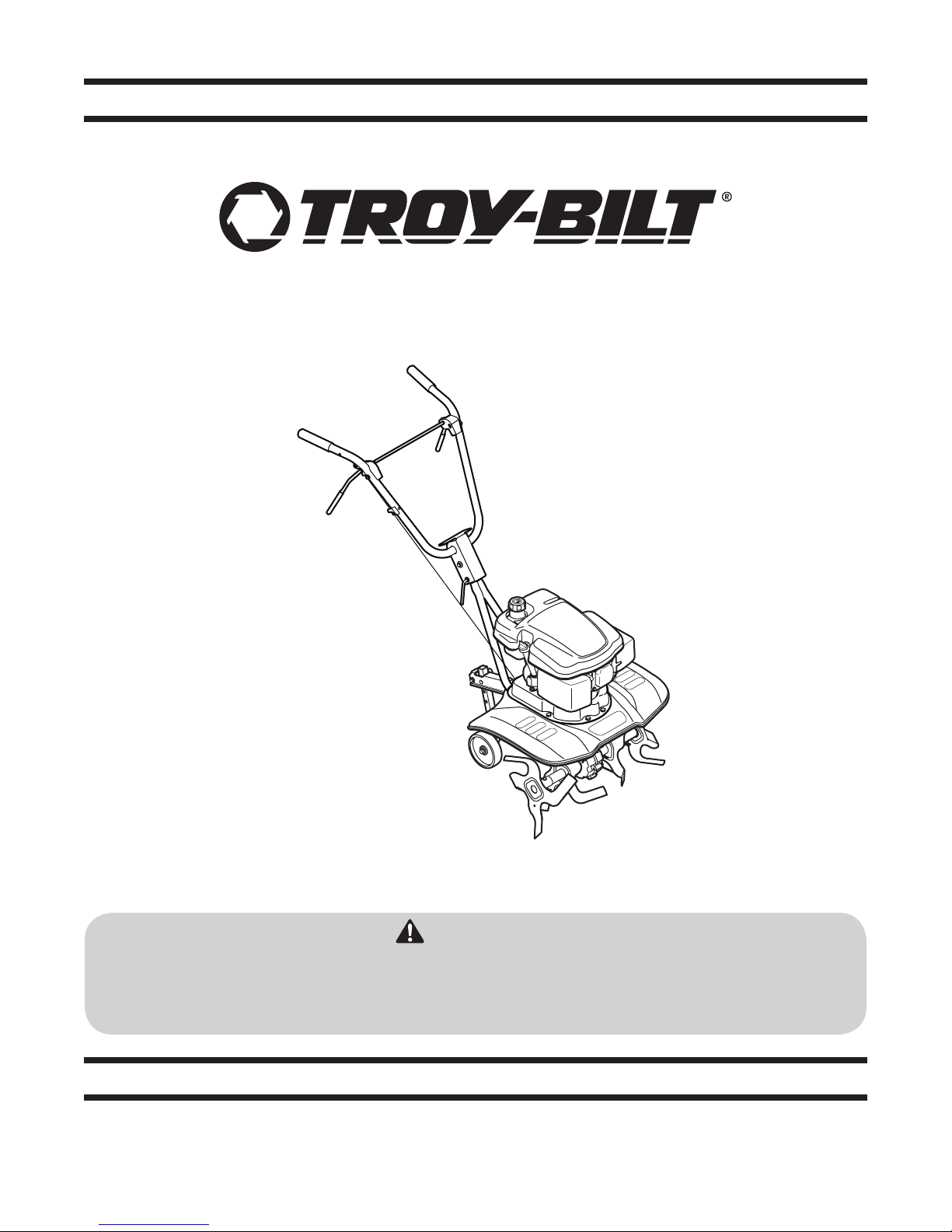

Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OperatOr’s Manual

World Rear Wheel Tiller — Series 200

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

P. O. Box 1386, 97 KENT AVENUE, KITCHENER, ON N2G 4J1

Printed In USA

WARNING

769-07679

(11.18.11)

Page 2

To The Owner

Thank You

Thank you for purchasing a machine manufactured by MTD. It

was carefully engineered to provide excellent performance when

properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD

Table of Contents

1

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

If you have any problems or questions concerning the machine,

phone your local authorized MTD service dealer or contact us

directly. MTD’s Customer Support telephone numbers, website

address and mailing address can be found on this page. We want

to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position.

The engine manufacturer is responsible for all engine-related

issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer’s

Owner’s/Operator’s Manual, packed separately with your

machine, for more information.

Safe Operation Practices ........................................ 3

Assembly & Set Up ................................................... 7

Controls ................................................................... 8

Operation ................................................................. 9

Service .....................................................................12

Troubleshooting .....................................................13

Parts List ..................................................................14

Warranty ................................................................. 15

Maintenance & Adjustment .................................11

Record Product Information

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate

the model plate by standing at the operator’s position and

looking down at the rear of the machine. This information will be

necessary, should you seek technical support via our web site,

Customer Support Department, or with an authorized service

dealer.

Model NuMber

Serial NuMber

Customer Support

Please do

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

NOT

return the unit to the retailer from which it was purchased, without first contacting Customer Support.

◊ Visit our web at www.troybilt.ca

◊ Locate your nearest dealer from Customer Support: 1-800-668-1238

◊ Contact Troy Bilt • P.O. Box 1386 • 97 Kent Avenue • Kitchener, Ontario, Canada • N2G 4J1

2

Page 3

Important Safe Operation Practices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet. Failure to observe the following safety instructions could result in serious

injury or death.

2

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4. Never allow adults to operate this machine without proper

instruction.

5. Keep the area of operation clear of all persons, particularly

small children and pets. Stop machine if anyone enters the

area.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used. Remove all stones, sticks, wire, and other foreign

objects which could be tripped over and cause personal

injury.

2. Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Loose fitting clothes or jewelry can be

caught in moving parts. Never operate this machine in bare

feet or sandals.

3. Disengage clutch levers and shift (if provided) into neutral

(“N”) before starting the engine.

4. Never leave this machine unattended with the engine

running.

5. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

Safe Handling of Gasoline:

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

c. When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than ½

inch below bottom of filler neck to allow space for

fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

3

Page 4

l. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

1. Do not put hands or feet near rotating parts. Contact with

the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence of

alcohol or drugs.

3. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles.

4. Keep bystanders away from the machine while it is in

operation. Stop the machine if anyone enters the area.

5. Be careful when tilling in hard ground. The tines may catch

in the ground and propel the tiller forward. If this occurs,

let go of the handle bars and do not restrain the machine.

6. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic. Do

not carry passengers.

7. Never operate the machine at high transport speeds on

hard or slippery surfaces.

8. Exercise caution to avoid slipping or falling.

9. Look down and behind and use care when in reverse or

pulling machine towards you.

10. Start the engine according to the instructions found in this

manual and keep feet well away from the tines at all times.

11. After striking a foreign object, stop the engine, disconnect

the spark plug wire and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

12. Disengage all clutch levers (if fitted) and stop engine

before you leave the operating position (behind the

handles). Wait until the tines come to a complete stop

before unclogging the tines, making any adjustments, or

inspections.

13. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

14. Muffler and engine become hot and can cause a burn. Do

not touch.

15. Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause property

damage or personal injury.

16. Do not overload machine capacity by attempting to till soil

too deep at too fast of a rate.

17. If the machine should start making an unusual noise or

vibration, stop the engine, disconnect the spark plug wire

and ground it against the engine. Inspect thoroughly for

damage. Repair any damage before starting and operating.

18. Keep all shields, guards, and safety devices in place and

operating properly.

19. Never pick up or carry machine while the engine is running.

20. Use only attachments and accessories approved by the

manufacturer. Failure to do so can result in personal injury.

21. If situations occur which are not covered in this manual, use

care and good judgement. Contact Customer Support for

assistance and the name of you nearest servicing dealer..

Maintenance & Storage

1. Keep machine, attachments and accessories in safe

working order.

2. Allow a machine to cool at least five minutes before

storing. Never tamper with safety devices. Check their

proper operation regularly.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Before cleaning, repairing, or inspecting, stop the engine

and make certain the tines and all moving parts have

stopped. Disconnect the spark plug wire and ground it

against the engine to prevent unintended starting.

5. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of engine.

6. Maintain or replace safety and instruction labels, as

necessary.

7. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

8. Always refer to the operator’s manual for important details

if the machine is to be stored for an extended period.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

11. According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 130 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

4 Section 2 — impo rtant Safe operation practice S

Page 5

Spark Arrestor

WARNING! This machine is equipped with an internal combustion engine and should not be used on or near any

unimproved forest-covered, brushcovered or grass-covered land unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or provincial laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. A spark arrester for the

muffler is available through your nearest engine authorized service dealer.

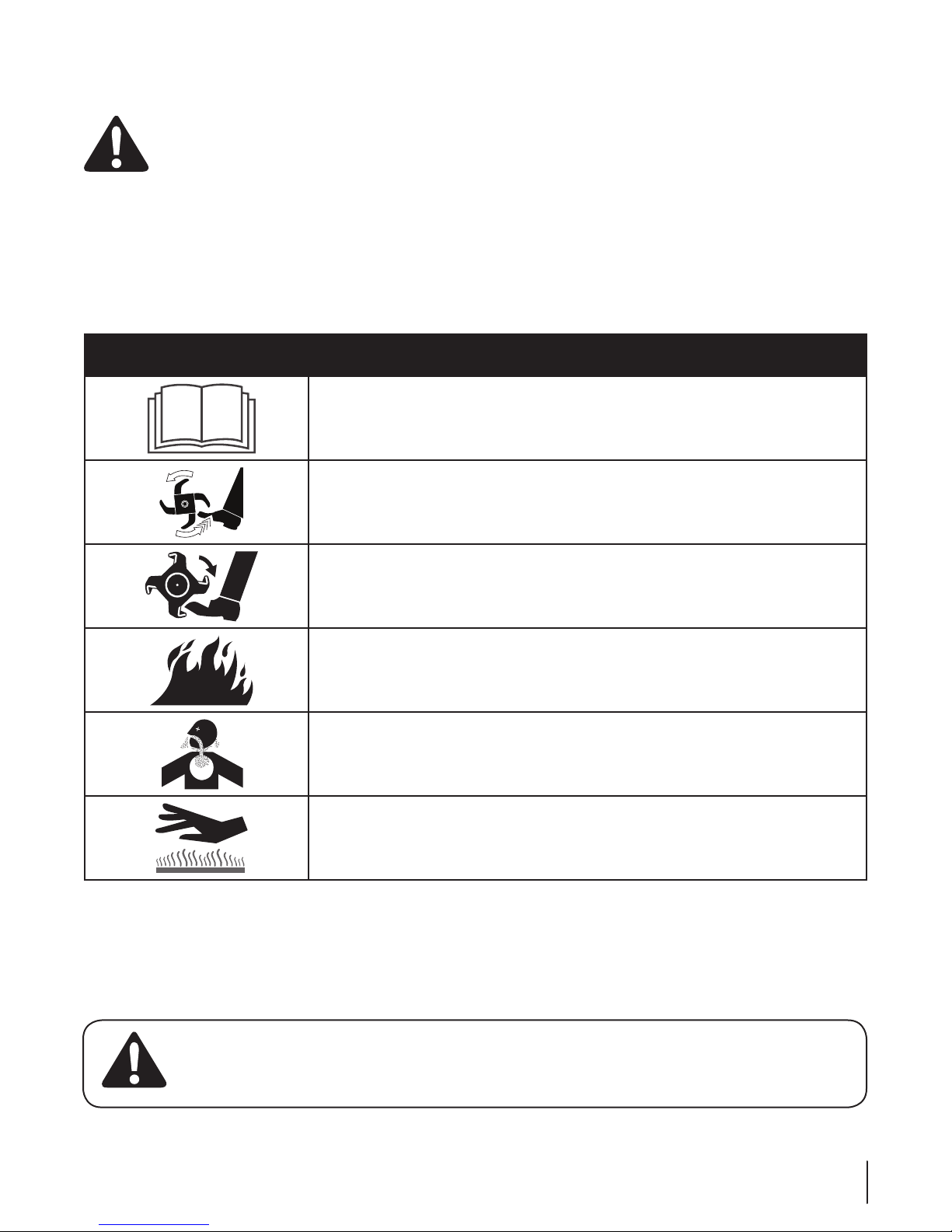

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

WARNING— ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING— ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING— HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

5Section 2 — impo rtant Safe operation practice S

Page 6

Assembly & Set-Up

Handle Crank

Washer

Retainer

Bracket

Nuts

Bolt

Contents of Carton

• OneTiller • One20oz.bottleSAE30Woil • OneTillerOperator’sManual

• OneEngineOperator’sManual

3

NOTE: Standbehindthetillerasifyouweregoingtooperate

it.Yourrighthandcorrespondstotherightsideofthetillerand

yourlefthandcorrespondstotheleftsideofthetiller.

NOTE: Thisoperator’smanualmaycovervariousmodelsoftillers.

Themachinesillustratedmayvaryslightlyfromyourtiller.

NOTE: Thetillerisshippedwithoutgasolineoroilintheengine.

Fillupgasolineandoilasinstructedintheaccompanyingengine

manualbeforeoperatingyourmachine.

Assembly

Handle

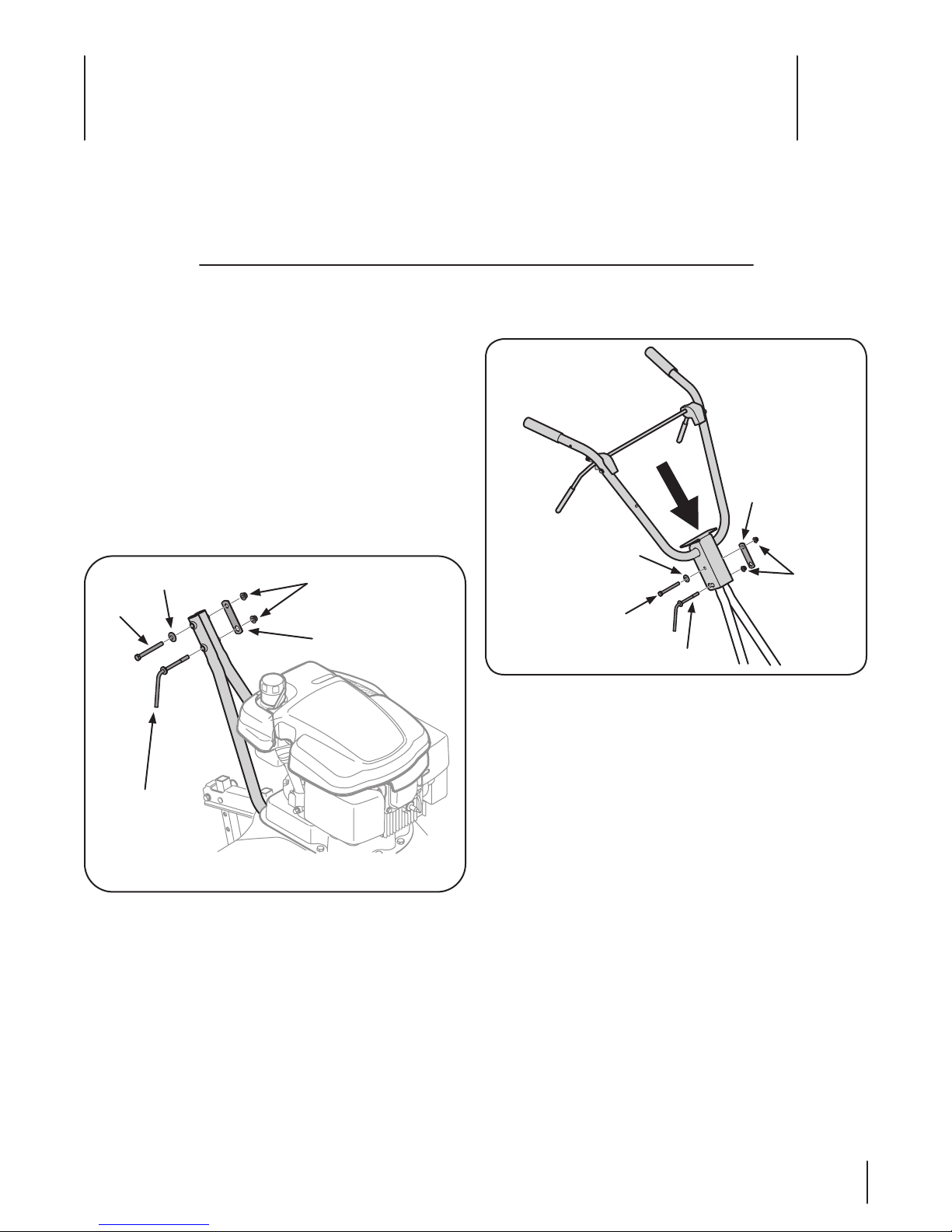

1. Removethehandlecrank,bolt,washer,retainerbracket

andtheflangelocknutsfromthelowerhandle.See

Fig.3-1.

Washer

Bolt

Handle Crank

Nuts

Retainer

Bracket

2. Positiontheupperhandleontothelowerhandle.SeeFig.

3-2.Aligntheholesonthelowerhandlewiththeholeson

theupperhandle.

Figure 3-2

3. Insertthehandlecrankthroughthelowerholeonthe

handleandsecurewiththenutremovedinstep1.See

Fig.3-2.

4. Inserttheboltandwasherthroughtheholeinthehandle

andsecurewiththeretainerbracketandthentheupper

nutremovedinstep1.SeeFig.3-2.

Figure 3-1

6

Page 7

Cotter Pin

Clevis Pin

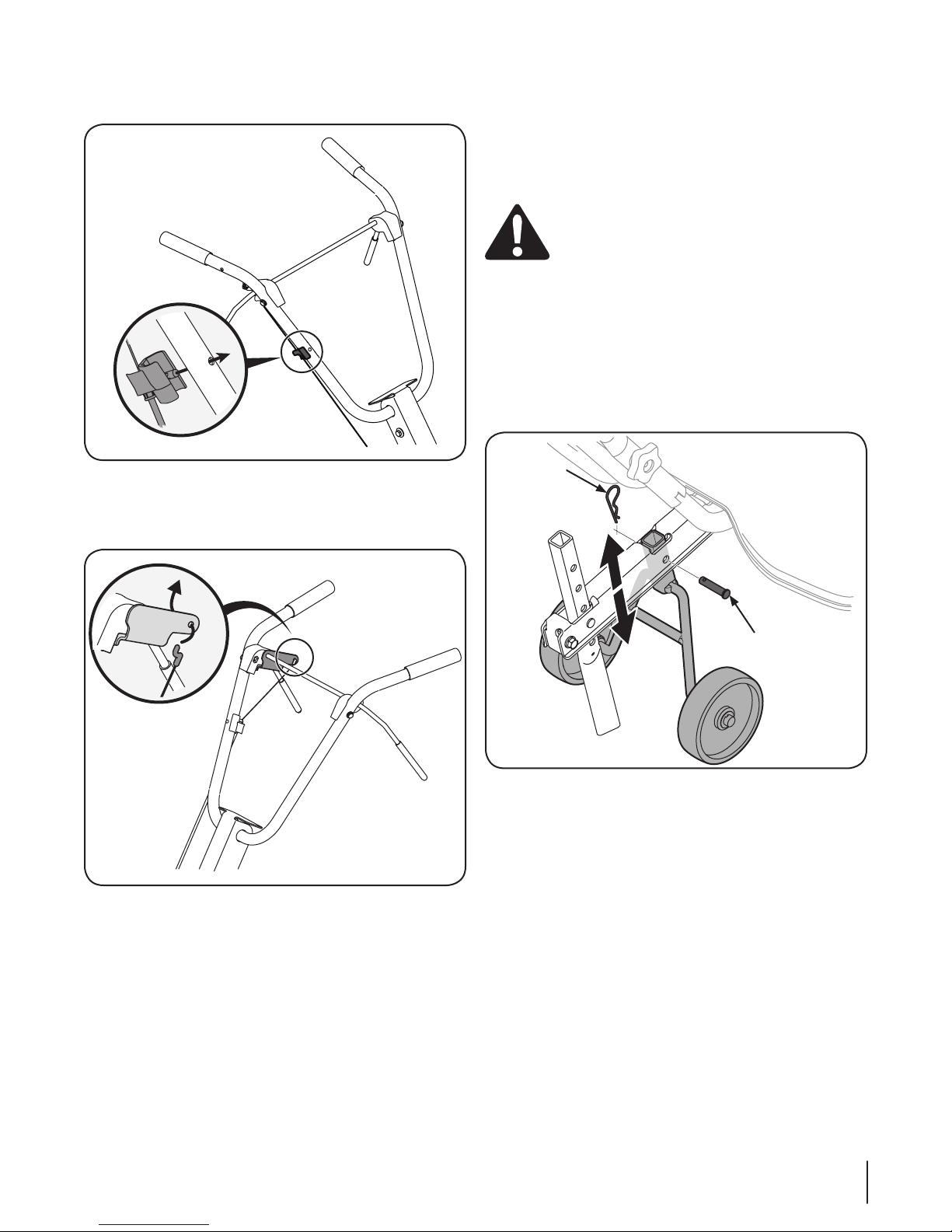

5. Insert the clutch cable handle fitting into the hole on the

right side of the upper handle. See Fig. 3-3.

Figure 3-3

6. Insert the Z-fitting on the clutch cable into the hole on the

tine clutch control. Hook the “Z” end into the opening from

the inside to the outside as shown in Fig. 3-4.

Set-Up

Gas & Oil Fill-Up

Service the engine with gasoline and oil as instructed in the

separate engine manual packed with your tiller. Read the

instructions carefully.

WARNING! Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel machine indoors or

while the engine is hot or running.

Adjustments

Wheels

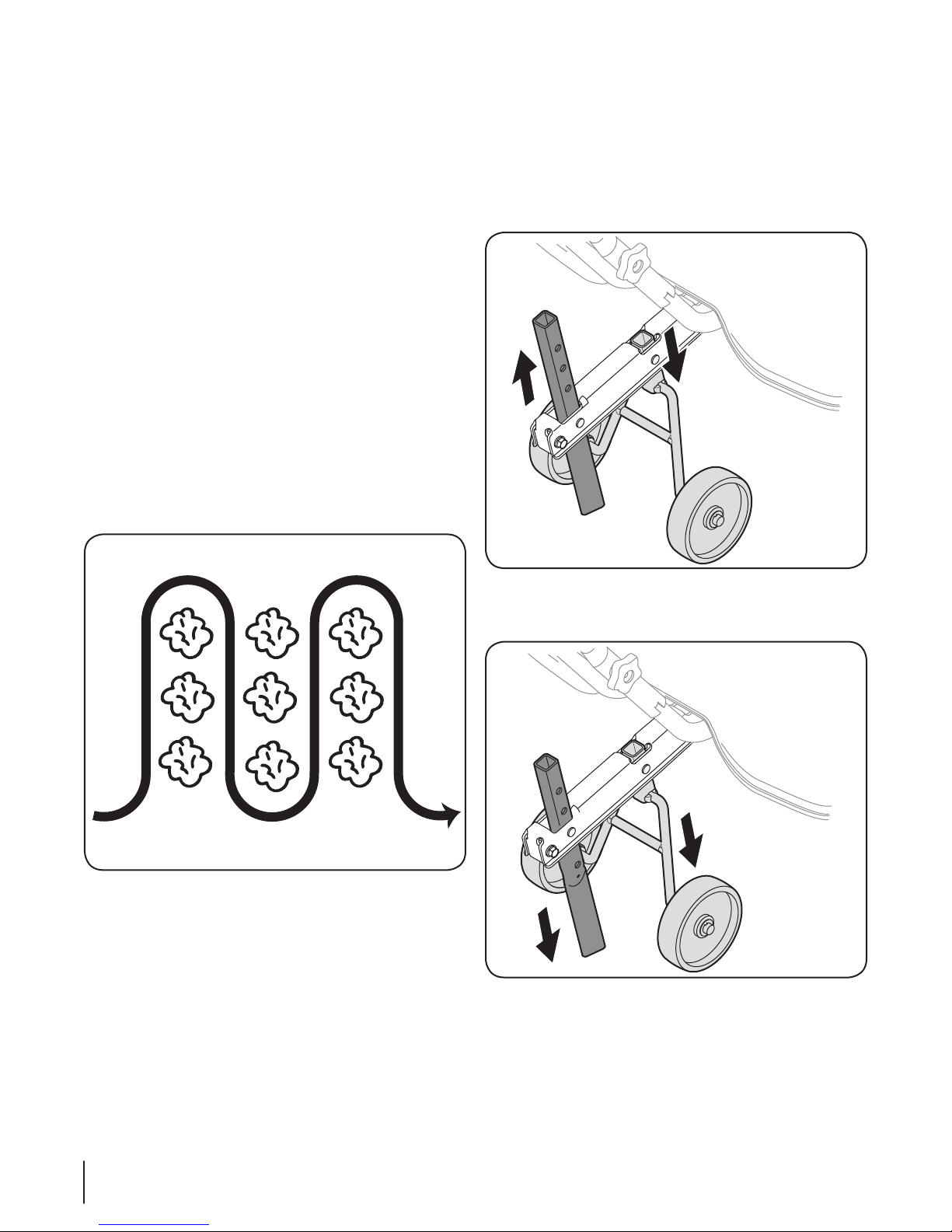

The tiller is shipped with the wheels adjusted such that the

unit sits level. Before tilling, the wheels must be raised. To do

this, remove the clevis and cotter pins, raise the wheels to the

desired position, then reattach pins to secure, Figure 3-5. For

transporting the tiller, reverse the steps to lower the wheels.

Figure 3-4

Figure 3-5

7Section 3 — ASSemb ly & Set-Up

Page 8

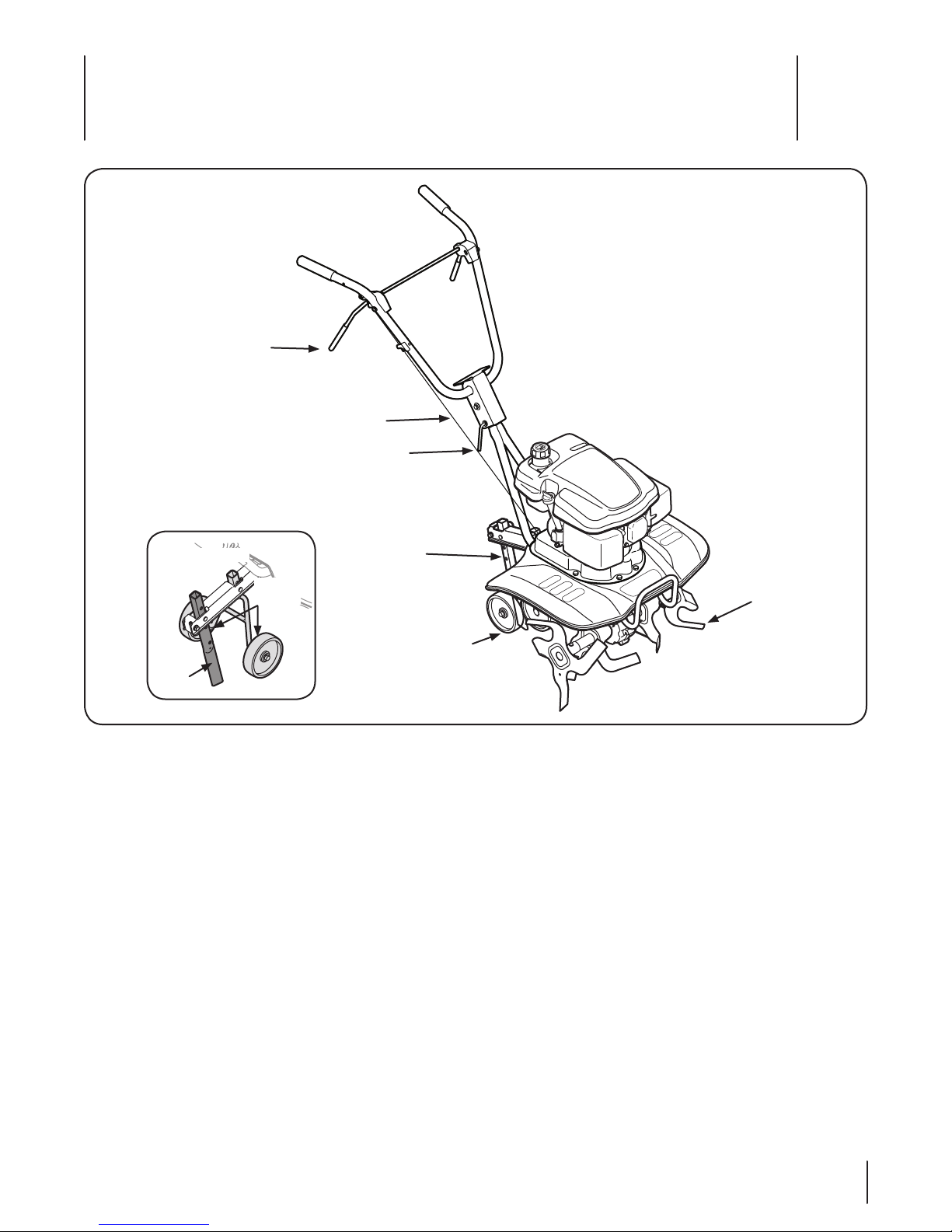

Controls & Features

Back of Tiller

Depth

Stake

Rear

Wheels

Tine Clutch Control

Clutch Cable

Handlebar Height Adjustment

4

Depth Stake

Rear Wheels

Figure 4-1

NOTE: This Operator’s Manual covers several garden tiller

models. The tiller depicted may differ from yours.

Tine Clutch Control

The clutch control lever is located on the upper handle.

Squeezing the lever against the handle engages the tine drive.

Release the lever to stop the tines from turning.

Handlebar Height Adjustment

The handlebar height is adjustable to three different settings. In

general, adjust the handlebars so they are at waist level when the

tines are 3-4” in the ground.

Tines

Depth Stake

The depth stake acts as a brake for the tiller and controls the

depth and speed at which the machine will operate.

Rear Wheels with Depth Stake

The rear wheels can be raised and lowered for transport and

storage. Refer to the Maintenance & Adjustments Section for

instructions on depth stake adjustment and the Assembly & Set-

Up Section for instructions on wheel adjustment.

Engine Controls

Refer to the engine manual for information and function of the

engine controls.

8

Page 9

Operation

54 32 1

5

WARNING! Read, understand, and follow all

instructions and warnings posted on the machine, in

this manual and in the separate engine manual

before operating.

WARNING! Be sure no one other than the operator

is standing near the tiller while starting the engine

or operating the unit. Never run the engine indoors

or in enclosed, poorly ventilated areas. Engine

exhaust contains carbon monoxide, an odorless and

deadly gas. Keep hands, feet, hair and loose clothing

away from any moving parts on the engine and the

tiller.

Starting & Stopping the Engine

With the spark plug wire disconnected from the spark plug,

perform the following checks and services before each use:

1. Check unit for loose or missing hardware. Service as

required.

2. Check engine oil level. See the Engine Operator’s Manual.

3. Check that all safety guards and covers are in place.

4. Check air cleaner and engine cooling system. See the

Engine Operator’s Manual.

WARNING! GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE. Follow the gasoline

safety rules in the Important Safe Operations

Practices section of this manual. Failure to follow

gasoline safety instructions can result in serious

personal injury and property damage.

5. Fill the fuel tank with gasoline according to the directions

in the Engine Operator’s Manual. Follow all instructions and

safety rules carefully.

6. Attach the spark plug wire to the spark plug.

WARNING! Never run the engine indoors or in an

enclosed, poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly

gas. Avoid the engine muffler and nearby areas.

Temperatures in these areas may exceed 150° F.

7. Release all of the controls on the tiller.

8. Start and stop the engine as instructed in the Engine

Operator’s Manual

The working depth of the machine may be predetermined by

setting the depth stake so that the wheels are about four inches

from the ground when the tines and depth stake are resting on

the ground. This setting will permit a working depth of about

four inches. When presetting the working depth, the handles

should be adjusted so the hand grips are a little above the waist.

The tiller will be lower when the tines and depth stake penetrate

the ground.

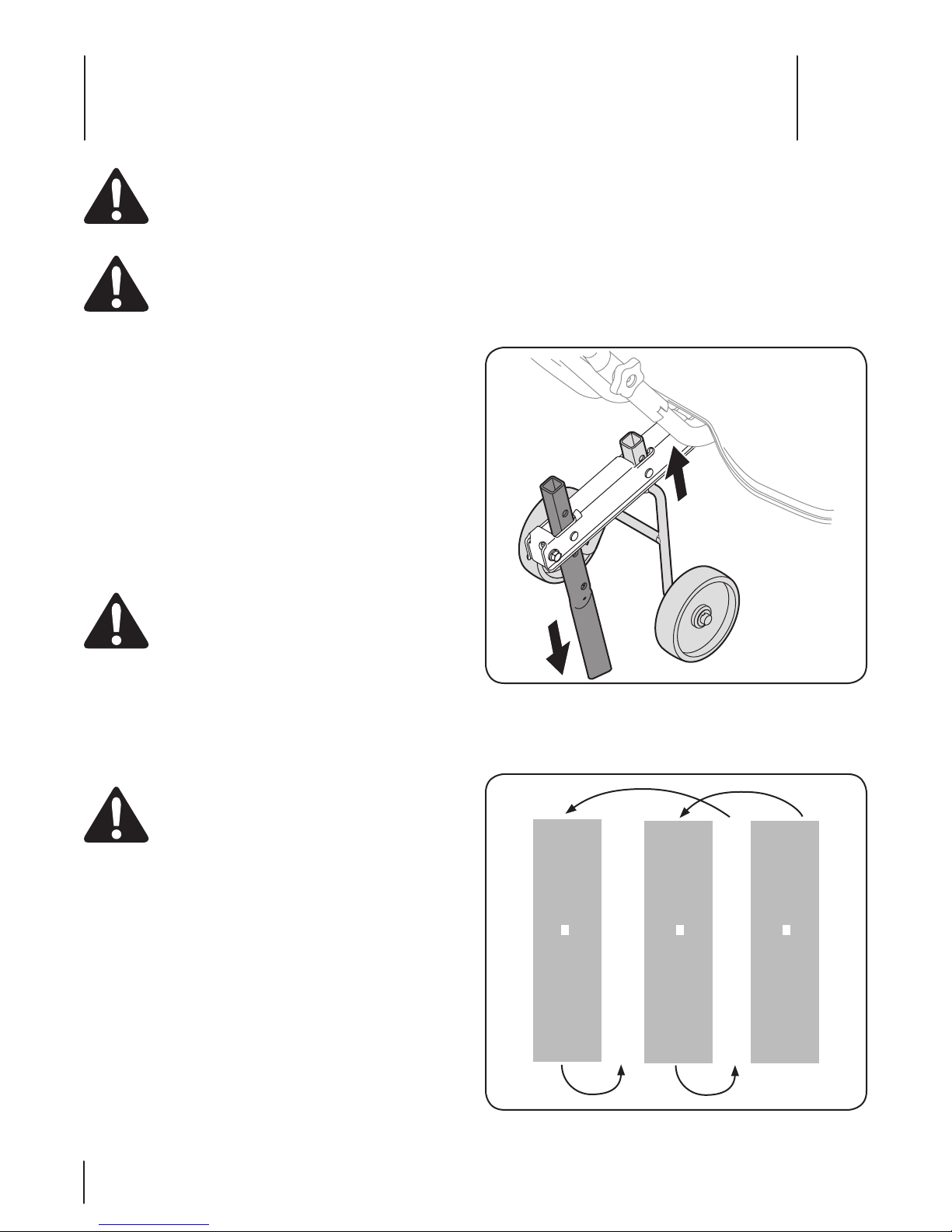

For tilling, the depth stake must be lowered and the wheels

must be raised. See Fig. 5-1.

Figure 5-1

When tilling, leave approximately eight inches of untilled soil

between the first and second tilling paths, then make the third

path between the first and second. See Fig. 5-2.

Using Your Tiller

Your tiller is designed for seed bed preparation, cultivating,

furrowing, and mulching.

Controlling Tilling and Depth Speed

By increasing the depth of the depth stake, the forward speed

of the machine is reduced and the working depth is increased.

When the depth stake is raised, the working depth of the

machine is reduced and the forward speed is increased.

9

Figure 5-2

Page 10

In some soils, the desired depth is obtained the first time over

the garden. In other soils, the desired depth is obtained by going

over the garden two or three times. Passes should be made

across the length and width of the garden alternately. Rocks

which are turned up should be removed from the garden area.

Handle Pressure

Further control of tilling depth and travel speed can be obtained

by variation of pressure on the handles. A downward pressure

on the handles will reduce the working depth and increase the

forward speed. An upward pressure on the handles will increase

the working depth and reduce the forward speed. The type of

soil and working conditions will determine the actual setting of

the depth stake and the handle pressure required.

Cultivating

For cultivating, a two to three inch depth is desirable. With

the outer tines installed (Series 240), the working width of the

machine is 22 or 24 inches. The working width of Series 220

machines is fixed at 16 inches

For cultivation, the tine width can be reduced to 13 inches

(Series 240), by removing the outer tines, refer to the Adjustment

Section. When laying out plant rows, be sure to allow enough

width to permit cultivation between the rows. In growing corn or

similar crops, check-row planting will permit cross cultivation and

practically eliminate hand hoeing, Fig. 5-3.

For proper decaying action, fertilizer should be applied and

worked in with the mulch materials. Breaking up leaves and straw

and mixing it with several inches of soil allows proper aeration of

the plant root system and retards the growth of weeds.

Transporting and Storing the Tiller

To transport the tiller, lower the wheels and move the depth

stake to the highest position. See Fig. 5-4.

Figure 5-3

The tiller has many uses other than tilling and cultivating a

garden. One of these is the preparation of lawn area for seeding.

The tiller will prepare a deep seed bed which will be free of hard

untilled spots, allowing a better stand of grass to grow. The tiller

is very useful for loosening hard soil for excavation with a shovel;

No tedious handwork will be necessary. Your tiller may be used

for mixing compost in the pile or for mixing it with the soil in

your garden. This should be done after the soil has been broken

to the full working depth. The compost should be worked in

to a depth of six to seven inches. This may be done by working

the length of the garden and then by making separate passes

across its width. The addition of decayed organic matter will

substantially increase the fertility of your garden.

Figure 5-4

To store the tiller, lower the wheels and orient the depth stake so

both are touching the ground. See Fig. 5-5.

Figure 5-5

10 Section 5— operation

Page 11

Maintenance & Adjustments

13-inch

22-inch

24-inch

Cotter

Pin

Clevis

Pin

WARNING! Before inspecting, cleaning or servicing

the tiller, shut off the engine and wait for all moving

parts to come to a complete stop. Disconnect the spark

plug. Failure to follow these instructions properly can

result in serious personal injury or property damage.

Maintenance

Engine

Refer to the Engine Operator’s Manual packaged with your

machine for all engine maintenance.

Tines

Clean the underside of the tine shield after each use. The dirt

washes off the tines easier if rinsed off immediately instead of

after it dries. Always towel dry the tiller afterwards and apply a

light coat of oil or silicone to prevent rusting or water damage.

NOTE: Never use a pressure washer to clean the tiller. Water can

penetrate tight areas of the tiller and cause serious damage.

6

Lubrication

Transmission

The transmission is pre-lubricated and sealed at the factory. It

requires no maintenance. See an authorized service dealer for

any service issues.

Tine Shaft and Wheel Shaft

Remove tine assemblies and wheel and lubricate the tine shaft

and wheel shaft at least once a season.

Adjustments

Tine Width

The tilling width 22” but can increase to 24 inches by removing

the clevis and cotter pins, sliding each outer tine out 1”, and

securing in this position with the pins. Reduce the tine width to

13 inches by removing the outer tines completely. See Fig. 6-1.

Depth Stake

The depth stake acts as a brake for the tiller and controls the

depth and speed at which the machine will operate, Figure 3-5.

Remove the clevis and cotter pins, raise or lower the depth stake,

then reattach pins to secure.

Figure 6-1

Off-Season Storage

If the tiller will not be used for a period longer than 30 days, the

following steps should be taken to prepare the tiller for storage.

• Clean the exterior of the engine and the entire tiller

thoroughly. Lubricate the tiller as described in the

Lubrication instructions.

• The use of pressure washers to clean your tiller is not

recommended. It may cause damage to pulleys, bearings,

or the engine. The use of pressure washers will result in

shortened life and reduce serviceability.

• Refer to the engine manual for engine storage instructions.

• Wipe tines with oiled rag to prevent rust.

• Store tiller in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

• When storing any type of power equipment in an

unventilated or metal storage shed, care should be taken

to rustproof the equipment. Using a light oil or silicone,

coat the equipment and especially any springs, bearings,

and cables.

11

Page 12

Lock Nut

Pulley

Belt

Service

7

Belt Replacement

Your tiller has been engineered with a belt made of special

material for longer life and better performance. Replace with

a factory-approved OEM belt. See the retailer from which you

purchased your tiller, an authorized MTD Service Dealer, or call

1-800-800-7310 for information regarding price and availability.

1. Remove the belt cover and engine by removing the six

screws and lock nuts holding the engine and cover to the

shield. See Fig. 7-1.

Screw

2. Loosen the lock nut shown in Fig. 7-2.

Figure 7-2

3. Unloop the belt from the pulleys. See Fig. 7-2.

4. Reassemble the new belt and tighten the lock nut.

5. Reattach b elt cover and engin e using the hardware removed

earlier.

Lock Nut

Figure 7-1

12

Page 13

Troubleshooting

Problem Cause Remedy

8

Engine Fails to start 1. Spark plug wire disconnected

2. Fuel tank empty or stale fuel

3. Throttle control lever (if equipped) not in

correct starting position

4. Choke not in ON position

5. Blocked fuel line

6. Faulty spark plug

7. Engine flooding

Engine runs erratic 1. Spark plug wire loose

2. Unit running on CHOKE

3. Blocked fuel line or stale fuel

4. Vent plugged

5. Water or dirt in fuel system

6. Dirty air cleaner

7. Carburetor out of adjustment

Engine overheats 1. Engine oil level low

2. Dirty air filter

3. Air flow restricted

4. Carburetor not adjusted properly

Tines do not engage 1. Foreign object lodged in tines

2. Tine clevis pin(s) missing

3. Belt worn and/or stretched

4. Pulley and idler not in correct adjustment

1. Connect wire to spark plug

2. Fill tank with clean, fresh gasoline

3. Move throttle lever to start position

4. Move lever to ON position

5. Clean fuel line

6. Clean, adjust gap, or replace

7. Wait a few minutes to restart, but do not

prime (if equipped)

1. Connect and tighten spark plug wire

2. Move choke lever to OFF

3. Clean fuel line; fill tank with clean, fresh

gasoline

4. Clear vent

5. Drain fuel tank. Refill with fresh fuel

6. Clean following engine manual

7. Refer to engine manual

1. Fill crankcase with proper oil

2. Clean air cleaner

3. Remove blower housing and clean

4. Refer to engine manual

1. Stop tiller completely, check and discard

foreign object

2. Replace tine clevis pin(s)

3. Replace belt

4. Take unit to authorized service

13

Page 14

Replacement Parts

Component Part Number and Description

9

642-04032 Right Hand Tine Assembly

642-04031 Left Hand Tine Assembly

714-04043 Bow-tie Pin

911-0415 Clevis Pin

946-04663 Clutch Cable

734-0973 Wheel, 5.0 x 1.38

Phone (800) 800-7310 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready).

Parts Manual downloads are also available free of charge at www.mtdproducts.com.

14

Page 15

MANUFACTURER’S LIMITED WARRANTY FOR

The limited warranty set forth below is given by Troy-Bilt LLC with

respect to new merchandise purchased and used in the United States

and/or its territories and possessions, and by MTD Products Limited

with respect to new merchandise purchased and used in Canada and/

or its territories and possessions (either entity respectively, “TroyBilt”).

“Troy-Bilt” warrants this product (excluding its Belts, Transmission

and Attachments as described below) against defects in material and

workmanship for a period of two (2) years commencing on the date

of original purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or workmanship.

This limited warranty shall only apply if this product has been

operated and maintained in accordance with the Operator’s Manual

furnished with the product, and has not been subject to misuse,

abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of other

peril or natural disaster. Damage resulting from the installation or use

of any part, accessory or attachment not approved by Troy-Bilt for use

with the product(s) covered by this manual will void your warranty as

to any resulting damage.

Belts are warranted to be free from defects in material and

workmanship for a period of thirty (30) days from the date of

purchase.

Transmission — Troy-Bilt warrants the transmission (including

all gears, shafts and housings) against defects in material and

workmanship for the life of the tiller, to the original purchaser only,

commencing on the date of original purchase or lease.

Attachments — Troy-Bilt warrants attachments for this product

against defects in material and workmanship for a period of one (1)

year, commencing on the date of the attachment’s original purchase

or lease. Attachments include, but are not limited to items such as:

grass collectors and mulch kits.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE, through your local authorized service dealer.

To locate the dealer in your area:

In the U.S.A.

Check your Yellow Pages, or contact Troy-Bilt LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-866-840-6483,

1-330-558-7220 or log on to our Web site at www.troybilt.com.

In Canada

Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call

1-800-668-1238 or log on to our Web site at www.mtdcanada.com.

This limited warranty does not provide coverage in the following

cases:

a. The engine or component parts thereof. These items may carry a

separate manufacturer’s warranty. Refer to applicable manufacturer’s warranty for terms and conditions.

b. Log splitter pumps, valves, and cylinders have a separate one-

year warranty.

c. Routine maintenance items such as lubricants, filters, blade

sharpening, tune-ups, brake adjustments, clutch adjustments,

deck adjustments, and normal deterioration of the exterior finish

due to use or exposure.

d. Service completed by someone other than an authorized service

dealer.

e. Troy-Bilt does not extend any warranty for products sold or

exported outside of the United States and/or Canada, and their

respective possessions and territories, except those sold through

Troy-Bilt’s authorized channels of export distribution.

f. Replacement parts that are not genuine Troy-Bilt parts.

g. Transportation charges and service calls.

h. Troy-Bilt does not warrant this product for commercial use.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose, applies after

the applicable period of express written warranty above as to the

parts as identified. No other express warranty, whether written or

oral, except as mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product, shall

bind Troy-Bilt. During the period of the warranty, the exclusive

remedy is repair or replacement of the product as set forth above.

The provisions as set forth in this warranty provide the sole and

exclusive remedy arising from the sale. Troy-Bilt shall not be liable

for incidental or consequential loss or damage including, without

limitation, expenses incurred for substitute or replacement lawn

care services or for rental expenses to temporarily replace a

warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions or limitations may not apply

to you.

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of safety features of

the product shall void this warranty. You assume the risk and liability

for loss, damage, or injury to you and your property and/or to others

and their property arising out of the misuse or inability to use the

product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased as a

gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This limited

warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

IMPORTANT: Owner must present Original Proof of Purchase to

obtain warranty coverage.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

GDOC-100023 REV. C

Page 16

Notes

16

Page 17

16

Notes

Page 18

GDOC-100023 REV. C

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

couverts par une garantie séparée d’un an.

b.

honorer la garantie.

IMPORTANT : Le propriétaire doit présenter le reçu original pour faire

d’autres droits qui varient selon les juridictions.

accorde des droits juridiques spécifiques et vous pouvez bénéficier

LES LOIS LOCALES ET CETTE GARANTIE : Cette garantie limitée vous

personne à laquelle le produit a été offert en cadeau.

Cette garantie limitée n’est offerte qu’à l’acheteur initial ou à la

l’utilisation incorrecte du produit ou de l’incapacité de l’employer.

en cas de perte, de dommage matériel ou de blessure résultant de

et non avenue. L’utilisateur assume tout risque et toute responsabilité

modification des caractéristiques de sécurité rendra la garantie nulle

cas supérieur au montant du prix d’achat du produit vendu. Toute

Le remboursement ou remplacement quel qu’il soit ne sera en aucun

pas s’appliquer dans votre situation.

la garantie tacite. Par conséquent, les exclusions ci-dessus peuvent ne

des dommages accessoires ou immatériels ou une limite à la durée de

Certaines juridictions ne permettent pas l’inclusion ou la restriction

produit sous garantie.

des pelouse ou les frais de location pour remplacer temporairement un

les frais de remplacement ou de substitution des services d’entretien

tout dommage accessoire ou immatériel comprenant, sans s’y limiter,

garantie. Troy-Bilt ne peut être tenue responsable pour toute perte ou

suite de la vente ou de la location-bail des produits couverts par cette

stipulations énoncées dans cette garantie offrent le seul recours à la

constitue le recours unique et exclusif à la disposition du client. Les

réparation ou le remplacement du produit dans les conditions ci-dessus

compris un concessionnaire/revendeur, pour n’importe quel produit. La

Troy-Bilt même si elle est offerte par toute personne ou entité, y

garantie expresse, à l’exception des stipulations ci-dessus, n’engage

applicable de la garantie écrite expresse ci-dessus. Aucune autre

particulier. Aucune garantie ne s’applique après la période de vigueur

garantie tacite de qualité marchande ou d’adaptabilité dans un but

Aucune garantie tacite ne s’applique, y compris sans s’y limiter, toute

h. Troy-Bilt ne garantit pas ce produit pour un utilisation commercial.

techniciens.

g. Les frais de transport des machines et de déplacement des

authentiques.

f. Les pièces de rechange si elles ne sont pas des pièces Troy-Bilt

des services d’exportation de Troy-Bilt.

respectifs, sauf si ces produits ont été vendus par l’intermédiaire

États-Unis et/ou du Canada, de leurs possessions et territoires

e. Troy-Bilt ne garantit pas les produits vendus ou exportés hors des

station technique agréée.

d. L’entretien ou les réparations effectués par quiconque autre qu’une

péries.

fait de l’utilisation de la machine ou de son exposition aux intemou du plateau de coupe et la détérioration normale de la finition du

guisages de lame et révisions, les réglages de frein, de l’embrayage

c. Les articles d’entretien courant tels que les lubrifiants, filtres, ai-

Les pompes, soupapes et pistons des fendeuses à bois sont

conditions de cette garantie.

séparément par la garantie du fabricant. Consultez les termes et

a. Le moteur et les pièces du moteur. Ces pièces sont garanties

Sans se limiter à ce qui précède, cette garantie ne couvre pas :

mtdcanada.com

N2G 4J1 ou appelez le 1-800-668-1238 ou visitez notre site web au www.

Au Canada : Adressez-vous à MTD Products Limited, Kitchener, Ontario,

toybilt.com

6483, 1-330 -558-7220. Vous pouvez aussi visiter notre site web au www.

LLC, P.O. Box 361131, Cleveland, Ohio 44136-0019 ou appelez le 1-866-840Aux États-Unis : Consultez les Pages Jaunes ou adressez-vous à Troy-Bilt

station technique agréée ou un concessionnaire dans votre région :

D’A CHAT, à la station technique agréée de votre localité. Pour localiser une

POUR FAIRE HONORER LA GARANTIE : Présentez UNE PREUVE

et les ensembles de déchiquetage.

Les accessoires comprennent, sans s’y limiter, les collecteurs d’herbe

période de une (1) ans, à compter de la date de l’achat ou du bail initial.

sont exempts de tout vice de matière et de main d’œuvre pendant une

Accessoires – Troy-Bilt garantit que les accessoires pour ce produit

d’achat ou du bail initial.

motoculteur, pour l’acheteur initial seulement, à compter de la date

tout vice de matière et de fabrication, durant toute la durée de vie du

engrenages, les arbres d’entraînement et les boîtiers) exempte de

Transmission – Troy-Bilt garantit la transmission (incluant tous les

d’achat au détail.

fabrication, pour une période de trente (30) jours à partir de la date

Les courroie s sont garantis exemptes de tout vice de matière et de

Troy-Bilt, rendront la garantie nulle et non avenue.

produit faisant l’objet de la notice d’utilisation n’est pas homologué par

d’un accessoire ou d’un équipement annexe, dont l’emploi avec le

naturel. Les dégâts causés par l’installation ou l’utilisation d’une pièce,

inondation ou de tout autre dégât causé par tout incident ou désastre

modification, d’un acte de vandalisme, d’un vol, d’un incendie, d’une

d’une négligence, d’un accident, d’un entretien incorrect, d’une

emploi incorrect ou abusif, d’une utilisation à des fins commerciales,

qui l’accompagne. De plus, le produit ne doit pas avoir fait l’objet d’un

et entretenu conformément aux instructions de la notice d’utilisation

Cette garantie limitée n’est applicable que si ce produit a été utilisé

s’avère défectueuse en raison d’un vice de matière ou de fabrication.

réparer ou à remplacer, gratuitement et à son choix, toute pièce qui

de deux (2) ans à compter de la date de l’achat initial et s’engage à

exempt de tout vice de matière et de fabrication pour une durée

transmission et les accessoiries comme décrits ce-dessous) est

Troy-Bilt garantit que ce produit (à l’exception de les courroies, la

respectivement appelée « Troy Bilt »).

Canada et/ou ses possessions et territoires (l’une ou l’autre entité

Limited, pour toutes les marchandises achetées et utilisées au

États-Unis, dans ses possessions et territoires, et par MTD Products

LLC pour toutes les marchandises neuves achetées et utilisées aux

La garantie limitée qui est énoncée ci-dessous est offerte par Troy-Bilt

GARANTIE LIMITÉE DU FABRICANT DES

Page 19

14

quant à leur emplacement.

vente à la page 2. Soyez prêt à fournir les numéros de modèle et de série de votre machine ou voir les renseignements à la page 2

REMARQUE : Vous pouvez télécharger un livret contenant la liste complète des pièces détachées. Adressez-vous au Service après-

734-0973 Roue, 5 po x 1,38 po

946-04663 Câble de l’embrayage

911-0415 Axe de chape

714-04043 Goupille fendue

642-04031 Dents - gauche

642-04032 Dents - droit

9

Pièce No. de pièce et description

Pièces de rechange

Page 20

13

technique agréée.

4. Faites réparer la machine par une station

3. Remplacez la courroie.

2. Remplacez l’axe de chape.

vérifiez et dégagez le corps étranger.

1. Arrêtez immédiatement le motoculteur,

4. Consultez la notice d’utilisation du moteur.

3. Consultez la notice d’utilisation du moteur.

2. Consultez la notice d’utilisation du moteur.

1. Faites le plein d’huile du carter.

7. Consultez la notice d’utilisation du moteur.

6. Consultez la notice d’utilisation du moteur.

plein avec une essence propre et fraîche.

carburateur et videz le réservoir. Faites le

5. Débranchez la conduite d’essence au

4. Nettoyez le trou d’aération.

plein avec une essence propre et fraîche.

3. Nettoyez la conduite d’essence. Faites le

2. Ouvrez le volet de départ.

1. Branchez et serrez le fil de la bougie.

7. Consultez la notice d’utilisation du moteur.

la bougie.

6. Nettoyez, régler l’écartement ou remplacez

essence propre et fraîche.

5. Videz le réservoir et faites le plein avec une

4. Ouvrez le volet de départ.

».

3. Placez l’obturateur à la position « Démarrage

2. Ajoutez de l’essence.

1. Branchez le fil de la bougie.

correctement réglées.

4. La poulie et la poulie de tension ne sont pas

3. Courroie usée ou étirée.

2. L’axe de chape des dents est manquant.

s’enclenchent pas

1. Objet dans les dents.

4. Carburateur mal réglé.

3. La circulation d’air est gênée.

2. Filtre à air sale.

7. Carburateur mal réglé.

6. Filtre à air sale.

5. Eau ou saleté dans le système de carburant.

bouché.

4. Trou d’aération du chapeau d’échappement

éventée.

3. Conduite d’essence bouchée ou essence

2. Volet de départ fermé.

1. Fil de la bougie.

7. Moteur noyé.

6. Bougie défectueuse.

5. Essence éventée.

4. Volet de départ fermé.

échéant)

3. Obturateur réglé incorrectement. (les cas

2. Réservoir d’essence vide.

Les dents ne

Le moteur surchauffe 1. Niveau d’huile trop bas.

irrégulièrement

Le moteur tourne

Le moteur ne démarre pas 1. Fil de la bougie débranché.

8

Problème Cause Solution

Dépannage

Page 21

Contre-écrou

Poulie

Courroie

12

Figure 7-2

Contre-écrou

Vis

précédemment.

5. Remontez le châssis et le moteur avec la boulonnerie retirée

place.

4. Installez la courroie neuve et remettez la poulie de tension en

3. Dégagez la courroie des poulies. Étape B, Figure 7-2.

support de la roue de tension. Étape A, Figure 7-2.

2. Retirez la vis à épaulement, la vis ordinaire et les écrous du

Figure 7-1

Figure 7-1.

écrous qui maintiennent le moteur et le châssis sur le cadre.

1. D émontez le châssis et l e moteur en retirant les si x vis et contrepièce à la station technique la plus proche.

commandez le modèle nécessaire en indiquant le numéro de la

n’importe quelle courroie. Si vous devez remplacer les courroies,

assure de meilleures performances. Ne les remplacez pas par

spécial, qui leur garantit une durée de vie plus longue et vous

Le motoculteur utilise des courroies réalisées dans un matériau

Replacement de la courroie

7

Service

Page 22

13 po

22 po

24 po

Goupille

fendue

Axe de

chape

11

à 13 pouces en retirant les dents extérieures. (Voir la Fig. 3-5.)

silicone.

et toutes les pièces mobiles, avec une huile légère ou de la

non ventilé. Enduisez toute la machine, en particulier les câbles

contre la rouille s’il doit être entreposé dans un abri métallique

REMARQUE: Il est très important de bien protéger le matériel

engrais par exemple.

Ne le remisez pas près de produits corrosifs comme des

t Remisez le motoculteur dans un endroit propre et sec.

empêcher de rouiller.

t Essuyez les dents avec un chiffon imbibé d’huile pour les

instructions de remisage.

t Consultez la notice d’utilisation du moteur quant aux

motoculteur et à limiter sa facilité d’entretien.

moteur. L’emploi d’eau a tendance à raccourcir la vie du

électriques, les fusées, les poulies, les roulements ou le

Cela risque en effet d’endommager les composants

d’arrosage pour nettoyer le tracteur est déconseillée.

t L’utilisation d’un nettoyeur sous pression ou d’un boyau

Lubrifiez le motoculteur selon les instructions.

t Nettoyez l’extérieur du moteur et tout le motoculteur.

période de plus de 30 jours, procédez de la façon suivante.

Si vous ne prévoyez pas d’utiliser le motoculteur pendant une

Remisage Hors Saison

Fig. 6-1

goupilles épingles. Pour cultiver le sol, réduisez la largeur de travail

pouce et bloquez-les en position avec les axes de chape et les

chape et les goupilles épingles, sortez les dents extérieures d’un

augmenter la largeur de travail à 24 pouces, enlevez les axes de

La largeur de travail du motoculteur est de 22 pouces. Pour

Réglage de la largeur des dents

Réglages

avec de l’huile.

Démontez les roues au moins une fois par saison et lubrifiez-les

Arbres des roues

avec de l’huile.

Démontez les dents au moins une fois par saison et lubrifiez-les

Arbre des dents

station technique agréée pour tout entretien.

l’usine. Elle ne nécessite aucune verification. Consultez une

La transmission a été lubrifiée et fermée hermétiquement à

Transmission

Lubrication

air doit être nettoyé. Consultez la notice d’utilisation du moteur.

performance du moteur et sa «noyade» indiquent que le filtre à

dans des conditions très poussiéreuses. Une mauvaise

d’utilisation normales. Nettoyez-le à intervalles plus rapprochés

Nettoyez le filtre à air toutes les 10 heures dans des conditions

Filtre à air

6

et peut gravement endommager la machine.

partout dans le motoculteur, en particulier dans le carter à chaîne

pression pour nettoyer le motoculteur. L’eau risque de pénétrer

REMARQUE: N’utilisez jamais un appareil de nettoyage sous

pour empêcher le rouille ou dommages de l’eau.

après et appliquez une couche mince de l’huile ou de silicone

pas sèche. Essuyez toujours le motoculteur avec une serviette

chaque utilisation. La saleté est plus facile à enlever si elle n’est

Nettoyez le dessous du dispositif de protection des dents après

Dents

l’équipement.

Consultez la notice d’utilisation du moteur qui accompagne

Moteur

Entretien

replacez les goupilles fendues.

fendues pour relever ou abaisser le guide de profondeur, puis

fonctionnement, Fig. 6-1. Retirez l’axe de chape et les goupilles

et de contrôler sa profondeur de travail et sa vitesse de

Le guide de profondeur permet à la fois de freiner le motoculteur

Réglage du guide de profondeur

dégâts matériels.

entraîner des dommages corporels graves ou des

bougie. Le non-respect de ces instructions peut

débranchez le fil de la bougie et éloignez-le de la

attendez que toutes les pièces soient immobiles,

ou d’entretenir la machine, arrêtez le moteur,

AVERTISSEMENT ! Avant d’inspecter, de nettoyer

Entretien et réglages

Page 23

5432 1

10 SECTION 5— UTILISATION

Fig. 5-5

Fig. 5-4

retardant la pousse des mauvaises herbes.

longtemps et de bien aérer les racines des plantes, tout en

de terre permettent à celle-ci de conserver l’humidité plus

des feuilles et de la paille et leur mélange dans plusieurs pouces

compost, mélangez les engrais au compost. Le déchiquetage

fertilité de votre jardin. Pour assurer la bonne décomposition du

organiques en décomposition augmente appréciablement la

repassez dans le sens de la largeur. L’addition de matières

Pour cela, travaillez dans le sens de la longueur du jardin, puis

compost doit être enterré à une profondeur de 6 à 7 pouces.

qu’elle ait été labourée à la profondeur de travail souhaitée. Le

Vous pouvez utiliser le motoculteur pour mélanger la terre après

travail ultérieur à la pelle. Plus besoin de travailler à la pioche.

révèlera aussi très utile pour aérer la terre calcaire pour tout

assurer une meilleure croissance de l’herbe. Le motoculteur se

travailler en profondeur et éliminer toutes les mottes pour

exemple préparer la terre pour semer un gazon. Vous pourrez

culture, vous rendra bien d’autres services. Vous pourrez par

Ce motoculteur, outre la préparation superficielle du sol et la

pratiquement tout binage. (Voir la Fig. 5-3).

quinconce permettront le travail du sol en croisant et élimineront

culture du maïs ou autre récolte semblable, les plantations en

suffisant pour permettre le passage du motoculteur. Pour la

Lorsque vous tracez des sillons, pensez à laisser un espace

la largeur des dents» dans la section des réglages.

de retirer les dents extérieures. Consultez le chapitre «Réglage de

Pour la préparation du sol, elle peut être réduite à 13 po. Il suffit

est de 22 ou 24 pouces.

Lorsque les dents extérieures sont installées, la largeur de travail

Il est conseillé de travailler à une profondeur de 2 à 3 pouces.

Préparation du sol

les guidons.

le réglage du guide de profondeur et la pression à appliquer sur

guide de profondeur touchent le sol. Fig. 5-5.

le guide de profondeur de façon que les pieds à l’extrémité du

Pour remiser le motoculteur, abaissez la roue avant, et placez

le guide de profondeur à la position la plus haute. Voir la Fig. 5-4.

Abaissez la roue avant pour transporter le motoculteur, et placez

Transport et remisage du motoculteur

Fig. 5-3

Fig. 5-2

Le type de sol et les conditions de travail déterminent également

augmente la profondeur de travail et ralentit les déplacements.

la vitesse de déplacement. Une pression vers le haut au contraire

pression vers le bas réduit la profondeur de travail et augmente

la vitesse de déplacement en appuyant sur les guidons. Une

Vous pouvez également contrôler la profondeur de travail et

Pression sur les guidons

Page 24

9

Fig. 5-1

notice d’utilisation du moteur.

8. Mettez le moteur en marche en suivant les directives de la

7. Relâchez toutes les commandes du motoculteur.

température peut dépasser 150ºF (66ºC).

avec le silencieux et les zones proches où la

carbone, un gaz inodore et mortel. Évitez tout contact

Les gaz d’échappement contiennent du monoxyde de

moteur à l’intérieur ou dans un espace clos et mal aéré.

AVERTISSEMENT ! Ne faites jamais tourner le

6. Branchez le fil sur la bougie.

et consignes de sécurité.

l’équipment. Suivez soigneusement toutes les instructions

dans le notice d’utilisation du moteur qui accompagne

5. Faites le plein du réservoir avec l’essence recommandée

importants.

dommages corporels graves et des dégâts matériels

manipulation de l’essence peut causer des

non-respect des consignes de sécurité concernant la

cailloux et pierres qui sont mis à jour.

le sens de la longueur, puis dans le sens de la largeur. Enlevez les

de profondeur avant chaque passage et parcourez le terrain dans

deux ou trois fois au même endroit. Dans ce cas, abaissez le guide

premier passage dans le jardin. Dans d’autres cas, il faut passer

Dans certains cas, la profondeur voulue est obtenue dès le

passage entre le premier et le deuxième, comme à la Fig. 5-2.

premier et le deuxième passage, puis effectuez un troisième

Laissez à peu près 8 pouces de terre non retournée entre le

doit être relevée, Fig. 5-1.

Pour labourer, le guide de profondeur doit être abaissé et la roue

pénètreront dans la terre.

sera moins haut quand les dents et le guide de profondeur

légèrement plus haut que la taille du conducteur. Le motoculteur

le guidon de manière que les poignées se trouvent à un niveau

la profondeur de travail est pré-réglée, il est nécessaire d’ajuster

donne une profondeur de travail de quatre pouces environ. Si

dents et le guide de profondeur reposent au sol. Ce réglage

que la roue se trouve à environ quatre pouces du sol quand les

déterminée par le réglage du guide de profondeur de manière

La profondeur de travail de la machine peut aussi être pré-

plus rapidement.

profondeur de travail sera réduite et la machine se déplacera

motoculteur. Par contre, si le guide de profondeur est relevé, la

guide de profondeur. Ceci aura aussi pour effet de ralentir le

Pour travailler plus en profondeur, enfoncez davantage le

Contrôle de la vitesse et de la profondeur de travail

sécurité à ce sujet dans cette notice d’utilisation. Le

PEUVENT EXPLOSER. Suivez les consignes de

HAUTEMENT INFLAMMABLE DONT LES VAPEURS

AVERTISSEMENT ! L’ESSENCE EST UN PRODUIT

accompagne l’équipement.

du moteur. Voir la notice d’utilisation du moteur qui

4. Vérifiez le filtre à air et le système de refroidissement

sont en place.

3. Vérifiez que tous les dispositifs de sécurité et couvercles

d’utilisation du moteur qui accompagne l’équipement.

2. Vérifiez le niveau de l’huile à moteur. Voir la notice

pièce ne manque. Serrez ou remplacez selon le besoin.

1. Vérifiez que la boulonnerie n’est pas desserrée et qu’aucune

entretiens suivants avant chaque utilisation :

Débranchez le fil de la bougie et effectuez les vérifications et

Démarrage et arrêt du moteur

motoculteur.

pièces en mouvement du moteur et de la

cheveux et vêtements non ajustés de toutes les

inodore mortel. Éloignez toujours vos mains, pieds,

contiennent du monoxyde de carbone, un gaz

ou mal ventilé. Les gaz d’échappement du moteur

tourner le moteur à l’intérieur ou dans un local clos

pendant l’utilisation du motoculteur.Ne faites jamais

du motoculteur lors du démarrage du moteur ou

d’autre que le conducteur ne se trouve à proximité

AVERTISSEMENT: Assurez-vous que personne

mise en paillis.

permettre la préparation des semis, la culture, le sillonnage et la

Ce motoculteur est une machine de précision conçue pour

Mode d’emploi du motoculteur

notice d’utilisation avant de la mettre en marche.

avertissements qui figurent sur la machine et dans la

comprendre et de suivre toutes les instructions et

AVERTISSEMENT: Assurez-vous de lire,

5

Utilisation

Page 25

commandes de moteur.

renseignements sur les fonctions supplémentaires des

Consultez la notice d’utilisation du moteur pour les

Commandes du moteur

et installation ».

instructions de réglage de la roue dans le chapitre « Assemblage

de profondeur dans le chapitre « Entretien et réglages » et les

et le remisage. Consultez les instructions de réglage du guide

La roue arrière peut être relevée et abaissée pour le transport

Roue arrière à guide de profondeur

fonctionnement.

et de contrôler sa profondeur de travail et sa vitesse de

Le guide de profondeur permet à la fois de freiner le motoculteur

Réglage du guide de profondeur

Figure 4-1

8

ou 4 po dans le sol.

trouve à la hauteur de la taille quand les dents sont enfoncées à 3

générale, il est recommandé d’ajuster le guidon pour qu’il se

Le guidon peut être ajusté à trois positions différentes. De façon

Réglage de la hauteur du guidon

embrayer les dents. Lâchez-la pour les arrêter.

sur le guidon supérieur. Pressez la manette contre le guidon pour

La manette de commande de l’embrayage des dents se trouve

Commande de l’embrayage des dents

qui s’appliquent à votre numéro de modèle.

différents de votre machine. Suivez seulement les instructions

motoculteurs. Les modèles illustrés peuvent être légèrement

REMARQUE: Cette notice concerne plusieurs modèles de

profondeur

Pneu arrière

Dents

arrière

profondeur

Guide de

hauteur du guidon

Réglage de la

Pneu

Câble de l’embrayage

Guide de

de dents

l’embrayage

Commande de

4

Commandes et caractéristiques

Page 26

Goupille

fendue

Axe de chape

7SECTION 3 — ASSE MBLAGE & MONTAGE

Figure 3-4

Figure 3-5

Figure 3-3

transporter le motoculteur.

travail. Procédez dans l’ordre inverse pour abaisser la roue pour

et repoussez-le. Figure 3-5. La roue se mettra en position de

roue avant. Pour cela, abaissez le support de la roue vers le sol

motoculteur soit de niveau. Avant de travailler, il faut relever la

À des fins d’expédition, les roues sont ajustées pour que le

Roues

Réglages

le moteur est chaud ou pendant qu’il tourne.

exploser. Ne faites jamais le plein à l’intérieur, quand

hautement inflammable et les vapeurs peuvent

manipulant de l’essence. Il s’agit d’un produit

AVERTISSEMENT : Faites très atten-tion en

machine. Veuillez lire ces instructions attentivement.

fournies dans la notice d’utilisation du moteur qui accompagne la

Faites les pleins d’essence et d’huile selon les instructions

Pleins d’essence et d’huile

Montage

Fig. 3-4.

dans l’ouverture, de l’intérieur vers l’extérieur, comme à la

de la commande des dents. Accrochez l’extrémité en Z

6. Insérez le raccord en Z du câble d’embrayage dans le trou

droite du guidon supérieur. Voir la Fig. 3-3.

5. Insérez le raccord du câble d’embrayage dans le trou sur la

Page 27

Manivelle du guidon

Rondelle

Support de

retenue

Écrous

Boulon

6

Figure 3-1

guidon

Manivelle du

Figure 3-2

retenue

Support de

Écrous

Boulon

Rondelle

trouvent sur le guidon inférieur. Voir la Fig. 3-1.

support de retenue et les contre-écrous à embase qui se

1. Retirez la manivelle du guidon, le boulon, la rondelle, le

Guidon

Assemblage

recommandés.

l’écrou supérieur enlevés au paragraphe 1. Voir la Fig. 3-2.

et maintenez-les en place avec le support de retenue et

4. Insérez le boulon et la rondelle dans le trou du guidon

1. Voir la Fig. 3-2.

guidon et maintenez-la avec l’écrou enlevé au paragraphe

3. Insérez la manivelle du guidon dans le trou inférieur du

inférieur avec les trous du guidon supérieur.

inférieur, étape A, Fig. 3-2. Alignez les trous du guidon

2. Positionnez le guidon supérieur au-dessus du guidon

d’utilisation du moteur quant au carburant et à l’huile à moteur

HUILE. Quand l’assemblage est terminé, consultez la notice

REMARQUE : Ce motoculteur a été expédié SANS ESSENCE NI

qui s’appliquent à votre numéro de modèle.

différents de votre machine. Suivez seulement les instructions

motoculteurs. Les modèles illustrés peuvent être légèrement

REMARQUE : Cette notice concerne plusieurs modèles de

déterminés du poste de conduite, derrière le motoculteur.

REMARQUE : Les côtés droit et gauche de la tondeuse sont

t Un motoculteur t Un bidon d’huile t Un notice d’utilisation t Une notice d’utilisation du moteur

Contenu du carton

3

Assemblage et Installation

Page 28

5SECTION 2 —CONSIGNES DE SÉCURITÉ

CONSERVEZ CES INSTRUCTIONS !

dans cette notice et sur la machine.

personnes qui peuvent lire, comprendre et respecter les avertissements et instructions qui figurent

AVERTISSEMENT: Votre responsabilité—Cette machine ne doit être utilisée que par des

nement de la machine. Laissez le moteur et le silencieux refroidir avant de les toucher.

Les pièces du moteur, en particulier le silencieux, ont tendance à chauffer pendant le fonctionAVERTISSEMENT – SURFACE CHAUDE

d’échappement contiennent du monoxyde de carbone, un gaz inodore et mortel.

Ne faites jamais fonctionner un moteur à l’intérieur ou dans un bâtiment mal ventilé. Les gaz

AVERTISSEMENT – MONOXYDE DE CARBONE

Laissez le moteur refroidir pendant au moins deux minutes avant de refaire le plein.

AVERTISSEMENT – L’ESSENCE EST UN PRODUIT INFLAMMABLE.

pièces en mouvement peut causer l’amputation des mains et des pieds.

N’approchez pas les mains ou les pieds des pièces en mouvement. Tout contact avec les

AVERTISSEMENT – DENTS EN MOUVEMENT

pièces en mouvement peut causer l’amputation des mains et des pieds.

N’approchez pas les mains ou les pieds des pièces en mouvement. Tout contact avec les

AVERTISSEMENT – DENTS EN MOUVEMENT

comprendre avant d’essayer d’assembler et d’utiliser la machine.

Veuillez lire et suivre toutes les instructions sur la machine et vous assurer de bien les

VEUILLEZ LIRE LA OU LES NOTICES D’UTILISATION.

Symbol Description

instructions sur la machine et vous assurer de bien les comprendre avant d’essayer d’assembler et d’utiliser la machine.

Cette page illustre et explique les symboles de sécurité qui peuvent se trouver sur cette machine. Veuillez lire et suivre toutes les

Symboles de sécurité

le pot d’échappement de cette machine.

agréée la plus proche peut vous fournir un pare-étincelles pour

de marche par l’utilisateur de la machine. La station technique

Si un pare-étincelles est utilisé, il doit être maintenu en bon état

provinciaux ou locaux (le cas échéant).

étincelles, conformément aux lois et règlements

d’échappement du moteur n’est pas muni d’un parerecouvert de broussailles ou d’herbe si le système

pas être utilisée sur un terrain non entretenu,

d’un moteur à combustion interne et elle ne doit

AVERTISSEMENT: Cette machine est équipée

Pare-étincelles

Modification (EM) et Three Way Catalyst (TWC) le cas échéant.

systèmes de contrôle des émissions de gaz suivants : Engine

de l’essence sans plomb ordinaire et peuvent être dotés des

équipement hors route) sont certifiés pour fonctionner avec

la Californie et de l’agence EPA fédérales pour SORE (petit

Les moteurs certifiés conformes aux normes régulatrices de

Avis concernant les émissions de gaz

Page 29

4 SECTION 2 — CONSIGNES DE SÉCURITÉ

blessures graves ou mortelles.

ces recommandations peut causer des accidents et des

ne sont pas usés de façon excessive. Le non-respect de

mécaniques et de sécurité sont en bon état de marche et

technique agréée pour vous assurer que tous les dispositifs

faites inspecter la machine chaque année par une station

de vie utile moyenne, achetez une machine neuve ou

heures de fonctionnement. Au terme de cette durée

a une durée de vie utile moyenne de sept (7) ans, ou 130

américaine de protection de l’environnement), ce produit

et la “U.S. Environmental Protection Agency” (EPA - Agence

Commission sur la sécurité des produits de consommation)

11. D’après la Consumer Products Safety Commission (CPSC -

l’environnement.

déchets et liquides qui risquent de nuire à la nature et à

10. Respectez les règlements concernant l’élimination des

9. Si le réservoir de carburant doit être vidangé, faites ceci dehors.

prolongé de la machine.

renseignement important concernant l’entreposage

8. Consultez toujours la notice d’utilisation pour tout

machine.

le déchargement, le déplacement, et remisage de cette

7. Suivez cette notice d’utilisation pour le chargement sûr,

au besoin.

6. Prenez soin des étiquettes d’instructions et remplacez-les

son régime maximal de fonctionnement sans danger.

le moteur s’emballer. Le régulateur maintient le moteur à

5. Ne modifiez pas le réglage du régulateur et ne laissez pas

accidentel.

à la terre contre le moteur pour empêcher tout démarrage

immobilisées. Débranchez le fil de la bougie et mettez-le

vérifiez que les dents et toutes les pièces mobiles se sont

4. Avant de nettoyer, de réparer ou d’examiner la machine,

les dommages.

En outre, inspectez visuellement la machine pour déceler

fréquemment et que la machine est en bon état de marche.

3. Vérifiez que tous les écrous, boulons et vis sont bien serrés

sécurité. Vérifiez souvent qu’ils fonctionnent bien.

avant de la remiser. Ne modifiez jamais les dispositifs de

2. Laissez la machine refroidir pendant au moins 5 minutes

annexe en bon état de marche.

1. Gardez la machine, les accessoires et autre équipement

Entretien et Remisage

chez vous.

de l’aide et le nom du concessionaire le plus proche de

Adressez-vous au concessionaire ou appelez pour obtenir

qui n’ont pas été abordées par cette notice d’utilisation.

21. Faites toujours preuve de bon sens dans des situations

conseilles risque de causer des blessures.

recommandés par le fabricant. Le non-respect de ces

20. N’utilisez que des accessoires et équipements annexe

tourne.

19. Ne levez ou portez jamais la machine tandis que le moteur

à leur place.

protectrices, carters et autres pièces de sécurité ne sont pas

18. Ne faites jamais fonctionner le motoculteur si les plaques

éventuel avant de remettre en marche.

machine n’est pas endommagée. Réparez tout dégât

et mettez le à la masse contre le moteur. Vérifiez que la

anormal, arrêtez le moteur, débranchez le fil de la bougie

17. Si la machine commence à vibrer ou à faire un bruit

trop profondément ou trop rapidement.

16. Ne fatiguez pas la machine en essayant de travailler le sol

peuvent causer des dégats et des blessures.

bâtiments ou de câbles souterrains. Les dents rotatives

15. Faites attention en travaillant près de clôtures, de

peuvent causer des brûlures. Ne les touchez pas.

14. Le silencieux et le moteur deviennent très chauds et

monoxyde de carbone, un gaz inodore très dangereux.

car les gaz d’échappement du moteur contiennent du

13. Ne faites jamais fonctionner la machine dans un local clos

ajustement quelconque ou d’examiner la machine.

immobilisée avant de déboucher les dents, de faire un

les guidons). Attendez que les dents se soit complètement

le moteur avant de quitter le poste de conduite (derrière

12. Débrayez toutes les commandes (le cas échéant) et arrêtez

tout dégât éventuel avant de remettre en marche.

Vérifiez que la machine n’est pas endommagée. Réparez

fil de la bougie et mettez le à la masse contre le moteur.

11. Si vous heurtez un objet, arrêtez le moteur, débranchez le

dans ce notice et éloignez vos pieds des dents à tout moment.

10. Mettez en marche la machine selon les instructions qui ce trouve

reculant ou en tirant la machine vers vous.

9. Regardez en bas et derrière vous et soyez prudent en

8. Soyez prudent pour éviter de glisser ou de tomber.

dures ou glissantes.

7. Ne déplacez jamais rapidement la machine sur des surfaces

passagers.

non évidents et à la circulation. Ne transportez pas de

allées ou chemins en gravier. Faites attention aux dangers

6. Soyez extrêmement prudent à proximité des routes,

et ne retiennent pas la machine.

avant. Si ceci se produit, laissez vont des barres de poignée

peuvent saisir sur le sol et propulser la motoculteur en

5. Faites attention en travaillant en terre dure. Les dents

s’approche.

quand elle est en marche. Arrêtez la machine si quelqu’un

enfants à une distance d’au moins 75 pieds de la machine

4. Gardez les spectateurs, les animaux de compagnie et les

fermement les guidons.

satisfaisant. Gardez toujours un bon équilibre et tenez

3. Travaillez en plein jour ou avec un éclairage artificiel

boissons alcoolisées ou pris de médicaments.

2. Ne vous servez pas de la machine après avoir bu des

peuvent amputer mains et pieds.

mouvement. Le contacte avec des pièces en mouvement

1. Ne placez jamais vos mains ou vos pieds près des pièces en

Fonctionnement

à gaz, radiateur, sèche-linge, etc.).

l’intérieur s’il y a une flamme, une étincelle (chauffe-eau

l. Ne remisez jamais la machine ou les bidons d’essence à

Page 30

3

débris imbibés d’essence.

éclaboussures de carburant ou d’huile et enlevez tous les

des brins d’herbe, feuilles et autres saletés. Essuyez les

k. Limitez les risques d’incendie en débarrassant le moteur

en marche le moteur.

autre endroit. Attendez 5 (cinq) minutes avant de mettre

sur le moteur et la machine. Déplacez la machine à une

j. En cas de débordement, essuyez toute éclaboussures

i. Resserrez bien le capuchon d’essence.

carburant.

d’un demi-pouce environ pour permettre l’expension du

h. Ne faites jamais déborder le réservoir. Laissez un espace

deux minutes avant de faire le plein.

chaud. Laissez le moteur refroidir pendant au moins

pas d’essence pendant que le moteur tourne ou s’il est

g. N’enlevez jamais le capuchon d’essence et n’ajoutez

inflammables risquent de s’accumuler.

f. Ne faites jamais le plein à l’intérieur car des vapeurs

autre chaleur incandescente.

e. Éteignez toute cigarette ou pipe, tout cigare ou toute

dispositif de blocage en position ouverte.

plein soit terminé. N’utilisez pas un gicleur équipé d’un

d’essence ou avec l’ouverture du bidon jusqu’à ce que le

d. Maintenez le gicleur en contact avec le bord du réservoir

plutôt que directement de la pompe à essence.

cela n’est pas possible, faites le plein avec un bidon

motorisé de la remorque et faites le plein par terre. Si

c. Dans le mesure du possible, déchargez l’équipement

terre et loin de votre véhicule avant de les remplir.

revêtement en plastique. Placez toujours les bidons par

d’une camionette dont le plancher est recouvert d’un

b. Ne faites jamais le plein dans un véhicule, ni à l’arrière

seulement.

a. Remissez le carburant dans des bidons homologués

immédiatement de vêtements.

sur vos vêtements s’enflammaient. Rincez votre peau et changez

être grièvement blessé si des éclaboussures sur votre peau ou

inflammable et les vapeurs risquent d’exploser. Vous pouvez

en manipulant de l’essence. Il s’agit d’un produit extrêmement

Pour éviter toute blessure ou dégât matériel, faites très attention

n.

Manipulation de l’essence:

spéciales dans la notice d’utilisatio

pendant que le moteur tourne, sauf en cas d’instructions

5. N’essayez jamais d’effectuer un réglage quelconque

moteur tourne.

4. Ne laissez jamais la machine sans surveillance quand le

le moteur.

la manette au point mort (“N”) avant de mettre en marche

3. Débrayez la barre d’embrayage et décalez (le cas échéant)

nus ou en portant des sandales.

pièces en mouvement. N’utilisez jamais la machine pieds

lâches ni des bijoux qui risquent de se prendre dans les

vêtements bien ajustés. Ne portez jamais des vêtements

2. Portez des chaussures robustes à semelle épaisse et des

pourraient vous trébuchez et causer des blessures.

les pierres, bâtons, fils métalliques et autres objets qui

1. Examinez soigneusement la zone de travail. Ramassez tous

Préparation

machine si quelqu’un s’approche.