Troy-Bilt PRO LINE 644HMBRONCO, PRO LINE 645AMBRONCO, PRO LINE Bronco 644H, PRO LINE Bronco 645A Operator's Manual

Page 1

0 TRtllcBILT' ----

Operator's Manual

Rear-tine Tiller Models

644HmBronco TM

645AmBronco TM

Model 644H Shown (bumper syles vary)

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 769-00585B

(11/2003)

Page 2

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 19

Safety 3 Off-season Storage 24

Assembly 6 Troubleshooting 25

Features and Controls 10

Operation 13 Warranty Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

www.troybilt:com CLEVELAND,01144136

330-558-7220

1-800-520"5520

Copy the model number here:

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreturntheunittotheretailerwithoutfirstcontactingCustomerSupport.

Ifyou have difficultyassembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

willget the four options reproduced here. Click on the appropriate buttonand help is

immediately available.

_S

The answer you are _ The answer you are

I lOOKingfor could be just ....,,_y.... _ ,,.........,_0._......... looking for could bejust

a mouse click away! a mouse click away!

I

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty to engine

and service. Please refer the

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

Page 3

n

Safety

SPARKARRESTERWARNINGTO RESIDENTSOFCALIFORNIAANDSEVERALOTHERSTATES

UnderCalifornia law, and underthe laws of several other states,you are not permitted to operatean

internalcombustion engine using hydrocarbon fuels on anyforest, brush, hay, grain, or grass

covered land; or land covered byanyflammable agricultural crop without an engine spark arrester in

continuous effectiveworking order.

The engineonthe unit is an internal combustion engine which burns gasoline,a hydrocarbon fuel, and must be equippedwith a

spark arrester muffler incontinuous effectiveworking order. Thespark attester must beattachedto the engine exhaustsystem in

such a mannerthat flames or heatfrom the systemwill not ignite flammable material. Failureof the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may also bea violation of otherstate

and/orfederal regulations, laws, ordinancesor codes. Contactyour local fire marshal or forest servicefor specific information

aboutwhich regulationsapply in your area.

Training

1. Carefully readthis

Owner's Manual,the

separateEngineOwner's

Manual,and any other literature you may

receive.Bethoroughly familiar with the

controls and the proper use of the tiller

and its engine. Know howto stop the unit

and disengagethe controls quickly.

2. Neverallow children to operate the

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe area of operationclear of all

persons, particularly children and pets.

4. Keepin mind that the operator or user

is responsiblefor accidents or hazards

occurring to other people,their property,

andthemselves.

Preparation

1. Thoroughly inspect thearea wherethe

tiller isto be usedand removeall foreign

objects.

2. Besure all tiller controls are released

and both wheelsare in the WheelDrive

position before starting the engine.

3. Do not operatethe tiller without

wearingadequateoutergarments. Avoid

loosegarments or jewelry that could get

caught in moving parts.

4. Do not operatethe tiller when barefoot

or wearing sandals,sneakers,or light

footwear. Wear protectivefootwear that

will improve footing on slippery surfaces.

5. Donot till near underground electric

cables,telephonelines, pipesor hoses. If

in doubt, contact your telephoneor utility

company.

6. Warning: Handlefuel with care; it is

highlyflammable and its vaporsare

explosive. Besureto takethe following

precautions:

a. Storefuel in containers specifically

designedfor this purpose.

b. Thegascap shall neverbe removed

or fuel addedwhile the engine is

running. Allow the engineto cool

for several minutes beforeadding

fuel.

c. Keepmatches,cigarettes, cigars,

pipes, openflames, and sparks

awayfrom the fuel tank and fuel

container.

d. Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Useafunnel or spout to prevent

spillage.

e. Replaceall fuel tank and container

caps securely.

I. If fuel isspilled, do not attempt to

start the engine, but movethe

machineawayfrom the areaof

spillage and avoidcreating any

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustments when engine

is running (unless recommendedby

manufacturer).

Operation

1. Do not put hands or feet nearor under

rotating parts. Thetines begin to rotate

oncethe engine startsand the Forward

Clutch Bail (or ReverseClutchControl) is

engaged.

2. Exerciseextremecaution whenon or

crossing gravel drives,walks, or roads.

Stay alert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine,remove the wire from the spark

plug and prevent it from touching the

spark plug, thoroughly inspectthe

machinefor any damage,and repairthe

damagebeforerestarting and operating

the machine.

4. Exercisecaution to avoidslipping or

falling.

5. If the unit should start to vibrate abnor-

mally, stop theengine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and check

immediately for thecause.Vibration is

generallya warning of trouble.

6. Stopthe engine, disconnect the spark

plug wire and preventit from touching

the spark plug wheneveryou leavethe

operating position, before unclogging the

tines, or when making any repairs,adjust-

ments or inspections.

Page 4

Section1: Safety

7. Takeall possible precautions when

leavingthe machineunattended.Stopthe

engine. Disconnectspark plug wire and

move it awayfrom the spark plug. Be

sure both wheels are in the WheelDrive

position.

8. Before cleaning, repairing, or inspect-

ing,stop the engineand makecertain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching the spark plug to prevent acci-

dentalstarting.

9. The flap on the tine hood must be

down when operatingthe tiller.

10. Never usethe tiller unless proper

guards, plates, or other safety protective

devicesare in place.

11. Do not run engine in an enclosed

area.Engineexhaustcontains carbon

monoxide gas,a deadly poisonthat is

odorless, colorless, andtasteless.

12. Keepchildren and pets away.

13. Never operatethe tiller under

engine powerif the wheels are in the

Freewheelposition.Inthe Freewheel

position,the wheelswill notholdthe

tiller backand therevolvingtines could

propelthe tiller rapidly, possibly

causinglossof control.Always engage

the wheelswith the wheel drive pins in

the WheelDrive position before starting

the engine orengaging thetines/wheels

with the Forward Clutch Bailor the

ReverseClutchControl.

14. Beawarethat thetiller may unexpect-

edly bounceupward or jump backward

and bepropelled towardyou if the tines

should strike extremely hard packedsoil,

frozen ground, or buried obstacleslike

largestones, roots, or stumps. If in doubt

about thetilling conditions, alwaysuse

thefollowing operating precautionsto

assist you in maintaining control of the

tiller:

a. Walk behindandto oneside ofthe

tiller, usingone handonthe han-

dlebars. Relaxyour arm, butuse a

securehandgrip.

b. Use a deepdepthregulator

setting.

c. Useslowerenginespeeds.

d. Clear the tilling area of all large

stones,rootsandotherdebris.

e. Avoidusingdownwardpressure

on handlebars.If needbe, use

slightupwardpressureto keep the

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lilt handlebarsto raise

tines out ofthesoil.

g. In an emergency,stoptines and

wheels by releasingwhichever

clutchcontrolis engaged. Donot

attemptto restrainthetiller.

15. Do not overloadthetiller's capacity

by attempting to till too deeplyattoo fast

a rate.

16. Neveroperatethetiller at high

transport speeds on slippery surfaces.

Look behind and usegreat care when

backing up.

17. Do not operatethe tiller on a slope

that istoo steepfor safety. When on

slopes,slow down and makesureyou

havegood footing. Never permitthe tiller

to freewheel down slopes.

18. Neverallow bystanders nearthe unit.

19. Only use attachments and acces-

sories that areapproved bythe manufac-

turer of the tiller.

20. Usetiller attachments and acces-

sories when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller ifyou are

tired, or underthe influenceof alcohol,

drugs or medication.

23. Operatorsshall not tamper with the

engine-governorsettings on the machine;

the governor controls the maximum safe

operatingspeedto protect the engineand

all moving partsfrom damagecausedby

overspeed. Authorized serviceshall be

sought if a problem exists.

24. Do not touch engine parts which may

be hot from operation. Let parts cool

down sufficiently.

25. Pleaseremember:You canalways

stop the tines and wheels by releasingthe

Forward Clutch control or the Reverse

Clutchcontrol (whichevercontrol you

haveengaged),or by moving thethrottle

control leveron the engineto "OFF"or

"STOP".

26. To load or unload thetiller, seethe

instructions in Section4 of this Manual.

27. Useextremecaution when reversing

or pulling the machinetowards you.

28. Startthe engine carefully according to

instructions andwith feet well awayfrom

the tines.

29. Neverpick up or carry a machine

while the engine is running.

Maintenance and Storage

1. Keepthe tiller, attachments and acces-

sories in safe working condition.

2. Checkall nuts, bolts, and screws at

frequent intervals for proper tightness to

besure the equipment is in safeworking

condition.

3. Neverstore thetiller with fuel in the

fuel tank insidea building where ignition

sources are presentsuch as hot water

and space heaters,furnaces, clothes

dryers,stoves, electric motors, etc.).

Allow engine to cool before storing in any

enclosure.

4. To reduce the chancesof afire hazard,

keepthe enginefree of grass, leaves,or

excessivegrease.

5. Storegasoline in acool, well-ventilated

area,safelyaway from any spark- or

flame-producing equipment. Store

gasoline in anapprovedcontainer, safely

away from the reachof children.

6. Referto the Maintenancesections of

this Manualand theseparate Engine

Owner's Manualfor instructions if the

tiller isto be stored for an extended

period.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire

is connected,exceptwhen specifically

instructed to do so.

8. If the fuel tank hasto be drained,do

this outdoors.

Page 5

Section1: Safety

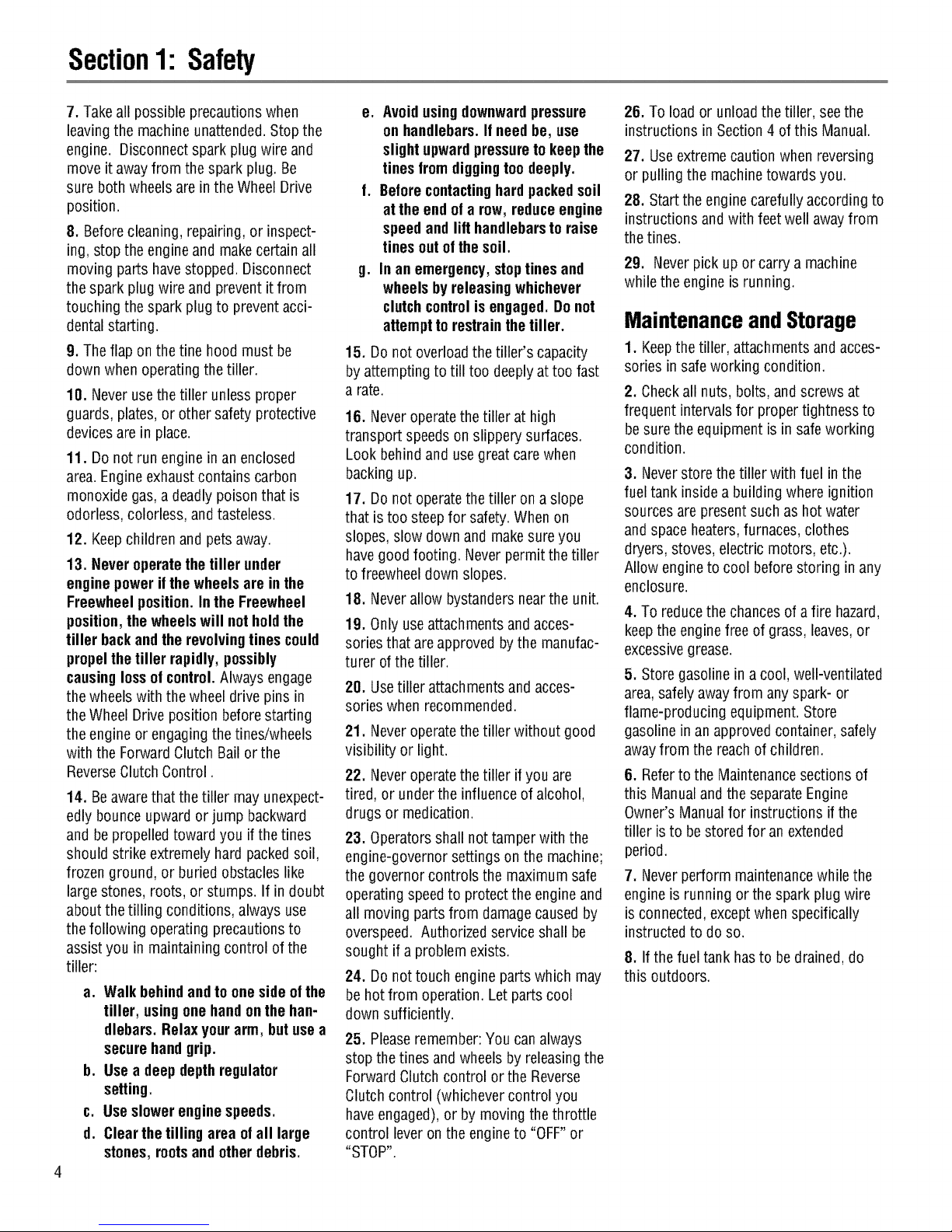

Decals

For your safety and the safety of others,

various safety and operational decals are

located on your unit (see Figure 1 below).

Keepthe decalscleanand legible atall

times. Contactyour local service dealer

or the factory for replacementsif any

decalsare damagedor missing.

Referto the separate parts catalogfor

decallocations, part numbers and

ordering instructions.

ForwardClutchControl

OperatingInstruction

ReverseClutchControl

OperatingInstruction

StartingStabilization

Messageon engine

Warning Messages

ontine hood

HotSurfaces

Warningonbelt cover

Figure 1: Location of Safety and Operating Decals (Model 644H shown).

Operating Symbols

Various symbols (shown here, with word

descriptions)are used on the tiller and engine

(your unit may not haveallof the symbols).

FAST SLOW STOP

i÷i I÷1 R

CHOKE CHOKE REVERSE

ON OFF

€,E--> <--lZ,

TILLERDIRECTION

ROTATING

TINES

BAIL BAIL

_-_ 0 _ ENGAGED DISENGAGED

LEVERDIRECTION

TO AVOID SERIOUS INJURY:

• READTHEOWNER'S MANUAL.

• KNOWLOCATIONSANDFUNCTIONSOFALL CONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEAND DISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINESOR MAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHEMACHINETOWARDSYOU.

Page 6

n

Assembly

WARNING

To prevent personal injury or

property damage, do not start

the engine until all assembly

steps are complete and you

have read and understandthe

safety and operating instruc-

tions in this manual.

Introduction

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in its entirety beforebeginning assembly.

NOTE: Enginesylesvary by model. The

engineon your tiller may appeardiffer-

ently than those shown in illustrations

and Figuresthroughout this manual.

Inspectunit

Inspectthe unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

aclaim. To protect your rights, put your

claim in writing and mail acopy to the

carrierwithin 15 daysafter the unit has

beendelivered.

STEP1: Unpacking Instructions

1. Removeanycardboard inserts and

packagingmaterial from the carton.

Removeany staples from the bottom of

the carton andthen lift the carton up and

off the unit.

2.Thetiller is heavyand you should not

attempt to remove itfrom the shipping

platform until the handlebarsare

installed. The procedure for removing the

tiller isexplainedin Step3 ofthese

assemblysteps.

NOTE:Becareful not to severely bendany

of the control cables on the unit.

3. Removeall unassembled parts and

the separatehardwarebagfrom the

carton. Checkthat you havethe items

listed below (contact your local dealeror

the factory if any items are missing or

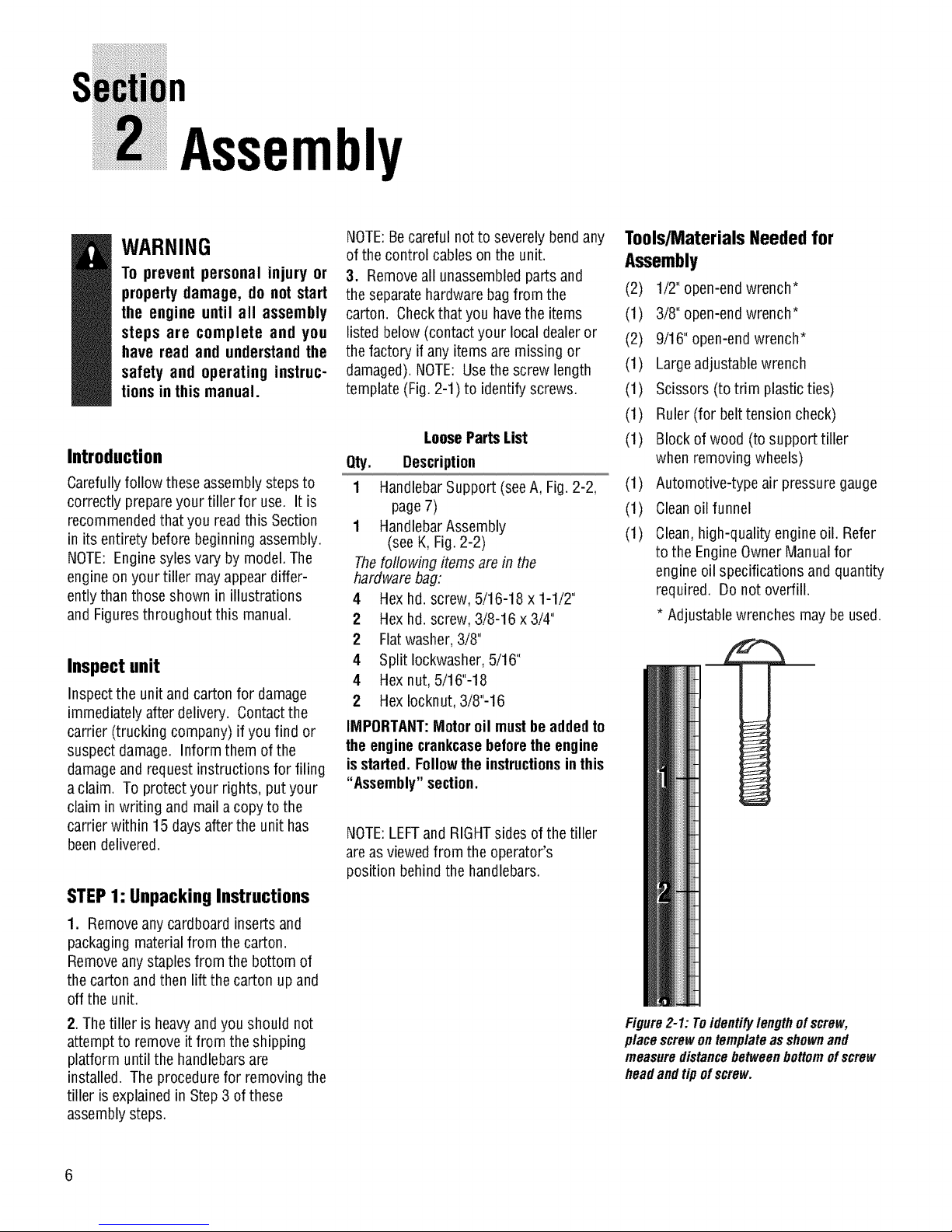

damaged). NOTE: Usethescrew length

template (Fig. 2-1)to identify screws.

LooseParts List

Qty. Description

1 HandlebarSupport (seeA, Fig.2-2,

page7)

1 HandlebarAssembly

(seeK, Fig.2-2)

Thefo//owing itemsare in the

hardwarebag:

4 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

4 Split Iockwasher,5/16"

4 Hexnut, 5/16"-18

2 HexIocknut, 3/8"-16

IMPORTANT:Motoroil mustbe addedto

the enginecrankcasebeforethe engine

isstarted. Followthe instructionsinthis

"Assembly" section.

NOTE:LEFTand RIGHTsides of the tiller

are as viewed from the operator's

position behindthe handlebars.

Tools/MaterialsNeededfor

Assembly

(2) 1/2" open-endwrench*

(1) 3/8" open-endwrench*

(2) 9/16" open-endwrench*

(1) Largeadjustable wrench

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tensioncheck)

(1) Block of wood (to support tiller

when removing wheels)

(1) Automotive-type air pressure gauge

(1) Cleanoil funnel

(1) Clean,high-quality engineoil. Refer

to the EngineOwnerManualfor

engine oil specifications and quantity

required. Do not overfill.

* Adjustable wrenchesmay be used.

Figure2-1: Toidentifylengthofscrew,

placescrewontemplateasshownand

measuredistancebetweenbottomofscrew

headandtipofscrew.

Page 7

STEP2: Attach Handlebar

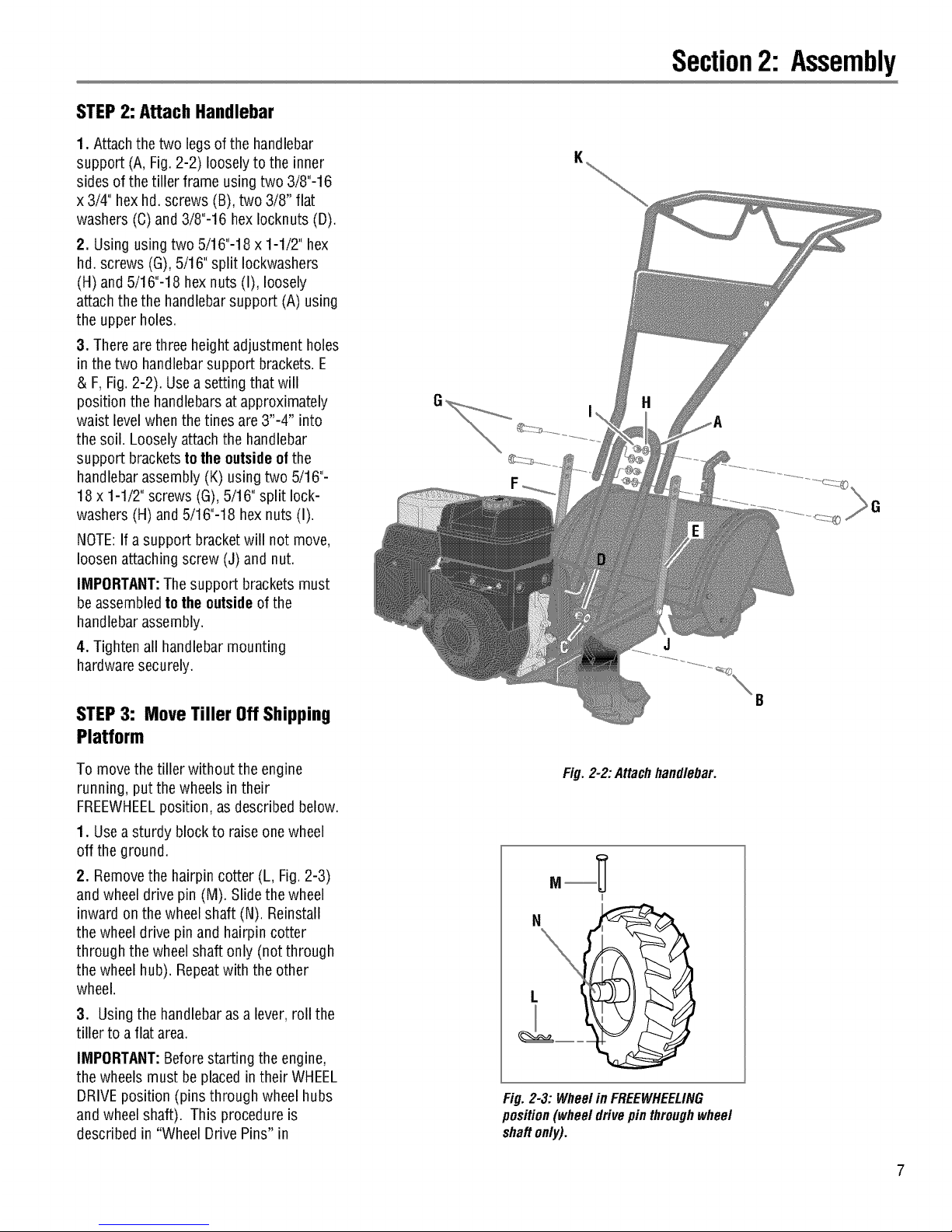

1. Attachthe two legsof the handlebar

support (A, Fig.2-2) loosely to the inner

sides of thetiller frame using two 3/8"-16

x3/4" hexhd. screws (B), two 3/8" flat

washers(C)and 3/8"-16 hexIocknuts (D).

2. Using using two 5/16"-18 x 1-1/2" hex

hd. screws (G), 5/16"split Iockwashers

(H) and 5/16"-18 hex nuts (I), loosely

attachthethe handlebarsupport (A) using

the upper holes.

3. Thereare three heightadjustment holes

in the two handlebarsupport brackets.E

& F, Fig.2-2). Usea setting that will

position the handlebarsat approximately

waist levelwhenthe tines are 3"-4" into

the soil. Looselyattach the handlebar

support bracketstothe outsideof the

handlebarassembly (K) using two 5/16"-

18 x 1-1/2" screws (G), 5/16" split lock-

washers(H) and 5/16"-18 hexnuts (I).

NOTE:If a support bracket will not move,

loosenattaching screw (J) and nut.

IMPORTANT:Thesupport brackets must

be assembledtothe outsideof the

handlebarassembly.

4. Tighten all handlebar mounting

hardwaresecurely.

STEP3: Move Tiller Off Shipping

Platform

To move the tiller without the engine

running, put the wheels in their

FREEWHEELposition, as described below.

1. Usea sturdy block to raiseonewheel

off the ground.

2. Removethe hairpin cotter (L, Fig.2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheelshaft (N). Reinstall

the wheel drive pin and hairpin cotter

through the wheel shaft only (not through

the wheel hub). Repeatwith the other

wheel.

3. Using the handlebaras a lever, roll the

tiller to aflat area.

IMPORTANT:Beforestarting the engine,

the wheels must be placedin their WHEEL

DRIVEposition (pins through wheel hubs

and wheel shaft). This procedureis

described in "Wheel Drive Pins" in

Section2: Assembly

Fig. 2-2: Attachhandlebar.

Fig. 2-3: Wheel in FREEWHEELING

position (wheel drivepin throughwheel

shaftonly).

Page 8

Section2: Assembly

STEP4: Install ForwardClutchCable

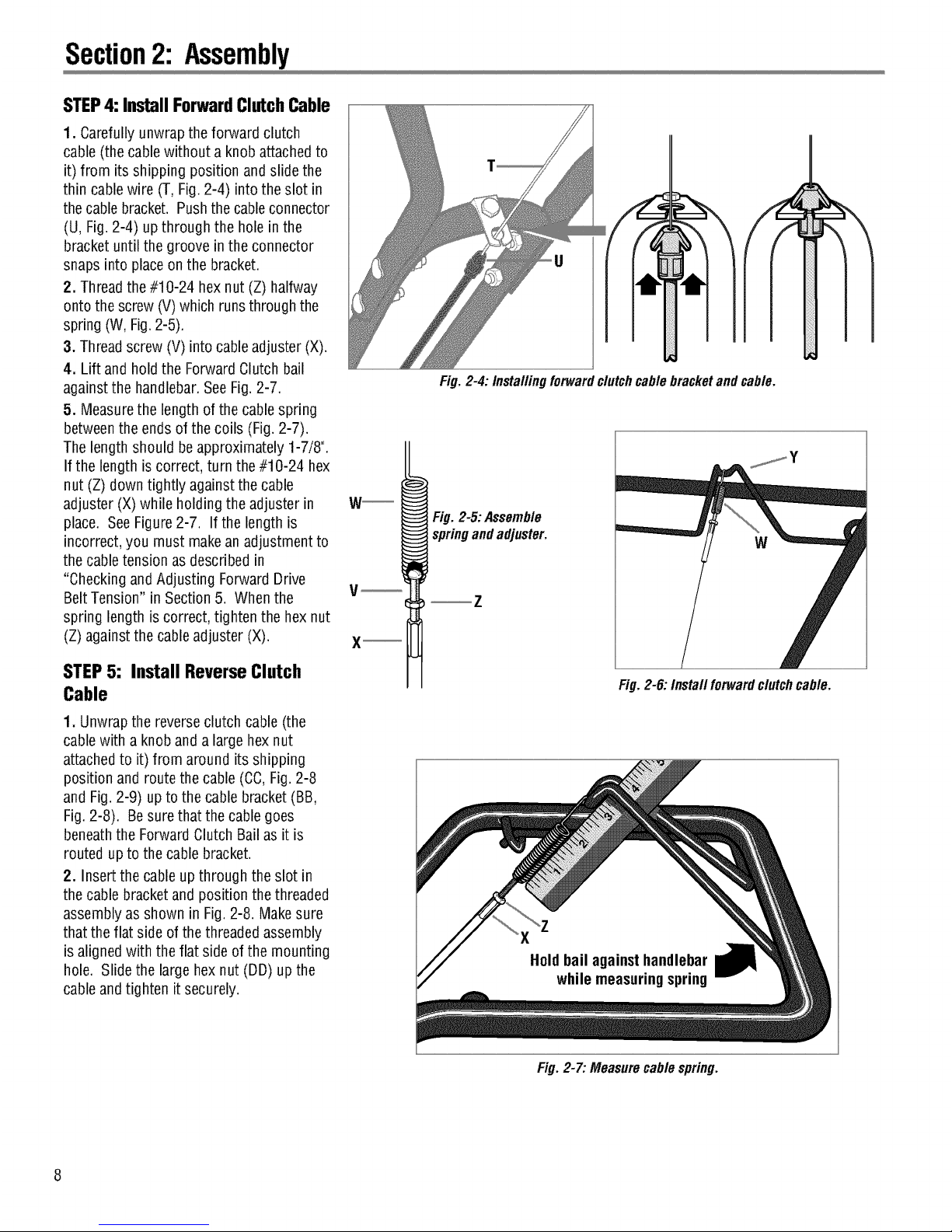

1. Carefully unwrap theforward clutch

cable (thecablewithout a knob attached to

it) from its shipping position and slidethe

thin cable wire (T, Fig.2-4) into the slot in

thecablebracket. Pushthe cableconnector

(U, Fig.2-4) up through the hole in the

bracketuntil the groove in the connector

snaps into placeon the bracket.

2. Threadthe #10-24 hex nut (Z) halfway

onto the screw(V) which runs through the

spring (W, Fig.2-5).

3. Threadscrew (V) intocableadjuster (X).

4. Lift and hold the ForwardClutch bail

against the handlebar.SeeFig.2-7.

5. Measurethe length of the cablespring

betweenthe ends ofthe coils (Fig.2-7).

Thelength should beapproximately 1-7/8".

If the length is correct, turn the #10-24 hex

nut (Z) downtightly againstthe cable

adjuster (X) while holding the adjuster in

place. SeeFigure2-7. If the length is

incorrect, you must makean adjustment to

the cabletension as described in

"Checking andAdjusting ForwardDrive

BeltTension" in Section 5. When the

spring length is correct, tighten the hex nut

(Z)against the cableadjuster (X).

STEP5: Install ReverseClutch

Cable

1. Unwrapthe reverseclutch cable (the

cablewith a knoband a large hex nut

attachedto it) from around its shipping

position and route the cable (CC,Fig.2-8

and Fig. 2-9) up to the cable bracket(BB,

Fig.2-8). Besure that the cablegoes

beneaththe ForwardClutch Bail asit is

routed upto the cablebracket.

2. Insertthe cableup through the slot in

the cablebracketand position the threaded

assembly as shown in Fig.2-8. Makesure

that the flat side of thethreaded assembly

isaligned with the flat sideof the mounting

hole. Slide the large hex nut (DD) up the

cableand tighten it securely.

Fig. 2-4: Installing forwardclutchcablebracketand cable.

Fig. 2-5: Assemble

springand adjuster.

Fig. 2-6: Install forwardclutch cable.

Fig. 2-7: Measure cable spring.

Page 9

Section2: Assembly

3. Usea cable tie (EE,Fig.2-9) to fasten

the reverseclutch cableto the left side

handlebar.

4. Test the function of the reverseclutch

cable by pulling the knob out and

releasingit. The knob should return to its

neutralposition (resting against bracket)

when it is released. If it doesn't, contact

your local dealer or the factory for

technical assistance.

BB

DD

Flat Side

Fig. 2-8: Install reverse cablemounting

bracketand the reverse clutchcable.

CC

Fig. 2-9: Route reverse clutchcable (CC)as

shown. Attachtohandlebar withcable tie

(EE).

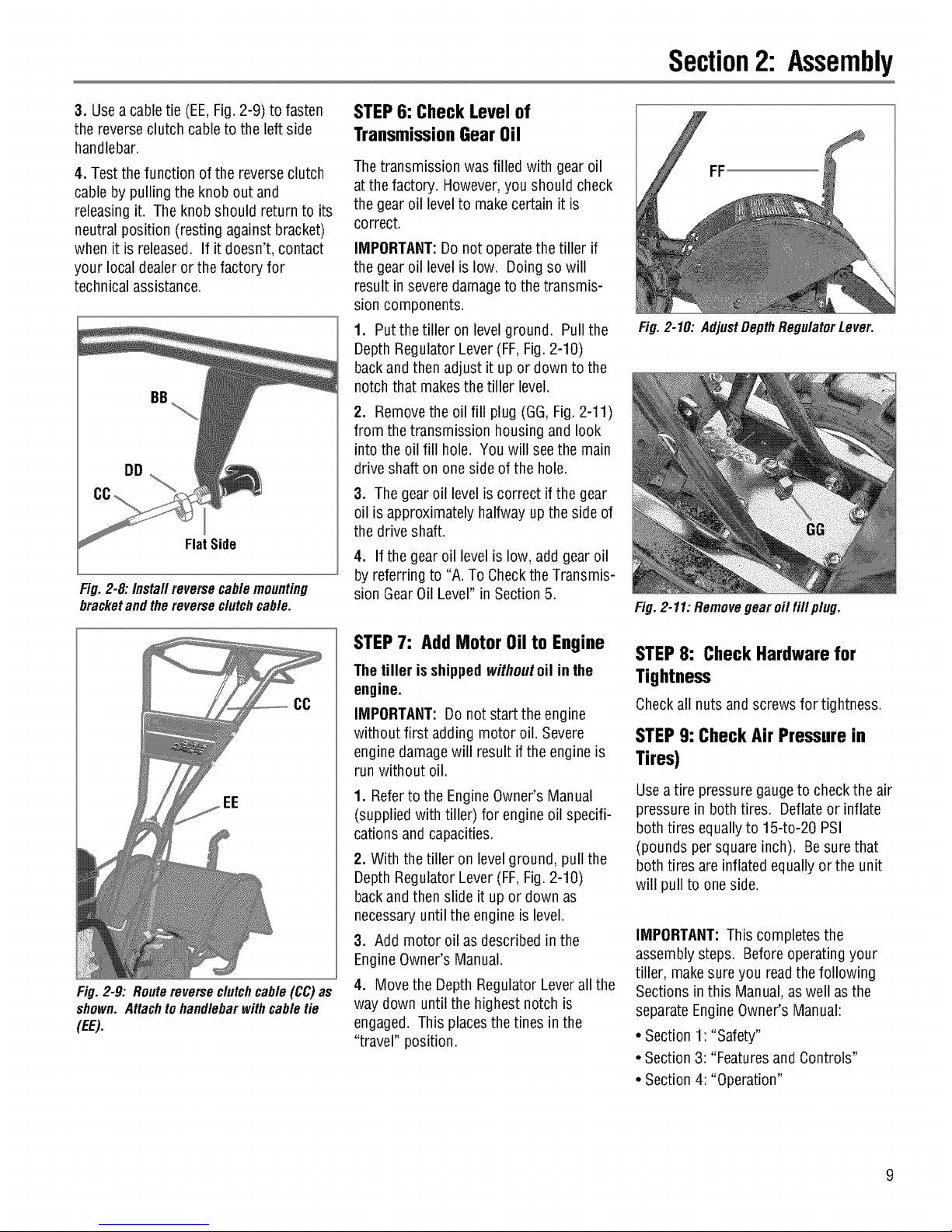

STEP6: CheckLevelof

TransmissionGearOil

Thetransmission was filled with gear oil

at thefactory. However,you should check

the gear oil levelto makecertain it is

correct.

IMPORTANT:Do notoperatethe tiller if

the gear oil level is low. Doingso will

result insevere damageto the transmis-

sign components.

1. Putthe tiller on levelground. Pullthe

DepthRegulator Lever(FF, Fig.2-10)

backand then adjust it up or down to the

notch that makesthe tiller level.

2. Removethe oil fill plug (GG,Fig. 2-11)

from the transmission housing and look

intothe oil fill hole. You will seethe main

drive shaft on oneside of the hole.

3. Thegear oil leveliscorrect if the gear

oil is approximately halfwayup the side of

the drive shaft.

4. If the gear oil level is low, add gear oil

byreferring to "A. To Checkthe Transmis-

sion GearOil Level" in Section 5.

STEP7: Add Motor Oil to Engine

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not start the engine

without first adding motor oil. Severe

engine damagewill result ifthe engine is

run without oil.

1. Referto the EngineOwner's Manual

(suppliedwith tiller) for engine oil specifi-

cations and capacities.

2. With the tiller on levelground, pull the

DepthRegulator Lever(FF, Fig.2-10)

backand then slide it up or down as

necessaryuntil the engine is level.

3. Add motor oil asdescribed in the

EngineOwner's Manual.

4. Movethe Depth RegulatorLeverall the

way down until the highest notch is

engaged. This placesthe tines in the

"travel" position.

Fig. 2-10: AdjustDepthRegulator Lever.

Fig. 2-11: Removegear oil fill plug.

STEP 8: Check Hardware for

Tightness

Checkall nuts and screws for tightness.

STEP9: CheckAir Pressurein

Tires)

Usea tire pressuregaugeto check the air

pressure in both tires. Deflateor inflate

both tires equallyto 15-to-20 PSI

(pounds per square inch). Besure that

both tires are inflatedequallyor the unit

will pull to one side.

IMPORTANT:This completesthe

assembly steps. Beforeoperating your

tiller, make sureyou readthe following

Sections in this Manual, aswell asthe

separateEngineOwner's Manual:

• Section 1: "Safety"

• Section3: "Featuresand Controls"

• Section 4: "Operation"

Page 10

n

FeaturesandControls

WARNING

Before operating your

machine, carefully read and

understand all safety, controls

and operating instructions in

this Manual, the separate

Engine Owner's Manual, and

on the decals onthe machine.

Failure to follow these

instructions can result in

serious personal injury.

Forward ReverseClutch

ClutchBail Control

Regulator

HandlebarHeight

Adjustment

Anti-ReverseStake

DrivePin

(on eachwheel)

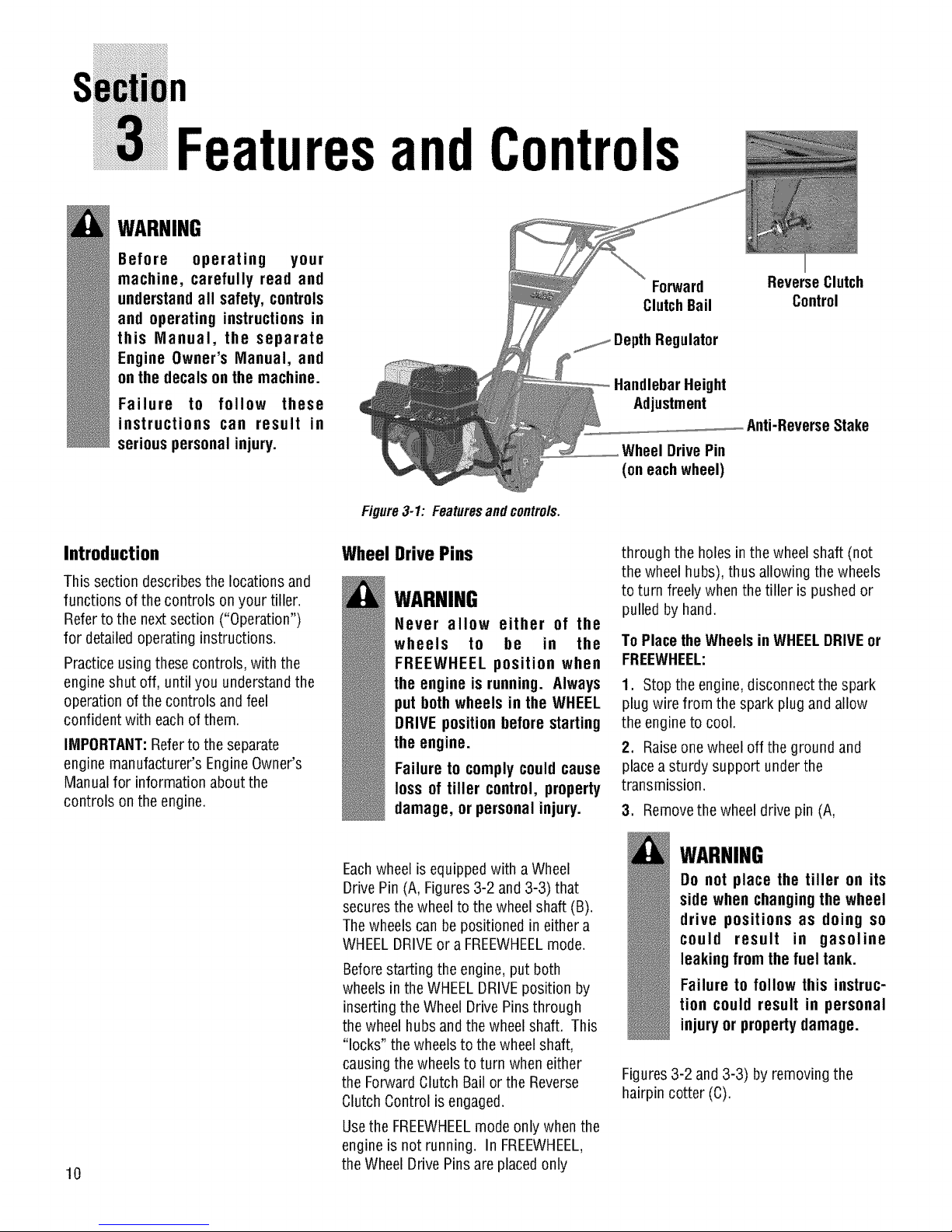

Figure3-1: Featuresand controls.

Introduction

This section describesthe locationsand

functions of thecontrols on your tiller.

Referto the nextsection ("Operation")

for detailed operating instructions.

Practiceusingthese controls, with the

engine shut off, until you understandthe

operationof the controls and feel

confident with eachof them.

IMPORTANT:Referto the separate

engine manufacturer's EngineOwner's

Manualfor informationabout the

controls on the engine.

WheelDrivePins

WARNING

Never allow either of the

wheels to be in the

FREEWHEEL position when

the engine is running. Always

put bothwheels in the WHEEL

DRIVE position before starting

the engine.

Failure to comply could cause

loss of tiller control, property

damage, or personal injury.

through the holes in the wheel shaft (not

the wheelhubs), thus allowing the wheels

to turn freely whenthe tiller is pushedor

pulled by hand.

To Placethe Wheels in WHEELDRIVEor

FREEWHEEL:

1. Stop the engine, disconnect the spark

plug wire from the spark plug and allow

the engineto cool.

2. Raiseone wheel off the ground and

placea sturdy support underthe

transmission.

3. Removethe wheeldrive pin (A,

10

Eachwheel is equippedwith a Wheel

Drive Pin (A, Figures3-2 and 3-3) that

securesthewheel to the wheel shaft (B).

Thewheels can be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

Beforestarting the engine, put both

wheels in the WHEELDRIVEposition by

inserting the WheelDrive Pinsthrough

the wheelhubs andthe wheel shaft. This

"locks" the wheels to the wheelshaft,

causing the wheels to turn when either

the ForwardClutch Bail orthe Reverse

ClutchControl isengaged.

Usethe FREEWHEELmode only whenthe

engine is not running. In FREEWHEEL,

the WheelDrive Pinsare placedonly

WARNING

Do not place the tiller on its

side when changing the wheel

drive positions as doing so

could result in gasoline

leaking from the fuel tank.

Failure to follow this instruc-

tion could result in personal

injury or propertydamage.

Figures3-2 and 3-3) by removingthe

hairpin cotter (C).

Page 11

Section3: FeaturesandControls

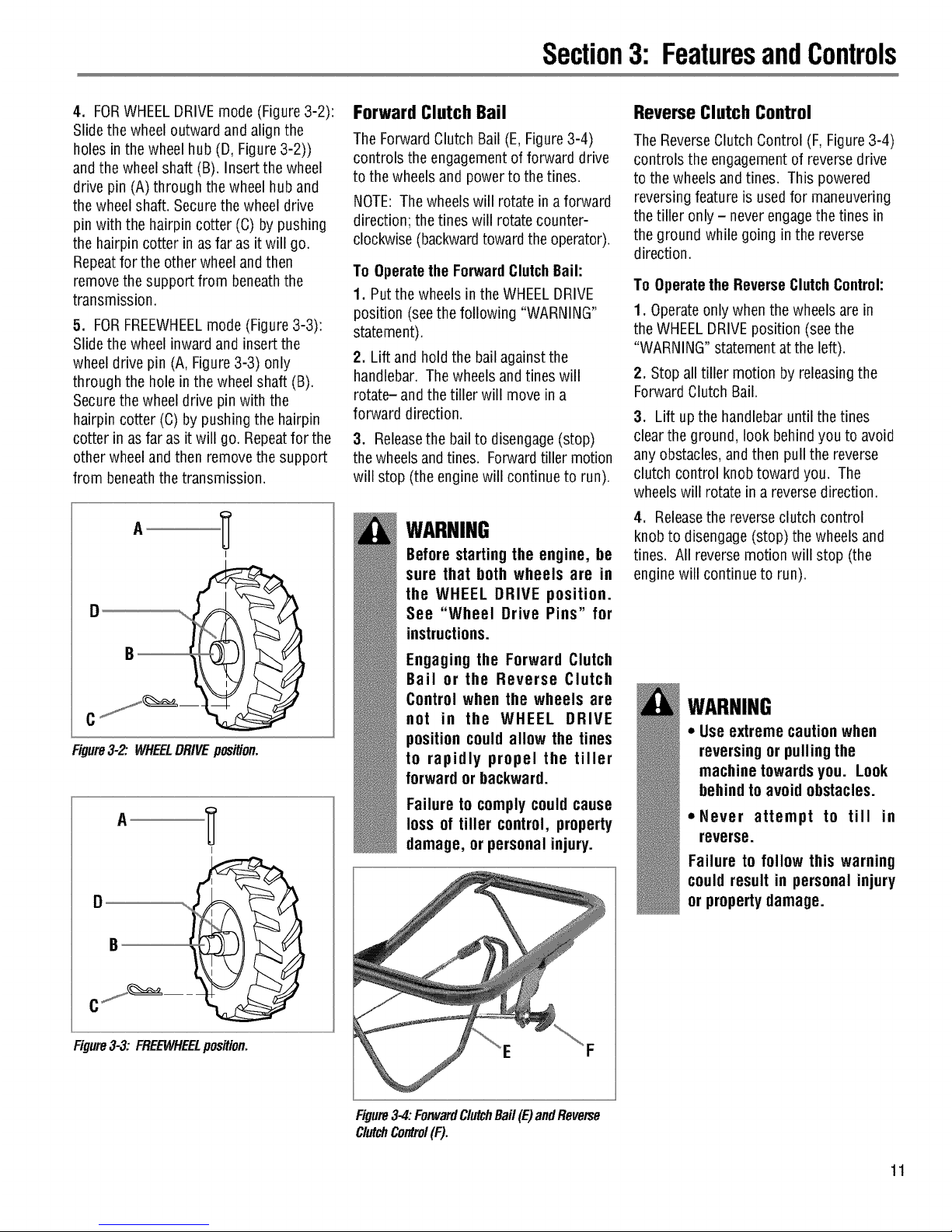

4. FORWHEELDRIVEmode (Figure3-2):

Slide the wheeloutward and align the

holesin the wheel hub (D, Figure3-2))

and the wheelshaft (B). Insert the wheel

drive pin (A) through the wheel hub and

the wheelshaft. Securethe wheel drive

pin with the hairpin cotter (C) by pushing

the hairpin cotter in asfar as it will go.

Repeatfor the other wheel and then

removethe support from beneaththe

transmission.

5. FORFREEWHEELmode(Figure 3-3):

Slide the wheel inwardand insert the

wheel drive pin (A,Figure3-3) only

through the hole in the wheelshaft (B).

Securethe wheeldrive pin with the

hairpin cotter (C)by pushing the hairpin

cotter in asfar as it will go. Repeatfor the

other wheeland then removethe support

from beneaththetransmission.

I

Figure3-2: WHEELDRIVEposition.

I

D

B

Figure3-3: FREEWHEELposition.

Forward Clutch Bail

The Forward ClutchBail (E, Figure3-4)

controls the engagementof forward drive

to the wheelsand powerto the tines.

NOTE:Thewheels will rotate in a forward

direction; the tines will rotatecounter-

clockwise(backwardtoward the operator).

To Operatethe Forward ClutchBail:

1. Put the wheels in the WHEELDRIVE

position (see the following "WARNING"

statement).

2. Lift and hold the bail againstthe

handlebar. The wheels andtines will

rotate- and thetiller will move in a

forward direction.

3. Releasethe bail to disengage(stop)

the wheelsandtines. Forwardtiller motion

will stop (the engine will continue to run).

WARNING

Before starting the engine, be

sure that both wheels are in

the WHEEL DRIVE position.

See "Wheel Drive Pins" for

instructions.

Engaging the Forward Clutch

Bail or the Reverse Clutch

Control when the wheels are

not in the WHEEL DRIVE

position could allow the tines

to rapidly propel the tiller

forward or backward.

Failure to comply could cause

loss of tiller control, property

damage, or personal injury.

ReverseClutchControl

The ReverseClutch Control (F, Figure3-4)

controls the engagementof reverse drive

to the wheels and tines. This powered

reversingfeature is usedfor maneuvering

the tiller only - neverengagethe tines in

the ground while going in the reverse

direction.

To Operatethe ReverseClutchControl:

1. Operateonlywhen the wheels are in

the WHEELDRIVEposition (seethe

"WARNING"statementat the left).

2. Stopall tiller motion by releasingthe

ForwardClutch Bail.

3. Lift upthe handlebaruntil the tines

clear theground, look behindyou to avoid

any obstacles,and then pull the reverse

clutch control knobtoward you. The

wheels will rotate in areverse direction.

4. Releasethe reverseclutch control

knobto disengage (stop) the wheels and

tines. All reversemotion will stop (the

engine will continue to run).

WARNING

• Use extreme cautionwhen

reversing or pulling the

machine towardsyou. Look

behindto avoid obstacles.

• Never attempt to till in

reverse.

Failure to follow this warning

could result in personal injury

or propertydamage.

Figure34: FonvardClutchBail (E)andReverse

ClutchControl(F).

11

Page 12

Section3: FeaturesandControls

DepthRegulatorLever

This lever(G, Figure3-5) controls the

tilling depth of the tines. Pullthe lever

straight backand slide it up or down to

engagethe notched height settings.

Thehighest notch (lever allthe way

down) raisesthe tines approximately 1-

1/2"off the ground. This "travel" setting

allows the tiller to be movedwithout the

tines digging into the ground. Also use

this setting when starting the engine.

Movethe lever upward to increasethe

tilling depth. Thelowest notch allows a

tilling depth of approximately 6"-8",

dependingon soil conditions.

Forbest results, begintilling atthe

deepestdepth possiblewithout causing

the tiller to bog down. Increasethetilling

depthfrom one passoverthe soil to the

next.

Shallow

Travel

Position

jG

Deep

_ Settings

HandlebarHeightAdjustment

The handlebarheight is adjustableto

three different settings (seeFigure3-6).

As a generalrule,adjust the handlebars

so they areat waist levelwhen thetines

are 3"-4" into the soil.

To Adjustthe Handlebars:

1. Stopthe engine, disconnectthe spark

plug wire from the spark plug and allow

the engineto cool.

2. Removethe screws, Iockwashersand

nuts, reposition the handlebars,and

reinstall the hardware.

Figure3-6: Handlebarheight adjustment.

Anti-ReverseStake

This stake is locatedat the rear ofthe

transmission, under the tine hood (see H,

Figure3-7). Its purpose is to automati-

cally help preventthe counter-rotating

tines from letting the tiller back up in the

direction of the operator if the tiller

wheels had beeninadvertently left in the

FREEWHEELposition. In this situation,

theAnti-Reverse Stakewill beforced

down into the ground, lifting the tines

upward out of the soil and helping

prevent backward motion of the tiller.

TheAnti-ReverseStakerequires noadjust-

ment, butshould be inspectedbefore

eachtiller useto verify that it swivels

freely. Removeanyclogged materials

(dirt, roots, rocks, etc.) that preventthe

Anti-ReverseStakefrom swinging freely.

L_

Figure3-5: Depth regulatorlever.

WARNING

• Place the Depth Regulator

Lever in the "travel"

position before starting the

engine. This position

prevents the tines from

touching the grounduntil you

are ready to begin tilling.

Failure to follow this warning

could result in personal injury

or propertydamage.

H

Figure3-7: Anti-ReverseStake.

ENGINECONTROLS

Referto the engine manufacturer's Engine

Owner's Manual(included in the tiller lit-

eraturepackage)to identifythe controls

on your engine.

IMPORTANT:Thecontrol for stopping the

engine is located on the engine.

12

Page 13

.........................Operation

WARNING

Before operating your

machine, carefully read and

understand all safety (Section

1), controls (Section 3) and

operating instructions(Section

4) in this Manual, in the

separate Engine Owner's

Manual, and on the decals on

the machine.

Failure to follow these instruc-

tions can result in serious

personal injury.

INTRODUCTION

Readthis Section ofthe manual thor-

oughly beforeyou start the engine. Then,

takethe time to familiarize yourself with

the basic operation of thetiller before

using it in the garden. Findan open, level

areaand practiceusing thetiller controls

without the tines engagingthe soil (put

tines in "travel" setting). Onlyafter

you've becomecompletely familiar with

thetiller should you begin using it in the

garden.

INITIAL OPERATION

Perform the following maintenanceduring

thefirst hours of newoperation (see

"Maintenance" section in this manual and

inthe EngineOwner's Manual).

1. Changeengineoil after first 2 hours of

newengine operation.

2. Checkfor loose or missing hardware

on unit. Tighten or replaceas needed.

3. Checktension on forward drive belt

after first 2 hours of operation.

4. Checktransmission gear oil level after

first 2 hours of operation.

ReverseClutchControl

(knobonbackofbracket)

__---_FonNard Clutch Bail

DepthRegulatorLever

Ii-Reverse Stake

Recoil

Figure4-1

Wheel DrivePin

(oneachwheel)

STARTINGANDSTOPPINGTHE

ENGINE

Pre-StartChecklist

Makethe following checks and perform

the following services beforestarting the

engine.

1. Readthe "Safety" and "Controls"

sections in this manual. Readthe

separateEngineOwner's Manual

provided bythe engine manufacturer.

2. Checkthat the wheelsare in the

WHEELDRIVEposition (wheel pins must

bethrough the wheel hubsand the wheel

shaft holes).

3. Checkunitfor looseor missing

hardware. Serviceas required.

4. Checkengine oil level. SeeEngine

Owner's Manual.

5. Checkthat all safety guards and

coversare in place.

6. Checkair cleaner andengine cooling

system. SeeEngineOwner's Manual.

7. Attachspark plug wire to spark plug.

8. Fillthe fuel tank with gasoline

according to the directions in the

separateEngineOwner's Manual. Follow

all instructions and safetyrules carefully.

DANGER

GASOLINE IS HIGHLY

FLAMMABLE AND ITS

VAPORSARE EXPLOSIVE.

Followgasolinesafetyrules in

this manual (see Section 1)

and in the separate Engine

Owner'sManual.

Failure to follow gasoline

safety instructionscan result

in serious personal injury

and property damage.

13

Page 14

Section4: Operation

Startingthe Engine

Thefollowing steps describe howto start

and stop the engine. Donotattemptto

engagetines or wheels untilyouhave

read all the operatinginstructionsin this

Section. Alsoreview the salety rules in

Section1: "Safety" and the tiller and

engine controlsinlormationin Section

3: "Features and Controls."

CAUTION

To help prevent serious

personal injury or damage to

equipment:

• Before starting engine, put

both wheels in the WHEEL

DRIVE position. Never have

the wheels in the

FREEWHEEL position when

the engine is running. When

the wheels are in

FREEWHEEL, they do not

hold back the tiller and the

tines could propel the tiller

rapidly backward.

• Before starting engine, put

Forward Clutch Bail (all

Models) and Reverse Clutch

Control in neutral (disen-

gaged) positionsby releasing

levers.

• Never run engine indoors or

in enclosed, poorly venti-

lated areas. Engine exhaust

contains carbon monoxide,

an odorless and deadly gas.

• Avoid engine muffler and

nearby areas. Temperatures

in these areas may exceed

150OF.

1. Completethe "Pre-Start Checklist" on

the previous page.

2. Put the wheels in the WHEELDRIVE

position (see "Wheel Drive Pins" in

Section 3).

3. Putthe DepthRegulator Leverin the

"travel" position (leverall the way down)

so that the tines areclear of the ground.

4. Releaseall controls on thetiller.

5. If engine is equipped with a fuel valve,

1t'urn4valve to open positionas instructed

in the separateEngineOwner's Manual.

6. Put ignition switch and/or throttle

control leveron engine in"ON," "RUN,"

"FAST"or "START" position asinstructed

in the separateEngineOwner's Manual.

7. Chokeor prime engineas instructed in

the separateEngineOwner's Manual.

8. Placeone hand on thefuel tank to

stabilizethe unit when you pull the starter

handle. Usethe recoil starter ropeto start

the engine as instructed in the separate

EngineOwner's Manual. Whenengine

starts, gradually movechoke lever(on

enginesso equipped)to "NOCHOKE,"

"CHOKEOFF"or "RUN" position.

WARNING

Hot surfaces can cause severe

burns. Do not touchmuffler or

adjacent areas.

9. Usethe "FAST"throttle speedsetting

whentilling.

WARNING

Keep away from rotating

tines. Rotating tines will

cause injury.

Stoppingthe Engineand Tiller

1. To stop the wheelsand tines, release

the ForwardClutch Bail orthe Reverse

ClutchControl -- whichever control is in

use.

2. To stop the engine, put thethrottle

control leveron engine in"OFF"or

"STOP"position.

OPERATINGTHE TILLER

Thefollowing pagesprovide guidelinesto

usingyour tiller effectively andsafely in

various gardening applications. Besure

to read "Tilling Tips & Techniques" in this

Section beforeyou actually putthe tines

into the soil.

This is a CRT(counter-rotating tine) tiller.

As the wheels pull forward, thetines

rotate backward.

This creates an "uppercut" tine action

which digs deeply, uprooting soil and

weeds. Don't overloadthe engine,but dig

asdeeplyas possible oneach pass. On

later passes,the wheels may tend to spin

in the soft dirt. Helpthem along by lifting

up slightly on the handlebar(palm facing

up).

1. Followthe "Pre-Start Checklist" on the

previous page. Besure that the wheels

are in the WHEELDRIVEposition.

2. Putthe Depth Regulator Lever in the

"travel" position (lever all the way down)

so that the tines are clear ofthe ground.

Usethis position when practicing with

your tiller or when moving to or from the

garden. Whenyou are readyto begin

tilling, you must move the Depth

Regulator Lever to the desireddepth

setting (see"Tilling Tips & Techniques").

Checkthat the Anti-Reverse Stakeswivels

freelybackandforth. Removeanyclogged

material on or around the stake.

Figure4-2: Use one handto guide tiller

whenmovingforward.

3. Start theengine and allow it to warm

up. Whenwarm, put throttle control in

fast speedsetting.

4. Forforward motion of wheelsand

powerto thetines:

(a) Pull the ForwardClutch Bailup and

hold it againstthe handlebar. Release

the bail to stop forward motion of

the wheelsand powerto the tines.

(b) As the tiller movesforward, relaxand

letthe wheelspullthe unit alongwhile

the tines dig. Walk behindand a

little to one side ofthe tiller. Usea

light but secure grip with one hand

on the handlebars,keepingyour arm

loose. SeeFigure4-2.

Page 15

Section4: Operation

WARNING

Do not push down on the

handlebars to try to make the

tiller till more deeply. This

prevents the wheels from

holding the tiller back and can

allow the tines to rapidly

propel the tiller backward

toward the operator, which

could result in loss of control,

property damage, or personal

injury.

Letthetiller moveat its own paceand do

not push down on the handlebarsto try to

dig deeper- this takes weight off the

wheels,cuts traction, andcausesthe tines

to try and propel the tiller.

5. Forreverse motion of the wheels and

tines:

(a) Look behindand exercisecaution

when operating in reverse. Donot

till while in reverse.

(b) Stop all forward motion before

reversing. Lift the handlebarswith

one hand until the tines areoff the

ground and then pull the Reverse

Clutch Control knob outto engage

reverse motion (see Figure4-3). To

stop reversemotion, let go of the

ReverseClutch Control knob.

6. To Turn the Tiller Around:

(a) Practice turning thetiller in a level,

open area. Bevery careful to keep

your feet and legs awayfrom the

tines.

(b) To makeaturn, lift the handlebars

until the engine andtines are

balancedover the wheels (Figure

4-4). Thetines must be out of the

ground while turning the tiller.

(c) With the tiller balanced,push

sideways on the handlebarto move

the tiller in the direction of the turn

(Figure4-5). After completing the

turn, slowly lower the tines into the

soil to resume tilling.

Figure4-3: Raise tines off groundandlook

behind whenmovingin reverse.

WARNING

Before tilling, contact your

telephone or utilities company

and inquire if underground

equipment or lines are used in

your area. Their representa-

tive will be glad to answer

your questions and tell you if

any of their equipment or lines

are buried underground on

yourproperty.

Turningthe Tiller Around

Figure4-4: Tobegin turn, lift handlebars

until engine and tinesare balancedover

wheels. Besure tinesare out of ground.

Figure4-5: Withtiller balanced over

wheels(and tines out of theground),push

handlebarssidewaystoturntiller.

StoppingtheTiller and Engine

1. To stop the wheels and tines, release

the ForwardClutch Bailor the Reverse

ClutchControl- whichever is engaged.

2. To stop the engine, movethe throttle

control leveron engineto "OFF"or

"STOP" position.

15

Page 16

Section4: Operation

16

TillingTips& Techniques

Letthetiller dothe work

* While tilling, relax and let thewheels

pull the tiller along whilethe tines do

the digging. Walk on the sidethat is

notyet finished (to avoid making foot-

prints in the freshly tilled soil) and

lightly, but securely grip the handlebar

with just one hand.SeeFigure4-2.

oAvoid thetemptation to push down on

the handlebarsin anattempt to force

the tiller to dig deeper. Doing sotakes

the weight off the poweredwheels,

causing them to losetraction. Without

the wheels helpingto hold the tiller

back,the tines will attempt to propel

the tiller backward towardthe

operator- often causingthe tiller to

skip rapidly acrossthe ground.

Tilling depths

• When preparing the soil, till a fresh

pathon each passrather than overlap-

ping passes. This gives the wheels

maximum traction on undisturbed soil.

SeeFigure4-6. Dig asdeeplyas

possible on eachpass without over-

loadingthe engine. Later passescan

be overlapped. (Watering the garden

area afew days prior to tilling will

maketilling easier,as will letting the

newly worked soil set for a day or two

beforemaking a final, deeptilling

pass.)

• When cultivating (breakingupthe

surfacesoil around plantsto help

destroyweeds), adjustthe tinesto dig

only1-1/2"to 2" deep. Usingshallow

tilling depths helpspreventinjuryto

plantswhose rootsoftengrow closeto

thesurface. If needed,lift up on the

handlebarsslightly topreventthe tines

from digging toodeeply. Cultivatingon

a regularbasisnotonlyeliminates

weeds,it also loosensandaeratesthe

soilfor bettermoistureabsorptionand

fasterplantgrowth.

Avoidtilling soggy,wetsoil

Tilling wet soil often results in large,

hardclumps of soil that can interfere

with planting. If time permits, wait a day

or two after heavyrainsto allow the soil

to dry before tilling. Test soil by

squeezing it into a ball. If it compresses

too easily, it istoo wet to till.

Avoidmakingfootprints

Wheneverpossible,walk onthe untilled

side ofthe unitto avoid makingfoot-

prints inyour freshly tilled or cultivated

soil. Footprintscausesoil compaction

that can hamperroot penetrationand

contribute to soil erosion. Theycan also

"plant" unwantedweed seedsback into

thefreshly tilled ground.

Choosingcorrectwheel

andtine speeds

With experience,you will find the "just

right" tilling depth andtilling speed

combination that is bestfor your

garden.

Setthe enginethrottle leverat a high

enough speed to give theengine

adequatepower andyet allow it to

operatewithout overloading it. Fastest

engine speedsmay bedesirablewhen

makingfinal passesthrough the

seedbedor when cultivating. Selection

of the correct engine speed, in relation

to the tilling depth,will ensurea suffi-

cient power levelto do the job without

causing the engineto labor.

Suggestedtilling patterns

• When preparinga seedbed,go over

the same pathtwice inthe first row,

then make individual passesright next

to eachother (see Figure4-6). When

finished in one direction, makesecond

passesata right angle asshown in

Figure4-7.

In very hardground it may takethree

or four overlapping passesto thor-

oughly pulverizethe soil. (SeeFigure

4-8.)

• If the garden sizewill not permit

lengthwiseand then crosswisetilling,

then overlapthe first passesby one-

halfa tiller width, followed by succes-

sive passesat one-quarter width (see

Figure4-8).

• With planning,you canallow enough

room betweenrows to cultivate (see

Figure4-9). Leaveroom for the hood

width, plus enough extra roomfor

future plantgrowth.

Figure4-6

Figure4-7

Figure4-8

%

Figure4-9

Page 17

Section4: Operation

TillingTips& Techniques

Clearing the tines

Dry grass, stringy stalks or tough vines

may becometangled in the tines. Follow

these proceduresto help avoidtangling

andto cleanthe tines, if necessary.

•To reducetangling, set the depth

regulatorto maximum depth.

• While tilling, try swayingthe handle-

barsfrom sideto side (about6" to 12").

This "fishtailing" action often clears the

tines of debris.

• If tangling occurs, lift the tines out of

the soil and run the tiller in reversefor

afew feet. This may unwind a good

dealof debris.

• It may be necessaryto removethe

debris by hand (a pocket knife will help

you to cut away the material).

WARNING

Before clearing the tines by

hand, stop the engine, allow

all moving parts to stop and

disconnect the spark plug

wire.

Failure to follow this warning

could result in personal

injury.

Tilling on slopes

If you must garden on a moderateslope,

pleasefollow two very important guide-

lines:

1.Till only on moderateslopes, neveron

steep ground where footing is difficult

(review safety rules in the "Safety"

section of this manual).

2. We recommendtilling up and down

slopes rather than terracing. Tilling

vertically on a slope allows maximum

planting areaand also leavesroom for

cultivating.

IMPORTANT:When tilling on slopes, be

sure the correct oil level is maintainedin

the engine (checkevery one-half hour of

operation). The inclineof theslope will

causethe oil to slant awayfrom its

normal leveland this can starve engine

parts of required lubrication. Keepthe

engine oil level at thefull point at all

times!

A. Tilling upand downslopes:

• To keepsoil erosionto a minimum, be

sure to add enough organic matter to

the soil so that it has good moisture-

holding texture and try to avoid leaving

footprints or wheel marks.

• When tilling vertically, try to makethe

first passuphill asthe tiller digs more

deeplygoing uphill than it does

downhill. Insoft soil or weeds,you

may haveto lift handlebars slightly

while going uphill.

B. Tilling acrossslopeswithout

usingterraces:

If previously describedtilling methods

aren't practicalfor you, thenyou can till

laterallyacross a slope. However,we

don't really recommend this method as

it cancreate unsurefooting and invites

soil erosion.

17

Page 18

Section4: Operation

LOADINGANDUNLOADINGTHE

TILLER

WARNING

Loading and unloading the

tiller into or from a vehicle is

potentially hazardous. We

don't recommend doing so

unless absolutely necessary,

as this could result in person-

al injury or property damage.

However, if you must load or

unload the tiller, follow the

guidelines given next.

• Before loading or unloading, stop the

engine,wait for all parts to stop

moving, disconnect the spark plug wire

and let the engine and muffler cool.

•Thetiller is too heavyand bulky to lift

safelyby one person.Two or more

peopleshould sharethe load.

• Usesturdy ramps and manually (engine

shut off) roll the tiller into and out of the

vehicle. Two or more people are needed

to do this.

• Rampsmust be strong enough to

support the combined weight of the tiller

and any handlers.The ramps should

providegood traction to prevent

slipping; they should haveside railsto

guide the tiller along the ramps; and

they should havea locking deviceto

secure them to the vehicle.

• The handlers should wearsturdy

footwear that will helpto prevent

slipping.

• Position the loading vehicle sothat the

rampangle is asflat as possible (the

less incline to the ramp,the better).

Turn thevehicle's engine off and apply

its parking brake.

° Whengoing up ramps, stand in the

normal operating position and push the

tiller aheadof you. Havea person at

eachsideto turn the wheels.

Whengoing down ramps, walk

backwardwith thetiller following you.

Keepalert for any obstacles behind you.

Position a person at eachwheel to

control the speed ofthe tiller. Nevergo

down ramps tiller-first, as the tiller could

tip forward.

Usewooden blocksto placeon the

downhill side of the wheels if you need

to stop the tiller from rolling down the

ramp. Also, usethe blocks to temporar-

ily keepthe tiller in place on the ramps

(if necessary),and to chock the wheels

in placeafter the tiller is in thevehicle.

Whenthe tiller is in the vehicle, prevent

it from rolling by chocking thewheels

with blocks and securelytie the tiller

down.

18

Page 19

Maintenance

WARNING

Before inspecting,

cleaning or servicing the

machine, shut off engine,

wait for all moving parts to

come to a complete stop,

disconnectspark plug wire

and move wire away from

spark plug.

Failure to follow these

instructions can result in

serious personal injury or

propertydamage.

REQUIRED MAINTENANCE SCHEDULE

PROCEDURE

Checkengine oil level

Cleanengine

Checkdrive belttension

Checknuts and bolts

Changeengine oil

Lubricate tiller

Serviceengine aircleanersystem

Checkgearoil levelin

transmission

Checktines for wear

Checkair pressure in tires

(if pneumatic)

Servicespark plug

CheckAnti-Reverse Stake

Before

Each

Use

e

e

Every

10

Hours

e

e

e

e

Every

30

Hours

As

Noted

And every 5

operating hours

A

t-

1-

A

1-

A

* Changemore frequently in dusty or dirty conditions, Changeafter first 2 hours of

break-in operation,

1- Checkafter first 2 hours of break-in operation,

A SeeEngine Owner'sManual for serviceintervals and instructions.

19

Page 20

Section5: Maintenance

WARNING Before inspecting,cleaning or servicing the unit, shut off engine, wait for all

partsto come to a completestop, disconnectspark plugwire and movewire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

TILLERLUBRICATION

Proper lubrication of the tiller is an

essentialpart of maintenance. After

every 10 operating hours, oil or grease

the lubrication points shown in Figures

5-1 and 5-1A and describedbelow.

Usea good quality lubricating oil (#30

weight engineoil is suitable) anda quality

generalpurpose grease(with a metal

lubricant, if available).

,, Removewheels, clean wheel shaft (A,

Fig.5-1) and applythin coating of

greaseto the shaft.

,, Greaseback,front andsides of depth

regulator lever(B, Fig.5-1).

,, Removetines, clean tine shafts (C,Fig.

5-1). Inspectfor rust, rough spots or

burrs (look around holes). Fileor sand

smooth, coat ends of shaft with grease.

,, Oil the threads on the handlebarheight

adjustment screws and the handlebar

attaching screws (D, Fig.5-1).

• ShiftingMechanism.Lightlyoil pivot

pointsfor smoothoperation(E,Fig.5-1A).

A

Figure5-1

Figure5-1A

CHECKFOROILLEAKS

Beforeeachuse,checkyour tiller for

signs of an oil leak- usually a dirty, oily

accumulation either on the unit or on the

floor where it hasbeen parked.

A little seepagearound a cover or oil seal

is usually nota causefor alarm. However,

if the oil drips overnight then immediate

attention is neededas ignoring a leakcan

result in severetransmission damage.

If a cover is leaking,try tightening any

loosescrews. If the screws are tight, a

newgasketor oil seal may berequired. If

the leak is from around a shaft and oil

seal,the oil sealprobably needsto be

replaced. Seeyour authorizeddealer or

contact the factory for serviceor advice.

IMPORTANT:Neveroperatethetiller if

the transmission is low on oil. Checkthe

oil levelafter every 30 hours of operation

andwhenever there isany oil leakage.

CHECKHARDWARE

Checkfor looseor missing hardware after

every 10 operating hours. Tighten or

replacehardwarebefore usingthe tiller.

Besure to check the screws underneath

the tiller hood (lift the hoodflap) that

securethe transmission cover andthe

depth regulator leverto the transmission.

CHECKTIREPRESSURE(on

machines equipped with

pneumatic tires)

Checkthe air pressure in both tires.

Deflateor inflate both tires evenly from

15-to-20 PSI (pounds persquare inch).

Besure that bothtires havethe sameair

pressure or the unit will tend to pull to

oneside.

NOTE:Yourtiller may not beequipped

with pneumatictires, eliminating the need

for air pressure checks.

TRANSMISSIONGEAROILSERVICE

Checkthe transmission gear oil level after

every30 hours of operation or whenever

you notice anyoil leak. Operatingthe

tiller when the transmission is low on oil

canresult in severe damage.

A. To ChecktheTransmission

GearOil Level:

1. Checkthe gearoil levelwhen the trans-

mission is cool. Gearoil will expand in

warm operatingtemperatures andthis

expansionwill provide an incorrect oil

levelreading.

2. With the tiller on levelground, adjust

the DepthRegulator Lever up or downto

the notch that makesthe tiller level..

3. Removethe oil fill plug (A, Fig.5-2)

from thetransmission housing and look

into the oil fill hole. You will seethe main

drive shaft on oneside of the hole.

4. Thegear oil level is correct if the gear

oil is approximately half way up the side

of the driveshaft.

5. If the gear oil level is low, add gear oil

asdescribed next. Ifthe gear oil levelis

okay,securely replacethe oil fill plug.

IMPORTANT:Do not operatethe tiller if

the gear oil level is low. Doing so will

result in severedamageto thetransmis-

sion components.

6. If adding only a few ounces of gear

oil, useAPI rated GL-4or GL-5 transmis-

sion gear oil having a viscosity of SAE

140, SAE85W-140 or SAE80W-90. If

refilling anempty transmission, use only

GL-4transmission gearoil havinga

viscosity of SAE85W-140 or SAE140.

NOTE:Do not useautomatic transmission

fluid or engine oil in the transmission.

7. While checking frequently to avoid

overfilling, slowly add gear oil into the oil

fill hole until it reachesthe halfway point

on the drive shaft.

8. Securely replacethe oil fill plug.

2O

Page 21

Section5: Maintenance

WARNING Before inspecting, cleaning or servicingthe unit, shut off engine, wait for all

partsto come to a completestop, disconnectsparkplug wire and movewire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

B. To Drainthe TransmissionGear Oil:

DANGER

Gasoline is highly flammable

and its vaporsexplosive. Fol-

low these safety practices to

prevent injury or property

damage from fire orexplosion.

,, Allow the engine and

muffler to cool before

draining the tiller's gasoline

tank.

,, Do not allow open flames,

sparks, matches or smoking

in the area.

,, Wipe away spills and push

tiller away from spilled fuel.

,, Use only an approved fuel

container and store it safely

out of the reach of children.

,, Do not store gasoline where

its vapors could reach an

open flame or spark, or

where ignition sources are

present (such as hot water

and space heaters, furnaces,

clothes dryers, stoves,

electric motors, etc.)

Thetransmission gear oil does not need

to bechangedunless it hasbeencontam-

inatedwith dirt, sandor metal particles.

1. Drain gasoline from thefuel tank or

run the engine until thefuel tank is empty.

See"DANGER"statementabove.

2. Drainthe oil from the engine.

3. Removethefour screws(B, Figure5-2)

and washersfrom thetransmission cover

and remove thecover and gasket.

4. Removethe left-side wheel.

5. Tilt the left-side wheel shaft into a

drain panand allow the gear oil to drain

through the top ofthe transmission.

6. After draining oil, reinstall the wheel,

install a newgasket (do not reuse old

gasket)and screw on transmission cover.

7. Refill transmission using GL-4gear oil

(SAE85W-140 or SAE140).

8. Refill theengine with motor oil and

replenishthe fuel tank with gasoline.

Figure5-2: Removeoilfi// plug(A)tocheck

gearoil/eve/andtoaddgearoil. Remove

fourcoverscrews(B)todraingearoil.

TINES

Thetines wear with useand they should

be inspected at the beginning of each

tilling seasonand after every30 operating

hours. The tines can be replacedindivid-

ually or asa completeset. Referto the

Parts List Section of this manualfor tine

identification information.

WARNING

This is a CRT(counter-rotating

tine) tiller and its tines must

be mounted in the direction

shown in Figure 5-3. If

mounted with curves in the

opposite direction, tiller will

dig poorly and be more likely

to run backward.

Failure to comply could result

in personal injury or property

damage.

NOTE:You mustfirst removethe tiller

hood before removing either a single tine

holder or individual tines. Removethe

two screws at thefront of the hood and

thetwo screws atthe rear ofthe hood

and lift off the hood. Besureto replace

the hood securelyafter changing a tine or

tine holders.

A. Tine Inspection:

With use,the tines will becomeshorter,

narrower and pointed. Badlyworn tines

will result in a loss of tilling depth and

reducedeffectiveness in general,and

specifically when chopping up and

turning under organic matter.

B. RemovingandInstalling

TineAssemblies

1. Usea 9/16" socket,6"extension, a

ratchet,and a9/16" box end wrench to

loosenthe nut (A, Figure 5-3) and screw

(B) that secure thetine holder to the tine

shaft.

2. Usea rubber mallet to tap thetine

holder loose. Slide tine assembly off.

3. RepeatSteps 1 and 2 aboveto remove

the other tine assembly.

4. Installing the tine assembly issimply

the reverseof its removal. First besure

to removeany rust, unevenspots or burrs

from the tine shaft usingfine sandpaper.

Thengreasethe tine shaft before rein-

stalling thetine assemblies. Besure all

the cutting edgesface so they will enter

the soil first when thetiller is moving

forward- this meansthe cutting edge on

the top of each tine faces towardthe

operator position. Tighten hardware.

C. RemovingandInstalling

IndividualTines

1. Usetwo 9/16" box end wrenchesto

removethe two screws (C, Figure 5-3)

and nuts (D) that securethe tine to its

tine holder.

NOTE:Ifthe nuts are rusted,apply pene-

trating oil, then loosen the hardware.

2. When installing individual tines, do so

in the reverseorder from which they were

removed. The two sets of inboard tines

are installed so one set faces toward the

transmission andthe other faces away

from it. Thesingle outboardtine set

facestoward thetransmission housing.

Also be sure the cutting edge at thetop

of eachfine facestoward the operator

position. (SeeFigure 5-3.)

21

Page 22

Section5: Maintenance

WARNING Beforeinspecting,cleaning or servicingthe unit, shutoff engine, wait for all

partsto come to a completestop, disconnectspark plugwire and movewire away fromspark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

TINED

OPERATOR C

POSITION

A

ENGINE

,'_ DENOTES CUTTING EDGE _3

OF TINE |

Figure5-3: Tines,tineholdersandinstallationhardware.

Figure5-4:LiftbailandchecklengthofClutchBailSpringtocheckforcorrectbelttension

(1-7/8").

CHECKINGANDADJUSTING

FORWARDDRIVEBELTTENSION

Maintaining correct tension on the

forward drive belt is important to good

tilling performanceand long belt life. A

loosebelt will slip on the engine and

transmission pulleys and causethe tines

and wheels to slow down - or stop com-

pletely- eventhough the engine is

running at full speed. A loose beltcan

also result in premature belt wear.

If you find you can not bring the Forward

ClutchBail all the way upto the bottom of

the upper handlebars,you will needto

loosenthe belt tension.

Also checkthe belt for cracks,cuts or

frayed edges and replaceit assoon as

possible.

• Checkbelt tension after the first two

hours of initial operation(new belt).

• Checkbelt tension after every 10

operatinghours.

To CheckForwardBeltTension:

1. Besure that the engine is stopped and

the spark plug wire is disconnectedand

moved awayfrom the spark plug.

2. Loosen nut "C" (Figure5-4) several

turns so it is about halfway upthe

threadedadjustment screw.

3. Lift the Forward ClutchBail up and

hold it to the bottom ofthe handlebars.

Measurethe length of the clutch bail

spring (A, Figure5-4) with a ruler. If the

belttension is correct, the length of the

coiled portion of the spring should be

approximately 1-7/8". Nut "C" should

then besnugged down againstthe top of

the adjuster (B).

4. If the spring istoo short, the belt

tension will betoo loose. If the spring is

too long, the belttension will betoo tight.

5. To adjust the length of the spring,

releasethe ForwardClutch Bail. Thread

the hex nut (C, Fig.5-4) halfwayup the

adjustment screw. Turn the screw inside

the spring (A, Figure5-4) counterclock-

wise (as viewed from the operator's

position) while holding the adjuster (B)

steadyto increasethe length of the

spring, or turn clockwise (asviewed from

the operator's position) to decreasethe

length ofthe spring.

NOTE:If you havedifficulty holding the

adjuster steady by hand,usea pliers or

wrench on the adjuster. Whileyou turn

the screw, keepthe Forward Clutch Cable

22

Page 23

Section5: Maintenance

WARNING Beforeinspecting,cleaningor servicingthe unit, shut off engine, wait for all

partsto cometo a complete stop, disconnectsparkplugwire and movewire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

from turning by gripping the upper endof

the threadedadjuster (B) with pliers.

6. RepeatStep 3 to measurethe length

of the clutch bail spring. Oncethe length

is correct, retighten the hex nutagainst

the top of the adjuster.

ForwardBeltReplacementInformation

If the drive belt needsto be replaced,see

your local authorizeddealer or phonethe

factory as instructed on Page2. Referto

the Parts List in the back of this manual

for correct components Use only OEM

(Original Equipment Manufacturer) fre-

placementbelts.A substitute belt may

not perform satisfactorily. Theprocedure

requiresaveragemechanicalability and

commonly availabletools.

FORWARDCLUTCH

BAILADJUSTMENT

If the ForwardClutch Bail doesnot

function properly, first checkthat the

forward drive belt is adjusted properly

(see"Checkingand Adjusting Forward

Drive Belt Tension"). If this fails to

correct the problem, contact the factory

technical service departmentor your

authorized dealerfor service advice.

CHECKINGANDADJUSTING

REVERSEDRIVEBELTTENSION

Maintaining correct tension on the

reversedrive belt is important to good

performanceand long belt life. A loose

belt will slip on the engine andtransmis-

sion pulleys and causethe tines and

wheels to slow down- or stop com-

pletely- eventhough the engine is

running at full speed. A loose belt can

also result in premature belt wear.

If there is no reverseaction when the

ReverseClutch Control knob is pulled

out, then the belttension istoo loose.

When checking belttension, also check

the belt for cracks,cuts or frayed edges

and replace it assoon as possible.

* Checkbelttension after the first two

hours of break-in operation (new belt).

- Checkbelttension after every 10

operatinghours.

To CheckReverseBeltTension:

1. Be surethat the engine is stopped and

the spark plug wire is disconnectedand

moved awayfrom the spark plug.

2. Removethe screw in the plastic belt

cover and slidethe cover (which is

attachedto the forward clutch cable) out

of the way.

3. Havean assistant pull the Reverse

ClutchControl knoball theway out and

hold it in that position. Measurethe

length of thecablewire betweenthe end

of thethreaded cableadjuster (A, Figure

5-5) andthe end ofthe Z-fitting (B) to

which the cablewire is attached.

4. The belttension is ideal if the cable

wire length measuresbetween1/8"to

1/4". If the length is lessthan 1/8" (and if

there is no reverseaction when the tiller

is running), then makethefollowing

adjustments. NOTE:If the length is more

than 1/4", no adjustment is needed,as

long as the reverseaction functions

properly.

5. Releasethe ReverseClutch Control

knob. Unthreadthe inner jam nut (C,

Figure5-6) oneto two turns and pull the

threaded cableadjuster (A, Figure5-6) to

the left until the inner jam nut rests

againstthe bracket.

6. Preventthe inner jam nut (C) from

turning and tighten the outer jam nut (D)

againstthe bracket. Preventthe outer

jam nut (D) from turning and tighten the

inner jam nut (C) against the bracket.

7. Measurethe gap by repeatingStep 3.

Readjustasneededby repeatingSteps5

and 6.

8. Reinstall the beltcover.

Figure5-5: Measure cable wire lengthto

checkfor correctreverse belt tension.

Figure5-6: Move threaded

adjuster (,4)to left to

increasebelt tension.

ReverseBeltReplacementInformation

If the drive belt needsto be replaced,see

your local authorizeddealer or phonethe

factory as instructed on Page2. Referto

the Parts List in the back of this manual

for correct components Use only OEM

(Original Equipment Manufacturer) fre-

placementbelts.A substitute belt may

not perform satisfactorily. Theprocedure

requiresaveragemechanicalability and

commonly availabletools.

23

Page 24

Section5: Maintenance

WARNING Before inspecting,cleaningor servicing the unit, shutoff engine, wait for all

partsto cometo a completestop, disconnectspark plugwire and movewire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

ENGINEOILSERVICE

Checkthe engine oil levelbeforestarting

the engine eachday and check it after each

5 hours of continuous operation. Running

the engine when it is low on oil will quickly

ruin the engine.

It is recommendedthat you changethe

motor oil after every 10 hours of operation

and evensooner when operating in

extremely dirty or dusty conditions. Refer

to the separateEngineOwner's Manualfor

detailedservice instructions.

A. To Checkthe Engine0il Level:

1. Move thetiller to a levelareaand shut

off the engine.

2. Levelthe engine by adjusting the Depth

Regulator Lever. The tines must be in

contact with the ground. Move the Anti-

ReverseStake backif necessary.

3. Cleanthearea aroundthe oil dipstick or

oil fill tube to prevent dirt from falling into

the crankcase.

4. Onengineswith an oil fill tube, remove

the filler cap, add oil (if required) until it

reachesthetop of the tubeand reinstall the

filler cap.

5. Onengineswith a dipstick, remove it,

wipe it clean,and reinstall it finger-tight.

Removethe dipstick and checkthe reading.

Add oil (if required) to bring the levelto the

FULLmark. Do not overfill.

B. To Changethe Engine0il:

Changethe engine oil as instructed in the

separateEngineOwner's Manual.

ENGINECLEANING

Keepthe engine clean to assure smooth

operationand to prevent damagefrom

overheating. Referto the separateEngine

Owner's Manualfor specific repair and

cleaninginstructions. All inspections and

services must be done with the engineshut

off and cool to the touch.

24

AIR CLEANERSERVICE

Theengine air cleanerfilters dirt and dust

out of the air before it enters the carbure-

tor. Operatingthe enginewith a dirty,

cloggedair filter cancause poor perfor-

manceand damageto the engine. Never

operatethe engine without the air cleaner

installed. Inspect and servicethe air

cleanermore often if operating in very

dusty or dirty conditions.

Servicethe air cleaneras instructed in the

separateEngineOwner's Manual.

SPARKPLUGSERVICE

Inspect and cleanor replacethe spark plug

after every 100 operating hours or

annually. Cleanthe plug and set the gap as

described in the separateEngineOwner's

Manual.

In some areas,locallaw requires using

resistor spark plugsto suppress ignition

signals. If the engine was originally

equippedwith a resistor spark plug, use

the same typefor replacement.

SPARKARRESTERSCREENSERVICE

If the engine muffler is equipped with a

spark attester screen, remove and cleanit

according to the time intervalsand instruc-

tions in the separateEngineOwner's

Manual.

THROTTLELEVERADJUSTMENT

If the engine does not respondto various

throttle leversettings, referto the separate

EngineOwner's Manualfor service infor-

mation or contact your local authorized

engineservice dealer.

CARBURETOR/GOVERNORCONTROL

ADJUSTMENTS