Page 1

1

769-00128 (02/2002)

®

CAUTION

Before installing the

Bumper/Guard, stop the

engine, wait for all moving

parts to stop, and allow the

engine to cool.

Disconnect the spark plug

wire and move it away from

the spark plug.

Remove the key from the

keyswitch on electric start

models.

Tools

Needed

(2) 1/2" Wrenches*

(1) 9/16" Wrench*

(1) 3/4" Wrench*

(2) 7/16" Wrenches**

(1) Flat Blade Screwdriver

(1) Needle-nose Pliers

* Adjustable wrench can be

substituted

** For newer model electric

start tillers

1

2

2

3

3

4

5

6

7

8

8

9

10

10

11

9

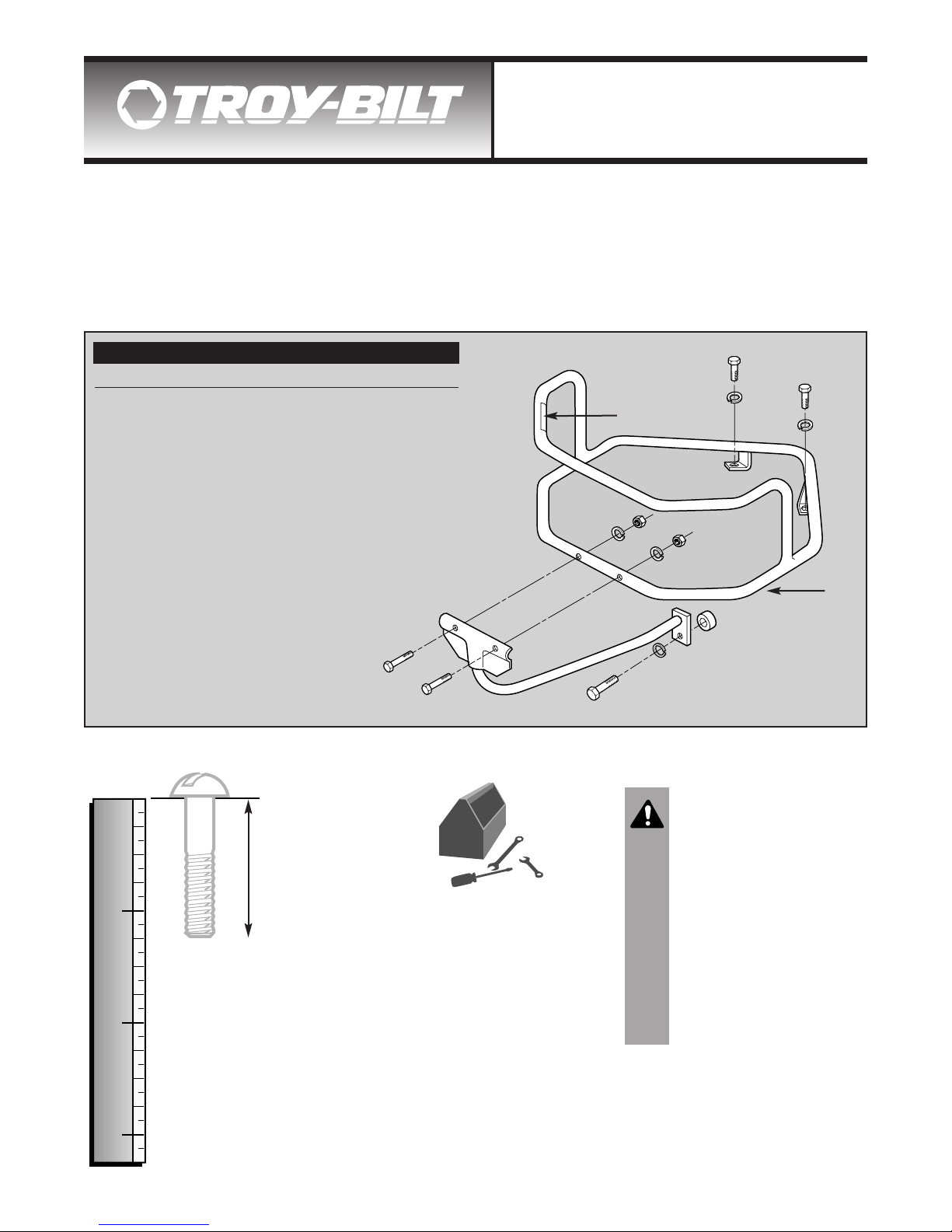

Parts List

Ref. # Part # Description Qty.

1 1910731 Wraparound Assembly .....................1

2 736-0169 Lockwasher, 3/8".............................. 2

3 710-0514 Screw, Hex hd., 3/8"-16 x 1"............. 2

4 1909748 Spacer, 1/2" ...................................... 1

5 736-0921 Lockwasher, 1/2".............................. 1

6 710-3181 Screw, Hex hd., 1/2"-13 x 1-1/2"....... 1

7 1910730 Bottom Brace Assembly ................... 1

8 710-0805 Screw, Hex Hd., 5/16"-18 x 1-1/2" .... 2

9 736-0119 Lockwasher, 5/16"............................ 2

10 710-0267 Nut, Hex, 5/16"-18............................ 2

11 777S30653 Decal ................................................ 1

— 1909784 Hardware Kit (includes Refs 2-6 &

Refs. 8-10) .......................................—

1

2

3

1

2

3

Screw Length

Guide

Place screw on top of

template and measure

distance between

bottom of screw head

and tip of screw.

Thank you for buying a Bumper/Guard for your Horse Model Tiller. To ensure safe

and proper installation of the Bumper/Guard, please read and carefully follow all

instructions. If you have any questions or concerns, be sure to contact us for assistance.

THANK

YOU!

Unpack and Check Parts

Check the contents of the shipping carton against the Parts List. Let us know if any parts are missing or damaged.

Fig. 1: Contents of shipping carton.

Horse Tiller Wraparound Bumper Guard

OEM-290-255 / 290-255-081

Page 2

2

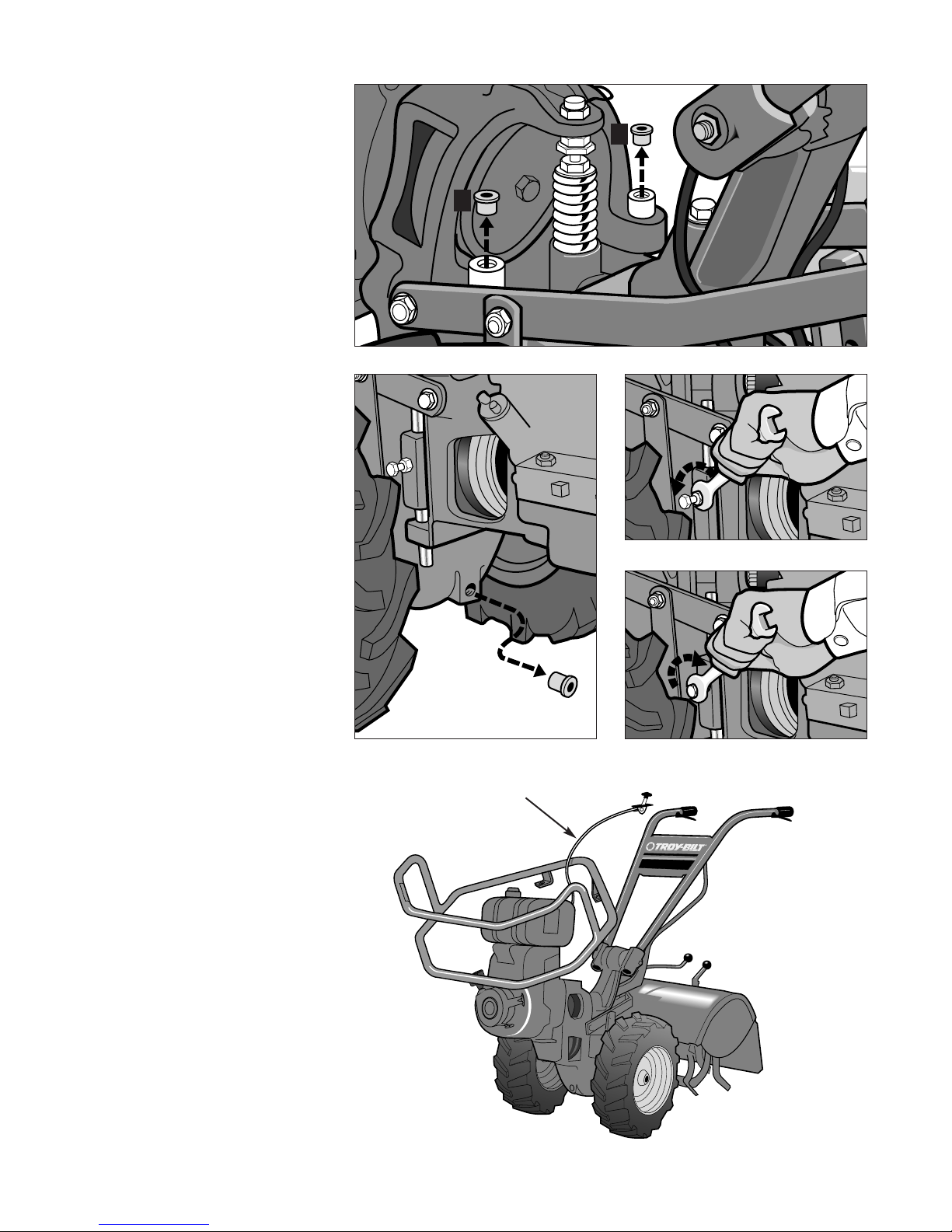

Fig. 2

A

B

A

Fig. 4

Fig. 4A

Fig. 5

Fig. 3

E

A. PREPARING YOUR TILLER

1. Stop the engine and wait for

all moving parts to stop.

Disconnect the spark plug

wire and move it away from

the spark plug. Remove the

ignition key on electric start

models.

2. Put the tines on the ground by

pulling the depth regulator lever

back and all the way up.

3. Using needle-nose pliers, twist

and remove the red plastic

thread protector plugs located

on the two engine mounting

bars (A, Fig. 2). Discard the

plugs.

4. Remove and discard the red

plastic thread protector plug

(B, Fig. 3) at the front of the

transmission.

5. On each side of the tiller, there

is a screw (Fig. 4), with a jam

nut, that holds each engine

mounting bar in place. Using a

1/2" wrench, unthread each jam

nut (not the screws) several

turns.

6. Using the same wrench, slowly

and carefully tighten each screw

(Fig. 4A) until you feel the screw

touch the engine mounting bar.

DO NOT USE EXCESSIVE

FORCE! Tighten each screw

just enough to prevent the

engine mounting bars from

turning when you later install

the bumper mounting screws.

7. On tillers equipped with 6HP

Tecumseh Engines:

a.) Disconnect the throttle lever

from the handlebar. (If the

throttle cable is inside the

handlebar, see your Owner’s

Manual for how to disconnect

the cable at the engine.)

b.) Remove the cable mounting

clips on the handlebar and

route the throttle lever and

cable up through the center

of the wraparound (see E,

Fig. 5).

c.) Set the wraparound over the

engine and reattach the

throttle lever and cable.

Page 3

3

1. If the battery is installed on your

tiller, extreme care must be

exercised to prevent the

possibility of a short circuit from

occurring while installing the

bumper assembly. Read the

WARNING above and follow all

battery safety rules printed in

your Horse Model Owner’s

Manual.

2. Disconnect the ground (negative

[-]) cable from the battery post

and bend it away from any metal

parts. Cover the exposed

battery post with a thick (1/2" or

more) layer of cardboard or

newspaper and tape the

covering in place.

NOTE: Depending upon your

engine model, various electrical

wires and cables may have to be

temporarily disconnected in order

to install the bumper wraparound.

Use the following steps that apply

to your unit. Call the factory

Technical Service Department if

you have any questions about

wires or cables that are not

covered in the following steps.

WARNING

• Batteries can generate

explosive gases. Keep

sparks, flames, or other

ignition sources away at all

times. Always shield eyes

when working near batteries.

• Before working with

electrical wires or

components, disconnect the

battery ground (negative [-])

cable from the battery. Bend

the cable safely away from

any metal parts.

• Do not lay tools or any

metal parts across the battery

terminals as this could result

in sparking or a short circuit.

B. ADDITIONAL PREPARATION

STEPS FOR ELECTRIC

START MODELS ONLY

Fig. 6

F

Fig. 7

G

Fig. 8

H

3. For 6HP Tecumseh Engines: If

the engine has a black plastic

terminal (F, Fig. 6) on the recharging line, pull the terminals

apart. Then proceed to Step C,

“Installing the Bumper” on page 4.

4. Briggs and Stratton Engines:

a. A green engine shutoff wire

leads from the ignition

switch, across the back of

the engine, and over to the

bottom, right side of the

engine. If the wire is attached

to a clip (G, Fig. 7), depress

the clip and remove the wire.

If the wire connects to

another wire by means of

plastic terminals (H, Fig. 8),

pull the terminals apart.

b. If the green wire is secured

to the engine fuel line with

plastic wire ties, loosen the

ties by pressing down on the

tie’s small locking tab while

pushing the long end of the

tie backwards. If the wire is

connected to a clip on the

back of the engine, remove

the wire from the clip.

c. Move the green wire off to

the left side of the tiller.

d. A red recharging wire with

plastic terminals (I, Fig. 9) leads

from the solenoid to behind the

starter motor. Disconnect the

terminals by spreading apart

the two tabs on the larger

terminal. Move the wire off to

the left side of the tiller.

e. Disconnect the starter motor

cable (J, Fig. 9) from the stud

on the starter motor. Replace

the mounting hardware on

the stud.

f. Disconnect the ignition ground

cable (K, Fig. 9) from the stud

on the side of the engine.

Replace the mounting hardware on the stud.

Fig. 9

K

I

J

Page 4

4

Fig. 10

N

Fig. 11

C. INSTALLING THE BUMPER

NOTE: The throttle cable is

positioned below the wraparound,

with the exception of the 6HP

Tecumseh model.

1. For NON-ELECTRIC

STARTING models:

a.) Hold the wrap-around level

and carefully lower it over

the fuel tank and the air

cleaner assembly (Fig. 10).

b.) Align the holes in the L-

shaped legs on the wraparound with the holes in the

tops of the two engine

mounting bars (L, Fig 10).

c.) Loosely attach the legs with

two 3/8"-16 x 1" screws (M,

Fig. 10) and 3/8" lock

washers (N). Leave the

screws very loose for now.

d.) Go to Step 3 on page 5.

2. For ELECTRIC STARTING

models:

a.) Put the Wheels/Tines/PTO

Lever in NEUTRAL.

b.) Hold the wraparound level

and carefully lower it over

the fuel tank and the air

cleaner assembly (Fig. 10).

NOTE: If your tiller has an hour

meter, remove it so the bumper

can fit under the battery bracket.

Reinstall the meter after you finish

the installation steps.

c.) Lower the front of the wrap-

around almost to the floor,

as shown in Fig. 11. Now,

slide the small curved

portion (with L-shaped legs)

between the bottom of the

battery bracket and the top

of the engine mount.

NOTE: If the wraparound will not

fit between the battery bracket and

the engine mount, use a 9/16"

wrench to loosen the two screws

that attach the battery bracket legs

to the transmission cover. Tilt the

battery bracket backward and

insert the wraparound. Retighten

the bracket mounting screws

securely.

d.) Align the holes in the L-

shaped legs on the wraparound with the holes in the

tops of the two engine

mounting bars (L, Fig 10).

e.) Loosely attach the legs with

two 3/8"-16 x 1" screws (M,

Fig. 10) and 3/8" lock

washers (N). Leave the

screws very loose for now.

M

L

Page 5

5

3. Assemble the 1/2"-13 x 1-1/2"

screw (O, Fig. 12), 1/2" lock

washer (P) and spacer (N) to

the end of the bottom brace (S).

4. Thread the screw (O) into the

threaded hole of the transmission (T). Do not tighten the

screw securely at this time.

5. Loosely attach the bracket on

the bottom brace to the front of

the wraparound using two

5/16"-18 x 1-1/2" screws (U,

Fig. 13), 5/16" lock washers (V)

and 5/16" hex nuts (W).

6. Check that the wraparound is

not touching any of the engine

parts. Then securely tighten the

mounting hardware as follows:

a.) Tighten screw (O, Fig. 12) at

front of transmission.

b.) Tighten screws (M, Fig. 10)

on top of motor mount bars.

c.) Tighten screws (U, Fig. 13)

at front of wrap-around.

d.) Unlock the two engine

mounting bars by first backing

off each screw (X, Fig. 14) no

more than 1/4-turn. Then,

using two wrenches, hold

each screw to prevent it from

turning and tighten the jam

nuts (Y, Fig. 14) securely

against the side of the motor

mount.

Fig. 12

Fig. 13

Fig. 14

S

P

N

T

O

X

Y

U

W

V

V

W

NOTE: This completes the

bumper assembly steps for NONELECTRIC START tillers. The

remaining assembly steps are for

ELECTRIC START tillers only.

IMPORTANT: SEE SPECIAL

RECOIL STARTING

INSTRUCTION ON PAGE 6.

7. For 6HP Tecumseh Engines:

Reconnect the black plastic

terminals (F, Fig. 6). Make sure

that the terminals fit together

securely. Your installation is

now complete. Reconnect the

ground (negative [-]) cable to

the battery.

8. Briggs and Stratton Engines:

a.) Depending on your engine

model, either reattach the

green engine shutoff wire to

the clip (G, Fig. 7) on the

control bracket, or reconnect

the plastic terminals (H, Fig.

8). On engines so equipped,

secure the green wire with

the plastic tie(s) removed

earlier.

b.) Reconnect the plastic

terminals (I, Fig. 9) on the

red recharging line.

c. Reconnect the starter motor

cable (J, Fig. 9).

d. Reconnect the ignition

ground cable (K, Fig. 9).

e. Reconnect the ground

(negative [-]) cable to the

battery.

Page 6

6

For Safety’s Sake When

Starting...

Slowly pull the recoil starter rope

to a point outside the bumper

(Fig. 15) before you give it your

“startup” pull.

By doing that, you won’t hit your

fingernails or knuckles on the

bumper as you start the engine.

Also, at the end of your pull, don’t

just let the rope go...it could wrap

around the bumper and maybe

even damage the recoil start

mechanism. Gently feed back the

rope as the recoil rewinds it.

Removing the Bumper Guard

Here’s the easiest way to remove

the Bumper Guard, using the

same steps as you did to

assemble it. Before starting,

disconnect the spark plug wire

and let the muffler and engine

cool down so you won’t get

burned on hot engine parts.

Also see battery WARNING on

page 3.

1. On electric starting tillers, first

disconnect the electric wires on

certain model engines as shown

in steps 2 through 4 on pg. 3.

2. Lock the engine mount bars

(Steps 5 and 6 on pg. 2) and

disconnect the throttle cable on

6HP tillers (Step 7 on pg. 2).

3. Loosen the screws (M, Fig. 10)

on top of the engine mount bars

and remove the screw (O, Fig.

12) on the bottom brace.

4. Remove the screws (U, Fig. 13)

from the front of the bumper and

remove the bottom brace.

5. Remove the screws on top of

the engine mount bars and lift

off the wraparound. Don’t forget

to loosen, then lock the engine

mount bar locking bolts

(explained in Step 6d on pg. 5)

and to reconnect the 6HP

throttle cable.

6. When replacing the bumper

guard, carefully follow the

assembly steps starting on pg. 2.

Fig. 15

CAUTION

Make sure all electrical wires

are securely reattached as

explained in Steps 7 and 8 on

pg 5.

For customer assistance, visit www.troybilt.com, contact your nearest authorized dealer or:

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OHIO 44136-0019, 1-866-840-6483

Printed in U.S.A. Form 769-00??? (02/02)

Loading...

Loading...