Page 1

Wide-Cut

TM

33"

Combination Mower

Models 753B

F753B

Operator’s Manual

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FORM NO. 770-10602F

(12/2003)

(fuel tank styles vary by engine model)

Page 2

For more details about your unit, visit our website at www.troybilt.com

TABLE OF CONTENTS

Content Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Features and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Off-Season Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Lubrications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Warrany Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new Wide-CutTMmower. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the information from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

• You can locate the model number by looking at the rear surface of the mower frame. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment

in the space below

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating,

specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed

separately with your unit for more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

Call

1- (330) 558-7220 or 1- (800) 520-5520 to reach a Customer Support representative. Please have

your unit’s model number and serial number ready when you call. See previous section to locate this information. You will be asked to enter the serial number in order to process your call .

Copy Model Number Here

www.troybilt.com

TROY-BILT LLC

P. O. BOX

CLEVELAND, OH 44136

330-558-7220

800-520-5520

361131

Copy Serial Number Here

Page 3

Safety Alert Symbol

This is a safety alert symbol. It is used in this

Owner’s Manual to alert you to potential

hazards. Whenever you see this symbol, read and obey the

safety message that follows it. Failure to obey the safety

message could result in personal injury or property

damage.

The engine exhaust from this product contains

chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm.

WARNING:

1

IMPORTANT

Safe Operation Practices for Walk-Behind Mowers

This cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

1. Read, understand, and follow all instructions on the machine and in the

manuals. Be thoroughly familiar with

the controls and the proper use of

the mower before starting.

2. Do not put hands or feet near or

under rotating parts. Keep clear of

the mower blade and discharge

opening at all times.

3. Only allow responsible individuals,

who are familiar with the instructions, to operate the mower.

4. Clear the area of objects such as

rocks, toys, wire, bones, sticks, etc.,

which could be picked up and

thrown by the blade.

5. Be sure the area is clear of other

people before mowing. Stop mower

if anyone enters the area. Keep bystanders at least 25 feet away from

the area of operation.

6. Do not operate the mower when

barefoot or wearing open sandals.

Always wear substantial foot wear.

7. Do not pull mower backwards

unless absolutely necessary. Look

down and behind before and while

moving backwards.

8. Do not operate the mower without

proper guards, plates, grass catcher

or other safety protective devices in

place.

9. Refer to provided instructions for

proper operation and installation of

accessories. Only use accessories

approved by Garden Way

Incorporated.

10. Stop the blade when crossing gravel

drives, walks, or roads.

11. Stop the engine and disconnect the

spark plug wire from the spark plug

whenever you leave the unit, before

cleaning the mower or unclogging

the chute.

12. Shut the engine off, wait until the

blade comes to a complete stop, and

disconnect the spark plug wire before installing or removing the

mulcher cover or the optional grass

catcher. Make certain that the grass

catcher is securely attached before

operating the mower. Empty the

grass catcher after each use–

decomposing debris could generate

enough heat to catch fire.

13. Mow in daylight or good artificial

light.

14. Do not operate the mower while

under the influence of alcohol or

drugs.

I. GENERAL OPERATION

Safety

1

Section

Page 4

2

15. Never operate mower in wet grass.

Always be sure of your footing; keep

a firm hold on the handle and walk;

never run.

16. Disengage the Wheel Drive Lever on

self-propelled models before starting

the engine.

17. If the unit should start to vibrate abnormally, stop the engine and disconnect the spark plug wire. Then

check immediately for the cause.

Vibration is generally a warning of

trouble.

18. Always wear safety goggles or safety

glasses with side shields when operating mower.

19. Watch for traffic when operating

near, or when crossing roadways.

20. Never attempt to carry children or

other passengers on the mower.

They could fall off and be seriously

injured, or they could interfere with

the safe operation of the mower.

21. Check the operation of the Operator

Presence Control Bar before each

use. See the Maintenance Section of

this manual for instructions. If the

engine runs longer than three seconds after the Operator Presence

Control Bar is released, the system

is not working properly. Immediately

contact your local service dealer or

the factory Technical Service

Department for instructions. Do not

use the mower until the mechanism

is repaired.

22. The mower is equipped with a safety

discharge chute, comes with special

mulcher covers, and offers an optional grass catcher. The safety discharge chute must be working properly at all times. Never attempt to

disconnect or otherwise cause this

discharge chute to cease working. If

used, mulcher cover or grass

catcher attachment must be installed

properly and function correctly. Do

not use your equipment otherwise.

23. Never run the engine in an enclosed

area. Engine exhaust contains carbon

monoxide, a deadly gas that is odorless, colorless, and tasteless. Always

run the engine outdoors and make

sure there is adequate ventilation.

II. SLOPE OPERATION

Slopes are a major factor related to

slip and fall accidents which can result

in severe injury. All slopes require

extra caution. If you feel uneasy on a

slope, do not mow it.

DO:

Mow across the face of slopes; never

up and down. Exercise extreme caution when changing direction on

slopes. Avoid slopes greater than

15o.

Remove objects such as rocks, tree

limbs, etc.

Watch for holes, ruts, or bumps. Tall

grass can hide obstacles.

DO NOT:

Do not mow near drop-offs, ditches,

or embankments. The operator could

loose footing or balance.

Do not mow excessively steep slopes.

Do not mow on wet grass. Reduced

footing could cause slipping.

III. CHILDREN

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

mower and to the mowing activity.

Never assume that children will remain

where you last saw them.

1. Keep children out of the mowing

area and under the watchful care of

a responsible adult.

2. Be alert and turn mower off if children enter the area.

3. Before and while moving backwards,

look behind and

down for small

children.

4. Never allow children to operate the

mower.

5. Use extra care when approaching

blind corners, shrubs, trees, or other

objects that may obscure vision.

IV. SERVICE

1. Use extra care in handling gasoline

and other fuels. They are flammable

and their vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add

fuel when the engine is running.

Allow engine to cool before refueling. Do not smoke.

c) Never refuel the machine

indoors.

d) Never store the machine or fuel

container inside where there is

an open flame, such as a water

heater, etc.

e) Move mower away from any

gasoline fumes before starting

the engine.

2. Never run an engine inside a closed

area.

3. Never make adjustments or repairs

with the engine running. Disconnect

the spark plug wire and keep the

wire away from the plug to prevent

accidental starting.

4. Keep all nuts and bolts, especially

the blade attachment bolts, tight and

keep equipment in good condition.

5. Never tamper with safety devices.

Check their operation regularly.

6. Keep mower free of grass, leaves or

other debris build-up. Clean up oil or

fuel spillage. Allow mower to cool

before storing.

7. After striking an object, stop the engine and disconnect the spark plug

wire. Inspect the mower and repair,

if necessary, before restarting.

8. Never attempt to make mower cutting height adjustments while the

engine is running.

9. Grass catcher components are subject to wear, damage and deterioration, which could expose moving

parts or allow objects to be thrown.

Frequently check components and

replace with factory recommended

parts, when necessary.

Section 1: Safety

Page 5

3

10. Mower blades are sharp and can

cut. Wrap the blade or wear gloves,

and use extra caution when servicing them.

11. Do not change the engine governor

setting or overspeed the engine.

12. Do not touch engine parts which

may be hot from operation. Allow

parts to cool completely before inspecting, cleaning or repairing the

mower.

13. To access the underside of the

mower, tip the mower rearward. Do

not tip the mower forward or on either of its sides, unless specifically

advised to do so in this manual.

14. Maintain or replace safety and instructional decals. Refer to the separate Parts Catalog for replacement

decal information.

15. For units equipped with electric

start:

a) Batteries produce explosive

gases. Keep sparks, flame,

cigarettes, etc., away. Ventilate

the area when charging the battery. Do not charge the battery in

an airtight space.

b) Do not use a battery charger

other than the one provided with

the mower.

c) The battery contains toxic mate-

rials. Do not damage the battery

case. If the case is broken or

damaged, avoid contact with the

battery contents.

d) Properly dispose of a damaged

or worn out battery. Check with

local authorities for proper disposal methods.

e) Do not short circuit the battery.

Severe burns and fire can result.

Section 1: Safety

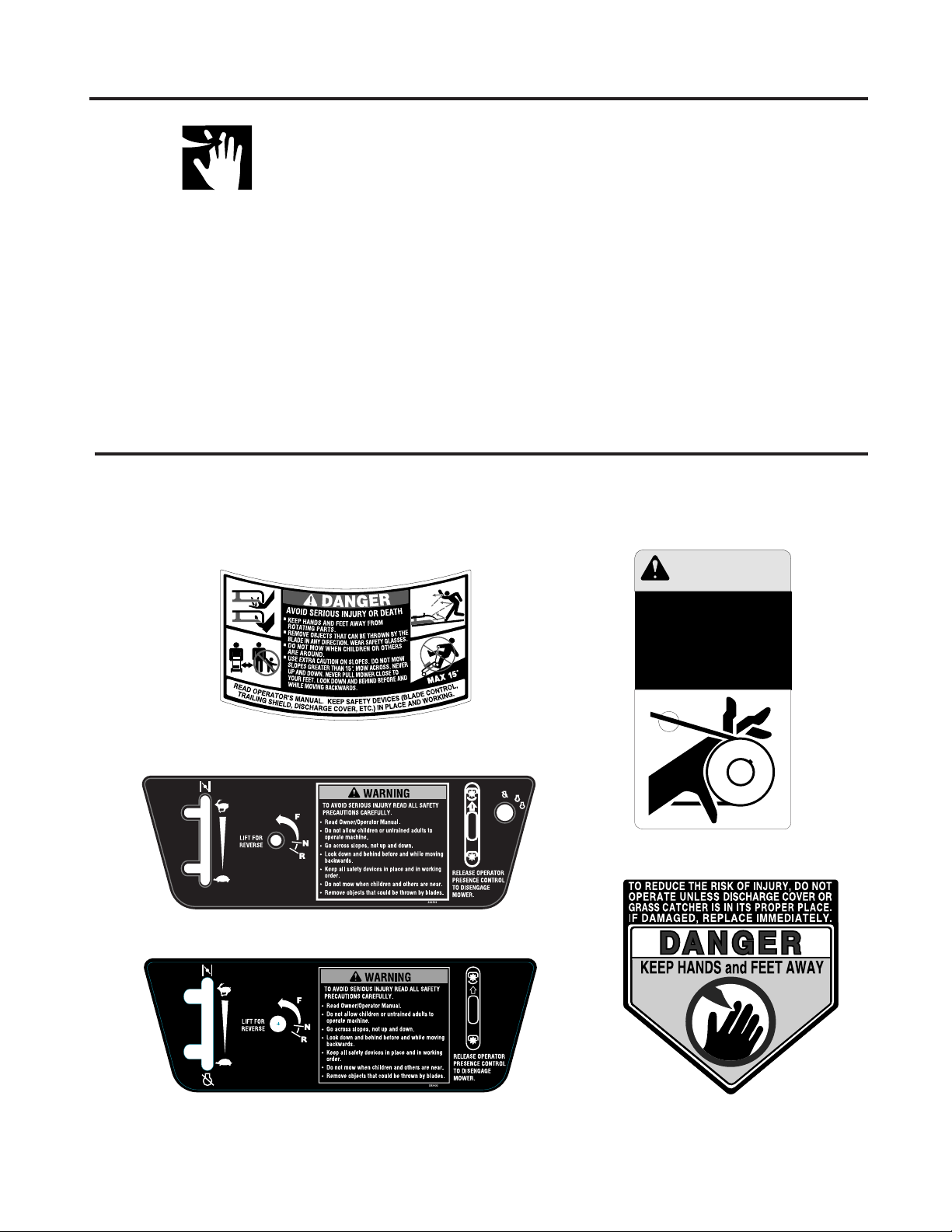

SAFETY DECALS

Make certain all safety decals on this equipment are kept clean and in good condition. The decals are shown (at reduced sizes)

below. If you need a replacement decal, please refer to the Parts Catalog that accompanied this Manual.

Beneath belt/pulley cover

On Control Panel (for electric start model)

On Control Panel (for recoil start model)

On left side of mower deck

On discharge chute

WARNING

PINCH POINTS

Do not operate with-

out all belt guards

in place.

Page 6

4

INTRODUCTION

Please carefully follow these assembly

steps to properly prepare your machine

for use. We recommend that you read

this Section in its entirety before beginning assembly.

NOTE: All references to left, right, front

and rear of the machine are determined

by standing behind the handlebars and

facing the direction of forward travel.

INSPECTION AFTER DELIVERY

Inspect the shipping crate and machine

immediately after delivery. Make sure

neither the carton/crate nor the contents

have been damaged.

If you find or suspect any damage, contact the carrier (trucking company)

immediately. Inform them of the specific

damage and that you wish to file a claim.

To protect your rights, be sure to put

this in writing to the carrier within 15

days. The carrier will let you know how

to proceed with your claim. Please let us

know if you need any assistance.

TOOLS/MATERIALS NEEDED:

• Wire Cutter

• Two 7/16” Wrenches

• 3/8” Wrench

• 1/2” Wrench

• Scissors or Pen Knife

• Needle-nose Pliers

• Tire Gauge

ASSEMBLY STEPS

STEP 1: Unpacking Mower

NOTE: LEFT and RIGHT sides of the unit

are as viewed from the operator’s position behind the handlebars.

1. Cut straps, if present, securing unit

to pallet. Leave unit on pallet during assembly (to safely remove unit from pallet, wait until you have completed assembly steps 1-4).

2. Remove any protective packaging

from around the handlebars. Cut the

plastic tie straps holding the control rods

and struts to the handlebars.

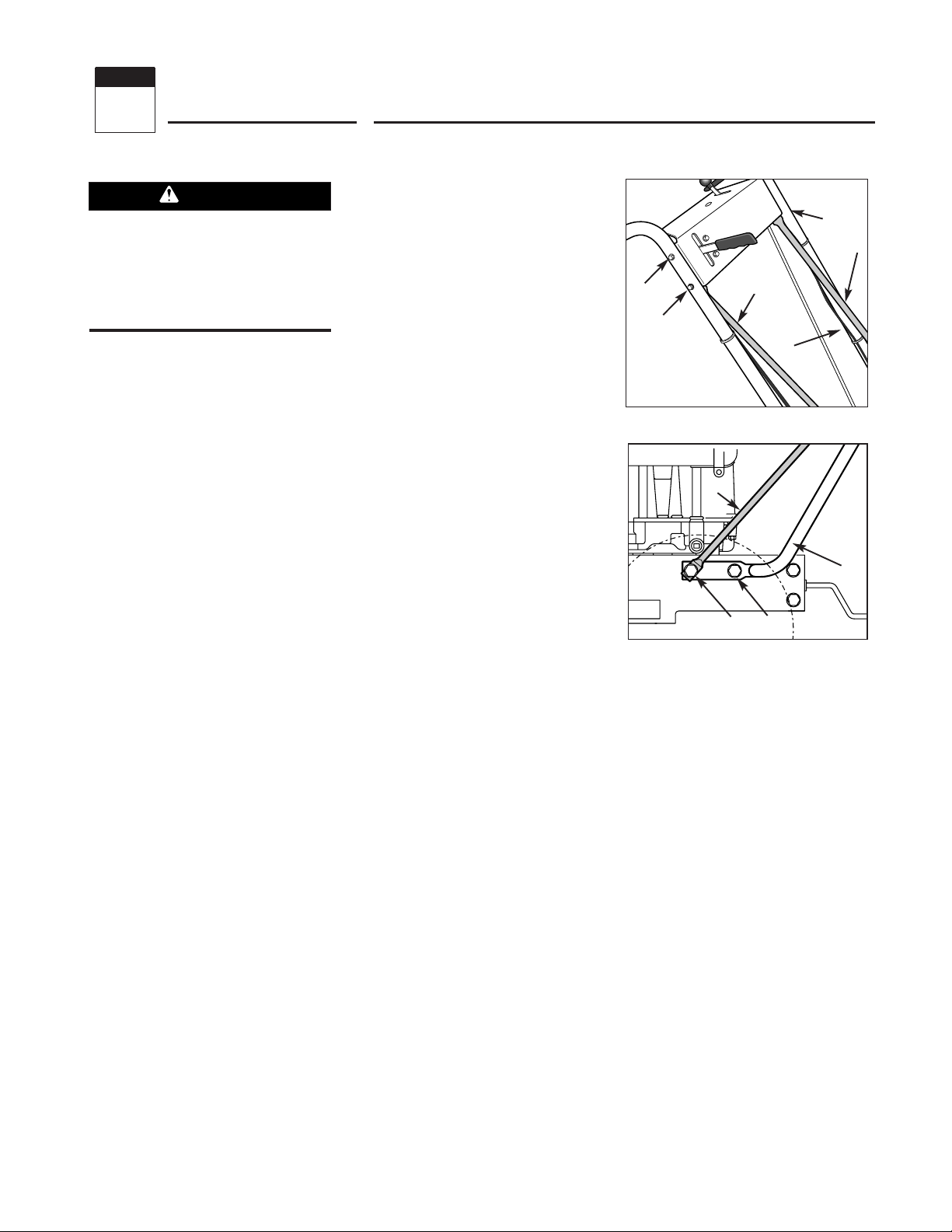

STEP 2: Attach Handlebars

to Engine Deck

NOTE: Four screws (D, Figure 2-2) are

used to connect the handlebars to the

engine deck. At the factory, two of these

screws (front) are threaded directly into

lock nuts welded to the back sides of the

deck. The remaining two screws (rear)

secure the lower handle to the deck.

1. Remove and save the two 5/16"-18 x

3/4" screws (front) mentioned in the

NOTE above.

2. Loosen, but do NOT remove, the two

5/16"-18 x 3/4" screws (rear). Leave the

cardboard insert found between the lefthand handlebar and engine deck, in

place.

3. Carefully pivot the handlebars over

the engine and position the handlebar

ends (E, Figure 2-2) against the sides of

the engine deck. Do not alloow the handlebars to rub against the engine while

pivoting them.

4. Loosely secure the right-hand handlebar end to the deck by reinserting the

screw (D, Figure 2-2) removed earlier.

Do not secure the left-hand handle at

this point in assembly.

5. Remove the cardboard insert from

between the left-hand handlebar and

engine deck

6. Remove the nut from the lower screw

(B, Figure 2-1) which secures the console to the handlebar on the left-hand

side of the unit.

7. Position a handlebar strut’s smaller

hole (A, Figure 2-1) over the screw (B,

Figure 2-1) on the INSIDE of the console, with the strut’s flat side against the

console.

8. Using the nut removed earlier, secure

the strut to the console/handlebar.

9. Align the loose end of the left-hand

handlebar strut (A, Figure 2-2) over the

front hole in the handlebar end. Secure

the strut and handlebar to the deck with

the 5/16"-18 x 3/4" screw (D, Figure 2-2)

removed earlier.

10. Remove the screw (front) that is

loosely securing the right-hand handlebar end to the deck. and repeat 6-9 on

the right-hand side of the unit.

11. On both sides of the unit, securely

tighten the screws (D, Figure 2-2) at the

lower ends of the handlebar before tightening the screws (B & F, Figure 2-1) on

the console.

To prevent personal injury or property

damage, do not attempt to start the

engine until all assembly steps are

complete and you have read and

understand the safety, controls and

operating instructions in this manual.

Figure 2-1

B

B

F

C

A

A

A

D

E

D

Figure 2-2: Attach handlebars and struts

to engine deck.

Assembly

2

Section

WARNING

Page 7

Section 2: Assembly

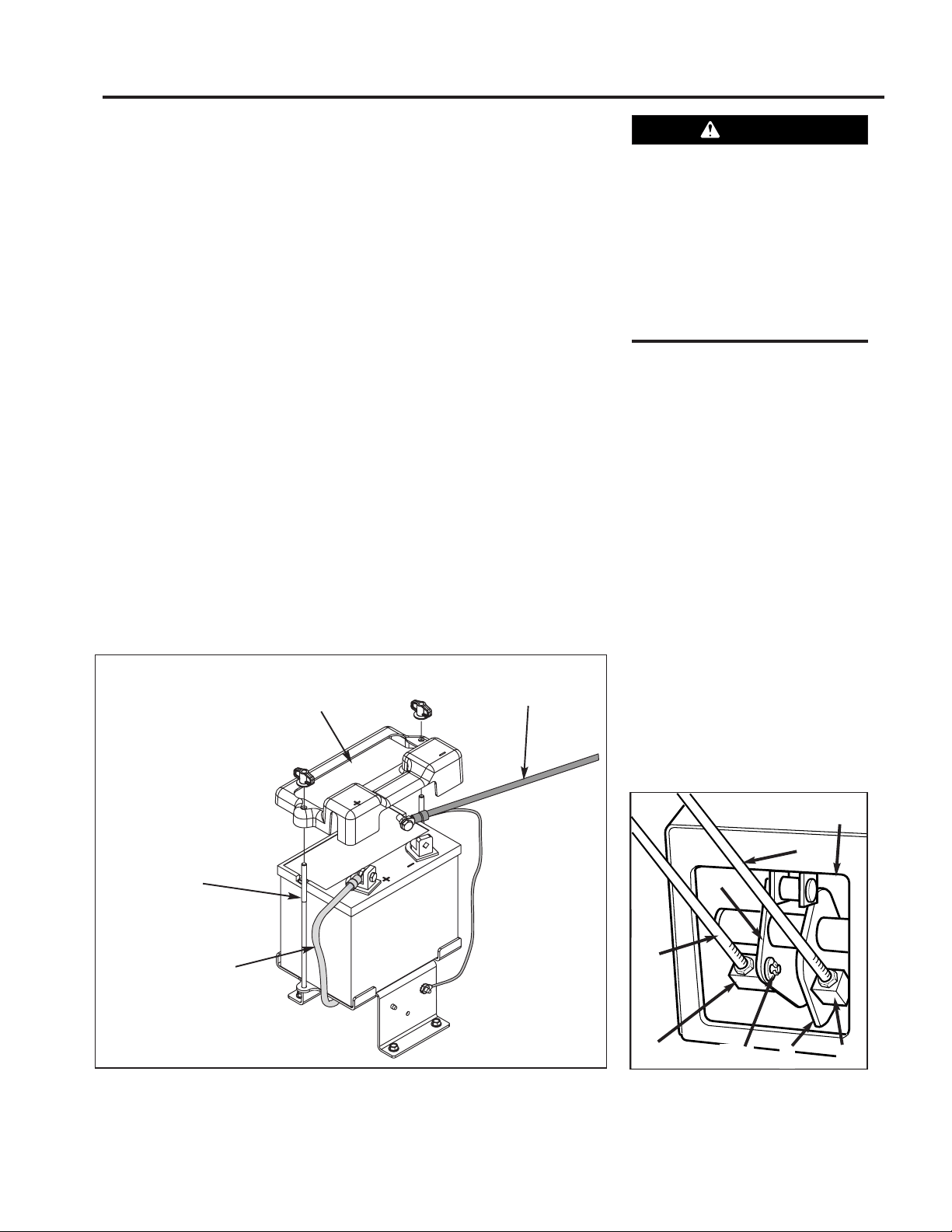

STEP 3 ATTACHING THE BATTERY

CABLES (MODEL F753B)

The positive battery terminal is marked

Pos. (+). The negative battery terminal is

marked Neg. (–).

The mower is shipped with the positive

(Red) cable secured to the positive terminal (+) on the battery. Attach the

ground (Black) cable to the negative ter-

minal (–) on the battery, as follows:

1. Remove the plastic battery cover (G,

Figure. 2-3) by unthreading the two wing

nuts (H, Figure. 2-3) which secure it to

the battery hold-down rods (I, Figure. 2-

3)

2. Remove the hex bolt and hex nut

from the ground cable / heavy black wire

(E, Figure. 2-3).

3. Secure the ground cable to the negative battery terminal (–) with the bolt and

hex nut just removed.

4. Resecure the battery cover.

IMPORTANT:

• If the battery is put into service after

the date shown on top of battery,

charge the battery as instructed in the

Maintenence section of this manual

prior to operating the mower.

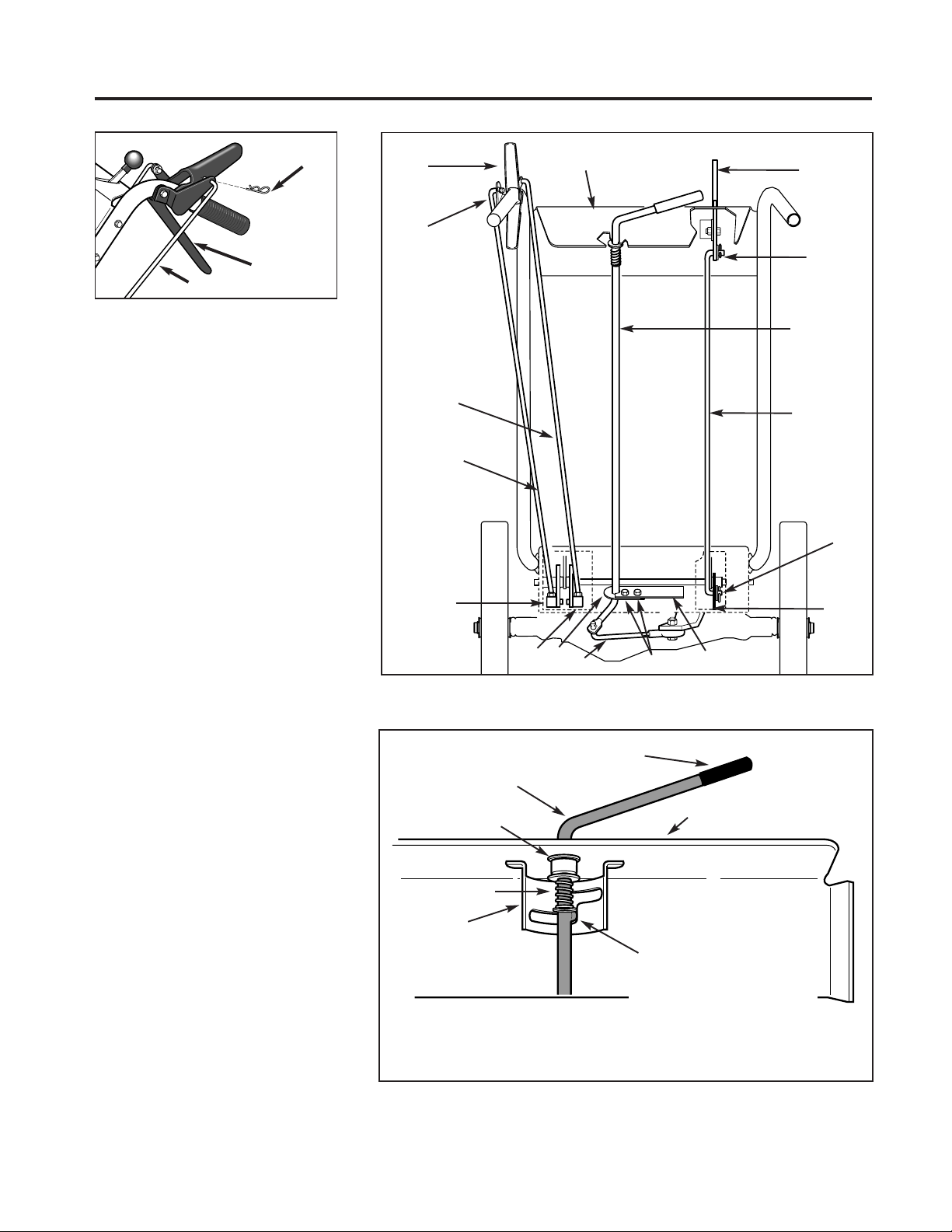

STEP 4: Attach Control Rods

A. Attach Wheel Drive Control Rod

1.

Locate the wheel drive control rod (F,

Figures 2-4A & 2-7) and remove the angled end from the left handlebar by removing the hairpin clip which secures it

to the Wheel Drive Control lever (V,

Figure 2-4A)

2. At left side of engine deck, insert

swivel block (H, Figures 2-4 & 2-5) on

wheel drive control rod into wheel drive

control arm (U, Figure 2-4).

3. Add a 5/16" washer (A, Figure 2-4)

and secure with a hairpin clip (B).

4. At upper end of control rod, re-insert

the angled end into the Wheel Drive

Control lever (V, Figure 2-4A) and reattach with hairpin clip (BB) removed

earlier.

B. Attach Operator Presence Control

Rod

1. Locate the Operator Presence Control

rod (E, Figures. 2-4 and 2-5)

. At bottom

of control rod, insert swivel block (G,

Figures 2-4 & 2-5) into control arm (T,

Figure 2-4).

2. Add one 5/16" washer and secure

with hairpin clip.

C. Attach Blade Drive Control Rod

1. Locate the blade drive control rod (C,

Figure 2-5). Insert one end of control rod

into blade drive bracket (D, Figure 2-5).

Add one 5/16" washer and attach with

hairpin clip (CC).

2. Insert the other end of rod into bottom end of Blade Drive Control lever (J,

Figure 2-5). Add one 5/16" washer and

attach with hairpin clip (AA).

D. Attach and Adjust Gear Select Lever

NOTE: The retaining plate (N, Figure 2-5)

mentioned in the following steps is secured to the rear of the mower with two

screws (O, Figure 2-5) and 1/4”-20 locknuts. Remove the retaining plate and

save it, along with the two screws, before proceeding with assembly.

Control rods are adjusted at the factory and should not require additional

adjustment during assembly. After assembling unit, control rod

adjustment should be checked (and

re-adjusted, if necessary) according to

information in Maintenance Section.

Failure to follow this instruction could

result in severe personal injury or

property damage.

Figure 2-3: Connect wire terminals to battery terminals.

H

H

G

I

Red

(Positive Cable)

Black

(Negative Cable)

Figure 2-4: Left-hand control rods detail.

F

H

E

W

G

U

A, B

T

5

WARNING

Page 8

Section 2: Assembly

1. Remove the vinyl grip (B, Figure 2-6)

from the gear select lever (I). Place the

wood edge against the edge of the grip

and slowly pull off the grip.

2. Insert nylon bushing (Z, Figure 2-6)

up into console (L).

3. Slide spring and washers (J) down

onto gear select lever.

4. Insert gear select lever (I) up through

nylon bushing (Z) in handlebar console

(L). Guide pin (K) on gear select lever into

groove in shift quadrant (P).

5. Hold lower part of gear select lever (I,

Figure 2-7) against bracket (M). Position

retaining plate (N), removed earlier, as

shown in Figure 2-7 (plate below

bracket). Secure plate with two 1/4"-20 x

1/2" screws (O) and 1/4”-20 locknuts removed earlier.

6. Slide grip (B, Figure 2-6) back onto

gear select lever (I).

7. Rotate gear select lever (I, Figures 26 & 2-7) clockwise until spur (K - short

rod) on gear select rod stops in the neutral position detent on the shift pattern

quadrant (Figure 2-6).

8. Move shift arm (X, Figure 2-7) from

side to side as necessary into each transmission gear detent until transmission is

in neutral.

NOTE: Moving shift arm (X) all the way to

the left, and then one notch back to the

right, should put transmission into neutral. When transmission is in neutral, unit

will move freely when pushed while holding the Operator Presence Control lever

(W, Figure 2-5) down. If transmission is

NOT in neutral, there will be a slight drag

on the wheels when pushing unit.

Figure 2-4A: Attach wheel drive control rod

to lever.

V

F

BB

Figure 2-5: Rear view of control rods.

G

N

P

O

H

F

E

I

C

J

AA

CC

D

L

M

V

W

Figure 2-6: Detail – Gear Select Lever in Neutral (N) position.

I

L

K

P

B

Z

Pin (K) must be in this detent

when transmission neutral is

adjusted.

J

6

Page 9

7

Section 2: Assembly

9. When shift arm (X) is in neutral position, rotate shift link (P) toward end of

gear select lever rod (I). Adjust length

of shift link (P) as necessary to fit into

hole in bottom of gear select lever (I).

NOTE: Pin (K) on Gear Select Lever (I)

must be held in the neutral position

detent on the shift quadrant (see Figure

2-6) while shift link (P, Figure 2-7) is

adjusted.

10. Insert hooked end of shift link (P,

Figure 2-7) into hole in bottom end of

gear select lever (I) and secure with

hairpin clip (Q).

NOTE: It may be necessary to lift gear

select lever (I) to install shift link (P).

11. Remove unit from shipping crate.

To remove, hold down Operator

Presence Control lever (W, Figure 2-5)

which releases the wheel brake.

12. With unit on level ground, hold

down Operator Presence Control lever

(W, Figure 2-5) and push unit forward

and backward. The wheels should move

freely. If not, adjust length of shift link

(P, Figure 2-7) as necessary.

13. Put the Gear Select Lever in neutral

(N), release all of the control levers and

try to push the unit forward and backward. The wheels should not turn. If

they do turn, an adjustment is necessary. DO NOT OPERATE THE UNIT

UNTIL THE WHEEL BRAKE MECHANISM

HAS BEEN ADJUSTED AND IS WORKING PROPERLY. See “Wheel Brake

Adjustment” in Section 5 “Maintenance.”

STEP 5: Secure Wire Harness

1. At the unattached end of the electrical

wire harness, there are four wires attached to a large plastic connector and

two wires attached to a small plastic

connector.

. Plug the large connector

into the bottom of the ignition keyswitch

that is located on the underside of the

handlebar console (not pictured).

3. Use two cable ties to secure the wire

harness to the right handlebar and away

from any moving parts. Place the ties

an equal distance apart.

STEP 6: Check Motor Oil Level

1. Move mower to a level area. Press

and hold Operator Presence Control

lever (W, Figure 2-5) to move mower.

2. The mower is shipped with oil in the

engine. However, you MUST check the

oil level according to the instructions provided in the separate Engine Owner’s

Manual included in the unit’s literature

package before starting the mower.

• Keep oil level at the FULL mark on the

dipstick to avoid engine damage.

• Change oil according to schedule and

instructions in Section 5 “Maintenance.”

STEP 7: Check Tire Pressure

1. Use a tire gauge to check the air

pressure in the rear tires. The air pressure should be between 15-20 PSI (20

PSI maximum).

2. Keep both tires equally inflated to

help prevent machine from pulling to

one side.

STEP 8: After Assembling and

Before Using Unit

1. Read this entire Owner’s Manual for

proper safety, operation and maintenance information.

2. Make sure spark plug wire is con-

nected to spark plug before starting unit.

Figure 2-7: Detail – Transmission Neutral Adjustment.

P

I

X

Y

Q

M

N

O

Do not use the mower if the wheels

continue to turn after releasing the

Operator Presence Control and the

Wheel Drive Control.

Severe personal injury or property

damage could result if this instruction

is not followed.

WARNING

Page 10

8

IMPORTANT: THE MOWER IS

EQUIPPED WITH A BLADE-BRAKECLUTCH CONTROL SYSTEM WHICH IS

DESIGNED TO STOP THE MOWER

BLADES WITHIN THREE (3) SECONDS

AFTER RELEASE OF THE OPERATOR

PRESENCE CONTROL. THIS SYSTEM

WILL STOP THE BLADES BUT NOT THE

ENGINE. THEREFORE, YOU CAN DISENGAGE THE BLADE DRIVE AT ANYTIME

WITHOUT HAVING TO STOP AND

RESTART THE ENGINE. THIS FEATURE

IS PARTICULARLY USEFUL WHEN YOU

NEED TO CROSS GRAVEL DRIVES OR

ROUGH TERRAIN AND YOU DO NOT

WANT THE SPINNING BLADES

TO STRIKE STONES OR HIDDEN

OBSTACLES.

MOWER FEATURES AND

CONTROLS

This section describes the various

features and controls on the unit. Refer

to the next section “Operation” for

detailed operating instructions. Also,

read the separate Engine Owner’s

Manual for a detailed explanation of the

proper use of the engine controls.

Operator Presence Control

The Operator Presence Control lever

(A, Figure 3-1) regulates the operation of

the rear wheel brake and the separate

Blade Drive Control. Always engage this

control before engaging the separate

blade drive or wheel drive controls.

Always disengage this control before

starting the engine.

To engage the Operator Presence

Control, press and hold the lever against

the handlebar grip. Doing so releases

the brake on the rear wheels, allowing

the wheels to turn. The engaged position

also permits the separate Blade Drive

Control to lock in its engaged position

(allows the mower blades to turn).

Releasing the lever (disengaged

position) applies the rear wheel brake

and quickly stops the wheels. Releasing

the lever will also disengage the Blade

Drive Control, which will apply a brake

that stops the blades within three (3)

seconds.

Blade Drive Control

Use this lever (B, Figure 3-1) to en-

gage drive to the mower blades.

To engage the blades, first engage the

Operator Presence Control (A, Figure 3-

1). Then, push the spring-loaded Blade

Drive Control lever (B) forward until it

stays in the engaged position.

To stop the blades, release the

Operator Presence Control (A). Doing so

will disengage the Blade Drive Control

(B) and automatically apply the brake

that stops the blades.

Always disengage the Blade Drive

Control before starting the engine. This

helps to ensure that the blades will not

start turning when the engine starts.

Before operating mower, be sure to

read all safety, controls and operating

instructions in this Manual and on

decals located on machine.

Severe personal injury or property

damage could result if this instruction

is not followed.

The blade-brake-clutch control system

should stop the mower blades within

three (3) seconds after release of the

Operator Presence Control.

If the blades do not stop within three

(3) seconds, put the Engine Throttle

Control in the STOP position.

Disconnect the spark plug wire and do

not operate the mower until the bladebrake-clutch control system has been

repaired.

B – BLADE

DRIVE CONTROL

A – OPERATOR

PRESENCE CONTROL

C – GEAR

SELECT LEVER

Disengage

Engage

Engage

Figure 3-1

Features and Controls

3

Section

Disengage

WARNING

WARNING

Page 11

9

Section 3: Features and Controls

Gear Select Lever

Use this lever (C, Figure 3-1) to select

any of four forward ground speeds (1 Slow, 2 and 3 - Medium, 4 - Fast), N

(Neutral) and R (Reverse). The gear shift

pattern is shown in Figure 3-2.

To avoid damaging the transmission, do not shift gears when the

mower is moving.

For forward travel, use one of the four

numbered settings. To select reverse,

shift to neutral and then pull up on the

lever. Turn the lever to the R (reverse)

position and release the lever.

Put the lever in N (neutral) to manually push the mower and when the

mower is not in use.

Wheel Drive Control

Use this lever (D, Figure 3-3) to engage and disengage drive to the wheels.

To engage the wheels, first select a

forward or reverse gear with the Gear

Select Lever and squeeze the Operator

Presence Control (A, Figure 3-3). Then,

squeeze the Wheel Drive Control lever

(D) against the handlebar grip. The

ground speed can be varied by increasing or decreasing pressure on the lever.

To avoid sudden acceleration, slowly

squeeze the lever when first engaging

the wheels.

Release the Wheel Drive Control to

disengage the wheels. The wheels will

gradually slow to a stop. NOTE: To stop

the wheels quickly, release the Operator

Presence Control along with the Wheel

Drive Control.

When starting the engine, the Wheel

Drive Control should be disengaged (released). This helps to ensure that the

wheels will not start turning when the

engine starts.

Cutting Height Control Lever

Use this lever (E, Figure 3-4) to adjust

the cutting height from 1 to 4 inches.

Note that actual cutting heights will vary

according to soil conditions.

Turn the lever clockwise to raise the

height or counterclockwise to lower the

height. A decal and pointer (not illus-

trated) on the right side of the mower

deck show the cutting height settings

ranging from A (highest) to G (lowest).

Mulcher Cover

The mulcher cover (F, Figure 3-5) is

pre-installed at the factory. It must be

kept in place when using the unit as a

mulching mower. The mulcher cover is

designed to keep the discharge chute

raised up while you mow. When the

cover is removed for side-discharge

mowing, the discharge chute lowers.

Refer to “4. Select Mulching or SideDischarge Mowing” in the Operation

Section for mulcher cover installation

instructions.

Figure 3-2:

Shift pattern

on console.

Operating Symbols Various symbols are used on the mower to indicate control settings (your model may not have all of the

symbols). These symbols are shown below with a description of their meaning.

FAST

SLOW

CHOKE

ENGINE

STOP

ENGINE

START

ENGINE

RUN

ENGAGE

DISENGAGE

Do not engage the Wheel Drive Control

without first engaging the Operator

Presence Control. Doing so could

result in wear or damage to the wheel

brake mechanism.

A – OPERATOR

PRESENCE CONTROL

D – WHEEL

DRIVE CONTROL

Disengage

Disengage

Engage

Engage

Figure 3-3

Figure 3-4

E – CUTTING HEIGHT

CONTROL LEVER

F

Figure 3-5

CAUTION

Page 12

10

Engine Throttle Control

This lever (G, Figure 3-6) is used to

adjust engine speeds and, on nonElectric Start models, to stop the engine.

Always run engine at fast speed setting

for best mower performance. The throttle settings are shown below.

Ignition/Starter Switch (Electric Start Model)

This three-position switch (H, Figure

3-6) is used to start and stop the

engine on electric start models. The ignition key settings are shown below. Do

not turn the key until you have read the

Operation Section in this Manual.

Always remove ignition key when

leaving mower unattended or when inspecting, cleaning or servicing mower.

Engine Recoil Starter

The recoil starter (I, Figure 3-7) is

used to “pull-start” the engine. Detailed

instructions for using the recoil starter

are found in the Operation Section of this

Manual and in the Engine Owner's

Manual. Do not pull the recoil starter

until you have read the Operation

Section.

Section 3: Features and Controls

STOP - Stops engine.

RUN - After starting, key

returns to run position.

START - Starts engine.

Release key when engine

starts.

Figure 3-6

G – THROTTLE CONTROL

H – IGNITION/STARTER

SWITCH

CHOKE

- Use when

starting a cold engine.

FAST - Use during mower

operation.

SLOW - Use when idling

engine.

STOP - Stops engine

(Non-electric Start Models

Only)

I – RECOIL

STARTER

Figure 3-7

Page 13

11

BEFORE OPERATING MOWER

1. Pre-Operation Checklist

With the spark plug wire disconnected

from the spark plug, perform the following checks and services before each use:

1. Review Section 1: “Safety” and Section

3, “Features and Controls” in this manual. Read the separate Engine Owner’s

Manual provided with the unit.

2. Check unit for loose or missing hardware. Tighten or replace as needed.

3. With the unit on level ground, check

the engine oil level according to the

instructions in the Engine Owner’s

Manual. The oil level should be at the

FULL mark on the dipstick or up to the

top of the oil fill hole on engines without a dipstick.

4. Check all levers for freedom of movement. Readjust or repair as needed

before starting engine.

5. Check that all guards and shields are

in place and properly secured.

6. Inspect the area to mowed and remove any debris which could be

picked up and thrown by the mower

blades.

7. Check that the mulcher cover is properly installed in the discharge opening

(see instructions in this Section).

Remove the mulcher cover to use the

side-discharge mowing feature.

8. On electric start models, check that

all wiring connections are clean and

tight.

9. Check the air pressure in the rear

tires (15-20 PSI). Keep tires inflated

equally.

10. Remove the fuel cap and check the

level of gasoline according to the instructions in the Engine Owner’s

Manual. Clean around fuel fill area

before removing fuel cap. Do not

check fuel level or add fuel while indoors or if engine is running or hot.

Allow engine to cool for three (3)

minutes. Fill the tank with fresh,

clean unleaded gasoline with a minimum octane rating of 77. Leave 1/2"

of space for fuel expansion. Do not

mix oil with gasoline. Do not use

gasoline which contains Methanol.

See the Engine Owner’s Manual for

instructions and precautions regarding the use of gasolines that are

blended with alcohols or ethers

(called oxygenated or reformulated

gasolines). Securely replace caps on

fuel tank and fuel container.

11. Attach spark plug wire to spark plug

after completing above checklist.

2. Set Mower Cutting Height

1. Release all controls before adjusting

the cutting height.

2. Adjust the cutting height from 1 to 4

inches by rotating the Cutting Height

Control lever (Figure 3-4) either clockwise to raise the height or counterclockwise to lower the height. Note that actual cutting heights will vary according

to grass and soil conditions. A decal and

pointer on the right side of the mower

deck indicates the height setting.

3. In heavy or tall grass, it is usually

better to make the first cut at a higher

setting and then make a second cut at

the desired height. In rough terrain, a

higher setting is recommended as it will

minimize the chances of the blade striking the ground or hidden obstructions.

Before operating mower, be sure to

read all safety, controls and operating

instructions in this Manual and on

decals located on machine.

Severe personal injury or property

damage could result if this instruction

is not followed.

GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE. To help

prevent severe personal injury or property damage:

• Follow gasoline safety rules in

Section 1: “Safety” of this Manual and

in the separate Engine Owner’s

Manual.

• Never remove the gasoline fill cap or

add fuel when indoors or when engine

is running or still hot. Allow engine to

cool at least three (3) minutes before

refueling.

• Keep smoking materials, sparks or

flames far away from fuel tank and fuel

container.

• Store gasoline in an approved fuel

container and in a well-ventilated area.

Store it safely out of the reach of children. Do not store gasoline where vapors can reach an open spark or flame

or where ignition sources are present

(such as hot water or space heaters,

furnaces, clothes dryers, stoves, electric motors, etc.).

• Fill tank to 1/2" below bottom of filler

neck to allow for fuel expansion. Wipe

up spilled gasoline immediately and

move mower away from gasoline fumes

before starting engine. Securely replace caps on fuel tank and fuel

container.

To avoid personal injury, do not adjust

cutting height while wheels or blades

are turning. Release all handlebar

controls and wait for all motion to stop

before adjusting cutting height.

Operation

4

Section

WARNING

DANGER

CAUTION

Page 14

12

3. Test Blade-Brake-Clutch

Control System

The mower is equipped with a bladebrake-clutch which is designed to stop

the mower blades within three (3)

seconds after release of the Operator

Presence Control or the Blade Drive

Control. Never tamper with, or attempt

to defeat the purpose of this safety

device.

The control system is a mechanical

device which is subject to wear.

Therefore, test the operation of the

blade-brake-clutch control system before

each use of the mower. Refer to "Blade

Brake Control Test" at the end of this

Section.

4. Select Mulching or SideDischarge Mowing

You can use the mower either as a

mulching mower or as a side-discharge

mower. To use the mulching feature, insert the mulcher cover as described

below. Remove the mulcher cover to

side-discharge grass clippings. The

mulcher cover is designed to keep the

discharge chute raised up while mowing.

When the cover is removed, the discharge chute will lower itself for sidedischarge mowing.

To install or remove mulcher cover:

1. Stop the engine and wait for all parts

to stop moving. Disconnect the spark

plug wire from the spark plug. Remove

the ignition key on electric start models.

2. To install the cover, insert the rightside tab of the cover into the front support bracket (A, Figure 4-1). Insert the

cover into the discharge opening, making sure that the slot (B) in the left side

of the cover is completely engaged in the

rear edge of the deck opening.

3. To remove the cover, slide the cover

to the right (front of mower) to disengage the slot (B) from the mower deck

and then pry the left-side of the cover

out and off.

MOVING THE MOWER WITHOUT

ENGINE POWER

The mower can be manually pushed

or pulled by putting the Gear Select

Lever (C, Figure 4-2) in N (neutral) and

pressing and holding the Operator

Presence Control (A, Figure 4-2) down

against the handlebar grip.

To stop the wheels at anytime,

release the Operator Presence Control.

STARTING AND STOPPING

THE ENGINE

To Start the Engine

1. Move mower to a level area.

2. Release all controls on mower to pre-

vent wheels or mower blades from rotating when engine starts.

3. Move Engine Throttle Control (E,

Figure 4-2) fully upward to choke setting

to start a cold engine or to fast (rabbit)

setting to start a warm engine.

Section 4: Operation

Before installing or removing mulching

cover, stop engine, wait for parts to

stop moving, and disconnect spark plug

wire. Remove ignition key on electric

start models.

To avoid injury:

• Keep hands and feet clear of mower

blades or other rotating parts.

• Look behind you to be sure there are

no obstacles before pulling recoil

starter rope.

Figure 4-1: Mulcher cover

B

A

Figure 4-2: Mower Controls

A – Operator

Presence Control

B – Blade Drive

Control

C – Gear Select Lever

D – Wheel Drive Control

E – Engine Throttle

Control

F – Ignition/Starter

Do not operate the engine in an

enclosed area. Engine exhaust

contains carbon monoxide, a deadly

gas that is odorless, colorless and

tasteless. Always run engine outdoors

and make sure there is adequate

ventilation.

WARNING

DANGER

WARNING

Page 15

Section 4: Operation

4. To start engine using recoil starter:

A. Stand on left side (as viewed from

behind handlebars) of machine. Be

sure your feet are safely away from

the underside of the mower deck and

all mower controls are released.

Place one foot on top of tire.

B. Grasp starter rope handle (Figure 3-

7) and pull slowly until rope pulls

slightly harder. Let rope rewind

slowly. Then pull rope with a rapid,

full arm stroke. Let rope return

slowly. If engine fails to start after

three pulls, repeat instructions starting with Step 2 (try setting throttle at

fast setting).

C. When engine starts, operate in fast

throttle setting (move throttle from

choke setting to fast setting).

5. To start engine using electric starter:

A. Stand behind the handlebars and re-

lease all mower controls.

B. Turn ignition key (F, Figure 4-2) fully

clockwise to crank engine. To avoid

damage to starter motor, do not

crank engine for longer than five seconds at a time. Also, allow 15 seconds between each start attempt. If

engine fails to start after three attempts, repeat instructions starting

with Step 2 (try setting throttle at fast

setting).

C. When engine starts, release key and it

will return to the run (middle) position.

D. Operate engine at fast throttle setting

(move throttle from choke setting to

fast setting).

NOTE: If the electric start system is not

functioning, the engine can be started

with the recoil starter. To do so, first put

the ignition key in the run (middle) position. Then follow Steps 1-4 above.

Leave the key in the run position during

engine operation.

To Stop the Engine

1. Release all mower controls to stop

wheels or mower blade.

2. Move throttle control down to slow

(turtle) position. (Whenever possible,

gradually reduce engine speed before

stopping engine.)

3. Move Throttle Control all the way

down to stop position (Non-electric Start

Models Only) or turn ignition key (electric start models) fully counterclockwise

to stop position.

4. On electric start models, remove the

ignition key before leaving the mower

unattended.

ENGAGING THE BLADES

To Engage the Blades

1. Start engine as described in “To Start

the Engine” instructions. Put engine

throttle in fast speed setting.

2. Press and hold Operator Presence

Control (A, Figure 4-2) against handlebar grip.

3. Slowly push Blade Drive Control (B,

Figure 4-2) fully forward until it stays in

the engaged position. The blades are

now rotating.

To Stop the Blades

To stop the blades, release the Operator

Presence Control.

TO ENGAGE THE WHEELS

1. Start engine as described in “To

Start the Engine” instructions.

2. FOR FORWARD TRAVEL:

A. Press and hold Operator Presence

Control (A, Figure 4-2) against handlebar grip.

B. Put the Gear Select Lever (C, Figure

4-2) into one of the numbered settings (1 - Slow, 2 and 3 - Medium, 4

- Fast). When first practicing with

the mower, put lever in No. 1 setting.

Select forward speeds according to

mowing conditions and terrain. Use

slower speeds on rough terrain or

when grass is heavy or thick. The

forward speed can be increased on

smooth terrain or if the grass cover

is light. Allow the wheels to stop

completely before shifting from one

forward speed into another.

C. To start the wheels, slowly squeeze

the Wheel Drive Control (D, Figure 4-

2). The harder you squeeze, the

faster the wheels will turn. To avoid

sudden acceleration, slowly squeeze

the lever.

D. TO STOP THE WHEELS:

• To stop drive power to the wheels,

release the Wheel Drive Control. The

wheels will gradually slow to a stop.

• To quickly stop the wheels, release

both the Wheel Drive Control and

the Operator Presence Control.

3. FOR REVERSE TRAVEL:

A. Stop the mower blades and wheels by

releasing the Operator Presence

Control (A, Figure 4-2).

B. Press and hold Operator Presence

Control against handlebar grip.

To avoid injury from rotating blades,

keep face, hands and feet clear of

mower blades at all times.

To avoid injury or property damage:

• Look behind the mower before

and during reverse operation.

• Stop the mower blades before operating in reverse.

Before engaging the Wheel Drive Lever

for the very first time, check that the

neutral (N) position on the Gear Select

Lever is properly adjusted. See

“Neutral Adjustment” in Section 5:

Maintenance for the procedure to

follow.

Failure to follow this instruction could

result in personal injury or property

damage.

• To avoid damaging the transmission,

do not shift gears while in motion.

• To avoid damaging the wheel brake

mechanism, do not engage the Wheel

Drive Control without first engaging the

Operator Presence Control.

13

DANGER

CAUTION

WARNING

WARNING

Page 16

Section 4: Operation

C. Put the Gear Select Lever (C, Figure

4-2) in R (reverse) setting by first

moving lever to N (neutral). Then

pull lever up, turn it to R position,

and release lever.

D. To start the wheels, slowly squeeze

Wheel Drive Control (D, Figure 4-2).

To avoid sudden acceleration, slowly

squeeze the lever.

E. TO STOP THE WHEELS:

• To stop drive power to the wheels,

release the Wheel Drive Control. The

wheels will gradually slow to a stop.

• To quickly stop the wheels, release

both the Wheel Drive Control and

the Operator Presence Control.

• Return the Gear Select Lever to the

N (neutral) position when you have

completed reverse operation. Allow

the wheels to stop completely before shifting from R (reverse) into a

forward speed.

The mower turns easily by pushing

the handlebars in the opposite direction

that you want to turn. The differential

mechanism inside the transaxle will

allow the inside turning wheel to stop or

slow down while the outside turning

wheel is powered by the drive system.

Reduce the wheel speed before turning the mower. For tight turns, disengage the Wheel Drive Control and manually push the mower through the turn (if

needed, put the Gear Select Lever in

neutral so the wheels turn freely).

MOWING TIPS AND HINTS

Mow When

Lawn Is Dry

For best results, avoid cutting grass

when it is wet. Wet grass tends to form

clumps which interfere with the cutting

action. The best time to mow is in the

late afternoon or early evening when the

grass is usually dry.

Cut Top 1/3 of

Grass Blades

Cutting more than 1/3 of grass length

may cause the grass to become excessively dry. In tall grass, it may be necessary to mow at a higher setting and then

mow again at the desired height. NOTE:

The cutting height is critical to achieving

a well-groomed lawn. You should experiment with various settings to find that

“just right” cutting height.

Vary Cutting Pattern

Vary the cutting pattern from week to

week to help prevent matting of the

grass. One week, mow from north to

south, the next week mow from east to

west. Overlap several inches when

mowing to obtain an even appearance.

Mowing on Slopes

Do not mow excessively steep slopes

(see WARNING statement that follows).

Slow down and exercise extreme caution

when changing direction on slopes.

Before mowing on slopes, check the engine oil level and make sure that the level

is at the FULL mark. Maintaining a FULL

oil level is particularly important when

operating on slopes as oil can be drained

away from vital engine parts.

Mulching Leaves

• The mower can be used to mow fallen

leaves. The leaf particles filter down into

the lawn and provide added fertilizer.

• The leaves must be dry in order to be

mulched.

• Use a slower ground speed if the

leaves are not mulched into fine particles.

• If you mulch oak leaves (which add acid

to the soil), add lime to the lawn in the

spring to reduce the acidity of the soil.

Keep Mower Blades Sharp

For best mower performance, keep the

blades sharp. Dull blades will tear,

bruise and split the ends of grass. See

blade sharpening instructions in Section

5: Maintenance.

Clean Mower Frequently

Clean the underside of the mower deck

frequently to remove grass build-up.

See mower cleaning instructions in

Section 5: Maintenance.

Precision Trimming

For precision trimming, use the slowest gear and inch the mower along by

“feathering” the Wheel Drive Control

lever. Or, disengage the wheel drive by

releasing the Wheel Drive Control so that

you can manually maneuver the mower

(if needed, put the Gear Select Lever in

neutral so that the wheels turn freely).

MAKING TURNS

1

3

To avoid injury or property damage:

• Before mowing, thoroughly inspect

area where mower is to be used and

remove all stones, sticks, wires,

bones, nails and other foreign objects.

• Disengage mower blades before

crossing gravel drives, roads, or sidewalks to prevent blades from throwing

stones or other hazardous objects.

To avoid injury or property damage:

• Maximum safe operating angle

is 15

o

.

• Exceeding maximum safe operating

angle may cause tipping or loss of

footing.

• Do not mow wet slopes.

• Mow across slopes, not up and down.

• Exercise extreme caution when

changing direction on slopes.

14

WARNING

WARNING

Page 17

15

Section 4: Operation

BLADE BRAKE CONTROL TEST

When the Operator Presence Control

is released during operation of the

mower, the engine does not stop, but

the blades should stop within three (3)

seconds. The following test provides a

visual test of whether the Blade Brake

Control System is functioning. Perform

this test before each use of the mower.

1. Park mower on a portion of lawn

which has not been recently mowed.

2. Set the cutting height so the mower

cuts 1/3 of the grass height.

3. Start the engine.

4. Press the Operator Presence Control

down against the handlebar grip and

push the Blade Drive Control fully forward until it stays in the engaged position.

5. Put the Gear Select Lever in the No. 1

setting.

6. Engage the wheels with the Wheel

Drive Control and drive the mower for

several feet. Then release the Operator

Presence Control.

A. Look at the lawn just mowed. The

lawn should be cut up to the point

where the Operator Presence Control

was released.

B. Press the Operator Presence Control

against the handlebar grip but DO

NOT re-engage the Blade Drive

Control. Drive the mower forward

for several more feet. Release the

Operator Presence Control and look

at the lawn. The grass should NOT

have been cut. This indicates that

the Operator Presence Control has

disengaged the blade drive and

stopped the blades.

7. If the mower cuts the grass in Step

6-B, the Operator Presence Control is

NOT disengaging the blade drive.

Immediately stop the engine, disconnect the spark plug wire, and move the

wire away from the spark plug.

8. Do not use the mower until the Blade

Brake Control System has been inspected, adjusted or repaired by an authorized dealer.

To avoid personal injury or property

damage, make sure that the mower is

on grass, and that the test area is clear

of foreign objects and bystanders before you begin the Blade Brake Control

Test.

If the Operator Presence Control or the

Blade Drive Control are not adjusted

correctly, the blades may continue to

rotate after release of the Operator

Presence Control. If the blades do not

stop within three (3) seconds of release

of the Operator Presence Control, move

the Engine Throttle Control to the STOP

position, disconnect the spark plug

wire, and move the wire away from the

spark plug. Do not operate the mower

until the Blade Brake Control System

has been repaired.

Failure to do this could result in personal injury or property damage.

WARNING

Page 18

Carefully read this Section on mower

and engine maintenance and service.

Performing the required maintenance

according to schedule will ensure the

proper performance and long life of your

machine.

NOTE: All references to left, right, front

and rear of the machine are determined by

standing behind the handlebars and facing

the direction of forward travel.

IMPORTANT: REFER TO

MAINTENANCE CHART IN THIS

SECTION FOR A LISTING OF REGULARLY SCHEDULED MAINTENANCE

PROCEDURES.

ENGINE SERVICE

Routine engine service is described

below. For more complete engine service information, refer to the engine

manual provided with your machine.

For complete engine service, contact an

authorized engine dealer.

ENGINE OIL

OIL LEVEL: With mower on level

ground, the engine oil level must be between the "ADD" and "FULL" marks on

the dipstick at all times. Check before

each use and every 5 operating hours.

OIL CHANGE: On a new engine, change

oil after first 2 hours of use, then change

oil regularly as specified on the

Maintenance Chart. Refer to Engine

Owner's Manual for oil capacity.

OIL TYPE: Use clean, high quality detergent oil having an A.P.I. service classification of SE, SF or SG. Use no special

additives with oil. Refer to the Engine

Owner’s Manual for recommended SAE

viscosity grades that match the starting

temperature anticipated before the next

oil change.

Checking Oil Level:

1. Park machine on level ground.

2. Stop engine, wait for parts to stop

moving, and disconnect spark plug

wire.

3. Clean area around dipstick (Z, Figure

5-1) to prevent dirt from entering oil fill

hole.

4. Remove dipstick. Oil level must be

between “ADD” and “FULL” marks. Do

not exceed “FULL” mark on dipstick.

5. To add oil, pour slowly into dipstick

opening. While adding, check oil level

frequently by securely replacing dipstick

and removing to read oil level. Wipe dipstick clean each time oil level is

checked.

6. After filling to “FULL” mark, securely

replace dipstick.

Changing Oil:

Change oil while engine is still warm

from recent operation. Warm oil flows

more freely and carries away more impurities.

1. Stop engine, wait for parts to stop

moving, and disconnect spark plug

wire.

2. Remove dipstick (Z, Figure 5-1).

3. Remove protective cap (A, Figure 5-

2) to expose oil drain port (B).

4. Push oil drain hose (D) (included in

hardware bag with unit) onto oil drain

port. Route other end of hose to an appropriate oil collection receptacle.

5. Twist oil drain fixture (C) to the open

position. Pull out. Drain oil completely.

6. Push in and twist oil drain fixture to

the closed position. Remove drain

hose. Replace protective cap (A).

7. Refill engine with fresh oil and securely replace dipstick.

NOTE: Please dispose of all waste materials in an ecologically responsible manner. Use proper waste material storage

containers.

Before inspecting, cleaning or servicing

the machine, shut off engine, make

sure that all moving parts have come to

a complete stop, disconnect spark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failure to follow these instructions can

result in personal injury or property

damage.

Figure 5-1: Briggs and Stratton engine oil

fill.

Z

Figure 5-2: Oil drain.

C

A

B

D

Maintenance

5

Section

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

16

WARNING

WARNING

Page 19

17

Section 5: Maintenance

ENGINE CLEANING

• Stop engine, wait for parts to stop

moving, disconnect spark plug wire,

and allow engine to cool before inspecting or cleaning engine.

• Daily or more often, before running engine, remove grass and chaff from recoil

finger guard or rotating screen to prevent

engine damage caused by overheating.

Also keep cooling vanes, governor linkage, springs and controls free of debris.

• Daily or more often, before running engine, clean muffler area (be sure muffler

is cool) to remove all grass and combustible debris. If engine is equipped

with a spark arrestor screen, remove assembly every 50 hours for cleaning and

inspection. Replace if damaged.

• Grass or chaff may clog engine's air

cooling system, especially after prolonged operation cutting tall, dry grass.

See Engine Owner's Manual for instructions on cleaning underneath the engine

blower housing.

AIR CLEANER SERVICE

Improper air cleaner maintenance can

cause engine damage. Refer to the

Engine Owner's Manual for more complete air cleaner service information.

SERVICE SCHEDULE:

Outer foam pre-cleaner - wash and re-oil

every 25 operating hours or every season, whichever occurs first.

Inner paper cartridge - clean or replace

every 100 operating hours or every season, whichever occurs first.

To Service Air Cleaner (Figure 5-3):

1. Stop engine, wait for parts to stop

moving, and disconnect spark plug

wire.

2. Unscrew mounting screws and/or remove knobs (D). Remove covers (E).

Remove paper cartridge (B) and foam

pre-cleaner (A). Separate foam precleaner from paper cartridge.

3. Wash foam pre-cleaner (A) in liquid

detergent and warm water. Squeeze dry

in a clean cloth.

4. Saturate foam pre-cleaner in clean

engine oil. Wrap in clean, absorbent

cloth and squeeze to remove all excess

oil.

5. Replace paper cartridge (B), if

necessary.

6. Reassemble air cleaner components.

Tighten knobs/screws (D) securely.

Secure cover assembly (E) on air

cleaner body.

SPARK PLUG

Inspect the spark plug (Figure 5-4) after

every 100 hours of operation. Be sure

the gap is set at .030". Do not reuse plug

if it is severely worn or damaged.

Best results are obtained with a new

plug. See Engine Owner's Manual to determine proper replacement plug. Use

of incorrect plug can cause engine damage.

NOTE: Do not clean spark plug in machines which use abrasive grit. Clean

spark plug by scraping or wire brushing,

or washing with a commercial solvent.

BATTERY (if applicable)

Charge battery if unit is to be stored for

longer than three weeks. During the

mowing season, the battery is kept

charged by the charging system on the

engine.

To Charge Battery:

1. Plug charger connector into wire harness connector located below ignition

switch in handlebar console.

2. Plug charger into 120V wall outlet.

(Note that battery charger is designed for

use indoors and should not be exposed to

rain or snow.)

3. Charge battery for 24-48 hours if unit

is to be stored for longer than three

weeks.

4. After charging, unplug charger from

outlet, then unplug charger from connector on wire harness located below

handlebar console.

CARBURETOR

The carburetor is adjusted at the factory.

It should not need to be reset. If black

exhaust is noted, check the air cleaner

first. An over-rich mixture is usually

caused by a poorly serviced or clogged

air cleaner element, not an improperly

adjusted carburetor. If readjustment is

necessary, refer to Engine Owner's

Manual or contact your engine dealer.

Figure 5-3: Briggs and Stratton air cleaner

assembly.

E

D

B

A

Figure 5-4: Spark plug.

Charge battery only with charger supplied with machine. Do not short circuit

battery wires. Remove any jewelry before working on or near the battery or

electric start system. Failure to follow

these instructions could result in personal injury or property damage.

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

.030" Feeler Gauge

WARNING

Page 20

18

ENGINE STORAGE

If engine will be unused for 30 days or

more, prepare it for storage by following

the recommended procedures found in

the Engine Owner’s Manual.

MOWER SERVICE

The following maintenance/repair procedures can be performed by either the

owner or an authorized service dealer.

See an authorized service dealer for

complete mower service.

TIPPING MOWER FOR SERVICE

When servicing the underside of the

mower for any reason, the mower

should only be tipped backward on its

rear wheels (and securely propped up to

prevent it from falling). Tipping the

mower forward or to either side could

result in damage to engine.

TIP: Before tipping mower, install a

small plastic sandwich style bag under

the gas cap and tighten securely. This

will virtually eliminate any fuel seepage

from the cap.

Be sure to remove the

plastic bag before re-using mower.

BELT COVER REMOVAL

The belt cover must be removed to perform several maintenance procedures.

To Remove Belt Cover:

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Remove four screws (R, Figure 5-5)

and remove cover.

To Reinstall Belt Cover:

1. Position belt cover in place.

2. Secure with the four screws removed

earlier.

BLADE SPINDLE BELT

REPLACEMENT

Follow this procedure to remove and replace the blade spindle drive belt (remove blade drive belt first; see “Blade

Drive Belt Replacement” in this Section).

1. Stop engine, wait for all parts to

stop moving and disconnect spark plug

wire.

2. Remove belt cover (see “Belt Cover

Removal”).

3. Align sight holes (O, Figure 5-6) in

pulley with spindle housing-to-mower

deck mounting bolts (L).

4. Loosen screw (J) and rotate arm (K)

to the rear.

5. Loosen four mounting bolts (L) securing spindle housing (beneath mower

deck) to mower deck.

6. Slide spindle housing (with pulley attached) toward center.

7. Replace belt (N) with new belt.

IMPORTANT: SET BLADES PERPEN-

DICULAR (90°) TO EACH OTHER.

8. Rotate arm (K) to move spindle

housing and apply tension to belt. Belt

cogs and pulley grooves must mesh together. When applying moderate finger

tension (8-12 lbs.), belt should deflect

approximately 1/2” (12.7 mm) at (P),

midpoint of deck.

9. Tighten bolts (L) to 15 ft.-lbs. (20.3

Nm). Tighten screw (J).

10. Blades must not contact deck.

Check and readjust as needed.

11. Reinstall blade drive belt and belt

cover (removed earlier).

Section 5: Maintenance

Before servicing underside of mower,

stop engine, wait for all parts to stop

moving, and disconnect spark plug

wire. Remove ignition key from

keyswitch on electric start models.

Failure to follow this instruction could

result in personal injury or property

damage.

Do not operate unit without belt cover

installed. Failure to follow this instruction could result in personal injury or

property damage.

Figure 5-5: Belt cover removal.

R

BLADES

MUST BE PERPENDICULAR

TO EACH OTHER

FRONT

Figure 5-6: Blade Spindle Belt.

N

P

J

O

M

L

K

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

WARNING

WARNING

Page 21

19

Section 5: Maintenance

BLADE DRIVE BELT

REPLACEMENT

Follow this procedure to remove and replace the blade drive belt. An assistant

will be needed.

To Remove Belt:

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Disengage blade drive control (Figure

5-7) by releasing all controls on the

mower.

3. Remove belt cover (see “Belt Cover

Removal”).

4. Loosen belt guides (B and C,

Figure 5-8).

5. Move flap bracket (N, Figure 5-8) out

of the way by loosening two screws (M).

6. Remove belt (A, Figure 5-8) from

around sheaves.

To Install Belt:

1. Route belt (A, Figure 5-8) around

sheaves as shown.

2. Have an assistant hold down

Operator Presence Control and then

push the Blade Drive Control forward

until it latches in place (Figure 5-7).

3. With the Blade Drive Control lever engaged, adjust and tighten belt guide (B)

to 1/32 - 1/16" away from tensioned

belt. (Be sure that belt does not contact

belt guide when belt is under tension.)

Secure belt guide (C) rotated into position as shown in Figure 5-8.

4. Disengage Blade Drive Control.

5. Re-tighten two screws (M, Figure

5-8) that secure flap bracket (N).

6. Reinstall belt cover securely.

Figure 5-7: Blade Drive Control.

RIGHT VIEW

Blade Drive Disengaged

Blade Drive Engaged

A

Figure 5-8: Blade drive.

B

J

C

I

H

G

K

L

A

X

M

M

N

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

Page 22

20

Section 5: Maintenance

BLADE BRAKE REPLACEMENT

Follow this procedure to install a new

blade brake.

To Remove Blade Brake:

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Remove belt cover as described in

“Belt Cover Removal” instructions.

3. Remove hardware (G, Figure 5-8)

securing blade brake (H).

4. Remove old brake (H) from idler

arm (I).

To Install Brake:

1. Position new brake (H) in place on

idler arm (I).

2. Center brake in sheave groove and

secure brake (H) with hardware (G) removed earlier.

3. Reinstall belt cover securely.

4. Test operation of blade brake (see

“Blade Brake Control Test” in Operation

section).

BLADE DRIVE BELT

ADJUSTMENT

If the blade drive belt is slipping due to

lack of belt tension, follow the steps

below.

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Remove belt cover as described in

“Belt Cover Removal” instructions.

3. With mower on level ground, adjust

blade cutting height at about 3" (measure from ground to flat portion of

blade).

4. With the Blade Drive Control (Figure

5-7) in the disengaged position, set a

gap of 1/8" between the spring (F, Figure

5-9) and flat washer (E) by adjusting the

nut (D).

5. Reinstall the belt cover securely.

6. Test the operation of the blade brake

(see “Blade Brake Control Test” in the

Operation section).

7. If the drive belt slips during operation, it may be necessary to

relocate idler (J, Figure 5-9) in the slot

provided in the mounting bracket. With

the engine stopped and the spark plug

wire disconnected,

loosen the hardware

on the idler (J) and slide it forward to

take up slack in the belt.

8. Engage the blade drive and measure

the distance (X, Figure 5-8) between the

centers of pulleys (K) and (L). The distance should be 5-1/2 to 5-5/8". After

obtaining the correct dimension, reinstall the belt cover securely and test the

operation of the blade brake.

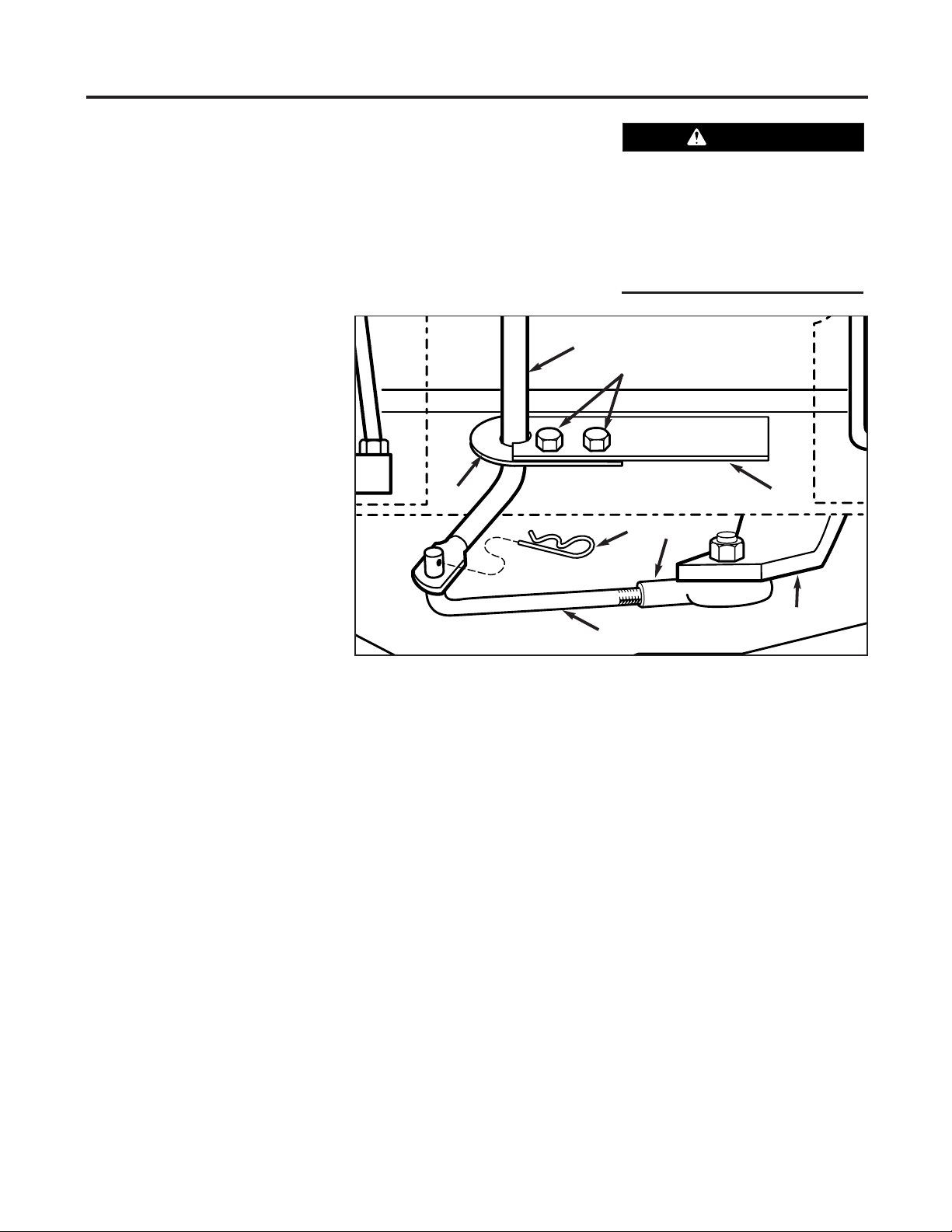

BLADE DRIVE CONTROL LEVER

ADJUSTMENT

Make the following adjustment if the

Blade Drive Control Lever releases during operation.

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Engage the Operator Presence

Control and the Blade Drive Control.

Without releasing the controls, look inside the cutout at the rear of the frame

and make sure the Operator Presence

Control latches (A and B, Fig. 5-10) are

fully engaged at point (C). If they are not

fully engaged, improper operation or

premature wear could result. To adjust,

loosen hex nut (D) and shorten length of

control rod (E). To avoid over-adjusting,

turn rod only 1 to 2 turns per adjustment.

3. Tighten hex nut securely after adjusting control rod.

4. Test by releasing the Operator

Presence Control. If properly adjusted,

the Blade Drive Control will disengage

when the Operator Presence Control is

released. Re-adjust as necessary by

repeating Steps 2 and 3.

Figure 5-9: Blade drive adjustment.

J

D

E

F

Adjust idler in direction

of arrow to tighten blade

drive belt

Figure 5-10: Blade Drive Control Lever

adjustment.

B

E

D

A

C

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

1/8"

Page 23

21

Section 5: Maintenance

WHEEL DRIVE BELT

REPLACEMENT

Follow this procedure to replace the

wheel drive belt.

1. Stop engine, wait for all parts to

stop moving, and disconnect spark

plug wire.

2. Release all mower controls.

3. Remove belt cover as described in

“Belt Cover Removal” instructions.

4. Locate wheel drive belt (O, Figure 5-

11) and remove it from top sheave of

engine sheave, backsided idlers (P and

Q) and transmission sheave (R).