Troy-Bilt TUFFY 634BM, TUFFY 634FM, Tuffy 630C, Bronco 634F, Super Bronco 634B Operator's Manual

Page 1

O TRO_ BILT

Operator's Manual

Rear-tine Tiller Models

630C Tuffy_

634Fm BroncoTM

634Bm Super BroncoTM

Model 634B Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable

local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of

California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or

contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTEDINU.S.A. FORM NO. 770-10594C

11/25/02

Page 2

TABLEOFCONTENTS

Content Page

CallingCustomerSupport.......................................................................................................2

Safety......................................................................................................................................3

Assembly................................................................................................................................6

FreaturesandControls............................................................................................................lg

Operation................................................................................................................................12

Maintenance...........................................................................................................................17

Off-SeasonStorage.................................................................................................................21

Troubleshooting......................................................................................................................22

Parts List ................................................................................................................................23

WarrantyInformation..............................................................................................................BackCover

FINDINGMODELNUMBER

This Operator'sManualisan important partof your newRear-tineTiller. It will helpyouassemble, prepareandmaintain the unit for

best performance. Pleasereadand understandwhat it says.

information from itinthespace providedbelow.This information isvery importantif you needhelpfrom our Customer

Beforeyoustart assemblingyour new equipment,pleaselocatethe modelplateon the equipment andcopy the

Support Departmentor an authorizeddealer.

You can locatethe model number by lookingon the rearsurfaceof thetine shield.A sample model plate is explainedbelow. For

future reference,pleasecopy the modelnumber andtheserial numberof the equipment inthe spacebelow.

Copythe model numberhere:

Copythe serial numberhere:

O TRII_BILT • _."__-_ _. _

www.troybilt.com CLEVELAND,OH44136

• 866-840-648_

330-558-7220

ENGINEINFORMATION

Theengine manufacturer is responsiblefor allengine-relatedissueswith regardto performance,power-rating, specifications,

warrantyand service. Pleasereferto the enginemanufacturer's Owner's/Operator'sManualpackedseparatelywith your unitfor more

information.

CALLINGCUSTOMERSUPPORT

If you havedifficulty assemblingthis product or haveanyquestionsregarding thecontrols, operationor maintenanceofthis unit,

pleasecall the CustomerSupport Department.

Call1- (330) 558-7228 or 1- (866) 848-6483to reacha Customer Support representative.Pleasehaveyour unit's

model numberandserial number readywhen you call.Seeprevioussection to locatethis information. You will be

askedto enterthe serial

Page 3

SECTION1: SAFETY

Thismachinemeetsvoluntarysafetystan-

dardB71.8-1996, whichissponsoredbythe

OutdoorPowerEquipmentInstitute,Inc.,

andis publishedbythe AmericanNational

StandardsInstitute.

WARNING

The engine exhaust from this productcontains

chemicals known to the State ofCalifornia to

cause cancer, birth defects or other reproduc-

SafetyAlertSymbol

in this manual and on the unit to alert

This is a safety alert symbol. Itis used

you to potential hazards. When you

see this symbol, read and obey the

message that follows it. Failu re to obey

safety messages could result in

persona t injury or property damage.

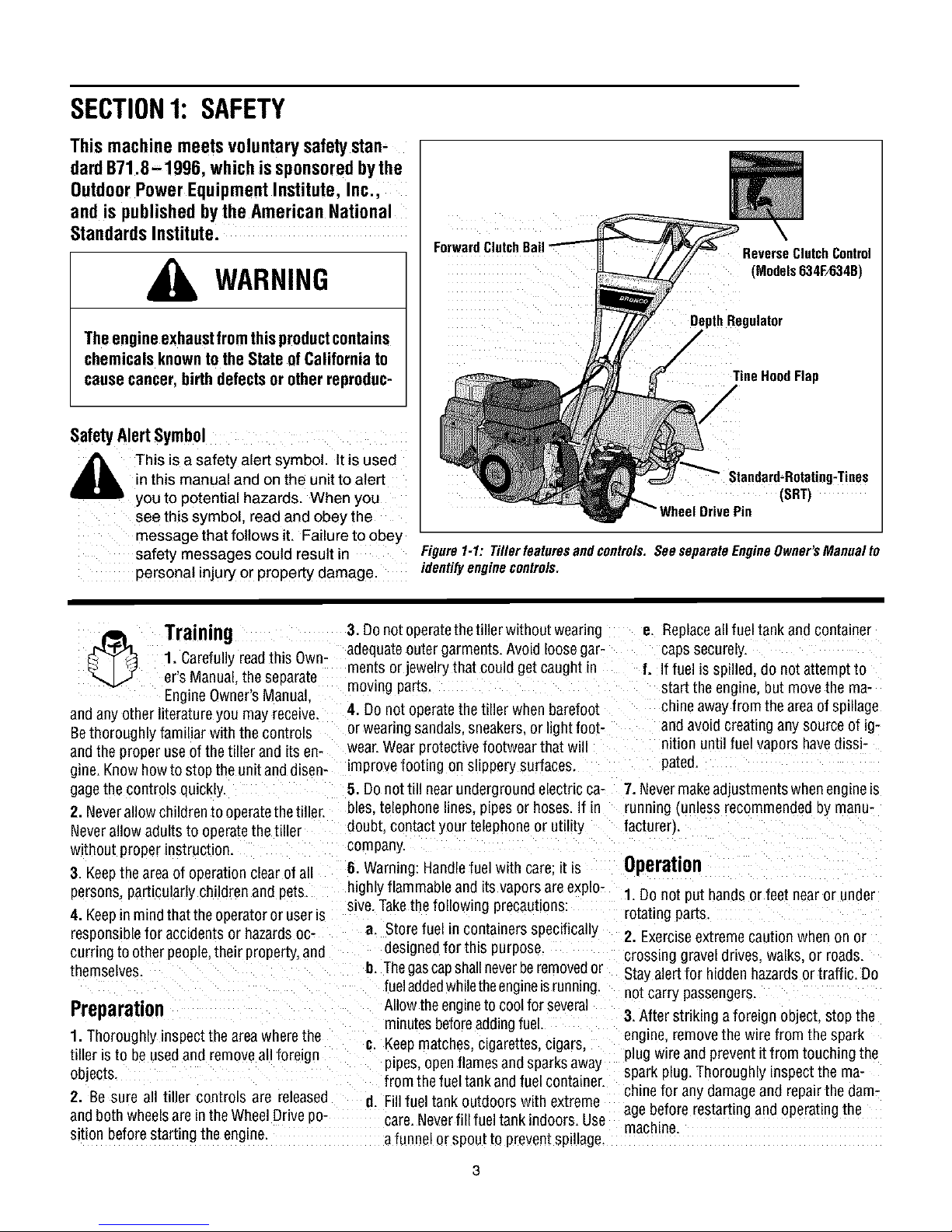

ForwardClutchB_

DepthRegulator

ReverseClutchControl

(Models634F/634B)

TineHoodFlap

/

(SRT)

Figure1-1:Tillerfeaturesandcontrols.SeeseparateEngineOwner'sManualto

identifyenginecontrols.

3. Donot operatethetiller without wearing

1. Carefullyreadthis Own-

Training

er's Manual.the separate

EngineOwner'sManual

andany other literatureyou may receive.

Bethoroughly familiar withthe controls

andthe proper use of the tiller and its en-

gine.Know howto stop the unitand dlsen- improve footing on slippery surfaces.

gagethe controls quickly.

2. Neverallow children to operatethetiller.

Neverallow adults to operatethe tiller

without proper instruction.

3. Keepthe area of operation clear of all

persons,particularly children and pets

4. Keepin mindthat theoperatoror useris

responsiblefor accidents or hazardsoc-

curring to other people,their property,and

themselves.

Preparation

1.Thoroughly inspectthe areawherethe

tiller isto be usedand removeall foreign

objects.

2. Be sure all tiller controls are released

andboth wheelsare in theWheelDrive po-

sition beforestarting the engine.

adequateouter garments. Avoid loosegar-

ments or jewelry that could get caught in

moving parts.

4. Do not operatethe tiller when barefoot

or wearing sandals,sneakers,or light foot-

wear.Wearprotective footwear that wi

5. Donottill near underground electricca- 7. Nevermakeadjustments when engine_s

bles. telephone lines, pipes or hoses.If in running {unlessrecommended oy manu-

doubt contact your telephoneor utility facturer).

company.

6. Warning: Handlefuel with care: it is Operation

highly flammableand its vaporsare explo-

sive.Takethe following precautions:

a. Storefuel in containersspecifically

desLgnedfor this 3urpose.

I]. Thegascapshallneverberemovedor

fueladdedwhiletheengineis running.

Allow theengineto coolfor several

m_nutesbeforeaddingfuel.

#. Keepmatches, cigarettes, cigars,

ptpes,openflames and sparksaway

from the fueltank and fuel container.

d. Fillfuel tank outdoors with extreme

care.Neverfill fueltank indoors. Use

a funnel orspou[ to preventspillage.

e. Replaceall fuel tank and container

caps securely.

f. If fuel is spilled, do not attempt to

start the engine, but movethe ma-

chine awayfrom the areaof sp_llage

and avoid creating any source of ig-

lit{on until fuel vapors havedissi-

pated.

1. Do not put hands or feet near or under

rotating parts

2. Exerciseextremecaution when on or

crossing gravel drives, walks, or roads.

Stayalertfor hidden hazardsor traffic. Do

not carry passengers.

3.Nter striking a foreign object, stop the

engine,removethe wire from the spark

plug wire andpreventitfrom touching the

spark plug. Thoroughly inspectthe ma-

chinefor any damageand repairthe dam-

agebefore restarting andoperatingthe

machine.

Page 4

4. Exercisecautionto avoid slippingor fall- If indoubtaboutthetilling conditions,al- 24. Donot touch engine parts which may

ing.

5. If the unit should start to vibrate aonor-

really,stop the engine,disconnect the

spark plug wire and prevent itfrom touch-

ing the sparkplug,and checkimmediately

for the cause. Vibration is generally a

warning of trouble.

6. Stopthe eng he.disconnectthe spark

plugwire and prevent itfrom touching the

spark plug, whenever you leavethe oper-

atingposition, beforeuncloggingthetines.

or whenmaking any repairs, adjustments

or inspections.

7. Takeall possible precautionswhen leav-

ing the machineunattended. Stop the en-

gine. Disconnectthe spark plug wire and

move it awayfrom thespark plug. Besure

that both wheelsare inthe Wheel Drive po-

sition.

8. Beforecleaning, repairing, or inspect-

ing, stop the engine and makecertain all

mowng parts havestopped. Disconnect

thespark plugwire and prevent itfrom

touching the spark plug to preventacci-

dentalstarting.

9. Theflapon thetine hood must bedown

when operatingthetiller.

tO. Neverusethetiller unless proper

guards, plates, or other safety protective

devicesare in place.

11. Donot run the engineman enclosed

area. Engineexhaust contains careen

monoxide gas. a deadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren andpetsaway.

13.Neveroperatethetiller underengine wheeldown slopes.

powerif the wheels are in theFreewheel

position.Inthe Freewheelposition, the

wheelswill not holdthe tiller backand the

revolving Linescould propelthetiller rapid-

ly,possibly causingloss of control. Always

engagethe wheels with the wheeldrive

pins in the Wheel Drive position before

starting the engineor engagingthe

tines/wheelswith the Forward ClutchBail

(all models_orthe ReverseClutchcontrol

(Models 634F/634Bonly}.

14. Be aware that the tiller may unex-

pectedlybounceupwardorjumpforward

if the tines shouldstrikeextremelyhard

packedsoil, frozenground,or buriedob-

stacleslike large stones, roots,or

stumps.

waysusethe followingoperatingprecau- behot from operation. Letparts cool down

tionsto assistyou inmaintainingcontrol sufficiently.

ofthe tiller: 25. Pleaseremember:Youcanalwaysstop

a. Walk behindandto oneside of the thetines andwheels by releasingthe For-

tiller, usingonehandonthe handle ward Clutch Bailor on Models 634Fand

barsRelax your arm, but usea 634B the ReverseClutchcontrol. _which-

securehandgrip.

b. Useshallower depthregulator

settings,workinggraduallydeeper

with each pass.

c. Useslowerenginespeeds.

d. Clearthe tilling area of all large

stones,rootsorotherdebris.

e. Avoidusingdownwardpressureon

thehandlebars.If needbe, use

slightupwardpressureto keep the

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the end of a row.reduceengine

speedandlift the handlebarsto

raise the tines outof the soil.

g. Inanemergency,stopthetinesand

wheels byreleasingwhichever

clutchcontrolis engaged.Do not

attemptto restrainthetiller.

15. Donot overloadthe tiller's capacityDy

attempting to till too deeplyattoo fast a

rate

16. Neveroperatethe tiller at high trans-

port speeds on hard or slippery surfaces.

Look behindand usecarewhen backing

up

17. Do not operatethetiller ona slopethai

is too steepfor safety.When onslopes,

slow down and makesure you havegood

footing. Never permit the tiller to free-

18. Neverallow bystandersnearthe umt.

19. Onlyuseattachments andaccessories

that areapprovedby the manufacturero1

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethe tiller without good

wsibility orlight.

22. Neveroperatethe tiller if you aretired:

or underthe influence ofalcohol, drugs or

medication.

23. Operatorsshall not tamper with the en-

gine-governor settings onthe machine:

the governor controls the maximum safe

operatingspeedto protectthe engine and

all movingparts from damagecaused by

overspeed. Authorized serviceshall be

sought if a problem exists.

evercontrol isengaged),or by movingthe

_gnitionswitch and/orthrottle control lever

on the engineto "OFF"or "STOP".

26. To load or unloadthe tiller, seethe in-

structions in Section4 of this Manual.

27. Useextreme caution when reversing

or pullingthe machinetowards you.

28. Start the enginecarefullyaccording to

instructionsand with feet well awayfrom

thetines.

29. Neverpickupor carry amachinewhile

theengine is running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories insafeworking condition.

2. Checkall nuts bolts, andscrews at

ervalsfor proper t_ghtnessto be surethe

equipment is insafeworking condition.

3. Neverstore thetiller with fuel inthefuel

tank insidea building where ignition sourc-

esare presentsuchashotwater andspace

heaters,furnaces, clothesdryers, stoves,

electric motors, etc.L Allow the engineto

cool neforestoring the unit inan'yenclo-

sure.

4. To reducethe chancesof afire hazard.

keepthe enginefree ofgrass, leaves,or ex-

cessivegrease.

5. Storegasolinein a cool. well-ventilated

area,safelyaway from any spark- or

flame-producing equLpment. Store gaso-

line in an approvedcontainer,safelyaway

from the reachof children.

6. Refedto the Maintenancesections of

this Manualand the separateEngineOwn-

er'sManualfor instructions if the unit isto

be stored for an extendedperiod.

7. Neverperform maintenancewhilethe

engineis runmng orthe spark plug wire is

connected,exceptwhen specificahy in-

structed to doso.

8. Ifthefueltankhastobedrained dothis

outdoors.

Page 5

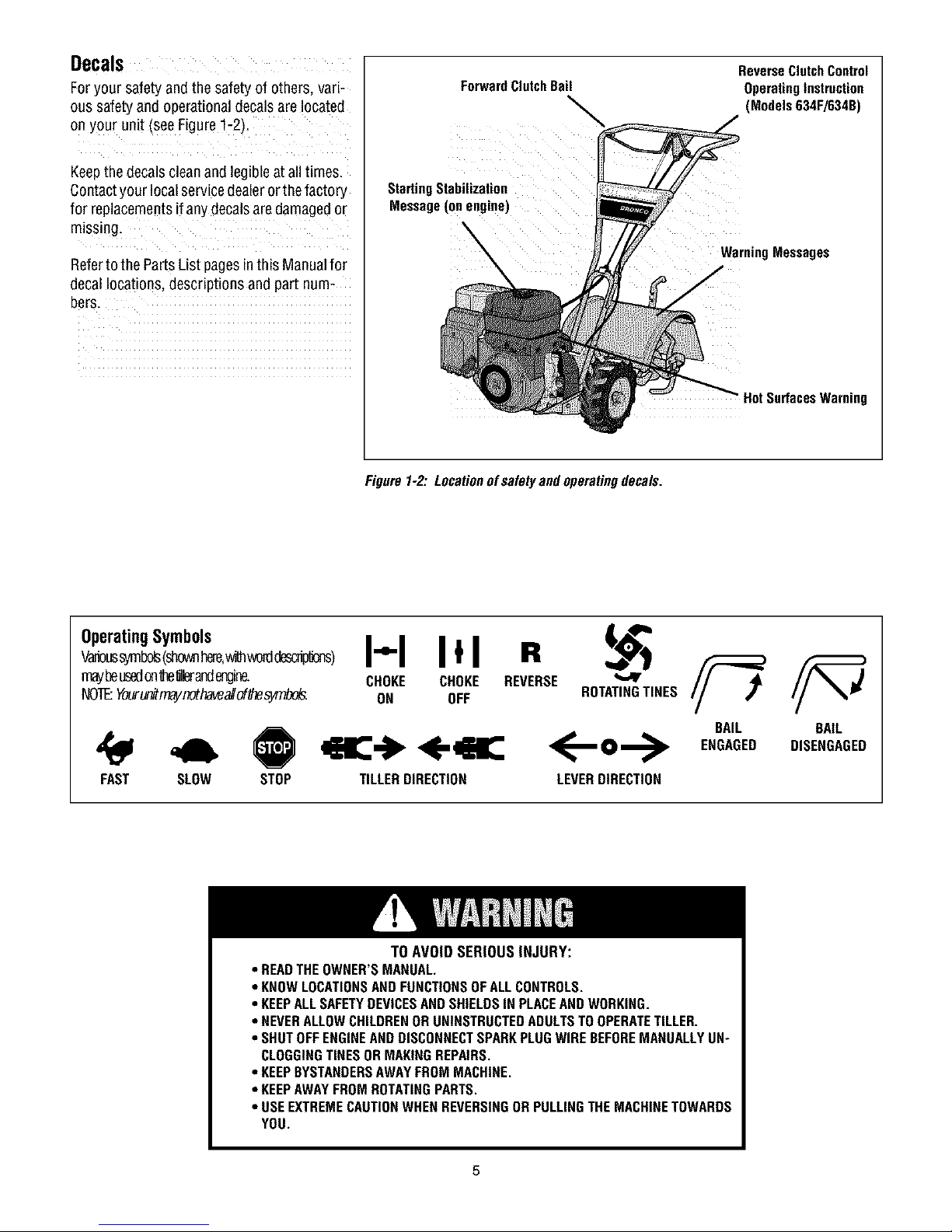

Decals

Foryour safety and the safetyof others, vari-

ous safetyand operationaldecalsare located

on your unit (seeFigure1-2)t

Keepthe decalsclean and legibleat alltimes.

Contactyour localservicedealerorthefactory

for replacementsif any decalsare damagedor

missing.

Referto the PartsList pagesinthis Manualfor

decallocations, descriptions and part num-

bers.

ForwardClutchBail

StartingStabilization

Message(onengine)

Figure1-2:Locationofsafetyandoperatingdecals.

ReverseClutchControl

OperatingInstruction

(Models634F/634B)

WarningMessages

HotSurfacesWarning

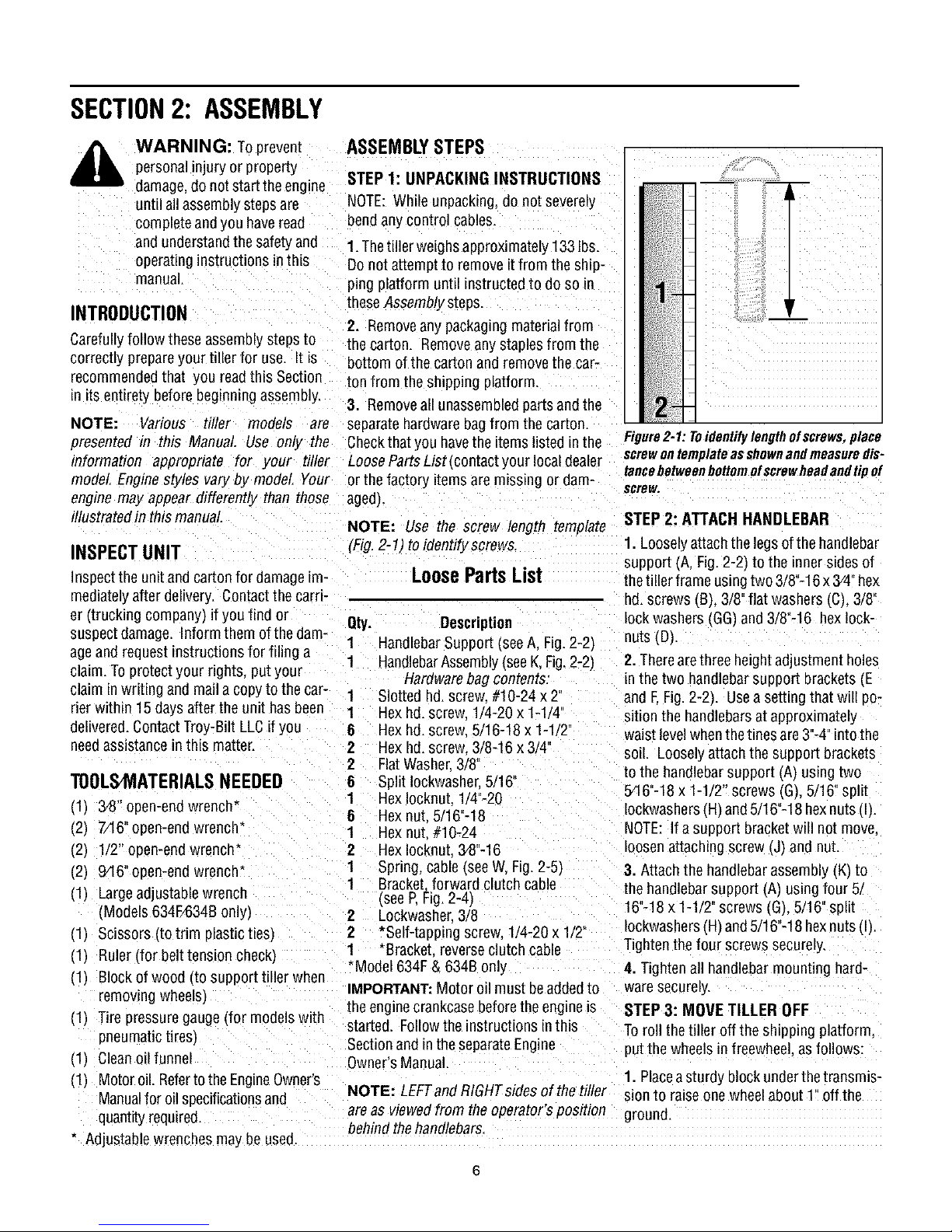

OperatingSymbols

w_s _bo_ (shownr_re,_ _crd_)

maybeusedonthellera_lmgine.

NOTEYour_mayr_thavealiof_s_.

FAST SLOW

STOP TILLERDIRECTION LEVERDIRECTION

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEAND WORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUN"

CLOGGINGTINESORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHEN REVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

I-'-I Itl R

CHOKE CHOKE REVERSE

ON OFF ROTATINGTINES

<--o-->

TO AVOID SERIOUS INJURY:

BAIL BAIL

ENGAGED DISENGAGED

Page 6

SECTION2: ASSEMBLY

WARNING: To prevent

personalinjury or property

damage,do notstart the engine

until all assemblysteps are

completeandyou have read

and understandthe safetyand

operatinginstructions in this

manual.

INTRODUCTION

Carefullyfollow these assemblysteps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in itsentirety before beginning assembly.

NOTE: Various tiller models are

presented in this Manual Use only the Checkthat you havethe items listedin the

information appropriate for your tiller LooseParts List (contactyour localdealer

model Engine styles varyby model Your or the factory itemsare missing or dam-

engine may appear differently than those aged).

illustratedin thismanual.

INSPECTUNIT

Inspectthe unitand carton for damageLm-

mediatelyafter delivery. Contactthe cam-

er (trucking company) if you find or

suspectdamage. Inform them of the dam-

ageand request instructions for filing a 1

claim. Toprotect your rights, put your

claim inwriting andma_la copyto the car- 1

rier within 15 days after the unit has been 1

delive'ed. Contact Troy-Bilt LLCil you 6

needassistancein this matter. 2

TOOLSMATERIALSNEEDED

Ill 3,8" open-endwrench* 6 Hex nut. 5/16"-18 Iockwashers(.H)and5/16"-18 hexnuts (I).

(.2) 7/16' open-end wrench" 1 Hexnut #10-24 NOTE: If a support bracketwill not move

12_ 1/2" open-endwrench* 2 HexIocknut.3,8"-16 loosenattaching screw (J) and nut.

(2) 946"open-end wrench* 1 Spring, cable(see W, Fig.2-5_ 3. Attach the handlebarassembly (.K_to

(1) Largead Jstablewrench (.seeP, Fig.2-4_ 16"-18x 1-1/2" screws (.G_,5/16" split

_Models634F/634Bonly} 2 Lockwasher 3/8

(.1J Scissors to trim plasticties/

(1) Ruler (for belttension check_

111 Blockof wood (to support tiller when

remowng wheels)

111 Tire pressure gauge(for modelswith

pneumatictires_

Ill Cleanoil funnel

111 Motoroil Refertothe Engine0wner's

Manualfor oilspecificationsand

quantityrequired.

* Adjustablewrenches mayDeused,

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE:While unpacking, do not severely

bendany control cables.

1.Thetiller weighsapproximately133 lbs.

Donot attempt to remove it from the ship-

ping platform until instructed to do so m

these Assembly steps.

2. Removeanypackagingmaterialfrom

the carton. Removeany staplesfrom the

bottom ofthe carton and removethe car-

ton from the shipping platform.

3. Removeall unassembledpartsand the

separatehardwarebagfrom the carton.

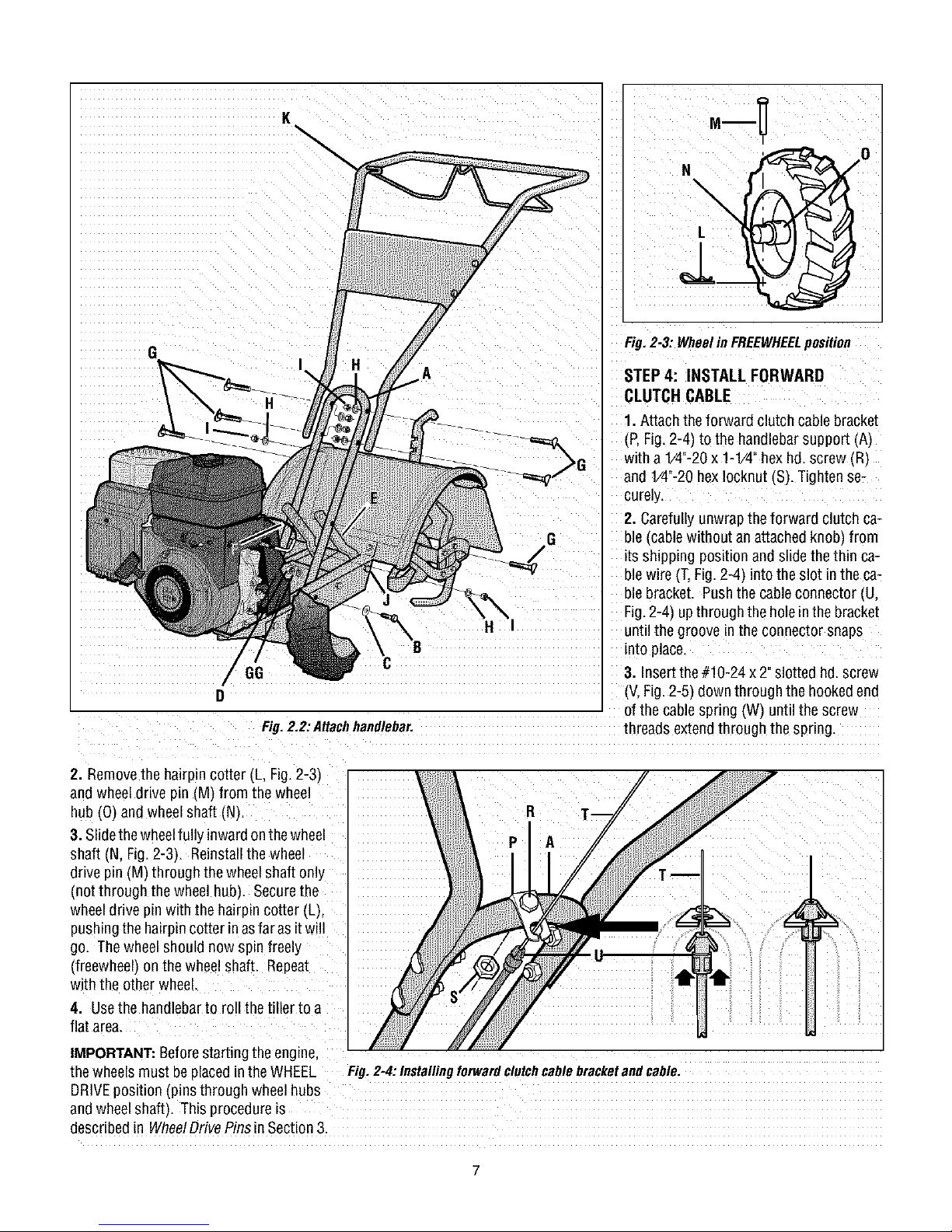

NOTE: Use the screw length template

(Fig.2-1) toidentify screws

LoosePartsList

Qty. Description

1

HandlebarSupport (seeA, Fig. 2-2_

HandlebarAssembly(seeK,Fig.2-2)

Hardwarebag contents:

Slotted hd. screw #10-24 x 2'

Hex hd. screw 1/4-20 x 1-1 '4

Hex hd. screw 5/16-18 x 1-1 2"

Hex hd. screw. 3/8-16 x 3/4

2

FlatWasher.3/8

6 Split Iockwashe_5/16"

1 HexIocknut. 1/4"-20 5Pi6"-18x 1-1/2" screws (G).5/16" split

1 Bracket.forward clutchcable the handlebarsupport (A) usingfour 5.

2

*Self-tappingscrew.1/4-20 x 1/2" IockwashersIHI and5/16"-18 hexnuts (I).

1 *Bracket reverseclutch cable

*Model 634F& 634B only

IMPORTANT:Motor oil must beaddedto

the enginecrankcase beforetheengine is

started. Followthe instructions inthis

Sectionand in the separateEngine

Owner'sManual.

NOTE: LEFTandRIGHTsidesofthetiller sion to raise one wheelabout l" off the

are as viewedfrom the operator's position ground.

behind the handlebars.

Figure2-1: Toidentifylengthofscrews,place

screwontemplateasshownandmeasuredis-

tancebetweenbottomofscrewheadandtipof

scrBw,

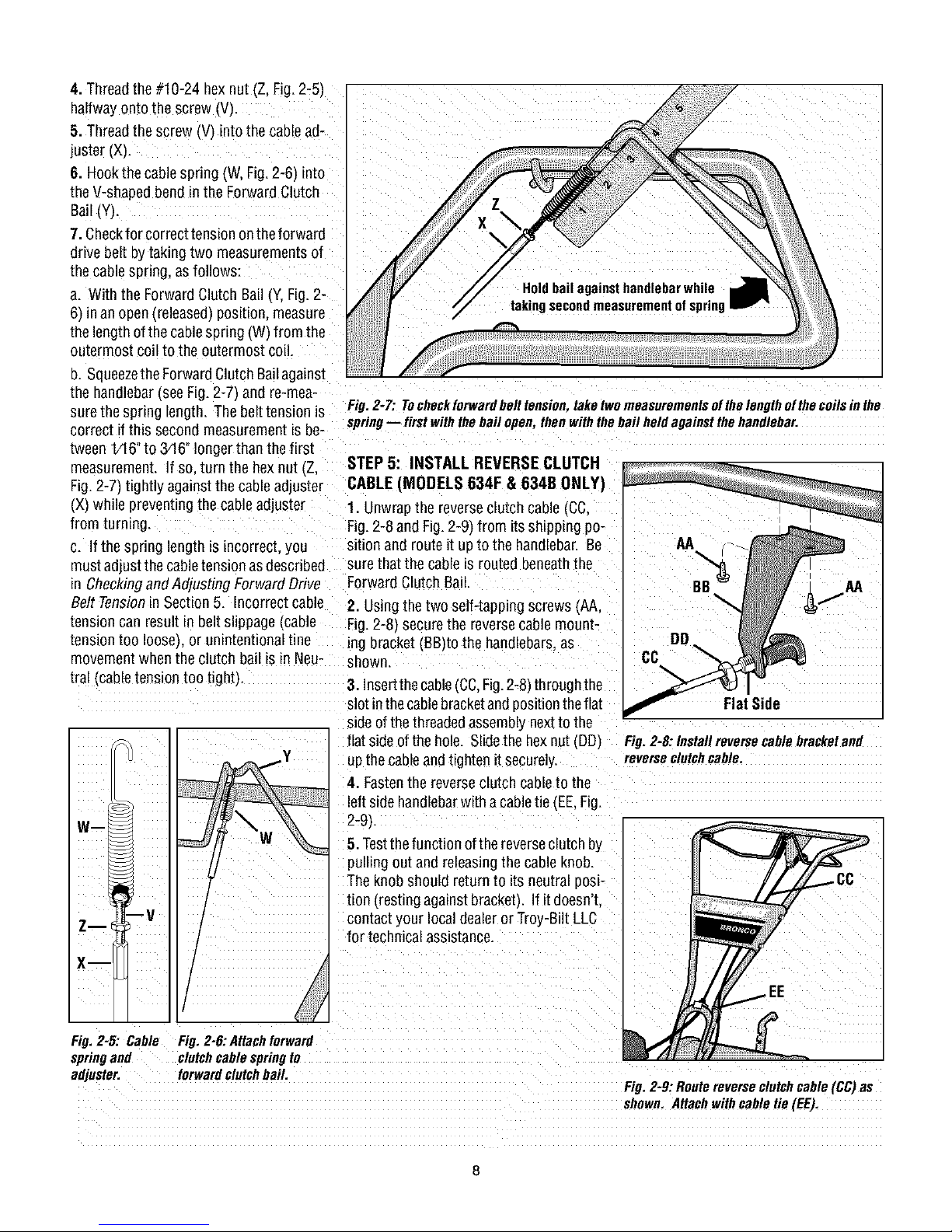

STEP 2: ATTACH HANDLEBAR

1. Looselyattach the legsof the handlebar

support (A, Fig.2-2) to the innersides of

thetiller frame usingtwo 3/8"-16x 3/4"hex

hd. screws (B), 3/8"flat washers(C), 3/8"

lock washers (GG_,and 3/8"-16 hexlock-

nuts (D_,

2. Therearethree height adjustment holes

in the two handlebarsupport brackets (.E

and E Fig. 2-2). Usea setting that will po-

sition the handlebarsat approximately

waist levelwhenthetines are3"-4"intothe

so_l. Looselyattachthe support brackets

to the handlebarsupport (.A_using two

Tightenthe four screwssecurely

4. Tighten all handlebarmounting hard-

waresecurely.

STEP3: MOVE TILLER OFF

Toroll thetiller off the shipping platform.

put the wheels in freewhee asfollows:

1. Placeasturdy block underthe transmis-

m

Page 7

Fig.2,2:AHachhandlebar, threads extendthrough the spring.

2. Removethe hairpin cotter (L, Fig.2-3)

and wheel drive pin (M) from the wheel

hub (0) and wheel shaft (N).

3. Slidethe wheelfully inwardonthewheel

shaft (N, Fig.2-3). Reinstallthe wheel

drive pin (M) through the wheelshaft only

(not through the wheel hub). Securethe

wheeldrive pin with the hairpin cotter (L),

pushingthe hairpincotter inasfar asit will

go. Thewheel should now spin freely

(freewheel) on the wheel shaft. Repeat

with the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

Fig. 2-3: Wheelin FREEWHEELposition

STEP4: INSTALL FORWARD

CLUTCH CABLE

1. Attach the forward clutch cablebracket

(P,Fig.2-4) to the handlebarsupport AI

with a1/4"-20x 1-1/42hexhd. screw (R)

and V4"-20 hexIocknut (S). Tightense-

curely.

2. Carefullyunwrapthe forward clutch ca-

ble (cable without anattachedknob, from

its shipping position and slidethe thin ca-

ble wire (T.Fig.2-4 intothe slot in the ca-

ble bracket. Pushthe cable connector (U.

Fig.2-4) upthrough the holein the bracket

until the groove inthe connector snaps

into place.

3. Insertthe #10-24 x 2"slotted hd.screw

(V,Fig.2-5) downthrough the hookedend

of the cable spring (W) until the screw

IMPORTANT:Beforestarting theengine,

thewheels must beplacedin the WHEEL Fig.2=4:Installingforwardclutchcablebracketandcable.

DRIVEposition (pins through wheelhubs

andwheelshaft). This procedureis

described in WheelDrivePinsin Section3.

Page 8

4. Threadthe #10-24 hexnut (Z,Fig. 2-5)

halfwayonto the screw (V).

5. Threadthe screw IV_into thecable ad-

juster (X).

6. Hookthe cable spring (W,Fig.2-6) into

theV-shaoedbend in the ForwardClutch

Bail _Y).

7. Checkfor correcttension ontheforward

drive belt by taking two measurementsof

thecablespnng, asfollows:

a. With the ForwardClutch Bail(Y,Fig.2-

6/in an open(released)position, measure

thelength ofthecablespring (W from the

outermost coil to the outermost coil.

n. Squeezethe ForwardClutchBailagainst

the handlebar(see Fig. 2-7_and re-mea-

surethe spring length, Thebelt tensionis

correct if this second measurementis be-

Fig.2-7: Tocheckforwardbelttension,taketwomeasurementsofthelengthofthecoilsinthe

spring-- firstwiththebailopen,thenwiththebailheldagainstthehandlebar.

tween 1/16"to 3/16"longer than thefirst

measurement. If so. turn the hexnut (Z.

Fig.2-7) tightly against the cableadjuster

(X_while preventingthe cableadjuster

from turnmg.

c. Ifthe spring length is incorrect, you

mustadjust the cabletension asdescribed

STEP 5: INSTALL REVERSECLUTCH

CABLE (MODELS 634F & 634B ONLY)

1. Unwrapthe reverseclutch cable(CC.

Fig.2-8 and Fig.2-9_from itsshipping po-

sition and route it upto the handlebar. Be

surethat the cableis routed beneaththe

in Checkingand Adjustin_ ForwardDrive Forward Clutch Bail.

Belt Tensionin Section 5. Incorrectcable

tension can result in belt slippage Icable

tension too IooseLor unintentional tine

movement when the clutch bail is in Neu-

tral Icable tension too tight}

2. Usingthe two self-tapping screws (AA,

Fig.2-8) securethe reversecable mount-

ing bracket(BB)to the handlebars,as

show_

3. Insertthe cable(CC,Fig.2-8) through the

slot inthecablebracketandpositiontheflat

sideofthe threadedassemblynextto the

flat sideof the hole. Slidethe hex nut (DD/

up the cable andtighten it securely

4. Fastenthe reverseclutch cable to the

left side handlebarwith a cabletie (EE,Fig.

Wm

2-9L

5. Testthefunction ofthe reverseclutch by

pulling out and releasing the cableknob.

Theknob should return to its neutral posi-

tion (resting against bracketL Ifit doesn't.

Zm

contact your localdealer or Troy-Bilt LLC

for technical assistance.

X--

CC

Flat Side

Fig. 2-8: Install reverse cable bracketand

reverseclutch cable,

Fig, 2-5: Cable

springand

adjuster.

Fig. 2-6: Attachforward

clutch cable spring to

forwardclutchbail.

Fig.2-9:Routereverseclutchcable(CC)as

shown.Attachwithcabletie(EL:).

Page 9

31bY I_: L;I'IEL;KLEVEL UI-

Thetransmission wasfilled with gearoil at

thefactory.However,youshouldcheckthe

gearoil levelatthis timeto makecertain it

is correct.

IMPORTANT:Donot operatethe tiller if the

gearoil levelis low. Doingso will result in

severedamageto thetransmission com-

ponents.

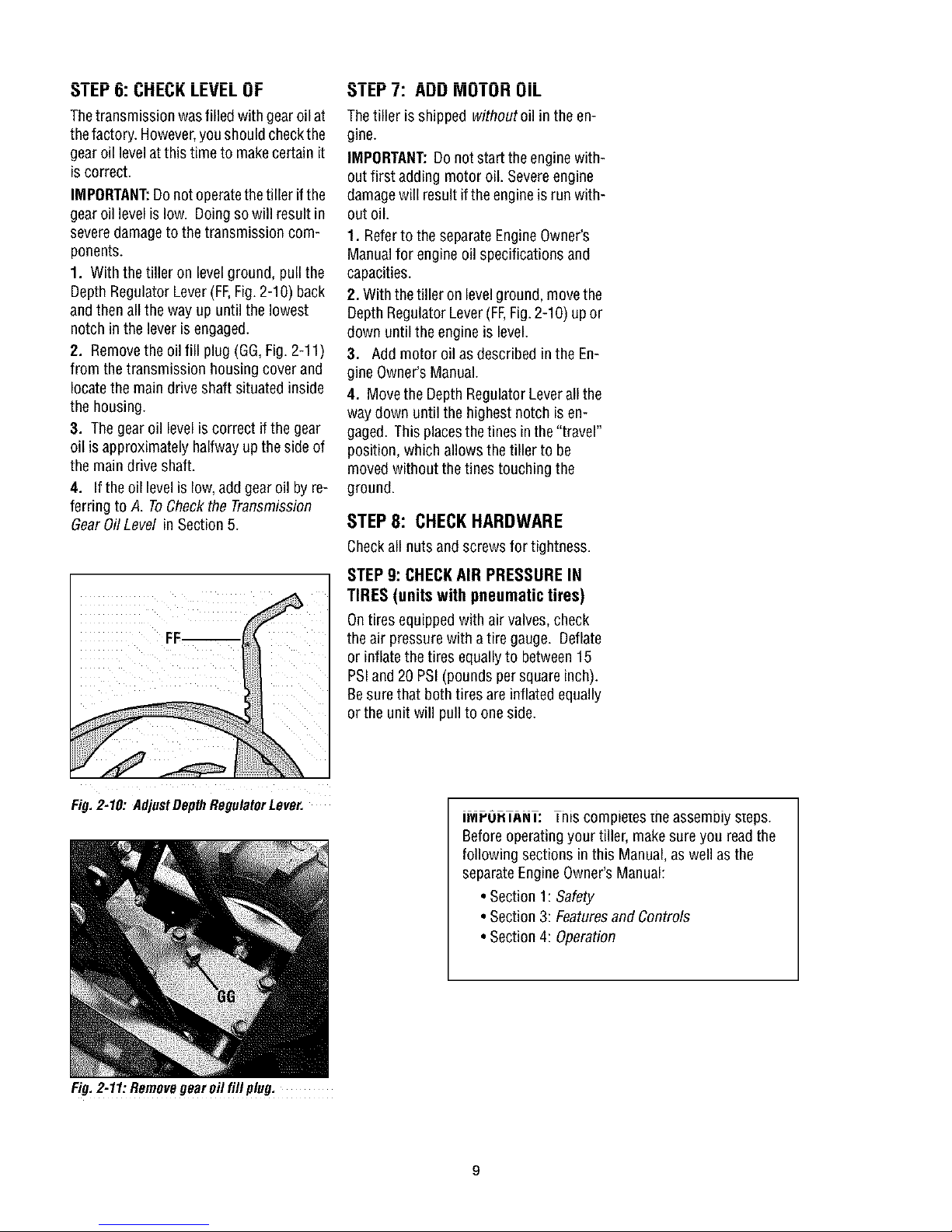

1. With the tiller on levelground, pull the

Depth RegulatorLever(FF,Fig.2-10) back

andthen all the way up until the lowest

notch inthe lever isengaged.

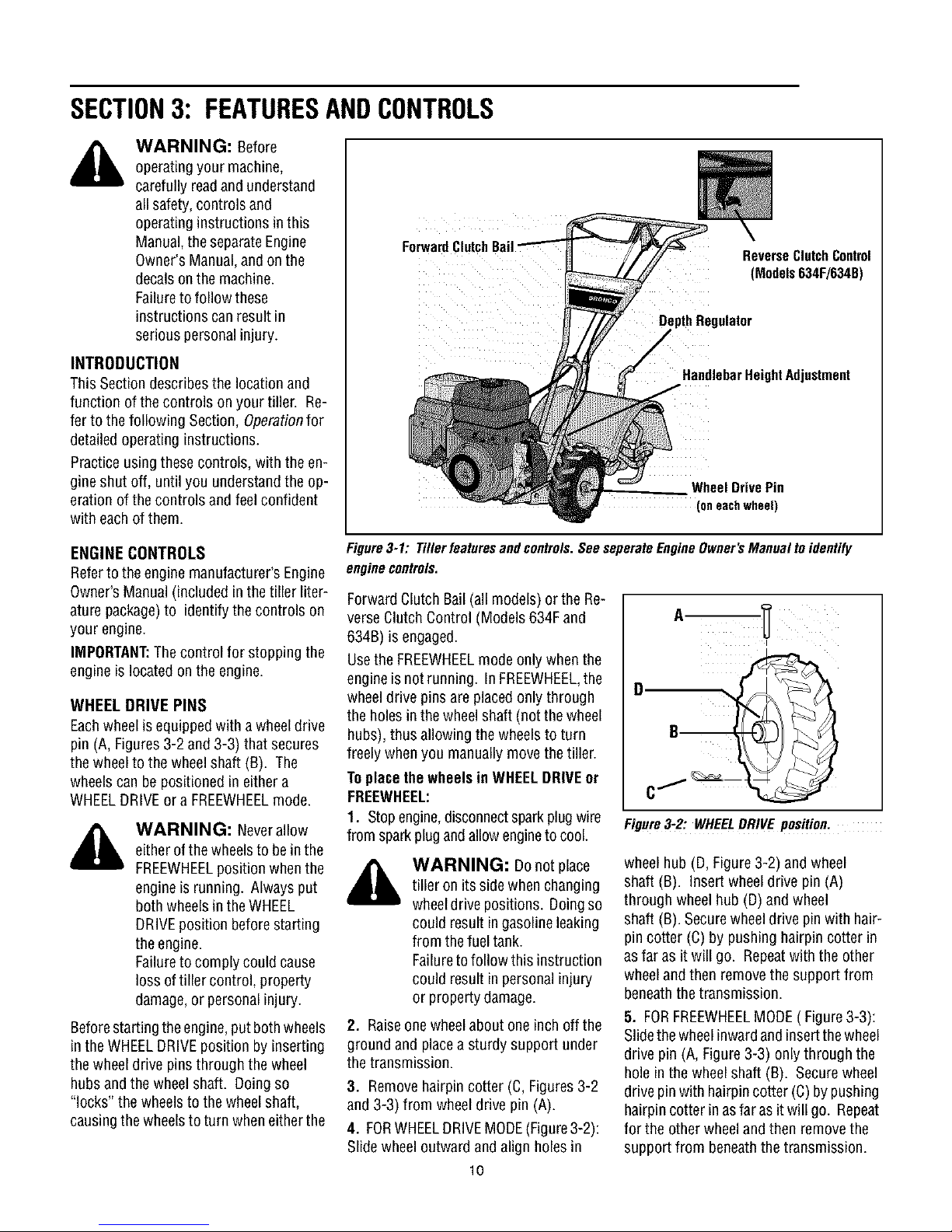

2. Removethe oil fill plug (GG,Fig.2-11)

from the transmission housingcover and

locatethe main drive shaft situated inside

the housing.

3. Thegear oil level is correct ifthe gear

oil isapproximately halfwayup theside of

the maindrive shaft.

4. If the oil levelis low,add gear oil byre-

ferring to A. ToCheckthe Transmission

GearOil Level inSection 5.

_IbY I: AUU MUIUH UIL

Thetiller isshipped withoutoil in theen-

gine.

IMPORTANT:Do not start theengine with-

outfirst adding motor oil. Severeengine

damagewill resultifthe engineis run with-

out oil.

1. Referto the separateEngineOwner's

Manualfor engine oil specifications and

capacities.

2. With thetiller on levelground, movethe

Depth RegulatorLever(FF,Fig.2-10) upor

down until the engineis level.

3. Add motor oil asdescribed in the En-

gine Owner'sManual.

4. Movethe DepthRegulatorLeverall the

way down until the highest notch is en-

gaged. This placesthetines in the "travel"

position, which allows the tiller to be

moved without thetines touching the

ground.

STEP8: CHECKHARDWARE

Checkall nuts and screws for tightness.

STEP 9: CHECKAIR PRESSURE IN

TIRES (units with pneumatic tires)

Ontires equipped with air valves, check

theair pressurewith atire gauge. Deflate

or inflatethe tires equallyto between15

PSIand20 PSI(pounds per squareinch).

Besure that both tires are inflated equally

orthe unit will pullto one side.

Fig. 2-10: AdjustDepth RegulatorLever.

Fig.2-11:Removegearoil fill plug,

IMrU. lANl: his compie[esme assemoiy steps.

Beforeoperatingyour tiller, makesure you readthe

following sections in this Manual,as well as the

separateEngineOwner'sManual:

• Section1: Safety

• Section3: Featuresand Controls

• Section4: Operation

Page 10

SECTION3: FEATURESANDCONTROLS

WARNING: Before

operatingyour machine,

carefully readand understand

all safety, controls and

operatinginstructions in this

Manual,the separateEngine

Owner's Manual,and on the

decalson the machine.

Failureto follow these

instructions canresult in

serious personal injury.

INTRODUCTION

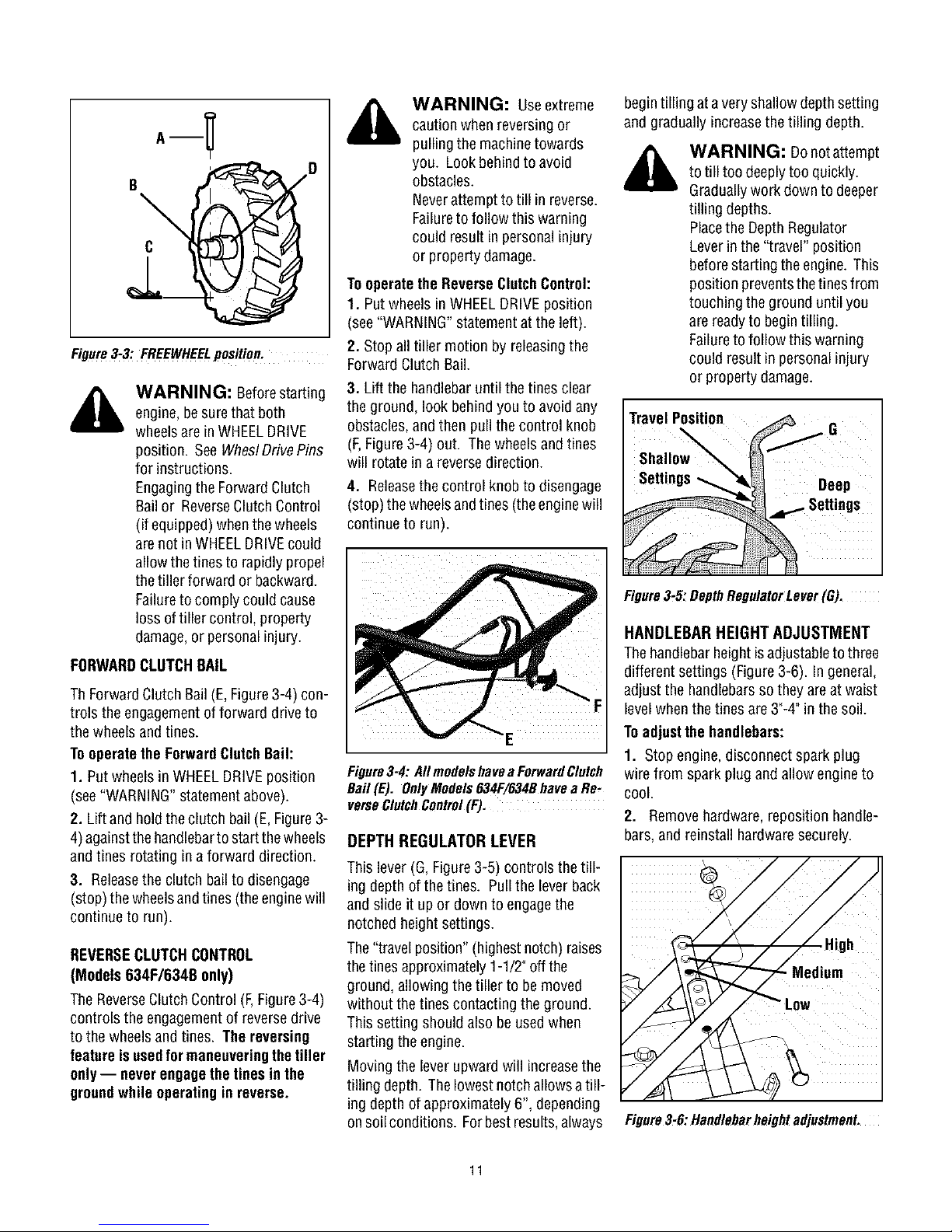

This Section describesthe location and

function of the controls onyour tiller. Re-

ferto thefollowing Section,Operationfor

detailedoperating instructions.

Practiceusing these controls, with the en-

gine shut off, until you understandthe op-

eration ofthe controls andfeelconfident

with eachof them.

Forward

Reverse ClutchControl

(Models634F/634B)

DepthRegulator

Handlebar HeightAdjustment

Wheel Drive Pin

(oneachwheel)

ENGINE CONTROLS

Referto the engine manufacturer's Engine

Owner'sManual (included inthe tiller liter-

ature package)to identify the controls on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is locatedon the engine.

WHEEL DRIVE PINS

Eachwheel is equippedwith awheeldrive

pin (A, Figures3-2 and 3-3) that secures

thewheelto the wheel shaft (B). The

wheelscan be positioned ineither a

WHEELDRIVEora FREEWHEELmode.

WARNING: Neverallow

eitherof thewheelsto bein the

FREEWHEELposition whenthe

engineis running. Alwaysput

both wheelsin theWHEEL

DRIVEposition beforestarting

theengine.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

Beforestarting theengine,put both wheels

in the WHEELDRIVEposition byinserting

thewheel drive pins through the wheel

hubsand the wheel shaft. Doingso

"locks" the wheels to the wheel shaft,

causingthe wheelsto turn wheneitherthe

Figure3-1: Tillerfeaturesandcontrols.SeeseperateEngineOwner'sManualtoidentify

enginecontrols.

Forward Clutch Bail (all models) or the Re-

verseClutch Control (Models 634Fand

634B) is engaged.

Usethe FREEWHEELmode only whenthe

engineis not running. In FREEWHEEL,the

wheeldrive pins are placed only through

theholes in thewheelshaft (not the wheel

hubs), thus allowing the wheelsto turn

freely whenyou manuallymovethe tiller.

Toplacethe wheels in WHEELDRIVEot

FREEWHEEL:

1. Stopengine,disconnectsparkplugwire

from sparkplug andallowengineto cool.

WARNING: Donot place

tiller on its side when changing

wheeldrive positions. Doing so

could result in gasoline leaking

from thefuel tank.

Failureto follow this instruction

could result in personal injury

or propertydamage.

2. Raiseonewheelabout one inch off the

ground and placea sturdy support under

thetransmission.

3. Removehairpin cotter (C, Figures3-2

and 3-3) from wheel drive pin (A).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheel outward and align holes in

10

Figure3-2: WHEELDRIVE position.

wheelhub (D,Figure3-2) and wheel

shaft (B). Insert wheeldrive pin (A)

through wheel hub (D)and wheel

shaft (B). Securewheeldrive pinwith hair-

pin cotter (C) by pushing hairpincotter in

asfar as it will go. Repeatwith the other

wheeland then removethesupport from

beneaththe transmission.

5. FORFREEWHEELMODE( Figure3-3):

Slidethe wheelinwardand insertthewheel

drive pin (A, Figure3-3) onlythrough the

hole in the wheel shaft (B). Secure wheel

drive pinwith hairpincotter (C)by pushing

hairpin cotter inasfaras it will go. Repeat

for the other wheeland then removethe

support from beneaththe transmission.

Page 11

Figure3-3: FREEWHEELposition.

,_ WARNING: Useextreme

caution when reversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.

Neverattempt totill inreverse.

Failureto follow this warning

could result in personal injury

or propertydamage.

Tooperatethe ReverseClutchControl:

1. Putwheels in WHEELDRIVEposition

(see"WARNING"statementat the left).

2. Stopall tiller motion by releasingthe

Forward Clutch Bail.

begintilling at avery shallow depthsetting

and gradually increasethe tilling depth.

WARNING: Donotattempt

totill too deeply too quickly.

Graduallywork downto deeper

tilling depths.

Placethe DepthRegulator

Leverin the "travel" position

beforestartingthe engine. This

position preventsthetines from

touching the grounduntil you

arereadyto begintilling.

Failureto follow this warning

could result in personalinjury

or property damage.

_, WARNING: Beforestarting 3. Lift the handlebaruntil the tines clear

engine,besurethat both theground, look behindyou to avoid any

wheelsare in WHEELDRIVE obstacles,and then pullthe control knob

position. SeeWheslDrivePins (F,Figure3-4) out. The wheelsand tines

for instructions, will rotate in a reversedirection.

Engagingthe ForwardClutch 4. Releasethe control knob to disengage

Bail or ReverseClutchControl (stop)the wheelsand tines (the enginewill

(if equipped) whenthewheels continue to run).

arenot in WHEELDRIVEcould

allowthe tines to rapidly propel

thetiller forward or backward.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

FORWARDCLUTCHBAIL

ThForwardClutch Bail(E,Figure3-4) con-

trols the engagementofforward drive to

thewheelsand tines.

Tooperatethe ForwardClutchBail:

1. Put wheelsin WHEELDRIVEposition Figure3-4:AIImodelshaveaForwardClutch

(see"WARNING"statementabove). Bail (E). OnlyModels634F/g34Bhavea Re,

verseClutchControl(F).

2. Lift and hold theclutch bail (E, Figure 3-

4)againstthehandlebartostartthewheels DEPTH REGULATOR LEVER

andtines rotating ina forward direction.

This lever (G,Figure3-5) controls the till-

3. Releasethe clutch bail to disengage ing depth of the tines. Pull the leverback

(stop) the wheelsandtines (theenginewill and slide it up ordown to engagethe

continue to run). notched height settings.

Figure3-5:DepthRegulatorLever(GJ.

HANDLEBAR HEIGHT ADJUSTMENT

Thehandlebar heightisadjustableto three

different settings (Figure3-6). In general,

adjust the handlebarsso they areat waist

levelwhenthe tines are 3"-4" in the soil.

Toadjustthe handlebars:

1. Stop engine, disconnect spark plug

wire from spark plugand allow engine to

cool.

2. Remove hardware,reposition handle-

bars, and reinstall hardwaresecurely.

REVERSECLUTCHCONTROL The"travel position"(highest notch) raises

(Models 634F/634B only) thetines approximately1-1/2"off the

TheReverseClutch Control (F,Figure3-4) without the tines contacting the ground.

controls the engagementof reverse drive This setting should also be usedwhen

to the wheelsand tines. Thereversing starting the engine.

featureis usedfor maneuveringthe tiller

only-- neverengage the tines in the Moving the leverupward will increasethe

groundwhile operatingin reverse, tilling depth. Thelowest notch allowsa till-

ground,allowing the tiller to be moved

ing depth of approximately 6", depending

on soil conditions. Forbestresults,always

11

Figure3-6:Handlebarheightadjustment.

Page 12

SECTION4: OPERATION

WARNING: Before ReverseClutchControl

operatingyour machine, (Models634F/634B)

carefully readand understand

all safety (Section 1),controls

(Section 3) and operating

instructions (Section 4) inthis

Manual,the separateEngine

Owner's Manual,and on the Clutch Bail

decalson the machine.

Failureto follow these

instructions canresult in

serious personal injury.

INTRODUCTION

Readthis OperationSection and the sepa-

rate EngineOwner's Manualbeforeyou

start the engine. Then,takethe time to fa-

miliarize yourself with the basicoperation

of thetiller before using it in the garden.

Findan open,levelareaand practiceusing

thetiller controls without thetines engag-

ing the soil (put tines in "travel" setting).

Onlyafter you've becomecompletely fa-

miliar with thetiller shouldyou begin using

it in the garden.

BREAK-IN OPERATION

Perform the following maintenanceafter

thefirst two (2) hours of new operation

(seeMaintenanceSection in this manual

and in the EngineOwner'sManual).

1. Changeengine oil.

2. Checkfor looseor missing hardwareon

unit. Tightenor replaceas needed.

3. Checktension onforward drive belt.

4. Checktransmission gear oil level.

STARTINGANDSTOPPING

Pre-StartChecklist

With the sparkplug wire disconnected

from the sparkplug,perform thefollowing

checksand services beforeeach use:

1. Readthe Safetyand ControlsSections

in this manual. Readthe separateEngine

Owner'sManual providedwith the unit.

2. Putthewheels intheWHEELDRIVE

position (wheel pins must bethrough

holes in wheel hubs and wheel shaft).

3. Checkunit for loose or missing hard-

ware. Serviceas required.

4. Checkengine oil level. See Engine

Owner'sManual.

Pin

Fig, 4-1

5. Checkthatall safetyguardsand covers

are in place.

6. Checkair cleanerand enginecooling

system. SeeEngineOwner'sManual.

WARNING: GASOLINEIS

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Follow gasolinesafety rules in

this Manual(see Section1) and

in the separateEngineOwner's

Manual.

Failureto follow gasolinesafety

instructions can result in

serious personal injury and

property damage.

7. Fillthefueltank with gasolineaccording

to the directions in theseparate Engine

Owner'sManual. Followall instructions

and safety rules carefully.

8. Attach spark plug wireto spark plug.

StartingtheEngine

Thefollowing steps describe how to start

and stop the engine.

WARNING: Donotattempt

to engagethetines or wheels

until you havereadall ofthe

operatinginstructions in this

Section. Also, reviewthesafety

rules in Section 1: Safety,and

the tiller and enginecontrols

information in Section3:

FeaturesandControls.

1. Completethe Pre-Start Checklist on

this page.

2. Putthe wheels inthe WHEELDRIVEpo-

sition (seeWheeIDrivePinsinSection 3 of

this manual).

,_ WARNING: To help

• Beforestartingengine, potbothwheels

in the WHEELDRIVE position. Never

have wheels in FREEWHEELposition

when engine is running. When the

wheels are in FREEWHEEL,they do not

hold backthe tiller and the tines could

propelthe tiller rapidly

ward orbackward.

• Before starting engine, pot Forward

Clutch Bail (all models) and Reverse

ClutchControl(Models 634F/634Bonly)

in neutral(disengaged) positionsby re-

leasing levers.

• Never run engine indoorsor in en-

closed, poorly ventilated areas. Engine

exhaust containscarbon monoxide, an

odorlessand deadlygas.

• Avoidenginemufflerandnearbyareas.

Temperaturesin theseareas mayexceed

150° F.

3. Movethe DepthRegulatorLever all the

way down to the "travel" position, sothat

thetines clearthe ground.

4. Releaseall controls on thetiller.

5. On engine'swith afuel shut-off valve,

turn valve to open position, as instructed

in the separateEngineOwner's Manual.

6. Putignition switch and/or throttle con-

trol leverlocated on engine in the "ON",

"RUN", "FAST"or "START"position, as in-

structed inthe EngineOwner's Manual.

7. Chokeor prime engine,as instructed in

EngineOwner'sManual.

8. Putone hand on fuel tank to stabilize

unit when pulling starter rope handle.

Thenuserecoil starter to start engine,as

instructed inthe EngineOwner's Manual.

Whenenginestarts, graduallymove choke

lever (if so equipped)to "NOCHOKE",

"CHOKEOFF"or "RUN" position.

9. Usethe "FAST"throttle speedsetting

whentilling.

prevent serious personalinjury

or damageto equipment:

12

Page 13

KEEPAWAYF_OMROTATING11NES.

ROTATING11NE$WILLCAUSEINJURY.

Stoppingthe EngineandTiller

1. Tostop the wheelsandtines, releasethe

ForwardClutch Bail(all models)or the Re-

verse Clutch Control (Models 634Fand

634B) -- whichevercontrol isin use.

2. Tostop theengine, putthe ignition

switch and/or thethrottle control leverin

the "OFF"or "STOP"position.

OPERATINGTHETILLER

Thefollowing operating instructionspro-

videguidelines to using your tiller effec-

tively and safely. Besureto read Tilling

Tips& Techniquesin this Section before

actually putting the tines into the soil.

NOTE:Thisis a traditional "Standard-Ro-

tating-Tine" (SRT)tiller with forward ro-

tating tines. It operatescompletely

differently from "Counter-Rotating-Tine"

(CRT)tillers or from front-tine tillers.

1. Followthe Pro-Start Checklist at the

beginning of this Section. Besurethat the

wheelsare in the WHEELDRIVEposition.

2. Movethe DepthRegulatorLeverall the

way down, sothat thetines clearthe

ground. Usethis position whenpracticing

with thetiller andwhen traveling between

tilling sites. Beforeactuallytilling, move

the leverto the desireddepth setting (see

Tilling Tips & Techniques).

3. Start engine and allow itto warm up.

Thenput throttle in "FAST"setting.

4. For forward motion of the wheelsand

tines:

(a) Pull ForwardClutch Bail (Fig. 4-1) up

againsthandlebar. Releasebailto stopfor-

ward motion of wheels and tines.

(b) Whentilling, relaxand letthe wheels

pull the unit while thetines dig. Walk be-

hindand a littleto oneside of the unit. Use

one hand, yet keepa light--but secure--

grip onthe handlebar(while keepingyour

arm loose). SeeFig.4-2. Let the unit

move at its own paceand do not push

down on the handlebarsto try and force

thetines to dig deeper--this takesweight

off the wheels,reduces traction, and caus-

esthe tines to try and propel the tiller.

WARNING: Donot push

down onthe handlebarsto try

to makethe tiller till more

deeply. This preventsthe

wheelsfrom holding the tiller

backand canallow thetines to

rapidly propelthe tiller forward,

which could result in loss of

control, property damage,or

personalinjury.

5. For reversemotion of the wheelsand

tines (Models 634F/634Bonly):

(a) Look behindand exercisecaution when

operating in reverse. Denottill while in

reverse.

(b) Stopall forward motion. Lift handle-

bar with one handuntil tines are off the

ground and then pull ReverseClutchCon-

trol knob out (seeFig.4-3). Tostop revers-

ing, let go of ReverseClutch Control knob.

(b) Swingthe handlebarto the left sothe

right wheeltakesa "step" backward.Next

swing the handlebarto the right so the left

wheel"steps" backward.Repeatasneeded.

(c) If longer distances needto becovered

in reverse,shut off the engine,then place

thetwo wheelsin FREEWHEEL.

7. ToTurnthe Tiller Around:

(a) Practiceturning thetiller in a level,

open area. Bevery carefulto keepyour

feetand legsawayfrom the tines.

(b) Tobeginaturn, liftthe handlebarsuntil

thetinesareoutofthe groundandtheengine

andtines are balancedoverthewheels(Fig.

4-4).

(c) With tiller balanced,push sidewayson

handlebarto steer in direction of turn (Fig.

4-5). After turning, slowly lowertines into

soil to resumetilling.

Fig.4-4: Tobeginturn,lift handlebarsuntil

tinesareoutofgroundandunitisbalanced.

Fig.4-2: Useonehandto guidetiller when handlebaruntil tines areoff theground.

movingforward.

Fig.4-5: Withtinesoutofground,pushhae-

dlebarssidewaystoturntiller.

Fig.4-3: Raisetinesoffgroundandlook StoppingtheTillerandEngine

behindwhenmovinginreverse. 1. Tostop thewheels and tines, release

6. To movethe Model630Cin reversefor

short distances:

(a) Releaseforward ClutchBail. Thenlift

the ForwardClutch Bail (all models) or the

ReverseClutch Control (Models 634Fand

634B) -- whichevercontrol is in use.

2. Tostop theengine, putthe ignition

switch and/orthe throttle control lever in

the "OFF"or "STOP"position.

13

Page 14

TILLING TIPS& TECHNIQUES

TillingDepths

_=i, WARNING: Before

A _• tilling, Contactyour

,m ==== telephoneor utilities

companyand inquireif

underground equipment or

linesare used on your

property.Donottill near

buried electric cables, deeper.(Wateringthe areaafew daysprior to tilling will maketilling easier,aswill lettingthe

telephone lines, pipesor newlyworkedsoil setfora dayortwo beforemakingafinal, deeptilling pass.)

hoses.

• Whencultivating(breakingupsurfacesoilaroundplantsto destroyweeds,seeFig.4-9), adjustthetines to digonly 1"to 2"deep. Using

shallowtilling depthshelpspreventinjuryto plantswhoserootsoftengrow closetothesurface. If needed,lift uponthehandlebarsslightly

to preventthetines from diggingtoo deeply.(Cultivatingona regularbasisnotonlyeliminatesweeds,it also loosensandaeratesthe soil

for bettermoistureabsorptionand fasterplantgrowth.)

• Avoid pushingdownon thehandlebarsinanattemptto forcethe tiller to dig deeper.Doing

sotakesthe weightoff the poweredwheels,causingthemto losetraction.Withoutthewheels

helpingto holdthe tiller back,thetineswill attemptto propelthetiller - often causingthetiller

to skip rapidlyacrossthe ground. (Sometimes,slight downwardpressureonthe handlebars

will helpgetthrougha particularlytough sectionof sodor unbrokenground,butin most cases

this won't benecessarY.)

• Avoid trying to digtoo deeplytoo quickly,especiallywhen bustingsodor when tilling soil

that hasn'tbeentilledfor sometime. Useshallowdepthregulatorsettings(onlyaninch ortwo

deep)forthefirst passesthrough the soil. Witheachsucceedingpass,diganotherinch ortwo

ChoosingCorrectWheel& Tine Speeds With experience,you will find the"just right" tillingdepth andtillingspeedcombination

that is bestfor yourgarden.

Setthe enginethrottle leverataspeedtogivetheengineadequatepowerandyetallow it to operateattheslowestpossiblespeed...atleast

until you haveachievedthe maximumtilling depthyou desire.Fasterenginespeedsmaybedesirablewhenmakingfinal passesthrough

theseedbedor whencultivating.Selectionofthecorrectenginespeed,in relationto thetilling depth,will ensureasufficientpower levelto

dothejobwithout causingtheengineto labor.

Let theTiller Dothe Work

Whiletilling, relaxandletthewheelspullthe

tiller along while the tines do the digging.

Walkonthe sidethat is notyet finished(to

avoidmakingfootprints inthefreshlytilled

soil) and lightly, but securelygrip the han-

dlebarwith justonehand,

AvoidMakingFootprints

Wheneverpossible, walk on the untilled

sideofthe unitto avoidmakingfootprints in

your freshlytilled or cultivatedsoil. Foot-

prints causesoil compactionthat canham-

per root penetration and contributeto soil

erosion. They can also !'plant" unwanted

weed seeds back into the freshly tilled

ground.

PreparingSeedbeds

• When preparinga seedbed,go overthe samepathtwice in the first row,then

overlapone-half the tiller width on therest ofthe passes(seeFig.6). When fin-

ishedin onedirection, makeasecondpassat arightangle,asshown in Fig.4-7.

Overlapeachpassfor bestresults(in very hardground,it maytakethreeor four

passesto thoroughly pulverizethesoil.)

• Ifthegardensizewill not permit lengthwiseandthen crosswisetilling,thenover-

lapthe first passesbyone-halfatiller

Fig. 4-8

AvoidTillingSoggy,WetSoil

Tillingwetsoil often resultsin large,hard

clumpsof soil that can interferewith plant-

ing.If timepermits, wait a dayor two after

heavyrainsto allow the soil to dry before

tilling. Testsoil bysqueezingitintoa ball. If

itcompressestoo easily,it istoo wetto till.

D

Fig. 4-6 Fig. 4-7

Cultivating

With planning, you can _ _ r_

allowenoughroom _ _-_"-(_"

betweenrows tocultivate _ _

(seeFig.4-9). Leaveroom _ _

for the hood width,

plus enough extra _ _'

roomfor future plant Fig. 4-9

growth.

14

Page 15

TILLING TIPS& TECHNIQUES(CON'T)

PowerComposting

Powercompostingsimplymeanstillingunderand burying in thesoilall manneroforganic WARNING: Whenpower

mattersuchascropresidues,leaves,grassclippingsandcovercrops. Thismaterialwillde, composting, do not keepthe

composeduringthenon-growingseasonandadd imPortantnaturalnutrientsto the so DepthRegulator Leverata

Thefirst placeto beginis with cropresiduessuchasleftovervines,stalks,stemsand roots• deepsetting if theti!ler jumps

Powercompostthesecropresiduesas soon astheyfinish bearing.Thesoonerthis isdone, or bucks.

thebetter,astendergreenmatteriseasiertotill under. Usethedeepestdepthregulatorset- If jumping or bucking occurs,

ting possiblewithoutcausingthe engineto laboror the tiller to jumpahead, movethe DepthRegulator

Leverdown to ashallow

Standingcornstalksof reasonableheightcanbepowercomposted.Pushing over (but not setting andthen slowly

uprooting)cornstalkswill oftenmakeit easierto chopupthe stalks•Keepthetines clearof increasethe tilling depth on

excessivetanglingby,fishtailing"orfrequentlyusingreverse.Makeseveralpasses,thenre- I t r

turnafewdayslatertofinishoffanyremainingstubble. Lee passes;, ... .

Aftertilling undercropresidues,addmoreorganicmattersuchasleaves,grassclippingsand cou d result n oersona n urv

evenkitchenscraps. Whentilled intothe soil,this organicmatterwill decomposeandadd

evenmore important nutrientsto the soil•

Afterpowercomposting,you maywantto planta "greenmanure'!covercrop to protectthesoilduringthe off-season.Yousimply grow a

cropof clover,alfalfa,buckwheat,peas,beans,ryegrass, grain,or kaleandthen till it intothe soil priorto the plantingseason.

TillingOnSlopes

t-allure[o follow tins warmng

Readthefollowingrecommendationsbeforetilling onslopes:

If

you mustgardenon a moderateslope,pleasefollow two very _mportantgmeennes:

1.Til!onlyon moderatemodes,neveronsteepgroundwherefootingisdifficult I reviewsafe-

ryrulesin Section1:Safetyof this manuaU.

2. We recommendtilling upand clownslopes ratherthan terracing. Tillingverticallyon a

slopeallowsmax_murrplantingareaand also leavesroomfor cultivating.

IMPORTANT,"Whentilling on slopes besurethe correct oil levelismaintainedintheengine

checkeveryone-halfhour of oeeratlonL Theinclineof the sloeewl causerne el to slant

awayfrom _tsnormalleveland_n_scanstarveenginepartsof requiredlubrication. Keepme

motorOHlevelatthefull eointatall times!

Tilling Upand DownSlopes(VerticalTilling)

• To keepsoil erosionto a minimum, besureto addenoughorganicmatterto the softsothat it hasgoodmoisture-holdingtextureandtry

toavoidleavingfootprintsor wheelmarks.

• Whentilling vertically,try to makethe first eass. _hillasthetiller digs moreaeeplygoing uphillthan itdoesdownhill. Insoftsoil or

weeas,you mayhaveto lift thehandlebarsslightlywhile goinguphill. Whengoingdownhill,overlapthe first passbyabout one-halfthe

width of the tiller.

TillingAcrossSlopesWithoutUsingTerraces(HorizontalTilling)

• f verticalor terracinggardeningaren't practicalfor you,then youcantill laterallyacrossa slope. We don't recommendthis methodas

t cancreateunsurefootingand invitessoil eromon.

• As interracegardemng,startatthetop oftheslopeandoverlapthe first passey _alfthewidthof thetiller. Foraddedstabilityofthetiller.

alwayskeepthe uphillwheelinthesoft. new_yhliedSOIL

WAF{NINEi: Donot

operatetiller onaslope too

steep for safeoperation. Till

slowly and besureyou have

good footing. Neverpermzt

tiller tofreewheel down

slopes.Failureto follow this

warning could result in

personalinjury.

TerraceGardening

• Whena slope_stoo steepor too shortfor verticaltilling, _tmaybenecessaryto t_llacrossthe sloae andcreateterracedrows.Terraces

arerowsthat arecut rotethe sideof a slope,creatinga narrow,but flat areaon whichto plant.

• Ona longs_ope,you can makeseveralterraces,onebelowthe other.

• Terracesshouldbeonly 2-to-3 feetwide.Diggingtoo far intothesideoftheslopewil! exposepoorsubsoilthat is unproductivefor plants.

15

Page 16

TILLING TIPS& TECHNIQUES(CON'T)

TerraceGardening(continued)

• Tocreateaterrace,startat the top of the slopeandworkdown.Gobackandforth

acrossthe first rowas shownin Fig.4-10.

• Eachsucceedinglowerterraceisstartedbywalkingbelowtheterraceyou'repre- e_ll_l___....__,_,.. _e

paring. Foraddedstabilityofthetiller,alwayskeeptheuphillwheelinthesoft, new-

ly tilled soil. Do not till the last 12"or moreof the downhill outsideedgeof each _1_

terrace. This untilled strip helps preventsthe terraces from breakingapartand

ClearingtheTines

Thetines haveaself-clearingactionwhich eliminatesmosttanglingof debris in

thetines. However,occasionallydry grass,stringystalksor tough vinesmaybe-

cometangled• Followthese proceduresto helpavoid tangling andto cleanthe

tines,if necessary.

• To reducetangling, set the depth regulatordeep enoughto get maximum

"chopping"actionasthetines chopthematerialagainsttheground. Also,try to

till undercrop residuesor covercropswhiletheyaregreen,moistandtender.

• While powercomposting,try swayingthe handlebarsfrom sideto side (about

6"to 12'_).This "fishtailing"action oftenclearsthetines of debris.

• If tanglingoccurs, liftthetinesout ofthe soiland runthetiller in reverse(if unit

is equippedwith poweredreverse) for a fewfeet. This reversingactionshould

unwinda gooddealof debris•

• It maybenecessaryto removethedebrisbyhand

(a pocketknifewill helpyouto cut awaythe mate-

rial).Besuretostop the engineanddisconnectthe

spark plugwirebeforeclearingthetines byhand.

_ WARNING: Beforeclearing the

tines byhand,stop the engine,allow

all movingpartsto stopand

disconnect the spark plug wire.

Removethe ignition keyon electric

start models.

Failureto follow this warning could

result in personalinjury.

LOADINGANDUNLOADING • Usesturdy rampsand manually(engine tiller aheadof you. Havea personat each

THETILLER shut off) roll the tiller into and out of the sideto turn the wheels.

vehicle.Two or morepeopleare neededto • When going down ramps, walk back-

,_ WARNING: Loadingand do this. ward with thetiller following you. Keep

• Before loading or unloading,stop the en- " " " , chock the wheels in placeafter the tiller is

gine,wait for allparts to stop moving, • Position the loadingvehicle sothat the in the vehicle.

disconnect the sparkplug wire and letthe ramp angle isas flat as possible (the less • After loadingthe tiller, prevent it from

engineand muffler cool. inclineto the ramp, thebetter). Turnthe rolling byengagingthe wheels in the

° Thetiller is t°° heavyand bulky t° lift vehicle'sengine °ff andapply its parking WHEELDRIVEposition. Chockthe wheels

safelyby one person Two or more people brake, with blocksandsecurelytie thetiller down.

should sharethe load. • When goingup ramps, stand in the

unloadingthe tiller intoa • Theramps must be strong enoughto alertfor any obstacles behindyou. Posi-

vehicle ispotentially hazardous support the combined weightof the tiller tion a person at eachwheel to control the

andwedon't recommenddoing and any handlers•Theramps should pro- speedof thetiller• Nevergo down ramps

sounlessabsolutelynecessary, vide goodtraction to preventslipping; they tiller-first, as the tiller could tip forward.

asthis could result in personal should havesiderails to guidethe tiller * Placewooden blocks onthe downhill

injury or property damage• alongthe ramps;and they should havea side ofthe wheelsif you needto stop the

However,if you must load or locking deviceto securethem to the tiller from rolling down the ramp. Also,

unloadthetiller, follow the vehicle• usethe blocksto temporarily keepthe tiller

guidelinesgiven next. • Thehandlersshouldwearsturdyfootwear inplaceontheramps(ifnecessary),andto

that will helpto preventshppmg

normal operating position and pushthe

16

Page 17

SECTION5: MAINTENANCE

,_ WARNING: Before

inspecting, cleaningor servicing

the machine,shut off engine,

wait for allmoving partsto come

to a completestop, disconnect

spark plug wire andmove wire

awayfrom spark plug. Remove

ignition key on electric Start

models.

Failureto follow these

instructions canresult in serious

personalinjury or property

damage.

MAINTENANCE SCHEDULE

PROCEDURE NOTES

Checkmotoroil level

Cleanengine

Checkdrivebelttension

Checknutsandbolts

Changemotoroil

Lubricatetiller

Serviceengineaircleanersystem

Checkgearoil levelintransmission

Checktinesfor wear

Checkair pressureintires

(if unithaspneumatictires)

Servicesparkplug

NOTES

I - Checkafter first 2 hours of break-in operation.

2 - eefora eachuse.

3 - Every 5 operating hours.

4, Every!Ooperatinghoura.

5 - Every 30 operating hours.

6 - Changemore frequently in dusty Conditions.

7 - See Engine Owner's Manual forservice

recommedations.

8- Whichevertimeintervaloccursfirst.

g - Changeaftergrst2hoursofbrsak-in

2,3

2,7

1,4

i, 4

4,6,9

4

1,5

5

TILLERLUBRICATION

After every10 Operatinghours, oil or

greasethe lubrication points shownin

Figure5-1 and described belOW,

Usecleanlubricating oil (#30weight motor

oil is suitable)and cleangeneralpurpose

grease(greasecontaining a metallubricant

is preferred, if available).

• Removethewheels,cleanthe wheel shaft

(A, Fig.5-1) and apply a thin coating of

greaseto the wheelshaft,

• Greasethe back,front and sidesofthe

depth regulator lever (B,Fig. 5-1).

• Removethe tines andcleanthetine shaft

(C, Fig.5-1). Use a file orsandpaperto

gently removeanyrust, burrs or rough

spots (especiallyaround holes in shaft).

Applygreaseto endsof shaft beforeinstall-

ing tines, thetiller hoodthat securethetransmis-

• Oilthe threads onthe handlebarheight sioncoverandthe DepthRegulatorLever

adjustment screwsandthe handlebar to thetransmission.

attaching screws (D, Fig.5-1). CHECK TIRE PRESSURE

If a cover is leaking,check for loose

screws. If the screws aretight, a new

gasket or oi!seal may be required.

If the leakis from around a shaft and oil

seal, the oilseal probably needsto be

replaced. Seeyour authorizeddealeror

contact the factory for service or advice.

IMPORTANT:Neveroperatethe tiller if

the transmission is low on oil. Check

the oil levelafter every30 hours of

operationand wheneverthere isany oil

leakage.

CHECKHARDWARE

Checkfor looseor missing hardwareaf-

ter every 10 operatinghoursand tighten

or replace(as needed)before reusing

tiller

Besureto checkthe screws underneath

(Models with pneumatic tires)

airOhecktheairpressureinbotht,reS.pressureshou,dbebetween15ps,The

B_ and 20 PSI(pounds persquareinch).

Keepbothtires equally inflatedto help

prevent machinefrom pullingto one

side.

TRANSMISSION

GEAROILSERVICE

Checkthe transmission gearoil level

after every30 hoursof operationor

wheneveryou noticeany oil leak. Oper-

ating thetiller when the transmission is

low on oil can result in severedamage.

Figure5.1

CHECKFOROILLEAKS

Beforeeachuse,checkthetiller for signsof

an oil leak-- usually a dirty, oily accumu-

lationeither on the unit or on thefloor.

A little seepagearound a cover or an oil

sealis usually not a causefor alarm.How-

ever,if the oildrips overnight, then imme-

diateattention is needed. Ignoring an oil

leakcanresult insevere transmission

damage] insidethe oil fill holeto locatethe main

17

A. ToChecktheTransmission

GearOil Level:

1. Checkthe gear oil levelwhenthe

transmission is cool. Gearoil will

expandin warm operatingtemperatures

andthis expansionwill provide an incor-

rect oil levelreading.

2. With thetiller onlevelground, pullthe

Depth RegulatorLeverall the way up.

3. Removethe oil fill plug (A, Fig.5-2)

from thetransmission housingand look

drive shaft situated belowthe hole.

Page 18

WARNING: Beforeinspecting, cleaningor servicingthe machine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

4. Thegear oil level is correct ifthe gear B. ToDrainthe TransmissionGearOil:

oil isapproximately halfwayupthe side of

the maindrive shaft.

5. If the gearoil levelislow. add gearoil

asdescribed next. If the geargellevelis

okay,securelyreplacethe oilfill plug.

IMPORTANT:Do not operatethe tiller ifthe

gear oil levelis low. Doingso will result i_

severedamageto the transmission com-

ponents.

Thetransmission gearoil doesnotneedto Thebole tines will wearwith useand

bechangedunless it hasbeencontaminat- should be inspectedat the beginning of

ed with dirt sand or metal particles, eachtilling seasonand after every30 oper-

1. Draingasolinefrom the fuel tank or run ating hours. Thetines can bereplacedel-

theengine until the fuel tank is empty.See ther individuallyor as acomplete set. See

'DANGER"statement below.

WARNING: Gasolineis

highlyflammableandits vapors

are explosive. Followthese

safety practicesto prevent

personalinjury or proper_y

damagefrom fire orexplosion.

• Allowthe engineandmufflerto coolfor

at least twominutesbeforedrainingthe

tiger's gasolinetank.

• Do not allow open flames, sparks,

matchesor smokinginthe area.

• Wipe awayspills and pushtiller away

fromspilledfuel.

• Use only an approvedfuel container

andstoreit safely outof the reachofchil- 2. Wheninstalling a single tine. besureto

dren.

Figure5-2: Removeoil fittplug (.4) to check

gear oil level andto add gear oil. Remove

fourcoverscrews(B) to drain gear oil.

6. If adding onlya few ouncesof gear oil.

useAPI ratedGL-4or GL-5gearoil having

a wscosEtyof SAE140. SAE85W-140 or

• Donotstore gasolinein an area where

its vapors couldreach an openflame or

spark, or where ignition sources are

present (such as hot water and space

heaters, furnaces, clothes dryers,

stoves,electricmotors,etc.)

SAE80W-90. If refilling an empty trans-

mission, useonly GL-4gear oil havinga

viscosity of SAE85W-140 or SAE140.

IMPORTANT:Do not useautomatic trans-

mission fluid or motor oil in the transmis-

sion.

7. While checking frequently to avoid

overfilling, slowly add gear oil into the oil

fill holeuntil it reachesthehalfwaypointon

thedrive shaft.

8. Securely replacethe oilfill plug.

2. Drainthe oil from the engine.

3. Removefour screws(B,Figure5-2) and

removetransmissioncoverandgasket.

4. Removethe left-side wheel.

5. Tilt the left-side wheelshaft into a drain

panand allowthe gearoil to drainthrough

the top of thetransmission.

6. Reinstallthe wheel.

7. Install a new gasket(do not reuse old

gasket and reinstallthe transmission cov-

er.

8. Refillthe transmission usingGL-4 gear the soil first whenthetiller movesforward.

ozltSAE 85W-140 or SAE140). Securethe tine assemblyto the tineshaft

9. Refillthe engine with motor oil and re- using the screw and Iocknut

plenishthe fuel tank with gasoline.

BOLO TINES

the Parts Lisl pagesfor tine identification

and part numbers,

A. Tine Inspection:

With use the tines will becomeshorter.

narrower and pointed. Badlyworn tines

will result in a loss of tilling depth,and re-

ducedeffectivenesswhen chopping up

andturning under organic matter.

B. Removin_nstalling a SingleTine:

1. With the engineshut off andthe spark

plug wire disconnected, removethe two

screws IA,Figure5-3), Iockwahers(Eband

nuts (B)that attacha single tine to a tine

holder. If needed,use penetratingoil on

the nuts.

position it so that its cutting edge (sharp)

will enter the soil first as the riflermoves

forward.

C. Removin_nstalling a TineAssembly:

1. A tine assemblyconsists of eighttines

mounted on atine ilolder.

2. If removing both tine assemblies mark

them "left" and "right" before removal.

Removethe screw (C, Figure 5-3), lock

washer (E_andIocknut [D that securethe

tineassembly to the tine shaft. Ifneces-

sary,usea rubber malletto tapthe tineas-

sembly outward off the shaft.

3. Beforereinstalling thetine assembly,in-

spectthetineshaftfor rust, roughspots or

burrs. Lightlyfile or sand.as needed. Ap-

ply a thin coat of greaseto the shaft.

4. Install each tine assembly so that the

cutting (sharp) edgeof the tines will enter

18

Page 19

WARNING: Beforeinspecting, cleaningor servicingthe machine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

FF_ONTi

FORWARD

SHAFT

C

\

Figure5-3: Installtinessothatcuttingedgeoftinesentersoftfirstwhentillermovesforward.

CHECKING AND ADJUSTING

FORWARD DRIVE BELT TENSION

It is important to maintain correct tension

on the forward drive belt. A loose beltwill

causethe tinesandwheelsto slowdown--

or stop completeiy -- eventhough the en-

gine _srunning atfull speed. A too tight

belt canresult in unintentionaltine move-

ment when the clutch bail is inthe Neutral

belttension is correct ifthis second mea- your localauthorized dealeror referto the

suremenl is between1/6' -to- 3/16"longer Parts List for ordering information. Use

than the first measurement, only afactory-authorized beltas an "over-

4. If the spring Lstoo short tless than 1/ the-counter" belt maynot perform satis-

16'1.thetension istoo loose. If the spring factorily. The procedure requires average

is too long _morethan 3/16'h.the tension mechanicalability andcommonly available

is too tight.

5. Toadjust the length of the spring:

a. Releasethe Forward ClutchBail.

(released)position.

• Check belt tension after the first two

hoursof break-inoperationand after every

10operating hours.

• At the end of eachtilling season,check

the beltfor cracks, cuts orfrayed edges

and replace it assoon as possible.

ToCheckForwardBeltTension:

1. Stop engine, wait for all partsto stop

mowng anddisconnect sparkplug wire.

2. With the ForwardClutch Bailinan open

(releasedl position,measureand note the

overalllengthofthecablespring (A,Figure

5-4) bymeasuringfrom the outermostcoil

to the outermost coil.

3. Squeezethe ForwardClutch Bail

againstthe handlebar(seeFigure5-4) and

Figure5-4: Tocheckforwardbelt tension, taketwomeasurementsofthe

nverelllengthofthe coilsin the spring-- firstwiththe clutchbail open,

thenwith theclutchbail closedagainstthe handlebar.

re-measurethe length of the coils. The

19

h Unthreadthe hexnut IC, Figure5-4)

halfway upthe adjustment screw (D_.

c. Unhookthe top of the spring from

the Forward ClutchBail.

d. Usepliers to preventtheadjuster (B_

from turning andturn the slotted screwlo-

cated insidethe spring clockwise ,viewed

from operator's position} to increaseten-

sion on the spring. Turnthe screw coun-

terclockwise to decreasetension. Once

adjusted,reattachthe spring to the For-

ward Clutch Ba_l.

e. RepeatSteps2and 3to re-measure

thelengthofthespring. Whenthe second

measurementis between1/16"-to- 3/16"

longerthanthefirst measurement,retighten

thehexnut(C)againstthetop oftheadjuster

(B/.

ReplacementBelt Information

If the drive belt needsto be replaced,see

tools.

Page 20

WARNING: Beforeinspecting, cleaningor servicingthe machine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

FORWARDCLUTCH

BAILADJUSTMENT

If the ForwardClutch Bail does not func-

tion properly,first checkthat theforward

drive belt is adjusted properly (seeCheck-

ing andAdjusting ForwardDrive Belt Ten-

sion). Ifthis fails to correct the problem,

contact Troy-Bilt LLCor your authorized

dealerfor service advice.

CHECKING AND ADJUSTING RE-

VERSE DRIVE BELT TENSION

(Models 634F/634B only)

It is important to maintaincorrect tension

on the reversedrive belt. A loose belt will

causethetines andwheelsto slow down-

or stopcompletely - eventhough the en-

gine is running at full speed.

Whenchecking belt tension, alsocheckthe

beltfor cracks, cuts or frayededgesand

replaceit as soon as possible.

• Check belt tension after thefirst two

hoursof break-inoperationand after every

10 operating hours.

ToCheckReverseBelt Tension:

1. Stop engine, waitfor all parts to stop

moving anddisconnect sparkplug wire.

2. Removescrew in plasticbelt coverand

slide beltcover (which is attachedto for-

ward clutch cable) out of the way.

3. Havean assistant pullthe Reverse

Clutch Control knoball theway out and

hold it inthat position. Measurethe length

of the cable wire betweenthe end of the

threadedcableadjuster (A,Figure5-5) and

theend of theZ-fitting (B) to which the ca-

ble wire is attached.

4. Thebelttension isidealifthe cablewire

lengthmeasuresbetween1/8"to 1/4". If it

is lessthan 1/8"(and if there is no reverse

actionwhenthetiller isrunning),then make

thefollowing adjustments

NOTE:Ifthe lengthis morethan 1/4",noad-

justment is needed--as longasthereverse

actionfunctions properly.

5. Releasethe ReverseClutch Control

knob.and then unthreadthe innerjam nut

(C, Figure 5-6) oneto two turns. Pullthe

threadedcableadjuster (A, Figure 5-6) to

the left untilthe innerjam nut (C)touches

the bracket.

6. Preventtheinnerjam nut(C)fromturn-

ing and tighten the outer jam nut (D)

againstthe bracket. Preventthe outer jam

nut (D) from turning andtighten the inner

jam nut (C) againstthe bracket.

7. Measurethe gapby repeating Step 3.

Readjustas neededby repeatingSteps 5

and 6.

8. Reinstall the belt cover.

Figure5-5: Measurecablewirelengthto

checkforcorrectreversebelttension.

Figure5-6: Movethreadedadjuster(,4)toleft

toincreasebelttension.

ReplacementBelt Information

If the drive belt needsto be replaced,see

your localauthorized dealeror referto the

Parts List for ordering information. Use

only a factory-authorized belt asan "over-

the-counter" belt may not perform satis-

factorily. The procedure requires average

mechanicalability andcommonly available

tools.

ENGINECLEANING

Keepingthe enginecleanwill helpto en-

suresmooth operationand prevent dam-

agefrom overheating. Referto the Engine

Owner'sManual for enginecleaningser-

vice intervals andinstructions. Besure

thatthe muffler iscool beforeservicingthe

engine.

AIRCLEANERSERVICE

Theair cleanerfilters dirt anddust out of

theair before it enters the carburetor. Op-

eratingthe enginewith a dirty, clogged air

filter can causepoor performanceand

damageto the engine. Neveroperate the

enginewithout the air cleanerinstalled. In-

spectand servicethe air cleanermore of-

ten if operating invery dusty or dirty

conditions. Referto the engineOwner's

Manualfor aircleanerserviceintervalsand

instructions.

ENGINEOILSERVICE

Checkthe engineoil levelbefore each use

andafter everyfive hours of continuous

operation. Running theengine when it is

low on oil will quickly ruin the engine.

It is recommendedthat youchangethe

motor oilafter every 10hours of operation

and even sooner when operating in ex-

tremelydirty ordusty conditions. Referto

the EngineOwner'sManualfor detailed

service instructions.

A. ToChecktheEngine0il Level:

1. Parkthe tiller on a levelareaand shut

off the engine.

2. Levelthe engine(usethe Depth Regu-

lator Leverto adjust the engineangle).

2O

Page 21

WARNING: Beforeinspecting, cleaningor servicingthe machine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

3. Cleanaround the oil dipstick or oil fill

tube (whicheverapplies) to preventdirt

from falling into the crankcase.

4. Onengines with an oil fill tube, remove

thefill capand add oil (if required) until it

reachesthetop of thefill tube. Reinstall

thefill cap.

5. Onengineswith adipstick, remove it

and wipe it clean. Reinsertthe dipstick,

tighten it securely,and removeit. Add oil

asneededto bring the levelupto the FULL

mark. Wipe dipstick cleaneachtime oil

levelis checked. Do not overfill. Tighten

dipstick securely.

B. ToChangethe EngineOil:

Changethe engine oil as instructed in the

EngineOwner'sManual.

SPARKPLUGSERVICE

Inspectand cleanor replacethespark plug

after every lOg operating hours orannual-

ly. Referto the EngineOwner'sManualfor

spark plug service instructions.

In some areas,local law requires using re-

sistor spark plugsto suppress ignition sig-

nals. Iftheenginewas originally equipped

with aresistor spark plug, usethe same

type for replacement.

SPARKARRESTERSCREEN

SERVICE

If the enginemuffler is equippedwith a

spark arrester screen,removeand cleanit

according to the service intervalsand in-

structions in the EngineOwner's Manual.

THROTTLELEVERADJUSTMENT

If the enginedoes not respondto various

throttle leversettings, refer to the Engine

Owner'sManualfor service information or

contact your localauthorized enginedeal-

er.

WARNING: Operators

shallnottamper with theengine

governor settings on the

machine;thegovernorcontrols

the maximum safeoperating

speedto protect theengineand

all moving partsfrom damage

causedbyoverspeed.

Authorized service shall be

sought if aproblemexists.

CARBURETOR/GOVERNOR

CONTROLADJUSTMENTS

Thecarburetor was adjustedat the factory

for best operatingspeed. Referto the En-

gine Owner'sManualfor any adjustment

information or seeyour authorizedengine

dealer.

Thegovernorcontrols the maximum safe

operatingspeedand protectsthe engine

andall moving parts from damagecaused

by overspeeding. Do not tamper with the

enginegovernor settings.

OFF-SEASONSTORAGE

Whenthe tiller won't beusedfor an ex-

tendedperiod,prepareit for storageasfol-

lows:

1. Cleanthe tiller andengine.

2. Doroutine tiller lubrication and check

for looseparts and hardware.

3. Protectthe engineand perform recom-

mendedengine maintenanceby following

the storage instructions found inthe En-

gine Owner's Manual. Besure to protect

thefuel lines, carburetor and fuel tank

from gum deposits byremoving fuel or by

treating fuel with a fuel stabilizer (follow

enginemanufacturer'srecommendations).

4. Store unit ina clean, dry area.

5. Neverstorethetiller with fuel inthefuel

tank in an enclosedareawhere gasfumes

could reachan open flame or spark, or

whereignition sourcesare present (space

heaters,hot water heaters,furnaces, etc.).

21

Page 22

WARNING: Beforeinspecting, cleaningor servicingthe machine,shut offengine,wait for all