Page 1

Operator’s Manual

Rear-tine Tiller

654J—Thoroughbred

D

0

7

7

4

9

A

C

™

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered or

grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine

authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO.

769-01146.fm

(3/17/2004)

Page 2

TABLE OF CONTENTS

Content Page

Customer Support 2

Safety 3

Assembly 6

Features and Controls 9

Operation 11

Content Page

Maintenance and Adjustments 15

Off-season Storage 21

Troubleshooting 22

Parts List 23

Warranty Information Back Cover

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new rear-tine tiller. It will help you assemble, prepare and maintain

the unit for best performance. Please r ead and understand wh at it says.

Before you start assembling your new equipment, please locate the mod el plate on th e equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by standing behind the unit and looking down at re ar surface of the tine shield. This

information will be necessary to use the manufacturer’s web site and/or help from the Customer Support

Department or an authorized service dealer.

Copy the model number here:

www.troybilt.com

TROY-BILT LLC

P. O. BOX

361131

CLEVELAND, OH 44136

330-558-7220

1-800-520-5520

Copy the serial number here:

CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from where it was purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the op tions below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

The answer you are

looking for could be just

a mouse click away!

If you prefer to reach a Customer Support Representat ive, please call 1(800) 520-5520.

The answer you are

looking for could be just

a mouse click away!

Engine

Manual

The engine manufa cturer is responsible for all engin e-related issues with regard s to

performance, power-rating, specifications, wa rranty and service. Please refer to the engine

manufacturer’s Owner’s/Operator’s Manua l, packed separately with your unit, for more

information.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instr uctions may result in persona l

injury. When you see this symbol—heed its warning.

DANGER: This machine was built to be operated according to the rules for safe operation in this man-

ual. As with any type of power equipme nt, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

California Proposition 65 Warning:

WARNING: Engine exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm.

Training

1. Carefully read this Operator’s Manual, the separate

Engine Owner/Operator’s Manual, and any ot her

literature you may receive. Be thoroughly familiar

with the controls and the proper use of the tiller and

its engine. Know how to stop the unit and

disengage the controls quickly.

2. Never allow children to operate the tiller. Never

allow adults to operate the tiller without proper

instruction.

3. Keep the area of operation clear of all persons,

particularly children and pets.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people, their property, and themselve s.

Preparation

1. Thoroughly inspect the area where the tiller is to be

used and remove all foreign objects.

2. Be sure all control levers are released before

starting the engine.

3. Do not operate the tiller without wearing adequate

outer garments. Avoid loose garments or jewe lry

that could get caught in moving parts.

4. Do not operate the tiller when barefoot or wearing

sandals, sneakers, or light footwear. Wear

protective footwear that will improve footing on

slippery surfaces.

5. Do not till near underground electric cables,

telephone lines, pipes or hoses. If in doubt, contact

your telephone or utility company.

6. Never make adjustments when engine is running

(unless recommended by the Engine

manufacturer).

WARNING: Handle fuel with care; it is highly flammable

and its vapors are explosive. Take the following precautions:

a. Store fuel in containers specifically de signed

for this purpose.

b. The gas cap shall never be removed or fuel

added while the engine is running. Allow the

engine to cool for several m inutes before

adding fuel.

c. Keep matches, cigarettes, cigars, pipes,

open flames, and sparks away from the fuel

tank and fuel container.

d. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Use a funnel or

spout to prevent spillage.

e. Replace all fuel tank and container ca ps

securely.

f. If fuel is spilled, do not attempt to start the

engine, but move the machine away from the

area of spillage and avoid creating any

source of ignition until fuel vapors have

dissipated.

Operation

1. Do not put hands or feet near or under rotating

parts.

2. Exercise extreme caution when on or crossing

gravel drives, walks, or roads. Stay alert for hid den

hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop th e engine,

thoroughly inspect the machine for an y damage,

and repair the damage before rest arting and

operating the machine.

4. Exercise caution to avoid slipping or falling.

5. If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

6. Stop the engine before unclogging the tines, or

when making any repairs, adjustments or

inspections.

7. Take all possible precautions when leaving the

machine unattended. Stop the engine and mo ve

the Wheel Shift Lever to FORWARD.

3

Page 4

8. Before cleaning, repairing, or inspecting, stop the

engine and make certain all moving parts have

stopped.

9. Always keep the tiller’s rear tine shield down.

10. Never use the tiller unless proper guards, pla te s , o r

other safety protective devices are in place.

11. Do not run engine in an enclosed area. Engine

exhaust contains carbon monoxide gas, a deadly

poison that is odorless, colorless, and tast eless.

12. Keep children and pets away.

13. Be aware that the tiller may unexpectedly bounce

upward or jump backward if the tines should strike

extremely hard packed soil, frozen ground, or

buried obstacles like large stones, roots, or stumps.

If in doubt about the tilling conditions, always use

the following operating precautions to assist you in

maintaining control of the tiller:

a. Walk behind and to one side of the tiller,

using one hand on the handlebars. Relax

your arm, but use a secure hand grip.

b. Use slower engine speeds.

c. Clear the tilling area of all large stones, roots

and other debris.

d. Avoid using downward pressure on

handlebars. If need be, use slight upward

pressure to keep the tines from digging too

deeply.

e. Before contacting hard packed soil at the e nd

of a row, reduce engine speed and lift

handlebars to raise tines out of the soil.

f. In an emergency, stop tines and wheels by

releasing the Wheel Engagement Handle.

Do not attempt to restrain the tiller.

15. Do not overload the tiller’s capacity by attempting to

till too deeply at too fast a rate.

16. Never operate the tiller at high transport speeds on

slippery surfaces. Look behind and use care when

backing up.

17. Do not operate the tiller on a slope that is too steep

for safety. When on slopes, slow down and make

sure you have good footing. Never permit the tiller

to freewheel down slopes.

18. Never allow bystanders near the unit.

19. Only use attachments and accessories that are

approved by Troy-Bilt LLC.

20. Never operate the tiller without good visibility or

light.

21. Never operate the tiller if you are tired, or under the

influence of alcohol, drugs or medication.

22. Operators shall not tamper with the enginegovernor settings on the machine; the governor

controls the maximum safe operating speed to

protect the engine and all moving parts from

damage caused by overspeed. Authorized service

shall be sought if a problem exists.

23. Do not touch engine parts which may be hot from

operation. Let parts cool down

24. Please remember: You can always stop the tines

and wheels by releasing the Wheel Engagement

Handle.

25. Use extreme caution when reversing or pulling the

machine towards you.

26. Start the engine carefully according to instructions

and with feet well away from the tines.

27. Never pick up or carry a machine while the engine

is running.

Maintenance and Storage

1. Keep the tiller, attachments and accessories in safe

working condition.

2. Check all nuts, bolts, and screws at frequent

intervals for proper tightness to be sure the

equipment is in safe working condition.

3. Never store the tiller with fuel in the fuel tank inside

a building where ignition sources are present such

as hot water and space heaters, furnaces, clothes

dryers, stoves, electric motors, etc.). Allow engine

to cool before storing in any enclosure.

4. To reduce the chances of a fire hazard, keep the

engine free of grass, leaves, or excessive grease.

5. Store gasoline in a cool, well-ventilated area, safely

away from any spark- or flame-producing

equipment. Store gasoline in an approved

container, safely away from the reach of children.

6. Refer to the storage instructions in the

Maintenance section of this Manual and the

separate Engine Owner’s Manual for inst ructions if

the tiller is to be stored for an extended period.

7. If the fuel tank has to be drained, do this outdoor s.

WARNING: YOUR RESPONSIBILITY Restrict the use of this power machine to person s who read,

understand and follow the warnings and instructions in this man ual and on the machin e.

4

Page 5

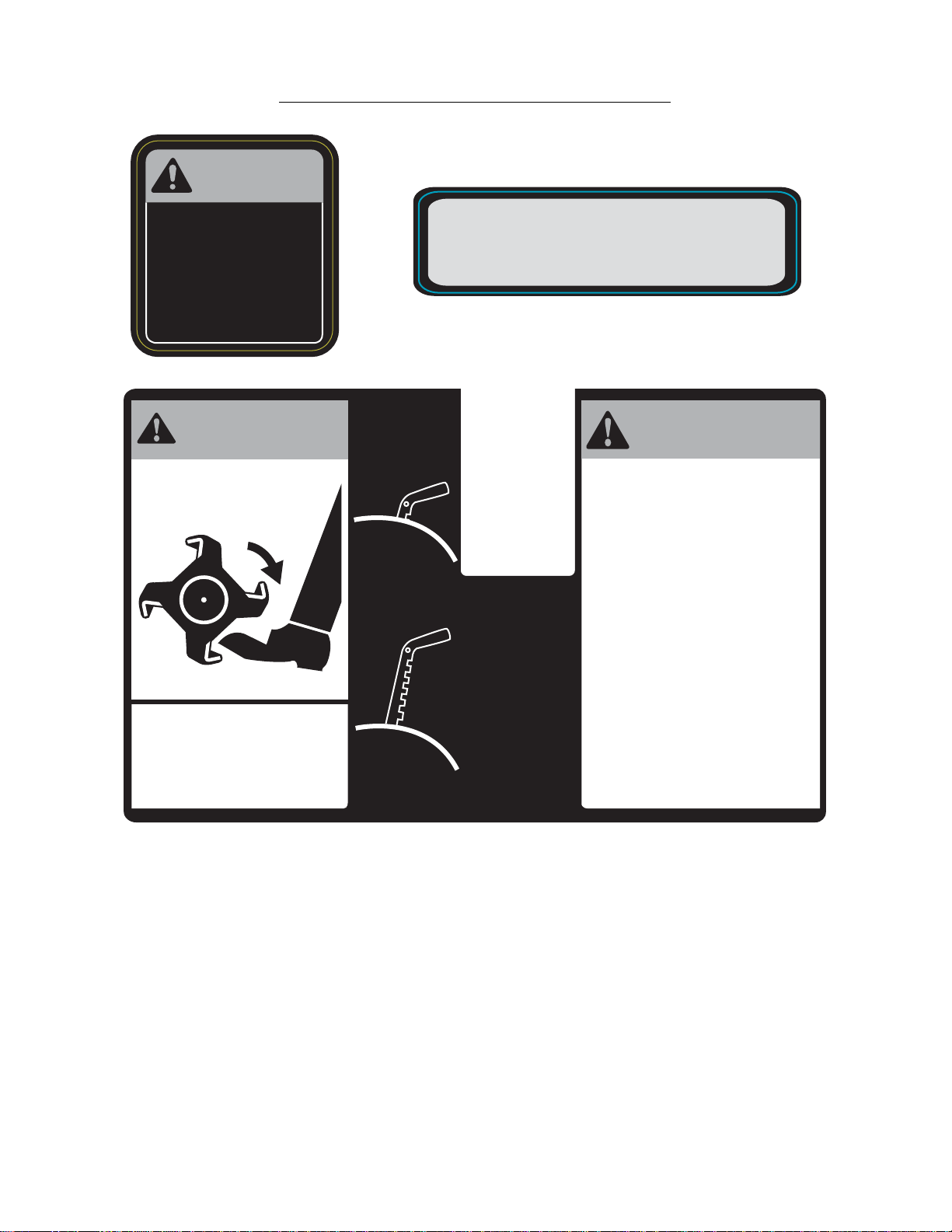

SAFETY LABELS FOUND ON YOUR TILLER

WARNING

Hot surfaces can

cause severe burns.

Do not touch

muffler or

S30647

adjacent areas.

WARNING

KEEP AWAY FROM

ROTATING TINES.

ROTATING TINES

WILL CAUSE INJURY.

CAUTION:

SLOWLY PULL STARTER ROPE BEYOND

BUMPER BEFORE STARTING.

DEPTH

STAKE

SHALLOW /

TRANSPORT

POSITION

DEEP /

FINAL TILLING

POSITION

WATCH OUT FOR HANDS.

I20943

WARNING

TO AVOID SERIOUS INJURY

1. READ THE OPERATOR'S MANUAL.

2. KNOW LOCATION AND FUNCTIONS

OF ALL CONTROLS.

3. KEEP ALL SAFETY DEVICES AND

SHIELDS IN PLACE AND WORKING.

4. NEVER ALLOW CHILDREN OR

UNINSTRUCTED ADULTS TO

OPERATE TILLER.

5. SHUT OFF ENGINE BEFORE

UNCLOGGING TINES OR MAKING

REPAIRS.

6. KEEP BYSTANDERS AWAY FROM

MACHINE.

7. KEEP AWAY FROM ROTATING

PARTS.

8. USE EXTREME CAUTION WHEN

REVERSING OR PULLING THE

MACHINE TOWARDS YOU.

5

Page 6

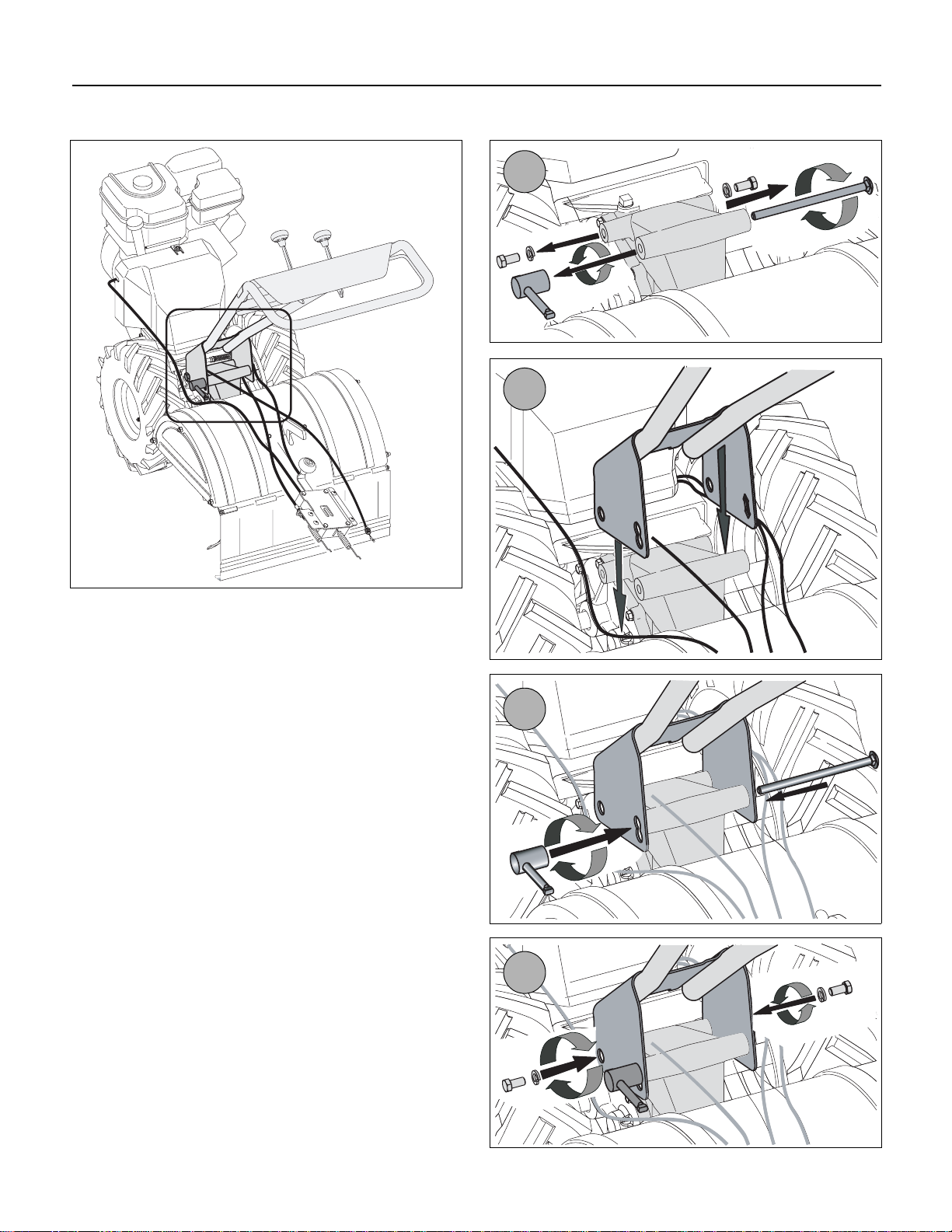

SECTION 2: ASSEMBLING THE TILLER

1

2

NOTE: All references to the RIGHT or LEFT side of the

tiller are observed from operator’s position.

Tools Needed for Assembly

• 9/16” Wrench (Handle Mount Bracket)

• 7/16” Wrench or Nutdriver (Control Box)

• Two 1/2” Wrenches (Threaded Cable Adjuster)

• Phillips Screwdriver (Control Box)

Attaching the Handle

NOTE: Before beginning assembly, unfasten the cables

and lay them across the back of the tiller. Having an

assistant will ease completion of the following steps.

1. Remove the lower handle hardware (two hex screws,

two lock washers, one carriage screw & one handle

crank) from the tiller’s frame.

2. Position the handle mount bracket over the tiller

frame.

3. Align the handle mount brack et’ s rear holes (either

upper or lower , dependin g on the operator’s height)

with the holes in the tiller frame. Insert the carriage

bolt through the holes from right to left and secure it

with the handle crank.

4. Align the handle mount bracket’s front holes with the

holes in the tiller frame. Using a 9/16” wrench, secure

the handle mount bracket to the tiller frame with the

hex screws and lock washers removed earlier.

3

4

6

Page 7

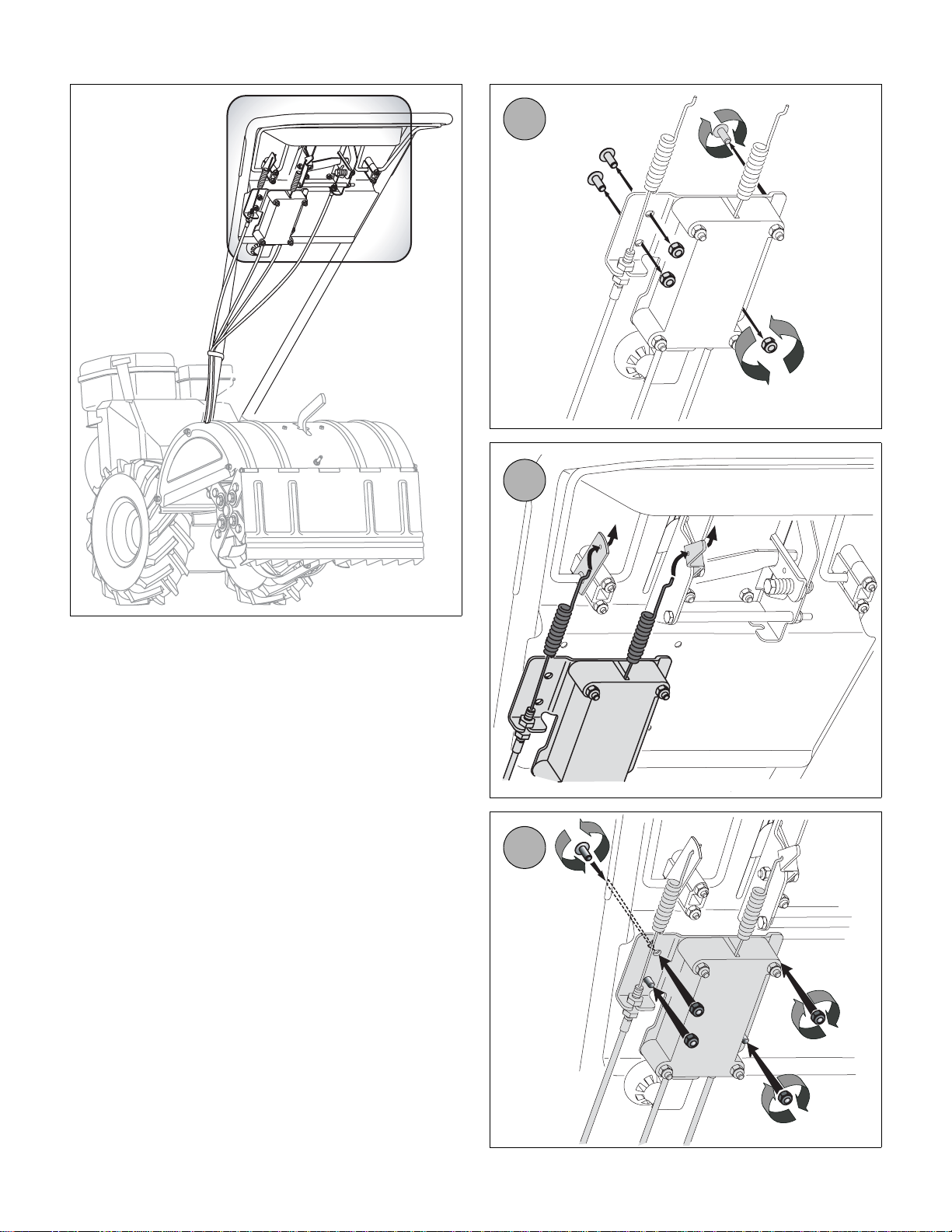

5

6

Attaching the Control Box

5. Remove the four Phillips screws and lock nuts from

the control box plate.

6. Insert the ends of the two springs into the holes found

in the control levers located on the underside of the

handle panel.

7. Using a Phillips screwdriver and a 7/16” wrench,

secure the control box to the underside of the handle

panel with the four screws and lock nuts removed

earlier.

7

7

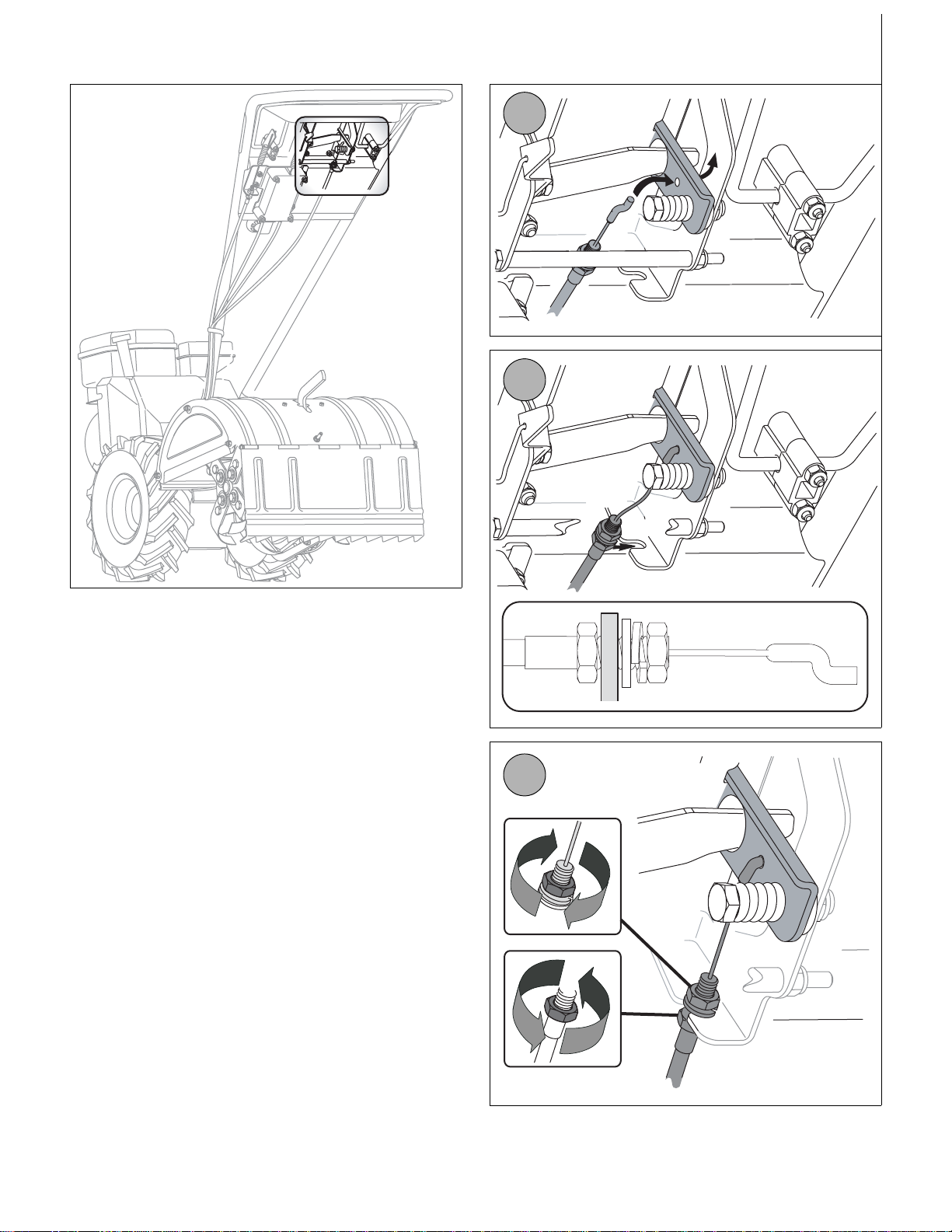

Page 8

8

9

Attaching the Shift Cable

8. Place the shift lever in the forward position. Insert the

end of the shift cable into the hole in shift lever

located on the underside the handle panel.

9. Position the shift cable’s threaded adjuster in the slot

found on the shift lever mount bracket. (one nut below

the mount bracket and the flat washer, lock washer

and second nut above the mount bracket. See Inset).

10. Adjust the shift cable as follows:

a. Using a ½” wrench, thread the bottom nut

upward until the cable is taut.

b. Using a ½” wrench, thread the top nut

downward to secure the adjuster to the mount

bracket.

Position the shift cable (and three other cables)

against the left handle tube. Secure them to the

handle with the cable tie provided as shown in the

illustration at the top of the page.

Gas and Oil Fill-up

Gasoline

Service the engine with gasoline as instructed in the

separate Briggs & Stratton Operator /Owner Manual

packed with your tiller. Read instructions carefully.

Oil

10

B

A

IMPORTANT:

bottle into the engine’s oil fill.

Pour the entire contents of the provided oil

8

Page 9

SECTION 3: KNOW YOUR TILLER

Wheel Shift Lever

Tine Direction Selector

Engine

Starter Handle

Read this operator’s manual and safety rules before

operating your tiller. Compare the illustrations above with

your unit to familiarize yourself with the location of various

controls. Save this manual for future reference.

Engine

See the Briggs & Stratton Owner/Operator manual

packed with your unit for the location and functi on of the

controls on the engine.

Starter Handle

The starter handle is located on the engine. Pull the

starter handle to start engine.

Wheel Shift Lever

The shift lever is located on the

right side of the handle panel

and has three positions,

FORWARD, NEUTRAL and

REVERSE. Place the wheel

shift lever in either FORWARD

or REVERSE before engaging

the drive handle. Always bring

the tiller to a complete stop

prior to moving the shift lever

from FORWARD to REVERSE

or vice-versa.

IMPORTANT:

shift lever. Doing so may result

in serious damage to the tiller’s

transmission.

Never force the

WHEEL DRIVE

F

N

R

I22311 AC

Wheel Engagement Handle

Tine Engagement Lever

Depth Regulator Lever

(Depth Stake)

Handle Height Adjuster

Wheel Engagement Handle

The wheel engagement handle

is located below the tiller’s

upper handle.

Closing the wheel engagement

handle with the wheel shift

lever in either FORWARD or

REVERSE will cause the tiller’s

wheels to drive.

Releasing/Opening the wheel

engagement handle

automatically stops the tiller’s

wheels from driving

NOTE: If the tiller’s tines and

wheels are engaged, releasing/

opening the wheel engagement

handle automatically stops

BOTH the tiller’s tines and the

tiller’s wheels from driving.

9

Page 10

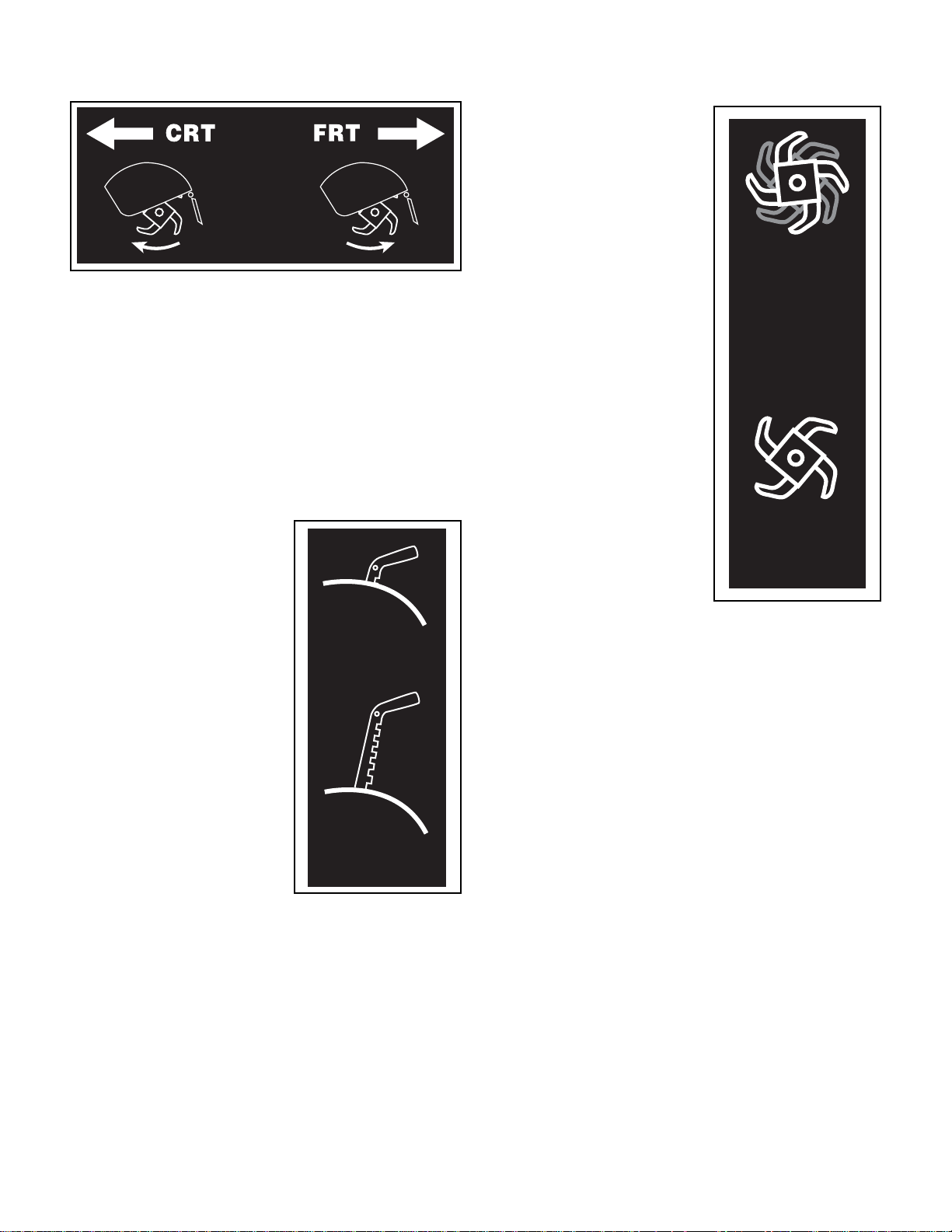

Tine Direction Selector

The tine direction selector (found in the lower left area the

handle panel) is used to alternate tine rotation bet ween

FRT mode (Forward Rotating Tines) to CRT mode

(Counter Rotating Tines).

• Operate the tiller in CRT mode when tilling virgin

ground, sod or hard soil.

• Operate the tiller in FRT mode when cultivating or

tilling soft ground or previously tilled soil.

IMPORTANT:

always lower the depth regulator lever (for a shallower

tilling depth).

When operating the tiller in FRT mode,

Depth Regulator Lever

The highest notch (lever all the

way down) raises the tines

approximately 1/2-inch off the

ground. This “travel” position

allows the tiller to be moved

without the tines digging into

the ground.

Moving the lever up increases

the tilling depth. The lowest

notch allows a tilling depth of

approximately six to eight

inches, depending on soil

conditions.

SHALLOW /

TRANSPORT

POSITION

Tine Engagement Lever

The tine engagement lever is

located on the left side of the

handle panel and has two

positions, ON and OFF. To

engage the tines and begin

tilling, place the lever in the ON

position. To disengage the

tines, move the lever into the

OFF position.

ON

NOTE: The tIne engagement

lever cannot be placed in the

ON position without first closing

the wheel engagement handle.

Also, the tIne engagement

lever cannot be placed in the

ON position unless the wheel

shift lever is in the FORWARD

position. Refer to Safety Interlock

System on Page 11.

TINES

OFF

Handle Height Adjuster

The handle mount bracket can be adjusted downward (for

shorter operators) or upward (for taller ope rators) using

the handle height adjuster . Align the handle mount

bracket’ s rear holes with the holes in the tiller frame. Insert

the carriage bolt through the holes from right to left and

secure it with the handle crank.

DEEP /

FINAL TILLING

POSITION

10

Page 11

SECTION 4: OPERATING YOUR TILLER

WARNING: Read, understand, and follow all

instructions and warnings on the machine, in

this manual and the Briggs & Stratton Owner/

Operator manual packed with your unit before

operating the tiler.

Safety Interlock System

IMPORTANT:

system for the protection of the operator. If the interlock

system should ever malfunction, do not operate the tiller.

Contact an authorized service dealer.

• The Wheel Engagement Handle must be in the closed

• The Wheel Shift Lever must be in the FORWARD

• The Wheel Shift Lever cannot be moved out of the

• The tines will automatically stop if the operator

• The wheels will automatically stop if the operator

Your tiller is equipped with an interlock

position in order to engage the tines

position in order to engage the tines.

FORWARD position unless the Tine Engagement

Lever is in the OFF position.

releases the Wheel Engagement Handle.

releases the Wheel Engagement Handle.

WARNING: Do not operate the tiller if the

interlock system is malfunctioning. This system

was designed for your safety and prot ection.

7. Set the tilling depth by moving the depth regulator

lever rearward, then either up or down into the

desired depth setting. Refer to Depth Regulator Lever on

Page 10.

NOTE: Move the Depth Regulator Lever int o the “travel”

position (lever all the way down) so that the tines clear the

ground. Use this position when practicing with or

transporting the tiller. When you are ready to begin tilling,

move the Depth Regulator Lever into the desired depth

setting. Refer to Depth Regulator Lever on Page 10.

Starting Engine

• Move choke control lever to CHOKE position.

NOTE: A warm engine may not req uire choking.

• Move throttle control lever to FAST (rabbit) position.

Pre-Start Checklist

Do the following before starting the engine.

1. Check unit for loose or missing hardware. Service as

required.

2. Check motor oil level. Refer to separate Briggs &

Stratton Operator/Owner Manual.

3. Check that all safety guards and covers are in place.

4. Check air cleaner and engine cooling system. Refer

to separate Briggs & Stratton Operator/Owner

Manual.

5. Select a tine direction (Refer to Tine Direction Selector

on page 10).

6. Fill the fuel tank with gasoline as instructed in the

separate Briggs & Stratton Operator/Owner Manual

packed with your tiller. Read instructions carefully.

WARNING: Gasoline is highly flammable and

its vapors are explosive. Follow gasoline safety

rules found on Page 3 in this manual, an d in the

separate Briggs & Stratton Operator/Owner

Manual. Failure to follow gasoline safety

instructions can result in serious personal injury

and property damage.

• Grasp the starter handle and pull the rope out slowly

until resistance is felt. When it becomes slightly

harder to pull the rope, slowly allow the rope to recoil.

Then pull rope with a rapid, con tinuous, full arm

stroke. Keep a firm grip on starter handle.

• Maintain a grip on the starter handle and allow the

rope to recoil slowly.

• Repeat the previous steps until engine starts. When

engine starts, move choke control gradually toward

the RUN position until the engine is running smoothly.

WARNING: Never run the engine indoors or

in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and

deadly gas.

11

Page 12

Stopping Engine

• Move throttle control lever to STOP position. See

Figure 1.

Figure 1

CAUTION: Never stop the engi ne by moving

the choke lever into the CHOKE position.

Backfire, fire or engine damage could result.

4. For forward motion of the wheels and power to the

tines:

a. Place the tine direction selector in either the

CRT position or FRT position.

NOTE: Operate the tiller in CRT mode when tilling virgin

ground, sod or hard soil. Operate the tiller in FRT mode

when cultivating or tilling soft ground or previously tilled

soil.

b. Place the wheel shift lever in the FORWARD

position.

c. Close the wheel engagement handle against

the handlebar to cause the wheels to drive.

d. Place the tine engagement lever in the ON

position to begin tilling.

IMPORTANT:

wheel engagement handle.

To stop the wheels and tines, release the

Operating the Tiller

WARNING: Before tilling new ground,

contact your telephone and utilities company to

inquire if underground lines are on the property.

The following pages provide guidelines to using your tiller

effectively and safely in various gardening applications.

Be sure to read Tilling Tips & Techniques in this Section

before you actually put the tines into the soil.

1. Follow the Pre-Start Checklist on page 11. Be sure that

the wheel shift lever is in the NEUTRAL position.

2. Start the engine and allow it to warm up for a few

minutes. Move the throttle control into the FAST

speed setting.

IMPORTANT:

the FAST (rabbit) position.

3. For forward or reverse motion o f the wheels and no

power to the tines:

NOTE: If you encounter difficulty repositioning the

wheel shift lever from FORWARD or REVERSE into

NEUTRAL or vice-versa, gently rock the tiller (slightly

push-and-pull the handlebar forward and backward) prior

to moving the wheel shift lever. Doing so will help fully

disengage the transmission’s internal drive clut ch.

Always operate the tiller with the throttle in

a. Place the tine engagement lever in the OFF

position.

b. Place the wheel shift lever in either the

FORWARD position or REVERSE position.

c. Close the wheel engagement handle against

the handlebar to cause the wheels to drive. To

stop the wheels, release the wheel

engagement handle.

WARNING: Do not push down on the

handlebar to try to make the tiller till more

deeply. Doing so prevents the wheels from

holding the tiller back and can allow the tines (in

CRT mode) to rapidly propel the tiller backward

toward the operator, which could result in loss of

control, property damage, or personal injury.

• As the tiller moves forward, relax and let the wheels

pull the unit along while the tines dig.

• Walk behind, and a little to one side of the tiller.

• Use a light but secure grip with one hand on the

handlebars, but keep your arm loose.

• Let the tiller move ahead at its own pace. Do not push

down on the handlebar in an attempt to force the tiller

to dig deeper. If necessary, stop the tiller, turn off the

engine and reposition the depth regulator lever to

adjust tilling depth before restarting and operating the

tiller.

5. To turn the tiller around:

a. Practice turning in a level, open area with the

tines not engaged.

b. To start a turn, carefully raise the handlebar

until the engine and tines are balanced over t he

wheels.

c. With the tiller balanced, push sideways on the

handlebar to move the tiller in the direction of

the turn. After completing the turn, slowly lower

the tines into the soil.

Stopping the Tiller and Engine

1. To stop the wheels and tines, r elease /open the wheel

engagement handle.

2. To stop the engine, move the engine throttle lever to

STOP. Refer to Figure 1.

12

Page 13

TILLING TIPS & TECHNIQUES

Tilling Depths

WARNING: Before

tilling, contact your

telephone or utilities

company and inquire if

underground equipment or

lines are used on your

property. Do not till near

buried electric cables,

telephone lines, pipes or

hoses

.

• When cultivating (breaking up surface soil around plants to destroy weeds), adjust the tines to dig only 1" to 2" deep. Using shallow tilling

depths helps prevent injury to plants whose roots often grow close to the surface. If needed, lift up on the handlebar slightly to prevent

the tines from digging too deeply. (Cultivating on a regular basis not only eliminates weeds, it also loosens and aerates the soil for better

moisture absorption and faster plant growth.) Watering the garden area a few days prior to tilling will make tilling easier, as will letting

the newly worked soil set for a day or two before making a final, deep tilling pass.

Choosing Correct Tine Depth & Rotation

• Operate the tiller in CRT mode when tilling virgin ground, sod or hard soil.

• Operate the tiller in FRT mode when cultivating or tilling soft ground or previously tilled soil.

IMPORTANT:

When operating the tiller in FRT mode, always lower the depth regulator lever (for a shallower tilling depth).

• This tiller can be operated in CRT (counter-rotating tine) mode. As the wheels pull forward,

the tines rotate backward. This creates an “uppercut” tine action which digs deeply, uprooting

soil and weeds. Don’t overload the engine when operating in CRT mode, but dig as deeply as

possible on each pass. On later passes, the wheels may tend to spin in the soft dirt. Help them

along by lifting up slightly on the handlebar (or simply switch to operating in FRT mode).

• Avoid the temptation to push down on the handlebar in an attempt to force the tiller to dig

deeper. Doing so takes the weight off the powered wheels, causing them to lose traction.

Without the wheels to hold the tiller back, the tines will attempt to propel the tiller backward,

towards the operator. (Sometimes, slight downward pressure on the handlebar will help get

through a particularly tough section of sod or unbroken ground, but in most cases this won’t

be necessary.)

With experience, you will find the “just right” tilling depth and tine rotation combination

that is best for your garden under specific conditions.

Let the Tiller Do the Work Avoid Making Footprints

While tilling, relax and let the wheels pull the

tiller along while the tines do the digging.

Walk on the side that is not yet finished (to

avoid making footprints in the freshly tilled

soil) and lightly, but securely grip the handlebar with just one hand.

Always operate

the tiller with the throttle in the FAST (rabbit) position.

Whenever possible, walk on the untilled

side of the unit to avoid making footprints in

your freshly tilled or cultivated soil. Footprints cause soil compaction that can hamper root penetration and contribute to soil

erosion. They can also “plant” unwanted

weed seeds back into the freshly tilled

ground.

Preparing Seedbeds

• When preparing a seedbed, go over the same path twice in the first row, then overlap one-half the tiller width on the rest of the passes (see Seedbed 1). When finished in one direction, make a second pass at a right angle (Seedbed 2). Overlap

each pass for best results (in very hard ground, it may take three or four passes to

thoroughly pulverize the soil.)

• If the garden size will not permit lengthwise and then crosswise tilling, then overlap the first passes by one-half a tiller

width, followed by successive passes

at one-quarter width (see Seedbed

3).

1

2

3

Seedbed 3

Avoid Tilling Soggy, Wet Soil

Tilling wet soil often results in large, hard

clumps of soil that can interfere with planting. If time permits, wait a day or two after

heavy rains to allow the soil to dry before

tilling. Test soil by squeezing it into a ball. If

it compresses too easily, it is too wet to till.

Seedbed 1 Seedbed 2

Cultivating

With planning, you can

allow enough room

between rows to cultivate.

Leave room for the hood

width, plus enough extra

room for future plant

growth.

13

Page 14

Tilling On Slopes

TILLING TIPS & TECHNIQUES (CON’T)

Read the following recommendations before tilling on slopes:

If you must garden on a moderate slope, please follow two very important guidelines:

1. Till only on moderate slopes, never on steep ground where footing is difficult (review safety rules in Section 1: Safety of this manual).

2. We recommend tilling up and down slopes rather than terracing. Tilling vertically on a

slope allows maximum planting area and also leaves room for cultivating.

IMPORTANT: When tilling on slopes, be sure the correct oil level is maintained in the engine

(check every one-half hour of operation). The incline of the slope will cause the oil to gravitate

WARNING: Do not

operate tiller on a slope too

steep for safe operation. Till

slowly and be sure you have

good footing. Never permit

tiller to freewheel down

slopes. Failure to follow this

warning could result in

personal injury.

away from its normal level and this can starve engine parts of required lubrication. Keep the

motor oil level at the full point at all times!

Tilling Up and Down Slopes (Vertical Tilling)

• To keep soil erosion to a minimum, be sure to add enough organic matter to the soil so that it has good moisture-holding texture and try

to avoid leaving footprints or wheel marks.

• When tilling vertically, try to make the first pass uphill as the tiller digs more deeply going uphill than it does downhill. In soft soil or weeds,

you may have to lift the handlebars slightly while going uphill. When going downhill, overlap the first pass by about one-half the width of

the tiller.

Clearing the Tines

The tines have a self-clearing action which eliminates most tangling of debris in the

tines. However, occasionally dry grass, stringy stalks or tough vines may become tangled. Follow these procedures to help avoid tangling and to clean the tines, if necessary.

• To reduce tangling, set the depth regulator deep enough to get maximum “chopping”

action as the tines chop the material against the ground. Also, try to till under crop

residues or cover crops while they are green, moist and tender.

• While tilling, try swaying the handlebars from side to side (about 6" to 12"). This

“fishtailing” action often clears the tines of debris.

• If tangling occurs, lift the tines out of the soil and run the tiller in reverse for a few

feet. This reversing action should unwind a good deal of debris.

• It may be necessary to remove the debris by hand (a

pocket knife will help you to cut away the material).

WARNING: Before clearing the

tines by hand, stop the engine, allow all

moving parts to stop. Failure to follow

this warning could result in personal

injury.

Loading and Unloading the Tiller

WARNING: Loading and

unloading the tiller into a vehicle is

potentially hazardous. Doing so is

NOT recommend unless

absolutely necessary, as this could

result in personal injury or

property damage. However, if you

must load or unload the tiller,

follow the guidelines given next.

• Before loading or unloading, stop the engine,

wait for all parts to stop moving and allow the

engine and muffler cool.

• The tiller is too heavy and bulky to lift safely

by one person. Two or more people should

share the load.

• Use sturdy ramps and manually (engine shut

off) roll the tiller into and out of the vehicle.

Two or more people are needed to do this.

• The ramps must be strong enough to support

the combined weight of the tiller and any handlers. The ramps should provide good traction

to prevent slipping; they should have side rails

to guide the tiller along the ramps; and they

should have a locking device to secure them to

the vehicle.

• The handlers should wear sturdy footwear that

will help to prevent slipping.

• Position the loading vehicle so that the ramp

angle is as flat as possible (the less incline to

the ramp, the better). Turn the vehicle’s engine

off and apply its parking brake.

• When going up ramps, stand in the normal

operating position and push the tiller ahead of

you. Have a person at each side to turn the

wheels.

14

• When going down ramps, walk backward

with the tiller following you. Keep alert for any

obstacles behind you. Position a person at

each wheel to control the speed of the tiller.

Never go down ramps tiller-first, as the tiller

could tip forward.

• Place wooden blocks on the downhill side of

the wheels if you need to stop the tiller from

rolling down the ramp. Also, use the blocks to

temporarily keep the tiller in place on the

ramps (if necessary), and to chock the wheels

in place after the tiller is in the vehicle.

• After loading the tiller, prevent it from rolling

by placing the wheel shift lever in the FORWARD position. Chock the wheels with blocks

and securely tie the tiller down.

Page 15

SECTION 5: MAINTENANCE AND ADJUSTMENTS

WARNING: Before performing any

maintenance, or repairs, turn the engine off and

allow it to cool, move the tiller to a level surface,

place the wheel shift lever in the FORWARD

position and chock the tiller’s wheels.

MAINTENANCE SCHEDULE

PROCEDURE NOTES

Check motor oil lev el 2, 3

Clean engine 2, 7

Check drive belt tension 1, 4

Check nuts and bolts 1, 4

Change motor oil 1, 4, 6

Lubricate tiller 4, 8

Service foam pre-cleaner air filter 7

Service paper air filter 7

Check gear oil level in transmission 1, 5

Check tines for wear 5

Check air pressure in tires 5

Service spark plug 7

Clean tiller 8

NOTES

1. After first 2 hours of break-in operation.

2. Before each use.

3. Every 5 operating hours.

4. Every 10 operating hours.

5. Every 30 operating hours.

6. Change more frequently in dusty or di rty conditions.

7. See Engine Owner’s Manual for service

recommendations.

8. After each use.

Engine

Check engine oil level before each use as instr ucted in

the Briggs & Stratton Operator/Owner Manual packed

with your unit. Follow the instructions carefully.

Engine Oil

Refer to the Briggs & Stratton Operator/Owner Manual

packed with your unit for instruction on changing the

engine oil and for information regarding the quant ity and

proper weight of motor oil.

Air Cleaner

Service the pre-cleaner, if so equipped, and cartridge/ air

cleaner element as instructed in the Briggs & Stratton

Operator/Owner Manual packed with your unit.

Spark Plugs

The spark plug should be cleaned and the gap reset once

a season. Refer to the Briggs & Stratton Operator/Owner

Manual for correct plug type and gap specifications.

Cleaning the Tiller

Any fuel or oil spilled on the machine sh ould be wiped off

promptly. Do NOT allow mud and debris to accumulate

around the cooling fins of the engine or on any other pa rt

of the machine, especially around the bottom frame

cover, under the belt cover, around the belts, pulleys,

shifter linkage and other moving parts.

• Remove the belt cover at least once a season and

clean any debris away from belts and pulleys

• Clean around the bottom frame cover and the

underside of the tine shield and with a garden hose

after each use.

IMPORTANT:

machine after each cleaning. Lubricate any pivot points

and all axles to inhibit rust from forming and metal parts

from corroding and seizing over time.

Thoroughly dry the tine shield and entire

Lubrication

WARNING: Before performing any

maintenance or repairs, turn the engine off and

allow it to cool, move the tiller to a level surface,

place the wheel shift lever in the FORWARD

position and chock the tiller’s wheels.

Engine

Lubricate the engine with motor oil as instructed in the

Briggs & Stratton Operator/Owner Manual packed with

your unit.

Pivot Points & Linkage

Lubricate all the pivot points on the depth regulator leve r,

handle height adjuster and levers (found on under side of

the handle panel) at least once a season with light oil.

Remove the belt cover at least once a season and clean

any debris away from belts and pulleys before lubricating

pivot points on pulley brackets with a light oil.

Axles (Wheel & Tine)

Remove each wheel and tine holder from its axle at least

once a season and before extended storage. Clean each

axle and lubricate with an all-purpose grease before

reinstalling each wheel and tine holder.

Transmission

Checking for Oil Leaks

Before each use, check your tiller for signs of an oil leak—

usually a dirty, oily accumulation either on the unit or on

the floor where it has been parked.

A little seepage around a cover or oil seal is usually not a

cause for alarm. If a small puddle forms below the tiller

within hours, however, then service is required.

15

Page 16

Ignoring a leak can result in severe transmission damage.

If a cover leaks, try tightening any loose screws or bolts. If

the fasteners are tight, a new gasket or oil seal may be

required. If the leak is from around a shaft and oil seal, t he

oil seal probably needs to be replaced. See a n authorized

service dealer.

Changing Oil

Oil level should be visually checked if evidence of a leak

is present. Oil should be added in such cases, but

changing the transmission oil as part of general

maintenance is unnecessary

Checking Oil Level

Check the oil level after every 30 hours of operation and

whenever there is any oil leakage.

IMPORTANT:

low on oil.

1. Position the tiller on a level surface.

2. Remove the fill plug found on the front of the

transmission. See Figure 2.

Never operate the tiller if the transmission is

Figure 3

IMPORTANT:

Ultra Black™ Silicone 5900) must be applied to these

screws before they can be reused without risking the loss

of transmission oil.

If loosened or removed, a sealant (Loctite

Adjustments

WARNING: Before performing any

maintenance or repairs, turn the engine off and

allow it to cool, move the tiller to a level surface,

place the wheel shift lever in the FORWARD

position and chock the tiller’s wheels.

Figure 2

3. The drive shaft (visible through the transmission plug

opening) should be half-submerged. If necessary,

slowly add SAE 85W140 oil until the drive shaft is

approximately half-submerged.

IMPORTANT:

transmission housing. Do NOT fully submerge the drive

shaft with oil. Doing so will not allow for oil expansion and

may result in serious damage to the transmission .

Do NOT add oil to the top of the

Checking Hardware

Check the unit for loose or missing hardware after every

10 operating hours. Loose or missing hardware can lead

to equipment failure, poor performance, or oil lea ks.

Be sure to check the three mounting screws located on

each of two end caps found at the rear of the transmission

(See Figure 3). Lift the tine flap to service those screws.

Handle Height

The handle mount bracket can be adjusted downward (for

shorter operators) or upward (for taller ope rators) using

the handle height adjuster .

• Unthread the handle crank and remove the carriag e

bolt which secures handle mount bracket to the tiller

frame. See Figure 4.

• Pivot the handlebar upward or downward to align the

handle mount bracket’s rear holes (either upper or

lower) with the holes in the tiller frame.

• Re-insert the carriage bolt through the holes from

right to left and secure it with the hand le crank.

16

Figure 4

Page 17

Shift Cable

If the tiller’s wheels do not “freewheel” when the wheel

shift lever is in the NEUTRAL position, the shift cable is in

need of adjustment. Refer to Step 10 on Page 8 for

detailed instructions.

Tine Engagement Cables

If the tines fail to drive when the tine engagement lever is

placed in the ON position, or if the tines fail to stop when

the tine engagement lever is placed in the OFF position,

DO NOT OPERATE THE TILLER. The tine engagement

c able is in need of adjustment.

1. Remove the belt cover by removing the top scre w and

washer (and loosening the side screws) which secure

it.

2. To adjust the cable:

a. Loosen the inside hex nut found on the cable

adjuster.

b. Loosen the outside hex nut found on the cable

adjuster.

c. Grasp the metal cable housing and gently pull

outward to take up slack (usually no more than

1/4-inch) in the cable before retightening both

hex nuts loosened earlier.

Wheel Engagement Cable

1. Adjust the wheel engagement cable as follows:

a. Using a ½” wrench, loosen the upper hex nut

found on the cable adjuster.

b. Loosen the lower hex nut found on the cable

adjuster.

c. Grasp the metal cable housing and gently pull

outward to take up slack (usually no more than

1/4-inch) in the cable before retightening both

hex nuts loosened earlier.

1

2

c

a

b

a

b

17

1

a

b

c

Page 18

SECTION 6: SERVICE

1

2

Changing the Belts

WARNING: Position the tiller on flat, level

surface, chock the wheels, shut the engine off

and allow it to cool before removing the belt(s).

All belts on your tiller are subject to wear and should be

replaced if any signs of wear are present.

IMPORTANT:

designed to engage and disengage safely. A substitut e

(non-OEM) belt can be dangerous by not disengaging

completely. For a proper working machine, always use

factory approved belts.

To replace the belts on your tiller, proceed as follows:

Tine Drive Belts

1. Remove the belt cover by removing the top scre w and

washer (and loosening the side screws) which secure

it.

2. Remove the belt keeper rod by removing the screw

and washers which secure it.

3. Remove the forward tine belt as follows:

The belts found on your tiller are specially

a. Loosen, but do not remove, the h ex nuts which

secure the two idler pulleys.

b. Unloop the belt from around the bottom pulley.

c. Unloop the belt from around the two idler

pulleys.

3

c

a

b

a

18

Page 19

4. Begin the removal the reverse tine belt as follows:

a. Apply pressure on the idler pulleys to relieve

tension on the reverse tine cable and the whe el

drive cable.

b. Carefully unhook each cable-end.

5. Unloop the wheel drive belt from around the engine

pulley.

6. Unloop the reverse tine belt from the engine pulley.

NOTE: Replace the reverse tine belt first and the

forward tine belt second. Lastly, reattach the wheel drive

belt to the engine pulley or proceed by replacing it.

NOTE: To install replacement belts, perform steps 1-6

in reverse order.

4

a

b

5

19

6

Page 20

1

Wheel Drive Belt

2

NOTE: The wheel drive belt is under the least amount of

load and will wear at a slower rate. It may not be

necessary to replace the wheel drive belt as often as the

tine belts. Inspect the belt and read the following steps

before proceeding.

1. Remove the left wheel by removing the cotter pin and

clevis pin which secure it. Use a jack stand or wood

blocks to secure the left wheel axle and stabilize the

tiller.

2. Remove the upper two screws which secure the

bottom frame cover and pivot it downward.

3. Remove the wheel drive belt from around the lower

idler pulley as follows:

a. Loosen, but do not remove, the h ex bolt which

secures the lower idler pulley.

b. Unloop the belt from around the lower idler

pulley and transmission pulley.

4. Remove the wheel drive belt from around the upper

idler pulley as follows:

a. Carefully remove the small spring from the

upper pulley’s idler bracket.

b. Gently pry the belt keeper tab up ward with a

flathead screwdriver.

c. Carefully unloop the wheel drive belt from

around the upper idler pulley.

3

a

b

a

Rear View Front View

b

NOTE: To install a replacement belt, perform steps 1-4

in reverse order.

20

4

a

c

b

Page 21

Tines

The tines will wear with use and should be inspected at

the beginning of each tilling season and after every 30

operating hours.

WARNING: Position the tiller on flat, level

surface, chock the wheels, shut the engine off

and allow it to cool before inspecting or

removing the tines.

NOTE: The tine shield end-covers (left side and right

side) must be removed in order to take off eithe r a single

tine holder or individual tines. The end-covers are

secured to the tine shield housing with three hex nuts

each.

Tine Inspection

With use, the tines will become shorter, narrower and

pointed. Badly worn tines will result in a loss of tilling

depth and reduced effectiveness when ch opping up and

turning under organic matter.

Removing and Installing Tines

1. Use a pair of pliers to remove the internal cotter pin

and clevis pin that secures each tine holder to the ti ne

shaft.

2. Use a rubber mallet to tap the tine holder free of th e

tine axle and slide the tine assembly off the tine axle.

1-2

3-6

NOTE: The tine shield and handlebar are not shown for

clarity. It is NOT necessary to remove the tine shield and

handlebar to service the tiller tines.

3. Use a 9/16" socket wrench, and a 9/16" box wrench

to remove the hex nuts, washer(s) and bolts that

secure each tine to the tine holder.

NOTE: It is recommended that tines be changed one at

a time for ease in reassembling

4. Install a replacement tine in th e exact orientation as

the tine just removed. Note the location and

orientation of washers were applicable.

5. Repeat Steps 1-through-4 above to r emove the oth er

tine assembly and individual tines.

6. When reinstalling the tine assemblies onto the tine

axles, be sure to first remove any rust, uneven spots

or burrs from the tine axle, using fine sandpaper .

Then grease the tine axle before reinstalling the tine

assemblies.

Tires

WARNING: Never exceed the maximum

inflation pressure shown on the sidewall of the

tire.

Refer to the tire sidewall for exact tire manufacturer’s

recommended or maximum psi. Do not overinflate.

Off-season Storage

When the tiller won’t be used for extended periods,

prepare it for storage as follows:

• Clean and lubricate the tiller as instructed in Section 7:

MAINTAINING YOUR TILLER on page 15.

• Check for loose parts and hardware (see Checking

Hardware on page 16) .

• Protect the engine by performing the engine stor age

instructions in the separate Briggs & Stratton

Operator/Owner Manual packed with your tiller.

• Store unit in a clean, dry area.

WARNING: Never store the ma chine or fuel

container indoors where there is an ope n fla me,

spark or pilot light such as on water heater,

furnace, clothes dryer or other gas appliance.

21

Page 22

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

Engine does not start 1. Spark plug wire disconnected. 1. Reconnect wire. (See Engine Owner’s Manual)

2. Engine Throttle Control Lever incorrectly set. 2. Put lever in START position.

3. Fuel tank empty. 3. Add fuel.

4. Choke control in incorrect position. 4. See Page 11, Starting the Engine.

5. Stale gasoline. 5. Drain fuel and add fresh fuel.

6. Dirty air filter. 6. Clean or replace filter.

7. Fouled or incorrectly gapped spark plug. 7. Inspect spark plug (see Engine Owner’s Manual)

8. Carburetor out of adjustment. 8. See Engine Service Dealer.

9. Misadjusted throttle control. 9. See Engine Service Dealer

10. Dirt or water in fuel tank. 10. See Engine Service Dealer.

Engine runs poorly. 1. Fouled or incorrectly gapped spark plug. 1. Inspect spark plug (see Engine Owner’s Manual).

2. Dirty air filter(s). 2. Clean or replace (see Engine Owner’s Manual).

3. Carburetor out of adjustment. 3. See Engine Service Dealer.

4. Stale gasoline. 4. Replace with fresh gasoline.

5. Dirt or water in fuel tank. 5. See Engine Service Dealer.

6. Engine cooling system clogged. 6. Clean air cooling system (see Engine Owner’s Manual).

Engine overheats. 1. Engine cooling system clogged. 1. Clean air cooling area (see Engine Owner’s Manual).

2. Carburetor out of adjustment. 2. See Engine Service Dealer.

3. Oil level is low. 3. Check oil level (see Engine Owner’s Manual).

Engine does not shut off 1. Misadjusted throttle control. 1. See Engine Owner’s Manual or Engine Service Dealer.

Wheels and Tines will not turn 1. Improper use of controls. 1. Review Section 3 and Section 4.

2. Worn, Broken or misadjusted belt(s). 2. Review Section 5 to adjust or replace belt.

3. Internal transmission wear or damage. 3. Contact local dealer or the factory.

4. Bolt and key loose in transmission pulley. 4. Tighten bolt. Check that key is in place.

Tines turn, but wheels don’t. 1. Wheel Drive Pins not in axle. 1. Replace Wheel Drive Pins

2. Internal transmission wear or damage. 2. Contact authorized service dealer

3. Wheel drive belt slipping 3. Review Section 5 to adjust wheel drive cable

4. Worn, Broken or misadjusted belt. 4. Review Section 5 to adjust or replace belt.

5. Wheel drive cable broken 5. Contact authorized service dealer.

Wheels Turn, but Tines Don’t. 1. Tine holder mounting hardware missing. 1. Replace hardware.

2. Internal transmission wear or damage. 2. Contact local Dealer or the Factory.

Poor tilling performance. 1. Worn tines. 1. See “Tines” (Section 5).

2. Improper Depth Regulator setting. 2. See “Tilling Tips & Techniques,” Section 4.

3. Belt(s) slipping. 3. See Section 5 to adjust tine cable(s) or replace belt.

22

Page 23

SECTION 7: MODEL 654J PARTS LIST

Wheels and Tines

87

12

13

16

15

6

5

4

10

11

1

3

2

17

18

9

REF

NO.

1 642-04015 Adapter Assembly, Tine

2 712-3054 Nut, 3/8-24, Hex, Lock

3 736-0169 Washer, Lock, 3/8, Regular Duty

4 736-0208 Washer, Flat, .51 x 1.5 x .07

5 736-0253 Washer, Bell, .525 x 1.00 x.050

6 738-0688 Screw, Shoulder 1/2 Dia x .325

7 738-0689 Screw, Shoulder 1/2 Dia x .180, 3/8-2

8 742-0305 Tine, Articulating

9 618-04120 Transmission Assembly, Dual Direction

PART NO. DESCRIPTION

14

REF

NO.

10 710-1194 Screw, Machine, #10-24, 1.00, Gr5

11 712-0161 Nut, Hex Lock, #10-24, Gr2, Nylon

12 746-04150 Cable, Shift, Wheel

13 634-0240 Wheel, Complete, 14 x 4.5 x 6, RH, Gray

14 634-0241 Wheel, Complete, 14 x 4.5 x 6, LH, Gray

15 711-1017 Pin, Clevis, .250 x 1.53

16 714-0104 Pin, Cotter, .072 Dia. x 1.13 Lg

17 714-0149B Internal Cotter Pin

18 711-0415 Pin, Clevis, 3/8, 1.75

23

PART NO. DESCRIPTION

Page 24

Handlebar and Controls

22

14

26

38

25

22

12

3

C

36

2

B

13

A

13

23

B

22

37

20

13

18

9

6

11

10

10

A

2

8

15

34

14

17

13

13

C

17

26

22

19

4

D

30

27

32

D

31

1

13

16

20

13

29

28

35

5

24

Page 25

Handlebar and Controls

REF

NO.

1 647-04026 Bail Assembly, Control, Wheel

2 649-04014 Handle Assembly, Loop

3 686-04038 Lever Assembly, Control, Tine

4 686-04040 Lever Assembly, Pivot

5 710-3119 Hex Screw, 3/8-16, .75, Gr5

6 710-04198 Screw, Carriage, 3/8-16, 6.00, Gr5

7 710-04202 Screw, Machine, 1/4-20, 2.500

8 710-0501 Hex Screw, 1/4-20, 2.0, Gr5

9 710-0539 Hex Screw, 3/8-24, 1.75, Gr5

10 710-0946 Screw, Machine, 1/4-20, 0.625

11 710-1656 Hex Screw, 1/4-20, 6.00, Gr5

12 712-0116 Nut, Jam Lock, 3/8-24, Gr5, Nylon

13 712-0324 Nut, Hex Lock, 1/4-20, Gr8, Nylon

14 720-04039 Knob, Shift

15 725-0157 Cable, Tie, 3/16 x .05 x 7.4

16 731-04616 Box, Control, Select, Tine

17 731-04644 Block, Mounting, Bail

18 732-0193 Spring, Compression, .39x.60 x .88 Lg

19 732-0590A Spring, Compression

20 736-0105 Washer, Bell, .375 x .870 x .063

22 736-3012 Washer, Wave, .390 x .625 x .016

23 736-3052 Washer, Flat, .406 x 1.00 x .105

25 738-04072 Screw, Shoulder, .373 x .830, 1/4-20

26 738-04088 Screw, Shoulder, .373 x .180 x 1/4-20

27 741-0862 Ball, Detent, .250

28 746-04098 Cable, Clutch, Drive, Wheel

29 746-04099 Cable, Clutch, Drive, Tine

30 746-04100 Cable, Engagement, Tine

31 746-04107 Block, Control, Select, Tine

32 746-04108 Block, Control, Engage, Tine

33 750-04226 Spacer, .270 x .375 x 5.00 Lg

34 786-04162 Bracket, Mounting, Control

35 786-04199 Crank, Adjustment, Handle

36 786-04212 Bracket, Mounting, Control

37 786-04213 Lever, Shift

38 786-04214 Bracket, Pivot, Interlock

PART NO. DESCRIPTION

25

Page 26

23

Drive System

6

Wheel Clutch Cable

(Shown for Reference)

8

15

25

Reverse Tine Clutch Cable

(Shown for Reference)

23

20

6

22

11

G

42

E

A

11

11

38

35

19

36

29

40

28

21

18

4

23

38

27

2

38

5

18

Forward Tine Clutch Cable

1

7

C

11

41

B

12

(Shown for Reference)

34

46

A

E

16

10

32

31

7

44

21

18

3

39

13

26

37

F

D

33

30

44

21

24

51

14

B

G

F

48

43

11

9

18

49

17

18

9

D

C

50

47

4

45

26

Page 27

Drive System

REF

NO.

1 686-04034 Bracket Assembly, Clutch

2 710-0117 Hex Screw, 5/16-24, 1.00, Gr5

3 710-0378 Hex Screw, 5/16-18, 2.50, Gr5

4 710-0599 Screw, Self-tapping, 1/4-20, 0.500

5 710-0624 Hex Screw, 5/16-24, 1.50, Gr5

6 710-0642 Screw, Self-tapping, 1/4-20, 0.750

7 710-0723 Hex Screw, 3/8-16, 1.25, Gr5

8 710-0902 Hex Screw, 3/8-24, 3.75, Gr5

9 710-3008 Hex Screw, 5/16-18, .75, Gr5

10 710-3144 Hex Screw, 3/8-16, 2.00, Gr5

11 712-0266 Nut, Jam Lock, 3/8-16, Gr2

12 712-0700 Nut, Flange, 9/16-18, Gr2

13 712-0702 Nut, Flange, 7/16-20, Gr2

14 714-04032 Key, Square, .1875 x 3.625

15 731-04590 Cover, Belt

16 732-0320 Spring, Extension, .38 x 3.25

17 732-0545 Extension Spring .35 x 1.14

18 736-0119 Washer, Lock, 5/16, Regular Duty

19 736-0185 Washer, Flat, .375 x .738 x .063

20 736-0329 Washer, Lock, 1/4, Regular Duty

21 736-0362 Washer, Flat, .330 x 1.25 x .06, Ht

22 736-0452 Washer, Bell, .396 x 1.140 x .095

23 736-3090 Washer, Flat, .260 x .720 x .060

24 1918749 Bumper

25 747-04191 Keeper, Belt

26 750-04221 Spacer, .330 x 1.25 x 1.605

PART NO. DESCRIPTION

REF

NO.

27 750-04223 Spacer, .390 x .750 x .812

28 750-04225 Spacer, 1.030 x 1.375 x .830 Lg

29 750-04258 Hub, Pulley, Input, 5/8

30 750-04259 Hub, Pulley, Input, 1/2

31 750-04261 Spacer, .330 x 1.250 x .845

32 750-0943 Spacer .33 x 1.0 OD

33 754-0346 V-belt

34 754-04036 Belt

35 754-04056 Belt

36 756-0137 Pulley, Idler, Flat w/ Flange 2.25 OD

37 756-0313 Pulley, Idler, Flat 1.88 OD

38 756-0399 Pulley, Idler, V-type 3.5 Dia

39 756-04081 Pulley, 3l, 3.088 Eff Dia

40 756-04082 Pulley, 4l, 5.0 Eff Dia

41 756-04090 Pulley, Engine, 3 Belt

42 786-0149 Keeper, Belt, Idler

43 786-04177 Frame, Engine

44 786-04178 Bracket, Clutch, Forward

45 786-04180 Cover, Bottom, Frame, Engine

46 786-04182 Bracket, Mounting, Cover, Belt

47 710-3056 Hex Screw, 5/16-18, 3.25, Gr5

48 712-0429 Nut, Hex Lock, 5/16-18, Gr5, Nylon

49 726-0201 Nut, Speed, .3125 ID

50 736-0451 Saddle Washer, 320 x .93 x .060

51 786-04223 Weight

PART NO. DESCRIPTION

27

Page 28

Transmission

55

18

48

31

35

53

10

58*

42

30

47

36

12

8

64-67*

59-63*

17

9**

5**

38

54

36

43

50

54

59-63*

57

26

49

37

37

21

68

24

70

17

39*

56

57

11

5

38

6

15

52

40

2

4

72

27

7**

13

20

51

1

23

19

51

16

39

33

41***

28

69

56

25

22

71

70

34

69

44

3

14

* Shims used "As Required" to obtain between .005" and .015" allowable end-play

** If loosened or removed, a sealant (Loctite Ultra Black™ Silicone 5900) must be applied

to these screws before they can be reused without risking the loss of transmission oil.

*** These washers are found only on replacement transmissions. Remove and discard

the washers when mounting the transmission to the tiller's tine shield bracket.

28

53

31

7**

Page 29

Transmission

REF

NO.

1 611-04033 Shaft Assembly, Detent

2 619-04069 Housing, Transmission

3 619-04070 Cover, Housing, Transmission

4 686-04039A Link Assembly, Shift

5 710-1880 Hex Screw, 5/16-18, .75, Gr5, Patch

6 710-0425 Screw, Machine, #10-24, 0.625

7 710-3015 Hex Screw, 1/4-20, .75, Gr5

8 710-04049 Flange Screw, 5/16-18, .625, Gr5

9 710-04048 Flange Screw, 5/16-18, 1.0, Gr5

10 711-04261 Shaft, Wheel, .750 Dia x 15.46 Lg

11 711-04263 Shaft, Tiller, Tine

12 711-04178 Shaft, Worm, Drive

13 711-04177 Shaft, Idler, .500 Dia x 1.823 Lg

14 711-04168 Shaft, Drive

15 712-0161 Nut, Hex Lock, #10-24, Gr2, Nylon

16 715-0221 Pin, Dowel, 3/16 x 3/4

17 716-04026 Ring, Retaining, External, 1.188 Dia Shaft

18 716-04027 Ring, Retaining, Int, 1.25 Dia Bore

19 716-0865 Ring, Snap, .500

20 717-04088 Gear, Spur, 30t

21 717-04084 Gear, Spur, 34t

22 717-04083 Gear, Spur, 10t

23 717-04087 Gear, Spur, 13t

24 717-04093 Gear, Worm, 30t

25 717-04090 Gear, Worm, 40t

26 718-04074 Collar, Clutch

27 718-04065 Cover, Bearing, Rear

28 718-04008 Cover, Bearing, Rear

30 721-0212 Oil Seal x .375

31 721-04073 Seal, Oil, .750 Shaft x 1.125 Bore

33 721-04069 O-Ring, 1/4 x 3/8 x .07

34 721-04065 Seal, .750 Shaft x1.783 Bore x .375

35 721-04064 Seal, .563 Shaft x 1.25 Bore x.25

36 721-04036 Seal, Oil, 1.00 Shaft x 1.500 Bore

37 736-04153 Washer, Flat, .751 x .975 x.01

PART NO. DESCRIPTION

REF

NO.

38 736-0119 Washer, Lock, 5/16, Regular Duty

39 736-0492 Washer, Flat, .760 x 1.500 x .010

40 736-0419 Washer, Flat, .62 x 1.12 x .03

41 736-3008 Washer, Flat, .344 x .750 x .120

42 736-04102 Washer, Flat, .5685 x .875 x .04

43 736-0495 Washer, Thrust, 1.00 x .632 x .025

44 736-0617 Washer, Thrust, .750 x 1.250 x.0615

45 737-0356 Grease, Seal

46 737-0353 Oil, 85w 140

47 741-04077 Bearing, Hub

48 741-04075 Bearing, 9/16 x 1.25 x .650 Lg

49 741-0973 Bearing, Sleeve, .627 x .81 x .80

50 741-0336 Bearing, Flange, 5/8 x 3/4 x 3/4

51 741-0678 Bearing, Sleeve, .503 x .626 x .600

52 741-0469 Bearing, Thrust, Roller .625x1.125x.078

53 741-0340 Bearing, Sleeve, .75 x 1.00 x 1.00

54 1909950 Ring, Heavy, External, .984 ID

55 1918377 Housing, Cover

56 GW-1086 Bushing, 1.005 x 1.25 x 1.5

57 GW-1132-2 Washer, Flat, 1.015 x 1.234 x .062

58 GW-1132-3 Washer, Flat, 1.015 x 1.234 x .010

59 GW-1166-1 Washer, Flat, 1.015 x 1.375 x .062

60 GW-1166-2 Washer, Flat, 1.015 x 1.375 x .030

61 GW-1166-3 Washer, Flat, 1.015 x 1.375 x .015

62 GW-1166-4 Washer, Flat, 1.015 x 1.375 x .010

63 GW-1166-5 Washer, Flat, 1.015 x 1.375 x .005

64 GW-1224-1 Washer, Flat, 1.50 x 1.75 x .010

65 GW-1224-2 Washer, Flat, 1.50 x 1.75 x .030

66 GW-1224-3 Washer, Flat, 1.50 x 1.75 x .005

67 GW-1224-4 Washer, Flat, 1.50 x 1.75 x .062

68 GW-50032 Gasket, Gear Housing

69 GW-9400 Cup, Bearing

70 GW-9401 Bearing, Cone

71 GW-9517 Ring, Retaining, Internal

72 GW-9727 Plug, Pipe, 3/8

PART NO. DESCRIPTION

29

Page 30

Tine Shield

13

3

16

9

A

7

10

4

A

2

5

8

18

12

13

7

10

7

1

21

19

4

4

20

REF

NO.

1 686-0044A Cover Assembly, End

2 710-0597 Hex Screw, 1/4-20, 1.00, Gr5

3 710-0604 Screw, Self-tapping, 5/16-18, 0.625,

4 710-0874 Hex Screw, 5/16-18, 1.25, Gr5

5 710-3039 Hex Screw, 5/16-18, .50, Gr5

6 712-0324 Nut, Hex Lock, 1/4-20, Gr8, Nylon

7 712-0429 Nut, Hex Lock, 5/16-18, Gr5, Nylon

8 715-0108 Pin, Spring, 1/4 Dia x 1.00 Lg

9 726-0106 Nut, Speed, Cap 1/4 Rod

10 736-3089 Washer, Flat, .345 x 1.00 x .100

11 738-0849 Screw, Hex, 5/16-18 x .75

PART NO. Description

22

14

20

15

7

7

7

6

REF

NO.

12 747-0432 Rod, Tiller Flap

13 786-0113 Shield, Tine, Rear

14 786-04171 Bar, Depth

15 786-04172 Bar, Drag, Depth

16 786-04179 Shield, Tine

17 786-04184 Bracket, Shield, Tine

18 786-04215 Bracket, Mounting, Bar, Depth, LH

19 786-04216 Bracket, Mounting, Bar, Depth, RH

20 GW-55088 Bush, .438 x .323 x .400

21 GW-9384 Spring Torsion

22 GW-9534 Spacer, .350 x .268 x .375

PART NO. Description

30

Page 31

NOTES

31

Page 32

TROY-BILT TILLER LIFETIME LIMITED WARRANTY

WHAT PRODUCT All Troy-Bilt branded rear tine walk-behind tillers with gear drive transmissions.

IS COVERED This warranty begins on the date of purchase and is warranted by Troy-Bilt LLC for the life of the

WHAT IS COVERED Troy-Bilt LLC will, at its option, repair or replace any part found to be defective in material or

BY THIS WARRANTY workmanship without charge for parts and labor

WHAT IS NOT This warranty does not apply to parts that have been damaged by accident, alteration, misuse,

COVERED BY THIS abuse, neglect, improper maintenance, vandalism, theft, fire, water, or damage because of peril

WARRANTY or other natural disaster.

tiller, to the original purchaser only.

This limited lifetime warranty also applies to non-powered attachments and accessories.

Powered attachments and accessories are warranted separately by their manufacturers. Refer

to the applicable manufacturer’s warranty on these items for terms and conditions.

The following items are not covered after the first year of this residential use limited warranty:

belts, batteries, bushings, seals, tines, tires, wheels, paint, appearance items, and similar items

that are normally replaced through periodic maintenance.

Charges for pick-up, delivery, and service calls are not covered by this warranty.

Service completed by someone other than an authorized service dealer is not covered by this

warranty.

Parts that are not genuine Troy-Bilt LLC service parts are not covered by this warranty.

The engine is warranted separately by the engine manufacturer. Refer to the engine

manufacturer’s warranty for terms and conditions.

LIMITED If used for commercial, institutional, industrial, rental, or demonstrator purposes, the warranty

COMMERCIAL on the tiller is limited in duration to 90 days from the date of purchase.

USE WARRANTY

This warranty does not apply to parts that have been damaged by accident, alteration, misuse,

abuse, neglect, improper maintenance, vandalism, theft, fire, water, or damage because of

peril or other natural disaster.

HOW TO OBTAIN Warranty service is available, with proof of purchase, through your local authorized service

SERVICE dealer. To locate a dealer in your area, consult your Yellow Pages, or contact Troy-Bilt LLC at

P.O. Box 361131, Cleveland, Ohio 44136-0019, 1-866-840-6483, or log on to our Web site at

www.troybilt.com.

The provisions set forth in this warranty provide the sole and exclusive remedy arising from the sale. Troy-Bilt LLC shall

not be liable for any incidental or consequential damage or expense of any kind, including but not limited to cost of

equipment rental, loss of profits, or costs of hiring services to perform tasks normally performed by the equipment.

Any implied warranties, including any implied warranty of merchantability or fitness for a particular purpose, shall be limited

in duration to the period of ownership by the original purchaser (and a maximum of 90 days from the date of sale if the tiller is

purchased for commercial or other non-residential use).

Some states do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions or limitations may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For customer assistance, contact your nearest authorized dealer, or contact us at:

TROY-BILT LLC, P.O. Box 361131, Cleveland, Ohio 44136-0019, 1-866-840-6483

32

Loading...

Loading...