True blue power TC2000 Series Installation Manual And Operating Instructions

Installation Manual and Operating Instructions

Model TC2000 Series

Static Electrical Power Converter

True Blue Power

Mid-Continent Instrument Co., Inc.

dba Mid-Continent Instruments and Avionics

9400 E. 34

Wichita, KS 67226 Manual Number 9019049

PH (800) 821-1212 FX (316) 630-0723 Rev C March 8, 2018

th

®

is a division of Mid-Continent Instrument Co., Inc.

Street N.

FOREWORD

This manual provides information intended for use by persons who, in accordance with current

regulatory requirements, are qualified to install this equipment. If further information is required,

please contact:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Customer Service Dept.

9400 E. 34th Street N.

Wichita, KS 67226 USA

PH (316) 630-0101

FX (316) 630-0723

www.truebluepowerusa.com

www.mcico.com

We welcome your comments concerning this manual. Although every effort has been made to

keep it free of errors, some may occur. When reporting a specific problem, please describe it

briefly and include the manual part number, the paragraph/figure/table reference and the page

number. Send your comments to:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Technical Publications

9400 E. 34th Street N.

Wichita, KS 67226 USA

PH (316) 630-0101

FX (316) 630-0723

All products produced by Mid-Continent Instrument, Co., Inc., including those identified as MidContinent Instruments and Avionics or True Blue Power, are designed and manufactured in

Wichita, KS, USA.

Copyright 2017

Mid-Continent Instrument Co., Inc.

Rev C, March 8, 2018 2 Manual Number 9019049

REVISION DETAIL

Revision Date Approved Detail

A 12/28/2017 BAW Initial release

B 01/26/2018 BAW

C 03/08/2018 JRC

Corrected formatting issues. Incorporated FAA

comments.

Changed paragraph 3.3.2.3 pin ‘E’ to pin ‘A’. Added

note page 5 on ground regulatory requirements.

Rev C, March 8, 2018 3 Manual Number 9019049

TABLE OF CONTENTS

SECTION 1 GENERAL DESCRIPTION .................................................................................. 5

1.1 INTRODUCTION ............................................................................................................ 5

1.2 TECHNICAL SPECIFICATIONS .................................................................................... 5

SECTION 2 PRE-INSTALLATION CONSIDERATIONS ........................................................ 6

2.1 COOLING ....................................................................................................................... 6

2.2 EQUIPMENT LOCATION ............................................................................................... 6

2.3 ROUTING OF CABLES .................................................................................................. 6

2.4 LIMITATIONS ................................................................................................................. 6

SECTION 3 INSTALLATION PROCEDURES ........................................................................ 8

3.1 GENERAL INFORMATION ............................................................................................ 8

3.2 UNPACKING AND INSPECTING EQUIPMENT ............................................................ 8

3.3 CABLE HARNESS ......................................................................................................... 8

3.3.1 Wire Gauge Selection ............................................................................................. 8

3.3.2 Pin Assignment Information .................................................................................... 9

3.3.3 Example Wiring Diagrams ..................................................................................... 10

3.3.4 Harness Verification .............................................................................................. 10

3.4 MOUNTING .................................................................................................................. 12

3.5 INSTALLATION COMPLETION ................................................................................... 13

3.6 INSTALLATION CAUTION ........................................................................................... 13

SECTION 4 OPERATION ..................................................................................................... 14

4.1 ELECTRICAL PERFORMANCE .................................................................................. 14

4.2 PROTECTIVE FEATURES .......................................................................................... 14

4.2.1 Remote On/Off ...................................................................................................... 14

4.2.2 Over-Temperature ................................................................................................. 14

4.2.3 Short Circuit And Over-Current ............................................................................. 14

SECTION 5 CONFORMANCE .............................................................................................. 15

5.1 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS ............................................ 15

5.2 ENVIRONMENTAL QUALIFICATION STATEMENT ................................................... 15

Rev C, March 8, 2018 4 Manual Number 9019049

1.1 INTRODUCTION

The model TC2000 Series Static Electrical Power Converter is a lightweight power converter that

translates an aircraft alternating current (AC) input of 115 volts at 360-800 Hertz to a 28 volt

direct current (DC) output. Additionally the TC2000 can be bench operated on AC Mains with

115 or 230 volts at 47-65 Hz input and provide a 28 volt direct current (DC) output (see Note 1

below).

The wide input operating voltage and frequency make the TC2000 suitable for nearly any

common business or commercial aircraft which provides 100-125 VAC between 360-800 Hertz.

The output of 71 amps @ 28 VDC produces 2000 watts of power to supply avionics,

instrumentation, seating, personal charging, lighting, and many other applications. The TC2000

Series Static Converter is FAA certified to TSO-C71 and tested to rigorous environmental

standards and levels of RTCA DO-160G. The small size and light weight in conjunction with its

installation flexibility (inside or outside the pressure vessel) make it an ideal choice for aircraft

power needs while reducing the challenges associated with other similar products.

Highlighted features include short circuit protection, overload capability, low voltage shut-down,

temperature monitoring, a self-resettable over-temperature disable and a remote on/off function.

The TC2000 Series has a robust Military-rated circular connector, and the rugged extrusion that

houses the unit is designed to help dissipate heat and provide mechanical strength against

vibration or other possibilities of damage. Two independent fans allow for a smaller unit and

quiet operation, and keep the internal components cool extending the life of the unit.

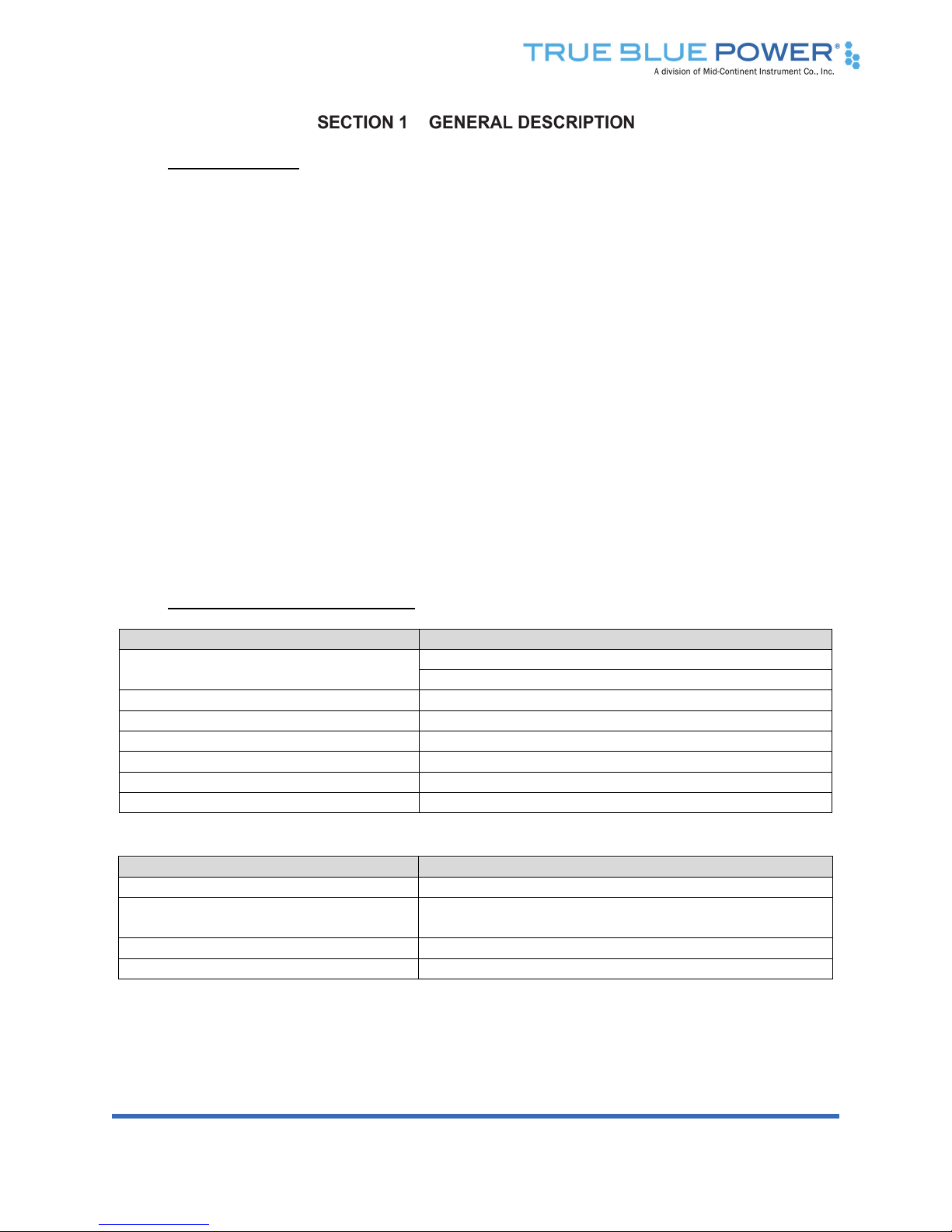

1.2 TECHNICAL SPECIFICATIONS

Electrical Attributes: Model TC2000

Input Voltage

Aircraft: 115VAC nominal, 360-800 Hz.

AC Mains: 115VAC or 230VAC, 47 to 65 Hz. (

Input Current (full load) 22 Amps nominal; 28 Amps max

Input Current (unit off) 2 Amps

Recommended Input Circuit Breaker 30 Amps (for 115VAC aircraft use)

Output Voltage 28VDC ± 0.5 VDC

Output Power 2000 watts (28VDC @ 71 Amps rated)

Efficiency 88% nominal

Table 1.1

Physical Attributes: Model TC2000

Weight: 9.9 lbs [4,49 kg]

Dimensions:

(not including connector mate)

14.00 inches x 6.32 inches x 3.46 inches (LxWxH)

[35,5 x 16,1 x 8,8 cm]

Mating Connector (and cable clamp): MCI P/N 9018993-1 and 9018550-2

Mounting: Base mount – orientation not critical

Table 1.2

Note 1: The TC2000 has not been tested to UL, CE, or other ground regulatory requirements. Powering from AC mains

is intended for testing or temporary use only.

Note 1)

Rev C, March 8, 2018 5 Manual Number 9019049

Loading...

Loading...