Troy-Bilt Pro line 675B-Pony Operator's Manual

0 TRtlV:BILT°

Operator's Manual

Rear-tine Tiller Model

675B--Pony ®

Model 675B Shown (bumper syles vary)

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit is equipped withan internal combustion engineand should not be usedon ornear any unimproved forest-covered, brush-covered or

grass-covered land unlessthe engine's exhaustsystem is equipped with aspark arrestor meeting applicable local or statelaws (if any). tf aspark arrestor is used, it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

ResourcesCode). Otherstates may have similar laws, Federallaws apply onfederal lands, A spark arrester for the muffler is availablethrough your nearest engine

authorized servicedealeror contact the service department, P,0, Box 361131Cleveland, Ohio44136-001 g.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTEDIN U.S.A. FORMNO. 769-00586A

9/22/03

TABLEOFCONTENTS

Content Page Content Page

Customer Support Maintenance 16

Safety 3 Off-season Storage 18

Assembly 6 Troubleshooting 23

Features and Controls 9 Parts List 24

Operation 11 Warranty Information Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new rear-tine tiller. It will help you assemble, prepare and maintain

the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

¢

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by standing behind the unit and looking down at rear surface of the tine shield. This

information will be necessary to use the manufacturer's web site and/or help from the Customer Support

Department or an authorized service dealer.

Copy the model number here:

Copy the serial number here:

www.t roybilt.com _L__U_5_SO_ _

CUSTOMERSUPPORT

PleasedoNOTreturnthe unittothe retailer fromwhereit waspurchased,withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

will get the four options reproduced here. Click on the appropriate button and help is

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

_mmediately available.

7_@ 8nswe_ you 8Fe " _e 8rtswer you ale

8 mouse crick away! "'"'° 8 mouse click away!

,

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regards to

)erformance,

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

power-rating, specifications, warranty engine

and service. Please refer to the

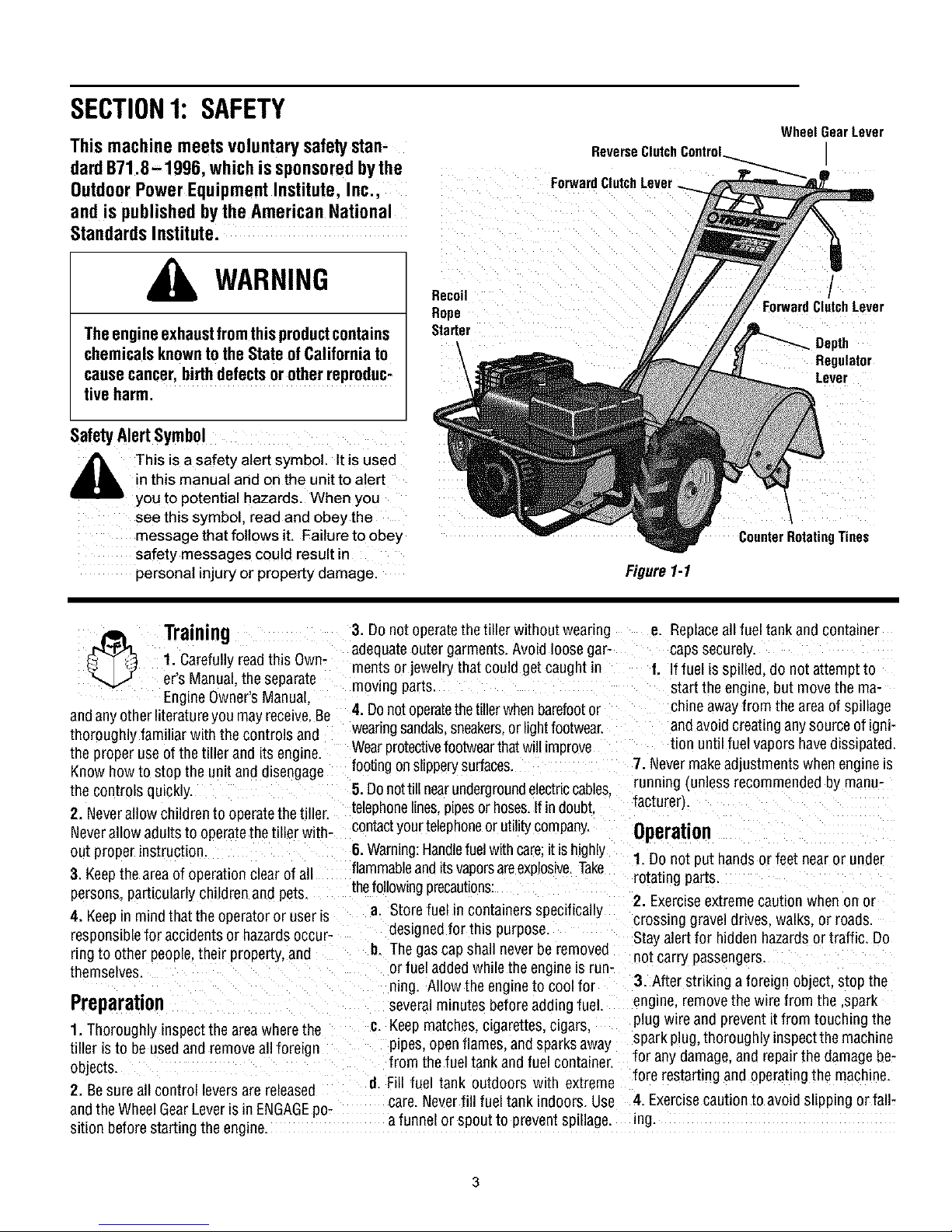

SECTION1: SAFETY

Thismachinemeetsvoluntarysafetystan-

dardB71.8-1996, whichis sponsoredbythe

OutdoorPowerEquipmentInstitute,Inc.,

andis publishedbythe AmericanNational

StandardsInstitute.

WheelGearLever

ReverseClutch

ForwardClutchLever

WARNING

Theengineexhaustfromthisproductcontains

chemicalsknowntotheStateofCaliforniato

causecancer,birthdefectsor otherreproduc-

Recoil

Rope

Starter

ForwardCl!tchLever

Regulator

Lever

tiveharm.

Safety Alert Symbol

i_ This is a safety alert symbol• Itis usec

in this manual and on the unit to alert

you to potential hazards. When you

see this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

personal injury or property damage.

Figure1-1

CounterRotatingTines

Training 3. Donot operatethetiller without weadng e. Replaceall fuel tank and container

j4.."P/_h. _ ^ . _ . ..i .. adequateouter garments•Avoid loosegar- caps securely•

I _J ]. uarerully reao[nls uwm ments orjewelry that could get caught in f. If fuel is spilled donot attempt to

_ ers :'v_nua_meseparate moving parts, start the engine, but movethe ma-

andanyotherliteratureyou mayreceive,Be 4.Donotoperatethetiller whenbarefootor chine awayfrom the areaof spillage

thoroughly familiar with the controls and weadngsandals,sneakers,or lightfootwear, andavoid creating any source of igni-

the nroneruse ofthe tiller and its ermine Wearprotectivefootwearthatwill improve tion until fuel vapors havedissipated.

Knowh_wtoosopt theunit anddsein_gage footingonslipperysurfaces. 7 Nevermakeadjustments whenengne s

the controls quickly 5 Donott nearundergroundeectrccabes, "

2. Neverallow childrento operatethetiller•

Neverallowadultsto operatethetillerwith-contactyourtelephoneorutilitycompany. Operation

out properinstruction 6. Warning:Handlefuel with care;it is highly 1 Dolopunt t banes....

3. Keepthe area of operation clear of all flammableandits vaporsareexplosive,Take rotatingparts.

p"r...... _i°' I°rl• _"il" ..... , _.t _ thefollowingprecautions:

_u._, _,_ _u _ y _u u_,, _,,u _ _. . . .. 2. Exerciseextremecaution when on or

4. Keepin mindthat the operatoror useris • crossing gravel drives, walks, or roads.

responsiblefor accidentsor hazardsoccur- " " " Staya errfor h dden hazardsortraff c Do

ringto other people their property, and h. Tbegascapshall neverbe removed not'carry passengers '

themselves• or rue_addeown _ethe eng ne s run-

EHylHU UWHg/b IVI_HU_I_

• • • • facturer).

• . . .

telephonehnes,pLpesor hoses Ifin doubt,

a Store fuel in containers specifically

desLgnedfor this purpose

ning. Allow the engine to cool for 3. After striking aforeign object,stop the

runmng (unlessrecommended by manu

near or

O!

!ee!

unoer

Preparation severalminutes beforeaddingfuel• engine, removethe wire from the ,spark

1.

Thoroughly

tiller ist0 be usedand removeall foreign pipes,openflames, andsparksaway f_is_arK[lUnpgm,norou(m_._,ns ec,memacmneiPrth"m "

objects, from the fuel tank and fuel container.

inspectthe area

wherethe

c. Keepmatches, cigarettes,cigars, plugwire andpreven! 1!fromtouching the

o a yea age,a o epa eoa ageoe

2.Besureallcontroileversarereieased Fillfueltankoutdoorswithextremeforeresta ingandoperatingthemachine.

andtheWheelGearLeverisin ENGAGEno care.Neverfill fuel tank indoors. Use 4•Exercisecaution to avoid slipping or fall-

.... _ " afunnel or spout to prevent spillage ng

s_ton beforestart ngthe engne. " "

5.Iftheunitshouldstarttovibrateabnormally,

stoptheengine,disconnectthesparkplug

w_reandpreventitfromtouchingthespark

plug,andcheckimmediatelyfor thecause.Vi-

bration [sgenerallyawarning of trouble.

6. Stopthe engine, disconnectthe spark

plugwire and prevent it from touch[% the

spark plug wheneveryou leavethe operat- d. Avoidusingdownwardpressureon

ing position, before unclogging thetines.

or when making any repairs, adjustments

or inspections.

7. Takeallpossible precautionswhenleav-

ing the machine unattended.Stopthe en-

gine. Disconnectspark plug wLreand

move it away from the spark plug. Move

WheelGearLeverto ENGAGE.

8. Beforecleaning, repairing, orinspect-

ing, stop theengineand makecertain all

mowng parts havestopped. Disconnect

the sparkplug wire and prevent it from

touching the spark plug to preventacci-

dentalstarting.

9. Always keepthe tiller tine hoodflap

down.

10. Neverusethe tiller unless proper

guards, plates,orothersafetyprotectivede- 17. Do notoperatethetiller ona slopethat

vicesare_nolace, is too steepfor safety. When on slopes,

11.Do not run engineinan enclosedarea. slow down andmakesure you havegood

Engineexhaust containscarbonmonoxide tooting. Neverpermitthetiller to freewheel

gas, adeadly poisonthat is odorless col-

orless,andtasteless.

12. Keepchildren and pets away.

13.Neveroperatethe tiller underengine

powerifthe WheelGearLever is in DIS-

ENGAGE(FREEWHEEL).tnthis position,

thewheelswill notholdthe tiller back

andthe revolvingtinescouldpropelthe

tiller rapidlybackward,possiblycausing

loss ofcontrol.Always movethe Wheel

GearLeverto ENGAGEbeforestarting the

engine or engagingthe tines_vheelswith

the ForwardClutchorthe ReverseClutch.

14. Beawarethatthe tiller may unexpect-

edly bounceupward or jumpbackwardil

thetines should strike extremely hard

packedsoil, frozen ground, or buried ob-

stacleslike largestones, roots, or stumps.

If in doubt aboutthe tilling conditions al-

ways usethe following operating precau-

tions to assist you in maintaining control

of thetiller:

a. Walk behindandto one sideofthe 25.Pleaseremember:Youcanalwayss_opthe

tiller, usingone handonthe han- tinesandwheelsbyreleasingtheForward

dlebars. Relaxyourarm. butusea ClutchLeverortheReverseClutchControl

secure handgrip. _whicheverleveryouhaveengaged)orbymov-

b. Useslower engme speeds, ingtheThrottleControlLeverto STOR

c. Clearthe tilling area of all large 26. Toloador unloadthetiller,seetheinstruc-

stones, rootsand other debris, tigrisinSection4 of this Manual

handlebars.If need be, useslight

upwardpressureto keepthe tines

from diggingtoo deeply.

e. Beforecontactinghardpackedsoil

at theend of a row. reduceengine

speedandlift handlebarstoraise

tines outof thesoil.

f. tn anemergency,stoptinesand

wheels byreleasingwhichever

ClutchLeverisengaged.Donotat-

temptto restrainthe tiller.

15. Donot overloadthe tiller's capacity by

attempting to till too deeplyattoo fast a

rate

16. Neveroperatethe tiller at high trans-

port speedson slLpperysurfaces. Lookoe-

hind and use carewhen backingup

down slopes.

18. Neverallow bystanders nearthe umt.

19. Ontyuseattachmentsandaccessories

that are approved by GardenWay Inc.

20. Usetiller attachmentsandaccessories

when recommended.

21. Neveroperatethetiller withoutgoodvis-

ibility or light.

22.Neveroperatethetilleril youaret_red,or Maintenancesection ofthis Manualandthe

underthe influenceofalcohol,drugsor medi- separateEngMeOwner'sManualfor in-

cation, struefions ifthe tiller is to be storedfor an

23.Operatorsshallnottamperwiththeengine-

governorsettingsonthemachine:thegovernor

controlsthemaximumsafeoperatingspeedto

protecttheengineandallmovingpartsfrom

damagecausedbyoverspeed.Authorizedser-

viceshallbesoughtira problemexists.

24.Donottouchenginepartswhichmaybe outdoors,

hotfrom operation.Letdartscooldown

27.Useextremecautionwhenreversingor

pullingthe machinetowardsyou,

28.Starttheenginecarefullyaccordingtoin-

structionsandwithfeetwellawayfromthe

trees.

29. Never3ickuporcarryamachinewhilethe

engineis running.

MaintenanceandStorage

1. Keepthe tiller,attachments and acces-

sories in safe workingcondition.

2. Checkall nuts. bolts, and screwsatfre-

quent intervalsfor proper t_ghmessto be

surethe equipment is in safeworking con-

dition.

3. Neverstorethetillerwithfuelinthefueltank

insideabuildingwhereignitionsourcesare

presentsuchashotwaterandspaceheaters

furnaces,clothesdryers,stoves,electricmo-

tors,etc.). Allowenginetocoolbeforestoring

inanyenclosure.

4.Toreducethechancesofafirehazard,keep

theenginefreeel grass,leaves,or excessive

grease.

5. Storegasoline in a cool.well-ventilated

area.safelyawayfrom anyspark-or flame-

producingequzpment.Storegasolinein an

approvedcontainer,safelyawayfrom the

reachofchildren.

6. Referto the storageinstructions in the

extendedpedod.

7. Neverperformmaintenancewhiletheen-

gine _srunmngor the sparkplugwire is

connected,exceptwhenspecifically _n-

structedto do so.

8. If thefueltankhasto bedrainer, dothis

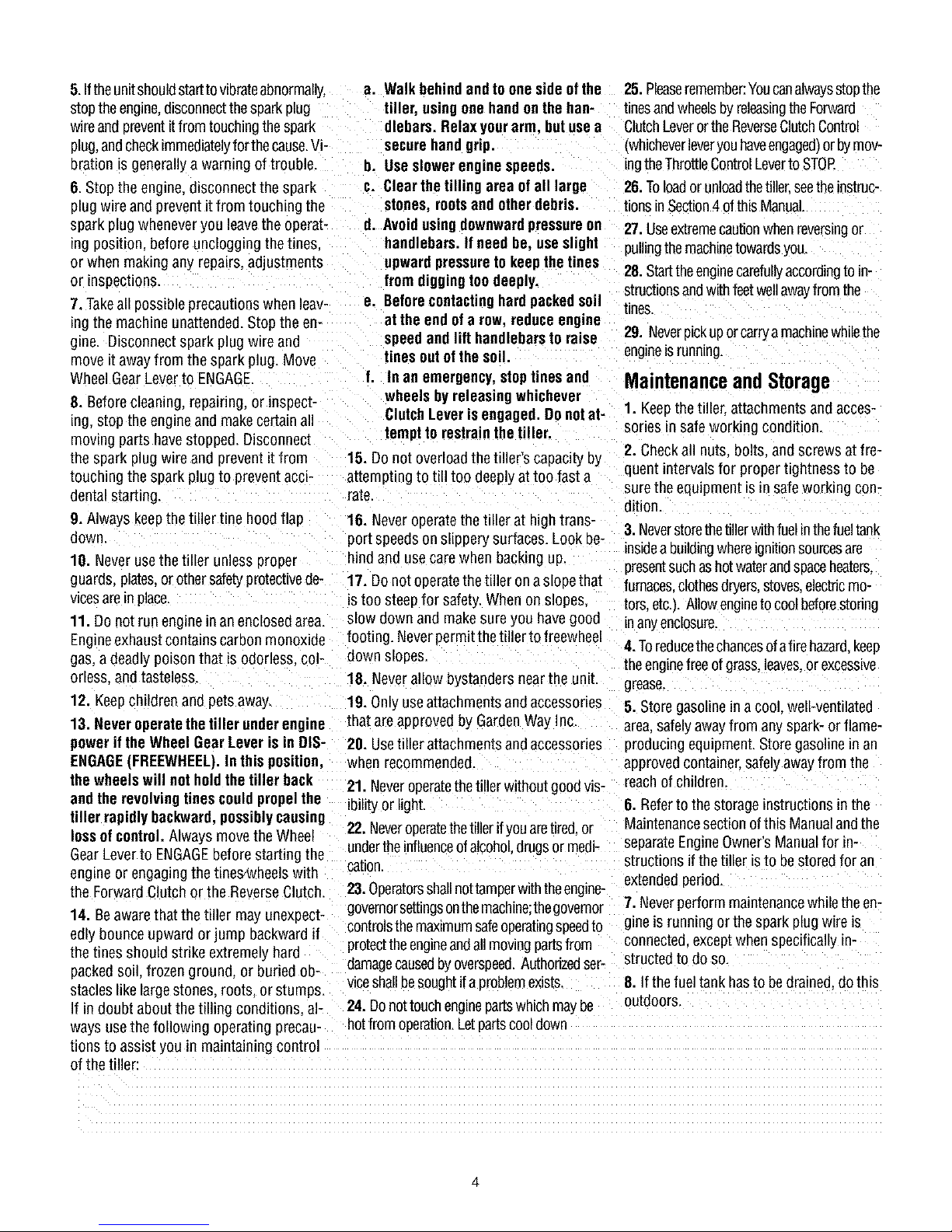

SafetyDecals

Foryour safetyandthe safetyof others,

various safety and operational decals are

located on your unit (see Figure 1-2 be-

low).

Keep the decals clean and legible at all

times. Contact your local service dealer or

the factory for replacements if any decals

are damaged or missing.

Refer to the Parts List in this manual for

decal locations, part numbers and ordering

instructions.

TineWarning

Message{onengine)

StartingStabilization _

ControlDescription

(onControlPanel)

WarningMessages

(onUnehood)

HotSurfaces_MovingBelts

Warning(on belt cover)

OperatingSymbols

Var_ss_nbds(shownhere,w_worddes_p_ons)

maybeusedonlhel_lera_lengine.

NOTEYour_maynotl_vea#ofb'Tesymbo_

0

FAST SLOW STOP

• READTHEOPERATOR'SMANUAL.

• KNOWLOCATIONSANDFUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUT OFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROM ROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

Figure1-2:Locationof Safetyand OperatingDecals

I-,-I I11

CHOKE CHOKE

OH OFF

TILLERDIRECTION

TO AVOIO SERIOUS INJURY:

R

REVERSE

ROTATINGTINES

LEVERDIRECTION

SECTION2: ASSEMBLY

WARNING: To prevent

personalinjury or property Ref.

damage,do notstartthe engine

until allassemblysteps are 1

completeandyou haveread

and understandthe safety and 4

operating instructions in this

Manual.

Introduction

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthatyou readthisSectionin

its entirety before beginningassembly.

Inspectunit

Inspectthe unitand carton for damageim-

mediatelyafterdelivery. Contactthe carri-

er (trucking company) if you find or

suspectdamage. Inform themof thedam-

ageand request instructions for filing a

claim. To protectyour rights, put your

claim in writing and maila copy to thecar-

rier within 15 daysafter the unit has been

delivered. Contactus at the factory if you

needassistancein this matter.

UnpackingandAssembly

Instrutions

STEP1:UNPACKINGINSTRUCTIONS

1. Removeanycard-board inserts and

packaging materialfrom the carton. Re-

move anystaplesfrom the bottom ofthe

carton and removethe carton.

2. Cutthe large,plastictie strap that se-

curesthetransmissiontube to theshipping

pallet. Leavethe handlebarson top of the

tiller to avoid damaginganycables.

3. A bagwith loose hardwareis insidethe

literature envelope. Checkthe contents

againstthe following list and Figure2-1.

Contactyour localdealer or the factory if

anyitems are missing or damaged.

NOTE: Forelectric start units, a second

hardwarebagis locatednearthe battery.

4. Thetiller is heavy. You should not at-

tempt to remove itfrom the shipping plat-

form until instructed to do so in these

"Assembly" steps.

HardwareBagParts List

Qty. Description

2 3/8-16 x 1" HexHd. Screw

2

1 KeyedWasher

3

1 WheelGearLeverKnob

1 HeightAdjustment Flange

(SeeFigure2-2)

5

2 3/8" FlatWasher

6

2 #10 Lockwasher

7

2 3,8"-16Nylock Lock Nut

8

2 #10-32x 1/2" RndHd Screw

9

2 #10-32Nut

10

1 Cotter Pin (not used)

11

4 Plastic TieStrap (2 not used)

Tools/ MaterialsNeeded

forAssembly

(1) 3/8" open-endwrench*

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench"

(1) Scissors (to trim plasticties)

(1) Ruler

(1) Smallboard(to tap plastic knobon

lever)

(1) Tire pressuregauge

(1) Cleanoil funnel

(1) Clean,high-qualitymotor oil. Referto

the separateEngineuwner's Manual

for motor oil specificationsand quan-

tity required.

* Adjustablewrenches may be used.

IMPORTANT:Motor oil must beaddedto

theenginecrankcasebeforetheengine is

started. Followthe instructions in this

"Assembly" Sectionand inthe separate

EngineOwner'sManual.

NOTE: LEFT and RIGHT sides of the

tiller are as viewed from the

operator's position behind the

handlebars.

STEP2: ATTACHHANDLEBARS

1. Cut the large,plastic cableties that se-

cure the handlebarends to the handlebar

mounting tabs on the transmission top

cover.

2. Gentlylift handlebar(do notoverstretch

attachedcable) and placehandlebarcross-

brace(B, Figure 2-3) in front of curved

heightadjustment bracket(C).

2

Figure2-1:Loosehardware(showninre-

ducedsize).

Figure2-2:Handlebarheightadjustmentuses

theflangeheadscrew.

Figure2-3: Forwardclutchcontrolcablenot

shownforclarity.

3. Withtheforwardclutchcable (N, Fig-

ure2-4) onthe insideofhandlebar,posi-

tion the handlebarends on the outside of

thetwo mounting tabs (M, Figure2-3) on

thetransmission top cover.

NOTE:Thecurved handlebar heightad-

justmentbracketappearsas shown in C,

Figure2-3for non-electricstart units. For

electricstart units, the bracketisloosened

and moved to one side.

4. Looselyattachthe handlebarsto the

mounting tabs with two 3/8-16 x1"screws

(headsof screws goto inside oftabs), 3/8"

flat washersand 3/8"-16 lock nuts (0, Fig-

ure 2-4).

3

Figure2-4: Attachhandlebars.

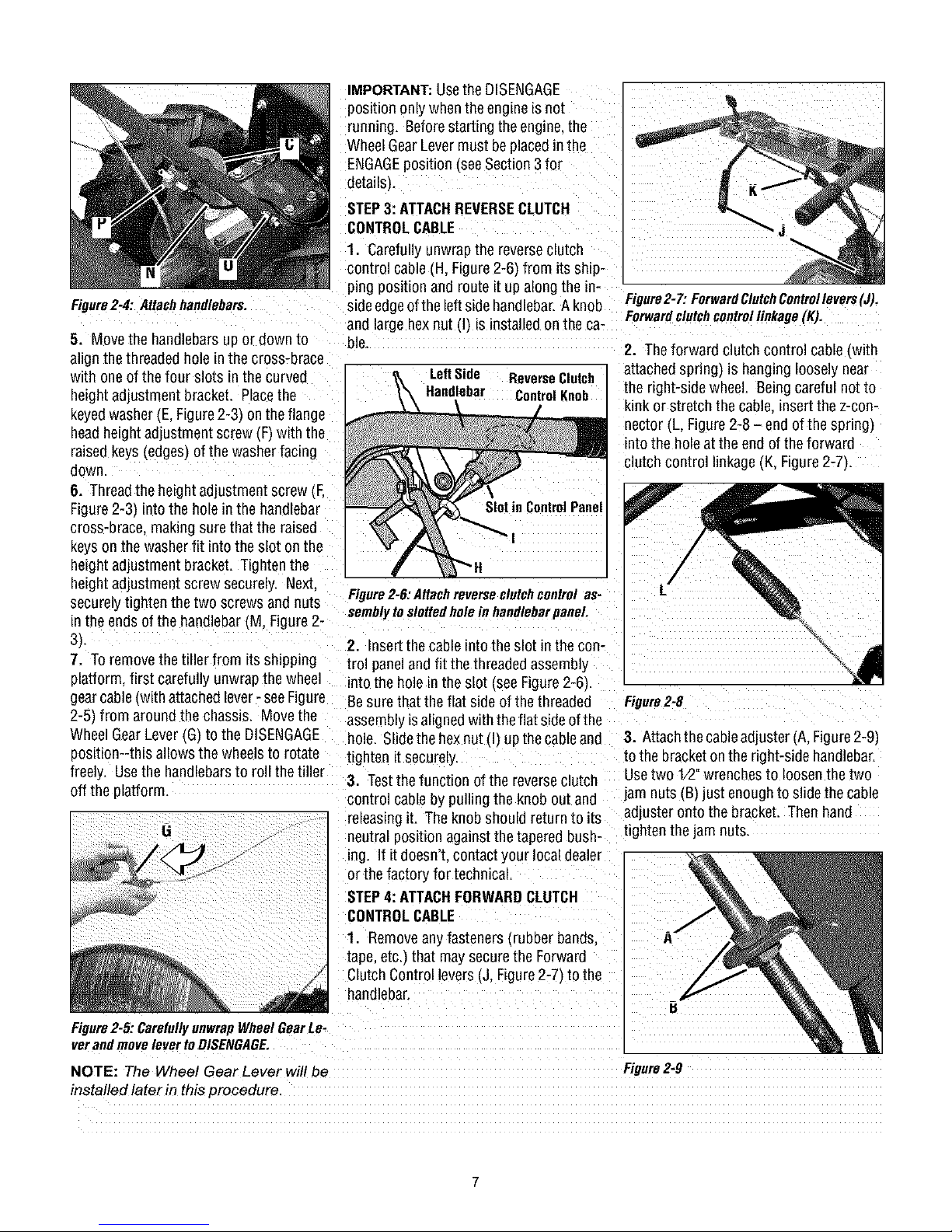

5. Movethe handlebars upor down to

align the threadedholein the cross-brace

with one of thefour slots in the curved

height adjustmentbracket. Placethe

keyedwasher(E, Figure2-3) onthe flange

headheightadjustment screw(F)with the

raisedkeys(edges) of the washerfacing

down.

6. Threadthe height adjustment screw (F,

Figure2-3_into the hole in the handlebar

cross-grace, makingsurethatthe raised

keysonthe washerfit into the slot on the

height adjustmentbracket. Tightenthe

height adjustmentscrew securely. Next.

securelybghtenthe two screws and nuts

in the ends ofthe handlebar IM, Figure 2-

3_

7. Toremovethe tiller from its shipping

platform, first carefully unwrapthe wheel

gearcable(with attachedlever- seeRgure

2-5 from aroundthe chassis. Movethe

WheelGearLever IG)to the DISENGAGE

position--this allows the wheels to rotate

freely. Usethe handlebarsto roll the tiller

off the platform.

13

Figure2-5: Carefullyunwrap Wheel Gear Le-

verandmove lever to DISENGAGE.

NOTE: The Wheel Gear Lever will be

installed later in this procedure.

IMPORTANT:Usethe DISENGAGE

position onlywhenthe engine isnot

running. Beforestarting theengine, the

WheelGearLevermust beplaced in the

ENGAGEposztlontsee Section3 for

detailsL

STEP3: ATTACHREVERSECLUTCH

CONTROLCABLE

1. Carefullyunwrap the reverseclutch

control cable(H, Figure2-6) from itsship-

pingposition and route it up alongthe in-

sideedgeofthe left side handlebar.A knob

and large hex nut (1_isinstalledonthe ca-

Die

LeftSide ReverseClutch

Handlebar ControlKnob

Figure2-7: ForwardClutchControllevers(J),

Forwardclutchcontrollinkage(K).

2. Theforward clutch control cable twith

attachedspring) is hanging loosely near

the right-side wheel. Being carefulnot to

kink or stretch the cable,insertthe z-con-

nector (L, Figure2-8-end of the spring}

into the hole atthe end of the forward

clutch control linkage(K, Figure2-7).

Figure2-6,"Attachreverseclutchcontrol

semblytoslottedholeinhandlebarpaneL

2. Insert thecable into the slot in the con-

trol paneland fit the threaded assembly

into the hole in the slot (seeFigure2-6).

Besure that the flat side ofthe threaded

Figure2-8

assemblyisalignedwith the flat side ofthe

hole. Slidethe hexnut(I) upthecable and

tighten it securely

3. Testthe funcbon of the reverseclutch

control cableby pulling the knob out and

releasingit. The knob should returnto its

neutral positionagainst the tapered bush-

3. Attachthecableadjuster (A, Figure2-9)

tothe bracket on the right-side handlebar

Usetwo 1/2 wrenches to loosen thetwo

lam nuts(B) just enoughto slide the cable

adjuster onto the bracket. Thenhand

tighten the jam nuts.

ing. If it doesn't, contact your localdealer

orthe factory fortechnical.

STEP4: ATTACHFORWARDCLUTCH

CONTROLCABLE

1. Removeany fasteners (rubber bands. A

tape, etc.I that may securethe Forward

ClutchControllevers (J, Figure2-7) to the

handlebar.

Figure2-9

/

L

B

CAUTION: Incorrect cable

adjustment couldcausethe

wheelsandtines to rotate

unexpectedly. Follow

a_ ustment procedures

carefully. Failureto dosocould

result in personal injury or

property damage.

4. Checkfor correct spring cable tension

asinstructed in Section 5. Checking and

Adjusting Forward Clutch Belt Tension.

5. Whentensioniscorrect,tighten thetwo

jam nuts (B) securely

STEP5: CHECKTRANSMISSIONGEAR

OILLEVEL

Thetransmission wasfilled with gearo11at

thefactory. However besure to checkthe

oil levelatthis time to makecertain it is

correct.

IMPORTANT:DOnot operatethe tiller if

thegearoil levelis low.Doingso will result

Enseveredamagetothe transmission

components.

Figure2-11: Addinggearoil.

NOTE: Do not use automatic

transmission fluid or motor oil in the

transmission.

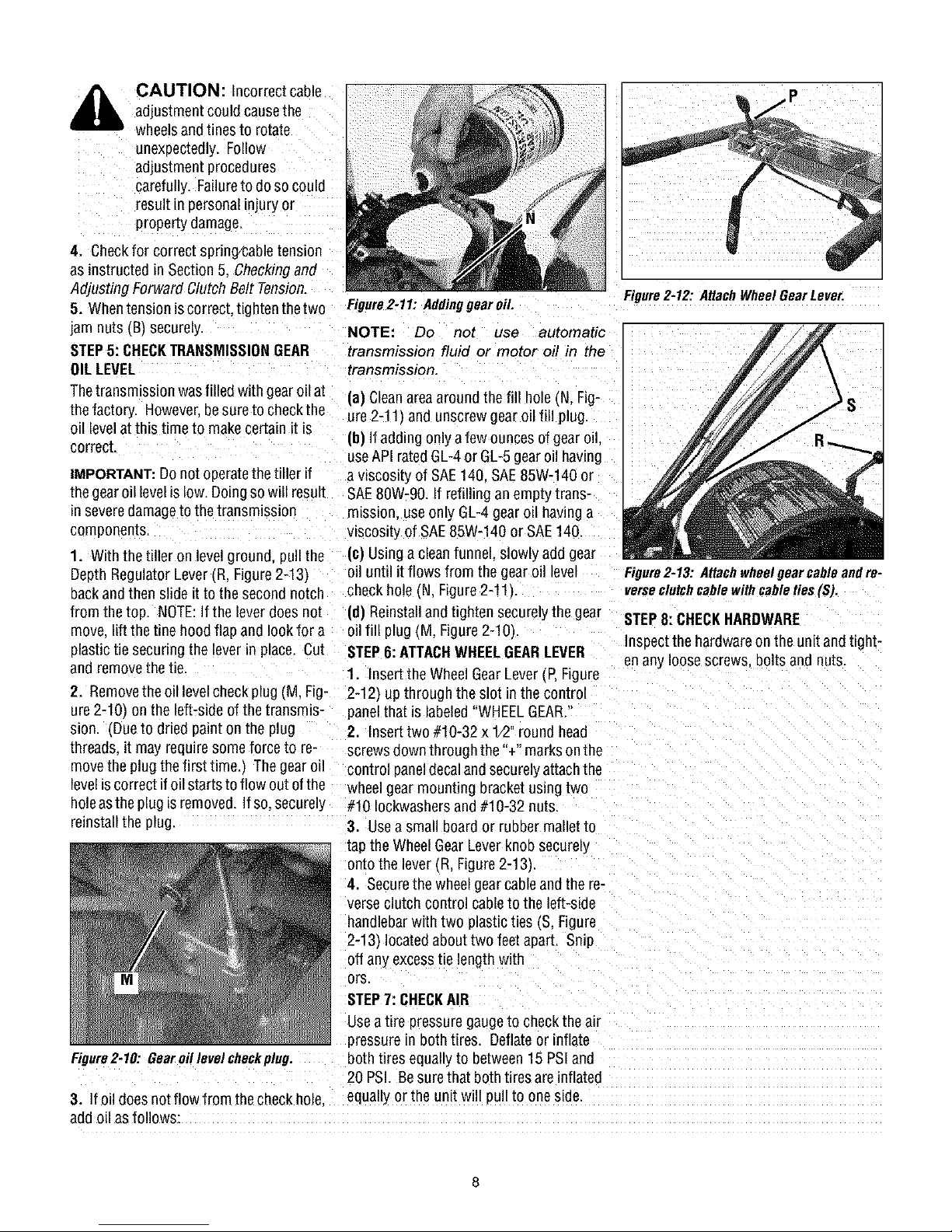

(a) Cleanareaaround the fill hole (N,Fig-

ure 2-11_and unscrewgearoil fill plug.

ib) If addingonly afew ouncesof gear oil,

useAPIrated GL-4or GL-5gearoil having

a wscostty of SAE140. SAE85W-140 or

SAE80W-90. If refilling an empty trans-

mission, useonly GL-4gear o_1havinga

wscosdy of SAE85W-140 or SAE140.

1. With the tiller on level ground, pull the (c) Using acleanfunnel, slowly add gear

Depth Regulator Lever _R.Figure2-13)

backand then slide it to the second notch

from the top. NOTE:If the lever doesnot

move. liftthe tine hood flap and lookfor a

plastictie securing the lever in place. Cut

and removethe tie.

oil until itflows from the gear oil level

checkhole _N.Figure2-11)

id) Reinstall and tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP6:ATTACHWHEELGEARLEVER

1. Insertthe Wheel GearLever (P,Figure

2. Removetheoil levelcheck plug (M, Fig- 2-12_up through the slot in the control

ure 2-10 onthe left-side ofthe transmis- panelthat is labeled"WHEELGEAR.'

sion. _Dueto dried paint on the plug 2. Inserttwo #10-32 x 1/2"round head

threads,it may requiresomeforce to re- screwsdownthrough the "+" marksonthe

movethe plug the first time._ The gearoil control paneldecalandsecurelyattachthe

leveliscorrect ifoil starts to flow out ofthe wheelgearmounting bracket usingtwo

holeasthe plugisremoved. If so.securely #10 Iockwashersand #10-32 nuts.

reinstall the plug.

3. Usea small boardor rubber mallet to

tap the Wheel GearLever knobsecurely

onto the lever (R. Figure 2-13).

4. Securethe wheel gearcable andthe re-

verseclutch control cable to the left-side

handlebarwith two plasticties (S, Figure

2-13_locatedabout two feet apart. Snip

off anyexcesstie lengthwith

ors.

STEP7: CHECKAIR

Usea tire pressuregaugeto checkthe air

pressure in both tires. Deflateor inflate

Figure2-10: Gearoillevelcheckplug.

both tires equallyLobetween15 PSIand

20 PSI. Besurethat both tires areinflated

3. If oil doesnotflow from thecheckbole.

equallyorthe unit w_llpull to one side.

addoil as follows:

Figure2-12: AttachWheelGearLever.

Figure2-13: Attachwheelgearcableandre-

verseclutchcablewithcableties(S).

STEP8:CHECKHARDWARE

Inspect the hardwareon the unit andtight-

enany loose screws, bolts and nuts.

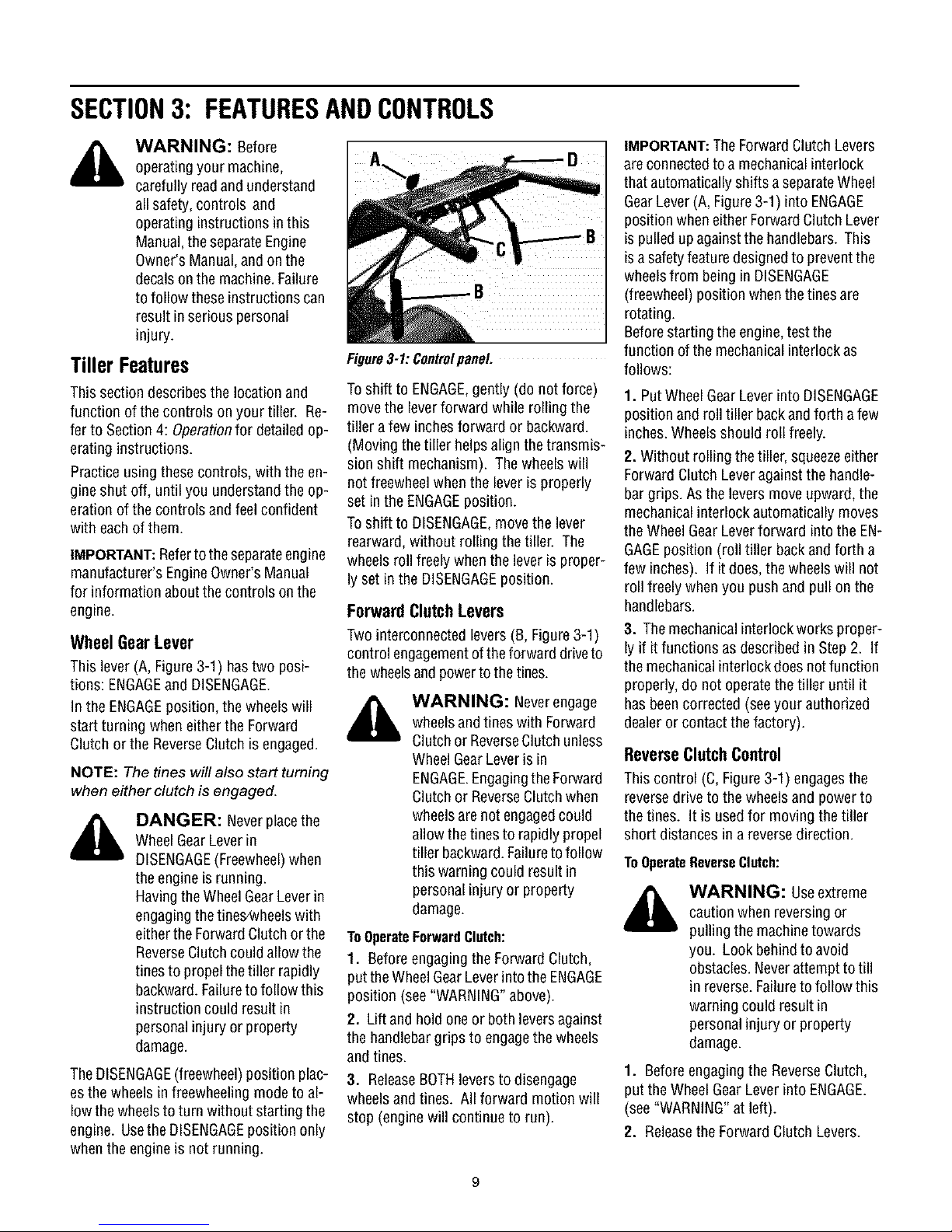

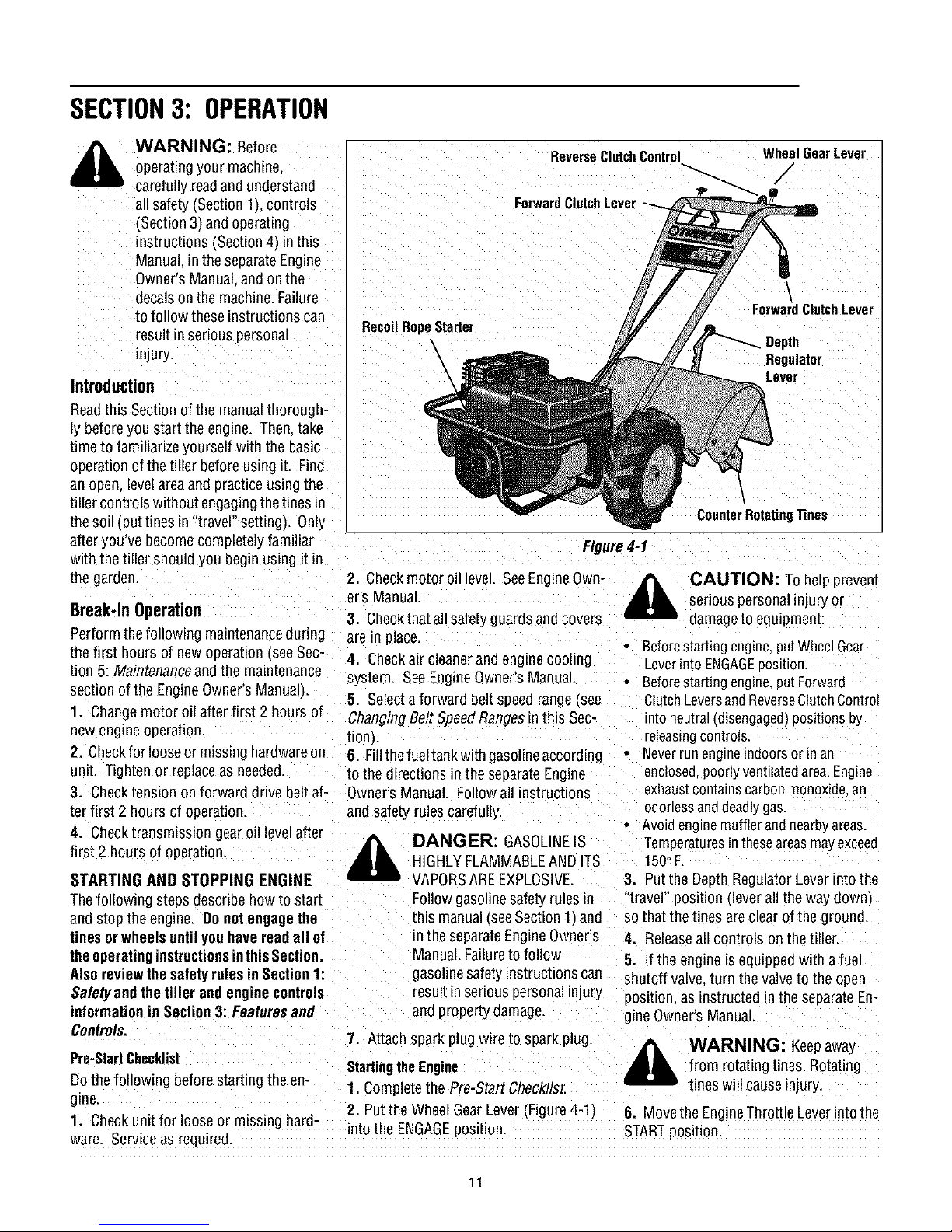

SECTION3: FEATURESANDCONTROLS

WARNING: Before

operatingyour machine,

carefully readandunderstand

all safety,controls and

operating instructions in this

Manual,the separateEngine

Owner's Manual,and onthe

decalson the machine.Failure

tofollow theseinstructions can

result in serious personal

injury.

Tiller Features

This section describesthe location and

function of thecontrols on your tiller. Re-

ferto Section 4: Operationfor detailed op-

erating instructions.

Practiceusing these controls, with the en-

gine shut off, until you understandthe op-

eration ofthe controls and feel confident

with eachof them.

IMPORTANT:Referto the separateengine

manufacturer's EngineOwner's Manual

for information about thecontrols on the

engine.

Wheel Gear Lever

This lever (A, Figure3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, the wheelswill

start turning when either the Forward

Clutch orthe ReverseClutch isengaged.

NOTE: The tines will also start turning

when either clutch is engaged.

DANGER: Neverplacethe

WheelGearLeverin

DISENGAGE(Freewheel)when

theengineisrunning.

HavingtheWheelGearLeverin

engagingthetines_vheelswith

eitherthe ForwardClutch or the

ReverseClutchcould allow the

tines to propel thetiller rapidly

backward.Failureto follow this

instruction could result in

personalinjury or property

damage.

TheDISENGAGE(freewheel)position plac-

esthe wheels infreewheeling modeto al-

low thewheelsto turn without starting the

engine. Usethe DISENGAGEpositiononly

whenthe engine is not running.

Figure3-1:Controlpanel

Toshift to ENGAGE,gently (do not force)

move the leverforward while rolling the

tiller afew inches forward or backward.

(Moving thetiller helpsalignthe transmis-

sion shift mechanism). The wheels will

not freewheelwhen the lever is properly

set in the ENGAGEposition.

Toshift to DISENGAGE,move the lever

rearward, without rolling the tiller. The

wheels roll freely when the leveris proper-

ly setin the DISENGAGEposition.

Forward Clutch Levers

Twointerconnected levers (B, Figure3-1)

control engagementoftheforward driveto

thewheelsandpowerto thetines.

WARNING: Neverengage

wheelsandtines with Forward

ClutchorReverseClutchunless

WheelGearLeveris in

ENGAGE.Engagingthe Forward

Clutchor ReverseClutchwhen

wheelsare not engagedcould

allow the tinesto rapidly propel

tiller backward.Failureto follow

this warning could resultin

personalinjury or property

damage.

ToOperateForwardClutch:

1. Beforeengaging the Forward Clutch,

putthe WheelGearLeverinto theENGAGE

position (see"WARNING"above).

2. Lift and holdone or both leversagainst

the handlebargrips to engagethe wheels

and tines.

3. ReleaseBOTHleversto disengage

wheelsand tines. All forward motion will

stop (engine will continue to run).

IMPORTANT:TheForwardClutchLevers

areconnectedto amechanicalinterlock

that automaticallyshifts a separateWheel

GearLever(A, Figure3-1) into ENGAGE

position when eitherForwardClutchLever

is pulledupagainst the handlebars. This

is asafetyfeature designedto preventthe

wheelsfrom being in DISENGAGE

(freewheel) position when the tines are

rotating.

Beforestartingthe engine,test the

function of the mechanicalinterlock as

follows:

1. PutWheelGearLeverinto DISENGAGE

position and roll tiller backandforth a few

inches.Wheelsshould roll freely.

2. Without rolling the tiller, squeezeeither

Forward Clutch Leveragainst the handle-

bar grips. As the levers move upward, the

mechanicalinterlock automatically moves

theWheelGear Leverforward intothe EN-

GAGEposition (roll tiller backandforth a

few inches). If it does,thewheelswill not

roll freely when you pushand pull on the

handlebars.

3. Themechanicalinterlock works proper-

ly if it functions asdescribed in Step 2. If

themechanicalinterlock doesnotfunction

properly, do not operatethe tiller until it

hasbeencorrected (seeyour authorized

dealer or contact the factory).

Reverse Clutch Control

This control (C, Figure3-1) engagesthe

reversedrive to the wheels andpowerto

thetines. It is usedfor moving the tiller

short distances in areversedirection.

ToOperateReverseClutch:

WARNING: Useextreme

caution whenreversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.Neverattemptto till

in reverse.Failureto follow this

warning could result in

personalinjury or property

damage.

1. Beforeengagingthe ReverseClutch,

put the Wheel GearLever into ENGAGE.

(see"WARNING"atleft).

2. Releasethe Forward Clutch Levers.

3. Tomove the tiller in reverse,first stop

all forward motion. Lift upthehandlebars

until thetines clearthe groundand pullthe

ReverseClutch leverout.

Thewheelswill rotateina reversedirection

aslongasthelever isheld in REVERSE.To

stop thewheelsandtines, releasethelever

and it will returnto NEUTRAL.Neverat-

tempttotill while movingin reversedi-

rection.

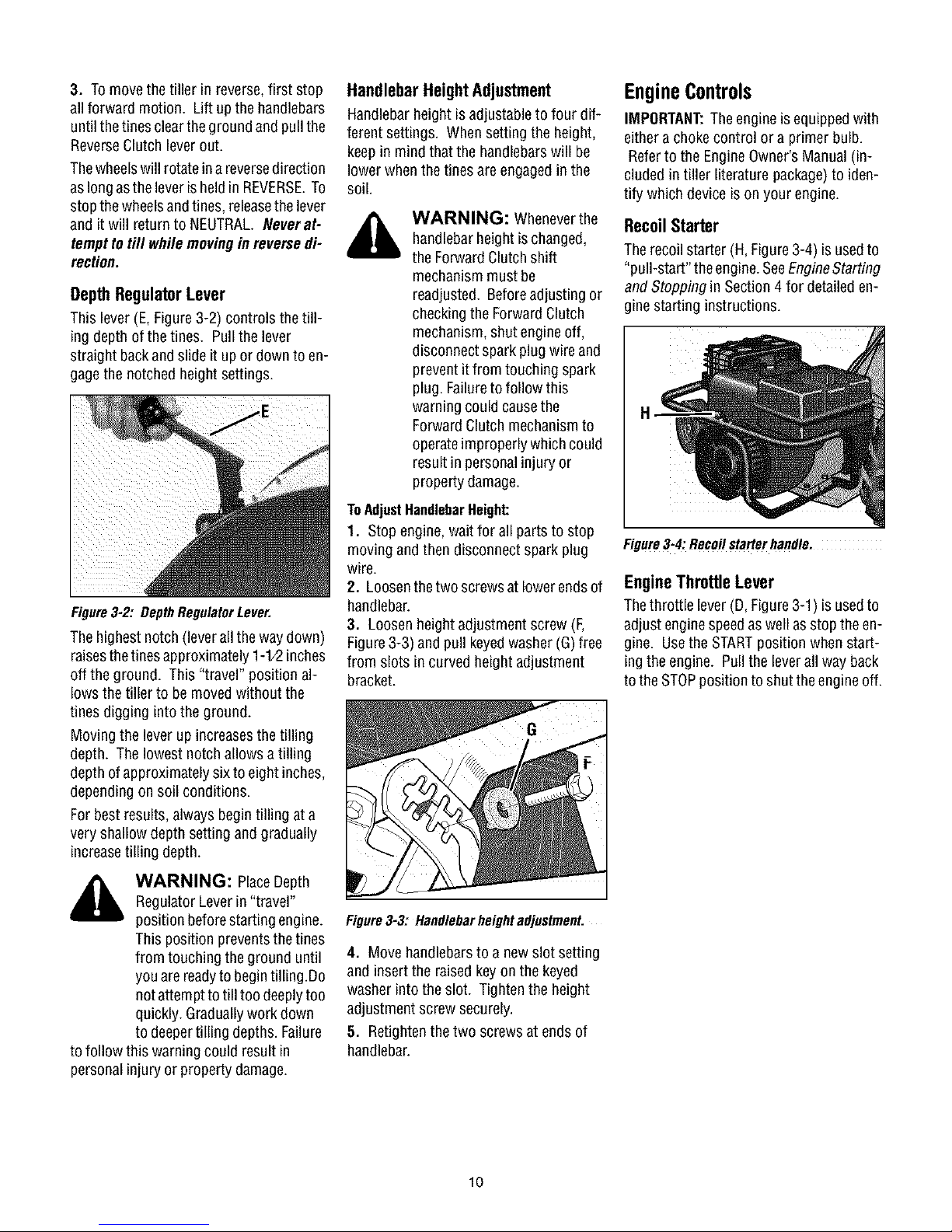

Depth Regulator Lever

This lever (E,Figure3-2) controls the till-

Engdepth of the trees. Pullthe lever

straight backand slide Etup or down to en-

gagethe notched height setbngs.

Figure32: DepthRegulatorLever,

Thehighestnotch (leverall theway down)

raisesthetinesapproximately 1-1/2 inches

off the ground. This "travel" position al-

lows the tiller to be movedwithout the

tines digging intothe ground.

Moving the leverup increasesthe tilling

depth. The lowest notch allows a tilling

depthof approximatelysixto eight inches,

dependingon soil conditions.

Forbestresults, alwaysbegin tilling at a

very shallow depth setting and gradually

increasetilling depth.

Handlebar Height Adjustment

Handlebarheight is adjustable to four dif-

ferent settings. When setting the height,

keepin mind thatthe handlebarswill be

lower whenthe tines are engagedin the

soil.

WARNING: Wheneverthe

handlebarheight ischanged,

the ForwardClutchshift

mechanism must be

readjusted. Beforeadjusting or

checkingthe ForwardClutch

mechanism,shutengine off,

disconnect spark plug wireand

prevent itfrom touching spark

plug. Failureto follow this

warning couldcausethe

ForwardClutch mechanismto

operateimproperly whichcould

result in personal injury or

property damage.

ToAdjustHandlebarHeight:

1. Stop engine,waitfor all parts to stop

moving and then disconnect spark plug

wire.

2. Loosenthetwoscrews atlowerendsof

handlebar.

3. Loosen heightadjustment screw (F,

Figure3-3) and pull keyedwasher (G)free

from slots in curved heightadjustment

bracket.

EngineControls

IMPORTANT:Theengineis equippedwith

eithera chokecontrol or a primer bulb.

Referto the EngineOwner'sManual (in-

cluded intiller literature package)to iden-

tify which device is on your engine.

RecoilStarter

Therecoil starter (H, Figure3-4) is usedto

"pull-start" the engine.SeeEngineStarting

and Stopping in Section4 for detaileden-

gine starting instructions.

Figure3-4:Recoilstarterhandle.

Engine Throttle Lever

Thethrottle lever (D, Figure3-1) is usedto

adjust enginespeedas wellasstop theen-

gine. Usethe STARTposition when start-

ing the engine. Pull the leverall way back

tothe STOPposition to shut theengine off.

_ ARNING: PlaceDepth

tofollow this warning could result in

personalinjury or property damage.

Regulator Leverin "travel"

position beforestarting engine.

This position preventsthe tines

from touching the ground until

youarereadyto begintilling.Do

notattemptto till too deeplytoo

quickly. Graduallywork down

to deepertilling depths. Failure

Figure3-3: Handlebarheightadjustment.

4. Move handlebarsto a newslot setting

and insert the raised keyon the keyed

washer into the slot. Tightenthe height

adjustment screw securely.

5. Retightenthe two screws at ends of

handlebar.

10

SECTION3: OPERATION

WARNING: Before

operatingyour machine.

carefully readandunderstand

all safety (Section 1Lcontrols

(Section 3) and operating

instructions ('Section4_inthis

Manual.in the separateEngine

Owner's Manual.and onthe

decalson the machine.Failure

to follow these instructions can

result in serious personal

injury.

Introduction

Readthis Sectionofthe manualthorough-

ly beforeyou start the engine. Then.take

time to familiarize yourself with the basic

operationofthe tiller before using it. Find

an open, levelareaand practiceusing the

tiller controls without engagingthe tines in

thesoil (put tines in "travel" setting). Only

afteryou've become completely familiar

with thetiller should you begin using it in

the garden.

Break-In Operation

Performthefollowing maintenanceduring

thefirst hours of newoperation see Sec-

tion 5: Maintenanceandthe maintenance

section of the EngineOwner'sManual).

1. Changemotor oil afterfirst 2 hours of

newengineoperation.

2. Checkfor loose or missing hardwareon

unit. Tightenor replaceas needed

3. Checktension on forward drive beltaf- Owner'sManual. Followall instructions

terfirst 2 hours of operation.

4. Checktransmission gear oil levelafter

first 2 hours of operation.

STARTING AND STOPPING ENGINE

Thefollowing steps describehowto start

and stop the engine. Do notengagethe

tinesorwheels untilyouhavereadall of

theoperatinginstructionsinthisSection.

AlsoreviewthesafetyrulesinSection1:

Safetyand thetiller andengine controls resultin serious personalinjury

informationin Section3: Featuresand

Controls.

Pre-StartChecklist

Dothe following beforestarting the en-

gine.

1. Checkunit for looseor missing hard-

ware. Serviceas required.

RecoilRopeStarter

2. Checkmotor oil level. SeeEngineOwn-

er's Manual.

3. Checkthatall safety guards and covers

are m place.

4. Checkair cleanerandengine cooling

system. SeeEngineOwner'sManual.

5. Selecta forward beltspeedrange(see

ChangingBelt SpeedRangesmthis Sec-

tlonJ.

6. Fillthefueltank with gasolineaccording

to the directions in the separate Engine

and safety rules carefully.

7. Attach spark plug wireto spark plug.

Startingthe Engine

1. Completethe Pre-Start Checklist.

2. Putthe Wheel GearLever (Figure4-1)

into the ENGAGEposition.

\

\

\

\

DANGER: GASOLINEIS

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Follow gasolinesafety rules in

this manual_seeSection11ane

in the separateEngineOwner's

Manual. Failureto follow

gasolinesafety instructions can

and property damage.

ReverseClutchControl

ForwardClutchLever

Figure4-1

WheelGearLever

/

ForwardClutchLever

Depth

Regulator

Lever

CounterRotatingTines

,_ CAUTION: To hefpprevent

• Beforestartingengine,putWheelGear

• Beforestartingengine,putForward

• Neverrunengineindoorsor In an

• Avoid engnemufflerandnearbyareas

3. Putthe Depth RegulatorLever into the

"travel" posdlon (leverall the waydown)

sothat thetines areclear of the ground.

4. Releaseall controls onthe tiller.

5. If the engine is equippedwith a fuel

shutoff valve,turn the valveto the open

position, as instructed in the separateEn-

gine Owner's Manual.

,_ WARNING: Keepaway

6. Movethe EngineThrottle Leverintothe

STARTposition.

serious personalinjury or

damageto equipment:

Leverinto ENGAGEuosdlon.

ClutchLeversandReverseClutchControl

1_oneu_ra_(d_sengaged)pos_t_onsby

releasingcontrols.

enclosed,poorlyventilatedarea.Engine

exhaustcontainscarbon monoxidean

odorlessanddeadlygas.

Temperaturesintheseareasmayexceeo

150°F.

from rotating tines. Rotating

tines will cause injury.

11

Loading...

Loading...