Troy-Bilt TOMAHAWK 15013, TOMAHAWK 15014, TOMAHAWK 15014S, TOMAHAWK 15015, TOMAHAWK 15016 Technical Manual

...Page 1

.

"

o

J:.IlQ~BILT

Technical

Manual

TOMAHAWK

®

Chipper/Shredder

4HP,

5HP&8HP

Models

GARDEN WAY INC.

Page 2

DRIVE SHAFT/CYLINDER

ASSEMBLY

REPLACEMENTINSTRUCTIONS

& OTHER SERVICE PROCEDURES

AND

INSPECTIONS

TROY-BILT®

5HP&8HP

SUPER TOMAHAWK®

Chipper/Shredder

Models 15012, 15013, 15014, 150

14S,

15015,

15016

& 47251

TROY-BILT®

4HP

TOMAHAWK®

Chipper/Shredder

Models

15017,15018,15028,

15028S, 15029

Page 3

TOOL LIST- Have all tools below ready at hand and enlist

the aid of a helper too, as a second person will make some

steps easier.

Combo Open End/Box End Wrenches: two

7/16";

two

112";

one

9/

16

" •

VB"

and %2" Hex Key (Allen) Wrenches • 9/

16

" Socket

Wrench with 6" Extension • Soft-Head Mallet (rubber

or

plastic) • 12" Long Drift Pin or Punch • Regular Pliers • 6Foot Length

of

ClotheslineorStrong Twine (capable of

supporting at least 40 pounds) • Flatblade

Screwdriver·

Penetrating Oil • Flashlight • Emery Cloth • 5-Foot (approx)

Long Broom Handle orLength ofPipe • Masking Tape • Rubber Bands (two), 3"

long·

Three-Foot Long 2"x4"

Wood·

Rags • Thick Gloves

DISASSEMBLY STEPS

AWARNING

Moving

partsonyour

equipment

can

cause

seri-

ous

personal

injury.

To

help

avoid

injury,

shut

off

the

engine,

let

all

mov-

ing

parts

stop

completely,

and

disconnect

the

spark

plug

wire

before

performing

any service procedures.

STEP 1.

Stop the engine and wait for the engine and mufflertocool

before proceeding.

STEP 2.

Remove the spark plug boot from the spark plug and secure

the boot safely away from the spark plug.

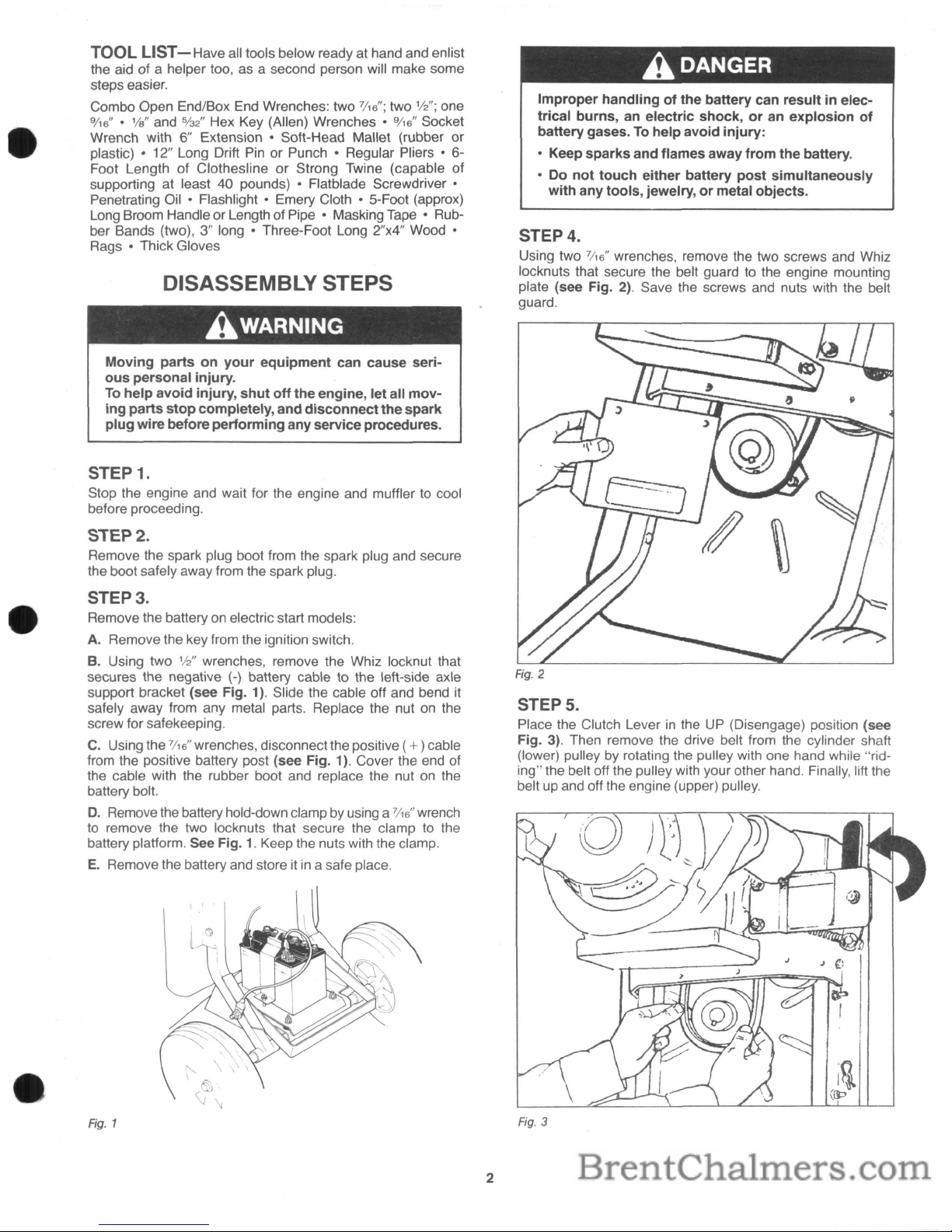

STEP 3.

Remove the battery on electric startmodels:

A. Remove the key from the ignition switch.

B. Using two

112"

wrenches, remove the Whiz locknut that

secures the negative

(-)

battery cable to the left-side axle

support bracket (see Fig. 1). Slide the cable off and bend it

safely away from any metal parts. Replace the nut on the

screw forsafekeeping.

C.

Using the

7/

16

" wrenches, disconnectthe positive (+)cable

from the positive battery post (see Fig. 1). Cover the end of

the cable with the rubber boot and replace the nut on the

battery bolt.

D.

Remove the battery hold-down clamp by using a

7/

16

" wrench

to

remove the two locknuts that secure the clamp to the

battery platform. See Fig.

1.

Keep the nuts with the clamp.

E.

Remove the battery and store itina safeplace.

Fig.

1

2

AOANGER

Improper

handlingofthe

battery

can

resultinelec-

trical

burns,anelectric

shock,oran

explosion

of

battery

gases.Tohelp

avoid

injury:

• Keep

sparks

and

flames

away

from

the

battery.

• Do

not

touch

either

battery

post

simultaneously

with

any

tools,

jewelry,ormetal

objects.

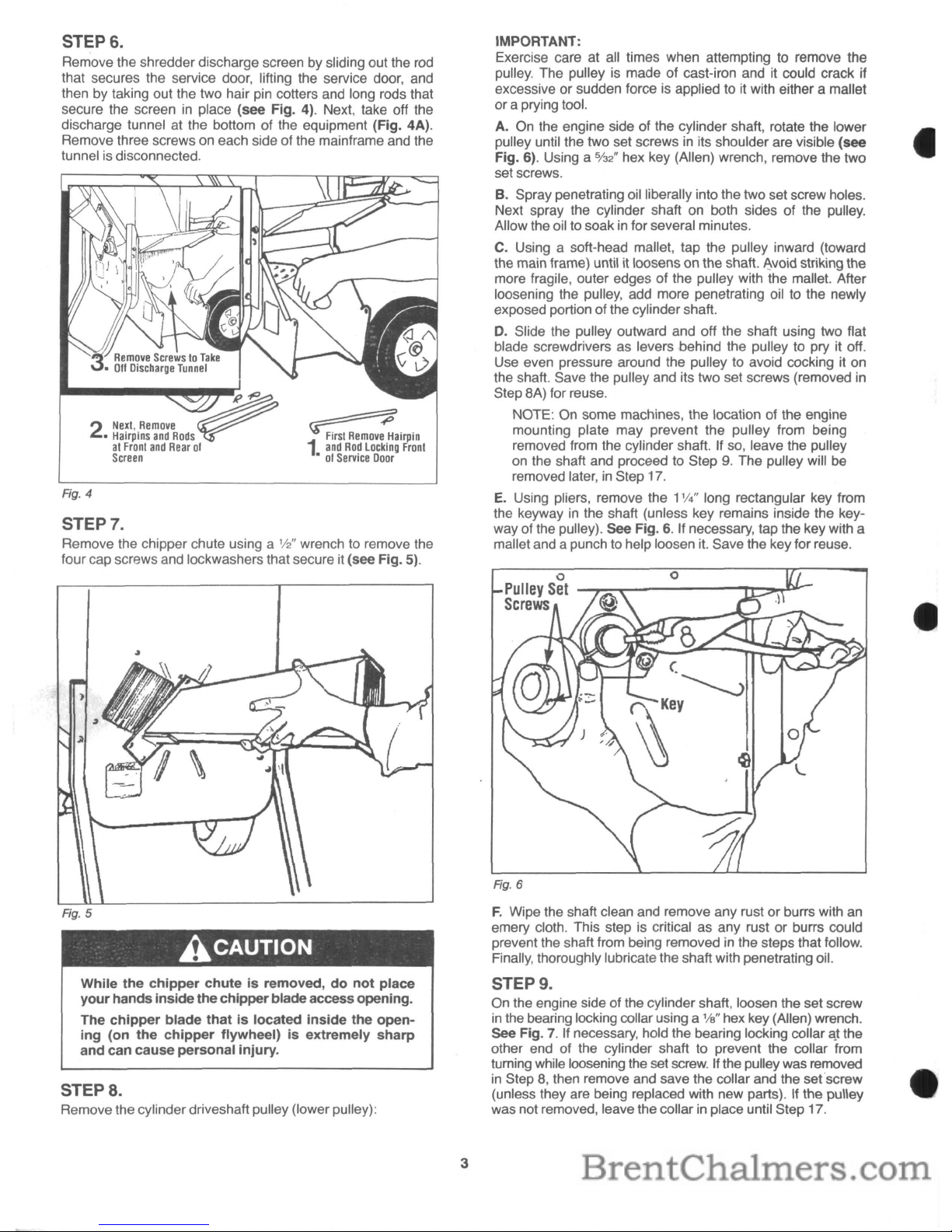

STEP 4.

Using two

7/

16

" wrenches, remove the two screws and Whiz

locknuts that secure the belt guard to the engine mounting

plate (see Fig.

2).

Save the screws and nuts with the belt

guard.

STEPS.

Place the Clutch Leverinthe UP (Disengage) position (see

Fig. 3). Then remove the drive belt from the cylinder shaft

(lower) pulley

by

rotating the pulley with one hand while "riding" the belt off the pulley with your otherhand. Finally, lift the

belt up and off the engine (upper) pulley.

Fig.

3

Page 4

ACAUTION

STEP8.

Remove the cylinder driveshaft pulley (lower pulley):

Ag.6

IMPORTANT:

Exercise care at all times when attempting to remove the

pulley. The pulley is made of cast-iron and it could crack if

excessive or sudden force is applied to it with either a mallet

or a prying tool.

A. On the engine side of the cylinder shaft, rotate the lower

pulley until the two set screws

in

its shoulder are visible (see

Fig. 6). Using a

%2" hex key (Allen) wrench, remove the two

set screws.

B. Spray penetrating oil liberally into the two set screw holes.

Next spray the cylinder shaft

on

both sides of the pulley.

Allow theoil to soak

in

for several minutes.

C. Using a soft-head mallet, tap the pulley inward (toward

the main frame) until it loosenson theshaft.

~void

striking the

more fragile, outer edges of the pulley with the mallet. After

loosening the pulley, add more penetrating oil to the newly

exposed portion ofthe cylinder shaft.

D.

Slide the pulley outward and off the shaft using two flat

blade screwdrivers as levers behind the pulley to pry it off.

Use even pressure around the pulley to avoid cocking it on

the shaft. Save the pulley and its two set screws (removed

in

Step 8A) for reuse.

NOTE: On some machines, the location of the engine

mounting plate may prevent the pulley from being

removed from the cylinder shaft. If so, leave the pulley

on

the shaft and proceed to Step9.The pulley will be

removed later,

in

Step

17.

E.

Using pliers, remove the 1W'long rectangular key from

the keyway

in

the shaft (unless key remains inside the key-

way ofthe pulley). See Fig.

6.

If necessary, tap the key with a

mallet and apunch to help loosen

it.

Save the key for reuse.

F.

Wipe the shaft clean and remove any rust or burrs with

an

emery cloth. This step is critical as any rust or burrs could

prevent the shaft from being removed in the steps thatfollow.

Finally, thoroughly lubricate the shaft with penetrating oil.

STEP 9.

On the engine side of the cylinder shaft, loosen the set screw

in

the bearing locking collarusing a

1/a"

hex key (Allen) wrench.

see

Fig.7.If necessary, hold the bearing locking collar

C!.t

the

other end of the cylinder shaft to prevent the collar from

turning while loosening the set

screw.

If the pulley wasremoved

in

Step8,then remove and save the collar and the set'screw

(unless they are being replaced with new parts). If the pulley

was notremoved, leave thecollar

in

place until Step 17.

1

~irPin

and

Rod

Locking

Front

•01Service

Door

?

ofO.

Next,

Remove

2.

Hairpins

and

Rods

at

Front

and

Rear

0'

Screen

Fig. 4

STEP 7.

Remove the chipper chute using a

112"

wrench to remove the

four cap screws and lockwashers that secure it (see Fig. 5).

While

the

chipper

chuteisremoved,donot

place

your

hands

inside

the

chipper

blade

access

opening.

The

chipper

blade

thatislocated

inside

the

open-

ing

(on

the

chipper

flyWheel)isextremely

sharp

and

can

cause

personal

injury.

STEP 6.

Remove the shredder discharge screen by sliding out the

rod

that secures the service door, lifting the service door, and

then by taking out the two hair pin cotters and long rods that

secure the screen

in

place (see Fig. 4). Next, take off the

discharge tunnel at the bottom of the equipment (Fig. 4A).

Remove three screws

on

each side of the mainframe and the

tunnel is disconnected.

3

Page 5

View

Underneath

Shredder

Fig.

9

Fig.

10

STEP 14.

Being careful to avoid any sharp edges on the cutting flails or

other metal parts (wear thick gloves for added protection),

reach down inside the shredder hopper and securely fasten a

clothesline or very strong twine around one of the cylinder

pins just behind the flywheel so the entire assembly will be

balanced. The rope or twine must

beingood condition (not

frayed or split) and

be

capable of supporting 40 or more

pounds. Pull the rope or twine taut to remove any slack and

securely fasten the upper end to a sturdy 2"x4" piece of wood

(see Fig. 10) spanning the shredder hopper. Tying up the

cylinder assembly

in

this manner will preventitfrom falling

to

the ground when you remove the cylinder shaftinthe following steps.

STEP 13.

On

the chipper side of the cylinder shaft, use a

1fa"

hex key

(Allen) wrench to loosen the set screw

in

the bearing locking

collar

(see Fig.

8).

Slide the collar off and save the collar

(unless being replaced with new parts).

STEP 15.

On

the chipper side of the main frame, use a

'/2"

wrench

to

remove the three Whiz locknuts that secure the two triangleshaped bearing

f1angettestothe main frame (see Fig.

11).

While loosening the nuts. apply slight outward pressure

to

the nutstoprevent the screws

from

turning.

o

STEP 12.

Remove the broom handle or stick from the shredder hopper.

Using a flashlight, look up inside the cylinder chamber and

locate the two screws that secure the cylinder assembly tube

to

the cylinder shaft (see Fig. 9). Being careful to avoid any

sharp edges on the cutting flails or other metal parts (wear

thick gloves for added protection), rotate the cylinder assembly until the locknuts on the screws are facing down. Remove

the locknutsusing a

9/

16

" wrench on the screwh('3ds and a

9/16"

socket wrench (with 6" extension adapter) on the locknuts.

After removing the locknuts, gently tap the screws out with a

long punch ordrift pin. Save the screws and nuts for reuse.

-_.~

~

LOCking/

Y

Collar

!

STEP 10.

Insert a broom handle or similar long stick down through the

top of the shredder hopper, wedging it behind one of the four

horizontal cylinder pins (cutting

flails are attached

to

cylinder

pins). Doing so will prevent the cylinder assembly and cylindershaft from rotating while you perform Step 11.

Fig.

7

STEP 11.

On the chipper side ofthe cylinder shaft, use a

9/

16

" wrench to

remove the screw, disc spring (conical) washer and heavy flat

washer from the end

of

the shaft (see Fig. 8). Save the

hardware for reuse.

4

Page 6

ACAUTION

While

the

chipper

chuteisremoved,donot

place

your

hands insidethe

chipper

bladeaccessopening.

The

chipper

blade

thatislocated

inside

the

open-

ing

(on

the

chipper

flyWheel)isextremely

sharp

and can

cause

serious

personal

injury.

STEP 16.

Remove the two flangettes and the bearing between them by

prying out the innerf1angette with a screwdriver, orby tapping

the opposite end of the cylinder shaft with a soft mallet. If

necessary, apply penetrating oil to the shaft to help free the

bearing. Save the f1angettes, bearing and three locknuts and

screws forreuse.

STEP 17.

Remove the cylindershaft:

A. Note the position of the cylinder shaft relative to the hole

in

the shredder wall (see Fig. 11). The shaft mustbecen-

tered vertically

in

the hole of the main frame. If it isn't centered, reposition the cylinder shaft by adjusting the length of

the rope or twine that supports the cylinder assembly.

B. On the engine side of the cylinder shaft, make certain that

the shaft

is

clean and free of any burrs or rust. It also must be

well-lubricated with oil. NOTE: If the pulley

is

still on the shaft,

be sure to clean and lubricate the shaft after the pulley

is

removedinStep D below.

C. Spray penetrating oil into the two screw holes in the cylin-

der assembly tube from which you removed the screws

in

Step 12 (seeFig. 9).

D.

On the engine side of the cylinder shaft, use a soft mallet

to tap the shaft a little toward the chipper side. As the shaft

moves forward, remove the pulley (if still on), its

key,

and the

locking collar if not doneso previously.

E.

Continue driving the shaft inward until the keyway end of

the shaft

is

flush with the slotted bearing sleeve on the engine

side of the main frame (see Fig. 12). Now spray additional

penetrating oil into the two screw holes mentioned in Step C

above.

F.

Using a long drift pin or

punCh,

drive the shaft all the way

out. If there

is

any binding along the

way,

spray additional oil

into the two screw holes

in

the cylinderassembly tube.

5

Fig.

12

STEP 18.

The cylinder assembly can now be slowly lowered to the

ground by unwrapping the rope or twine from the

2"x4" wood

at the top of the shredder hopper. Make certain that your feet

are not below the cylinder assembly as you unfasten the

rope. Now tilt the main frame back and roll it away from the

cylinder assembly.

ACAUTION

When

handling

the

cylinder

assembly,becareful

to

avoid

contacting

the

chipper

blade

thatislocated

on

the

chipper

flywheel.

The

chipper

bladeisextremely

sharp

and

can cause

personal

injury.

STEP 19.

Itisnot necessary to remove the bearing from the engine

side of the main frame unless it needs replacement (see

"Inspection of Parts" below).

To

remove the bearing and its

f1angettes, follow the same procedures given

in

Steps 15 and

16.

INSPECTION OF PARTS

Before reinstalling the following parts, inspect them for wear

ordamage as described below.

1. BEARINGS:

A.

Inner sleeve should turn freely. If action is rough, replace

bearing.

B.

Inner sleeve should feel secure inside outer race. If loose,

replace bearing.

C.

Keep bearings clean until reassembly.

2. DRIVE SHAFT:

A.

Inspect shaft for excessive wear (especiallyinbearing

areas), orcracks. Replace shaft ifexcessively worn orcracked.

B.

Inspect shaft for rust or burrs and remove with emery

cloth.

Page 7

3. CYLINDER ASSEMBLY:

A.

Rotate or replace shredder flail cutters as described

in

Owner/Operator Manual. While doing

so,

check that cylinder

pins are not bentby rolling pins

on

a flat surface. Also: always

use new roll pins coated with Loctite 242 sealantwhen securing

the cylinder pins to the cylinder assembly.

B.

Sharpen or replace chipper blade as describedinOwner/

Operator Manual.

C.

Check weld joints where flywheel and two flat plates join

cylinder assembly

tUbe.

Replace cylinder assembly if cracks

are evident.

D.

Check bore opening at each end of cylinder assembly

tube for burrs or rough edges and remove with metal file or

emery cloth.

E.

Inspect the two bolt holesinthe center of the cylinder

assembly tube for cracks or excessive wear. Replace cylinderassembly ifcracked orexcessively worn.

F.

Lubricate drive shaft with oil and carefully slide pulley end

of shaft through chipper sideof cylinder assembly tube. Shaft

should slide easily through tube. If not, remove shaft and

inspect shaftand tube for burrs or rough edges.

4. DRIVE BELT:

A.

Inspect belt for cracks, cuts, or fraying. Replace belt if

in

poor condition.

5. INSIDE THE

CHAMBER:

A.

While the cylinder assemblyisremoved, nowisa good

time to clean the insideof yourequipment.

B.

Using a wire brush or putty knife, scrape off the built-up

residue that's

on

the inner walls of the chipper/shreddercham-

ber.

Once clean, inspect all interior and exterior welds for

cracks or breaks. It's important for structural integrity that

cracked orbroken welds be repaired.

REASSEMBLY

STEP 1.

If the bearing on the engine side of the main frame has been

removed, install a new bearing by following Steps A through

D.

Ifthe bearing has notbeen removed, proceedtoStep

2.

A.

The bearing must be free from dirt, rust or other foreign

matter. Apply a light coating of oil to the inside wall of the

bearing sleeve and outerrace before installation.

B.

Insert the slotted sleeve of the bearing into the recessed

bore ofone of the flangette plates (see Fig. 13).

"-.....01.-------/

Flangette

Plates

Rg. 13

6

C. Place the second flangette over the flat side of the bearing, with the lip of the

f1angette

facing outward (seeFig. 13).

D.

With the bearing sleeve facing out, line up the holesinthe

f1angettes

with the notchesinthe wall of the main frame.

Loosely (hand-tighten only) secure the f1angettes

in

place

with three carriage bolts

(5/16"-18x3f4")

and Whiz locknuts

(5/

16

"-18). Be suretoinsert the bolts from inside the chamber

wall

so

that the locknuts areonthe outside (see Fig. 14). The

locknuts will be securely tightened

in

a later step.

STEP

2.

If the bearingonthe engine side of the main frame was not

removed during the disassembly steps, loosen the three Whiz

locknuts that secure the flangettes to the chamber wall (see

Fig. 14). Loosen each locknut two or three turns. Then apply

a light coating of oil

to

the inside walls of the slotted bearing

sleeve.

•

Fig. 14

STEP 3.

Install a

f1angette

on the chipper sideof the main frame:

A. Insert three carriage bolts

(5I16"-18x3f4")

through the flan-

gette mounting notches

in

the chamber wall (see Fig. 15).

Be

suretoinsert the bolts from inside the wallsothat the threads

face outward.

B. Place masking tape over the bolt heads to hold the bolts

in

place.

C.

Gently place the

f1angette

with the deep bore over the

bolts, with the lip of the recessed bore facing inward.

Fig. 15

Page 8

Fig.

17

o

o

)

C. Insert the keyway end of the cylinder shaft through the

chipper side of the main frame and into the cylinder shaft

tube ofthe cylinder assembly.

D.

Using a soft mallet, tap the shaft through the tube and out

through the bearing

on

the engine side of the main frame.

Stop when the end of the shaft extends approximately 1

W'

past the bearing shoulder (seeFig. 17).

STEP6.

On

the engine side of the equipmentand with the writing side

of the bearing locking collar facing outward, slide the collar

over the keyway end of the cylinder shaft until the collar

covers the slotted sleeve of the bearing (see Fig. 18). Do not

tighten the set screw

in

the collarat this time.

STEP

7.

Install the keyinthe keyway of the cylinder shaft (see Fig.

19). Seat the key firmly

in

the keyway by tapping itinwith a

mallet.

Fig.

18

ACAUTION

D.

Place masking tape along the edges of the flangette to

hold

itinplace (see Fig. 15).

E.

Carefully slip a rubber band over the three boltsto prevent

them from moving (see Fig. 15). The bearing and the outer

flangette will be installed

in

later steps.

Fig.

16

STEP 4.

Install the cylinder assembly:

A. Be sure that the ends ofthe cylinder shaft tube have been

carefully inspected for any nicks or burrs that would prevent

free travel of the cylinder shaftthrough the tube. See "Inspection of Parts".

B. Position the main frame over the cylinder assembly, making sure that the chipper blade

on

the cylinder flywheel is

facing the chipper chute side of the main frame (see Fig. 16).

When

handling

the

cylinder

assembly, be careful

to

avoid

contacting

the

chipper

blade

thatislocafed

on

the

chipper

flywheel.

The

chipper

bladeisextremely sharpand can cause

personal

injury.

C.

If the clothesline was removed, retie it around one of the

cylinder pins just behind the flywheel as described previously

(see Fig. 16).

D.

Feed the rope or twine up through the chamber and pull

the cylinder assembly up until the cylinder shaft

tUbeisat

the

same height

as

the two bearing mounting holesinthe walls of

the main frame. Securely fasten the rope or twine to the

length of2"x4" wood again.

STEPS.

Install the cylinder shaft:

A. Make certain that the cylinder assembly

is

securely tied to

a strong rope orcord.

B. Be sure that the cylinder shaft has been carefully inspected

for any nicksor burrs and that

it

is lubricated with oil.

7

Page 9

Rg.

19

o

o

~.

sure that the rubber band on the three bolts is not caught

between the bearing and the flangelle.

Fig.

21

STEPS.

Install the pulley on the cylinder shaft, with the shoulder of the

pulley facing outward (see Fig. 20).

Do

not tighten the two

set screws

in

the pulley at this time.

c-·

Bearing

Sleeve

Fig. 22

C.

Gently place the remaining f1angelle over the three bolts,

with the lip of the recessed bore facing outward. Loosely

(hand-tighten only) securethe f1angettes with three Whiz locknuts

(5116"-18).

See Fig.

23.

The three locknuts will be securely

tightened

in

a laterstep,

o

o

Fig. 20

STEP 9.

On

the chipper side of the cylinder shaft, tap the shaft inward

(see Fig. 21)

if

the pulley on the engine side of the cylinder

shaft does not go all the way on the shaft. Back

on

the chipper side of the machine, be sure to reinstall on the shaft the

shield washer and shim(s) which you removed earlier.

STEP 10.

Install the bearing and outer f1angette on the chipper side of

the main frame:

A. The bearing must be free from dirt, rust or other foreign

matter. Apply alight coatingof oil to the bearing slotted sleeve

and outer race before installation.

B. With the slotted sleeve of the bearing facing outward,

slide the bearing over the cylinder shaft until it

is

seated

inside the recessed lip ofthe inner flangette (see Fig. 22). Be

C-

'-"-

-'

8

Page 10

D.

Cut and remove the rubber band, along with the strips of

tape

on

the edges of the inner flangette. Do not be concerned

if you cannot

remove all ofthe rubber band or tape.

STEP 11.

On the engine side of the cylinder shaft, tap the shaft inward

until the chipper side end of the shaft is nearly flush with the

end of the slotted bearing sleeve. The shaft should be slightly

recessed inside the sleeve as shown

in

Fig. 24.

STEP 12.

On the chipper side of the cylinder shaft, install the bearing

locking collar

over the bearing sleeve, covering the sleeve

completely

(see

Fig. 25).

Do

not tighten the set screwinthe

collar at this time.

Fig.

25

STEP 13.

On the chipper side of the cylinder shaft, install the screw

(3Je"-16x3f4"),

conical washer and heavy flat washer

(see

Fig.

26). The conical washer goes

on

the screw first, with the

domed side of the washer facing the screw head. Fingertighten the screw until it

is

snug.

STEP 14.

Being careful to avoid any sharp edges on the cutting flails or

other metal parts (wear thick gloves for added protection),

reach inside the shredder hopper and

remove the rope or

twine from the cylinderassembly.

9

!J

Fig.

26

STEP 15.

Rotate the cylinder shaft pulley so that the keyway is at either

the

3 o'clock or 9 o'clock position (see Fig. 27). While holding

the pulley

in

this position, rotate the cylinder assembly until

the two screw holes

in

the cylinder assembly tube are aligned

with the holes

in

the cylinder shaft. Use a nail orthin punch to

help you align the holes. Replace the two screws

(3Je"-16x2")

and locknuts, tightening them

very

securely.

o

Fig.

27

STEP 16.

On the chipper side of the cylinder shaft, use a

112"

wrench to

tighten the three Whiz locknuts

on

the f1angette mounting

bolts (see

Fig. 28). Tighten the nuts very securely.

IMPORTANT:

Be

sure to follow Steps 17 through 19 exactly to assure cylin-

der shaft alignment.

Page 11

!J

\\

(Chipper

Side)

Fig.

28

STEP 17.

Replace the broom handleorstick down through the cylinder

assembly. Using a

9/

16

" wrench, tighten the screw

in

the chip-

per side end

of

the cylindershaft very securely.

Then,

loosen

the

screw

one (1) fullturn. See

Fig

29.

Fig.

29

STEP 18.

On

the chipper sideofthe cylinder shaft, use a

1Je"

hex key

(Allen) wrench to tighten the set screw

in

the bearing locking

collar

very securely.

STEP 19.

Return to the screwinthe end of the cylinder shaft (see Fig.

29) and tighten it

verysecurely.

STEP 20.

On the engine side of the cylinder shaft, tighten the three

Whiz locknuts on the flangette mounting bolts (see Fig. 30).

Tighten the nuts

very securely.

10

STEP 21.

While still on the engine side of the cylinder shaft, tighten the

set screw

in

the bearing locking collar very securely. While

doing so, make certain that the collar remains flush (all the

way around) against the shoulder of the bearing. See Fig.

30.

STEP 22.

Align the cylindershaft pulley directly underthe engine (upper)

pulley, apply Loctite 242 sealant liberally to the threads

of

the

twoset screws, and securely install theset screws

(5/

16

"-18x%")

in

the pulley, tightening themto 110 inch-Ibs. Before tightening

the set screws, make certain that the belt grooves

in

the two

pulleys areperfectly aligned.

See

Fig. 31. Remove the broom

handle or stick.

STEP 23.

Install the drive belt on the pUlleys by referring to the "Belt

Replacement Instructions"

in

the Owner/Operator Manual.

STEP 24.

Replace the belt cover over the lower pulley and use two

7/16"

wrenches to install the two screws ('I4"-20x%") and Whiz

locknuts.

Page 12

STEP 25.

Replace the chipper chute and use a%"wrench to install the

four screws

(5f16"-18xS/a")

and lockwashers.

STEP2R.

Replace the shredderscreen, securing the two long rods with

the hair pin cotters. Also secure the service door with its

rod

and hair pin cotter.

STEP 27.

On

electric start models, replace the battery and its cables by

reversing Step 3 of the disassembly steps. Make certain that

the negative

(-)

postonthe batteryisthe post closest you on

the battery platform as you face the engine. Last, you can

reconnect the plug wire to the spark plug.

OTHER SERVICE PROCEDURES AND INSPECTIONS

Inspecting Welds

Inspect all exterior steel surfaces of the Tomahawk Chipper/Shredder mainframe to see if any of the welds have broken. Welding

repairs must be completed before the Chipper/Shredder

is

used again.

Inspecting

the

Retainer Flap

The retainer flap is the rubber piece inside the shredder hopper by which you must pass all material that you wish to shred. The

retainer flap should

beingood condition and securely attached,asits function is to prevent kickback of materials that are being

processed inside the Chipper/Shredder chamber. Flap replacement is

quick-just

loosen and remove the two screws that secure the

flap to the chipper/shredderand replace the flap.

Torque Specifications

The following screws have specific torque tightening requirements:

The set screw

in

the bearing locking collar: 60

inch/pounds.

The screw that holds the driveshaftinposition within the bearings: 30

foot/pounds.

The two set screwsinthe lower belt pulley: 110

inch/pounds.

The three screwsthat hold the bearing flangettes: 140

inch/pounds.

Troy.Bilt

Manufacturing

Co.,

102nd Street & 9th Ave., Troy, New York 12180

Call Toll-Free: 1-800-833-6990

Garden

Way

Canada,

Inc.,

1515 Matheson BlVd., Unit B11, Mississauga,

Ontario

L4W 2P5

Local

calls

only

(416 Area Code): 624-8423·From Ontario & Quebec Provinces call Toll-Free: 1-800-387-3351

From WesternCanada

& Maritime

Provinces

call Toll-Free: 1-800-387-3316

SR2841189

Printed

in

USA

c 1989Garden

Way

Inc.

Loading...

Loading...