Page 1

$12.

50

. -

~

"

..

f<

•

•

,

~l

:

"J

'

i '

••.

•

'f

~.

J.

ilj, I

..~f·

~B1LT

Technical

Manual

•

JUNIOR®

•

PONY®

•

ECONO-HORSETM

..

\ t

.,

\

.-

...

, 1

..

.

,

.

I

t

GAF~DEN

WAY INC.

I

..

-~

.::.J

......

Page 2

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

5/90

TABLE

OF

CONTENTS

SECTION 1

General Information..............................................................................................................................

1-1

Safety First..........................

1-1

Quick Reference Repair Index............... 1-2

SECTION 2

Transmission Troubleshooting

~

2-1

Forward and Reverse Shifting Problems..

2-1

Wheels and/or Tines Do Not Turn................................................

2-1

Wheel Shaft Moves..................................................................................................................... 2-2

Noise From Rear Tiller Bearing 2-2

Oil Leaks 2-3

SECTION 3

Pre-Service Inspection..........................................................................................................................

3-1

SECTION 4

Servicing the Transmission..................................................................................................................

4-1

Housing Cover............................................................................................................

4-1

Removal

4-1

Inspection...............................................................................................................................

4-1

Installation

4-1

Drive Shaft Assembly.............................................................................................................................. 4-2

Removal 4-2

Inspection : :...................................................... 4-3

Installation................................................................................................................................... 4-4

Input Pinion Shaft and Gear Assembly................................................................................................... 4-5

Removal 4-5

Inspection.................................................................................................................................... 4-6

Installation................................................................................................................................... 4-6

Wheel Shaft Assembly............................................................................................................................ 4-6

Removal 4-6

Inspection 4-7

Installation , 4-8

Eccentric Shaft Assembly................................................................................. 4-9

Removal 4-9

Inspection.................................................................................................................................... 4-9

Installation 4-9

Tiller Tine Shaft Assembly..................................................................................................................... 4-10

Removal

4-1

0

Inspection...................................................................................................................................

4-11

Installation.................. 4-12

INDEX

5-1

Page 3

SECTION

1:

General

Information

.

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

1-1

5/90

• This manual provides transmission

service information for the following

TROY-BILT® Roto Tiller-Power

Composters built by TROY-BILT

Manufacturing Company, Troy, New

York:

JUNIOR® Model

--

Serial Number

M67999 and

Up.

PONY® Model--Serial Number

S186072 and Up.

Econo-Horse

™ Model

--

Serial

Number

E1

001

and Up.

• This manual was written for and

intended to be used by professional

service technicians who have been

trained

in

the proper servicing of out-

door power equipment.

• All information, illustrations, and

specifications contained

in

this man-

ual are based

on

the latest information available at the time of publication. The right is reserved to make

changes at any time without notice.

If you have any questions concerning the information

in

this manual

please contact:

Technical Service Department

TROY-BILT Manufacturing Company

102nd

St.

& 9th Avenue

Troy, New York 12180

Call Toll-Free: 1-800-833-6990

A This symbol is used to alert

you to important safety mes-

sages

in

this manual andondecals

affixed to the tiller. When you see

this symbol, carefully read and follow

its safety message. Failure to do so

could result

in

·personal injury or

property damage.

• This manual is divided into four

sections as shown

in

the Table of

Contents. For best results, read

each section

in

its entirety before

attempting any repair work.

• This manual is designed to be

used

in

combination with the tiller's

Owner/Operator Manual.

The

Owner/Operator Manual contains

additional service

and

maintenance

information that

is

notcoveredinthis

manual.

Refer to "Quick Reference

Repair Index"

in

this section for a listing of the service and maintenance

topics that are covered

in

the

Owner/Operator Manual.

• Service and maintenance informa-

tion regarding engines is not covered

in

this manual. Such information can

be obtained by consulting the

Service Repair Manual available

from the engine manufacturer.

You

should, however, call our Technical

Service Department with questions

concerning engine replacement or

interchangeability.

• Throughout this manual, you will

see references to the left and right

sides of the tiller. This refers to the

left and right sides of the tiller as you

would see them when standing

in

the

operator's position.

Safety First!

When workingonthe tiller or its

engine, closely follow operating

instructions and recommended safe-

ty practices at all times. Failure to do

so could result

in

personal injury or

property damage. Here are some

basic safety precautions you should

keep

in

mind at all times when doing

repair work:

KNOW THE TILLER AND ENGINE!

Read the Owner/Operator Manual

carefully.

Be

sure you know what

each tiller and engine control does

before

you

attempttooperate

it.

Read and follow all safety rules.

Never allow inexperienced persons

or children

to

operate the tillerorits

engine.

WEAR PROPER APPAREL!

Do

not

wear loose clothing

or

jewelry that

could get caught

in

moving parts of

the tiller or its engine.

AVOID MOVING PARTS! Keep

hands, feet, hair, clothing, and tools

safely away from moving parts when

the engine

is

running.

AVOID ACCIDENTAL STARTING!

When servicing the machine, prevent

unintentional starting of the engine

by disconnecting the spark plug wire

and keeping the wire away from the

spark plug. Place the engine throttle

control

in

the OFF position and disengage the Maneuvering Clutch and

the Forward Clutch.

WEAR EYE PROTECTION! Safety

goggles or a face shield should be

worn whenever there is the possibili-

ty of danger to the eyes from flying

parts or particles.

PREVENT FIRES AND EXPLOSIONS!

Gasolineishighly

flammable and explosive and should

be used and stored with extreme

caution. Keep gasoline away from

open flame, sparks, and do not

smoke

in

the vicinity of gasoline cans

or fuel tanks. Do not add gasoline to

a fuel tank when the engine

is

run-

ning or still

hot. Fill the fuel tank out-

doors,

in

a well-ventilated area.

Store gasoline

in

a cool, well-ventilated place, safely away from any spark

or flame producing equipment. Store

only

in

a U.L. approved container

and safely out of reach of children.

Wipe off any spilled gasoline and

move the engine away from gasoline

fumes before starting engine.

Use

flammable cleaning solvents

only according

to

recognized safety

practices

(never

use

gasolineasa

cleaning solvent). Oily rags and

waste should

be

packedina U.L.

approved,

covered metal safety con-

tainer

to

prevent fire from sponta-

neous combustion.

Page 4

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

1-2

5/90

HANDLE BATTERIES WITH CARE!

Batteries contain sulfuric acid that

can cause blindness, burn skin, and

eat through clothing. Wear safety

goggles when working near the battery or when handling battery acid.

Removal all rings and metal jewelry

when working

on

the battery or elec-

trical system.

Batteries also produce explosive

gases. Keep sparks, flames, and

cigarettes away. Ventilate when

charging or using

inanenclosed

space.

Do

not cause a short circuit by

touching both battery terminals at the

same time with tools or other metallic

objects. Also, do not allow a tool or

other metallic object to touch a terminal that

is

not grounded andanadjacent metallic part that is grounded.

A spark from a short circuit could

cause

an

explosion of battery gases

or gasoline.

AVOID ENGINE EXHAUST FUMES!

Do

not

run

the engineinan

enclosed

area. Exhaust gases contain carbon

monoxide,

an

odorless and deadly

poison. Provide adequate ventilation

at all times. After running the

engine, don't touch the muffler or

other hot engine parts until they have

cooled down.

HANDLE PARTS CAREFULLY!

With continued use, the teeth

on

gears and worms may wear to sharp,

knife-like edges. Therefore, when

handling these parts, use care to

avoid cutting yourself.

REPLACEMENT PARTS! Use only

genuine Troy-Bilt replacement parts.

Replacement parts manufactured by

others could present safety hazards

even though they may fit

on

this tiller.

SECTION

1:

General

Information

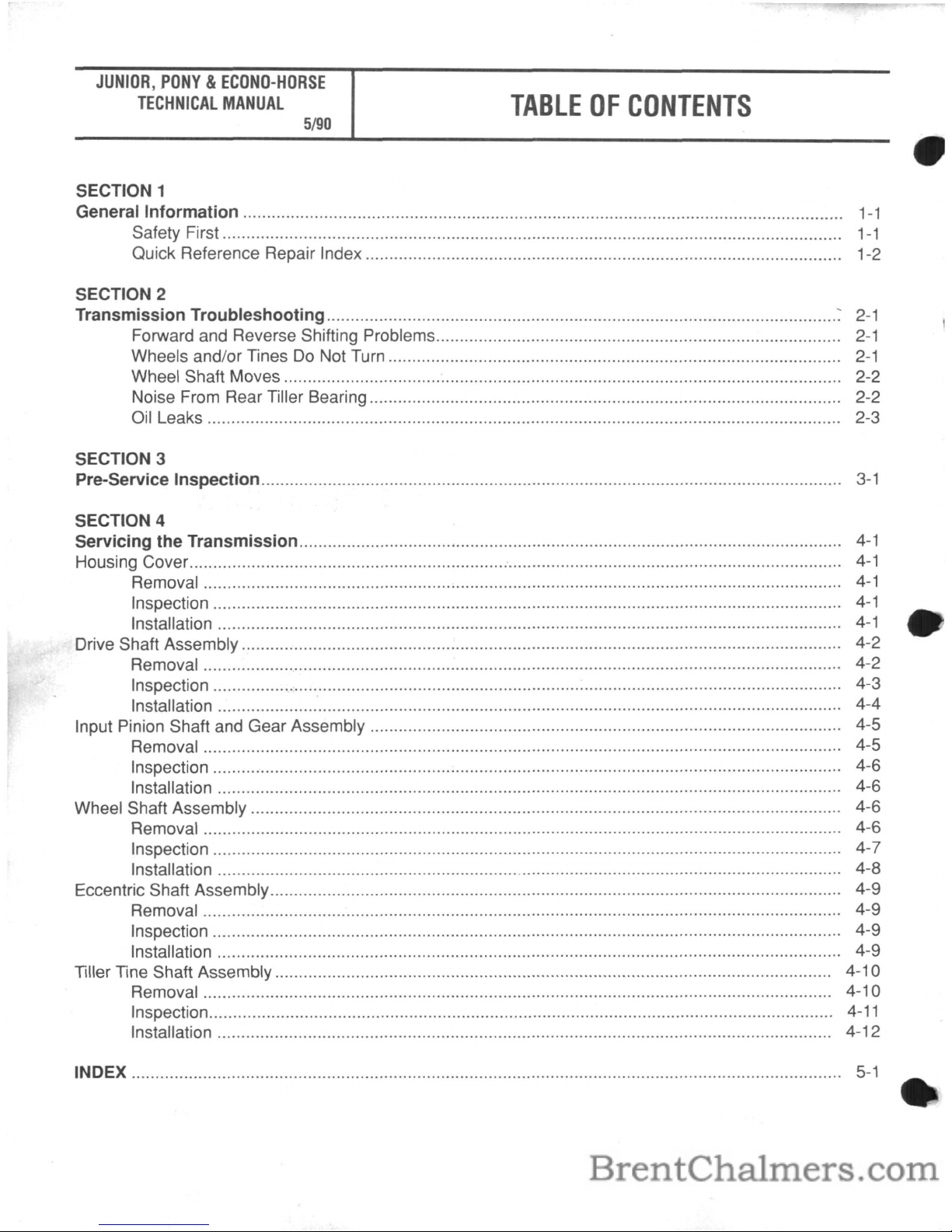

Quick Reference Repair Index

To

obtain service information for the following topics, please refer to either

this Technical Manual or the tiller's Owner/Operator Manual, as indicated

in

the table below.

TECHNICAL

OWNER/OPERATOR

MANUAL

MANUAL

Air Cleaner

X

Battery

X

Bearing Cap, Tiller Housing

X

Bearings, Drive Shaft

X

Bearings, Tiller Tine Shaft

X

Bearings, Wheel Shaft

X

Belts

X

Bolo Tines

X

Bronze Bushings

X

Carburetor

X

Clutch

X

Cover, Transmission

X

Depth Regulator

X

Drive Shaft

X

Eccentric Lever

X

Electric Start System

X

Engine

X

Fuel

X

Handlebar Height Adjustment

X

Ignition System

X

Input Pinion Shaft Assembly

X

Lubrication Points

X

Oil (Engine and Transmission)

X

Gear Oil Level CheckPlug

X

Gear Oil Drain Plug

X

Throttle Cable

X

Tiller Housing Cover

X

Tiller Tine Shaft

X

TiresIWheels

X

Transmission Gear Oil

X

Wheel Shaft

X

Worm, Tiller Drive Shaft

X

Worm Gear, Wheel Shaft

X

Worm Gear, Tiller Shaft

X

Page 5

SECTION2:Transmission

Troubleshooting

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

2-1

5/90

The following charts list the

most common problems experienced with the tiller drive

train. Symptoms of problems

are listed along with possible

remedies. If following the

repair procedures does not

correct the problem. call the

TROY-SILT Tiller Technical

Service Department at TOLLFREE: 1-800-833-6990.

Forward and Reverse

Shifting Problems

A

WARNING: When servicing the machine, prevent uninten-

tional starting of the engine by disconnecting the spark plug

wire and keeping the wire away from the spark plug. Place

the engine throttle control

in

the OFF position and disengage

the Maneuvering Clutch and the Forward Clutch.

Symptom Remedy

Forward Clutch

or

maneu- The pivot bolt on the Forward/Reverse Idler Assembly may be:

vering Clutch shifting levers

• over-tightened

~

do

not

engageordisengage.

• rusted

• broken

• misaligned

Wheels and/or Tines Do Not

Turn

Symptom Remedy

Wheels turn

but

the tines

do

• The rear bearing on the drive shaft may have failed.

not. • One or both of the bearings on the tiller tine shaft may have failed.

• The bronze worm gear on the tiller tine shaft may be damaged.

Wheelsdonot

turn

but

the For the Econo-Horse and Pony models:

tines do. • The clutch cable may be frozen, broken, kinked or out of adjustment.

• The bolt at the end of the eccentric shaft lever may be loose.

• The eccentric lever may be broken.

• The dogs on the wheel shaft clutch may be broken or severely worn.

• The teeth

on

the wheel shaft worm gear may be broken or severely worn.

For the Econo-Horse, Pony and Junior models:

• The teeth on the wheel shaft worm gear may

be

broken or severely worn.

• The drive shaft worm gear may be severely worn.

• On the Junior model only, the wheel drive pin may not

be

engaged through the wheel hubs.

Wheels and tinesdonot

• Check the tensiononthe drive belts (see Owner/Operator Manual).

turn.

• Make sure the bolt that holds the transmission drive pulleyistightened. the washer is present, and the transmission pulley key

is

installed.

Page 6

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

2-2

5/90

Wheels and/or Tines Do Not

Turn (continued)

SECTION2:Transmission

Troubleshooting

Symptom

Remedy

Wheels and tines turn on top

• Check the tensiononthe drive belts (see Owner/Operator Manual).

of the ground but hesitate or

• Make sure the input pinion assemblyisin

good condition and that all the parts are

stop when in soil. present.

-

• Check the condition of the bronze worm gearonthe tiller tine shaft and the worm

gear

on

the wheel shaft; one or both may be damaged.

Wheel Shaft Moves

To

One Side

Symptom

Remedy

The wheel shaft moves to

• One or both snap rings are out of the groove(s).

one side. • Check for excessive play

in

wheel shaft. End play should be .000" to .005".

Noise from Rear Tiller Bearing

Symptom

Remedy

A growling or whining noise

• Inspect the drive shaft bearing and bearing race for wear or damage.

from the tiller housing rear • Inspect the tine shaft bearings for wear or damage.

bearing. • Inspect the tiller shaft bronze worm gear for wear or damage.

Oil Leaks

Symptom

Oil is leaking from the wheel

shaft oil seals.

Remedy

•Anoil sealisworn or damaged. Check for side-to-side and vertical playinthe wheel

shaft and replace seal.

• Give new seals time

to

lap

in.

• Inspect the wheel shaft for minor damage at the oil seal location:

a.

Inspect for corrosion, pitting, or scoring.

b.

Use emery clothtoremove any minor defects.

c.

Attempt to seat the seal so thatitisonan

undamaged part of the shaft.

d.

Replace the wheel shaft if necessary.

•

Be

sure the transmissionisfilled with SAE 90 or 140 gear oil. A lighter viscosity oil

will cause leakage.

• Make sure that a non-hardening gasket sealer was applied to the outside diameter of the

oil seal prior to its installation.

• Make sure the housing bore has no nicks or scratches that would permit oil to seep out

between the seal and the housing.

Page 7

SECTION2:Transmission

TroUbl~hooting

Oil Leaks (continued)

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

2-3

5/90

,

..

J.

I

Symptom

Oil leaks from the rear of

the tiller housing.

Oil is leaking from the oil seal

on the input pinion shaft.

Oil

is

leaking from the

transmission housing cover.

Oil

is

leaking from the

eccentric shaft (Econo-Horse

and Pony models only).

Oil

is

leaking from any pipe

plug

in

the transmission

housing.

Oil

is

leaking from the front

bearing cap (older model

tillers) or the transmission

bore seal (newer model

tillers).

Remedy

If

the leakisfrom the oil sealsonthe tiller tine shaft:

• Make sure the seals have non-hardening gasket sealer around the outside edges.

•

An

oil sealisworn or damaged; replace the seal.

• Inspect the tiller tine shaft for minor damage at the oil seal location:

a.

Inspect for corrosion, pitting, or scoring.

b.

Use emery cloth to remove any minor defects.

c.

Replace the tiller tine shaft if necessary.

• Check for sand holes (imperfections

in

the cast iron) or cracksinthe housing.

If

the leakison the left side of the tiller housing:

• Apply non-hardening gasket sealer to each of the tiller housing cover screws and

tighten the screws.

• Replace any worn or damaged gaskets.

• Make sure the housing cover bore and the housing bore have no nicks or scratches that

would permit oil to seep out.

• Check for excessive play

in

the tiller tine shaft.

If

the leakisfrom the rear bearing cap:

• Inspect the rear bearing cap:

a.

Make sure the screws are the correct length.

b.

Apply non-hardening gasket sealer to each of the rear bearing cap screws and

tighten the screws.

• Replace a worn or damaged gasket.

• Make sure the leak

is

at the front oil seal.

You

could be seeing a leak from the air

cleaner, transmission housing cover, or an engine oil seal.

• Check the transmission gear oil level when the unit

is

cold.Ifitisoverfilled, drainitto

the proper level.

• Replace a worm or damaged oil seal.

• Make sure the housing cover bolts are tight.

• See if the oil level

is

too high;ifso, drain the oil to the proper level.

• Check to see

if

the threads on the plastic oil fill plug are stripped.

• Replace a worn or damaged gasket.

• Replace the oil seal.

• Inspect shaft for corrosion, pitting, or scoring.

• Check to see if the plug

is

cross-threaded.

• Remove the pipe plug and apply a layer of non-hardening gasket sealer. Then

reinstall the plug.

• On units equipped with a front bearing cap:

a.

Apply a coating of non-hardening gasket sealer to each of the front bearing

cap screws and tighten the screws.

b.

Replace a worn or damaged gasket.

c.Ifoil seeps through the cap, replace the cap.

• On units equipped with a transmission bore seal, replace the seal.

Page 8

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

3-1

5/90

Before you begin your repair or

maintenance procedure, take a

moment

to

perform a pre-service inspection of the following

transmission parts.

In

doing

so,

you may discover addition-

al

problems that can be cor-

rected while the tiller

isinyour

shop.

A

SECTION3:Pre-Service

Inspection

WARNING: When servicing the machine, prevent uninten-

tional starting of the engine by disconnecting the spark plug

wire and keeping the wire away from the spark plug.

Place

the engine throttle control in the OFF position and disengage

the Maneuvering Clutch and the Forward Clutch.

Input Pinion GearlTransmission

Drive Pulley

• Checkifoilisleaking from the

input pinion shaft oil seal. If you see

oil, make sure it

is

not originating

from the transmission bore seal (or

bearing cap

on

older model tillers),

which

is

located just above the input

pinion shaft oil seal.

If

the oilisleaking from the input pinion shaft oil

seal, replace the seal.

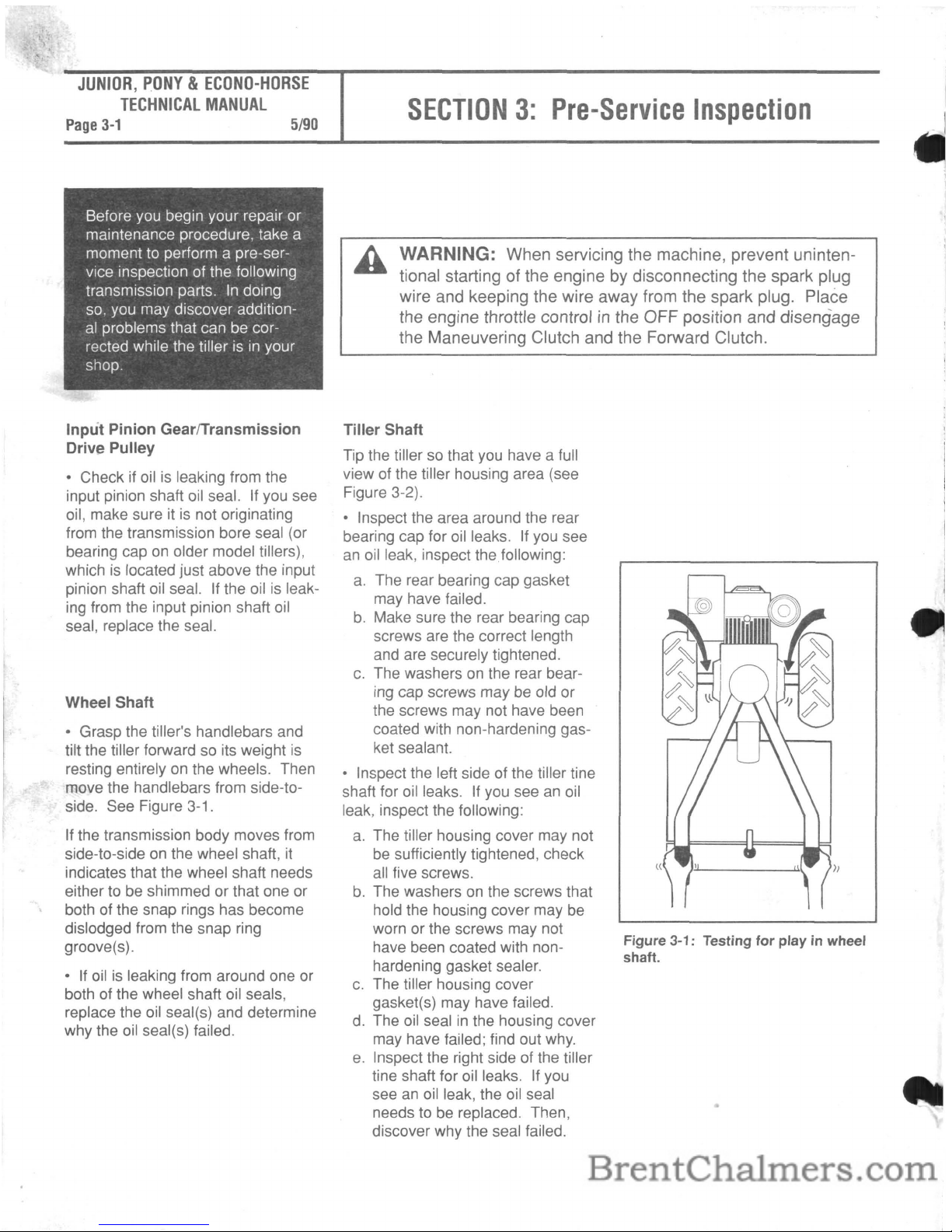

Wheel Shaft

• Grasp the tiller's handlebars and

tilt the tiller forward

so

its weight

is

resting entirely on the wheels. Then

move the handlebars from side-toside. See Figure

3-1

.

If

the transmission body moves from

side-to-side on the wheel shaft,

it

indicates that the wheel shaft needs

either to be shimmed or that one or

both of the snap rings has become

dislodged from the snap ring

groove(s).

• If oil

is

leaking from around one or

both of the wheel shaft oil seals,

replace the oil seal(s) and determine

why the oil seal(s) failed.

Tiller Shaft

Tip the tillersothat you have a full

view of the tiller housing area (see

Figure 3-2).

• Inspect the area around the rear

bearing cap for oil leaks.

If

you see

an

oil leak, inspect the following:

a.

The rear bearing cap gasket

may have failed.

b.

Make sure the rear bearing cap

screws are the correct length

and are securely tightened.

c.

The washersonthe rear bearing cap screws may

be

old or

the screws may not have been

coated with non-hardening gasket sealant.

• Inspect the left side of the tiller tine

shaft for oil leaks. If you see

an

oil

leak, inspect the following:

a.

The tiller housing cover may not

be

sufficiently tightened, check

all five screws.

b.

The washersonthe screws that

hold the housing cover may be

worn or the screws may not

have been coated with nonhardening gasket sealer.

c.

The tiller housing cover

gasket(s) may have failed.

d. The oil seal

in

the housing cover

may have failed; find out

why.

e.

Inspect the right side of the tiller

tine shaft for oil leaks.

If

you

see

an

oil leak, the oil seal

needs to be replaced. Then,

discover why the seal failed.

Figure 3-1: Testing

for

play

in wheel

shaft.

Page 9

SECTION3:Pre-Service

Inspection

JUNIOR,

PONY&EeONO-HORSE

TECHNICAL

MANUAL

Page

3-2

5/90

,-\rlf1I~--REAR

BEARING CAP

HOUSING COVER GASKET

Figure 3-2: Pre-service inspectionofthe

tiller

tine shaft area.

• Check the tiller tine shaft for play:

Using two hands, grasp the tiller tine

shaft and rotate the shaft back and

forth.

You

should be able to rotate

the shaft slightly.

If you cannot rotate the shaft at all,

it

means that the side cover needs to

be shimmed outward using various

thicknesses of gaskets. This procedure

is

explainedinSection 4 of this

manual (see "Tiller Tine Shaft

Assembly").

Being able to rotate the shaft more

than a small amount means the tiller

tine shaft

is

either shimmed incorrectly (too many gaskets) or that the

bronze worm gear has worn.

• There should be no end play, vertical play or diagonal play

in

the tiller

tine shaft. If you find such play, tighten

the tiller housing cover bolts. If

this does not eliminate the play,

insert a shim between the gear and

bearing (use

an

arbor press to

remove the bearing)

on

the tiller tine

shaft. The shim should be of the

type used to shim the wheel shaft.

Eccentric Shaft (Econo-Horse and

Pony Models Only)

See if oil is leaking around the

eccentric shaft oil seal. If so, replace

the oil seal and determine why the oil

seal failed.

Transmission Bore Seal (or Front

Bearing Cap on Older Model

Tillers)

• On newer model tillers, see if oil is

leaking from the transmission bore

seal at the front of the transmission.

If

so, replace the seal and determine

why the oil seal failed.

• On older model tillers, inspect the

following:

a.

The front bearing cap gasket

may have failed.

b.

Make sure the bearing cap

screws are the correct length

and are sufficiently tightened.

Also, make sure the screws

have been coated with nonhardening gasket sealer.

Shaft Tube

If

the weld that holds the tube

between the tiller housing and the

transmission housing becomes

loose, it must be rewound and welded

at the Factory.

Throttle Cable

The throttle cable should move freely

and should effectively control the

engine speed. If it does not, the

cable may be rusted

in

its sleeve

(use penetrating oil to free the cable)

or there may be some problem with

the engine.

Wheel Gear Control

lever

(Econo-

Horse and Pony Models Only)

The wheel gear control lever cable

should move freely, as well as effectively engage and disengage the

clutch and gear. If it does not, check

the cable for damage or rust (use

penetrating oil if rusted), or there

may be some problem with the

eccentric shaft assembly.

Page 10

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-1

5/90

SECTION4:Servicing

the

Transmission

This section provides instructions

on

how to service various

subassemblies on the Junior,

Pony and Econo-Horse transmissions.

A

WARNING: When servicing the machine, prevent uninten-

tional starting of the engine by disconnecting the spark plug

wire and keeping the wire away from the spark plug. Place

the engine throttle control in the OFF position and disengage

the Maneuvering Clutch and the Forward Clutch.

Transmission

Housing Cover

These instructions describe how to

service the housing cover for the

tiller transmission. Use Figure

4-1

as

a reference for part locations

in

these instructions.

Removal

1.

Remove the six bolts

(1)

and

lockwashers (if present) that hold the

housing cover

(2)

to the transmission

housing.

2.

Remove the housing cover (2).

3.

Remove and discard the housing

cover gasket (3).

Inspection

Inspect the housing cover for cracks

and check that the plastic oil fill plug

(4)isin

good condition.

Installation

1.

Install a new gasket

(3)onthe

transmission housing.

2.

Place the housing cover

(2)

on

the transmission housing.

3.

Secure the housing cover with the

six bolts

(1)

and lockwashers (if any).

Figure 4-1:

Servicing

the

housing

cover

(Econo-Horse

and

Pony

transmis-

sion

housing

shown).

Page 11

SECTION4:Servicing

the

Transmission

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-2

5/90

Drive Shaft

Assembly

These instructions describe how to

service the drive shaft assembly for

the tiller transmission. Use Figures

4-2 and 4-3 as references for part

locations

in

these instructions.

Before you can perform these

instructions you must first remove

the transmission housing cover. See

the "Transmission Housing Cover"

removal instructions

in

this section.

NOTE

1:

Tillers that fall within the

following serial number ranges are

equipped with a front bearing cap

and gasket as shown

In

Figure 4-2,

Items 3 and

4.

Newer model tillers

(those with serial numbers higher

than listed below) have a transmission bore seal (Figure 4-2, Item

1)

that requires a special snap ring

(Figure 4-3, Item 16).

Junior Model: SIN M67999 -

M01

00969

Pony Model: SIN S186072 - S0242649

Econo-Horse: SIN E1001 - E0032773

of the transmission. After the oil is

drained. apply a coating of non-hardening gasket sealer

on

the threads

and reinstall the plug.

2.

On newer model tillers, pry the

transmission bore seal

(1

) out and

discard

it.

On older model tillers,

remove the three bolts (2) from the

front bearing cap (3) and remove the

bearing cap and bearing cap gasket

(4). Discard the gasket.

3.

Remove the three bolts

(5)

that

secure the rear bearing cap (6). Also

remove the three nylon washers (7),

if present. The nylon washers are

not reusable.

4.

Remove the rear bearing cap (6)

and the rear bearing cap gasket (8).

Discard the gasket.

5.

Slide the drive shaft (9) toward

the rear of the transmission just

enough to force the shim(s) (10) and

the rear bearing cup

(11)

out.

NOTE: Keep each bearing cup

paired with its bearing if you intend to

reuse them. Each bearing cup

wears differently according to its

bearing.

6.

Slide the drive shaft

l:i

few inches

more toward the rear of

fhe transmission. Then reach through the top

cover opening and remove the front

bearing (12), front bearing cup (13),

main drive shaft spur gear (14), and

the drive shaft key (15).

NOTE: Keep the bearing and bearing cup together if you intend to

reuse them.

7.

Slide the drive shaft out through

the rear of the transmission housing;

it will pass over the tiller tine shaft

gear cluster.

8.

On

newer model tillers, remove

the snap ring (16) located inside the

housing bore. This snap ring retains

the front bearing.

9.

The rear bearing is pressed-on

and can be removed (if necessary)

with

an

arbor press and a bearing

puller attachment.

NOTE 2: Two basic types of drive

shafts may have been installed at

the factory:

an

integral worm design

(the worm gears are machined

directly from the shaft material), and

a welded worm design (the worm

gears are welded to the shaft and

can be identified by blue weld beads

at either end of the worms). Each

design has its own part number and

requires specific related parts.

Before installing a new drive shaft or

related drive shaft parts, first determine which type of shaft you are

working with. See the tiller parts catalog for parts ordering information.

Removal

1.

Drain the transmission gear oil by

removing the oil drain plug located

below the wheel shaft

on

the left side

Figure 4-2: Remove these parts

priortoremoving

the

drive

shaft

assembly

(Econo-Horse and Pony

transmission

housing

shown).

Page 12

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Pag~

4-3

5/90

,

~,

SECTION4:Servicing

the

Transmission

~

14

I

12

C~'3

1'~1~

~..~J

Figure 4-3: The drive shaft assembly.

Inspection

These instructions describe how to

inspect vital parts

on

the drive shaft

assembly.

In

addition to inspecting

the parts you have removed, you

should also inspect any replacement

parts you will use.

NOTE: Thoroughly degrease and

clean all parts before inspection.

Drive

Shaft

Worms

-The

forward

and rear worms

on

the drive shaft

should not be excessively worn.

Since only the middle segment of a

worm

isincontact with the cast iron

worm gear

on

the wheel shaft or the

bronze worm gear

on

the tiller tine

shaft, you can compare the outside

threads of the worm with the middle

threads.

If

the width of the threads

in

the middleishalf or less than the

width of the threads at the ends of

the worm, discard the drive shaft.

See Figure 4-4.

Also, inspect the worms for heat

damage. If a worm has a bluish

color then proper lubrication has not

been maintained and the drive shaft

should

be

discarded.

Bearings

- If the bearing has a

bluish color then proper lubrication

has not been maintained; discard the

bearing and bearing cup.

Also,

if

the bearingisscored or

excessively worn, dirt may have con-

taminated the housing; discard the

bearing and bearing cup.

Inspect for chipped or broken roller

bearings, and inspect the bearing

cage for damage.

NOTE: Bearings and bearing cups

must be replaced

in

pairs.

Do

not

mix old and new bearings and bearing cups.

Keyway

-The

keyway should be just

wide enough to fit the

key.

If the keyway has expanded, discard the drive

shaft.

Spur

Gear - If the gear teeth are

broken or excessively worn, discard

the spur gear.

Page 13

SECTION4:Servicing

the

Transmission

Wear

Area

~

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-4

5/90

Figure 4-4:

Inspecting

the

drive

shaft

worm.Ifwormisworn

more than 50%

in wear area

shown

above,

discard

the

drive

shaft.

Installation

Use Figures 4-2 and 4-3 as references for part locations

in

these

instructions.

1.

Insert the drive shaft (9)infrom

the rear of the transmission.

2.

Install the key (15)inthe drive

shaft keyway.

3.

Place the spur gear (14)onthe

drive shaft. Make sure the. hub of the

gear is facing rearward.

4.

Lubricate the front bearing (12)

with #30 weight oil and install the

bearing into the transmission housing from the outside of the housing.

5.

On newer model tillers, install the

front bearing cup (13) into the transmission housing until it clears the

snap ring groove. On older model

tillers, install the front bearing cup

(13) flush with the outside edge of

the transmission housing.

6.

On

newer model tillers, install the

snap ring (16).

7.

On newer model tillers, apply a

layer of non-hardening gasket sealer

around the outside edge of the trans-

mission bore seal

(1) and install the

seal.

8.

On older model tillers, install a

new gasket

(4)

on

the front bearing

cap

(3) and seat the cap flush with

the transmission housing. Apply a

coating of non-hardening gasket

sealer to the three bearing cap bolts

(2) and securely replace the bolts.

9.

Slide the drive shaft all the way

forward.

10. Install the rear bearing cup (11)

using the rear bearing cap (6) as a

driver (a gasket should not be

installed

on

the rear bearing cap at

this time). Seat the bearing cap flush

with the transmission housing.

11.

Hold the rear bearing cap tightly

in

place with one hand and check the

play

in

the drive shaft. There should

be between

.005" and .010" end play.

Remove the rear bearing cap and

shim

(10) as necessary.

12. Place a new gasket (8)

on

the

rear bearing cap.

13. Install the rear bearing cap and

secure it with the three bolts

(5) and

nylon washers (if the washers are

not available, apply a coating of nonhardening gasket sealer to the tip of

the bolts).

14. Check again for correct end play

and add or subtract shims as need-

ed.

Page 14

JUNIOR,

PONY&ECONO·HORSE

TECHNICAL

MANUAL

Page

4-5

5/90

SECTION4.Servicing

the

Transmission

Input Pinion Shaft

and

Gear

Assembly

These instructions

describe

how

to

service the input pinion shaft and

gear

assembly. Use Figure

4-4

as a

reference for part locations in these

instructions.

Before you can perform these

instructions you

must

first remove

the drive shaft assembly. See the

drive shaft

assembly

removal instruc-

tions in this section.

NOTE:

Junior

and

Pony

model tillers

that fall within the following serial

number

ranges are equipped with a

double groove pulley as

shown

in

Figure 4-4, Item

3.

Newer

model

Junior and Pony model tillers (those

with serial numbers higher than listed

below) have a single groove pulley

(Figure 4-4, Item 4) that requires a

special

washer

and key (Figure 4-4,

Items

6 and 7):

Junior Model: SIN M67999 -

M01

00969

Pony Model: SIN S186072 - S0242649

Removal

1 . Remove the bolt (1) and

disc

spring

washer

(2)

that

holds the

transmission pulley to the input pin-

ion shaft.

2.

For newer model

Junior

and Pony

tillers remove the large

washer

(6).

3. Remove the transmission pulley

(3, 4

or

5).

4. Remove the key (7

or

8) from the

keyway

on the

input

pinion shaft.

5.

Remove

the support

washers

(9).

6.

Remove

the oil seal (10), taking

care

nottodamage

the

input

pinion

shaft

or

the inside

diameterofthe

housing bore.

7.

Remove the drive

shaft

if you

have

not already

done

so.

8.

Remove

the

set

screw

(17) from

the left side

of

the transmission

housing.

9.

Slide the input pinion

gear

and

shaft

assembly

(11-16)

out

through

the front

of

the transmission housing.

10.

Remove

the front

snap

ring (11).

12. Remove the

two

washers

(12)

and the bushing (13).

13. Remove the rear

snap

ring (15).

14. Finally, remove the input pinion

gear

(16).

Single Groove Pulley

--

.....

~~

Econo-Horse Pulley

~

5

8

~1

Figure 4-4: The input pinion shaft and gear assembly.

Page 15

SECTION4:Servicing

the

Transmission

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-6

5/90

Inspection

These instructions describe how to

inspect vital parts on the input pinion

gear and shaft assembly.

In

addition

to inspecting the parts you have

removed, you should also inspect

any replacement parts you will use.

NOTE: Thoroughly degrease and

clean all parts before inspection.

Input Pinion

Gear-

Make sure the

gear teeth are

in

good condition. If

they are broken or excessively worn,

discard the gear.

Input Pinion

Shatt-

•

If

the shaftisscored around the oil

seal area, discard the shaft. If the

shaft

is

pitted around the oil seal

area, you may be able to relocate the

oil seal to a smooth area. If the shaft

is

slightly corroded around the oil

seal area, try using a #400 grit emery

cloth to clean the area.

• The two snap ring grooves should

be just wide enough to fit the snap

rings.

If

the grooves have expanded,

discard the shaft. Also, examine the

edges of the snap ring grooves.

If

either the forward-facing edge on the

front snap ring groove or the rearfacing edge on the rear snap ring

groove are rounded off do not reuse

the shaft. These are the edges that

bear the force of the snap ring.

o Keyway - The keyway should be

just wide enough to fit the key. If the

keyway has expanded, discard the

shaft.

o Threads at Front of Shaft - Check

the threads at the front of the shaft.

If

the threads are notingood condition,

replace the shaft.

Bushing - If the bushing is cracked,

discard

it.

Installation

Refer to Figure 4-4 as a reference for

part locations

in

these instructions.

1.

Install the input pinion gear (16)

on

the input pinion shaft (14). The shaft

and gear have flat spots that you

must line up before installing the

gear on the shaft.

2.

Install the snap ring (15) that

retains the input pinion gear to the

shaft. The rounded side of the snap

ring should face to the front of the

transmission. Although not easy to

observe, the snap ring as a rounded

side and a flat side.

3.

Install a washer (12)onthe front

of the shaft.

4.

Install the bushing (13) on the

shaft, making sure that the groove

in

the bushingisfacing forward.

5.

Install the second washer (12).

6.

Install the snap ring (11) that

retains the bushing and washers.

7.

Install the assembled gear and

shaft into the transmission housing.

8.

Apply a drop of removable thread

locking compound on the set screw

(17). Slowly install the screw, checking to make sure the screw fits inside

the groove

on

the bushing.

Tap

the

end of the shaft with a mallet to help

seat the screw and then tighten the

screw (do not tighten the screw so

much that you damage the bushing).

9.

Apply a layer of non-hardening

gasket sealer around the outside

edge of a new oil seal (10) and install

the seal.

10. Install the two washers (9).

11

. Install the key (7 or8)in

the key-

way of the input pinion shaft.

12. For the Econo-Horse and older

model Junior and Pony tillers, install

the transmission pulley

(3or5),

disc

spring washer (2), and bolt (1).

Securely tighten the bolt.

13. For newer model Junior and

Pony tillers, install the transmission

pulley

(tl), large washer

(6).

disc

spring washer (2), and bolt

(1)

Securely tighten the

bolt

Wheel Shaft

Assembly

These instructions describe how to

service the wheel shaft assembly.

Use Figure 4-5 as a reference for

part locations in these instructions.

Removal

1.

Drain the transmission gear oil.

2.

Remove the clevis pins that hold

the wheels on the wheel shaft. Then

remove the wheels.

NOTE:

If the wheels are rusted to the

shaft and you have a wheel puller,

try

to pull the left wheel off (the left side

of the wheel shaft must pass through

the housing in order to remove the

wheel shaft).

If

you cannot pull the

left wheel off, you will have to saw it

off. After sawing the wheel shaft, use

a file to smooth off the end of the

shaft to ensure that it will pass

smoothly through the worm gear

clutch.

3.

For the Junior model only, remove

the snap ring retainer (1) from

the left

side of the wheel shaft.

II)',

,

4.

Remove the oil seal (2) ffom the

left side of the wheel shaft.

5.

Remove and discard the snap ring

(3) from the left side of the wheel

shaft.

6.

Remove the shim

(4)

from the left

side of the wheel shaft.

7.

Remove the transmission housing

cover

(see

instructions at beginning

of this section).

8.

Using a soft mallet. tap the wheel

shaft

(7)tothe right untilitcomes

out

You

may feel resistance from the

oil seal

on

the right side of the shaft.

NOTE: The key

(6)onthe wheel

shaft will force the right side bushing

(5)

out

along with the oil seal (2),

snap ring

(3)

and shim (4). On the

Junior model.

it

will also force out

the

snap ring (1).

Page 16

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-7

5/90

SECTION4:Servicing

the

Transmission

I r

Figure 4·5: The wheel shaft assembly.

6

/'

ECONO/PONY

~

I MODEL

I

2

____

5\\

44\'\

3~

JUNIOR

MODE~

p _

1 "

~

',>

6 '

"v,

JUNIOR

MODEL

7

9.

If you had to cut the wheel shaft

to remove a wheel, you will have to

use

an

old wheel shaft as a driver. (If

you use this procedure, it is possible

to mushroom the end of the wheel

shaft, making it

impossible to pass it

through the wheel drive worm gear.

If

this happens, it will be necessary

to crack the worm gear

in

half to

remove the wheel shaft.)

10. After removing the wheel shaft,

remove the hi-pro key (6).

11.

For the Econo:Horse and Pony

models: remove the wheel drive

worm gear (8), shim (9), and clutch

(10) from the transmission housing.

(See NOTE below).

For the Junior Model: remove the .

shims (9), wheel drive worm gear

(8),

and spacer

(11)

from the transmis-

sion housing.

NOTE:

To

remove the wheel drive

worm gear it may be necessary to

first remove the input pinion shaft

gear. If so, refer to the input pinion

shaft and gear assembly removal

instructions

in

this section.

12. Insert a drift pin

in

the right side

of the transmission housing and

drive the left side bushing (5) out of

the housing. Be careful not to damage the inside of

the

housing with the

drift

pin.'

~~

Inspection

These instructions describe how to

inspect vital parts on the wheel shaft

assembly.

In

addition to inspecting

the parts you have removed, you

should also inspect any replacement

parts you will use.

NOTE: Thoroughly degrease and

clean all parts before inspection.

Wheel Shaft -

o

If

the shaft is pitted or slightly worn

around the oil seal areas, you may

be able to relocate the seals to a

smooth area.

o If the shaft is badly scored or worn

around the oil seal areas, discard the

shaft.

o If there is corrosion around the oil

seal areas, try using a #400 grit

emery cloth to clean the area.

Page 17

SECTION4:Servicing

the

Transmission

JUNIOR,

PONY&ECONO·HORSE

TECHNICAL

MANUAL

Page

4-8

5/90

• Examine both ends of the wheel

shaft for burrs or rough edges that

could prevent the shaft from passing

through the wheel drive worm gear

(and the clutch

on

Econo-Horse or

Pony models). Use a file or emery

cloth to remove any rough edges.

o

If

the outside edges of the snap

ring grooves are rounded, you will

have to discard the wheel shaft as

these edges bear the force of the

snap rings. If the grooves have

expanded you may be able to use

shims to take up the slack (place the

shims

on

the shaft, notinthe

groove). If not, discard the wheel

shaft.

Wheel Drive Worm Gear -

o Check the bore of the gear for

rough edges or burrs that could

score the wheel shaft.

o If there are any broken or exces-

sively worn teeth, discard the gear.

o For the Econo-Horse and Pony

models: if the clutch dogs have worn

a groove more than 1/4 through the

wall of the gear (usually due to

speed shifting), discard the gear.

Clutch (Econo-Horse and Pony

models only) -

o If the clutch dogs are excessively

rounded, discard the clutch.

o

If

any clutch dogs are missing, dis-

card the clutch.

o If the keyway is damaged, you may

be able to straighten it with a file.

Otherwise, discard the clutch.

Installation

Use Figure 4-5 as a reference for

part locations

in

these instructions.

1.

Install the hi-pro key

(6)

firmly

in

the keyway of the wheel shaft (7).

2.

Make sure that the wheel drive

worm gear (8) slides freely over the

ends of the wheel shaft. For the

Econo-Horse and Pony models,

check that the clutch slides freely

over the ends of the wheel shaft and

over the hi-pro

key.

3.

Grease the center of the wheel

drive worm gear (8) and press the

shim

(9),

into the gear.

4.

For the Junior model:

o Slide the wheel shaft

(7)

in

from the right side of the transmission housing. Note that

the keyway

on

the shaftisnot

centered between the two

inner snap ring grooves.

You

must insert the side of the

wheel shaft that has the short-

estdistance between the key-

way and the snap ring

grooves.

o

As

the wheel shaft passes

through the inside of the

transmission housing, install

(in the following order) the

wheel drive worm gear (8)

and the spacer (11). Then

push the shaft the rest of the

way through until its ends

are protruding

an

equal distance from' both sides of the

housing.

o Insert the other shim

(9)

in

through the left side of the

transmission housing.

For the Econo-Horse and Pony

models:

o Make sure the eccentric shaft

shifting pin

is

facing up, or at

12

o'clock, inside the housing

(If the eccentric shaft assembly

has been removed, it must

be

installed at this time. See the

"Eccentric Shaft Assembly"

installation instructions

in

this

section).

o Gently place the wheel drive

worm gear

(8)

and clutch

(10)

into the housingsothat the

eco'!ntric shifting-pin

fits

into

the groove

of

the clutch.

• Slide the wheel shaft

(7)

in

from the right side of the transmission housing and through

the clutch and worm gear.

Note that the keyway is not

centered between the two

snap ring grooves.

You

must

insert the side of the wheel

shaft that has the longest distance between the keyway and

the snap ring grooves.

o Push the shaft through until its

ends are p'rotruding

an

equal

distance from both sides of the

housing.

o Make sure that the eccentric

lever moves the clutch freely

from side to side

on

the wheel

shaft.

5.

Using #30 weight oil, lubricate

the two wheel shaft bushings (5).

6.

Making sure the two oil pick-up

grooves

on

the bushing are facing in,

use a hammer to install one bushing

ab~u!

1/8 of the wayinthe housing.

7.

Using a rubber hammer and a

driver, and making sure the oil pickup grooves are facing in, install the

other bushing so that the edge of the

bushing

is

flush with the edge of the

counter bore

in

the transmission

housing. Then finish installing the

first bushing

in

a similar manner.

8.

Use a rubber mallettostrike

down

on

the wheel shaftonboth

sides of the housing. This will loosen

the shaft and make it easy

to

turn.

9.Inone of the sides, install a shim

(4)

and a snap ring

(3).

The

flat side

of the snap ring (although not easy

to

observe, thereisa flat side and a

rounded side) should face the outside edge

of

the groove. Gently tap

this end of the shaft inward

so

that

the snap ring

is

flush against the

bushing.

10.

Gotothe other side and shim

(4)

the

gap between the bushing and

the snap ring groove.

Page 18

,JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-9

5/90

SECTION4:Servicing

the

Transmission

11.

Install a snap ring (3). The flat

side of the snap ring should face the

outside edge of the groove.

12. Test for end play. There should

be 0.000" to 0.005" play and the

wheel shaft should turn freely. Add

or remove shims (4) as needed.

13. Apply a layer of non-hardening

gasket sealer to the outside edges of

the two oil seals (2) and install them

at each end of the wheel shaft.

14. For the Junior model: install the

snap rings

(1)inthe outside snap

ring grooves.

Eccentric Shaft

Assembly

5.

Remove the oil seal (5).

6.

Remove the spring (6).

Inspection

Make sure the eccentric shaft (3) is

not scored, pitted, or heavily corroded around the oil seal area. If the

shaft has minor pitting, scoring, or

corrosion, you may be able to

smooth it with

an

emery cloth.

Otherwise, you should discard the

shaft.

Installation

1.

Install the eccentric shaft pin (4)

on

the end of the eccentric shaft (3).

2.

Install the spring (6)onthe shaft.

3.

Install the eccentric shaft from the

inside of the transmission housing.

4.

Install the wheel shaft. See

"Wheel Shaft Assembly"

in

this sec-

tion for installation instructions.

5.

Apply a coating of non-hardening

gasket sealer to the outside edge of

the oil seal (5) and install the seal

from the outside of the transmission

housing.

6.

Install the eccentric shaft lever (2)

on

the eccentric shaft. When doing

so, make sure the lever is extended

to the left side of the housing and

that the longer arm on the lever is

closest to the transmission housing.

7.

Install the hex head screw (1) that

secures the eccentric lever to the

eccentric shaft.

These instructions, which explain

how to service the eccentric shaft

assembly, apply to the Econo-Horse

and Pony models only. Use Figure

4-6 as a reference for part locations

in

these instructions.

Removal

1.

Remove the wheel shaft. See

"Wheel Shaft Assembly"

in

this sec-

tion for removal instructions.

2.

Remove the hex head screw (1)

that secures the eccentric lever (2) to

the eccentric shaft (3). Then remove

the eccentric lever.

3.

Remove the eccentric shaft pin

(4)

from the eccentric shaft.

4.

Remove the eccentric shaft (3) by

pushing it toward the inside of the

transmission housing.

111

5

Figure 4-6: The eccentric shaft assembly.

r~~6

3

i

~~4

I

J

Page 19

SECTION4:Servicing

the

Transmission

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-10

5/90

Tiller Shaft

Assembly

These instructions describe how to

service the tiller shaft assembly. Use

Figures 4-7 and 4-8 as a reference

for part locations

in

these instruc-

tions.

NOTE: Tillers that fall within the following serial number ranges are

equipped with roller bearings that are

used with the

PIN

20798 tiller shaft

only (see Figure 4-8, Items 8 and 6).

New tiller models (those with serial

numbers higher than shown below)

have ball bearings that are used with

the

PIN

20896 tiller shaft only (see

Figure 4-8, Items 9 and 7).

Junior Model: SIN M67999 -

M01

00969

Pony Model: SIN S186072 - S0242649

Econo-Horse: SIN E1001 - E0032773

a.

At the rear of the drive shaft

transmission tube, remove the

rear bearing cap and any

shims. Then, place your hand

over the bore opening to prevent the drive shaft from slipping backwards out of the

transmission tube (which

could cause the front drive

shaft bearing to fall down

inside the transmission housing).

b.

Insert a screwdriver through

the tine holder mounting hole

in

the tine shaft and carefully

rotate the shaft clockwise until

the rear bearing cup

on

the

drive shaft

is

flush with the

transmission bore opening.

c.

Apply tape over the bore

opening to prevent the drive

shaft from slipping backwards

and proceed to Step

5.

5.

To

remove the tiller shaft assem-

bly,

first use a soft mallet to strike

downward

on

the right side of the

tiller tine shaft. This will collapse the

right side oil seal

(5)

and help the

tiller cluster to come out. Remove

the tiller tine shaft

(6or7)

and the

attached worm gear (11), bearings

(8

or 9), and woodruff key (12).

6.

Place the tiller housing cover

(3)

onanopen vise so that the outer

edges are supported.

Tap

out the oil

seal (5), being careful not to scratch

the inside of the cover (or the bearing race that

is

used with older model

tillers).

7.

Remove the

oil

seal (5) from the

right side of the transmission housing.

Asinthe previous step, be care-

ful not to damage the inside

of

the

cover (or the bearing race

on

older

model tillers).

Removal

1.Ifthe tine holders are rusted onto

the tiller tine shaft and penetrating oil

does not free them, it will be necessary to cut the holders lengthwise

in

two places, 180 degrees apart.

Then use a chisel to break them off

the shaft.

2.

Remove the five bolts (1) and

nylon washers (2), if

any,

that secure

the tiller housing cover (3). Discard

the washers. Have a pan ready to

collect the gear oil that will pour out

when you remove the tiller housing

cover

in

the next step.

3.

Remove the tiller housing cover

by gently tapping the right side of the

tine shaft inward with a mallet.

Remove and discard the housing

cover gasket(s) (4).

·4. On newer model tillers (those

equipped with ball bearings instead

of roller bearings

on

the tine shaft),

the main drive shaft must be repositioned slightly

in

order to remove the

tine shaft. Follow Steps 4a-4c:

Figure 4-7: The

tiller

shaft

housing

cover.

5~

Page 20

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-11

5/90

SECTION4:Servicing

the

Transmission

10

9

.'~

7

9

10

-~,

~,

Figure 4-8: The

tiller

shaft assembly.

8.

On

older model tillers, remove the

bearing cups (10) from the housing

cover and from the right side of the

transmission housing.

Be

careful not

to scratch the inside of the cover or

the transmission housing when

removing the cups.

NOTE:

You

only need to remove the

bearing cups

if

you willbeusing new

roller bearings. If you replace a

bearing you must also replace the

cup. Keep each cup paired with its

bearing if you intend to reuse them.

Each cup wears differently according

to its bearing.

9.Todisassemble the gear and

bearing assembly:

a.

Place the tiller tine shaft

assembly

onanarbor press.

b.

Force the shaft down. This

will dislodge one bearing.

c.

Turn the shaft assembly 180

degrees and use the arbor

press to dislodge the other

bearing.

d.

Slide the worm gear

(11)

off

the shaft.

e.

Remove the woodruff key

(12).

Inspection

These instructions describe how to

inspect vital parts

on

the tiller shaft

assembly.

In

addition to inspecting

the parts you have removed, you

should also

in

ect any replacement

parts you will use.

NOTE: Thoroughly degrease and

clean all parts before inspection.

Tiller Tine Shaft -

• The shaft should not be scored, pitted, or corroded

in

the areas where

the

oil

seals are located. If the shaft

is

scored, pitted, or corroded, try

using

an

emery cloth to clean the

area. If the scoring, pitting, or corro-

sion

is

too extensive (which would

result

inanoil leak), discard the shaft.

• Remove any burrs or rough spots

on

the ends of the shaft that could

cut the oil seals when they are

installed.

• The keyway should be just wide

enough to fit the

key.

If the keyway

has expanded, discard the shaft.

Worm Gear - If the gear teeth are

damaged or excessively worn, dis-

card the gear.

Bearings-

• If the bearing has a bluish color

then proper lubrication has not been

maintained; discard the bearing and

bearing

cup,

• If the bearing is scored or exces-

sively worn, dirt may have gotten

inside the housing. If so, replace the

bearing and bearing cup.

• If a bearing makes a growling

noise or does not spin freely, discard

the bearing.

Page 21

SECTION4:Servicing

the

Transmission

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

4-12

5/90

Installation

Use Figures 4-7 and 4-8 as refer-

ences for part locations

in

these

instructions.

1.

On

newer model tillers (those

equipped with ball bearings instead

of roller bearings

on

the tiller tine

shaft), the drive shaft inside the

transmission tube must be repositioned slightly before the tiller tine

shaft can be installed. Follow the

. procedure outlinedinSteps 4-a

through 4-c of the previous tiller tine

shaft removal instructions.

2.

Install the woodruff) key (12)

in

the tiller tine shaft(6or 7).

3.

Slide the bronze worm gear

(11)

on

the shaft. The worm gear should

be centered over the woodruff

key.

4.

Useanarbor press to install the

bearings

(8or9)

flush against the

bronze worm gear. While doing so,

make certain that the bronze worm

gear

is

centered over the woodruff

key.

5.

Useanemery cloth to clean the

tine shaft, especially around the oil

seal locations.

6.

On

older model tillers, install a

bearing cup (10)

in

the housing cover

(3)

by using a piece of wood as a

driver to seat the cup. Make sure the

tapered bearing cup is correctly oriented to receive the bearing. Also

make sure the bearing cup goes fully

inside the cover; no metal should be

visible between the bearing cup and

the inside edge of the cover. Use the

same technique to install a bearing

cup (10))

in

the right side of the tiller

housing.

7.

Insert the tiller tine shaft assembly

in

the tiller housing. Make sure the

side

on

the bronze worm gear whose

gear edges are the sharpest is facing

towards the rear of the machine.

8.

Install a new gasket

(4)onthe

tiller housing cover (3).

As

you begin

the shimming procedure, start with

the thinnest gasket, which

is

0.010"

thick.

Do

not install the oil seals

(5)

at this time.

9.

Temporarily secure the cover

in

place using two bolts (1) about 180

degrees apart.

1

O.

Using the right side of the tiller

tine shaft, check the shaft for play:

a.

Using two hands, grasp the

shaft and rotate it back and

forth.

b.

You

should be able to rotate

the shaft slightly. This means

the tiller tine shaft

is

shimmed

correctly.

c.Ifyou cannot rotate the shaft,

remove the 0.010" gasket and

install a 0.030" gasket.

If

nec-

essary, begin using gaskets

in

pairs to gradually increase the

thickne.ss of the gasket. For

example, if a 0.030" gasket

is

insufficient, use a 0.030" and

0.010" gasket together. If this

combination is not sufficient,

use two 0.030" gaskets, etc.,

until the shaft is shimmed correctly.

d.

There should benoend play,

vertical play or diagonal play

in

the tiller tine shaft.Ifyou

find such play, tighten the two

housing cover bolts.

If

this

does not eliminate the play,

insert a shim (use the same

shim as used

on

the wheel

shaft - using the thinnest shim

first and then switching

to

thicker shims as necessary)

between the worm gear and

the bearing

on

the tiller tine

shaft.

11.

Repeat steps 9 and10until

you

obtain the correct amount of play

in

the tiller tine shaft. Then remove the

two bolts from the housing cover.

12.

Using ,lew Nylon washers

(2).

bolt the coverinplace with

all

five

bolts (1). Note that the Nylon washers function as oil seals.

If

the washers are not available, coat the tips of

the bolts with non-hardening gasket

sealer.

13. Apply a layer of non-hardening

gasket sealer to the outside edge of

an

oil seal (5). Then install the oil

seal

on

the right side of the tiller

housing so that the seal

is

flush with

the housing.

14. Install another oil seal (5)

in

the

tiller housing cover.

Page 22

JUNIOR,

PONY&ECONO-HORSE

TECHNICAL

MANUAL

Page

5-1

5/90

A

H

INDEX

Q

Assembling/Installing,

Drive Shaft Assembly, 4-4

Eccentric Shaft Assembly, 4-9

Housing Cover,

4-1

Input Pinion Shaft &

Gear

Assembly,4-6

Tiller Tine Shaft Assembly, 4-12

Wheel Shaft Assembly, 4-8

B

Bearings,

Drive Shaft, 2-2, 4-2, 4-3, 4-4

Tine Shaft, 2-2, 4-10, 4-11, 4-12

c

Cover,

Tiller Tine Shaft, 4-10, 4-12

Transmission Top,

4-1

D

Drive Shaft Assembly,

Inspection, 4-3

Installation, 4-4

Removal, 4-2

E

Eccentric Shaft Assembly,

Inspection, 4-9

Installation, 4-9

Removal, 4-9

G

General Information,

1-1

Housing Cover,

Tiller Tine Shaft, 4-10, 4-12

Transmission Top,

4-1

I

Input Pinion

Gear

Shaft & Gear,

Inspection, 3-1, 4-6

Installation, 4-6

Removal, 4-5

Inspecting,

Drive Shaft Assembly, 4-3

Eccentric Shaft Assembly, 4-9

Housing Cover,

4-1

Input Pinion Shaft & Gear, 4-6

Pre-SeNice,

3-1

Tine Shaft Assembly,

3-1,4-11

Wheel Shaft Assembly,

3-1

, 4-7

Installing,

Drive Shaft Assembly, 4-4

Eccentric Shaft Assembly, 4-9

Housing Cover,

4-1

Input Pinion Shaft & Gear, 4-6

Tine Shaft Assembly, 4-12

Wheel Shaft Assembly, 4-8

o

Oil Leaks, 2-2, 2-3

Oil Seals,

Drive Shaft, 4-2, 4-4

Eccentric Shaft, 4-9

Input Pinion Shaft, 4-5, 4-6

Tine Shaft, 4-10, 4-12

Wheel Shaft, 4-6, 4-8

p

Pre-Service Inspection,

3-1

Quick Reference Repair Index, 1-2

R

Removing,

Drive Shaft Assembly, 4-2

Eccentric Shaft Assembly, 4-9

Housing Cover,

4-1

Input Pinion Shaft & Gear, 4-5

Tine Shaft Assembly, 4-10

Wheel Shaft Assembly, 4-6

5

Safety Rules, 1-1, 1-2

Shimming,

Drive Shaft, 4-4

Wheel Shaft, 4-8, 4-9

Tine Shaft, 4-12

T

Throttle Cable, 3-2

Tiller Tine Shaft Assembly,

Inspection, 3-1,

4-11

Installation, 4-12

Removal, 4-10

Transmission Bore Seal, 3-2

Troubleshooting,

2-1

w

Wheel

Gear

Control Lever, 3-2

Wheel Shaft Assembly,

Inspection,

3-1,4-7

Installation, 4-8

Removal, 4-6

Page 23

Page 24

OTRQY-SILT

!Ub~C~O~~2AE~~~r9t~~~roy,NewYork12180

a I Toll-Free: 1-800-833-6990

GARDEN

WAY

CANAOA, INC., 1515 Matheson Blvd.,

Unit

B11,

Mississauga,

Ontario

L4W 2P5

Local

calls

only

(416 Area Code): 624-8423 • From

Ontario

& Quebec

Provinces

call

Toll-Free: 1-800-387-3351

From Western Canada &

Maritime

Provinces

call Toll-Free: 1-800-387-3316

-

MN1400590

."

..

PrintedinU.S.A. ©1990 Garden Way Inc.

Loading...

Loading...