Page 1

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

TEMPERATURE

CONTROLS/

THERMOMETER/TIMERS

www.truemfg.com

117

Page 2

NOTES

118

Page 3

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

TEMPERATURE

CONTROLS/

THERMOMETER/TIMERS

www.truemfg.com

Temperature Control Repairs

119

Page 4

TRUE

SUBJECT TO CHANGE

TECHNICAL SERVICE MANUAL - ALL MODELS

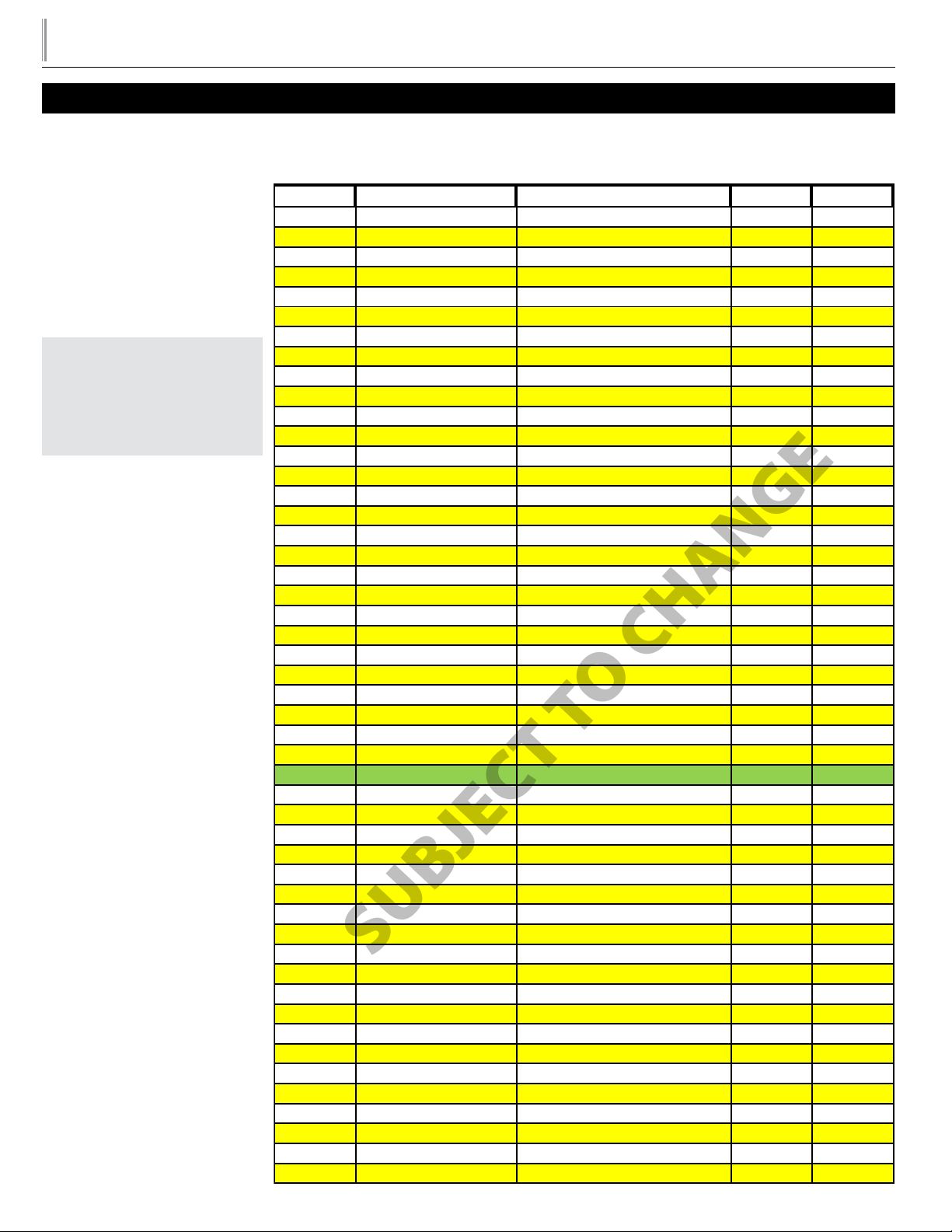

HOW TO DIAGNOSE

www.truemfg.com

STEP 1 - Control must operate

within its pre-calibrated range of

temperatures.

STEP 2 - Cut-in is the ON tem-

perature.

STEP 3 - Cut-out is the OFF tem-

perature.

NOTE:

All temps are at mid-point

setting #5. All temps advised

have a +/- 2 degree variance.

Confirmed Calibration

TRUE P/N MFG P/N APPLICATION CUT-IN CUT OUT

800303 9531N376 35 15

800304 9530N1490 -9 -15

800306 9531N251 40 19

800312 9530N1284 -8 -15

800313 9531N335 37 16

800320 9530N1185 33 27

800325 9530N1318 RED WINE, CHOCOLATE 62 55

800335 9530N1376 38 20

800340 9530N1155 26 11

800345 077B1264 -3 -16

800357 9530266 -3 -8

800358 077B1214 -9 -14

800363 9530C311 -3 -13

800366 077B6806 37 17

800368 077B6857 42 23

800369 077B1212 -3 -12

800370 077B1216 -14 -25

800371 077B6863 42 24

800382 077B6856 37 18

800383 077B1227 0 -6

800384 077B1229 25 19

800385 077B1228 WHITE WINE 43 34

800386 077B6871 41 20

800387 077B6887 FLOWER COOLER 39 21

800390 9530N1329 SUPER NOVA 13 8

800393 077B6827 42 21

800395 931N370 HIGH ALTITUDE 40 23

800399 9530C304 0 -5

822212 CAP-075-174R HEATED

822213 077B6894 37 22

822214 077B1309 31 17

822223 077B1331 26 9

831931 077B1277 -2 -9

831932 3ART56VAA4 40 18

831987 077B0995 RED WINE, CHOCOLATE 57 50

908854 077B6926 36 10

908975 077B1352 -16 -32

911427 077B1354 38 26

913382 077B1367 -11 -23

917838 077B1369 0 -14

930794 091X9775 42 25

933190 091X9796 42 19

958745 3ART55VAA4 39 18

958747 095X0028 37

958857 3ART5VAA198 8 -6

959268 3ART55VAA3 40 26

960640 3ART55VAA5 43 20

962728 3ART55VAA6 42 20

963056 3ART55VAA2 39 16

120

Page 5

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

HOW TO CHECK THE CUT-IN AND CUT-OUT OPERATION OF A

TEMPERATURE CONTROL

OPERATION INSTRUCTIONS

Tools Required

• 1/4" Nut Driver of Socket

• Digital Thermometer of Equivalent

• Multi-Meter (Optional)

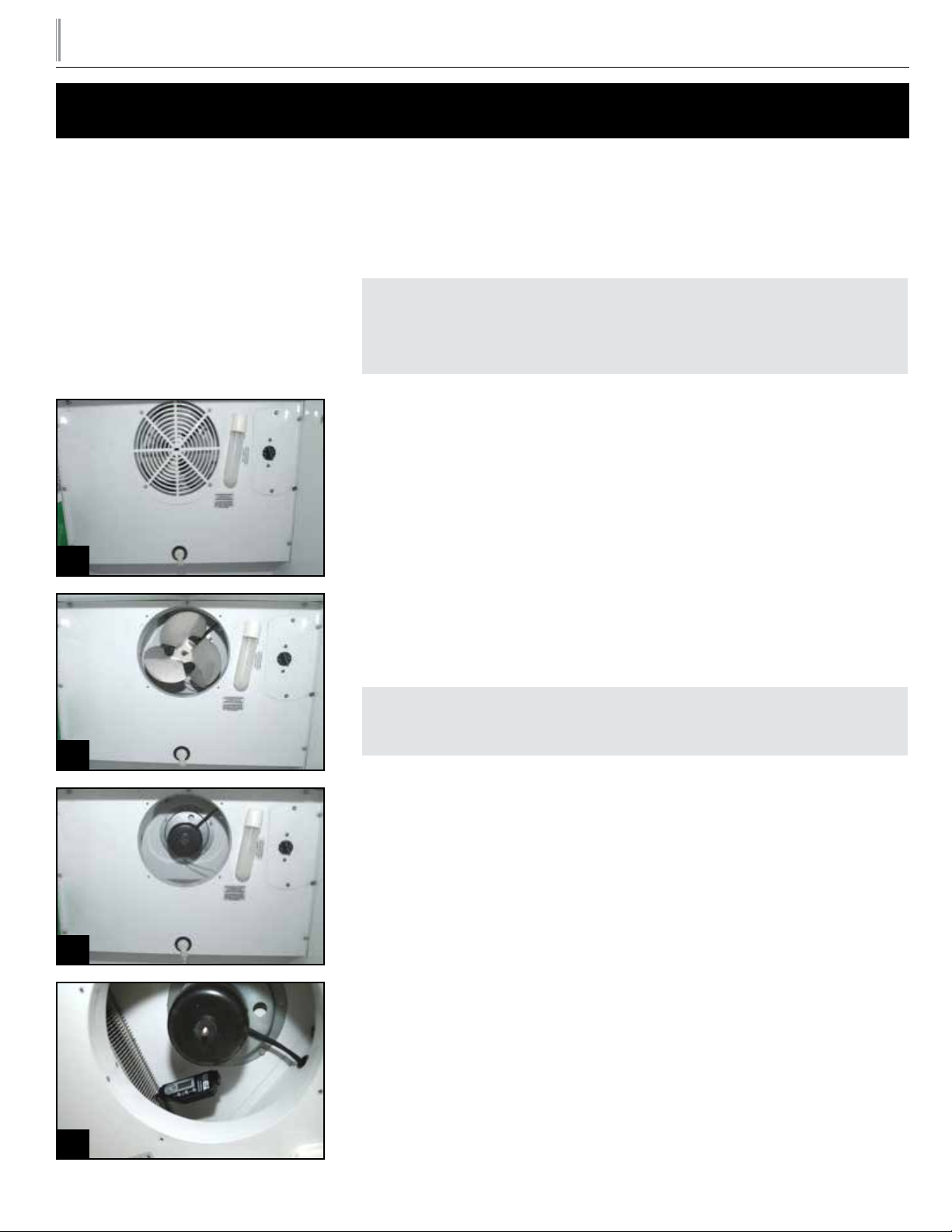

1

STEP 1 - Disconnect the power to the cabinet.

STEP 2 - Locate the temperature control and note its setting. The temperature control

should be set at mid-range, about 5.

NOTE: If the control was set to high (colder) this could be why the product is

freezing. Reset the control and check the cabinet operation in 24-48 hours. You

may have to use your multi-meter to check and see if the control has power and is

closing.

STEP 3 - Remove the four 1/4" hex head screws that secure the fan guard in place. This

will expose the evaporator motor fan blade. Keep in mind that there might be more than

one evaporator fan motor.

STEP 4 - Remove the nut that holds the fan blade in place. See image 2.

STEP 5 - Remove the fan blade. If there are additional fan blades remove all. See image 3

STEP 6 - Insert your digital thermometer into the evaporator coil as close to the tem-

perature control copper tube as possible. This would be to the right side of the opening.

See image 4.

STEP 7 - Plug the unit in. The compressor should come on. The evaporator temperature

will come down very fast allowing you to see approximately what temperature the control

opened up and the compressor shut off. This is your cut-out point. Check this against the

spec’s for the control to determine if the operation is where is should be.

NOTE: This process should not take more than 10 minutes. If it does, there might

be a problem with the refrigeration system.

2

STEP 8 - Open up the cabinet door (s) to allow the warm air to come into the cabinet.

This will warm up your evaporator coil and close the temperature control, turning the

compressor on. This is your cut-in point. Check this against the spec’s for the control to

determine if the operation is where it should be.

THE TEMPERATURES THAT YOU READ COULD BE + 2˚ F.

STEP 9 - Based on your ndings you may have to replace or adjust the control Repeat

Steps 7 and 8 several times to verify the operation after you have made the necessary

3

repairs.

STEP 10 - Remove the power cord. Starting with Step 5 and working backwards place

the fan blade and fan guard in place and put the unit back together.

STEP 11 - Plug the unit back in.

Most of the cooler temperature controls are

coil sensing constant cut-in controls.

4

121

Page 6

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

REPLACING TEMPERATURE CONTROLS IN GDM-7, GDM-10, AND

GDM-12 MODELS (OLD MODELS)

INSTALLATION INSTRUCTIONS

STEP 1 - Unplug Cooler and turn temperature control to “off ”

(“0”) position.

STEP 2 - Pull off the black control knob from the control.

STEP 3 - Remove the mounting plate from the evaporator housing.

STEP 4 - Remove the temperature control from the plate and dis-

connect the 2 wires.

STEP 5 - Remove the lamp from the front of the cooler and remove the front panel.

STEP 6 - Reach in to the side of the evaporator coil and remove

the permagum from around the control bulb. Then remove the old

thermostat control bulb from the sleeve completely.

STEP 7 - Insert the new thermostat control bulb into the new

copper sleeve extension until about 1/2 inch protrudes from the

swaged end. Using a low temperature lubricant on the control bulb

is advisable.

STEP 8 - Using the protruding end of the control bulb as a guide,

insert it into the copper sleeve (elbow) in the rear of the evaporator.

Then push the sleeve extension over the end of the elbow to lock

the two tubes together.

STEP 9 - Gently push the control bulb through the joined sleeves

in 1-2 inch increments until it reaches the end inside the evaporator,

taking care not to kink the line.

STEP 10 - Seal both ends of the new control sleeve with permagum

to keep moisture out.

STEP 11 - Remove the mounting plate from the evaporator housing.

Connect the 2 wires to the new control, the control to the mounting

plate, the plate to the cooler, and replace the control knob.

STEP 12 - Turn the control knob to the #5 setting.

STEP 13 - Reassemble front of cooler and plug it in.

FRONT OF COOLER

Temperature

Control

New Copper Sleeve

Extension

EVAPORATOR

Standard

Copper

Sleeve

Permagum

122

Page 7

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

TEMPERATURE CONTROL REPLACEMENT (FOR GDM & T-SERIES FREEZER

CABINETS WITH LARGER THAN 1/3 H.P. COMPRESSORS)

INSTALLATION INSTRUCTIONS

STEP 1 - Removing Power: Disconnect power to the unit.

WARNING:

Failure to disconnect power

to the unit may result in

electrocution to eld personnel.

STEP 2

Slide Door

Remove Louvered Grill:

WITH DANFOSS CONTROL.

Swing Door

Remove Louvered Grill:

Qualied Repair Personnel

• These repairs should be performed by a

qualied service technician.

Tools Required

• Phillips-head Bit

• 1/4" Nut Driver Bit

• Wire Cutters

• Drill

• Needle-Nose Pliers

• Wire Strippers

• Crimping Tool

• Voltmeter

• Plastic Mallet or Hammer

• Slotted Screwdriver

Contents of Relay Kit

• Relay (and mounting screws)

• Relay Shield (and mounting screws)

• (4) Relay wires: 2 blacks, 1 pink, 1 white

with insulated female spade connectors

on one end.

• Grommet

• (4) Sta-con connectors

• New temperature control

• Instructions

A. To remove grill, loosen upper screw

on each end of grill and remove lower

screws. Gently swing grill forward and up.

1a - Removing louvered grill

(slide door model)

STEP 3 - Accessing Wire Connections:

A. Remove ballast box cover by back-

ing out two hex head screws. (See

Image 2).

NOTE: Wiring diagram is positioned

on inside cover.

STEP 4 - Relay Connection Mounting:

A. With slotted screw driver and plastic

mallet or hammer, drive out knock out

positioned on left side of ballast box.

(See Image 3).

B. Install the supplied grommet* into the

knockout hole. (See Image 4).

C . Mount relay to underside of unit

on the left side of ballast box, and

3/4" back from the front edge of the

underside.

NOTE: Mount relay next to the ballast box, so that when the relay shield

is installed it covers the relay and all

exposed wiring.

A. Remove screws as indicated by ar-

rows.

1b - Removing louvered grill

(swing door model)

2 - Removing ballast box cover

3 - Driving out knockout

4 - Installing the grommet

123

Page 8

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

Relay should be anchored with two self-tapping screws, (supplied in kit), as pictured in

Image 5.

STEP 5 - Relay Temperature Control Wiring:

A. Connect the wires included in kit to the relay as follows:

1. Connect one black wire to one of the normally open contacts of the relay.

2. Connect the other black wire to the other normally open contact on the relay.

5 - Anchoring relay

6 - Relay wiring diagram

7 - Routing relay wires

3. Connect the pink wire to one side of the relay coil.

4. Connect the white wire to the other side of the relay coil.

NOTE: Each relay has a wiring diagram on the side of it. (See Illustration 6).

B. Feed wires into the ballast box through the knockout. (See Image 7).

C . Using the Sta-Con connectors in the relay kit, make the following connections inside

the ballast box:

1. Locate the pink wire coming from the temperature control and connecting to

the black compressor receptacle wire. Cut this connection and connect this pink

wire from the temp control to the pink wire going to the relay.

2. Connect one black wire on relay to the black wire cut from the compressor

receptacle.

3. Connect the white wire coming from the relay to the white wire bundle that is

connected to the white on the main power cord.

4. Connect one black wire to the black wire bundle that is connected to the outgoing terminal on the main power switch located on the ballast box.

STEP 6 - Replace existing temperature control with new Danfoss control in repair kit:

(See Image 8).

8 - Temperature control leads

124

A. Connect one pink wire from old control to terminal #4 on new temperature con-

trol.

B. Connect other pink wire from old control to terminal #3 on new Danfoss tempera-

ture control.

Page 9

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

STEP 7 - Anchor the Relay Shield: (See Image 9).

A. Secure the new relay by attaching the relay shield.

B. Relay shield includes two self-tapping screws. When installing shield, place shield in

position to cover relay and all exposed wiring.

STEP 8 - Checking Relay Operation:

A. Unplug the condensing unit from the compressor receptacle ( located on the ballast

box).

B. Turn the new control to the “0”, (zero), position by aligning the zero indication on

control knob with the arrow stamped into the evaporator housing. Ensure that control is off by listening for an audible click. This will indicate an off position.

C . Plug voltmeter into compressor receptacle.

D. Plug cabinet into power source.

www.truemfg.com

9 - Anchoring relay whield

Securing Ballast Box:

A. Reinstall ballast box cover.

B. Anchor cover with two screws.

C . Check voltage at compressor receptacle. Voltage should equal voltage at wall outlet.

D. If voltage is correct, turn temperature control to “0”, (zero).

E. Plug condensing unit cord back into the compressor receptacle.

STEP 9 - Replacing Louvered Grill:

A. Reinstall grill by reversing earlier procedure.

STEP 10 - Re-connect Power Cord.

STEP 11 - Return Temp Control to normal setting, and check cabinet operation.

125

Page 10

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

TMC-49/49D-S/58/58D-S TEMPERATURE CONTROL RELAY KIT

INSTALLATION INSTRUCTIONS

Tools Required

• Drill

• 7/16" Drill Bit

• Philips Screwdriver

• 1/4" Nut Driver

TEMPERATURE CONTROL RELAY KIT

INCLUDES (936481):

• (1) Temperature Control (822213)

• (1) Temperature Control Relay (800182)

• (1) Cover (890353)

• (1) Bushing (811209)

• (1) Pink Wire (800705)

• (1) White Wire (800706)

• (2) Black Wires (800720) All wires come

with insulated Sta-con connectors installed.

STEP 1 - Inspect the supplied temperature control relay kit for all its parts.

STEP 2 - Remove the power supply from the cabinet.

STEP 3 - Remove the louvered grill (bottom rear of the cabinet). Locate the electrical box

on the lower right hand side of the compressor compartment. The compressor compartment is at the bottom of the cabinet. Remove the cover to the electrical box. (See Image 1).

STEP 4 - Place the wires on the temperature control relay. The two black wires go on

terminals #4 and #6. The pink wire should go on terminal #1 and the white wire should

go on terminal #0.

STEP 5 - Secure the temperature control relay near the electrical box using two of the

screws that were supplied. Be sure to leave enough room to allow the cover to be put on.

(See Image 2).

STEP 6 - Drill a 7/16" hole in the end of the electrical box and place the plastic bushing in it.

STEP 7 - Locate the pink wire coming from the temperature control, which connects to

the black compressor receptacle wire. Cut this wire and connect the pink wire from the

temperature control relay to this pink wire. Be sure to run the wires through the hole that

was just drilled in the front of the electrical box.

STEP 8 - Connect one black wire from the relay (Normally open contact point), to the

black wire cut from the compressor receptacle. Be sure to run the wires through the hole

that was just drilled in the front of the electrical box.

• (4) Screws (830592)

• (4) White Wire Nuts (802143)

NOTE:

First, remove the power to the unit

STEP 9 - Connect the white wire coming from the temperature control relay to the

white wire bundle that is connected to the main power cord. Be sure to run the wires

through the hole that was just drilled in the front of the electrical box.

STEP 10 - Connect the lone black wire (Normally open contact point) to the black wire

bundle that is connected to the main power cord. Be sure to run the wires through the

hole that was just drilled in the front of the electrical box.

STEP 11 - Install the cover around the temperature control relay using the remaining two

screws. (See Image 3).

STEP 12 - Install the cover back on the electrical box.

STEP 13 - Plug the unit back in and check the operation of the temperature control.

STEP 14 - Reinstall the louvered grill.

1 2 3

126

Page 11

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

DANFOSS TEMPERATURE CONTROL REPLACEMENT FOR REFRIGERATORS &

FREEZERS

INSTALLATION INSTRUCTIONS

(FOR TPP, TUC, TWT, & TSSU CABINETS WITH LARGER THAN 1/3 H.P. COMPRESSORS)

WARNING:

Failure to disconnect power

to the unit may result in

electrocution to eld personnel.

Qualied Repair Personnel

These repairs should be performed by a

qualied service technician.

Tools Required

• Phillips-head Bit

• 1/4" Nut Driver Bit

• Wire Cutters

• Drill

• Needle-Nose Pliers

• Wire Strippers

• Crimping Tool

• Voltmeter

• Plastic Mallet or Hammer

STEP 1 - Removing Power - Disconnect power to unit.

NOTE: Step 2 and 3 are related to TSSU, TUC, and TWT-72 models only. All

other models go directly to Step 4.

STEP 2 - Removing shelving standards and I-beams (for TUC, TSSU, & TWT-72 only):

A. To remove side shelf standards back-out two plastic thumb screws on either side

of the cabinet (See Image 1a). Then back-out four 1/4" hex screws that support the

center I-beam in the rear of the cabinet (See Image 1b). Mark locations and positions of standards with tape for easly installation.

STEP 3 - Removing Evaporator Housing Cover (TUC, TSSU, & TWT-72).

A. Remove four slotted thumb screws with a standard screw driver. Then remove two

Phillips-head screws next to the temperature control knob. At this point all cabinets with pans (TSSU models) can have the pans removed for easier access to the

temperature control. Gently move the evaporator cover away from the rear of the

cabinet to reveal the temperature control. (See Image 2).

STEP 4 - Locating and removing temperature control (for all models):

A. The temperature control is inside the cabinet on the right-hand side. Back-out two

thumb screws holding the temperature control plate in place. (See image 3).

STEP 5 - Replace existing temperature control with new Danfoss control in repair kit:

A. Once the temperature control is revealed you can then disconnect the old tempera-

ture control (remove the control knob and then back out two phillips screws).

• Slotted Screwdriver

Contents of Relay Kit

• Relay (and mounting screws)

• Relay Shield (and mounting screws)

• (4) Relay wires: 2 blacks, 1 pink, 1 white

with insulated female spade connectors

on one end.

• Grommet

• (4) Sta-con connectors

• New temperature control

• Instructions

Kit Part Numbers

• #882635 for the TPP-93, TUC/TWT-93,

TSSU-72-18’s

• #882636 for the TSSU-72-30M-B’s

• #883552 for the TPP-119, TWT-119, TUC-119

B. Unplug control wiring from old control.

C . Pull control capillary out of 3/16" tubing inserted into coil.

1a

1b

2 3

127

Page 12

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

4

www.truemfg.com

NOTE: Be careful not to pull 3/16" tubing out of coil.

D. To install new control push control capillary into 3/16" tubing until it stops. This

must be a minimum of 8 inches. Using permagum reseal around capillary & 3/16”

tubing.

STEP 6 - Installing and wiring relay for all TPP, TUC, TWT, and TSSU cabinets (REFRIGER ATO R S ONLY ):

A. The new relay can be installed in the back of the cabinet behind the rear grill (phil-

lips screws will need to be backed out of the rear grill for easy access.

B. Pull wire pair down until it stops. You should have approximately 4 inches of wire

to work with. This amount of wire will be more than enough.

NOTE: After pulling the wire down, cut the wire so there is equal distance from

the relay and to the source from which you pulled the wire down from.

5

6

7

C. Cut the wire pair for the temperature control as shown in image 5. This pair is

located on the side of the receptacle opposite the mounting screw location.

D. Strip each wire approximately 1/2" (See image 6).

E. Mount relay to back wall using provided self tapping screws. (See image 7).

F. Connect both ends of the previously cut ribbed wire with a 14ga loose black wire

using a supplied Sta-con. Connect other end of wire to the normally open contacts

of the relay. (See image 8 & 13 for the next 3 steps).

G. Connect the smooth wire from the junction block to the other loose black wire.

Connect other end of wire to the other normally open contacts of the relay.

H. Connect the smooth wire from inside the cooler (temp control) to the supplied

pink wire. Connect the other end of the pink wire to one side of the relay coil.

I. Cut visible white wire. Strip both ends. Reconnect along with supplied loose white

wire. Connect other end of white wire to the other side of the relay coil.

FOR FREEZERS:

A. Cut the yellow wire from the junction block (leave enough wire to connect wires

to the relay). Connect yellow wire from junction block to terminal #6. Connect

other yellow wire to #1.

B. Cut the black wire that travels from junction block to interior of cabinet. Black

loose wire terminal #4 connects to both ends of cut black wire. (See image 11 &

12).

8

128

C. Cut white wire that is connected to blue heater wire, white wire from relay and

white wire from junction block.

STEP 7 - Installing new Danfoss temperature control:

A. Connect one black wire from old control one of the horizontal terminals on the

new temperature control.

Page 13

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

B. Place the plastic-coated spade clip on secondary on the other horizontal terminal.

C. Connect other black wire from old control to the single ver tical terminal on the

new temperature control. (See image 9).

STEP 8 - Checking Relay Operation:

A. Unplug the condensing unit from the compressor receptacle (located on the bal-

last box).

www.truemfg.com

B. Plug cabinet into power source.

C. Turn the new control to the “0”, (zero), position by aligning the zero indication on

control knob with the arrow stamped into the evaporator housing. Ensure that

control is off by listening for an audible click. This will indicate an off position.

D. Plug voltmeter into compressor receptacle.

E. Turn control between 4-5 and check voltage at receptacle. Receptacle voltage

should be at cabinet rating.

F. If voltage is correct, unplug main power, reinstall compressor cord, and reinstall

components.

STEP 9 - Reinstall rear grill and all other components.

STEP 10 - Re-connect Power Cord.

STEP 11 - Return Temp Control to normal (#5 position) setting, and check cabinet

operation.

9 - Danfoss temperature control wiring.

10 - Relay wiring diagram for refrigerators

Relay

Blue Wire

12 - Freezer wiring

11 - Relay wiring diagram for freezers

Yellow Wire

Black Wire

White Wire

13 - Relay wiring illustration for refrigerators

129

Page 14

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

DANFOSS TEMPERATURE CONTROL REPLACEMENT FOR TD-95-38 UNITS

INSTALLATION INSTRUCTIONS

WARNING:

Failure to disconnect power

to the unit may result in

electrocution to eld personnel.

Qualied Repair Personnel

These repairs should be performed by a

qualied service technician.

Tools Required

• Phillips-head Bit

• 1/4" Nut Driver Bit

• Wire Cutters

• Drill

• Needle-Nose Pliers

• Wire Strippers

• Crimping Tool

STEP 1 - Removing Power:

A. Disconnect power to the unit and move bin dividers out of the way.

STEP 2 - Removing Temperature Control Panel:

A. To remove temperature control panel use a 1/4" nut driver bit to remove 5 screws

(See Image 1a). Image 1b displays the backside of the temperature control panel.

Removing Temperature Control Cover (TD Models).

• Voltmeter

• Plastic Mallet or Hammer

• Slotted Screwdriver

Contents of Relay Kit

• Relay (and mounting screws)

• Relay Shield (and mounting screws)

• (4) Relay wires: 2 blacks, 1 pink, 1 white

with insulated female spade connectors

on one end.

• Grommet

• (4) Sta-con connectors

• New temperature control

• Instructions

Kit Part Numbers

• #883694 for the TD-95-38 models

1a

STEP 3 - The temperature control can be released from the

panel by using a phillips head screw driver (See Image 2).

Replace existing temperature control with new

Danfoss control in repair kit:

A. Once the temperature control is revealed you can then

disconnect the old temperature control (remove the control knob and then back out two Phillips screws).

B. Unplug control wiring from old control.

C . Pull control capillary out of 3/16" tubing inserted into coil.

NOTE: Be careful not to pull 3/16" tubing out of coil.

D. To install new control push control capillar y into 3/16" tubing until it stops. This must

be a minimum of 8 inches. Using permagum reseal around capillary & 3/16” tubing.

1b

2

130

Page 15

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

STEP 4 - Installing and wiring relay:

A. The new relay can be installed in the back of the cabinet behind the rear grill (phil-

lips screws will need to be backed out of the rear grill for easy access).

B. Pull wire pair down until it stops. You should have approximately 4 inches of wire to

work with. This amount of wire will be more than enough.

NOTE: After pulling the wire down, cut the wire so there is equal distance from

the relay and to the source from which you pulled the wire down from.

C . Cut the wire pair for the temperature control as shown in image 4. This pair is lo-

cated on the side of the receptacle opposite the mounting screw location.

D. Strip each wire approximately 1/2". (See image 5).

www.truemfg.com

3

E. Mount relay to back wall using provided self tapping screws. (See image 6).

F. Connect both ends of the previously cut ribbed wire with a 14ga loose black wire

using a supplied Sta-con. Connect other end of wire to the normally open contacts

of the relay. (See image 7 & 10 for the next 3 steps).

G. Connect the smooth wire from the junction block to the other loose black wire.

Connect other end of wire to the other normally open contacts of the relay.

H. Connect the smooth wire from inside the cooler (temp control) to the supplied

pink wire. Connect the other end of the pink wire to one side of the relay coil.

I. Cut visible white wire. Strip both ends. Reconnect along with supplied loose white

wire. Connect other end of white wire to the other side of the relay coil.

7

4

5

86

0

4

9 - Relay wiring diagram for refrigerators

White wire Pink wire

1

Black Wire

6

10 -

White Wire

Smooth Black Wire

Ribbed Black Wire

Ribbed Black Wire

Pink Wire

Relay

Relay wiring illustration for refrigerators

Smooth Black Wire

Junction

Black Wire

131

Page 16

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

STEP 5 - Installing new Danfoss temperature control:

A. Connect one black wire from old control one of the horizontal terminals on the

new temperature control.

B. Place the plastic-coated spade clip on secondary on the other horizontal terminal.

C. Connect other black wire from old control to the single ver tical terminal on the

new temperature control. (See Image 8).

STEP 6 - Checking Relay Operation:

A. Unplug the condensing unit from the compressor receptacle (located on the bal-

last box).

B. Plug cabinet into power source.

C. Turn the new control to the “0”, (zero), position by aligning the zero indication on

control knob with the arrow stamped into the evaporator housing. Ensure that

control is off by listening for an audible click. This will indicate an off position.

D. Plug voltmeter into compressor receptacle.

E. Turn control between 4-5 and check voltage at receptacle. Receptacle voltage

should be at cabinet rating.

F. If voltage is correct, unplug main power, reinstall compressor cord, and reinstall

components.

STEP 7 - Reinstall rear grill and all other components.

STEP 8 - Re-connect Power Cord.

STEP 9 - Return Temp Control to normal (#5 position) setting, and check cabinet

operation.

132

Page 17

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

DANFOSS TEMPERATURE CONTROL REPLACEMENT FOR

TBB-3G, TBB-4PT, TBB-GAL-3G, TDD-3G, TDD-4G MODELS

INSTALLATION INSTRUCTIONS

www.truemfg.com

WARNING:

Failure to disconnect power

to the unit may result in

electrocution to eld personnel.

Qualied Repair Personnel

These repairs should be performed by a

qualied service technician.

Tools Required

• Phillips-head Bit

• 1/4" Nut Driver Bit

• Wire Cutters

• Drill

• Needle-Nose Pliers

• Wire Strippers

• Crimping Tool

STEP 1 - Removing Power:

A. Disconnect power to the unit.

STEP 2 - Removing temperature control housing (for TDD models only):

A. To remove temperature control housing use a 1/4" nut driver bit to back-out screws.

A top cover will need to be removed before the cover containing the temperature

control (See Image 1a & 1b). Image 2 displays the backside of the temperature

control panel.

Removing Temperature Control Cover (TDD Models).

1a 1b 2

• Voltmeter

• Plastic Mallet or Hammer

• Slotted Screwdriver

Contents of Relay Kit

• Relay (and mounting screws)

• Relay Shield (and mounting screws)

• (4) Relay wires: 2 blacks, 1 pink, 1 white

with insulated female spade connectors

on one end.

• Grommet

• (4) Sta-con connectors

• New temperature control

• Instructions

Kit Part Numbers

• #883772 for the TBB-3G, TBB-4PT,

TBB-GAL-3G, TDD-3G, TDD-4G models

STEP 3 - The temperature control can be released

from the panel by using a phillips head screw driver

(See Image 3).

Replace existing temperature control with new Danfoss

control in repair kit:

A. Once the temperature control is revealed you

can then disconnect the old temperature control

(remove the control knob and then back out two

Phillips screws).

B. Unplug control wiring from old control.

C . Pull control capillary out of 3/16" tubing inserted

into coil.

NOTE: Be careful not to pull 3/16" tubing out of coil.

D. To install new control push control capillar y into 3/16" tubing until it stops. This must

be a minimum of 8 inches. Using permagum reseal around capillary & 3/16" tubing.

STEP 4 - Installing and wiring relay:

A. The new relay can be installed in the back of the cabinet behind the rear grill (Phil-

lips screws will need to be backed out of the rear grill for easy access).

3

133

Page 18

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

B. Pull wire pair down until it stops. You should have approximately 4 inches of wire

to work with. This amount of wire will be more than enough.

NOTE: After pulling the wire down, cut the wire so there is equal distance from

the relay and to the source from which you pulled the wire down from.

4

5

6

C. Cut the wire pair for the temperature control as shown in image 5. This pair is

located on the side of the receptacle opposite the mounting screw location.

D. Strip each wire approximately 1/2". (See image 6).

E. Mount relay to back wall using provided self tapping screws. (See image 7).

F. Connect both ends of the previously cut ribbed wire with a 14ga loose black wire

using a supplied Sta-con. Connect other end of wire to the normally open contacts

of the relay. (See image 8 & 11 for the next 3 steps).

G. Connect the smooth wire from the junction block to the other loose black wire.

Connect other end of wire to the other normally open contacts of the relay.

H. Connect the smooth wire from inside the cooler (temp control) to the supplied

pink wire. Connect the other end of the pink wire to one side of the relay coil.

I. Cut visible white wire. Strip both ends. Reconnect along with supplied loose white

wire. Connect other end of white wire to the other side of the relay coil.

STEP 5 - Installing new Danfoss temperature control:

A. Connect one black wire from old control one of the horizontal terminals on the

new temperature control.

B. Place the plastic-coated spade clip on secondary on the other horizontal terminal.

7

8

134

C. Connect other black wire from old control to the single ver tical terminal on the

new temperature control. (See Image 9).

STEP 6 - Checking Relay Operation:

A. Unplug the condensing unit from the compressor receptacle (located on the bal-

last box).

B. Plug cabinet into power source.

C. Turn the new control to the “0”, (zero), position by aligning the zero indication on

control knob with the arrow stamped into the evaporator housing. Ensure that

control is off by listening for an audible click. This will indicate an off position.

D. Plug voltmeter into compressor receptacle.

E. Turn control between 4-5 and check voltage at receptacle. Receptacle voltage

should be at cabinet rating.

F. If voltage is correct, unplug main power, reinstall compressor cord, and reinstall

components.

White wire Pink wire

Page 19

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

0

4

6

9 - Danfoss temperature control wiring 10 - Relay wiring diagram for refrigerators

STEP 7 - Reinstall rear grill and all other components.

STEP 8 - Re-connect Power Cord.

STEP 9 - Return Temp Control to normal (#5 position) setting, and check cabinet operation.

1

Black Wire

White Wire

Smooth Black Wire

Ribbed Black Wire

Ribbed Black Wire

Pink Wire

Relay

11

- Relay wiring illustration for refrigerators

Smooth Black Wire

Black Wire

Junction

135

Page 20

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

DANFOSS TEMPERATURE CONTROL REPLACEMENT FOR TRCB-110 UNITS

INSTALLATION INSTRUCTIONS

WARNING:

Failure to disconnect power

to the unit may result in

electrocution to eld personnel.

Qualied Repair Personnel

These repairs should be performed by a qualied

service technician.

Tools Required

• Phillips-head Bit

• 1/4" Nut Driver Bit

• Wire Cutters

• Drill

• Needle-Nose Pliers

• Wire Strippers

• Crimping Tool

• Voltmeter

STEP 1 - Removing Power:

A. Disconnect power to the unit. The temperature control is located behind the top left

drawer. Remove this drawer.

STEP 2 - Removing temperature control (for TRCB-110 only):

A. After locating the temperature control back-out the two screws holding it in place.

(See Image 1). Image 2 displays the backside of the temperature control.

Removing Temperature Control

1

STEP 3 - The temperature control can be released from the panel by using a phillips

head screw driver (See Image 3). Replace existing temperature control with new Danfoss

control in repair kit:

2

• Plastic Mallet or Hammer

• Slotted Screwdriver

Contents of Relay Kit

• Relay (and mounting screws)

• Relay Shield (and mounting screws)

• (4) Relay wires: 2 blacks, 1 pink, 1 white

with insulated female spade connectors on

one end.

• Grommet

• (4) Sta-con connectors

• New temperature control

• Instructions

Kit Part Numbers

• #883773 for the TRCB-110 model

A. A. Once the temperature control is revealed you can then disconnect the old tem-

perature control (remove the control knob and then back out two Phillips screws).

B. Unplug control wiring from old control.

C . Pull control capillary out of 3/16" tubing inserted into coil.

NOTE: Be careful not to pull 3/16" tubing out of coil.

D. To install new control push control capillar y into 3/16" tubing until it stops. This must

be a minimum of 8 inches. Using permagum reseal around capillary & 3/16" tubing.

STEP 4 - Installing and wiring relay:

A. The new relay can be

installed in the back of

the cabinet behind the

rear grill (Phillips screws

will need to be backed

out of the rear grill for

easy access).

B. Pull wire pair

down until it stops.

You should have

Removal of Side Grill

Placement of Relay

(above compressor)

136

Page 21

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

approximately 4 inches of wire to work with. This amount of wire will be more

than enough.

NOTE: After pulling the wire down, cut the wire so there is equal distance from

the relay and to the source from which you pulled the wire down from.

www.truemfg.com

C. Cut the wire pair for the temperature control as shown in image 5. This pair is

located on the side of the receptacle opposite the mounting screw location.

D. Strip each wire approximately 1/2". (See image 5).

E. Mount relay to back wall using provided self tapping screws. (See image 6).

F. Connect both ends of the previously cut ribbed wire with a 14ga loose black wire

using a supplied Sta-con. Connect other end of wire to the normally open contacts

of the relay. (See image 7 & 10 for the next 3 steps).

G. Connect the smooth wire from the junction block to the other loose black wire.

Connect other end of wire to the other normally open contacts of the relay.

H. Connect the smooth wire from inside the cooler (temp control) to the supplied

pink wire. Connect the other end of the pink wire to one side of the relay coil.

I. Cut visible white wire. Strip both ends. Reconnect along with supplied loose white

wire. Connect other end of white wire to the other side of the relay coil.

STEP 5 - Installing new Danfoss temperature control:

A. Connect one black wire from old control one of the horizontal terminals on the

new temperature control.

B. Place the plastic-coated spade clip on secondary on the other horizontal terminal.

3

4

5

C. Connect other black wire from old control to the single ver tical terminal on the

new temperature control. (See Image 8).

STEP 6 - Checking Relay Operation:

A. Unplug the condensing unit from the compressor receptacle (located on the bal-

last box).

B. Plug cabinet into power source.

C. Turn the new control to the “0”, (zero), position by aligning the zero indication on

control knob with the arrow stamped into the evaporator housing. Ensure that

control is off by listening for an audible click. This will indicate an off position.

D. Plug voltmeter into compressor receptacle.

E. Turn control between 4-5 and check voltage at receptacle. Receptacle voltage

should be at cabinet rating.

F. If voltage is correct, unplug main power, reinstall compressor cord, and reinstall

components.

6

7

White wire Pink wire

137

Page 22

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

www.truemfg.com

0

4

6

8 - Danfoss temperature control wiring 9 - Relay wiring diagram for refrigerators

STEP 7 - Reinstall rear grill and all other components.

STEP 8 - Re-connect Power Cord.

STEP 9 - Return Temp Control to normal (#5 position) setting, and check cabinet operation.

1

Black Wire

10

White Wire

Smooth Black Wire

Ribbed Black Wire

Ribbed Black Wire

Pink Wire

Relay

Smooth Black Wire

Junction

Black Wire

- Relay wiring illustration for refrigerators

138

Page 23

TRUE

TECHNICAL SERVICE MANUAL - ALL MODELS

TDBD TEMPERATURE CONTROL RELAY RETROFIT

RETROFIT INSTRUCTIONS

www.truemfg.com

STEP 1 - Disconnect the electrical power to the unit.

STEP 2 - Remove the louvered grill on the backside of the unit or

the strait side.

STEP 3 - Remove the electrical box cover facing the outside wall.

(See image 1).

STEP 4 - Also remove the three 1/4" hex head screws holding the

panel for the condensing unit receptacle.

NOTE: This will give better access to drill the holes to mount

the new relay.

STEP 5 - Now mount the new relay close to the condensing unit

receptacle.

NOTE: Check clearances before mounting

STEP 6 - Looking at the condensing unit receptacle you will see a

pink wire attached to its black wire remove the pink wire.

STEP 7 - Place a push on connector on the pink wire and attach it

to the new relays #0 terminal.

STEP 8 - The black wire on the receptacle will now get its power

from the new relays #6 terminal by adding a push on connector to

the black wire from the receptacle.

STEP 9 - Now you will need to pull a new wire from the main

power lines black wire you will need to splice into this with the other

black wires already attached to this line and hook the new wire to the

#4 terminal on the new relay.

STEP 10 - You also need to pull a new wire from the main neutral

wire bundle over to the #1 terminal on the new relay.

STEP 11 - Now when the new temperature control closes it will

send power to the coil on the relay and close the contacts on the

relay sending power to the condensing unit.

Box Cover

1

139

Page 24

NOTES

140

Loading...

Loading...