Troy-Bilt 7 HP, 8 HP, Pto Horse Tiller 7 HP, Pto Horse Tiller 8 HP Technical Manual

·0

TRIly;.S1LT

'-

Technical

Manual

PTO

HORSE

Tiller

Models

7 HP

8 HP

GARDEN WAY INC.

..

PTO

HORSE

MODEL

TECHNICAL

MANUAL

4/90

TABLE

OF

CONTENTS

SECTION

1.

General Information

1-1

Safety First

1-1

Quick

Reference Repair Index 1-2

SECTION

2.

Transmission Troubleshooting. . . . ... . . . . .

..

2-1

Forward and Reverse

Shifting

Problems

2-1

Wheel Speed

Shifting

Problems 2-2

Wheels

and/or

TinesDoNot

Turn 2-3

Wheel Shaft Moves To

One

Side.

. . . . . . .

..

2-4

Noise From Rear

Tiller

Bearing.

. . . . . . . .

..

2-4

Oil

Leaks 2-5

SECTION

3.

Pre-Service Inspection

....

. . . . . . . . . . . . . . .

..

3-1

SECTION

4.

Transmission Removal and Installation

4-1

Removal

4-1

Separating/Attaching

the

PTa

Power

Unit

and

Tiller

Attachment

Transmissions.

. . .

..

4-2

Installation.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-3

SECTION

5.

Servicing

the

PTO Power Unit

Transmission

5-1

PTa

Power

Unit

Housing

Cover

5-1

Removal

5-1

Inspection

5-2

Installation 5-2

Neutral

Plunger

Assembly 5-2

PTa

Power

Unit

Drive

Shaft.

. . . . . . . . . . . . .

..

5-3

Removal 5-3

Inspection 5-4

Installation.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

5-4

Pinion Shaft

Assembly.

. . . . . . . . . . . . . . . . . .

..

5-5

Removal 5-5

Inspection 5-6

Installation 5-7

SECTION

5.

Servicing the PTO Power Unit Transmission

(continued)

Wheel Shaft Assembly 5-8

Removal 5-9

Inspection 5-9

Installation 5-9

Eccentric Shaft Assembly 5-10

Removal 5-10

Inspection 5-10

Installation 5-10

SECTION

6.

Servicing

the

Tiller Attachment

Transmission

6-1

Tiller

Drive Shaft

Assembly.

. . . . . . . . . . . . . .

..

6-1

Removal

6-1

Inspection 6-2

Installation 6-3

Tiller

Tine

Shaft Assembly

'.

. . . . . . . . . . .

..

6-3

Removal 6-3

Inspection 6-5

Installation.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-5

SECTION

7.

Special Repairs and Procedures

7-1

Installing a

New

Tines/PTa

Clutch

Lever

Assembly

7-1

Removing the Existing Assembly

7-1

Installing a

New

Assembly

7-1

Removing a Rusted Wheel 7-2

Removing the Wheel Shaft

Without

Disassembling the Transmission 7-2

Removal 7-2

Installing the Wheel

Shaft.

. . . . . . . . . . . . .

..

7-3

Identifying a Bubbled Wheel Shaft 7-4

Testing

for

a Bubbled Wheel Shaft 7-4

Tightening

the Castle

Nut

On the Wheel

Speed Lever 7-4

Index.... .... . . . . . . . .... . . .... . . . . .

8-1

SECTION1:General

Information

PTO

HORSE

MODEl

TECHNICAL

MANUAL

Page

1-1

4/90

• This manual provides transmission service information

for

the

PTO HORSE Model TROY-BILT®

Roto Tiller-Power Composter built

by TROY-BILT Manufacturing

Company, Troy, New York. Use

this manual

for

tillers with serial

numbers 640000 and up.

• This manual was written

for

and

intended to be used by professional service technicians

who

have been trained in the proper

servicing

of

outdoor

power

equipment.

• All information, illustrations, and

specifications contained in this

manual are based on the latest

information available at the time

of

publication. The rightisreserved

to make changes at any time

without notice. If you have any

questions concerning the information contained in this manual

please contact:

Technical Service Department

TROY-BILT® Manufacturing

Company

102nd Street and 9th Avenue

Troy, New York

12180

Call Toll-Free: 1-800-833-6990.

This symbol

is

used to alert you to

important safety messages in this

manual and on decals affixed to

the tiller. When you see this symbol, carefully read and follow its

safety message. Failure to

do

so

could result in personal injury

or

property damage.

• This manual is divided into

seven sections

as

shown in the

Table

of

Contents. For best

results, read each section in its

entirety before attempting any

repair work.

• This manual

is

designed to be

used in combination with the PTO

Horse Model Owner/Operator

Manual. The Owner/Operator

Manual contains additional service

and

maintenance information that

is

not

covered in this manual.

Refer to

"Quick

Reference Repair

Index"

in

this section

for

a listing

of

the service and maintenance

topics that are covered in the

Owner/Operator Manual.

• Service and maintenance information regarding engines is

not

covered in this manual. Such

information can be obtained by

consulting the Service Repair

Manuals available from the engine

manufacturer. You should,

how-

ever, call

our

Technical Service

Department with questions

con-

cerning engine replacement

or

interchangeability.

•

Throughout

this manual, you

will

see

references to the left and

right sides

of

the tiller. This refers

to the left and right sides

of

the

tiller

as

you would see them stand-

ing in the operator's position.

Safety First

When working on the tillerorits

engine, closely follow operating

instructions and recommended

safety practices at all times.

Failure to

do

so could result in

personal injury

or

property damage. Here are some basic safety

precautions you should keep in

mind at all times when doing

repair work:

KNOW THE TILLER AND

ENGINE! Read the

Owner/Operator Manual carefully.

Be sure you know what each tiller

and engine control does before

you attempt to operate it.

Read and follow all safety rules.

Never allow inexperienced persons

or

children to operate the

tiller

or

its engine.

WEAR PROPER APPAREL!

Don't wear loose clothing

or

jewelry that could get caught in

moving parts

of

the tillerorits

engine.

AVOID MOVING PARTS!

Keep hands, feet, hair, clothing,

and tools safely away from moving

parts when the engine

is

running .

AVOID ACCIDENTAL STARTING!

When servicing the machine, prevent unintentional starting

of

the

engine by disconnecting the spark

plug wire and keeping the wire

away from the spark plug. Place

engine controls in the OFF position and shift the Wheels/

Tines/PTO Drive Lever into

NEUTRAL.

WEAR

EYE

PROTECTION!

Safety goggles

or

a fac shield

should be worn wh ver there is

the possibility

of

danger to the

eyes from flying parts

or

particles.

PREVENT FIRES AND

EXPLOSIONS! Gasoline

is

highly

flammable and explosive

and should be used and stored

with extreme caution. Keep gasoline away from open flame, sparks,

and

do

not smoke in the vicinity

of

gasoline cansorfuel tanks.

Do

not

add gasoline to a fuel tank when

the engine is running

or

still hot.

Fill the fuel tank outdoors, in a

well-ventilated area. Store gasoline in a cool, well-ventilated

place, safely away from any spark

or

flame producing equipment.

Store

only

in a U.L. approved

con-

tainer and safely

outofreach

of

children. Wipe

off

any spilled gasoline and move the engine away

from gasoline fumes before starting engine.

Use flammable cleaning solvents

only

according to recognized

safety practices (never use gasoline

as

a cleaning solvent).

Oily

rags and waste should be packed

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

1-2

4/90

in a U.L. approved covered metal

safety

containertoprevent fire

from

spontaneous combustion.

HANDLE BATTERIES WITH

CARE!

Batteries contain

sulfuric

acid that can cause blindness,

burn skin, and eat

through

clothing. Wear safety goggles

when

working

near the battery

or

when handling battery acid.

Remove all rings and metal

jewelry when

working

on the bat-

tery

or

electrical system.

Batteries also

produce

explosive

gases. Keep sparks, flames, and

cigarettes away. Ventilate when

chargingorusing in an enclosed

space.

Do

not

cause a short

circuit

by

touching

both battery terminals at

the same

time

with toolsorother

metallic objects. Also,donot

allow

a tool

or

other

metallic object to

touch

a terminal thatisnot

grounded

and an adjacent metallic

part that

is

grounded.

A spark

from a short

circuit

could

cause

an explosion of battery gases

or

gasoline.

AVOID ENGINE EXHAUST

FUMES!

Do

not

run the engine

in an enclosed area. Exhaust

gases contain carbon monoxide,

an odorless and deadly poison.

Provide adequate ventilation at all

times. After

running

the engine,

don't

touch

the

mufflerorother

hot

engine parts until they have

cooled down.

HANDLE PARTS CAREFULLY!

With

continued

use, the teeth on

gears and

worms

may

wear

to

sharp, knife-like edges. Therefore,

when handling these parts, use

care

to

avoid

cutting

yourself.

REPLACEMENT PARTS!

Use

only

genuine

Troy-Bilt

replacement parts. Replacement

parts manufactured by others

could

present safety hazards even

though

they may fit on this tiller.

SECTION1:General

Information

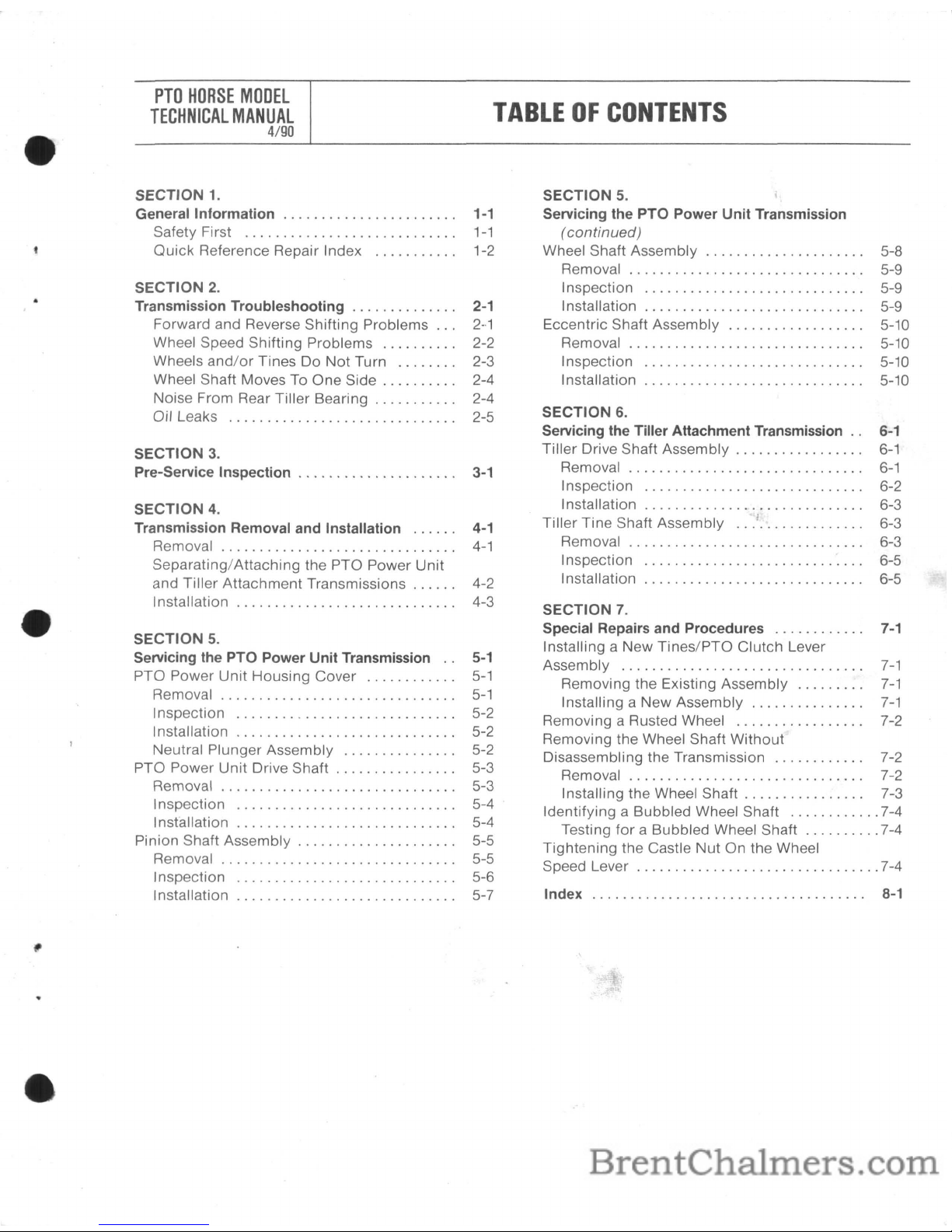

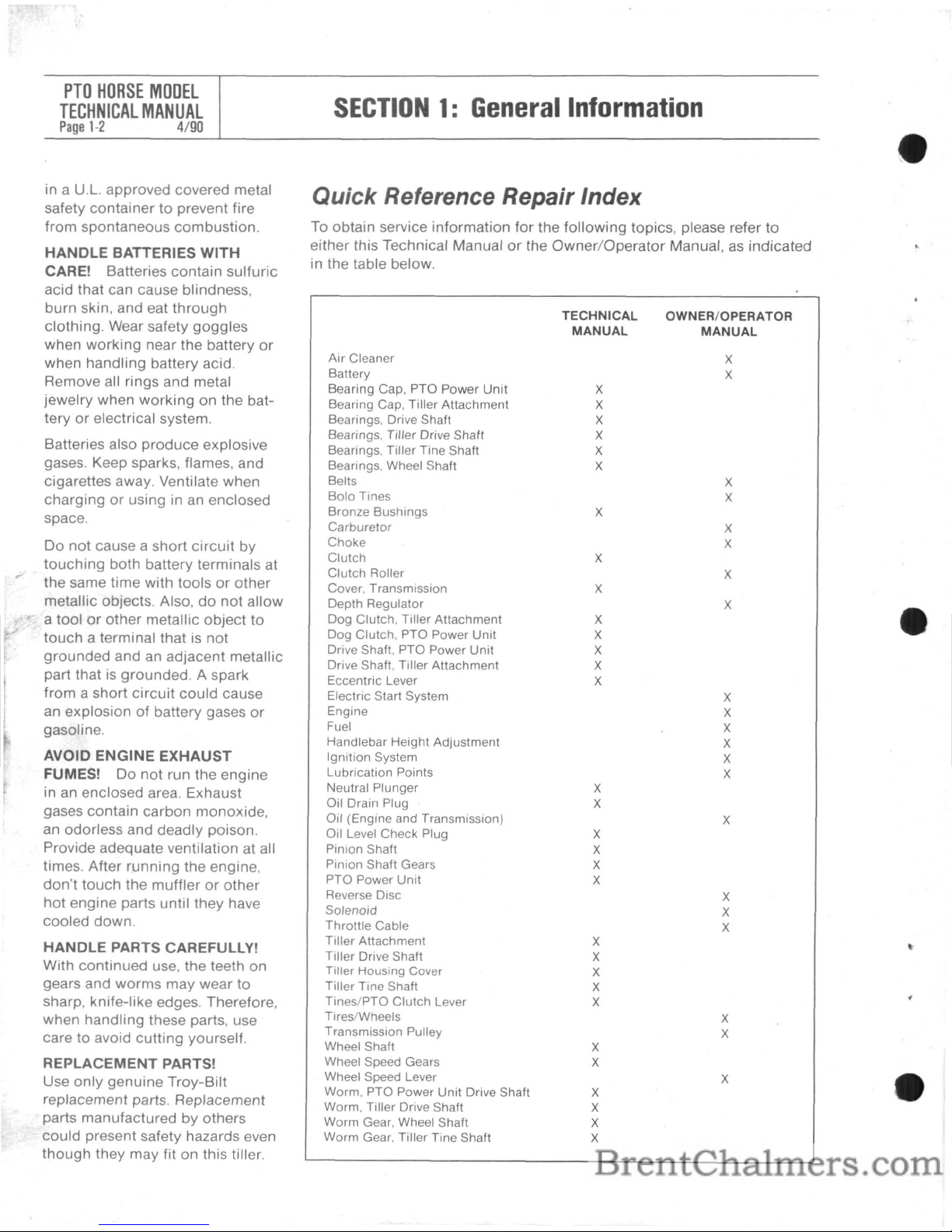

Quick Reference Repair Index

To obtain service information

for

the

following

topics, please refer

to

either this Technical Manualorthe

Owner/Operator

Manual,asindicated

in the table below.

TECHNICAL

OWNER/OPERATOR

MANUAL

MANUAL

Air

Cleaner

X

Battery

X

Bearing Cap,

PTa

Power

Unit

X

Bearing Cap, Tiller Attachment

X

Bearings, Drive Shaft

X

Bearings. Tiller Drive Shaft

X

Bearings, Tiller Tine Shaft

X

Bearings, Wheel Shaft

X

Belts

X

Bolo

Tines

X

Bronze Bushings

X

Carburetor

X

Choke

X

Clutch

X

Clutch

Roller

X

Cover, Transmission

X

Depth Regulator

X

Dog Clutch, Tiller

Attachment

X

Dog Clutch,

PTa

Power Unit

X

Drive Shaft,

PTa

Power Unit

X

Drive Shaft, Tiller Attachment

X

Eccentric Lever

X

Electric Start System

X

Engine

X

Fuel

X

Handlebar Height Adjustment

X

Ignition System

X

Lubrication Points

X

Neutral Plunger

X

Oil Drain Plug

X

Oil (Engine and Transmission)

X

Oil Level Check Plug

X

Pinion Shaft

X

Pinion Shaft Gears

X

PTa

Power

Unit

X

Reverse Disc

X

Solenoid

X

Throttle

Cable

X

Tiller Attachment

X

Tiller Drive Shaft

X

Tiller Housing Cover

X

Tiller Tine Shaft

X

Tines/PTa

Clutch

Lever

X

Tires/Wheels

X

Transmission Pulley

X

Wheel Shaft

X

Wheel Speed Gears

X

Wheel Speed Lever

X

Worm,

PTa

Power Unit Drive Shaft

X

Worm, Tiller Drive Shaft

X

Worm Gear, Wheel Shaft

X

Worm Gear, Tiller Tine Shaft

X

SECTION2:Transmission

Troubleshooting

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

2·1

4/90

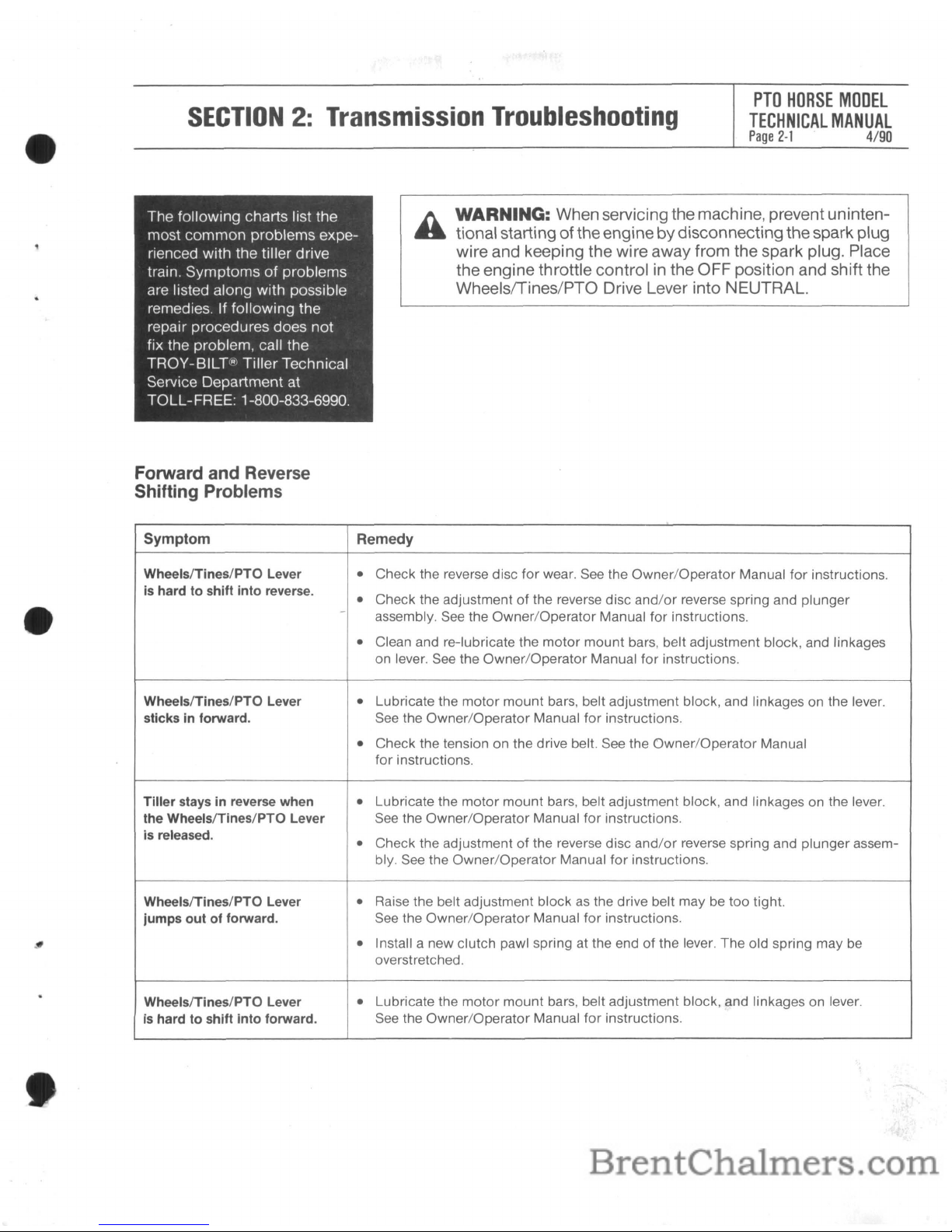

The following charts list the

most

common

problems experienced with the tiller drive

train. Symptoms

of

problems

are listed along with possible

remedies. If following the

repair procedures does not

fix the problem, call the

TROY-BILT(R)

Tiller Technical

Service Department at

TOLL-FREE: 1-800-833-6990.

Forward and Reverse

Shifting Problems

WARNING: When servicing the machine, prevent uninten-

tional starting

of

theengine bydisconnectingthe spark plug

wire and keeping the wire away from the spark plug. Place

the engine throttle control in the OFF position and shift the

Wheelsrrines/PTO Drive Lever into NEUTRAL.

Symptom Remedy

WheelslTines/PTO Lever

•

Check the reverse disc

for

wear. See the

Owner/Operator

Manual

for

instructions.

is hard

to

shift

into

reverse.

Check the adjustment

of

the reverse disc

and/or

reverse spring and plunger

•

-

assembly. See the

Owner/Operator

Manual for instructions.

•

Clean and re-Iubricate the

motor

mount

bars, belt adjustment block, and linkages

on lever. See the

Owner/Operator

Manual

for

instructions.

WheelslTines/PTO Lever

•

Lubricate the

motor

mount

bars, belt adjustment block, and linkages on the lever.

sticks in forward. See the

Owner/Operator

Manual

for

instructions.

•

Check the tension on the drive belt. See the

Owner/Operator

Manual

for instructions.

Tiller

stays in reverse when

•

Lubricate the

motor

mount

bars, belt adjustment block, and linkages on the lever.

the WheelslTines/PTO Lever

See the Owner/Operator Manual for instructions.

is released.

Check the adjustment

of

the reverse disc

and/or

reverse spring and plunger assem-

•

bly. See the

Owner/Operator

Manual

for

instructions.

WheelslTines/PTO Lever

•

Raise the belt adjustment blockasthe drive belt may be too tight.

jumps

outofforward.

See the

Owner/Operator

Manual for instructions.

•

Install a new clutch pawl spring at the end of the lever. The old spring may be

overstretched.

WheelslTines/PTO Lever

•

Lubricate the

motor

mount

bars, belt adjustment block, and linkages on lever.

is hard

to

shift

into

forward.

See the

Owner/Operator

Manual for instructions.

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

2-2

4/90

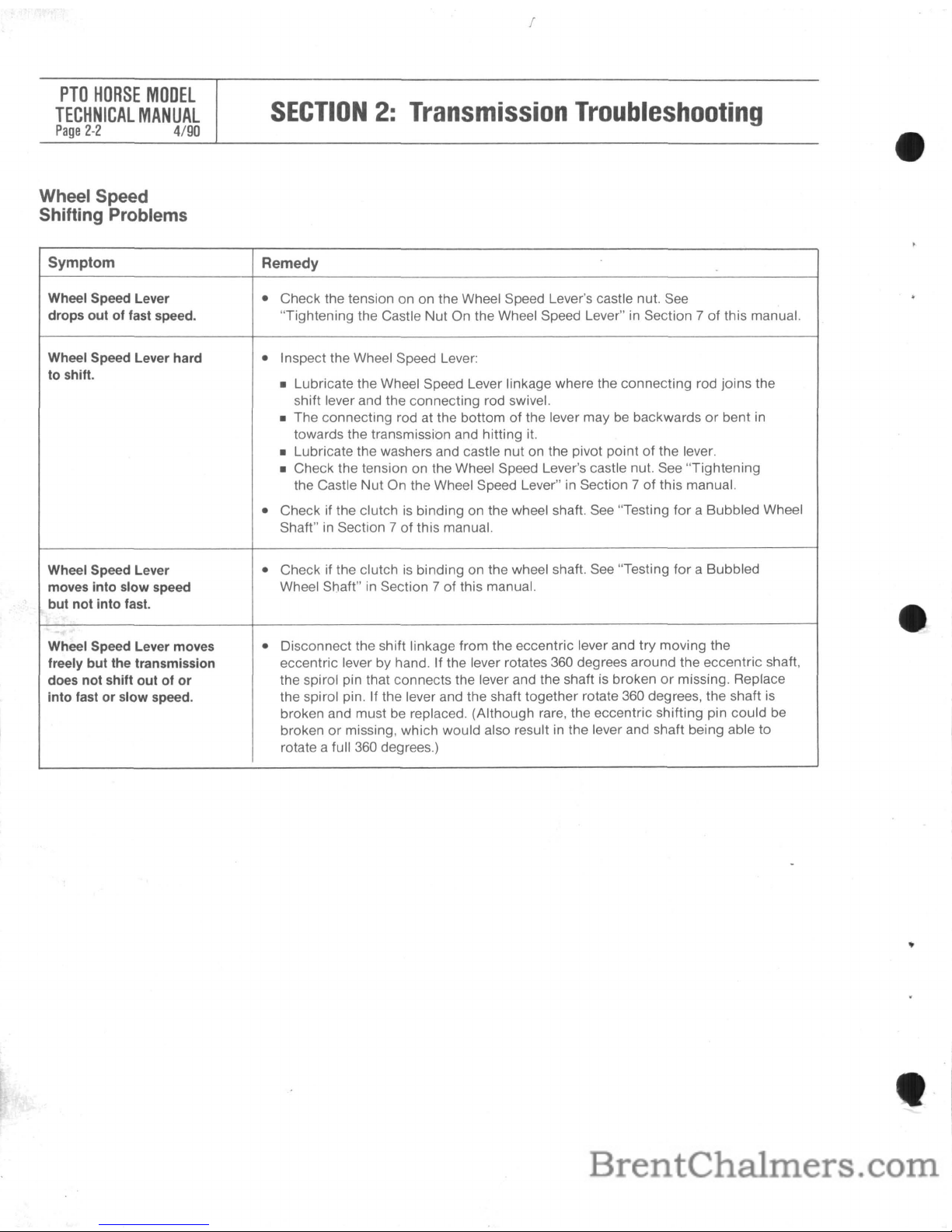

Wheel Speed

Shifting Problems

I

SECTION2:Transmission

Troubleshooting

Symptom

Remedy

Wheel Speed Lever

•

Check the tension on on the Wheel Speed Lever's castle nut.

See

drops out of fast speed. "Tightening the Castle

Nut

On the Wheel Speed Lever"inSection 7 of this manual.

Wheel Speed Lever hard

•

Inspect the Wheel Speed Lever:

to shift.

• Lubricate the Wheel Speed Lever linkage where the connecting rod joins the

shift lever and the connecting rod swivel.

• The connecting rod at the bottom

of

the lever maybebackwardsorbent

in

towards the transmission and hitting it.

• Lubricate the washers and castle nut on the pivot point

of

the lever.

• Check the tension on the Wheel Speed Lever's castle nut. See "Tightening

the Castle Nut On the Wheel Speed Lever" in Section 7

of

this manual.

•

Check if the clutchisbinding on the wheel shaft.

See

"Testing

for

a Bubbled Wheel

Shaft"

in

Section 7ofthis manual.

Wheel Speed Lever

•

Check if the clutchisbinding on the wheel shaft.

See

"Testing

for

a Bubbled

moves into slow speed

Wheel Shaft"inSection 7ofthis manual.

but not into fast.

Wheel Speed Lever moves

•

Disconnect the shift linkage from the eccentric lever and try moving the

freely but the transmission

eccentric lever by hand. If the lever rotates

360

degrees around the eccentric shaft,

does not shift out of

or

the spirol pin that connects the lever and the shaftisbrokenormissing. Replace

into fast or slow speed.

the spirol pin. If the lever and the shaft together rotate 360 degrees, the shaft

is

broken and must be replaced. (Although rare, the eccentric shifting pin could be

broken

or

missing, which would also resultinthe lever and shaft being able to

rotate a full

360

degrees.)

SECTION2:Transmission

Troubleshooting

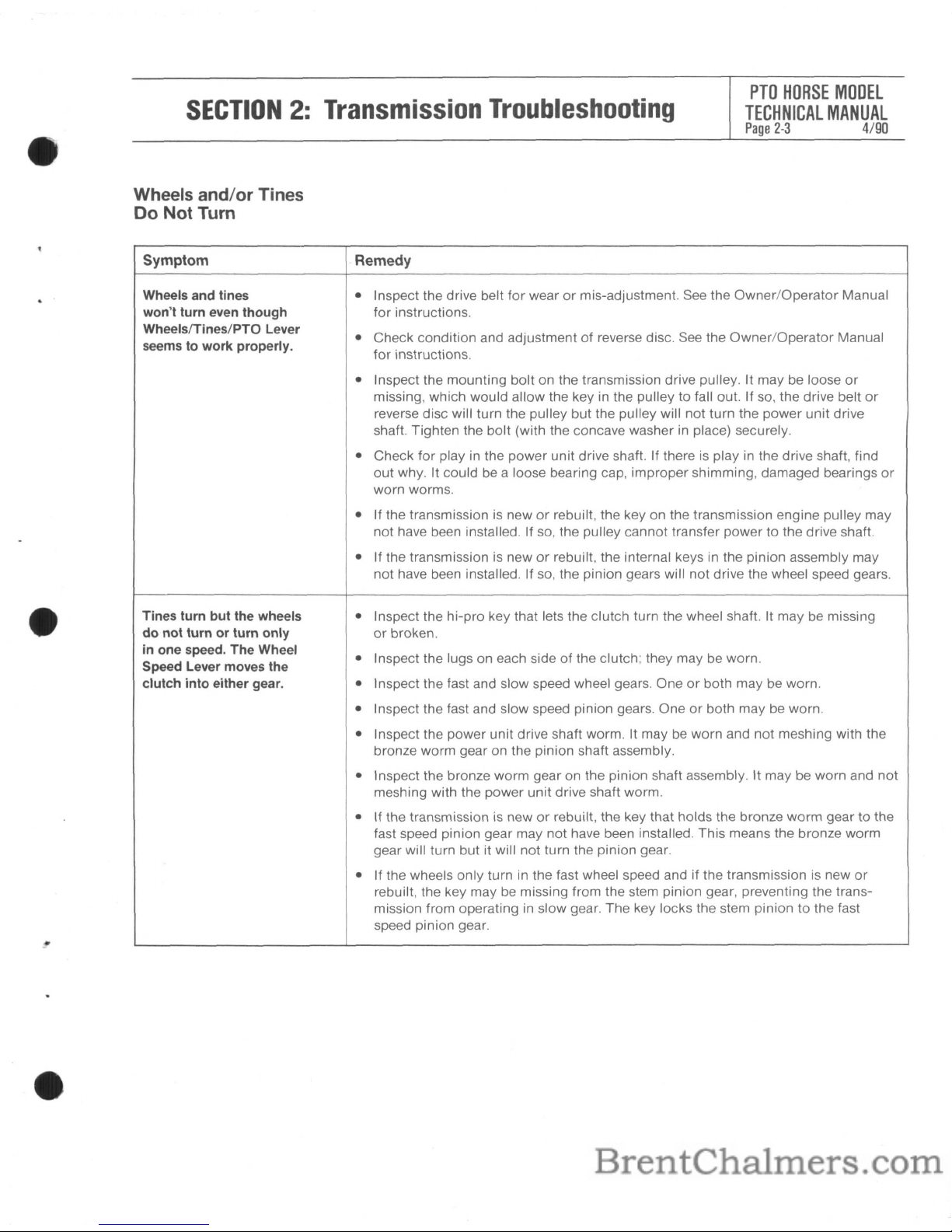

Wheels and/or Tines

Do

Not Turn

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

2·3

4/90

Symptom

Wheels and tines

won't turn even though

Wheels/Tines/PTO Lever

seems to work properly.

Tines turn but the wheels

do

not turn or turn only

in one speed.

The

Wheel

Speed Lever moves the

clutch into either gear.

Remedy

• Inspect the drive belt for wearormis-adjustment. See the

Owner/Operator

Manual

for instructions.

• Check condition and adjustment

of

reverse disc. See the

Owner/Operator

Manual

for instructions.

• Inspect the

mounting

bolt on the transmission drive pulley. It may be loose

or

missing, which would allow the key in the pulley to

fallout.

If so, the drive belt

or

reverse disc will turn the pulley but the pulley will not turn the power

unit

drive

shaft. Tighten the bolt (with the concave washer in place) securely.

• Check for play in the power

unit

drive shaft. If there is play in the drive shaft, find

out

why. It could be a loose bearing cap, improper shimming, damaged bearings

or

worn worms.

• If the transmission is new

or

rebuilt, the key on the transmission engine pulley may

not have been installed. If so, the pulley cannot transfer power to the drive shaft.

• If the transmission is new

or

rebuilt, the internal keys in the pinion assembly may

not have been installed. If so, the pinion gears will not drive the wheel speed gears.

• Inspect the

hi-pro

key that lets the clutch turn the wheel shaft. It may be missing

or

broken.

• Inspect the lugs on each side

of

the clutch; they may be worn.

• Inspect the fast and slow speed wheel gears. Oneorboth may be worn.

• Inspect the fast and slow speed pinion gears. One

or

both may be worn.

• Inspect the power unit drive shaft worm. It may

be

worn and not meshing with the

bronze worm gear on the pinion shaft assembly.

• Inspect the bronze

worm

gear on the pinion shaft assembly. It may be worn and

not

meshing with the power unit drive shaft worm.

• If the transmission is new

or

rebuilt, the key that holds the bronze

worm

gear to the

fast speed pinion gear may not have been installed. This means the bronze worm

gear will turn but it will not turn the pinion gear.

• If the wheels only turn in the fast wheel speed and if the transmission is new

or

rebuilt, the key maybemissing from the stem pinion gear, preventing the transmission from operating in slow gear. The key locks the stem pinion to the fast

speed pinion gear.

PTO

HORSE

MOOEL

TECHNICAL

MANUAL

Page

2-4

4/90

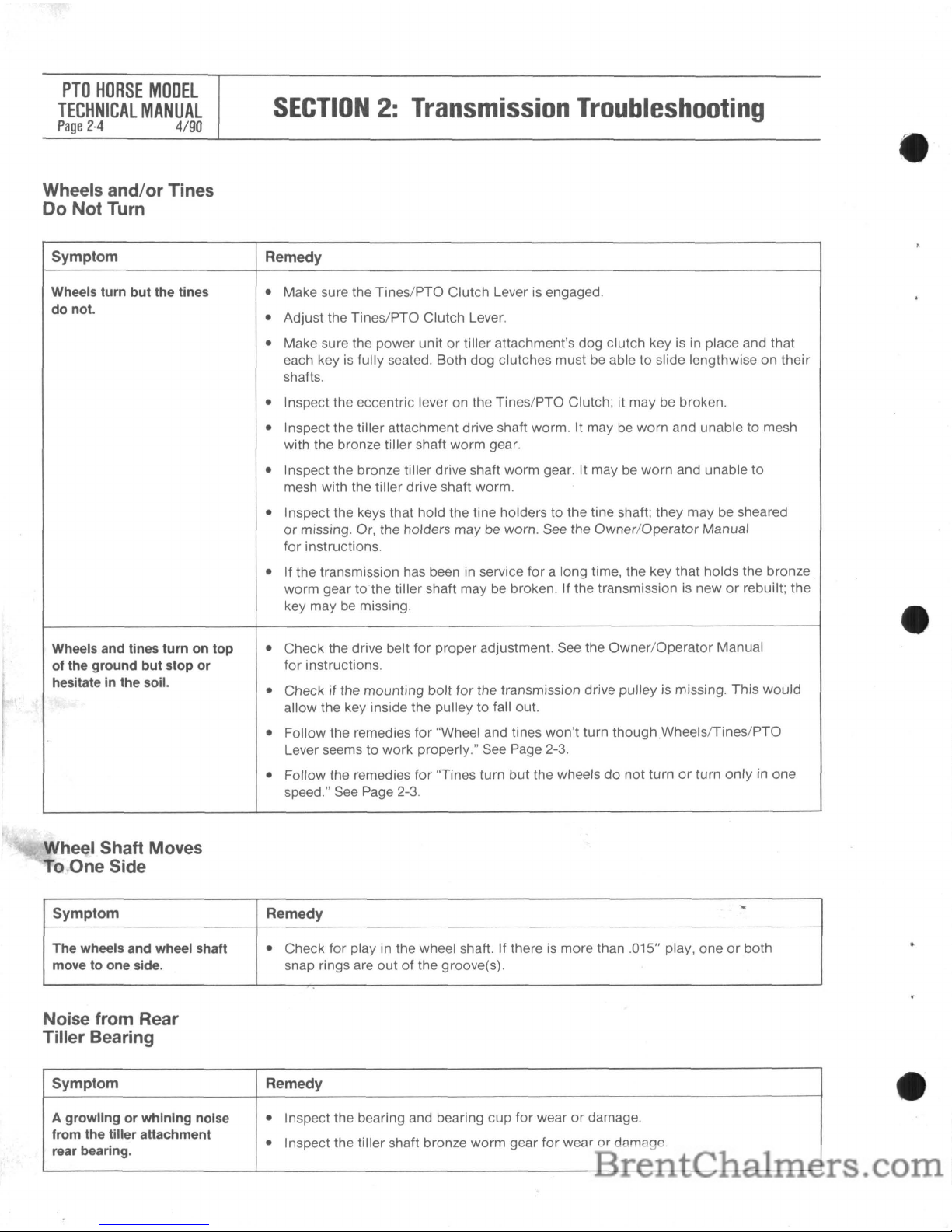

Wheels and/or Tines

Do

Not Turn

SECTION2:Transmission

Troubleshooting

Symptom

Remedy

Wheels turn but the tines

•

Make sure the Tines/PTO Clutch Leverisengaged.

do not.

Adjust the Tines/PTO Clutch Lever.

•

•

Make sure the power unitortiller attachment's dog clutch keyisin place and that

each key

is

fUlly seated. Both dog clutches must be able to slide lengthwise on their

shafts.

•

Inspect the eccentric lever on the Tines/PTO Clutch; it may be broken.

•

Inspect the tiller attachment drive shaft worm. It maybeworn and unable to mesh

with the bronze tiller shaft worm gear.

•

Inspect the bronze tiller drive shaft worm gear.

It may

be

worn and unable to

mesh with the tiller drive shaft worm.

•

Inspect the keys that hold the tine holders to the tine shaft; they may be sheared

or

missing. Or, the holders may be worn. See the Owner/Operator Manual

for

instructions.

•

If the transmission has beeninservice

for

a long time, the key that holds the bronze

worm gear to the tiller shaft may be broken. If the transmission

is

neworrebuilt; the

key may

be

missing.

Wheels and tines turn on top

•

Check the drive belt for proper adjustment.

See

the Owner/Operator Manual

of the ground but stop or

for

instructions.

hesitateinthe soil.

Check if the mounting

bolt

for the transmission drive pulley is missing. This would

•

allow the key inside the pulley to

fallout.

•

Follow the remedies for "Wheel and tines won't turn

thoughWheelslTines/PTO

Lever seems to work properly." See Page 2-3.

•

Follow the remedies

for

"Tines turn

but

the wheelsdonot

turnorturn

only

in one

speed."

See

Page 2-3.

Wheel Shaft Moves

To.One Side

Symptom Remedy

"

The

wheels and wheel shaft

•

Check for playinthe wheel shaft. If there is more than .015" play, oneorboth

move to one side. snap rings are

outofthe groove(s).

Noise from Rear

Tiller Bearing

Symptom Remedy

A growling or whining noise

•

Inspect the bearing and bearing cup

for

wearordamage.

from the tiller attachment

Inspect the tiller shaft bronze worm gear

for

wearordamage.

•

rear bearing.

SECTION2:Transmission

Troubleshooting

Oil Leaks

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

2-5

4/90

..

Symptom

Oil leaks from the wheel

shaft oil seals.

Oil leaks from the rear

of the tiller attachment

housing.

Remedy

• An oil sealiswornordamaged.

Check

for

side-to-side

and vertical play in the

wheel shaft and replace seal.

• Give new seals time

to

lap in.

• Inspect the wheel shaft

for

minor

damage at the oil seal location:

• Inspect

for

corrosion,

pitting,orscoring.

• Use emery

clothtoremove any

minor

defects.

•

Attempttoseat the seal so that itisonanundamaged

partofthe shaft.

• Replace the wheel shaft if necessary.

•

Determineifthe

seal fits

looselyinthe

transmission

bore

Contact

the

TROY-SILT

Technical Service

Department

for

a special seal.

• Be sure the transmission

is

filled

with

SAE 90orSAE 140 gear oil. A

lighter

viscosity

oil will cause leakage.

• Make sure that a

non-hardening

gasket sealer was appliedtothe

outside

diameter

of

the oil seal

priortoits installation.

• Make sure the

housing

bore hasnonicksorscratches that

would

permit

oil

to

seep

out

between the seal and the housing.

If

the

leakisfrom

the oil sealsonthe tiller tine shaft:

• Make sure the seals have

non-hardening

gasket sealer

around

the

outside

edges.

• An oil seal is

wornordamaged; replace the seal.

• Inspect the

tiller

tine shaft

for

minor

damage

at the oil seal location:

• Inspect

for

corrosion,

pitting,orscoring.

• Use

emery

clothtoremove any

minor

defects.

• Replace the

tiller

tine shaft if necessary.

•

Check

for

sand holes

(imperfections

in the cast

iron)orcracks

in the

housing

cover.

If the leak

isonthe left sideofthe

tiller

housing:

•

Apply

non-hardening

gasket sealer to eachofthe

tiller

housing

cover

screws

and

tighten

the screws.

• Replace any

wornordamaged

gaskets.

• Make sure the

housing

cover bore has no nicksorscratches

that

would

permit

oil

to

seep out.

• Make sure the

housing

bore hasnonicksorscratches

that

would

permit

oil

to

seep

out

beteen

the

seal and the housing.

If the leak is

from

the rear bearing cap:

• Inspect the rear bearing cap:

•

Make

sure the screws are the

correct

length.

•

Apply

non-hardening

gasket sealertoeachofthe rear

bearing

cap

bolts

and

tighten

the bolts.

• Replace a

wornordamaged gasket.

•

Check

for

excessive play in

the

tiller

tine shaft.

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

2-6

4/90

Oil Leaks

SECTION2:Transmission

Trouleshooting

Symptom

Remedy

Oil leaks from the front oil seal

•

Replace a wornordamaged oil seal and check for play in the shaft.

on the power unit drive shaft.

•

Apply

a layerofnon-hardening

gasket sealertoeachofthe

front

bearing

cap

bolts

Oil could appear in the base of

and tighten the bolts.

the motor mount under the

pulley. (Make sure this

is

not

•

Replace a wornordamaged gasket.

an oil leak from the neutral

Make sure the leakisat the

front

oil seal. You

could

be seeing oil that leaked

from

•

plunger assembly, whichisan

the engine air cleaner,

power

unit

housing

cover,orengine seal.

oil relief point.)

•

Check the transmission gear oil level when the

unitiscold.

If

overfilled,

drain

it to

the

proper

level.

Oil leaks from the handlebar

•

Loosen and remove the oil level check plugtomake sure the oil level is correct.

base or the bottom of the

If

the transmission is overfilled, let the excess oil drain out.

reverse spring and plunger

•

See if oil is leaking

from

the neutral plunger.Ifoilisleaking

from

here, take

no

assembly.

action; the neutral

plungerisan oil relief point.

Oilisleaking from the

•

Replace the oil seal.

eccentric shaft and lever.

Oil

is

leaking from any

•

Remove the pipe plug and

apply

a layerofnon-hardening

gasket sealer.

Then

pipe plug in the transmis- re-install the plug.

sion housing.

•

Check

to seeifthe plug is cross-threaded.

Oilisleaking between

•

Tighten the

housing

cover bolts.

the power unit housing cover

•

Replace the gasket.

and the housing.

•

A special transmission cover gasket (Part No. 9260) may be required if

the

leak

continues.

SECTION3:Pre-Service

Inspection

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

3-1

4/90

WARNING:

When

servicing

the

machine,

prevent

uninten-

tional

startingofthe

enginebydisconnecting

the

spark

plug

wire

and

keeping

the

wire

away

from

the

spark

plug.

Place

the

engine

throttle

controlinthe

OFF

position

and

shift

the

Wheels/Tines/PTa

Drive

Lever

into

NEUTRAL.

,

Before

you

begin

your

repair

or

maintenance procedure

take a

momenttoperform a

pre-service inspection

of

the

following transmission parts.

In

doing

so, you may discover additional problems

that can be corrected while

the tiller is in

your

shop.

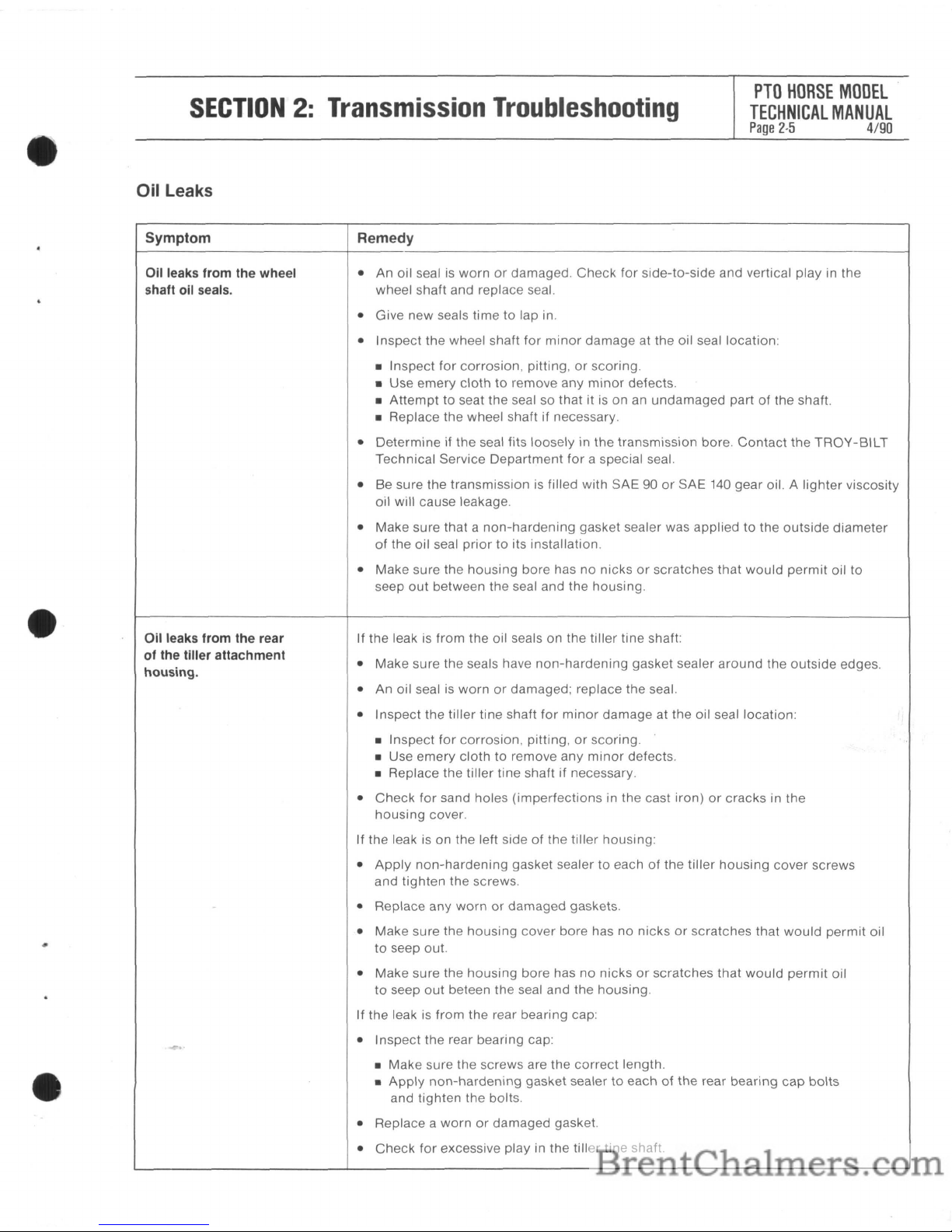

Wheel Shaft - Inspect the wheel

shaft for movement and oil leaks:

• Grasp the tiller's handlebars and

tilt the tiller forward so its weight

is resting entirely on the wheels

and move the tiller side-to-side.

See Figure 3-1.

Figure

3-1:

Pre-Disassembly

Inspection

of

the

Wheel Shaft.

If the tiller moves more than .015"

from side-to-side on the wheel

shaft, it indicates that the wheel

shaft needs either

to

be shimmed

or

that oneorbothofthe snap

rings has become dislodged from

the snap ring groove(s).

• If oil is leaking from around one

or

both of the wheel shaft oil seals,

replace the oil seal(s) and determine

why

the oil seal(s) failed.

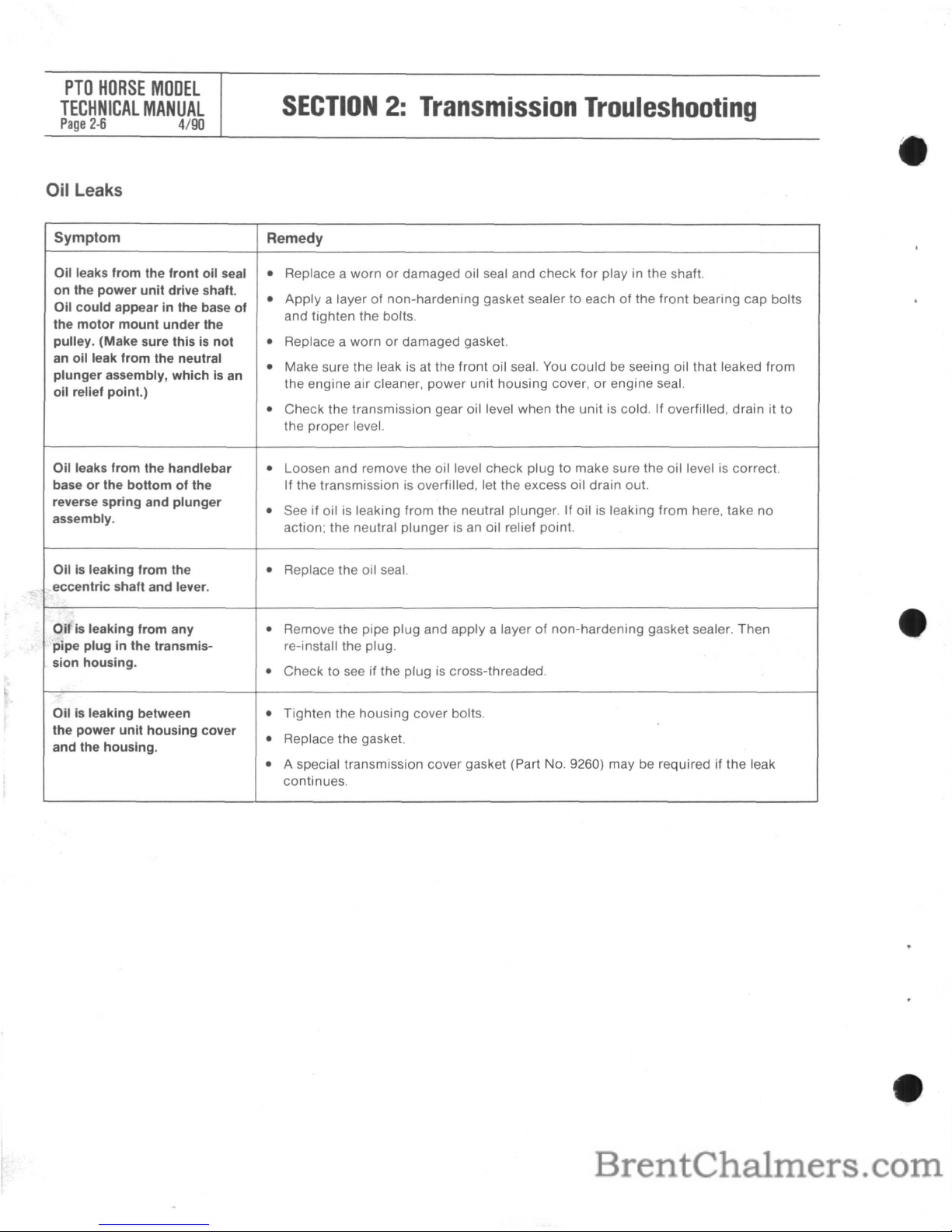

PTO Power Unit Drive Shaft

Pulley -

Check the PTO drive shaft

pulley (see Figure 3-2) for end play

and oil leaks:

Drive Shaft

Pulley

Figure

3-2:

Pre-Disassembly

Inspection

of

the

Drive

Shaft

Pulley.

• Using

two

hands, grasp the drive

shaft pulley and pull it in and

out

to

check

for

end play.

There should be .005" to .010" play.

If the drive shaft pulley has more

play, the bolt that holds the pulley

may need

to

be tightened. This bolt

should be tightened to

170

inch/lbs.

If tightening does

not

reduce the

play, the PTO power unit drive

shaft needs to be shimmed.

• Look for oil leaks around the

pulley. If you see oil, make sure

that it did

not

come from the neutral plunger on the housing cover;

this

is

an oil relief point.

If you suspect

an

oil leak from

around the pulley, inspect the following:

a.

The bolts holding the front

bearing cap may

not

be suffi-

ciently tightened.

b.

The

washers on the bolts that

hold the front bearing cap may be

worn

or

the bolts may not have

been coated with non-hardening

gasket sealer.

c.

The

front bearing cap gasket

may have failed.

d.

The

front drive shaft oil seal

may have failed; find

out

why.

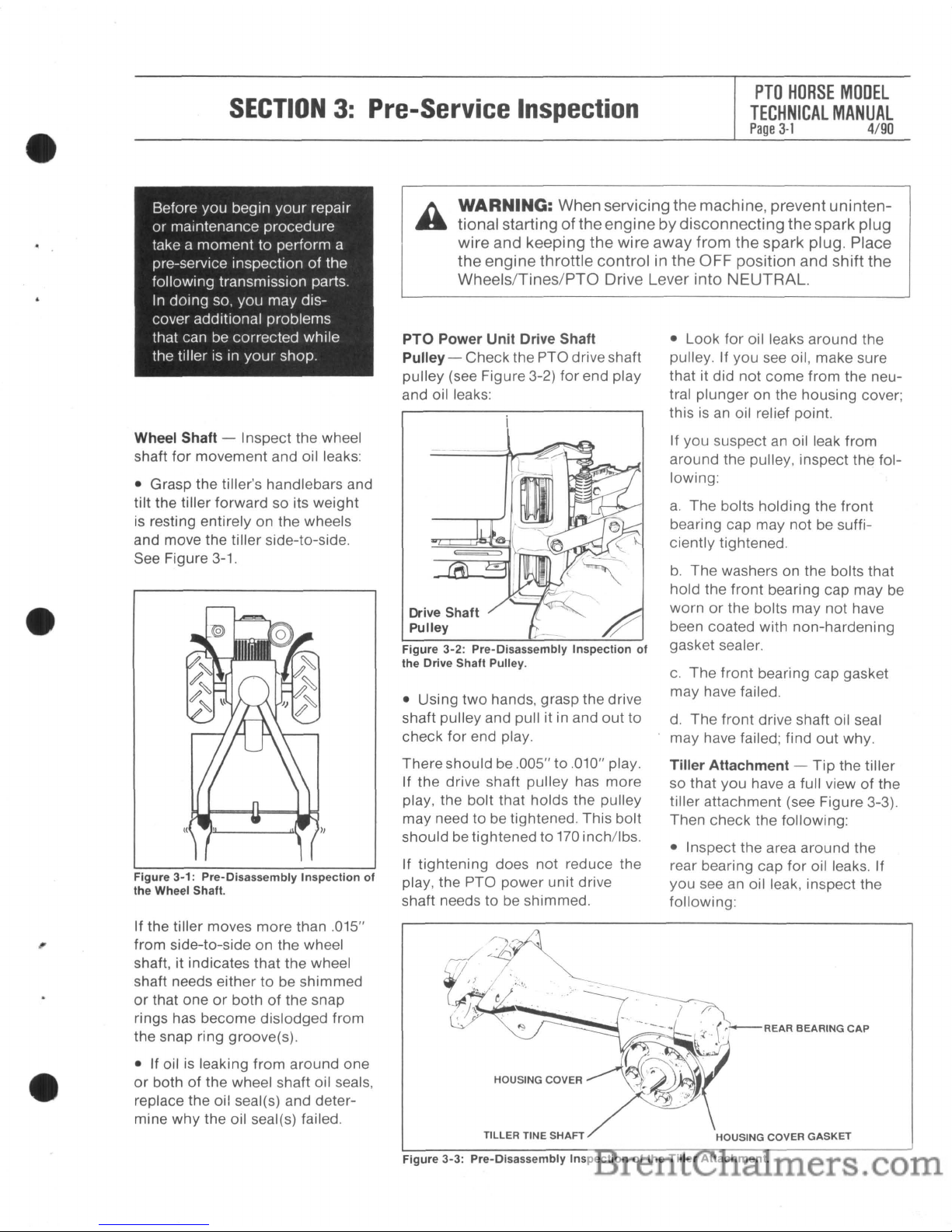

Tiller Attachment -

Tip

the tiller

so that you have a full view

of

the

tiller attachment (see Figure 3-3).

Then check the following:

• Inspect the area around the

rear bearing cap

for

oil leaks. If

you see an oil leak, inspect the

following:

HOUSING COVER

GASKET

Figure

3-3:

Pre-Disassembly

Inspectionofthe

Tiller

Attachment.

PTO

HORSE

MODEL

TECHNICAL

MANUAL

Page

3-2

4/90

SECTION3:Pre-Service

Inspection

a.

The bolts holding the rear bearing cap may not be sufficiently

tightened.

b.

The washers on the bolts that

hold the rear bearing cap may be

worn

or

the bolts may not have

been coated with non-hardening

gasket sealer.

c.

The rear bearing cap gasket

may have failed.

• Inspect the left side

of

the ti lIer

tine shaft for oil leaks. If you see

an

oil leak, inspect the following:

a.

The tiller housing cover may

not be sufficiently tightened;

check all five bolts.

b.

The washers on the bolts that

hold the tiller housing cover may

be worn

or

the bolts may

not

have

been coated with non-hardening

gasket sealer.

c.

The tiller housing cover

gasket(s) may have failed.

d.

The tiller housing cover oil seal

may have failed; find out why.

• Inspect the right side

of

the tiller

tine shaft for oil leaks. If you see

an

oil leak, the oil seal needs to be

replaced. Then, discover why the

oil seal failed.

• Check the tiller tine shaft

for

play:

Using

two

hands, grasp the tiller

tine shaft and rotate the shaft back

and forth.

You should be able to rotate the

shaft slightly and to hear a small

click. This means the

tiller tine

shaft

is

shimmed correctly.

If you cannot rotate the shaft and

do not hear a click, it means that

the side cover needs to be

shimmed outward using various

thicknesses of gaskets. This

procedure

is

explained in Section

6

of

this manual (see "Tiller Tine

Shaft Assembly").

Being able to rotate the shaft more

than a small amount and hearing a

louder click means the tiller tine

shaft is either shimmed incorrectly

(too many gaskets)

or

that the

bronze worm gear

is

wearing out.

• There should be no end play,

vertical play

or

diagonal play in

the tiller tine shaft. If you find such.

play, tighten the tiller housing

cover bolts.

If this does not eliminate the play,

a shim may need to be installed

on the tiller tine shaft,

as

explained

in Section 6 of this manual.

PTO

Power Unit and Tiller

Attachment Drive Shaft

Connection -

Engage the Tines/

PTO Clutch Lever and turn the

pulley at the front

of

the PTO

power unit. The dog clutches

between the tiller attachment and

the PTO power unit should

engage and the tiller tine shaft

should move

as

you turn the pul-

ley. If the dog clutches

do

not

engage, the Tines/PTO Clutch

Lever may need to be adjusted.

Loading...

Loading...