Revision D • December 30, 2020

FOREWORD

This manual provides information intended for use by persons who, in accordance with current

regulatory requirements, are qualified to install this equipment. If further information is required,

please contact:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Customer Service Dept.

9400 E. 34th St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

www.truebluepowerusa.com

www.mcico.com

We welcome your comments concerning this manual. Although every effort has been made to

keep it free of errors, some may occur. When reporting a specific problem, please describe it

briefly and include the manual part number, the paragraph/figure/table number and the page

number. Send your comments to:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Technical Publications

9400 E. 34

th

St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

Download the current

version of this

installation manual

using your

smartphone or tablet.

© Copyright 2019

Mid-Continent Instrument Co., Inc.

1 Manual Number 9019288 • Revision D, December 30, 2020

TABLE OF CONTENTS

SECTION 1 GENERAL DESCRIPTION 4

1.1 INTRODUCTION 4

1.2 PHYSICAL

1.3 UNIT

1.4 TECHNICAL

1.5 IMPORTANT

ATTRIBUTES 4

ARCHITECTURE 5

SPECIFICATIONS 6

SAFETY INFORMATION 8

SECTION 2 PRE-INSTALLATION CONSIDERATIONS 10

2.1 COOLING 10

2.2 EQUIPMENT

2.3 ROUTING

LOCATION 10

OF CABLES 10

2.4 LIMITIATIONS 11

2.5 MODIFICATION 11

SECTION 3 INSTALLATION 12

3.1 GENERAL 12

3.2 PRE-INSTALLATION

INSPECTION 12

3.3 PARTS 12

3.4 INSTALLATION 13

SECTION 4 OPERATION 21

4.1 DESCRIPTION 21

4.2 CONSTRUCTION

4.3 OPERATIONAL

4.4 BATTERY

COMMUNICATION 29

AND THERORY OF OPERATION 21

MODES 24

4.5 PERFORMANCE 35

SECTION 5 CONFORMANCE 37

5.1 DISPATCH VERIFICATION AND IN-FLIGHT MONITORING 37

5.2 INSTRUCTIONS

5.3 CONTROL

5.4 OPTIONAL

5.5 COMPONENT

5.6 STORAGE

5.7 END

OF LIFE 45

FOR CONTINUED AIRWORTHINESS 37

MODE 38

SERVICE 41

SERVICE 43

INFORMATION 44

5.8 DISPOSAL 45

5.9 DO-311A

5.10 DO-160

COMPLIANCE QUALIFICATION FORM 46

ENVIRONMENTAL QUALIFICATION FORM 47

2 Manual Number 9019288 • Revision D, December 30, 2020

REVISION HISTORY

Rev Date Detail Approved

A 08/02/2019 Initial release. BAW

B 10/01/2019

Revised EQF, added DO-311A Compliance Qualification

Form and provided additional limitation details (sec 2.5)

WVC

Updated style and brand to meet Marketing and

Engineering guidelines.

C 05/21/2020

Added downloadable event log feature and instructions to

load/download custom configuration parameters. Updated

DLR

DO-160 qual and installation instructions to include

grounding recommendations.

D 12/30/2020

Revised mounting instructions, corrected number of cells,

updates related to software version 1.0.2.

WVC

3 Manual Number 9019288 • Revision D, December 30, 2020

SECTION 1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The TB40 series Advanced Lithium-ion Battery, part numbers 6430040-( ), are designed to deliver

high current capability to start piston and turbine aircraft engines and subsequently, provide power

to the aircraft electrical bus in the event of generator function loss. The TB40 is a sophisticated

®

energy storage and power system that utilizes state-of-the-art Nanophosphate

lithium-ion battery

cell technology to optimize performance, safety, life and weight when compared to traditional or

competing aircraft batteries. The design of the battery includes detailed focus on key electrical,

mechanical, and software elements that combine to provide exceptional performance and safety

that meets and exceeds the latest regulatory and industry standards. The TB40 is a complete

battery solution providing significant value and benefit to an aircraft designer, owner and operator.

Key features of the TBX series (inclusive of the TB20, TB30, TB40 and TB60) include real-time

state of charge and capacity reporting, programmable battery parameters configurable to individual

installations, and maintenance-free operation with on-condition end of life. Multiple safety

protections, continuous data monitoring, and an on-board status indicator also add value,

reliability, and reduced cost of ownership for the life of the product.

The TBX series Advanced Lithium-ion Batteries require professional use and minimal service to

deliver maximum performance and value as designed. This manual contains information related to

the specifications, installation, operation, storage, scheduled service and other related topics

associated with the proper care and use of this product.

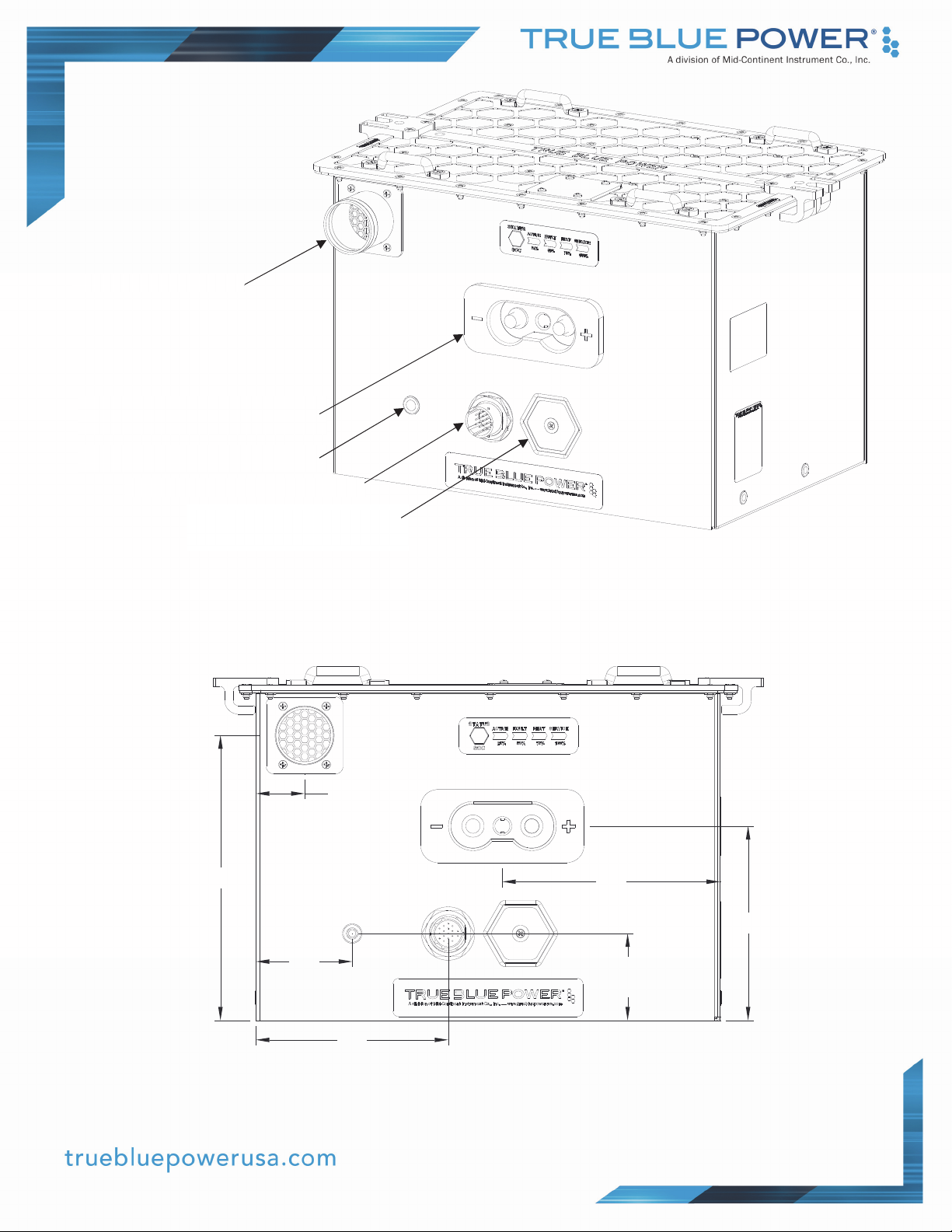

1.2 PHYSICAL ATTRIBUTES

The TB40 is a single, integrated component contained in a metal enclosure with multiple interface

connections. There is a primary 2-pin, industry standard mil-spec quick disconnect power

receptacle, an 18-pin circular communications connector, and a threaded grounding location. A

USB service port and an integrated push-button status indicator with LED indicators are available

for ground operations as well. The lid of the enclosure includes two hold-down features on either

side to support typical aircraft mounting. Handles integrated into the lid of the enclosure provide

ease of lifting and carrying for installation, removal and transport. The 1.50 inch diameter vent port

can be located on either the front or top of the unit for an exhaust connection that directs any

released emissions appropriately.

4 Manual Number 9019288 • Revision D, December 30, 2020

1.3 UNIT ARCHITECTURE

The unit is comprised of two primary building blocks:

Battery cell modules with on-board monitoring, logic, and protections

Battery Management System (BMS) with control and communication functions

Each battery module consists of thirty-two (32) cells arranged as eight (8) groups of four (4)

parallel cells, connected in series. The cells are connected with welded bus bars which contain an

individual fuse for each cell in the module. Each module contains multiple temperature monitors

and an integrated heater that improves cold weather performance. Four modules connected in

parallel through a network of bus bars provide combined power to the main connector and thus the

aircraft.

The Battery Management System (BMS) is a microprocessor-based system that monitors

individual signals provided by each module, manages battery operation and reports status

information to the aircraft. It also manages heater functionality, stores operating parameters,

contains an event log and provides interface capability.

Additional components in the unit include independent Resistance Temperature Detectors (RTDs)

that produce analog electrical signals accessible through the 18-pin connector for redundant

temperature monitoring.

5 Manual Number 9019288 • Revision D, December 30, 2020

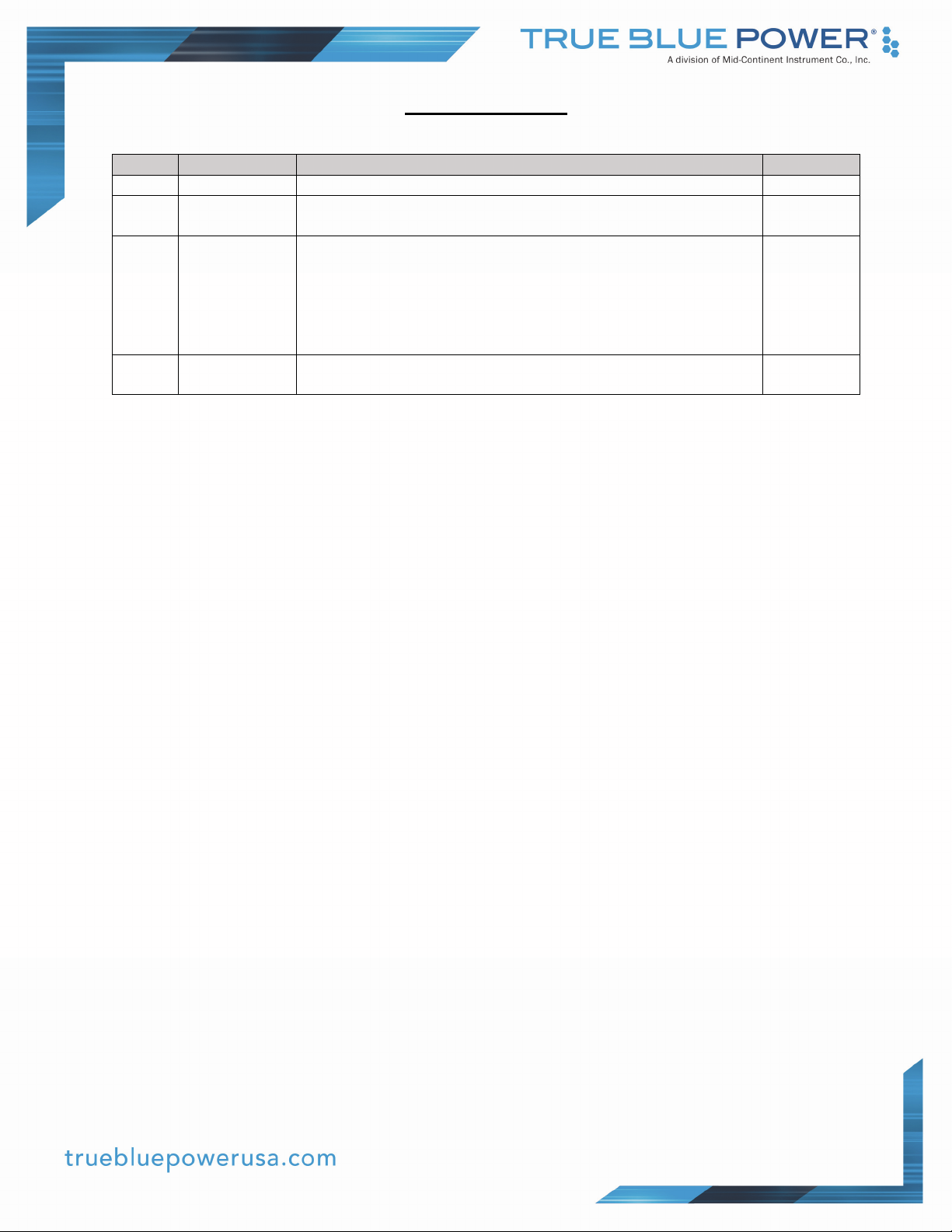

1.4 TECHNICAL SPECIFICATIONS

Electrical Attributes

Power Input 28.8 volts DC Nominal, 400A Max

Power Output 26.4 volts DC Nominal, Continuous Current 525A;

Battery Capacity

Power Peak Current (I

Power Rated Current (I

40 amp hours (Ah) @ 23°C

) 1390A (at 18.5V CV discharge);

PP

) 1125A (at 18.5V CV discharge)

PR

(Beginning of Life)

Table 1.1

Physical Attributes

Weight 36.6 pounds (16.65 kg)

Dimensions at base

(not including vent, lid and

12.1 x 8.21 x 9.2 inches (see Figure 1.1)

[308 x 208 x 236 mm]

connectors)

Quick Disconnect Power Receptacle

Communications Connector

USB Service Data Port

2-pin per MIL-PRF-18148/3 form factor (MS3509)

18-pin per MS3114E14-18P

USB 2.0, Type-A port

Mounting See Section 3.4.2

Table 1.2

Qualifications

Certification FAA TSO-C179b, Class A-4B

Performance Qualification RTCA/DO-311A Minimum Operational Performance

Standard for Rechargeable Lithium Batteries and Battery

Systems (See Section 5.9)

Environmental Qualification RTCA/DO-160G (See Section 5.10)

Software Qualification RTCA/DO-178C, Design Assurance Level (DAL) A

Table 1.3

6 Manual Number 9019288 • Revision D, December 30, 2020

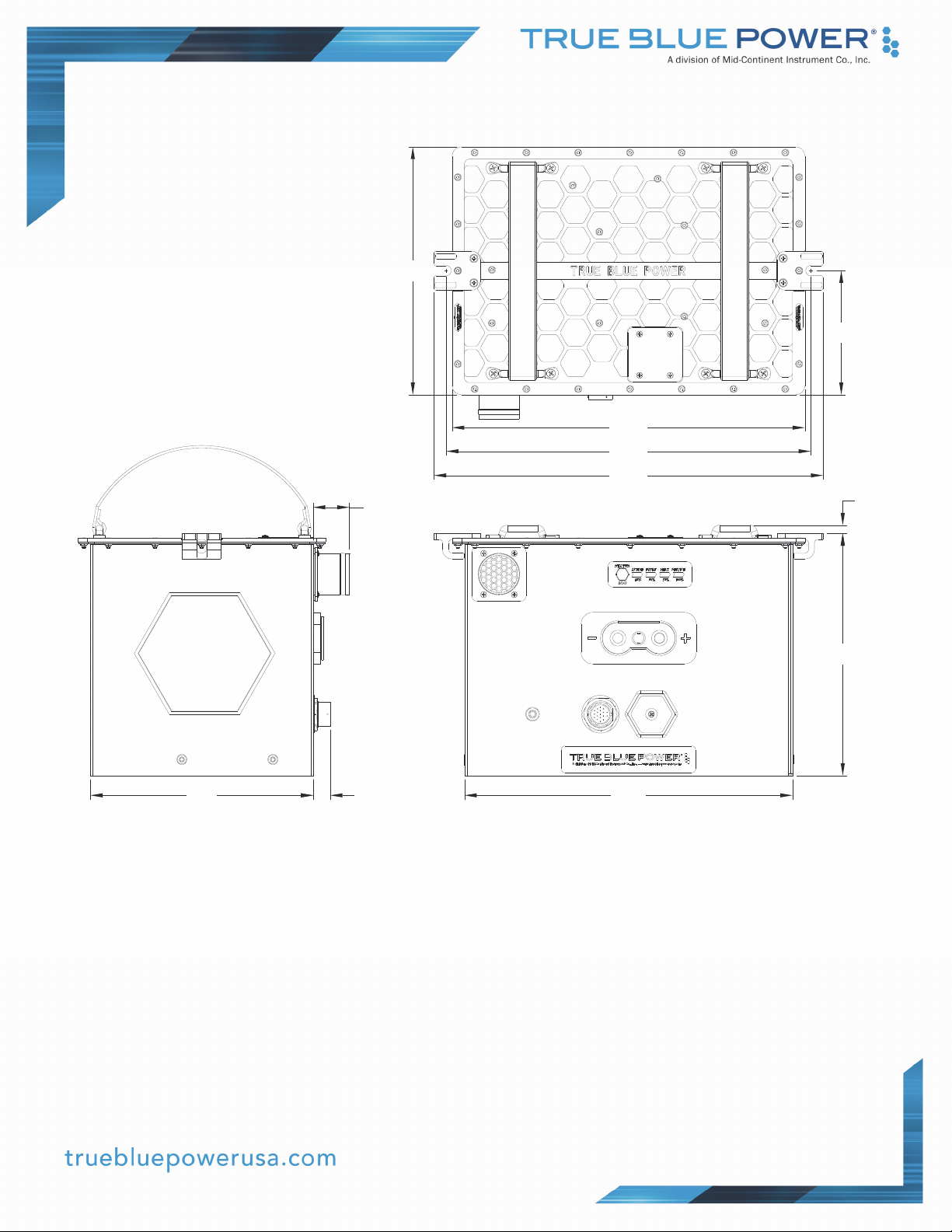

9.1

4.6

13.0

13.5

14.4

1.3

0.3

8.2 0.6

12.1

Figure 1.1

Outline Drawing

8.9

7 Manual Number 9019288 • Revision D, December 30, 2020

W

W

1.5 IMPORTANT SAFETY INFORMATION

Read this safety information BEFORE maintaining or servicing the battery.

1.5.1 Symbol Definition

This section describes the precautions necessary for safe operations. The following safety

symbols have been placed throughout the guide.

ARNING

Warnings identify conditions or practices that could result in personal injury.

CAUTION

Cautions identify conditions or practices that could result in damage to the equipment.

1.5.2 Handling Precautions

ARNING

The battery pack’s energy is high enough to sustain an ARC flash. Always wear safety

glasses, fire retardant smocks, and use insulated tools when servicing the battery.

Remove metal items such as rings, bracelets, and watches when working with battery

packs. A battery could produce a short circuit current high enough to weld jewelry to metal

and cause a severe burn.

Always use appropriate Electrostatic Discharge (ESD) protection while working with the

battery pack.

All connections for battery pack testing must include appropriate short-circuit protection.

The battery pack service area shall be properly ventilated and egress paths shall be

unobstructed.

Specialized breathing filters are not required under normal use.

Always use electrically insulated tools.

Never smoke or allow a spark or flame near the battery pack.

Use caution to reduce the risk of dropping a metal tool on the battery. Dropping a tool

could spark or short circuit the battery pack.

Turn all accessories off before removing the ground terminal.

Use appropriate lifting devices or equipment for handling batteries; use battery handles

where provided.

8 Manual Number 9019288 • Revision D, December 30, 2020

1.5.3 Additional Precautions

The following design and operation factors are required for safe use.

CAUTION

It is not acceptable to combine or use any battery cells or modules other than those

approved by True Blue Power within this battery pack.

There are no limitations in storing or using this battery in the vicinity of other battery

chemistries. This battery does not emit or absorb any gas during storage, transportation or

during normal operating conditions.

Batteries must not be installed with the output terminals reversed. A reversed battery could

be charged by other batteries in the circuit during discharge; or discharged by the charging

system during charge.

Battery terminals must be covered with non-conductive protective devices to avoid any

possibility of shorting during handling, shipping or storage.

1.5.4 Shipping

True Blue Power lithium-ion cells and batteries are designed to comply with all applicable

shipping regulations as prescribed by industry and regulatory standards. This includes

compliance with the UN recommendations on the Transport of Dangerous Goods, IATA

Dangerous Goods Regulations, applicable U.S. DOT regulations for the safe transport of

lithium-ion batteries, and the International Maritime Dangerous Goods Code. In accordance

with IATA and per UN 3480, PI 965, Section 1A and 1B, when shipped by air, the True Blue

Power Advanced Lithium-ion Battery will be shipped with a state of charge (SOC) not to

exceed 30% of rated capacity. This battery is classified as a Class 9 Dangerous Goods. If the

battery requires shipment, please contact the manufacturer for additional instructions on

proper procedures.

CAUTION

NOTE: The unit is shipped with approximately 30% state-of-charge (SOC). Upon

receipt the battery shall be fully charged using the procedures listed in this manual

(prior to storage and again prior to installation/use).

Upon receipt the battery shall be fully charged. Batteries that are stored thereafter shall be

fully recharged at a minimum every six (6) months, following the procedure set forth in

Section 5.4.2. For more detailed storage instructions refer to Section 5.6.

9 Manual Number 9019288 • Revision D, December 30, 2020

SECTION 2 PRE-INSTALLATION CONSIDERATIONS

2.1 COOLING

No internal or external cooling of the unit is required. The unit is designed to operate over a wide

temperature range and includes internal thermal monitoring and protection circuits. See Section 4

for more details.

2.2 EQUIPMENT LOCATION

The True Blue Power Advanced Lithium-ion Battery is designed for mounting flexibility, allowing for

installation with no requirement for temperature or pressure control. Although not required,

optimum performance and life can be achieved by mounting the battery in a temperature controlled

section of the aircraft. In addition to altitude and temperature tolerance, the unit is designed to

withstand high levels of condensing humidity. However, installation locations where the unit could

be subject to standing or direct water exposure should be avoided. The unit should be mounted in

the upright position.

Failure mode, effects, and criticality analysis of the battery has shown that the potential for the

release of toxic or flammable gases as a result of any potential condition is extremely

improbable. However, for additional risk mitigation, the unit is designed with a vent which should

be connected and diverted overboard in the event of such an occurrence. Details for vent

installation are provided in Section 3. For additional precaution, installation near potential sources

of ignition should be avoided.

Consideration should be given to how the status and reporting functions of the battery will be

displayed within the aircraft. At a minimum, critical parameters determined at the time of

certification should be available to the pilot and/or crew. Additionally, existing aircraft systems

which are designed to work with traditional batteries may need alteration in order to accommodate

the slight change in voltage output of this lithium-ion battery and the communication capabilities

available.

2.3 ROUTING OF CABLES

The power terminal wires associated with the unit are heavy gauge wire and carry significant

power. Be aware of routing cables near other electronics or with other wire bundles that may be

susceptible to high energy flow.

Avoid sharp bends in both the power cables and the signal cabling and be cautious of routing near

aircraft control cables. Also avoid proximity and contact with aircraft structures, avionics

equipment, or other obstructions that could chafe wires during flight and cause undesirable effects.

Cables should not run adjacent to heaters, engine exhausts, or other heat sources. The signal

cable bundle wires are recommended to be no smaller than 24 gauge.

10 Manual Number 9019288 • Revision D, December 30, 2020

2.4 LIMITIATIONS

The conditions and tests for TSO approval of this article are minimum performance standards.

Those installing this article, on or in a specific type or class of aircraft, must determine that the

aircraft installation conditions are within the TSO standards. TSO articles must receive additional

installation approval prior to being operated on each aircraft. The article may be installed only

according to 14 CFR Part 43 or the applicable airworthiness requirements.

The TBX series operates at temperatures up to 70°C. If, however, internal cell temperatures

exceed 72°C, charging is disabled until cell temperatures fall below 62°C.

2.5 MODIFICATION

This product has a nameplate that identifies the manufacturer, part number, description,

certification(s) and technical specifications of the unit. It also includes the “MOD” or modification

number representing notable changes in the hardware design of the unit.

Modification (MOD) 0 is the initial release of the product and is identified on the nameplate by the

lack of marking on the MOD numbers 1 through 9 (i.e. 1-9 are visible). All subsequent

modifications are identified on the nameplate by the marking/blacking out of that particular MOD

number (i.e. for MOD 1, the number 1 is not visible and 2-9 are visible - see Figure 2.1 for

examples). MODs do not have to be sequentially inclusive and may be applied independent of

each other.

For additional details regarding specific changes associated with each MOD status refer to the

product published Service Bulletins at www.truebluepowerusa.com.

MOD 0

MOD 1

MOD 1

& MOD 2

Figure 2.1

Nameplate and MOD Status Example

11 Manual Number 9019288 • Revision D, December 30, 2020

SECTION 3 INSTALLATION

3.1 GENERAL

This section contains mounting, electrical connections and other information required for

installation. These instructions represent a typical installation and are not specific to any aircraft.

3.2 PRE-INSTALLATION INSPECTION

Unpacking: Carefully remove the battery from the shipping container. The shipping container and

packing are designed specifically for the transit of lithium batteries and approved by international

transportation agencies. These materials should be retained for use should the unit require future

shipment.

Inspect for Damage: Inspect the shipping container and unit for any signs of damage sustained in

transit. If necessary, return the unit to the factory using the original shipping container and packing

materials. File any claim for damages with the carrier.

CAUTION

Note: The unit is shipped at approximately 30% state of charge (SOC).

Upon receipt, the battery shall be fully charged using the procedures listed

in this manual (prior to storage and again prior to installation/use).

3.3 PARTS

3.3.1 Included Parts

A. TB40 Advanced Lithium-ion Battery MCIA P/N 6430040-( )

B. Installation and operation manual MCIA P/N 9019288

3.3.2 Available Parts

A. Connector Kit MCIA P/N 9018042-1

i. Power Connector Kit

ii. Communications connector kit

B. Vent Kit MCIA P/N 9018043

i. High temp vent hose (48”)

ii. Vent clamps (x2)

C. Helicopter Mounting Kit MCIA P/N 9019576-3

i. Corner Brackets (x4)

ii. Silicone Pad

D. MX Charger MCIA P/N 282-101

E. PRO Charger MCIA P/N ACM-1260-101

3.3.3 Installer Supplied Parts

A. Wires

B. Appropriate hold-down hardware

12 Manual Number 9019288 • Revision D, December 30, 2020

W

3.4 INSTALLATION

ARNING

DO NOT SHORT TERMINALS AT ANY TIME!

Extreme care and caution should be applied when handling and connecting to the unit. Danger of

short circuit and subsequent arc flash, electrical burns or equipment damage can occur if not

handled properly.

Install the battery in the aircraft in accordance with the aircraft manufacturer’s instructions and the

following sections. If connecting batteries in parallel contact manufacturer for guidelines on parallel

operation.

3.4.1 Harness Preparation

Prepare aircraft wiring with mating connectors in accordance with the proper Wire Size and

Type (Table 3.1), Connection Features (Figure 3.1) and Pin Identification Diagrams (Figures

3.3 and 3.4).

Proper grounding requires connecting the ground lug on the chassis to the aircraft frame. In

addition, connect the ground lug to the 18-pin data communication connector backshell along

with the cable shield and any signal shields.

Use of PTFE, ETFE, TFE, Teflon or Tefzel insulated wire is recommended for aircraft use.

Recommended wire sizes and types are identified in Table 3.1 below. *Note: Wire gauge size

for power connections is dependent on the particular aircraft installation, taking into

consideration cable length, load profile, etc.

Wire Gauge Wire Type Connector Pins

000 AWG * Stranded Copper Power +/-

Wire Size and Type

18-24 AWG Stranded Copper Comm (18-pin) A-U

Table 3.1

Wire Size and Type

13 Manual Number 9019288 • Revision D, December 30, 2020

1½ inch Vent Port

Quick Disconnect Receptacle

per MS3509 (MIL-PRF-18148/3)

¼-20 Threaded Ground Lug

18-pin Data Communication

USB Access Cover

Figure 3.1

Connection Features

1.3

7.4

2.5

5.0

5.7

5.1

3X

2.3

Figure 3.2

Connection Locations

14 Manual Number 9019288 • Revision D, December 30, 2020

Communication Connector

(18-pin)

Pin Description

K

HSRD

M

LA

NB

PUTJ

EFG

C

A Analog SOC

B Battery Disable Input

C Heater Disable Input

D RTD-1A

Figure 3.3

Communication Connector

E RTD-1B

F RTD-2A

G RTD-2B

H ARINC 429 (A)

J Service Discrete

K Fault Discrete

L Heating Discrete

M Min Capacity Discrete

N Analog Ground

P Spare / BMS Ref *

R Spare

S ARINC Shield

T Engine Start Discrete

U ARINC 429 (B)

Table 3.2

Communication Connector Pinout

Negative/

Ground Pin

Positive/

Power Pin

Power Receptacle

(2-pin)

Pin

+

-

Description

28VDC power in

Aircraft Ground

Figure 3.4

Power Connector

* Note: Communication Connector pin P is a BMS ground reference.

This does not apply to any of the TBX battery models with p/n ending in -1.

15 Manual Number 9019288 • Revision D, December 30, 2020

3.4.2 Securing the Unit

The battery is designed to be secured in the aircraft using hold-down rods. The hold-down

features are integrated into the lid of the battery. The hold-down consists of a slot for the

hold-down rod, open to the outboard sides, and two perpendicular slots on each side to keep

the rod vertical using an alignment washer. The battery is then secured with the appropriate

nut or hardware designed to mate with the rod. Tighten the nut or equivalent to approximately

25 in-lbs (2.8 Nm). It is recommended to constrain the battery bottom with angle brackets or

similarly constructed features in the aircraft.

9.1

1.5

13.0

13.5

14.4

0.8 0.2

0.4

0.41.11.4

4.6

5.5

0.2 deep

Figure 3.5

Hold-Down Mounting Features

16 Manual Number 9019288 • Revision D, December 30, 2020

TB40 installations in a rotary wing environments require the helicopter mounting kit (see

Section 3.3.2), which includes corner braces and a silicone pad to limit overall motion of the

battery. Alternative/similar mounting hardware can be used at the discretion of the installer.

Figure 3.6

Helicopter Mounting Kit

17 Manual Number 9019288 • Revision D, December 30, 2020

t

3.4.3 Vent Installation

It is recommended that the battery be operated with the vent tube in place when installed in

the aircraft. The vent port is 1.50 inches in diameter and has a protrusion just inboard around

the outside diameter to help prevent any disengagement of the attached vent tube.

There are two possible locations for the vent port to be configured. The default position is on

the front face of the unit in the upper left corner. The alternate location is on the top of the

unit on the front-center of the lid. See Figure 3.2 and 3.5 for the vent location dimensions.

Both locations are eligible for certified installation. If the alternate location is desired, simply

remove the four screws and vent port from its original location, remove the four screws and

blank plate from the alternate location, switch the positions and reinstall. Visually verify that

the silicone gasket between the port or plate and the case fully covers the holes in the case

and has not squeezed completely out from under either part. Screw torque applied should be

approximately 5.5 in-lbs. See Figure 3.6 for a diagram of the vent and blank plate assembly.

A Vent Kit is available that includes a high temperature vent hose and hose attachment

hardware (see Section 3.3.2). Contact True Blue Power for potential alternatives. The vent

tube should be properly and securely attached to an aircraft exit point which would allow any

gaseous emissions to be vented overboard. The battery produces no emissions during

normal operation. Emissions will only be present in the event of a battery failure. Be sure to

locate the vent where emitted gases would not be directed toward any of the aircraft’s air

intake points.

Blank Plate

Gaske

Gasket

Vent Port

Figure 3.6

Vent Location Option

18 Manual Number 9019288 • Revision D, December 30, 2020

3.4.4 Custom Programmable Parameters

The True Blue Power Advanced Lithium-ion Battery is designed with software control that

provides the ability to configure it with custom parameters that are specific to the aircraft. This

can only be done while the battery is not in flight and is in Control Mode (see 4.3.2).

Custom configuration parameters are loaded onto the unit using a standard USB 2.0

compatible flash drive (see Section 5.3.2). A fixed file format and file name with valid data

parameters is required to be loaded onto the battery. Invalid file formats or data will be

rejected and not allowed to load. Contact True Blue Power to coordinate parameter and file

creation for your application.

The following parameters are available for configurable customization:

Charge Current Limit

Setting the charge current limit restricts the maximum current that the battery is allowed to

consume from the aircraft electrical bus. Because of the very low internal impedance of the

battery, it can provide extremely fast charging and discharging at high current. For some

aircraft that have limited electrical power available, or to manage power consumption at a

known amount, a current limit may be desired.

The Charge Current Limit can also be disabled (by setting Charge Current Limit to 0),

allowing the battery to charge as quickly as possible and take up to its maximum charge

current. The Charge Current Limit parameter is not required; it is set to 0 (disabled) as the

initial factory default.

End of Life

Setting an End of Life capacity provides an ARINC and discrete signal to indicate when the

battery is approaching, or at, End of Life and in need of replacement. This is based on a

comparison of the programmed value with the battery’s real-time capacity measurement. End

of Life capacity is determined in accordance with the specific aircraft requirements at time of

the battery installation certification. This is typically the minimum capacity required to provide

power to critical aircraft systems for a particular period of time in the case of primary power

generation loss. The End of Life capacity parameter and indication is not required; it is set to

0Ah (disabled) as the initial factory default.

Minimum Capacity

Setting a Minimum Capacity value provides an ARINC and discrete signal that validates the

state of charge against the aircraft’s specific required minimum for emergency operations.

This is typically used to verify that the battery has been charged sufficiently prior to dispatch

to support an emergency mission profile. A Minimum Capacity parameter and indication is

not required to be programmed; it is set to 0% (disabled) as the initial factory default.

19 Manual Number 9019288 • Revision D, December 30, 2020

Engine Start

Setting the Engine Start parameters provides ARINC and a discrete signal indicating that the

required amount of energy and peak current, given the existing environmental conditions and

state of the battery, is available to complete a full engine start. This indication is useful to

avoid a potential ‘hot start’ with a turbine engine due to the battery depleting before

completing the start sequence. Coordinate with the manufacturer to determine the proper

Engine Start parameter values based on specific engine start characteristics.

o The first Engine Start parameter is Start Energy required. An Engine Start

parameter of 0Wh bypasses evaluating the energy for an engine start.

o The second Engine Start parameter is Engine Start Peak Current required. An

Engine Start Peak Current parameter of 0A bypasses evaluating the maximum

current required for an engine start.

The Engine Start parameters are not required to be programmed; they are both set to 0

(disabled) as the initial factory default.

3.4.5 Event Log

The True Blue Power Advanced Lithium-ion Battery is designed with software features

providing downloadable event logging capability which captures fault and failure events as

well as high current discharges typically occurring during engine starts. The event log can

capture approximately 45,000 time stamped events available for downloading to a USB 2.0

compatible flash drive. If the number of events exceeds the maximum number of events, then

older events are overwritten. Downloading events can only be done while the battery is not in

flight and is in Control Mode (see Section 4.3.2).

To download the event log onto a USB flash drive, follow instructions in Section 5.3.4.

Contact True Blue Power for further details with respect to the event log.

20 Manual Number 9019288 • Revision D, December 30, 2020

SECTION 4 OPERATION

4.1 DESCRIPTION

The True Blue Power TBX series Advanced Lithium-ion Battery is designed to supply power for

starting an aircraft engine and providing emergency backup power to aircraft systems in the event

of primary power generation loss. It utilizes rechargeable Nanophosphate lithium-ion cells in a

parallel and series configuration to provide the specified voltage, power and total energy capacity.

The unit supplies power through a connector with positive and negative power terminals and

provides battery status and communication through an 18-pin circular connector.

4.2 CONSTRUCTION AND THERORY OF OPERATION

4.2.1 Cells

The TB40 Advanced Lithium-ion Battery contains 128 individual cylindrical lithium-ion cells.

Lithium-ion battery cells have a very high energy density, producing more power than

comparable battery types in a significantly lighter package. The cell’s high-performance

Nanophosphate chemistry is a proprietary form of lithium iron phosphate (LiFePO4). The

lithium iron phosphate chemistry provides safety enhancements over alternative lithium

technologies by producing a cell that is more abuse tolerant to external conditions like overcharge or short circuit. It has a very low self-discharge rate, high cycle life, and is more stable

with significantly less-energetic failure modes. The Nanophosphate advantage enhances

typical lithium iron phosphate chemistries by providing exceptional power and energy. The

combination of these characteristics make it an excellent choice for use in aircraft

applications where high power, less weight, and enhanced safety are of utmost importance.

4.2.2 Battery Modules

The TB40 is comprised of four identical battery modules. In each module, four individual cells

are connected in parallel to form a battery string; and eight strings are connected in series to

produce a module of 32 total cells. At a full, rested charge, each cell (and string of cells)

supplies approximately 3.3 VDC. The individual cells provide up to 120A of current and 2.5Ah

of energy, or capacity. When connected as described above, each module is rated to provide

10Ah of energy at 26.4VDC. When four modules are connected in parallel, the battery

provides a voltage of 26.4VDC, a total capacity of 40Ah, and a peak current of 1500A. Each

module contains two circuit boards, the Control and Switch boards. Monitoring wires are used

to report cell voltages to the Control board for balancing, protections, status and health.

Additionally, each module has multiple temperature sensors, bus bars with individual cell

fuses, cell heaters and mechanical construction designed to secure the cells for an aircraft

environment. The individual cell fuses allow for the potential of a single cell failure to occur

without a significant safety concern or complete loss of function.

21 Manual Number 9019288 • Revision D, December 30, 2020

Switch Board

The Switch board incorporates high-power transistors used to enable and disable

charging or discharging of the unit. This allows for the unit to take action based on its own

monitoring and protections to prevent damage to the product. The Switch board also

contains the current limiting functionality. This important feature allows the battery to

control the amount of current it will accept from aircraft. Although the very low internal

impedance of lithium-ion cells produces benefits of fast charging and high power, it also

can accept as much or more than many aircraft power generation systems can supply.

The current limiting feature prevents the unit from utilizing the full available power of the

aircraft so that other key systems can remain active. The Switch board also includes the

unit’s ability to measure current flow of the battery as a protective input.

Control Board

The Control board contains the logic to collect cell parameters and report to the Battery

Management System (BMS). It also receives decisions back from the BMS and sends

information to the Switch board to enable, limit, or disable charging and discharging.

4.2.3 Battery Management System (BMS)

The BMS board is independent of the modules and manages the power control and external

data interface of the battery. Using cell and battery conditions passed to it by the Control

boards, the BMS microcontroller and software provide instructions back to the Control

boards, and through it, the Switch boards, to control the battery. The software logic monitors

the battery functions and provides protections for conditions such as short circuit, overtemperature, over-discharge and others. It also controls the internal heaters. The BMS

generates battery status and data that is provided to the aircraft through the 18-pin

communication connector for cockpit monitoring. Data is provided in serial (ARINC 429),

discrete, and analog formats. The BMS provides the logic that operates the built-in/on-board

visual status indicator on the outside of the case as well.

The software is qualified to RTCA/DO-178C, Design Assurance Level A (DAL A). The battery

contains no airborne electronic hardware, known as AEH or complex hardware.

4.2.4 Resistance Temperature Detectors

There are two Resistance Temperature Detectors (RTDs) in the unit that supply direct analog

resistance through four pins on the 18-pin connector for independent temperature monitoring.

Each RTD uses two pins of the connector (see Figure 3.3 and Table 3.2) and are

characterized with a resistive output. See Section 4.4.1 for details.

22 Manual Number 9019288 • Revision D, December 30, 2020

4.2.5 Case and Hardware

The mechanical construction plays a key role in the design to specifically support optimal

functionality, mitigate and contain any potential failure, and withstand the expected aircraft

environment. Material selections, component design, assembly processes and test all

contribute to the performance and safety of the product.

Nickel bus bars are used to connect the individual cells within the modules. Larger bus bars

then connect each module to the main connector to deliver the battery power. Temperature

and electrical insulating materials are used to support the cells within the modules and to

isolate all internal surfaces from the metal case. Each module uses an internal aluminum

heat sink that connects to the machined lid for thermal management, particularly during

charge current limiting and high discharges. A threaded connection is provided for

convenience to ground the battery to the airframe. A nylon handle is used for ease of

transport and handling.

The case is constructed to address the unique needs of lithium technology. In particular, it is

designed to contain and direct emitted gases overboard, maintain a safe external

temperature and pressure, constrain any debris or flame and ultimately to prevent any effect

on its surroundings in the aircraft, even during a worst-case failure scenario.

4.2.6 Visual Status Indicator

The battery has a built-in/on-board status indicator incorporated into the front face of the

battery. This can be used to quickly and visually determine the battery’s status and state of

charge either on the aircraft or off, during storage or service. The status indicator will identify

any of the following states: ACTIVE, FAULT, HEAT, and/or SERVICE. It can also be used to

assess the state of charge. More details can be found in Sections 4.3 and 4.4.

4.2.7 Data Exchange Access

The front face of the battery has a sealed hexagonal access cover below the main power

connector, secured with a single screw. When removing the cover, it reveals access to a

USB Type-A port, a recessed service button, and a service light. These can be used in

Control Mode to update the battery software, configure its customizable parameters, validate

the custom parameters and download the event log. More details can be found in Section

5.3.

23 Manual Number 9019288 • Revision D, December 30, 2020

4.3 OPERATIONAL MODES

The battery has three basic modes of operation: Sleep Mode, Control Mode, and Active Mode.

These modes, and associated functionality, are explained below.

4.3.1 Sleep Mode

Sleep Mode is used to disable the power output of the battery and reduce internal energy

consumption to preserve resting state of charge. When the battery is in Sleep Mode, the

battery is not charging or discharging, the internal battery heaters are inactive, all active

communications are disabled, and internal energy consumption is reduced by 90% with

respect to Active Mode.

In Sleep Mode, up to 30mA of power is available that enables low power devices to operate

without causing the battery to transition to Active Mode. The battery is also capable of

monitoring the terminals for an external load or charge and the external control discrete

inputs (battery disable and heater disable) while in Sleep Mode.

The battery will enter Sleep Mode when the Battery Disable control discrete is engaged

(closed), when the battery is inactive or when the STATUS/SOC button is held for 3 seconds.

The battery is inactive when all of the following conditions are true:

Internal battery voltage is less than 27.5VDC (unless STATUS/SOC button is held for

3 seconds while in Active Mode)

Five minutes after:

o No charge or discharge (<400mA)

o No protections actively being applied

o Pre-heat cycle is off

4.3.2 Control Mode

Control Mode is reserved exclusively for the following interactions with the battery:

Battery Software Update

Installing Custom Programmable Parameters

Downloading Custom Programmable Parameters

Downloading Event Log

Control Mode is not available or accessible in flight. In order to enter Control Mode, the

battery must not be charging or discharging, the service button must be pressed, and a valid

USB flash drive must be present in the USB port.

Additional information regarding the customization of the configuration parameters can be

found within Section 3.4.4. Information regarding software updates, custom programmable

parameters and event log can be found in Section 5.3.

24 Manual Number 9019288 • Revision D, December 30, 2020

4.3.3 Active Mode

In Active Mode, the battery is fully functional and available to provide power barring no

protections are being enforced and the battery is operating properly. In Active Mode, the

battery continuously monitors all cells and battery conditions to manage operation and

mitigate exceedances as needed through its various protection methods. Data and status is

available through the communication connector and the heater is available in cold conditions

while in Active Mode. Each major function available during Active Mode is described in

further detail below.

The following figure and table summarizes the transitional conditions between the Sleep

Mode, Active Mode, and Control Mode.

Figure 4.1

Operational Modes State Diagram

25 Manual Number 9019288 • Revision D, December 30, 2020

Engine Start

The TB40 battery can provide a peak current of 1500A for the purpose of aircraft engine

starting. It will provide a maximum of 1120A (280A maximum per module) for up to 15

seconds and below 525A continuously. The low internal impedance of the

Nanophosphate lithium-ion chemistry allows extremely high current delivery while

maintaining higher voltage than traditional battery types. This equates to a higher total

power delivery, producing quicker, stronger starts, lower engine temperatures, more start

attempts when needed, and a higher remaining battery capacity following engine start.

The higher voltage also means better power to supporting systems during an engine

start.

Providing Aircraft Power

When the aircraft’s power generation systems are offline or fail, the unit will provide

immediate power to the equipment/loads on the associated power bus. As the unit’s

capacity is used, the voltage will begin to drop until the unit is fully depleted. A fully

charged unit will initially provide approximately 28 volts. Depending on the load, the

battery will provide an average of approximately 25.5 volts for the duration of discharge.

See Section 4.5. for more details on available capacity.

In order to avoid depleting the unit’s power and ensure availability for the next flight, be

sure to turn off all aircraft systems, lights and accessories after a flight. If the unit is

depleted, see Section 5.4.2 for charging instructions.

Maintaining Charge

After engine start, the unit recharges and maintains charge by accepting power from the

aircraft power generation system. The battery can be customized to set the charge

current limit such that the battery will only draw a pre-determined maximum amount of

current from the aircraft bus. The time required to replenish the capacity of the battery is

a function of the depth of initial discharge and the value of the current limit. See Section

3.4.4 for more details on the configurable current limit feature.

At maximum charge current, a fully depleted battery can be recharged to 95% SOC in

less than 15 minutes. In typical applications, the unit is likely to be fully recharged from

the aircraft power generation system within several minutes following an engine start.

26 Manual Number 9019288 • Revision D, December 30, 2020

Heating

The battery is designed to support an engine start from as low as -5°C (23°F), depending

upon the engine start profile, without pre-heat required. Below this temperature, the

performance of the unit begins to decrease in current and energy delivery as the

electrolyte in the cells begins to thicken and the internal impedance increases to retard

ion flow. To address this, each module contains an individual heater which is powered by

the cells themselves, even at very low temperatures.

The heaters are available at all times when the battery is both in Active Mode and when

the Battery and Heater Disable signals are off/inactive. The heaters will only provide heat

when active and when the battery temperature is sensed below 0°C. The heaters will stop

heating when the internal battery temperature is above 5°C. The heaters will

automatically turn on and off as needed until the battery enters Sleep Mode or the Heater

Disable signal is engaged. When the heaters are active, they consume approximately

300W each for a total of 1200W on a TB40 battery.

Pre-Heat Cycle

The battery has the ability to pre-heat itself at temperatures down to -40°C (-40°F)

utilizing the internal, self-powered heaters, bringing the battery up to full operational

capability. Pre-heat time will vary depending on temperature but can be fully warmed in

15 minutes or less after turning the heaters on.

(See Section 4.5 for more details on pre-heat times and energy use.)

The battery transitions to Active Mode and the ACTIVE green LED on the Status Indicator

blinks once every three seconds when in the Pre-Heat Cycle .

The Pre-Heat Cycle can be initiated in one of two ways:

(Battery Disable signal, if installed, must not be engaged/closed)

From Sleep Mode press the STATUS/SOC button.

Toggle the Heater Disable signal from open > closed > open.

The Pre-Heat Cycle will continue to maintain the battery temperature for one hour, and

then enter Sleep or Active Mode (per 4.3.1, 4.3.3), unless one of the following occurs:

Press and hold the STATUS/SOC button for 3 seconds.

Battery will immediately transition to Sleep Mode if the battery is not charging or

discharging.

Close/ground the Heater Disable signal (if installed).

If the Pre-Heat Cycle has been active for less than 5 minutes, the HEAT yellow

LED will be on until the battery enters Sleep Mode (4.3.1).

If the Pre-Heat Cycle has been active for more than 5 minutes, it will

immediately transition to Sleep Mode.

Close/ground the Battery Disable signal (if installed)

Battery will immediately transition to Sleep Mode.

27 Manual Number 9019288 • Revision D, December 30, 2020

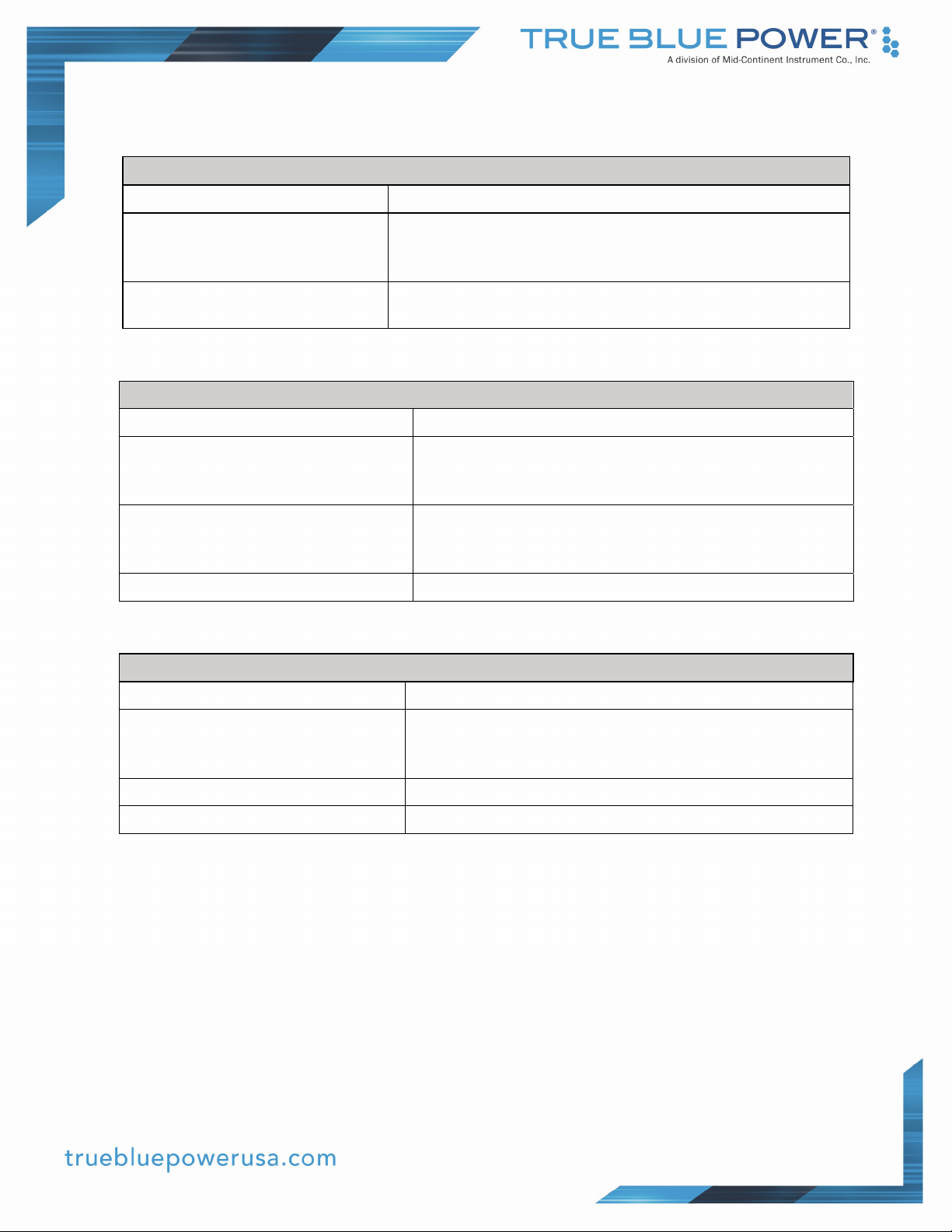

The TBX series Advanced Lithium-ion Battery has built-in protections for conditions that

may exceed specified operating limits:

Protection

Battery Protections

Parameter(s) Action Recovery

Under Voltage

(low current)

If discharge current < 160A and

battery voltage < 16VDC or cell

string voltage < 1.8VDC

Under Voltage

(high current)

If discharge current > 160A and

battery voltage < 12VDC or cell

string voltage < 1.0VDC

Over Discharge Any module cell string voltage <

1.2VDC and current

< 100mA for 10 seconds

Over Voltage Module voltage > 30.6VDC

or

Any cell string voltage > 3.8

VDC

Over Current Battery discharges > 1120A

(280A per module) for more

than 15 seconds

Discharging

disabled

Battery Voltage > 20VDC and

Cell string voltage > 2.5VDC

(Charging will be limited to

4A/Module until Module Voltage >

20VDC or Module Cell String

Voltage > 2.5VDC)

Discharging

disabled

Battery Voltage > 20VDC and

Cell string voltage > 2.5VDC

(Charging will be limited to

4A/Module until Module Voltage >

20VDC or Module Cell String

Voltage > 2.5VDC)

Module is

disabled Factory Service

Charging

disabled

Module voltage < 29.2 VDC

and

All cell string voltages < 3.6 VDC

Discharging

Disabled

External Load removed or charging

current detected

Short Circuit Battery detects current > 1500A

for > 100ms

Over

Temperature

(Discharging)

Any cell temperature > 95°C

or

Discharge control circuitry

>130°C

Over

Temperature

(Charging)

Cell Over

Any cell temperature > 72°C

or

Charge control circuitry >130°C

Any cell temperature > 110°C Module is

Temperature Fail

Discharging

Disabled

Discharging

Disabled

Charging

disabled

disabled

External Load removed or charging

current detected

All cell temperatures < 80°C

and

Discharge control circuitry < 90°C

All cell temperatures < 62°C

and

Charge control circuitry < 90°C

Factory Service

Table 4.1

Battery Protections

28 Manual Number 9019288 • Revision D, December 30, 2020

4.4 BATTERY COMMUNICATION

When in Active Mode, the Advanced Lithium-ion Battery presents multiple status indications and

data to the aircraft for display and monitoring on appropriate systems. These are supplied as either

serial, discrete, or analog signals. The various outputs and their definition are supplied in Sections

4.4.1 through 4.4.3. Locations and descriptions of each pin of the 18-pin communications

connector are listed in Figure 3.3 and Table 3.2.

The battery also provides an on-board status indicator that can be used on- or off-aircraft to

determine current health and state of charge; see Section 4.4.4.

4.4.1 Analog Communication Signals

The battery provides two pieces of data via analog outputs. These are temperature data from

the dual, independent RTDs and analog state of charge.

Each RTD has a resistance of 100 ohms at 0°C. Resistance (ohms) for all temperatures (T,

in degrees Celsius) can be calculated using the following formula(s):

2

(per specification) Resistance = 100 x [1 + (0.00390833 x T) + (0.00000057753 x T

)]

(linear approximation) Resistance = (0.3781 x T) + 100.24

(temp from resistance) Temperature = (R – 100.24) / 0.3781

RTDResistancevs.Temperature

200

175

150

125

Resistance(Ω)

100

75

‐40

‐30

The battery also provides the state of charge as an analog output. The state of charge of the

battery is represented from 0 to 100% as 0 to 5VDC. This signal can be used to drive either a

digital or mechanical indication of the state of charge in lieu of the serial communication

signals if preferred. The voltage reference is between Pin A (‘Analog SOC’) and Pin N

(‘Analog Ground’).

‐20

0

102030405060708090

‐10

100

110

Temperature(°C)

Figure 4.2

RTD Resistance vs. Temperature

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

29 Manual Number 9019288 • Revision D, December 30, 2020

4.4.2 Discrete Communication Signals

Discrete signals are available to provide both basic battery status and simplified indication of

battery readiness specific to the aircraft’s requirements. In some cases, where serial data

cannot be integrated with the aircraft’s avionics or other messaging systems, the discrete

battery status signals can be used to meet minimum regulatory annunciation requirements for

lithium batteries.

Each discrete output is normally open and provides an active low/ground when the condition

is true as described below. The circuit consists of a MOSFET connected to the battery

negative (ground) with a series resistance of 60Ω. Each pin is current limited to 50mA.

Discrete Communication Signals

Heating Active when the Heater is providing heat.

Fault Active when the battery has an internal fault. Internal faults may be

temporary and may result in partial or fully degraded functionality.

Faults may clear with time or upon next usage. Verify battery health

and availability by cross-checking other parameters (voltage, state of

charge, etc.).

Service Active when the battery has a permanent fault. Service faults may

result in partial or fully degraded function. Verify battery health and

availability by cross-checking other parameters (voltage, capacity,

state of charge, etc.). Battery should be submitted for service in

accordance with the aircraft’s flight manual supplement.

Min Capacity Active when the battery has determined that its state of charge is

BELOW the value programmed according to the aircraft’s

customizable configuration parameters.

Engine Start Active when the battery has determined that its available energy is

NOT sufficient to fully complete an engine start. The requirements to

complete an engine start must be programmed according to the

aircraft’s customizable configuration parameters.

Table 4.2

Discrete Output Definitions

There are two discrete inputs as described below. Both are normally open and are required

to be grounded to activate their function.

Battery Disable: This input, when grounded, manually and fully disables the battery,

including power and communication.

Heater Disable: This input, when grounded, manually disables the heaters from

operating.

30 Manual Number 9019288 • Revision D, December 30, 2020

4.4.3 Serial Communication Signals

The battery generates a sophisticated array of situational status and data available for realtime reporting and awareness. This is provided to the aircraft in the form of serial data using

the ARINC 429 protocol. Below is the definition of the data the battery provides. Contact the

manufacturer to receive additional details associated with the format of the data provided for

each label.

ARINC 429 Parameter Descriptions

Label Parameter Name Definition

271 Battery Discrete

Outputs

Provides equivalent serial representation of the previously defined

Discrete Communication Signals described in 4.4.2.

340 DC Current Amperage being supplied (discharge (+)) or accepted (charging (-)).

341 DC Voltage Voltage at the battery terminals.

342 Battery Temp Internal temperature of the battery (°C).

343 Deliverable

Energy

Amount of energy the battery can currently deliver at a 1C rate.

Deliverable Energy is defined as State of Charge (%) x Current

Maximum Capacity.

Example: A TB40 has aged and its current maximum capacity is

36Ah, instead of its original beginning-of-life 40Ah. If its current

State of Charge is 80%, then:

Deliverable Energy = 80% x 36Ah = 28.8Ah.

344 Capacity Current maximum capacity of the battery. This is the real-time

tracking of the battery’s capacity that decreases over time with age

and use.

345 State of Charge Total amount of charge the battery has, in relation to its capacity (%).

346 Life Remaining Percent of capacity left before the battery’s capacity reaches the

programmed End of Life.

Example: A TB40 has been programmed for End of Life of

30Ah for a given aircraft. The current capacity, due to aging, is

now 36Ah, then:

Life Remaining = (36Ah – 30Ah) / (40Ah – 30Ah) = 6 /10 = 60%.

350 Software Version Loaded software version presented as X.Y.Z (Example: 1.0.1).

351 Operational Status Provides three discrete states: Charging, Charge Limiting,

Discharging.

352 Fault Status Provides discrete indication of any active faults (see next page).

377 Equipment ID ARINC defined equipment identifier: 0B3.

Table 4.3

ARINC 429 Label Definition

31 Manual Number 9019288 • Revision D, December 30, 2020

ARINC 429 Label Format Definition

Sig

Label Parameter Name Data Type Range Units

271

340 DC Current BNR ± 4096 A 15 0.125 250 500

341 DC Voltage BNR 64 V 15 0.001953 250 500

342 Battery Temperature BNR ± 512 C 12 0.125 1000 2000

343 Deliverable Energy BNR 512 Ah 13 0.0625 1000 2000

344 Capacity BNR 512 Ah 13 0.0625 1000 2000

345 State of Charge BNR 128 % 11 0.0625 1000 2000

346

350 Software Version DISCRETE X.Y.Z - - - 1000 2000

351 Operational Status DISCRETE - - - - 500 1000

352 Fault Status DISCRETE - - - - 500 1000

Battery Discrete

Outputs

Estimated Life

Remaining

DISCRETE - - - - 250 500

BNR 128 % 11 0.0625 1000 2000

Bits

Resolution

Transmit Interval

(ms)

Min Max

377 Equipment ID DISCRETE - - - - 1000 2000

Table 4.4

ARINC 429 Label Format

Fault Status Indications for ARINC Label 352:

Invalid Configuration

Stack Over Voltage

Cell Over Voltage

Charge Cell Over-temp (Disable Charging)

Over Current

Short Circuit

Cell Under Voltage

Stack Under Voltage

Discharge Cell Over-temp (Disable Discharging)

FET Over-temp

Continuous BIT Fault

Continuous BIT Failure

End of Life

Over-Discharge

Heater Fault

Heater Fail

32 Manual Number 9019288 • Revision D, December 30, 2020

4.4.4 On-board Status Indicator

The on-board Status Indicator can provide on-demand health status and state of charge. It

can also be used to manually transition the battery from Sleep Mode to Active Mode by

pressing the STATUS button. This can be used to check status, state of charge, or to initiate

the heaters to pre-heat the battery (if the battery is cold).

When the battery is in Active Mode, status is continuously displayed. Status is listed as one

or more of four states as listed below. For each state, a lighted chevron will appear under the

associated label on the Status Indicator. Note that the gray chevrons in Figure 4.3 are not

visible (black) on the Status Indicator until a lighted annunciator segment is active.

Active Solid Green indicator: Battery is Active.

Flashing Green indicator: Battery is in Pre-Heat Cycle.

Fault Solid Yellow indicator: Battery has an internal fault. A fault is also

communicated through both the discrete fault signal and via ARINC.

See Section 4.4.3 for further description.

Heat Flashing White indicator: Battery heaters are currently heating.

Solid Yellow indicator: Heater is disabled.

Service Solid Red indicator: Battery has a permanent fault. A service fault is

also communicated through both the discrete service signal and via

ARINC. See Section 4.4.3 for further description.

The Status Indicator can also provide on-demand state of charge. By temporarily pressing

the STATUS/SOC button, the chevrons will quickly cycle in blue, indicating a change to state

of charge indication. The Status Indicator will display nine different state of charge ranges for

approximately six seconds as described below in Table 4.5. See 4.4.4.1 for additional

functions of the STATUS/SOC button.

State of Charge

0 - 10 % Flash Yellow Off Off Off

10 - 15 % Dim Green Off Off Off

15 - 25 % Solid Green Off Off Off

25 - 40 % Solid Green Dim Green Off Off

40 - 50 % Solid Green Solid Green Off Off

50 - 65 % Solid Green Solid Green Dim Green Off

65 - 75 % Solid Green Solid Green Solid Green Off

75 - 90 % Solid Green Solid Green Solid Green Dim Green

90 - 100 % Solid Green Solid Green Solid Green Solid Green

Indicator 1

“25%”

Indicator 2

“50%”

Indicator 3

“75%”

Indicator 4

“100%”

Table 4.5

State of Charge Indication

33 Manual Number 9019288 • Revision D, December 30, 2020

Figure 4.3

On-Board Status Indicator

STATUS/SOC Button

Pressing the STATUS/SOC Button serves several purposes.

From Active or Sleep Mode:

o Cycles the chevrons in blue, followed by the state of charge (SOC)

indication, followed by continuous display of the Status indication.

o Initiates a self-test of all battery discrete outputs which are set to active for

10 seconds.

From Sleep Mode (in addition to above):

o Places the battery into Pre-Heat Cycle.

From Active Mode, when pressing and holding for three seconds:

o Transitions to Sleep Mode

If the battery is charging or discharging, it will blink the ACTIVE green

LED and then remain Active (not enter Sleep Mode).

34 Manual Number 9019288 • Revision D, December 30, 2020

4.5 PERFORMANCE

4.5.1 Capacity

Capacity is the measurement of the energy stored in the battery and most often is used to

determine the length of time a particular electrical load can be operated. A standard measure

of rechargeable battery capacity is the current-over-time performance (measured in amphours) called the “C” rate.

The C-rate is a function of the size of the load in relation to the capability of the battery. A 1C

rate corresponds to a constant current load (in amps) which the battery can supply for one

hour. The TB40 has a 1C rating of 40Ah and thus can supply 40 amps for one hour. Note that

many typical lead-acid batteries, and some lithium systems as well, are defined at a 1/20

(0.05) or 1/5

th

(0.2) C-rate. This is defined as the constant load that can be applied over 20 or

5 hours, respectively. For example, a lead-acid battery rated at 40Ah at a 0.2 C-rate can

deliver 8A for 5 hours (8A x 5 hours = 40Ah). However, that same system typically does not

perform linearly at higher C-rates. For instance, the same 40Ah lead-acid battery rated at

0.2C may typically only support a 40A load for 45 minutes, not a full hour, resulting in a true

1C capacity of only 30Ah. The capacity for these types of batteries is generally defined by a

logarithmic function of load versus time. So, when doubling the load, a lead-acid battery will

last less than half the time.

One of the significant advantages of lithium-ion technology is its constant capacity versus

load. As the load on the TB40 increases, its capacity maintains its rating proportionately. As

an example, if the standard 1C load of 40A is doubled to the 2C load of 80A, the discharge

duration is proportionally cut in half to 30 minutes. Doubling the load again to 160A would

deplete the battery in 15 minutes.

th

35 Manual Number 9019288 • Revision D, December 30, 2020

4.5.2 Temperature Performance

The TBX series incorporates cell technology that performs well over temperature extremes. It

can support an engine start from as low as -5°C (23°F), depending upon the engine start

profile. Cold temperature performance is extended to as low as -40°C (-40°F) when using the

internally powered heater and allowing the appropriate pre-heat time. This feature prevents

the necessity to remove the unit from the aircraft when stored at extremely low temperatures

overnight or for longer periods of time. The battery also exhibits excellent high temperature

performance, rated for operation as high as 70°C (158°F). The data below demonstrates

expected pre-heat duration based on the battery starting at several different cold

temperatures.

BatteryHeatingPerformance

10

0

‐10

‐20

Temperature(°C)

‐30

‐40

024681012141618

Time(Minutes)

‐40C

Ambient

‐20C

Ambient

0CAmbient

Figure 4.4

Battery Heating Performance

36 Manual Number 9019288 • Revision D, December 30, 2020

SECTION 5 CONFORMANCE

5.1 DISPATCH VERIFICATION AND IN-FLIGHT MONITORING

The main ship battery typically serves two primary purposes: engine start and emergency backup

power.

Engine Start: In order to attempt an engine start, the user should verify that the FAULT signal is

not active. It is also recommended that the battery be fully pre-heated (HEATING signal not

active) for an engine start. If used, the pre-programmed Engine Start indicator can also be

used to verify that the battery is ready to start an engine.

Dispatch for Emergency Backup Power: If the aircraft has a minimum backup power

requirement for loss of aircraft electrical generation in emergency operation, the user may need

to verify battery capacity prior to flight. This can be done in various ways, possibly including an

SOC verification or verifying the Minimum Capacity indicator. Check with the aircraft operating

requirements for specific procedures. Once battery capacity is verified as sufficient, the battery

is ready for dispatch.

During flight, the battery is capable of providing a number of status indications and health

monitoring information to the cockpit or crew through its communication outputs (see Section 4.4).

In-Flight Monitoring: Typically, all annunciations from the unit should be inactive during flight.

However, the HEATING signal may be observed depending on the temperature of the unit and

does not represent a hazard or loss of function. An indication of the FAULT signal or

independent monitoring of the RTD sensors could require action or degraded function. Consult

your aircraft flight manual for details.

5.2 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

No periodic scheduled maintenance is necessary for continued airworthiness of the TBX series

Advanced Lithium-ion Batteries. If the battery is stored for more than six (6) months, refer to

Section 5.4.2 for charging instructions. If the unit fails to perform to specifications, the unit must be

removed and serviced by True Blue Power or their authorized designee.

True Blue Power will have, on occasion, the need to update the software of the TBX series

Advanced Lithium-ion Batteries to improve and/or enhance functionality or performance.

With the TBX Battery’s easy field-upgrade option, the unit does not have to be returned to the

factory, and in most cases, may not have to be removed from its installation.

Software updates are typically communicated to the public via Service Bulletins issued by True

Blue Power and can be found on the product website www.truebluepowerusa.com. Refer to

Section 5.3 for updating the TBX series Advanced Lithium-ion Battery software.

37 Manual Number 9019288 • Revision D, December 30, 2020

5.3 CONTROL MODE

For control mode operations (e.g. software updates, custom programmable parameters and event

log) refer below to Figure 5.1 and Table 5.1.

Service Button

Service

Light

USB Port

Figure 5.1

USB Service Port

Update Status Light Status

Idle White

Reading / Writing USB Storage Blue

Operation In Progress Yellow

Operation Successful Green

Operation Error Red

Table 5.1

Service Light Status

5.3.1 Software Update

A. Download the approved software update file from

https://www.truebluepowerusa.com/software-updates/ to the root directory of a standard

FAT formatted USB 2.0 compatible flash drive, ensuring the filename is exactly

update.muf.

B. Remove the USB access cover.

C. Insert the configured USB flash drive into the USB Type-A port on the battery.

D. With the battery idle (no charge or discharge current, no active protections), press and

hold the blue service button (located above and to the left of the USB port) until the

service light (located above and to the right of the USB port) changes from solid white

to blinking white (approximately 3 seconds) and release before the flashing white stops

(5 seconds).

E. While the battery is reading from or writing to the USB flash drive the service light will

blink yellow when installing the software update.

38 Manual Number 9019288 • Revision D, December 30, 2020

F. Once the software update is completed the service light will blink green (if software

update completed successfully) or blink red (if software update did not complete

successfully).

G. Remove the USB flash drive and the battery will reboot into flight mode with updated

software.

H. Replace the USB access cover securely.

5.3.2 Load Custom Programmable Parameters

A. Download the installer configuration file to the root directory of a standard FAT formatted

USB 2.0 compatible flash drive, ensuring the filename is exactly installer.cfg. Contact

True Blue Power to coordinate parameter and file creation for your application.

B. Remove the USB access cover.

C. Insert the configured USB flash drive into the USB Type-A port on the battery.

D. With the battery idle (no charge or discharge current, no active protections), press and

hold the blue service button (located above and to the left of the USB port) until the

service light (located above and to the right of the USB port) changes from solid white to

blinking white (approximately 3 seconds) and release before the flashing white stops (5

seconds).

E. While the battery is reading from or writing to the USB flash drive the service light will

blink yellow when installing the custom programmable parameters.

F. Once the custom programmable parameters update is completed the service light will

blink green (if custom programmable parameters update completed successfully) or

blink red (if custom programmable parameters update did not complete successfully).

G. Remove the USB flash drive and the battery will reboot into flight mode with updated

custom programmable parameters.

H. Replace the USB access cover securely.

5.3.3 Verify Custom Programmable Parameters and Software Version

A. To verify custom programmable parameters or the currently loaded software version,

place an empty text file named getcfg.cmd onto the root directory of a standard FAT

formatted USB 2.0 compatible flash drive. Contact True Blue Power if you have

questions regarding creation of the getcfg.cmd file.

B. Remove the USB access cover.

C. Insert the configured USB flash drive into the USB Type-A port on the battery.

D. With the battery idle (no charge or discharge current, no active protections), press and

hold the blue service button (located above and to the left of the USB port) until the

service light (located above and to the right of the USB port) changes from solid white to

39 Manual Number 9019288 • Revision D, December 30, 2020

blinking white (approximately 3 seconds) and release before the flashing white stops (5

seconds).

E. While the battery is reading from or writing to the USB flash drive the service light will

blink yellow when the battery is downloading the custom programmable parameters onto

the USB flash drive.

F. Once the custom programmable parameter update is completed the service light will

blink green (if custom programmable parameters download completed successfully) or

blink red (if custom programmable parameters download did not complete successfully).

G. The USB flash drive will now have a file named installer.txt that can be viewed with any

text editor. In addition to validating the custom programmable parameters, the

installer.txt file also provides a timestamp when the installer.txt file was created and also

displays the battery software version. Note: If the USB flash drive contains both the

installer.cfg and getcfg.cmd files in the root directory, the custom programmable

parameters will be installed first and then the getcfg.cmd file will generate the installer.txt

file in this sequence.

H. Remove the USB flash drive and the battery will reboot into flight mode.

I. Replace the USB access cover securely.

5.3.4 Download Event Log

A. To download the battery event log place an empty text file named getlog.cmd onto the

root directory of a standard FAT formatted USB 2.0 compatible flash drive. Contact True

Blue Power if you have questions regarding creation of the getlog.cmd file.

B. Remove the USB access cover.

C. Insert the configured USB flash drive into the USB Type-A port on the battery.

D. With the battery idle (no charge or discharge current, no active protections), press and

hold the blue service button (located above and to the left of the USB port) until the

service light (located above and to the right of the USB port) changes from solid white to

blinking white (approximately 3 seconds) and release before the flashing white stops (5

seconds).

E. While the battery is reading from or writing to the USB flash drive the service light will

blink yellow when the battery is downloading the event log onto the USB flash drive. A

full event log (approximately 45,000 entries; 8MB maximum) may take up to 8 minutes to

download to the USB flash drive.

F. Once the event log is downloaded the service light will blink green (if event log download

completed successfully) or blink red (if event log download did not complete

successfully).

G. The USB flash drive will now have a file named eventlog.csv that can be imported into a

spreadsheet for viewing and further analysis.

H. Remove the USB flash drive and the battery will reboot into flight mode.

I. Replace the USB access cover securely.

40 Manual Number 9019288 • Revision D, December 30, 2020

W

5.4 OPTIONAL SERVICE

The True Blue Power Advanced Lithium-ion Battery is a maintenance-free product. No scheduled

maintenance is required once installed. The procedures described in this section are included for

verification of battery performance only on an as-needed, or on-condition, basis. Note, however,

that the battery MUST be recharged every six (6) months when not in use.

ARNING

EXTREME care and caution should be applied when handling the unit. Danger of short circuit,

electrical burns or equipment damage can occur if not handled properly. Be EXTREMELY cautious

to avoid shorting terminals, dropping metal objects, hardware or tools on top of or down into the

battery. REMOVE ALL JEWELRY before working with the battery.

5.4.1 Visual Inspection

A. Verify that proper communication is available to the cockpit to validate the battery is

transmitting data appropriately. To perform this, turn on the avionics master and

deactivate the battery disable (if installed). Verify battery operating parameters are

displayed appropriately according to the aircraft installation (voltage, SOC, capacity,

CAS messages, etc.).

B. Visually inspect the power terminals and Communication connector to make sure they

are secure. Inspect the vent connection and make sure the vent hose/tube is secure.

Verify that none of the connections are loose and there are no signs of damage, wear or

corrosion.

C. Remove the unit from the aircraft. Visually inspect the exterior of the battery casing for

signs of damage or wear. Verify that the lid is secure and not loose. Verify that no

damage has occurred which would prevent the battery from maintaining its air-tight seal.

Inspect the battery area of the aircraft for any signs of improper installation or unusual

wear.

D. Some wear is expected due to normal use (for instance: scratches on the bottom of the

battery or near the hold-down points). However, if there are any anomalous or

concerning visual indicators, the unit should be evaluated and tested for repair or

replacement by an authorized repair facility.

5.4.2 Charging

In order to charge the unit off-aircraft, follow the steps listed below:

A. Set the power supply to a constant voltage of 28.8VDC.

(If using a Christie RF80-K, see Alternate Method at the end of this section)

B. Limit the maximum current of the power supply to 40A (or less).

C. Charge the battery until the charge current tapers to less than 2.0A.

41 Manual Number 9019288 • Revision D, December 30, 2020

Alternate Method:

A. Using a Christie RF80-K, set the Mode Switch to “CHARGE” and the Charge Method

Switch to 12 (CONSTANT POTENTIAL / CELLS LEAD ACID). Adjust charge current to

40A.

B. With this method, the voltage will start at approximately 26VDC and a current of 40A. It

will rise to approximately 28.8VDC as the current drops.

C. Charge the battery until the charge current tapers to less than 2.0A.

5.4.3 Capacity Check

Most aircraft are certified to use the battery’s reserve energy to maintain critical systems in

the event of a main power generation loss for a minimum period of time. The required