Troy-Bilt TUFFY 643B, TUFFY 645A, TUFFY 643C, Tuffy/Bronco CRT 643C, Super Bronco 643B Operator's Manual

...Page 1

®

O m m 'w//////al&_,411111111111111F

Operator's Manual

/ m mllllllllllllllllml m

Rear-tine Tiller Models

643C m Tuffy¢ / Bronco CRT

643B, 645A -- Super BroncoTM

Mode1645A Shown

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark attester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Troy-Bilt LLC, P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTEDINU.S.A. FORMNO. 769-00585E.

11/11/05

Page 2

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 17

Safety 3 Off-season Storage 21

Assembly 6 Troubleshooting 22

Features and Controls 10 Parts List 24

Operation 12 Warranty Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new tiller. Itwill help you assemble, prepare and maintain the unit for

best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Copy the model number here:

www.troybilt.com CLEVELAND,OH44136

P. O. BOX 361131

330-558-7220

866-840-6483_

CUSTOMERSUPPORT

PleasedoNOTreturnthe unit totheretailer without firstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

/)_,'_'_ ;<;W";; jiI_)7,/_;7

;J< / I+ 1_,7_ .............. ......

Copy the serial number here:

_!_I_O ,f__< <;:k_;_....._/ y'

7%%%'7_-'.........................................

Iilo I1 II ff bl _ll i {_1 7 7fl ,

< ........ ,,,,,

If you prefer to reach a Customer Support Representative, please call 1(866) 840-6483.

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

Page 3

SECTION1: SAFETY

This machine meets voluntary safety stan-

dard B71.8-1996, which is sponsoredbythe

Outdoor Power Equipment Institute, Inc.,

and is published bythe American National

Standards Institute.

WARNING

The engine exhaust from this productcontains

chemicals known to the State of California to

cause cancer, birth defects or other reproduc-

tive harm.

SafetyAlertSymbol

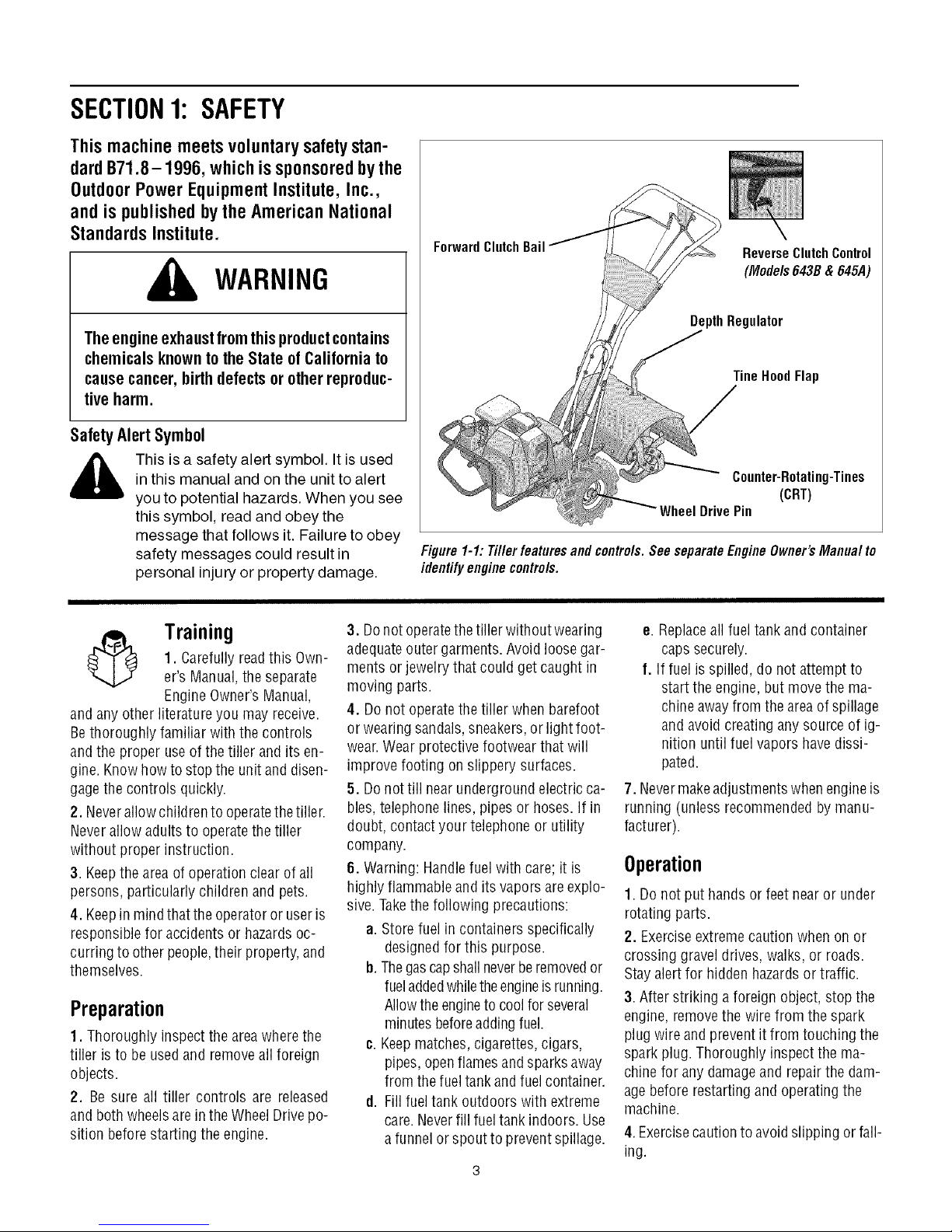

ForwardClutchBail

ReverseClutchControl

(Mode/s643B&645A)

DepthRegulator

TineHoodFlap

,_ This is a safety alert symbol. It is used

and any other literature you mayreceive.

Bethoroughly familiar with the controls

andthe proper useof the tiller and its en-

gine. Knowhowto stop the unit and disen-

gagethe controls quickly.

2. Neverallow childrento operatethetiller.

Neverallow adults to operatethe tiller

without proper instruction.

3. Keepthe area of operationclear of all

persons, particularly children and pets.

4. Keepin mindthat the operatoror user is

responsible for accidentsor hazardsoc-

curring to otherpeople,their property,and

themselves.

in this manual and on the unit to alert

you to potential hazards. When you see

this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

personal injury or property damage.

3. Donot operatethetiller without wearing

1. Carefully readthis Own-

Training

er's Manual,the separate

Engine Owner'sManual,

adequateouter garments. Avoid loose gar-

ments or jewelry that could get caught in

moving parts.

4. Donot operatethe tiller when barefoot

or wearing sandals, sneakers,or light foot-

wear.Wearprotective footwear that will

improve footing on slippery surfaces.

5. Donottill nearunderground electricca-

bles, telephone lines, pipes or hoses.If in

doubt, contactyour telephoneor utility

company.

6. Warning: Handlefuel with care; it is

highly flammableand its vaporsareexplo-

sive.Takethe following precautions:

a. Storefuel in containers specifically

b. Thegascapshall neverberemovedor

Preparation

1. Thoroughly inspect the areawherethe

tiller is to be usedand removeall foreign

objects.

2. Be sure all tiller controls are released

and both wheelsare inthe Wheel Drive po-

sition beforestarting the engine.

c. Keepmatches,cigarettes, cigars,

d. Fillfuel tank outdoors with extreme

Counter-Rotating-Tines

(CRT)

Drive Pin

Figure 1-1: Tiller featuresand contre/s.See separateEngineOwner'sManua/ to

identifyenginecontre/s.

e. Replaceall fueltank andcontainer

caps securely.

f. Iffuel isspilled, do not attempt to

start the engine,but move the ma-

chineawayfrom the areaof spillage

and avoid creating any source of ig-

nition until fuel vapors havedissi-

pated.

7. Nevermakeadjustments when engineis

running (unless recommendedby manu-

facturer).

Operation

1. Do not put hands or feetnear or under

rotating parts.

designedfor this purpose.

fueladdedwhiletheengineisrunning.

Allowthe engineto coolforseveral

minutesbeforeaddingfuel.

pipes, openflamesandsparks away

from thefuel tank and fuelcontainer.

care.Neverfill fueltank indoors. Use

a funnel or spout to preventspillage.

2. Exerciseextremecaution when on or

crossing gravel drives, walks, or roads.

Stay alert for hidden hazardsor traffic.

3. After striking a foreign object, stop the

engine, removethe wire from the spark

plug wire andprevent it from touching the

spark plug. Thoroughly inspect the ma-

chine for any damageand repairthe dam-

agebefore restarting and operatingthe

machine.

4.Exercisecautionto avoidslipping orfall-

ing.

Page 4

5.Iftheunitshouldstarttovibrateabnor-

mally,stoptheengine,disconnectthe

sparkplugwireandpreventitfromtouch-

ingthesparkplug,andcheckimmediately

forthecause.Vibrationisgenerallya

warningoftrouble.

6.Stoptheengine,disconnectthespark

plugwireandpreventitfromtouchingthe

sparkplug,wheneveryouleavetheoperat-

ingposition,beforeuncloggingthetines,

orwhenmakinganyrepairs,adjustments

orinspections.

7.Takeallpossibleprecautionswhenleav-

ingthemachineunattended.Stoptheen-

gine.Disconnectthesparkplugwireand

moveitawayfromthesparkplug.Besure

thatbothwheelsareintheWheelDrivepo-

sition.

8.Beforecleaning,repairing,orinspect-

ing,stoptheengineandmakecertainall

movingpartshavestopped.Disconnect

thesparkplugwireandpreventitfrom

touchingthesparkplugtopreventacci-

dentalstarting.

9.Theflaponthetinehoodmustbedown

whenoperatingthetiller.

10.Neverusethetillerunlessproper

guards,plates,orothersafetyprotective

devicesareinplace.

11.Donotruntheengineinanenclosed

area.Engineexhaustcontainscarbon

monoxidegas,adeadlypoisonthatis

odorless,colorless,andtasteless.

12.Keepchildrenandpetsaway.

13. Neveroperatethe tiller underengine

powerif thewheels arein theFreewheel

position.Inthe Freewheelposition, the

wheelswill not hold the tiller back andthe

revolvingtines could propel thetiller rapid-

ly,possibly causingloss of control. Always

engagethe wheels with the wheel drive

pins in theWheel Drive position before

starting the engine or engaging the

tines_vheelswith the Forward Clutch Bail

(all models)or the ReverseClutchcontrol

(Models 643B& 645A only).

14. Be aware that the tiller may unex-

pectedlybounceupwardorjumpforward

if thetines shouldstrikeextremelyhard

packedsoil, frozenground,or buriedob-

stacleslike largestones, roots,or

stumps.

If indoubtaboutthe tilling conditions,al-

ways usethe following operating precau-

tionsto assistyouin maintainingcontrol

of thetiller:

a. Walk behindandto one side of the

tiller, usingone handon thehandle

barsRelax yourarm, but usea

securehandgrip.

b. Useshallowerdepthregulator

settings,working graduallydeeper

with each pass.

c. Useslowerenginespeeds.

d. Clearthetilling area of all large

stones,rootsor other debris.

e. Avoidusingdownwardpressureon

thehandlebars.If needbe, use

slight upwardpressureto keep the

tinesfrom diggingtoodeeply.

f. Beforecontacting hard packedsoil

at the endof a row,reduceengine

speedand lift the handlebarsto

raise the tines out of the soil.

g. In an emergency, stopthetinesand

wheels byreleasing whichever

clutch controlis engaged.Do not

attemptto restrainthetiller.

15. Donot overloadthe tiller's capacityby

attempting to till too deeply at too fast a

rate.

16. Neveroperate the tiller at high trans-

port speeds onhard or slippery surfaces.

Look behind and usecarewhen backing

up.

17. Donot operatethetiller on aslope that

is too steep for safety.When on slopes,

slow down and makesure you have good

footing. Neverpermit thetiller to freewheel

down slopes.

18. Neverallow bystandersnearthe unit.

19. Onlyuseattachmentsand accessories

that areapproved by the manufacturer of

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethe tiller without good

visibility orlight.

22. Neveroperatethe tiller if you aretired;

or underthe influence ofalcohol, drugs or

medication.

23. Operatorsshall not tamper with theen-

gine-governor settings onthe machine;

the governor controls the maximum safe

operatingspeedto protect the engineand

all movingparts from damagecaused by

overspeed.Authorized serviceshall be

sought if a problem exists.

24. Do not touch engine parts which may

behot from operation.Let parts cool down

sufficiently.

25. Pleaseremember:Youcan alwaysstop

the tines and wheels by releasingthe For-

ward Clutch Bailor on Models 643B &

645Athe ReverseClutchcontrol, (which-

evercontrol isengaged),or bymoving the

ignition switch and/orthrottle control lever

on the engineto "OFF" or "STOP".

26. Toload or unloadthe tiller, seethe in-

structions in Section4 of this Manual.

27. Useextreme caution when reversing

or pullingthe machinetowards you.

28. Startthe enginecarefully accordingto

instructions and with feetwell away from

the tines.

29. Neverpick up or carry a machinewhile

the engineis running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories in safeworking condition.

2. Checkall nuts, bolts, and screws for

proper tightness to besurethe equipment

is in safeworking condition.

3. Neverstore thetiller with fuel in thefuel

tank inside abuilding whereignition sourc-

esare presentsuchashot waterandspace

heaters,furnaces, clothes dryers, stoves,

electric motors, etc.). Allow the engine to

cool beforestoring the unit in any enclo-

sure.

4. Toreducethe chancesof a fire hazard,

keepthe enginefreeofgrass, leaves,or ex-

cessivegrease.

5. Storegasolinein acool, well-ventilated

area,safelyawayfrom anyspark- or

flame-producing equipment. Store gaso-

line in an approvedcontainer,safelyaway

from the reachof children.

6. Referto the Maintenancesections of

this Manualand the separateEngineOwn-

er'sManualfor instructions ifthe unitis to

bestored for an extendedperiod.

7. Neverperform maintenancewhilethe

engineis running orthe sparkplug wire is

connected,exceptwhen specifically in-

structed to do so.

8. Ifthe fueltank hasto be drained,dothis

outdoors.

Page 5

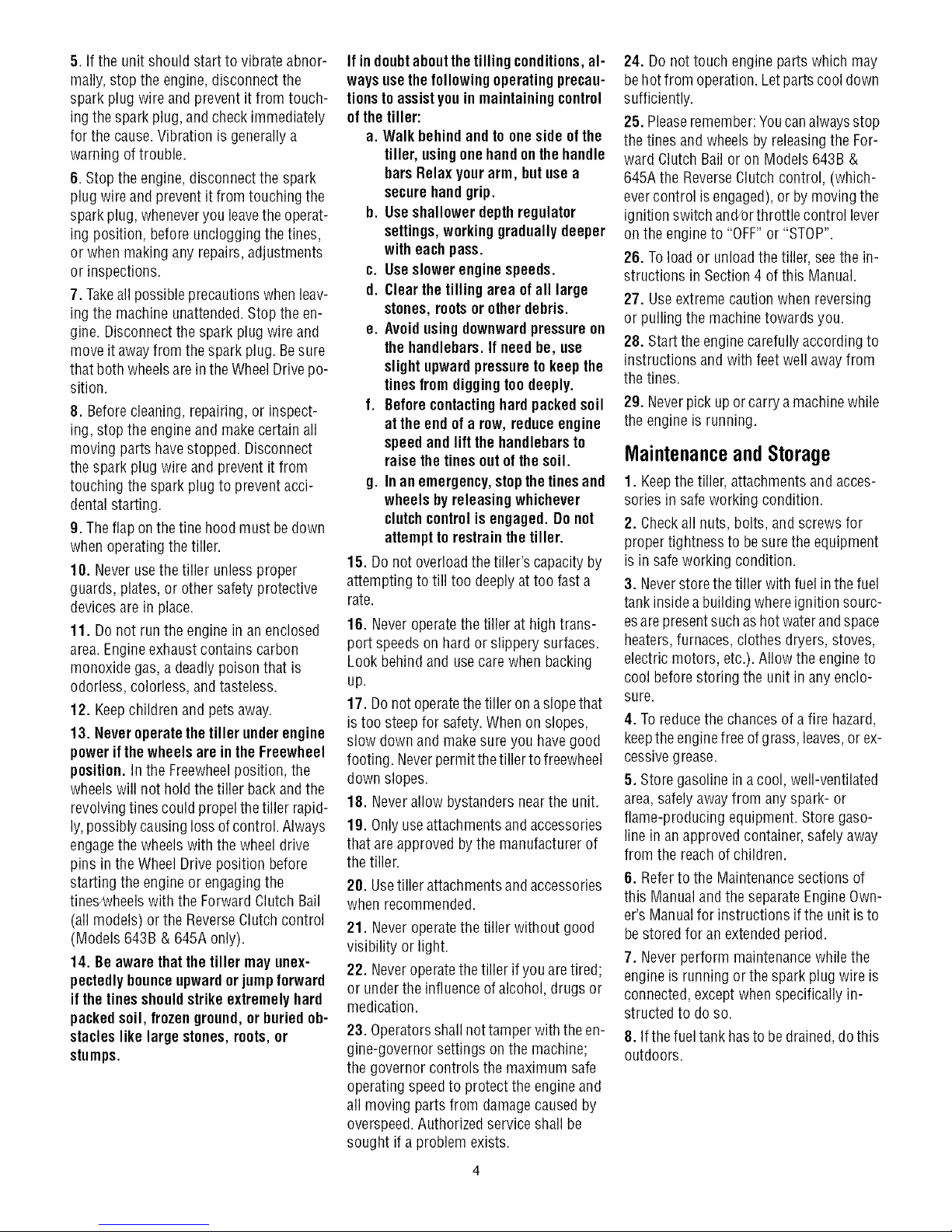

Decals

Foryour safety and the safetyof others, vari-

ous safety andoperational decalsare located

on your unit (seeFigure 1-2).

ForwardClutch Bail

ReverseClutch Control

OperatingInstruction

Keepthe decalsclean and legible atall times.

Contactyour localservicedealeror thefactory

for replacementsif any decalsaredamagedor

missing.

Referto the Parts List pagesin this Manualfor

decallocations, descriptionsand part num-

bers.

_ (Models 643B& 645A

StartingStabilization

Message(on engine)

WarningMessages

Hot Surfaces Warning

Figure1-2: Locationof safety and operatingdeca/s.

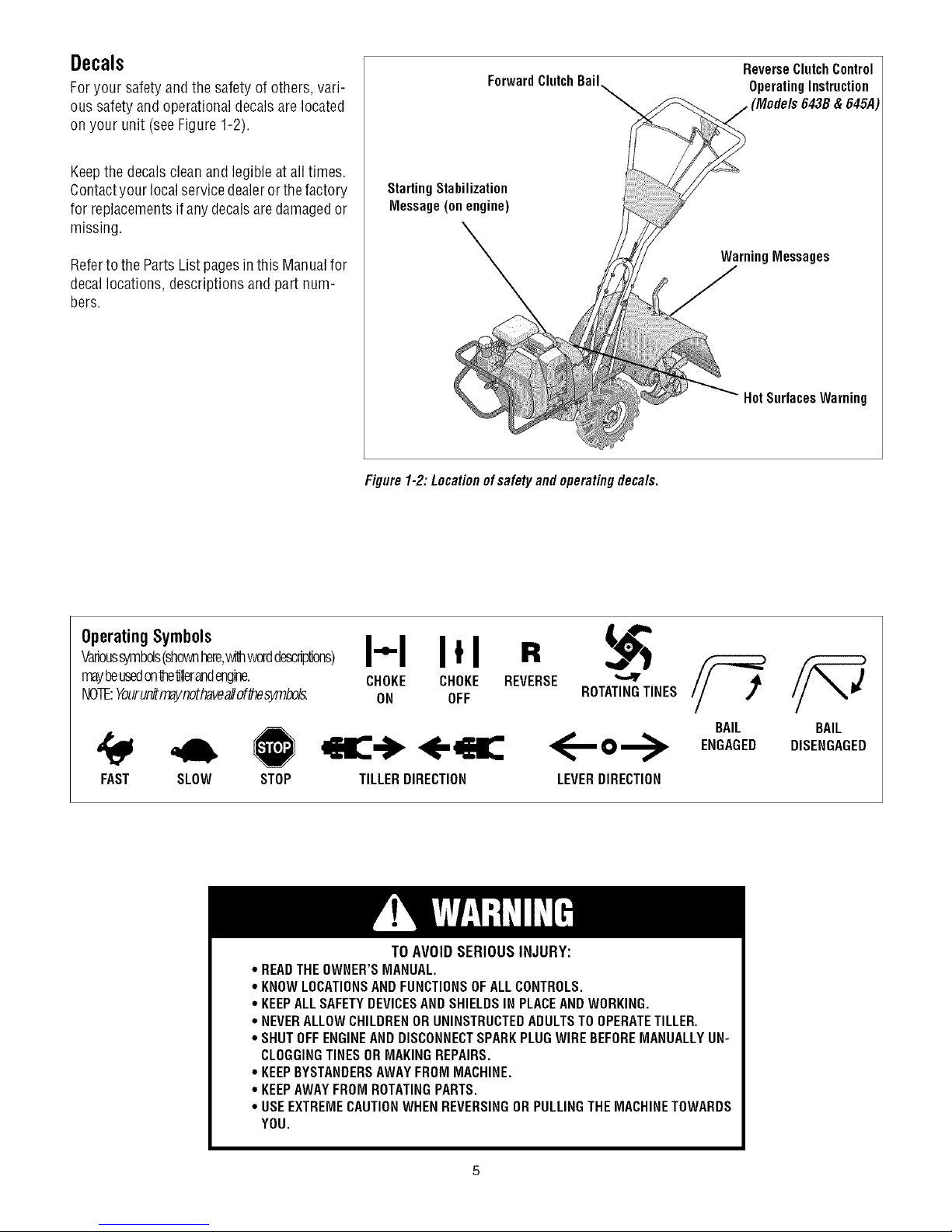

OperatingSymbols

Varioussymbols(shownhere,_dthworddescrip'dons)

maybeusedonte'dllerandengine.

NOTE:YourunihT_ynothaveallof_esymbols.

FAST SLOW STOP

* READTHEOWNER'SMANUAL.

* KNOWLOCATIONSANDFUNCTIONSOFALLCONTROLS.

* KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEAND WORKING.

. NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTOOPERATETILLER.

° SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

° KEEPBYSTANDERSAWAYFROMMACHINE.

° KEEPAWAYFROM ROTATINGPARTS.

° USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHE MACHINETOWARDS

YOU.

I"1 I*1 R

CHOKE CHOKE REVERSE

ON OFF ROTATINGTINES

<--o-->

TILLERDIRECTION

TO AVOID SERIOUS INJURY:

LEVERDIRECTION

BAIL

ENGAGED

BAIL

DISENGAGED

Page 6

SECTION2: ASSEMBLY

WARNING: Toprevent

personalinjury or property

damage,do notstart the engine

until all assemblysteps are

completeandyou have read

and understandthesafety and

operating instructions in this

manual.

INTRODUCTION

Carefullyfollow theseassemblysteps to

correctly prepareyour tiller for use. It is

recommendedthatyou readthis Sectionin

its entirety beforebeginning assembly.

NOTE: Various tiller models are

presented in this Manual. Use only the

information appropriate for your tiller

model. Enginestyles vary by model, Your

engine may appear differently than those

illustrated in this manual.

INSPECTUNIT

Inspect the unitand carton for damageim-

mediatelyafter delivery.Contactthe carrier

(trucking company) if you find or suspect

damage.Inform them of the damageand

request instructions for filing a claim. To

protect your rights, put your claim in writ-

ing and maila copyto the carrierwithin 15

days after the unit has beendelivered.

ContactTroy-Bilt LLCif you needassis-

tance inthis matter.

TOOLS/ MATERIALSNEEDED

(2) 1/2" open-end wrench*

(2) 9/16" open-endwrench*

(1) 3/8" open-endwrench*

(1) Largeadjustable wrench

(Models 643B & 645A only)

(1) Scissors (totrim plasticties)

(1) Ruler (for belttension check)

(1) Block of wood (to support tiller when

removing wheels)

(1) Tirepressure gauge(for models with

pneumatictires)

(1) Cleanoil funnel

(1) Motor oil. Refertothe EngineOwner's

Manualfor oilspecificationsand

quantityrequired.

* Adjustable wrenchesmay be used.

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE:While unpacking, do not severely

bend any control cables.

1.Thetiller weighs approximately 133 Ibs.

Do notattempt to remove it from the ship-

ping platform until instructed to do so in

these Assembly steps.

2. Removeany packagingmaterial from

the carton. Removeany staples from the

bottom of the cartonand removethe car-

ton from the shipping platform.

3. Removeall unassembledparts andthe

separatehardwarebag from the carton.

Checkthat you havethe items listed in the

LooseParts List (contactyour localdealer

or the factory itemsare missing or dam-

aged).

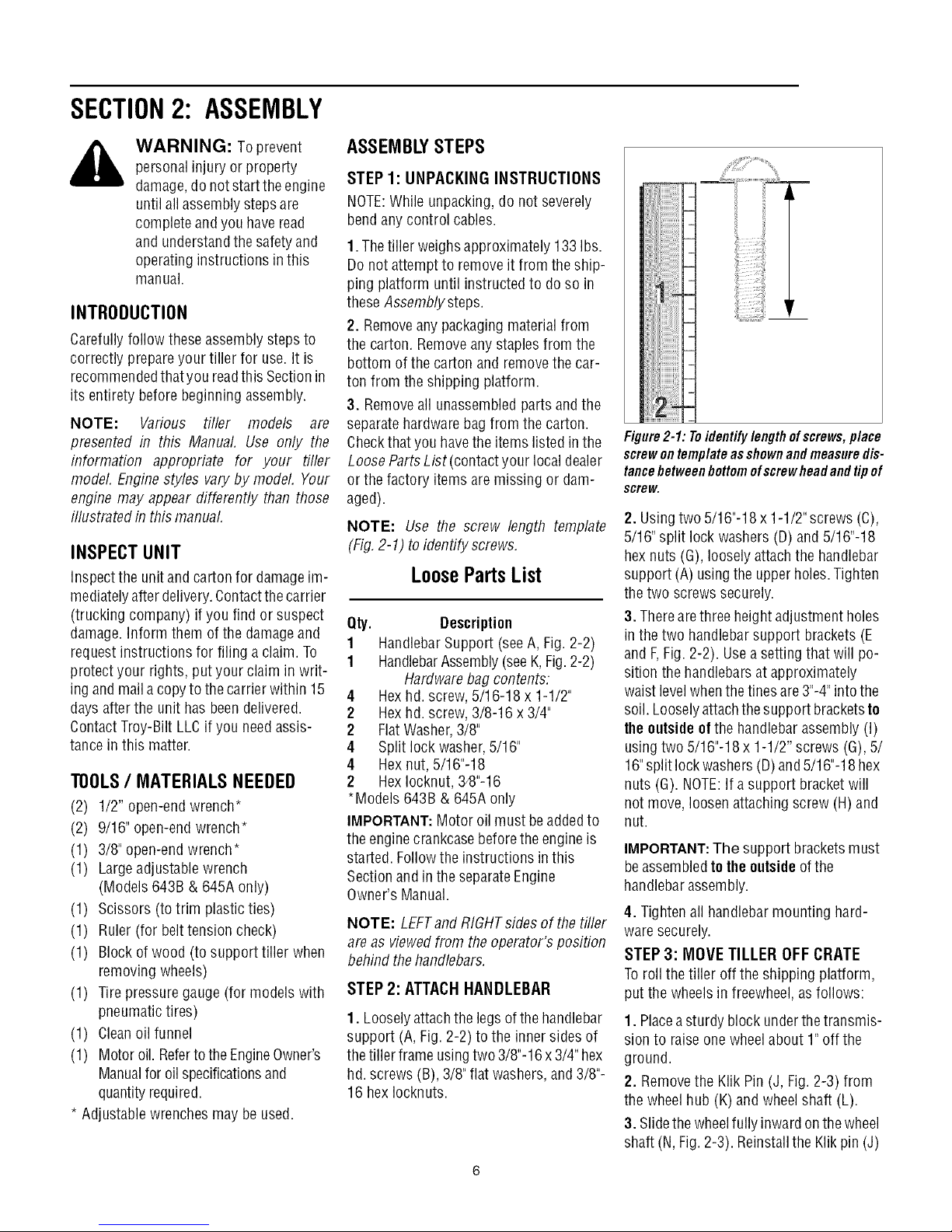

NOTE: Use the screw length template

(Fig,2-1) to identify screws,

LooseParts List

Qty. Description

1 HandlebarSupport (seeA, Fig. 2-2)

1 HandlebarAssembly(seeK,Fig.2-2)

Hardwarebag contents:

4 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 FlatWasher,3/8"

4 Split lock washer,5/16"

4 Hex nut, 5/16"-18

2 HexIocknut,3_8"-16

*Models 643B & 645Aonly

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebeforetheengine is

started. Followthe instructions inthis

Sectionand in the separateEngine

Owner's Manual.

NOTE: LEFTandRIGHTsides of thetiller

are as viewedfrom theoperator's position

behind the handlebars.

STEP 2: ATTACHHANDLEBAR

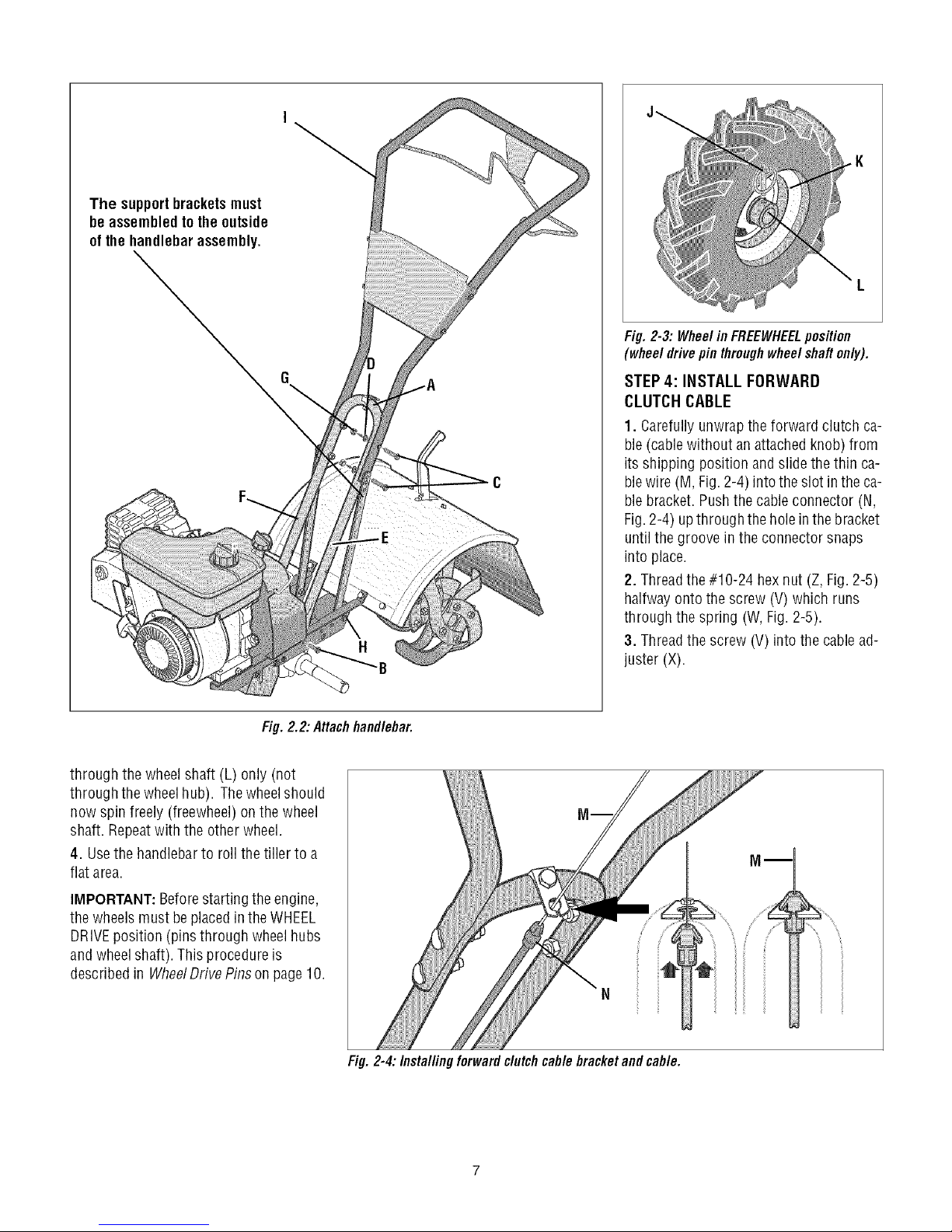

1. Looselyattachthe legs of thehandlebar

support (A, Fig. 2-2) to the innersides of

the tiller frame usingtwo 3/8"-16x3/4" hex

hd.screws (B),3/8" flat washers, and3/8"-

16 hexIocknuts.

_iiii

Figure2-1: Toidentifylengthofscrews,place

screwontemplateasshownandmeasuredis-

tancebetweenbottomofscrewheadandtipof

screw.

2. Usingtwo 5/16"-18x 1-1/2"screws (C),

5/16"split lock washers (D) and 5/16"-18

hexnuts (G), loosely attach the handlebar

support (A)usingthe upperholes.Tighten

thetwo screws securely.

3. Therearethree height adjustment holes

in the two handlebar support brackets (E

and F,Fig. 2-2). Usea setting that will po-

sition the handlebarsat approximately

waist levelwhenthetines are3"-4"intothe

soil. Looselyattachthe support bracketsto

theoutsideof the handlebarassembly (I)

usingtwo 5/16"-18x 1-1/2" screws (G), 5/

16"split lockwashers(D)and5/16"-18 hex

nuts (G). NOTE:If asupport bracketwill

not move, loosenattaching screw (H) and

nut.

IMPORTANT:The support bracketsmust

beassembledto theoutside ofthe

handlebarassembly.

4. Tightenall handlebarmounting hard-

waresecurely.

STEP 3: MOVE TILLER OFF CRATE

Toroll the tiller off the shipping platform,

put the wheels in freewheel, asfollows:

1. Placeasturdy block underthetransmis-

sion to raise one wheelabout 1" off the

ground.

2. Removethe Klik Pin (J, Fig. 2-3) from

the wheelhub (K) and wheelshaft (L).

3. Slidethe wheelfully inwardonthewheel

shaft (N,Fig. 2-3). Reinstallthe Klikpin (J)

Page 7

The supportbracketsmust

be assembledto theoutside

of the handlebarassembly.

Fig.2-3: WheelinFREEWHEELposition

(wheeldrivepin throughwheelshaftonly).

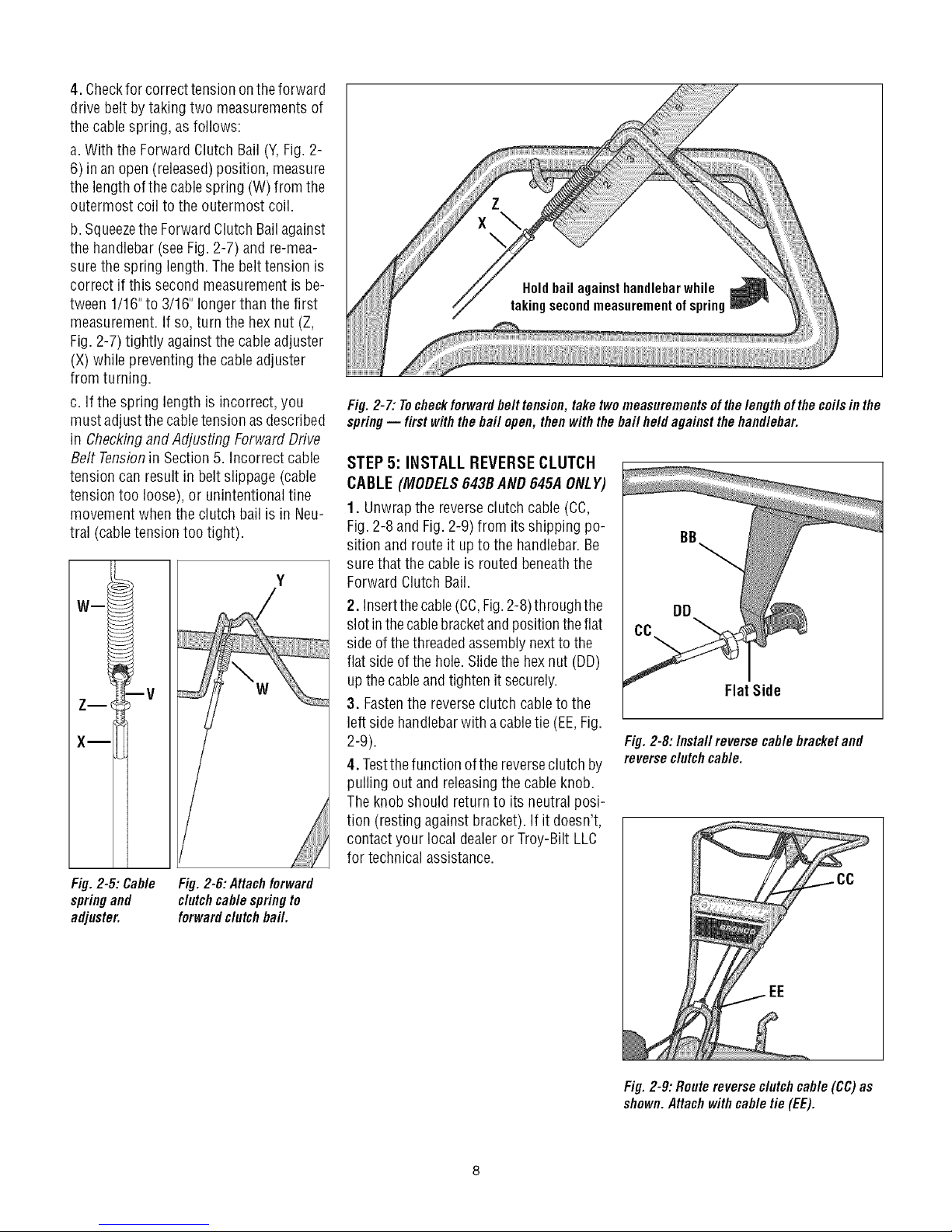

STEP 4: INSTALL FORWARD

CLUTCH CABLE

1. Carefullyunwrapthe forward clutch ca-

ble(cablewithout an attachedknob) from

its shipping position andslide the thin ca-

blewire (M, Fig.2-4) intothe slot in the ca-

blebracket. Pushthe cableconnector (N,

Fig.2-4) upthrough the holein thebracket

untilthe groove in the connector snaps

into place.

2. Threadthe#10-24 hexnut (Z, Fig. 2-5)

halfway ontothe screw (V)which runs

through the spring (W,Fig. 2-5).

3. Threadthe screw (V) into the cablead-

juster (X).

Fig. 2.2: Attachhandlebar.

through the wheel shaft (L) only (not

through thewheelhub). Thewheelshould

now spin freely (freewheel)on the wheel

shaft. Repeatwith the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

IMPORTANT:Beforestarting the engine,

the wheels must beplacedin theWHEEL

DRIVEposition (pinsthrough wheelhubs

andwheelshaft). This procedureis

described in WheelDrivePins on page 10.

Fig. 2-4:/nstal/ing forward clutchcable bracketand cable.

Page 8

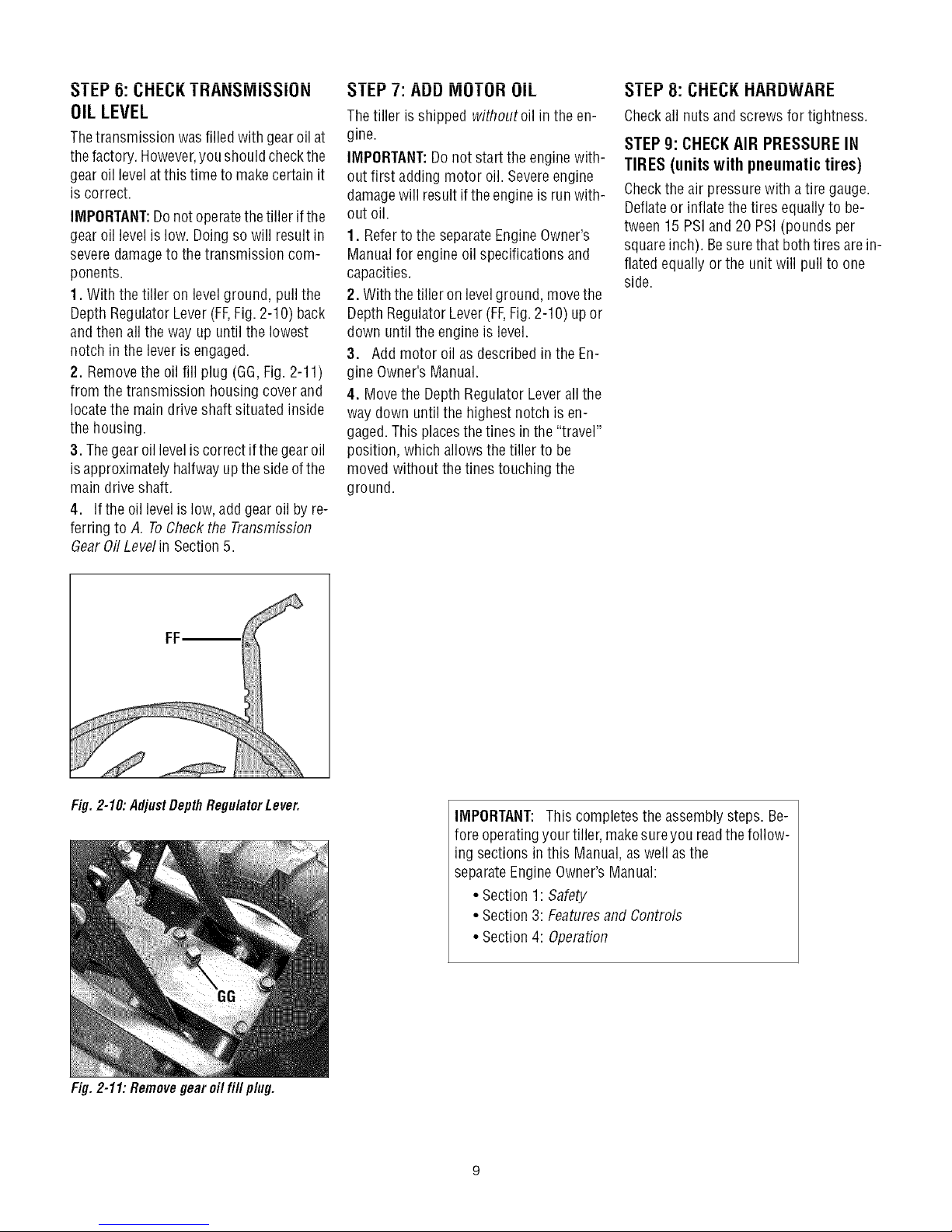

4. Checkfor correcttension ontheforward

drive belt bytaking two measurementsof

the cablespring, as follows:

a.With the Forward Clutch Bail (Y,Fig. 2-

6) in an open (released)position, measure

the length ofthe cable spring (W) from the

outermost coil to the outermost coil.

b. Squeezethe ForwardClutch Bailagainst

the handlebar(see Fig. 2-7) and re-mea-

surethe spring length. Thebelt tension is

correct if this second measurementis be-

tween 1/16"to 3/16" longer thanthe first

measurement.If so,turn the hexnut (Z,

Fig. 2-7) tightly against the cable adjuster

(X) while preventing the cable adjuster

from turning.

c. Ifthe spring length is incorrect, you

must adjustthe cabletension asdescribed

in Checkingand Adjusting ForwardDrive

Belt Tensionin Section5. Incorrect cable

tension can result inbelt slippage (cable

tension too loose), or unintentional tine

movement when the clutch bail is in Neu-

tral (cabletension too tight).

Wm

W

: v

iiiiiiiiiiiiiiii

Fig. 2-7: Tocheckforwardbelt tension, take twomeasurementsof thelengthofthe coilsin the

spring-- first withthebah open, then withthe bah held against thehandlebar.

STEP 5: INSTALL REVERSECLUTCH

CABLE(MODELS643BAND 645A ONLY)

1. Unwrapthe reverseclutch cable (CC,

Fig.2-8 and Fig.2-9) from itsshipping po-

sition androute it up to the handlebar.Be

surethat the cableis routed beneaththe

Forward Clutch Bail.

2. Insertthecable(CC,Fig.2-8)through the

slot inthecablebracketandpositiontheflat

sideof thethreadedassemblynextto the

flat side of the hole.Slidethe hexnut (DD)

up the cable andtighten it securely.

3. Fastenthe reverseclutch cable to the

left side handlebarwith acabletie (EE,Fig.

2-9).

4. Testthefunction ofthe reverseclutch by

pulling out and releasingthe cable knob.

Theknob should return to its neutral posi-

tion (resting against bracket). If it doesn't,

contact your local dealeror Troy-Bilt LLC

for technical assistance.

Fig. 2-8: Install reverse cable bracketand

reverseclutchcable.

Flat Side

Fig.2-5: Cable

springand

adjuster.

Fig. 2-6: Attachforward

clutchcable spring to

forwardclutch bail

Fig. 2-9: Routereverse clutchcable (CC)as

shown.Attachwithcable tie (EE).

Page 9

5! =-P6:CHECKTRAHSMiSSiOH

OILLEVEL

Thetransmission wasfilledwith gearoil at

thefactory. However,you shouldcheckthe

gear oil levelatthis time to makecertain it

is correct.

IMPORTANT:Donot operatethe tiller ifthe

gear oil level is low. Doingso will result in

severedamageto the transmission com-

ponents.

1. With the tiller on levelground, pull the

Depth RegulatorLever(FF,Fig. 2-10) back

andthen all theway up until the lowest

notch inthe lever isengaged.

2. Removethe oil fill plug (GG,Fig. 2-11)

from the transmission housing cover and

locatethe main drive shaft situated inside

the housing.

3. Thegear oil leveliscorrect if the gearoil

isapproximately halfway upthe sideofthe

main driveshaft.

4. Ifthe oil levelislow, addgear oil by re-

ferring to A, ToCheckthe Transmission

GearOil Level in Section5.

I El."/: AUU IVlUI UH UIL

Thetiller isshipped withoutoil in the en-

gine.

IMPORTANT:Donot start the engine with-

out first adding motor oil. Severeengine

damagewill resultif the engineis run with-

out oil.

1. Referto the separateEngineOwner's

Manualfor engine oil specifications and

capacities.

2. With thetiller on levelground, movethe

Depth RegulatorLever(FF,Fig.2-10) up or

down until the engine is level.

3. Addmotor oil as describedin the En-

gine Owner's Manual.

4. Movethe DepthRegulator Leverall the

way down untilthe highest notch is en-

gaged.This placesthe tines in the"travel"

position, which allows the tiller to be

moved without thetines touching the

ground.

_ I L:I."8: L;Ht:L;KHAHUWAHt:

Checkall nuts and screws for tightness.

STEP 9: CHECKAIR PRESSURE IN

TIRES (units with pneumatic tires)

Checkthe air pressurewith atire gauge.

Deflateor inflatethe tires equally to be-

tween 15 PSiand 20 PSi (pounds per

squareinch). Besurethat both tires arein-

flated equally orthe unit will pull to one

side.

Fig. 2-10: AdjustDepth Regu/atorLever.

Fig. 2-11: Removegear oil fill plug.

IMPORTANT: This completesthe assembly steps. Be-

fore operatingyour tiller, makesureyou readthefollow-

ing sectionsin this Manual,as well as the

separateEngineOwner'sManual:

• Section 1: Safety

• Section 3: Featuresand Controls

• Section 4: Operation

Page 10

SECTION3: FEATURESANDCONTROLS

_ ARNING: Before

INTRODUCTION

This Section describesthe location and

function ofthecontrols onyourtiller. Refer

to the following Section, Operationfor de-

tailed operatinginstructions.

Practice usingthese controls, with the en-

gine shut off, untilyou understandthe op-

eration ofthe controls andfeelconfident

with eachof them.

ENGINE CONTROLS

Referto the enginemanufacturer'sEngine

Owner'sManual (included in the tiller liter-

aturepackage)to identify the controls on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is locatedonthe engine.

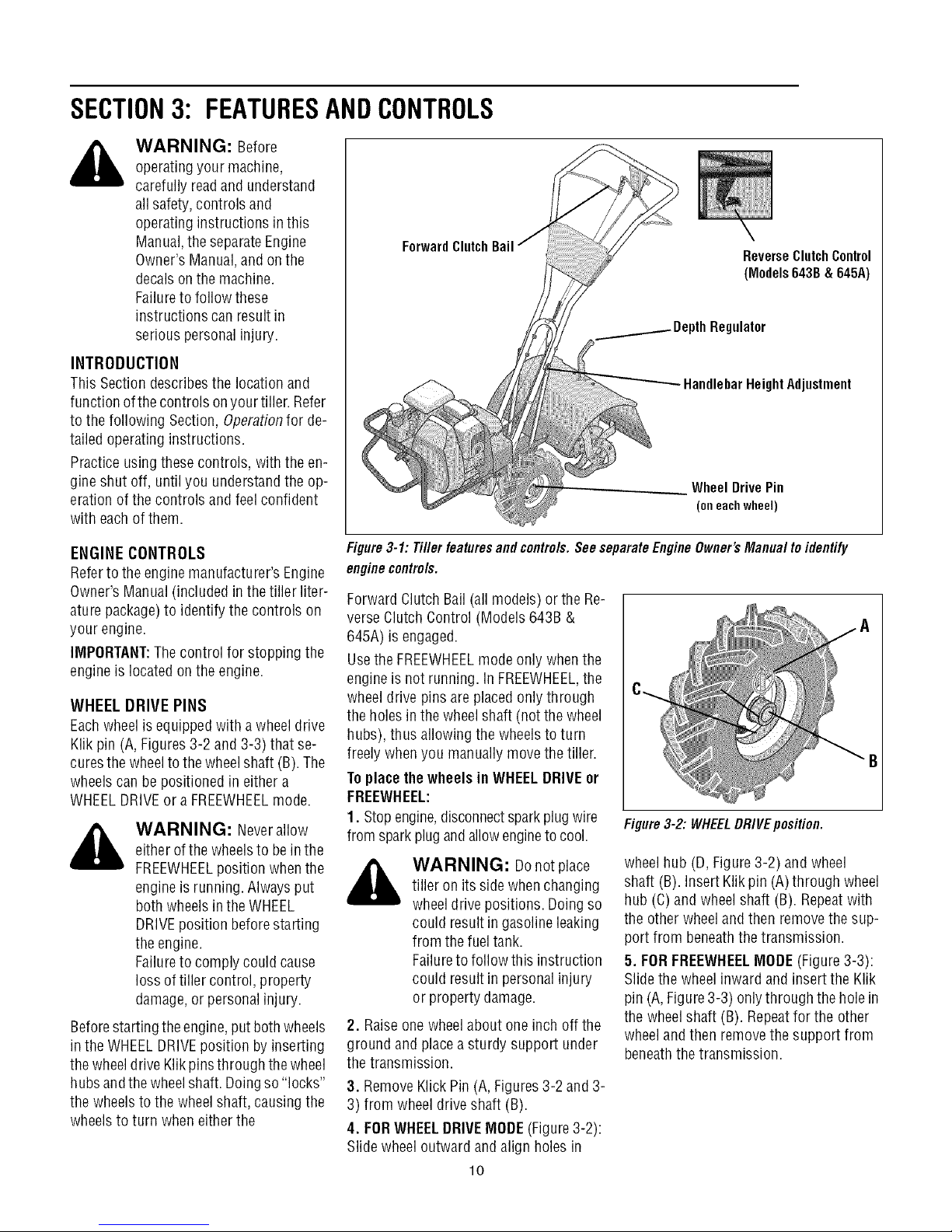

WHEEL DRIVE PINS

Eachwheel is equippedwith a wheel drive

Klik pin (A, Figures3-2 and 3-3) that se-

curesthe wheelto the wheel shaft (B).The

wheelscan be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

_ WARNING: Neverallow

Beforestarting the engine,put both wheels

in the WHEELDRIVEposition byinserting

the wheeldriveKlikpinsthrough the wheel

hubsandthewheelshaft. Doingso "locks"

the wheels to the wheelshaft, causing the

wheelsto turn when eitherthe

operatingyour machine,

carefully readand understand

all safety, controls and

operating instructions in this

Manual,the separateEngine

Owner's Manual,and on the

decalson the machine.

Failureto follow these

instructions can result in

serious personal injury.

either ofthewheelsto bein the

FREEWHEELposition whenthe

engineis running. Alwaysput

both wheelsin the WHEEL

DRIVEposition beforestarting

the engine.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

ForwardClutch

Wheel Drive Pin

Figure3-1: Tiller features and controls.See separateEngine Owner's Manual toidentify

enginecontrols.

Forward Clutch Bail (all models) or the Re-

verse Clutch Control (Models 643B &

645A) is engaged.

Usethe FREEWHEELmode only whenthe

engineis not running. InFREEWHEEL,the

wheeldrive pinsare placedonly through

the holes in thewheelshaft (not the wheel

hubs), thus allowing the wheelsto turn

freely when you manually movethe tiller.

Toplacethe wheels in WHEELDRIVEor

FREEWHEEL:

1. Stopengine,disconnectsparkplug wire

from sparkplug andallowengineto cool.

_ WARNING: Donotplace

2. Raiseone wheelabout one inch off the

ground andplaceasturdy support under

the transmission.

3. RemoveKlick Pin (A, Figures3-2 and 3-

3) from wheel driveshaft (B).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheel outward andalign holes in

tiller on its sidewhen changing

wheeldrivepositions. Doingso

could result ingasoline leaking

from the fuel tank.

Failureto follow this instruction

could result in personal injury

or propertydamage.

lO

Figure3-2: WHEELDRIVEposition.

wheelhub (D,Figure 3-2) and wheel

shaft (B). Insert Klik pin(A) through wheel

hub (C)and wheelshaft (B). Repeatwith

the other wheelandthen removethe sup-

port from beneaththe transmission.

5. FORFREEWHEELMODE(Figure 3-3):

Slide the wheelinward and insert the Klik

pin (A,Figure3-3) onlythrough thehole in

the wheelshaft (B). Repeatfor the other

wheeland then removethe support from

beneaththe transmission.

ReverseClutchControl

(Models643B&645A)

Regulator

HeightAdjustment

(oneachwheel)

"B

Page 11

Figure3-3: FREEWHEELposition.

WARNING: Beforestarting

engine,besurethat both

wheelsare in WHEELDRIVE

position. SeeWheelsDrivePins

for instructions.

Engagingthe Forward Clutch

Bail or ReverseClutchControl

(if equipped) whenthewheels

arenot in WHEELDRIVEcould

allowthe tinesto rapidly propel

the tiller forward or backward.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

FORWARDCLUTCHBAIL

TheForward Clutch Bail(D, Figure3-4)

controls the engagementof forward drive

to the wheelsand tines.

Tooperatethe ForwardClutchBail:

1. Put wheelsin WHEELDRIVEposition

(see"WARNING"statement above).

2. Lift and holdthe clutch bail (D,Figure 3-

4) againstthe handlebarto startthewheels

andtines rotating in a forward direction.

3. Releasethe clutch bail to disengage

(stop) the wheels andtines (theenginewill

continue to run).

REVERSECLUTCHCONTROL

(Models 643B & 645A only)

TheReverseClutchControl (E,Figure3-4)

controls the engagementof reversedrive

to the wheelsandtines.The reversingfea-

ture is used for maneuvering the tiller

only-- never engage the tines in the

ground while operatingin reverse.

WARNING: Useextreme

caution when reversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.

Neverattemptto till in reverse.

Failureto follow this warning

could result in personal injury

or propertydamage.

Tooperatethe ReverseClutchControl:

1. Putwheels in WHEELDRIVEposition

(see"WARNING"statement at the left).

2. Stopall tiller motion by releasingthe

Forward Clutch Bail.

3. Lift the handlebar untilthe tines clear

the ground, look behindyou to avoid any

obstacles,and then pull the control knob

(E, Figure3-4) out.The wheels andtines

will rotate in a reversedirection.

4. Releasethe control knobto disengage

(stop) the wheels andtines (theenginewill

continue to run).

Figure3-4:Allmodelshavea ForwardClutch

Bail(E). OnlyModel634,4haveaReverse

ClutchCentre/(F).

DEPTHREGULATORLEVER

Thislever(F,Figure3-5) controls thetilling

depth of thetines. Pullthe lever backand

slide it up or downto engagethe notched

height settings.

The"travel position" (highestnotch) raises

the tines approximately1-1/2"off the

ground, allowingthe tiller to bemoved

without the tines contacting the ground.

This setting should also be usedwhen

starting the engine.

Moving the lever upwardwill increasethe

tilling depth.The lowest notch allows a till-

ing depthof approximately6", depending

on soil conditions.For best results,always

begintilling atavery shallow depthsetting

and gradually increasethe tilling depth.

to till too deeplytoo quickly.

WARNING: Donotattempt

Graduallywork downto deeper

tilling depths.

Placethe DepthRegulator

Leverin the "travel" position

beforestarting theengine.This

position prevents thetines from

touching the ground untilyou

are readyto begintilling.

Failureto follow this warning

could result in personalinjury

or propertydamage.

TravelPosition

Figure3-5: DepthRegulatorLever (G).

HANDLEBARHEIGHT ADJUSTMENT

Thehandlebarheight isadjustableto three

different settings (Figure3-6). In general,

adjust the handlebarsso they areat waist

levelwhenthe tines are3"-4" in the soil.

Toadjust the handlebars:

1. Stopengine,disconnectspark plugwire

from sparkplug and allow engineto cool.

2. Removehardware,reposition handle-

bars,and reinstall hardwaresecurely.

High

Medium

Figure3-6: Handlebarheightadjustment.

11

Page 12

SECTION4: OPERATION

_ ARNING: Before

operatingyour machine,

carefully readand understand

all safety (Section 1),controls

(Section 3) and operating

instructions (Section4) inthis

Manual,the separateEngine

Owner's Manual,and on the

decalson the machine.

Failureto follow these

instructions can result in

serious personal injury.

INTRODUCTION

Readthis OperationSection andthe sepa-

rate EngineOwner'sManualbeforeyou

start the engine.Then,take the time to fa-

miliarize yourself with the basic operation

of thetiller before usingit in the garden.

Findan open,levelareaand practice using

the tiller controls without thetines engag-

ing the soil (put tines in "travel" setting).

Onlyafter you've becomecompletely fa-

miliar with thetiller shouldyou beginusing

it in the garden.

BREAK-INOPERATION

Perform the following maintenanceafter

the first two (2) hours of new operation

(see MaintenanceSection in this manual

and in the Engine Owner'sManual).

1. Changeengineoil.

2. Checkfor looseor missinghardwareon

unit. Tightenor replaceas needed.

3. Checktension onforward drive belt.

4. Checktransmission gear oil level.

STARTINGANDSTOPPING

Pre-StartChecklist

With the spark plug wire disconnected

from the sparkplug, perform the following

checksand services beforeeach use:

1. Readthe Safetyand Controls Sections

in this manual. Readthe separateEngine

Owner's Manualprovidedwith the unit.

2. Putthe wheels inthe WHEELDRIVEpo-

sition (wheel pins must be through holes

in wheelhubs andwheel shaft).

3. Checkunit for loose or missing hard-

ware. Serviceas required.

4. Checkengineoil level.SeeEngineOwn-

er's Manual.

ReverseClutchControl

(Mode/s643B&

ClutchBail

Fig. 4-1

5. Checkthat all safety guards andcovers

are in place.

6. Checkair cleanerand engine cooling

system. SeeEngineOwner's Manual.

_ WARNING: GASOLINEIS

7. Fillthefueltank with gasoline according

to the directions inthe separate Engine

Owner's Manual.Follow all instructions

and safety rules carefully.

8. Attachspark plug wire to spark plug.

Startingthe Engine

Thefollowing steps describe how to start

and stop the engine.

_ WARNING: Donotattempt

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Followgasolinesafety rules in

this Manual(seeSection 1)and

in the separateEngineOwner's

Manual.

Failureto follow gasoline safety

instructions can result in

serious personal injury and

property damage.

to engagethetines or wheels

until you havereadall ofthe

operatinginstructions in this

Section.Also, reviewthe safety

rules in Section1: Safety,and

the tiller and enginecontrols

information in Section3:

Featuresand Controls.

DepthRegulator

DrivePin

1. Completethe Pre-StartCheckliston this

page.

2. Putthe wheels inthe WHEELDRIVEpo-

sition (seeWheelDrivePinsin Section3 of

this manual).

,_ WARNING: Tohelp

• Before starting engine, put both

wheels in the WHEELDRIVEposition.

Never have wheels in FREEWHEELpo-

sition when engine is running.When

thewheels are in FREEWHEEL,theydo

not hold back the tiller and the tines

couldpropelthe tiller rapidly

forwardor backward.

• Before starting engine, put Forward

Clutch Bail (all models) and Reverse

Clutch Control (Models 643B & 645A

only)in neutral (disengaged)positions

by releasinglevers.

• Never run engine indoors or in en-

closed,poorlyventilatedareas. Engine

exhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

• Avoidenginemufflerandnearbyareas.

Temperaturesin these areas may ex-

ceed 150° F.

3. Movethe Depth RegulatorLeverall the

way down to the "travel" position, sothat

thetines clearthe ground.

4. Releaseall controls on the tiller.

5. Onengine's with afuel shut-off valve,

turn valve to openposition, as instructed

in the separateEngine Owner'sManual.

6. Put ignition switch and/or throttle con-

trol leverlocated on engine in the "ON",

"RUN", "FAST"or "START"position, asin-

structed inthe EngineOwner's Manual.

7. Chokeor prime engine,as instructed in

EngineOwner's Manual.

8. Put one hand onfuel tank to stabilize

unitwhenpulling starter ropehandle.Then

userecoilstarter to start engine,as in-

structed inthe EngineOwner's Manual.

Whenenginestarts, graduallymove choke

lever (if so equipped) to "NO CHOKE",

"CHOKEOFF"or "RUN" position.

9. Usethe "FAST"throttle speedsetting

whentilling.

preventserious personalinjury

or damageto equipment:

12

Page 13

Stopping the Engineand Tiller

1. Tostop the wheelsandtines, releasethe

Forward Clutch Bail (all models) orthe Re-

verse Clutch Control (Models 643B &

645A) -- whichevercontrol is in use.

2. Tostop the engine,put the ignition

switch and/or thethrottle control leverin

the "OFF"or "STOP"position.

OPERATINGTHETILLER

Thefollowing operating instructions pro-

videguidelinesto using your tiller effec-

tively and safely. Besure to read Tilling

Tips & Techniquesinthis Section before

actually putting the tines into the soil.

This is a"Counter-Rotating-Tine" (CRT)

tiller. It operatesdifferently from "Stan-

dard-Rotating-Tine" (SRT)tillers. Asthe

wheels pull forward, the tines rotate back-

ward, creating an "uppercut" action which

digs deeply, uprooting soil and weeds.

1. Followthe Pre-Start Checklistatthe be-

ginning of this Section. Besurethat the

wheelsare in the WHEELDRIVEposition.

2. Movethe DepthRegulator Leverall the

way down, so that thetines clearthe

ground. Usethis position when practicing

with thetiller and when travelingbetween

tilling sites. Beforeactuallytilling, move

the leverto the desireddepth setting (see

Tilling Tips & Techniques).

3. Start engineand allow it to warm up.

Thenput throttle in "FAST"setting.

4. Forforwardmotion of the wheelsand

powerto the tines:

(a) PullForward Clutch Bail (Fig.4-1) up

against handlebar.Releasebail to stopfor-

ward motion of wheels and tines.

(b) Whentilling, relaxand letthe wheels

pull the unit while thetines dig.Walk be-

hind anda littleto onesideof the unit. Use

one hand, yet keepa light--but secure--

grip onthe handlebar (while keepingyour

arm loose). SeeFig.4-2. Letthe unit move

at its own paceand donot pushdown on

the handlebarsto try and forcethe tines to

dig deeper-- this takes weight off the

wheelsand reducestraction.

,_ WARNING: Donotpush

down onthe handlebarsto try

to makethe tiller till more

deeply.This prevents the

wheelsfrom holding the tiller

backand canallowthe tines to

rapidly propelthe tiller forward,

which could resultin loss of

control, property damage,or

personalinjury.

5. Forreverse motion ofthe wheelsand

tines (Models643B & 645A only):

(a) Look behindand exercisecautionwhen

operating in reverse.Do not till while in

reverse.

(b) Stopall forward motion. Lift handlebar

with one handuntil tines areoff the ground

andthen pull ReverseClutchControl knob

out (seeFig.4-3). Tostop reversing,letgo

of ReverseClutch Control knob.

(b) Swing the handlebarto theleft so the

rightwheeltakes a "step" backward.Next

swing the handlebarto the rightso the left

wheel"steps" backward.Repeatas needed.

(c) If longer distances needto becovered

in reverse,shut off the engine,then place

thetwo wheels in FREEWHEEL.

7. ToTurnthe Tiller Around:

(a) Practiceturning the tiller in a level,

openarea.Beverycarefulto keepyour feet

and legs away from the tines.

(b) Tobeginaturn, lift the handlebarsuntil

thetinesareoutofthe groundandtheengine

andtinesarebalancedoverthewheels(Fig.

4-4).

(c)With tiller balanced,push sideways on

handlebarto steer in directionof turn (Fig.

4-5). After turning, slowly lower tines into

soil to resumetilling.

Fig. 4-4: Tobegin turn,lift handlebarsuntil

tinesare outof groundand unit is balanced.

Fig.4-2:Useonehandtoguidetiller when

movingforward.

Fig.4-3:Raisetinesoffgreundandlook

behindwhenmovinginreverse.

6. Tomovethe Model643Cin reversefor

short distances:

(a) Releaseforward ClutchBail.Thenlift

handlebaruntiltines are off theground.

13

Fig. 4-5: With tines out of greund,push han-

dlebarssidewaysto turn tiller.

StoppingtheTillerandEngine

1. Tostop the wheelsandtines, releasethe

Forward Clutch Bail (all models) orthe Re-

verse Clutch Control (Models 643B &

645A) -- whichevercontrol is in use.

2. Tostop the engine,put the ignition

switch and/orthe throttle control leverin

the "OFF"or "STOP"position.

Page 14

TILLINGTIPS& TECHNIQUES

Tilling Depths

WAHNING: Before

tilling, contactyour

telephoneor utilities

companyand inquire if

undergroundequipment or

lines are usedon your

property. Donottill near

buriedelectric cables,

telephonelines, pipes or

hoses.

• Whencultivating(breakingupsurfacesoil aroundplantsto destroyweeds,seeFig.4-9), ajust thetinesto digonly 1"to 2" deep.Using

shallowtilling depthshelpspreventinjury to plantswhoseroots often growclose to the surface.If needed,lift up onthe handlebars

slightlytopreventthetinesfrom diggingtoo deeply.(Cultivatingona regularbasisnot onlyeliminatesweeds,it alsoloosensandaerates

thesoil for bettermoistureabsorptionandfaster plantgrowth.)Wateringthegardenareaafewdayspriorto tillingwill maketilling easier,

aswill lettingthe newlyworkedsoil setfor a dayor two beforemakinga final, deeptilling pass.

This is a CRT(counter-rotatingtine)tiller. Asthewheelspullforward,the tinesrotateback-

ward. Thiscreatesan "uppercut" tine actionwhich digs deeply,uprootingsoil and weeds.

Don't overloadthe engine,but dig asdeeplyas possibleon eachpass.Onlaterpasses,the

wheelsmaytendto spinin thesoft dirt. Helpthemalongbylifting upslightlyonthehandlebar

(onehand,palm up,works mosteasily).

Avoidthe temptationtopushdownon thehandlebarsinan attemptto force thetiller to dig

deeper.Doingsotakesthe weightoff the poweredwheels,causingthemto lose traction.

Withoutthe wheelsto holdthetillerback,thetineswill attemptto propelthetiller backward,

towardsthe operator.(Sometimes,slightdownwardpressureonthehandlebarswill helpget

througha particularlytoughsectionofsodor unbrokenground,butin mostcasesthiswon't

benecessary.)

ChoosingCorrectWheel& TineSpeeds With experience,you will find the "just right" tilling depthandtilling speedcombination

that is bestfor yourgarden.

Setthe enginethrottle leverata speedto givetheengineadequatepowerandyetallowit tooperateattheslowestpossiblespeed...atleast

until youhaveachievedthe maximumtilling depthyou desire.Fasterenginespeedsmaybe desirablewhenmakingfinal passesthrough

theseedbedor whencultivating.Selectionofthecorrectenginespeed,in relationto the tilling depth,will ensureasufficientpowerlevelto

do the jobwithout causingtheengineto labor.

Letthe Tiller DotheWork

Whiletilling, relaxandletthe wheelspullthe

tiller along while the tines do the digging.

Walkon thesidethat is notyet finished(to

avoidmakingfootprints inthe freshly tilled

soil) and lightly,but securelygrip the han-

dlebarwith just onehand.

AvoidMakingFootprints

Wheneverpossible, walk on the untilled

sideof the unit to avoidmakingfootprints in

your freshly tilled or cultivated soil. Foot-

prints causesoil compactionthat canham-

per root penetrationand contributeto soil

erosion. They can also "plant" unwanted

weed seeds back into the freshly tilled

ground.

Preparing Seedbeds

•Whenpreparingaseedbed,go overthesamepathtwiceinthefirst row,thenover-

lapone-halfthetiller width ontherest ofthe passes(seeFig.6).Whenfinishedin

onedirection,makea secondpassat a right angle,as shownin Fig.4-7. Overlap

eachpassfor best results(invery hardground,it maytakethreeor four passesto

thoroughlypulverizethesoil.)

• If thegardensizewill not permitlengthwiseandthencrosswisetilling, then over-

lapthefirst passesbyone-halfatiller

width,followedbysuccessivepasses ....................v .................................

at one-quarterwidth(seeFig.4-8). _ _

Fig. 4-8

AvoidTillingSoggy, WetSoil

Tilling wet soil often resultsin large,hard

clumpsof soil that caninterferewith plant-

ing.If time permits,wait aday or two after

heavyrainsto allow the soil to dry before

tilling. Testsoil bysqueezingit intoa ball.If

itcompressestooeasily,it is too wetto till.

m_

Fig. 4-6 Fig. 4-7

Cultivating

With planning, you can =,,_r,_, ..,'qr_

allow enoughroom _" _ (_

betweenrows to cultivate _ _

(seeFig.4-9). Leaveroom _ _

for the hood width,

plus enough extra _ _'

roomfor future plant Fig.4-9

growth.

14

Page 15

TillingOnSlopes

TILLINGTIPS& TECHNIQUES(CON'T)

Readthe followingrecommendationsbeforetilling onslopes:

Ifyou must gardenon a moderateslope,pleasefollowtwo veryimportantguidelines:

1.Tillonlyon moderateslopes,neveronsteepgroundwherefootingisdifficult (reviewsafe-

ty rulesin Section1:Safetyofthis manual).

2. We recommendtilling up and down slopes ratherthan terracing. Tilling vertically on a

slopeallows maximumplantingareaandalso leavesroomfor cultivating.

IMPORTANT:Whentilling onslopes, besurethecorrectoil levelis maintainedintheengine

(checkeveryone-halfhour of operation).Theinclineof the slopewill causethe oil to slant

WAHNING: Do not

operatetiller onaslopetoo

steepfor safe operation.Till

slowly and besureyou have

good footing. Neverpermit

tiller to freewheeldown

slopes.Failureto follow this

warning could result in

personalinjury.

awayfrom its normallevelandthis canstarveenginepartsof requiredlubrication.Keepthe

motor oil levelatthe full pointatall times!

Tilling Upand DownSlopes(Vertical Tilling)

• To keepsoil erosionto aminimum, besureto addenoughorganicmatterto thesoil sothat it hasgoodmoisture-holdingtextureandtry

to avoidleavingfootprints or wheelmarks.

• Whentilling vertically,tryto makethefirst passuphillas thetillerdigsmoredeeplygoinguphillthanitdoesdownhill.Insoft soil or weeds,

youmayhaveto lift the handlebarsslightlywhile going uphill.Whengoingdownhill, overlapthefirst passby about one-halfthewidth of

thetiller.

Clearingthe Tines

Thetines have a self-clearing action which eliminates most tangling of debris in the

tines. However,occasionally dry grass, stringy stalks or tough vines maybecome tan-

gled. Follow these proceduresto help avoid tangling and to cleanthe tines, if neces-

sary.

•To reducetangling, setthe depth regulatordeep enoughto get maximum "chopping"

action as the tines chop the material against the ground. Also, try to till under crop

residues or covercrops while they are green, moist andtender.

• While tilling, try swaying the handlebars from side to side (about 6" to 12"). This

"fishtailing" action often clearsthe tines of debris.

• Iftangling occurs, lift the tines out of the soil and run the tiller in reverse(if unit is

equippedwith poweredreverse) for a few feet.This reversing action should unwind a

good deal of debris.

• It may benecessaryto removethe debris by hand(a

pocketknifewill helpyou to cut awaythe material). Be

sure to stop the engineand disconnect the sparkplug

wire beforeclearing the tines by hand.

tines by hand,stop the engine,allow all

WARNING: Beforeclearing the

moving partsto stop and disconnect the

spark plug wire. Removethe ignition key

on electric start models.

Failureto follow this warning could result

in personalinjury.

LoadingandUnloadingtheTiller

_ ARNING: Loading and

• Beforeloading or unloading, stopthe engine,

wait for all parts to stop moving,

disconnect the spark plug wire and let the en-

gine and muffler cool.

• Thetiller is too heavy and bulky to lift safely

by one person. Twoor morepeople should

sharethe load.

unloadingthe tiller into avehicle is

potentially hazardousandwe don't

recommend doing so unless

absolutelynecessary,as thiscould

result in personal injury or

property damage.

However,if you must load or

unloadthe tiller, follow the

guidelines given next.

• Usesturdy ramps and manually (engine shut

off) roll the tiller into and out ofthe

vehicle. Two or more people areneededto do

this.

• Theramps mustbe strong enoughto support

the combined weight of the tiller and any han-

dlers. Theramps should provide good traction

to prevent slipping; they shouldhavesiderails

to guidethe tiller alongthe ramps; and they

should havealocking deviceto securethem to

the

vehicle.

• Thehandlersshouldwearsturdyfootwear that

will helpto preventslipping.

• Positionthe loading vehicle so that the ramp

angleis asflat as possible (the less inclineto

the ramp, the better). Turn the

vehicle'sengineoff and apply its parking brake.

15

• When going up ramps, stand in the

normal operating position and push the tiller

ahead of you. Havea person at eachside to

turn the wheels.

• When going down ramps, walk backward

with the tiller following you. Keep alert for any

obstaclesbehind you. Position a person at

eachwheel to control the speedof the tiller.

Nevergo down ramps tiller-first, as the tiller

could tip forward.

• Placewooden blocks on the downhill side of

the wheels if you needto stop the tiller from

rolling down the ramp. Also, use the blocks to

temporarily keep the tiller in place onthe

ramps (if necessary),and to chockthe wheels

in place after the tiller is in the vehicle.

• After loading the tiller, prevent it from rolling

byengaging the wheels in the WHEELDRIVE

position. Chockthe wheelswith blocks and se-

curelytie the tiller down.

Page 16

TILLINGTIPS& TECHNIQUES(CON'T)

TerraceGardening(continued)

• Tocreateaterrace,startat the top of the slopeand work down. Gobackand

forth acrossthefirst rowas shownin Fig.4-10.

• Eachsucceedinglowerterraceis startedby walking belowthe terraceyou're 0 m_

preparing.Foraddedstabilityofthetiller,alwayskeeptheuphillwheelinthesoft,

newlytilled soil. Donottill the last 12" or moreof the downhill outsideedgeof

eachterrace.Thisuntilled strip helpspreventstheterracesfrom breakingapart

andwashingdownhill. It alsoprovidesa walkingpathbetweenrows. _, REPEAT

Fig. 4-10

LOADINGAND UNLOADING

THE TILLER

,_ WARNING: Loadingand

• Before loading or unloading,stop the en-

gine,wait for all parts to stop moving,

disconnect the sparkplug wire and letthe

engineand muffler cool.

•The tiller istoo heavyand bulky to lift

safelyby one person. Twoor more people

should sharethe load.

unloading the tiller into a

vehicleis potentially hazardous

andwedon't recommenddoing

so unlessabsolutelynecessary,

asthis could result in personal

injury or property damage.

However,if you must load or

unloadthe tiller, follow the

guidelinesgivennext.

• Usesturdy ramps and manually (engine

shut off) roll thetiller into and out of the

vehicle.Twoor more peopleare neededto

do this.

• The ramps must bestrong enoughto

support the combined weight of the tiller

and any handlers. The rampsshould pro-

videgoodtraction to preventslipping; they

should haveside rails to guidethe tiller

along the ramps; andthey should havea

locking deviceto securethem to the

vehicle.

•The handlersshouldwearsturdy footwear

that will helpto preventslipping.

• Position the loading vehicle so that the

ramp angle is asflat aspossible (the less

incline to the ramp,the better). Turn the

vehicle'sengine off and apply its parking

brake.

• When going up ramps,stand in the

normal operating position and push the

tiller aheadof you. Havea person at each

sideto turn the wheels.

•When going down ramps,walkbackward

with thetiller following you. Keepalertfor

anyobstacles behind you. Position aper-

son ateachwheelto control the speedof

thetiller. Nevergo down ramps tiller-first,

asthe tiller could tip forward.

•Placewoodenblocksonthe downhill side

of the wheels if you needto stop the tiller

from rolling down the ramp. Also, usethe

blocksto temporarily keepthe tiller in

placeon the ramps (if necessary),and to

chockthe wheels in placeafter the tiller is

in the vehicle.

• After loading the tiller, prevent it from

rolling byengagingthe wheels in the

WHEELDRIVEposition. Chockthewheels

with blocksandsecurelytiethetiller down.

16

Page 17

SECTION5: MAINTENANCE

WARNING: Before

inspecting, cleaning or servicing

the machine,shut off engine,

wait for allmoving partsto come

to acomplete stop, disconnect

spark plug wire and movewire

awayfrom spark plug. Remove

ignition keyon electricstart

models.

Failureto follow these

instructions can result in serious

personalinjury or property

damage.

MAINTENANCESCHEDULE

PROCEDURE

Checkmotor oil level

Cleanengine

Checkdrive belttension

Checknuts and bolts

Changemotor oil

Lubricate tiller

Serviceengine air cleaner system

Checkgearoil levelin transmission

Checktines for wear

Checkair pressure in tires

(if unit haspneumatic tires)

Servicespark plug

NOTES

1 Checkafter first 2 hours of break-in operation.

2 Beforeeach use.

3 Every5 operating hours.

4 Every 10operating hours,

5 Every30 operating hours,

6 Changemore frequently in dusty conditions.

7 - See EngineOwner's Manual forservice

recommendations.

8 - Whichever time interval occurs firsL

g - Changeafter first 2 hours of break-in

NOTES

2,3

2,7

1,4

1,4

4,6,9

4

1,5

5

5

TILLER LUBRICATION

After every10 operating hours, oil or

greasethe lubrication points shownin

Figure5-1 and described below.

Usecleanlubricating oil (#30weight motor

oil is suitable) and cleangeneralpurpose

grease(greasecontaininga metallubricant

is preferred, if available).

• Removethe wheels,cleanthe wheelshaft

(A,Fig. 5-1) and applya thin coating of

greaseto the wheel shaft.

• Greasethe back,front and sides of the

depthregulator lever (B, Fig.5-1).

• Removethetines andclean the tine shaft

(C,Fig.5-1). Useafile or sandpaperto gen-

tly removeany rust, burrs or roughspots

(especiallyaround holes in shaft). Apply

greaseto ends of shaft beforeinstalling

tines.

• Oil thethreads on the handlebar height

adjustment screwsand the handlebar

attaching screws (D, Fig.5-1).

D B

Figure5-1

CHECKFOROILLEAKS

Beforeeachuse,checkthetiller for signsof

an oil leak-- usually a dirty, oily accumu-

lation eitheron the unit or on the floor.

A littleseepagearound acover or an oil

sealis usually not a causefor alarm. How-

ever,if the oil drips overnight, then imme-

diateattention is needed. Ignoring an off

leakcanresult in severetransmission

damage!

17

If acover is leaking,check for loose

screws. If the screws are tight, anew

gasket or oil seal may be required.

If the leakis from around a shaft andoil

seal, the oil seal probably needsto be

replaced.Seeyour authorized dealeror

contact the factoryfor serviceor advice.

IMPORTANT:Neveroperatethe tiller if

thetransmission islow on oil.Checkthe

oil levelafter every 30 hours of

operationand wheneverthere is any oil

leakage.

CHECKHARDWARE

Checkfor looseor missing hardwareaf-

ter every 10operatinghoursandtighten

or replace(asneeded)before reusing

tiller

Besureto checkthe screws underneath

thetiller hoodthat securethe transmis-

sioncoverandthe DepthRegulatorLever

to thetransmission.

CHECKTIRE PRESSURE

(Modelswith pneumatictires)

Checkthe air pressurein bothtires. The

air pressureshould bebetween 15 PSi

and 20PSi (pounds per squareinch).

Keepbothtires equally inflated to help

prevent machinefrom pulling to one

side.

TRANSMISSION

GEAROILSERVICE

Checkthe transmission gear oil level

after every30 hours of operation or

wheneveryou notice any oil leak.Oper-

ating thetiller when the transmission is

low on oil can result in severedamage.

A. To ChecktheTransmission

GearOil Level:

1. Checkthe gear oil level when the

transmission is cool. Gearoil will

expandin warm operatingtemperatures

and this expansionwill providean incor-

rect oil level reading.

2. With thetiller onlevelground, pull the

Depth Regulator Leverall the way up.

3. Removethe oil fill plug (A,Fig. 5-2)

from thetransmission housingandlook

insidethe oil fill hole to locatethe main

driveshaft situated below the hole.

Page 18

moving partsto come to a completestop, disconnectspark plug wireand move wireawayfrom

WARNING: Beforeinspecting, cleaningor servicing the machine,shut offengine,wait for all

spark plug. Failureto follow these instructions canresult in serious personalinjury orproperty

damage.

4. Thegear oil leveliscorrect if the gearoil

isapproximately halfway upthe sideofthe

main driveshaft.

5. Ifthe gearoil levelislow, addgear oilas

described next. If the gearoil levelis okay,

securely replacethe oil fill plug.

IMPORTANT:Donot operatethe tiller ifthe

gear oil level is low. Doingso will result in

severedamageto the transmission com-

ponents.

Figure5-2:Removeofffi/I p/ug(tl) to check

gearoff levelandtoaddgearoiL Remove

fourcoverscrews(B)todraingearoil.

6. If adding only a few ounces of gear oil,

useAPIratedGL-4or GL-5gearoil having

a viscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an emptytrans-

mission, useonly GL-4gear oil having a

viscosity of SAE85W-140 or SAE140.

IMPORTANT:Donot use automatic trans-

mission fluid or motor oil in the transmis-

sion.

7. Whilecheckingfrequentlyto avoid over-

filling, slowly add gear oil into the oil fill

hole until it reachesthe halfway point on

the driveshaft.

8. Securely replacethe oilfill plug.

B. ToDrain theTransmissionGearOil:

Thetransmission gearoil doesnot needto

bechangedunless it hasbeencontaminat-

ed with dirt, sand or metal particles.

1. Draingasolinefrom thefuel tank or run

the engine until thefuel tank is empty.See

"DANGER"statement below.

WARNING: Gasolineis

highlyflammableandits vapors

areexplosive. Followthese

safety practicesto prevent

personalinjury or property

damagefrom fire or explosion.

Allow the engine and muffler to cool

for at least two minutesbefore drain-

ingthe tiller's gasolinetank.

Do not allow open flames, sparks,

matchesorsmokingin thearea.

Wipe away spills and pushtiller away

from spilledfuel.

Use only an approved fuel container

and store it safely out of the reach of

children.

Donotstoregasolinein anarea where

itsvaporscould reach an open flame

or spark, orwhere ignitionsourcesare

present(such as hot water and space

heaters, furnaces, clothes dryers,

stoves,electricmotors,etc.)

2. Drainthe oil from the engine.

3. Removefour screws(B,Figure5-2) and

removetransmissioncoverandgasket.

4. Removethe left-side wheel.

5. Tilt the left-side wheelshaft into adrain

panand allowthe gearoil to drainthrough

the top of thetransmission.

6. Reinstallthe wheel.

7. Install a newgasket (do not reuse old

gasket)and reinstall thetransmission cov-

er.

8. Refill thetransmission using GL-4gear

oil (SAE85W-140 or SAE140).

g. Refill the enginewith motor oil and re-

plenishthe fuel tank with gasoline.

BOLOTINES

Thebolo tines will wearwith useand

should beinspected at the beginning of

eachtilling seasonandafterevery 30 oper-

ating hours. Thetines can be replacedei-

ther individually or as acomplete set. See

the Parts List pagesfor tine identification

and part numbers.

A. Tine Inspection:

With use,the tines will becomeshorter,

narrower and pointed. Badlyworn tines

will result in aloss of tilling depth,and re-

ducedeffectivenesswhenchopping up

andturning under organic matter.

B. Removing4nstalling a Single Tine:

1. With the engine shut off and the spark

plug wire disconnected,remove the two

screws (A, Figure5-3) and nuts (B)that at-

tachasingle tine to atine holder.If needed,

usepenetrating oil on the nuts.

2. When installing a singletine, besureto

position it so that its cutting edge (sharp)

will enter the soft first asthe tiller moves

forward.

C. Removing4nstallingaTineAssembly:

1. Atine assemblyconsists of eight tines

mounted on atine holder.

2. If removing both tine assemblies,mark

them "left" and "right" before removal. Re-

move the screw (C, Figure5-3) and lock-

nut (D)that securethetineassemblyto the

tineshaft. If necessary,usea rubber mallet

to tapthe tine assembly outward off the

shaft.

3. Beforereinstalling the tine assembly,in-

spectthe tineshaft for rust, roughspots or

burrs. Lightly file or sand, asneeded.Ap-

ply a thin coat of greaseto the shaft.

4. Install each tine assemblyso that the

cutting (sharp) edge of thetines wifl enter

thesoil first whenthefiller movesforward.

Securethe fine assemblyto the tine shaft

usingthe screwand Iocknut

18

Page 19

,_ WARNING: Beforeinspecting, cleaningor servicing the machine,shut offengine,wait for all

moving partsto come to a completestop, disconnectspark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions canresult in serious personalinjury orproperty

damage.

C

\

FORWARD

Figure5-3: Install tinesso that cuttingedge oftines entersoftfirst when tiller movesforward.

CHECKINGAND ADJUSTING

FORWARDDRIVE BELT TENSION

It is important to maintain correct tension

on the forward drive belt.A loosebelt will

causethe tinesandwheelsto slow down--

or stop completely -- eventhough the en-

gine is running at full speed.A too tight

belt can result in unintentionaltine move-

ment when the clutch bail isin the Neutral

(released)position.

• Checkbelt tension after the first two

hours ofbreak-inoperationandafter every

10 operatinghours.

• At the end of eachtilling season,check

the beltfor cracks,cuts or frayed edges

and replace it as soonas possible.

ToCheckForwardBeltTension:

1. Stopengine,wait for all parts to stop

moving anddisconnect spark plug wire.

2. With the ForwardClutchBailinan open

(released)position, measureand notethe

overalllengthofthecablespring (A, Figure

5-4) by measuringfrom the outermost coil

to the outermost coil.

3. SqueezetheForwardClutchBailagainst

the handlebar(see Figure 5-4) and re-

measurethe length of the coils. Thebelt

tension is correct if this second measure-

ment is between1/6"-to- 3/16"longer than

the first measurement.

4. If the spring is too short (lessthan

1/16"),the tension is too loose. If the

spring istoo long (more than 3/16"), the

tension is too tight.

5. Toadjust the length of the spring:

a. Releasethe Forward Clutch Bail.

Figure5-4: Tocheckforwardbelt tension, taketwomeasurementsofthe

overa//length of thecoilsin the spring-- first withthedutch bail open,

thenwith thedutch bail closedagainst the handlebar.

19

b. Unthreadthe hexnut (C,Figure5-4)

halfway up the adjustment screw (D).

c. Unhookthe top ofthe springfrom the

Forward Clutch Bail.

d. Usepliers to preventthe adjuster (B)

from turning andturn the slotted screwlo-

cated inside the spring clockwise (viewed

from operator'sposition) to increaseten-

sion onthe spring. Turnthescrewcounter-

clockwiseto decreasetension. Once

adjusted, reattachthe spring to the For-

ward Clutch Bail.

e.RepeatSteps2and3to re-measurethe

lengthofthespring.Whenthesecondmea-

surementis between1/16"-to-3/16"longer

thanthefirst measurement,retightenthe hex

nut (C)againstthetop oftheadjuster(B).

ReplacementBelt Information

If the drive belt needsto be replaced,see

your local authorizeddealeror referto the

Parts Listfor ordering information. Use

only a factory-authorizedbelt as an"over-

the-counter" belt may not perform satis-

factorily. Theprocedure requires average

mechanicalability andcommonly available

tools.

Page 20

,_ WARNING: Beforeinspecting, cleaningor servicing the machine,shut offengine,wait for all

moving partsto come to a completestop, disconnectspark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions canresult in serious personalinjury orproperty

damage.

FORWARDCLUTCH

BAIL ADJUSTMENT

If the Forward Clutch Baildoes not func-

tion properly,first checkthat the forward

drive belt is adjusted properly (see Check-

ing andAdjusting Forward Drive Belt Ten-

sion). If this fails to correct the problem,

contact Troy-Bilt LLCor your authorized

dealerfor service advice.

CHECKINGANDADJUSTINGRE-

VERSEDRIVEBELTTENSION

(Models643B & 645A only)

It is important to maintain correct tension

on the reversedrive belt. A loose belt will

causethetines andwheelsto slow down -

or stopcompletely - eventhough the en-

gine is running at full speed.

Whenchecking belttension, also checkthe

belt for cracks, cuts or frayed edgesand

replaceit as soon as possible.

• Checkbelt tension after the first two

hours ofbreak-inoperationandafter every

10 operatinghours.

ToCheckReverseBeltTension:

1. Stopengine,wait for all parts to stop

moving anddisconnect spark plug wire.

2. Removescrew in plastic beltcover and

slide beltcover (which is attachedto for-

ward clutch cable) out of the way.

3. Haveanassistant pull the Reverse

Clutch Control knob all the way out and

hold it inthat position. Measurethelength

of the cablewire betweenthe end of the

threadedcableadjuster (A,Figure5-5) and

the end of the Z-fitting (B)to which the ca-

ble wire is attached.

4. Thebelttension is idealif the cablewire

lengthmeasuresbetween1/8"to 1/4".If it is

lessthan 1/8"(andif there isno reverseac-

tion whenthe tiller is running),thenmake

the following adjustments

NOTE:Ifthe lengthis morethan 1/4",noad-

justment isneeded--as longasthe reverse

actionfunctions properly.

5. Releasethe ReverseClutchControl

knob.andthen unthread the inner jam nut

(C, Figure 5-6) oneto two turns. Pull the

threaded cableadjuster (A, Figure5-6) to

the left untilthe innerjam nut (C) touches

the bracket.

6. Preventthe inner jam nut (C) from turn-

ing and tighten the outer jam nut (D)

againstthe bracket. Preventthe outer jam

nut (D)from turning and tighten the inner

jam nut (C) againstthe bracket.

7. Measurethe gapby repeatingStep 3.

Readjustasneededby repeating Steps 5

and 6.

8. Reinstallthe belt cover.

Figure5-5: Measure cable wire lengthto

checkfor correctreversebelt tension.

Figure5-6:Movethreadedadjuster(,4)toleft

toincreasebelttension.

Replacement Belt Information

If the drive belt needsto be replaced,see

your local authorizeddealeror referto the

Parts Listfor ordering information. Use

only a factory-authorizedbelt as an "over-

the-counter" belt may not perform satis-

factorily. Theprocedure requires average

mechanicalability andcommonly available

tools.

ENGINECLEANING

Keepingthe engineclean will helpto en-

sure smooth operation and prevent dam-

agefrom overheating.Referto the Engine

Owner's Manualfor enginecleaning ser-

vice intervals andinstructions. Besure

thatthe muffler iscool beforeservicingthe

engine.

AIRCLEANERSERVICE

Theair cleaner filters dirt and dust out of

the air before it enters the carburetor.Op-

eratingthe enginewith a dirty, cloggedair

filter can causepoor performanceand

damageto the engine. Neveroperatethe

enginewithout the aircleanerinstalled. In-

spectand service the air cleanermore of-

ten if operating in very dusty or dirty

conditions. Referto the engine Owner's

Manualfor air cleanerserviceintervalsand

instructions.

ENGINEOIL SERVICE

Checkthe engineoil level beforeeachuse

and after every five hours of continuous

operation. Runningthe engine when it is

low on oil will quickly ruin theengine.

It is recommendedthat you changethe

motor oilafter every 10hours of operation

and even sooner when operating in ex-

tremely dirty or dustyconditions. Referto

the EngineOwner'sManualfor detailed

serviceinstructions.

A. ToChecktheEngineOil Level:

1. Parkthetiller ona levelareaandshut off

the engine.

2. Leveltheengine (usethe Depth Regula-

tor Leverto adjust the engineangle).

2O

Page 21

moving partsto come to a completestop, disconnectspark plug wireand move wireawayfrom

WARNING: Beforeinspecting, cleaningor servicing the machine,shut offengine,wait for all

spark plug. Failureto follow these instructions canresult in serious personalinjury orproperty

damage.

3. Cleanaround the oil dipstick or oil fill

tube (whicheverapplies) to preventdirt

from failing into the crankcase.

4. Onengines with an oil fill tube, remove

the fill cap and add oil (if required) until it

reachesthetop ofthefill tube. Reinstallthe

fill cap.

5. Onengines with a dipstick, remove it

and wipe it clean. Reinsertthe dipstick,

tighten it securely,and removeit. Add oil

asneededto bring the levelupto theFULL

mark. Wipe dipstick cleaneachtime oil

levelis checked. Donot overfill. Tighten

dipstick securely.

B. ToChangetheEngineOil:

Changethe engine oil as instructed in the

EngineOwner's Manual.

SPARKPLUGSERVICE

Inspect andcleanor replacethespark plug

after every 100 operating hours or annual-

ly. Referto the EngineOwner'sManualfor

spark plug serviceinstructions.

In some areas,local law requires using re-

sistor spark plugsto suppress ignition sig-

nals. If the enginewas originally equipped

with a resistor spark plug, use the same

type for replacement.

SPARKARRESTERSCREEN

SERVICE

If the engine muffler is equipped with a

spark arresterscreen, removeand cleanit

according to the service intervalsand in-

structions in the EngineOwner'sManual.

THROTTLELEVERADJUSTMENT

If the engine does not respondto various

throttle leversettings, referto the Engine

Owner'sManual for serviceinformation or

contact your localauthorized engine

dealer.

WARNING: Operators

shallnottamper withtheengine

governorsettings onthe

machine;the governor controls

the maximum safeoperating

speedto protect theengineand

all moving parts from damage

causedby overspeed.

Authorizedserviceshall be

sought if aproblem exists.

CARBURETOR/GOVERNOR

CONTROLADJUSTMENTS

Thecarburetor wasadjusted at the factory

for best operatingspeed. Referto the En-

gine Owner's Manualfor any adjustment

information or seeyour authorizedengine

dealer.

Thegovernor controls the maximumsafe

operatingspeedand protects the engine

andall moving partsfrom damagecaused

by overspeeding.Donot tamper with the

enginegovernor settings.

OFF-SEASONSTORAGE

Whenthetiller won't be usedfor an

extendedperiod, prepareit for storageas

follows:

1. Cleanthetiller and engine.

2. Do routine tiller lubrication andcheck

for looseparts and hardware.

3. Protectthe engine and perform recom-

mendedengine maintenanceby following

the storage instructions found in the

EngineOwner'sManual. Besureto protect

the fuel lines, carburetor and fuel tank

from gum deposits byremoving fuel or by

treating fuel with a fuel stabilizer (follow

enginemanufacturer'srecommendations).

4. Store unit in a clean,dry area.

5. Neverstore thetiller with fuel in thefuel

tank in an enclosedareawhere gasfumes

could reachan open flame or spark, or

whereignition sourcesare present (space

heaters,hot water heaters,furnaces, etc.).

21

Page 22

moving partsto come to a completestop, disconnectspark plug wireand move wireawayfrom

WARNING: Beforeinspecting, cleaningor servicing the machine,shut offengine,wait for all

spark plug. Failureto follow these instructions canresult in serious personalinjury orproperty

damage.

TROUBLESHOOTING

PROBLEM

Enginedoes notstart

Enginerunspoorly.

Engineoverheats.

Enginedoesnotshotoff

WheelsandTineswillnotturn

Tinesturn,butwheelsdon't,

WheelsTurn,butTinesDon't,

Poor tilling performance.

POSSIBLECAUSE

1. Spark plug wire disconnected.

2. Engine Throttle Control Lever incorrectly set.

3. Fueltank empty.

4. Choke control (if so equipped) in incorrect position.

5. Stale gasoline.

6. Dirty airfilter.

7. Defective or incorrectly gapped spark plug.

8. Carburetor out of adjustment.