Page 1

Owner

/Operator

Manual

JUNIOR

TOMAHAWK®

Chipper

/Shredder

• Safety

• Preparation

• Controls

•

Operation

•

Maintenance

Page 2

• •

Dear Owner:

We've prepared this

Owner/Operator

Manual to guideyou in the

proper

use

of

your

new

JUNIOR

TOMAHAWK® Chipper/Shredder and we've included a

special section on Safety Instruction which we urge you to read completely.

Your safety, and the safety

of

otheroperatorsand those around you, make the

Safety Instruction - and the entire Manual - "must reading"

before

you

put

this

equipment

to work. There's a section on Maintenance and Service too, so

you'll be able to keep

your

Chipper/Shredder running at peak performance at

all times.

Of course, if you have any questions

or

problems at all with operationorservice, please

contact

our

Technical

Service Department rightaway (the phone

numberison the next page). Don't hesitate toask

for

assistance.Wewant

to

do

all we possibly can to makethe time you spend using thisequipmentas productiveand as enjoyableascan be.

WE'RE HERE

TO

SERVE

YOU.

Thank you,

)P4M!d,gr:

Dean Leith, Jr.

Sales Manager

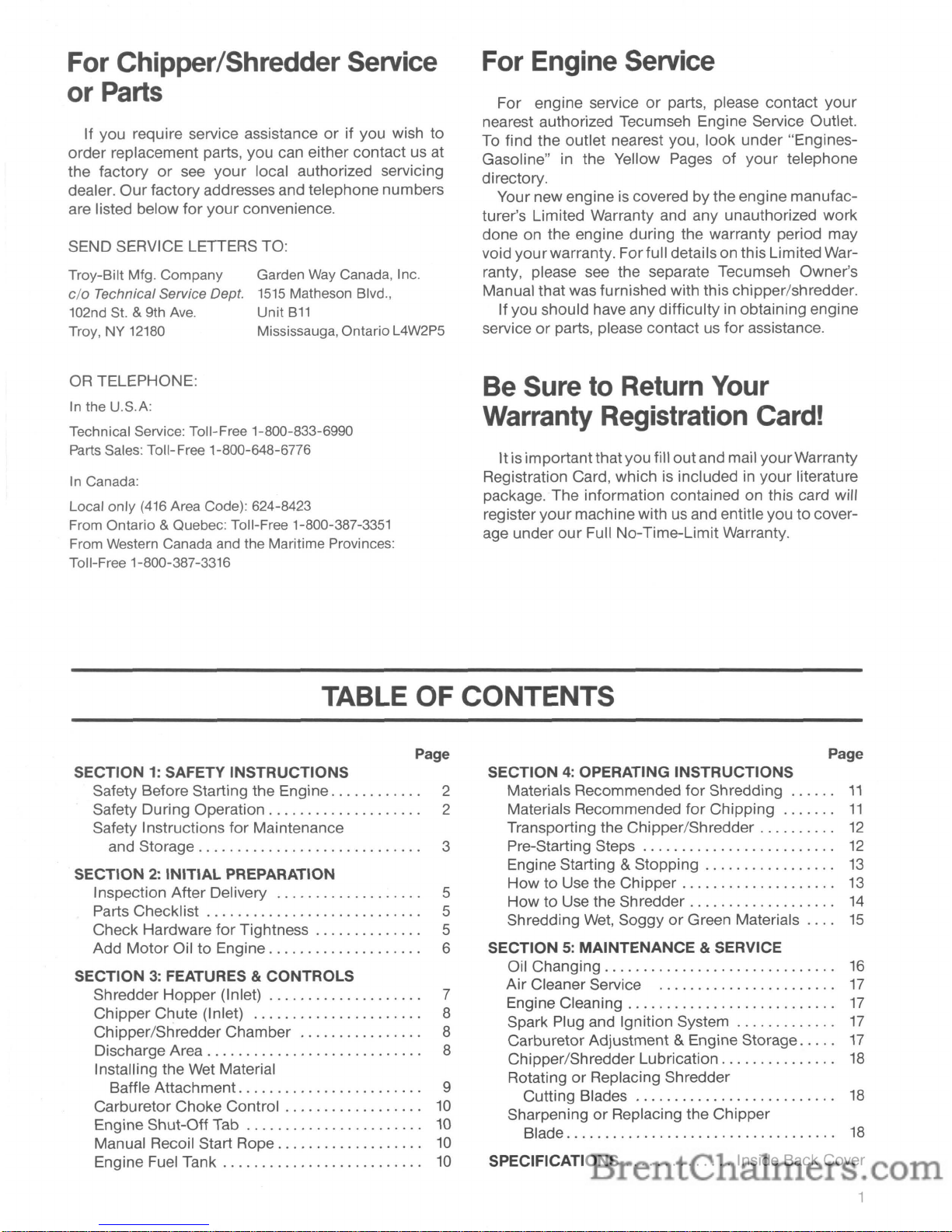

IMPORTANT

-

WRITE

THE

SERIAL

NUMBER OF YOUR JUNIOR TOMAHAWK®

CHIPPER/SHREDDER IN THE SPACE PROVIDED BELOW

...

To providefast and efficientservice, should you

con-

tact us, we'll need to

know

the SERIAL NUMBER of

your

Chipper/Shredder. The photo at right shows you

where to look to find this number. For ready reference,

please record

your

Serial

Number

and delivery date

below.

Serial

Number

Delivery Date

Your Serial

Numberislocated here.

A WARNING

TO

ALL CALIFORNIA AND OTHER POWER EQUIPMENT OPERATORS

Under

California

Law, and

under

the lawsofseveral otherstates, you are

not

permittedtooperatean internal

combustion

engine

using

hydrocarbon

fuels on any forest covered, brush coveredorgrass covered land,oron land covered with

grain, hay,

or

other

flammable agricultural crop,

without

an engine spark arrester in

continuous

effective

working

order.

The

engine on

your

power

equipment, like most

outdoor

power

equipment, is an internal

combustion

engine

that burns

gasoline, a

hydrocarbon

fuel. Therefore,

your

power

equipment

must

be equipped with a spark arrester

muffler

in

continuous

effective

working

order.

The

spark arrester

must

beattached to

the

engineexhaustsystem in such a

manner

that flamesorheat from the system will

not

ignite flammable material. Failureofthe

owner/operatorofthe

equipment

to

comply

with

this regulationisa

misdemeanor

under

California law, and may also be a violationofother

state

and/or

federal regulations, laws, ordinances,orcodes.

Contact

your

local fire marshalorforest service

for

specific information

about

what regulations apply in

your

area.

Page 3

SEND SERVICE LETTERS TO:

For

Chipper/Shredder

Service

or

Parts

If

you

require service assistanceorif you wish to

order

replacement parts,

you

can either

contact

us at

the

factory

or

see

your

local authorized servicing

dealer.

Our

factory addresses and telephone numbers

are listed below

for

your

convenience.

Troy-Bilt Mfg.

Company

c/o

Technical Service Dept.

102nd St. & 9th Ave.

Troy, NY 12180

Garden Way Canada, Inc.

1515

Matheson Blvd.,

Unit

B11

Mississauga, OntarioL4W2P5

For

Engine

Service

For engine serviceorparts, please contact

your

nearest authorized Tecumseh Engine Service Outlet.

To find the outlet nearest you, look

under

"Engines-

Gasoline" in the Yellow Pages

of

your

telephone

directory.

Your new engine is covered by the engine manufac-

turer's Limited Warranty and any unauthorized

work

done on the engine during the warranty period may

void

your

warranty.

Forfull

details on this Limited War-

ranty, please see the separate Tecumseh Owner's

Manual that was furnished with this chipper/shredder.

If

you

should have any

difficulty

in obtaining engine

service

or

parts, please contact us

for

assistance.

OR TELEPHONE:

In the U.S.A:

Technical Service: Toll-Free 1-800-833-6990

Parts Sales: TolI- Free 1-800-648-6776

In Canada:

Local

only

(416 Area Code): 624-8423

From Ontario

& Quebec: Toll-Free 1-800-387-3351

From Western Canada and the Maritime Provinces:

Toll-Free 1-800-387-3316

Be

Sure

to

Return

Your

Warranty

Registration

Card!

Itis important that

you

fill

out

and mail

yourWarranty

Registration Card, which is included in

your

literature

package. The information contained on this card will

register

your

machine with us and entitle

youtocover-

age under

our

Full

No-Time-Limit

Warranty.

TABLE

OF CONTENTS

Page

SECTION1:SAFETY

INSTRUCTIONS

Safety Before Starting the

Engine.

. . . . . . . . . . . 2

Safety During

Operation.

. . . . . . . . . . . . . . . . . . . 2

Safety Instructions

for

Maintenance

and

Storage.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION2:INITIAL

PREPARATION

Inspection After Delivery 5

Parts

Checklist.

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Check

Hardware

for

Tightness . . . . . . . . . . . . . . 5

Add

Motor

OiltoEngine.

. . . . . . . . . . . . . . . . . . . 6

SECTION3:FEATURES &

CONTROLS

Shredder

Hopper

(Inlet) 7

Chipper

Chute (Inlet) 8

Chipper/Shredder Chamber 8

Discharge

Area.

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Wet Material

Baffle

Attachment.

. . . . . . . . . . . . . . . . . . . . . . . 9

Carburetor

Choke

Control.

. . . . . . . . . . . . . . ...10

Engine Shut-Off Tab

10

Manual Recoil Start

Rope.

. . . . . . . . . . . . . . . ...10

Engine Fuel

Tank.

. . . . . . . . . . . . . . . . . . . . . . ...10

Page

SECTION4:OPERATING

INSTRUCTIONS

Materials Recommended

for

Shredding

11

Materials Recommended

for

Chipping

11

Transporting the

Chipper/Shredder.

. . . . . . ...12

Pre-Starting Steps

12

Engine Starting &

Stopping.

. . . . . . . . . . . . . ...13

How

to Use the

Chipper.

. . . . . . . . . . . . . . . . ...13

HowtoUse the

Shredder.

. . . . . . . . . . . . . . . ...14

Shredding Wet,

SoggyorGreen

Materials....

15

SECTION5:MAINTENANCE

& SERVICE

Oil

Changing.

. . . . . . . . . . . . . . . . . . . . . . . . . . ...16

Air

Cleaner Service

17

Engine

Cleaning.

. . . . . . . . . . . . . . . . . . . . . . . ...17

Spark Plug and Ignition System

17

Carburetor Adjustment & Engine Storage. . ...17

Chipper/Shredder

Lubrication.

. . . . . . . . . . . ...18

RotatingorReplacing Shredder

Cutting Blades

18

SharpeningorReplacing the

Chipper

Blade

,.

..

18

SPECiFiCATIONS Inside Back Cover

1

Page 4

SECTION

1:

SAFETY INSTRUCTIONS - IMPORTANT!

A DANGER

CONTACT

WITH ROTATING

CUTTING

BLADES INSIDE DISCHARGE OPENING WILL CAUSE SERIOUS

PERSONAL INJURY!

CUTTING

BLADES ARE ROTATING WHILE MACHINE IS RUNNING,

AND

CON-

TINUE

TO

ROTATE

UNTIL

ENGINE COMES TO A COMPLETE STOP.

KEEP HANDS, FEET, FACE,

AND

CLOTHING

OUT

OF SHREDDER HOPPER

INLET

AND

CHIPPER CHUTE

INLET

AND

AWAY FROM THE DISCHARGE AREA AND MOVING PARTS AT

ALL

TIMES

TO

AVOID

SERIOUS INJURY. BEFORE

DOING

MAINTENANCE

OR SERVICE, PUSH

SHUT-OFF

TAB

(On

Top

Of

Engine)

AGAINST

SPARK PLUG

AND

HOLD

THERE

UNTIL

ALL MOVING PARTS HAVE COME TO A

COMPLETE STOP. DISCONNECT THE SPARK PLUG WIRE.

Please read and

follow

all ofthe safetyinstructions in

this Safety Section. Failure to

comply

can result in

seriouspersonal

injuryorpropertydamage. Ifyou have

questions,

or

are

not

completely sure

about

any of the

information

found

hereorelsewhere in this Manual,

pleasecall us

for

assistance before

you operate

your

equipment.

SAFETY BEFORE

STARTING THE ENGINE

1.

Become

familiar

with

this

Owner/OperatorManual before

attempting

to

operate

your

equipment.

2.

Know

where the engine Shut-OffTabislocated and

howtouse it. This tab-shaped control is next to the

spark plug on

top

of the engine.Tostop machine,

hold Tab against thespark plug until the engine has

stopped completely.

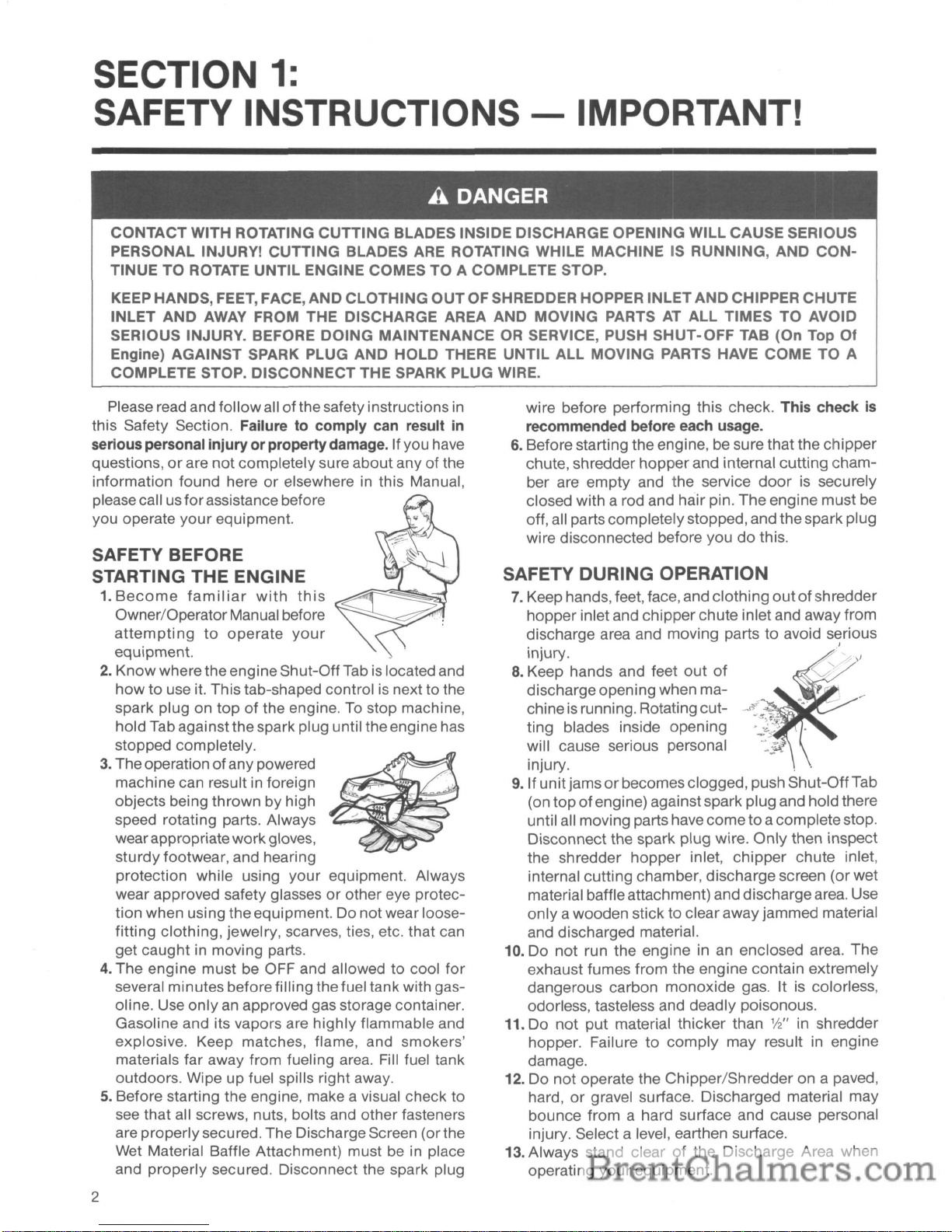

3.

The operation ofanypowered

machine can result in foreign

objects being

thrown

by high

speed rotating parts. Always

wearappropriatework gloves,

sturdy

footwear, and hearing

protection while using

your

equipment. Always

wear approved safety glasses

or

other eye protection when using theequipment. Do notwear loosefitting clothing, jewelry, scarves, ties, etc. that can

get caught in moving parts.

4.

The engine must be OFF and allowed to cool

for

several minutes beforefilling the fuel tank with gasoline. Use

only

an approved gas storage container.

Gasoline and its vapors are

highly

flammable and

explosive. Keep matches, flame, and smokers'

materials far away from fueling area. Fill fuel tank

outdoors. Wipe up fuel spills right away.

5.

Before starting the engine, make a visual check to

see

that all screws, nuts, bolts and other fasteners

are properlysecured. The Discharge Screen (orthe

Wet Material Baffle Attachment) must be in place

and properly secured. Disconnect the spark plug

2

wire before performing this check. This

check

is

recommended before each usage.

6.

Before starting the engine, be sure that the

chipper

chute, shredder

hopper

and internal

cutting

cham-

ber are empty and the service

doorissecurely

closed

with

a rod and hair pin.

The

engine must be

off, all parts completelystopped, and the spark plug

wire disconnected before you

do

this.

SAFETY DURING OPERATION

7.

Keep hands, feet, face, and

clothing

outofshredder

hopper inlet and chipper chute inlet and away from

discharge area and moving parts

to

avoid serious

• • .J

inJury.

./:

,J

8.

Keep hands and feet

out

of

~'

dischargeopening when machine

is

running. Rotatingcutting blades inside opening

will cause serious personal

injUry.

9.Ifunit

jamsorbecomesclogged, push

Shut-Off

Tab

(on

topofengine) againstspark plug and holdthere

until all moving parts have

cometoacomplete stop.

Disconnect the spark plug wire.

Only

then inspect

the shredder

hopper

inlet, chipper chute inlet,

internal cutting chamber, discharge screen (orwet

material baffleattachment) and dischargearea. Use

only

a wooden sticktoclearaway jammed material

and discharged material.

10.

Do

not

run the engine in an enclosed area.

The

exhaust fumes from the engine contain extremely

dangerous carbon monoxide gas. It is colorless,

odorless, tasteless and deadly poisonous.

11.

Do

not

put

material thicker than W' in shredder

hopper. Failure

to

comply

may result in engine

damage.

12.

Do

not operate the

Chipper/Shredder

on a paved,

hard,

or

gravel surface. Discharged material

may

bounce from a hard surface and cause personal

injury. Select a level, earthen surface.

13. Always stand clear

of

the Discharge Area when

operating

your

equipment.

Page 5

22. Do

not

transportormove

your

equipment

whilethe

engine is running.

23. Do

not

tamper with the governor setting on the

engine. The governor controls the maximum safe,

operating speed and protects the engine and other

moving parts from damage that can be caused

by

overspeeding.

24. Rotating cutting blades

do

not

stop until the

engine is off.

25.

~;ui~~e~~e:~:nY~~~

~?-:.

,..F££T;-,<t

c

standers

or

pets are

~,

{b

=-

=>

= = =

nearby. Keep bystand-

~

ers at least25feet away from this equipment.

26. Processed material exitsat high speed from the Dis-

charge Opening. Keep away

from the Discharge Opening

and the Discharge Area while

operating unit. When shred-

~~~~~~r,

ding, stand on the side

of

II'

your

unitoppositethe engine.

This way, you will

not

be

close

to

the

hot

exhaust

L~~~~~~~

muffler.

~

27. When shredding wet, heavy materials, always have

the Wet Material Baffle Attachment securely in

place (the Discharge Screen must be removed first,

then theWet Material Baffle Attachment

is

installed).

SAFETY INSTRUCTIONS

FOR MAINTENANCE

AND PROPER STORAGE

28. Before service, maintenance, cleaning, inspection,

changing the

sh

redder DischargeScreenorthe Wet

Material Baffle Attachment,

or

workofany

other

kind istobe done, be sure to push engine Shut-Off

Tab (on top

of

engine) against the spark plug and

hold the Tab there until the engine is

off

and all

moving parts have

come

to a complete stop. Then,

disconnect

thespark plug wire from the spark plug.

Allow a

hot

muffler to cool before working near it.

29. Store this

equipment

where children will

not

have

access

to

it. Always

disconnect

thespark plug wire.

30. Be sure the

Chipper/Shredder

is stored in an area

where any gasolinevapors (fumes) from the engine

can

not

reach an open flame, sparks,orflame-

producing

equipment

suchasa

hot

water heater

pilot light, a woodstove,

or

a furnace.

31. For seasonal storage, drain all gasoline

from

the

fuel tank and dispose

of

it in asafe manner. Then run

the engine until the small

amountofgasoline left in

the carburetor and fuel line has been used up. Dis-

connect

the spark plug wire

for

storage. Let the

engine cool before putting unit in storage.

14. Do

not

put

hands, feet, face,orany

other

parts

of

your

body

or

clothing

near the

Chipper

Chute,

ShredderHopper,

or

DischargeArea. Cutting blades

will begin

to

rotate and build

up

speed once the

engine is running. Personal

in-

jury

will

occur

unless rotating

cutting blades have completely

stopped.

15. Do

not

allow children

or

un-

trained

adults

to

operate the

equipment.

16. When feeding appropriate material intothe Chipper

or

Shredder, be extremely careful that pieces of

metal, rocks, bottles, nails, cans and any other

for-

eign objects are

not

included. Use organic mate-

rials only!

17. Shut

off

the engine immediatelyifthe

Chipper/

Shredderstrikes

any

foreign objectordevelops

any

unusual noisesorvibrations. Push Engine Shut-Off

Tab (on

topofengine) against the spark plug and

hold the Tab there until the engine

is

off

and all

moving parts have come

to

a complete stop. Then,

disconnect the spark plug wire from the spark plug

and take the

followi

ng steps:a.Inspect

for

damage;

b.

If a foreign

object

is present, remove it;c.Check

for

loose partsorhardware, and tighten if loose;

d.

Replaceorrepair damaged parts before starting

the engine.

18.

Do

not

allowenginesurfaces, especially aroundthe

cooling

fins and muffler,tobecome clogged with

leaves, grass, oil, grease,

or

any

other

combustible

material. Keep these areas clean toavoid a potential

fire hazard.

19.

Do

not

allow

chippedorshredded materialtobuild

up

in,orclog, the Discharge Area -

clogging

pre-

vents

proper

dischargeofmaterials and can result

in kickback

of

material

up

through

the Shredder

HopperorChipper

Chute. In

orderto

remove mate-

rial

from

the discharge area, use a long-handled

shovel

or

long stick.

NEVER

USE

YOUR

HANDS

OR

FEET! Rotating blades

cut

1,14"

from Discharge

Screen. Keep away!

Never

putyourhands or feet in

the discharge opening.

20. Keep all safety shields, guards, screens and deflec-

tors

securely in place,

properly

secured, and in

good

condition.

Do

not operate the unit unless the

Shredder

Hopperissecurelybolted in placeandthe

service

doorisclosed with a rod and hair pin. Keep

your

face and

body

back away from the shredder

and

chipper

feed inlet openings.

21.

Do

not

overreach when

feeding material into the

Shredder

HopperorChipper Chute. Always keep

arms parallel

to

theground

A~~~

~:tb~L

whilefeeding material into

-l

Shredder Hopper. Keep

proper

footing and

good

_·'ta!~IIrt:~.-A/l.JL-

balance atall times.

Obey

thesafetyand instruction

decals on

your

equipment at all times.

3

Page 6

MAKESURE THE SAFETY DECALS ON YOUR EQUIPMENTARE KEPT CLEANAND

IN

GOOD

CONDITION SO YOU CAN FOLLOW THE INSTRUCTIONS ON THEM!

Please

contactusimmediately

for

replacement

decals

should

they

become

wornorunreadable.

#2. ThisDecal appears onceonthe

top

of

your

equipment inside the shredder

hopper.

ROTATING

CUTTING BLADES

INSIDE DISCHARGE OPENING

WILL

CAUSE

SERIOUS PERSONAL

INJURY.

KEEPAWAY!

KEEP

HANDS AND

FEET

OUT

OF

DISCHARGE OPENING

WHEN

MACHINE IS RUNNING, AND

KEEP

SERVICE

DOOR

SECURED

WITH

ROD

AND HAIR PIN.

PROCESSED MATERIAL EXITS

AT

HIGH

SPEED

BELOW.

KEEP

HANDS AND FEET

AWAY

FROM

DISCHARGE AREA

TO

AVOID

INJURY.

#5.

This

Decal appears

once

on the side

of

your

chipper/shredder

right next

to

the discharge area.

HOT

SURFACES

CAN

CAUSE

SEVERE

BURNS.

00

NOT

TOUCH

MUFFLER

OR

ADJACENT

AREAS.

#6.

This Decal appears once

rightnexttothe mufflerarea.

KEEP HANDS AND FEET OUT

OF INLET AND DISCHARGE

OPENINGS WHILE MACHINE

IS

RUNNING

TO

AVOID

SERIOUS PERSONAL INJURY.

-------------------

NO HANDS BELOW THIS LINE

ROTATING CHIPPER

BLADE

WILL

CAUSE

SERIOUS PERSONAL

INJURY. KEEP HANDS

AWAY

FROM CHIPPER

CHUTE

INLETATALL

TIMES.

#3.

This Decal appears once

on the

sideofyourequip-

ment nexttothe

chipper

chute.

ADANGER

ROTATING CUTTING

BLADES

INSIDE DISCHARGE OPENING

WILL

CAUSE SERIOUS

PERSONAL INJURY.

KEEPAWAY!

KEEP HANDS

AND

FEET OUT OF

DISCHARGE OPENING AND

AWAY

FROM DISCHARGE AREA WHEN

MACHINE IS RUNNING.

#1.

This

Decal appears once on

the

frontofyour

equipment

next

to

the discharge area.

#4.

This Decal is located in the neckofyour

equipment

inside

the

mainframe. It's

only

visible when the shredder

hopperisdis-

connected and removed

for

servicing

or

repair.

A DANGER

THE ROTATING SHREDDER CUTTING BLADES INSIDE THE

DISCHARGE OPENING

CUT

'I."

FROM THE DISCHARGE

SCREEN. CONTACT WITH ROTATING CUTTING BLADES

WILLRESULT IN SERIOUS PERSONAL INJURY. KEEP HANDS

AND

FEET

OUT

OF DISCHARGE OPENING AND

AWAY

FROM DISCHARGE AREA WHEN MACHINE IS RUNNING.

INORDER

TO

REMOVE CHIPPEDORSHREDDED MATERIAL

FROM THE DISCHARGE AREA, USE A LONG-HANDLED

SHOVEL

OR

LONG STICK- NEVER USE YOUR

HANDS

OR

FEET! IF MATERIAL SHOULD EVER

CLOG

THE CHAMBER,

DISCHARGE TUNNEL

OR

DISCHARGE OPENING,ORTHE

MACHINESHOULDREQUIRE MAINTENANCE

OR

SERVICE,

ALWAYS STOP

UNIT

BY PUSHING ENGINE SHUT-OFF TAB

(On Top

Of

Engine) AGAINST SPARK PLUG AND HOLD

THERE

UNTIL

ALL

MOVINGPARTS HAVE COMETOA

COMPLETE STOP. DISCONNECTTHE SPARK PLUG WIRE. USE A

LONG STICK TO CLEAR THE CLOGGED MATERIAL.

Shredder Hopper

Rotating Shredder

Cutting

Blades

cut

W' Away From The Discharge Screen

- KEEP HANDS

AND

FEET

AWAY

from Discharge Area and Discharge

OpeningAt AllTimesTo Avoid Serious

Personal Injury!

'I." Between

Shredder Blades

and Discharge Screen

Discharge

j-'T---

Screen

Rubber

,/7---

Retainer

Flap

Chipper Aywheel

Chipper Blade

Chipper/Shredder

Mainframe

4

Page 7

SECTION

2:

INITIAL PREPARATION

STEP

1:

Inspection After Delivery

STEP

2:

Checklist

of

Components

Shipped

To

You

NowthatyourTROY-BILT® JUNIORTOMAHAWK®

Chipper/Shredderhasarrived, you'll find it's easy toget

your

equipment ready

for

use. Be sure to follow all

directions

in

this Section!

~®

®

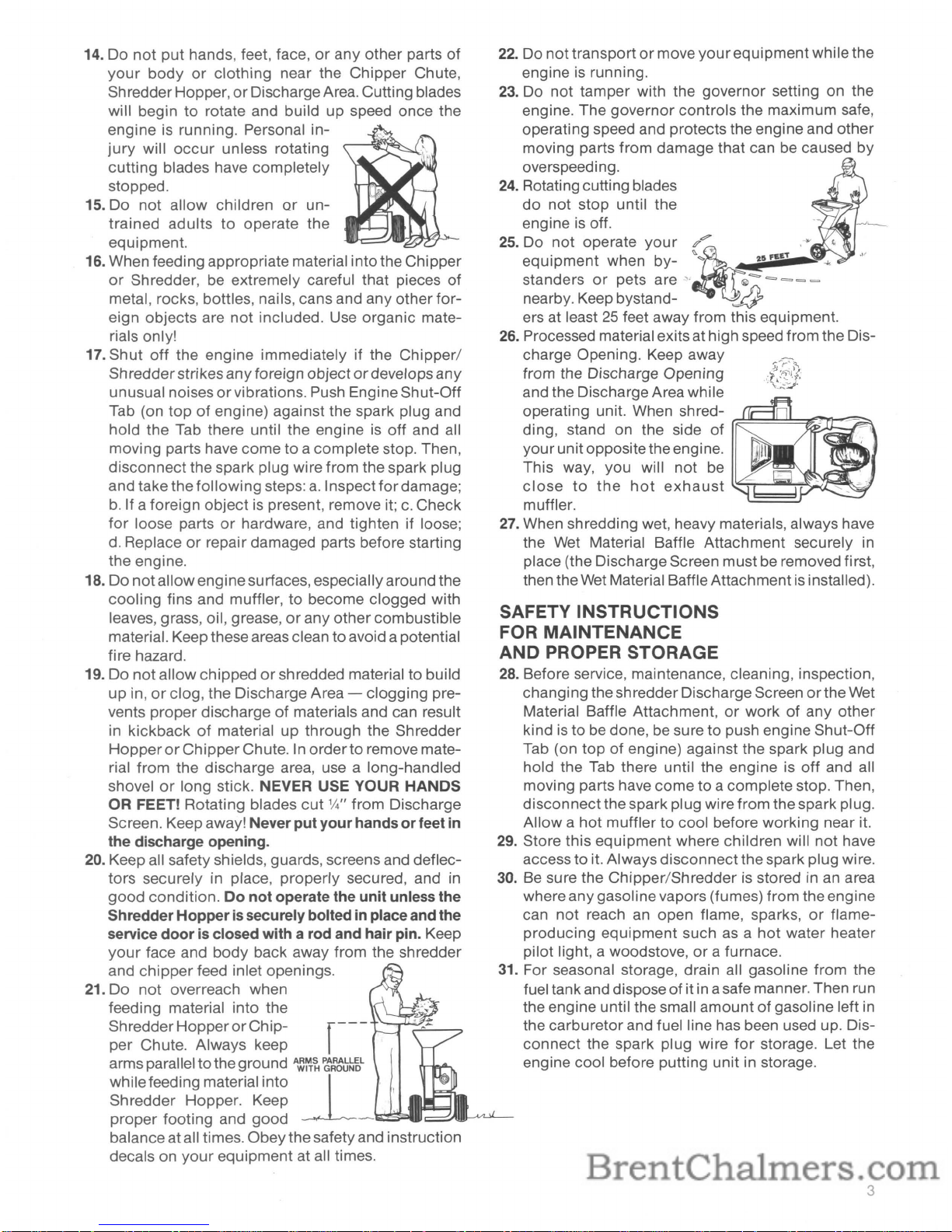

(Photo 2

-1

) Make sure

you

received everything shown.

STEP

3:

Check Hardware

For Tightness

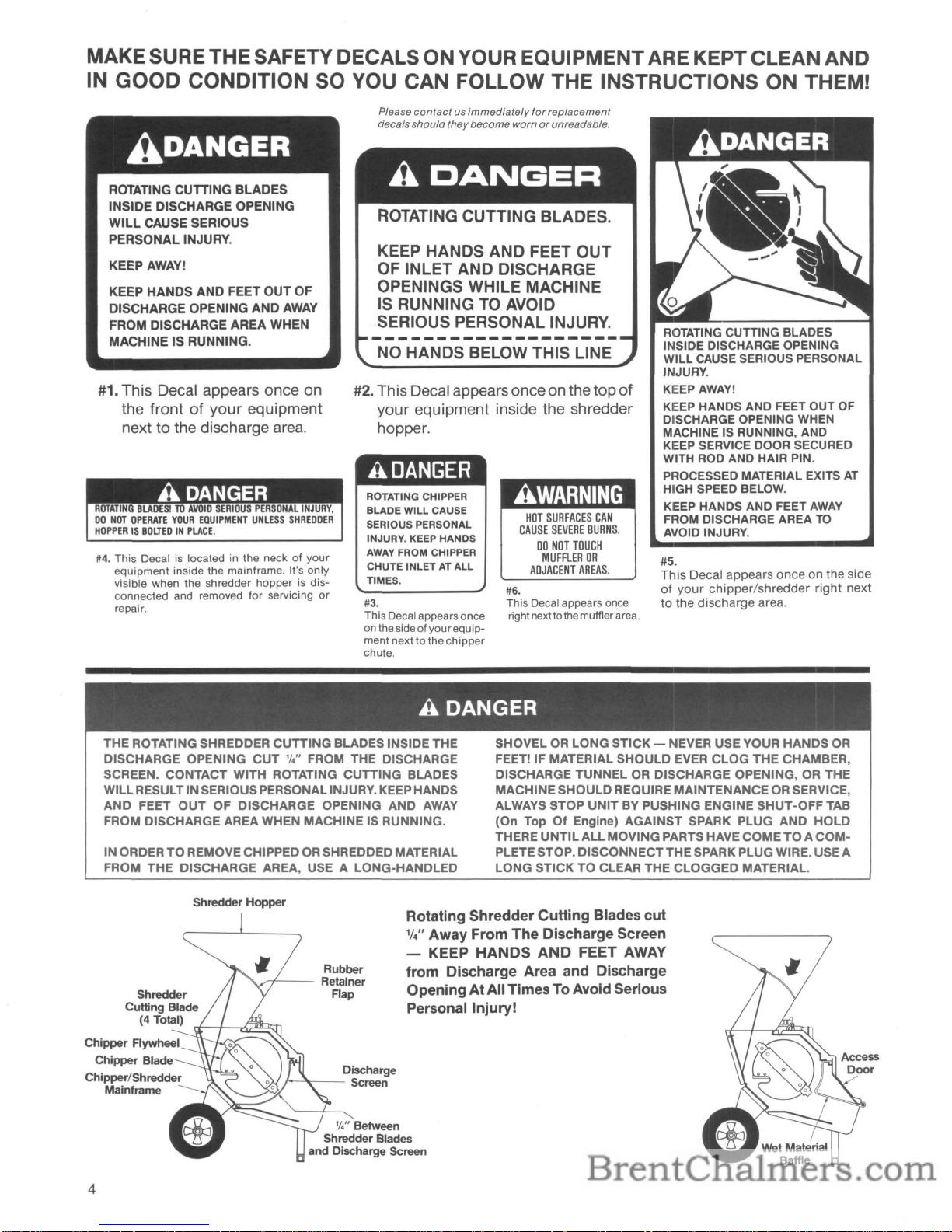

Useanadjustablewrench to verifythe tightnessofall

hardware (bolts and nuts) on

your

equipment. If you

find

anything looseormissing,donot

use the equip-

mentuntilthe hardwareis tightened

or

the missing item

is replaced with a genuine TROY-BILT® replacement

part. Work around all

four

sidesofthe chipper/sh-

redder with

your

wrench. See Photo 2-2 below: the

bolts and nuts securing the shredder hopper to the

mainframe are indicated - they must

be

very secure.

Qty.

Item Description

Photo

2-1

Ref. No.

Your chipper/shredder was shipped to you com-

pletely assembled, but we've also included

an

impor-

tant attachment

for

shredding wet material, plus a few

otheritems

for

your

convenienceand safety. Please be

sure you received them

as

listed and shown below.

Contact us if anything is missing.

Safety Goggles (universal fit) . . . .... . .. . ....1

2 Hex Key Wrench -

1/8"

1

(for

service procedures)

3 Oil Funnel

......................•.........

1

4 Wet Material Baffle

Attachment.

. . . . . . . . . ...1

5 Hair Pin Clip (extra) 1

6 Leaf

Tamper.

. . .. . . . . . . . . .. . . . . . . . . .. . ....1

7 Maintenance Roll Pin Kit (includes

four

spare roll pins and one tubeofLoctite 242

sealant - to be used when worn shredder

blades need replacement

or

rotation 1

IMPORTANT-

Motor

oil mustbe added tothe engine

before starting! This Section provides full instructions.

Do

not

operate

your

equipment

until

you

haveread this

Owner/Operator

Manual completely.

Inspect

your

chipper/shredderright afterit has been

delivered. Make sure neither the carton nor the

con-

tents have been damaged. If you findorsuspect dam-

age, contactthe trucking company (carrier) right away.

Inform them of the specific damage and that you wish

tofile aclaim.

Be sure to

put

this in writing to the carrier

within

15

days after

your

unit

arrived to

protect

your

rights. The carrierwill let you

know

how

to proceed. Of

course, if you need assistance, let

us

know.

(Photo 2-2) Double-checkhardware tightness all aroundthe

equipment - especially the shredder hopper.

5

Page 8

STEP 4: Add Motor Oil

To

Engine

Yourengine was shipped "dry"to avoid anypossible

leakage problems during transit.

To

add the required

amount and type

of

motor

oil to the engine crankcase,

please follow these instructions.

Note: the engine must

be

level

foranaccurate oil

level reading. Please move your equipment off the

shipping platformand to level ground. Refer toSection 4

in this Manual

for

transporting instructions if you're

unsure about

how

to move the chipper/shredder.

Procedure:

Use aclean, high quality detergentmotoroil that

is

a

classified "For Service:

SForSG." A new engine will

require approximately

21

ounces of oil.

In temperaturesabove

32°

F,

useSAE 30viscosity

0;1

(SAE 10W30isan acceptable substitute).Intemperatures below

32°

F,

use SAE 5W30 (SAE 10Wisan

acceptable substitute). Note:Intemperatures below

0° F ONLY, SAE

OW30

isanacceptable substitute.

DO

NOT

USE SAE 10W40 OIL.

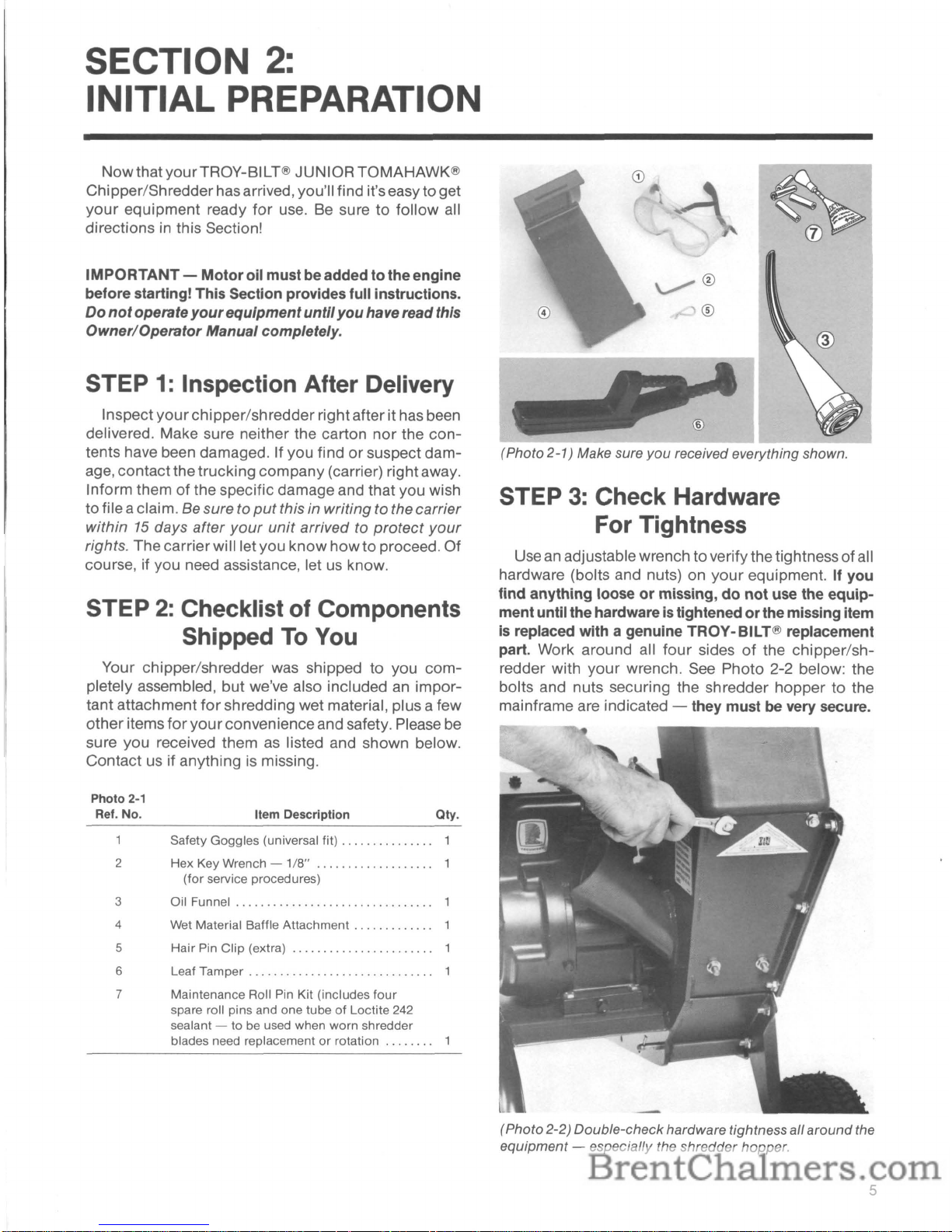

1.

Unscrew and remove the Oil Fill Plug near the bot-

tom

of

the engine on the left-hand side (side with the

choke lever/carburetor). Turn it counterclockwise to

take it off - refer to Photo

2-3.

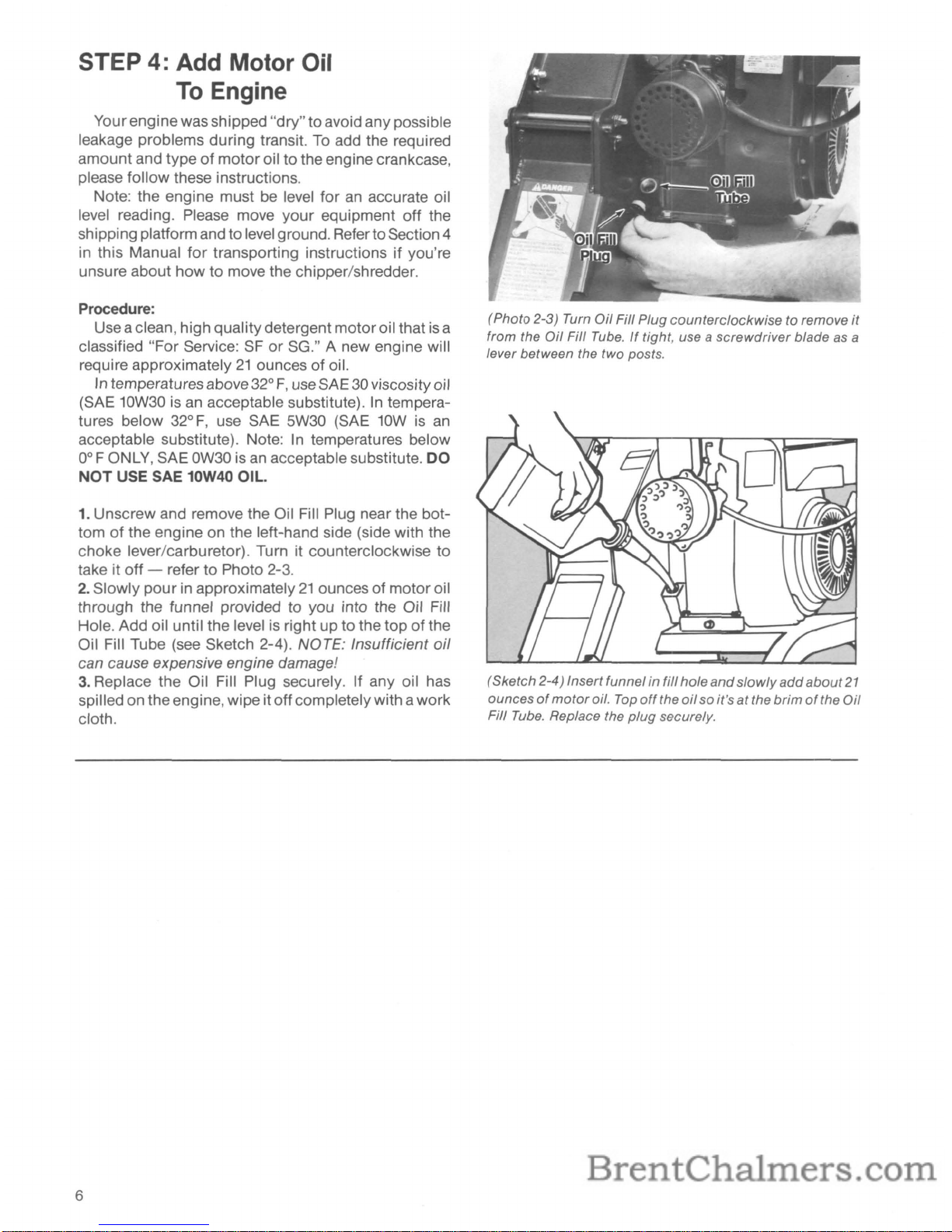

2.

Slowly

pour

in approximately21ounces of motor oil

through the funnel provided to you into the Oil Fill

Hole. Add oil until the level

is

right up to the

topofthe

Oil Fill Tube (see Sketch 2-4). NOTE: Insufficient

oil

can cause expensive engine damage!

3.

Replace the Oil Fill Plug securely. If any oil has

spilled on theengine, wipe itoffcompletely with awork

cloth.

6

(Photo 2-3) Turn

Oil

Fill Plug

counterclockwise

to remove

it

from the

Oil

Fill

Tube.Iftight, use a

screwdriver

blade as a

lever between the two posts.

(Sketch

2-4) Insertfunnel in fill

hole

and

slowly

add

about

21

ouncesofmotor

oil.

Top

off

the

oil

so it's

at

the

brimofthe

Oil

Fill

Tube.

Replace the

plug

securely.

Page 9

SECTION

3:

FEATURES &CONTROLS

Before putting

your

new JUNIOR TOMAHAWK®

Chipper/Shredder to work on the projects you've been

planning, please read this Section completelyto understand exactly

how

the equipment works and the loca-

tion and function ofall thefeatures and controls. Basic-

ally, there are chipper/shredderfeatures and there are

engine features.

Chipper/Shredder

Features

&Controls

Please refer to Photo

3-1

to locate the following

chipper/shredder features and controls:

1.

Shredder Hopper (inlet)

2.

Chipper Chute (inlet)

3. Chipper/Shredder Chamber

4. Discharge Area

(Includes Discharge Screen and Wet Material Baffle

Attachment)

(Photo

3-1)

Your

equipment

has the

features/controls

shown

above.

1.

Shredder Hopper (Inlet)

The Shredder

Hopper

(see Photo 3-2

for

a closeup)

is located at the

topofthe unit and is the opening into

which

all materialstobe shredded should be fed. A

rubber retainer flap is secured to the hopper. Loose,

bulky material must be pushed past the retainer flap

with

your

Leaf Tamper in

order

to enterthe main

chipper/shredder chamber where revolving steel cutting

blades

do

the shredding (see "Danger" above). The

retainer flap

isanimportant feature -itprevents kick-

back

of

materials! Do Not Use Your Equipment Unless

The Rubber Retainer Flap

is

Securely Fastened. Most

organic materials can be shredded. Section 4 provides

alistof materials.

IMPORTANT- DoNot Put Materials

Thicker Than

112"

In

Shredder Hopper. Failure

To

Comply May

ResultInEngine Damage.

A

DANGER

CONTACT WITH INTERNAL ROTATING CUTTING

BLADES WILL CAUSE SERIOUS PER-

SONAL INJURY. DO

NOT

PUT HANDS, FACE,

FEET, OR CLOTHING INTO THE SHREDDER

HOPPER,

CHIPPER

CHUTE,

DISCHARGE

OPENING

OR

NEAR THE DISCHARGE AREA

AT

ANYTIME. BEFORE DOING MAINTENANCE

OR

SERVICE, PUSH SHUT-OFF

TAB

(On Top Of

Engine) AGAINST SPARK PLUG AND HOLD

THERE

UNTIL

ALL

MOVING

PARTS HAVE

COME

TO

A COMPLETE STOP. DISCONNECT

THE SPARK PLUG WIRE. AFTER ALL MOVING

PARTS HAVE STOPPED COMPLETELY, USE

ONLY A WOODEN STICK

TO

CLEAR JAMMED

MATERIAL, BLOCKAGES, OR DISCHARGED

MATERIAL.

(Photo

3-2) The

top-loading

Shredder

Hopper

can

be used

to

shred

organic

materialsupto

112"

in thickness.

A

DANGER

I

SHREDDED PARTICLES CAN KICKBACK UP

THROUGH THE SHREDDER HOPPER INLET

UNLESS THE RUBBER RETAINER FLAP IS IN

PLACE AND SECURELY FASTENED. PERSONAL INJURY CAN RESULT FROM FLYING

PARTICLES.

BEFORE USING YOUR EQUIPMENT,

BE

SURE

THE RETAINER FLAP

IS

SECURELY ATTACHED

AND THAT YOU ARE WEARING PROTECTIVE

SAFETY GOGGLES

OR

GLASSES.

7

Page 10

2.

Chipper Chute (Inlet)

The Chipper Chute on the side of

your

equipment

lets you process into "chips" larger materials that the

Shreddercan't handle. The Chipper Chute

is

shown

in

aclose-up in Photo 3-3. Branchesfed intothe chute are

turned into "chips" by a revolving blade mounted on a

flywheel.

We

recommend that branches and vines from

%,'-to-2" in diameterbe fed intothe Chipper Chute. Cut

your

materials into manageable lengths before pro-

cessing them.

A DANGER

Internal

Chipper/Shredder

Chamber

"Cutaway View"

4.

Discharge Area

The Discharge Area is located near the bottom of

yourequipment. This

is

whereall chipped and shredded

materials exit once they've been processed.

See

Photo

3-5

for

a close-up view of the Discharge Area.

The holes

in

the Discharge Screen

not

only

provide

an

exit

for

processed materials, but hole size deter-

mines

how

finely materials are shredded. Shreddings

can't

be

discharged until they've been reduced to less

than the hole size

in

the screen. The Discharge Screen

supplied with

your

equipment is a general-purpose

screen designed to handle many kinds of materials

efficiently - it has

%" diameter holes which let all but

wetand green materials exitquickly.Also supplied with

your

machine is a Wet Material Baffle Attachment that

thoroughlyprocesseswet, heavymaterial with minimal

clogging.

It

must be used in placeofthe standard

screen when processing wet leaves, half-rotted compost, gone-by vegetables, and similar wet materials.

Access Via Service Door

__

Regular%"Discharge Screen

(Photo 3-4)

Shown

above is the

combination

chipper

fly-

wheel/shredder

cylinder

assembly. The flywheel holds the

chipper

blade - feed material

into

the

chipper

chute

and

the

chipper

blade will processitinto

chippings.Orfeed

other

material

into

the shredder

hopper

and

the rotating

cutting

blades will process

it.

(Photo 3-5) Close-upofthe general-purpose Discharge

Screen.

Chipped

and

shredded

materials

exit

through

the

holesin thescreen. A special

Wet

Material Baffle

Attachment

for

processing wet, green materialsis alsoprovided. The

Wet

Material Baffle

Attachment

is usedinplaceofthe Discharge

Screen when

you

wantto

shred

wet, heavymaterials like wet

leaves,

and

gone-by

vegetables.

3.

Chipper/Shredder Chamber

CONTACT WITH INTERNAL ROTATING

CUT-

TNG

BLADES WILL CAUSE SERIOUS PER-

SONAL INJURY.

DO

NOT

PUT HANDS, FACE,

FEET, OR

CLOTHING

INTO THE SHREDDER

HOPPER,

CHIPPER

CHUTE,

DISCHARGE

OPENING, OR NEAR THE DISCHARGE AREA

AT ANYTIME.BEFOREDOING MAINTENANCE

OR SERVICE, PUSH SHUT-OFFTAB (On TopOf

Engine) AGAINST SPARK PLUG AND HOLD

THERE

UNTIL

ALL

MOVING

PARTS HAVE

COME

TO

A COMPLETE STOP. DISCONNECT

THE SPARK PLUG WIRE. AFTER

ALL

MOVING

PARTS HAVE STOPPED COMPLETELY, USE

ONLY A WOODEN STICK

TO

CLEAR JAMMED

MATERIAL.

Inside the steel mainframe chamber of

your

equip-

ment

is

a flywheel/cylinder-assembly thatisbolted

directly to the engine PTO shaft. The round flywheel

has achipper bladeattached to it. Thecylinderassembly also holds the shredder flail cutting blades that do

all the shredding. When your engine is running, the

chipper blade and the shredder cutting blades revolve

at the same time - making either chipping

or

shred-

ding available to you. See Photo 3-4

for

a view inside

the mainframe chamber showing the chipper blade

and shredder cutting blades.

(Photo

3-3)

The

Chipper

Chute is for processing larger,

heavier branches ('/2"-to-2" in diameter).

8

Page 11

As Photo 3-6 shows, the Discharge Screen can be

taken

out

to allow any blockages to be removed with a

stick. First stop the engine (hold engine Shut-Off Tab

against spark plug), wait

for

all moving parts to stop

completely, and then disconnect the spark plug wire.

Unlock

the Service

Door

(remove hair pin clip and rod

securing it); remove the

two

hairpin clipsand rods that

attach the screen; lift the Service Door, and slide the

screen out. (Note: to remove the Wet Material Baffle

Attachment,

only

one rod must be removed.) After

cleaning the screen

or

the chipper/shredder chamber

with a stick, be sure

to

securely replace the screen (or

the Baffle Attachment) with the properfasteners. When

reinstalling the screen, be sure that the end with the

smaller

"hook"

(see Photo 3-6) goes in toward the

bottom, rear of the discharge opening. NEVER OPERATE YOUR EQUIPMENT UNLESS THE DISCHARGE

SCREEN (OR WET MATERIAL BAFFLE ATTACHMENT) IS SECURELY

AND

PROPERLY ATTACHED

OR PERSONAL INJURY

COULD

OCCUR. THE SER-

VICE DOOR

MUST

ALSO BE CLOSED

AND

PROP-

ERLY SECURED.

'®

Pull Discharge

Screen Out

(Photo

3-6)

To

remove

Discharge

Screen, remove

two

hair

pin

clips

and

rods

securing

screen

and

one

hair

pin

clip

and

rod

securing

bottomofService Door.

A DANGER

CONTACT

WITH INTERNAL ROTATING

CUT-

TNG

BLADES

WILL

CAUSE SERIOUS PER-

SONAL

INJURY. KEEP HANDS, FEET, FACE,

AND

CLOTHING

OUT

OFSHREDDER HOPPER

INLET, CHIPPER

CHUTE

INLET,

AND

AWAY

FROM DISCHARGE AREA AND MOVINGPARTS

AT

ALL

TIMES. ROTATING

CUTTING

BLADES

ARE

TURNING

WHEN THE ENGINE IS RUN-

NING.

TO

CLEAR

THE

DISCHARGE SCREEN,

OR ANY INTERNAL

JAMS

OR BLOCKAGES,

PUSH

SHUT-OFF

TAB

(On

Top

of

Engine)

AGAINST

SPARK PLUG

AND

HOLD

THERE

UNTIL

ALL

MOVING PARTS HAVE COMETOA

COMPLETE STOP.

DISCONNECT

THE SPARK

PLUG WIRE. AFTER

ALL

PARTS HAVE STOP-

PED, USE A

STICK

OR SHOVEL

TO

CLEAR

MATERIAL OR BLOCKAGES.

IMPORTANT -

The

Hair

Pin Clips are specially de-

signed

for

your

equipment

andshould bethe

only

style

pin ever used on

your

machine. Failuretoreplace the

Hair

Pin Clips

properly

Could

ResultInA

Condition

That Creates The RiskOfSerious Personal Injury.

To Install the Wet Material

Baffle Attachment:

With engine shut off and spark plug wire disconnected, unlock Service Door (remove hair pin clip and

rod securing it); remove two hair pin clips and rods that

attach discharge screen; lift Service Door and slide

screen out. Note the 2-inch long slot in one end of the

baffle.

Lift

theService Doorand insertthe baffle intothe

opening, slotted end first. Hookthe slotoverthe tabthat

is

located on the inside upper end ofthe Service Door.

Align thetwo holes at theother end of the baffle with the

two

holes at the end of the Service

Door

and securethe

baffle to the

door

with a rod and hair pin clip. Finally,

close

door

and secure it with a rod and hair pin

clip. See Photo 3-8.

(Photo

3-7) With Discharge Screen removed, install Wet

Material Baffle Attachment. The

slot

in the baffle

hooks

over

the tab

on

the inside,

upper

endofthe Service Door.

Secure Service

Door

with

rod

and

hair pin

clip

(Photo

3-8)

Attach

other

endofBaffle

Attachment

to the

Service

Door

usingarod

and

hair

pin

clip. Close the Service

Door

and

secureitwith a

rod

and

hair

pin

clip.

9

Page 12

Engine

Features

&

Controls

1.

Carburetor

Choke

Control

2.

Engine

Shut-Off

Tab

3.

Manual Recoil Start Rope

4.

Fuel Tank

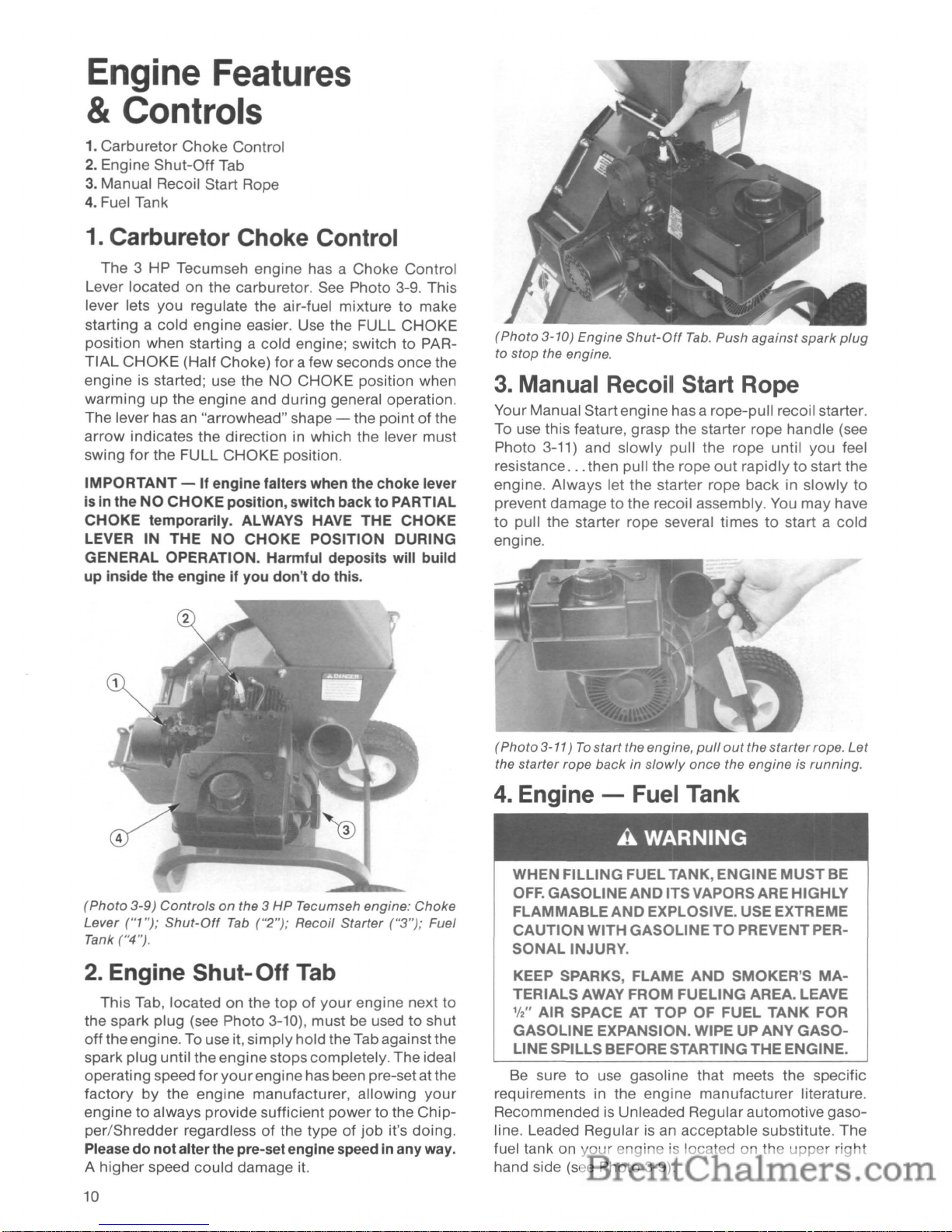

1.

Carburetor Choke Control

The 3 HP Tecumseh engine has a Choke

Control

Lever located on the carburetor. See Photo 3-9. This

lever lets you regulate the air-fuel mixture

to

make

starting a

cold

engine

easier. Use the FULL

CHOKE

position when starting a cold engine; switchtoPAR-

TIAL

CHOKE

(Half Choke)

for

a few seconds once the

engine is started; use the NO

CHOKE

position when

warming

up the engine and during general operation.

The lever has an "arrowhead" shape - the

pointofthe

arrow

indicates the

direction

in which the lever must

swing

for

the FULL

CHOKE

position.

IMPORTANT

- If

engine

falters when the

choke

lever

is

in

the

NO

CHOKE

position,

switch

backtoPARTIAL

CHOKE

temporarily. ALWAYS HAVE

THE

CHOKE

LEVER

IN

THE

NO

CHOKE

POSITION

DURING

GENERAL

OPERATION. Harmful deposits will

build

up

inside the engineifyou

don'tdothis.

(Photo

3-9)

Controlsonthe 3 HP Tecumseh engine: Choke

Lever

("1 ");

Shut-Off

Tab

("2");

Recoil Starter

("3");

Fuel

Tank ("4").

2.

Engine Shut-Off Tab

This

Tab, located on the

topofyour

engine next

to

the spark plug (see Photo 3-10), must be usedtoshut

off

the engine. To use it,

simply

hold theTab againstthe

spark

plug

until the

engine

stopscompletely. The ideal

operating speed

for

your

enginehas been pre-set at the

factory

by

the engine manufacturer, allowing

your

enginetoalways provide sufficient power to the

Chip-

per/Shredder

regardlessofthe type of

job

it's doing.

Please

do

not

alterthe pre-setenginespeed in

any

way.

A

higher

speed

could

damage it.

10

(Photo

3-10) Engine

Shut-Off

Tab.

Push against

spark

plug

to stop the engine.

3.

Manual Recoil Start Rope

Your Manual Startengine has a rope-pull recoil starter.

To use this feature, grasp the starter rope handle (see

Photo 3-11) and

slowly

pull the rope until you feel

resistance

...

then pull

the

rope

out

rapidlytostart the

engine.

Always

let the starter rope back in

slowly

to

prevent damagetothe recoil assembly. You

may

have

to

pull the starter rope several timestostart a

cold

engine.

(Photo3-11)Tostartthe engine,

pull

out

thestarterrope.

Let

the starter rope back in

slowly

once the engine is running.

4.

Engine - Fuel Tank

A WARNING

WHEN

FILLING

FUELTANK,

ENGINE

MUST

BE

OFF.

GASOLINE

AND

ITSVAPORSARE HIGHLY

FLAMMABLE

AND

EXPLOSIVE. USEEXTREME

CAUTION

WITH

GASOLINETOPREVENTPER-

SONAL

INJURY.

KEEP SPARKS,

FLAME

AND

SMOKER'S

MA-

TERIALS

AWAY FROM

FUELING

AREA. LEAVE

W'

AIR SPACE AT

TOP

OF

FUEL

TANK

FOR

GASOLINE

EXPANSION. WIPEUPANY

GASO-

LINESPILLS BEFORESTARTING

THE

ENGINE.

Be sure

to

use gasoline that meets the specific

requirements in the engine manufacturer literature.

Recommended is Unleaded Regular automotive gasoline. Leaded Regular is an acceptable substitute.

The

fuel tank on

your

engine is located on the

upper

right

hand side (see Photo 3-9).

Page 13

SECTION

4:

OPERATING INSTRUCTIONS

A DANGER

CONTACT

WITH ROTATING

CUTTING

BLADES

INSIDE DISCHARGE OPENING WILL CAUSE

SERIOUS PERSONAL INJURY!

READ

THE

COMPLETE OWNER/OPERATOR

MANUAL,

INCLUDING

THESE

OPERATING

INSTRUCTIONS,

BEFORE

USING

YOUR

EQUIPMENT.

This Section provides you with detailed information

on the use of

your

Chipper/Shredder, lots of helpful tips

to make jobs

go

faster and smoother, andanimportant

Checklist

of

Pre-Starting Steps and Engine Starting

Steps that you should always

use.

Please read

allofthe

information

in

this

Section before

you

start

the engine.

IMPORTANT - Do not allow processed material

to

buildupbeneath the machineorinthe Discharge Area. If

material can not freely exit

via

the discharge opening,

it

will

continuetocirculate within the processing chamber

leading

to

clogs and the possibilityofhaving someofthe

material being "blown" back

up

through the

feed

hopper.

To

remove discharged material or blockages,

push

Engine Shut-Off Tab (on topofengine) against spark

plug and hold there until

all

moving parts

have

cometoa

complete stop. Disconnect the spark plug wire. Then,

use

along-handled

shovel

or sticktomove

material from

beneath and around discharge area. With machine

still

turned

off,

check that the holesinthe screen are not

clogged.

To

do

this,

just

open the Service Door and

inspect the screen

as

showninPhoto 3-6. Clean out any

clogged holes with a

small

stick.

Use

The

Shredder For Most Materials;

Use

The

Chipper For Big Tough Jobs

To getthe greatestbenefitsfrom

your

equipment, it's

importanttoknow

which

materialsare best fed intothe

Shredder

hopper

and which ones are best fed into the

Chipper

chute. Under no circumstances should you

feed metal, glass, bottles, plastic, cans, rocks or other

such foreign objects into your equipment. Please see

examples

of

appropriate materials for chipping and

shredding listed below.

IMPORTANT- Do not shred materials thickerthan

112"

in

diameter - engine damage could result.

Materials Best Suited For Shredding:

Duetothe

wide

varietyofmaterials that can be

shredded, and

theirvery

different physical characteris-

tics,

we suggest that you feed limited quantitiesofany

material to begin with.

Bulk

and lengths can be

increased if

you

find the material is being processed

without

any

difficulty. Your judgementisimportant -

be sure

not

to overload the Shredder. Overloading will

cause engine speed to decrease significantly. Always

feed material slowly into the shredder.

• Twigs and branches -

up

to W' in diameter in the

Shredder hopper. Several small branches can be fed

into the Shredder

hopper

at once providing their

combined diameterisless than W'. Long branches (more

than 2-to-3 feet)

shouldbecuttomake them more

manageable. Green materials should be allowedto dry,

or

processed in small batches with

dry

materials,

to

avoid windingupand binding the cylinder.

• Leaves, grass clippings, and all

other

light, loose

materials. These process most easily.

• Organic waste materials and

organic

garbage (be

sure

to

first remove all metal, bottles, cans, rocks, and

plastic).

• Sections

of

vines less than W' in diameter. Long vines

should be

cuttomanageable lengths - 2-to-3 feet.

• Wood chips processed

by

the

Chipper

if even finer

particles are required.

• All paper trash.

• Partially finished compost.

• Stalks and most brush material.

• A mixture

of

anyofthe materials listed above.

Materials Best Suited For Chipping:

•

Thicker

branches - from W' to

2"

in diameter,

depending uponthe hardness

of

wood. Extremely hard

knots will

not

process very well. Short,

thick

branches

(up to

2"

in diameter) that are left over after an original

longerbranch was fed

through

the

chipper

mayalso be

chipped - move these shorter stubs

through

the

chipper with the next long branch you'll be chipping.

• Tough

W'to2"

diameterstalks and vines.

Cut

them to

manageable lengths -

no

more

than fiveorsix feet

long - before chipping them.

A DANGER

CONTACTWITH ROTATING

CUTTING

BLADES

INSIDE

THE

UNIT

AND

INSIDE

THE

DIS-

CHARGE

OPENING

WILL CAUSE SERIOUS

PERSONAL

INJURY.

THE

CHIPPER

AND

SHREDDER BLADES ROTATEATEXTREMELY

HIGH

SPEED.

NEVER

PUT

YOUR HANDS, FEET OR ANY

OTHER PART OF YOUR

BODY

INTO

THE

CHIPPER

CHUTE

INLET OR SHREDDER

HOP-

PER INLET. KEEP

HANDS

AND

FEET

OUT

OF

DISCHARGE OPENING WHEN

MACHINE

IS

RUNNING.

BEFORE SERVICING OR

UNCLOG-

GING

JAMMED

MATERIAL, PUSH

SHUT-OFF

TAB

(On Top Of Engine)

AGAINST

SPARK

PLUG

AND

HOLD

THERE

UNTIL

ALL

MOVING

PARTS HAVE

COME

TO

A COMPLETE STOP.

DISCONNECT

THE

SPARK PLUG WIRE.

11

Page 14

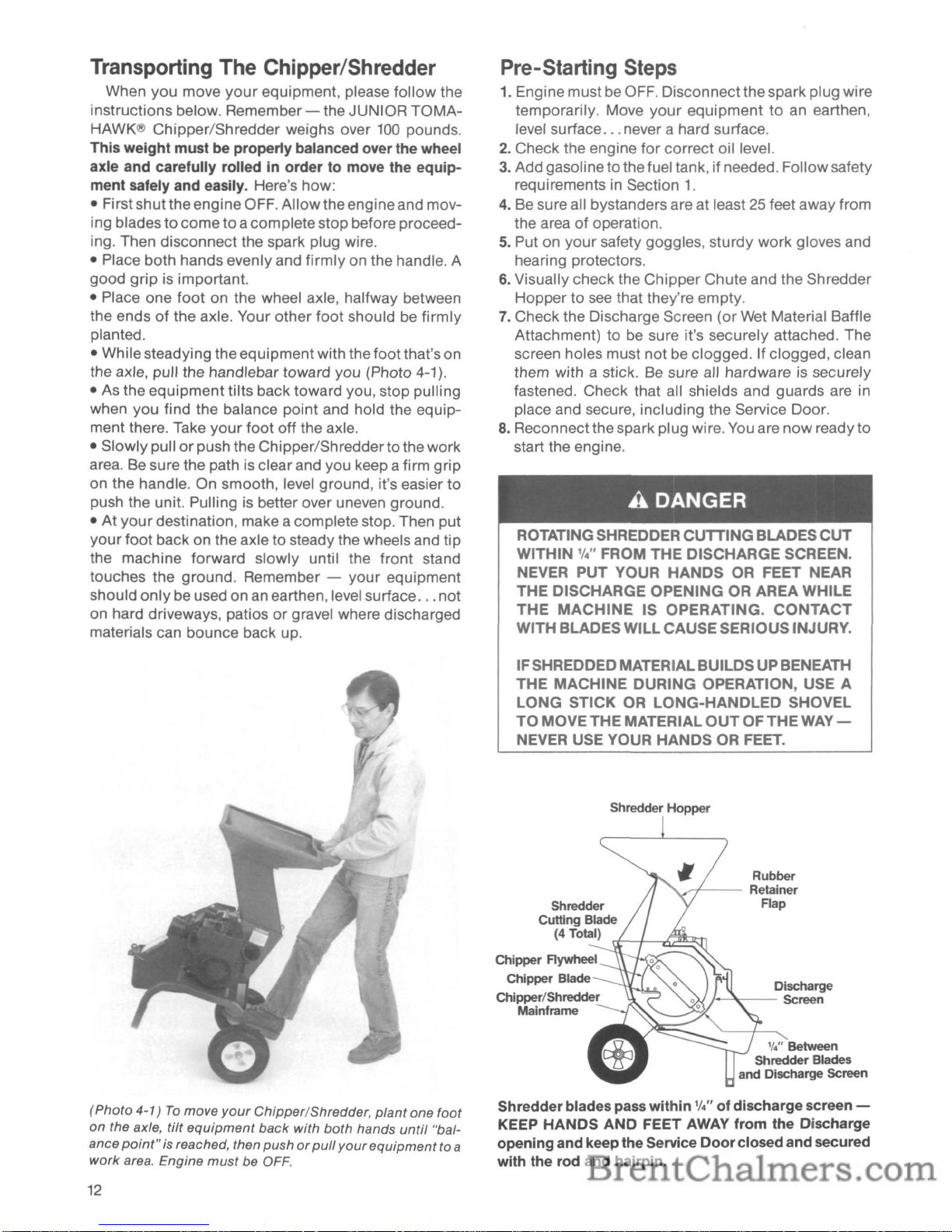

Transporting The Chipper/Shredder

When

you

move

your

equipment, please

follow

the

instructions below. Remember - the JUNIOR

TOMA-

HAWK® Chipper/Shredder weighs over

100

pounds.

This weight must be properly balanced over the wheel

axle and carefully rolled in

ordertomove the

equip-

ment safely and easily. Here's how:

• First

shuttheengine

OFF. Allow theengine and mov-

ing blades

to

cometoacomplete stop before proceed-

ing. Then disconnect the spark plug wire.

• Place both hands evenly and

firmly

on the handle. A

good

grip

is important.

• Place one

foot

on the wheel axle, halfway between

the ends

of

the axle. Your other foot shouldbefirmly

planted.

• While steadying the equipment with thefoot that'son

the axle, pull the handlebar toward you (Photo 4-1).

• As the

equipment

tilts back toward you, stop pulling

when you find the balance point and hold the equipment there. Take

your

foot off the axle.

• Slowly pull

or

push the

Chipper/Shreddertothe

work

area. Be sure the path is clear and you keep a firm grip

on the handle. On smooth, level ground, it's easier

to

push the unit. PUlling is better over uneven ground.

•

At your

destination, make a complete stop. Then put

your

foot

back on the axle to steady the wheels and tip

the machine forward slowly until the front stand

touches the ground. Remember -

your

equipment

should

only

be used on an earthen, level surface

...

not

on hard driveways, patios

or

gravel where discharged

materials can bounce back up.

Pre-Starting Steps

1.

Engine must be OFF. Disconnectthe spark plug wire

temporarily. Move

your

equipmenttoan earthen,

level surface

...

never a hard surface.

2.

Check the engine

for

correct oil level.

3.

Add gasolinetothefuel tank, if needed. Followsafety

requirements in Section

1.

4.Besure all bystanders are at least25feet away from

the area

of

operation.

5.

Put on

your

safety goggles, sturdy work gloves and

hearing protectors.

6.

Visually check the Chipper Chute and the Shredder

Hopper to see that they're empty.

7.

Check the Discharge Screen (or Wet Material Baffle

Attachment) to be sure it's securely attached. The

screen holes must not be clogged. If clogged, clean

them with a stiCk. Be sure all hardware is securely

fastened. Check that all shields and guards are in

place and secure, including the Service Door.

8.

Reconnectthe spark plug wire.

You

are

now

ready

to

start the engine.

A DANGER

ROTATING SHREDDERCUTTING BLADES

CUT

WITHIN

114"

FROM THE DISCHARGE SCREEN.

NEVER PUT YOUR

HANDS

OR FEET NEAR

THE DISCHARGE OPENING OR AREA WHILE

THE

MACHINE

IS

OPERATING.

CONTACT

WITH BLADES WILLCAUSE SERIOUS INJURY.

Shredder Hopper

IFSHREDDEDMATERIAL BUILDSUPBENEATH

THE

MACHINE

DURING OPERATION, USE A

LONG

STICK

OR

LONG-HANDLED

SHOVEL

TO

MOVETHE MATERIAL

OUTOFTHE

WAY

-

NEVER USE YOUR

HANDS

OR FEET.

'I'" Between

Shredder Blades

and Discharge Screen

Discharge

J--T---

Screen

Rubber

..r+--

Retainer

Flap

Chipper Flywheel

Chipper Blade

Chipper/Shredder

Mainframe

(Photo

4-1)

To

move

your

Chipper/Shredder,

plant

one foot

on

the axle,

tilt

equipment

back

with

both

hands

until

"bal-

ance

point"

is reached, then pushorpull

your

equipment

to a

work

area. Engine

mustbeOFF.

Shredderblades pass

within

1f4"

of

dischargescreen -

KEEP

HANDS

AND FEET AWAY from the Discharge

openingand keep theService

Door

closedand secured

with the rod and hairpin.

12

Page 15

Engine Starting &Stopping Steps

A DANGER

ROTATING

CUTTING

BLADES

INSIDE

THE

CHIPPER/SHREDDER CHAMBER ARE IN OPERATION ONCE THE ENGINE IS STARTED.

CONTACT

WITH

CUTTING

BLADES

WILL

CAUSE SEVERE INJURY.

KEEP HANDS, FEET, FACE

AND

CLOTHING

OUT

OF SHREDDER

INLET

AND

CHIPPER

INLET,

AND

AWAY

FROM DISCHARGE AREA

AT

ALL

TIMES.

How

To Start:

1. Move the Carburetor Choke Control LevertoFULL

CHOKE

Position (see Photo 3-9) if the engine is

being started "cold."

2.

Grip

the Starter rope handle securely (Photo 3-11).

Pull the rope

out

slowly

until you feel resistance.

Then

quickly

pull the starter rope

firmly

all the way

out

to start the engine. Several attempts may be

needed.

3.

Once the engine starts, let it warm

for

a few seconds

with the

Choke

Lever in "Full" position. Then move

the

choketo"Partial" position

for

a few seconds -

finally move thechoke

to

"No

Choke." As soonasthe

engine starts, the

cylinder

assembly

holding

the

shredderflail cutter blades and the chipperdisc hold-

ing the

chipper

blade start

to

revolve.

In

a few

secondsthe blades will be atfull speed - 3600 RPM!

How

To Stop:

4.

STOP- Move the

Shut-Off

Tab up againstthe spark

plug and hold

it

there until the engine has stopped

completely. LISTEN - Remove hearing protection.

Be

certain

that

all

moving

parts have

stopped

completely.

How

To Use The Chipper

After

the engine is started, the chipper blade will

rotate at 3600 revolutions per minute.

Be

sure to wear

approvedsafety goggles, glovesand hearing protection.

Position yourself directly in

frontofand a couple

of

feetawayfrom the Chipper Feed Chute (see Photo4-2).

The

chipper

will process branches from

%"

to2"in

diameter. To reduce branches to small chips,

simply

grip

one endofa branch

firmly

with both hands and

feed the otherend

of

the branch

into

the

chipper

chute.

Keep the branch away from

your

body

to avoid any

bounceback, and

don't

overreach. Hold the branch

firmly

so you can

control

the rateoffeed at all times

(see Photos 4-3 and 4-4).

All branches should be evenly rotated when fed into

the chipper. This will help

to

prevent the bark from

turning

into long stripsorstrings that can get tangled

around the internal drive shaft. Removing tangles is

time-consuming as the machine must be shut off, so

please rotate branches.

(Photo 4-2) Feed material

into

chipperatproper

angle,

and

rotate branches.Donot

overload the chipper.

(Photo

4-3)

Hold

branches firmly; feed in smoothly.

A DANGER

CONTACTWITH ROTATING

CUTTING

BLADES

INSIDETHE

UNIT

WILL

CAUSESERIOUS PER-

SONAL

INJURY.

BLADES

ROTATE

WHEN

ENGINE IS ON,

AND

STOP AFTER ENGINE IS

SHUT

OFF.

KEEP HANDS, FEET, FACE

AND

CLOTHING

OUT

OF THE CHIPPER

CHUTE

INLET

AND

SHREDDER HOPPER INLET,

AND

AWAY FROM

THE DISCHARGE OPENING WHEN

MACHINE

IS RUNNING.

Feed the branch into the

chipper

chute until just a

few inches stick

out

from the chute. NEVER

put

your

hands

into

the

chipper

chute.

Short

stubsofbranches

may be pushed

through

the

chipper

with the next

13

Page 16

branch. Pay close attention to engine speed. If the

engine slows down, reduce feed pressure and let the

engine build

up

to full speed again before continuing.

Avoid overloading the chipper.

(Photo

4-4)Ifengine speed starts to slow, reduce feed pres-

sure and let engine speed

build

up.

How

To

Use The Shredder

Once the engine on

your

equipment has been

started, the flail cutting blades inside the cutting

chamber

revolve at a high rateofspeed and the

Shredder is ready to use. Of course, you must wear

safety goggles, work gloves, and hearing protection.

Stand 1-to-2 feet from the Shredder

Feed

Hopper-

don'tstand where the hotenginemufflerislocated.

See

Photo 4-5

for

correct position. You'll

see

the safety

decal, the operating instructions decal, and rubber

retaining flap in the feed hopper. Have

your

Leaf

Tamper

handyifyou're

going

to process loose

materials.

(Photo

4-5)

When using the Shredder, stand 1-to-2 feetaway

from the top-loading

hopper

and release materials into

it.

14

A DANGER

CONTACTWITH ROTATING CUTTING BLADES

INSIDETHE

UNIT

Will

CAUSE SERIOUS PER-

SONAL INJURY.

KEEP HANDS, FEET, FACE AND

CLOTHING

OUT OF THE CHIPPER CHUTE INLET AND

THE SHREDDER HOPPER INLET, AND AWAY

FROM THE DISCHARGE OPENING WHEN

MACHINE

IS

RUNNING.

A steady flow of materials into the Shredder

Feed

Hopper provides the most effective results.

See

Photo

4-5. Thefeed rate

for

branches, vines and brush can be

controlled

by

lightlypushing and gUiding the farend of

material until it extends above the top

of

the hopper.

At this point,

lET

GO OF THE MATERIAL. It's best to

cut long branches and vines into more manageable

2-to-3 foot lengths.

IMPORTANT- The shredderblades can tugsuddenly

atmaterial being fed intothe ShredderFeed Hopper,so

don't hold on tightly to branches and vines, and don't

feed material straight down

into

the

hopper

with

your

arm pointing downward toward the opening. Instead,

keep

your

arm parallel tothe

ground

andseveral inches

above the top edge of the hopper.

Also: don't put any part

of

your

bodyorclothing

inside the hopper

or

near the discharge area; stand

clear

of

the dischargearea; and keep face and

body

out

ofthe Shredderinlet,

outofthe dischargeopening, and

away from the discharge area.

1---

(Photo

4-6)

Feed materials in steadily

and

slowly,

but

don't

overload the shredder. Your Leaf Tamper can hang conveniently

on

the shredder handle, ready for use.

Under certain conditions, it may become necessary

to push bulky material into the Shredder

Feed

Hopper.

DO

NOT

USE YOUR

HANDS

-Instead,

use

your

leaf

Tamper,ora small diameter stickofa size that will be

shredded

if

it contacts the rotating cutting blades.

Page 17

When you have loose materials to process, such

as

leaves or grass clippings, just drop them into the

hopper opening. Use a stick or tamper to push this

material past the rubber retaining flap.

See

Photo 4-6

and Photo 4-7. Do not allow combustible materials to

contact the engine.

IMPORTANT

-If

the engine

slows

down while feeding

material,

stop

right away and give

the

engine time

to

come uptofull

speed.

Feed the shredder slowly. Materials and conditions

vary considerably. After a learning period, you will

know how to process different materials best.

----

(Photo 4-7) Use

your

Leaf Tamper to push loose materials

into the shredder-chamber. Position the Tamper

so the

"stop" faces UP

as shown in the photo.

The

"stop"prevents

the Tamper from going too far

in.

A DANGER

THE

DISCHARGE

AREA AND DISCHARGE

OPENING ARE DANGEROUS. SEE SECTION1

FOR

SAFETYINSTRUCTIONSTOAVOID INJURY.

Shredding Wet, Soggy, or

Green Materials

Wetorgreen materials (suchaswet, matted leaves,

gone-byvegetables, green vegetation like squash vines,

etc.) will clog the

3,4"

holesofthe standard discharge

screen.

Before shredding these types

of

materials, shut

engineoff, let all moving partscome to acomplete stop,

and disconnect spark plug wire; then remove the dis-

charge screen from the machine, install the Wet Material Baffle

as

explained on page9,and secure the ser-

vice

door

with its rod and hairpin clip.

You

can now

shred wet

or

green materials.

These types

of

materials willbeshredded to a fine

consistency when you follow this procedure. If you

All shredded materials will

be

discharged through

the opening which

is

at the sideofyour

equipment,

nearthe bottom. See Photo 4-8. Always keep clear

of

the discharge opening since the materials exit with

considerable velocity. The standard discharge screen

that came with

your

Chipper/Shredderisa perforated

screen with

3,4"

holes. This screenisgenerally best for

making compost.

NO

TE:

Wet,

green,

gummy

material should

not

be

used in the Shredder with the standard

3/

4 " Discharge

Screen - it will very quickly become clogged.

We

strongly recommend that you use the Wet Material

Baffle Attachment

in

placeofthe standard screen

for

material like this.

(Photo 4-8) Finely shredded material ready to use.

preferaneven finer consistency, you may wish to process the material a second time. NOTE: green cornstalks will

be

shredded into3-4" chunks; reprocessing

is

recommended if you desire a finer material.

DO

NOT

use the optional Collection Bag when

shredding wet

or

green

material-

doing so will cause

clogging.

A DANGER

WITH DISCHARGE SCREEN REMOVED,

DO

NOT

SHRED BRUSH, BRANCHES, OR OTHER

DRY MATERIALS - THEY WILL EXIT THE DISCHARGE OPENING

AT

HIGH SPEED.

15

Page 18

SECTION

5:

MAINTENANCE & SERVICE

Engine

Maintenance/Service

Your TROY-BILT®

JUNIOR

TOMAHAWK

Chipper/

Shredderisequipped with a 3 HPTecumseh engine. It

is four-cycle, air-cooled, and gasoline powered. DO

NOT

MIX

OIL

WITH

YOUR GASOLINE. Read and

follow

allofthe service and maintenance information

given here and in the accompanying engine manufacturer

literaturetokeep the engine running at peak

performance. If

you

need engine repairsorparts,

con-

tact

your

local authorized Tecumseh dealer

for

assist-

ance.

The

dealerwill needtoknow

the engine identifi-

cation

numberstohelpyou.

The

Tecumseh enginehas

MODEL

and SERIAL NUMBERS.

They

are located on

topofthe engine

blower

housing, near the spark plug,

per Photo

5-1.

(Photo

5-1)

LocationofTecumseh engine 1.0. numbers.

A

WARNING

MOVING PARTS ON YOUR EQUIPMENT CAN

CAUSE SERIOUS PERSONAL INJURY.

BEFORE MAINTENANCE OR SERVICE PROCEDURES ARE PERFORMED, PUSH SHUT-

OFF

TAB

(On Top Of Engine) AGAINST SPARK

PLUG AND HOLD THERE UNTILALL MOVING

PARTS HAVE COME

TO

A COMPLETE STOP.

DISCONNECT THE SPARK PLUG WIRE.

Change Engine Oil

As

Recommended

Rememberto

check

the engine oil/evel

priorto

each

usage and at least every

two

hours

during

continuous

operation. The oil level must a/ways be up to the top

of

the oil fill tube on the 3 HP Tecumseh engine.

16

Oil Change Schedule For Your Engine

Initial Oil Change - After First 2

HoursofOperation

Schedule Thereafter

- Every 10

HoursofOperation

To

Change The Engine Oil:

1. Run the engine a few minutes to warm the oil. Then

stop the engine and

disconnect

the spark plug wire.

2. The Tecumseh engine has

two

oil drain plugs on

opposite sides

of

the engine near the engine base.

Either drain plug may be used. See Photo

5-2.

(Photo 5-2) Left-side

oil

drain

plugonTecumseh engine.

3. Clean

thoroughly

around the Oil

FiJI

Cap, then

remove the fill cap to vent crankcase

for

fast

drain-

age. Also - prop upthe footstand with awood

2"

x4"

to aid in draining the oil.

4. Place an oil collection pan beneath the Oil Drain

Plug.

Now

remove the drain plug and allow all the

dirty

oil and sludge to drain

out

completely. Replace

the drain plug

- put gasket sealant on the threads.

5. You're

now

ready to add fresh oil. Add

motor

oil until

the level is right up

to

the topofthe Oil Fill Tube

(about

21

ounces - see Sketch 2-4). Replace the oil

fill cap.

6.

Start the engine

outdoors

and let it warm up. Check

the level again after shutting the engine off, and be

sure there is no leakage around the drain plug. If

leaking, tighten it.

Page 19

Air Cleaner Service

The air cleaner prevents

dirt

and dust from entering

the engine

through

the carburetor. Itisvery important

that the air cleaner filter be replaced if dirty, and prop-

erly installed at all times. This will prevent premature

wear

or

damagetothe engine. A clean fi Iteralso avoids

starting and overheating problems.

3

HP

Tecumseh Air Filter

Service Schedule

&

Replacement Procedure:

Service Schedule - Inspect filter every

10

operating

hours, sooner if needed. See engine literature

for

full

instructions. Replace the filter annually,

or

more often

with extremely dusty

or

dirty

conditions.

To

Replace

Air

Filter -

1)

Loosen both outer screws

holding air cleaner cover in place;

2)

Twist cover to the

left, then remove cover with the air filter inside it (see

Photo 5-3); 3) Check tightness

of

mounting screws on

back

mounting

plate (Photo

5-4);4)Clean the back

plate and the

outer

cover, then install the new

air

filter

and reassemble the components.

Areas To Be Kept Clean

Your

equipment

has an air-cooled engine, so it is

important

that

airbe able to circulate freelytokeep the

engine cool while running. Always remove dirt, grass

and debris from the following areas: the cooling fins;

engine covers; the

air

intake screen just behind the

starter rope. Use a brush

for

thorough

cleaning regu-

larly. See Photo 5-5

for

reference. Also keep the air

holes in the center

of

the

front

coverofyour

machine

clean. Always shut

off

the engine, make sure all parts

have stopped completely, and disconnect the spark

plug wire before cleaning these air holes. Use a small

wire

or

pieceofcoat hanger to unclog the

air

holes.

Spark Plug And Ignition

System Information

3

HP

Tecumseh Specifications - Use a Champion J-8

or

the equivalent. Proper electrode gapis.030". (Note:

Canadian owners must use a Champion RJ-17LM Re-

sistor Plug

to

comply

with government standards). Do

not blast clean thespark plug. Ifspark plug is damaged

or

badly worn, please install a new plug. Your engine

has a dependable, maintenance-free solid-state ignition, eliminating the need

for

points and condenser.

For further information on spark plugs and ignition

systems, see separate engine manufacturer literature.

(Photo

5-3)

Air

cleaner

outer

cover

and

air filter.

(Photo

5-4)

Tecumseh air cleaner back

mounting

plate.

Check to see both screws are secure.

(Photo

5-5)

Keep the engine

cooling

fins clean.

Carburetor Adjustment,

Engine Storage

&Other

Engine Maintenance/Service

Please refer to the engine manufacturer brochure

which was included in

your

literature package

for

furtherdetailsand coverage on topics suchascarbure-

tor

adjustment, etc. Remember:

your

closest

autho-

rized engine dealer is

fully

equipped to handle all

repairs, parts orders and engine warranty service.

17

Page 20

Chipper/Shredder

Maintenance

And

Service

A

WARNING

MOVING PARTS ON YOUR EQUIPMENT CAN

CAUSE SERIOUS PERSONAL INJURY.

BEFORE MAINTENANCE

OR

SERVICE PRO-

CEDURES

ARE

PERFORMED, PUSH ENGINE

SHUT-OFF

TAB

(On TopofEngine) AGAINST

SPARK PLUG AND HOLD THERE UNTIL

ALL

MOVING PARTS HAVE COMETOA COMPLETE

STOP. DISCONNECT THE

SPARK

PLUG WIRE.

Lubrication

Recommendations

An all-purposespray-type lubricantshould be used a

couple

of

times a year to keep moving partsingood

condition

and operating smoothly. Apply lubricant to

these areas:

1)

the Service Door;2)the wheel hubs.

NO

TE:Agood

qualitygrease containing a meta/lubri-

cant

may

be substituted for the spray-type lubricant.

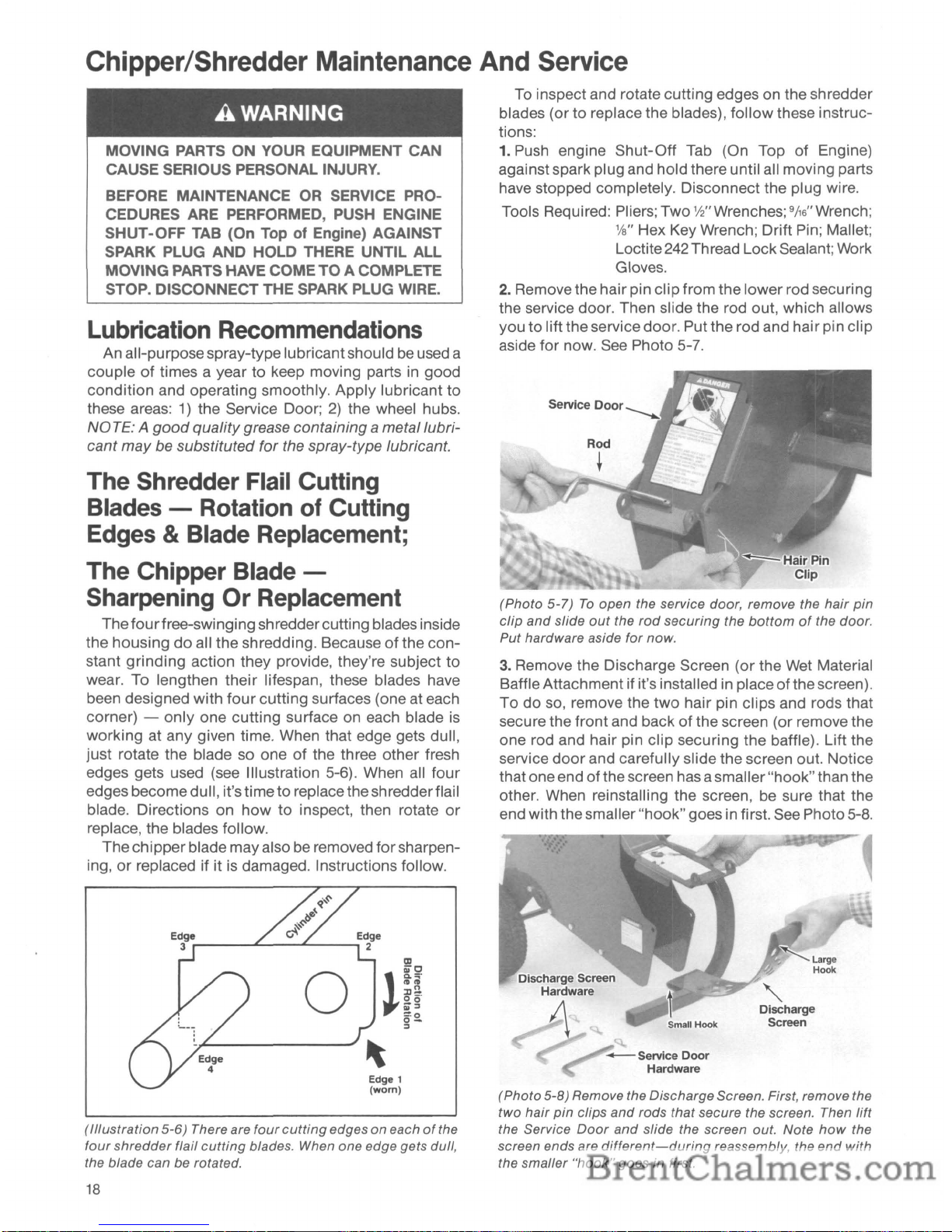

The Shredder

Flail

Cutting

Blades

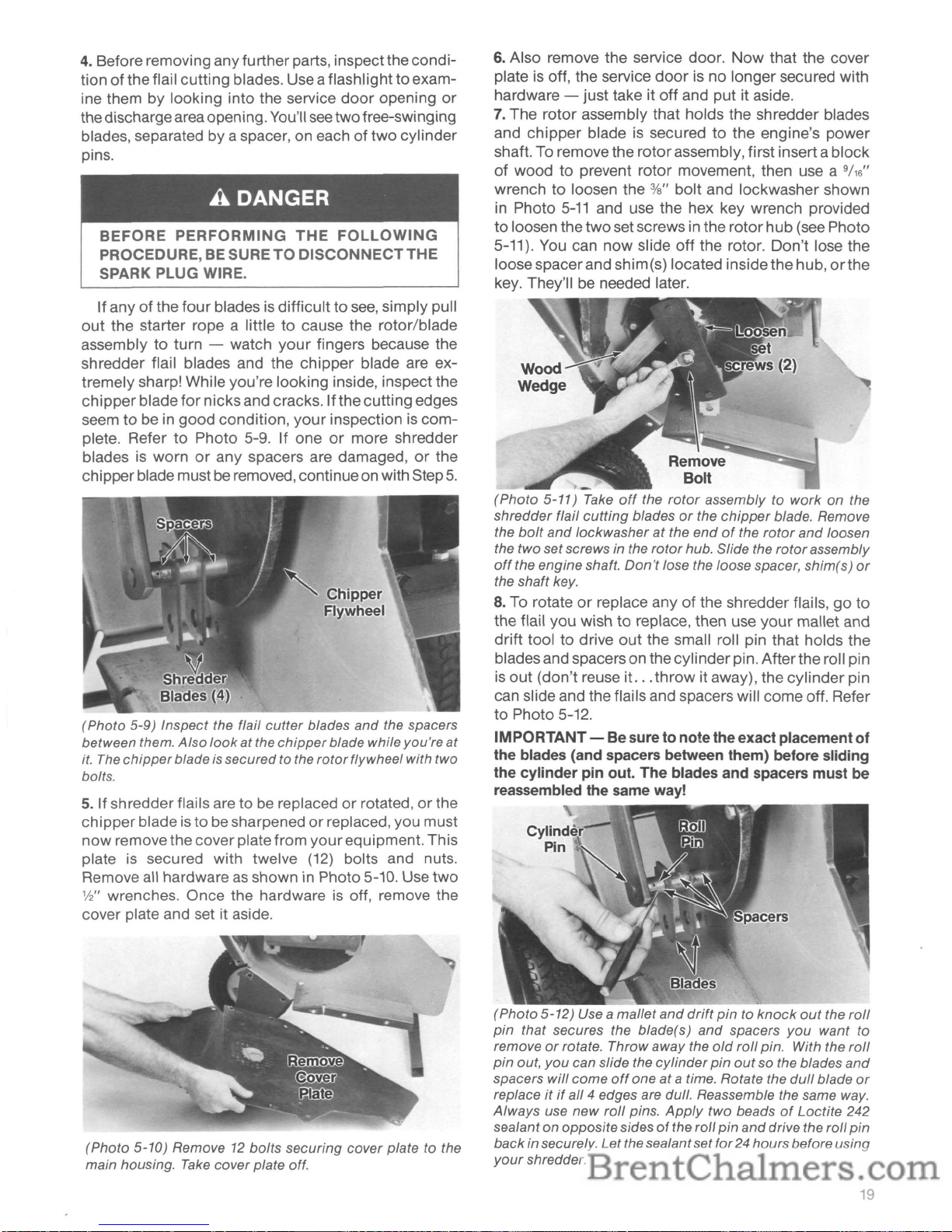

-