Troy-Bilt 12087, 12088, 12089, 12090, PTO HORSE 12087 Owner's/operator's Manual

...

$ 7.50

Owner/Operator

Manual

PTO

HORSE®

Tiller

•

Safety

•

Assembly

•

Features

and

Controls

•

Operation

•

Maintenance

)

Be

sure

to

fill

out

and

return

your

Owner

Registration

Card,

which

is

located in

your

literature

pack-

.~~~

••

age.

The

infor-

mation

con-

tained

on

this

card will

register

your machine with us and entitle

you

to

full

coverage

under

our

Full No-Time-Limit Warranty.

NOTE: A Warranty Transfer Card

is included

in

this Manual. This

card should be filled out and returned to us ONLY if you transfer

ownership of your machine

to

someone else.

Be

SureToReturn

Your

Owner

Registration

Card

Thisisa safety alert

symbol.

Itisused

in

this Owner/Operator

Manual to alert you

to

potential hazards.

Whenever you see

this

symbol,

read

and

obey

the

safety

message

that

follows

it.

Failure to obey the safety message

could result in petsonal injury or

property damage.

Dear Owner,

You

now own oneofthe finest reartine rototillers available. Your new PTO

Horse Model tiller allows you to till and

cultivate your garden with ease, and accomplish dozens

of

other property management projects as well. Its PTO capability allows it to power a variety

of

attachments, including a chipper/shredder

and a generator. Your tiller is famous for

its ruggedness, performance and highquality engineering.

We

know you'll

enjoy using it.

Please carefully read this ManuaL It

tells you how

to

safely and easily assem-

ble, operate and maintain your machine.

Be sure that you and any other operators

carefullyfollow the recommended safety

practices

at

all times. Failure to do so

could result in personal injury

or

prop-

erty damage.

Of

course,ifyou should ever have any

problems or questions, or for a free replacement copy

of

this Manual, please

contact your local authorized service

dealer or call us Toll-Free. Our telephone numbers and mailing addresses

are listed on Page 4 and on the back

cover

of

this ManuaL

We

want to be sure that you are com-

pletely satisfied at all times.

This machine meets voluntary safety standard B71.8 - 1986, which

is

sponsored by

the Outdoor Power Equipment Institute, Inc.,

and

is

published by the American National

Standards Institute.

A

WARNING:

The

engine

exhaust

from

this

product

contains

chemicals

knowntothe

State

of

California

to

cause

cancer,

birth

de-

fects,orother

reproduc-

tive

harm.

2

Owner's

Record

Please write the Model

and

Serial

numbers

of

your machine

in

the spaces provided.

You

can

find the location

of

these numbersbyreferringtothe illustration

below.

Model Number:

Serial Number:

Model

and

Serial Number location

Table

of

Contents

SERVICE

INFORMATION

4

SECTION1:SAFETY

5

Training

5

Preparation

6

Operation

6

Maintenance

and

Storage

8

Decals

8

SECTION2:ASSEMBLY

9

SECTION3:FEATURES

AND

CONTROLS

20

Tiller

Features

and

Controls

Identification

20

Engine

Features

and

Controls

Identification

23

SECTION4:OPERATION

24

Break-In

Operation

25

Test

Forward

Interlock

Safety

System

26

Starting

and

Stopping

the

Engine

27

Cold

Weather

Operation

28

To

Operate

Tiller

29

Turning

Around

30

Transporting

Your

Tiller

31

To

Change

Belt

Speeds

32

Tillinginthe

Garden

34

The

PTO

Power

Unit

.40

SECTION5:MAINTENANCE&REPAIRS

44

Required

Maintenance

Schedule

.44

Tighten

Bolts

and

Nuts

.45

Tiller

Lubrication

.46

Transmission

Gear

Oil

Maintenance

.46

Drive

Belt

Maintenance

.49

Reverse

Drive

Maintenance

52

Bolo

Tine

Maintenance

54

Tine

Shaft

Maintenance

56

Tire

and

Wheel

Maintenance

56

Engine

Oil

Maintenance

56

Air

Cleaner,

Throttle

Cable,

Ignition

System,

Spark

Plug

57

Battery

Care

58

Storing

the

Tiller

60

Inspect

Forward

Interlock

Wiring

System

60

Troubleshooting

Forward

Interlock

Safety

System

60

TROUBLESHOOTING

PROCEDURES

61

ATTACHMENTS&ACCESSORIES

64

TILLER

SPECiFiCATIONS

65

INDEX

66

NO-TIME-L1MIT

WARRANTY

Back

Cover

3

Address

HOW

TO

REACH

US

~

t=:J

If

you have any

Questions or

Problems...

...Please contact

your

local TROY-BILT® Tiller

authorizeddealer or call or write the Factory. When calling

or writing, please be sure to provide the Model

and

Serial

Numbers

of

your

machine (refer to Page 3).

Our trained parts special-

ists will gladly assist you

if

you have any difficulty

in

identifying the part that you need.

number, description, and quantity

of

the part you need. Then,

call or write our Parts

Department, being sure to

provide the Model and

Serial Numbers

of

your

machine.

"Engines-Gasoline" (call us if you

need assistance in obtaining engine service or parts).

Please remember that your engine

is

covered by the engine manufacturer's Limited Warranty. Any

unauthorized work performed on

the engine during the warranty period may void the warranty. For

full details on the engine manufacturer's Limited Warranty, refer to

the separate Engine Owner's

Manual.

If

your engine should ever require

service or repair, contact

your nearest

authorized

engine service

dealer.

To

find the name and address

of

your nearest authorized engine

service dealer, look

in

the Yellow

Pages

of

the telephone book under

If

You

Need

Engine

Service:

Factory specified replacement

parts for your machine are

available from either your

TROY-BILT® Tiller authorized dealer or directly

from the Factory.

To

order a part from

the Factory, refer to

your separate Parts

Catalog to find the part

If

You

Need

Parts:

Canada

(Toll

Free)

For

Technical

Service

and

Parts

Service:

1-800-225-3585

Canada

Mon.-Fri.,

8

A.M.to4:30

P.M.

Canada

Garden

Way

Incorporated,

320

Van

Sickle

Rd.,

Unit

12,

St.

Catherines,

Ont.

L2R

6P7

U.S.A.

(Toll

Free)

U.S.A.

Garden

Way

Incorporated,

102nd

St.

&

9th

Ave.,

Troy,

N.Y.

12180

For

Technical

Service:

1-800-520-5520

For

Parts

Service:

1-800-648-6776

Overseas

callers

may

use:

518-391-7000

U.S.A.

Mon.-Fri.,

8

A.M.ta7P.M.

Saturday

9

A.M.to4

PM.

4

S clio

Safety

A

WARNING

4.

Familiarize yourself with all

of

the safety and operating decals on

this equipment and on any

of

its

attachments or accessories.

S.

Do not run engineinan enclosed area. Engine exhaust contains carbon monoxide gas, a

deadly poison that

is

odorless, col-

orless, and tasteless.

6. Do not allow hands or any

other part

of

the body or clothing

near the rotating tines or near any

other moving part. The tines

begin to rotate

forward once

the engine

starts, the

Tines/PTO

Clutch Lever is

in

the ENGAGE

R~\EfT~N~AT~::SO:I~~~~~::I~jNuE~y.

position, the

Forward Interlock Levers are

squeezed closed and the

Wheels/Tines/PTO Drive Lever is

shifted to FORWARD. The tines

rotate in Reverse whether the

Interlock Levers are squeezed

closed or left open.

WARNINGTOALL

CALIFORNIA

AND

OTHER

POWER

EQUIPMENT

OPERATORS

A

TRAINING

3. Keep the areaofoperation clear

of

all persons, particularly small

children and pets. Keep bystanders at least

25

feet away from

the area

of

operation.

1. Read this Owner/Operator

Manual and the separate Engine

Owner's Manual carefully before

operating this equipment. Be completely familiar with the controls

and the proper use

of

this equipment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children or untrained adults to operate this equipment.

Under California law, and under the laws of several other states,

you are not permitted to operate

an

internal combustion engine

using hydrocarbon fuels

on

any forest-covered, brush-cov-

,---=.

ered, or grass-covered land, oronland covered with grain,

:;;;~==~~~~

hay, or other flammable agricultural crop, withoutanen-

gine spark arrester

in

continuous effective working order.

The engineonyour power equipment, like most outdoor power equipment,isan

internal combustion engine that burns gasoline, a hydrocarbon fuel. Therefore,

your power equipment mustbeequipped with a spark arrester mufflerincontinuous effective working order. The spark arrester must

be

attached to the engine

exhaust system

in

such a manner that flames or heat from the system will not ignite flammable material. Failure of the owner/operator of the equipment to comply with this regulation

is

a misdemeanor under California law, and may alsobea

violation of other state and/or federal regulations, laws, ordinances, or codes.

Contact your local fire marshal or forest service for specific information about

what regulations apply

in

your area. Contact your authorized engine dealer for information about obtaining a spark arrester.

Thisisa

safety

alert

symbol. Itisused

in

this

Owner/

Oper-

ator

Manual

and

on

your equipment

to

alert

youtopoten-

tial

hazards.

Whenever

you

see

this symbol,

read

and

obey

the

safety

message that follows

it.

Failure

to

obey

those safety

messages

could

re-

sultinserious

per-

sonal

injuryorcause

property

damage.

Please

read

and

follow

allofthe

safety

rulesinthis

Safety

Section.

Failuretocomply

could

result

in

serious

personal

injuryorprop-

erty

damage.

If

you

should

lend

this

equipment

to

another

person,

make

sure

that

heorshe

reads,

understands,

and

always

follows

these

safety

in-

structions.

If

you

are

not

completely

sure

about

anyofthe

information

found

hereorelsewhereinthe

Manual,

please

contact either

your

local

authorized

dealerorthe

factory

for

assistance.

5

Safety

7. Before inspecting or servicing

any part

of

the equipment, shut off

the engine, wait for all moving

parts to come to a complete stop,

disconnect spark plug wire from

PREPARATION

o

o

1. Thoroughly inspect the area

where the tiller will be used. Remove foreign objects before tilling.

2. Put the WheelsfTines/pTO

Drive Lever

in

NEUTRAL before

starting the engine.

3. Do not operate the tiller without

wearing suitable clothing. Avoid

loose garments or jewelry that

could get caught in moving parts

of

the tillerorits engine.

OPERATION

1. Do not put hands or feet near or

under rotating parts.

2. Use extreme caution when on or

crossing driveways, walks or roads.

Be alert for hidden hazards or traffic. Do not carry passengers.

3.

If

you hit a foreign object, stop

the engine (remove key on electric

start models), let all moving parts

come to a complete stop, disconnect spark plug wire and move

wire away from the spark plug,

and inspect for damage. Repair

damage before restarting.

spark plug and move wire away

from the spark plug.

8. Do not operate this equipment

if

you are under the influence

of

4. Do not operate the tiller when

you are barefoot, in

san_~-~~~n

daIs, sneakers or

,4

other light footwear.

Wear shoes that grip

well on slippery surfaces.

5. Do not till near underground

electric cables, telephone lines,

pipes, or hoses. Contact your telephone or utility to verify locations

of

underground cables or lines.

6. Handle gasoline with care; it is

flammable, the vapors explosive.

a.

Use an approved gas container.

b. Gas cap shall never be re-

moved or fuel added with engine running. Engine shall be

4. Exercise caution to avoid slipping or falling.

5.

If

abnormal tiller vibration occurs, stop engine immediately, disconnect the spark plug wire and

move wire away from spark plug.

Check for the cause. Carefully inspect for any damage. Fix the problem before using the tiller again.

6. Stop the engine, remove the key

on electric start models, and disconnect the spark plug wire and

move wire away from spark plug

before leaving the operating position, unclogging tines, or making

repairs, adjustments or inspections.

7. Before leaving tiller unattended,

shift to NEUTRAL, stop engine

(remove key on electric start models), and disconnect spark plug

wire and move wire away from

plug to prevent accidental starting.

8. Before cleaning, repairing or inspecting, stop the engine (remove

6

alcohol, medication, or when you

are tired or ill.

allowed to cool before refueling. Operators shall not smoke.

c.

Keep matches, cigarettes,

cigars, pipes, open flames, or

sparks away from the fuel

tank and fuel container.

d.

Fill fuel tank outdoors using

extreme caution. Never add

fuel indoors. Use a funnel or

spout to prevent spillage.

e. Replace fuel cap securely and

clean up fuel spills before

starting the engine.

7. Never attempt to make any adjustments while the engine is run-

ning or the spark plug wire

is

con-

nected, except when so instructed.

key on electric start models), let all

moving parts stop, and disconnect

spark plug wire and move wire

away from spark

plug to prevent

accidental

~~~~

starting. Foe.::..--

....".i!i'"~"'"

electrical

safety on electric start models, al-

ways disconnect the negative (-)

cable from the battery post.

9. Flap on tine hood must be down

when running tiller, unless using

the hiller/furrower attachment.

10. Never operate the tiller unless

safety guards or other protective

devices are in place.

11. Do not run the engine in an en-

closed area. Engine exhaust contains carbon monoxide gas, a

deadly poison that is odorless, colorless, and tasteless.

12. Keep children and pets away.

13. Never operate the tiller under

engine power

if

the Wheel Speed

Lever

is in the

FREE

WHEEL

po-

sition. In

FREE

WHEEL, the

wheels will not hold the tiller back

and the revolving tines could propel the tiller rapidly, possibly causing loss

of

control. Always engage

the Wheel Speed

Lever

in either

FAST

or

SLOW

position before

starting the engine or engaging the

tines with the

Wheelsffines/PTO

Drive Lever.

14.

The

tiller could unexpectedly

bounce upward or

jump

forward

and be propelled away from you if

the tines strike

or

catch very hard-

packed soil, sod, frozen ground,

or

any buried obstacle such as large

stones or roots.

If

in doubt about

tilling conditions, use the following precautions to assist you in

maintaining tiller control:

a.

Walk behind and on either

side

of

the tiller, using one

hand on the handlebars.

Relax your arm, but use a secure hand grip.

b. Use shallow depth regulator

settings, gradually working

deeper with each tilling pass.

c. Use slower wheel, tine and en-

gine throttle speeds.

d. Clear the tilling area

of

big

stones, roots and other debris.

e. Avoid putting downward pres-

sure on the handlebars.

If

necessary, apply slight upward

pressure to prevent the tines

from digging too deeply.

f. Avoid contacting hard-packed

soil

or

sod at the endofa row

by reducing engine speed and

lifting handlebars up to raise

tines out

of

the soil.

g. In an emergency, stop the

tines and wheels by shifting

the Wheelsffines/PTO Drive

Lever

to NEUTRAL.Ifyou

can not reach the lever

or

have

lost control

of

the tiller,

let

go

of

the handlebars and all con-

trols.

Do

not try to restrain it.

15.

Do

not overload the machine

capacity by trying to till too deeply

at too fast a rate.

16. Never use the tiller at high

ground speeds on slippery surfaces.

17. Do not operate tiller on a slope

too steep for safety. On slopes,

slow down and be sure you have

good footing.

Don't

let the tiller

"free-wheel" down slopes.

18. Clear the area

of

bystanders be-

fore tilling.

19. Use only attachments and ac-

cessories approved by Troy-Bilt

Manufacturing Company.

20. Use tiller attachments and accessories when recommended.

21. Never operate the tiller without

good visibility or light.

22. Never operate the tiller

if

you

are fatigued, or under the influence

of

alcohol, drugs or medication.

23. Operators shall not tamper with

the engine-governor settings on the

machine; the governor controls the

maximum safe operating speed and

protects the engine and all moving

parts from damage caused by over-

speed. Authorized service shall be

sought if a problem exists.

24.

Do

not touch engine parts that

may be hot from operation (muffler,

fins, etc.). Make certain

all parts

have cooled down before inspecting, cleaning or repairing.

25.

POISONIDANGER-

CAUSES

SEVERE

BURNS.

The

battery on electric start models contains sulfuric acid. Avoid contact

with skin, eyes or clothing.

Antidotes:

External-

Flush imme-

diately with lots

of

water.

Internal-

Drink large quantities

of

waterormilk. Follow with milk

of

magnesia, beaten eggs or vegetable

oil. Call a doctor immediately.

Eyes-

Flush with water for15min-

utes. Get prompt medical attention.

Keep out

of

reachofchildren.

7

Safety

26.

DANGER-

BATTERIES

PRODUCE

EXPLOSIVE

GASES.

Keep sparks, flame

or

smoking materials away. Ventilate

when charging battery or using in

an enclosed space. Always shield

eyes when working near battery.

27.

Remember-To

stop tines and

wheels, either put Wheels/

Tines/PTO Drive Lever in NEUTRAL, or move Throttle Lever to

STOP position.

If

you lose control

of

the tiller and can not reach the

levers, let go

of

the handlebars and

controls and do not try to restrain

the tiller. The Forward Interlock

Safety System will stop the engine.

28. Look behind and exercise caution when backing up.

For

added

safety, put Wheel Speed Lever in

SLOW

position before reversing.

29. When loading or unloading the

tiller, always disengage the tines

and use slower wheel and engine

throttle speeds. Use sturdy ramps

wide and strong enough to easily

support the tiller (280-to-325 Ibs.,

depending on model) and operator.

Never go down ramps

in

FOR-

WARD

drive-the

tiller could tip

forward, exposing you to the tines

(which should be disengaged).

Always use REVERSE drive and

back down ramps. To go up ramps,

use FORWARD drive and walk up

following the tiller.

30.

The

Forward Interlock Safety

System should be tested for correct

functioning every time the tiller

or

PTO power unit is used. See

Section 4 in this Manual for the test

procedure to take.

31.

If

using the optional Dozer

Blade, either remove the tine attachment, or disengage the tines

with the Tines/PTO Clutch Lever.

Revolving tines are dangerous.

Safety

MAINTENANCE

AND

STORAGE

1. Never perform maintenance

when engine is running or spark

plug wire is connected except

when specifically directed to do so.

2. Keep tiller, attachments and accessories

in

safe working condition.

3. Check all nuts, bolts, and screws

frequently for proper tightness.

Always verify your equipment is in

safe working condition.

4. Never store the machine with

fuel in the fuel tank inside a building where fumes may reach

an

open flame or spark, or where igni-

tion sources are present (such

as

hot water and space heaters, furnaces, clothes dryers, etc.).

5. Let the engine cool down before

storing it in an enclosure.

6.

To

reduce fire hazard possibili-

ties, keep the engine free

of

grass,

leaves or grease.

7. Store gasoline

in

a cool, wellventilated area, safely away from

any spark- or flame-producing

equipment. Store gasoline in an

approved container, safely out

of

the reachofchildren.

8. Refer to the Maintenance section

in

this Manual for storage

information if your tilleristo be

stored for an extended period.

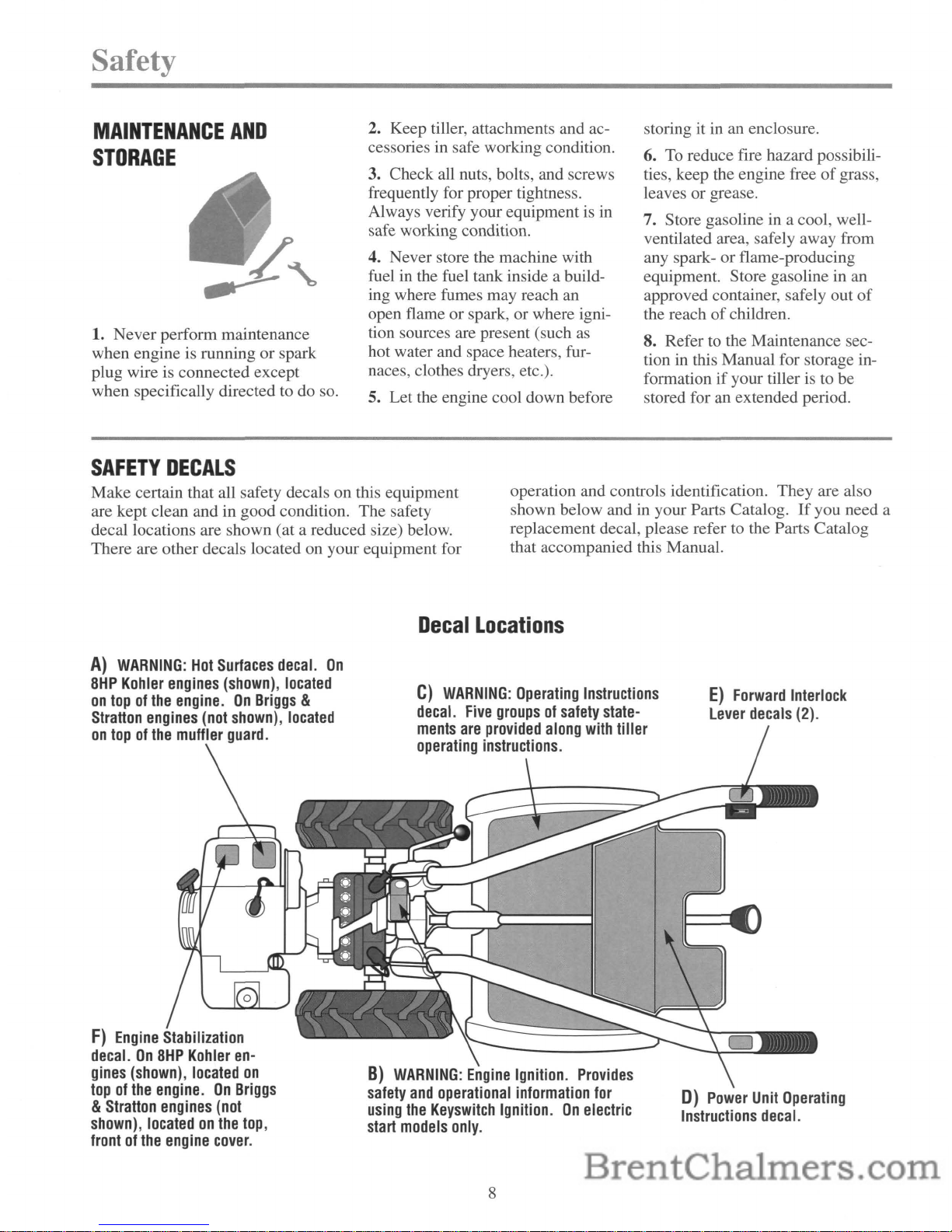

SAFETY

DECALS

Make certain that all safety decals on this equipment

are kept clean and in good condition. The safety

decal locations are shown (at a reduced size) below.

There are other decals located on your equipment for

operation and controls identification. They are also

shown below and

in

your Parts Catalog.Ifyou need a

replacement decal, please refer to the Parts Catalog

that accompanied this Manual.

A)

WARNING:

Hot

Surfaces

decal.

On

8HP

Kohler

engines

(shown),

located

on

topofthe

engine.

On

Briggs

&

Stratton

engines

(not

shown),

located

on

topofthe

muffler

guard.

F)

Engine

Stabilization

decal.On8HP

Kohler

en-

gines

(shown),

located

on

topofthe

engine.

On

Briggs

&

Stratton

engines

(not

shown),

locatedonthe

top,

frontofthe

engine

cover.

Decal

Locations

C)

WARNING:

Operating

Instructions

decal.

Five

groupsofsafety

state-

ments

are

provided

along

with

tiller

operating

instructions.

B)

WARNING:

Engine

Ignition.

Provides

safety

and

operational

information

for

using

the

Keyswitch

Ignition.

On

electric

start

models

only.

8

E)

Forward

Interlock

Lever

decals

(2).

D)

Power

Unit

Operating

Instructions

decal.

eelio

Assembly

Please

carefully

follow

the

steps

in

this

Sectiontoproperly

assemble

your

new

machine.

These

steps

will

not

take

very

long

and

they

will

assure

youofhaving

assem-

bled

your

machine

correctly.

WARNING

To

prevent personal injury

or

property

damage,donot

start

the

engine

until

all

assembly

steps

are

complete

and

you

have

read

and

understand

the

safety

and

operating instructionsinthis

Manual.

Subjects covered in this Section:

• Inspection After Delivery

:

~:~:~k::::

~::d~:::::ng

Contents

~

• Remove Tiller from Shipping

Platform

I}

• Connect

Forward

Intl!tlock

Wire

Harness

• Attach WheelslTineslPTO Drive Leve

• Check

Gear

Oi Levels in

Power

Unitt

and

Tine Attachment Tral1smissions

t

rL

• Add

Motor

Oil to ·Iler Engin

.J'!~,'.

"-.

~/v

j

• Attach Engine Throttle

Leverto

Handlebar

• Adjust the

Air

Pressur

·n the Tires "

• Assembling the Electric

Start

System

Tools

Needed:

One

3/8"

Open

End

or

Adjustable

Wrench

One

9/16"

Open

End

or

Adjustable

Wrench

One

3/4"

Open

End

or

Adjustable

Wrench

Two

7/16"

Open

End

or

Adjustable

Wrenches

Two

1/2"

Open

End

or

Adjustable

Wrenches

One

Flat

Blade

Screwdriver

Scissors

(to

trim

plastic

ties)

Quality

Motor

Oil

(refertothe

Engine

Owner

Manual

provided

with

your

unit

for

motor

oil

specifica-

tions

and

capacities).

Tire

Pressure

Gauge

A

strong

4112"

high

prop

(a

wood

box,abrick,

or

boards)

I

Inspection

After

Delivery

Inspect your machine immediately

after it has been delivered. Make

sure that neither the carton nor the

contents have been damaged.

If

you find or suspect any damage,

contact the carrier (trucking company) right away. Inform them

of

the specific damage and that you

wish to file a claim.

To

protect

your rights, be sure

to

put this

in

writingtothe carrier within

15

days after your machine arrives.

The carrier will let you know how

to proceed with your claim.

Please let us know

if

you need any

assistance with this matter.

IMPORTANT:

Motor

oil

must

be

added

to the engine before it

is

started.

The

procedure for

adding oil is explained

later

on

in these assembly instructions.

9

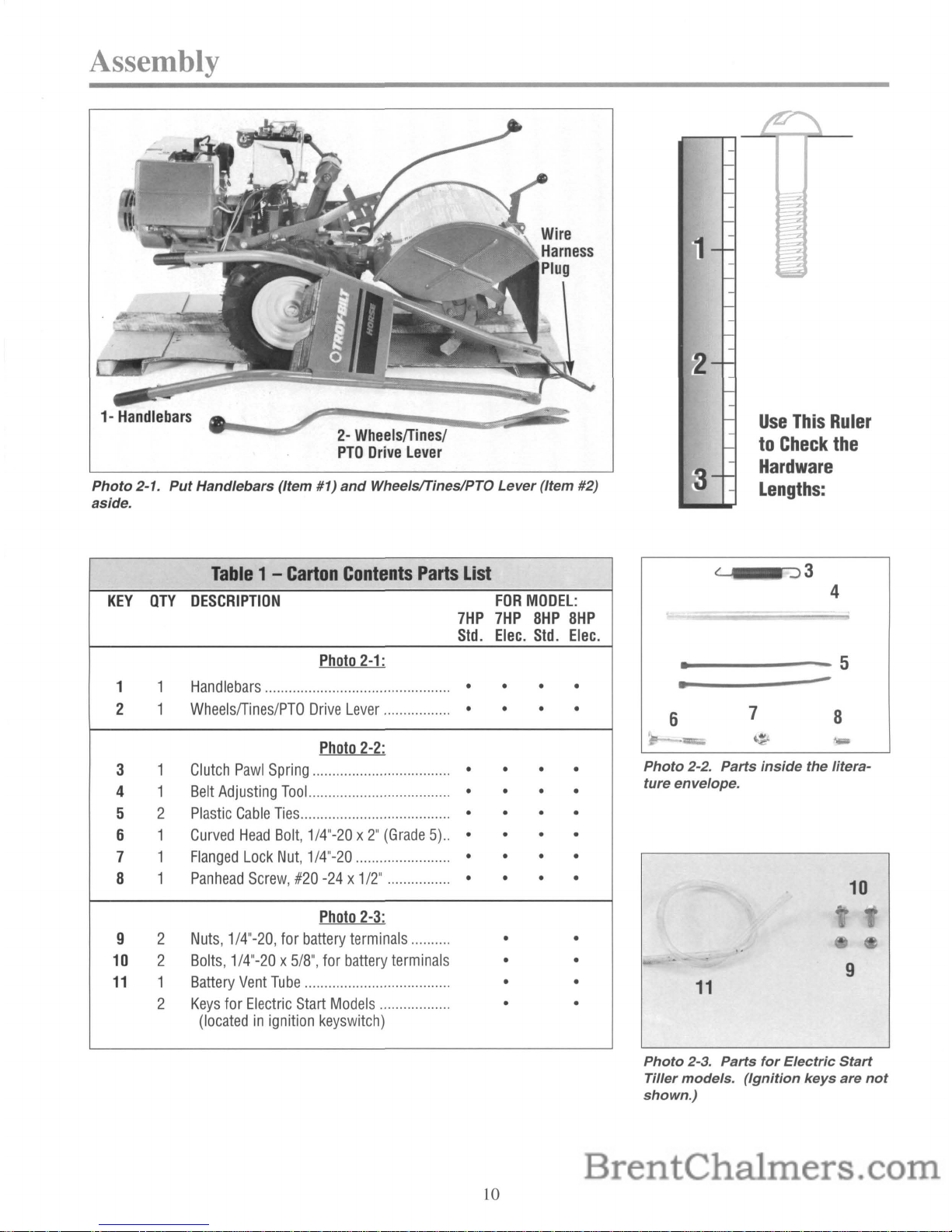

STEP1:Unpacking

Contents

If

you haven't done so, unpack

and check the loose parts as listed

in

the table on page

10.

Contact

us

if

any parts are missing.

A. Remove the handlebars and

the WheelslTineslPTO Drive

Lever (Items 1 and 2 in Photo

2-1).

You

may need to cut a plastic tie to free the handlebars from

its shipping location. Set them on

a clean surface. Do not get dirt on

the wire harness plug located at

the bottom

of

the handlebars!

B. Remove the loose parts from

the plastic envelope that contained

these instructions (Items 3 through

8 in Photo 2-2).

C.

If

you ordered an Electric Start

Tiller, take out the items from a

sealed plastic hardware package

under the battery clamp (Items 9

through

11

in Photo 2-3). Your ig-

nition keys are in the keyswitch.

Use

This

Ruler

to

Check

the

Hardware

Lengths:

Assembly

1-

Handlebars

2-

Wheels/Tines/

PTO

Drive

Lever

Photo

2-1.

Put

Handlebars (/tern #1)

and

Wheelsflines/PTO

Lever

(/tern #2)

aside.

Table1-Carton

Contents

Parts

List

KEY

OTY

DESCRIPTION

FOR

MODEL:

7HP

7HP

8HP

8HP

Std.

Elec.

Std.

Elec.

Photo

2-1:

1 1

Handlebars

...............................................

• • • •

2 1

Wheels/Tines/PTO

Drive

Lever

.................

• • • •

Photo

2-2:

3

1

Clutch

Pawl

Spring

...................................

• • • •

4

1

Belt

Adjusting

Tool

.................................... • • • •

5 2

Plastic

Cable

Ties

......................................

• • • •

6 1

Curved

Head

Bolt,

1/4"-20x2"

(Grade5)..

• • • •

7 1

Flanged

Lock

Nut,

1/4"-20

........................

• • • •

8 1

Panhead

Screw,

#20

-24x1/2"

................

• • • •

Photo

2-3:

9

2

Nuts,

1/4"-20,

for

battery

terminals

..........

• •

10

2

Bolts,

1/4"-20x5/8",

for

battery

terminals

• •

11

1

Battery

Vent

Tube

.....................................

• •

2

Keys

for

Electric

Start

Models

..................

• •

(locatedinignition

keyswitch)

10

~_;-:)3

4

•

-5

•

-

6

7

8

1lIlIl;;;;"

~

...

Photo

2-2. Parts

inside

the litera-

ture envelope.

10

9

11

Photo

2-3. Parts

for

Electric

Start

Tiller models.

(Ignition

keys

are

not

shown.)

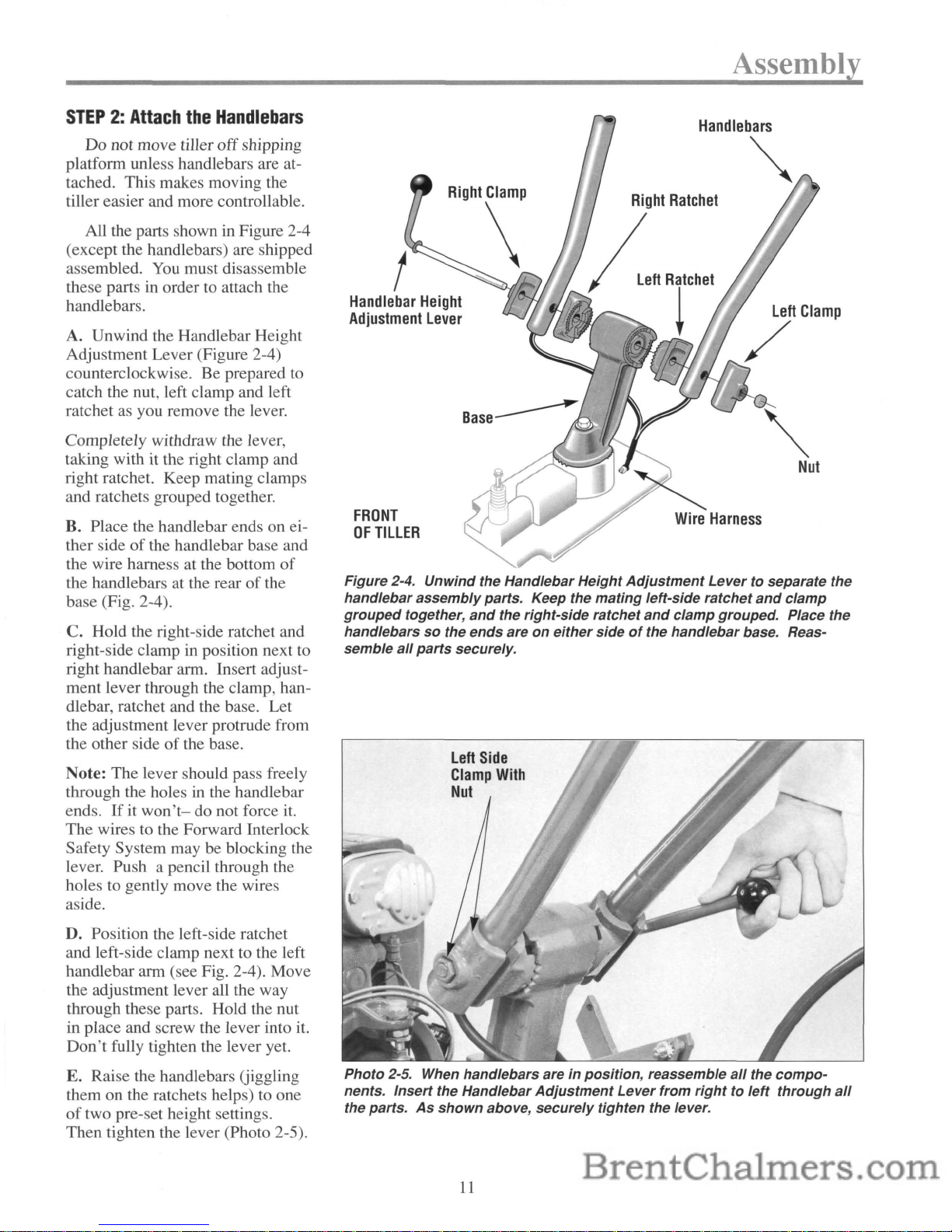

STEP2:Attach

the

Handlebars

Do not move tiller

off

shipping

platform unless handlebars are attached. This makes moving the

tiller easier and more controllable.

All the parts shown in Figure 2-4

(except the handlebars) are shipped

assembled.

You

must disassemble

these parts in order to attach the

handlebars.

A. Unwind the Handlebar Height

Adjustment Lever (Figure 2-4)

counterclockwise. Be prepared to

catch the nut, left clamp and left

ratchet as you remove the lever.

Completely withdraw the lever,

taking with it the right clamp and

right ratchet. Keep mating clamps

and ratchets grouped together.

B. Place the handlebar ends on either side

of

the handlebar base and

the wire harness at the bottom

of

the handlebars at the rearofthe

base (Fig. 2-4).

C.

Hold the right-side ratchet and

right-side clamp in position next

to

right handlebar arm. Insert adjustment lever through the clamp, handlebar, ratchet and the base. Let

the adjustment lever protrude from

the other side

of

the base.

Note: The lever should pass freely

through the holes

in

the handlebar

ends.

Ifitwon't-

do not force

it.

The wires to the Forward Interlock

Safety System may be blocking the

lever. Push a pencil through the

holes to gently move the wires

aside.

D. Position the left-side ratchet

and left-side clamp next to the left

handlebar arm (see Fig. 2-4). Move

the adjustment lever all the way

through these parts. Hold the nut

in place and screw the lever into

it.

Don't

fully tighten the lever yet.

E. Raise the handlebars Uiggling

them on the ratchets helps) to one

of

two pre-set height settings.

Then tighten the lever (Photo 2-5).

Assembly

Handlebars

~

Handlebar

Height

Adjustment

Lever

FRONT

OF

TILLER

Figure 2-4. Unwind the Handlebar Height

Adjustment

Levertoseparate the

handlebar

assembly

parts. Keep the mating left-side ratchet

and

clamp

grouped

together,

and

the right-side ratchet

and

clamp grouped. Place the

handlebars

so

the ends areoneither

sideofthe handlebar base. Reas-

semble

all

parts

securely.

Left

Side

Clamp

With

Nut

Photo 2-5. When handlebars are in position, reassemble

all

the

compo-

nents. Insert the Handlebar

Adjustment

Lever from

righttoleft

through

all

the parts.

As

shown

above, securely tighten the lever.

11

Assembly

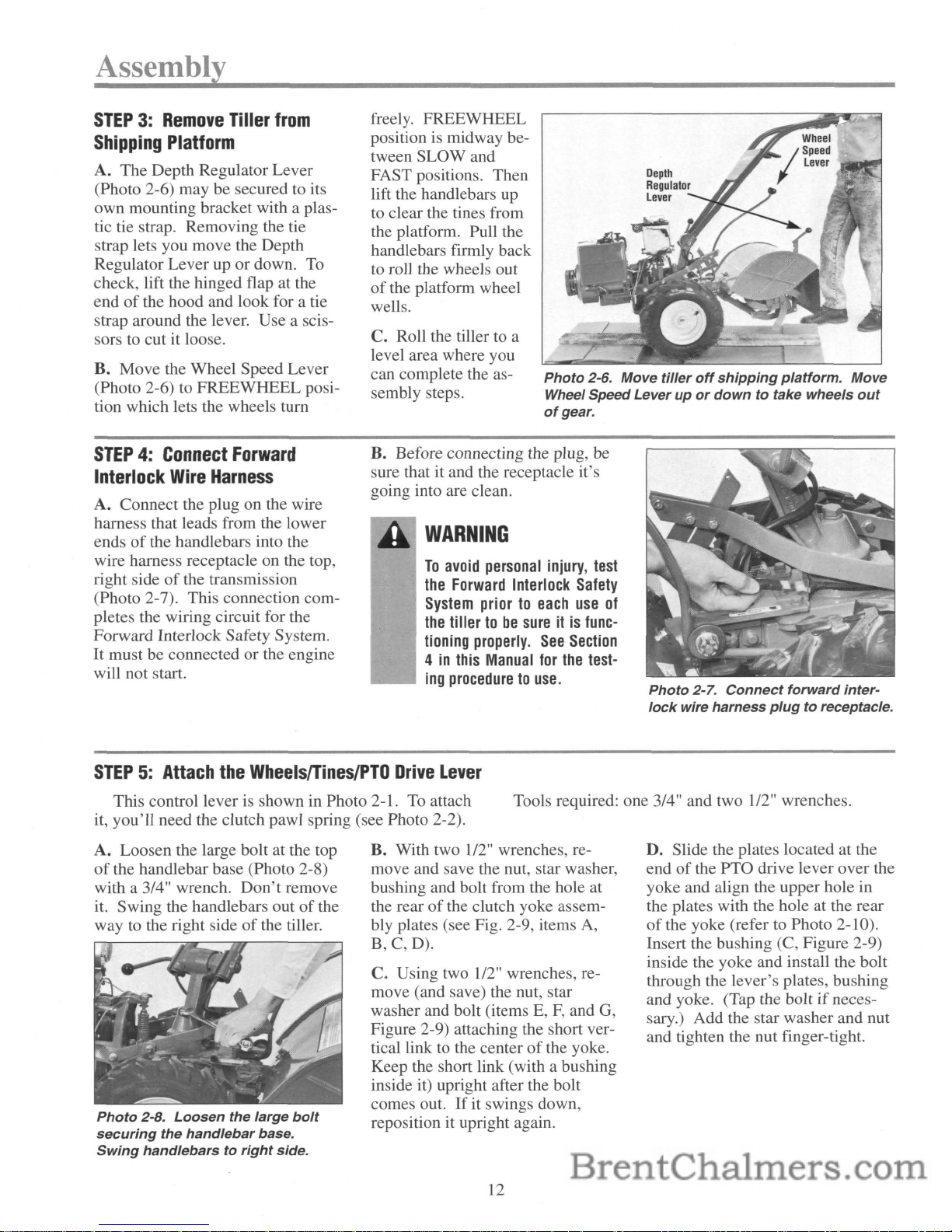

STEP3:Remove

Tiller

from

Shipping

Platform

A. The Depth Regulator Lever

(Photo 2-6) may be secured to its

own mounting bracket with a plas-

tic tie strap. Removing the tie

strap lets you move the Depth

Regulator Lever up or down. To

check, lift the hinged flap at the

end

of

the hood and look for a tie

strap around the lever. Use a scissors to cut it loose.

B. Move the Wheel Speed Lever

(Photo 2-6) to FREEWHEEL position which lets the wheels

tum

freely. FREEWHEEL

position is midway between SLOW and

FAST positions. Then

lift the handlebars up

to

clear the tines from

the platform. Pull the

handlebars firmly back

to roll the wheels out

of

the platform wheel

wells.

C. Roll the tiller to a

level area where you

can complete the assembly steps.

Photo

2-6. Move

tiller

off

shipping

platform.

Move

Wheel Speed Lever up

or

down

to take wheels

out

of

gear.

STEP4:Connect

Forward

Interlock

Wire

Harness

A. Connect the plug on the wire

harness that leads from the lower

ends

of

the handlebars into the

wire harness receptacle on the top,

right side

of

the transmission

(Photo 2-7). This connection completes the wiring circuit for the

Forward Interlock Safety System.

It

must be connected or the engine

will not start.

B. Before connecting the plug, be

sure that it and the receptacle it's

going into are clean.

WARNING

To

avoid

personal

injury,

test

the

Forward

Interlock

Safety

System

priortoeach

use

of

the

tillertobe

sureitis

func-

tioning

properly.

See

Section

4inthis

Manual

for

the

test-

ing

proceduretouse.

Photo

2-7.

Connect

forward

inter-

lock

wire harness

plug

to receptacle.

STEP5:Attach

the

Wheels/Tines/PTO

Drive

Lever

This control lever is shown in Photo 2-1.

To

attach

it, you'll need the clutch pawl spring (see Photo 2-2).

Tools required: one 3/4" and two 1/2" wrenches.

A. Loosen the large bolt at the top

of

the handlebar base (Photo 2-8)

with a 3/4" wrench.

Don't

remove

it. Swing the handlebars out

of

the

way to the right side

of

the tiller.

Photo

2-8.

Loosen

the large

bolt

securing

the

handlebar

base.

Swing

handlebarstoright

side.

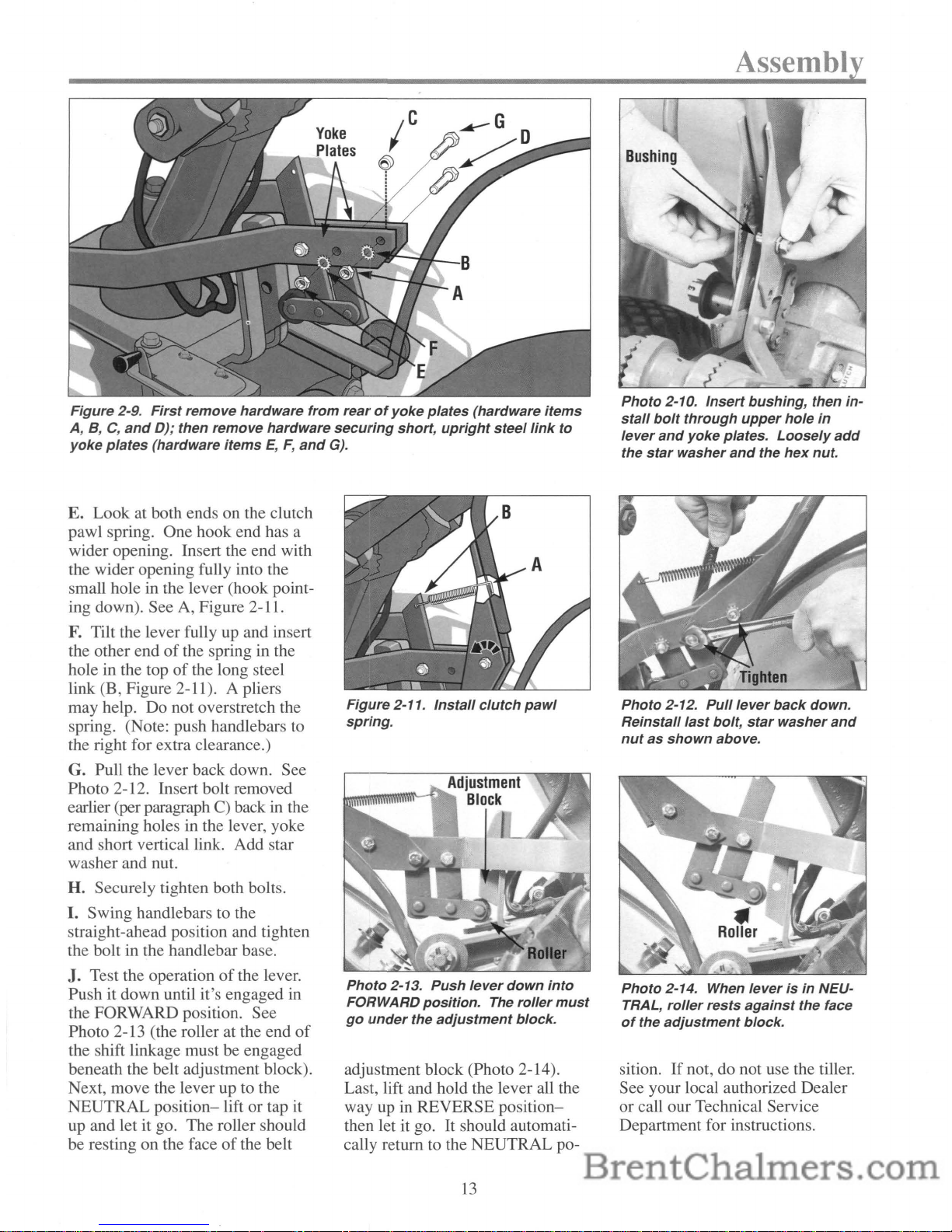

B. With two 1/2" wrenches, re-

move and save the nut, star washer,

bushing and bolt from the hole at

the rear

of

the clutch yoke assem-

bly plates (see Fig. 2-9, items

A,

B,C,D).

C. Using two 1/2" wrenches, re-

move (and save) the nut, star

washer and bolt (items E,

F,

and G,

Figure 2-9) attaching the short vertical link to the center

of

the yoke.

Keep the short link (with a bushing

inside it) upright after the bolt

comes out.

If

it swings down,

reposition it upright again.

12

D. Slide the plates located at the

end

of

the

PTa

drive lever over the

yoke and align the upper hole in

the plates with the hole at the rear

of

the yoke (refer to Photo 2-10).

Insert the bushing (C, Figure 2-9)

inside the yoke and install the bolt

through the lever's plates, bushing

and yoke. (Tap the bolt

if

necessary.) Add the star washer and nut

and tighten the nut finger-tight.

Figure 2-9.

First

remove hardware from rearofyoke

plates

(hardware items

A,

B,C,and

D); then remove hardware

securing

short,

upright

steel

link

to

yoke

plates

(hardware items

E,F,and

G).

Assembly

Photo 2-10.

Insert

bushing, then in-

stall

bolt

through

upper

hole

in

lever

and

yoke plates.

Loosely

add

the

star

washer

and

the

hex

nut.

E.

Look at both ends on the clutch

pawl spring. One hook end has a

wider opening. Insert the end with

the wider opening fully into the

small hole in the lever (hook point-

ing down). See A, Figure 2-11.

F.

Tilt the lever fully up and insert

the other end

of

the spring in the

hole in the top

of

the long steel

link (B, Figure 2-11). A pliers

may help. Do not overstretch the

spring. (Note: push handlebars to

the right for extra clearance.)

G. Pull the lever back down. See

Photo 2-12. Insert bolt removed

earlier (per paragraph

C) back in the

remaining holes in the lever, yoke

and short vertical link. Add star

washer and nut.

H.

Securely tighten both bolts.

I.

Swing handlebars to the

straight-ahead position and tighten

the bolt

in

the handlebar base.

J. Test the operation

of

the lever.

Push it down until it's engaged in

the FORWARD position. See

Photo 2-13 (the roller at the end

of

the shift linkage must be engaged

beneath the belt adjustment block).

Next, move the lever up to the

NEUTRAL

position-

lift or tap it

up and let it go. The roller should

be resting on the face

of

the belt

Figure 2-11.

Install

clutch

pawl

spring.

Photo

2-13. Push

lever

down

into

FORWARD position. The roller

must

go

under

the

adjustment

block.

adjustment block (Photo 2-14).

Last, lift and hold the lever all the

way up

in

REVERSE position-

then let it go.

It

should automati-

cally return to the NEUTRAL po-

13

Photo 2-12.

Pull

lever

back

down.

Reinstall

last

bolt,

star

washer

and

nutasshown

above.

Photo

2-14. When

leverisin

NEU-

TRAL,

roller

rests

against

the face

of

the

adjustment

block.

sition.Ifnot, do not use the tiller.

See your local authorized Dealer

or call our Technical Service

Department for instructions.

Assembly

STEP6:Check

Gear

Oil

LevelsinPower

Unit

Transmission

and

Tine

Attachment

Transmission

Your tiller has two separate

transmissions: one for the Power

Unit; the other for the Tine Attachment. Both were filled with

SAE

#85W-140

weight gear oil (with

an A.P.I rating

of

GL-4) at the

Factory. Please check level in

both

transmissions to verify that levels

are still correct.

To

Check

Power

Unit

Transmission:

A. Put the tiller on level ground.

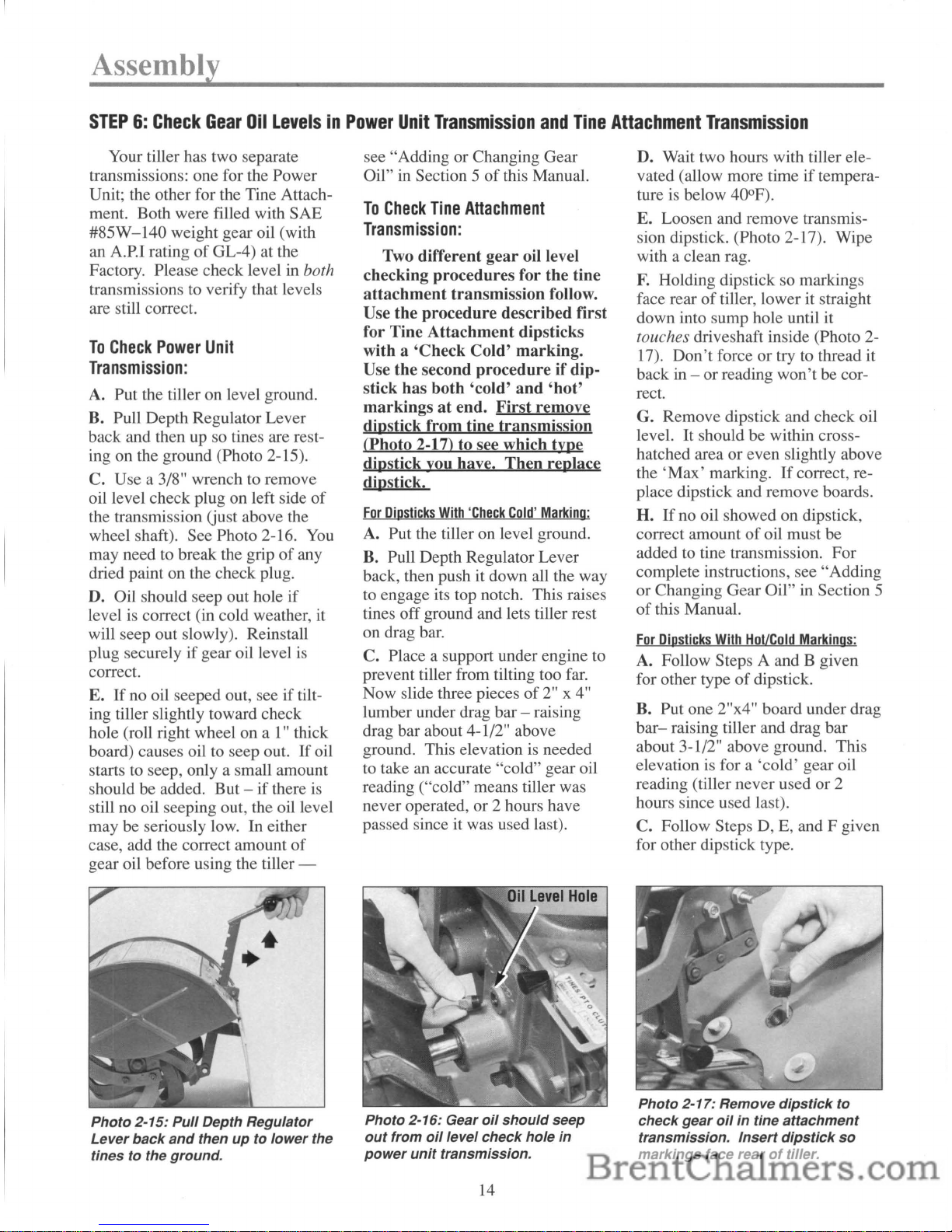

B. Pull Depth Regulator Lever

back and then up so tines are resting on the ground (Photo 2-15).

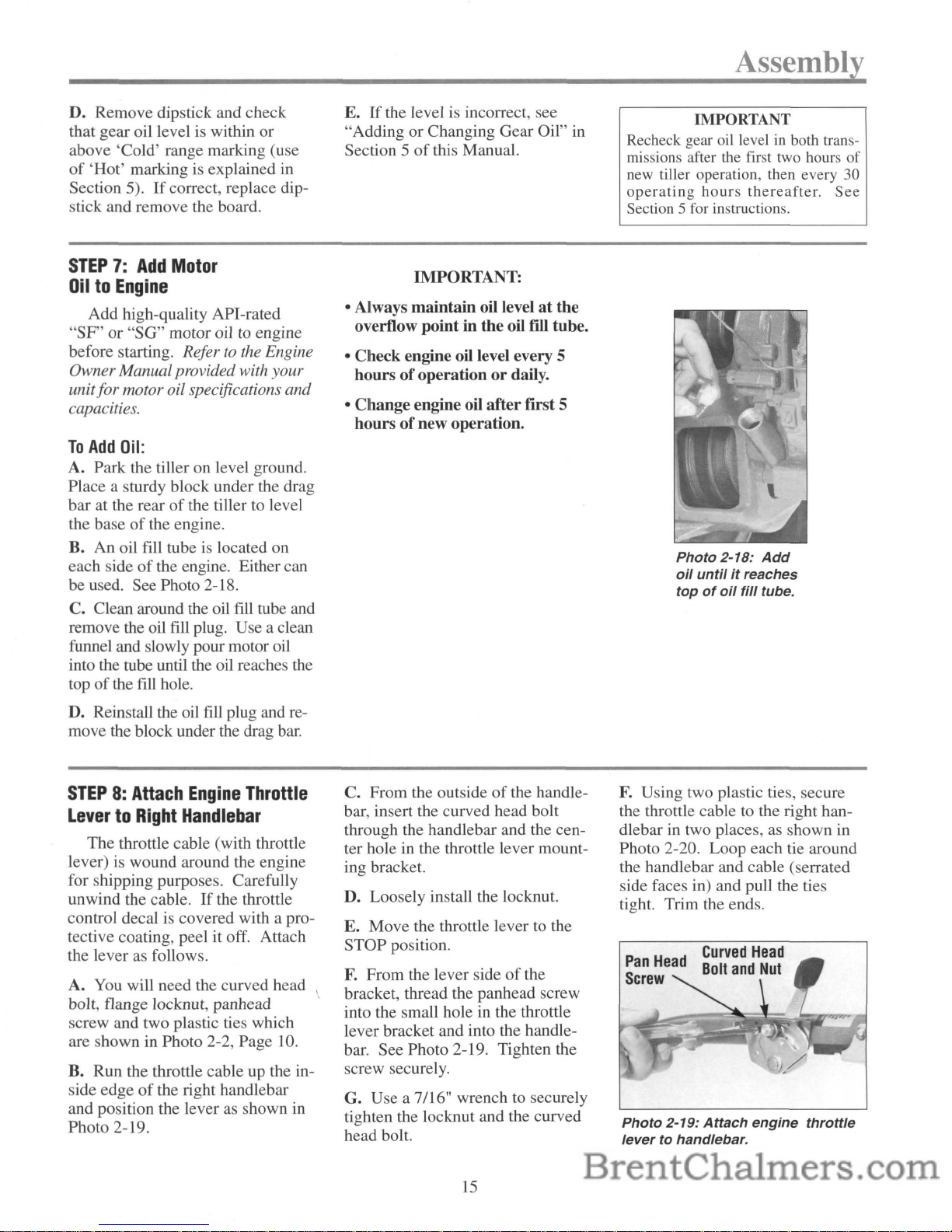

C. Use a 3/8" wrench to remove

oil level check plug on left side

of

the transmission Gust above the

wheel shaft). See Photo 2-16. You

may need to break the grip

of

any

dried paint on the check plug.

D. Oil should seep out hole if

level is correct (in cold weather, it

will seep out slowly). Reinstall

plug securely

if

gear oil level

is

correct.

E.

If

no oil seeped out, seeiftilting tiller slightly toward check

hole (roll right wheel on a I" thick

board) causes oil to seep out.

If

oil

starts to seep, only a small amount

should be added.

But-if

there is

still no oil seeping out, the oil level

may be seriously low. In either

case, add the correct amount

of

gear oil before using the tiller -

Photo 2-15:

Pull

Depth Regulator

Lever

back

and

thenupto

lower

the

tines

to

the ground.

see"

AddingorChanging Gear

Oil" in Section 5

of

this Manual.

To

Check

Tine

Attachment

Transmission:

Two different gear oil level

checking procedures for the tine

attachment transmission follow.

Use the procedure described first

for Tine Attachment dipsticks

with a 'Check Cold' marking.

Use the second procedure ifdipstick has both 'cold'

and

'hot'

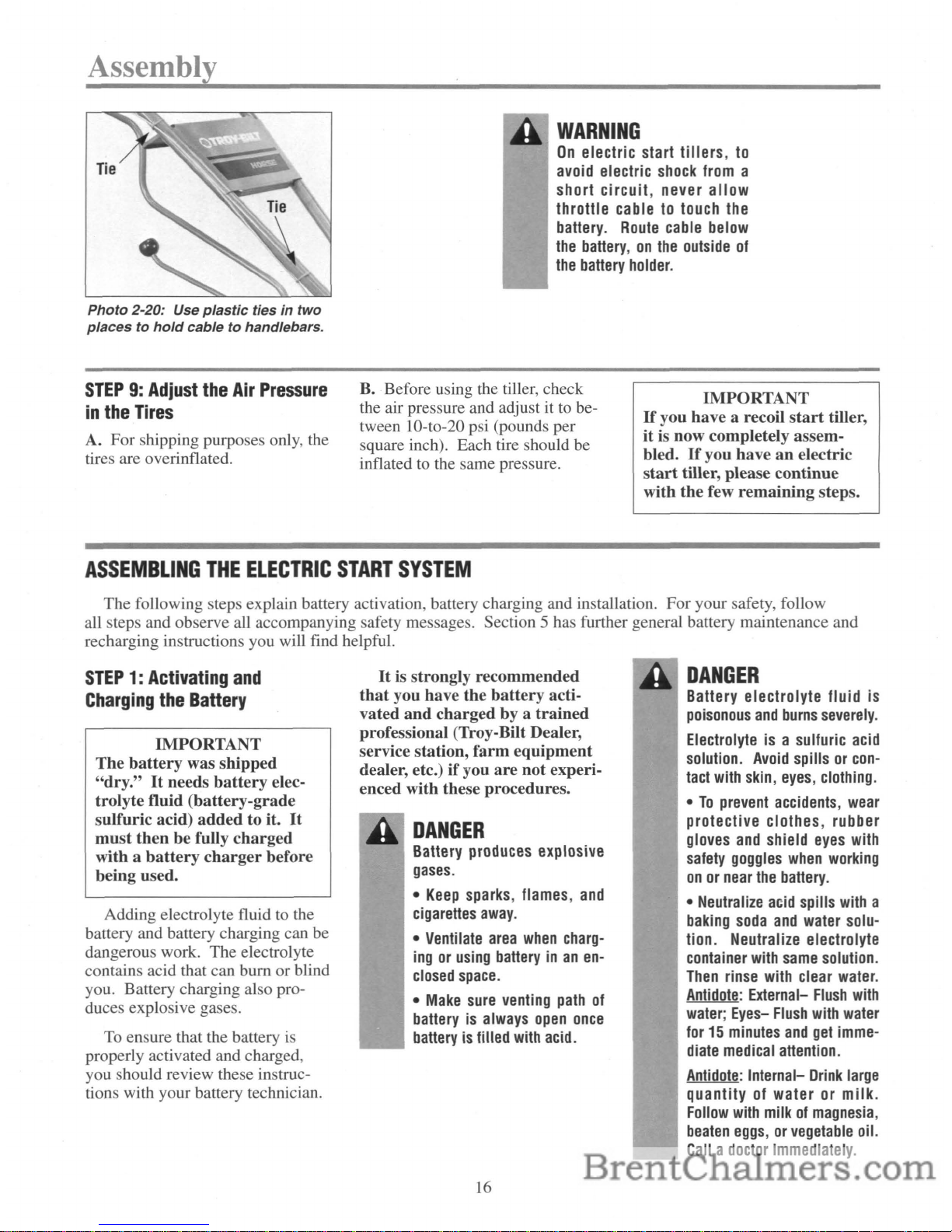

markingsatend. First remove

dipstick from tine transmission

(Photo 2-17) to see which type

dipstick you have. Then replace

dipstick.

For

Diosticks

With

'Check

Cold'

Marking:

A. Put the tiller on level ground.

B. Pull Depth Regulator Lever

back, then push it down all the way

to engage its top notch. This raises

tines

off

ground and lets tiller rest

on drag bar.

C. Place a support under engine to

prevent tiller from tilting too far.

Now slide three pieces

of

2" x 4"

lumber under drag bar - raising

drag bar about 4-1/2" above

ground. This elevation is needed

to take an accurate "cold" gear oil

reading ("cold" means tiller was

never operated,

or

2 hours have

passed since it was used last).

Photo 2-16: Gear

oil

should

seep

out

from

oil

level

check

hole

in

power

unit

transmission.

14

D. Wait two hours with tiller elevated (allow more time

if

tempera-

ture is below 40°F).

E. Loosen and remove transmis-

sion dipstick. (Photo 2-17). Wipe

with a clean rag.

F.

Holding dipstick so markings

face rear

of

tiller, lower it straight

down into sump hole until it

touches driveshaft inside (Photo 2-

17).

Don't

forceortry to thread it

back in -

or

reading

won't

be cor-

rect.

G. Remove dipstick and check oil

level.

It

should be within cross-

hatched area

or

even slightly above

the

'Max'

marking.Ifcorrect, re-

place dipstick and remove boards.

H.

If

no oil showed on dipstick,

correct amount

of

oil must be

added to tine transmission.

For

complete instructions, see

"Adding

or

Changing Gear Oil" in Section 5

of

this Manual.

For

Dipsticks

With

Hot/Cold

Markings:

A. Follow Steps A and B given

for other type

of

dipstick.

B. Put one 2"x4" board under drag

bar-

raising tiller and drag bar

about 3-1/2" above ground. This

elevation is for a

'cold'

gear oil

reading (tiller never used

or

2

hours since used last).

C. Follow Steps D,

E,

and F given

for other dipstick type.

Photo 2-17: Remove

dipstick

to

check

gear

oilintine

attachment

transmission.

Insert

dipstick

so

markings

face rearoftiller.

D. Remove dipstick and check

that gear oil level is within or

above 'Cold' range marking (use

of

'Hot'

marking is explained

in

Section 5).Ifcorrect, replace dip-

stick and remove the board.

STEP7:Add

Motor

OiltoEngine

Add high-quality API-rated

"SF"

or

"SG"

motor oiltoengine

before starting.

Refer to the Engine

Owner Manual provided with your

unitfor

motor oil specifications

and

capacities.

To

Add

Oil:

A. Park the tiller on level ground.

Place a sturdy block under the drag

bar at the rear

of

the tiller to level

the base

of

the engine.

B.

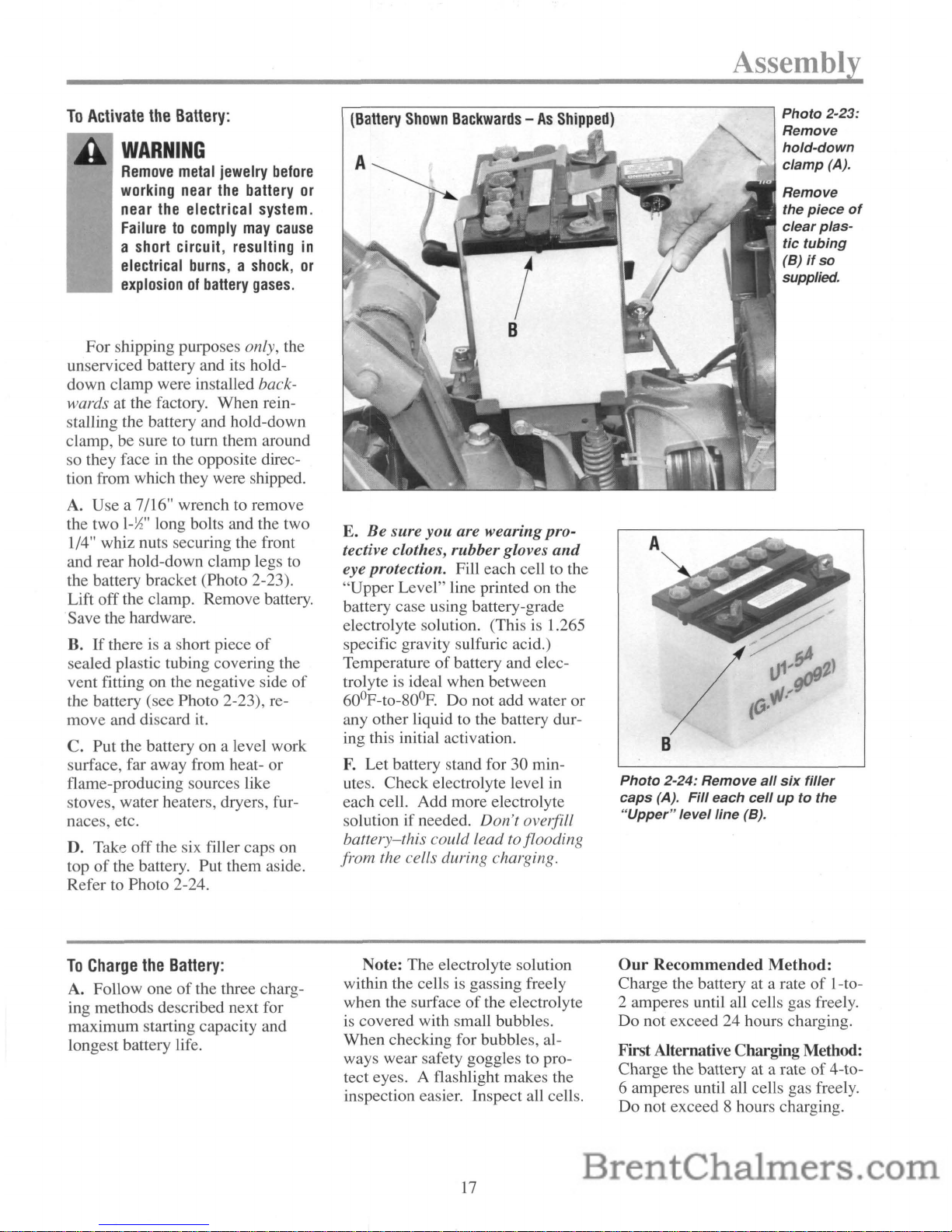

An oil fill tubeislocated on

each side

of

the engine. Either can

be used. See Photo 2-18.

C. Clean around the oil fill tube and

remove the oil

fill

plug. Use a clean

funnel and slowly pour motor oil

into the tube until the oil reaches the

top

of

the fill hole.

D. Reinstall the oil fill plug and

re-

move the block under the drag

bar.

STEP8:Attach

Engine

Throttle

LevertoRight

Handlebar

The throttle cable (with throttle

lever) is wound around the engine

for shipping purposes. Carefully

unwind the cable.

If

the throttle

control decal

is

covered with a protective coating, peel it off. Attach

the lever as follows.

A. You will need the curved head

bolt, flange locknut, panhead

screw and two plastic ties which

are shown in Photo 2-2, Page

10.

B. Run the throttle cable up the inside edge

of

the right handlebar

and position the lever

as

shown in

Photo 2-19.

E.Ifthe level is incorrect, see

"Adding or Changing Gear Oil" in

Section 5

of

this Manual.

IMPORTANT:

• Always maintain oil level

at

the

overflow point in the oil

fill tube.

• Check engine oil level every 5

hours ofoperation

or

daily.

• Change engine oil after first 5

hours ofnew operation.

C.

From the outsideofthe handle-

bar, insert the curved head bolt

through the handlebar and the center hole in the throttle lever mount-

ing bracket.

D. Loosely install the locknut.

E.

Move the throttle lever to the

STOP position.

F.

From the lever sideofthe

bracket, thread the panhead screw

into the small hole in the throttle

lever bracket and into the handlebar. See Photo 2-19. Tighten the

screw securely.

G. Use a

7/16" wrench to securely

tighten the locknut and the curved

head bolt.

15

Assembly

IMPORTANT

Recheck gear oil levelinboth transmissions after the first two hours

of

new tiller operation, then every 30

operating

hours

thereafter.

See

Section 5 for instructions.

Photo

2-18:

Add

oil

untilitreaches

topofoil

fill

tube.

F.

Using two plastic ties, secure

the throttle cable to the right handlebar in two places,

as

shown in

Photo 2-20. Loop each tie around

the handlebar and cable (serrated

side faces in) and pull the ties

tight. Trim the ends.

Photo

2-19:

Attach

engine

throttle

levertohandlebar.

Assembly

Photo

2-20: Use

plastic

tiesintwo

placestohold

cable to handlebars.

WARNING

On

electric start tillers,

to

avoid

electric

shock

from

a

short circuit, never allow

throttle cable

to

touch

the

battery.

Route

cable

below

the

battery,onthe

outside

of

the

battery

holder.

STEP9:Adjust

the

Air

Pressure

in

the

Tires

A. For shipping purposes only, the

tires are overinflated.

B. Before using the tiller, check

the air pressure and adjust it

to

between 10-to-20 psi (pounds per

square inch). Each tire should be

inflated to the same pressure.

IMPORTANT

If

you have a recoil

start

tiller,

it is now completely assembled.

If

you haveanelectric

start

tiller, please continue

with the few

remaining

steps.

ASSEMBLING

THE

ELECTRIC

START

SYSTEM

The following steps explain battery activation, battery charging and installation. For your safety, follow

all steps and observe all accompanying safety messages. Section 5 has further general battery maintenance and

recharging instructions you will find helpful.

STEP1:Activating

and

Charging

the

Battery

IMPORTANT

The

battery

was shipped

"dry."Itneeds

battery

elec-

trolyte fluid

(battery-grade

sulfuric acid)

added

to it.

It

must

then

be fully

charged

with a

battery

charger

before

being used.

Adding electrolyte fluidtothe

battery and battery charging can be

dangerous work. The electrolyte

contains acid that can burn or blind

you. Battery charging also produces explosive gases.

To

ensure that the battery

is

properly activated and charged,

you should review these instructions with your battery technician.

It

is strongly recommended

that

you have the

battery

acti-

vated

and

chargedbya

trained

professional (Troy-Bilt Dealer,

service station,

farm

equipment

dealer, etc.)ifyou

are

not

experi-

enced with these procedures.

DANGER

Battery

produces

explosive

gases.

•

Keep

sparks,

flames,

and

cigarettes

away.

•

Ventilate

area

when

charg-

ingorusing

batteryinan

en-

closed

space.

•

Make

sure

venting

path

of

batteryisalways

open

once

batteryisfilled

with

acid.

16

DANGER

Battery electrolyte fluid is

poisonous

and

burns

severely.

Electrolyteisa sulfuric

acid

solution.

Avoid

spillsorcon-

tact

with

skin,

eyes,

clothing.

•Toprevent

accidents,

wear

protective clothes, rubber

gloves

and

shield

eyes

with

safety

goggles

when

working

onornear

the

battery.

•

Neutralize

acid

spills

with

a

baking

soda

and

water

solution. Neutralize electrolyte

container

with

same

solution.

Then

rinse

with

clear

water.

Antidote:

External-

Flush

with

water;

Eyes-

Flush

with

water

for15minutes

and

get

imme-

diate

medical

attention.

Antidote:

Internal-

Drink

large

quantityofwaterormilk.

Follow

with

milkofmagnesia,

beaten

eggs,orvegetable

oil.

Calladoctor

immediately.

To

Activate

the

Battery:

WARNING

Remove

metal

jewelry

before

working

near

the

battery

or

near

the

electrical system.

Failuretocomply

may

cause

a short circuit, resulting

in

electrical

burns,ashock,

or

explosionofbattery

gases.

For shipping purposes only, the

unserviced battery and its hold-

down clamp were installed back-

wards at the factory. When reinstalling the battery and hold-down

clamp, be sure to turn them around

so they face

in

the opposite direc-

tion from which they were shipped.

A.

Use a 7/16" wrench to remove

the two

I-liz"

long bolts and the two

1/4" whiz nuts securing the front

and rear hold-down clamp legs

to

the battery bracket (Photo 2-23).

Lift off the clamp. Remove battery.

.Save the hardware.

B.

If

there is a short piece

of

sealed plastic tubing covering the

vent fitting on the negative side

of

the battery (see Photo 2-23), remove and discard

it.

C. Put the battery on a level work

surface, far away from heat- or

flame-producing sources like

stoves, water heaters, dryers, furnaces, etc.

D. Take off the six filler caps on

top

of

the battery. Put them aside.

Refer

to

Photo 2-24.

To

Charge

the

Battery:

A. Follow oneofthe three charging methods described next for

maximum starting capacity and

longest battery life.

E.

Be

sure

you

are wearing pro-

tective clothes, rubber gloves

and

eye protection. Fill each celltothe

"Upper Level" line printed on the

battery case using battery-grade

electrolyte solution. (This is 1.265

specific gravity sulfuric acid.)

Temperature

of

battery and electrolyte is ideal when between

60

0

F-to-80°F. Do not add water or

any other liquid to the battery during this initial activation.

F.

Let battery stand for 30 min-

utes. Check electrolyte level

in

each cell. Add more electrolyte

solution if needed. Don't overfill

battery-this could lead to flooding

from the cells during charging.

Note: The electrolyte solution

within the cells

is

gassing freely

when the surface

of

the electrolyte

is covered with small bubbles.

When checking for bubbles, always wear safety goggles to protect eyes. A flashlight makes the

inspection easier. Inspect all cells.

17

Assembly

Photo

2-23:

Remove

hold-down

clamp

(A).

Remove

the

piece

of

clear

plas-

tic

tubing

(B)

if

so

supplied.

Photo

2-24: Remove

all

six

filler

caps

(A).

Fill

each

cell

uptothe

"Upper"

level

line

(B).

Our

Recommended

Method:

Charge the battery at a rateofI-to2 amperes until all cells gas freely.

Do not exceed 24 hours charging.

FirstAlternative Charging Method:

Charge the battery at a rateof4-to6 amperes until all cells gas freely.

Do not exceed 8 hours charging.

Assembly

Second Alternative Charging Method:

Charge the battery at a rate from

6-to-12 amperes until all cells gas

freely. Do not exceed 4 hours

charging time.

B. Turn

off

the charging equipment and disconnect the charger

cables from the battery terminals.

C. Recheck electrolyte level

in

each cell. Top off any low cells

with electrolyte solution up to the

"Upper" level line.

D. Securely replace all six filler

caps. Use a baking soda and water

mixture to rinse off electrolyte that

may have spilled on the battery.

DANGER

Never

jump

start

the

battery

withavehicle

batteryorcharg-

ing

system.

This

may

produce

a battery explosion,

causing

acidorelectrical

burns.

STEP2:Connect

the

Wire

Harness

Receptacle

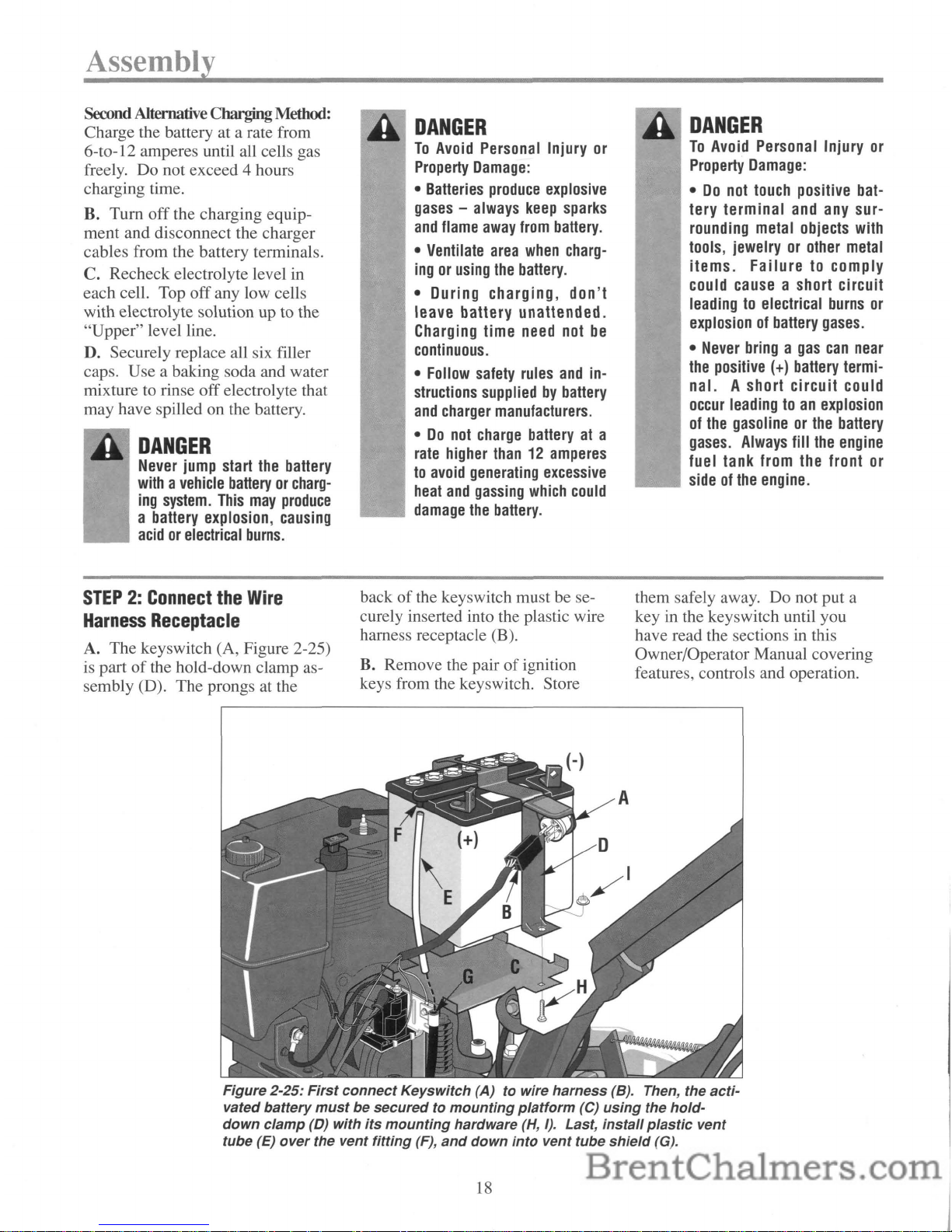

A. The keyswitch (A, Figure 2-25)

is part

of

the hold-down clamp as-

sembly (D). The prongs at the

DANGER

To

Avoid

Personal Injury

or

Property

Damage:

•

Batteries

produce

explosive

gases

- always

keep

sparks

and

flame

away

from

battery.

•

Ventilate

area

when

charg-

ingorusing

the

battery.

• During charging, don't

leave battery unattended.

Charging time

need

not

be

continuous.

•

Follow

safety

rules

and

in-

structions

suppliedbybattery

and

charger

manufacturers.

•Donot

charge

batteryata

rate

higher

than12amperes

to

avoid

generating

excessive

heat

and

gassing

which

could

damage

the

battery.

backofthe keyswitch must be securely inserted into the plastic wire

harness receptacle (B).

B. Remove the pair

of

ignition

keys from the keyswitch. Store

DANGER

To

Avoid

Personal Injury

or

Property

Damage:

•

Do

not

touch

positive

bat-

tery terminal

and

any

surrounding metal objects with

tools, jewelry

or

other

metal

items. Failure to comply

could

cause

a short circuit

leadingtoelectrical

burns

or

explosionofbattery

gases.

•

Never

bringagas

can

near

the

positive

(+)

battery

termi-

nal. A short

circuit

could

occur

leadingtoan

explosion

of

the

gasolineorthe

battery

gases.

Always

fill

the

engine

fuel tank from the front

or

sideofthe

engine.

them safely away. Do not put a

key

in

the keys witch until you

have read the sections in this

Owner/Operator Manual covering

features, controls and operation.

Figure

2-25:

First

connect

Keyswitch

(A)towire

harness

(8). Then, the

acti-

vated

battery

mustbesecuredtomounting

platform

(C)

using

the

hold-

down

clamp

(D)

with

its

mounting

hardware

(H,

I).

Last,

install

plastic

vent

tube

(E)

over

the vent

fitting

(F),

and

down

into

vent

tube

shield

(G).

18

STEP3:Installing

the

Battery

A. Carefully place the activated

battery back on the battery mounting platform as seen in Fig. 2-25.

The sideofthe battery with the

terminals (the posts)

and

the fill

lines on it

must

face the rear

of

the tiller. [Another way to verify

the correct placement

of

the bat-

tery is when the positive

(+) bat-

tery post is on the left side

of

the

tiller as you face forward when

standing behind the handlebars.]

CAUTION

Incorrect installationofthe

battery

can

resultinelectri-

cal

system

damage.

Follow

these

installation

instructions carefullytoavoid

damagetoyour

tiller.

STEP4:Installing

the

Battery

Cables

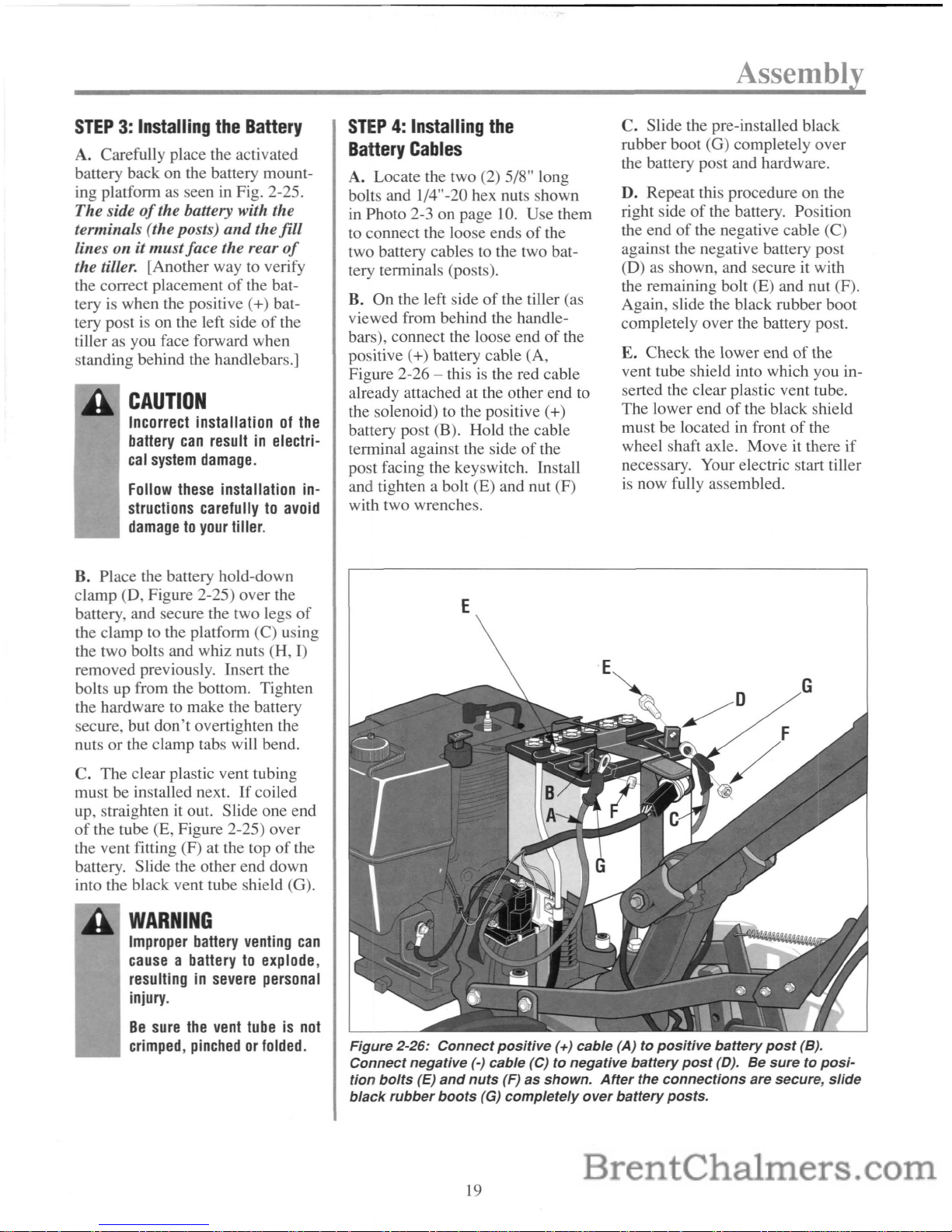

A. Locate the two (2) 5/8" long

bolts and 1/4"-20 hex nuts

shown

in Photo 2-3 on page 10. Use them

to connect the loose ends

of

the

two battery cables to the two battery terminals (posts).

B.

On

the left sideofthe tiller (as

viewed from behind the handlebars), connect the loose

endofthe

positive

(+) battery cable (A,

Figure 2-26 - this is the red cable

already attached at the other end to

the solenoid) to the positive

(+)

battery post (B). Hold the cable

terminal against the side

of

the

post facing the keyswitch. Install

and tighten a bolt (E) and nut (F)

with two wrenches.

Assembly

e.

Slide the pre-installed black

rubber boot (G) completely

over

the battery post and hardware.

D. Repeat this procedure on the

right side

of

the battery. Position

the

endofthe negative cable (C)

against the negative battery

post

(D) as shown, and secure it with

the remaining bolt (E) and nut (F).

Again, slide the black rubber boot

completely

over

the battery post.

E.

Check

the lower

endofthe

vent tube shield into which you inserted the clear plastic vent tube.

The

lower endofthe black shield

must be located in front

of

the

wheel shaft axle.

Move

it there

if

necessary. Your electric start tiller

is now fully assembled.

B. Place the battery hold-down

clamp

(D, Figure 2-25)

over

the

battery, and secure the two legs

of

the clamp to the platform (C) using

the two bolts and whiz nuts (H, I)

removed previously. Insert the

bolts up from the bottom. Tighten

the hardware to make the battery

secure, but

don't

overtighten the

nuts

or

the clamp tabs will bend.

e.

The

clear plastic vent tubing

must

be installed next.Ifcoiled

up, straighten it out. Slide one end

of

the tube (E, Figure 2-25) over

the vent fitting (F) at the top

of

the

battery. Slide the other end down

into the black vent tube shield (G).

WARNING

Improper

battery

venting

can

cause

a batterytoexplode,

resultinginsevere

personal

injury.

Be

sure

the

vent

tubeisnot

crimped,

pinchedorfolded.

E

Figure

2·26:

Connect

positive

(+) cable (A) to

positive

battery

post

(B).

Connect negative (-) cable (C)

to negative

battery

post

(D).Besuretoposi-

tion

bolts

(E)

and

nuts

(F)

as shown.

After

the

connections

are secure,

slide

black

rubber

boots

(G)

completely

over

battery

posts.

19

eclio

Features and Controls

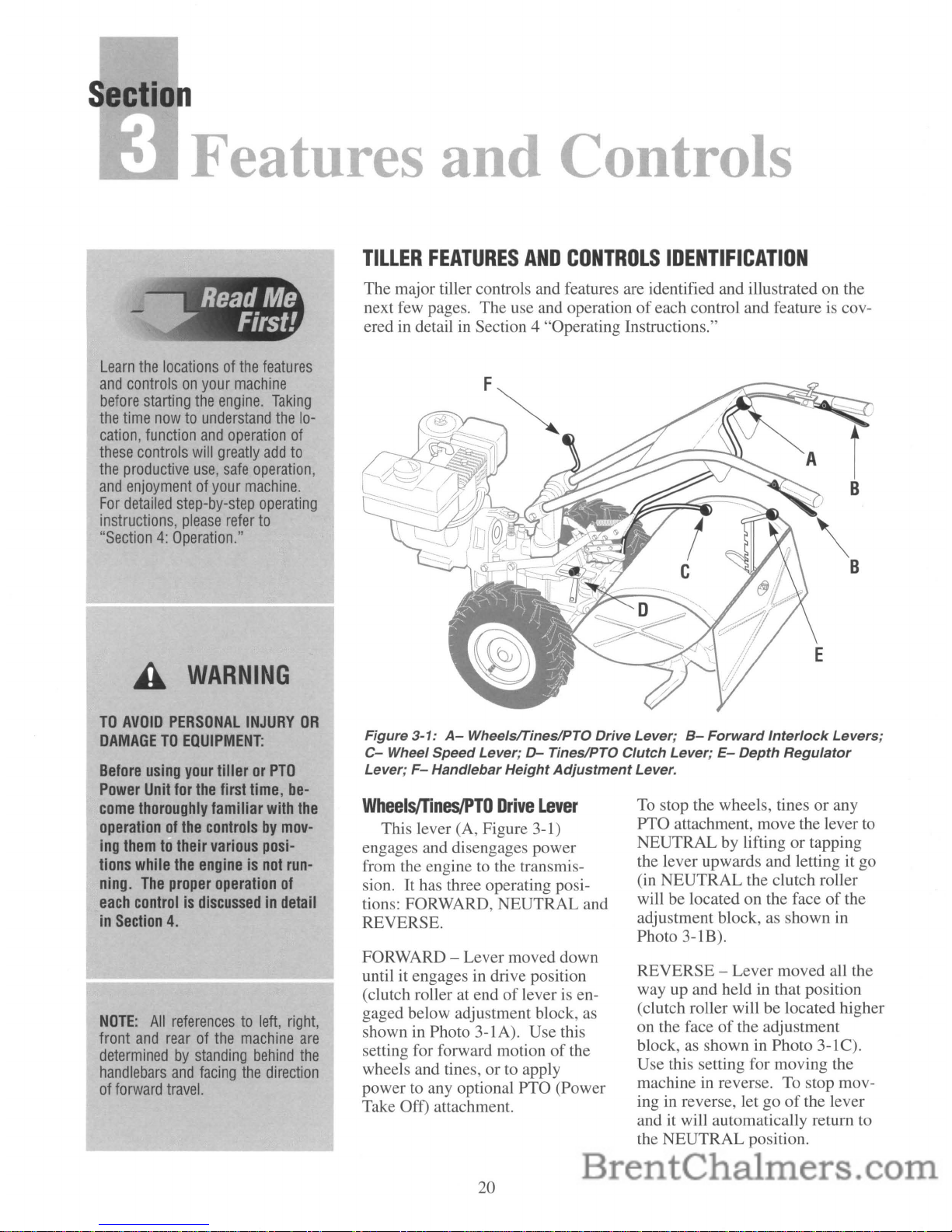

TILLER

FEATURES

AND

CONTROLS

IDENTIFICATION

The major tiller controls and features are identified and illustrated on the

next few pages. The use and operation

of

each control and feature is cov-

ered

in

detail in Section 4 "Operating Instructions."

Figure 3-1:A-Wheelsflines/PTO Drive Lever;

B-

Forward Interlock Levers;

C-

Wheel Speed Lever;D-Tines/PTO Clutch Lever;E-Depth Regulator

Lever;

F-

Handlebar Height Adjustment Lever.

Learn

the

locationsofthe

features

and

controlsonyour

machine

before

starting

the

engine.

Taking

the

time

nowtounderstand

the

lo-

cation,

function

and

operation

of

these

controls

will

greatly

add

to

the

productive

use,

safe

operation,

and

enjoymentofyour

machine.

For

detailed

step-by-step

operating

instructions,

please

refer

to

"Section4:Operation."

WARNING

TO

AVOID

PERSONAL

INJURY

OR

DAMAGETOEQUIPMENT:

Before

using

your

tillerorPTO

Power

Unit

for

the

first

time,

be-

come

thoroughly

familiar

with

the

operationofthe

controlsbymov-

ing

themtotheir

various

posi-

tions

while

the

engineisnot

run-

ning.

The

proper

operation

of

each

controlisdiscussedindetail

in

Section

4.

NOTE:

All

referencestoleft,

right,

front

and

rearofthe

machine

are

determinedbystanding

behind

the

handlebars

and

facing

the

direction

of

forward

travel.

WheelS/Tines/PTO

Drive

Lever

This lever (A, Figure 3-1)

engages and disengages power

from the engine

to

the transmis-

sion.

It

has three operating positions: FORWARD, NEUTRAL and

REVERSE.

FORWARD - Lever moved down

until it engages in drive position

(clutch roller at end

oflever

is engaged below adjustment block, as

shown in Photo 3-1A). Use this

setting for forward motion

of

the

wheels and tines, or to apply

power

to

any optional PTO (Power

Take Off) attachment.

20

To

stop the wheels, tinesorany

PTO attachment, move the lever

to

NEUTRAL by liftingortapping

the lever upwards and letting it go

(in NEUTRAL the clutch roller

will be located on the face

of

the

adjustment block, as shown in

Photo

3-lB).

REVERSE - Lever moved all the

way up and held in that position

(clutch roller will be located higher

on the face

of

the adjustment

block,

as

showninPhoto 3-1C).

Use this setting for moving the

machine in reverse. To stop moving in reverse, let go

of

the lever

and it will automatically return to

the NEUTRAL position.

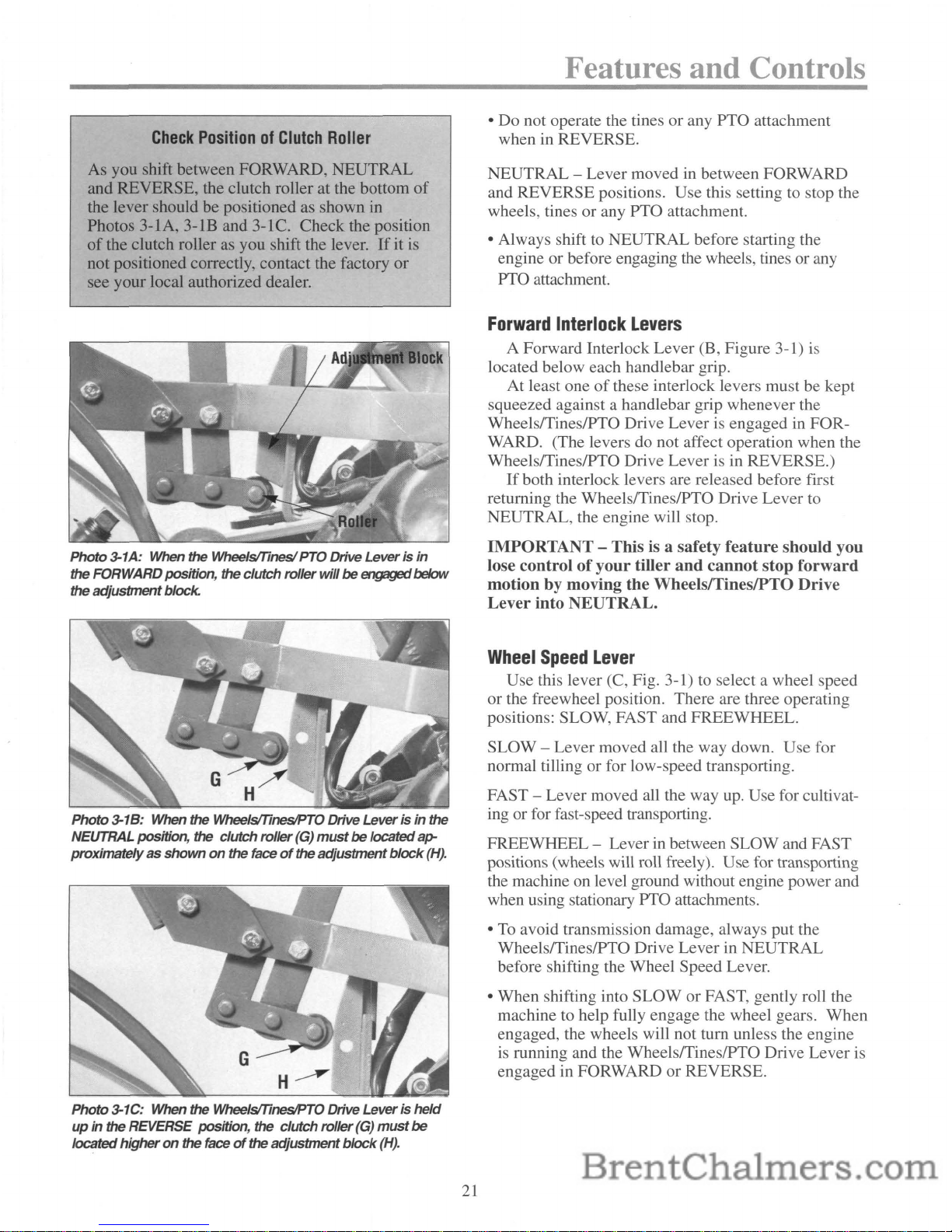

Check

PositionofClutch

Roller

As you shift between FORWARD, NEUTRAL

and REVERSE, the clutch roller at the bottom

of

the lever should be positioned as shown in

Photos 3-1A,

3-lB

and 3-1C. Check the position

of

the clutch roller as you shift the lever.Ifit

is

not positioned correctly, contact the factory or

see your local authorized dealer.

Photo

3-1A: When

the

WheelslTinesi PTO Drive

Leverisin

the

FORWARDposition, the

clutch

roller

will

be

engaged below

the

adjustment

block.

Photo

3-1

B:

When

the

WheelslTinesIPTO Drive

Leverisin

the

NEUTRALposition,

the

clutch

roller

(G)

mustbelocated

atr

proximatelyasshown

on

the

face

of

the

adjustment

block

(H).

H~

Photo

3-1C: When the WheelslTinesIPTO Drive

Leverisheld

upinthe REVERSE position,

the

clutch

roller

(G)

must

be

located

higheronthe face

of

the

adjustment

block

(H).

21

Features and Controls

• Do not operate the tines or any

PTa

attachment

when in REVERSE.

NEUTRAL - Lever moved in between FORWARD

and REVERSE positions. Use this setting to stop the

wheels, tines or any

PTa

attachment.

• Always shift

to

NEUTRAL before starting the

engine or before engaging the wheels, tines or any

PTa

attachment.

Forward

Interlock

Levers

A Forward Interlock Lever (B, Figure 3-1) is

located below each handlebar grip.

At least one

of

these interlock levers must be kept

squeezed against a handlebar grip whenever the

WheelsfTineslPTO Drive Lever

is

engaged in FOR-

WARD. (The levers do not affect operation when the

WheelsfTineslPTO Drive Lever is in REVERSE.)

If

both interlock levers are released before first

returning the WheelsfTines/PTO Drive Lever to

NEUTRAL, the engine will stop.

IMPORTANT - This is a safety feature should you

lose control

of

your

tiller

and

cannot

stop

forward

motion by moving the WheelslTineslPTO Drive

Lever into NEUTRAL.

Wheel

Speed

Lever

Use this lever (C, Fig. 3-1)toselect a wheel speed

or the freewheel position. There are three operating

positions: SLOW, FAST and FREEWHEEL.

SLOW - Lever moved all the way down. Use for

normal tilling or for low-speed transporting.

FAST - Lever moved all the way

up.

Use for cultivat-

ing or for fast-speed transporting.

FREEWHEEL - Lever

in

between SLOW and FAST

positions (wheels will roll freely). Use for transporting

the machine on level ground without engine power and

when using stationary

PTa

attachments.

•

To

avoid transmission damage, always put the

WheelsfTineslPTO Drive Lever in NEUTRAL

before shifting the Wheel Speed Lever.

• When shifting into SLOW or FAST, gently roll the

machine to help fully engage the wheel gears. When

engaged, the wheels will not turn unless the engine

is

running and the WheelsfTineslPTO Drive Lever is

engaged in FORWARD or REVERSE.

Loading...

Loading...