AMPS DC

Higher than normal amp draws without load may signal that belt tension is too tight or there is a

problem in the Drive Motor or PWM. Perform the Drive Motor Test and visually check the motor

brushes before replacing the PWM. Higher than normal amp draws with load after normal readings

without load signal belt and deck friction which may require lubrication or replacement.

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

TEST PROCEDURES

SPEED SENSOR TEST

This test is used to verify sensor operation in conditions of speed fluctuation, E2: Cal error, S4:

Sensor error, E2: Overspeed error or Unsuccessful Calibration.

455 Treadmill

Set voltmeter to volts DC. Treadmill power on and speed at 0 mph

Attach voltmeter leads across outside 2 contacts at J1 on PWM

With magnet in front of sensor, 0 VDC

With no magnet in front of sensor, 5 VDC

Check the sensor on every magnet, adjust sensor until voltage shows

In calibration mode before pressing Start, the tread belt can be moved manually and the Met light

will blink when a magnet is in front of the sensor.

VOLTAGE TO DRIVE MOTOR TEST

This test is used to diagnose conditions of NO Belt Movement, or Speed Fluctuations

Set voltmeter to volts DC and adjust speed on Control Panel to 4 mph

Attach red voltmeter lead to MTR1 on PWM with motor wires attached

Attach black voltmeter lead to MTR2 on PWM with motor wires attached

NOTE: The reason that we do not narrow down PWM output voltage is that the PWM output is a pulse

signal. The sampling rate of the voltmeter used will determine what output voltage the voltmeter is able to

read.

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

0 VDC signals no PWM output

166 VDC signals open circuit in motor or motor connection

Operating voltage will lay between 0 VDC and 166 VDC

TEST PROCEDURES

Page 18

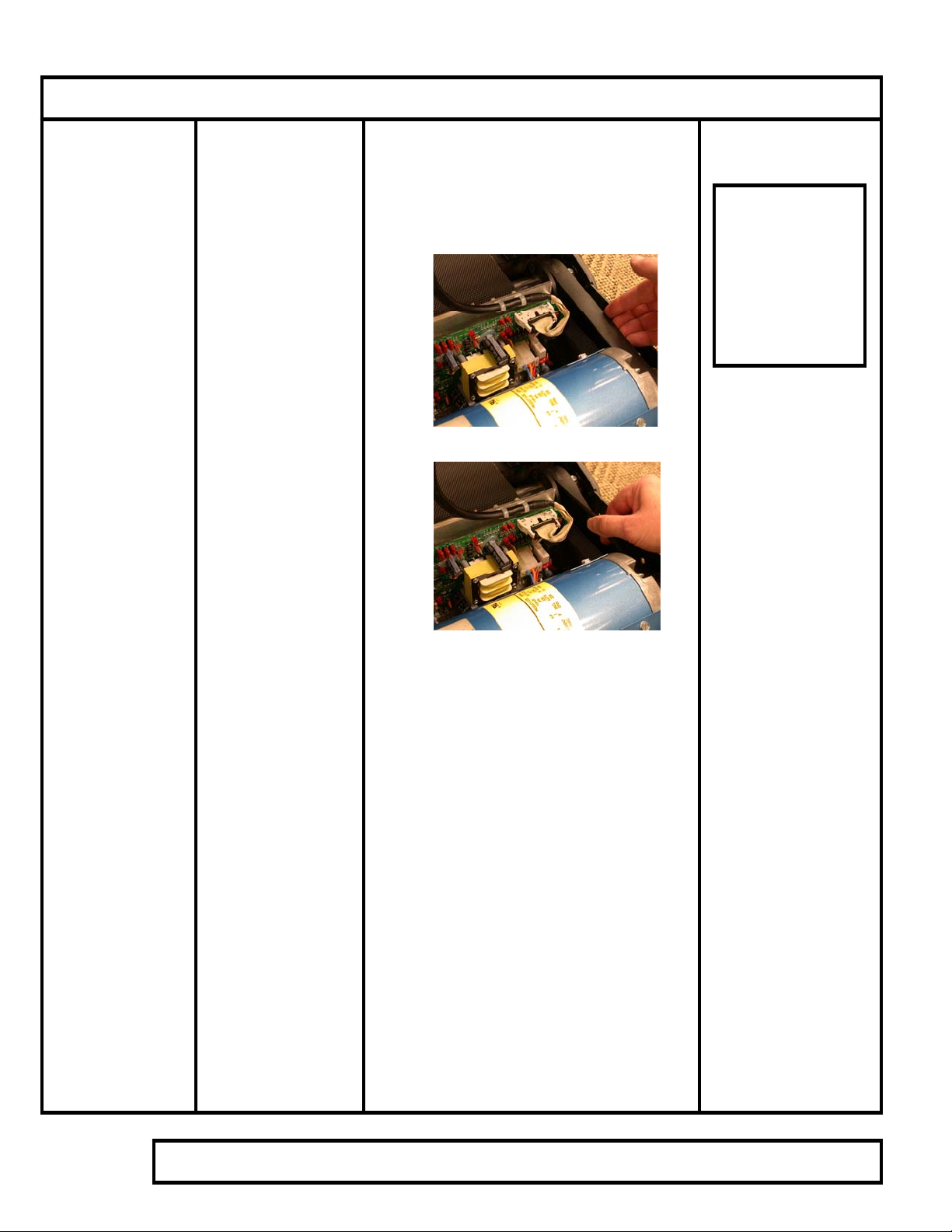

DRIVE MOTOR TEST

This test is used in conditions of No Belt Movement.

Unplug treadmill and set voltmeter to volts DC

Disconnect motor leads from PWM

DRIVE BELT TENSION TEST

This test is used in front roller replacement and in conditions of belt slipping.

TREADBELT TENSION TEST

This test will address belt slipping and is used in any roller replacement or deck replacement. Ensure that

the drive belt is properly tensioned before adjusting tread belt tension. Belt and deck wear and/or lack of

lubrication can cause the tread belt to show symptoms similar to loose tread belt tension- check these

conditions before adjusting tread belt tension.

Turn treadmill on and adjust speed to 2 mph

If hesitation or slip is detected, tighten tread belt tension bolts ¼ turn

Tread belt tension is too tight if the belt feels stiff to touch with no give or the belt groans against the rollers.

You should be able to insert your hand between the belt and deck palm up almost to your thumb when the

belt is at proper tension.

Page 19

Place 1 voltmeter lead in each motor wire

Gently spin the motor flywheel and check for voltage DC

2-5 VDC means normal motor operation

0 VDC means motor malfunction

Place two fingers on top of the drive belt halfway between the front roller pulley and the drive motor

pulley.

With moderate pressure push down on belt

If belt deflects down more than 1/8 “, tighten motor mounts

If belt deflects down less than 1/8 “, loosen motor mounts.

It is also possible to twist the belt; you should be able to twist the belt almost to a vertical position

Walk heavily on the belt pulling slightly against belt movement

Repeat until no hesitation or slip is encountered. Check at higher speeds

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

TEST PROCEDURES

INCLINE POTENTIOMETER CALIBRATION TEST

This test can correct E1: Minimum conditions and aid in diagnosis of incline problems with finding zero or

target incline.

Set voltmeter to Ohms (Ω) with treadmill unplugged from wall

If incline potentiometer needs adjustment, remove swivel pins and use Up and Down keys to make

adjustment. (See diagram on T-6)

VOLTAGE TO INCLINE MOTOR TEST

This test is utilized in conditions of No Incline Movement, Incline Fluctuation, or E1: Minimum.

Set voltmeter to AC volts. To access incline plug, PWM screws may need to be removed.

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

455:

Place 1 voltmeter lead on pin 3 (Blue) and 1 lead on pin 2 (Orange)

Check for 800 Ohms

455: In calibration mode before pressing Start, the Distance window displays the incline number.

With the treadmill at zero, the number should be between 160 and 180. 0 often indicates a wire

harness misconnection or failure of signal to panel.

As the unit inclines during calibration, watch the numbers in the Distance window, if they do not

increase by at least 60 from the zero value, an E1: Minimum error will result. Then the zero value

may need to be reset to a lower value.

Place voltmeter leads across White and Black while pushing UP button

10 VAC indicates normal PWM output, 0 VAC signals no output

Place voltmeter leads across Red and White while pushing Down button

110 VAC indicates normal PWM output, 0 VAC signals no output

TEST PROCEDURES

Page 20

Belt / Deck Wear Test

1.

2.

Push Off Test

Place the machine in Calibration mode, elevate to the highest elevation- speed should be set to 0. Stand on

the tread belt positioning yourself close to the console; push off with moderate force. The elevation

combined with your weight and the force of the push should cause the belt to carry you all the way to the

end of the machine*. If the test does not carry you to the end of the machine lubricate the belt using True

Fitness liquid silicone. After lubricating the belt/deck perform the push off test again. If it does not pass the

test after lubricating replace the belt and deck

* Note: Residential treadmills may only carry about ¾ of the distance of the deck due to higher tension on

the belt.

This is a simple physical test to gauge the general level of friction present between the deck and belt.

While the treadmill is not running, inspect the condition of the underside of the tread belt. The fabric

should be soft and porous. If the belt appears glazed- replace the belt.

While the treadmill is not running, slide your hand under the belt and feel the surface of the deck.

The deck should feel smooth with no abrasions or scratches.

If any abrasions or scratches are found- replace the deck.

TEST PROCEDURES

Page 21

Support Services 800-883-8783 Mon-Fri 8:30am-5:00pm Central Time Zone Fax: 636-272-7148

455

Wiring Diagram

Page 22

Page 22

455 Parts List

WEIGHT

CONTROL PANEL

455

70150000 SAFETY SWITCH ASSY.

70177400 REMOVABLE SAFETY KEY

PWM

ss90

SPEED SENSOR

(SS90 STYLE)

DATA CABLE

70337800 450 HRC DATA CABLE

DRV MTR

44lbs.

DRV BELT

70006300 210J10 POLY-V DRIVE BELT

ELEVATION MTR

10lbs. 70113200 INCLINE MOTOR

(ELEVATIONHARDWARE)

70118900 TORQUE ARM SWIVEL PIN

70183200 START CAPACITOR FOR INCLINE MOTOR

70013500 SCREW FOR START CAPACITOR

LLS

70121000 LOWER LIMIT SWITCH

70125700 LLS SCREW 10X 1/4

70120500 LLS TO PWM WIRE

ELEVATION RACK

15lbs. 70281001 ELEVATION RISER SUB ASSY.

WHEEL

POWER CORD

70253100 9 FT. POWER CORD

3lbs. 70132500 MOTOR CONTROLLER SS90

PART # DESCRIPTION

70242103 Control Panel Assembly

70013500 PWM SCREW 10-32 X 3/8

70243200 CIRCUIT BOARD SPEED SENSOR

70243300 SP. SENSOR SCREW 4-40 X 1/4

70325900

70115500 3/8 X 1 1/2 CLEVIS PIN

70116700 1/16 DIA. X 1 5/16 COTTER PIN

70176701 Molded wheels

70008200 STRAIN RELIEF BUSHING

3HP DRIVE MOTOR 10 MPH 8 mph

455 treadmil parts list

Page 23

ON / OFF SWITCH

70251100 ROCKER ON/OFF SWITCH

CIRCUIT BREAKER

70017200 15 AMP CIRCUIT BREAKER SWITCH

TREADBELT

9lbs. 70159300 17 3/4" X 107 3/4" 2 PLY TREADBELT

DECK

40lbs. 70157700 FLEX DECK

70020200 DECK SCREW 10/32 X 1 1/4

FRONT ROLLER

455 front roller

REAR ROLLER

13lbs.

70158900 ROLLER BOLT

70159000 5/16 INTERNAL TOOTH LOCK WASHER

STRADDLE COVERS

70162101 LT & RT STRADDLE COVERS

70030900 3/8 X 1/16 X 108 FT. DBL. STICK TAPE

70243400 BLUE TAPE 1/2 X 150 FT. ROLL

PEDESTAL

455 pedestal

70155900 PEDESTAL SCREWS

FRAME

450/455 70255903 FRAME WELDMENT ADJ. FRONT ROLLER

70155200 BUMPER FEET

70020200 BUMPER FEET SCREW 10/32X1 1/4PPH

LUBRICATION

70348900 LUBE STICK

70349000 SILICONE PACKET (1 APPLICATION)

Pediatric Handrails

9lbs.

70359200

70359000

70233800 ROUND PEDESTAL WELDMENT

70226501 455 Pediatric Handrails

450/455 ADJ. ROLLER

REAR ROLLER

Page 24

Loading...

Loading...