Page 1

TRUE FOOD SERVICE

EQUIPMENT, INC.

2001 East Terra Lane • O’Fallon, Missouri 63366-4434 • (636)240-2400

Fax (636)272-2408 • Toll Free (800)325-6152 • Intl Fax# (001)636-272-7546

Parts Dept. (800)424-TRUE • Parts Dept. Fax# (636)272-9471 • www.truemfg.com

Project Name:

Location:

Item #: Qty:

Model #:

AIA #

SIS #

Model:

TBB-24GAL-72

Underbar Refrigeration:

Solid Swing Door Galvanized Top 24" Back Bar Cooler

Scan cod e

for video

TBB-24GAL-72

True’s refrigerated back bar

coolers are designed with

enduring quality and value.

Our commitment to using the

highest quality materials and

oversized refrigeration assures

colder product temperatures

and years of trouble free service.

Oversized, factory balanced,

refrigeration system holds 33°F

to 38°F (.5°C to 3.3°C).

Exterior - heavy duty, wear

resistant laminated black vinyl

front and sides. Matching black

aluminum back. Galvanized

steel top designed to slide

under existing cabinetry.

Interior - Stainless steel oor

with ½" (13 mm) reinforced lip

and heavy gauge galvanized

steel walls.

NSF-7 approved for packaged

and bottled product.

Positive seal doors.

Entire cabinet structure and

solid doors are foamed-in-place

using Ecomate. A high density,

polyurethane insulation that has

zero ozone depletion potential

(ODP) and zero global warming

potential (GWP).

ROUGH-IN DATA

Model Doors

Capacity

12 oz.

Cans

Chart dimensions rounded up to the nearest ⁄" (millimeters rounded up to next whole number).

Cabinet Dimensions

(inches)

½

Barrels L D† H

Shelves

(mm)

HP Voltage Amps

Specications subject to change without notice.

NEMA

Config.

Cord

Length

(total ft.)

(total m)

Crated

Weight

(lbs.)

(kg)

TBB-24GAL-72 3 84 6-pks 3** 4 71⁄ 23¾ 34¼ ⁄ 115/60/1 5.2 5-15P 7 415

1826 604 870 N/A N/A 2.13 189

†Depth does not include 1" (26 mm) for rear bumpers.

T

RUE

R

EFRIGERATION

MADE IN

U.S.A.

SINCE 1945

8/16

®

Printed in U.S.A.

APPROVALS: AVAILABLE AT:

Page 2

Model:

TBB-24GAL-72

Underbar Refrigeration:

Solid Swing Door Galvanized Top 24" Back Bar

Cooler

STANDARD FEATURES

DESIGN

True’s refrigerated back bar coolers are

•

designed with enduring quality and value.

Our commitment to using the highest

quality materials and oversized refrigeration

assures colder product temperatures and

years of trouble free service.

REFRIGERATION SYSTEM

Factory engineered, self-contained, capillary

•

tube system using environmentally friendly

(CFC free) 134A refrigerant.

Extra large evaporator coil balanced with

•

higher horsepower compressor and large

condenser; maintains cabinet temperatures

of 33°F to 38°F (.5°C to 3.3°C).

Sealed, cast iron, self-lubricating evaporator

•

fan motor(s) and larger fan blades give

True back bar coolers a more ecient low

velocity, high volume airow design. This

unique design ensures faster temperature

pull down of warm product, colder holding

temperatures and faster recovery in high

use situations.

Condensing unit accessed from behind

•

front grill, slides out for easy cleaning and

maintenance.

CABINET CONSTRUCTION

Exterior - heavy duty, wear resistant

•

laminated black vinyl front and sides.

Matching black aluminum back. Galvanized

steel top designed to slide under existing

cabinetry.

Interior - Stainless steel oor with ½"

•

(13 mm) reinforced lip and heavy gauge

galvanized steel walls.

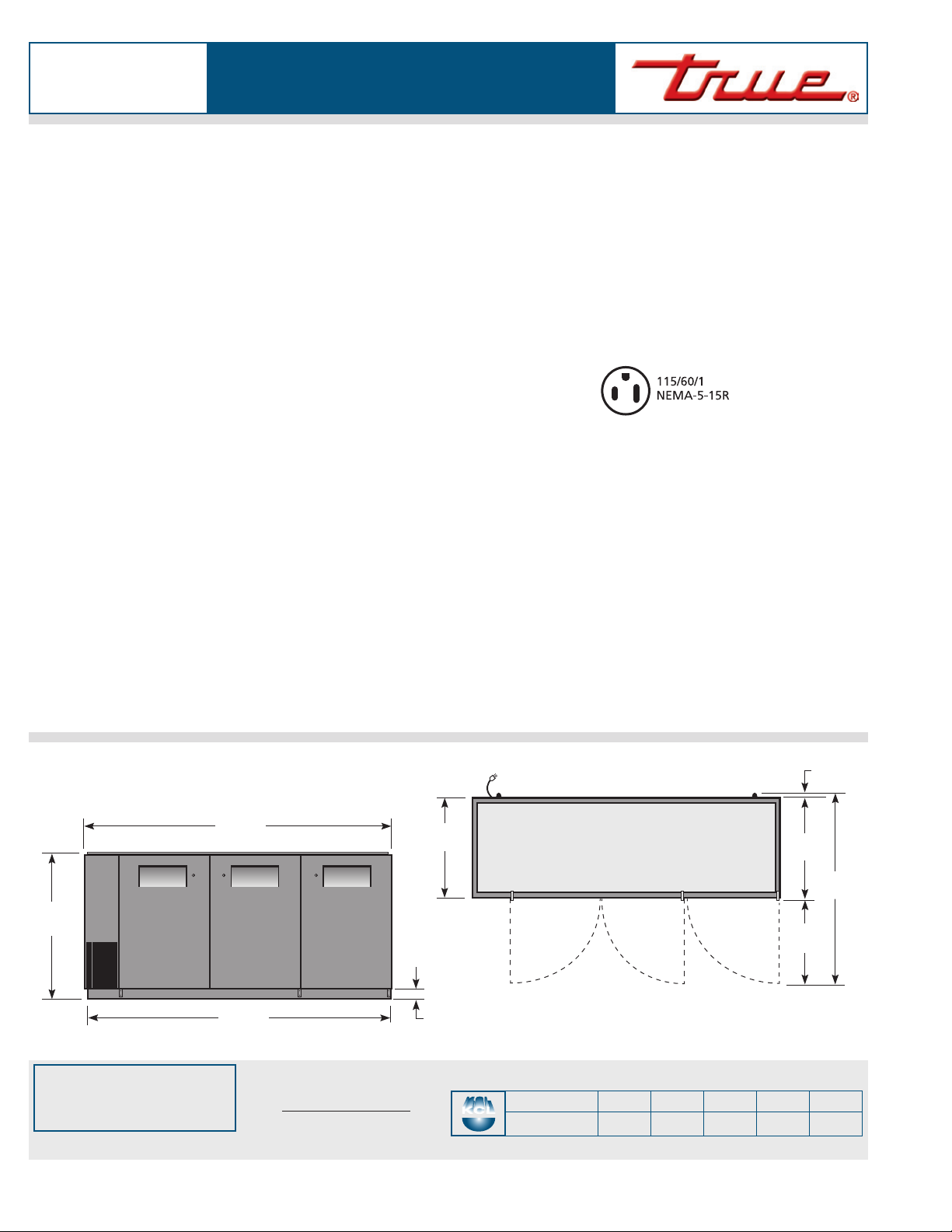

PLAN VIEW

Door threshold protector prevents damage

•

to cabinet from routine loading of product.

Insulation - entire cabinet structure and

•

solid doors are foamed-in-place using

Ecomate. A high density, polyurethane

insulation that has zero ozone depletion

potential (ODP) and zero global warming

potential (GWP).

Welded, heavy duty steel frame rail, black

•

powder coated for corrosion protection.

DOORS

Wear-resistant laminated black vinyl exterior

•

with heavy gauge galvanized steel liner.

Each door tted with 12" (305 mm) long

•

recessed handle that is foamed-in-place

with a sheet metal interlock to ensure

permanent attachment.

Positive seal doors.

•

Magnetic door gaskets of one piece

•

construction, removable without tools for

ease of cleaning.

Door locks standard.

•

SHELVING

Four (4) adjustable, heavy duty, black PVC

•

coated wire shelves. Two (2) long shelves

which span behind the left and center

doors: 40"L x 18"D (1016 mm x 458 mm).

Two (2) shelves behind right door: 19⁄"L x

18"D (493 mm x 458 mm). Four (4) chrome

plated shelf clips included per shelf.

Aluminum shelf support pilasters. Shelves

•

are adjustable on ½" (13 mm) increments.

LIGHTING

Fluorescent interior lighting. Safety

•

shielded.

MODEL FEATURES

Evaporator is epoxy coated to eliminate the

•

potential of corrosion.

Designed to accommodate a variety of

•

beer kegs. Depending on tapping kit

used, ½barrels may not t.

Listed under NSF-7 for the storage and/or

•

display of packaged or bottled product.

ELECTRICAL

Unit completely pre-wired at factory and

•

ready for nal connection to a 115/60/1

phase, 15 amp dedicated outlet. Cord and

plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❑ 230 - 240V / 50 Hz.

❑ 6" (153 mm) standard legs.

❑ 6" (153 mm) seismic/anged legs.

❑ 2 ½" (64 mm) diameter castors.

❑ 4" (102 mm) diameter castors.

❑ Additional shelves.

1"

(26 mm)

717/8"

(1826 mm)

347/32"

(870 mm)

713/8"

(1813 mm)

ELEVATION

Three year warranty on all parts

and laborand an additional 2 year

*RESIDENTIAL APPLICATIONS: TRUE assumes no liability for parts or

labor coverage for component failure or other damages resulting

from installation in non-commercial or residential applications.

WARRANTY

warranty on compressor.

(U.S.A. only)

*

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

23"

(585 mm)

2"

(51 mm)

KCL

2321/32"

(601 mm)

445/8"

(1134 mm)

1931/32"

(508 mm)

PLAN VIEW

Model Elevation Right Plan 3D Back

TBB-24GAL-72 TFJX65E TFJX65S TFJX65P TFJX653

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • O’Fallon, Missouri 63366-4434 • (636)240-2400 • Fax (636)272-2408 • Toll Free (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

Loading...

Loading...