Page 1

Operator's Manual

r®

Rear-tine Tiller

Model 675B

Model 675B Shown (bumper styles vary)

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit isequippedwith an internal combustion engineand should notbe usedon or near any unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust system isequipped with a spark arrester meeting applicablelocal or state laws(if any). If aspark arrester isused, it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

ResourcesCode). Otherstates may havesimilar laws. Federallaws apply on federal lands. A spark arrester for the muffler isavailable through your nearest engine

authorized servicedealer or contact the service department P.O. Box 361131Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTEDIN U.S.A. FORMNO. 769-00586B

9/13/04

Page 2

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 16

Safety 3 Troubleshooting 23

Assembly 6 Parts List 24

Features and Controls 9 Warranty Back Cover

Operation 11

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Copy the model number here:

OTRDV-BILT T,OV-BmLTLLC

www.troybilt.com CLEVELAND,OH44136

,. 1-800-520-552_

P. O. BOX 361131

330-558-7220

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreh/m thel/nit totheretailer withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

_ 7>,,,,

/;/ ,> ;'V }/ )

..... f ; @; t ;D

j;_ ?" #'s " 4t, ' F_ i/!s ,

* ;,, #FOX }_ j,"

,,, >,, rL;," ¢j ,_ <# ft, *x J ,7;; _

'_,-., _tf';_'ivc ,l

,v yO, ,_;7f'_;:'

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

Page 3

SECTION1: SAFETY

This machine meets voluntary safetystan-

dard B71.8-1996, which is sponsored bythe

Outdoor Power Equipment Institute, Inc.,

and is published by the American National

Standards Institute.

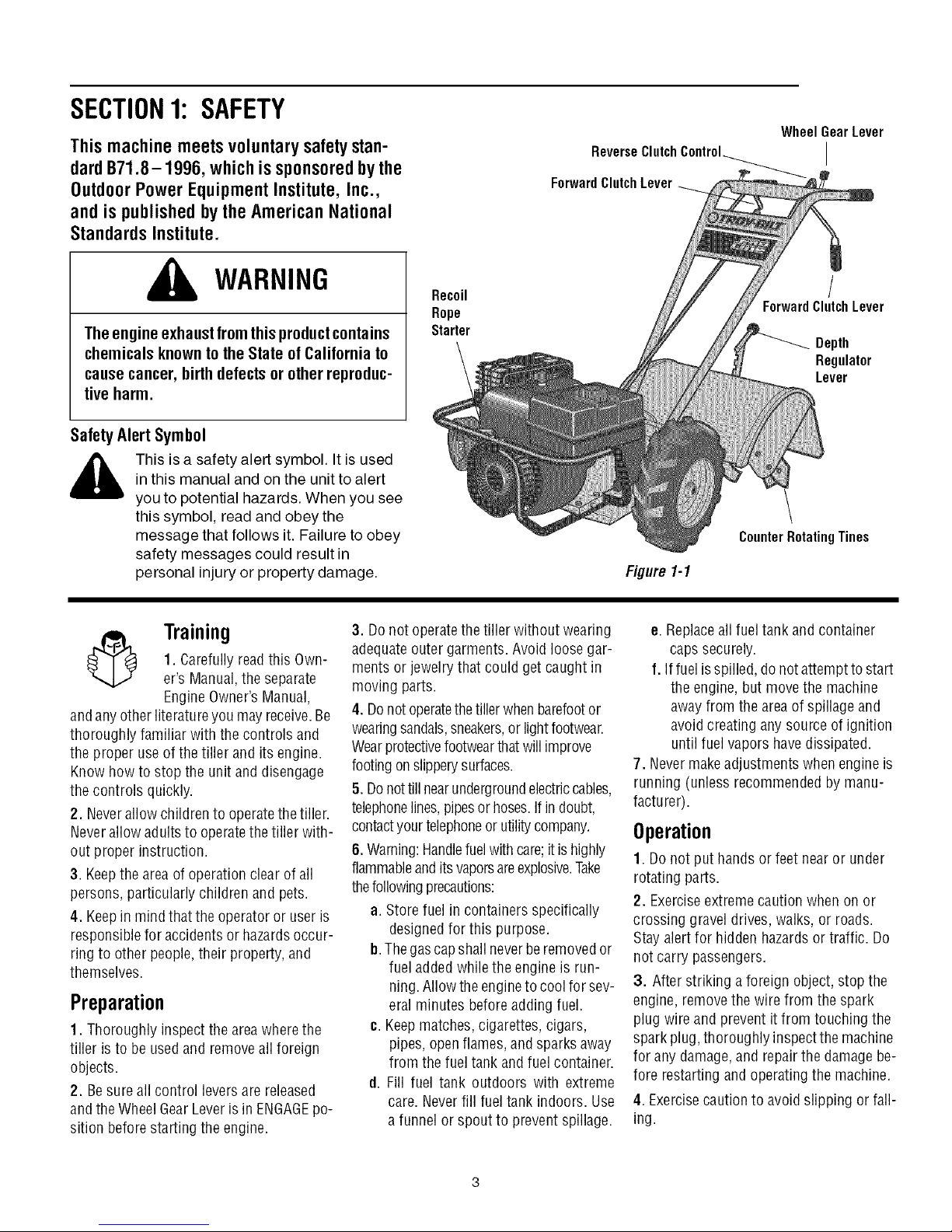

Wheel GearLever

ReverseClutch Control_ I

ForwardClutch Lever

WARNING

The engine exhaustfrom this productcontains

chemicals known to the State of California to

cause cancer, birth defects or other reproduc-

tive harm.

SafetyAlertSymbol

,_ This is a safety alert symbol. It is used

andanyotherliteratureyou mayreceive.Be

thoroughly familiar with the controls and

the proper use ofthe tiller and its engine.

Know howto stop the unit and disengage

the controls quickly.

2. Neverallow childrento operatethetiller.

Neverallow adultsto operatethetiller with-

out proper instruction.

3. Keepthe area of operationclear of all

persons, particularly children and pets.

4. Keepin mind that the operatoror user is

responsiblefor accidents or hazardsoccur-

ring to other people,their property, and

themselves.

Preparation

1. Thoroughly inspect the areawherethe

tiller is to be usedand removeall foreign

objects.

2. Besure allcontrol leversare released

andthe WheelGearLever isin ENGAGEpo-

sition beforestarting the engine.

in this manual and on the unit to alert

you to potential hazards. When you see

this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

personal injury or property damage.

3. Donot operatethetiller without wearing

1. Carefullyreadthis Own-

Training

er's Manual,the separate

EngineOwner's Manual,

adequateouter garments. Avoid loosegar-

ments orjewelry that could getcaught in

moving parts.

4. Donotoperatethetillerwhenbarefootor

wearingsandals,sneakers,or light footwear.

Wearprotectivefootwearthatwill improve

footingonslipperysurfaces.

5. Donottillnearundergroundelectriccables,

telephonelines,pipesor hoses.If indoubt,

contactyour telephoneorutilitycompany.

6.Warning:Handlefuelwith care;itis highly

flammableandits vaporsareexplosive.Take

thefollowingprecautions:

a. Storefuel in containers specifically

b.Thegascapshall neverberemovedor

c. Keepmatches,cigarettes, cigars,

d. Fill fuel tank outdoors with extreme

Recoil

Rope

Starter

designedfor this purpose.

fuel addedwhile the engine is run-

ning.Allow theengineto coolfor sev-

eral minutes beforeadding fuel.

pipes, openflames, andsparksaway

from the fueltank and fuel container.

care. Neverfill fueltank indoors. Use

a funnel or spout to prevent spillage.

/

ForwardClutchLever

Depth

Regulator

Lever

CounterRotatingTines

Figl/re 1-1

e. Replaceall fueltank and container

caps securely.

f. If fuel isspilled, donot attemptto start

the engine,but move the machine

awayfrom the area of spillageand

avoidcreating anysource of ignition

until fuelvapors havedissipated.

7. Nevermakeadjustments whenengineis

running (unless recommendedby manu-

facturer).

Operation

1. Do not put hands orfeet near or under

rotating parts.

2. Exerciseextreme caution when on or

crossing gravel drives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine,remove thewire from the spark

plug wire and prevent it from touching the

spark plug,thoroughly inspectthe machine

for any damage,and repairthe damagebe-

fore restarting and operatingthe machine.

4. Exercisecautionto avoidslipping or fall-

ing.

Page 4

5.Iftheunitshouldstarttovibrateabnormally,

stoptheengine,disconnectthesparkplug

wireandpreventitfromtouchingthespark

plug,andcheckimmediatelyforthecause.Vi-

brationisgenerallyawarningoftrouble.

6.Stoptheengine,disconnectthespark

plugwireandpreventitfromtouchingthe

sparkplugwheneveryouleavetheoperat-

ingposition,beforeuncloggingthetines,

orwhenmakinganyrepairs,adjustments

orinspections.

7.Takeallpossibleprecautionswhenleav-

ingthemachineunattended.Stoptheen-

gine.Disconnectsparkplugwireandmove

itawayfromthesparkplug.MoveWheel

GearLevertoENGAGE.

8.Beforecleaning,repairing,orinspect-

ing,stoptheengineandmakecertainall

movingpartshavestopped.Disconnect

thesparkplugwireandpreventitfrom

touchingthesparkplugtopreventacci-

dentalstarting.

9.Alwayskeepthetillertinehoodflap

down.

10.Neverusethetillerunlessproper

guards,plates,orothersafetyprotectivede-

vicesareinplace.

11.Donotrunengineinanenclosedarea.

Engineexhaustcontainscarbonmonoxide

gas,adeadlypoisonthatisodorless,col-

orless,andtasteless.

12.Keepchildrenandpetsaway.

13. Neveroperate thetiller underengine

powerif the WheelGearLever is in DIS-

ENGAGE(FREEWHEEL).Inthis position,

thewheels will notholdthe tiller back

andthe revolvingtines could propelthe

tiller rapidlybackward,possiblycausing

lossofcontrol. Always move theWheel

GearLeverto ENGAGEbefore starting the

engine or engagingthe tines4Nheelswith

the Forward Clutch or the ReverseClutch.

14. Beawarethat the tiller may unexpect-

edly bounceupward or jump backward if

the tines should strike extremely hard

packedsoil, frozen ground, or buried ob-

stacleslike largestones, roots, or stumps.

If in doubt aboutthe tilling conditions, al-

ways usethe following operating precau-

tions to assist you in maintaining control

of thetiller:

a. Walkbehindand to one sideof the

tiller, usingone handon thehan-

dlebars.Relax yourarm, butuse a

securehandgrip.

b. Use slower enginespeeds.

c. Clear thetilling areaof all large

stones,rootsand other debris.

d. Avoidusingdownwardpressureon

handlebars.If needbe, useslight

upwardpressureto keepthe tines

from diggingtoo deeply.

e. Beforecontacting hardpackedsoil

at the endof a row,reduceengine

speedand lift handlebarsto raise

tines out of thesoil.

f. In an emergency, stoptines and

wheels by releasingwhichever

ClutchLeverisengaged.Donotat-

temptto restrainthe tiller.

15. Donot overloadthe tiller's capacityby

attempting to till too deeplyat too fast a

rate.

16. Neveroperatethetiller at hightrans-

port speedsonslippery surfaces. Lookbe-

hind and use care when backing up.

17. Donot operatethetiller on aslopethat

is too steep for safety.When onslopes,

slow down and makesure you havegood

footing. Neverpermit thetiller to freewheel

down slopes.

18. Neverallow bystandersnearthe unit.

19. Onlyuse attachmentsand accessories

that are approved byGardenWay Inc.

20. Usetiller attachmentsandaccessories

when recommended.

21. Neveroperatethetiller withoutgoodvis-

ibility or light.

22. Neveroperatethetillerif youaretired,or

underthe influenceofalcohol,drugsormedi-

cation.

23.Operatorsshallnottamperwiththeengine-

governorsettingsonthemachine;thegovernor

controlsthemaximumsafeoperatingspeedto

protecttheengineandallmovingpartsfrom

damagecausedby overspeed.Authorizedser-

viceshallbesoughtif a problemexists.

24. Donottouchenginepartswhichmaybe

hotfromoperation.Letpartscooldown

25.Pleaseremember:Youcanalwaysstopthe

tinesandwheelsby releasingtheForward

ClutchLeverortheReverseClutchControl

(whicheverleveryou haveengaged)orbymov-

ingtheThrottleControlLeverto STOP.

26.Toloador unloadthetiller,seetheinstruc-

tionsinSection4ofthisManual.

27. Useextremecautionwhenreversingor

pullingthe machinetowardsyou.

28.Starttheenginecarefullyaccordingtoin-

structionsandwithfeetwellawayfromthe

tines.

29.Neverpickupor carryamachinewhilethe

engineis running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories in safeworking condition.

2. Checkall nuts, bolts, andscrews at fre-

quent intervalsfor proper tightness to be

surethe equipment is in safeworking con-

dition.

3. Neverstorethetillerwithfuelinthefueltank

insideabuildingwhereignitionsourcesare

presentsuchashotwaterandspaceheaters,

furnaces,clothesdryers,stoves,electricmo-

tors,etc.).Allowenginetocoolbeforestoringin

anyenclosure.

4.Toreducethechancesofafirehazard,keep

theenginefreeofgrass,leaves,or excessive

grease.

5. Storegasoline in acool, well-ventilated

area,safelyawayfrom any spark- orflame-

producingequipment. Store gasolinein an

approvedcontainer,safelyawayfrom the

reachof children.

6. Referto the storageinstructions in the

Maintenancesectionof this Manualandthe

separateEngineOwner'sManualfor in-

structions ifthe tiller is to be storedforan

extendedperiod.

7. Neverperformmaintenancewhiletheen-

gine is running orthe spark plugwire is

connected,exceptwhen specificallyin-

structedto do so.

8. If the fueltank hasto be drained,dothis

outdoors.

Page 5

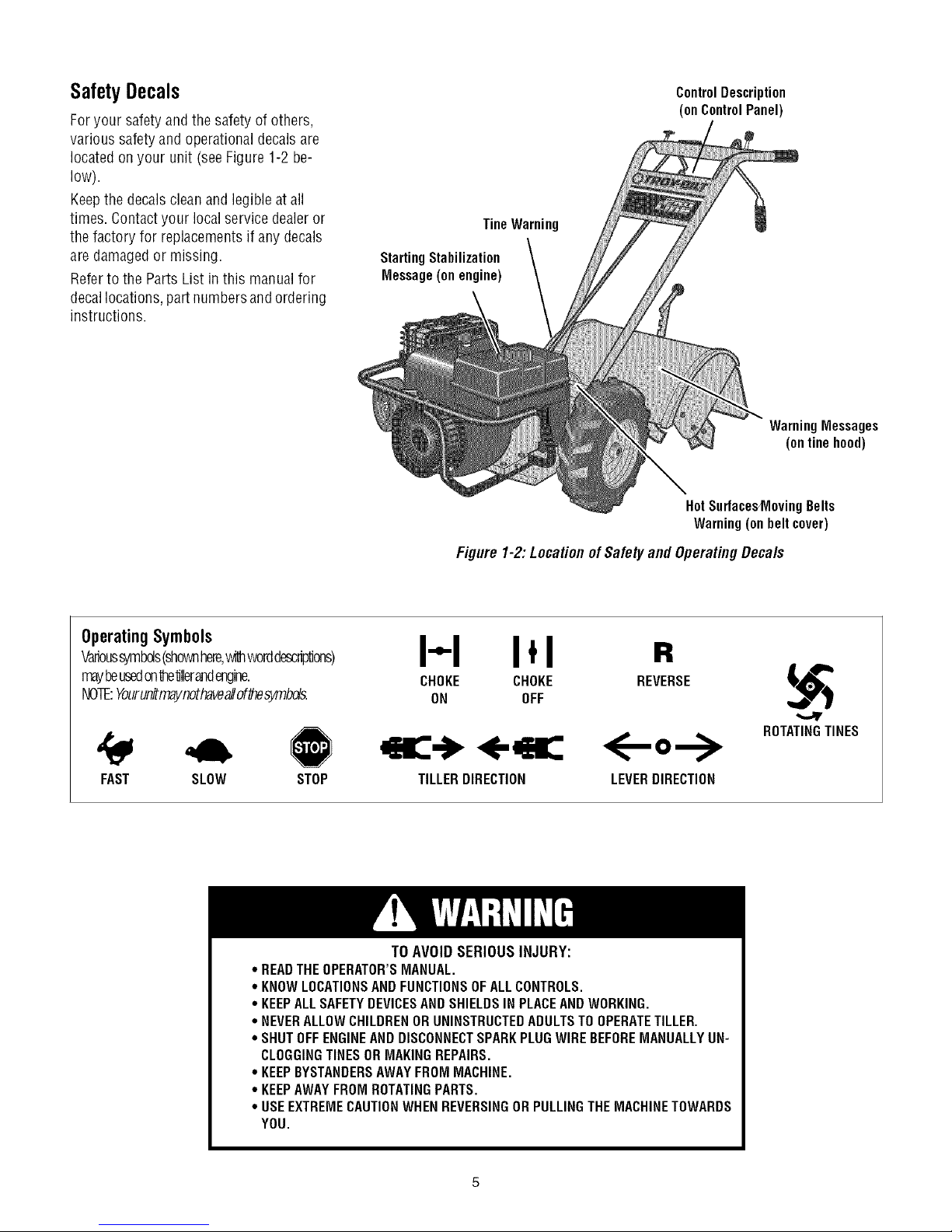

SafetyDecals

Foryour safety andthe safety of others,

various safety andoperationaldecals are

located on your unit (seeFigure 1-2be-

low).

Keepthe decalscleanand legible atall

times. Contactyour local service dealeror

the factory for replacementsif anydecals

are damagedor missing.

Referto the Parts List in this manual for

decallocations, partnumbersand ordering

instructions.

ControlDescription

(onControlPanel)

TineWarning

StartingStabilization

Message(onengine)

WarningMessages

(onlinehood)

HotSurfacesMovingBelts

Warning(onbeltcover)

OperatingSymbols

Varioussymbds(shownhere,withworddescriptions)

mayheusedon'dle'dllerandengine.

NOTE:Yourunitmaynothaveallof_esymbds.

FAST SLOW STOP

* READTHEOPERATOR'SMANUAL.

* KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

* KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

. NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

° SHUTOFFENGINEAND DISCONNECTSPARKPLUGWIREBEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

. KEEPBYSTANDERSAWAYFROM MACHINE.

. KEEPAWAYFROM ROTATINGPARTS.

° USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

Figure 1-2:Locationof Safetyand OperatingDecals

I-.-I I,I

CHOKE CHOKE

ON OFF

TILLERDIRECTION

TO AVOID SERIOUS INJURY:

R

REVERSE

ROTATINGTINES

<--

LEVERDIRECTION

Page 6

SECTION2: ASSEMBLY

WARNING: Toprevent

personalinjury or property

damage,do notstartthe engine

until allassemblysteps are

completeandyou haveread

and understandthe safety and

operatinginstructions in this

Manual.

Introduction

Carefullyfollow these assemblysteps to

correctly prepareyour tiller for use. It is

recommendedthatyou readthis Sectionin

its entirety beforebeginning assembly.

Inspect unit

Inspect the unitand carton for damageim-

mediatelyafter delivery.Contactthe carrier

(trucking company) if you find or suspect

damage. Inform them of the damageand

request instructions for filing a claim. To

protect your rights, put your claim in writ-

ing and maila copyto the carrierwithin 15

days after the unit has beendelivered.

Contact usatthe factory ifyou needassis-

tance in this matter.

Unpackingand Assembly

Instructions

STEP1:UNPACKINGINSTRUCTIONS

1. Removeanycard-board inserts and

packaging materialfrom the carton. Re-

move anystaples from the bottom ofthe

carton and removethe carton.

2. Cutthe large,plastictie strapthat se-

curesthe transmissiontubeto theshipping

pallet. Leavethe handlebarson top ofthe

tiller to avoid damaginganycables.

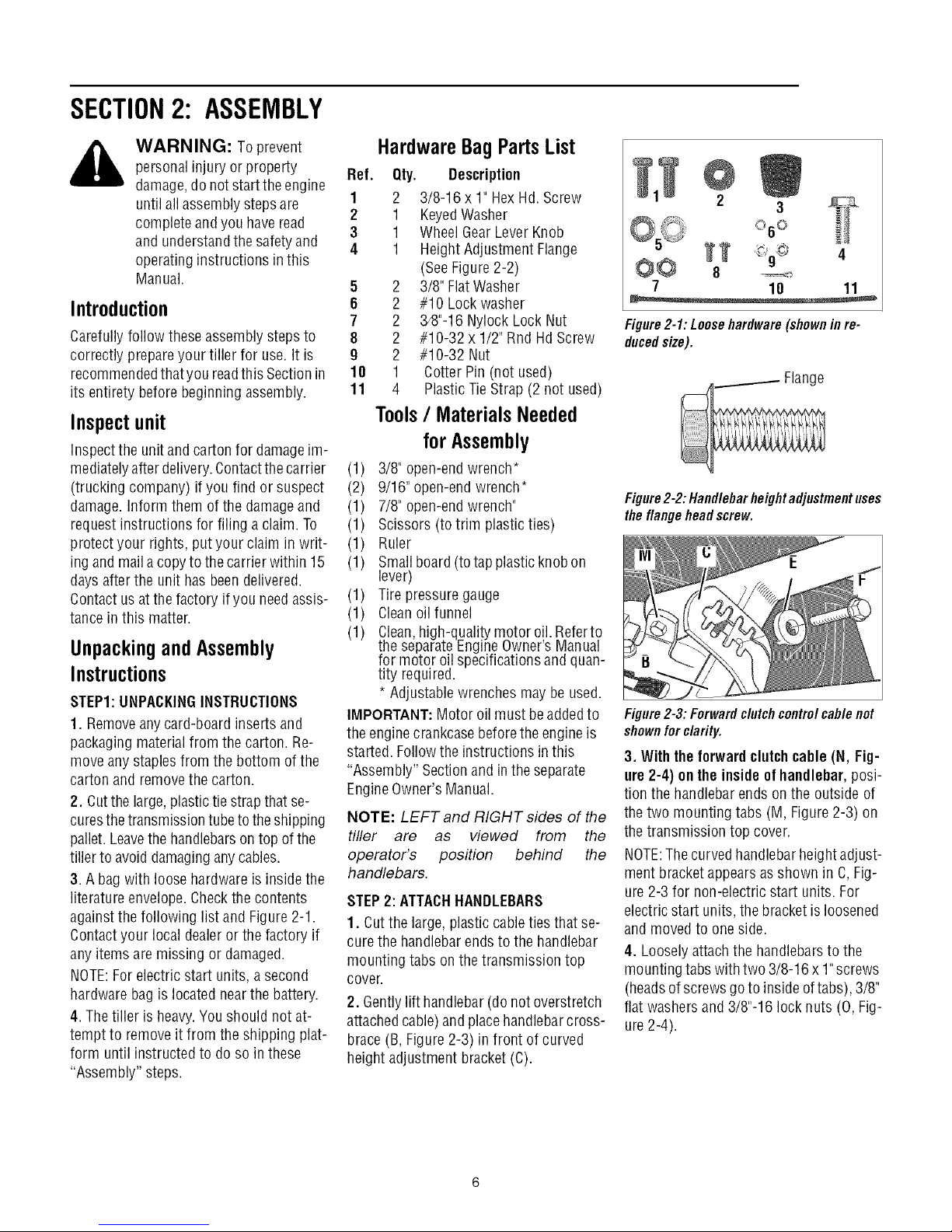

3. Abag with loosehardware is inside the

literature envelope.Checkthe contents

againstthe following list and Figure2-1.

Contactyour local dealeror the factory if

anyitems are missing or damaged.

NOTE:Forelectric start units, a second

hardwarebag is locatednearthe battery.

4. Thetiller is heavy.Youshould not at-

tempt to removeit from the shipping plat-

form until instructed to do so in these

"Assembly" steps.

HardwareBagPartsList

Ref. Qty. Description

1 2 3/8-16 x 1" HexHd. Screw

2 1 KeyedWasher

3 1 WheelGearLeverKnob

4 1 Height Adjustment Flange

(SeeFigure2-2)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16Nylock Lock Nut

8 2 #10-32 x 1/2" Rnd HdScrew

9 2 #10-32 Nut

18 1 CotterPin (not used)

11 4 PlasticTieStrap (2 not used)

Tools/ MaterialsNeeded

forAssembly

(1) 3/8" open-endwrench*

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench"

(1) Scissors (totrim plasticties)

(1) Ruler

(1) Smallboard (totap plastic knobon

lever)

(1) Tirepressure gauge

(1) Cleanoil funnel

(1) Clean,high-quality motor oil. Referto

the separateEngineOwner'sManual

for motor oil specificationsand quan-

tity required.

* Adjustablewrenchesmay be used.

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebeforethe engine is

started. Followthe instructions inthis

"Assembly" Sectionand in the separate

EngineOwner'sManual.

NOTE: LEFT and RIGHT sides of the

tiller are as viewed from the

operator's position behind the

handlebars.

STEP2: ATTACHHANDLEBARS

1. Cutthe large, plastic cableties that se-

curethe handlebarends to the handlebar

mounting tabs onthe transmission top

cover.

2. Gentlylift handlebar(do not overstretch

attachedcable) and placehandlebarcross-

brace(B, Figure2-3) in front of curved

height adjustmentbracket (C).

4

O@ 8

7 10 11

Figure2-1:Loosehardware(shownin re-

ducedsize).

Figure2-2: Handlebarheightadjustmentuses

the flangehead screw.

Figure2-3:Forwardclutchcontrolcablenot

shownforclarity.

3. Withtheforwardclutchcable (N, Fig-

ure 2-4) ontheinside of handlebar,posi-

tion the handlebarends onthe outside of

thetwo mounting tabs (M, Figure 2-3) on

thetransmission top cover.

NOTE:Thecurved handlebarheightadjust-

ment bracket appearsas shown in C, Fig-

ure 2-3 for non-electric start units. For

electricstart units, the bracketisloosened

and moved to one side.

4. Loosely attach the handlebarsto the

mounting tabs withtwo 3/8-16 x 1"screws

(headsof screws goto inside of tabs), 3/8"

flat washersand 3/8"-16 lock nuts (O, Fig-

ure2-4).

Page 7

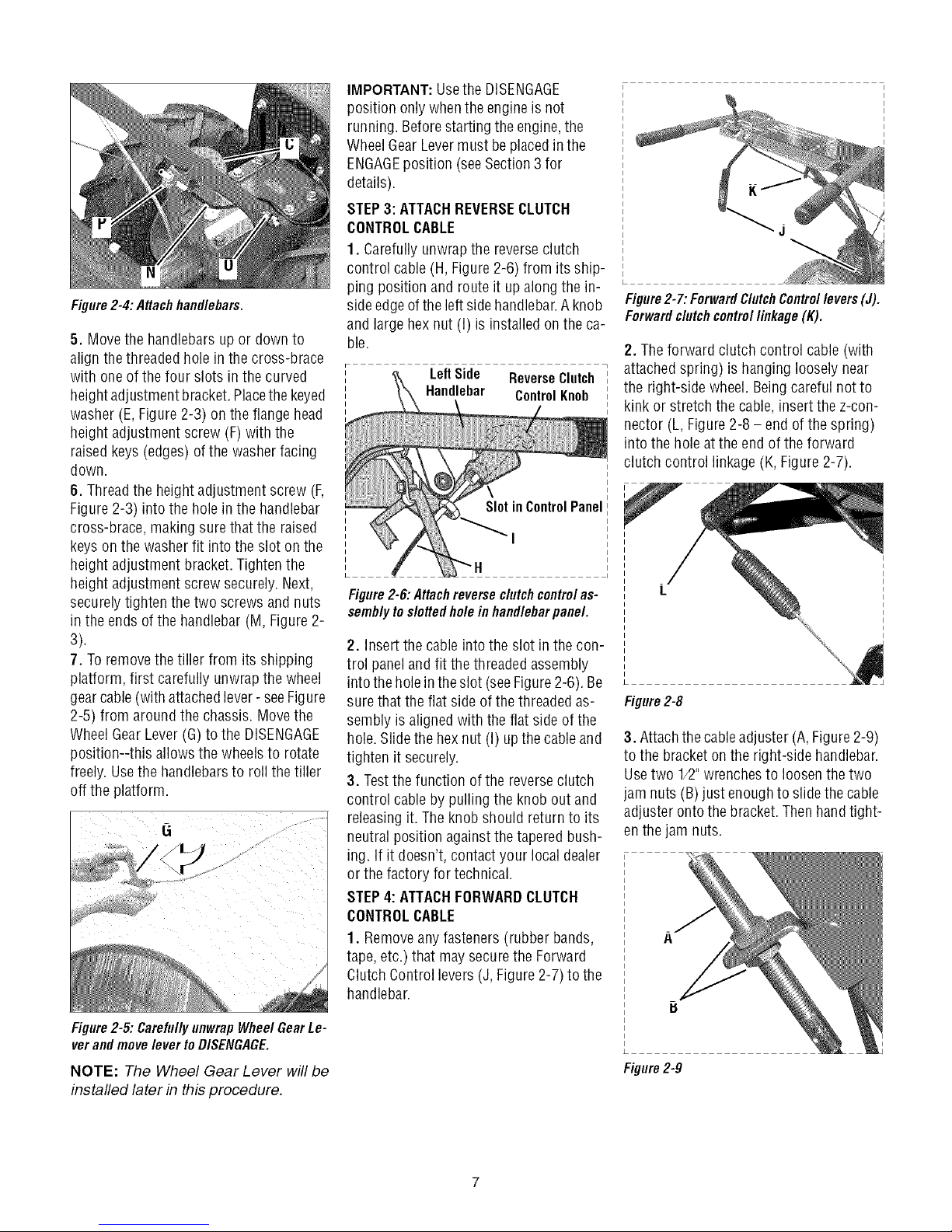

Figure2-4: Attachhandlebars.

5. Move the handlebarsup or downto

align thethreaded hole in the cross-brace

with one of thefour slots in the curved

heightadjustment bracket.Placethekeyed

washer (E, Figure2-3) on the flange head

height adjustmentscrew (F)with the

raised keys(edges)of the washerfacing

down.

6. Threadthe height adjustment screw (F,

Figure2-3) into the holein the handlebar

cross-brace, makingsurethat the raised

keyson the washerfit intothe slot on the

height adjustmentbracket. Tightenthe

height adjustmentscrew securely.Next,

securelytighten thetwo screws and nuts

in the ends of the handlebar (M,Figure2-

3).

7. Toremovethe tiller from its shipping

platform, first carefully unwrap the wheel

gearcable(with attached lever- seeFigure

2-5) from around the chassis. Movethe

WheelGearLever(G) to the DISENGAGE

position--this allows the wheelsto rotate

freely. Usethe handlebarsto roll the tiller

off the platform.

IMPORTANT:Usethe DISENGAGE

position onlywhenthe engineis not

running. Beforestartingthe engine,the

WheelGear Levermust be placedin the

ENGAGEposition (seeSection3 for

details).

STEP3: ATTACHREVERSECLUTCH

CONTROLCABLE

1. Carefullyunwrap the reverseclutch

control cable(H, Figure 2-6) from its ship-

ping position and route it upalong the in-

sideedgeofthe left sidehandlebar.Aknob

and large hexnut (I) is installed on theca-

ble.

Left Side ReverseClutch

Handlebar Control Knob

SlotinControlPanel

'1

Figure2-6:Attachreverseclutchcontrolas-

semblytodotted holeinhandlebarpanel.

2. Insert the cableinto the slot inthe con-

trol paneland fit the threaded assembly

intothe holein theslot (seeFigure2-6). Be

surethat the flat sideof the threaded as-

sembly is aligned with theflat side of the

hole.Slide the hexnut (I) upthecable and

tighten it securely.

3. Testthe function ofthe reverseclutch

control cableby pulling the knob out and

releasingit. Theknob should return to its

neutral position againstthe taperedbush-

ing. If it doesn't, contact your local dealer

or the factory for technical.

STEP4: ATTACHFORWARDCLUTCH

CONTROLCABLE

1. Removeany fasteners (rubber bands,

tape, etc.) that may securethe Forward

ClutchControl levers(J, Figure 2-7) to the

handlebar.

Figure2-7: ForwardClutchControllevers(J).

Forwarddutch controllinkage (K).

2. Theforward clutch control cable (with

attachedspring) is hanging looselynear

the right-side wheel. Beingcareful not to

kink or stretch the cable,insert the z-con-

nector (L, Figure2-8 - end of the spring)

into the hole atthe end ofthe forward

clutch control linkage(K, Figure2-7).

Figure2-8

3. Attachthecableadjuster (A, Figure2-9)

to the bracketon the right-side handlebar.

Usetwo 1/2"wrenchesto loosenthe two

jam nuts (B)just enoughto slidethe cable

adjuster ontothe bracket.Then handtight-

enthe jam nuts.

Figure2-5:CarefullyunwrapWheelGearLe-

verandmoveleverto DISENGAGE.

NOTE: The Wheel Gear Lever will be

installed later in this procedure.

Figure2-9

Page 8

CAUTION: Incorrect cable

adjustment couldcausethe

wheelsandtines to rotate

unexpectedly.Follow

adjustment procedures

carefully. Failureto dosocould

result in personal injury or

property damage.

4. Checkfor correct spring/caNetension

as instructedin Section 5, Checkingand

Adjusting Forward Clutch Belt Tension.

5. Whentension is correct, tightenthe two

jam nuts (B) securely.

STEP5: CHECKTRANSMISSIONGEAR

OILLEVEL

Thetransmission was filled with gearoil at

the factory. However,besure to checkthe

oil levelatthis time to makecertain it is

correct.

IMPORTANT:Do not operatethe tiller if

the gearoillevelislow. Doingso will result

in severedamagetothe transmission

components.

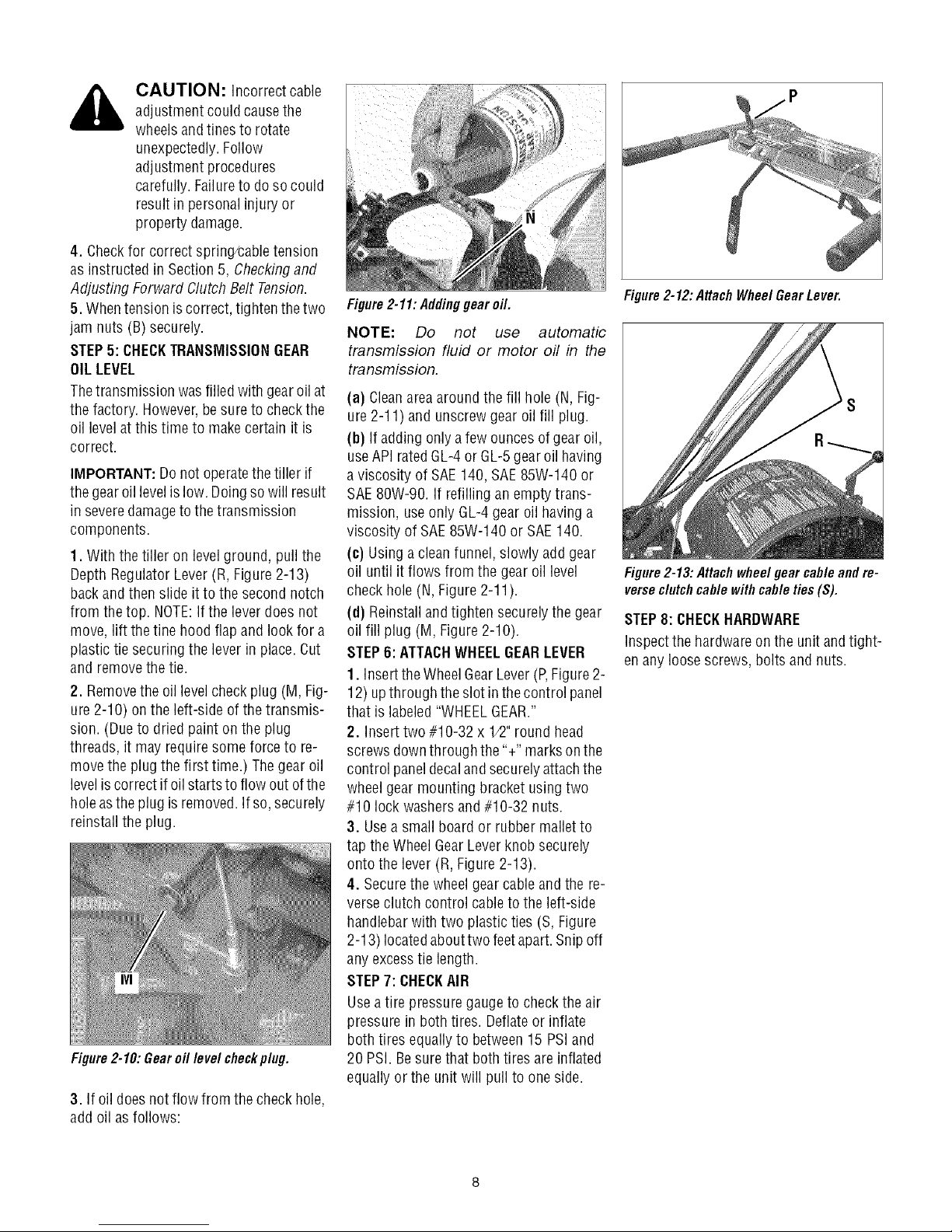

1. With the tiller on level ground, pull the

Depth Regulator Lever(R, Figure 2-13)

backand then slide it to the second notch

from thetop. NOTE:Ifthe lever does not

move, lift thetine hood flapand look for a

plastic tie securing the lever in place.Cut

and removethe tie.

2. Removethe oil levelcheck plug (M, Fig-

ure 2-10) on the left-side of thetransmis-

sion. (Dueto dried paint onthe plug

threads, it mayrequire some forceto re-

move the plug the first time.) Thegear oil

levelis correct if oilstarts to flow out ofthe

holeastheplug isremoved.If so, securely

reinstall the plug.

Figure2-10: Gear oil level checkplug.

3. If oil doesnot flow from the checkhole,

add oil as follows:

Figure2-11:Addinggearoil.

NOTE: Do not use automatic

transmission fluid or motor oil in the

transmission.

(a) Cleanareaaround the fill hole (N, Fig-

ure 2-11) and unscrewgear oil fill plug.

(b) If adding onlya fewounces ofgear oil,

useAPI rated GL-4or GL-5gearoil having

a viscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an emptytrans-

mission, useonly GL-4gear oil havinga

viscosity of SAE85W-140 or SAE140.

(c) Using aclean funnel, slowly add gear

oil until it flows from the gear oil level

checkhole (N, Figure 2-11).

(d) Reinstalland tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP6: ATTACHWHEELGEARLEVER

1. Insertthe WheelGearLever(P,Figure2-

12) upthrough theslot in thecontrol panel

that is labeled"WHEELGEAR."

2. Insert two#10-32 x 1/2"round head

screws downthrough the'%" marks onthe

control paneldecalandsecurelyattachthe

wheelgear mounting bracket usingtwo

#10 lock washersand #10-32 nuts.

3. Usea small board or rubber malletto

tap the Wheel GearLever knob securely

onto the lever (R, Figure2-13).

4. Securethe wheelgear cable and the re-

verseclutch control cableto the left-side

handlebarwith two plastic ties (S, Figure

2-13) locatedabouttwo feetapart.Snip off

anyexcesstie length.

STEP7: CHECKAIR

Usea tire pressuregauge to checkthe air

pressure in both tires. Deflateor inflate

both tires equallyto between15 PSiand

20 PSI. Besure that both tires are inflated

equallyor the unit will pull to one side.

Figure2-12: Attach Wheel GearLever.

Figure2-13:Attachwheelgearcableandre-

verseclutchcablewithcableties(S).

STEP8: CHECKHARDWARE

Inspectthe hardwareon the unit andtight-

en anyloose screws, boltsand nuts.

Page 9

SECTION3: FEATURESANDCONTROLS

_ ARNING: Before

Tiller Features

This section describesthe locationand

function ofthecontrols on yourtiller. Refer

to Section4: Operationfor detailedoperat-

ing instructions.

Practice usingthese controls, with the en-

gine shut off, until you understandthe op-

eration ofthe controls and feel confident

with eachof them.

IMPORTANT:Referto theseparateengine

manufacturer's EngineOwner's Manual

for information about thecontrols onthe

engine.

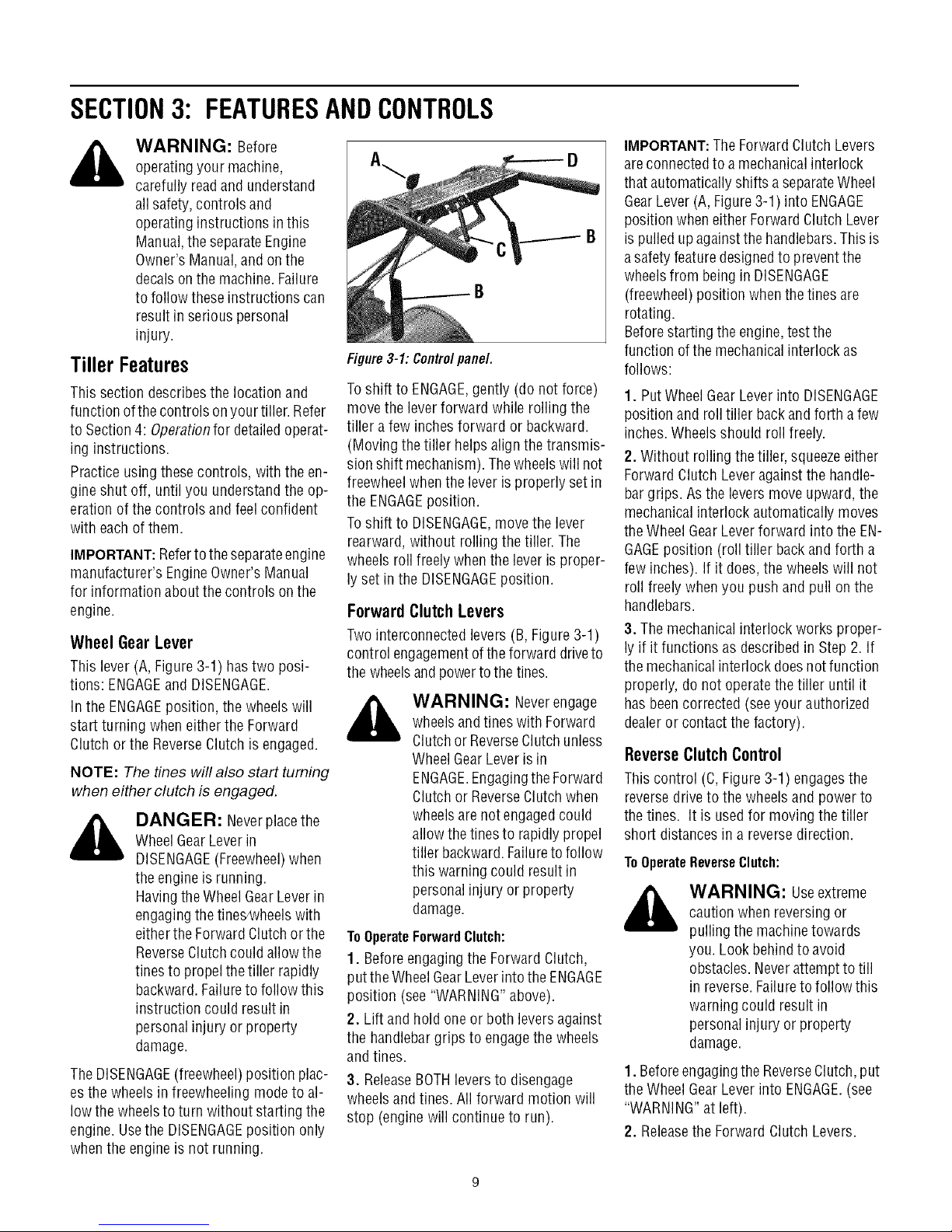

Wheel Gear Lever

This lever (A,Figure3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, the wheelswill

start turning when either the Forward

Clutch orthe ReverseClutch is engaged.

NOTE: The tines will also start turning

when either clutch is engaged.

,_ DANGER: Neverplacethe

TheDISENGAGE(freewheel)position plac-

esthe wheels infreewheeling modeto al-

low thewheelsto turn without starting the

engine.Usethe DISENGAGEposition only

whenthe engine is not running.

operatingyour machine,

carefully readand understand

all safety,controls and

operatinginstructions in this

Manual,the separateEngine

Owner's Manual,andon the

decalson the machine.Failure

to follow these instructions can

result in serious personal

injury.

WheelGearLever in

DISENGAGE(Freewheel)when

the engineis running.

HavingtheWheelGearLeverin

engagingthetines_vheelswith

eitherthe Forward Clutchorthe

ReverseClutch couldallow the

tines to propel thetiller rapidly

backward.Failureto follow this

instruction could result in

personalinjury or property

damage.

Figure3-1: Controlpanel.

Toshift to ENGAGE,gently (do not force)

move the leverforward while rolling the

tiller afew inches forward or backward.

(Moving thetiller helpsalign the transmis-

sionshift mechanism). Thewheelswill not

freewheelwhenthe leveris properly setin

the ENGAGEposition.

Toshift to DISENGAGE,move the lever

rearward, without rolling the tiller.The

wheels roll freelywhen the leveris proper-

ly setin the DISENGAGEposition.

ForwardClutchLevers

Twointerconnected levers (B, Figure3-1)

control engagementofthe forward driveto

the wheelsandpowerto the tines.

,_ WARNING: Neverengage

ToOperateForwardClutch:

1. Beforeengagingthe ForwardClutch,

putthe Wheel GearLeverintothe ENGAGE

position (see "WARNING"above).

2. Lift and holdone or both leversagainst

the handlebargrips to engagethe wheels

andtines.

3. ReleaseBOTHleversto disengage

wheelsand tines. All forward motion will

stop (engine will continue to run).

wheelsandtines with Forward

Clutchor ReverseClutchunless

WheelGearLever is in

ENGAGE.EngagingtheForward

Clutchor ReverseClutchwhen

wheelsare not engagedcould

allowthe tinesto rapidly propel

tiller backward.Failureto follow

this warning could result in

personalinjury or property

damage.

IMPORTANT:The ForwardClutch Levers

areconnectedto amechanicalinterlock

that automaticallyshifts a separateWheel

GearLever(A,Figure3-1) into ENGAGE

position when eitherForwardClutch Lever

is pulledupagainstthe handlebars.This is

asafety featuredesignedto preventthe

wheelsfrom being in DISENGAGE

(freewheel)position when the tines are

rotating.

Beforestarting the engine,testthe

function ofthe mechanicalinterlock as

follows:

1. PutWheel GearLeverinto DISENGAGE

position and roll tiller backand forth a few

inches.Wheels should roll freely.

2. Without rollingthe tiller, squeezeeither

Forward Clutch Leveragainst the handle-

bargrips. Asthe levers move upward,the

mechanicalinterlock automatically moves

theWheel GearLeverforward into the EN-

GAGEposition (roll tiller backand forth a

few inches). If it does,the wheels will not

roll freely whenyou push and pull on the

handlebars.

3. The mechanicalinterlock works proper-

ly if it functions as describedin Step 2. If

themechanical interlock does not function

properly, do not operatethe tiller until it

hasbeencorrected (seeyour authorized

dealeror contact the factory).

Reverse Clutch Control

This control (C,Figure3-1) engagesthe

reversedrive to the wheels andpower to

thetines. It is usedfor moving thetiller

short distances in a reversedirection.

ToOperateReverseClutch:

_ ARNING: Useextreme

1. Beforeengagingthe ReverseClutch,put

theWheel GearLever into ENGAGE.(see

"WARNING"at left).

2. Releasethe Forward ClutchLevers.

caution whenreversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.Neverattemptto till

in reverse.Failureto follow this

warningcould result in

personalinjury or property

damage.

Page 10

3.Tomovethetillerinreverse,firststopall

forwardmotion.Liftupthehandlebarsun-

tilthetinesclearthegroundandpullthe

ReverseClutchleverout.

Thewheelswillrotateinareversedirection

aslongastheleverisheldinREVERSE.To

stopthewheelsandtines,releasethelever

anditwillreturntoNEUTRAL.Neverat-

temptto till whilemovingin reversedi-

rection.

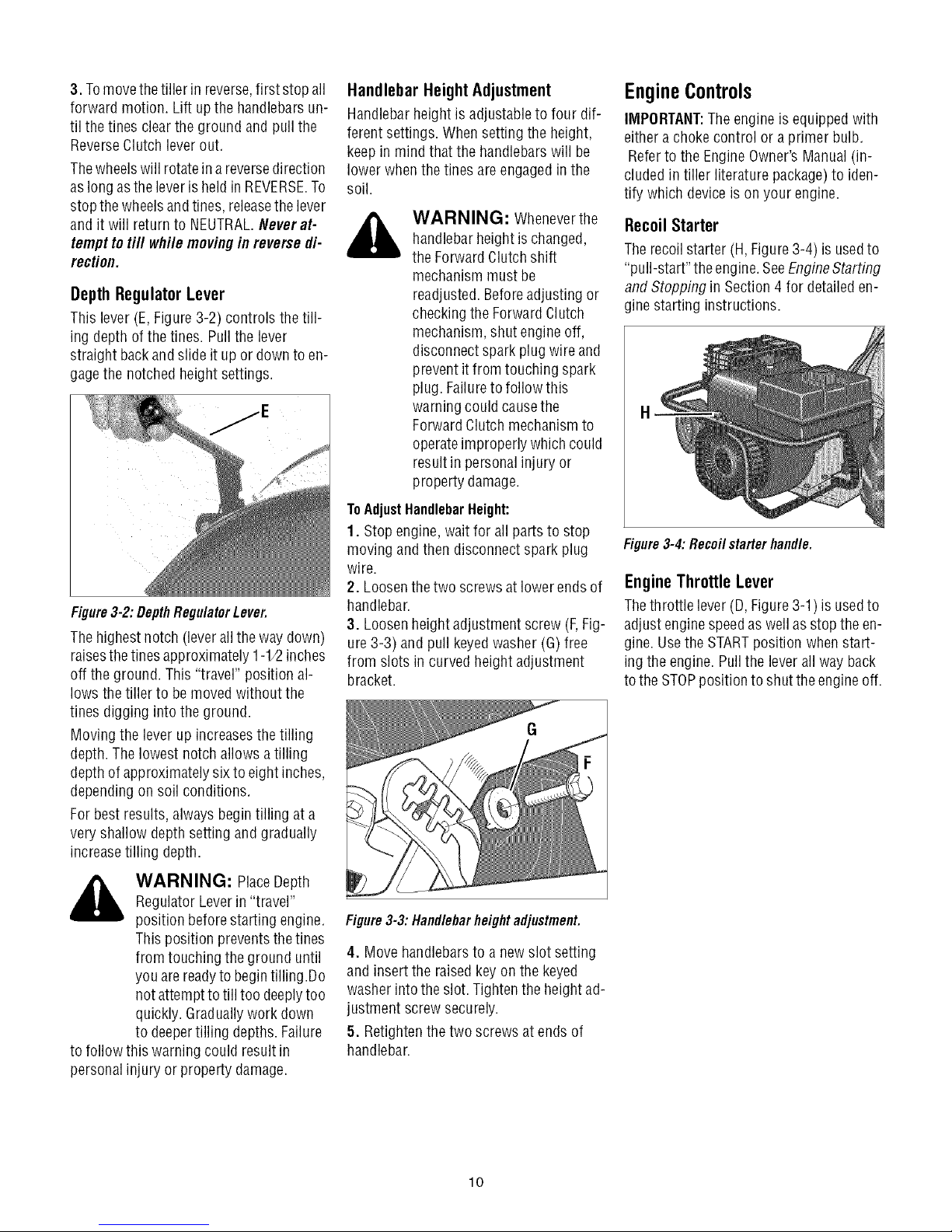

DepthRegulatorLever

This lever (E,Figure3-2) controls the till-

ing depthof the tines. Pullthe lever

straight backandslide it upor downto en-

gagethe notchedheight settings.

Figure3-2:DepthRegulatorLever.

Thehighest notch(leverall the way down)

raisesthe tinesapproximately1-1/2inches

off the ground. This"travel" position al-

lows the tiller to bemoved without the

tines digging into the ground.

Moving the lever up increasesthetilling

depth. Thelowest notch allows a tilling

depthof approximatelysix to eight inches,

dependingon soil conditions.

Forbest results, always begin tilling at a

very shallow depth setting and gradually

increasetilling depth.

Handlebar HeightAdjustment

Handlebarheight is adjustableto four dif-

ferent settings. Whensetting the height,

keepin mindthat the handlebarswill be

lower whenthe tines areengagedin the

soil.

WARNING: Wheneverthe

handlebarheight ischanged,

the ForwardClutchshift

mechanism must be

readjusted.Beforeadjusting or

checkingthe ForwardClutch

mechanism,shut engineoff,

disconnect spark plugwire and

prevent itfrom touching spark

plug. Failureto follow this

warningcould causethe

ForwardClutch mechanismto

operateimproperly which could

result in personal injury or

property damage.

ToAdjustHandlebarHeight:

1. Stopengine, wait for all parts to stop

moving andthen disconnectspark plug

wire.

2. Loosenthe two screws atlower endsof

handlebar.

3. Loosenheight adjustment screw (F,Fig-

ure 3-3) and pull keyedwasher (G)free

from slots in curved height adjustment

bracket.

EngineControls

IMPORTANT:Theengineis equippedwith

eithera chokecontrol ora primer bulb.

Referto the EngineOwner's Manual(in-

cluded intiller literature package)to iden-

tify which deviceis on your engine.

Recoil Starter

Therecoil starter (H, Figure3-4) is usedto

"pull-start" theengine.SeeEngineStarting

and Stopping in Section4 for detaileden-

gine starting instructions.

H

Figure3-4: Recoil starter handle.

EngineThrottle Lever

Thethrottle lever (D, Figure3-1) is usedto

adjust enginespeedas wellas stop the en-

gine. Usethe STARTposition whenstart-

ing the engine. Pullthe lever all way back

tothe STOPpositionto shut the engineoff.

,_ WARNING: PlaceDepth

to follow this warning could result in

personalinjury or property damage.

Regulator Leverin "travel"

position beforestarting engine.

This position preventsthetines

from touching the ground until

you arereadyto begintilling .Do

notattempt to till too deeplytoo

quickly. Graduallywork down

to deepertilling depths.Failure

Figure3-3: Handlebarheight adjustment.

4. Move handlebarsto a new slot setting

and insert the raisedkeyon the keyed

washer intothe slot. Tightenthe heightad-

justment screw securely.

5. Retightenthe two screws atends of

handlebar.

lO

Page 11

SECTION3: OPERATION

WARNING: Before

operatingyour machine,

carefully readand understand

all safety (Section1),controls

(Section 3) andoperating

instructions (Section4) inthis

Manual,in the separateEngine

Owner's Manual,andon the

decalson the machine.Failure

to follow these instructions can

result in serious personal

injury.

Introduction

Readthis Section of the manualthorough-

ly beforeyou start the engine.Then,take

time to familiarizeyourself with the basic

operation of the tiller before using it. Find

an open, levelareaand practiceusing the

tiller controls without engagingthe tines in

the soil (put tines in "travel" setting). Only

after you've becomecompletely familiar

with thetiller should you begin using it in

the garden.

Break-In Operation

Perform thefollowing maintenanceduring

the first hours of newoperation (seeSec-

tion 5: Maintenanceandthe maintenance

section of the EngineOwner'sManual).

1. Changemotor oil after first 2 hours of

newengine operation.

2. Checkfor loose or missinghardwareon

unit. Tighten or replaceas needed.

3. Checktension on forward drive belt af-

ter first 2 hours of operation.

4. Checktransmission gear oil levelafter

first 2 hours of operation.

STARTING AND STOPPING ENGINE

Thefollowing steps describehow to start

and stop the engine. Donot engagethe

tinesorwheels untilyouhavereadall of

theoperatinginstructionsinthisSection.

Alsoreviewthe safetyrules in Section1:

Safetyand the tiller andenginecontrols

informationin Section3: Featuresand

Controls.

Pre-StartChecklist

Dothe following beforestarting the en-

gine.

1. Checkunit for looseor missing hard-

ware. Serviceas required.

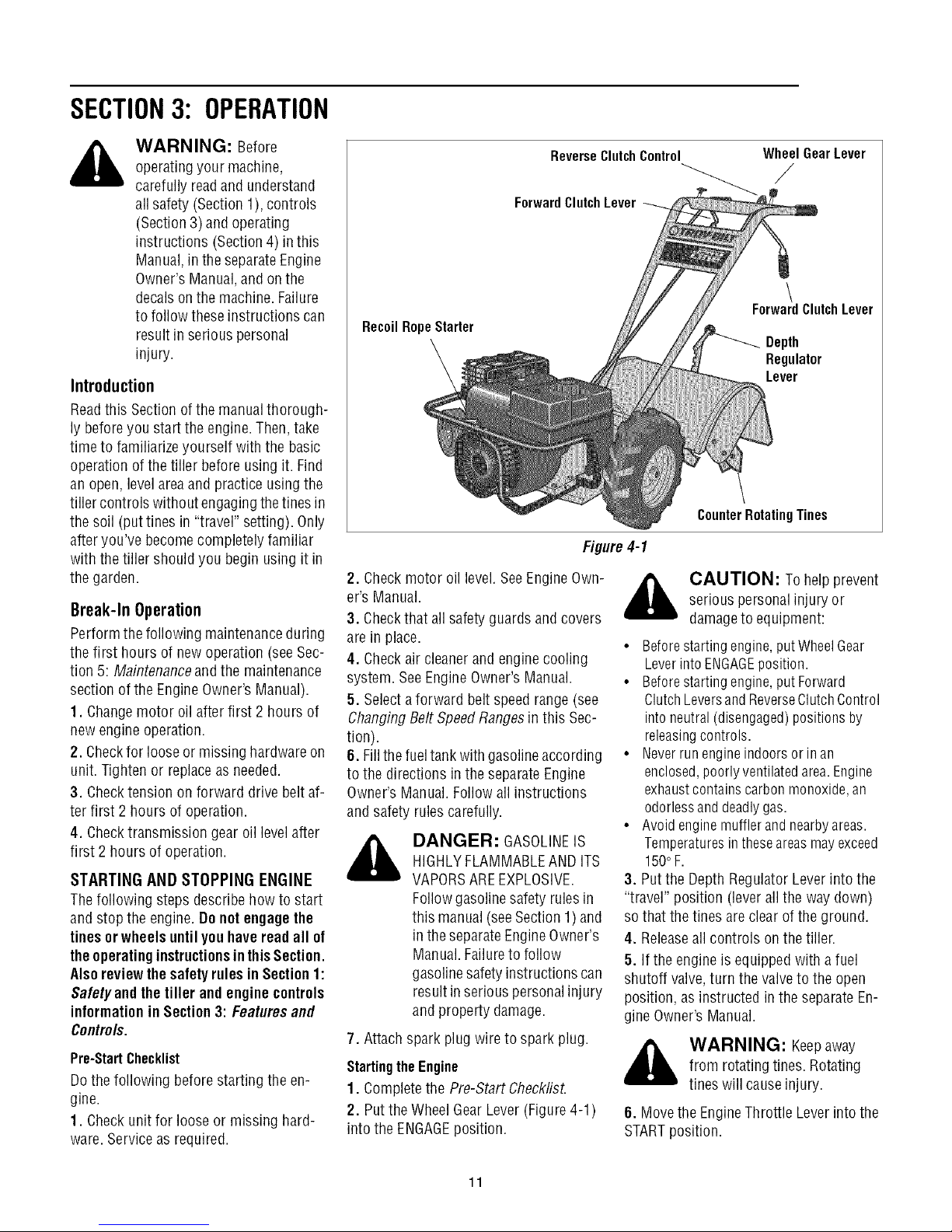

ReverseClutchControl

ForwardClutchLever

RecoilRopeStarter

Figure4-1

2. Checkmotor oil level.SeeEngineOwn-

er's Manual.

3. Checkthat allsafety guards andcovers

are in place.

4. Checkair cleanerand enginecooling

system. SeeEngineOwner's Manual.

5. Selectaforward belt speedrange (see

ChangingBelt SpeedRangesin this Sec-

tion).

6. Fillthefueltank with gasolineaccording

to the directions inthe separate Engine

Owner's Manual.Follow allinstructions

and safety rules carefully.

_k ANGER: GASOLINEIS

7. Attachspark plug wire to spark plug.

Startingthe Engine

1. Completethe Pre-Start Check/isL

2. Putthe WheelGear Lever(Figure4-1)

into the ENGAGEposition.

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Followgasolinesafety rules in

this manual (seeSection 1)and

in the separateEngineOwner's

Manual.Failureto follow

gasolinesafety instructions can

result in seriouspersonalinjury

and property damage.

WheelGearLever

/

\

ForwardClutchLever

Depth

Regulator

Lever

CounterRotatingTines

_, AUTION: To helpprevent

• Beforestartingengine,putWheelGear

• Beforestartingengine,putForward

• Neverrunengineindoorsor inan

• Avoid enginemufflerand nearbyareas.

3. Putthe DepthRegulatorLeverinto the

"travel" position (lever all the way down)

sothat the tinesare clear ofthe ground.

4. Releaseall controls on the tiller.

5. If the engine is equipped with afuel

shutoff valve,turn the valveto the open

position, asinstructed in the separateEn-

gine Owner's Manual.

_ WARNING: Keepaway

6. Movethe EngineThrottle Leverinto the

STARTposition.

serious personalinjury or

damageto equipment:

LeverintoENGAGEposition.

ClutchLeversandReverseClutchControl

intoneutral (disengaged)positions by

releasingcontrols.

enclosed,poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

Temperaturesintheseareasmayexceed

150oF.

from rotating tines. Rotating

tines will causeinjury.

11

Page 12

7. Chokeorprimethe engineas instructed

in the separateEngine Owner'sManual.

8. Checkbehind you to avoid contacting

anyobstacles when pullingthe starter

rope. Placeone hand onthe fuel tankto

stabilizethe unit and usethe recoil starter

to start the engineas instructed in the En-

gine Owner's Manual.Whenthe engine

starts,gradually movethe chokelever (on

enginesso equipped)to the NOCHOKE,

CHOKEOFForRUNposition,whicheverap-

plies.

9. Usethe FASTthrottle speedsetting

whentilling.

StoppingtheEngine

1. Tostop the wheelsandtines, releasethe

Forward Clutch levers or the Reverse

Clutch Control(whichever control is in

use).

2. Tostop the engine,move the Engine

Throttle Leverinto the STOPposition.

OperatingTiller

_ ARNING: Beforetilling,

Thefollowing pagesprovideguidelinesto

using your tiller effectivelyand safely in

various gardening applications.Besureto

read Tilling Tips & Techniquesin this Sec-

tion beforeyou actuallyput the tines into

the soil.

1. Followthe Pre-Start Checkl/ston the

previous page.BesurethattheWheel Gear

Leveris in the ENGAGEposition.

2. Movethe DepthRegulatorLeverintothe

"travel" position (leverall the way down)

sothat the tinesclearthe ground. Usethis

position when practicingwith or transport-

ing the tiller. When you are readyto begin

tilling, movethe Depth RegulatorLever

into the desired depthsetting (see Tilting

Tips & Techniques).

3. Startthe engineandallow itto warm up.

Whenwarm, movethe throttle control into

the FASTspeed setting.

contact yourtelephoneand

utilities companyto inquire if

underground linesare onyour

property.

4. Forforward motion ofthe wheels and

powerto the tines:

(a) Pull up and holdthe ForwardClutch

leversagainstthe handlebars.Tostop

the wheelsandtines, releaseboth le-

ve rs.

WARNING: Donot push

down onthe handlebarsto try

to makethetiller till more

deeply.This preventsthe

wheelsfrom holding the tiller

backand can allow the tines to

rapidly propelthe tiller

backwardtoward the operator,

which could resultin loss of

control, property damage,or

personalinjury.

(b) Asthe tiller movesforward, relaxand

letthe wheelspull theunit along while

thetines dig.Walk behind anda little

to onesideof the tiller. Usealight but

securegrip with one handon thehan-

dlebars,but keepyour armloose. See

Figure4-2. Letthe tiller move ahead

atits ownpace.Donotpush downon

the handlebarsto try and forcethe

tiller to dig deeper- this takes weight

off the wheels,reducestraction, and

causesthe tines to try andpropel the

tiller.

5. Forreverse motion ofthe wheelsand

tines:

(a) Look behind andexercisecaution

whenoperating in reverse.Donot till

while in reverse.

(b) Stop all forward motion before re-

versing. Lift the handlebarswith one

hand untilthetines areoff the ground

andthen pullthe ReverseClutchcon-

trol out (seeFigure 4-3). Tostop re-

verse motion, let go of the Reverse

Clutch Control.

6. Toturn the tiller around:

(a) Practice turning in alevel,openarea.

Bevery carefulto keepyour feet and

legsaway from the tines.

(b) To start aturn, reducethe engine

speedandthen lift the handlebarsun-

til the engine andtines are balanced

overthe wheels (Figure4-4).

(c) With the tiller balanced,push side-

ways onthe handlebarto move the

tiller in the direction of the turn (Fig-

ure 4-5). After completing the turn,

slowly lowerthe tines into the soil

and increasethe enginespeed.

12

Figure4-2:Useonehandtoguidetillerwhen

movingforward.

Figure4-3:Raisetinesoffgroundandlookbe-

hindwhenmovinginreverse.

Figure4-4: Findbalancepoint before turning.

Figure 4-5

Page 13

StoppingtheTiller andEngine

1. Tostop the wheelsand tines, releasethe

Forward Clutch levers orthe Reverse

Clutch Control(whichever is engaged).

2. Tostop the engine,move the Engine

Throttle Leverto STOR

3. Ifthe engineisequippedwith a fuel shut-

off valve,closethevalveasinstructed inthe

EngineOwner's Manual.

_k WARNING: Before

changingbelt speeds,stop

engine,wait for allparts to stop

moving, letengine cooland

disconnect spark plugwire.

Failureto follow these

instructions could resultin

personalinjury.

ChangingBelt RangeSpeeds

Thetiller hastwo forward beltrangespeeds

forthe wheelsandtines: LowandHigh.The

two rangesareobtained bymoving the for-

ward drive belt betweentwo sets of

grooves onthe forward drive pulley andthe

transmission drive pulley.

NOTE:TheHighspeed beltrange is recom-

mendedfor all tilling purposes. The Low

speedbelt rangewill operate thetines and

wheels ata slower forward speed,which

may be suitablein some conditions (such

astilling invery hard ground).

ToChangefrom Lowto HighSpeed:

1. Stopthe engine,allow it to cool, anddis-

connectthe spark plug wire.

2. MovetheWheelGearLeverintothe DIS-

ENGAGEposition.

3. Removethe two nuts from the plastic

belt coveron top of thetransmission and

removethe belt cover.

4. From beneaththe tiller, movethe for-

ward drivebelt out ofthe transmission low

speedgroove (B,Figure4-10) and into the

high speedgroove (D).

5. Pull upwardon the belt to removeany

slackand slip the belt out ofthe engine

drive pulley low speedgroove (A, Figure4-

10) and into the high speedgroove (C).

NOTE:Ifthe belt isdifficult to move,pull on

theenginestart ropewhilepushing thebelt

with your finger (engine drive pulleywill

turn as start ropeis pulled).

6. Checkthatthe beltiswithinthe forward

beltguide (E,Figures4-10 and4-11) onthe

right-side of the unit and is within the for-

ward idler (F,Figure4-11) on the left-side.

Besurethat the beltissituatedin thecenter

grooves (Cand D,Figure 4-10) of the en-

gine (upper) and transmission (lower) pul-

leys.

7. Reinstallthe plastic beltcover andse-

cure it with thetwo nuts.

8. PutWheel GearLeverin ENGAGEand re-

connect spark plug wire beforeattempting

to start the engine.

ToChangefrom HightoLowSpeed:

1. Stopthe engine,allow it to cool, and dis-

connect the spark plug wire.

2. PutWheelGearLeverin DISENGAGE.

3. Removethetwo nuts from the plastic

beltcover on top of the transmission and

removethe belt cover.

4. From beneaththetiller, move the for-

ward drivebelt out ofthe transmission pul-

leyhigh speedgroove (D,Figure4-10) and

into the low speedgroove (B).

5. Pull upwardon the belt to removeany

slack andslip the belt out of the engine

drivepulley highspeed groove (C,Figure4-

1O)and into the low speed groove (A).

NOTE:Ifthe beltis difficult to move,pull on

the enginestart ropewhile pushing the belt

with your finger (enginedrive pulley will

turn asstart ropeis pulled).

6. Checkthat the belt iswithin theforward

beltguide (E,Figures4-10 and4-11) onthe

right-side of the unit and is within the for-

ward idler (F,Figure4-11) on the left-side.

Besurethat the belt is situated in the rear

grooves (A and B,Figure4-10) of the en-

gine (upper) and transmission (lower) pul-

leys.

7. Reinstallthe plastic beltcover andse-

cure it with thetwo nuts.

8. Putthe WheelGearLever in ENGAGE

and reconnectthe sparkplug wire before

attempting to start the engine.

(Low) (High)

,c l

(Low) (High)

Figure4-10:Right-sideviewofengineand

transmissionpulleys(engineisatright-sideof

view).

Figure4-11:Topviewofforwarddrivepulley

system(engineisatleft-sideof view).

everse

Belt

13

Page 14

TILLINGTIPS& TECHNIQUES

Tilling Depths

WAHNING: Before

tilling, contact your

telephoneor utilities

companyand inquire if

undergroundequipment or

lines areusedon your

property. Donot till near

buriedelectric cables,

telephonelines, pipesor

hoses.

• Whencultivating(breakingupsurfacesoilaroundplantsto destroyweeds,seeFig.4-9), ajust thetinesto dig only 1"to 2"deep.Using

shallowtilling depthshelpspreventinjury to plantswhoseroots often growclose to the surface.If needed,lift up onthe handlebars

slightlyto preventthetinesfrom diggingtoo deeply.(Cultivatingona regularbasisnot onlyeliminatesweeds,it alsoloosensandaerates

thesoil for bettermoistureabsorptionandfasterplantgrowth.)Wateringthegardenareaafewdayspriorto tillingwill maketillingeasier,

aswill lettingthe newlyworkedsoil setfor adayor two beforemakinga final,deeptilling pass.

This is a CRT(counter-rotatingtine) tiller. Asthewheelspullforward, the tinesrotateback-

ward. Thiscreatesan "uppercut" tine actionwhich digs deeply,uprootingsoil andweeds.

Don't overloadthe engine,but dig asdeeplyaspossibleon eachpass.Onlaterpasses,the

wheelsmaytendto spininthesoftdirt. Helpthemalongbylifting upslightly onthehandlebar

(onehand,palm up,works mosteasily).

Avoidthe temptationto pushdownon thehandlebarsinanattemptto force thetiller to dig

deeper.Doingsotakestheweightoff the poweredwheels,causingthemto losetraction.

Withoutthe wheelsto holdthetillerback,the tineswill attemptto propelthetiller backward,

towardsthe operator.(Sometimes,slightdownwardpressureonthe handlebarswill helpget

througha particularlytoughsectionofsodor unbrokenground,butin mostcasesthiswon't

benecessary.)

ChoosingCorrectWheel& TineSpeeds With experience,you will find the "just right" tilling depthandtilling speedcombination

that is bestfor yourgarden.

Setthe enginethrottleleverata speedto givetheengineadequatepowerandyetallowit tooperateattheslowestpossiblespeed...atleast

until youhaveachievedthe maximumtilling depthyou desire.Fasterenginespeedsmaybe desirablewhen makingfinal passesthrough

theseedbedor whencultivating.Selectionofthe correctenginespeed,in relationtothe tilling depth,will ensureasufficientpowerlevelto

do thejobwithout causingtheenginetolabor.

Letthe Tiller DotheWork

Whiletilling, relaxandletthe wheelspullthe

tiller along while the tinesdo the digging.

Walkon the side that is not yet finished(to

avoidmakingfootprints in the freshly tilled

soil) andlightly,but securelygrip the han-

dlebarwith just onehand.

AvoidMakingFootprints

Wheneverpossible, walk on the untilled

sideof theunitto avoidmakingfootprints in

your freshly tilled or cultivatedsoil. Foot-

prints causesoil compactionthat can ham-

per root penetrationand contributeto soil

erosion. They can also "plant" unwanted

weed seeds back into the freshly tilled

ground.

Preparing Seedbeds

•Whenpreparingaseedbed,go overthesamepathtwiceinthefirst row,then over-

lapone-halfthetiller width ontherest of the passes(seeFig.6). Whenfinishedin

onedirection,makea secondpassat a rightangle,as shownin Fig.4-7. Overlap

eachpassfor best results(invery hardground,it maytakethreeor four passesto

thoroughlypulverizethesoil.)

• If the gardensizewill not permitlengthwiseandthencrosswisetilling, thenover-

lapthefirst passesbyone-halfatiller

width,followedby successivepasses ....................v .................................

at one-quarterwidth(seeFig.4-8). _ _

Fig. 4-8

AvoidTilling Soggy,WetSoil

Tilling wetsoil often results in large,hard

clumpsof soil that can interferewith plant-

ing.If time permits,wait adayor two after

heavyrainsto allow the soil to dry before

tilling. Testsoil by squeezingit into a ball.If

itcompressestoo easily,it is too wet to till.

Fig. 4-6 Fig.4-7

Cultivating

With planning, you can ==.._vp. ==_._v_

allow enoughroom _" _ (_

betweenrows to cultivate _ _

(seeFig.4-9). Leaveroom _ _

for the hood width,

plus enough extra _ _'

roomfor future plant Fig.4-9

growth.

14

Page 15

TillingOn Slopes

TILLINGTIPS& TECHNIQUES(CON'T)

Readthe followingrecommendationsbeforetilling on slopes:

Ifyou mustgardenon amoderateslope,pleasefollowtwo veryimportantguidelines:

1.Till only on moderateslopes,neveronsteepgroundwherefootingisdifficult (reviewsafe-

ty rulesinSection1:Safetyof this manual).

2. We recommendtilling up and down slopes ratherthan terracing.Tilling vertically on a

slopeallows maximumplantingareaandalsoleavesroomfor cultivating.

IMPORTANT:Whentilling onslopes,besurethecorrectoil levelis maintainedin theengine

(checkeveryone-half hour of operation).The inclineof the slopewill causethe oilto slant

WAHNING: Donot

operatetiller on aslopetoo

steepfor safeoperation.Till

slowly andbesureyou have

good footing. Neverpermit

tiller to freewheeldown

slopes.Failureto follow this

warning could result in

personalinjury.

awayfrom its normallevelandthis canstarveenginepartsof requiredlubrication.Keepthe

motor oil levelatthefull pointat all times!

Tilling Upand DownSlopes(Vertical Tilling)

• Tokeepsoil erosionto aminimum,besureto addenoughorganicmatterto thesoil sothat it has goodmoisture-holdingtextureandtry

to avoidleavingfootprints or wheelmarks.

• Whentilling vertically,tryto makethefirst passuphillasthetillerdigsmoredeeplygoing uphillthan itdoesdownhill.Insoft soil or weeds,

youmayhaveto lift the handlebarsslightlywhilegoing uphill. Whengoingdownhill, overlapthefirst passby aboutone-halfthewidth of

thetiller.

Clearingthe Tines

Thetineshavea self-clearingactionwhicheliminatesmosttanglingof debrisinthe

tines.However,occasionallydrygrass,stringystalksortoughvinesmaybecometan-

gled.Followtheseproceduresto helpavoidtanglingandto cleanthe tines,if neces-

sary.

•Toreducetangling,setthedepthregulatordeepenoughto getmaximum"chopping"

actionasthetines chopthe materialagainsttheground.Also,try to till undercrop

residuesor covercropswhiletheyaregreen,moistandtender.

• Whiletilling,try swayingthehandlebarsfrom sideto side(about6"to 12").This

"fishtailing"actionoftenclearsthe tinesof debris.

• Iftanglingoccurs,lift thetinesout ofthesoilandrunthetiller in reverse(if unitis

equippedwith poweredreverse)forafewfeet.Thisreversingactionshouldunwinda

gooddealofdebris.

• It may benecessaryto remove the debris by hand(a

pocketknifewill helpyou to cut awaythe material). Be

sure to stop the engineand disconnect the sparkplug

wire before clearing thetines by hand.

tines by hand,stop the engine,allow all

WARNING: Beforeclearing the

moving parts to stop and disconnect the

spark plugwire. Removethe ignition key

on electric start models.

Failureto follow this warning could result

in personalinjury.

Loading andUnloadingtheTiller

,_ WARNING: Loadingand

•Beforeloadingorunloading,stoptheengine,

waitfor allpartsto stopmoving,

disconnectthesparkplugwireandletthe en-

gineandmufflercool.

•Thetilleristooheavyandbulkytolift safely

byoneperson.Twoor morepeopleshould

sharetheload.

unloadingthetillerintoavehicleis

potentiallyhazardousandwedon't

recommenddoingso unless

absolutelynecessary,asthiscould

resultinpersonalinjuryor

propertydamage.

However,ifyoumustloador

unloadthetiller,followthe

guidelinesgivennext.

• Use sturdy ramps and manually (engineshut

off) roll the tiller into and out of the

vehicle. Two or more people are neededto do

this.

• The ramps must bestrong enoughto support

the combined weight of the tiller and any han-

dlers. Theramps should providegood traction

to prevent slipping; they should have side rails

to guide the tiller along theramps; andthey

should havea locking deviceto securethemto

the

vehicle.

• The handlersshould wearsturdyfootwearthat

will helpto preventslipping.

• Position the loading vehicle so that the ramp

angleis as flat as possible(the less inclineto

the ramp,the better). Turn the

vehicle'sengineoff and applyits parkingbrake.

15

• When going up ramps, stand in the

normal operating position and push the tiller

ahead of you. Havea personat each sideto

turn the wheels.

• When going down ramps,walk backward

with the tiller following you. Keepalert for any

obstacles behindyou. Position a person at

eachwheel to control the speedof thetiller.

Nevergo down ramps tiller-first, asthe tiller

could tip forward.

• Placewooden blocks on thedownhill side of

the wheels if you needto stop the tiller from

rolling down the ramp. Also, use the blocks to

temporarily keep thetiller in place onthe

ramps (if necessary),andto chockthe wheels

in place after thetiller is in the vehicle.

• After loadingthe tiller, prevent it from rolling

byengaging the wheelsin the WHEELDRIVE

position. Chock the wheelswith blocksand se-

curelytie the tiller down.

Page 16

SECTION5: MAINTENANCE

,_ WARNING: Before

inspecting, cleaningor

servicingthe machine,shut off

engine,wait for allmoving

parts to cometo a complete

stop, disconnectsparkplug

wireand movewire awayfrom

spark plug. Removeignition

key onelectric start models.

Failureto follow these

instructions can result in

serious personalinjury or

property damage.

MAINTENANCESCHEDULE

PROCEDURE NOTES

Chockmotor oil level 2, 3

Cleanengine 2, 7

Checkdrive belt tension 1,4

Checknuts and bolts 1,4

Change motor oil 1,4, 6

Lubricate tiller 4

Service foam pre-cleanerair filter 7

Service paper air filter 7

Checkgear oil levelin transmission 1, 5

Checktines for wear 5

Checkair pressure intires 5

Service spark plug 7

NOTES

1- After first 2 hours of break-in operation.

2 - Beforeeach use.

3 - Every5 operating hours.

4 - Every 10 operating hours.

5 - Every30 operating hours.

6 - Changemore frequently in dusty or dirty

conditions.

7 - See EngineOwner's Manual forservice

recommendations.

8 - Whichever time interval occurs first.

Tiller Lubrication

Proper lubrication of the tiller is anessen-

tial part of your maintenanceprogram. Af-

ter every 10operating hours, oil orgrease

the lubrication points shown in Figures5-

1 and 5-2 anddescribed below.

Usegeneral purpose lubricating oil (#30

weight motor oil is suitable)and ageneral

purpose grease(metal lubricant is pre-

ferred, if available).

• Removewheelsandcleanwheelshaft (A,

Figure5-1). Apply a thin coating of

greaseto shaft before reinstalling

wheels.

• Greaseback,front and sides of depth

regulator lever (B, Figure 5-1).

D L

E

Figure5-1

• Removetines and cleantine shafts (C,

Figure5-1). Inspect for rust, rough

spotsor burrs (especiallyaroundholes).

Fileor sand smooth and coatends of

shaft with grease.

• Oil the threadson the handlebarheight

adjustment handle(D, Figure5-1).

• Oilthe outer casingsof theenginethrot-

tle cableandthe wheel gearcable (E,

Figure5-1). Allow oil to soak inandthen

wipe off anyexcess.

• Oil the various pivotpoints (F,Figure 5-

2) on the shifting mechanism,the han-

dlebar,and the idler arms (do not allow

oil on the belts or pulleys).

Figure5-2

Check Tire Air Pressure

Checktheair pressure inbothtires. Deflate

or inflate both tires evenlyto between15

and 20 PSi (pounds persquare inch). Be

surethat bothtires haveequalair pressure

or the unit will pull to oneside.

Check For Oil Leaks

Beforeeach use,checkyour tiller for signs

ofan oil leak--usually adirty, oilyaccumu-

lation either on the unit or onthe floor

whereit has been parked.

A little seepagearound a coveror oil seal

is usuallynot acausefor alarm. However,

if the oil drips overnight,then immediate

attention is needed--ignoring a leak can

result in severetransmission damage.

If a coverleaks,try tightening any loose

screws or bolts. If thefastenersaretight, a

newgasket or oil seal maybe required. If

theleak is from arounda shaft and oilseal,

the oilsealprobably needsto be replaced.

Seeyour authorized dealeror contact the

factory for service or advice.

IMPORTANT:Neveroperatethe tiller if the

transmission is low on oil. Checkthe oil

levelafter every30 hours of operationand

wheneverthere is anyoil leakage.

CheckHardware

Checkthe unit for loose or missing hard-

wareafter every10operatinghours. Loose

or missing hardwarecan leadto equip-

ment failure, poor performance, or oil

leaks.

Besureto check the three end cap mount-

ing screws locatedat the rearof thetrans-

mission (Figure5-3). Liftthe tine flap to

servicethose screws.

EndCap

Figure5-3

Transmission Gear Oil Service

Checkthe transmission gear oil levelafter

every 30 hours of operation orwhenever

you noticeanyoil leak.Operatingthe tiller

whenthe transmission is lowon oil canre-

sult in severe damage.

16

Page 17

moving partsto come to a complete stop, disconnectspark plug wireand movewireawayfrom

WARNING: Beforeinspecting,cleaningor servicing the machine,shut off engine,wait for all

spark plug. Failureto follow theseinstructions canresult inserious personal injury or property

damage.

A. ToCheckTransmission

1. Checkthe gear oil levelwhenthe trans-

mission is cool. Gearoil expandsin warm

operatingtemperatures andwill result in

an incorrect oil level reading.

2. Tocheck the gear oil level (andto add

oil, if necessary), referto STEP5."Check

GearOilLevelin Transmissionin Section2

of this manual.

D.ToDrainandRefilltheTransmission:

Thetransmission gear oil doesnot needto

be changedunless it hasbeencontaminat-

ed with dirt, sand or metal particles.

1. Propupthe left side of the unitsecurely.

Removethe left-side wheel by removing

the wheel mounting hardware.

2. Unscrewthe plastic gearoil fill plug

from thetop ofthe transmission

3. Placea clean panbelow the transmis-

sion drain plug (Figure5-4) and remove

the drainplug. Theoil will startflowing out

of the drain hole (it mayflow slowly, espe-

cially in cold temperatures).

Figure5-4: Remove drain plug to drain trans-

missiongear oil (also remove oil fill plug and

oil level checkplug).

4. Removethe transmission gear oil level

checkplug that is locateda few inches

abovethe left-side wheelshaft (N, Figure

2-11).

5. Whenthe oil stops flowing, tilt the

transmission forward to drain oil from the

rear of the transmission.

6. After draining the oil, clean the threads

of the drain plug,apply anon-hardening,

removablegasketsealantto the threads,

and securelyreinstall the drain plug.

7. Usea clean funnel to slowly add SAE

140 or SAE85W-140 weight gearoil (with

an API rating of GL-4only) to the trans-

mission. Thetransmission holdsapproxi-

mately3-1/4 pints (52-54 ounces).Tilt the

tiller slightly backwardsto make sure the

gear oil reachesthe rear (tine) endof the

transmission. Stop adding gearoil when it

beginsto flow from the oillevelcheckhole

on the side of the

ion.

8. Securely reinstallthe oil level check

plug.

9. Securelyreinstallthe gearoil fill plug on

top of the transmission.

10. Reinstallthe wheeland removethe

prop.

EngineOil Service

Checkthe motor oil level beforestarting

the engineeachdayandafter each5 hours

of continuous operation. Runningthe en-

gine whenthe oil level is low will quickly

ruin the engine.

It is recommendedthatyou changethe

motor oil after every10hours of operation

and evensoonerwhen operating inex-

tremely dirty or dusty conditions.

A.ToCheckthe Motor0il Level:

1. Move the tiller to a levelareaand stop

the engine.

2. Levelthe engine by moving the Depth

Regulator Leverinto the secondnotch

from the top.

3. Cleantheareaaroundthe oil dipstick or

oil fill tube (whichever applies) to prevent

dirt from falling into the crankcase.

4. Onengineswith an oil fill tube, remove

the filler cap andadd oil (if required) until

it reachesthe top of thetube. Reinstallthe

filler cap.

5. Onengineswith a dipstick, removeit,

wipe it clean, andreinstall it finger4ight.

Removethe dipstick againand check the

reading.Add oil (if required) to bring the

levelto the FULLmark. Donot overfill.

B. ToChangethe Motor Oil:

Changethe motor oil as instructed in the

separateEngineOwner's Manual.

Air CleanerService

Theengineair cleanerfilters dirt and dust

out ofthe air before it entersthe carbure-

tor. Operatingthe enginewith a dirty,

cloggedair filter can causepoor perfor-

manceand damageto the engine. Never

operatethe engine without the air cleaner

installed. Inspectandservicethe airclean-

er more often if operatingin very dusty or

dirty conditions.

Servicethe aircleanerasinstructed in the

separateEngineOwner's Manual.

SparkPlugService

inspectand cleanor replacethespark plug

after every 100operating hours or annual-

ly. Cleanthe plugand set the gapas de-

scribed in the separateEngineOwner's

Manual.

Insome areas,local law requires using re-

sistor sparkplugsto suppress ignition sig-

nals. If the enginewas originally equipped

with a resistor spark plug, usethe same

type for replacement.

SparkArrester Screen Service

If the engine muffler is equipped with a

spark arresterscreen, removeand cleanit

accordingto thetime intervals and instruc-

tions in the separateEngineOwner's Man-

ual.

EngineCleaning

Theenginemust be kept cleanto assure

smooth operationand to preventdamage

from overheating. Referto the separate

EngineOwner's Manualfor specific repair

and cleaninginstructions. All inspections

andservices must bedonewith the engine

shut off and coolto thetouch.

17

Page 18

moving partsto come to a complete stop, disconnectspark plug wireand movewireawayfrom

WARNING: Beforeinspecting,cleaningor servicing the machine,shut off engine,wait for all

spark plug. Failureto follow theseinstructions canresult inserious personal injury or property

damage.

Carburetor / Governor Adjustment

,_ WARNING: Operators

Thecarburetor wasadjusted at the factory

for best operating speed. Referto the sep-

arateEngineOwner's Manualfor anyad-

justment information or seeyour

authorizedengine service dealer.

Thegovernor controls the maximum safe

operatingspeed and protects the engine

andall moving parts from damagecaused

by overspeeding.Donot tamper with the

enginegovernor settings. Seekauthorized

service if a problem exists.

Throttle Control Adjustment

If the engine doesnot respondto various

throttle leversettings, referto theseparate

EngineOwner's Manualfor service infor-

mation or contactyour localauthorizeden-

gine service dealer.

Wheel Gear Cable Adjustment

Whenthe Wheel GearLeveris in DISEN-

GAGE,the wheelswill roll freely (free-

wheel). Thewheelsshould not roll freely

whenthe lever is in ENGAGE.If the wheels

roll freely when the Wheel GearLever is in

ENGAGE,thewheelgearcable needsto be

adjustedas describedbelow.

1. With the engineshut off andthe spark

plug wire disconnected,put the Wheel

GearLeverin ENGAGE.

2. Loosenthe top adjustment nut

the wheelgearcablebracketlocatedonthe

left side rearof the transmission.

3. Pushwheelgearcable(B) downand roll

tiller slightly forward or backward until ec-

centric lever (C) engages (locks) wheels.

Holdcable in that position andtighten top

(A) and bottom (D)adjustment nuts.

shallnot tamper withtheengine

governorsettings; the governor

controls the maximum safe

operatingspeedto protectthe

engineandall moving parts

from damagecausedby

overspeed.Authorizedservice

shallbe soughtif a problem

exists.

Figure5-5: Wheelgear cableassembly.

4. MoveWheelGearLeverto ENGAGEand

DISENGAGEseveraltimes to checkadjust-

ment.The wheelsshould not roll when the

lever is in ENGAGE,but they should roll

whenthe leveris in DISENGAGE.Readjust

the cableas required.

OffSeasonStorage

Whenthe tiller won't beusedfor extended

periods, prepareit for storage as follows:

1. Cleanthe tiller and engine.

2. Do routinetiller lubrication (see Tiller

Lubrication) andcheckfor loosepartsand

hardware(see CheckHardware).

3. Protectthe engine by performing the

enginestorageinstructions inthe separate

EngineOwner's Manual.

NOTE:Besureto protect thefuel lines,car-

buretor andfuel tankfrom gum deposits

by removingfuel or bytreating fuel with a

fuel stabilizer (follow engine manufactur-

er's recommendations).

4. Store unit ina clean,dry area.

5. Neverstore the tiller with fuel in the fuel

tank in an enclosedareawhere gasfumes

could reachan openflame or spark, or

whereignition sources are present(space

heaters,hot water heaters,furnaces, etc.).

Tines

Thetines will wear with use andshould be

inspectedat the beginning of eachtilling

seasonandafter every30 operatinghours.

Tinescanbe replacedindividually or as a

completeset. Neverinspect or servicethe

tines unlessthe engineis stoppedandthe

spark plug wire is disconnected.

18

NOTE: The tiller hood must be

removed to take off either a single tine

holder or individual tines. The hood is

secured to the transmission housing

with two rear bolts and two front bolts.

TineInspection

With use,the tines (Figure5-6) will be-

comeshorter,narrowerand pointed.Badly

worn tines will result in a loss oftilling

depthand reducedeffectiveness when

chopping up andturning under organic

matter.

RemovingandInstalling

Figure5-6:Fourfine gangs:twoperside.

1. Usea 9/16" socket,6"extension, a

ratchet, and a9/16" box wrench to loosen

the nut (A,Figure5-7) and bolt (B)that se-

curethe tine holderto the tine shaft.

2. Usea rubber malletto tap thetine hold-

er loose.

3. Slidethetine assemblyoff thetineshaft.

4. RepeatSteps 1-through-3 aboveto re-

move the othertine assembly.

5. Installing the tine assembly is simply

the reverseof its removal. Besure thecut-

ting edgesface sothey will enterthe soil

first whenthetiller ismoving forward- this

meansthe cuttingedgesface towardthe

operator position.

First besureto removeany rust, uneven

spots or burrs from the tine shaft, using

fine sandpaper.Thengreasethe tine shaft

before reinstallingthe tine assemblies.

Tightenthe hardwarevery securely.

Page 19

,_ WARNING: Beforeinspecting, cleaning or servicing the machine,shut off engine, wait for all

moving partsto come to a complete stop, disconnectspark plug wireand movewireawayfrom

spark plug. Failureto follow theseinstructions canresult inserious personal injury or property

damage.

C

SHAFT

ENGINE

I_ ENOTES CUTTING EDGE IOF TINE

Figure5-7:Completetineassemblies--holders, tinesandhardware.

_b ARNING: This is a CRT

(counter-rotating tine) tiller

and its tinesmust bemounted

in the direction shown in

Figure5-7. Failureto comply

could resultin personalinjury

or property damage.

2. Wheninstalling individual tines, install

them inthe reverseorder from whichthey

were removed.Thetwo sets of inboard

tines are installed so onefine facesto-

wardthe transmission housing and the

otherfine faces awayfrom it. Thesingle

outboardtine on eachside facestoward

the transmission housing. Also be sure

the cutting edgesface sothey will enter

the soil first when thetiller is moving for-

ward-this meansthecuttingedgesface

toward the operator position.

CheckingAndAdjustingTension

OnDriveBelts

Whilechecking belt tension, alsocheck

for cracks, cuts or frayed edges.Abelt

that is in poor condition should be re-

placed.

_ ARNING: Follow the

Maintaining correct tension on the drive

belts is important to good tilling perfor-

manceand long belt life.A loose beltwill

slip on theengine andtransmission pul-

leys and causethe tines and wheelsto

slow down - or stop completely - even

though theengineis runningatfull speed.

A loose beltwill also result in premature

wearto the belt.

Thetension on a new forward drive belt

should becheckedafter the first two (2)

hours of operation.Thereafter,check the

tension after every ten (10) hours of

operation.

Thereversedrive belt, becauseit is used

infrequently, will not requirean initial ten-

sion adjustment until asignificant num-

ber of operating hours has passed.

beltadjustment instructions

carefully. An incorrect

adjustment could result in the

ForwardClutchmechanism

engagingtoo soon.This could

causeloss of tiller control and

result in personal injury or

property damage.

ToCheckandAdjustTensionontheForward

DriveBelt:

1. Checkingfor correct belttension is the

sameasthat described in item 5, Step 4:

AttachForward ClutchRod. Beforecheck-

ing, shut off the engine,disconnect the

spark plug wire,andallow theengineand

D

muffler to cool down. If, after following

the adjustment procedures,you cannot

getthe correct gap on the forward clutch

rod adjustment bracket, you will needto

makea secondary adjustment as de-

scribed next.

2. Disconnectthe ForwardClutchRod (A,

Figure5-9) from the swivel plate (B)by

removing the innermost hairpin cotter

(C).

3. Unthreadthe ForwardClutchRod(in a

counterclockwise directionas viewed

from the front ofthe unit) until oneor two

threads on the rod extendabovethe rect-

angular nut (D, Figure5-10) onthe for-

ward clutch bracket.

4. Removethe belt cover.

5. Slip the forward drive belt (E,Figure

he engine-drivenforward drive pulleyby

pushing it off (awayfrom engine) with

your left handwhile pulling enginestarter

rope with your right hand.

6. Onthe left side ofthe unit (from oper-

ator's position) removethe hairpin cotter

from the clevis pin (F,Figure5-11) that

connectsthe forward idler arm (G)to the

forward adjustable link (H). Push inward

on the forward idler arm (G) andremove

the clevis pin (F).

7. Thereare two holes inthe forward ad-

justable link (H, Figure5-11). Pushin-

ward onthe forward idler arm (G) and

install theclevis pin (F)through the inner

holein the forward adjustablelink (H)and

outthrough the singlehole intheforward

idler arm (G). Securethe clevis pinwith

the hairpin cotter.

19

Page 20

,_ WARNING: Beforeinspecting, cleaning or servicing the machine,shut off engine, wait for all

moving partsto come to a complete stop, disconnectspark plug wireand movewireawayfrom

spark plug. Failureto follow theseinstructions canresult inserious personal injury or property

damage.

C (E) Removebelt

Figure5-9: Disconnect ForwardClutch Rod

and moveforward drivebelt out of groove in

engine forward drivepulley.

Figure5-10: Oneor two threadson Forward

Clutch Rodshould he exposed aboverectan-

gular nut.

NOTE: While pushing inward on the

forward idler arm, be sure that the

forward drive belt is moved off to the

right side of the tiller. This creates

more room to install the clevis pin

when the forward idler arm is 3ushed

inward.

IMPORTANT:When the clevispin Is

installed in the inner holeofthe forward

adjustablelink, the number of additional

belttension adjustmentsare limited. If,

with future tension adjustments,you find

that you cannot screw the forward clutch

rod anyfarther into the rectangularnut on

the forwardclutch bracket,it meansthat

the forward drivebelt must be replaced.

Beforedoing so,the clevispin must be

returnedto the OUTSIDEhole inthe

forward adjustablelink.

8. Replacethe forward drive belt inthe

Highspeed groove (groove closest to en-

gine) or the Lowspeedgroove (rearmost)

grooveof the enginedrivepulleyandinthe

matching groove of the transmission pul-

ley. Besure the belt is to the inside of the

wire formedbeltguide (I, Figure5-12) and

to the inside of the forward drive idlerpul-

ley (J).

Figure5-13

ToCheckand AdjustTensiononthe Re-

verseDrive Belt:

1. Removethe belt cover after first shut-

ting off the engine,disconnecting the

spark plug wire, andallowing the engine

and muffler to cool down.

2. Standat the front of thetiller and use

your left handto pushthe reverseidler

arm (K, Figure 5-13) inward asfar as pos-

sible (the reverseidler pulley [L] is at-

tached to the reverseidler arm).

Holdthe idler arm in this position and look

atthe position ofthe belt tension guide

mark (M, Figure5-14) that isstampedinto

the faceof the reverseadjustable link (N,

Figure5-14).

• Thetension is correct if the guide mark

(M, Figure5-14) isanywhereto the left of

the guide pin (0), asviewed from the

Figure5-11: Remove clevispin fromouter

hole inforwardadjustable linkand move toin-

ner holein link.