Page 1

TRUE FOOD SERVICE

EQUIPMENT, INC.

2001 East Terra Lane • O’Fallon, Missouri 63366

(636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl Fax# (001)636-272-7546

Parts Dept. (800)424-TRUE • Parts Dept. Fax# (636)272-9471 • www.truemfg.com

Project Name:

Location:

Item #: Qty:

Model #:

AIA #

SIS #

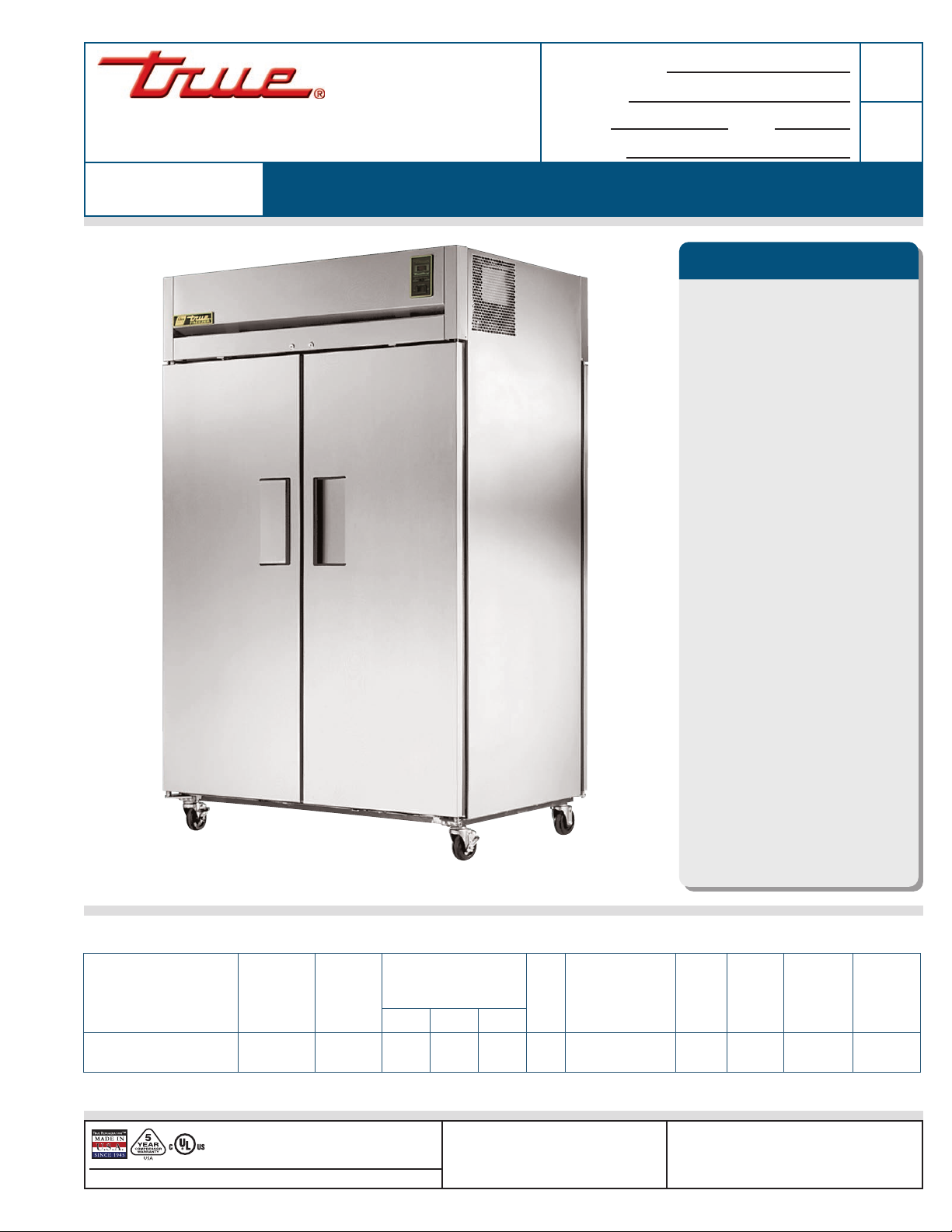

Model:

TG2FPT-2S-2S

TG Spec Series:

Pass-Thru Solid Swing Door Freezer

TG2FPT-2S-2S

Designed using the highest quality

materials and components to

provide the user with colder product

temperatures, lower utility costs and

exceptional food safety.

Oversized, factory balanced,

refrigeration system holds -10°F

(-23.3°C) for the best in food

preservation.

300 series stainless steel doors and

front. Anodized quality aluminum

exterior sides, back and bottom.

NSF approved, white aluminum

interior sides and back liner. 300 series

stainless steel door liner and oor with

coved corners.

Adjustable, heavy duty PVC coated

shelves.

Positive seal self-closing doors with

120°stay open feature. Lifetime

guaranteed door hinges.

Lifetime guaranteed recessed door

handles.

Entire cabinet structure and solid

doors are foamed-in-place using

Ecomate. A new, innovative, high

density, polyurethane insulation that

has zero ozone depletion potential

(ODP) and zero global warming

potential (GWP).

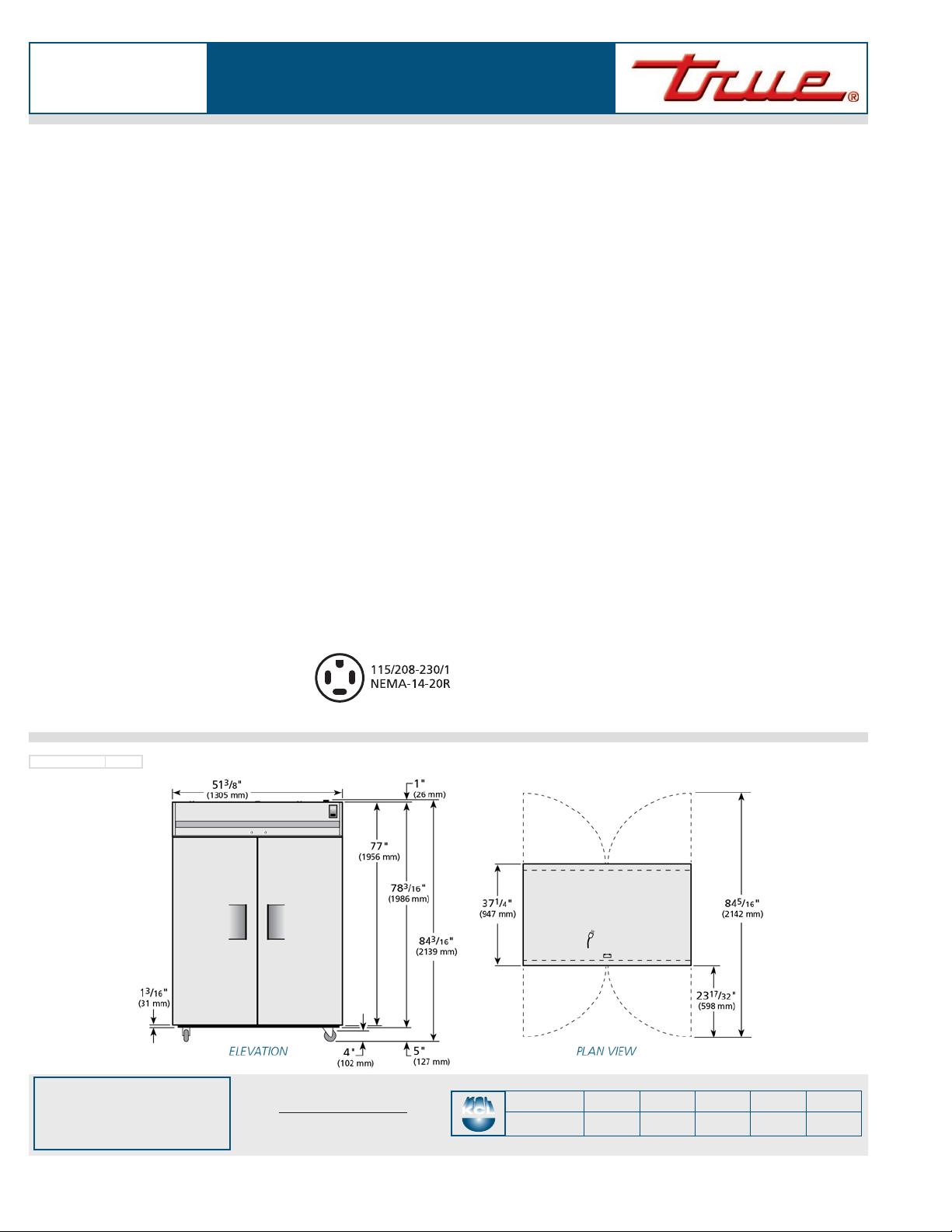

Rough-In Data

Model Doors Shelves

Chart dimensions rounded up to the nearest ⁄" (millimeters rounded up to next whole number).

Cabinet Dimensions

(inches)

(mm)

HP Voltage Amps

Specications subject to change without notice.

NEMA

Config.

Cord

Length

(total ft.)

(total m)

Crated

Weight

(lbs.)

(kg)L D H*

TG2FPT-2S-2S 2 fr/ 2 bk 6 51⁄ 37¼ 78¼ 1 115/208-230/60 9.1 14-20P 9 754

1305 947 1988 2.74 342

* Height does not include 5" (127 mm) for castors, 6" (153 mm) for optional legs, and 1" (26 mm) for system mechanical components.

Requires 115/208-230/60Hz, single phase, 3 pole, 4 wire circuit

ApprovAls: AvAilAble At:

Printed in U.S.A.

Page 2

Model:

TG2FPT-2S-2S

TG Spec Series:

Pass-Thru Solid Swing Door Freezer

StanDaRD FeatuReS

DESIGN

True’s solid door pass-thru’s are designed with

•

enduring quality that protects your long term

investment.

Designed using the highest quality materials and

•

components to provide the user with colder product

temperatures, lower utility costs and exceptional food

safety.

REFRIGERATION SYSTEM

Factory engineered, self-contained, capillary tube

•

system using environmentally friendly (CFC free) 404A

refrigerant.

Extra large evaporator coil balanced with higher

•

horsepower compressor and large condenser

maintains -10°F (-23.3°C) cabinet temperature. Ideal

for both frozen foods and ice cream.

Sealed, cast iron, self-lubricating evaporator fan

•

motor(s) and larger fan blades give True reach-in’s

a more ecient low velocity, high volume airow

design. This unique design ensures faster temperature

recovery and shorter run times in the busiest of

foodservice environments.

Top mounted refrigeration system with evaporator

•

positioned out of food zone to maximize capacity.

Automatic defrost system time-initiated, temperature-

•

terminated. Saves energy consumption and provides

shortest possible defrost cycle.

Automatic evaporator fan motor delay during defrost

•

cycle.

CABINET CONSTRUCTION

Exterior - 300 series stainless steel doors and

•

rainshield. Anodized quality aluminum sides, rear and

bottom.

Interior - NSF approved white aluminum side walls

•

and back liner. 300 series stainless oor with coved

corners.

Insulation - entire cabinet structure and solid doors

•

are foamed-in-place using Ecomate. A new, innovative,

high density, polyurethane insulation that has zero

ozone depletion potential (ODP) and zero global

warming potential (GWP).

Welded, heavy duty steel frame rail, black powder

•

coated for corrosion protection.

Frame rail tted with 4" (102 mm) diameter stem

•

castors - locks provided on front set.

DOORS

Front and rear doors are 300 series stainless steel

•

exterior and door liners. Doors open within cabinet

dimension.

Door locks standard.

•

Lifetime guaranteed recessed door handles. Each

•

door tted with 12" (305 mm) long recessed handle

that is foamed-in-place with a sheet metal interlock to

ensure permanent attachment.

Positive seal self-closing doors with 120°stay open

•

feature. Lifetime guaranteed door hinges.

Magnetic door gaskets of one piece construction,

•

removable without tools for ease of cleaning.

SHELVING

Six (6) adjustable, heavy duty PVC coated wire shelves

•

23½" x 28⁄" (597 mm x 732 mm). Four (4) shelf

supports included per shelf. Shelves adjustable on 6"

(153 mm) increments.

Four (4) dierent interior kits available (see Kit

•

Options). Pilasters and tray slides require eld

installation.

LIGHTING

Incandescent interior lighting - lights activated by

•

rocker switch mounted above doors, safety shielded.

MODEL FEATURES

Exterior digital temperature display, available with

•

either°F or°C .

Evaporator epoxy coated to eliminate the potential of

•

corrosion

NSF-7 compliant for open food product.

•

ELECTRICAL

Unit completely pre-wired at factory and ready for

•

nal connection to a 115/208-230/60 Hz, single phase,

3 pole, 4 wire, 20 amp dedicated outlet. Cord and

plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

6" (153 mm) standard legs. ❑

6" (153 mm) seismic/anged legs. ❑

6" (153 mm) stainless steel legs. ❑

Stainless steel rail skirt for use with legs (eld ❑

installed).

Metal door handle(s) (factory installed). ❑

Additional shelves. ❑

Electronic temperature control (factory installed). ❑

Correctional facilities options. ❑

Curb mountable units. ❑

Remote cabinets (condensing unit supplied by others; ❑

system comes standard with 404A expansion valve

and requires R404A refrigerant). Consult factory

technical service department for BTU information. All

remote units must be hard wired during installation.

KIT OPTIONS

Upcharge applies. Lead time may apply.

Kit #1: Nine (9) sets of #1 type tray slides and pilasters ❑

(eld installed), bottom support of one (1) 18"L x 26"D

(458 mm x 661 mm) pan or two (2) 14"L x 18"D (356

mm x 458 mm) pans.

Kit #2: One (1) set half-section #2 steel rod tray slides ❑

and pilasters (eld installed), rim support of one (1)

18"L x 26"D (458 mm x 661 mm) pan.

Kit #3: Six (6) sets of universal type tray slides and ❑

pilasters (eld installed), bottom support of one (1)

18"L x 26"D (458 mm x 661 mm) pan, two (2) 14"L x

18"D (356 mm x 458 mm) pans or two (2) 12"L x 20"D

(305 mm x 508 mm) pans.

Kit #4: Three (3) chrome shelves 23 ❑ ½"L x 28⁄"D

(597 mm x 732 mm). Four (4) shelf supports included

per shelf (eld installed; adjustable on 6" (153 mm)

increments. Optional wall mounted shelf support

pilasters (eld installed) with four (4) shelf clips per

shelf available; adjustable on½" (13 mm) increments

(must order at time of cabinet order).

Additional kit option components available ❑

individually.

Plan VIew

CUBIC FEET

* Based on ANSI/AHAM HRF-1-2004

One year warranty on all parts

and labor and an additional 4

year warranty on compressor.

56

WARRANTY

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

KCL

Model Elevation Right Plan 3D Back

TG2FPT-2S-2S TFQY54E TFQY96S TFQY96P TFQY963

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

Loading...

Loading...