Page 1

TRUE RESIDENTIAL

®

15 INCH AND 24 INCH UNDERCOUNTER SERVICE MANUAL

“A” AND “B” REVISIONS

PRESERVE THE MOMENT

®

Page 2

TABLE OF CONTENTS

INTRODUCTION 1

INSTALLATION CHECKLIST 2

SAFETY PRECAUTIONS / DATA TAG INFORMATION 3

DEPARTMENT CONTACT INFORMATION 4

ELECTRICAL SPECIFICATIONS 5

DUAL ZONE HOME ALARM SYSTEM 6

UN CR ATI NG 7

LEVELING REFRIGERATOR 8

INSTALLATION ANTI-TIP BRACKETS 9-10

INSTALLING THE DOOR STOP 11

INSTALLING 90˚ DOOR HINGE (OPTION) 11-13

DRAWER DEPTH ADJUSTMENTS 14

DRAWER FRONTS ADJUSTMENTS 15

DRAWER GLIDES ADJUSTMENTS 15

DOOR REMOVAL 16

STAINLESS STEEL & STAINLESS GLASS DOOR ADJUSTMENTS 17

OVERLAY PANEL AND OVERLAY PANEL GLASS / GLASS DOOR ADJUSTMENTS 18

WINE SHELVING ADJUSTMENTS / GLASS SHELVING ADJUSTMENT 19

LED LIGHTING 20

STACKING KIT 21-2 2

TECHNICAL DATA 23

SOFTWARE INFORMATION AND START UP MODE 24

SEQUENCE OF OPERATION 25

USER INTERFACE COMMANDS 26-27

DEFROST 28

EVAPORATOR COVER REMOVAL 29-30

EVAPORATOR SECTION LAYOUT 31-32

PROBES VALUES 32

EVAPORATOR FAN DRIVER 32

CONTROL BOARD REPLACEMENT AND MODEL SELECT SEQUENCE OF OPERATION 33

WIRING DIAGRAMS 34-44

COMPRESSOR OPERATION 45

TYPES OF COMPRESSORS AND SPECIFICATIONS 46

VARIABLE SPEED COMPRESSOR DIAGNOSTICS 47

INVERTER BOARD DIAGNOSTICS TABLE 48

COMPRESSOR COMPARTMENT LAYOUT 49

SEALED SYSTEM 50

GOOD REFRIGERATION PRACTICES 51

SYSTEM PRESSURES 51

TROUBLESHOOTING, REPAIRS AND REPLACEMENT 52-54

MAINTENANCE 55

STAINLESS STEEL CARE AND CLEANING 56

GASKET CLEANING 57

GENERAL MAINTENANCE 57

WARRANTY 58

15 & 24 INCH SERVICE MANUAL

Page 3

CONTACT INFORMATION

TRUE RESIDENTIAL

®

Page 4

INTRODUCTION

I n s t a l l a t I o n C h e C k l I s t

s a f e t y P r e C a u t I o n s

D a t a ta g I n f o r m a t I o n

D e P a r t m e n t C o n t a C t I n f o r m a t I o n

e l e C r I C a l s P e C I f I C a t I o n s

D u a l Z o n e h o m e a l a r m s y s t e m

u n C r a t I n g

1 - 22

l e v e l I n g r e f r I g e r a t o r

I n s t a l l a t I n g a n t I - tI P B r a C k e t s

I n s t a l l a t I n g th e D o o r s t o P

I n s t a l l I n g 9 0˙ D o o r h I n g e ( o P t I o n )

D r a w e r D e P t h a D j u s t m e n t s

D r a w e r f r o n t s a D j u s t m e n t s

D r a w e r g l I D e s a D j u s t m e n t s

D o o r r e m o v a l

s t a I n l e s s st e e l & s t a I n l e s s g l a s s D o o r a D j u s t m e n t s

o v e r l a y P a n e l & o v e r l a y Pa n e l g l a s s D o o r a D j u s t m e n t s

w I n e s h e l v I n g a D j u s t m e n t s / g l a s s s h e l v I n g a D j u s t m e n t

l e D l I g h t I n g

s t a C k I n g k I t

15 & 24 INCH SERVICE MANUAL

1

Page 5

INSTALLATION CHECKLIST

To ensure a proper installation, this checklist should be completed to ensure that no part of the process has

been overlooked.

Has the electrical circuit been verified of using a dedicated 15-amp circuit with the ground plug attached

and correct polarity. Discrepancies in the supplied power can cause serious damage and potentially void

all warranty. Please see page (5) for a more detailed description of electrical guidelines.

Have all the packaging materials been removed? NOTE: please make sure the toe kick which is taped to

the back of the unit is removed prior to pushing the unit in place.

Have the anti-tip brackets been installed securely and are they properly engaging the unit? NOTE: the

location of the anti-tip brackets is taped within the toe kick packaging. For installation instructions please

see page (9).

Is the unit leveled properly with all leveling legs making contact with the floor? Has the toe kick been

installed? Proper leveling should be done from the inside of the unit rather than the top exterior of the unit.

Has the door stop been installed?

Has the customer been given the installation / user guide? NOTE: A lock is standard on stainless steel

units, therefore the key to the lock is taped to the back of the user/install guide. Overlay paneled units will

not come with a lock or key.

Have stainless steel surfaces been inspected for any imperfections? This is to be done by the authorized

True dealer or installer with the customer, upon completion of installation. Stainless steel doors, handles

and shelves are covered by limited 30-day warranty for cosmetic defects.

Is the unit operating properly? If not, is the unit plugged in? Is the breaker on? Is the display illuminated

and say “off”? For all control operations and sequences please refer to “user interface commands on True

Precision control” section in the table of contents per the model of the unit you are installing.

Does the customer understand the unit’s operation?

Make sure the unit is operating and cooling for 24 hours prior to loading with product. NOTE: loading the

unit with some bottles of water will provide assurance the unit is working properly during this 24-hour

time-frame.

Verify all the shelves are securely in place.

Has the Dual Zone wine unit been connected to an external alarm system? Refer to page (6)

TRUE RESIDENTIAL

2

®

Page 6

SAFETY PRECAUTIONS

• This refrigerator must be properly installed and located in accordance with the installation instructions

before it is used.

• Do not allow children to climb, stand or hang on the shelves in the refrigerator. They could damage the

refrigerator and seriously injure themselves.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

• Keep hands away from the “pinch point” areas (gaps between the doors and between the doors and

cabinet) small areas are not necessarily safe.

• Unplug the refrigerator before cleaning and making repairs.

NOTE: WE STRONGLY RECOMMEND THAT ALL SERVICING BE PERFORMED BY A QUALIFIED

INDIVIDUAL.

• Setting temperature control to OFF only removes power from the refrigeration system, it does not remove

power from other circuits. For example, temperature control board and lights.

DATA TAG INFORMATION

Data tags are located on the interior upper left hand wall. The serial # is the method we track all pertinent

information for the unit.

15 & 24 INCH SERVICE MANUAL

3

Page 7

DEPARTMENT CONTACT INFORMATION

TRUE-RESIDENTIAL.COM/SUPPORT

SERVICE DEPARTMENT – SUPPORTS AND TRAINS FIELD SERVICE PROVIDERS ON TRUE RESIDENTIAL EQUIPMENT

HELPS TROUBLESHOOT AND REPAIR SERVICE ISSUES IN THE FIELD ON TRUE RESIDENTIAL PRODUCTS

Residential Phone Number : 844-746-9423

Fax : 636-980-8510

Email : TrueResidentialService@truemfg.com

Mike Hurd

Dave Swift

Hours: Monday-Thursday 7:00AM-7:00PM CST

Friday 7:00AM-6:00PM

Saturday 8:00AM-12:00PM

WARRANTY DEPARTMENT – ANSWERS QUESTIONS REGARDING WARRANTY STATUS

PROCESSES WARRANTY CLAIMS & WARRANTY PARTS ORDERS FROM SERVICE PROVIDERS

Residential Phone Number : 844-849-6179

Fax : 636-980-8510

Email: TrueResidentialWarranty@truemfg.com

Stephanie Bouxsein

Diane Javaux

Submit Claims to: TrueResidentialWarranty@truemfg.com

Hours: Monday-Thursday 7:00AM-7:00PM CST

Friday 7:00AM-6:00PM

PARTS DEPARTMENT – OFFERS NON-WARRANTY PARTS SUPPORT

Residential Phone Number : 844-849-6226

Fax : 636-272-9471

Email: TrueResidentialParts@truemfg.com

Gabriela Childers

Abby Baker

Hours: Monday-Thursday 7:00AM-7:00PM CST

Friday 7:00AM-6:00PM

FOR COMMERCIAL PRODUCT INFORMATION, PLEASE CALL 800-325-6152

TRUE RESIDENTIAL

4

®

Page 8

THANK YOU

FOR YOUR PURCHASE

Page 9

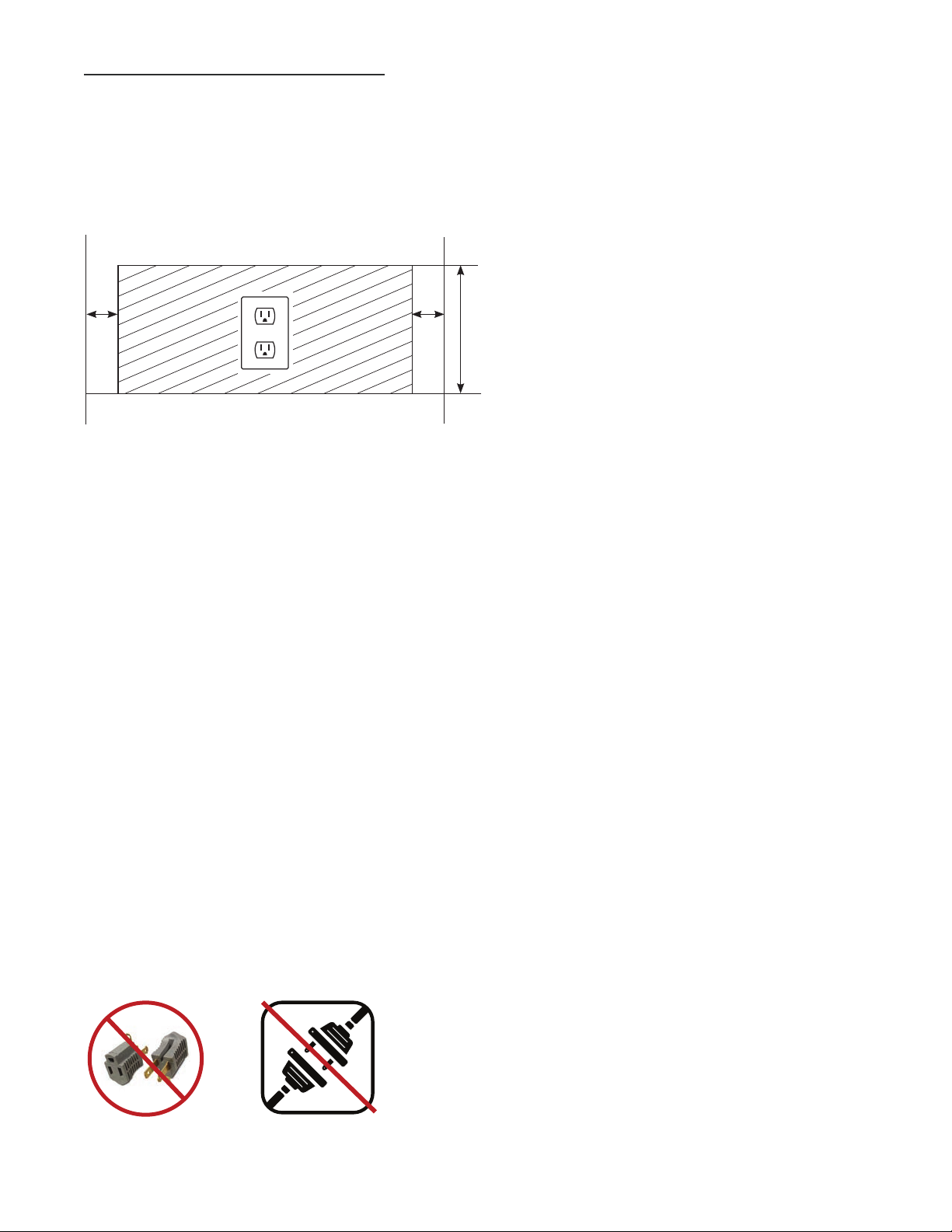

ELECTRICAL SPECIFICATIONS

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For personal

safety, this appliance must be properly grounded.

To minimize the depth of the cutout opening, the electrical outlet must be positioned as shown below. Outlet

must be flush with wall.

Rear wall of cut out

2” 2”

8”

Before your new unit is connected to a power supply, check the incoming voltage with a volt meter. If anything

less than 100% of the rated voltage for operation is noted, correct immediately.

The power cord of this appliance is equipped with a 3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall outlet to minimize the possibility of electric shock hazard from this appliance. A 115V

AC, 60 Hz, 15 amp circuit breaker and electrical supply are required.

Each unit requires a dedicated circuit. Have the wall outlet and circuit checked by a qualified electrician to

make sure the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your personal responsibility and obligation to have it replaced with

the properly grounded 3 prong wall outlet.

Do not use an extension cord or two prong adaptor. Electrical ground is required on this appliance.

The unit should always be plugged into its own individual electrical circuit, which has a voltage rating that

matches the rating plate. This provides the best performance and also prevents overloading house wiring

circuits which could cause a fire hazard from overheated wires. Never unplug your refrigerator by pulling on

the power cord. Always grip plug firmly and pull straight out from the outlet.

Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use

a cord that shows cracks or abrasion damage along its length or at either end. When moving the refrigerator

away from the wall, be careful not to roll over or damage the power cord.

WARNING: COMPRESSOR WARRANTIES ARE VOID IF

THE UNIT IS MORE THAN 7 FT. (2.1M) FROM PLUG-IN

CONNECTION OR IF AN EXTENSION CORD IS USED.

15 & 24 INCH SERVICE MANUAL

5

Page 10

HOME ALARM SYSTEM - DUAL ZONE WINE CABINET ONLY

Dual Zone wine units are provided with three wires located behind the kick-plate that may be connected

to a home alarm system. These connections are for low voltage, low current circuits similar to those used

as signals for alarms on doors and windows. Refer to the specifications of your alarm system to determine

the type of circuit used.

The color codes for the different circuits are as follows:

• Normally closed contacts: White with black and violet

• Normally open contacts: White with blue and black

• Common: White with black

CAUTION: ANY UNUSED TERMINALS SHOULD BE FULLY INSULATED AND ALL WIRES

SHOULD BE SECURED AWAY FROM MOVING PARTS AND SHARP EDGES.

TRUE RESIDENTIAL

6

®

Page 11

UNCRATING

Required Tools:

• Cutting utensil (utility knife)

• Claw hammer or tin snips

The following procedure is recommended for uncrating

the unit:

MOVE YOUR UNIT AS CLOSE TO THE FINAL LOCATION AS

POSSIBLE BEFORE REMOVING THE WOODEN SKID.

A. Remove nails securing cardboard box to the wooden

skid. Then discard any outer packaging (cardboard,

clear plastic).

B. IMPORTANT: Cut polyband and remove styrofoam

block from underside of the door.

INSPECT FOR CONCEALED DAMAGE.

IMMEDIATELY FILE A CLAIM WITH THE FREIGHT

CARRIER IF THERE IS DAMAGE.

A

B

C. Remove skid by carefully lifting the refrigerator off

and place skid aside.

D. Open the unit and remove any packing material.

Styrofoam, tape, and any other material used for

shipping purposes.

NOTE: KEYS FOR THE LOCK ARE PROVIDED WITH

THIS PACKET. STAINLESS STEEL UNITS

COME STANDARD WITH LOCKS. OVERLAY

PANEL READY UNITS WILL NOT BE EQUIPPED

WITH LOCKS.

NOTE: ANTI-TIP BRACKETS KIT AND DOOR STOP

ARE PACKED WITHIN THE TOE KICK WHICH

IS TAPED TO THE BACK OF THE UNIT. IF

THEY ARE NOT IN THE TOE KICK THEY WILL

BE PACKAGED INSIDE THE UNIT WITH THIS

M A NUAL.

C

D

PACKING MATERIAL

TOE KICK IS ATTACHED

TO BACK OF UNIT

FOR ANY MISSING OR BROKEN PARTS.

PLEASE CONTACT THE DEALER FROM

WHOM YOU PURCHASED THE UNIT.

15 & 24 INCH SERVICE MANUAL

7

Page 12

LEVELING THE UNIT

NOTE: PROPER LEVELING OF YOUR TRUE UNIT

IS CRITICAL TO OPERATING SUCCESS.

EFFECTIVE CONDENSATE REMOVAL AND

DOOR OPERATION WILL BE EFFECTED BY

LEVELING.

STEP 1 - Move the unit near the final location.

STEP 2 - Level your unit from the interior floor front

to back and side to side with a level. If the

refrigerator is not level adjust the stainless

steel leg levelers. The leg levelers can be

adjusted by turning CCW to reach the desired

leveling height as shown in the illustration

below.

STEP 3 - Free plug and cord from back of unit.

STEP 4 - The unit should be placed close enough to

the electrical supply so that extension cords

are never used. Plug unit directly into the

wall outlet.

STEP 5 - Once installed in final location, re verify level

and make final adjustments to the front legs.

STEP 6 - Insert the toe kick on the clips (A) Version or

magnets (B) version.

TRUE RESIDENTIAL

8

®

Page 13

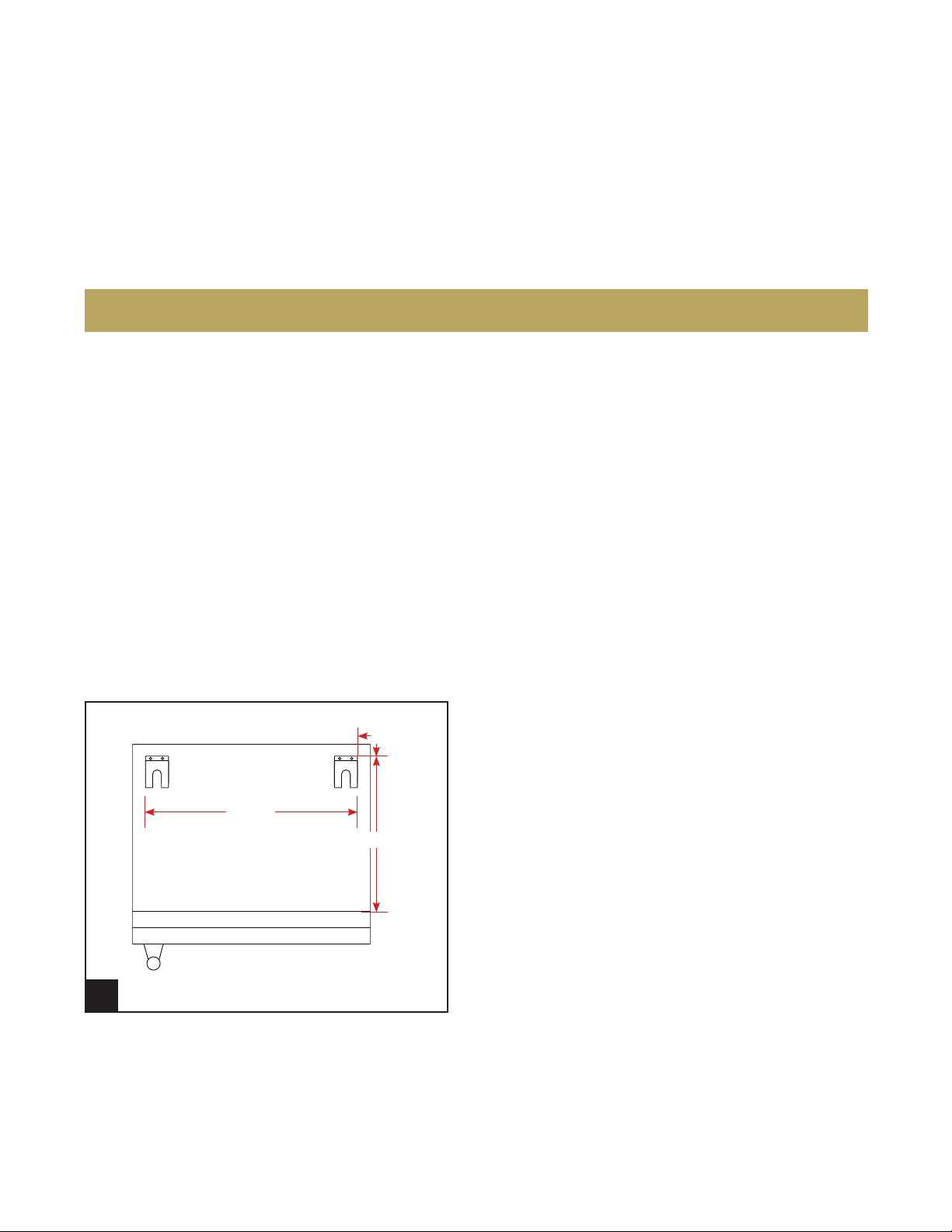

ANTI-TIP BRACKET INSTALLATION

3.23.17 AC

TRUE RESIDENTIAL

®

211354

PRODUCT ADVISEMENT

KIT INCLUDES

• 2 Anti-tip brackets

• 4 Concrete screws (blue)

• 4 Wood screws (brass)

TOOLS REQUIRED

• Power drill

• Measuring Tape

IMPORTANT!

ALL FREE STANDING DRAWER (TUR-24D) OR STACKED UNITS MUST HAVE ANTI-TIP BRACKETS INSTALLED.

TIP-OVER HAZARD: A CHILD OR ADULT CAN TIP THE REFRIGERATOR. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN PROPERTY OR BODILY HARM.

BEFORE MOVING UNIT TAKE PRECAUTIONS TO PROTECT THE FLOOR.

Read all installation instructions first. Install the anti-tip brackets to hold both rear legs of the unit. Follow these steps

to secure the brackets to the floor before moving the unit into final operating position.

Contact a qualified floor installer for the best procedure of drilling mounting holes through your type of floor.

STEP 1

Back

3/16 "

22

Front

ANTI-TIP BRACKET (TOP VIEW)

1

18

27/ 32"

1/2"

Determine the location of the unit. The anti-tip

brackets will be installed 27/32" inset from the back

and sides of the unit. You can also measure 18 1/2"

from the front of the unit (not including the lower

louver grill). Using the bracket as a template, mark

the holes for drilling.

15 & 24 INCH SERVICE MANUAL

9

Page 14

ANTI-TIP BRACKET INSTALLATION

3.23.17 AC

TRUE RESIDENTIAL

®

211354

PRODUCT ADVISEMENT

2

STEP 2

To mount the anti-tip bracket to wood floor, drill pilot

holes for each of the bracket holes. To mount the

anti-tip bracket to concrete or ceramic floor use a

masonry bit to drill pilot holes. Align anti-tip bracket

holes with the holes in the floor. Fasten anti-tip

bracket with screws provided using the brass colored

screw for wood, or blue colored masonry screw for

concrete.

STEP 3

Move unit into final position making sure rear leveling

legs slide into the anti-tip brackets.

3

TRUE RESIDENTIAL

10

®

Page 15

DOOR STOP INSTALLATION

INSTRUCTIONS FOR STAINLESS STEEL MODELS

ALL UNITS ARE PROVIDED WITH AN OPTIONAL DOOR STOP. WHEN INSTALLED, THE DOOR STOP WILL PREVENT

DAMAGE TO SURROUNDING CABINETS BY RESTRICTING THE DOOR FROM OPENING PAST APPROXIMATELY 120º

WITH A STANDARD HINGE OR 90º WITH AN 90º HINGE (OPTIONAL).

Hinge

Door stop

STEP 1

To install the door stop, use the 2 screws provided

and secure the bracket to the bottom of the door on

the same side as the hinge.

(OPTIONAL) 90° HINGE INSTALLATION

INSTRUCTIONS FOR STAINLESS STEEL MODELS

KIT INCLUDES

• 90º Hinge (left or right)

• Door stop bracket (left or right)

TOOLS REQUIRED

• 3/8" Socket wrench

• Phillips screwdriver

Door stop

installed

1

STEP 1

Remove toe kick.

15 & 24 INCH SERVICE MANUAL

11

Page 16

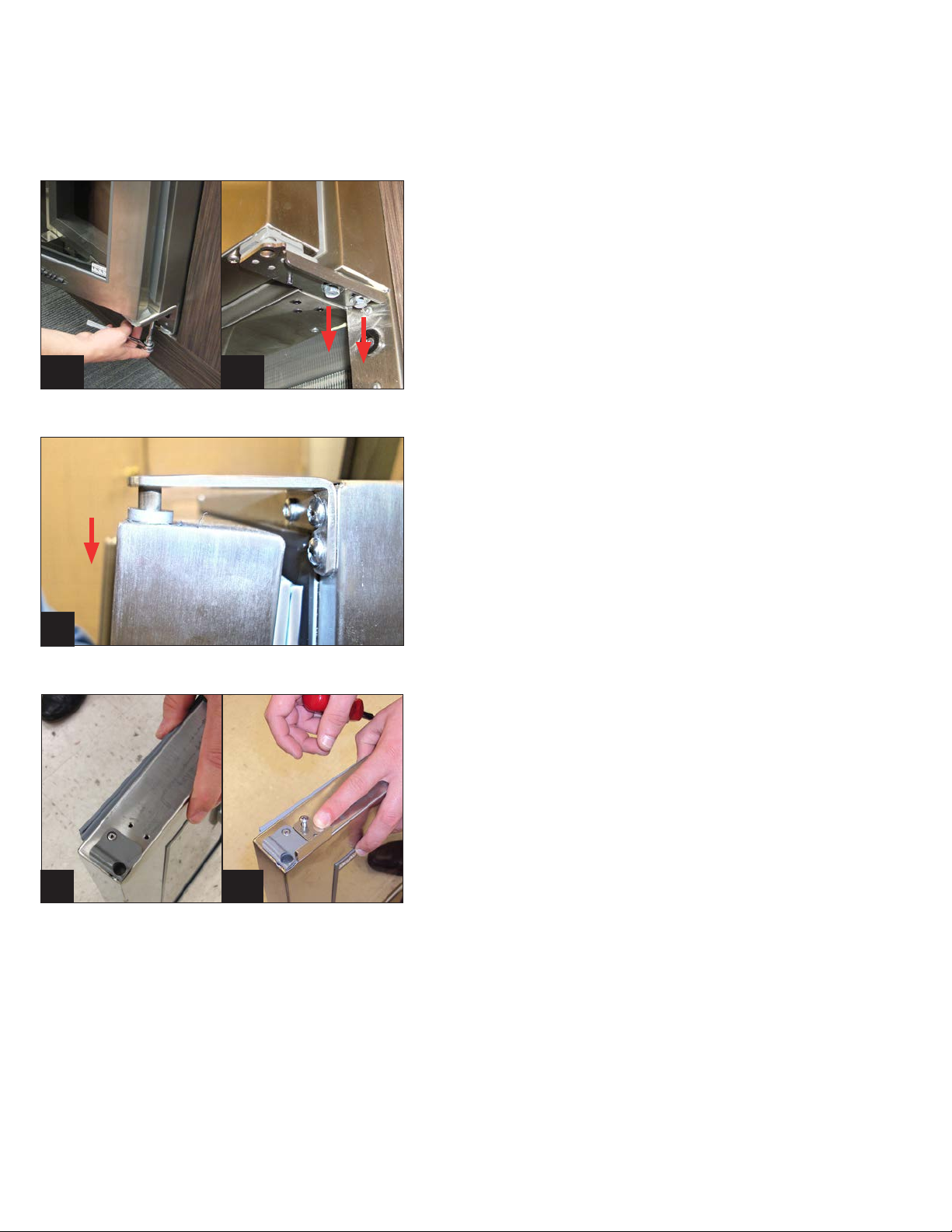

(OPTIONAL) 90° HINGE INSTALLATION

INSTRUCTIONS FOR STAINLESS STEEL MODELS

STEP 2

WARNING: Support the door while removing hinge.

Door is heavy and weight will cause it to drop if not

supported.

Remove 2 3/8" bolts to detach 120º door hinge

(standard).

2a

3

2b

STEP 3

Slowly remove door from unit by sliding down from

top hinge.

STEP 4

Install door stop using screws already installed.

Reinstall door by sliding up into top hinge.

4a

TRUE RESIDENTIAL

12

4b

®

Page 17

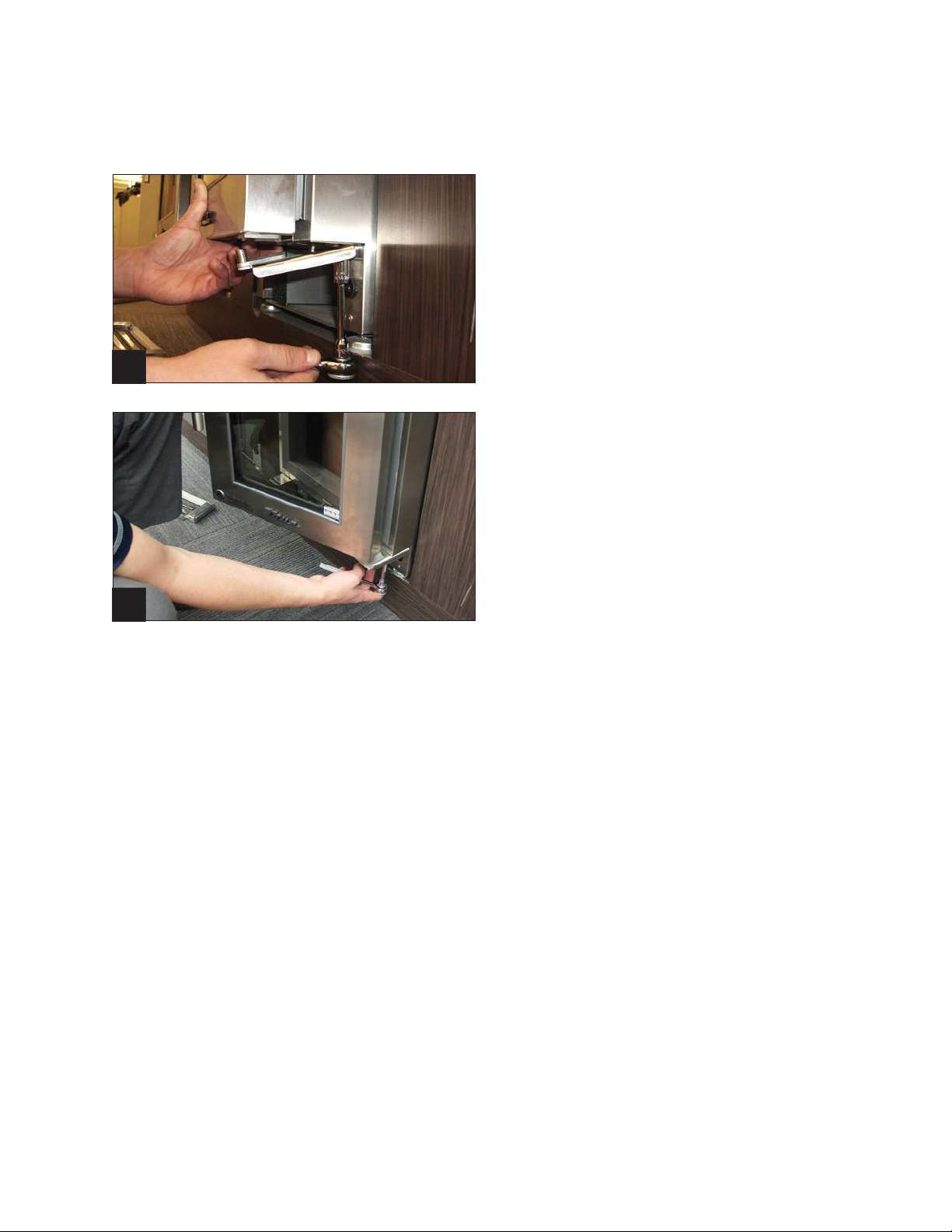

(OPTIONAL) 90° HINGE INSTALLATION

INSTRUCTIONS FOR STAINLESS STEEL MODELS

STEP 5

Install 90º hinge with the 2 3/8" bolts that you

removed. Note: Do not tighten screws all the way

until door adjustments have been made.

5

STEP 6

Align door with lock latch and light switch.

Tighten screws.

6

15 & 24 INCH SERVICE MANUAL

13

Page 18

DRAWER DEPTH ADJUSTMENT

1

STEP 1

Loosen the left and right screws that mount the drawer

frame to the slide. See Image 1.

2

STEP 2

To bring the drawer out to the front of the unit, pull the

drawer out where the tab is seated towards the rear of the

unit. See Image 2.

STEP 3

Hold drawer position and tighten screws.

TRUE RESIDENTIAL

14

®

Page 19

DRAWER FRONTS ON TRUE DRAWER REFRIGERATORS ADJUSTMENT

STEP 1 - Open the drawer that needs adjustment.

STEP 2 - Locate the two Phillips screws on each side of the drawer frame.

See figure 1

STEP 3 - Loosen the 2 screws on each side to get left to right movement

on the drawer front.

STEP 4 - Hold adjustment in place and re tighten the screws back down.

FIGURE 1.

DRAWER GLIDES ON TRUE DRAWER REFRIGERATORS ADJUSTMENT

STEP 1 - Remove screws (one on each side) on top of drawers at front.

STEP 2 - Remove drawers (lift out from the front)

STEP 3 - Loosen the two screws on the glide

STEP 4 - Use bottom screw to adjust glide

STEP 5 - Tighten side screws

STEP 6 - Replace drawer by aligning into tabs (in back)

STEP 7 - Reinsert screws in front

1

3

6

2

4

5

7

15 & 24 INCH SERVICE MANUAL

15

Page 20

DOOR REMOVAL

STEP 1 - Remove the louver grill from the bottom of

the unit by simply pulling the grill toward the

front of the unit. See image 1.

STEP 2 - Support the door with your knee or a block to

prevent the door from falling to the ground

when the bolts are removed.

STEP 3 - Remove the two 3/8-inch bolts from the

bottom hinge using a ratchet and socket. See

image 2A and 2B.

STEP 4 - Pull the hinge out of the bottom of the door

and set it aside.

1

STEP 5 - Once these two bolts are removed, slightly

open the door, still supporting the weight

with your knee or a block, slowly allow the

door to drop down off the top hinge pin. See

image 3.

STEP 6 - Reinstall door by reversing sequence.

2A

3

2B

TRUE RESIDENTIAL

16

®

Page 21

STAINLESS STEEL & STAINLESS GLASS DOOR ADJUSTMENTS

ALL VERSIONS

PLEASE NOTE: DOOR HINGING ON TRUE PRODUCTS ARE NOT INTERCHANGEABLE. IT IS NEVER RECOMMEND TO

ATTEMPT MOVING DOOR HINGING TO THE OPPOSITE SIDE THE UNIT WAS BUILT WITH. THIS MAY CAUSE SERIOUS

DAMAGE AND HARM.

STEP 1 - Make sure the unit is completely level and

in place.

STEP 2 - Remove the bottom louver grill from the

unit. See image 1.

NOTE: A version grills are clipped in and B

version grills are held on with magnets.

1

STEP 3 - With the door shut loosen the two 3/8-inch

bolts. See image 2.

STEP 4 - While supporting the door, open slightly

and shift the door up or down on the

handle side. See image 3.

STEP 5 - Hold the adjusted door and retighten

the two 3/8 inch bolts until very snug to

prevent the adjustment from coming loose.

STEP 6 - Test the door by opening and closing,

making sure the door is not hitting the lock

latch (image 4a) and ensure that the door

makes contact with the door switch (image

4b).

STEP 7 - Re-install the louver grill.

2

3

4A 4B

15 & 24 INCH SERVICE MANUAL

17

Page 22

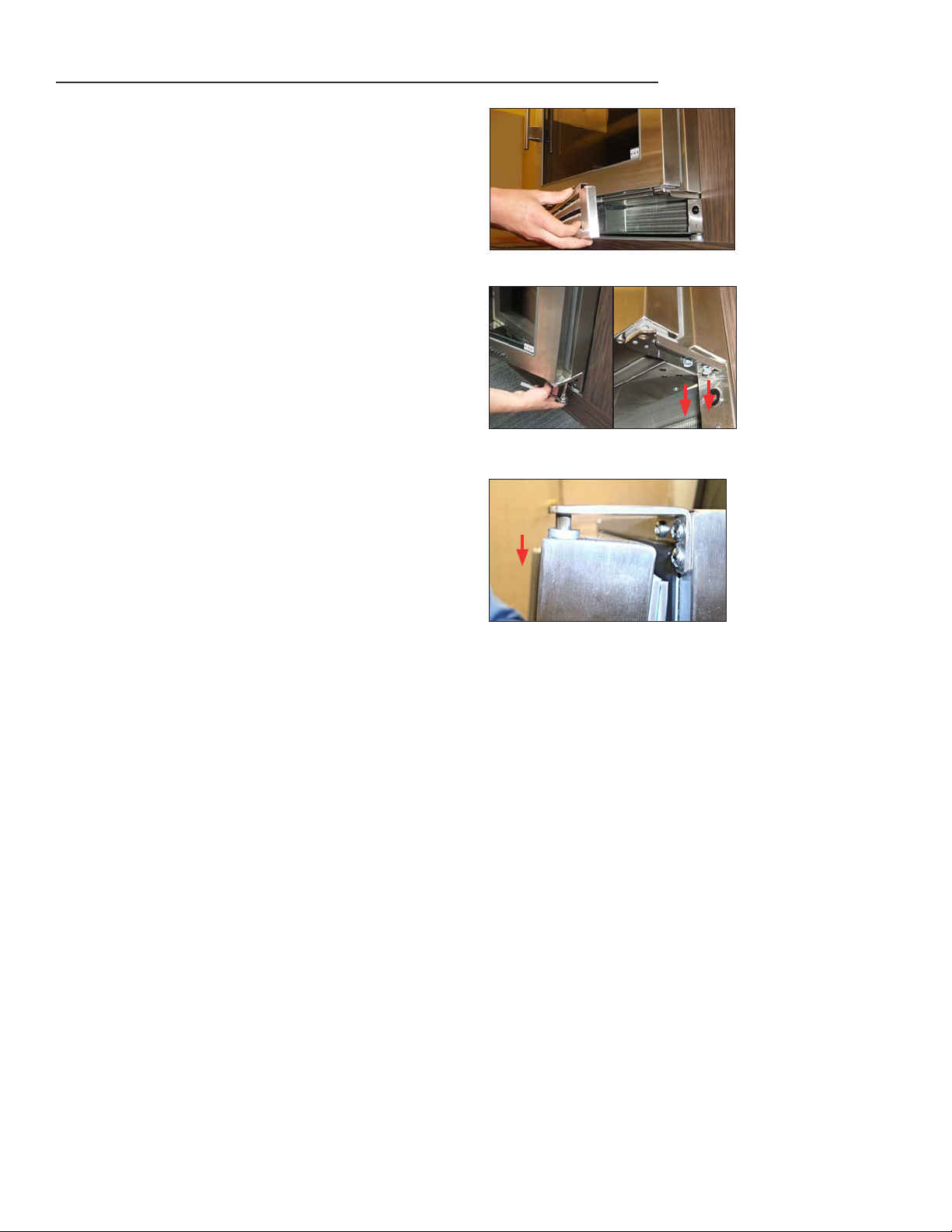

OVERLAY PANEL & OVERLAY PANEL GLASS DOOR ADJUSTMENTS

PLEASE NOTE: DOOR HINGING ON TRUE PRODUCTS ARE NOT INTERCHANGEABLE. IT IS NEVER RECOMMEND TO

ATTEMPT MOVING DOOR HINGING TO THE OPPOSITE SIDE THE UNIT WAS BUILT WITH. THIS MAY CAUSE SERIOUS

DAMAGE AND HARM.

DOOR ADJUSTMENT UP AND DOWN - ALL VERSIONS

STEP 1 - Make sure the unit is completely level and

in place.

STEP 2 - Remove the bottom louver grill from the

unit. See image 1.

NOTE: A version grills are clipped in and B

version grills are held on with magnets.

1

STEP 3 -

STEP 4 - While supporting the door, open slightly

STEP 5 - Hold the adjusted door and retighten

DOOR ADJUSTMENT LEFT TO RIGHT

STEP 1 - Loosen the top and bottom Phillips screws

STEP 2 - Shift the entire door left or right to align to

With the door shut loosen the two 3/8-inch

bolts. See image 2 and 3.

and shift the door up or down on the

handle side. See image 4.

the two 3/8 inch bolts until very snug to

prevent the adjustment from coming loose.

(do not remove screws unless you want to

remove the door). See image 5 and 6.

desired position. See image 7.

2

3

4

STEP 3 - While holding the door in position re-tighten

the upper and bottom screws to hold new

adjustment.

STEP 4 - To adjust the upper only, loosen the two

screws on the upper hinge bracket and shift

door accordingly. See image 5.

STEP 5 - To adjust the bottom only, loosen the two

screws on the bottom hinge bracket and

shift door accordingly. See image 6.

TRUE RESIDENTIAL

18

®

65

7

Page 23

WINE SHELVING ADJUSTMENT

The glide out wine shelves in TBC, TWC and TWZ-DZ

models consist of 3 pieces. These pieces are the wire

wine rack and 2 mounting bracket/glide assemblies

(one for the hinge side and one for the non-hinge side).

To remove the wine shelf, pull up on the front of the

wine rack and it will separate from the two mounting

brackets. The two mounting brackets may now be

removed from the pilasters by lifting straight up then

pulling the brackets out of the pilasters.

NOTE: WHEN REINSTALLING THE BRACKETS,

THE BRACKET WITH THE LARGER VIBRATION

BUMPER MUST BE INSTALLED ON THE SAME

SIDE OF THE CABINET AS THE DOOR HINGE.

WHEN REINSTALLING THE WINE RACK, BE

SURE THAT THE BACK OF THE RACK HOOKS

UNDERNEATH THE TAB ON THE GLIDE.

The tab on the front of the glide must also fit securely

in the gap between the handle and the rack (see

illustration). If the fit is too tight, you may need to

loosen the screws on the back of the handle to increase

the gap.

The wine shelves are held securely by the anti-vibration

bumpers. If there is too much play side-to-side, tighten

the bumpers against the compartment walls by rotating

with your fingers.

GLASS SHELVING ADJUSTMENT

The glide out glass shelves are already attached

to the mounting bracket/glide assemblies.

To install the glass shelves insert mounting

brackets into pilasters.

To remove the glass shelves, simply lift straight

up then pull the brackets out of the pilasters.

ANTI-VIBRATION

BUMPERS

15 & 24 INCH SERVICE MANUAL

19

Page 24

4.10.17 AC

TRUE RESIDENTIAL

®

981897

PRODUCT ADVISEMENT

STACKING KIT INSTRUCTIONS

TOOLS REQUIRED

• 5/16-inch socket and ratchet

• Level

• Floor proctor

• Extra person(s)

KIT INCLUDES

• (1) Louver grill. Note: A version models will use

clips to mount the grill. B version models will

have magnets.

• (2) stacking brackets

• (4) 5/16 inch screws

• Anti-tip bracket kit

STACKING

BRACKETS

1

• Uncrate and secure doors, shelving, and drawers to prevent damage when handling the units.

• Install the anti-tip bracket per instructions (see separate).

• Verify the anti-tip brackets are properly located by trial fitting the lower unit in place. If so pull the unit back out

to prepare Step 1.

PROTECT THE FLOOR, SURROUNDING CABINETRY AND THE UNITS AT ALL TIMES.

THIS PROCEDURE REQUIRES ASSISTANCE FROM EXTRA PERSON(S).

STEP 1

Carefully lift the top cabinet and place on the lower

cabinet making sure the upper unit is flush with the

lower unit’s sides and back.

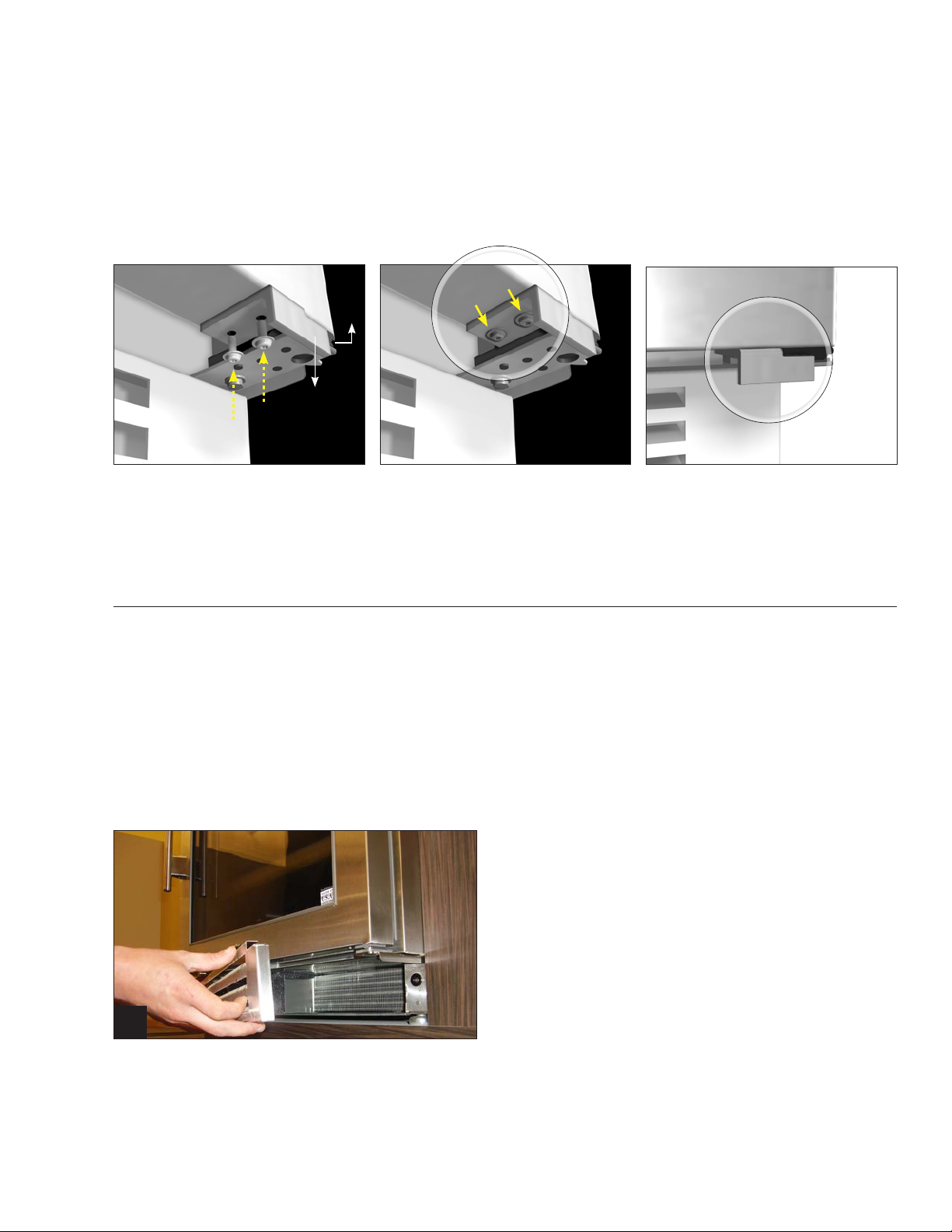

STEP 2

Install the rear stacking brackets using the provided

5/16-inch screws. NOTE: DO NOT TIGHTEN THE

BRACKETS ALL THE WAY UNTIL LATER STEPS.

See Image 1.

LED LIGHTING

• The lighting in all True Residential

• Each compartment has 1 or 2 LED modules that are powered by a driver.

• The modules have an IC chip in them to change their color. A short power interruption is the trigger to

change the color.

• If the colors are ever out of sync, they can be reset by changing the color 10 times in a row. This will reset

all modules back to white.

• The LED modules run off a 10V DC power supply which is located next to the microprocessor control. The

WHEN LIGHTS ARE SET TO GO OFF WHEN THE DOOR IS SHUT, 30 SECONDS LATER THE LED’S WILL HAVE A SPLIT

SECOND FLASH. THIS IS BY DESIGN TO ALLOW THE LED’S TO RELEASE STORED ELECTRICITY. IT WILL DO THIS

ONLY ONE TIME, EACH TIME THE DOOR IS SHUT.

IF THE LIGHTS ARE SET TO STAY ON EVEN WHEN THE DOOR IS SHUT, THIS WILL NOT OCCUR.

power supply has 115V AC incoming, then 10V DC outgoing.

®

Undercounter Models is an LED module system.

RED AND BLUE

10V DC

BLACK AND WHITE

120V AC

TRUE RESIDENTIAL

20

®

Page 25

4.10.17 AC

TRUE RESIDENTIAL

®

981897

STACKING KIT INSTRUCTIONS

PRODUCT ADVISEMENT

KIT INCLUDES

• (1) Louver grill. Note: A version models will use

clips to mount the grill. B version models will

have magnets.

• (2) stacking brackets

TOOLS REQUIRED

• 5/16-inch socket and ratchet

• Level

• Floor proctor

• Extra person(s)

• (4) 5/16 inch screws

• Anti-tip bracket kit

PROTECT THE FLOOR, SURROUNDING CABINETRY AND THE UNITS AT ALL TIMES.

• Uncrate and secure doors, shelving, and drawers to prevent damage when handling the units.

• Install the anti-tip bracket per instructions (see separate).

• Verify the anti-tip brackets are properly located by trial fitting the lower unit in place. If so pull the unit back out

to prepare Step 1.

THIS PROCEDURE REQUIRES ASSISTANCE FROM EXTRA PERSON(S).

STEP 1

Carefully lift the top cabinet and place on the lower

STACKING

BRACKETS

cabinet making sure the upper unit is flush with the

lower unit’s sides and back.

STEP 2

Install the rear stacking brackets using the provided

5/16-inch screws. NOTE: DO NOT TIGHTEN THE

BRACKETS ALL THE WAY UNTIL LATER STEPS.

See Image 1.

1

15 & 24 INCH SERVICE MANUAL

21

Page 26

4.10.17 AC

TRUE RESIDENTIAL

®

981897

PRODUCT ADVISEMENT

STACKING KIT INSTRUCTIONS

STEP 3

Level the upper and lower unit front to back and left

to right by placing a small level on the interior floor.

See Image 2.

STEP 4

Now tighten all (4) 5/16-inch screws to secure the

brackets to the units.

STEP 5

Carefully put the stacked units in their final setting.

Make sure the bottom unit’s rear legs are securely

locked into the anti-tip brackets.

STEP 6

Install supplied louver grill on upper unit. See Image 3.

2

3

24 INCH

TRUE RESIDENTIAL

22

®

Page 27

TECHNICAL DATA

s o f t w a r e I n f o r m a t I o n a n D st a r t u P m o D e

s e q u e n C e o f o P e r a t I o n

u s e r I n t e r f a C e C o m m a n D s

23 - 44

D e f r o s t

e v a P o r a t o r C o v e r r e m o v a l

e v a P o r a t o r s e C t I o n l a y o u t

P r o B e v a l u e s

e v a P o r a t o r f a n D r I v e r

C o n t r o l B o a r D r e P l a C e m e n t & m o D e l s e l e C t s e q u e n C e o f o P e r a t I o n

w I r I n g D I a g r a m s

15 & 24 INCH SERVICE MANUAL

23

Page 28

SOFTWARE INFORMATION AND START UP MODE

All software codes will be displayed every time the machine is powered up (power must be disconnected)

– the software code will be displayed for a minimum of 25 seconds. (Does not apply to ice machine or

uprights)

1) Software Version: 66 (does not apply to ice machine or uprights)

• Only used for A version models (Model number will finish with the letter “A”)

Example:

º

F

º

C

ICE

2) Software Code: 73 (does not apply to ice machine or uprights)

• Only used for B version models (Model number will finish with the letter “B”)

• This software code was replaced by software version: 94

• If a control board has software code “73” and fails, will be replaced with new software version “94”

MODEL

SIZE

HINGE

DOOR

EDITION

TWC - 24DZ - L - SG - A

TRUE WINE

CABINET

24”

DUAL ZONE

HINGED ON LEFT

HANDLE ON RIGHT

STA INLESS

GLASS

Example:

º

F

º

C

ICE

MODEL

SIZE

HINGE

DOOR

EDITION

TWC - 24DZ - L - SG - B

TRUE WINE

CABINET

24”

DUAL ZONE

HINGED ON LEFT

HANDLE ON RIGHT

STA INLESS

GLASS

SECOND

REVISION

3) Software Code: 94 (does not apply to ice machine or uprights)

• Currently used on B version models (Model number will finish with the letter “B”)

• Software version “94” has a hard-reset option. A hard reset will eliminate the need to disconnect

power to the unit to verify software and program the model when needed.

Example:

º

F

º

C

ICE

MODEL

SIZE

HINGE

DOOR

EDITION

TWC - 24DZ - L - SG - B

TRUE WINE

CABINET

24”

DUAL ZONE

HINGED ON LEFT

HANDLE ON RIGHT

STA INLESS

GLASS

SECOND

REVISION

HARD-RESET PROCEDURE

In order to perform a hard-reset of the machine please follow these steps:

i. Turn the unit Off using the power button (hold for 3 seconds)

ii. Press and hold the +

iii. A successful hard-rest will show a 3-digit code for 25 seconds followed by “94” for 20 seconds. After

a total of 45 seconds, compartment temperature will be displayed.

HARD-RESET FEATURE MAY NOT FUNCTION FOR ALL B VERSION UNITS. IF THE

DISPLAY CONTINUES TO SHOW “OFF” AFTER PERFORMING A HARD-RESET.

TRUE RESIDENTIAL

24

®

Page 29

SEQUENCE OF OPERATION

The operating system consist of these components.

ELECTRONIC CONTROL BOARD – Main control of the entire unit’s functionality. The control board is located in the

interior ceiling for all models except (TUF & DZ) TUF board location is behind the rear back cover. DZ boards are

located in the interior ceiling of the center mullion.

COMPRESSOR – Variable speed and single speed compressors depending on version. Please see page 47

CONDENSER FAN MOTOR – Located behind the rear panel of the unit. The condenser fan should always run while the

compressor is running.

24" units - 120VAC condenser fan motor

15" units - 10VDC condenser fan motor

EVAPORATOR FAN MOTOR – Located behind the interior back cover. The evaporator fan motor will cycle off with the

refrigeration cycle on refrigerators. On wine units the evaporator fan will run all the time. The fan will always shut off

when the door is opened.

ONE COMPARTMENT PROBE (Labeled with two blue stripes on "A"versions) (solid blue on "B"versions) – this sensor

controls the cut in and cut out of the refrigeration system.

ONE EVAPORATOR PROBE (Labeled with 1 blue stripe on "A"versions) ( solid blue on "B"versions) – this sensor

controls the defrost function. (Described in detail in the "Defrost" section of this manual)

When power is supplied, the LCD will show a software version code for a minimum of 25 seconds. This is for

manufacturing process only.

From the “off” to the "on" position using the interface power button, the following will happen:

1. Interior LED lights will illuminate.

2. Display readout will show interior cabinet temp based off the compartment probe.

3. After a 2-minute delay the refrigeration system will start.

The refrigeration system (compressor, condenser fan motor, evaporator fan motor) will run until cut out temperature is

reached.

PLEASE NOTE: THE CUT OUT TEMPERATURE IS BASED ON THE COMPARTMENT PROBE, NOT THE DISPLAY

TEMPERATURE. OUR DISPLAY TEMPERATURE IS A CALCULATION AND IS NOT REFLECTING REAL TIME TEMP.

Once the cut out temperature is reached the we will shut the refrigeration system off.

The cycle will repeat when the compartment probe tells the control board to cut back in.

NOTE: THE CONTROL HAS A PRESET 7 MINUTE ANTI SHORT CYCLE.

DUAL ZONE

The TWC-24DZ has two zones which can be independently set for different temperatures.

Each zone has its own display, evaporator coil, evaporator fan and probes.

The zones share the compressor, condenser coil, and condenser fan motor.

Refrigerant is directed to either zone through a bi-stable solenoid valve.

Only one zone can be cooled at a time.

The control continually checks to see which zone is demanding for cooling. If both zones need cooling, the control will

switch from cooling one zone to the other every 20 minutes.

NOTE: THE UPPER ZONE HAS PRIORITY WHEN THE CABINET IS FIRST POWERED ON AND WILL ONLY START TO

COOL THE LOWER AFTER THE UPPER ZONE SET POINT HAS BEEN MET (ONLY ON START UP)

15 & 24 INCH SERVICE MANUAL

25

Page 30

USER INTERFACE COMMANDS ON TRUE PRECISION CONTROL

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 73

tWC-24/tBC-24/tUR-24/tUR-24d

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

Software Version

73ºC

º

F

ICE

º

C

Code is displayed for 45 seconds when power is

supplied to the unit.

Off / On

º

F

ICE

º

C

Power unit off / on.

Set Point

º

F

ICE

º

C

Press to display set point.

Decrease Set Point

º

F

ICE

º

C

Press to decrease set point.

Minimum set points:

33ºF - Refrigerators

40ºF - Wine units

Increase Set Point

º

F

ICE

º

C

Press to increase set point.

Maximum set points:

47ºF - Refrigerators

65ºF - Wine units

Accent Light

º

F

ICE

º

C

Turn accent light on/off. When icon is displayed, light

remains on at all times.

Color

Switch LED colors - Slowly press and release to

switch between 14 colors.

Alarm

º

F

ICE

º

C

Set high temperature and door ajar alarm.

Door ajar - 7 minutes.

High Temps (1 consecutive hour):

50°F - Refrigerator

70°F - Wine Cabinet

+

Temperature Scale

º

F

ICE

º

C

Toggle between °C / °F.

“B” Revision ContRol BoARd 73

tWC-24/tBC-24/tUR-24/tUR-24d

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

+

Lock

º

F

ICE

º

C

Lock / Unlock Keypad.

+

Sabbath Mode

º

F

ICE

º

C

Sets Sabbath mode – Star K certified. Kosher

compliant.

+

Showroom Mode

º

F

ICE

º

C

Displays set point.

Lights are fully functional.

Deactivates refrigeration system.

Disables power off function.

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 94

tWC-24/tBC-24/tUR-24/tUR-24d

®

On/Off (hold 3 seconds)

TRUE RESIDENTIAL

26

®

Press and release to show set point for 5 seconds.

After 5 seconds the display will resort back to

average box temp.

NOTE: 15 inch units use "up" or "down" button

Press to decrease set point.

Minimum set points:

33˚F - Refrigerators

40˚F - Wine Units

-4˚ F - Freezer

Press to increase set point.

Maximum set points:

47˚F - Refrigerators

65˚F - Wine Units

-4˚ F - Freezer

Press and release the button combination to start the color cycle.

Press and release the button combination again to choose the

desired color.

NOTE: Dual Zone models will use "mode + light"

NOTE: 15 inch models will use "light + up arrow"

NOTE: "A" version has 3 colors.

Activates / deactivates alarm

NOTE: 15 inch units use "POWER + DOWN"

24 inch models only

NOTE: 15 inch units use "light" button

Display set point.

Lights are fully functional.

Deactivates refrigeration system.

Disables power off function.

NOTE: 15 inch units use "light" button

Page 31

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

+

Lock

º

F

ICE

º

C

Lock / Unlock Keypad.

+

Sabbath Mode

º

F

ICE

º

C

Sets Sabbath mode – Star K certified. Kosher

compliant.

+

Showroom Mode

º

F

ICE

º

C

Displays set point.

Lights are fully functional.

Deactivates refrigeration system.

Disables power off function.

+

Hard Reset (hold 3 sec)

To initiate hard reset, unit must be in the “off”

position. This feature is used to reset the control.

Refrigeration Error

º

F

ICE

º

C

Unit has not reached desired set point after 15 hours

of run down. Service recommended. Power unit off

and back on to reset.

Compartment Probe

Failure Only

º

F

ICE

º

C

Compartment probe has failed.

Evaporator Probe Failure

Only

º

F

ICE

º

C

Evaporator probe has failed.

Both Probe Failure

º

F

ICE

º

C

Compartment and evaporator probes have failed.

Change both and reset power to the control board to

clear the error message. Unit will run 3 min. on and 3

min. off until probes are changed.

High Temperature Alarm

Set high temperature alarm.

High Temps (1 consecutive hour):

50°F - Refrigerator

70°F - Wine Cabinet

Door Ajar Alarm Door is ajar (7 minutes)

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 94

tWC-24/tBC-24/tUR-24/tUR-24d

º

F

ICE

º

C

º

F

ICE

º

C

º

F

ICE

º

C

USER INTERFACE COMMANDS ON TRUE PRECISION CONTROL

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 73

tWC-24/tBC-24/tUR-24/tUR-24d

CONTROL COMMANDS

04 .10.17 AC

TRUE RESIDENTIAL

®

206582

Compartment Probe

Failure (Zone 2)

º

F

ICE

º

C

Compartment probe has failed in Zone 2.

Evaporator Probe Failure

(Zone 2)

º

F

ICE

º

C

Evaporator probe has failed in Zone 2.

Both Probe Failure

(Zone 2)

º

F

ICE

º

C

Compartment and evaporator probes have failed in

Zone 2. Change both and reset power to the control

board to clear the error message.

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 94

tWC-24dZ

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

Software Version

94ºC

º

F

ICE

º

C

Code is displayed when power is supplied to the unit or a

hard-reset is done.

Off / On (hold 3 sec)

º

F

ICE

º

C

Power unit off / on.

Set Point

º

F

ICE

º

C

Press to display set point.

Decrease Set Point

º

F

ICE

º

C

Press to decrease set point.

Minimum set points:

-4ºF

Increase Set Point

º

F

ICE

º

C

Press to increase set point.

Maximum set points:

4ºF

+

Initiate Manual Defrost

Defrost will terminate at the following temperature or time.

Termination temperature:

40ºF

Termination time:

30 minutes

“B” Revision ContRol BoARd 94

tUF-24

08 .10.17 SB

TRUE RESIDENTIAL

®

206582

CONTROL COMMANDS

+

Lock

º

F

ICE

º

C

Lock / Unlock Keypad.

+

Sabbath Mode

º

F

ICE

º

C

Sets Sabbath mode – Star K certified. Kosher

compliant.

+

Showroom Mode

º

F

ICE

º

C

Displays set point.

Lights are fully functional.

Deactivates refrigeration system.

Disables power off function.

+

Hard Reset (hold 3 sec)

To initiate hard reset, unit must be in the “off”

position. This feature is used to reset the control.

Refrigeration Error

º

F

ICE

º

C

Unit has not reached desired set point after 15 hours

of run down. Service recommended. Power unit off

and back on to reset.

Compartment Probe

Failure Only

º

F

ICE

º

C

Compartment probe has failed.

Evaporator Probe Failure

Only

º

F

ICE

º

C

Evaporator probe has failed.

Both Probe Failure

º

F

ICE

º

C

Compartment and evaporator probes have failed.

Change both and reset power to the control board to

clear the error message. Unit will run 3 min. on and 3

min. off until probes are changed.

High Temperature Alarm

Set high temperature alarm.

High Temps (1 consecutive hour):

50°F - Refrigerator

70°F - Wine Cabinet

Door Ajar Alarm Door is ajar (7 minutes)

KE Y

COMBINATIONS

LCD READOUTS DESCRIPTION

“B” Revision ContRol BoARd 94

tWC-24/tBC-24/tUR-24/tUR-24d

º

F

ICE

º

C

º

F

ICE

º

C

º

F

ICE

º

C

Initiate Manual Defrost

(freezer only)

®

To initiate hard reset, unit must be in the "off" position.

This feature is used to reset the control.

NOTE: 15 inch units use "light" button

NOTE: 94V only

Note: 94V only.

Defrost will terminate at the following temperature or time.

Termination temperature: 40˚F

Termination time: 30 minutes

NOTE: 94 V only

Evaporator Probe Failure Only

Compartment Probe

Compartment Probe Failure

(Upper zone on DZ)

Failure

Only

Evaporator Probe

Failure

(Upper zone on DZ)

Compartment and

Evaporator Probes

(Upper zone on DZ)

Failed

Compartment Probes

Failure DZ Only

(Lower zone)

Evaporator Probe

Failure DZ Only

(Lower zone)

Compartment and

Evaporator Probes

Failed DZ Only

(Lower zone)

Evaporator probe failure. change probe and interrupt power to

reset. NOTE: 94 V ONLY

Cycle off evaporator probe using a 2˚ degree offset

Compartment probe failure. change probe and interrupt power to

reset. NOTE: 94 V ONLY

NOTE: 94 V only

Each time the unit calls for cooling, we will run the

evaporator fan for 10 minutes before running the

compressor.

NOTE: 94 V only

High temp alarm

Unit will run in safe mode as follows:

50 degrees F / 1 hour - refrigerator

10 minutes off / 10 minutes evaporator fan only

70 degrees F / 1 hour - wine cabinet

10 minutes fan and compressor

32 degrees F / 1 hour - freezer

Cycle repeats until both probes are changed

NOTE: 94V only

NOTE: 94 V only

Set high temperature alarm.

High Temps (1 consecutive hour):

50˚F - Refrigerator / 70˚F - Wine Cabinet

NOTE: 94V only

NOTE: 94 V only

compartment probe in bottom zone has failed. Change probe and

interrrupt power to reset.

NOTE:94V ONLY. DUAL ZONE ONLY.

NOTE: 94 V only

Cycle off evaporator probe using a 2˚ degree offset

NOTE: 94 V only

Each time the unit calls for cooling, we will run the

evaporator fan for 5 minutes before running the

compressor.

NOTE: 94 V only

Unit will run in safe mode as follows:

10 minutes off / 10 minutes evaporator fan only

10 minutes fan and compressor

Cycle repeats until both probes are changed

NOTE: 94 V only

time.

15 & 24 INCH SERVICE MANUAL

27

Page 32

DEFROST SEQUENCE OF OPERATION

08.10 .17 SB

®

206582

KEY

COMBINATIONS

LCD READOUTS DESCRIPTION

Software Version

94ºC

º

F

ICE

º

C

Code is displayed when power is supplied to the unit or a

hard-reset is done.

Off / On (hold 3 sec)

º

F

ICE

º

C

Power unit off / on.

Set Point

º

F

ICE

º

C

Press to display set point.

Decrease Set Point

º

F

ICE

º

C

Press to decrease set point.

Minimum set points:

-4ºF

Increase Set Point

º

F

ICE

º

C

Press to increase set point.

Maximum set points:

4ºF

+

Initiate Manual Defrost

Defrost will terminate at the following temperature or time.

Termination temperature:

40ºF

Termination time:

30 minutes

“B” Revision ContRol BoARd 94

tUF-24

08.10 .17 SB

®

206582

KEY

COMBINATIONS

LCD READOUTS DESCRIPTION

Software Version

94ºC

º

F

ICE

º

C

Code is displayed when power is supplied to the unit or a

hard-reset is done.

Off / On (hold 3 sec)

º

F

ICE

º

C

Power unit off / on.

Set Point

º

F

ICE

º

C

Press to display set point.

Decrease Set Point

º

F

ICE

º

C

Press to decrease set point.

Minimum set points:

-4ºF

Increase Set Point

º

F

ICE

º

C

Press to increase set point.

Maximum set points:

4ºF

+

Initiate Manual Defrost

Defrost will terminate at the following temperature or time.

Termination temperature:

40ºF

Termination time:

“B” Revision ContRol BoARd 94

tUF-24

1) 7-minute anti-short cycle has elapsed.

2) Compartment probe reaches the cut-in point.

3) Control board checks the evaporator coil temperature probe. If the evaporator coil probe is below 38ºF the

evaporator fan will start and run while the compressor and condenser fan remain off.

4) Once the evaporator coil probe reaches 38 °F, the control will allow the compressor and condenser fan motor

to run until cut out temperature is reached.

5) This process will be repeated upon each call for cooling.

NOTE: – Wine units run the evaporator fan(s) all the time.

FREEZER MODELS ONLY

1) Three methods of initiating defrost:

a) the control reached the max compressor run time (60 hours)

b) the evaporator probe has reached -25˚F.

C) initate manual defrost by pressing and holding for 3 seconds

NOTE: – The control will prohibit defrost the first 4 hours of plugging the unit in.

3) Compressor, evaporator fan and condenser fan shut off during defrost.

4 ) The drain tube heater, evaporator coil heater and drain trough heater will energize until time or temperature

is met.

a) Maximum defrost run time is 30 mins.

b) termination temperature is 40 degrees based off evaporator probe temperature.

5) While in defrost, the display will continue to show tempature which is filtered and will not reflect normal

flucuation.

NOTE: – The only time the display will show "def" is when a manual defrost is intiated by pressing

and holding

6) Once the defrost cycle ends, the control board will delay the following components:

a) Delay compressor after defrost - 2 minutes.

b) Delay evaporator fan motor after defrost - 6 minutes.

TRUE RESIDENTIAL

28

®

Page 33

EVAPORATOR COVER REMOVAL

A VERSION

• Remove all shelves from the unit.

• Remove two Phillips screws on upper part of evaporator cover.

• Slide cover down and out.

15 & 24 INCH SERVICE MANUAL

29

Page 34

EVAPORATOR COVER REMOVAL

B VERSION

• Remove all shelves from the unit.

• Remove two Phillips screws on upper part of evaporator cover. See Picture 1

• Slide the cover down and pull out.

NOTE: YOU MAY NEED TO LIFT UP ON THE LEFT AND RIGHT SHELF STANDARD WITH A SCREWDRIVER.

PLEASE SEE PICTURE 2.

Loosening the shelf standard may be necessary if lifting wasn’t successful. Remove the top gray cap and

loosen the screw, do not remove the screw. See Picture 3.

PICTURE 1 PICTURE 2

PICTURE 3

TRUE RESIDENTIAL

30

®

Page 35

EVAPORATOR SECTION LAYOUT

A VERSION

EVAPORATOR FAN MOTOR AND BLADE

COMPARTMENT PROBE

(2 BLUE STRIPES)

EVAPORATOR PROBE (1 BLUE STRIPE)

EVAPORATOR COIL

15 & 24 INCH SERVICE MANUAL

31

Page 36

EVAPORATOR SECTION LAYOUT

B VERSION

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR DRIVER

BLUE PROBE – DEFROST ASSIST PROBE

BLACK PROBE – CUT IN & CUT OUT

T (F°) Ω

14° 55.3K

23° 42.3K

32° 32.6K

41° 25.3K

50° 19.9K

59° 15.7K

68° 12.5K

77° 10K

86° 8K

95° 6.5K

104° 5.3K

EVAPORATOR FAN DRIVERPROBE VALUES

The evaporator fan motor driver is located directly next to the evaporator fan.

The motor driver will have 120V AC coming in and 12V DC going to the motor.

120V AC

12V DC

TRUE RESIDENTIAL

32

®

Page 37

CONTROL BOARD REPLACEMENT & MODEL SELECT SEQUENCE OF OPERATION

11.17.16 • SB

TRUE RESIDENTIAL

®

Control Board Replacement & Model Select Sequence of Operation

964208

TRUE RESIDENTIA

A

SINGLE ZONE ONLY

B

SINGLE ZONE ONLY

The control is located in the interior ceiling on single zone models (see images A & B).

Control is located in the lower compartment ceiling of dual zone models (see image C).

Remove Phillips screws that hold the control board cover.

Power should always be disconnected from the unit prior to changing the control board.

This will require unplugging the unit and / or shutting the breaker off.

DO NOT apply power to the unit until you are ready to program per table below.

MODEL SELECT SEQUENCE OF OPERATION

Since the same control board is used on multiple models it is necessary to set up the

control to the proper code for the model you are working on.

1. Reconnect power to the unit.

2. Once power is supplied, the control board will display a 3-digit code.

3. Within 30 seconds of applying power, press and hold the power button until you see

“0” or “000”.

4. Release the power button and use the up arrow to scroll up until you find the code for

the model you are working on. See table below.

5. Wait for the display to time out until the compartment temperature is displayed.

Programming is now complete.

6. After a 2-minute delay, all components will start and run until the set point is

reached.

NOTE: If you miss step 3 in allowed time, the model select sequence will not function and

you will have to reset power to the unit.

All B version replacement boards have a hard-reset option to initiate the programming

sequence.

C

DUAL ZONE ONLY

HARD-RESET PROCEDURE

1. Press and hold the power button until the display reads “OFF”.

2. Press and hold the MODE + UP buttons at the same time until “OFF” disappears. A 3-digit code will be displayed.

Immediately move to step 3.

3. Press and hold the power button for a minimum of 15 seconds until “0” is displayed.

4. Release the power button and use the up arrow to scroll up until you find the code for the model you are working on. See

table below.

5. Wait for the display to time out until the compartment temperature is displayed. Programming is now complete.

MODEL A VERSION MODEL B VERSION CODE

TUR-24-A

TBC-24-A

TUR-24BD-A

TUR-24DD-A

TUR-24D-A TUR-24D-B 102

TWC-24-A TWC-24-B 001

TWC-24DZ-A TWC-24DZ-B 300

TUR-15-A TUR-15-B 105

TWC-15-A TWC-15-B 002

* NOTE: Same codes for A and B versions.

TUR-24-B

TBC-24-B

TUR-24BD-B

TUR-24DD-B

TUF-24-B 200

101

15 & 24 INCH SERVICE MANUAL

33

Page 38

WIRING DIAGRAM

RESIDENTIAL UNDERCOUNTER 24D

WIRING DIAGRAM

P/N 958860

PART NUMBER 958860

TRUE UNDERCOUNTER DRAWERED UNIT

“A” VERSION

RED

ORANGE

YELLOW

BLACK

GREEN

EVAP FAN MOTOR

POWER CORD

SMOOTH

RIBBED

MODE

LED

LED

SMOOTH

RIBBED

BLUE STRIPE X 1

PROBE EVAP

PROBE CAB

BLUE STRIPE X 2

WHITE

BLACK

GREEN

BLACK

BLACK

BLACK

BLACK

J32

ICE

J1

J29

J33

J30

EXTRENAL DISPLAY

J4

J31

F°

C°

DISPLAY BOARD

LED DRIVER

J2

CONTROL

J3

J16

J7

BOARD

J17

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

RED

LED

LED

ENERGY

LIGHT

ALARM

SAVER

RED

BLACK

RED

BLACK

BLACK

WHITE

MULLION HEATER

BLUE

BLUE

DRAWER SWITCH 1

TRUE RESIDENTIAL

34

YELLOW

ORANGE

BLACK

PURPLE

SMOOTH

RIBBED

YELLOW

DRAWER SWITCH 2

GREEN

COMPRESSOR

®

INVERTER

COND FAN MOTOR

Page 39

LOW VOLTAGE

HIGH VOLTAGE

PROBE CAB

PROBE EVAP

BLUE STRIPE X 2

BLUE STRIPE X 1

DRAWER SWITCH 2

YELLOW

YELLOW

LED

BLACK

ORANGE

MODE

BLACK

LED DRIVER

DISPLAY BOARD

ICE

C°

F°

BLACK

RED

LED

ALARM

LIGHT

COLOR

BLACK

GREEN

RIBBED

SMOOTH

EVAP. FAN

BLACK

ORANGE

PURPLE

CONTROL

BOARD

J33

J32

J30

J4

J3

J31

J16

J29

J17

J43

J36

J42

J41

J40

J39

J38

J37

J35

J2

J1

J7

J25

J28

J26

J27

J23

J24

J34

CONTROL

J2

BOARD

J29

J1

J7

J26

J38

J37

J35

J28

J27

J25

J24

J23

J34

RED

YELLOW

RED

BLACK

GREEN

LED

BLACK

LED

BLACK

RED

BLACK

BLACK

LOW VOLTAGE

LOW VOLTAGE

ALARM

COLOR

LIGHT

F°

C°

DISPLAY BOARD

ICE

MODE

BLACK

YELLOW

ORANGE

RED

HIGH VOLTAGE

HIGH VOLTAGE

WIRING DIAGRAM

PART NUMBER 958860

TRUE UNDERCOUNTER DRAWERED UNIT

“A” VERSION

J3

J31

J2

CONTROL

J16

BLACK

RED

LED

BLACK

BLACK

LED

RED

BLACK

BLACK

LED

BLACK

LED

BLACK

RED

LED DRIVER

BLUE STRIPE X 1

BLUE STRIPE X 2

PROBE EVAP

PROBE CAB

DRAWER SWITCH 2

YELLOW

YELLOW

J32

J1

J29

J33

J4

J30

J7

BOARD

J17

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

BLUE

BLUE

DRAWER SWITCH 1

GREEN

J29

J33

J32

J30

J1

CONTROL

BOARD

J4

J3

J31

J2

J7

J17

J16

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

BLACK

SMOOTH

ORANGE

PURPLE

GREEN

SMOOTH

BLACK

WHITE

WHITE

GREEN

RIBBED

EVAP. FAN

BLACK

INVERTER

COMPRESSOR

RIBBED

COND. FAN

LED DRIVER

MULLION HEATER

15 & 24 INCH SERVICE MANUAL

35

Page 40

RED

ORANGE

YELLOW

BLACK

WIRING DIAGRAM

PART NUMBER 957875

TRUE 24” UNDERCOUNTER MODELS

“A” VERSION

F°

LED

MODE

SMOOTH

WHITE

BLACK

ICE

DISPLAY BOARD

BLACK

BLACK

LED DRIVER

C°

RED

LED

COLOR

LIGHT

ALARM

RED

BLACK

GREEN

EVAP FAN MOTOR

POWER CORD

SMOOTH

RIBBED

RIBBED

BLUE STRIPE X 1

PROBE EVAP

PROBE CAB

BLUE STRIPE X 2

GREEN

J2

J7

BOARD

CONTROL

J16

ORANGE

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

J17

YELLOW

BLACK

PURPLE

SMOOTH

RIBBED

YELLOW

J1

J29

J33

J3

J4

J30

J32

J31

DOOR SWITCH

TRUE RESIDENTIAL

36

GREEN

COMPRESSOR

®

INVERTER

COND FAN MOTOR

Page 41

LOW VOLTAGE

HIGH VOLTAGE

RED

WHITE

BLACK

GREEN

WIRING DIAGRAM

PART NUMBER 956598

TRUE 15” UNDERCOUNTER MODELS

“A” VERSION

LIGHT

DISPLAY BOARD

WHITE

BLACK

SMOOTH

F°

C°

ICE

LED DRIVER

LED

RED

RED

BLACK

GREEN

EVAP FAN MOTOR

POWER CORD

RIBBED

SMOOTH

RIBBED

BLUE STRIPE X 1

PROBE EVAP

PROBE CAB

BLUE STRIPE X 2

GREEN

J29

J33

J32

J30

J1

J4

J3

J31

BOARD

CONTROL

J16

ORANGE

J17

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

BLACK

PURPLE

FAN DRIVER

RED

BLUE

YELLOW

WHITE

DOOR SWITCH

J34

J2

J7

COMPRESSOR

INVERTER

GREEN

COND FAN MOTOR

15 & 24 INCH SERVICE MANUAL

37

Page 42

LOW VOLTAGE

LOW VOLTAGE

WIRING DIAGRAM

PART NUMBER 956598

TRUE 15” UNDERCOUNTER MODELS

“A” VERSION

F°

C°

ICE

LIGHT

GREEN

WHITE

BLACK

RED

HIGH VOLTAGE

HIGH VOLTAGE

RED

DISPLAY BOARD

BLACK

LED

BLACK

RED

LED DRIVER

BLUE STRIPE X 1

PROBE EVAP

PROBE CAB

BLUE STRIPE X 2

DOOR SWITCH

WHITE

YELLOW

J1

J2

J7

BOARD

J29

CONTROL

J33

J4

J32

J30

J3

J17

J16

J31

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

TRUE RESIDENTIAL

38

GREEN

J32

J1

CONTROL

J29

J33

J4

J30

®

J2

BOARD

J3

J16

J31

J7

J17

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

BLACK

SMOOTH

ORANGE

PURPLE

GREEN

GREEN

BLACK

INVERTER

COMPRESSOR

COND. FAN

DRIVER

LED DRIVER

WHITE

RIBBED

EVAP. FAN

Page 43

WIRING DIAGRAM

PART NUMBER 982900

TRUE UNDERCOUNTER DRAWERED UNIT

“B” VERSION

RED

ORANGE

YELLOW

BLACK

GREEN

BLACK

WHITE

WHITE

GREEN

BLACK

WHITE

ICE

BLACK

BLACK

J29

J33

J32

F°

C

°

RED

BLACK

BLUE

RED

GRAY

J2

J1

J4

J3

J30

J31

J34

J7

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

J16

J17

BLUE

BROWN

RED

BLACK

GREEN

WHITE

PURPLE

SMOOTH

RIBBED

YELLOW

YELLOW/WHITE

YELLOW/WHITE

YELLOW

15 & 24 INCH SERVICE MANUAL

39

Page 44

WIRING DIAGRAM

PART NUMBER 980395

TRUE 24” UNDERCOUNTER MODELS

“B” VERSION

RED

ORANGE

YELLOW

BLACK

GREEN

BLACK

WHITE

WHITE

GREEN

BLACK

WHITE

ICE

BLACK

BLACK

J29

J33

J32

F°

C

°

RED

BLACK

BLUE

RED

GRAY

J2

J1

J4

J3

J30

J31

J34

J7

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

J16

J17

BLUE

RED

BROWN

BLACK

TRUE RESIDENTIAL

40

YELLOW/WHITE

WHITE

PURPLE

SMOOTH

RIBBED

YELLOW/WHITE

GREEN

®

Page 45

WIRING DIAGRAM

PART NUMBER 982979

TRUE 15” UNDERCOUNTER MODELS

“B” VERSION

RED

ORANGE

YELLOW

BLACK

GREEN

BLACK

WHITE

WHITE

GREEN

BLACK

WHITE

F°

C

°

ICE

RED

BLACK

BLUE

RED

GRAY

BLUE

J2

J1

J29

J33

J4

J3

J32

J30

J31

J34

J7

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

J16

J17

BROWN

ORANGE

WHITE/RED

WHITE/BLUE

WHITE

BROWN

BLUE

RED

ORANGE

BLACK

PURPLE

GREEN

BLACK

YELLOW/WHITE

YELLOW/WHITE

15 & 24 INCH SERVICE MANUAL

41

Page 46

LOW VOLTAGE

WIRING DIAGRAM

PART NUMBER 952612

TRUE 24” DUAL ZONE WINE CABINET

“A” VERSION

ALARM

LIGHT

F°

C°

F°

C°

MODE

RED

WHITE

GREEN

HIGH VOLTAGE

ICE

ICE

BLACK

J2

J1

BLACK

BLACK

RED

RED

LED

LED

LOWER

DISPLAY BOARD

UPPER

BLACK

BLACK

BLACK

LED

BLACK

LED

BLACK

LED DRIVER

RED

J29

BLACK STRIPE X 2

BLUE STRIPE X 2

BLACK STRIPE X 1

BLUE STRIPE X 1

PROBE EVAP Z2

PROBE EVAP Z1

PROBE COMPT Z2

PROBE COMPT Z1

YELLOW /WHITE

YELLOW /WHITE

DOOR SWITCH

J33

J4

J32

J30

J3

J31

J7

BOARD

CONTROL

J17

J16

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

TRUE RESIDENTIAL

42

GREEN

J32

®

J1

CONTROL

J29

J33

J4

J30

J2

BOARD

J3

J31

J7

J34

J24

J23

J25

J27

J26

J28

J35

J37

J38

J39

J40

J41

J42

J36

J43

BLACK

WH/BN

BROWN

BLACK

PURPLE

GREEN

ORANGE

REF. VALV E

WHITE

INVERTER

OG/WH

WHITE

GREEN

RIBBED

EVAP.FAN Z1

RIBBED

EVAP.FAN Z2

COMPRESSOR

RIBBED

COND. FAN

J17

J16

BLACK

LED DRIVER

WHITE

Page 47

WIRING DIAGRAM

PART NUMBER 982539

TRUE 24” DUAL ZONE WINE CABINET

“B” VERSION

RED

BLACK

BROWN

BLUE

F°

C

°

ICE

F°

C

°

ICE

BLUE

BROWN

RED

BLACK

GREEN

WHITE

PURPLE

15 & 24 INCH SERVICE MANUAL

43

Page 48

WIRING DIAGRAM

PART NUMBER 988399

TRUE 24” FREEZER

“B” VERSION

BLACK

GREEN/YELLOW

WHITE

WHITE

WHITE

WHITE

HEATER

DRAIN

HEATER

3967 - 4849

DRAIN

HEATER

(TUF-24D

ONLY)

MULLION

HEATER

COIL

PAN

TUBE

WHITE

BLACK

WHITE

BLUE

WHITE

BLACK

WHITE

WHITE

WHITE

BLUE

WHITE

WHITE

BLACK

(SMOOTH)

GR AY

(TUF-24D

ONLY)

BLACK

BLUE

C:/Users/josher/Desktop/987697 DECAL.jpg

GR AY

WHITE

WHITE

LN

J1

GR AY

L1

J7

J2

REF

J34

VALVE

J24

J23

J25

J27

J26

J28

J35

J37

DEFROST

LZ1 NC

LZ1 COM

LZ1 NO

LZ2 NC

LZ2 COM

LZ2 NO

CONDENSER

ICE 1

GR AY

GR AY

BLACK

BLACK/WHITE

PINK

BLUE

BLUE

BLUE

ORANGE

BLUE

BLACK

WHITE

BLACK

BLACK

DTS

RED

BLACK

(RIBBED)

BLACK

BLACK/WHITE

RED

RED

BOARD

CONTROL

J39

EVAP1 Z1

BROWN

BROWN

BROWN

BLUE

C:/Users/josher/Desktop/FAN DRIVER.jpg

10K

BLUE

10K

BLACK

(TUF-24D

ONLY)

YELLOW

TRUE RESIDENTIAL

44

EVAP Z2

COMPT Z1 COMPT Z2 EVAP Z1

J32

J33

J30

(N.C)

YELLOW

®

DISPLAY

BOARD

WHITE/YELLOW

WHITE/YELLOW

J41

J36

J43

J3

DOOR Z1 DOOR Z2

(N.C)

EVAP1 Z2

COMPRESSOR

L1

GR AY

PURPLE

GREEN/YELLOW

L

N

WHITE

BLUE

BLACK

RED

RED

Page 49

COMPRESSOR INFORMATION

ty P e s o f C o m P r e s s o r s a n D s P e C I f I C a t I o n s

45 - 49

v a r I a B l e s P e e D C o m P r e s s o r D I a g n o s t I C s

I n v e r t e r B o a r D D I a g n o s t I C s ta B l e

C o m P r e s s o r C o m P a r t m e n t l a y o u t

15 & 24 INCH SERVICE MANUAL

45

Page 50

TYPES OF COMRESSORS AND SEPCIFICATIONS

All "A" version units were equipped with a variable speed compressor.

24 inch "B" version units have a single speed compressor.

15 inch "B" version unit have a variable speed compressor.

The compressor compartment can be accessed by removing the rear panel. This will also gain access to the

compressor inverter board and condenser fan motor.

Any time a compressor needs to be changed out, you must go with the OEM compressor that the unit was built

with.

We do not recommend going from a single speed to a variable speed or vice versa.

Call Residential Tech support at 844-746-9423 with questions or concerns.

VARIABLE SPEED

ALL VERSIONS / 15"

INCH B VERSIONS

MODELS/VERSIONS

SINGLE SPEED

REFRIGERATOR / WINE FREEZER

Brand EMBRACO EMBRACO EMBRACO

Model EM20HSC EM 3D5 0HLT VEM Y3H

Nominal Voltage /

Frequency

115-127V / 60HZ 115-127V / 60HZ 1 ~ 230V / 53-150HZ 3 ~

Refrigerant R-134 A R-134 A R-134 A

Start Device TSD - 115V TS D2- 115V INVERTER

Run Capacitor 5µF (175VAC) 15µF (200VAC) N/A

Start Capacitor N/A N/A N/A

Start Winding Resistance 13.18 (Ω at 77°F) +/- 8% 5.92 (Ω at 77°F) +/- 8% 16.07 (Ω at 77°F) +/- 8%

Run Winding Resistance 9.25 (Ω at 77°F) +/- 8% 5.42 (Ω at 77°F) +/- 8% 16.07 (Ω at 77°F) +/- 8%

Locked Rotor Amperage 5.22A 8.0A N/A

Full Load Amperage .86A 1.34A N/A

TRUE RESIDENTIAL

46

®

Page 51

VARIABLE SPEED COMPRESSOR DIAGNOSIS (SOME MODELS)

16Ω

16Ω

150 VAC.

16Ω

Example A Example B

150 VAC.

150 VAC.

The variable speed compressor is comprised of two components:

1. The inverter board.

2. The compressor.

The compressor speed board is supplied power from the AC line cord. This AC power is converted to DC power

on the board. The DC power is sequentially switched to the three motor windings to drive the compressor. By

adjusting the speed at which these three windings are switched the speed of the compressor can be adjusted.

The switching speed is determined by the amp draw of the compressor. As the load increases the amperage

of the compressor goes up the speed board speed up to compensate. As the amperage goes down the speed

board will slows the compressor down. The resulting speed will adjust between 4500 rpm and 1600 rpm.

PLEASE NOTE: THE VARIABLE SPEED COMPRESSOR IS A 3 PHASE DC COMPRESSOR APPLYING LINE

VOLTAGE TO COMPRESSOR WILL DAMAGE IT.

The VCC looks very similar to a standard single speed compressor. The three terminals on the side of the

compressor look the same also. However when taking resistance measurements around the terminals to the

outside of the case do not let the different motor design cause confusion. The first check is still to verify that

there is NO continuity to the case itself. This is the same as with any standard compressor. When checking

between the three terminals, the resistance measurements should be equal regardless of which two terminals

you are checking. There are three identical windings attached to these terminals so the resistance of the

windings should be equal. It should never read 0 or infinity ohms. With the compressor at 77º the windings will

read about 16 ohms each (see example A).

15 & 24 INCH SERVICE MANUAL

47

Page 52

Testing the inverter board:

1. Test for line voltage to the inverter. There should be 120V AC between black and orange wires. If no,

check wire harness.

2. Test for signal from temp control board. There should be 120V AC on purple. If no, test the temp

control board.

Because of the frequency of the following voltage tests, not all multimeters may be capable of measuring the

correct voltage. These tests were made using a good quality multimeter, i.e. Fluke, U.E.I., and Amp Probe

brands. The voltage read by your meter will most likely not match the readings made with another meter. The

goal is to verify the presence of the drive signals.

3. Test for output voltage of the inverter board. With the leads still attached to the compressor and

your meter set for 200V AC, test for voltage between all the windings. If your meter reads 150V,

for example, between two windings, it should read 150V between all the rest of the terminals (see

example B). If it does not read same voltage at all three windings, suspect the speed board as being

faulty.

INVERTER BOARD DIAGNOSTICS TABLE

LED STATUS LED STATUS DESCRIPTION

1 FLASH

15 seconds

2 FLASH

5 seconds

3 FLASH

5 seconds

4 FLASH

5 seconds

Control communication problem.

Normal operation

VCC inverter problem.

VCC compressor problem.

• Pull down cycle - if inverter doesn’t sense

the thermostat signal for 10 minutes.

• Normal cycle - if inverter doesn’t receive the

thermostat signal for 4 hours

• Some problem on the inverter hardware

• Is not possible to keep the speed over 1,600

rpm in an overload or overvoltage situation

• Inverter is reaching the max power even at

the minimum speed (1,600 rpm)

• Starting fail

• Rotor position fail

• Over 221ºF internal inverter temperature

1 FLASH

NOTE: PRIOR TO CONDEMING THE INVERTER BOARD. OHM THE COMPRESSOR OUT TO MAKE SURE IT'S

NOT SHORTED TO GROUND NOR HAS AN OPEN WINDING.

TRUE RESIDENTIAL

48

Temperature protection activated.

®

• Over 203ºF internal inverter temperature

• Power limit decreases to protect the inverter

Page 53

COMPRESSOR COMPARTMENT LAYOUT

“A” V ERSION

A. Inverter Board

B. Condenser Fan Motor

C. Low Side Process Tube

D. High Side Process Tube

E. Cap Tube

A

B

“ B ” V E R S I O N

A

B

15 I N C H V E R S I O N

C

C

D

D

E

A. Condenser Motor

B. Start Components

C. High Side Process Tube

D. Liquid Line Filter Drier

E. Low Side Process Tube

E

A. Inverter Board

B. Condenser Fan Motor

(located behind inverter board)

C. High Side Process Tube

D. Cap Tube

E. Low Side Process Tube

C

A

B

D

E

15 & 24 INCH SERVICE MANUAL

49

Page 54

SE A L E D S Y S T E M

43 - 48

g o o D r e f r I g e r a t I o n P r a C t I C e s

s y s t e m P r e s s u r e s

tr o u B l e s h o o t I n g , r e P a I r s & r e P l a C e m e n t

TRUE RESIDENTIAL

50

®

Page 55

GOOD REFRIGERATION PRACTICES

GOOD REFRIGERATION PRACTICES WILL ALWAYS START WITH GOOD DETECTIVE WORK TO FIND OUT

WHAT CAUSED THE FAILURE SO WE CAN ELIMINATE THE POSSIBILITY OF A REPEAT FAILURE. BELOW