Page 1

Operator’s Manual

Log Splitter

Model LS275

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (S ection 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO

769-00088.fm

.

(2/2002)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Log Splitter ............................................................................5

Know Your Log Splitter......................................................................................7

Operating Your Log Splitter ...............................................................................8

Adjusting Your Log Splitter ................................................................................10

Maintaining Your Log Splitter............................................................................. 10

Storing Your Log Splitter....................................................................................12

Troubleshooting................................................................................................. 12

Parts List............................................................................................................14

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new log splitter. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing behind the unit and looking down at the hydraulic tank.

A sample model plate is explained below. For future reference, please copy the model number and

the serial number of the equipment in the space below.

Copy the model number here:

www.troybilt.com

TROY-BILT LLC

P. O. BOX

CLEVELAND, OH 44136

330-558-7220

866-840-6483

361131

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, powerrating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s

Manual packed separately with your unit for more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls,

operation or maintenance of this unit, please call 1-866-840-6483 or 1-330-558-7220 to reach a

Customer Support representative. Please have your unit’s model number and serial number

ready when you call. See previous section to locate this information. You will be asked to enter

the serial number in order to process your call.

For more details about your unit, visit our website at www.troybilt.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol - heed its warning.

WARNING: Engine exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects

or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. This machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

General Practices

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and proper operation. Know

how to stop the machine and disengage them quickly.

3. Never allow children under 16 years to operate this

machine. Children,16 years and over, should read and

understand instructions and safety rules in this manual

and should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Many accidents occur when more than one person

operates the machine. If a helper is assisting in loading

logs, never activate the control until the helper is a

minimum of 10 feet from the machine.

6. Keep bystanders, helpers, pets, and children at least 20

feet from the machine while it is in operation.

7. Never allow anyone to ride on this machine.

8. Never transport cargo on this machine.

9. Hydraulic log splitters develop high fluid pressures during

operation. Fluid escaping through a pin hole opening can

penetrate your skin and cause blood poisoning,

gangrene, or death. Give attention to the following

instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked,

cracked, or damaged hoses, fitting, or tubing.

c. Stop the engine and relieve hydraulic system

pressure before changing or adjusting fittings,

hoses, tubing, or other system components.

d. Do not adjust the pressure settings of the pump or

valve.

5. Leaks can be detected by passing cardboard or wood,

while wearing protective gloves and safety glasses, over

the suspected area. Look for discoloration of cardboard

or wood.

6. If injured by escaping fluid, see a doctor immediately.

Serious infection or reaction can develop if proper

medical treatment is not administered immediately.

7. Keep the operator zone and adjacent area clear for safe,

secure footing.

8. If your machine is equipped with an internal combustion

engine and it is intended for use near any unimproved

forest, brush, or grass covered land, the engine exhaust

should be equipped with a spark arrester. Make sure you

comply with applicable local, state, and federal codes.

Take appropriate firefighting equipment with you.

9. This machine should be used for splitting wood only, do

not use it for any other purpose.

10. Follow the instructions in the manual(s) provided with any

attachment(s) for this machine.

Preparation

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles during

operating this machine.

3. Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

4. Make sure machine is on level surface before operating.

5. Always block machine to prevent unintended movement,

and lock in either horizontal or vertical position.

6. Always operate this machine from the operator zone(s)

specified in the manual.

7. Logs should be cut with square ends prior to splitting.

8. Use log splitter in daylight or under good artificial light.

9. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never overfill the fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to provide

space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

3

Page 4

equipment. move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

j. Allow machine to cool 5 minutes before storing.

Operation

1. Before starting this machine, review the “Safety

Instructions”. Failure to follow these rules may result in

serious injury to the operator or bystanders.

2. Never leave this machine unattended with the engine

running.

3. Do not operate machine while under the influence of

alcohol, drugs, or medication.

4. Never allow anyone to operate this machine without

proper instruction.

5. Always operate this machine with all safety equipment in

place and working. Make sure all controls are properly

adjusted for safe operation.

6. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

7. When loading a log, always place your hands on the

sides of the log, not on the ends, and never use your foot

to help stabilize a log. Failure to do so, may result in

crushed or amputated fingers, toes, hand, or foot.

8. Use only your hand to operate the controls.

9. Never attempt to split more than one log at a time unless

the ram has fully extended and a second log is needed to

complete the separation of the first log.

10. For logs which are not cut square, the least square end

and the longest portion of the log should be placed

toward the beam and wedge, and the square end placed

toward the end plate.

11. When splitting in the vertical position, stabilize the log

before moving the control. Split as follows:

a. Place log on the end plate and turn until it leans

against the beam and is stable.

b. When splitting extra large or uneven logs, the log

must be stabilized with wooden shims or split

wood between the log and end plate or ground.

12. Always keep fingers away from any cracks that open in

the log while splitting. They can quickly close and pinch

or amputate your fingers.

13. Keep your work area clean. Immediately remove split

wood around the machine so you do not stumble over it.

14. Never move this machine while the engine is running.

15. This machine should not be towed on any street, highway

or public road without checking the existing federal, state,

or local vehicle requirements. Any licensing or

modifications such as taillights, etc., needed to comply, is

the sole responsibility of the purchaser. If a “Statement of

Origin” is required in your state, see your local dealer.

16. Do not tow machine faster than 45mph.

17. See Transporting the Log Splitter section in this manual

for proper towing instructions once all federal, local, or

state requirements are met.

Maintenance and Storage

1. Stop the engine, disconnect the spark plug and ground it

against the engine before cleaning, or inspecting the

machine.

2. Stop the engine and relieve hydraulic system pressure

before repairing or adjusting fittings, hoses, tubing, or

other system components.

3. To prevent fires, clean debris and chaff from the engine

and muffler areas. If the engine is equipped with a spark

arrester muffler, clean and inspect it regularly according

to manufacturers instructions. Replace if damaged.

4. Periodically check that all nuts and bolts, hose clamps,

and hydraulic fittings are tight to be sure equipment is in

safe working condition.

5. Check all safety guards and shields to be sure they are in

the proper position. Never operate with safety guards,

shields, or other protective features removed.

6. The pressure relief valve is preset at the factory. Do not

adjust the valve.

7. Never attempt to move this machine over hilly or uneven

terrain without a tow vehicle or adequate help.

8. For your safety, replace all damaged or worn parts

immediately with original equipment manufacturer’s

(O.E.M.) parts only. “Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!”

9. Do not alter this machine in any manner, alterations such

as attaching a rope or extension to the control lever, or

adding to the width or height of the wedge may result in

personal injury.

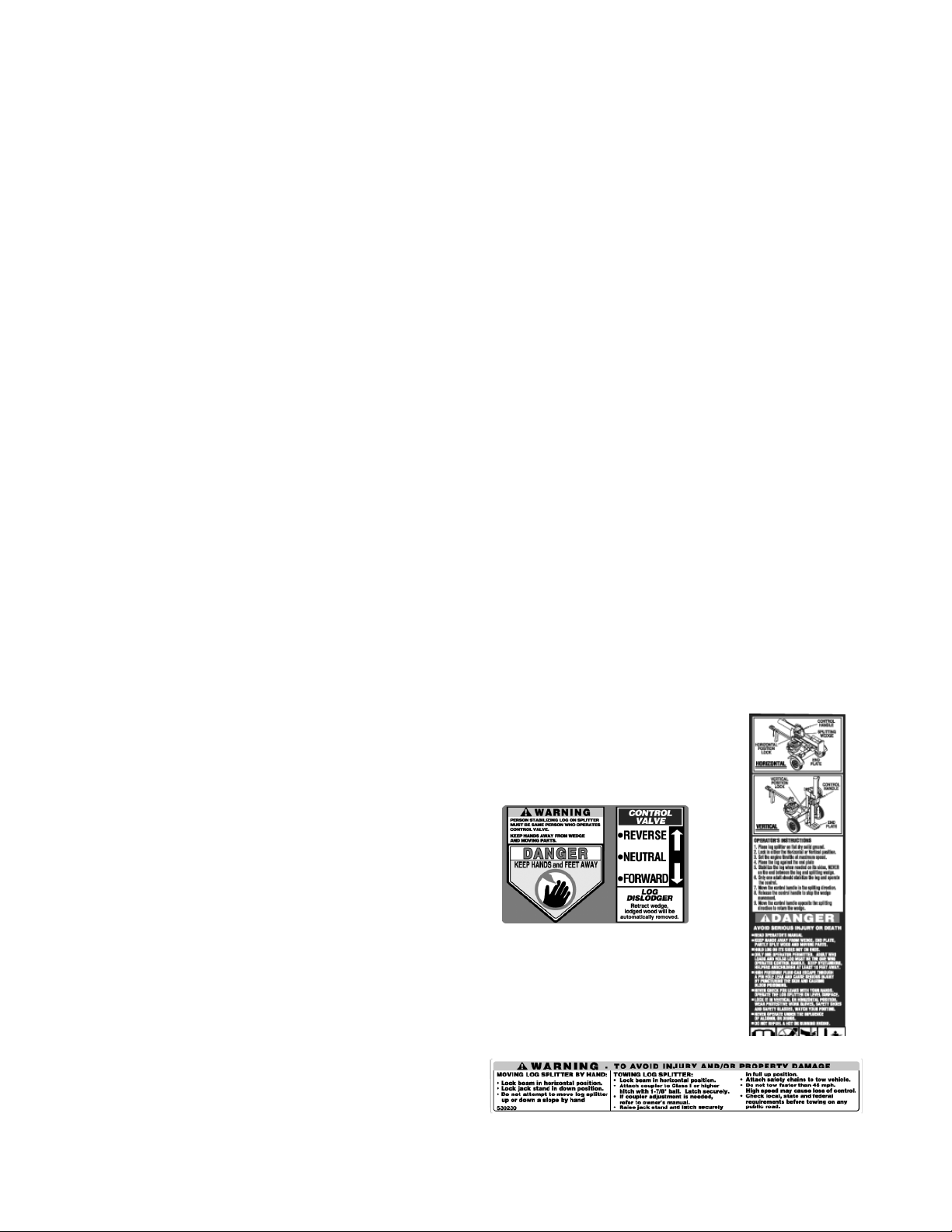

Your Responsibility

Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this

manual and on the machine. Some of the safety labels are

reproduced here. Always follow directions on safety labels

found on your equipment.

4

Page 5

SECTION 2: ASSEMBLING YOUR LOG SPLITTER

Unpacking from Crate

• Pry top, sides, and ends off the crate. Set panels

aside to avoid tire puncture or personal injury.

• Remove and discard plastic bag that covers unit.

• Remove any loose parts if included with unit (i.e.,

operator’s manual, etc.)

• Cut and remove straps which secure parts to

bottom of crate. Unbolt any remaining parts which

may be bolted to the bottom of the crate.

WARNING: Use extreme caution unpacking

this machine. Some components are very

heavy and will require additional people or

mechanical handling equipment.

Loose Parts In Carton

• Tongue assembly

• Bottle of engine oil

• Tail light kit

Before Assembly

• Disconnect the spark plug wire and ground against

the engine to prevent unintended starting.

Attaching the Tongue

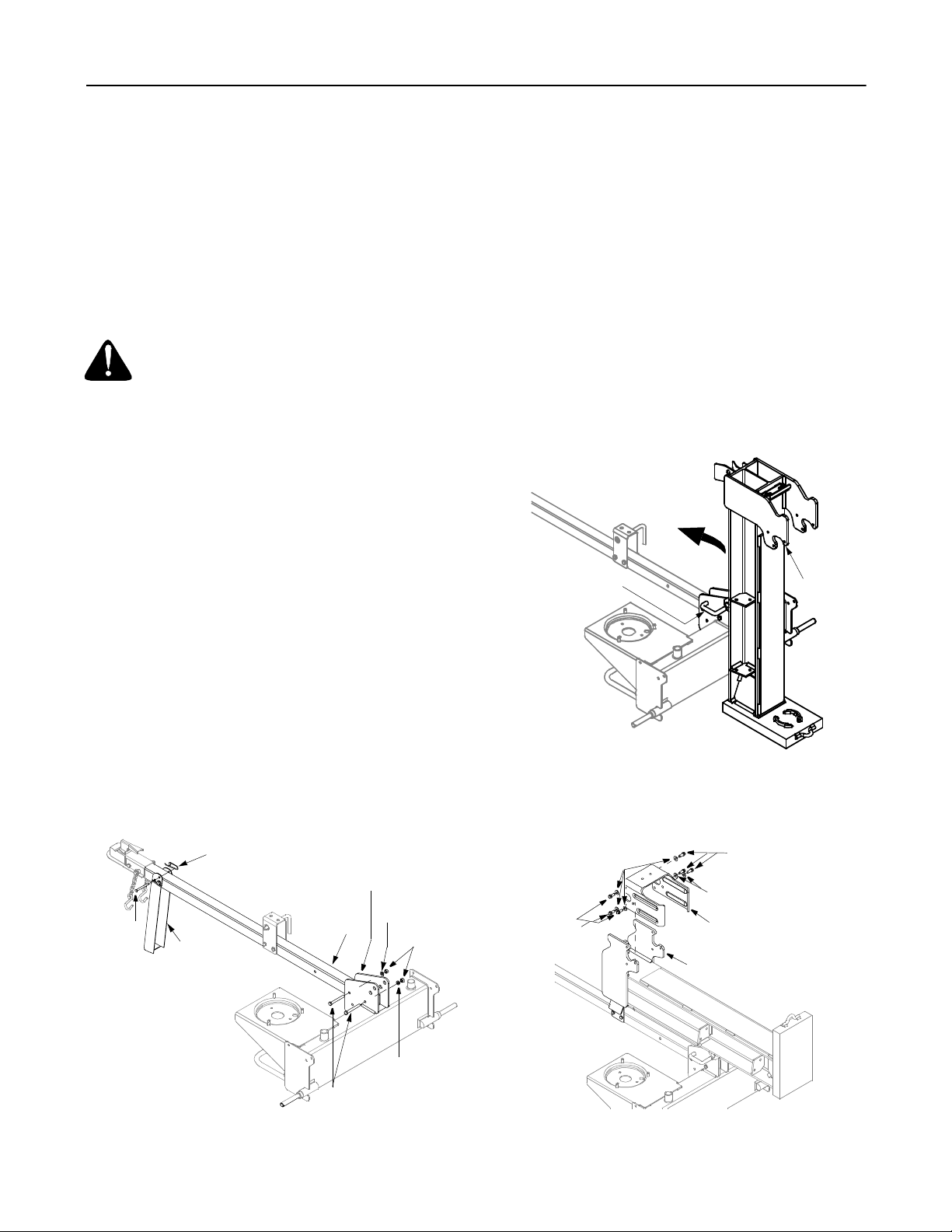

• With the log splitter still standing upright, remove

two hex bolts, lock washers, and hex nuts from the

end of the tongue. See Figure 1.

• Align the holes in the tongue with the holes in the

tank bracket and secure with hardware just

removed. See Figure 1.

NOTE: High pressure hose must be above the tongue

assembly.

Connecting Cylinder to Beam

• The log splitter is shipped with the beam in the

vertical position. Pull out the vertical lock beam,

rotate it back, and pivot the beam to the horizontal

position until it locks. See Figure 2.

Vertical

Lock Beam

Beam

NOTE: Reference to right or left hand side of the log

splitter is observed from the operating position.

Assembling the Tongue

Attaching the Jack Stand

• The jack stand is shipped in the transport position.

Remove the spring clip and clevis pin and pivot the

jack stand towards the ground to the operating

position.

• Secure the jack stand in position with the clevis pin

and spring clip. See Figure 1.

Spring Clip

Bracket

Lock

Clevis

Pin

Tongue

Jack

Stand

Hex Bolt

Washer

Hex Nut

Lock

Washer

Figure 2

• Disconnect the dislodger from the beam weld

bracket by removing the six hex screws and flat

washers. See Figure 3.

Flat Washer

Hex Screw

Hex Screw

Flat Washer

Dislodger

Beam Weld Bracket

Figure 1

Figure 3

5

Page 6

• Disconnect the log cradle from the beam on the

side of the control valve. See Figure 4.

Lock

Washer

Hex Bolt

Hex

Nut

Disconnect

Log Cradle

Figure 4

• Lift and slide the cylinder up to the top of beam and

into the weld brackets.

• Attach the dislodger over the wedge assembly and

secure with hardware, previously removed, to the

weld brackets. See Figure 5.

NOTE: Once the six hex screws are tightened, there

may be a slight gap between the dislodger and the weld

brackets. This gap is normal.

• Reattach the log cradle to the side of the beam with

the control valve, aligning the ends of the cradle

with the beam flanges. See Figure 5.

• Roll log splitter off the bottom crate.

Preparing the Log Splitter

• Lubricate the beam area (where the splitting wedge

will slide) with engine oil; do not use grease.

• Remove vented reservoir dipstick, which is located

in front of the engine on top of the reservoir tank.

See Figure 6.

• Fill the reservoir tank with Dexron III automatic

transmission fluid or 10W AW hydraulic fluid.

NOTE: The reservoir tank has a capacity of 3.5 gallons.

• Check fluid level using the dipstick. See Figure 6.

• Do not overfill. Replace vented dipstick securely,

tightening it until the top of the threads are flush

with top of the pipe.

Dipstick

Reservoir

Tan k

Figure 6

• Make sure the spark plug wire is disconnected.

Then prime the pump by pulling the recoil starter as

far as it will go. Repeat approximately 10 times.

• Reconnect the spark plug wire and start engine

following instructions in the OPERATION section.

• Use control handle to engage the wedge to the

farthest extended position. Then retract the wedge.

• Refill tank as specified on the dipstick.

Attach log

cradle here

NOTE: Failure to refill the tank will void unit’s warranty.

• Extend and retract the wedge 12 complete cycles

to remove trapped air in the system ( the system is

“self-bleeding”).

• Refill reservoir within range marked on the dipstick.

WARNING: Much of the original fluid has

been drawn into the cylinder and hoses. Make

certain to refill the reservoir to prevent damage

to the hydraulic pump.

NOTE: Some fluid may overflow from the vent plug as

the system builds heat and the fluid expands and seeks

a balanced level.

• Attach taillights as instructed in the taillight kit

manual included with your log splitter.

Figure 5

6

Page 7

SECTION 3: KNOW YOUR LOG SPLITTER

Compare the illustration in Figure 7 below with the controls on your log splitter, and get familiar with its features

before starting to operate. Know how to stop the machine quickly in the event of an emergency.

Cylinder

Tongue

Jack Stand

Horizontal

Beam Lock

Control Handle

Wedge

Beam Assembly

Log Cradle

Vertical Beam Lock

Reservoir Tank

Tail Light

Horizontal

Beam Lock

How it works

Reverse

To ret urn we d g e

Neutral

Control

Handle

Forward

Vertical

Beam Lock

To st op

To split wood

Figure 7

Control Handle

The control handle has three positions. See Figure 7.

• Move control handle FORWARD or DOWN to

move wedge down to split wood.

NOTE: Control handle will return to neutral position as

soon as handle is released.

• Release the control handle to stop the wedge

movement.

• Move control handle BACK or UP to return the

wedge toward the cylinder. The control handle will

lock in the disengaged position. It will return to

neutral automatically when the return stroke is

complete.

Beam Locks

These two locks, as their name suggests, are used to

secure the beam in the horizontal or the vertical

position. The vertical beam lock is located next to the oil

filter. The horizontal beam lock is located on the beam

support latch bracket. See Figure 7.

Engine Controls

See the accompanying engine manual for the location

and function of the controls on the engine.

Stopping Engine

• Move throttle control lever to STOP or OFF

position.

• Turn off the fuel valve.

• Disconnect spark plug wire and ground against the

engine to prevent unintended starting.

IMPORTANT:

in the engine. Be certain to service engine with gasoline

and oil as instructed in the accompanying engine

manual before operating your machine.

7

This unit is shipped without gasoline or oil

Page 8

SECTION 4: OPERATING YOUR LOG SPLITTER

• Fill up gasoline if necessary.

WARNING: Read, understand, and follow all

instructions and warnings on the machine and

in this manual before operating.

WARNING: Wear leather work gloves,

safety shoes, ear protection, and safety

glasses when operating log splitter. Ensure

safe footing.

Gas and Oil Fill-Up

• Service the engine with gasoline and oil as

instructed in the engine manual packed with your

log splitter. Read instructions carefully.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Never

fuel machine indoors or while the engine is hot

or running.

NOTE: Gasoline can be added to the engine when the

log splitter is in either the horizontal or vertical position.

However, there are less obstructions when the unit is in

the vertical position.

Starting Engine

• Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug wire is

fastened securely over metal tip of the spark plug.

• Turn the fuel valve to the ON position.

• Move choke lever to CHOKE position.

• Turn the throttle control lever to the FAST position.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point).

• Pull rope with a rapid, full arm stroke. Keep firm grip

on starter handle. Let rope rewind slowly. Repeat

until engine cranks.

• After engine starts, move choke lever to OFF

position. Place throttle lever to the speed desired.

For best performance, the engine is designed to be

operated at the FAST throttle position.

• If weather is cold, run wedge up or down beam 6 to

8 times to circulate the hydraulic fluid.

• Lubricate with engine oil the beam area where

splitting wedge will slide. Do not use grease to

lubricate. Make sure to lubricate both the front and

the back of the beam face.

• Attach spark plug wire to the spark plug.

Using the Log Splitter

• Place the log splitter on level, dry ground.

• Place the beam in either the horizontal or vertical

position and lock in place with the appropriate

locking rod.

• Block the front and back of both wheels.

• Place the log against the end plate and only split

wood in the direction of the grain.

• To stabilize the log, place your hand only on sides

of log. Never place hand on the end between the

log and the splitting wedge.

• Only one adult should stabilize the log and operate

the control handle, so the operator has full control

over the log and the splitting wedge.

Control Handle

1. Move control handle FORWARD or DOWN to split

wood.

2. Release the control handle to stop the wedge

movement.

3. Move control handle BACK or UP to return the

wedge.

Vertical Position

• Pull the horizontal beam lock out to release the

beam and pivot the beam to the vertical position.

• To lock the beam in the vertical position, pull out on

the vertical beam lock and rotate it to secure the

beam. See Figure 7.

• Stand in front of the unit to operate the control

handle and to stabilize the log. See Figure 8A.

A

WARNING: When starting a warm engine,

the muffler and surrounding areas are hot and

can cause a burn. Do not touch.

Before Each Use

• Remove the dipstick and check hydraulic fluid level.

Refill if necessary.

• Check engine oil level. Refill if necessary.

B

Figure 8

8

Page 9

Horizontal Position

• Pull the vertical beam lock out and rotate it down.

See Figure 7. Pivot beam to the horizontal position.

The beam will lock automatically in horizontal

position.

• Stand behind the reservoir tank to operate control

handle and to stabilize the log. See Figure 8B.

WARNING: Always use the log splitter in the

vertical position when splitting heavy logs.

• Pivot beam lock down to release the beam.

Carefully pull back on beam and lower it to the

horizontal position.The horizontal beam lock will

lock automatically. See Figure 7.

Operating Tips

Always:

1. Use clean fluid and check fluid level regularly.

2. Use Dexron III Automatic Transmission Fluid or

10W AW hydraulic fluid.

3. Use a filter (clean or replace regularly)

4. Use a breather cap on fluid reservoir.

5. Make sure pump is mounted and aligned properly.

6. Use a flexible “spider” type coupling between

engine and pump drive shafts.

7. Keep hoses clear and unblocked.

8. Bleed air out of hoses before operating.

9. Flush and clean hydraulic system before restarting

after servicing.

10. Use “pipe dope” on all hydraulic fittings.

11. Allow time for warm-up before splitting wood.

12. Prime the pump before initial start-up by turning

over the engine with spark plug disconnected.

13. Split wood along the grain (lengthwise) only.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Use a solid engine /pump coupling.

3. Operate through relief valve for long.

4. Attempt to adjust unloading or relief valve settings

without pressure gauges.

5. Operate with air in hydraulic system.

6. Use teflon tape on hydraulic fittings.

7. Attempt to cut wood across the grain.

Raising and Lowering Beam

• Use control handle to run wedge up and down

beam 6 to 8 times to circulate the hydraulic fluid,

which will warm and thin the fluid.

• Place log splitter on a firm, level surface.

• To raise the beam for vertical operation: Pull out

the vertical beam lock on the tongue.

• Pivot beam lock down to release the beam.

• Move the beam to the vertical position. Secure it

with the beam lock on the reservoir tank assembly.

• To lower the beam: Pull out the horizontal beam

lock on the reservoir tank.

Transporting the Log Splitter

IMPORTANT:

before transporting the log splitter.

• Lower the beam to its horizontal position. Make

certain the beam is locked securely with the

horizontal beam lock.

• Remove spring clip and clevis pin from jack stand.

• Support the tongue and pivot the jack stand up

against the tongue. See Figure 9.

Jack Stand

• Secure with the spring clip and clevis pin previously

removed. See Figure 9.

• Attach coupler hitch to a class I or higher 1-7/8” ball

on a towing vehicle; latch securely.

• Connect the safety chains to the towing vehicle.

• Plug in the tail lights to the tail light connector on the

tow vehicle.

NOTE: Use caution when backing up. It is

recommended to use a spotter outside the vehicle.

Always turn fuel valve to OFF position

Tongue

Assembly

a. If coupler hitch does not fit on ball: Turn

adjustment nut one turn counter-clockwise.

b. If coupler hitch is too loose on ball: Turn

adjustment nut one turn clockwise.

Clevis Pin

Spring

Clip

Figure 9

WARNING: Do not tow faster than 45mph

and check local, state, and federal

requirements before towing on any public road.

9

Page 10

SECTION 5: ADJUSTING YOUR LOG SPLITTER

NOTE: The gibs may be rotated and/or turned over for

WARNING: Do not at any time make any

adjustments without first stopping engine,

disconnecting spark plug wire, and grounding it

against the engine.

Wedge Assembly Adjustment

As normal wear occurs and there is excessive “play”

between the wedge and beam, adjust the bolts on the

side of the wedge assembly to eliminate excess space

between the wedge and the beam. See Figure 10.

• Loosen the jam nuts on the two adjustment bolts on

the side of the wedge. Turn the adjustment bolts in

until snug and then back them off slowly until the

wedge assembly will slide on the beam.

• Tighten the jam nuts securely against the side of

the wedge to hold the adjustment bolts in this

position.

even wear.

• Loosen the lock nuts under the each back plate and

slide the gibs out.

• Turn or replace the gibs.

• Reassemble the back plate and secure with the

lock washers and lock nuts.

• Readjust the bolts on the side of the wedge

assembly.

Adjustment

Bolt

Gibs

Jam Nut

Gib Adjustment

Periodically remove and replace the “gibs” (spacers)

between the wedge assembly and the back plate.

See Figure 10.

Lock Nut

SECTION 6: MAINTAINING YOUR LOG SPLITTER

8. Excessive heating of the hydraulic system

WARNING: Before cleaning, lubricating,

repairing, or inspecting, disengage the control

lever and stop engine. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

Conditions that will void Warranty

1. Failure to maintain proper fluid level in reservoir

2. Changing the relief valve setting or pressure

adjustment of control valve without proper

knowledge and instruction from the factory

WARNING: Higher pressure could cause

the hoses to burst, cylinder to rupture, and

intense fluid to be released, which could result

in serious personal injury.

3. Disassembling the pump

4. Use of incorrect hydraulic fluid

5. Allowing the flexible pump coupler to deteriorate

without proper and regular inspection

6. Lack of lubrication or improper lubrication of the

beam or unit

7. Improper adjustment of splitting wedge

9. Attempting to start unit in temperatures under 20°F

without pre-heating fluid in reservoir

10. Unattended leaks in hydraulic system

Hydraulic Fluid

• Check the hydraulic fluid level in the log splitter

reservoir tank before each use.

• Maintain fluid level within the range specified on the

dipstick at all times.

• Change the hydraulic fluid in the reservoir every

100 hours of operation.

• Disconnect the suction hose from the bottom of the

reservoir tank and drain the fluid into a suitable

container. Refill using only Dexron III automatic

transmission fluid or 10W AW hydraulic fluid.

NOTE: Please dispose of used hydraulic fluid and

engine oil at approved recycling centers only.

• Since contaminants in fluid may damage the

hydraulic components, you will have to drain the

fluid and flush the reservoir tank and hoses with

kerosene whenever any repair work is performed

Figure 10

Lock

Washer

10

Page 11

on the tank, hydraulic pump or valve. For this job,

contact your nearest service dealer.

Hydraulic Filter

• Change the hydraulic filter every 50 hours of

operation. Use only a 10 micron hydraulic filter.

Order part number 723-0405.

Beam and Splitting Wedge

• Lubricate both sides of the beam (where it comes

into contact with the splitting wedge), before each

use, with engine oil. The wedge plate on the log

splitter is designed so the gibs on the side of the

wedge plate can be removed and rotated and/or

turned over for even wear.

• Make certain to readjust the adjustment bolts so

wedge moves freely, but no excess space exists

between the wedge plate and the beam.

Hose Clamps

• Check, before each use, if hose clamps on the

suction hose (attached to the side of the pump) are

tight. Check the hose clamps on the return hose at

least once a season.

• Loosen set screw on pump coupling half and

remove coupling half.

• Slide new engine coupling half onto the engine

shaft until the end of the shaft is flush with the inner

portion of the coupling half. (There must be space

between end of the engine support bracket and

coupling half). Tighten set screw.

• Install pump coupling half and key on pump shaft.

Rotate coupling half until set screw faces opening

in shield. Do not tighten set screw.

• Install nylon “spider” onto engine coupling half.

• Align pump coupling half with nylon “spider” by

rotating engine using starter handle. Slide coupling

half into place while guiding three mounting bolts

through holes in pump support bracket.

• Secure with nuts and washers removed earlier.

• Set .010” to .060” clearance between the nylon

“spider” and the engine coupling half by sliding a

matchbook cover between the nylon “spider” and

the engine coupling half and moving pump coupling

half as needed. Secure pump coupling half with set

screw. See Figure 11.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

Engine

Refer to the engine manual for all maintenance needs.

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert,

located between the pump and the engine shaft. Over

time, the coupler will harden and deteriorate.

Replace the coupler if you detect vibration or noise

coming from the area between the engine and the

pump. If the coupler fails completely, you will

experience a loss of power.

IMPORTANT:

as a blow will cause permanent damage to the engine.

• Remove three nuts and lock washers that secure

the pump to the coupling shield. Two nuts are at the

bottom corners and one is in the top center.

• Remove the pump.

• Rotate the engine by slowly pulling starter handle

until engine coupling half set screw is visible.

Loosen set screw using allen wrench and slide

coupling half off engine shaft.

Never hit the engine shaft in any manner,

Gear Pump

Set

Screw

Nylon

“Spider”

Insert

Clearance

Engine

Figure 11

Steel

Coupling

Halves

Tires

See sidewall of tire for recommended pressure.

Maximum tire pressure under any circumstances is 30

p.s.i. Maintain equal pressure on all tires.

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause tire/rim

assembly to burst with force sufficient to cause

serious injury.

11

Page 12

SECTION 7: STORING YOUR LOG SPLITTER

Prepare your log splitter for storage at the end of the

season or if the log splitter will not be used for 30 days

or more.

WARNING: Never store machine with fuel

in the fuel tank inside of building where fumes

may reach an open flame or spark, or where

ignition sources are present such as hot water

and space heaters, furnaces, clothes dryers,

stoves, electric motors, etc.

• Clean the log splitter thoroughly.

NOTE: We do not recommend the use of pressure

washers or garden hose to clean your unit. They may

cause damage to electric components, spindles,

pulleys, bearings or the engine. The use of water will

result in shortened life and reduce serviceability.

• Wipe unit with an oiled rag to prevent rust,

especially on the wedge and the beam.

• Drain fuel tank. Always drain fuel into approved

container outdoors, away from open flame. Be sure

that engine is cool before draining the fuel. Do not

smoke while handling fuel.

• Start the engine and let it run until the fuel lines and

carburetor are empty.

• Remove spark plug. Holding a rag over the cylinder

hole, pour approximately 1/2 ounce (approximately

one tablespoon) of engine oil into cylinder and

crank slowly to distribute the oil.

• Replace spark plug.

• Do not store gasoline from one season to another.

• Replace your gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

SECTION 8: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever not in correct

starting position.

4. Choke not in CHOKE position.

5. Engine not primed properly.

6. Blocked fuel line.

7. Faulty spark plug.

Engine runs erratic 1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

NOTE: For repairs beyond those listed above, contact your nearest authorized service center.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to FAST position.

4. Move choke to CHOKE position.

5. Prime engine.

6. Clean fuel line.

7. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See authorized service dealer.

12

Page 13

Hydraulic Troubleshooting

Problem Cause Remedy

Cylinder rod will not move 1. Broken drive shaft.

2. Shipping plugs left in hydraulic

hoses.

3. Set screws in coupling not adjusted

properly.

4. Loose shaft coupling.

5. Gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil level.

9. Damaged directional valve.

10. Blocked directional valve.

Slow cylinder shaft speed

while extending and

retracting.

Leaking cylinder 1. Broken seals.

Engine runs but wood will

not split or wood splits too

slowly

Engine stalls during

splitting

Engine will not turn or

stalls under low load

conditions

Leaking pump shaft seal 1. Broken drive shaft.

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil level.

6. Contaminated oil.

7. Directional valve leaking internally.

8. Internally damaged cylinder.

2. Scored cylinder.

1. Small gear section damaged.

2. Pump check valve leaking.

3. Excessive pump inlet vacuum.

4. Incorrect oil level.

5. Contaminated oil.

6. Directional valve leaking internally.

7. Overloaded cylinder.

8. Internally damaged cylinder.

1. Low horsepower/weak engine.

2. Overloaded cylinder.

1. Engine/pump misalignment.

2. Frozen or seized pump.

3. Low horsepower/weak engine.

4. Hydraulic lines blocked.

5. Blocked directional valve.

2. Engine/pump misalignment.

3. Gear sections damaged.

4. Poorly positioned shaft seal.

5. Plugged oil breather.

1. See authorized service dealer.

2. Disconnect hydraulic hoses, remove

shipping plugs, reconnect hoses.

3. See operator’s manual for correct

adjustment.

4. Correct engine/pump alignment as

necessary.

5. See authorized service dealer.

6. See authorized service dealer.

7. Flush and clean hydraulic system.

8. Check oil level.

9. See authorized service dealer.

10. Flush and clean hydraulic system.

1. See authorized service dealer.

2. Make certain pump inlet hoses are clear

and unblocked-use short, large

diameter inlet hoses.

3. See authorized service dealer.

4. See authorized service dealer.

5. Check oil level.

6. Drain oil, clean reservoir, and refill.

7. See authorized service dealer.

8. See authorized service dealer.

1. See authorized service dealer.

2. See authorized service dealer.

1. See authorized service dealer.

2. See authorized service dealer.

3. Make certain pump inlet hoses are clear

and unblocked.

4. Check oil level.

5. Drain oil, clean reservoir, and refill.

6. See authorized service dealer.

7. Do not attempt to split wood against the

grain.

8. See authorized service dealer.

1. See authorized service dealer.

2. Do not attempt to split wood against the

grain or see authorized service dealer.

1. Correct alignment as necessary.

2. See authorized service dealer.

3. See authorized service dealer.

4. Flush and clean hydraulic system.

5. Flush and clean hydraulic system.

1. See authorized service dealer.

2. Correct alignment as necessary.

3. See authorized service dealer.

4. See authorized service dealer.

5. Make certain reservoir is properly

vented.

NOTE: For repairs beyond those listed here, contact your nearest authorized service center.

13

Page 14

SECTION 9: PARTS LIST FOR MODEL LS275

12

22

15

40

23

44

13

12

1

16

68

33

28

69

29

85

31

30

31

85

54

70

61

66

53

56

59

62

64

58

48

57

60

C

65

A

75

63

26

74

55

51

C

52

39

14

45

36

38

46

37

47

17

35

18

48

24

B

25

49

26

27

32

34

50

2

11

5

4

6

B

7

8

19

20

3

A

9

10

21

41

72

42

43

84

67

14

73

79

72

71

81

82

48

77

81

79

76

78

80

83

Page 15

Model LS275

Ref.

No.

1. 718-0769 Hydraulic Cylinder

2. 727-0634 Hydraulic Tube

3. 710-1018 Hex Cap Screw 1/2-20 x 2.75

4. 737-0192 90 Degree Solid Adapter

5. 781-0526 Hose Guard

6. 737-0153 Return Elbow

7. 718-0481 Control Valve

8. 781-0538 Hose Guard

9. 710-0515 Hex Cap Screw 1/2-20 x 3.50

10. 719-0550 Wedge Assembly

11. 737-0238 Nipple Pipe 1/2-14

12. 712-0239 Lock Nut 1/2-20

13. 712-0711 Hex Jam Nut 3/8-24

14. 710-0459A Hex Cap Screw 3/8-24 x 1.5

15. 781-0351 Adjustable Gib

16. 710-0604A Hex Washer Screw 5/16-18 x .625

17. 781-1054 Support Bracket

18. 681-0162 Beam Assembly

19. 736-0300 Flat Washer .406 ID x .875 OD

20. 710-0654A Hex Washer Screw 3/8-16 x 1.0

21. 781-1048 Dislodger

22. 781-0790 Back Plate

23. 736-0921 Lock Washer 1/2

24. 737-0312 Adapter 3/4-14

25. 727-0443 Return Hose 3/4” ID x 44” Lg.

26. 726-0132 Hose Clamp 5/8”

27. 737-0316 Filter Housing

28. 781-04000 Fender

29. 710-1238 Hex Washer Screw 5/16-18 x .875

30. 712-3010 Hex Nut 5/16-18

31. 736-0119 Lock Washer 5/16

32. 781-1024 Fender Mounting Bracket

33. 723-0405 Oil Filter

34. 710-0376 Hex Cap Screw 5/16-18 x 1.0

35. 681-0164 Light Bracket LH

36. 625-0062 Taillight

37. 711-1587 Clevis Pin

38. 736-0116 Flat Washer .635 ID x .93 OD

39. 714-0470 Cotter Pin

40. 781-1027 Light Bracket RH †

41. 710-3097 Carriage Bolt 3/8-16 x 1.0

Part No. Part Description

725-2058 RH Taillight Assembly

725-2059 LH Taillight Assembly

725-2060 Wiring Harness

Ref.

No.

42. 712-0798 Hex Nut 3/8-16

43. 781-0682 Log Tray

44. 781-0686 Log Tray Bracket

45. 681-0161 Frame Assembly

46. 726-0214 Push Cap

47. 732-0583 Compression Spring

48. 710-0521 Hex Bolt 3/8-16 x 3”

49. 781-0690 Lock Rod

50. 737-0348 Vented Dipstick

51. 710-1338 Hex Screw 5/16-24 x 3.25

52. 710-0654A Hex Washer Screw 3/8-16 x 1.0

53. 634-0186 Wheel Assembly

54. 712-0359 Slotted Nut 3/4-16

55. 714-0162 Cotter Pin

56. 734-0873 Hub Cap

57. 719-0353 Coupling Shield

58. 714-0122 Square Key 3/16” x .75

59. 718-0686 Flexible Coupling

60. 712-0123 Hex Nut 5/16-24

61. 736-0119 Lock Washer 5/16” ID

62. 781-0097 Rear Coupling Support Bracket

63. 727-0633 Hose

64. 718-0683 Gear Pump (11gpm)

65. 737-0329 45 Degree Elbow

66. 727-0502 High Pressure Hydraulic Hose

67. 781-0788 Tongue Tube Assembly

68. 747-1261 Latch Rod

69. 781-1045 Latch

70. 715-0120 Spiral Pin

71. 732-3127 Spring Compression

72. 736-0169 L-Washer 3/8”

73. 712-0798 Hex Nut 3/8-16

74. 710-0944 Hex Cap Screw 3/8-16 x 4.25

75. 736-0262 Flat Washer .385 ID x .870 OD

76. 713-0433 Chain

77. 750-0497 Spacer .375 ID x .625 OD

78. 727-0311 Coupling Hitch

79. 712-0375 Hex Lock Nut 3/8-16

80. 711-0813 Clevis Pin

81. 736-0185 Flat Washer .375 ID x .738 OD

82. 732-0194 Spring Pin

83. 781-0789 Jack Stand

84. 736-0351 Flat Washer .760 ID x .500 OD

85. 736-0371 Flat Washer

Part No. Part Description

15

Page 16

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Troy-Bilt LLC

with respect to new merchandise purchased and used in the

United States, its possessions and territories.

Troy-Bilt LLC warrants this product against defects for a

period of two (2) years commencing on the date of original

purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or

workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance

with the Operator’s Manual furnished with the product, and

has not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril

or natural disaster. Damage resulting from the installation or

use of any accessory or attachment not approved by Troy-Bilt

LLC for use with the product(s) covered by this manual will

void your warranty as to any resulting damage.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear parts or

component failures will be covered on the product for a period

of 90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in materials or workmanship of

OTHER component parts. Normal wear parts and

components include, but are not limited to: batteries, belts,

blades, blade adapters, grass bags, rider deck wheels, seats,

snow thrower skid shoes, shave plates, auger spiral rubber,

and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact Troy-Bilt LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-866-840-6483 or 1330-558-7220, or log on to our Web site at www.troybilt.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to

applicable manufacturer’s warranty for terms and

conditions.

b. Log splitter pumps, valves, and cylinders have a sepa

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal

deterioration of the exterior finish due to use or

exposure.

d. Troy-Bilt LLC does not extend any warranty for

products sold or exported outside of the United States,

its possesions and territories, except those sold

through Troy-Bilt LLC’s authorized channels of export

distribution.

e. Parts that are not genuine Troy-Bilt parts are not

covered by this warranty.

f. Service completed by someone other than an

authorized service dealer is not covered by this

warranty.

g. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind Troy-Bilt LLC. During the period of the

warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. TroyBilt LLC shall not be liable for incidental or consequential

loss or damage including, without limitation, expenses

incurred for substitute or replacement lawn care services

or for rental expenses to temporarily replace a warranted

product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

Loading...

Loading...