Page 1

Operator’s Manual

Log Splitter

Model LS338

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

covered, brush-covered or grass-covered land unless the engi ne’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrest er for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

PRINTED IN U.S.A.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

FORM NO

769-00089A.fm

.

(10/2002)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Oper ation Practices...................................................................3

Assembling Your Log Splitter ............................................................................5

Know Your Log Splitter......................................................................................9

Operating Your Log Splitter...............................................................................10

Adjusting Your Log Splitter ................................................................................12

Maintaining Your Log Splitter.............................................................................12

Storing Your Log Splitter....................................................................................14

Troubleshooting.................................................................................................14

Parts List............................................................................................................16

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new log splitter. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipme nt, please locate the model plate on the

equipment and copy the information from it in the space provided below. The infor mation on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing behind the unit and looking down at the hydraulic tank.

A sample model plate is explained below. For future reference, please copy the model number and

the serial number of the equipment in the space below.

Copy the model number here:

www.troybilt.com

TROY-BILT LLC

P. O. BOX

CLEVELAND, OH 44136

330-558-7220

866-840-6483

361131

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, powerrating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s

Manual packed separately with your unit for more information.

CALLING CUSTOME R SUPPORT

If you have difficulty assembling this product or have any questions regar ding the controls,

operation or maintenance of this unit, please call 1-866-840-6483 or 1-330-558-7220 to reach a

Customer Support representative. Please have your unit’s model number and serial number

ready when you call. See previous section to locate this information. You will be asked to enter

the serial number in order to pr ocess your call.

For more details about your unit, visit our website at w ww.troybilt.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING:

This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol - heed its warning.

WARNING: Engine exh aust, some of its constitu ents, and certa in vehicle components

contain or emit ch emicals known to the Sta te of Cal ifornia to cause cancer , birth defe cts

or other reproductiv e harm.

DANGER:

As with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. This machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

This machine was built to be operated according to the r ules for safe operation in this manual.

General Practices

1. Read, understand, a nd follow all in struction s on the

machine and in the manual(s ) before a ttempting to

assemble and o perate. Keep this ma nual in a safe pl ace

for future and regular re ference a nd for orde ring

replacement parts.

2. Be familiar with all controls and proper ope ration. Know

how to stop the machine and dis engage th em quic kly.

3. Never allow childre n under 16 years to op erate this

machine. Children ,16 years and ove r, should read and

understand instruc tions a nd safety rules in this ma nual

and should be tra ined and supervised by a pa rent.

4. Never allow adults to operate this machine without

proper instruction.

5. Many accidents occ ur when more than one perso n

operates the machin e. If a he lper is a ssisting i n loading

logs, never activat e the control un til the h elper is a

minimum of 10 f eet from t he ma chine.

6. Keep bystanders, helpers, pets , and children at least 20

feet from the machin e while it is in operatio n.

7. Never allow anyo ne to ride on this machine .

8. Never transport cargo o n this mac hine.

9. Hydraulic log sp litters develo p high flui d pressures du ring

operation. Fluid escap ing through a pin hole openi ng can

penetrate your sk in and c ause blo od poiso ning,

gangrene, or death. Give atten tion to the follo wing

instructions at all tim es:

a. Do not check for leaks with you r hand.

b. Do not operate machine with frayed, kinked,

cracked, or dam aged hos es, fitt ing, or tu bing.

c. Stop the engine and relieve hydraulic system

pressure before c hanging o r adjusti ng fitt ings,

hoses, tubing, o r other system compone nts.

d. Do not adjust the pres sure settings of the pump or

valve.

5. Leaks can be detec ted by p assing c ardboard or wood,

while wearing protective glov es and safety glas ses, over

the suspected area. Look for discolor ation o f cardboa rd

or wood.

6. If injured by escap ing fluid , see a d octor immed iately.

Serious infection or reaction c an deve lop if pro per

medical treatment i s not adm inistere d immediate ly.

7. Keep the operator zo ne and a djacent a rea cl ear for sa fe,

secure footing.

8. If your machine is equip ped with an internal comb ustion

engine and it is intended for use n ear an y unimpr oved

forest, brush, or gr ass covere d land, th e engine exhaust

should be equipped with a spa rk arrester. Make su re you

comply with appl icable l ocal, st ate, and f ederal codes.

Take appropriate f irefighting equipm ent with you.

9. This machine s hould be used for splitting wood o nly, do

not use it for any ot her pur pose.

10. Follow the instruct ions in the manual(s) pr ovided with any

attachment(s) for t his machin e.

Preparation

1. Always wear safe ty shoes or heavy boots.

2. Always wear safe ty glass es or safety goggles during

operating this ma chine.

3. Never wear jewelry or loose cl othing th at might become

entangled in movin g or rotati ng part s of the mac hine.

4. Make sure machine is on l evel su rface befo re operatin g.

5. Always block ma chine to preven t uninten ded move ment,

and lock in eit her horizonta l or ve rtical po sition.

6. Always operate this machine f rom the operator zone(s)

specified in the m anual.

7. Logs should be cut with s quare end s prio r to split ting.

8. Use log splitter i n daylig ht or unde r good arti ficial l ight.

9. To avoid personal injury or property damage use extre me

care in handling gasolin e. Gasol ine is e xtremely

flammable and the v apors are explosiv e. Serious

personal injury c an occur w hen gas oline is spilled o n

yourself or your c lothes which c an ignit e. Wash y our skin

and change immedi ately.

a. Use only an approved gasoline cont ainer.

b. Extinguish all cigarettes, cigars , pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel w hile th e

engine is hot or running.

e. Allow engine to cool a t least two minu tes before

refueling.

f. Never overfill the fu el tank. Fill tank to no more

than 1/2 inch b elow bottom o f filler nec k to provide

space for fuel expansion.

g. Replace gasoline cap and t ighten se curel y.

h. If gasoline is spill ed, wipe i t off the e ngine an d

3

Page 4

equipment. move mac hine to another area . Wait 5

minutes before start ing the e ngine.

i. Never store the machine or fu el contai ner in side

where there is a n open fl ame, spar k or pilo t light

as on a water heater, s pace he ater, furnac e,

clothes dryer or other gas ap pliances .

j. Allow machine to cool 5 mi nutes bef ore storin g.

Operation

1. Before starting this machine, review t he “Safety

Instructions”. Failure to follow these rules may result in

serious injury to th e operator or bystander s.

2. Never leave this machine unattended with the eng ine

running.

3. Do not operate mac hine while under the influenc e of

alcohol, drugs, o r medica tion.

4. Never allow anyone to ope rate this machine without

proper instruction.

5. Always operate this machin e with all safet y equipmen t in

place and working. M ake sure all control s are prop erly

adjusted for safe op eration.

6. Do not change the engine gove rnor settings or

overspeed the engin e. The gov ernor con trols the

maximum safe operating spe ed of the engine.

7. When loading a lo g, alwa ys place y our hands on the

sides of the log , not on th e ends, and neve r use you r foot

to help stabiliz e a log. Failure to do so, m ay result i n

crushed or amputated fingers, toe s, hand, or foot.

8. Use only your han d to opera te the co ntrols.

9. Never attempt to sp lit more than one log at a t ime unle ss

the ram has fully exten ded and a sec ond log is nee ded to

complete the separa tion o f the first log.

10. For logs which are not cut s quare, the least squa re end

and the longest p ortion of the log s hould be placed

toward the beam and wedge, and the s quare en d placed

toward the end plate.

11. When splitting in the verti cal positi on, stabi lize the log

before moving the c ontrol. Spl it as follow s:

a. Place log on the en d plate a nd turn un til it le ans

against the beam a nd is st able.

b. When splitting ext ra large o r uneven logs, the log

must be stabili zed with w ooden shi ms or s plit

wood between the log and end plate or ground .

12. Always keep fingers away fr om any crac ks that open in

the log while spl itting. They ca n quickl y close and pin ch

or amputate your fingers.

13. Keep your work ar ea clean . Immedi ately remov e split

wood around the machine so you do not stumble over it.

14. Never move this machine while the eng ine is running.

15. This machine shoul d not be towed on any street , highway

or public road without che cking the existing federal, st ate,

or local vehicle re quiremen ts. Any li censing or

modifications suc h as taillights, etc., needed to comply, is

the sole responsibi lity of the purchaser. If a “Stateme nt of

Origin” is required i n your state, see your l ocal dealer .

16. Do not tow machine faster than 45mph.

17. See Transporting the Log Spli tter secti on in this manua l

for proper towing ins tructions once al l federal , local, o r

state requirements are met.

Maintenance and Storage

1. Stop the engine, di sconnec t the spa rk plug a nd gro und it

against the engi ne before clean ing, or in specting the

machine.

2. Stop the engine an d relieve hydrauli c syste m pressure

before repairing or adjusting fi ttings, h oses, tub ing, or

other system compone nts.

3. To prevent fires, cle an debris and cha ff from the engine

and muffler areas . If the en gine is equipped with a spark

arrester muffler, cl ean and inspect it regu larly accord ing

to manufacturers instructions . Repla ce if dam aged.

4. Periodically check that all nuts and bolts, h ose clamps ,

and hydraulic fi ttings are ti ght to be sure e quipment is in

safe working conditi on.

5. Check all safety g uards and s hields to b e sure they are in

the proper positio n. Never op erate wi th safety gu ards,

shields, or other protective f eatures re moved.

6. The pressure relie f valve is preset at the facto ry. Do n ot

adjust the valve.

7. Never attempt to m ove this machine over hil ly or une ven

terrain without a tow vehicle or adequa te help.

8. For your safety, repla ce all d amaged o r worn pa rts

immediately with ori ginal eq uipment m anufactu rer’s

(O.E.M.) parts only. “Use of p arts which do not meet th e

original equipme nt speci fications may lead to improp er

performance and com promise safety!”

9. Do not alter this mach ine in any ma nner, alteratio ns such

as attaching a rope or extens ion to th e control lever, or

adding to the width or height of the wedge ma y result in

personal injury.

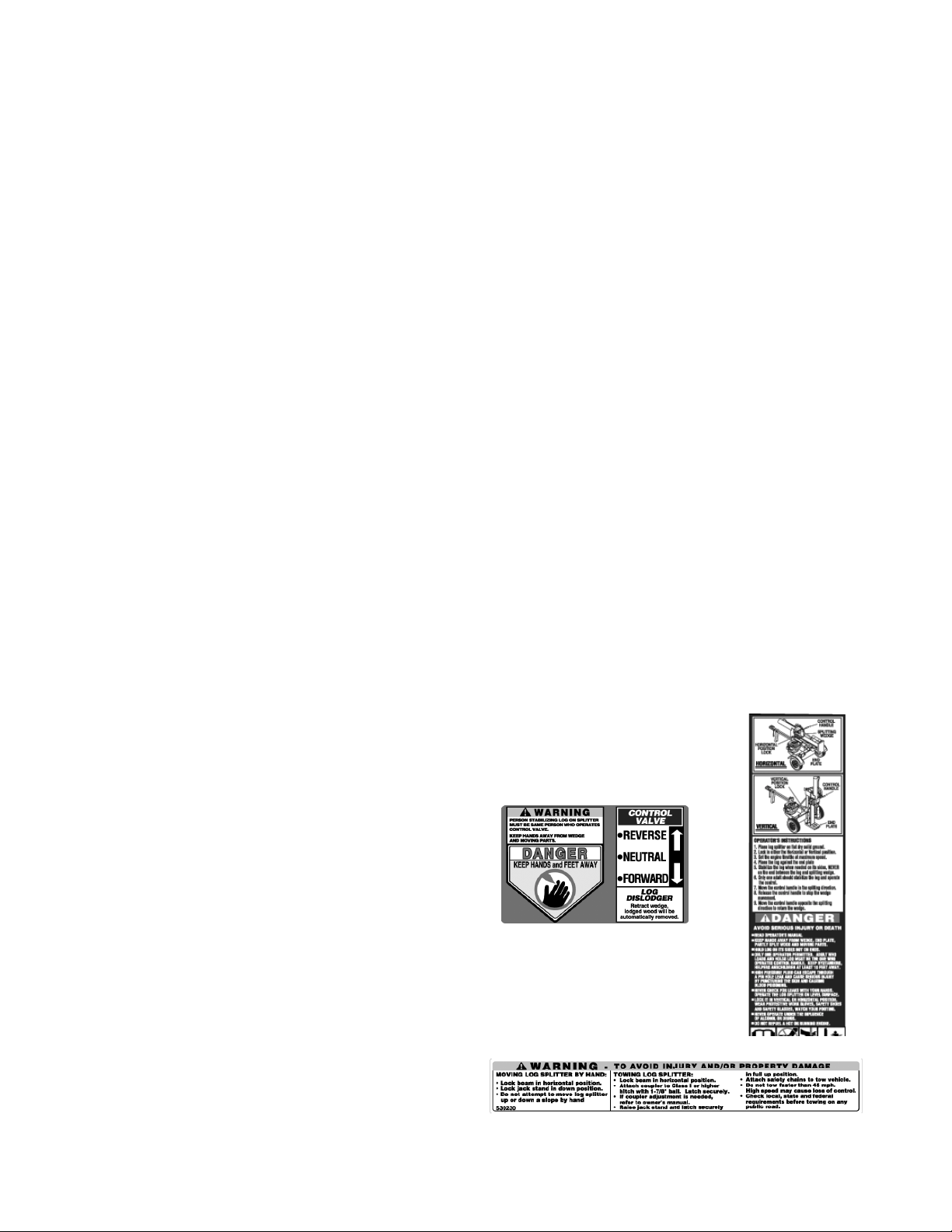

Your Responsibility

Restrict the use o f this po wer machine to person s who read ,

understand and fo llow the w arnings an d instruc tions in this

manual and on t he machi ne. Some of the sa fety labe ls are

reproduced here. Al ways foll ow directi ons on s afety lab els

found on your eq uipment.

4

Page 5

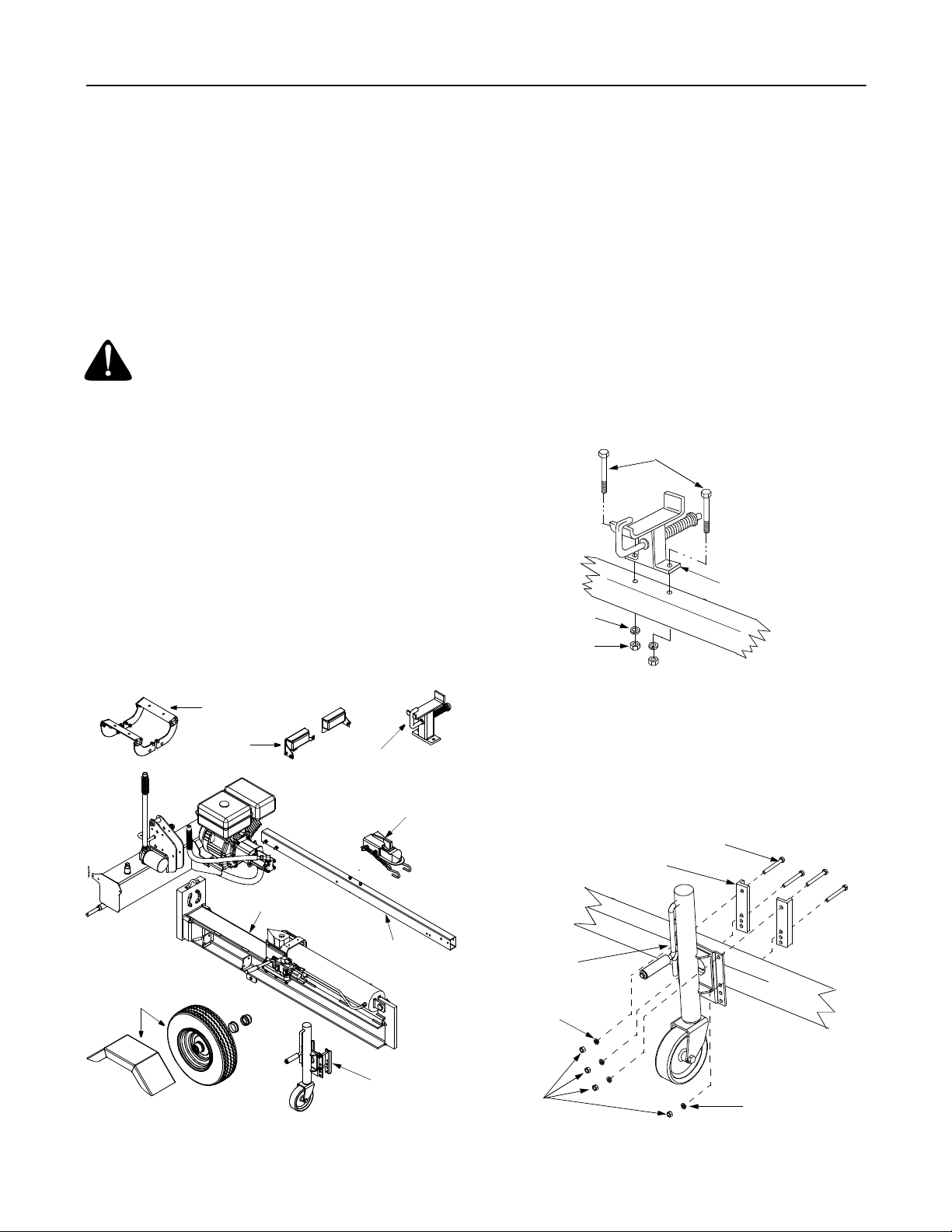

SECTION 2: ASSEMBLING YOUR LOG SPLITTER

Unpacking from Cr ate

• Pry top, sides, and ends off the crate. Set panels

aside to avoid tire puncture or personal injury.

• Remove and discard plastic bag that covers unit.

• Remove any loose parts if included with unit (i.e.,

operator’s manual, etc.)

• Cut and remove straps which secu re parts to

bottom of crate. Unbolt any remaining parts which

may be bolted to the bottom of the crate.

WARNING:

unpacking this machine. Some components

are very heavy and will require extra people or

mechanical handling equipment to move.

Use extreme caution whil e

Loose Parts

1. Reservoir Tank and Engine-Pump Assembly

2. Engine-Pump Assembly Hardware

3. Wedge, Beam and Cylinder Assembly

4. Tongue Assembly

5. Wheels

6. Hitch Assembly

7. Beam Support/Latch Bracket

8. Log Cradle Brackets and Hardware

9. Fenders

10. Adjustable Jack Stand Assembly

11. Tail Light Kit

12. Hub Cap (2)

Before Assembling

• Disconnect spark plug wire and ground against the

engine to prevent unintended starting of the log

splitter. To locate the spark plug, please refer to the

engine manual, shipped seperately with the unit.

Attaching Beam Support/Latch Br acket

The beam support is already attached to the tongue

before shipping. If not, follow instructions below:

• Remove two hex bolts, lock washers, and hex nuts

from the tongue. See Figure 2.

• Place the beam support/latch bracket on the

tongue and secure with the hardware just removed.

Tighten securely.

Hex Bolts

Beam Support/

Lock

Washer

Hex Nut

Figure 2

Latch Bracket

T

o

n

g

u

e

Wheel & Fender

Assembly

Log Cradle

T ail Light

Kit

Wedge, Beam

& Cylinder Assemb ly

Figure 1

Beam Support/

Latch Bracket

Hitch Assembly

T ongue

Assembly

Jack Stand

Attaching Jack Stand

• Remove four hex bolts, lock washers, and hex nuts

that secure jack stand mounting brackets to the

jack stand. See Figure 3.

• Place the jack stand halfway between beam

support/latch bracket and end of tongue.

Hex Bolts

Mounting

Brackets

Jack Stand

T

o

n

Lock

Washer

Hex

Nuts

Lock Washer

Figure 3

g

u

e

5

Page 6

• Insert he x bol ts th rough top ho les in jack stand

mounting brackets and holes in jack stand. Secure

with lock washers and hex nuts. See Figure 3.

• Insert hex bolts through upper holes in the bottom

of mounting brackets and jack stand. Secure with

lock washers and hex nuts. See Figure 3.

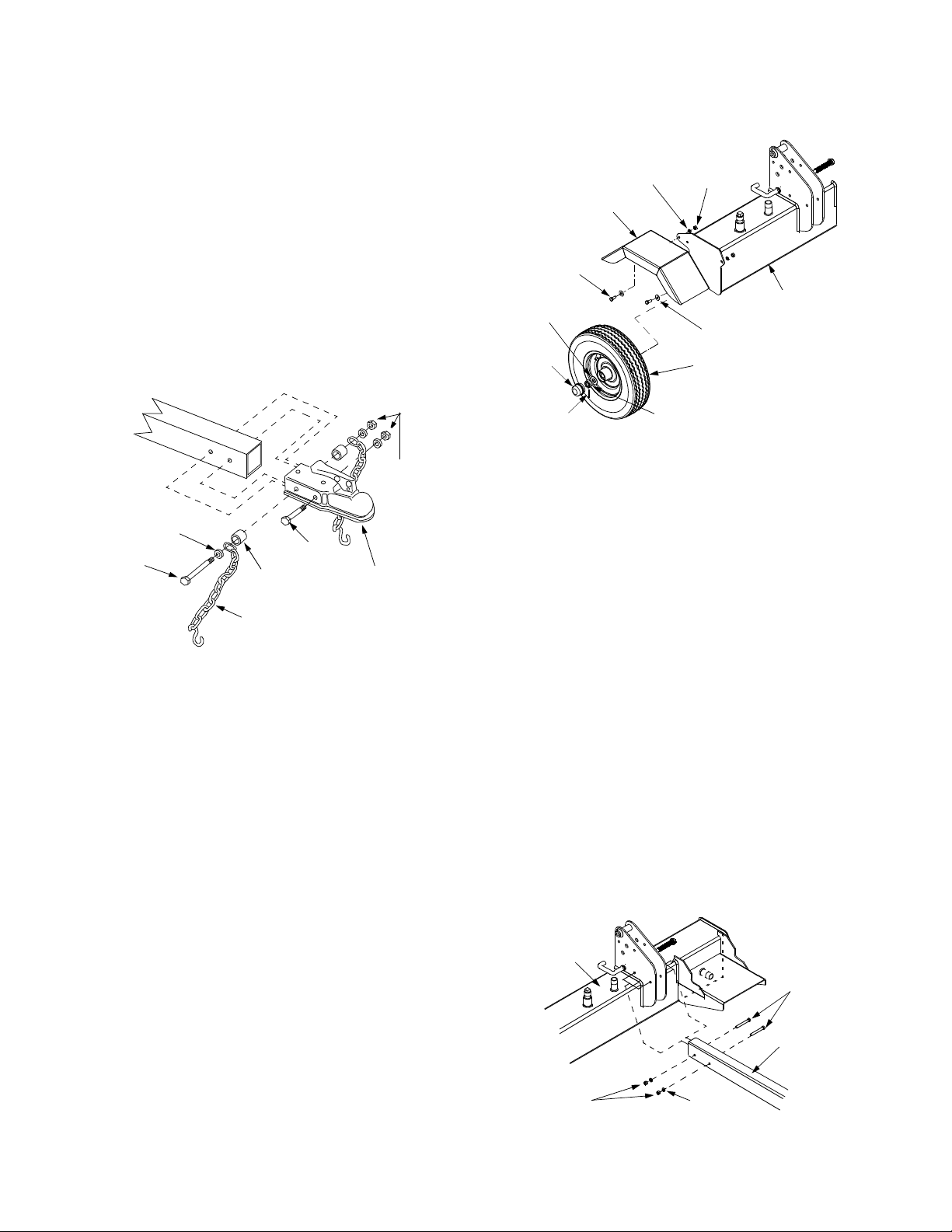

Hitch Assembly

The hitch assembly is already attached to the tongue

before shipping. If not, follow instructions below:

• Remove the hardware from the hitch assembly and

place the hitch on the end of the tongue.

• Insert hex bolt through flat washer, end of safety

chain, spacer, and then rear hitch hole. Pivot the

end of sa fety chain so it faces the ball e nd of hit ch.

See Figure 4.

• Insert cotter pins through slots in nuts and holes in

axle and secure by bending the ends of the cotter

pins in opposite directions. See Figure 5.

Lock

Washer

Fender

Hex

Bolt

Flat

Washer

Hub Cap

Hex

Nut

Flat

Washer

Wheel

Reservoir

Tank

T

ongue

Lock

Nut

Flat

Wash er

Hex

Bolt

Spacer

Chain

Hex

Bolt

Hitch

Assembly

Figure 4

• Insert other spacer, safety chain, and flat washer

on the other end of the hex bolt and secure with hex

lock nut. See Figure 4.

• Insert hex bolt through the front hole of hitch and

secure with flat washer and hex lock nut. Tighten

both hex nuts to 23 ft-lbs.

Attaching Wheels

• Block up the reserv oir tank assembly about eight to

twelve inches .

• Remove and discard plastic shipping caps on the

outside of the wheels.

• Remove the co tter pi n, hex slot ted nut, and flat

washer from each axle.

NOTE: It is recommended that you polish the axles with

emery cloth before you install the wheels.

Cotter Pin

Hex Slotted

Nut

Figure 5

• The wheels should spin freely and there should be

no side to side play.

• Place hub caps in position on wheels and tap on to

the axle wit h a soft hamme r or mall et.

IMPORT ANT :

Maximum tire pressure under any

circumstance is 30 psi. Equal tire pressure should be

maintained at all times.

Attaching Fenders

• Remove the hex nuts, lock washers, flat washers,

and hex bolts from the side of tank.

• Determine the proper assembly holes in the

fenders over the tires against the tank.

• Insert hex bolts through flat washers, holes in

fenders, and tank. See Figure 5. Secure fender with

lock washers and hex nuts. Tighten securely.

Attaching the Tongue

• Remove two hex bolts, lock washers, and hex nuts

on the front of the reservoir tank. See Figure 6.

• Place the tongue in position and secure with

hardware just removed.

• Remove the reservoir tank from the blocks.

Reservoir

Tank

Hex

Bolts

• Place a wheel on each axle with the valve stem

facing outward. See Figure 5.

• Place a flat washer on each axle and secure with

hex slotted nut.

• Tighten slotted nut until snug and then back off

approximately 1/3 turn or until one of the slots on

the slott ed nut lin es up with t he ho le in the axle.

T ongue

Hex

Nuts

Lock

Washe rs

Figure 6

6

Page 7

Attaching Beam

• For shipping purposes, the pressure hose is

attached to the pump on the engine and to the

control valve on the cylinder.

• Disconnect the pressure hose from the adapter on

the pump.

• Stand the wedge, beam, and cylinder assembly

upright with cylinder toward the top. An assistant

may be helpful.

• Remove cotter pin and clevis pin from welded

brackets on beam assembly and move the

reservoir tank assembly in position against the

beam.

• Insert clevis pin just removed through brackets on

beam and reservoir tank assembly. Secure with

cotter pin by bending the ends of the pin in opposite

directions.

Cotter

Pin

Clevis

Pin

Brackets

Hex

Bolts

Hex

Nuts

Pump

Facing

Out

Reservoir

Tank

Engine

Mounting

Bracket

Lock

Washer

Figure 8

Attaching The Hoses

Suction Hose

• The suction is attached to the reservoir tank,

beneath the engine mounting bracket. Loosen the

hose clamp on the free end of the hose. Remove

any protective insert from the end of the hose. See

Figure 9.

Reservoir

Tank

Figure 7

Attaching Engine-Pump Assembly

• Place the engine and pump assembly in position on

the engine mounting br acket wit h the pum p facing

out. See Figure 8.

• Align holes in base of engine with appropriate holes

in engine mounting bracket.

• Secure the engine and pump assembly with four

hex bolts, lock washers, and hex nuts packed with

the Operato r’s Manua l.

• Secure with lock washers and hex nuts. Tighten to

14 ft-lbs.

Attached

T o Engine

Attached To

Reservoir Tank

Suction Hose

Pump

Hose

Clamp

Pressure

Hose

Figure 9

• Remove the protective cap from the fitting on the

bottom of the pump (some oil may flow from pump).

Attach the end of the suction hose to the fitting on

the bottom of the pump. Place the hose clamp at

the base of the fitting and tighten securely.

Pressure Hose

• The pressure hose is attached to the control valve.

Route the hose between the beam and the tongue.

Secure the pressure hose to the adapter on the top

of the pump. See Figure 9.

Return Hose

• The return hose is attached to the top of the control

valve. Loosen the hose clamp on the free end of the

hose. Cut the securing strap. Remove any

protective insert from the end of the hose.

7

Page 8

• Remove the protective cap from the fitting on top of

the filter head. Attach the end of the hose to the

fitting on top of the filter. Pl ace the hose clamp at

the base of the fitting and tighten securely. See

Figure 10.

Attached

Control Valve

Hose

Clamp

Filter

Head

To Cylinder

• Insert four carriage bolts through the log cradle and

cradle support brackets. Secure with lock washers

and hex nuts. Tighten all carr iage bolts and nuts.

• Repeat on the other side.

Preparing the Log Splitter

• Lubricate the beam area where the splitting wedge

will slide with engine oil. Do not use grease.

• Remove vented reservoir dipstick, which is located

in front of the engine on top of the reservoir tank.

See Figure 12.

Reservoir

Dipstick

Attached To

Reservoir Tank

Filter

Return Hose

Figure 10

Attaching the Log Cradle

• Pull the beam lock on the beam support/latch

bracket out and pivot it down. Carefully lower the

wedge, beam, and cylinder assembly to the

horizontal position. Pull out and rotate beam lock to

secure beam in the horizontal position.

NOTE:

shipped in the same box with the log cradle.

• Place one cradle support bracket against the lower

Lock Washers

& Hex Nuts

• Insert two carriage bolts through the cradle support

• Attach the second cradle support bracket to the

• Place one log cradle over the support brackets and

The hardware for attac hing the log cradle is

outside surface of one of the beam flanges.

See Figure 11.

Log

Cradles

Cradle

Support

Bracket

Beam

Flanges

Carriage

Bolts

Figure 11

bracket and the beam flange. Secure with lock

washers and hex nuts. Do not tighten at this time.

same side of the beam in the same manner.

align the bolts holes.

Figure 12

• Fill the reservoir tank with Dexron III automatic

transmission fluid or 10W AW hydraulic fluid.

• Check fluid le vel using the dipst ick. The rese rvoir

tank has a capacity of approximately 7 gallons. Do

not overfill.

• Replace vented dipstick securely. Tighten the

dipstick until the top of the threads are flush with the

top of the pipe.

• If not already, disconnect the spark plug wire and

prime the pump, by pulling the recoil starter to turn

the engine over approximately 10 times.

• Reconnect the spark plug wir e.

• Start engine according toinstructions on page 10.

• Use control handle to engage the wedge to the

farthest extended position and then retract it.

• Refill t ank t o with in th e rang e spe cifie d on t he

dipstick.

• Extend and retract the wedge 12 complete cycles

to remove trapped air (system is “self-bleeding”).

• Much of the original fluid has been drawn into the

cylinder and hoses. Make certain to refill the

reservoir to prevent extreme damage to the

hydraulic pump. Failure to refill the tank will void

your warranty.

NOTE: Some fluid may overflow from the vented

reservoir dipstick as the system builds heat and the

fluid expands and seeks a balanced level.

IMPORT ANT :

Do not operate the log splitter without the

proper amount of transmission fluid in the reservoir.

8

Page 9

SECTION 3: KNOW YOUR LOG SPLITTER

Compare the illustration in Figure 13 below with the controls on your log splitter, and get familiar with its features

before starting to operate. Know how to stop the machine quickly in the event of an emergency.

Tongue

Jack Stand

Cylinder

Horizontal

Beam Lock

Contr o l Handle

Reservoir Tank

Tail Light

Wedge

Beam Assembly

Log Cradle

Vertical Beam Lock

Horizontal

Beam Lock

How it works

Reverse

T o ret urn

Neutral

Control

Handle

Forward

Vertical

Beam Lock

wedge

To stop

To split wood

Figure 13

Control Handle

The control handle has three positions. See Figure 13.

• Move control handle FORWARD or DOWN to

move wedge down to split wood.

NOTE: Control handle will return to neutral position as

soon as handle is released.

• Release the control handle to stop the wedge

movement.

• Move control handle BACK or UP to return the

wedge toward the cylinder. The control handle will

lock in the disengaged position. It will return to

neutral automatically when the return stroke is

complete.

Horizontal & Vertical Beam Locks

These two locks, as their name suggests, are used to

secure the beam in the horizontal or the vertical

position. The vertical beam lock is located next to the oil

filter. The horizontal beam lock is located on the beam

support latch bracket. See Figure 13.

Engine Controls

See the accompanying engine manual for the location

and function of the controls on the engine.

Stopping Engine

• Turn engine switch to OFF position.

• Turn off the fuel valve.

• Disconnect spark plug wire and ground against the

engine to prevent unintended starting.

IMPORT ANT :

in the engine. Be certain to service engine with gasoline

and oil as instructed in the accompanying engine

manual bef ore opera ting your machine.

9

This unit is shipped without gasoline or oil

Page 10

SECTION 4: OPERATING YOUR LOG SPLITTER

For best performance, the engine is designed to be

WARNING:

instructions and warnings on the machine and

in this manual before operating.

Read, understand, and follow all

operated at the FAST throttle position.

• If weather is cold, run wedge up or down beam 6 to

8 times to circulate the hydraulic fluid.

WARNING:

safety shoes, ear protection, and safety

glasses when operating log splitter. Ensure

safe footing.

Wear leather work gloves,

Gas and Oil Fill-Up

• Service the engine with gasoline and oil as

instructed in the engine manual packed with your

log splitter. Read instructions carefully.

WARNING:

handling ga soline . Gasoline is extreme ly

flammable and the vapors are explosive. Never

fuel machine indoors or while the engine is hot

or running.

NOTE: Gasoline can be added to the eng ine whe n the

log splitter is in either the horizontal or vertical position.

However, there are less obstructions when the unit is in

the vertical positio n.

Use extreme care when

Before Each Use

• Remove the dipstick and check hydraulic fluid level.

Refill if necessary.

• Check engine oil le vel. Refi ll if necessar y.

• Fill up gasoline if necessary.

• Lubricate with engine oil the beam area where

splitting wedge will slide. Do not use grease to

lubricate. Make sure to lubricate both the front and

the back of the beam face.

• Attach spark plug wire to the spar k plug.

WARNING:

the muffler and surrounding areas are hot and

can cause a burn. Do not touch.

When starting a warm engine,

Using the Log Splitter

• Place the log splitter on level, dry ground.

• Place the beam in either the horizontal or vertical

position and lock in pl ace with the appropriate

locking rod.

• Block the front and back of both wheels.

• Place the log against the end plate and only split

wood in the direction of the grain.

• To stabilize the log, place your hand only on sides

of log. Never place hand on the end between the

log and the splitting wedge.

• Only one adult should stabilize the log and operate

the control handle, so the operator has full control

over the log and the splitting wedge.

Control Handle

1. Move control handle FORWARD or DOWN to split

wood.

2. Release the control handle to stop the wedge

movement.

3. Move control handle BACK or UP to return the

wedge.

Vertical Position

• Pull the horizontal beam lock out to release the

beam and pivot the beam to the vertical position.

A

Starting Engine

• Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug wire is

fastened securely over metal tip of the spark plug.

• Turn the fuel valve to the ON position.

• Move choke lever to CHOKE position.

• Slide the throttle control lever about one-third way

towards the FAST position.

• Turn engine switch to ON position.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point).

• Pull rope with a rapid, full arm stroke. Keep firm grip

on starter handle. Let rope rewind slowly. Repeat

until engine cranks.

• After en gine s tarts , mov e chok e leve r to O FF

position. Place throttle lever to the speed desired.

B

Figure 14

10

Page 11

• To lock the beam in the vertical position, pull out on

the vertical beam lock and rotate it to secure the

beam. See Figure 13.

• Stand in front of the unit to operate the control

handle and to stabilize the log. See Figure 14A.

Horizontal Position

• Pull the vertical beam lock out and rotate it down.

See Figure 13. Pivot beam to the horizontal

position. The beam will lock automatically in

horizontal position.

• Stand behind the reservoir tank to operate control

handle and to stabilize the log. See Figure 14B.

Operating Tips

Always:

1. Use clean fluid and check fluid level regularly.

2. Use Dexron III Automatic Transmission Fluid or

10W AW hydraulic fluid.

3. Use a filter (clean or replace regularly)

4. Use a breather cap on fluid reservoir.

5. Make sure pump is mounted and aligned properly.

6. Use a flexible “spider” type coupling between

engine and pum p drive sh afts.

7. Keep hoses clear and unblocked.

8. Bleed air out of hoses before operating.

9. Flush and clean hydraulic system before restarting

after servicing.

10. Use “pipe dope” on all hydraulic fittings.

11. Allow time for warm-up before splitting wood.

12. Prime the pump before initial start-up by turning

over the engine with spark plug disconnected.

13. Split wood along the grain (lengthwise) only.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Use a solid engine /pump coupling.

3. Operate through relief valve for long.

4. Attempt to adjust unloading or relief valve settings

without pressure gauges.

5. Operate with air in hydraulic system.

6. Use teflon tape on hydraulic fittings.

7. Attempt to cut wood across the grain.

• Place log splitter on a firm, level surface.

• To raise the beam for vertical operation: Pull out

the horizontal beam lock on the tongue.

• Pivot beam lock down to release the beam.

• Move the beam to the vertical position. Secure it

with the beam lock on the reservoir tank assembly.

WARNING:

vertical position when splitting heavy logs.

• To lower the beam: Pull out the vertical beam lock

on the reservoir tank.

• Pivot beam lock down to release the beam.

Carefully pull back on beam and lower it to the

horizontal position. See Figure 13.

• Pull out the beam lock on the tongue, pivot it

upwards and release it to hold the beam. Make

certain it is latched securely.

Always use the log splitter in the

Transporting the Log Splitter

IMPORT ANT :

before transporting the log splitter.

• Lower the beam to its horizontal position. Make

certain the beam is locked securely with the

horizontal beam lock.

• Raise the adjustable jack stand by turning the crank

handle clockwise.

• Attach hitch coupler to a class I or higher hitch with

a 1-7/8” ball on the towing vehicle, making sure to

latch securely.

• Connect the sa fety chai ns to the to wing vehi cle.

NOTE: Use caution when backing up. It is

recommended to use a spotter outside the vehicle.

Always turn the fuel valve to OFF position

a. If the coupler hitch does not fit on the ball,

turn the adjus tment nut one tu rn c ount erclockwise.

b. If the coupler hitch is too loose on the ball,

turn the adjus tment nut o ne tu rn c lockwi se.

WARNING:

and check local, state, and federal

requirements before towing on any public road.

Do not tow faster than 45mph

Raising and Lowering Beam

• Use control handle to run wedge up and down

beam 6 to 8 times to circulate the hydraulic fluid,

which will warm and thin the fluid.

• Plug in the tail lights as instructed in the tail light kit

manual included with your log splitter.

11

Page 12

SECTION 5: ADJUSTING YOUR LOG SPLITTER

NOTE: The gibs may be rotated an d/or tu rned ove r for

WARNING:

adjustments without first stopping engine,

disconnecting spar k plug wire, and grounding it

against the engine.

Wedge Assembly Adjustment

As normal wear occurs and there is excessive “play”

between the wedge and beam, adjust the bolts on the

side of the wedge assembly to eliminate excess space

between the wedge and the beam. See Figure 15.

• Loosen the jam nuts on the two adjustment bolts on

the side o f the wedg e.

• Turn the adjustment bolts in until snug and then

back them off slowly until the wedge assembly will

slide on the beam.

• Tighten the jam nuts securely against the side of

the wedge to hold the adjustment bolts in this

position.

Do not at any time make any

even wear.

• Loosen the lock nuts under each back plate and

slide the gibs out.

• Turn or replace the gibs.

• Reassemble the back plate and secure with the

lock washers and lock nuts.

• Readjust the bolts on the side of the wedge

assembly.

Adjustment

Bolt

Lock Washer

Jam Nut

Gibs

Gib Adjustment

Periodically remove and replace the “gibs” (spacers)

between the wedge assembly and the back plate.

See Figure 15.

Lock Nut

SECTION 6: MAINTAINING YOUR LOG SPLITTER

7. Improper adjustment of splitting wedge

WARNING:

repairing, or inspecting, disengage the control

lever and stop engine. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

Conditions that will void Warranty

1. Failure to maintain proper fluid level in reservoir

2. Changing the relief valve setting or pressure

adjustment of control valve without proper

knowledge and instruction from the factory

WARNING:

the hoses to burst, cylinder to rupture, and

intense fluid to be released, which could result

in serious personal injury .

3. Disassembling the pump

4. Use of incorrect hydraulic fluid

5. Allowing the flexible pump coupler to deteriorate

without proper and regular inspection

6. Lack of lubrication or improper lubrication of the

beam or unit

Before cleaning, lubricating,

Higher pressure could cause

8. Excessive heating of the hydraulic system

9. Attempting to start unit in temperatures under 20°F

without pre-heating fluid in reservoir

10. Unattended leaks in hydraulic system

Hydraulic Fluid

• Check the hydr aulic fluid leve l in the log split ter

reservoir tank before each use.

• Maintain fluid level within the range specified on the

dipstick at all times.

• Change the hydraulic fluid in the reservoir every

100 hours of operation.

• Disconnect the suction hose from the bottom of the

reservoir tank and drain the fluid into a suitable

container. Refill using only Dexron III automatic

transmission fluid or 10W AW hydraulic fluid.

NOTE: Please dispose of used hydraulic fluid and

engine oil at approved recycling centers only.

• Since contaminants in fluid may damage the

hydraulic components, you will have to drain the

fluid and flush the reserv oir tank and hoses with

Figure 15

Lock

Washer

12

Page 13

kerosene whenever any r epair work is performed

on the tank, hydraulic pump or valve. For this job,

contact your nearest service dealer.

Hydraulic Filter

• Change the hydraulic filter every 50 hours of

operation. Use only a 10 micron hydraulic filter.

Order part number 723-0405.

Beam and Splitting Wed ge

• Lubricate both sides of the beam (where it comes

into contact with the splitting wedge), before each

use, with engine oil. The wedge plate on the log

splitter is designed so the gibs on the side of the

wedge plate can be removed and rotated and/or

turned over for even wear.

• Make certain to readjust the adjustment bolts so

wedge moves freely, but no excess space exists

between the wedge plate and the beam.

Hose Clamps

• Check, before each use, if hose clamps on the

suction hose (attached to the side of the pump) are

tight. Check the hose clamps on the return hose at

least once a season.

• Loosen set screw on pump coupling half and

remove coupling half.

• Slide new engine coupling half onto the engine

shaft until the end of the shaft is flush with the inner

portion of the coupling half. ( There must be space

between end of the engine support bracket and

coupling half). Tighten set screw.

• Install pump coupling half and key on pump shaft.

Rotate coupling half until set screw faces opening

in shield. Do not tighten set screw.

• Install nylon “spider” onto engine coupling half.

• Align pump coupling half with nylon “spider” by

rotating engine using starter handle. Slide coupling

half into place while guiding three mounting bolts

through holes in pump support bracket.

• Secure with nuts and washers removed earlier.

• Set .010” to .060” clearance between the nylon

“spider” and the engine coupling half by sliding a

matchbook cover between the nylon “spider” and

the engine coupling half and moving pump coupling

half as needed. Secure pump coupling half with set

screw. See Figure 16.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

Gear Pump

Engine

Refer to the engine manual for all maintenance needs.

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert,

located between the pump and the engine shaft. Over

time, the co upler wi ll harde n and dete riorat e.

Replace th e coupler if you detec t vibrati on or noi se

coming from the area between the engine and the

pump. If the coupler fails completely, you will

experience a loss of power.

IMPORT ANT :

as a blow will cause permanent damage to the engine.

• Remove thr ee nut s and lock wa shers t hat se cure

the pump to the coupling shield. Two nuts are at the

bottom corners and one is in the top center.

• Remove t he pu mp.

• Rotate the engine by slowly pulling starter handle

until engine coupling half set screw is visible.

Loosen set screw using allen wrench and slide

coupling half off engine shaft.

Never hit the engine shaft in any manner,

Set

Screw

Nylon

“Spider”

Insert

Clearance

Engine

Figure 16

Steel

Coupling

Halves

Tires

See sidewall of tire for recommended pressure.

Maximum tire pressur e under any circumstances is 30

p.s.i. Maintain equal pressure on all tires.

WARNING:

p.s.i.) when seating beads may cause tire/rim

assembly to burst with force sufficient to cause

serious injury.

Excessive press ure (over 3 0

13

Page 14

SECTION 7: STORING YOUR LOG SPLITTER

Prepare your log splitter for storage at the end of the

season or if the log splitter will not be used for 30 days

or more.

WARNING:

in the fuel tank inside of building where fumes

may reach an open flame or spark, or where

ignition sources are present such as hot water

and space heater s, fu rnac es, cl othe s dry ers,

stoves, electric motors, etc.

• Clean the log splitter thoroughly.

NOTE: We do not recommend the use of pressure

washers or garden ho se to clean your unit. These m ay

cause damage to electric components, spindles,

pulleys, bearings or the engine. The use of water wi ll

shorten life and reduce serviceability.

• Wipe unit wi th an oile d rag to pr event rust ,

especially on the wedge and the beam.

Never store machine with fuel

• Drain fuel tank. Always drain fuel into approved

container outdoors, away from open flame. Be sure

that engine is cool before draining the fuel. Do not

smoke while handling fuel.

• Start the engine and let it run until the fuel lines and

carburetor are empty.

• Remove spark plug, pour approximately 1/2 ounce

(approximately one tablespoon) of engine oil into

cylinder and crank slowly to distribute oil.

• Replace spar k plug.

• Do not store gasoline from one season to another.

• Replace your gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

SECTION 8: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Fuel shut -off va lve cl osed .

4. Throttle control lever not in correct

starting position.

5. Choke not in CHOKE pos ition.

6. Engine not primed properly.

7. Blocked fuel line.

8. Faulty spark plug.

Engine runs erratic 1. Spark plug wire loos e.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

NOTE: For repairs beyond those listed above, contact your nearest authorized service center.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Turn the valve to ON position.

4. Move throttle lever to FAST position.

5. Move choke to CHOKE position.

6. Prime engine.

7. Clean fuel line.

8. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See authorized service dealer.

14

Page 15

Hydraulic Troubleshooting

Problem Cause Remedy

Cylinder rod will not move 1. Broken drive shaft.

2. Shipping plugs left in hydraulic

hoses.

3. Set screws in coupling not adjusted

properly.

4. Loose shaft coupling.

5. Gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil l evel.

9. Damaged directional valve.

10. Blocked directional valve.

Slow cylinder shaft speed

while extending and

retracting.

Leaking cylinder 1. Broken seals.

Engine runs but wood will

not split or wood splits too

slowly

Engine stalls during

splitting

Engine will not turn or

stalls under low load

conditions

Leaking pump shaft seal 1. Broken drive shaft.

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil l evel.

6. Contaminated oil.

7. Directional valve leaking internally.

8. Internally damaged cylinder.

2. Scored cylinder.

1. Small gear section damaged.

2. Pump check valve leaking.

3. Excessive pump inlet vacuum.

4. Incorrect oil l evel.

5. Contaminated oil.

6. Directional valve leaking internally.

7. Overloaded cylinder.

8. Internally damaged cylinder.

1. Low horsepower/weak engine.

2. Overloaded cylinder.

1. Engine/pump mi salignment.

2. Frozen or seized pump.

3. Low horsepower/weak engine.

4. Hydraulic lines blocked.

5. Blocked directional valve.

2. Engine/pump mi salignment.

3. Gear sections damaged.

4. Poorly positioned shaft seal.

5. Plugged oi l breath er.

1. See authorized service dealer.

2. Disconnect hydr aulic hose s, remove

shipping plugs, reconnect hoses.

3. See operator’s manual for correct

adjustment.

4. Correct engine/pump alignment as

necessary.

5. See authorized service dealer.

6. See authorized service dealer.

7. Flush and clean hydraulic system.

8. Check oil level.

9. See authorized service dealer.

10. Flush and clean hydraulic system.

1. See authorized service dealer.

2. Make certain pump inlet hoses are clear

and unblocked-use short, large

diameter inlet hoses.

3. See authorized service dealer.

4. See authorized service dealer.

5. Check oil level.

6. Drain oil, clean reservoir, and refill.

7. See authorized service dealer.

8. See authorized service dealer.

1. See authorized service dealer.

2. See authorized service dealer.

1. See authorized service dealer.

2. See authorized service dealer.

3. Make certain pump inlet hoses are clear

and unblocked.

4. Check oil level.

5. Drain oil, clean reservoir, and refill.

6. See authorized service dealer.

7. Do not attempt to split wood against the

grain.

8. See authorized service dealer.

1. See authorized service dealer.

2. Do not attempt to split wood against the

grain or see authorized service dealer.

1. Correct alignment as necessary.

2. See authorized service dealer.

3. See authorized service dealer.

4. Flush and clean hydraulic system.

5. Flush and clean hydraulic system.

1. See authorized service dealer.

2. Correct alignment as necessary.

3. See authorized service dealer.

4. See authorized service dealer.

5. Make certain reservoir is properly

vented.

NOTE: For repairs beyond those listed here, contact your nearest authorized service center.

15

Page 16

SECTION 9: PARTS LIST FOR MODEL LS338

21

28

31

24

29

26

16

65

23

22

7

8

66

3

45

80

83

85

92

11

10

9

15

4

1

43

44

82

84

37

13

20

12

6

89

47

90

46

36

87

41

30

47

40

42

48

39

65

25

27

32

38

66

33

64

49

86

67

41

NOTE:

reference only, may not resemble the

engine on your equipment .

54

79

68

69

66

65

The engine, shown here for

51

53

50

55

58

59

53

57

61

78

38

39

76

64

72

74

60

72

71

74

73

64

66

77

16

65

66

64

70

Page 17

Model LS338

Ref.

No.

1.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

20. 681-0129A Beam Assem bly

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

Part No. Part Description

781-0686 Log Tray Bracket

781-0682 Log Tray

710-3097 Carriage Bolt 3/8-16 x 1.0

719-0550 Wedge Assembly

712-0239 Lock Nut 1/2-20

710-1018 Hex Cap Screw 1/2-20 x 2.75

710-1806 Hex Screw 1/2-13 x 3.25

781-0351 Adjustable Gib

712-0711 Hex Jam Nut 3/8-24

710-0459A Hex Cap Screw 3/8-24 x 1.5

781-0790 Back Plate

736-0921 Lock Washer 1/2

736-0300 Flat Washer .406 ID x .875 OD

710-0514 Hex Screw 3/8-16 x 1.0

781-0525 Dislodger

714-0211 Cotter Pin

718-0313 Hydraulic Cylinder 31/33 Ton

711-1135 Clevis Pin

727-0471 Hydraulic Tube

727-0443 Return Hose 3/4” ID x 44” Lg.

781-0526 Hose Guard

726-0132 Hose Clamp 5/8”

737-0153 Return Elbow

737-0264 90 Degree Solid Male Adapter

737-0312 3/4” Hose Adapter

718-0481 Control Valve

737-0316 Filter Housing

723-0405 Oil Filter

727-0502 High Pressure Hydraulic Hose

781-0538 Hose Guard

714-0470 Cotter Pin 1/8”

738-0805 Hinge Pin 1/2 x 4.8” Lg.

726-0214 Push Cap

732-0583 Compression Spring 4”

736-0116 Flat Washer .635 ID x .93 OD

781-0690 Locking Rod

737-0348 Vented Dipstick

781-04002 Fender Assembly

736-0371 Lock Washer 5/16

710-3038 Hex Screw

681-0178A Frame Assembly 7.0 Gal

736-0119 Lock Washer 5/16

Ref.

No.

48.

49.

50.

51.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

89.

90.

92.

Part No. Part Description

712-0123 Hex Nut 5/16-24

710-0409 Hex Cap Screw 5/16-24 x 1.75

710-1253 Hex Cap Screw 5/16-24 x 5.25

781-0098A Front Support Bracket Coupling

736-0119 Lock Washer 5/16

710-0237 Hex Cap Screw 5/16-24 x .625

719-0315 Shoulder Spacer

714-0114 Key

712-0123 Hex Screw 5/16

718-0685 Flex Coupling

781-0097 Rear Coupling Support Bracket

737-0264 Adapter 7/8-14

718-0684 Pump (16 gmp)

726-0174 Hose Clamp

727-0451 Suction Hose

710-0521 Hex Cap Screw 3/8-16 x 3.0

712-0798 Hex Nut 3/8-16

736-0169 Lock Washer 3/8

781-0680A Tube

710-0411 Hex Cap Screw 3/8-16 x 4.0

681-0110 Support Beam Assembly

681-0006 Adjustable Jack Stand

710-0944 Hex Cap Screw 3/8-16 x 4.25

736-0262 Flat Washer .385 ID x .870 OD

713-0433 Chain

750-0497 Spacer

727-0311 Hitch Coupler

712-0375 Lock Nut 3/8-16

712-3008 Hex Jam Nut 3/8-16

721-0168 Bearing Seal

741-0987 Bearing Cone

634-0186 Wheel Assembly

634-0180 Rim Assembly

736-0351 Flat Washer .76” ID x 1.5” OD

712-0359 Slotted Nut 3/4-16

714-0162 Cotter Pin 5/32” x 1-1/4” Lg.

734-0873 Hub Cap

681-0074 Light Bracket Assembly LH

625-0009 Tail Light Assembly

781-0624 Light Bracket Assembly RH

712-3010 Hex Nut

712-3022 Lock Nut 1/2-13

17

Page 18

MANUFACTURER’S LI MITED WARRANTY FOR:

The limited warran ty set for th belo w is giv en by Troy -Bilt LLC

with respect to ne w merchand ise purc hased an d used i n the

United States, its possess ions an d territorie s.

Troy-Bilt LLC warrants this prod uct against defects for a

period of two (2) ye ars comm encing on the da te of o riginal

purchase and will, a t its opt ion, rep air or repl ace, free of

charge, any part found to b e defecti ve in materi als or

workmanship. Thi s limit ed warranty shall only ap ply if th is

product has been operated and main tained in accorda nce

with the Operator’s Manual fur nishe d with the product, a nd

has not been subject to misus e, abuse, comme rcial use,

neglect, accident, impro per maintenance , alteration,

vandalism, theft, f ire, water, o r damage because of other p eril

or natural disast er. Damage resultin g from the inst allation or

use of any accessory or attachment not approved by Troy-Bilt

LLC for use with the product(s ) covered by this manu al will

void your warranty as to any resulting damage.

Normal wear parts or compone nts thereo f are sub ject to

separate terms as f ollows: All normal wear par ts or

component failur es will be co vered on t he product for a period

of 90 days regard less of ca use. After 90 days , but within the

two year period, no rmal wear p art fai lures will be cove red

ONLY IF caused by d efects i n materials or workman ship of

OTHER component parts. Normal wear parts and

components inclu de, but a re not lim ited to: batteri es, belts,

blades, blade a dapters, gr ass bags, r ider de ck wheels , seats ,

snow thrower skid sho es, shave plates, a uger spiral ru bber,

and tires.

HOW TO OBTAIN SERVICE: Warranty serv ice is ava ilable,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate t he dea ler in yo ur area, c heck yo ur

Yellow Pages, or co ntact Troy -Bilt LLC at P.O. Box 361131,

Cleveland, Ohio 44136-001 9, or call 1 -866-84 0-6483 or 1 330-558-7220, or log on to our Web site at www.troy bilt.com .

This limited warra nty does not prov ide cove rage in th e

following cases:

a. The engine or component parts thereof. The se item s

carry a separate manufacturer’ s warranty. Refe r to

applicable manufac turer’s warra nty for te rms and

conditions.

b. Log splitter pumps, valves , and cylin ders hav e a sepa

rate one year warranty.

c. Routine maintenan ce items such a s lubric ants, filt ers,

blade sharpening, tune-ups, brake adjustments, cl utch

adjustments, de ck adjus tments, and normal

deterioration of th e exterio r finish d ue to use or

exposure.

d. Troy-Bilt LLC does not extend any warranty for

products sold or exported outside of the United States,

its possesions and terr itories, e xcept tho se sold

through Troy-Bilt LL C’s author ized cha nnels of expor t

distribution.

e. Parts that are not genuine Troy-Bilt p arts are n ot

covered by this warranty .

f. Service completed by someone oth er than an

authorized servi ce deale r is not cov ered by this

warranty.

g. Transportation charges and se rvice calls are n ot

covered.

No implied warranty, including any implied war ranty of

merchantability of fitness fo r a particular p urpose,

applies after the applic able period of express w ritten

warranty above as to the parts as identified. No other

express warranty, wh ether written or oral, ex cept as

mentioned above, given by any person or entity,

including a dealer or re tailer, with respe ct to any product,

shall bind Troy-Bilt LLC. During the p eriod of t he

warranty, the excl usive remed y is rep air or repla cement

of the product as set fo rth above.

The provisions as se t forth in this warranty provide the

sole and exclusive remedy ar ising fro m the sale. TroyBilt LLC shall not be liable for incidental or conseque ntial

loss or damage includ ing, without limitation, e xpenses

incurred for substitute or replaceme nt lawn care services

or for rental expense s to temporaril y replac e a warrante d

product.

Some states do not allow the exclusion or limitation of

incidental or co nsequent ial da mages, o r limitat ions o n how

long an implied warranty l asts, so the abov e exclu sions or

limitations may not app ly to you.

In no event shall re covery of any k ind be gre ater than t he

amount of the purcha se price of the pro duct sold. Alteration

of safety features of th e produc t shall void this warran ty.

You assume the risk and lia bility fo r loss, dam age, or in jury to

you and your property and/or to others a nd their p roperty

arising out of the misus e or inabi lity t o use the product.

This limited warranty shal l not extend to anyone othe r than the

original purchaser or to the pers on for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty g ives yo u specif ic legal rights, a nd you m ay

also have other rights w hich va ry from s tate to sta te.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

Loading...

Loading...