Page 1

0 TRtII BILT --

Operator's Manual

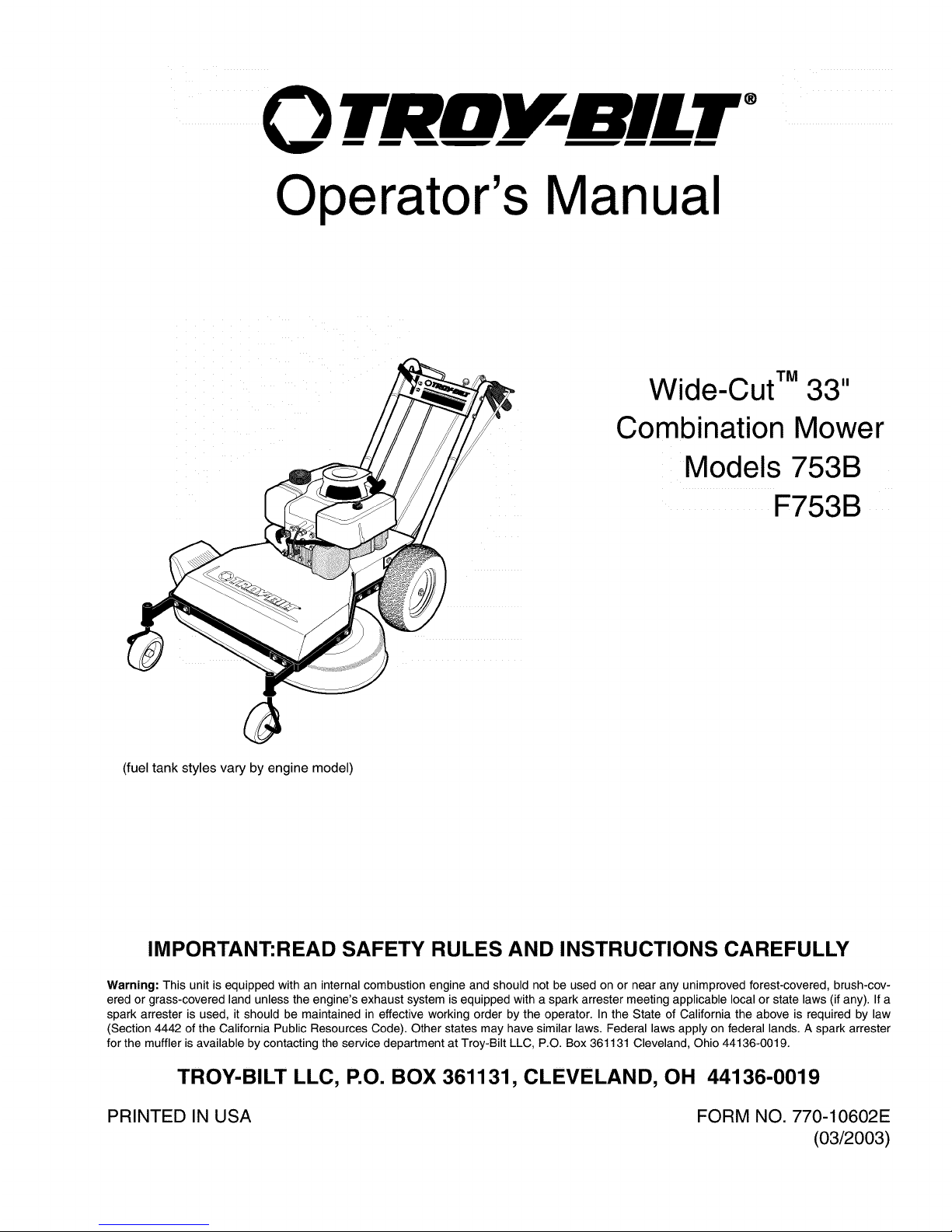

Wide-CutTM 33"

Combination Mower

Models 753B

F753B

(fuel tank styles vary by engine model)

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-cov-

ered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FORM NO. 770-10602E

(03/2003)

Page 2

TABLEOFCONTENTS

Content Page

Safety ................................................................... 1

Assembly................................................................. 4

Features and Controls....................................................... 8

Operation ................................................................ 11

Maintenance .............................................................. 16

Off-Season Storage ........................................................ 24

Lubrications............................................................... 25

Troubleshooting ........................................................... 27

Parts List................................................................. 28

Warrany Information........................................................ BackCover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new Wide-Cut TM mower. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the infor-

mation from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is ex-

plained below. For future reference, please copy the model number and the serial number of the equipment in

the space below

OTRItV BILT. TROY-BILT LLC

P. 0. BOX 361131

www.troybilt.com CLEVELAND, 0H44136

330-558-7220

_. 866-840-6483_

Copy Model Number Here

Copy Serial Number Here

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating,

specifications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual packed

separately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

your unit's model number and serial number ready when you call. See previous section to locate this in-

formation. You will be asked to enter the serial number in order to process your call.

Page 3

Safety

WARNING:

The engine exhaust from this product contains

chemicals known to the State of California

to cause cancer, birth defects, or other reproduc-

tive harm.

SafetyAlertSymbol

_, his is a safety alert symbol. It is used in this

Owner's Manual to alert you to potential

hazards. Wheneveryou seethis symbol, readandobeythe

safety messagethat follows it. Failureto obey the safety

message could result in personal injury or property

damage.

IMPORTANT

Safe Operation Practicesfor Walk-Behind Mowers

This cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructionscould result in serious injury or death.

I. GENERALOPERATION

1.

.

Read,understand,andfollow all in-

structionson the machineandin the

manuals.Bethoroughlyfamiliar with

thecontrols andthe proper useof

themower beforestarting.

Donot put handsorfeet nearor

under rotatingparts. Keepclear of

themower bladeand discharge

openingatall times.

3. Onlyallow responsibleindividuals,

whoarefamiliar with the instruc-

tions,to operatethe mower.

4. Clearthe areaof objectssuch as

rocks,toys, wire, bones,sticks, etc.,

which could be pickedupand

thrown by the blade.

.

5. Besurethe areais clearof other

peoplebeforemowing.Stop mower

if anyoneentersthearea. Keepby-

standersat least25 feetawayfrom

the areaofoperation.

6. Do not operatethe mowerwhen

barefootor wearingopensandals.

Alwayswearsubstantialfoot wear.

Donot pull mower backwards

unlessabsolutelynecessary.Look

downand behindbeforeandwhile

moving backwards.

8. Do not operatethe mowerwithout

properguards,plates,grasscatcher

or other safetyprotectivedevicesin

place.

9. Referto providedinstructionsfor

properoperationand installationof

accessories.Onlyuseaccessories

approvedby GardenWay

Incorporated.

10. Stopthebladewhencrossinggravel

drives,walks, or roads.

11. Stoptheengineand disconnectthe

sparkplug wire from thesparkplug

wheneveryou leavethe unit, before

cleaningthe moweror unclogging

the chute.

12. Shutthe engineoff, wait untilthe

blade comesto a completestop, and

disconnectthespark plugwire be-

fore installing or removingthe

mulchercoveror the optionalgrass

catcher. Makecertainthat thegrass

catcheris securelyattachedbefore

operatingthe mower.Emptythe

grass catcheraftereachuse-

decomposingdebriscouldgenerate

enoughheatto catchfire.

13. Mow in daylightor goodartificial

light.

14. Do not operatethemowerwhile

underthe influenceofalcoholor

drugs.

Page 4

Section1: Safety

15.

16.

17.

Neveroperatemowerin wet grass.

Alwaysbesureof your footing; keep

a firm hold onthe handleandwalk;

never run.

Disengagethe WheelDriveLeveron

self-propelledmodelsbeforestarting

theengine.

If the unitshould startto vibrateab-

normally,stop theengineanddis-

connectthe sparkplug wire. Then

checkimmediatelyfor thecause.

Vibrationis generallyawarning of

trouble.

18. Alwayswearsafetygogglesor safety

glasseswith sideshieldswhenoper-

ating mower.

19. Watchfor traffic whenoperating

near,or whencrossingroadways.

20. Neverattemptto carrychildrenor

otherpassengerson themower.

Theycouldfall off and beseriously

injured,or theycould interferewith

thesafeoperationof the mower.

21. Checkthe operationof the Operator

PresenceControlBarbeforeeach

use.Seethe MaintenanceSectionof

this manualfor instructions. If the

enginerunslongerthanthreesec-

ondsafter theOperatorPresence

Control Baris released,the system

is not working properly. Immediately

contactyour localservicedealeror

thefactory TechnicalService

Departmentfor instructions. Donot

usethe moweruntilthe mechanism

is repaired.

22. Themoweris equippedwitha safety

dischargechute,comeswith special

mulchercovers,and offers an op-

tionalgrass catcher. Thesafetydis-

chargechute mustbeworking prop-

erly atalltimes. Neverattemptto

disconnector otherwisecausethis

dischargechuteto ceaseworking. If

used,mulchercover or grass

catcherattachmentmust beinstalled

properlyandfunction correctly. Do

not useyour equipmentotherwise.

23. Neverrun theenginein an enclosed

area.Engineexhaustcontainscarbon

monoxide,adeadlygasthat is odor-

less,colorless,andtasteless.Always

runtheengineoutdoorsand make

surethere is adequateventilation.

II. SLOPEOPERATION IV.SERVICE

Slopesarea majorfactorrelatedto

slipandfall accidentswhichcanresult

in severeinjury. All slopesrequire

extracaution.Ifyoufeel uneasyona

slope,donotmowit.

DO:

Mow acrossthefaceof slopes;never

upand down. Exerciseextremecau-

tion whenchangingdirection on

slopes.Avoid slopesgreaterthan

150.

Removeobjectssuch asrocks,tree

limbs,etc.

Watchfor holes,ruts, or bumps.Tall

grass can hideobstacles.

DONOT:

1. Useextracare in handlinggasoline

andotherfuels.Theyareflammable

andtheir vaporsare explosive.

a) Useonlyan approvedcontainer.

b) Neverremovegascap or add

fuelwhen the engineis running.

Allowengineto coolbeforerefu-

eling.Do not smoke.

c) Neverrefuelthe machine

indoors.

d) Neverstore themachineor fuel

containerinsidewhere there is

an openflame,such asawater

heater,etc.

e) Movemowerawayfrom any

gasolinefumes beforestarting

theengine.

2. Neverrunan engineinside aclosed

area.

III. CHILDREN

Tragicaccidentscanoccurifthe opera-

torisnotalerttothepresenceofchil-

dren.Childrenare oftenattractedtothe

mowerandtothe mowingactivity.

Neverassumethatchildrenwill remain

whereyoulastsawthem.

1. Keepchildren out of the mowing

areaand underthe watchful careof

a responsibleadult.

Bealertandturn moweroff if chil-

drenenterthearea.

.

3.

4. Neverallow children to operatethe

mower.

5. Useextracarewhen approaching

blind corners, shrubs,trees,or other

objectsthat mayobscurevision.

Beforeandwhile movingbackwards,

look behindand down for small

children.

3. Nevermakeadjustmentsor repairs

with the enginerunning. Disconnect

thesparkplug wire and keepthe

wireawayfrom the plugto prevent

accidentalstarting.

Keepall nuts andbolts,especially

thebladeattachmentbolts,tight and

keepequipmentin goodcondition.

Nevertamperwith safety devices.

Checktheir operationregularly.

6. Keepmowerfree of grass,leavesor

otherdebris build-up. Cleanup oil or

fuelspillage.Allow mowerto cool

beforestoring.

7. Afterstriking an object,stop the en-

gineand disconnectthe sparkplug

wire. Inspectthe mowerand repair,

if necessary,beforerestarting.

8. Neverattemptto makemowercut-

ting heightadjustmentswhilethe

engineis running.

9. Grasscatchercomponentsaresub-

jectto wear, damageanddeteriora-

tion, which couldexposemoving

parts or allowobjectsto bethrown.

Frequentlycheckcomponentsand

replacewith factory recommended

parts,when necessary.

Donot mowneardrop-offs, ditches,

or embankments.Theoperatorcould

loosefooting or balance.

4.

Donot mowexcessivelysteepslopes.

Donot mowon wet grass.Reduced

footing could causeslipping. 5.

Page 5

Section1: Safety

13.

10. Mower bladesaresharp andcan

cut.Wrap the bladeor weargloves,

and useextracautionwhenservic-

ing them.

11. Do notchangetheenginegovernor

settingor overspeedthe engine.

12. Do nottouch enginepartswhich

may behot from operation.Allow

partsto cool completelybeforein-

specting,cleaningor repairingthe

mower.

14.

Toaccessthe undersideof the

mower,tip the mower rearward.Do

nottip the mowerforward or on ei-

ther of its sides,unlessspecifically

advisedto do so in this manual.

Maintainor replacesafetyand in-

structionaldecals. Referto the sep-

aratePartsCatalogfor replacement

decalinformation.

15. For unitsequippedwith electric

start:

a) Batteriesproduceexplosive

gases.Keepsparks,flame,

cigarettes,etc.,away. Ventilate

theareawhenchargingthe bat-

tery.Do not chargethebatteryin

anairtight space.

b) Donot usea batterycharger

otherthan the oneprovidedwith

the mower.

c) Thebatterycontainstoxic mate-

rials. Do notdamagethe battery

case.If thecaseis brokenor

damaged,avoidcontactwith the

batterycontents.

d) Properlydisposeof adamaged

or worn outbattery.Checkwith

localauthorities for proper dis-

posalmethods.

e) Donot short circuit the battery.

Severeburnsandfire can result.

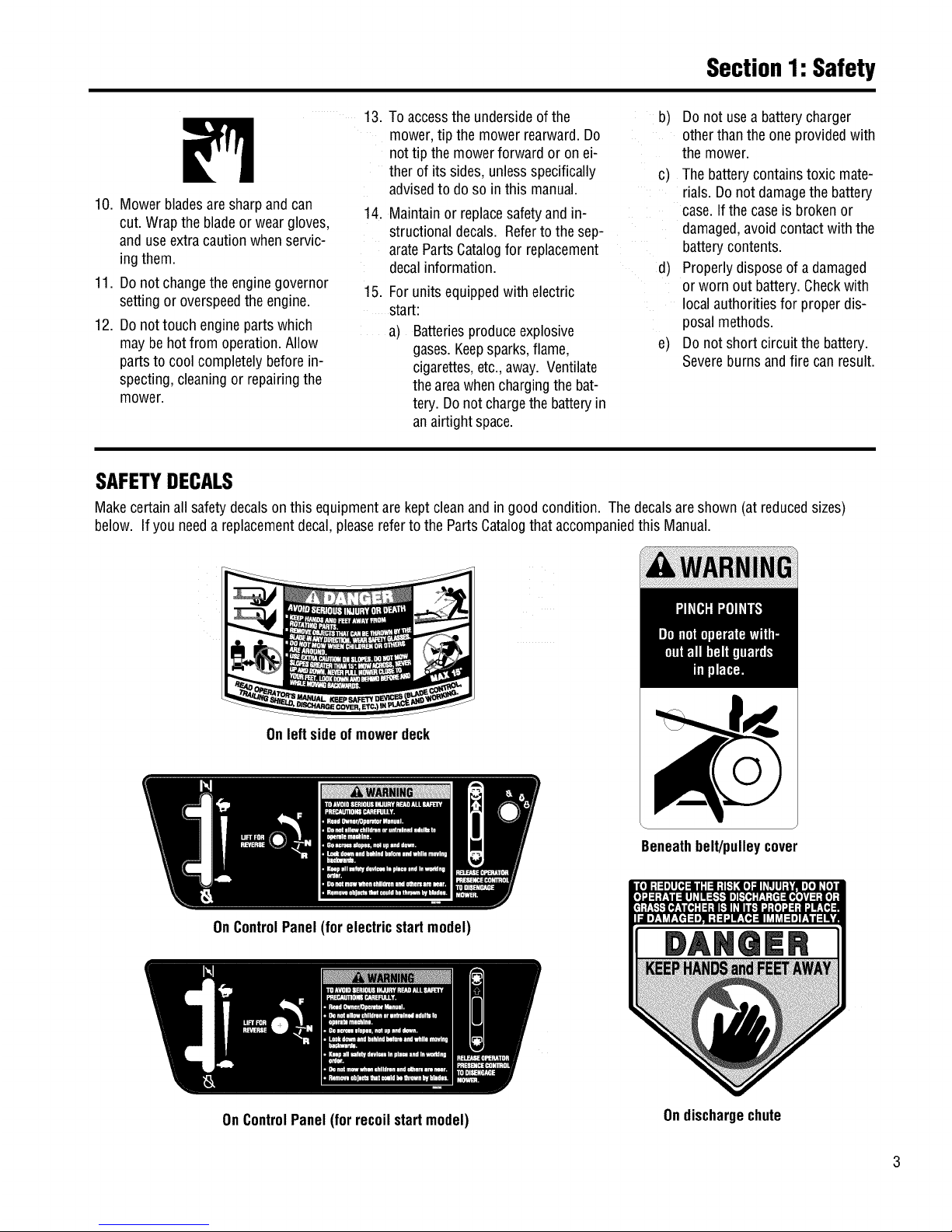

SAFETYDECALS

Makecertainall safetydecalsonthis equipmentare keptcleanandin good condition. Thedecalsareshown (at reducedsizes)

below. If you needa replacementdecal,pleasereferto the PartsCatalogthataccompaniedthis Manual.

Onleftside ofmowerdeck

OnControlPanel(for electricstartmodel)

Beneathbelt/pulleycover

OnControlPanel (for recoilstartmodel)

DANQER

Ondischargechute

Page 6

Assembly

ASSEMBLYSTEPS

To preventpersonal injury or property

damage, do not attempt to start the

engine until all assembly steps are

complete and you have read and

understand the safety, controls and

operatinginstructionsinthismanual.

INTRODUCTION

Pleasecarefullyfollow theseassembly

stepsto properlyprepareyour machine

for use. Werecommendthatyou read

this Sectionin its entiretybeforebegin-

ningassembly.

STEP1: Unpacking Mower

NOTE:LEFTand RIGHTsides ofthe unit

areasviewedfrom the operator'sposi-

tion behindthehandlebars.

1. Cutstraps, if present,securingunit

to pallet. Leaveuniton pallet during as-

sembly(to safelyremoveunit from pal-

let, wait until youhavecompletedas-

semblysteps 1-4).

2. Removeanyprotectivepackaging

from aroundthe handlebars.Cutthe

plastictie strapsholdingthecontrol rods

and struts tothe handlebars.

NOTE:All referencesto left, right,front

and rearof the machineare determined

bystandingbehindthehandlebarsand

facingthe direction offorward travel.

INSPECTIONAFTERDELIVERY

Inspectthe shippingcrateand machine

immediatelyafterdelivery. Makesure

neitherthe carton/cratenor the contents

havebeendamaged.

If you find or suspectany damage,con-

tact thecarrier(truckingcompany)

immediately. Informthem of thespecific

damageandthatyou wish to file a claim.

To protectyour rights, besureto put

this in writing to thecarrierwithin 15

days. Thecarrierwill letyou knowhow

to proceedwithyour claim. Pleaseletus

knowif you needany assistance.

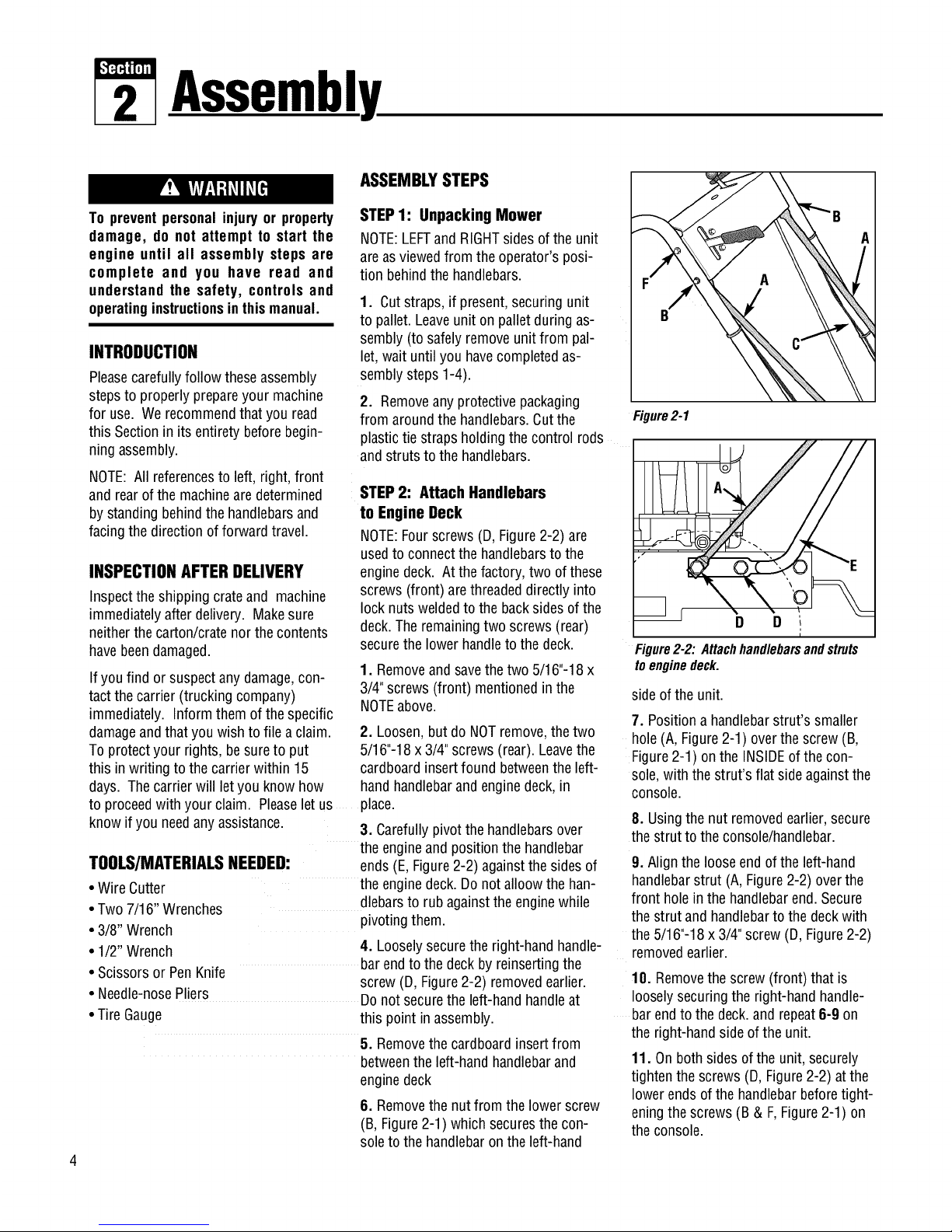

STEP2: Attach Handlebars

to Engine Deck

NOTE:Fourscrews(D, Figure2-2)are

usedto connectthehandlebarsto the

enginedeck. At the factory, two of these

screws (front) arethreadeddirectlyinto

lock nuts weldedto thebacksidesof the

deck.The remainingtwo screws (rear)

securethe lowerhandleto the deck.

1. Removeandsavethe two 5/16"-18 x

3/4"screws (front) mentionedin the

NOTEabove.

2. Loosen,but do NOTremove,the two

5/16"-18x 3/4" screws(rear). Leavethe

cardboardinsertfound betweenthe left-

hand handlebarandenginedeck,in

place.

3. Carefullypivotthehandlebarsover

• Wire Cutter

• Two7/16" Wrenches

• 3/8" Wrench

• 1/2" Wrench

• Scissorsor PenKnife

theengineandpositionthe handlebar

TOOLS/MATERIALSNEEDED: ends(E, Figure2-2) againstthe sides of

theenginedeck.Do not alloow thehan-

dlebarsto rubagainsttheenginewhile

pivoting them.

4. Looselysecurethe right-handhandle-

barendto the deck byreinsertingthe

screw(D, Figure2-2) removedearlier.

• Needle-nosePliers

Donot securethe left-handhandleat

• Tire Gauge this pointin assembly.

5. Removethecardboardinsertfrom

betweentheleft-handhandlebarand

enginedeck

8. Removethenut from the lower screw

(B,Figure2-1) which securesthecon-

soleto thehandlebaron theleft-hand

Figure2-1

D D ,

i

Figure2-2:Attachhandlebarsandstruts

toenginedeck.

sideof the unit.

7. Positiona handlebarstrut's smaller

hole (A, Figure2-1) overthescrew(B,

Figure 2-1) on the INSIDEofthe con-

sole,with the strut's flat sideagainstthe

console.

8. Usingthe nut removedearlier,secure

thestrut to theconsole/handlebar.

9. Align theloose endof theleft-hand

handlebarstrut (A,Figure2-2) overthe

front holein the handlebarend.Secure

thestrut and handlebartothedeckwith

the5/16"-18x3/4" screw(D, Figure2-2)

removedearlier.

10. Removethe screw (front) that is

looselysecuringthe right-handhandle-

barendto the deck.and repeat6-9 on

the right-handsideof the unit.

11. On bothsidesofthe unit, securely

tightenthe screws(D, Figure2-2)atthe

lowerends of the handlebarbeforetight-

eningthescrews (B & F,Figure2-1) on

theconsole.

Page 7

Section2: Assembly

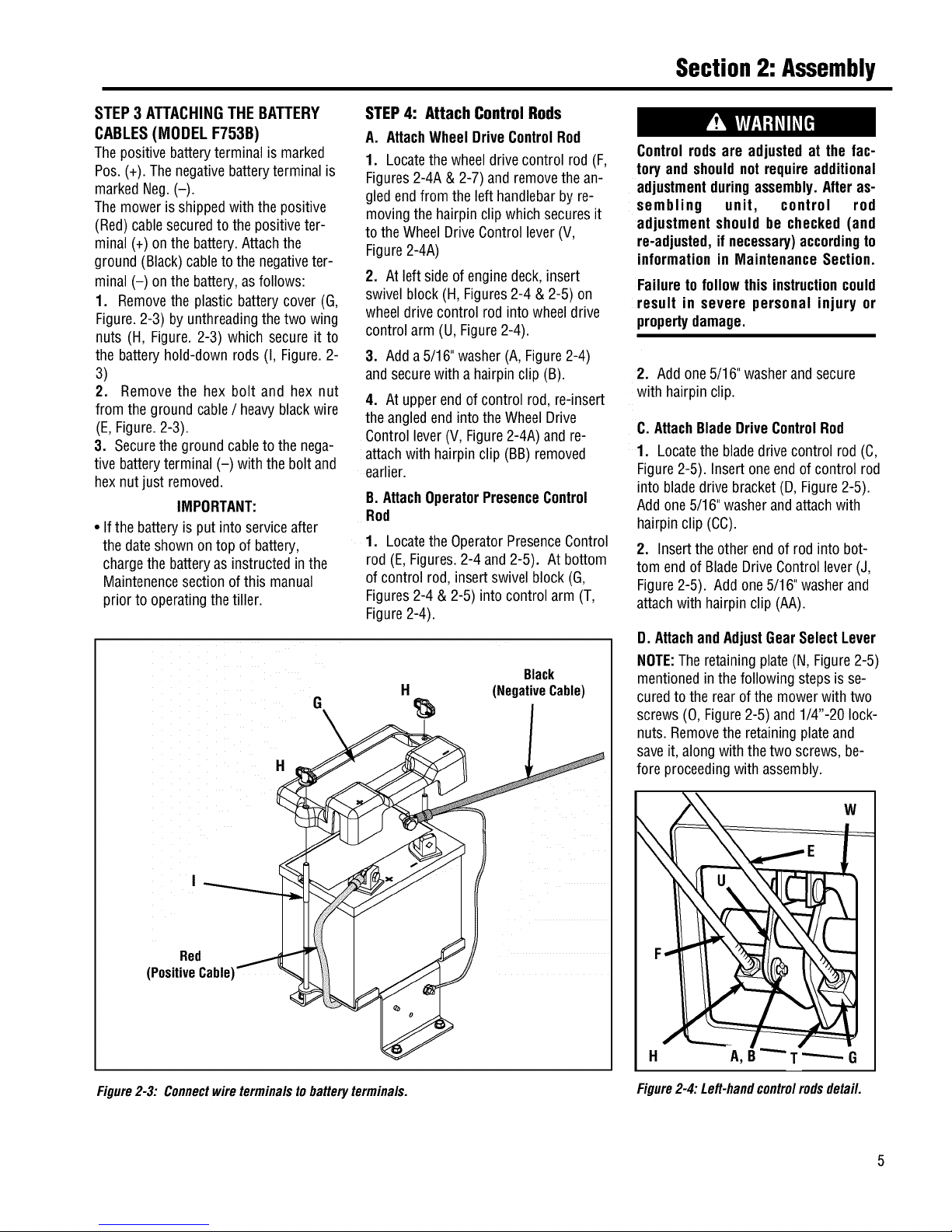

STEP3 ATTACHINGTHEBATTERY

CABLES(MODEL F753B)

Thepositive batteryterminal is marked

Pos.(+). Thenegativebatteryterminalis

markedNeg.(-).

Themowerisshipped with thepositive

(Red)cablesecuredto the positiveter-

minal (+) onthe battery.Attachthe

ground (Black)cableto the negativeter-

minal (-) onthe battery,asfollows:

1. Removethe plasticbatterycover (G,

Figure.2-3) byunthreadingthe two wing

nuts (H, Figure. 2-3) which secure it to

the batteryhold-down rods (I, Figure.2-

3)

2. Remove the hex bolt and hex nut

from the groundcable/ heavyblackwire

(E,Figure.2-3).

3. Securetheground cableto thenega-

tive batteryterminal (-) with the bolt and

hexnut just removed.

IMPORTANT:

• If the batteryis putinto serviceafter

the dateshownontop of battery,

chargethe batteryasinstructedin the

Maintenencesectionof this manual

prior to operatingthetiller.

STEP4: Attach Control Rods

A. AttachWheelDriveControlRod

1. Locatethewheel drivecontrol rod(F,

Figures2-4A & 2-7) and removethe an-

gledendfrom theleft handlebarby re-

movingthe hairpinclip whichsecuresit

to theWheelDriveControllever(V,

Figure2-4A)

2. Atleft sideof enginedeck,insert

swivelblock (H,Figures2-4 & 2-5) on

wheeldrive control rod into wheeldrive

control arm (U, Figure2-4).

3. Adda5/16"washer(A, Figure2-4)

andsecurewith a hairpinclip (B).

4. Atupperend ofcontrol rod,re-insert

the angledend into the Wheel Drive

Controllever(V,Figure2-4A) and re-

attach with hairpinclip (BB) removed

earlier.

B.AttachOperatorPresenceControl

Rod

1. LocatetheOperatorPresenceControl

rod (E, Figures.2-4and 2-5). At bottom

ofcontrol rod, insert swivelblock (G,

Figures2-4 & 2-5) into control arm (T,

Figure2-4).

H

Black

(NegativeCable)

H

Red /

(PositiveCable)

Figure2-3: Connectwireterminalstobatteryterminals.

Controlrodsare adjusted at the fac-

tory andshouldnot requireadditional

adjustmentduringassembly.Afteras-

sembling unit, control rod

adjustment should be checked (and

re-adjusted,ifnecessary)accordingto

informationin Maintenance Section.

Failureto follow this instructioncould

result in severe personal injury or

propertydamage.

2. Addone5/16"washerand secure

with hairpinclip.

C.AttachBladeDriveControlRod

1. Locatethe bladedrivecontrol rod (C,

Figure2-5). Insertoneendof control rod

into bladedrivebracket(D,Figure2-5).

Add one5/16"washerandattachwith

hairpinclip (CC).

2. Insertthe otherendof rod into bot-

tom endof BladeDriveControl lever(J,

Figure2-5). Add one5/16"washerand

attachwith hairpin clip (AA).

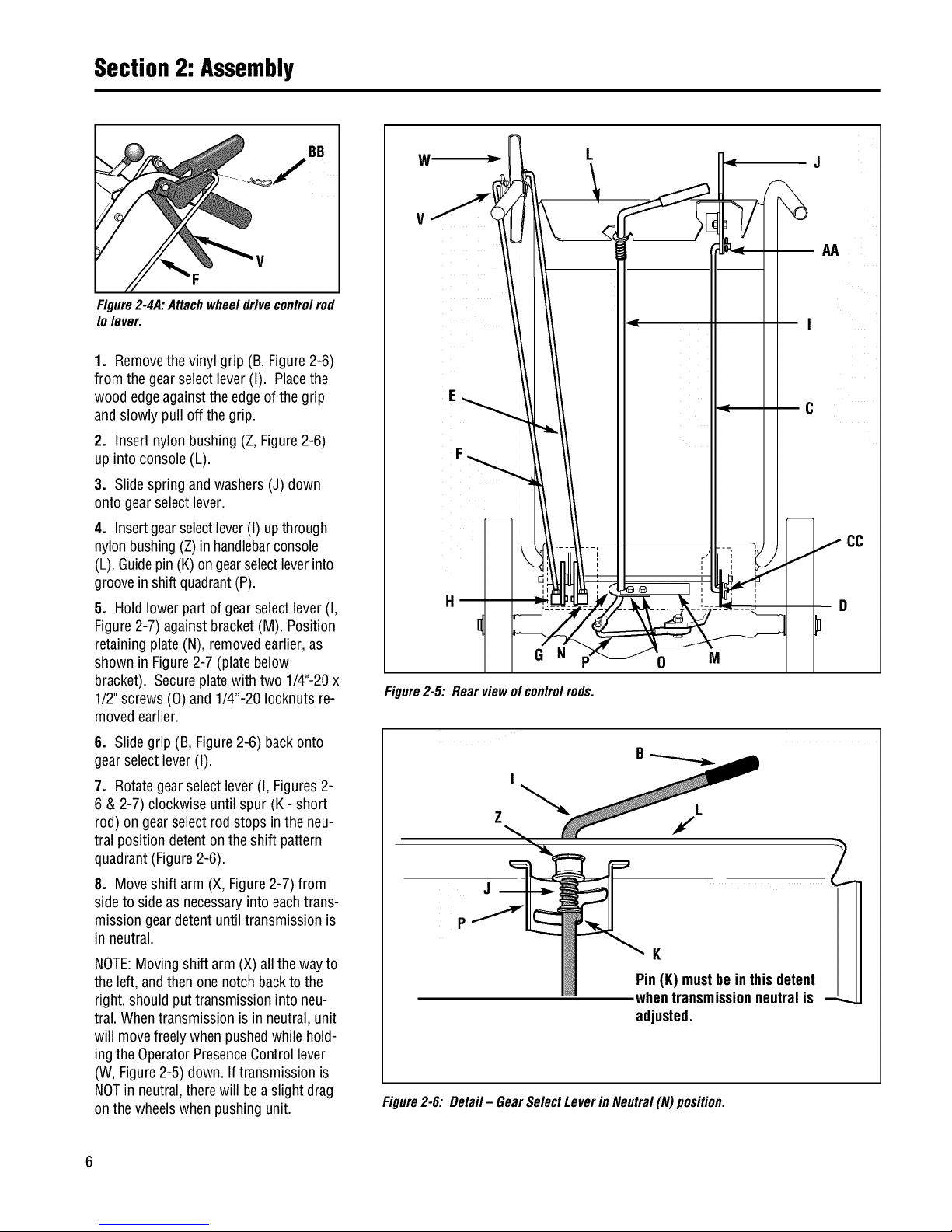

D. AttachandAdjustGearSelectLever

NOTE:The retainingplate(N,Figure2-5)

mentionedin thefollowing stepsis se-

curedto the rearofthe mowerwith two

screws (O, Figure2-5) and1/4"-20 lock-

nuts.Removethe retainingplateand

saveit, along with thetwo screws,be-

fore proceedingwith assembly.

W

H A,B _G

Figure2-4:Left-handcontrolrodsdetail.

Page 8

Section2: Assembly

BB

Figure2-4A:Attachwheeldrivecontrolrod

tolever.

1. Removethevinyl grip (B,Figure2-6)

from the gearselectlever (I). Placethe

woodedgeagainsttheedgeofthe grip

andslowly pull off the grip.

2. Insertnylon bushing(Z, Figure2-6)

up into console(L).

3. Slidespringandwashers(J) down

ontogearselectlever.

4. Insertgearselectlever(I) upthrough

nylonbushing(Z)in handlebarconsole

(L).Guidepin (K)ongearselectleverinto

grooveinshift quadrant(P).

5. Holdlower part of gearselectlever(I,

Figure2-7) againstbracket(M). Position

retainingplate(N), removedearlier, as

shown in Figure2-7(platebelow

bracket). Secureplatewith two 1/4"-20x

1/2"screws(0) and1/4"-20 Iocknutsre-

movedearlier.

6. Slidegrip (B, Figure2-6) backonto

gearselectlever (I).

7. Rotategearselectlever(I, Figures2-

6 & 2-7) clockwiseuntilspur (K - short

rod) ongearselectrod stops in theneu-

tral position detenton theshift pattern

quadrant(Figure2-6).

8. Moveshift arm (X, Figure2-7)from

sideto sideas necessaryintoeachtrans-

missiongeardetentuntil transmissionis

in neutral.

NOTE:Movingshift arm(X) allthe wayto

theleft, andthen onenotch backtothe

right, should puttransmissioninto neu-

tral. Whentransmissionis in neutral,unit

will movefreely whenpushedwhilehold-

ingthe OperatorPresenceControllever

(W, Figure2-5) down.If transmissionis

NOTin neutral,therewill beaslight drag

on the wheelswhenpushingunit.

W

J

V

F

G N

Figure2-5:Rearviewofcontrolrods.

0

M

C

f

2

K

Pin(K)mustbe inthisdetent

whentransmissionneutralis --_

adjusted.

Figure2-6: Detail - GearSelectLeverin Neutral(N) position.

6

Page 9

Section2: Assembly

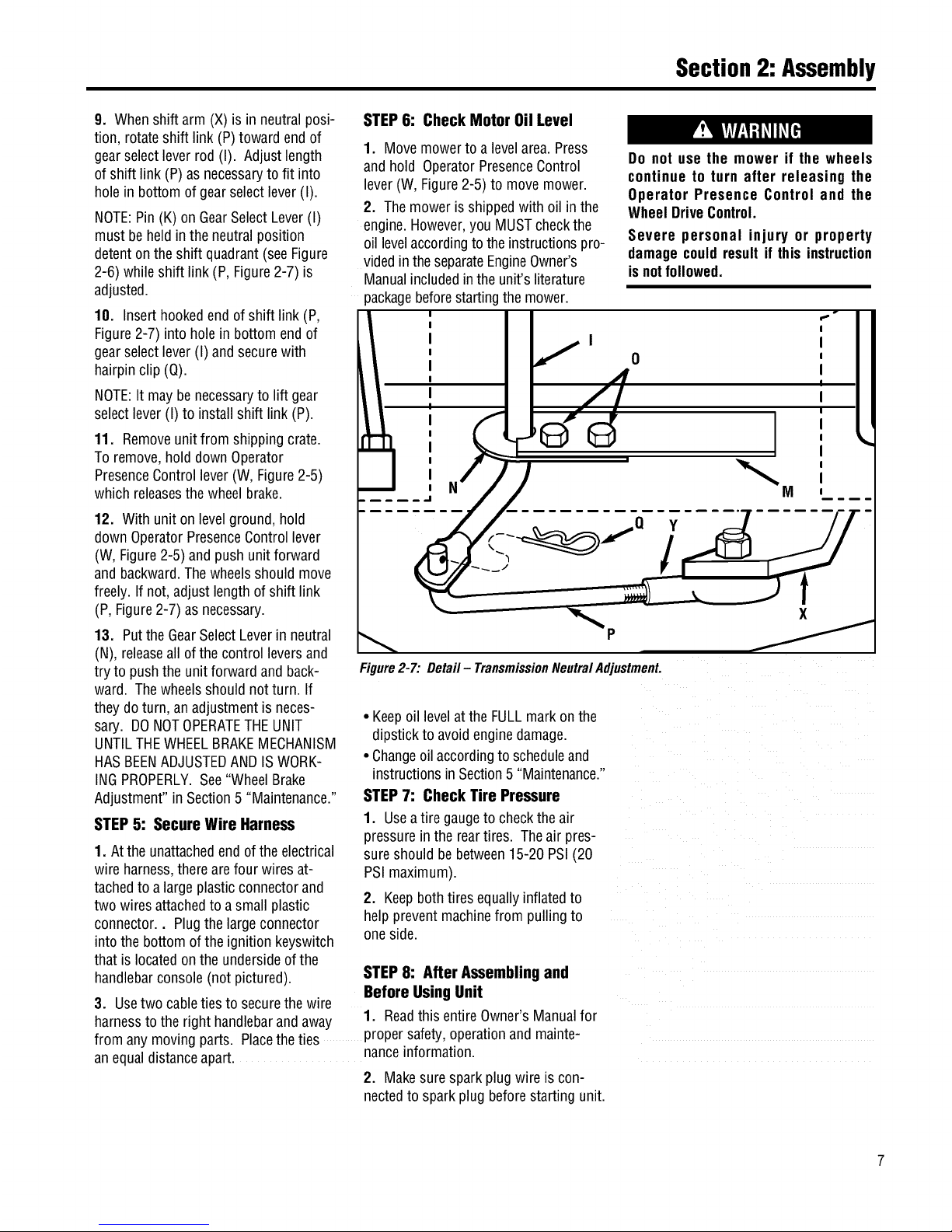

9. Whenshift arm (X)is in neutralposi-

tion, rotateshift link (P)toward endof

gearselectlever rod (I). Adjustlength

of shift link (P)asnecessaryto fit into

hole in bottomof gearselectlever(I).

NOTE:Pin(K) on GearSelectLever(I)

must beheld inthe neutralposition

detentonthe shift quadrant(seeFigure

2-6) while shift link(P, Figure2-7) is

adjusted.

10. Inserthookedendof shift link (P,

Figure2-7) into holein bottom end of

gearselectlever (I) andsecurewith

hairpinclip (Q).

NOTE:Itmay benecessaryto lift gear

selectlever (I) to install shift link (P).

11. Removeunitfrom shippingcrate.

Toremove,hold down Operator

PresenceControllever (W, Figure2-5)

which releasesthewheelbrake.

12. Withunit on levelground,hold

downOperatorPresenceControllever

(W, Figure2-5) and pushunitforward

and backward.Thewheelsshouldmove

freely.If not, adjust length of shift link

(P, Figure2-7)as necessary.

13. Putthe GearSelectLeverin neutral

(N), releaseall of the control leversand

try to pushthe unitforward and back-

ward. Thewheelsshould notturn. If

they doturn, an adjustmentisneces-

sary. DONOTOPERATETHEUNIT

UNTILTHEWHEELBRAKEMECHANISM

HASBEENADJUSTEDAND ISWORK-

INGPROPERLY.See"WheelBrake

Adjustment"in Section5 "Maintenance."

STEP5: Secure Wire Harness

1. Atthe unattachedendof theelectrical

wire harness,therearefour wires at-

tachedto a largeplasticconnectorand

two wires attachedto a small plastic

connector.. Plugthelargeconnector

intothe bottom ofthe ignitionkeyswitch

that is locatedonthe undersideofthe

handlebarconsole(notpictured).

3. Usetwo cableties to securethewire

STEP6: Check Motor Oil Level

1. Movemowerto a levelarea.Press

and hold OperatorPresenceControl

lever(W,Figure2-5) to movemower.

2. Themoweris shippedwith oil in the

engine.However,youMUSTcheckthe

oil levelaccordingto theinstructionspro-

videdintheseparateEngineOwner's

Manualincludedinthe unit'sliterature

packagebeforestartingthemower.

Do not use the mower if the wheels

continue to turn after releasing the

Operator Presence Control and the

WheelDriveControl.

Severe personal injury or property

damagecouldresult if this instruction

isnotfollowed.

I f o

Figure2-7:Detail- TransmissionNeutralAdjustment.

• Keepoil levelatthe FULLmarkon the

dipstick to avoidenginedamage.

• Changeoil accordingtoscheduleand

instructionsin Section5 "Maintenance."

STEP7: Check Tire Pressure

1. Useatire gaugeto checktheair

pressurein the reartires. The air pres-

sureshould bebetween15-20 PSI (20

PSImaximum).

2. Keepbothtires equallyinflatedto

helppreventmachinefrom pullingto

oneside.

STEP8: After Assemblingand

Before UsingUnit

1. ReadthisentireOwner'sManualfor

harnessto theright handlebarandaway o.

from any movingparts. Placethe ties propersaTety,operationand mainte-

anequaldistanceapart, nanceinformation.

2. Makesuresparkplug wire iscon-

nectedto sparkplug beforestarting unit.

Page 10

FeaturesandControls

Before operating mower, be sure to

read all safety, controlsandoperating

instructions in this Manual and on

decalslocatedonmachine.

Severe personal injury or property

damage couldresult it this instruction

isnotfollowed.

IMPORTANT: THE MOWER IS

EQUIPPED WITH A BLADE-BRAKE-

CLUTCHCONTROLSYSTEMWHICH IS

DESIGNED TO STOP THE MOWER

BLADESWITHIN THREE(3) SECONDS

AFTERRELEASEOF THE OPERATOR

PRESENCECONTROL. THIS SYSTEM

WILL STOPTHEBLADESBUTNOTTHE

ENGINE.THEREFORE,YOUCANDISEN-

GAGETHE BLADEDRIVEAT ANYTIME

WITHOUT HAVING TO STOP AND

RESTARTTHEENGINE.THIS FEATURE

IS PARTICULARLYUSEFULWHENYOU

NEEDTO CROSSGRAVELDRIVESOR

ROUGHTERRAIN AND YOU DO NOT

WANT THE SPINNING BLADES

TO STRIKE STONES OR HIDDEN

OBSTACLES.

MOWERFEATURESAND

CONTROLS

This sectiondescribesthe various

featuresand controlson the unit. Refer

to the nextsection "Operation"for

detailedoperatinginstructions. Also,

readthe separateEngineOwner's

Manualfor adetailedexplanationofthe

proper useofthe enginecontrols.

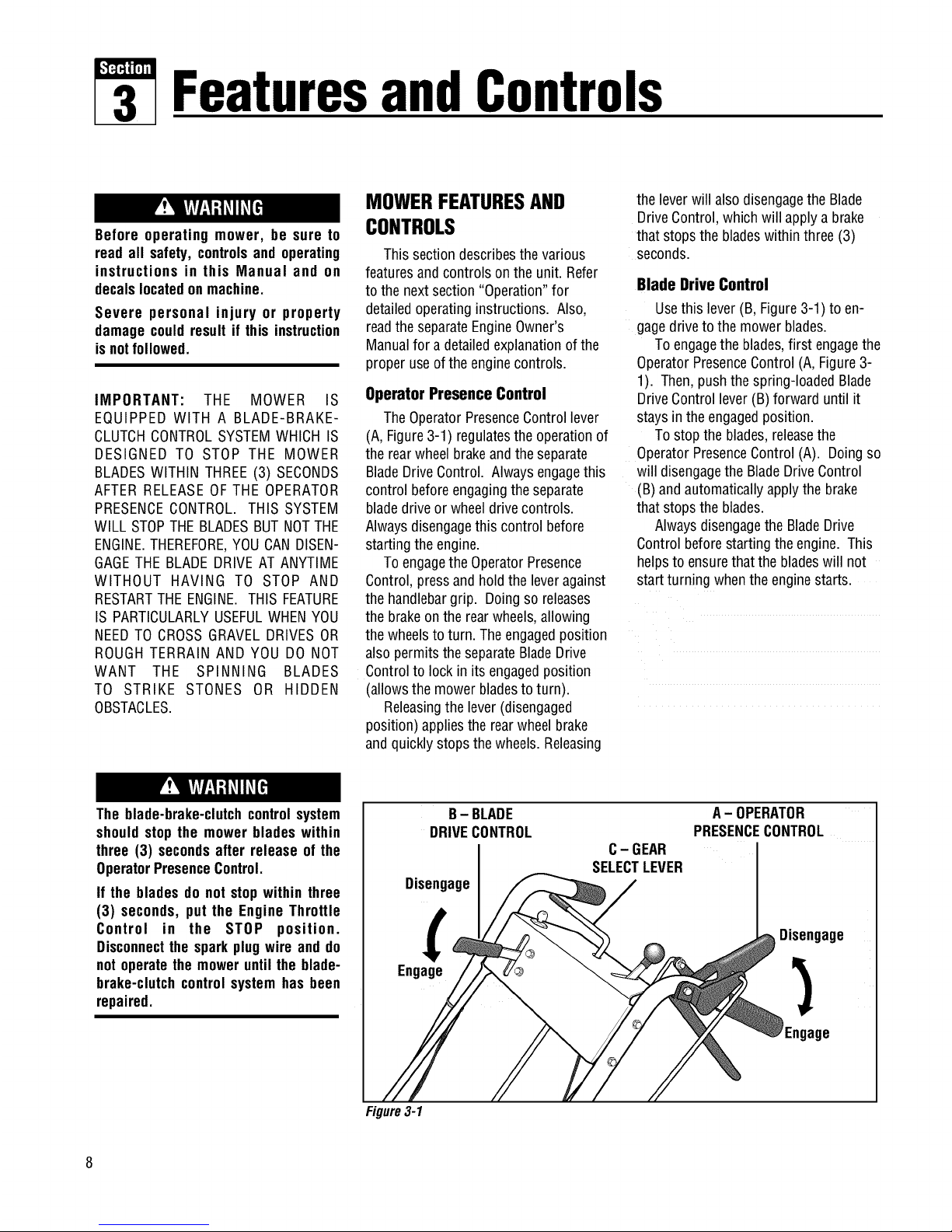

Operator Presence Control

TheOperatorPresenceControllever

(A, Figure3-1) regulatesthe operationof

the rearwheelbrakeandtheseparate

BladeDriveControl. Alwaysengagethis

control beforeengagingtheseparate

bladedriveor wheeldrivecontrols.

Alwaysdisengagethis control before

startingthe engine.

Toengagethe OperatorPresence

Control,pressand holdthe leveragainst

the handlebargrip. Doingso releases

the brakeontherearwheels,allowing

the wheelsto turn. Theengagedposition

alsopermits the separateBladeDrive

Controlto lock in its engagedposition

(allowsthe mowerbladesto turn).

Releasingthe lever (disengaged

position) appliesthe rearwheelbrake

andquicklystopsthe wheels. Releasing

the leverwill alsodisengagethe Blade

DriveControl,which will apply a brake

that stops the bladeswithinthree (3)

seconds.

Blade Drive Control

Usethis lever(B, Figure3-1) to en-

gagedriveto themower blades.

Toengagethe blades,first engagethe

OperatorPresenceControl(A,Figure3-

1). Then,pushthe spring-loadedBlade

DriveControllever(B)forward until it

stays in theengagedposition.

Tostop the blades,releasethe

OperatorPresenceControl(A). Doingso

will disengagethe BladeDriveControl

(B) andautomaticallyapplythe brake

that stops the blades.

AlwaysdisengagetheBladeDrive

Controlbeforestarting the engine. This

helpsto ensurethatthe bladeswill not

startturning whenthe enginestarts.

The blade-brake-clutchcontrolsystem

shouldstop the mower blades within

three (3) secondsafter release of the

OperatorPresenceControl.

If the bladesdo not stopwithin three

(3) seconds, put the Engine Throttle

Control in the STOP position.

Disconnectthe sparkplugwire and do

not operatethe moweruntil the blade-

brake-clutchcontrol systemhas been

repaired.

B- BLADE

DRIVECONTROL

Disengage

Engage

C- GEAR

SELECTLEVER

A-OPERATOR

PRESENCECONTROL

Disengage

Engage

Figure3-1

Page 11

Section3: FeaturesandControls

Operating Symbols Varioussymbolsare usedon the mowerto indicatecontrol settings (your modelmay nothaveall of the

symbols).Thesesymbolsareshown below with a descriptionof their meaning.

ENGINE ENGINE ENGINE

FAST SLOW CHOKE ENGAGE DISENGAGE STOP START RUN

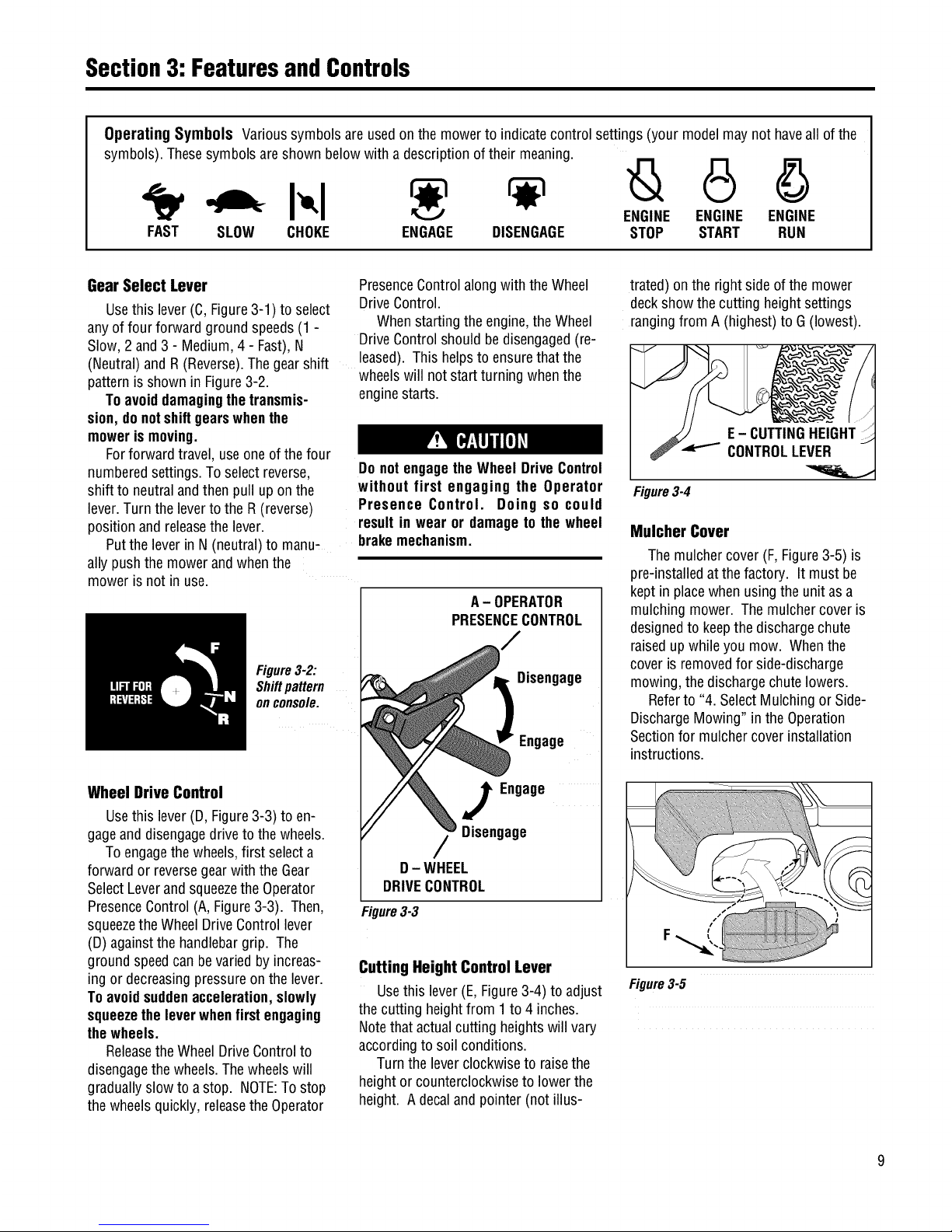

Gear Select Lever

Usethis lever (C,Figure3-1) to select

anyof four forward groundspeeds(1 -

Slow,2 and3 - Medium,4 - Fast),N

(Neutral)and R (Reverse).Thegearshift

patternisshown in Figure3-2.

Toavoiddamagingthetransmis-

sion, donotshiftgearswhenthe

mowerismoving.

Forforward travel,useoneof the four

numberedsettings.Toselectreverse,

shift to neutralandthenpull upon the

lever.Turnthe leverto theR (reverse)

positionand releasethe lever.

Putthe leverin N (neutral)to manu-

ally pushthe mowerand whenthe

moweris not in use.

PresenceControlalong with theWheel

DriveControl.

Whenstarting theengine,theWheel

DriveControlshouldbedisengaged(re-

leased).This helpsto ensurethat the

wheelswill not start turning whenthe

enginestarts.

Do notengagetheWheel DriveControl

without first engaging the Operator

Presence Control. Doing so could

resultin wear or damageto the wheel

brakemechanism.

Figure3-2:

Shiftpattern

onconsole.

A- OPERATOR

PRESENCECONTROL

Disengage

Engage

Wheel Drive Control

Usethis lever (D, Figure3-3)to en-

gageanddisengagedriveto the wheels.

Toengagethe wheels,first selecta

forward or reversegearwith theGear

SelectLeverandsqueezetheOperator

PresenceControl(A, Figure3-3). Then,

squeezetheWheelDriveControllever

(D)againstthe handlebargrip. The

ground speedcanbevariedby increas-

ing or decreasingpressureon the lever.

Toavoidsuddenacceleration,slowly

squeezetheleverwhenfirstengaging

thewheels.

Releasethe WheelDriveControlto

disengagethewheels.Thewheelswill

graduallyslow to a stop. NOTE:Tostop

the wheelsquickly, releasethe Operator

J Engage

Disengage

D- WHEEL

DRIVECONTROL

Figure3-3

Cutting Height Control Lever

Usethis lever(E, Figure3-4) to adjust

thecutting heightfrom 1to 4 inches.

Notethat actualcutting heightswill vary

accordingto soil conditions.

Turnthe leverclockwiseto raisethe

heightor counterclockwiseto lowerthe

height. Adecalandpointer (notillus-

trated) onthe right sideofthe mower

deckshow the cutting heightsettings

rangingfrom A(highest)to G(lowest).

Figure3-4

Mulcher Cover

Themulchercover (F,Figure3-5) is

pre-installedatthe factory. It must be

kept in placewhen using the unit asa

mulchingmower. The mulchercoveris

designedto keepthedischargechute

raisedupwhile you mow. Whenthe

cover is removedfor side-discharge

mowing,the dischargechutelowers.

Referto "4. SelectMulching or Side-

DischargeMowing"in the Operation

Sectionfor mulchercoverinstallation

instructions.

Figure3-5

Page 12

Section3: FeaturesandControls

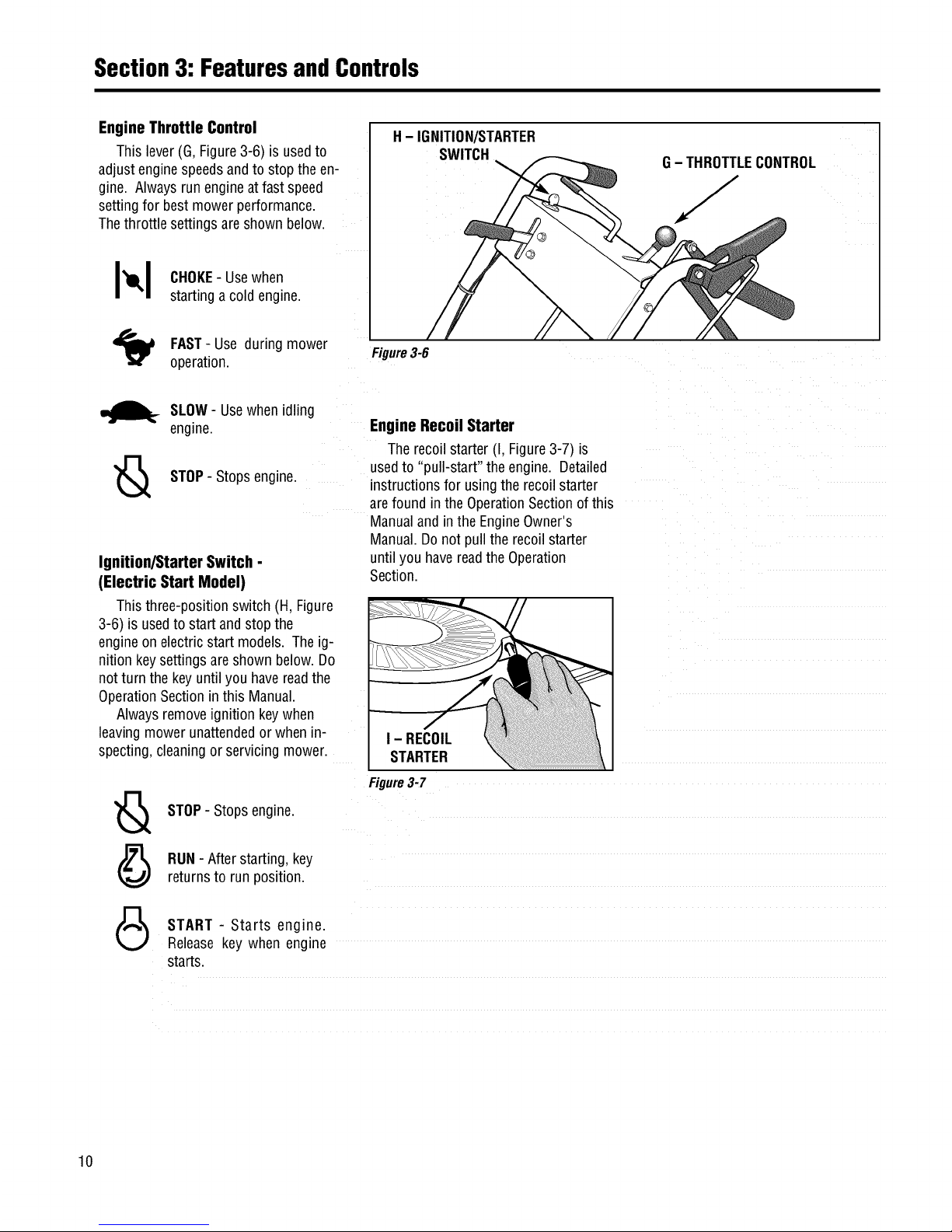

Engine Throttle Control

This lever(G,Figure3-6) is usedto

adjust enginespeedsandto stopthe en-

gine. Alwaysrun engineat fastspeed

settingfor bestmower performance.

Thethrottle settings areshown below.

H- IGNITION/STARTER

SWITCH

G- THROTTLECONTROL

J

I_1 CHOKE-Usewhen

startinga coldengine.

FAST- Use during mower

operation.

Figure3-6

_._ SLOW- Usewhenidling

engine.

STOP- Stopsengine.

Ignition/Starter Switch -

(Electric Start Model)

Thisthree-positionswitch (H, Figure

3-6) is usedto startand stop the

engineon electric start models. Theig-

nitionkeysettings areshown below.Do

notturn the keyuntilyou havereadthe

OperationSectioninthis Manual.

Alwaysremoveignition keywhen

leavingmower unattendedor when n-

specting,cleaningor servicing mower.

Engine Recoil Starter

Therecoilstarter (I, Figure3-7)is

usedto "pull-start" the engine. Detailed

instructionsfor usingtherecoilstarter

arefound in theOperationSectionof this

Manualandin the EngineOwner's

Manual.Donot pull the recoilstarter

untilyou havereadthe Operation

Section.

I - RECOIL

STARTER

STOP- Stopsengine.

RUN- Afterstarting, key

returnsto run position.

Figure3-7

START - Starts engine.

Releasekey when engine

starts.

10

Page 13

Operation

Before operating mower, be sure to

read all safety, controlsandoperating

instructions in this Manual and on

decalslocatedonmachine.

Severe personal injury or property

damage couldresult if this instruction

isnotfollowed.

BEFOREOPERATINGMOWER

1. Pre-OperaUon Checklist

With the sparkplug wiredisconnected

from thespark plug,performthefollow-

ing checksandservicesbeforeeachuse:

1. ReviewSection1:"Safety"andSection

3, "FeaturesandControls"in this man-

ual. ReadtheseparateEngineOwner's

Manualprovidedwith theunit.

2.Checkunitfor looseor missinghard-

ware.Tightenor replaceasneeded.

3. With the uniton levelground,check

theengineoil level accordingto the

instructionsin the EngineOwner's

Manual. Theoil levelshould beat the

FULLmarkonthe dipstick or up tothe

top ofthe oil fill holeon engineswith-

out a dipstick.

4. Checkall leversfor freedomof move-

ment.Readjustor repairas needed

beforestarting engine.

5. Checkthatall guards andshieldsare

in placeandproperly secured.

6. Inspecttheareato mowedandre-

moveanydebris which couldbe

pickedup andthrown bythe mower

blades.

7. Checkthatthe mulchercoveris prop-

erlyinstalledin the dischargeopening

(seeinstructions in this Section).

Removethe mulchercoverto usethe

side-dischargemowingfeature.

8. Onelectricstart models,checkthat

all wiring connectionsarecleanand

tight.

9. Checktheair pressurein the rear

tires (15-20 PSI). Keeptires inflated

equally.

GASOLINEIS HIGHLYFLAMMABLEAND

ITS VAPORSAREEXPLOSIVE.To help

preventseverepersonalinjuryor prop-

ertydamage:

• Follow gasoline safety rules in

Section1: "Safety" of this Manualand

in the separate Engine Owner's

Manual.

• Neverremovethe gasolinefill cap or

add fuel when indoorsor when engine

is runningor still hot.Allow engineto

coolat leastthree (3) minutesbefore

refueling.

• Keep smokingmaterials, sparksor

flamesfar awayfromfuel tank andfuel

container.

• Store gasoline in an approvedfuel

containerandin a well-ventilatedarea.

Storeit safely outof the reachof chil-

dren. Do notstore gasolinewhereva-

porscan reachan opensparkor flame

or where ignition sourcesare present

(suchas hot water or space heaters,

furnaces,clothesdryers, stoves,elec-

tric motors,etc.).

• Fill tankto 1/2"below bottomoffiller

neckto allowfor fuel expansion.Wipe

up spilled gasoline immediately and

movemowerawayfromgasolinefumes

before starting engine. Securely re-

place caps on fuel tank and fuel

container.

10.Removethefuelcap andcheckthe

levelof gasolineaccordingto the in-

structions in the EngineOwner's

Manual.Cleanaroundfuel fill area

beforeremovingfuel cap. Donot

checkfuel level or addfuelwhile in-

doorsor if engineis running or hot.

Allow engineto cool for three (3)

minutes. Fillthe tankwith fresh,

cleanunleadedgasolinewith a mini-

mum octanerating of 77. Leave1/2"

ofspacefor fuel expansion.Donot

mix oil with gasoline.Donot use

gasolinewhich containsMethanol.

SeetheEngineOwner'sManualfor

instructions and precautionsregard-

ingthe useofgasolinesthat are

blendedwith alcoholsor ethers

(calledoxygenatedor reformulated

gasolines). Securelyreplacecapson

fuel tankandfuel container.

11.Attach sparkplug wireto spark plug

after completingabovechecklist.

2. Set Mower Cutting Height

To avoid personalinjury, do notadjust

cuttingheightwhile wheels or blades

are turning. Release all handlebar

controlsandwait for all motionto stop

beforeadjustingcuttingheight.

1. Releaseall controls beforeadjusting

thecutting height.

2. Adjustthecutting heightfrom 1to 4

inchesby rotatingthe CuttingHeight

Controllever(Figure3-4) eitherclock-

wiseto raisethe heightor counterclock-

wiseto lowerthe height. Notethat ac-

tualcutting heightswill vary according

to grassandsoil conditions. A decaland

pointeron the right side of themower

deckindicatesthe height setting.

3. In heavyor tall grass,it is usually

betterto makethefirst cut at a higher

settingandthen makeasecondcut at

thedesiredheight. In roughterrain, a

highersetting is recommendedasit will

minimizethe chancesof the bladestrik-

ing the ground or hidden obstructions.

11

Page 14

Section4: Operation

3. TestBlade-Brake-Clutch

Control System

Themower isequippedwith a blade-

brake-clutchwhich is designedto stop

the mowerbladeswithin three(3)

secondsafter releaseofthe Operator

PresenceControlor the BladeDrive

Control. Nevertamperwith, or attempt

to defeatthe purposeofthis safety

device.

Thecontrol systemisa mechanical

devicewhich issubject to wear.

Therefore,testthe operationofthe

blade-brake-clutchcontrol systembefore

eachuseofthe mower.Referto "Blade

BrakeControlTest"atthe end ofthis

Section.

4. Select Mulching or Side-

Discharge Mowing

Beforeinstallingor removingmulching

cover, stop engine, wait for parts to

stopmoving,anddisconnectsparkplug

wire. Remove ignition key on electric

startmodels.

Youcanusethe mowereitheras a

mulchingmoweror asaside-discharge

mower. To usethe mulchingfeature,in-

sert the mulchercover asdescribed

below. Removethemulchercoverto

side-dischargegrassclippings. The

mulchercover is designedto keepthe

dischargechute raisedup while mowing.

Whenthe cover is removed,the dis-

chargechutewill loweritselffor side-

dischargemowing.

Toinstall or removemulchercover:

1. Stopthe engineand waitfor all parts

to stop moving. Disconnectthespark

plug wire from thespark plug. Remove

theignition keyon electric start models.

2. Toinstallthe cover,insertthe right-

sidetab of thecoverinto thefront sup-

port bracket(A, Figure4-1). Insertthe

cover into thedischargeopening,mak-

ing sure that theslot (B) in theleft side

of thecover is completelyengagedinthe

rearedgeof thedeckopening.

B

Figure4-1:Mulchercover

STARTINGANDSTOPPING

THEENGINE

Do not operate the engine in an

enclosed area. Engine exhaust

containscarbon monoxide, a deadly

gas that is odorless, colorless and

tasteless. Alwaysrunengineoutdoors

and make sure there is adequate

ventilation.

3. Toremovethe cover,slidethecover

to the right (front of mower)to disen-

gagethe slot (B) from the mowerdeck

andthenprythe left-sideof the cover

out andoff.

MOVINGTHEMOWERWITHOUT

ENGINEPOWER

Themowercan bemanuallypushed

or pulledbyputting the GearSelect

Lever(C,Figure4-2) in N(neutral)and

pressingandholdingthe Operator

PresenceControl(A, Figure4-2) down

againstthe handlebargrip.

To stopthewheelsatanytime.

releasetheOperatorPresenceControl.

ToStart the Engine

1. Movemowerto a levelarea.

2. Releaseall controls on mowerto pre-

ventwheelsor mower bladesfrom rotat-

ing when enginestarts.

3. MoveEngineThrottle Control(E,

Figure4-2) fully upwardto chokesetting

to starta cold engineor to fast (rabbit)

settingto starta warmengine.

Toavoidinjury:

• Keephandsand feet clear of mower

blades or other rotating parts.

• Lookbehindyouto be surethereare

no obstacles before pulling recoil

starterrope.

F-Ig

B- Blade Drive

Control

C - Gear Select Lever

E - Engine Throttle

Control

A-Operator

Presence Control

I

Figure4-2: MowerControls

D- Wheel Drive Control

12

Page 15

Section4: Operation

4. Tostart engineusing recoil starter:

A. Standonleft side(as viewedfrom

behindhandlebars)of machine.Be

sureyour feet aresafelyawayfrom

the undersideof the mowerdeckand

all mowercontrolsare released.

Placeonefoot ontop of tire.

B. Graspstarterropehandle(Figure3-

7) andpull slowly until ropepulls

slightly harder.Letroperewind

slowly. Thenpull ropewith a rapid,

full arm stroke. Letropereturn

slowly. If enginefails to startafter

threepulls, repeatinstructionsstart-

ingwith Step2 (try settingthrottle at

fast setting).

C. Whenenginestarts, operateinfast

throttle setting(movethrottle from

chokesettingto fastsetting).

5. Tostart engineusing electricstarter:

A. Standbehindthehandlebarsandre-

leaseallmowercontrols.

B.Turnignition key(F, Figure4-2)fully

clockwiseto crank engine.To avoid

damageto startermotor,do not

crank enginefor longerthanfive sec-

ondsat atime.Also, allow 15sec-

ondsbetweeneachstart attempt.If

enginefails to start afterthreeat-

tempts, repeatinstructionsstarting

with Step2 (try settingthrottle atfast

setting).

C. Whenenginestarts,releasekeyandit

will returnto therun (middle) posi-

tion.

D. Operateengineatfast throttle setting

(movethrottle from chokesettingto

fast setting).

NOTE:Ifthe electricstart system is not

functioning,theenginecanbestarted

with the recoilstarter. Todo so,first put

theignition keyin the run (middle)posi-

tion. Thenfollow Steps1-4 above.

Leavethekey inthe run position during

engineoperation.

ToStop the Engine

1. Releaseall mowercontrolsto stop

wheelsor mower blade.

2. Movethrottlecontrol downto slow

(turtle) position. (Wheneverpossible,

graduallyreduceenginespeedbefore

stoppingengine.)

3. MoveThrottleControlall the way

downto stop position orturn ignition

key(electricstart models)fully counter-

clockwiseto stop position.

4. Onelectric start models,removethe

ignitionkey beforeleavingthemower

unattended.

ENGAGINGTHE BLADES

- Fast). Whenfirst practicingwith

the mower,putleverin No.1 setting.

Selectforward speedsaccordingto

mowingconditionsandterrain. Use

slower speedson roughterrain or

whengrass isheavyor thick. The

forward speedcanbeincreasedon

smoothterrain or if thegrass cover

is light. Allowthewheelsto stop

completelybeforeshifting from one

forward speedinto another.

To avoid injuryfrom rotatingblades,

keep face, hands and feet clear of

mowerbladesatall times.

To Engage the Blades

1. Startengineas describedin "To Start

the Engine"instructions. Putengine

throttle in fast speedsetting.

2. Pressandhold OperatorPresence

Control(A,Figure4-2) againsthandle-

bargrip.

3. Slowly pushBladeDriveControl(B,

BeforeengagingtheWheel DriveLever

for the very first time, checkthat the

neutral(N) positionon the GearSelect

Lever is properly adjusted. See

"Neutral Adjustment" in Section 5:

Maintenance for the procedure to

follow.

Failureto follow this instructioncould

result in personal injury or property

damage.

Figure4-2) fully forward until it staysin C.

the engagedposition. Thebladesare

nowrotating.

To Stop the Blades

Tostop the blades,releasetheOperator

PresenceControl.

TO ENGAGETHEWHEELS

• To avoiddamagingthetransmission,

donotshiftgearswhilein motion.

• To avoiddamagingthe wheel brake

mechanism,do notengagethe Wheel

DriveControlwithoutfirst engagingthe

OperatorPresenceControl.

1. Start engineasdescribedin "To

Startthe Engine"instructions.

2. FORFORWARDTRAVEL:

Tostart the wheels,slowly squeeze

theWheel DriveControl(D, Figure4-

2). Theharderyou squeeze,the

fasterthe wheelswill turn. To avoid

suddenacceleration,slowlysqueeze

the lever.

D.TOSTOPTHEWHEELS:

• To stopdrive powertothewheels,

releasetheWheelDriveControl. The

wheelswillgraduallyslowto astop.

• To quickly stop thewheels,release

boththe WheelDriveControland

theOperatorPresenceControl.

3. FORREVERSETRAVEL:

Toavoidinjuryorpropertydamage:

• Look behind the mower before

andduringreverseoperation.

• Stopthemowerbladesbeforeeperat-

ingin reverse.

A. PressandholdOperatorPresence

Control (A, Figure4-2) againsthan-

dlebargrip.

B. Putthe GearSelectLever(C,Figure

4-2) intoone ofthe numberedset-

tings (1 - Slow,2 and3 - Medium,4

A. Stop the mowerbladesandwheelsby

releasingtheOperatorPresence

Control(A, Figure4-2).

B. Pressandhold OperatorPresence

Controlagainsthandlebargrip.

13

Page 16

Section4: Operation

C.

O.

E,

Putthe GearSelectLever(C, Figure

4-2) in R(reverse)setting byfirst

movingleverto N(neutral). Then

pull lever up,turn itto Rposition,

and releaselever.

To startthewheels,slowly squeeze

WheelDriveControl(D, Figure4-2).

Toavoid suddenacceleration,slowly

squeezethe lever.

TOSTOPTHEWHEELS:

• To stopdrive powertothewheels,

releasetheWheelDriveControl.The

wheelswillgraduallyslow to astop.

• To quickly stop thewheels,release

both theWheelDriveControland

theOperatorPresenceControl.

• ReturntheGearSelectLeverto the

N (neutral)positionwhenyou have

completedreverseoperation. Allow

thewheelsto stop completelybe-

foreshifting from R(reverse)into a

forward speed.

MowWhen

LawnIsDry

Forbestresults,avoidcuttinggrass

whenit iswet. Wetgrasstendsto form

clumpswhich interferewith thecutting

action. Thebesttime to mow isin the

lateafternoonor earlyeveningwhenthe

grassis usuallydry.

1

CutTop1/3 of /-_

GrassBlades __'

Cuttingmorethan 1/3 of grasslength

maycausethe grassto becomeexces-

sivelydry. Intall grass,it maybeneces-

saryto mowat a highersetting andthen

mow againat thedesiredheight. NOTE:

Thecutting heightis critical to achieving

a well-groomedlawn. Youshouldexper-

iment with varioussettingsto find that

"just right" cutting height.

MAKINGTURNS..... _

VaryCuttingPattern

Themowerturns easily bypushing

thehandlebarsin the oppositedirection

that you wantto turn. Thedifferential

mechanisminsidethe transaxlewill

allowthe inside turning wheelto stop or

slow down whilethe outsideturning

wheelis poweredbythe drive system.

Reducethewheelspeedbeforeturn-

ing the mower.Fortight turns, disen-

gagethe WheelDriveControlandmanu-

Varythe cutting patternfrom weekto

weekto help preventmattingofthe

grass. Oneweek,mowfrom northto

south,the nextweekmow from eastto

west. Overlapseveralincheswhen

mowingto obtainan evenappearance.

MowingonSlopes

allypush the mowerthroughthe turn (if

needed,putthe GearSelectLeverin

neutralso the wheelsturn freely).

MOWINGTIPSANDHINTS

Toavoidinjuryorpropertydamage:

• Before mowing, thoroughly inspect

area where mower is to be usedand

remove all stones, sticks, wires,

bones,nailsandotherforeignobjects.

• Disengage mower blades before

crossinggraveldrives, roads, or side-

walksto preventbladesfrom throwing

stonesor otherhazardousobjects.

Toavoidinjury orpropertydamage:

• Maximum safe operating angle

is150.

• Exceedingmaximum safe operating

angle may cause tipping or loss of

footing.

• Donotmowwet slopes.

• Mowacrossslopes,notupanddown.

• Exercise extreme caution when

changingdirectiononslopes.

MulchingLeaves

• The mowercan beusedto mowfallen

leaves.Theleafparticlesfilter downinto

thelawn andprovideaddedfertilizer.

• The leavesmust bedry in order to be

mulched.

• Usea slowerground speedifthe

leavesarenot mulchedinto fine parti-

cles.

• If you mulch oakleaves(whichaddacid

tothe soil), addlime to the lawn inthe

springto reducetheacidityofthe soil.

KeepMowerBladesSharp

Forbestmowerperformance,keepthe

bladessharp. Dullbladeswill tear,

bruiseandsplit the endsof grass. See

bladesharpeninginstructions in Section

5: Maintenance.

Donot mowexcessivelysteepslopes

(seeWARNINGstatementthatfollows).

Slowdown andexerciseextremecaution

whenchanging directionon slopes.

Beforemowing on slopes,checktheen-

gine oil levelandmakesurethatthe level

is attheFULLmark. Maintaininga FULL

oil levelis particularlyimportantwhen

operatingon slopesasoil canbe drained

awayfrom vital engineparts.

CleanMowerFrequently

Cleanthe undersideof the mowerdeck

frequentlyto removegrass build-up.

Seemowercleaninginstructionsin

Section5: Maintenance.

PrecisionTrimming

Forprecisiontrimming, usethe slow-

estgearand inch the mower alongby

"feathering"the WheelDriveControl

lever. Or,disengagethe wheeldrive by

releasingtheWheelDriveControlso that

you canmanuallymaneuverthemower

(if needed,putthe GearSelectLever in

neutralso that thewheelsturn freely).

14

Page 17

Section4: Operation

BLADEBRAKECONTROLTEST

Whenthe OperatorPresenceControl

is releasedduringoperationof the

mower,the enginedoesnot stop, but

thebladesshouldstop within three(3)

seconds. The followingtest providesa

visualtest ofwhetherthe BladeBrake

ControlSystemisfunctioning. Perform

this test beforeeachuseof the mower.

1. Parkmoweron aportion of lawn

which has notbeenrecentlymowed.

2. Setthecutting height so the mower

cuts 1/3of thegrassheight.

To avoid personal injury or property

damage,make sure thatthe moweris

ongrass,andthatthe testarea isclear

of foreignobjectsand bystandersbe-

fore you beginthe Blade BrakeControl

Test.

If the OperatorPresenceControlor the

Blade Drive Controlare not adjusted

correctly,the blades may continueto

rotate after release of the Operator

PresenceControl. If the blades do not

stopwithinthree(3) secondsofrelease

ofthe OperatorPresenceControl,move

the EngineThrottleControlto the STOP

position, disconnect the spark plug

wire, andmovethewire awayfromthe

sparkplug. Do not operatethe mower

until the Blade Brake ControlSystem

hasbeenrepaired.

Failureto do this couldresult in per-

sonalinjuryor propertydamage.

3. Starttheengine.

4. PresstheOperatorPresenceControl

downagainstthe handlebargrip and

pushthe BladeDriveControlfully for-

ward until it staysin the engagedposi-

tion.

5. Putthe GearSelectLeverin the No.1

setting.

6. Engagethe wheelswith the Wheel

DriveControlanddrivethe mowerfor

severalfeet. Thenreleasethe Operator

PresenceControl.

A.

Lookat the lawn just mowed.The

lawnshould becut upto the point

wherethe OperatorPresenceControl

was released.

B. Pressthe OperatorPresenceControl

againstthe handlebargrip but DO

NOTre-engagethe BladeDrive

Control. Drivethe mowerforward

for severalmorefeet. Releasethe

OperatorPresenceControlandlook

atthe lawn.Thegrassshould NOT

havebeencut. This indicatesthat

theOperatorPresenceControlhas

disengagedthe bladedriveand

stoppedtheblades.

7. If the mowercutsthegrass in Step

6-B,the OperatorPresenceControlis

NOTdisengagingthe bladedrive.

Immediatelystopthe engine,discon-

nectthesparkplugwire,andmovethe

wireawayfromthesparkplug.

8. Donotusethe mower untilthe Blade

BrakeControlSystemhas beenin-

spected,adjustedor repairedbyan au-

thorized dealer.

15

Page 18

Maintenance

Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

plugwireandmovewireawayfromsparkplug.Removeignitionkey(elecb'icstartmodels).

Failuretofollowtheseinstructionscanresultinseriouspersonalinjuryorpropertydamage.

Carefully read this Section on mower

and engine maintenance and service.

Performing the required maintenance

according to schedule will ensure the

proper performanceandlong lifeof your

machine.

Beforeinspecting,cleaningor servicing

the machine, shut off engine, make

surethatall movingpartshavecometo

a completestop,disconnectsparkplug

wire and move wire away from spark

plug. Removeignition key on electric

startmodels.

Failureto followtheseinstructionscan

result in personal injury or property

damage.

NOTE: All referencesto left, right, front

and rearof themachinearedeterminedby

standingbehindthe handlebarsandfacing

thedirectionofforwardtravel.

IMPORTANT:REFERTO

MAINTENANCECHARTINTHIS

SECTIONFORA LISTINGOFREGU-

LARLYSCHEDULEDMAINTENANCE

PROCEDURES.

ENGINESERVICE

Routineengineserviceis described

below. Formorecompleteengineser-

vice information, referto theengine

manualprovidedwith your machine.

Forcompleteengineservice,contactan

authorizedenginedealer.

ENGINEOIL

OIL LEVEL:With moweron level

ground,the engineoil levelmust bebe-

tweenthe"ADD"and "FULL"markson

the dipstickatall times. Checkbefore

eachuseandevery5 operatinghours.

OILCHANGE:Ona newengine,change

oil afterfirst 2 hoursof use,then change

oil regularlyas specifiedon the

MaintenanceChart. Referto Engine

Owner'sManualfor oil capacity.

OILTYPE:Useclean,high qualitydeter-

gent oil havinganA.P.I. serviceclassifi-

cation of SE,SFor SG. Useno special

additiveswith oil. Referto the Engine

Owner'sManualfor recommendedSAE

viscosity gradesthat matchthe starting

temperatureanticipatedbeforethe next

oil change.

CheckingOilLevel:

1. Park machineon levelground.

2. Stopengine, waitforpartstostop

moving,anddisconnectsparkplug

wire.

3. Cleanareaarounddipstick (Z,Figure

5-1) to preventdirtfrom enteringoil fill

hole.

4. Removedipstick. Oillevelmustbe

between"ADD" and "FULL"marks. Do

notexceed"FULL" markon dipstick.

5. To addoil, pourslowlyinto dipstick

opening. Whileadding,check oil level

frequently bysecurely replacingdipstick

and removingto readoil level.Wipe dip-

stick cleaneachtime oil levelis

checked.

6. Afterfilling to "FULL"mark,securely

replacedipstick.

ChangingOil:

Changeoil while engineis still warm

from recentoperation. Warm oil flows

morefreely andcarriesawaymore im-

purities.

1.Stopengine, waitforpartstostop

moving,anddisconnectsparkplug

wire.

2. Removedipstick(Z, Figure5-1).

3. Removeprotectivecap(A, Figure5-

2) to exposeoil drain port (B).

4. Pushoil drain hose (D) (includedin

hardwarebagwith unit) onto oil drain

port. Routeother end ofhoseto anap-

propriateoil collectionreceptacle.

5. Twist oil drainfixture (C)to the open

position. Pullout. Drainoil completely.

6. Pushin andtwist oil drain fixture to

the closedposition. Removedrain

hose.Replaceprotectivecap (A).

7. Refillenginewith fresh oil andse-

curelyreplacedipstick.

NOTE:Pleasedisposeofall waste mate-

rialsin an ecologicallyresponsibleman-

ner. Useproperwastematerialstorage

containers.

Figure5-1:BriggsandStrattonengineoil

fill.

Figure5-2:Oildrain.

16

Page 19

Section5: Maintenance

W!_LW:I-'t_II_[_I Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

i1"_ plugwireandmovewireawayfromsparkplug.Removeignitionkey(ele_icstartmodels).

MI

Failuretofollowtheseinstructionscanresultinseriouspersonalinjuryorpropertydamage.

ENGINECLEANING

• Stopengine, waitforpartstostop

moving,disconnectsparkplugwire,

andallowenginetocoolbeforein-

spectingorcleaningengine.

• Dailyor more often,beforerunningen-

gine,removegrassand chafffrom recoil

fingerguardor rotatingscreento prevent

enginedamagecausedbyoverheating.

Alsokeepcoolingvanes,governorlink-

age,springsandcontrolsfree of debris.

• Dailyor more often, beforerunningen-

gine,cleanmufflerarea(besure muffler

is cool)to removeall grassandcom-

bustibledebris. If engineis equipped

with a sparkarrestorscreen,removeas-

semblyevery50 hoursfor cleaningand

inspection.Replaceif damaged.

• Grassor chaff mayclog engine'sair

coolingsystem,especiallyafterpro-

longedoperationcutting tall, drygrass.

SeeEngineOwner'sManualfor instruc-

tions on cleaningunderneaththeengine

blowerhousing.

AIR CLEANERSERVICE

Improperair cleanermaintenancecan

causeenginedamage.Refertothe

EngineOwner'sManualfor morecom-

pleteair cleanerserviceinformation.

SERVICESCHEDULE:

Outerfoam pre-cleaner-washand re-oil

every25 operatinghoursor everysea-

son, whicheveroccursfirst.

Innerpapercartridge- clean or replace

every100 operatinghoursor everysea-

son, whicheveroccursfirst.

ToServiceAir Cleaner(Figure5-3):

1. Stopengine,waitfor partsto stop

moving,anddisconnectsparkplug

wire.

2. Unscrewmountingscrewsand/or re-

moveknobs (D). Removecovers(E).

Removepapercartridge(B) andfoam

pre-cleaner(A). Separatefoam pre-

cleanerfrom papercartridge.

3. Washfoam pre-cleaner(A)in liquid

A

Chargebattery only with chargersup-

pliedwith machine.Donotshortcircuit

batterywires. Removeanyjewelry be-

fore working on or near the battery or

electricstart system. Failuretofollow

these instructionscouldresult in per-

sonalinjuryorpropertydamage.

Figure5-3: BriggsandStrattonair cleaner

assembly.

detergentandwarm water. Squeezedry

in aclean cloth.

4. Saturatefoam pre-cleanerinclean

engineoil. Wrapin clean,absorbent

cloth andsqueezeto removeall excess

oil.

5. Replacepapercartridge(B), if

necessary.

6. Reassembleaircleanercomponents.

SPARKPLUG

Inspectthe sparkplug (Figure5-4) after

every 100hours of operation.Besure

the gapis setat .030".Donot reuseplug

if it is severelywornor damaged.

Bestresultsare obtainedwith a new

plug. SeeEngineOwner'sManualto de-

termine proper replacementplug. Use

of incorrectplugcancauseenginedam-

age.

NOTE:Donot cleanspark plug in ma-

chines which useabrasivegrit. Clean

spark plug byscrapingor wire brushing,

or washingwith a commercialsolvent.

BATTERY(if applicable)

Chargebatteryif unit is to bestoredfor

longerthanthreeweeks.Duringthe

mowingseason,the batteryis kept

chargedby the chargingsystemonthe

engine.

ToChargeBattery:

1. Plugchargerconnectorintowire har-

nessconnectorlocatedbelowignition

switch in handlebarconsole.

2. Plugchargerinto120Vwall outlet.

Tightenknobs/screws(D) securely. (Notethat batterychargeris designedfor

Secure coverassembly(E)on air useindoorsandshouldnot beexposedto

cleanerbody. rainorsnow.)

3. Chargebatteryfor 24-48 hours if unit

is to bestoredfor longerthan three

weeks.

.030' FeelerGauge

4. After charging,unplugchargerfrom

outlet,then unplugchargerfrom con-

nector on wireharnesslocatedbelow

handlebarconsole.

CARBURETOR

Thecarburetor isadjustedatthe factory.

It should not needto be reset. If black

exhaustis noted,checkthe air cleaner

first. An over-rich mixture is usually

causedbya poorly servicedor clogged

air cleanerelement,not an improperly

adjustedcarburetor. If readjustmentis

necessary,referto EngineOwner's

Manualor contactyourenginedealer.

Figure5-4: Sparkplug.

17

Page 20

Section5: Maintenance

• !'T_TI-_I-'{_JI_[€']I Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

t _ plugwireandmovewireawayfromsparkplug.Removeignitionkey(elecb'icstartmodels).

MI

Failuretofollowtheseinstructionscanresultinseriouspersonalinjuryorpropertydamage.

ENGINESTORAGE Thebelt covermust be removedto per-

form severalmaintenanceprocedures.

If enginewill be unusedfor 30 daysor

more,prepareit for storage byfollowing To RemoveBeltCover:

the recommendedproceduresfound in 1. Stopengine,wait forall partsto

the EngineOwner'sManual. stopmoving,anddisconnectspark

plug wire.

5. Loosenfour mounting bolts (L) se-

curingspindle housing (beneathmower

deck)to mowerdeck.

6. Slidespindlehousing (with pulleyat-

tached)towardcenter.

7. Replacebelt(N) with newbelt.

MOWERSERVICE

Thefollowing maintenance/repairproce-

durescan be performedbyeitherthe

owneror anauthorizedservicedealer.

Seeanauthorizedservicedealerfor

completemowerservice.

TIPPING MOWER FOR SERVICE

and removecover.

To ReinstallBeltCover:

1. Positionbelt cover in place.

2. Securewiththe four screwsremoved

earlier.

2. Removefour screws(R, Figure5-5) IMPORTANT:SETBLADESPERPEN-

DICULAR(90°) TOEACHOTHER.

8. Rotatearm (K)to movespindle

housingandapplytensionto belt. Belt

cogsand pulley groovesmust meshto-

gether.Whenapplying moderatefinger

tension (8-12 Ibs.),beltshoulddeflect

approximately1/2" (12.7mm) at (P),

midpointof deck.

Before servicing undersideof mower,

stop engine, wait for all parts to stop

moving, and disconnect spark plug

wire. Remove ignition key from

keyswifch on electric start models.

Failureto follow this instructioncould

result in personal injury or property

damage.

Whenservicingthe undersideof the

mowerfor anyreason,the mower

should onlybetipped backwardon its

rearwheels(andsecurelyproppedupto

preventit from falling). Tippingthe

mowerforward or to either side could

resultin damageto engine.

TIP:Beforetipping mower, installa

small plastic sandwichstylebag under

the gascapandtighten securely. This

will virtually eliminateanyfuelseepage

from thecap. Besureto removethe

plastic bagbeforere-usingmower.

BELTCOVERREMOVAL

Do not operateunitwithout belt cover

installed. Failureto followthisinstruc-

tion couldresult in personalinjury or

propertydamage.

Figure5-5: Beltcoverremoval.

BLADESPINDLE BELT

REPLACEMENT

Followthis procedureto removeandre-

placethe bladespindledrivebelt (re-

movebladedrive beltfirst; see"Blade

DriveBeltReplacement"inthis Section).

1. Stopengine,wait forall partsto

stopmovinganddisconnectsparkplug

wire.

9. Tightenbolts (L) to 15ft.-Ibs. (20.3

Nm).Tightenscrew (J).

10. Bladesmustnotcontact deck.

Checkandreadjustas needed.

11. Reinstallbladedrive beltand belt

cover (removedearlier).

t

FRO_T

J

MUST BE PERPENDICULAR

TO EACH OTHER

Figure5-6: BladeSpindleBell

2. Removebeltcover(see"BeltCover

Removal").

3. Alignsight holes(0, Figure5-6) in

pulleywith spindlehousing-to-mower

deckmountingbolts (L).

4. Loosenscrew(J) and rotatearm (K)

to the rear.

18

Page 21

Section5: Maintenance

W!_LY_TI:I-'t_II_[_IBeforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

t _ plugwireandmovewireawayfromsparkplug.Removeignitionkey(elecb'icstartmodels).

Failuretofollowtheseinslxuctionscanresultinseriouspersonalinjuryorpropertydamage.

BLADEDRIVEBELT

REPLACEMENT

Followthis procedureto removeand re-

placethe bladedrivebelt. Anassistant

will be needed.

ToRemoveBelt:

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Disengagebladedrivecontrol (Figure

5-7) byreleasingall controls onthe

mower.

BladeDriveDisengaged

BladeDriveEngaged

\\

RIGHTVIEW

Figure5-7: BladeDriveControl

3. Removebeltcover (see"BeltCover

Removal").

4. Loosenbeltguides (BandC,

Figure5-8).

5. Moveflap bracket(N, Figure5-8) out

ofthe way by looseningtwo screws (M).

8. Removebelt(A, Figure5-8)from

aroundsheaves.

To InstallBelt:

1. Routebelt (A, Figure5-8) around

sheavesasshown.

2. Haveanassistanthold down

OperatorPresenceControlandthen

pushthe BladeDriveControlforward

until it latchesin place(Figure5-7).

3. With the BladeDriveControlleveren-

gaged,adjustandtighten beltguide (B)

to 1/32- 1/16"awayfrom tensioned

belt. (Besurethat beltdoesnot contact

beltguidewhenbelt isundertension.)

Securebelt guide(C) rotatedinto posi-

tion asshownin Figure5-8.

4. DisengageBladeDriveControl.

5. Re-tightentwoscrews (M, Figure

5-8) that secureflap bracket(N).

6. Reinstallbeltcover securely.

G \

\

H

M

Figure5-8: Bladedrive.

19

Page 22

Section5: Maintenance

W!_LY_II:I;t_II_[_I Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartsto stop,disconnectspark

i_ _ plugwireandmovewireawayfromsparkplug.Removeignitionkey(electricstartmodels).

Failuretofollowtheseinslxuctionscanresultinseriouspersonalinjuryorpropertydamage.

BLADEBRAKEREPLACEMENT

Followthis procedureto installa new

bladebrake.

ToRemoveBladeBrake:

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Removebeltcoveras describedin

"Belt CoverRemoval"instructions.

3. Removehardware(G,Figure5-8)

securingbladebrake(H).

4. Removeoldbrake(H)from idler

arm (I).

To InstallBrake:

1. Positionnew brake(H)in placeon

idler arm (I).

2. Centerbrakein sheavegrooveand

securebrake(H) with hardware(G) re-

movedearlier.

3. Reinstallbeltcover securely.

4. Testoperationof bladebrake(see

"BladeBrakeControlTest" in Operation

section).

BLADEDRIVEBELT

ADJUSTMENT

Ifthe bladedrive beltis slipping dueto

lackof belttension,follow the steps

below.

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Removebeltcoveras describedin

"Belt CoverRemoval"instructions.

3. With moweron levelground, adjust

bladecuttingheightat about 3" (mea-

surefrom ground to flat portion of

blade).

4.With the BladeDriveControl (Figure

5-7) inthe disengagedposition,set a

gapof 1/8"betweenthespring (F,Figure

5-9) andflat washer(E)by adjustingthe

nut (g).

5. Reinstallthe beltcoversecurely.

20

\

Adjust idlerin direction

of arrow to tighten blade

...drive belt

D

1/8" E

Figure5-9:Bladedriveadjustment.

6. Testthe operationofthe bladebrake

(see"BladeBrakeControlTest" in the

Operationsection).

7. If the drive beltslips during opera-

tion, it may benecessaryto

relocateidler (J, Figure5-9)in the slot

providedin the mounting bracket.With

theenginestoppedandthesparkplug

wiredisconnected,loosenthehardware

onthe idler(J)and slideitforward to

take upslack inthe belt.

8. Engagethebladedriveand measure

the distance(X,Figure5-8) betweenthe

centersof pulleys(K) and(L). Thedis-

tanceshould be5-1/2to 5-5/8". After

obtainingthe correct dimension,rein-

stall the beltcoversecurelyandtestthe

operationof the bladebrake.

BLADEDRIVE CONTROLLEVER

ADJUSTMENT

Makethefollowing adjustmentif the

BladeDriveControlLeverreleasesdur-

ing operation.

1. Stopengine, waitforall partsto

stopmoving,anddisconnectspark

plug wire.

2. EngagetheOperatorPresence

Controlandthe BladeDriveControl.

Without releasingthecontrols, look in-

sidethe cutoutat the rearofthe frame

and makesurethe OperatorPresence

Controllatches(Aand B, Fig.5-10) are

fully engagedatpoint (C). If theyare not

fully engaged,improper operationor

prematurewearcould result. To adjust,

loosenhexnut (D) andshortenlengthof

control rod (E).Toavoid over-adjusting,

turn rod only 1 to 2 turns per adjust-

ment.

3. Tighten hexnut securelyafter adjust-

ing control rod.

4. Test by releasingtheOperator

PresenceControl. If properlyadjusted,

the BladeDriveControlwill disengage

whenthe OperatorPresenceControlis

released.Re-adjustasnecessaryby

repeatingSteps2 and3.

C

E A

Figure5-10: BladeDriveControlLever

adjustment.

Page 23

Section5: Maintenance

W!_LW:I-'t_II_[_I Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

t _ plugwireandmovewireawayfromsparkplug.Removeignitionkey(ele_icstartmodels).

Failuretofollowtheseinstructionscanresultinseriouspersonalinjuryorpropertydamage.

WHEELDRIVE BELT

REPLACEMENT

Followthis procedureto replacethe

wheeldrive belt.

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Releaseallmowercontrols.

3. Removebeltcoveras describedin

"Belt CoverRemoval"instructions.

4. Locatewheeldrive belt(0, Figure5-

11) and removeit from top sheaveof

enginesheave,backsidedidlers(P and

Q)andtransmissionsheave(R).

5. Install newbeltasshownin Figure5-

11. Beltmust be installed"insideout "-

"V" sideof belt lies against

enginesheaveonly. Flatsideof beltlies

againsttransmissionsheave(R) and

back-sidedidlers (Pand Q).

6. Makesurebeltis inside belt guide (S,

Figure5-11).

7. Reinstallbeltcover securely.

l

Figure5-11: Wheeldrivebeltreplacement.

gagewheeldriveby squeezingWheel

DriveControluntil it contactshandlebar.

4. Wheelsshouldslip on pavedsurface.

8. An adjustmentto thedrive beltmay

be necessary.See"WheelDriveBelt If they do not, anadjustmentis required.

Adjustment"inthis Section. ToAdjust WheelDriveBelt:

1. Stopengine, waitforall partsto

stopmoving,anddisconnectspark

plug wire.

2. Removecotter pin (A, Figure5-12A)

from upperend of Wheel DriveControl

rod.Slide rod outof leverassembly.

3. Loosenjam nut(D, Figure5-12).

4. Threadrod (E, Figure5-12) oneor

two turns clockwisefor moretension or

counterclockwisefor lesstension.

5. Insertrod backinto hole in Wheel

DriveControlleverandinstallcotter pin.

Bendendsof cotter pin to secure.

6. Retestwheeltraction. Repeatadjust-

mentprocedure,if necessary.Most

comfortableoperationwill beobtained

whenthe adjustmentallowsthe leverto

just makecontactwith the handgripas

sufficient wheeltractionis achieved.

Whenadjustmentiscomplete,tighten

jam nut (D) firmly againstblock (B).

WHEELDRIVE BELT

ADJUSTMENT

Thewheel drive beltrequiresanadjust-

ment if lossof drive belttension (slip-

page)occurs. This is mostnoticeable

whenmoretraction is required(suchas

going up slopes).

ToTestWheelTraction:

1. Parkmachineon a paved(concrete,

etc.)surfacewith front edgeup against

a sturdy wall,fence, etc.

2. PutGearSelectLeverin No.1 setting.

IMPORTANT:DONOTPARKAGAINSTA

PAINTEDORSIDEDWALL. TESTING

THEWHEELDRIVESYSTEMREQUIRES

MACHINETOBEFORCIBLYPUSHED

AGAINSTWALL. DAMAGETO PAINTOR

SIDINGCOULDRESULT.

3. With enginerunning,and machine

placedfirmly up againstwall, hold down

OperatorPresenceControlandfully en-

A

Figure5-12A

WHEELBRAKEADJUSTMENT

Thisadjustment mayberequiredif the

machinedoesnot holdon a hill with the

OperatorPresenceControldisengaged,

or if thebrakedrags with the Operator

PresenceControlengagedandthe trans-

missionin neutral.

1. Stopengine, waitforall partsto

stopmoving,anddisconnectspark

plug wire.

2. Disengage(release)theOperator

PresenceControl (M, Figure5-13).

21

Page 24

Section5: Maintenance

W!_LW:I-'t_II_[_I Beforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspark

t _) plugwireandmovewireawayfromsparkplug.Removeignitionkey(electricstartmodels).

Failuretofollowtheseinstructionscanresultinseriouspersonalinjuryorpropertydamage.

Figure5-12: Wheeldrivebelt adjustmenL

M

i

I

I

i

'N

0

Figure5-13: WheelbrakeadjustmenL

3. Slowlyadjustat nut(0), if necessary,

until thedistancebetweenthe backof

brakearm (N)and bracket(P)is3/8"-

5/16". Usesmall adjustments(1/4turn

maximum).NOTE:It maybe necessary

to relievespringtensionwhen decreas-

ing distance. To do so, havean assis-

tant engagetheOperatorPresence

Controlwhileyouadjustthe nut.

22

TRANSMISSION NEUTRAL

ADJUSTMENT

Followthis proceduretoadjust neutral

onthetransmission.

1. Stopengine, waitforall partsto

stopmoving,anddisconnectspark

plug wire.

2. Rotateshift rod (I, Figures5-14 and

5-15) clockwise until it stopsin theneu-

tral (N) position (from forward gear

positions).

3. Hold downOperatorPresenceControl

(M, Figure5-13) andpushunitforward

and backward.Unitshould movefreely.

If not, continuewith Step4.

4. Removecotterpin securingshift link

(P, Figure5-15)to shift rod (I).

5. Moveshift arm(X) backandforth as

necessaryintoeachdetentuntil trans-

mission isin neutral.NOTE:Moving

shift arm (X)clockwise allthe wayto the

left, andthenonenotch backcounter-

clockwise,shouldputtransmission into

neutral.Whentransmission is in neutral,

unit will movefreelywhenpushedwhile

holdingthe OperatorPresenceControl

leverdown. If transmissionis NOTin

neutral,therewill bea slight drag onthe

wheelswhenpushingunit.

8. Whenshift arm (X)is in neutral posi-

tion, rotateshift link (P) untilhooked

endfits backinto hole in bottomendof