Revision Q • Oct 6, 2020

FOREWORD

This manual provides information intended for use by persons who, in accordance with current

regulatory requirements, are qualified to install this equipment. If further information is required, please

contact:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Customer Service Dept.

9400 E. 34th St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

www.truebluepowerusa.com

www.mcico.com

We welcome your comments concerning this manual. Although every effort has been made to keep it

free of errors, some may occur. When reporting a specific problem, please describe it briefly and

include the manual part number, the paragraph/figure/table number and the page number. Send your

comments to:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Technical Publications

9400 E. 34

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

© Copyright 2015

Mid-Continent Instrument Co., Inc.

th

St. N.

Download the current

version of this

installation manual

using your smartphone

or tablet.

1 Manual Number 9016798 • Revision Q, October 6, 2020

TABLE OF CONTENTS

SECTION 1 GENERAL DESCRIPTION 4

1.1 PURPOSE 4

1.2 PHYSICAL

1.3 FUNCTIONAL

1.4 TECHNICAL

SECTION 2 PRE-INSTALLATION CONSIDERATIONS 6

2.1 COOLING 6

2.2 EQUIPMENT

2.3 ROUTING

2.4 LIMITATIONS 7

2.5 MODIFICATIONS 7

DESCRIPTION 4

DESCRIPTION 4

SPECIFICATIONS 5

LOCATION 6

OF CABLES 6

SECTION 3 INSTALLATION 11

3.1 GENERAL 11

3.2 PRE-INSTALLATION

INSPECTION 11

3.3 PARTS 11

3.4 INSTALLATION 12

SECTION 4 OPERATION 21

4.1 DESCRIPTION 21

4.2 THEORY

4.3 INSTALLED

OF OPERATION 21

OPERATION 24

4.4 MAINTENANCE 25

4.5 PERFORMANCE 27

SECTION 5 CONFORMANCE 30

5.1 TEST AND VERIFICATION INTERVALS 30

5.2 COMPONENT

5.3 STORAGE

MAINTENANCE MANUAL 30

INFORMATION 30

5.4 DISPOSAL 31

5.5 ENVIORNMENTAL

QUALIFICAION STATEMENT 32

2 Manual Number 9016798 • Revision Q, October 6, 2020

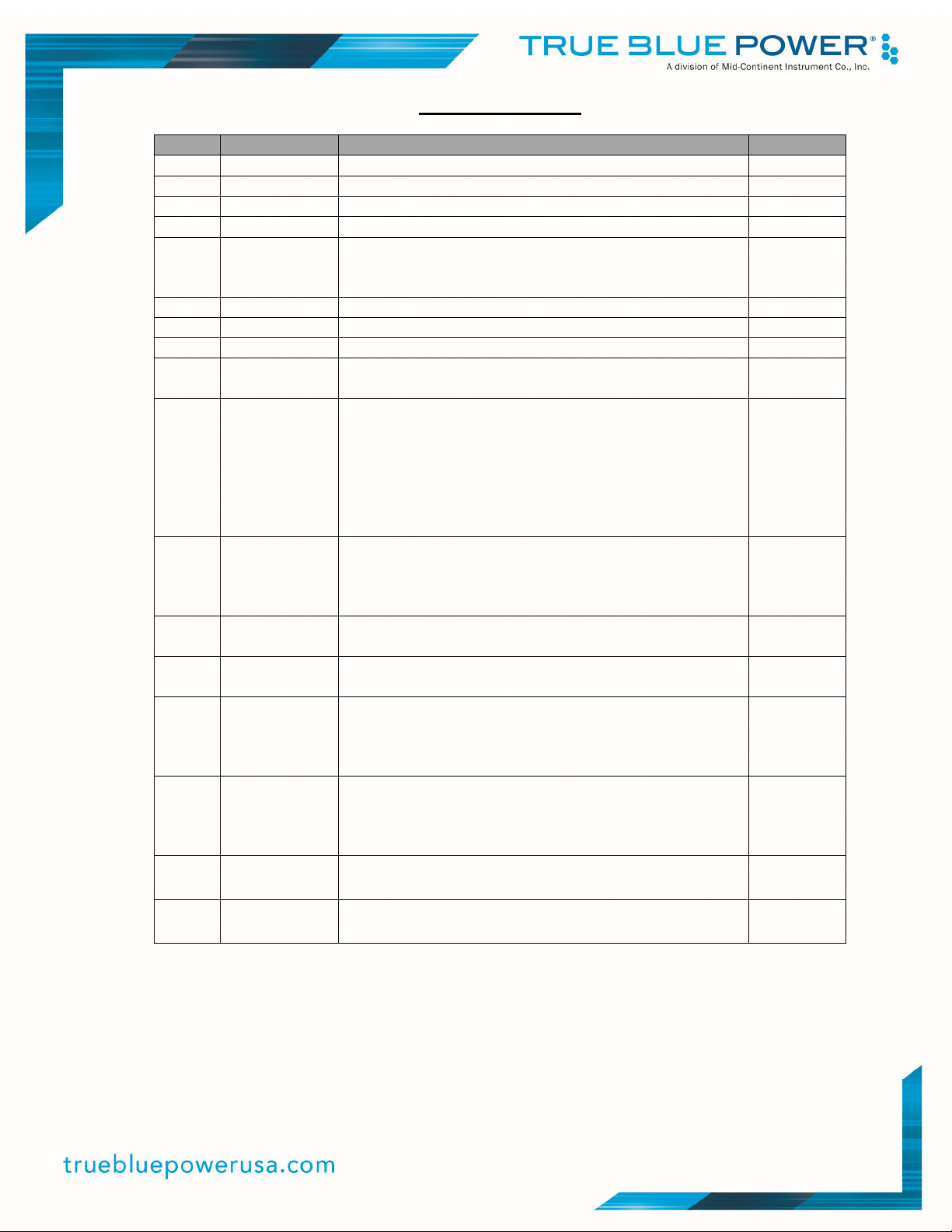

REVISION HISTORY

Rev Date Detail Approved

1 04/30/2009 Preliminary release. BAW

2 12/02/2009 Updated information. BAW

A 03/11/2010 Production release. BAW

B 04/15/2010 Revised Figure 3.3 Installation Diagram. BAW

Added MCI P/N 54-2007-1 to diode options in

C 05/18/2010

Section 3.3.2. Add Section 4.3.5 and related

information regarding MD835-2 version.

D 10/12/2010 Update unit picture with True Blue Power label. MKN

E 01/13/2011 Updated to include optional annunciator switch. JDS

F 04/14/2011 Added 9017201 5V Module as an optional part. BAW

G 07/27/2011

Added additional installation instructions for

9017201 5V Module.

Update manual to add references to True Blue

Power division of Mid-Continent Instrument Co.,

Inc. Identify new model number “TS835-( )” while

H 07/06/2012

maintaining unit part number references as

“MD835-( )”. Added information associated with

new -5 version and Mod 1 improvements. Updated

certification from FAA TSO C179 to C179a.

Add ETSO to Table 1.2. Updated Section 2.2 and

J 11/15/2012

2.4 for equipment location limitations. Removed

4.2.6. Updated 4.2.7. Add 4.2.8 regarding

software/complex hardware.

K 01/6/2014

L 02/26/2015

Updated document for vented version that applies

to all 835 units.

Add Mod 3: Extended filtering for high-transient

load current.

Change Environmental Qualification table: For

M 12/06/2016

CONDITION “Lightning Induced Transient

Susceptibility” change DESCRIPTION OF TEST to

A3H3L3.

Update 3.2 and 5.3 with information regarding state

N 11/22/2017

of charge for shipping and recharge intervals for

storage. Added cold test clarification. Minor format

and reference updates.

P 05/14/2020

Q 10/06/2020

Update style and brand to meet Marketing and

Engineering guidelines.

Updated section 5.5 Radio Frequency

Susceptibility.

BAW

MKN

BAW

BAW

JDS

CAS

KW

BAW

DLR

VAA

3 Manual Number 9016798 • Revision Q, October 6, 2020

SECTION 1 GENERAL DESCRIPTION

1.1 PURPOSE

The TS835 series Emergency Power Supply (EPS) is designed to supply DC power to the aircraft

emergency bus when the main power bus has been de-energized. This emergency power can be

utilized to maintain operation of required equipment in the event of a primary system power loss.

During normal aircraft operation, the TS835 EPS will utilize the aircraft’s primary power bus to

recharge or maintain existing charge at full capacity.

1.2 PHYSICAL DESCRIPTION

The TS835 EPS consists of a single chassis with a 13-pin ARINC-style connector for electrical

interface. Units with modification (MOD) 2 include a factory replaceable fuse that limits the output

current of the EPS. The unit is designed to be mounted in a ¼-ATR aircraft equipment rack. The end

plate of the unit also provides an alignment hole that mates with the mounting rack. A handle on the

front of the unit allows ease of removal and a convenient carrying method. There is an adjustment on

the front of the unit for setting the variable 3.0-5.5VDC output for the -5 version of the product.

1.3 FUNCTIONAL DESCRIPTION

During typical operation, the TS835 utilizes input power from the primary aircraft power supply to

charge and/or maintain the charge on the internal battery cells. In the event of primary aircraft power

loss, the TS835 will automatically supply power to the associated external loads without interruption.

4 Manual Number 9016798 • Revision Q, October 6, 2020

1.4 TECHNICAL SPECIFICATIONS

Electrical Attributes

Power Input 20 to 32 VDC, 5.2A max

20A max total

Power Output

Primary: 24.5 VDC nominal; Auxiliary: 3.0-5.5VDC

adjustable (5A max)

Battery Capacity 4.5 Ah nominal @ 1C rate

Maintenance Perform capacity check every 2 years

Reliability 10 year expected life (80% initial capacity retained)

Table 1.1

Physical Attributes

Weight 4.8 pounds (2.16 kg)

Dimensions

(see Figure 2.2)

12.7 inches long max. (+1 inch for handle)

3.1 inches high max. (excluding rear tab)

2.3 inches wide max.

Mating Connector ITT Cannon DPXB-13-33S-0001 or equivalent

Mounting 1/4 ATR Rack

Table 1.2

Qualifications

Certification

Performance Qualification

FAA TSO-C179a

EASA TSO (ETSO) C179a

RTCA DO-311 Minimum Operational Performance

Standards for Rechargeable Lithium Battery Systems

RTCA DO-160G See Section 5.5

Environmental Qualification

With MD835 5V Module (P/N 9017201) installed: DO160E, Section 20 (HG); DO-160F, Section 22 [A4G44]

Table 1.3

5 Manual Number 9016798 • Revision Q, October 6, 2020

SECTION 2 PRE-INSTALLATION CONSIDERATIONS

2.1 COOLING

No internal or external cooling of the unit is required. The unit is designed to operate over a wide

temperature range and is designed with internal thermal monitoring and protection circuits. See

Section 4: Operation for more details.

2.2 EQUIPMENT LOCATION

The TS835 EPS is designed for mounting flexibility, allowing for installation with no requirement for

temperature or pressure control. Although not required, optimum performance and life can be

achieved by mounting the TS835 in a temperature controlled section of the aircraft. In addition to

altitude and temperature tolerance, the unit is also designed to withstand high levels of condensing

humidity. However, installation locations where the unit could be subject to standing or direct water

exposure should be avoided. Tested and certified mounting includes the use of a standard ¼-ATR

avionics mounting rack. Access to the rear connector may be needed for installation but the nature of

the rack allows for convenient removal and installation of the unit from the front.

Failure mode, effects, and criticality analysis of the TS835 has shown that the potential for the release

of toxic or flammable gases as a result of over charge and over discharge conditions is extremely

improbable. However, if the unit does not have the add-on vent kit and exhaust hose, the unit should

be installed in a well-ventilated (positive flow) compartment for additional risk mitigation. The unit shall

not be installed in compartments where lines, tanks or equipment containing fuel, oil or other

flammable fluids are present; nor shall it be installed adjacent to engine firewalls or sources of ignition.

2.3 ROUTING OF CABLES

The wires and cable bundle associated with the unit are heavy gauge wire and carry significant power.

Be aware of routing cables near other electronics or with other wire bundles that may be susceptible to

high energy flow.

Avoid sharp bends in cabling and exhaust hose. Avoid routing near aircraft control cables. Also avoid

proximity and contact with aircraft structures, avionics equipment, or other obstructions that could

chafe wires and hoses during flight, and cause undesirable effects. The interconnect cables and

exhaust hose should not run adjacent to heaters, engine exhausts, or other heat sources.

6 Manual Number 9016798 • Revision Q, October 6, 2020

2.4 LIMITATIONS

The conditions and tests for TSO approval of this article are minimum performance standards. Those

installing this article, on or in a specific type or class of aircraft, must determine that the aircraft

installation conditions are within the TSO standards. TSO articles must have separate approval for

installation in an aircraft. The article may be installed only according to 14 CFR part 43 or the

applicable airworthiness requirements.

See Section 4.5 for Performance Specifications and potential limitations and ratings under various

environmental and application installations. Also see Section 2.2 for limitations associated with

equipment installation location.

2.5 MODIFICATIONS

Each model TS835 (part number MD835-( )) has a nameplate that identifies

the manufacturer, part number, description, certifications and technical

specifications of the unit. It also includes the “MOD” or modification number

representing notable changes in the revision history of the unit (See Table 2.2).

The following are descriptions of the current modification releases of the

TS835 EPS.

MOD 0

Modification (MOD) 0 is identified on the nameplate by the lack of marking on the MOD numbers 1

through 9 (i.e. 1-9 are visible).

Mod 0 is the initial release of the TS835 EPS.

MOD 1

Modification (MOD) 1 is identified on the nameplate by the marking/blacking out of MOD number 1 (i.e.

1 is not visible and 2-9 are visible).

Mod 1 of the TS835 EPS contains the following changes from MOD 0:

-Updated TSO from C179 to C179a

-The external installation of CR1 diode per Installation Wiring Diagrams is NOT required (optional)

-The 3.0 amp maintenance fast charge feature has been removed

-Standard charge rate during both operation and maintenance has been increased from 0.8 amps to

3.5 amps

-Adjustable 5 volt auxiliary power output is available for TS835-5 model

-Connector has been modified to accept multiple mating connector configurations for -1 and -5 models

7 Manual Number 9016798 • Revision Q, October 6, 2020

MOD 2

Modification (MOD) 2 is identified on the nameplate by the marking/blacking out of MOD number 2 (i.e.

1 and 2 are not visible; 3-9 are visible).

Mod 2 of the TS835 EPS contains the following changes from MOD 1:

-End plates and connecter are sealed to prevent discharge gases from escaping these locations.

-Case has a ‘vent’ hole, covered by a label, for gases to escape in the event of a catastrophic

overcharge. The label can be removed and an MCIA vent kit (p/n 9017983), and customer supplied

high temperature silicone hose, can be installed for controlled venting.

MOD 3

Modification (MOD) 3 is identified on the nameplate by the marking/blacking out of MOD number 3 (i.e.

1, 2 and 3 are not visible; 4-9 are visible).

Mod 3 of the TS835 EPS contains the following changes from MOD 2:

-Extended filtering for high-transient load current.

8 Manual Number 9016798 • Revision Q, October 6, 2020

6.45 CG (ref)

1.37 CG (ref)

3.1

2.365

12.68

Ø.221 Alignment hole

Auxiliary

output

Connector

keying.

Nameplate

adjustment

(-5 only)

Figure 2.2 TS835 Outline Drawing

1.000

3.87

Model Number

Mid-Continent

Part Number

Identifying Feature

TS835-1 MD835-1 Standard model

TS835-2 MD835-2 Fuse bypass option

Additional auxiliary output (3-

TS835-5 MD835-5

Table 2.2 Model and Part Numbers

9 Manual Number 9016798 • Revision Q, October 6, 2020

5.5VDC)

Pin #

A Power input from aircraft

B Power output to emergency bus

C Power input from MD835 Pin 11

D Test (out) to MD835 Pin 2

E Test (in) to MD835 Pin 6

F Power output to MD835 pin 10

G Aircraft ground

Connector Pinout

Figure 2.3

MD835 Control Switch Annunciator Outline Drawing and Pinout

Specifications

Power Input 28 VDC 15 amps max

Lighting LEDs

Weight 0.33 lbs

Temperature -55°C to 70 °C

Altitude 0 to +55,000 Ft.

Connector MS3102E16S-1P

Mating Connector MS3106F16S-1S

Color Bezel and Case: Black

Arm, Off, Test Labels: Opaque and Backlit White

STBY Annunciator: Backlit Amber on discharge

TEST Annunciator: Backlit Green (pass); no light (fail)

Table 2.3 MD835 Annunciator Specifications

10 Manual Number 9016798 • Revision Q, October 6, 2020

SECTION 3 INSTALLATION

3.1 GENERAL

This section contains mounting, electrical connections and other information required for installation.

These instructions represent a typical installation and are not specific to any aircraft.

3.2 PRE-INSTALLATION INSPECTION

A. Unpacking: Carefully remove the TS835 EPS from the shipping container. The shipping

container and packing are designed specifically for the transit of lithium batteries and

approved by international transportation agencies. These materials should be retained for

use should these units require future shipment.

B.

C. Inspect for Damage: Inspect the shipping container and units for any signs of damage

sustained in transit. If necessary, return the units to the factory using the original shipping

container and packing materials. File any claim for damages with the carrier.

D.

E. NOTE: The unit is shipped with approximately a 30% state-of-charge (if shipped by air) or

a 50% state-of-charge (if shipped by ground) to extend storage life and prevent loss of

capacity. Perform a complete charge on the TS835 using the procedures listed in this

manual upon receipt (prior to storage and again prior to installation/use).

3.3 PARTS

Included Parts

A. MD835-( ) Emergency Power Supply

B. 20A mini blade fuse, installed (MCI p/n 9016763 or equivalent)

C. Installation Manual (MCI p/n 9016798)

D. CR1 diode kit (MCI p/n 9017207, Mod 0 units only)

Installer Supplied Parts

A. Rack: ¼ ATR (MCI p/n 5120-107-C01 or equivalent)

B. Mating Connector: 13-pin ARINC (MCI p/n 9016600-2, -4, -5 or equivalent)

C. Emergency Fuse Bypass Switch (-2 version only):

Two position (off-on, capable of appropriate current for applied load)

(Panel Controls)

D. MCI Control Switch Annunciator (MCI p/n 9017176)

E. Annunciator Mating Connector: 7-pin circular (MCI p/n 9017119 or equivalent)

- OR, alternative option -

F. Panel Switch: Three position (off-on-momentary, capable of 20A minimum)

G. Test Annunciator: 327 lamp or equivalent

11 Manual Number 9016798 • Revision Q, October 6, 2020

Optional Parts

(For Emergency Power “On” Annunciation)

(This feature is included in the MCI Control Switch Annunciator p/n 9017176)

A. Diodes: 1N5614 (qty of 2), or equivalent

B. Annunciator: 327 lamp or equivalent

(To add 5VDC Auxiliary Power Output to -1 or -2 versions)

(This feature includes CR1 diode and Mating Connector)

C. MD835 5V Module (MCI p/n 9017201)

(To attach a vent hose to the MD835 unit; this is only for units made after 1/15/14)

D. Vent kit, MCI p/n 9017983. Use with ¾” ID x 1” OD min. high temp silicone tubing.

3.4 INSTALLATION

Install the EPS in the aircraft in accordance with the aircraft manufacturer’s instructions and the

following steps:

HARNESS PREPARATION

A. If using the MD835 5V Module (MCI p/n 9017201)

i. Prepare aircraft wiring with mating connector in accordance with Installation Wiring

Diagram Figure 3.5

ii. MD835 5V Module includes the Mating Connector shown in Figure 3.2

B. If using the MD835 Control Switch Annunciator (MCI p/n 9017176)

i. Prepare aircraft wiring with mating connectors and appropriate interconnects per

Figure 3.3 and 2.3

C. If installing an MD835-( ) MOD 0

i. The CR1 Diode identified in the Installation Wiring Diagrams is REQUIRED as an

external installation component for Mod 0 units which do not use the MD835 Control

Switch Annunciator or the MD835 5V Module.

ii. Prepare aircraft wiring with mating connector in accordance with Installation Wiring

Diagram Figure 3.3

iii. See RACK PREPARATION and Figure 3.7 below for CR1 diode mounting instructions.

D. If installing an MD835-( ) MOD 1, MOD 2, or MOD 3

i. Prepare aircraft wiring with mating connector in accordance with Installation Wiring

Diagram Figure 3.3

ii. The CR1 Diode is optional for Mod 1, Mod 2 and Mod 3 units and allows the emergency

loads or bus to be powered through the main bus when the battery is removed from the

installation.

iii. The CR1 Diode is included as part of the MD835 5V Module or Control Switch

Annunciator if used. If not used, instructions for installing the CR1 diode can be found in

Step C.ii above.

12 Manual Number 9016798 • Revision Q, October 6, 2020

RACK PREPARATION

A. Select location in accordance with Section 2 and mount the ¼ ATR rack according to the

aircraft manufacturer’s recommended specification. (See sample of ¼ ATR rack in Figure

3.6. Other racks may vary.)

B. Refer to the Unit Connector Figure 3.1 and Mating Connector Figure 3.2 to ensure that the

three half-hex alignment pins are installed correctly to mate with the alignment holes in the

unit connector. Note: there are three possible configurations as shown in the figures

referring to the MD835-( ) versions and their corresponding alignment pins.

C. If used, install the MD835 5V Module in the ¼ ATR rack according to MCI P/N 9017201

drawing. See Figure 3.8.

D. If required, install CR1 diode onto rack. Firmly mount diode to a thermally conductive

surface/heatsink. An electrical insulator which is thermally conductive must be placed

between the diode and heatsink (included with unit in CR1 diode kit). Mounting the diode to

the side of the ATR rack is an acceptable location. See figure 3.7 for an example.

PANEL PREPARATION

A. Plan for parts in a location accessible to the pilot or crew during flight, typically located in

the instrument panel or other position in the cockpit.

B. Install the MD835 Control Switch Annunciator, or other 3-way switch and test annunciation

lamp, in the instrument panel. For the MD835-2 unit, install the user supplied Emergency

Fuse Bypass switch in the instrument panel. Installation of the Emergency Power On

annunciation lamp is optional (included with MD835 Control Switch Annunciator). See Figure

3.3, 3.4 or 3.5.

If using the MD835 Control Switch Annunciator (MCI p/n 9017176)

i. Cut the instrument panel using the bezel dimensions and hole locations shown in

Figure 2.3.

ii. Set the brightness of the ARM/OFF/TEST backlight for night time viewing using the

adjustment on the side of the unit

If the MD835 Control Switch Annunciator is not used

i. Parts must be provided and installed which include a panel switch (S1), a power

diode (CR1), and an annunciator (DS2) per Section 3.3 and Figure 3.3.

C. For optional indication of active battery output power (Emergency Power On)

i. Parts CR2, CR3, DS2, and R1 are required to be incorporated into the wiring harness

and panel installation per Figure 3.3.

ii. These parts are included internally as part of the MD835 Control Switch Annunciator.

13 Manual Number 9016798 • Revision Q, October 6, 2020

FINAL INSTALLATION

A. Install the mating harness into the ¼ ATR rack. If MD835 5V Module is installed, adjust

trimpot on Module for desired Auxiliary Power Supply output (3.0-5.5V).

B. Slide the MD835-( ) into the ¼ ATR rack ensuring that the large, spring-loaded alignment

pin mates with the Index Hole on the rear flange of the unit. Hand-tighten the spring nut of

the rack onto the locking tab of the unit to secure. If the MD835 5V Module is installed, the

mating connector may need to be aligned to the MD835. Loosen MD835 5V Module

screws, install MD835 into ¼ ATR rack, tighten top two screws, remove MD835, and then

tighten remaining screws to secure MD835 5V Module.

C. For MD835-5 version, set the output voltage (3.0-5.5V) of the Auxiliary Power Supply by

gently turning the adjustment screw accessed through the front of the unit. See Figure 2.2.

D. If using the MCI vent kit p/n 9017983, remove the label from the MD835 case marked ‘Vent

Cover’. Install the vent, with the supplied gasket between the vent and the case. Fasten

the vent with the supplied screws using a medium strength thread locker. Install a user

supplied ¾” ID x 1” OD minimum high temperature silicone tubing. Use a clamp to attach

the silicone hose to the vent. Make sure tubing is securely fastened, and no kinks or sharp

bends exists anywhere in the silicone tubing.

E. NO INTERNAL OR EXTERNAL COOLING OF THE UNIT IS REQUIRED.

14 Manual Number 9016798 • Revision Q, October 6, 2020

(

y)

MD835-1, -5 MD835-2

Pin 1 (reserved)

Pin 2 Test Switch

Pin 3 (reserved)

Pin 4 (reserved)

Pin 5 3-5.5VDC Aux Out (-5 only)

Pin 6 Test Output

Pin 7 Power Ground (optional)

Pin 8 (reserved)

Pin 9

Pin 10 24-32 VDC In

Pin 11 20-26 VDC Out

Pin 12 Power Ground

Pin 13 (reserved)

Connector Pinout

Fuse Bypass (-2 only), OR

5V Enable

-5 onl

no te: unus ed/ reser ved pi ns

may no t be p op ulat ed

Figure 3.1 Pinout and Unit Connector

MCI P/N 9016600-2 MCI P/N 9016600-4 MCI P/N 9016600-5

(for MD835-1 or -5) (for MD835-2) (for MD835-5 (optional))

Figure 3.2 Mating Connectors

15 Manual Number 9016798 • Revision Q, October 6, 2020

10

11

12

15A

4

S1

3

CR1

1

6

2

9

7

S2

DS2

EMER

POWER

BATTERY

TEST

EMERGENCY

FUSE BYPASS

(-2 VERSION)

ON/ARMED

OFF

TEST

5

DS1

CR2

EMER

POWER

2

CR3

R1

200 OHM

10 W

ON

ESSENTIAL

BUS

EMERGENCY

BUS

CR1 - 1N3620

CR2 & CR3 - 1N5614

DS1 & DS2 - 327 LAMPS

(OR EQUIVALENTS)

MASTER

BATTERY

RELAY

AIRCRAFT

POWER

1 CR1 IS REQUIRED FOR MOD 0 UNITS

CR1 IS OPTIONAL FOR MOD 1 AND ABOVE

(SEE SECTION 3.3.1 AND NOTE 4 BELOW)

2 INSTALL CR2, CR3, DS1, AND R1 IF ANNUNCIATION OF EMERGENCY POWER ON IS REQUIRED.

(SEE SECTION 3.3.3 AND NOTE 4 BELOW)

3 S1 IS ON-OFF-MOMENTARY SWITCH.

4 THIS PART OF THE CIRCUIT IS INCLUDED IN THE MCI MD835 SWITCH ANNUNCIATOR P/N 9017176

5 INSTALLER SUPPLIED SWITCH (S2) FOR -2 FUSE BYPASS VERSION

6 USE AWG 16 WIRE FOR POWER AND GROUND.

ALL OTHER LINES CAN BE AWG 22 WIRE.

Figure 3.3

Installation Wiring Diagram

MD835-1 and MD835-2

16 Manual Number 9016798 • Revision Q, October 6, 2020

15A

4

S1

3

10

CR1

1

11

6

2

9

5

13

5

7

12

EMER

POWER

BATTERY

DS2

TEST

LIGHTING BUS /

DIMMING CONTROL

RELAY

ON/ARMED

OFF

TEST

ESSENTIAL

BUS

5V LIGHTING LOAD

DS1

CR2

EMER

POWER

2

CR3

R1

200 OHM

10 W

6

ON

ESSENTIAL

BUS

EMERGENCY

BUS

CR1 - 1N3620

CR2 & CR3 - 1N5614

DS1 & DS2 - 327 LAMPS

(OR EQUI VALENTS)

MASTER

BATTERY

RELAY

AIRCRAFT

POWER

1

CR1 IS REQUIRED FOR MOD 0 UNITS

CR1 IS OPTIONAL FOR MOD 1 AND ABOVE

(SEE SECTION 3.3.1 AND NOTE 4 BELOW)

2 INSTALL CR2, CR3, DS1, AND R1 IF ANNUNCIATION OF EMERGENCY POWER ON IS REQUIRED.

(SEE SECTION 3.3.3 AND NOTE 4 BELOW)

3 S1 IS ON-OFF-MOMENTARY SWITCH.

4 THIS PART OF THE CIRCUIT IS INCLUDED IN THE MCI MD835 SWITCH ANNUNCIATOR P/N 9017176

5 9 AND 13 CONNECTED I NTERNALLY. EI THER CAN BE USED FOR 5V INPUT/ENABLE.

6 SUGGESTED 5V INSTALLATION. INSTALLER SUPPLIED COMPONENTS.

7 USE AWG 16 WIRE FOR POWER AND GROUND.

ALL OTHER LINES CAN BE AWG 22 WIRE.

Figure 3.4

Installation Wiring Diagram

MD835-5

17 Manual Number 9016798 • Revision Q, October 6, 2020

10

11

12

5

1

CR1

1

2

6

2

5

4

3

6

9017201

6-POLE

TERMINAL

BLOCK

4

S1

3

EMER

POWER

BATTERY

DS2

TEST

5VDC OUT

CR1 IS INCLUDED IN THE MCI MD835 5V MODULE P/N 9017201.

1

(SEE SECTION 3.3.3)

2 INSTALL CR2, CR3, DS1, AND R1 IF ANNUNCIATION OF EMERGENCY POWER ON IS REQUIRED.

(SEE SECTION 3.3.3 AND NOTE 4 BELOW)

3 S1 IS ON-OFF-MOMENTARY SWITCH.

ON/ARMED

OFF

TEST

CR2

2

CR3

R1

200 OHM

10 W

15A

DS1

EMER

POWER

ON

ESSENTIAL

BUS

EMERGENCY

BUS

CR2 & CR3 - 1N5614

DS1 & DS2 - 327 LAMPS

(OR EQUIVALENTS)

MASTER

BATTERY

RELAY

AIRCRAFT

POWER

4 THIS PART OF THE CIRCUIT IS INCLUDED IN THE MCI MD835 SWITCH ANNUNCIATOR P/N 9017176

THIS PART OF THE CIRCUIT IS INCLUDED IN THE MCI MD835 5V MODULE P/N 9017201

5

(PORTIONS OF INTERNAL CIRCUITRY NOT SHOWN)

6 USE AWG 16 WIRE FOR POWER AND GROUND.

ALL OTHER LINES CAN BE AWG 22 WIRE.

(3) Power

(2) 20-26VDC

Out

Ground

(4) Test

Switch

(5) Test

Indicator

(1) 28VDC

IN

(6) 5VDC Out

(See Note 5)

2.7-5.5VDC

Adjustable Output

Figure 3.5 Installation Wiring Diagram

MD835-1 With 9017201 5V Module

18 Manual Number 9016798 • Revision Q, October 6, 2020

(14.43)(1.67)

(12.50)

2.35

Spring Nut

1.50

Alignment Pin

4X

0.175 THRU

100

Ø

9.002.40

0.337

(4.45)

(0.38)

(3.89)

(0.48)

Figure 3.6

Installation Rack Drawing

Per P/N 5120-107-C01

DPXB Cut-Out

per ARINC 404

19 Manual Number 9016798 • Revision Q, October 6, 2020

Item Qty Description

1 1 Screw 4-40x7/16 Pan Phil Blk Patch

2 1 Washer Lock #4 Split SS

3 1 Washer Flat #4x0.315 OD, 0.025 thk

4 1 Diode, 400V, 60A, TO-247

5 1 Pad, Insulating, SilPad 900S

6 1 Nut 4-40 Hex

Figure 3.7

Example Installation of CR1 Diode

(p/n 54-2007-1) into Rack

Figure 3.8

Installation of 5V Module

(p/n 9017201) into Rack

20 Manual Number 9016798 • Revision Q, October 6, 2020

SECTION 4 OPERATION

4.1 DESCRIPTION

The True Blue Power TS835 Emergency Power Supply is designed to supply backup power to any

load desired in the case of primary power loss in an aircraft. It utilizes rechargeable lithium iron

nanophosphate chemistry to provide 20.0-28.0VDC and 4.5 Ampere-hours of capacity at the 1C rate

(see “Performance” below). It utilizes a 13-pin ARINC-style connector and is designed to be installed

in a standard ¼ ATR equipment rack.

4.2 THEORY OF OPERATION

The TS835 Emergency Power Supply system provides a nominal voltage of 24.5VDC and a fuselimited maximum power output of 20 amps. The TS835-5 model also provides an additional auxiliary

output that is adjustable (3.0-5.5VDC). The unit is designed to receive a 20-32VDC input from the

aircraft.

Maintaining Charge

In normal operation, the unit continuously monitors the input voltage from the aircraft’s

essential bus and only provides battery power when the input is lost. The unit uses the aircraft

power to maintain a full charge on the battery cells. This is not a constant load on the aircraft.

The charging circuit only activates when the voltage on the cells drops below a set value.

When in this recharging mode, the load on the aircraft system is typically less than 0.3A, but

can be as high as 5.5A if recharging an empty battery (~3.5A) and powering the heater (~1.7A)

in a cold environment. When the aircraft voltage drops below 24V, the battery will stop charging

in order to minimize the load on the main power system.

Discharge

In order to produce battery power, the unit must first have input power applied, then removed.

(4.2.4. Automatic Shut-off) When the input voltage to the unit is applied and drops below

21.5V, the unit will begin supplying power to the associated load. The output voltage can range

from 28.0 to 20.0VDC during a discharge cycle. However, the output voltage is typically

between 24-25V during the majority of the discharge time (after the first 5% is discharged and

then until about 15% of the battery’s capacity is remaining). The unit will shut itself off when the

voltage provided by the internal cells reaches approximately 19.5V. This is to prevent

permanent damage to the unit or individual cells. At the end point voltage of 19.5V, the battery

has approximately 1% of remaining power available. Therefore this precautionary shut off does

not significantly detract from the amount of available power that might be supplied to the load in

an emergency.

21 Manual Number 9016798 • Revision Q, October 6, 2020

Auxiliary Power Output

For the TS835-5 model, the Auxiliary Power Output is available and typically used for lighting of

required equipment during an emergency. The output is adjustable from 3.0V to 5.5V and

provides up to 5A of current. While the auxiliary power is available during both normal and

emergency operation, an equivalent installation to that shown in Figure 3.5 is recommended

such that it is only connected to the required load when primary aircraft power is lost.

If the aircraft power should return to normal levels, the battery will cease to provide an output

when the aircraft voltage exceeds the battery voltage. The unit will begin recharging the cells (if

needed) when the aircraft power returns to 24V or higher.

Automatic Shut-off

This feature allows the unit to prevent accidental or excessive self discharge when the aircraft

is not in use. When the input voltage drops below 21.5V and the load is below 150mA for a

period of 5 minutes (or no load exists), then the unit will turn itself off and the output power is

no longer available. The unit can be activated either with an input voltage greater than 22V or

by activating the test feature. This safety and functional feature prevents downtime of the

aircraft by ensuring that the unit is charged and ready for operation prior to each flight.

Remote Test

The unit has a self-test feature that can be accessed remotely through a pair of pins on the

connector. When activated via a switch from the panel, the circuit will close and light an

annunciator if the unit passes the built-in self-test routine. This indicates a minimum of 80% of

the unit’s current capacity is available and also verifies that the heater and temperature

monitoring is operational.

Battery Performance and Capacity

Based on new nanoscale materials initially developed at MIT, low impedance nanophosphate

electrode technology provides significant performance advantages over alternative high power

technologies. A standard measure of rechargeable battery capacity involves both the currentfor-time performance (i.e. amp-hours) and also the “C” rate.

Many typical lead acid batteries, and some lithium systems as well, are defined at a 1/20

(0.05) or 1/10

th

(0.1) C-rate. This is defined as the constant load that can be applied over 20 or

10 hours, respectively. For example, a battery rated at 5 Ah at a 0.1 C-rate can deliver 0.5A for

10 hours (0.5A x 10 hours = 5Ah). However, that same system typically does not perform

linearly at higher C-rates. As an example, a 5Ah lead acid battery rated at 0.1C can typically

support approximately a 3.6A load for 1 hour (equal to a 1C capacity of 3.6Ah). The capacity is

defined by a logarithmic function of load versus time. Therefore, loads applied to this type of

battery which exceed the rated C-rate quickly decrease the time available. Applying a 5A load

to a 5Ah battery rated at 0.1C does not last 1 hour, rather would last approximately 36 minutes.

Doubling the load to 10A for the same system would last less than half the time, or

approximately 15 minutes.

th

22 Manual Number 9016798 • Revision Q, October 6, 2020

One of the significant advantages to the lithium nanophosphate technology is its constant

capacity versus load (see Figure 4.2). The TS835 is rated for 4.5Ah at the 1C rate. This will

support a 4.5A load for 1 hour of operation. However, its constant capacity versus load

capability means that at double the load, or 9.0A, the battery still maintains the linear (instead

of logarithmic) relationship of load versus time, producing 30 minutes (or 0.5 hours) of power

(9.0A x 0.5 hours = 4.5Ah at 2C rate). Similar results can be found at the maximum power

rating of the TS835. For a 20A load (or approximately a 4.5C rate), the battery will last

approximately 13.5 minutes (4.5Ah / 20A = 0.225 hours = 13.5 minutes). Ultimately, this allows

a much longer lasting battery at all load levels.

The battery cells are stable and perform well over temperature. While comparable technologies

suffer significantly from the effects of high temperature, the lithium cells used in the TS835 can

retain more than 90% of their capacity after 200+ full discharge cycles at 60°C.

True Blue Power’s use of lithium nanophosphate cells translates to less long term maintenance

costs. At the 1C rated load of 4.5A, data from the cell manufacturer demonstrates that 80% of

the original capacity is retained after 7000+ complete discharge and recharge cycles. While the

emergency use of the TS835 system in an aviation application may only experience a few

complete discharges in its lifetime, its cycle life also translates to calendar life. The cell

manufacturer asserts a projection of more than 10 years of usable life in the field.

Heater

Although the cells are designed to operate at low temperatures, the unit also incorporates a

heater to provide additional performance at even lower temperatures. A temperature

monitoring circuit is incorporated in the cell pack that is used to activate the heater when

ambient temperature drops below approximately 0°C. (The heater draws about 1.7A when in

use.) This prevents the cell electrolyte from freezing during discharge or charging at extremely

low temperatures.

A temperature monitor in the circuit also checks for any over-temperature condition that could

arise from either the cells or the heater. A fault would result in the unit shutting down to prevent

damage to the pack.

The replaceable fuse in the unit prevents damage to equipment in the event of a short circuit at

the load.

Software and Complex Hardware

No software or complex hardware is incorporated in the design of this product.

23 Manual Number 9016798 • Revision Q, October 6, 2020

4.3 INSTALLED OPERATION

The following are operating instructions for using the TS835 Emergency Power Supply when installed

in an aircraft.

Remote Test

The remote test activation switch installed in the panel (MCI p/n 9017176 or installer provided)

has three positional settings: OFF (latched), ARM (latched), and TEST (momentary). On the

MD835 Control Switch Annunciator, the ARM/OFF/TEST display is opaque white for daytime

viewing and backlit (dimmable) for night time viewing. Brightness can be set on the side of the

annunciator during installation.

To test the TS835 (typically required by the aircraft operation manual prior to dispatch), press

and hold the three-way switch into the Test position. When installed correctly (per Figure 3.3)

the test annunciation light will illuminate. Release the switch. This indicates that the TS835 has

a minimum of 80% of the unit’s current capacity available and also verifies that the heater and

temperature monitoring is operational. This indicates that the battery has a minimum of 80%

capacity available and is qualified for use. On the MD835 Control Switch Annunciator, the

green “TEST” annunciation light will appear.

For most accurate results, the remote test procedure should be to select the TEST position on

the panel switch from the OFF position prior to activating the system (see Section 4.3.2.) and

prior to applying power to the essential aircraft bus.

When operating at cold temperature (below 0°C), it is possible that the self test will fail until the

battery has warmed up due to the internal heater function or aircraft ambient heating.

Activation

To activate or “arm” the system prior to flight, place the three-way activation switch in the ARM

or ON position. This will apply power to the unit, allowing it to maintain its maximum charge

capability and to provide uninterrupted power to the loads on the emergency bus should

primary aircraft power fail. If installed, the optional “Emergency Power On” feature provides

annunciation of when the battery is in use/discharging. This feature is included in the MD835

Control Switch Annunciator and is indicated by an amber “STBY” annunciation.

Disarm

By placing the three-way activation switch in the OFF position, the input voltage to the unit will

be disconnected, disabling both the ability of the battery to charge or discharge. The activation

switch should always be kept in the OFF position when not in use to prevent accidentally

discharging the battery.

24 Manual Number 9016798 • Revision Q, October 6, 2020

Resetting the Automatic Shut-off

The unit is designed to shut down within 5 minutes to prevent unwanted discharge in the event

that input power is lost and the load is below 150mA. In order to reactivate the unit for charging

or discharge, restore an input voltage of 22-32V or briefly activate the test feature and then

return the switch to the ARM position. Either action will reset the automatic timer and allow the

unit to function properly

Emergency Fuse Bypass (TS835-2 ONLY)

The TS835-2 has a fuse bypass feature available. When installed, a panel mounted switch

allows the pilot or crew to route battery power around the internal fuse of the TS835. This

would allow the emergency bus to remain powered in the event that primary aircraft power fails

and the internal fuse of the TS835 was open.

Auxiliary Power Output

An auxiliary power output is available for the TS835 that simultaneously provides the primary

24.5V nominal output as well as a separate adjustable 3.0-5.5V lighting output. This can be

provided by adding the MD835 5V Module (p/n 9017201) to the TS835-1 or TS835-2 models or

is a built-in feature of the TS835-5 model. This output is available during normal operation

(aircraft power available) and emergency operation. However, it is recommended that an

external relay be provided on the 5V output so that it only provides power to the emergency

lighting bus load when aircraft power has failed. (See Figure 3.4)

4.4 MAINTENANCE

.

Because the cells are designed to maintain their charge-holding capability over time, True Blue Power

is recommending a two-year maintenance cycle. The two-year check includes a full charge, discharge,

and recharge while evaluating the discharge time against minimum requirements. Additionally, at any

time when the capacity of the unit is in question or after being utilized in an in-flight emergency

situation, True Blue Power recommends conducting this procedure.

Standard Charging

A. If 28V power is applied to the primary input pin (power on pin 10, ground on pin

12), a standard charge will take approximately 1.5 hours for a fully discharged unit

(up to 8 hours for Mod 0). The current draw should be 0.15 - 3.5A throughout the

charge cycle. Use of a power supply capable of 5A is recommended to provide full

charge current.

B. When the current draw of the unit reaches 0.15A or below, the unit is fully

charged.

25 Manual Number 9016798 • Revision Q, October 6, 2020

Fast Charging (Mod 0 units only)

By grounding an additional pin on the connector during charging (pin 4), the unit can be put

into ‘fast charge’ mode. This allows the unit to draw up to 3A and fully charge the battery cells

in approximately 2 hours. The unit must be removed from the airplane to utilize the fast charge

procedure.

A. To manually fast charge a unit, apply a ground to pin 4 to enable the fast charge

mode.

B. Apply 28.9 ±0.1VDC of power to the input pin (pin 10) and connect the ground to

pin 12. THE POWER SUPPLY MUST BE SET TO A CONSTANT CURRENT OF

3.0A. The unit will draw 3.0A of power until the batteries have been charged to the

voltage set limit. At that time, the current draw will begin to decrease and the

voltage of the cells will remain constant. (CCCV method – constant current,

constant voltage)

C. When the current draw of the power supply reaches approximately 1.0A or below,

complete the charge cycle by removing the ground to pin 4 and follow step

4.4.1.B. above. (Do not allow the unit to remain in fast charge mode for extended

periods of time once the current draw reaches this low level.)

Capacity Verification

To test the unit for capacity verification, apply the following procedure @ 15°-40°C:

A. Charge the unit using either the Standard Charge or Fast Charge method

described in Section 4.4.1 and 4.4.2, respectively.

B. Apply 28.0V to the input pin.

C. Provide constant current load to the output (pin 11) of 4.5A. (Tek Power TP3711 A

or equiv.)

D. Remove the input power.

E. Monitor the time required from removal of input power until the unit stops

providing output power to the load.

F. To be approved for service in standard applications, the unit must provide 48

minutes of output power per the required procedure listed above.

NOTE: For a specific aircraft installation and certification, this value can be altered

based on the particular load supported and the time necessary for regulatory or

application need.

G. Recharge the unit per Section 4.4.1 or 4.4.2.

26 Manual Number 9016798 • Revision Q, October 6, 2020

4.5 PERFORMANCE

Two of the many advantages of lithium battery technology are the relatively constant output voltage

over time and the linear performance of capacity at multiple load levels. The performance of the

TS835 in these regards is demonstrated in Figures 4.1 and 4.2, respectively.

Actual capacity of the TS835 Emergency Power Supply may vary considerably depending on

temperature, charge status, and battery condition. Low temperatures can temporarily degrade battery

capacity. If the unit is stored below -18°C (0°F) for 3 hours or more prior to dispatch, refer to Figure 4.3

for required warm-up time and available capacity. The warm-up procedure requires input power to be

applied and the activation switch to be in the On/Arm position.

The TS835 is designed for high cycle life and long calendar life. However, all batteries degrade in

performance over time, even when correctly maintained. Figure 4.4 demonstrates cycle life at various

temperatures. A poorly maintained battery will suffer accelerated degradation in excess of the

guidelines given in this document. Extended storage in a highly discharged state or at high ambient

temperatures (above +35°C) may permanently damage a battery or reduce its performance. Complete

charging is required every six months if not in use.

27 Manual Number 9016798 • Revision Q, October 6, 2020

Figure 4.1 Nominal Battery Capacity and Voltage Output

Figure 4.2 Nominal Battery Capacity versus Load

28 Manual Number 9016798 • Revision Q, October 6, 2020

Figure 4.3 Nominal Battery Capacity versus Warm-up Time

Figure 4.4 Cycle Life versus Temperature

29 Manual Number 9016798 • Revision Q, October 6, 2020

SECTION 5 CONFORMANCE

5.1 TEST AND VERIFICATION INTERVALS

A remote (in-panel) test (see Section 4.3.1) should be performed prior to flight to verify the state of

charge of the battery. Should the test not pass, the unit should be removed and either recharged or

capacity checked (per Section 4.4.3). If the unit continues to fail the remote test, it should be returned

to the manufacturer for maintenance.

Routine testing and capacity verification should be performed on a bi-annual schedule (every 24

months) from date installed. See Section 4.4 for maintenance and test procedures.

For short uses of the unit in the aircraft, the aircraft system will recharge the unit on its own. An inpanel test can help determine whether the unit requires removal and recharge.

A full capacity check (Section 4.4) should be performed any time there is concern regarding the

capacity of the unit. Mid-Continent recommends removal of the unit and performance of a full capacity

test any time after having incurred an in-flight loss of power or subsequent activation and use of the

TS835 Emergency Power Supply.

5.2 COMPONENT MAINTENANCE MANUAL

The cells, electronics, fuse, and other components that comprise the TS835 EPS, are not user

replaceable items. Therefore, data is not available from the manufacturer to conduct field repairs in the

case of a faulty or expired product.

Estimated life and recommended replacement interval for the internal battery cells can extend up to 10

years. In the event that the unit exhibits failure, insufficient capacity, or expired life, contact True Blue

Power for overhaul, exchange, or replacement.

5.3 STORAGE INFORMATION

In normal use, the TS835 EPS utilizes the input power supplied to maintain the proper charge voltage

and sustain the battery cells at peak capacity. Although the chemistry of the cells used in the TS835

maintain an extremely low relative self-discharge rate, all batteries will slowly self-discharge if left

unused for long periods. In addition, self-discharge rates are directly related to the storage

temperature. Higher storage temperatures will result in faster self-discharge rates. Recommended

maximum storage temperature is 30° (86°F). Exposure to higher storage temperatures for sustained

periods of time are possible, but may increase the self-discharge rate or result in some loss of

capacity.

Rechargeable lithium ion batteries must be stored in a dry, well-ventilated area. They must not be kept

in the same area as highly flammable materials. The unit can be stored in the same area as other

battery chemistries. The TS835 does not emit or absorb any gas during storage, transportation, or

during normal operating conditions.

30 Manual Number 9016798 • Revision Q, October 6, 2020

SHELF LIFE: As lithium-ion batteries are limited to being shipped at a maximum of 30% state of

charge (SOC), the battery shall be fully charged upon receipt. Batteries that are stored shall be

fully recharged at a minimum every 6 months, following the procedure set forth in Section 4.4.1

or 4.4.2. If the storage time is unknown, a battery should be recharged prior to reaching 20V.

STORAGE TEMPERATURE: Exposure to temperatures above 30°C (86°F) for sustained

periods of time are possible, but may increase the self-discharge rate or result in some

permanent loss of capacity. Storage temperatures above 50ºC (122°F) are to be avoided.

5.4 DISPOSAL

NOTE: All lithium ion batteries are classified by the federal government as non-hazardous

waste and are safe for disposal as normal municipal waste. However, these batteries do

contain recyclable materials and recycling options available in your local area should be

considered when disposing of this product. Do not incinerate.

CAUTION

31 Manual Number 9016798 • Revision Q, October 6, 2020

5.5 ENVIORNMENTAL QUALIFICAION STATEMENT

MODEL NUMBER: TS835-( ) PART NUMBER: MD835-( )

DESCRIPTION: Emergency Power Supply CERTIFICATION: FAA TSO-C179a

MANUFACTURER: True Blue Power, a division of Mid-Continent Instrument Co., Inc.

ADDRESS: 9400 E. 34th St. North, Wichita, KS 67226, USA.

SPECIFICATION: Test Specification (TS) 443 Test Data Sheet (TDS) 443

STANDARD: RTCA DO-160, Rev F, dated 12/06/2007 and Rev G, dated 12/08/10

CONDITIONS SECTION DESCRIPTION OF TEST

Temperature and Altitude 4 Category F2

Temperature Variation 5 Category S2

Humidity 6 Category B

Operational Shock and Crash Safety 7 Category B

Vibration 8 Fixed Wing: Category R; Curves C, C1

Rotorcraft: Category U; Curve G

Rotorcraft: Category U2; Curve F, F1

Explosion 9 Category E

Waterproofness 10 Category X

Fluids 11 Category X

Sand and Dust 12 Category S

Fungus 13 Category F

Salt Fog 14 Category S

Magnetic Effect 15 Category Z

Power Input 16 Category Z(XX)

Voltage Spike 17 Category A

Audio Frequency Conducted Susceptibility 18 Category Z

Induced Signal Susceptibility 19 Category ZC

Radio Frequency Susceptibility 20 Category YY

Emission of Radio Freq Energy 21 Category H

Lightning Induced Transient Susceptibility 22 Category A3H3L3

Lightning Direct Effects 23 Category X

Icing 24 Category X

ESD 25 Category A

Fire, Flammability 26 Category X

REMARKS:

Section 4: Category F2 with excursions as declared by the manufacturer:

4.5.3 Short-Time Operating High Temp: +85°C

4.5.4 Operating High Temp: +85°C

4.6.2 Decompression: +8,000 feet

4.6.3 Overpressure: -15,000 feet

32 Manual Number 9016798 • Revision Q, October 6, 2020

Loading...

Loading...