Page 1

T_RO BILT_

Operator's Manual

Rear-tine Tiller Models

630C Tuffy

634F BroncoT.

Model 634A Shown

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Troy-BiltLLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTEDIN U.S.A. FORMNO. 770-10594D

11/19/03

Page 2

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 17

Safety 3 Off-season Storage 21

Assembly 6 Troubleshooting 22

Features and Controls 10 Parts List 23

Operation 12 WarrantyBackCover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Z Z

Copy the model number here:

ZZZ ZZZZZ ZZZZZZ Z Z ZZ

'mJ_._JN_'_e" TROY-BILT LLC

H_._ar _=wm_m P.O. BOX 361131

www.troybilt.com CLEVELAND, OH 44136

_, 1-800-520-5520

330-558-7220

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreturnthe unitto theretailer withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

The answer you are

looking for could be just

I

, miTeuat_lme _Jolm] _e_eJlr Rb_e_eJ yea_S.

Service Locater

Nee_i J_cal a_i_fa=_?' _li_tk he/e T,_fh_{

•_R_h_ize_B sewi_e celklei_ J_ V_Y_H ,_e_.

Manuals OnMine

Nee(J a malarial au_d'el U_altsmist?DewJ_lead

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

and service. Please refer to the

Page 3

SECTION1: SAFETY

Thismachinemeetsvoluntarysafetystan,

dardB71.8-1996, whichissponsoredbythe

OutdoorPowerEquipmentInstitute,Inc.,

andis publishedbythe AmericanNational

StandardsInstitute.

WARNING

Theengineexhaustfromthisproductcontains

chemicalsknowntotheStateofCaliforniato

causecancer,birthdefectsor otherreproduc-

ForwardClutchB_

ClutchControl

(Models634FJ634A)

Depth Regulator

TineHoodFlap

_i&, in this manual and on the unit to alert

personal injury or property damage.

and anyother literatureyou may receive. 4. Do not operatethe tiller when barefoot

Bethoroughly familiar with the controls or wearing sandals,sneakers,or light foot-

andthe proper use of the tiller and its en- wear.Wearprotective footwear that will nition until fuel vapors havedissi-

gine.Know howto stop the unit anddisen- improve footing on slippery surfaces.

gagethe controls quickly.

2. Neverallow childrento operatethe tiller.

Neverallow adults to operatethe tiller

without proper instruction.

3. Keepthe area of operation clearof all

persons,particularly children and pets. highly flammable and its vapors areexplo-

4. Keepin mind that theoperatoror useris sive. Takethe following precautions:

responsiblefor accidents or hazardsoc-

curring to other people,their property,and designedfor this purpose.

themselves.

Preparation

1. Thoroughly inspect thearea wherethe

tiller is to be used and removeall foreign

objects.

2. Be sure all tiller controls are released

and bothwheelsare in the WheelDrive po-

sition beforestarting the engine.

This is a safety alert symbol. It is used

youto potential hazards. When you

see this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

Figure1-1:Tillerfeaturesandcontrols.SeeseparateEngineOwner'sManualto

identifyenginecontrols.

Training 3. Do not operatethetiller without wearing

"_ @ 1. Carefullyreadthis Own- adequateoutergarments. Avoid loosegar-

er's Manual,the separate ments or jewelry that could get caught in

EngineOwner'sManual, moving parts.

5. Do nottill nearunderground electric ca- 7. Nevermakeadjustmentswhen engineis

bles, telephonelines, pipes or hoses.If n running (unless recommendedby manu-

doubt, contact your telephone or utility facturer).

company.

6. Warning: Handlefuel with care: it is Operation

a. Storefuel in containers specifically

b. Thegascapshall neverberemovedor

fueladdedwhiletheengineis running.

Allow the enginetocool for several

minutesbeforeaddingfuel.

c. Keepmatches,cigarettes,cigars,

pipes, openflamesand sparks away

from thefueltankandfuelcontainer.

d. Fillfuel tank outdoorswith extreme

care.Neverfill fuel tank indoors. Use

afunnel or spout to preventspillage.

dard-Rotating-Tines

(SRT)

DrivePin

e. Replaceall fuel tank and container

capssecurely.

f. If fuel is spilled, do notattemptto

start the engine,but movethe ma-

chineawayfrom the areaof spillage

and avoidcreating any source of ig-

pated.

1. Do not put handsor feet nearor under

rotating parts.

2. Exerciseextremecaution when on or

crossing gravel drives,walks, or roads.

Stayalert for hiddenhazardsor traffic. Do

not carry passengers.

3.After striking aforeign object, stop the

engine,remove the wire from the spark

plug wire and prevent it from touchingthe

spark plug. Thoroughly inspect the ma-

chinefor any damageandrepairthe dam-

age beforerestarting and operatingthe

machine.

Page 4

4.Exercisecautiontoavoidslippingorfall-

ing.

5.Iftheunitshouldstarttovibrateabnor-

mally,stoptheengine,disconnectthe

sparkplugwireandpreventitfromtouch-

ingthesparkplug,andcheckimmediately

for the cause. Vibration isgenerally a barsRelax yourarm, butuse a

warning of trouble, securehandgrip.

6. Stop the engine, disconnectthe spark

plugwire and preventitfrom touchingthe settings,workinggraduallydeeper

spark plug,whenever you leavethe oper-

atingposition,before uncloggingthetines, c. Useslowerenginespeeds.

or when makingany repairs, adjustments d. Clearthetillingarea ofall large

or inspections, stones,rootsorotherdebris.

7. Takeall possible precautions whenleav-

'rig the machineunattended. Stopthe en- the handlebars.If needbe, use

gine. Disconnectthe spark plug wire and slightupwardpressureto keep the instructions and with feet well awayfrom

move itawayfrom the spark plug. Besure

that both wheelsare inthe WheelDrive po-

sition.

8. Before cleaning,repairing, or inspect- raise thetines outof thesoil. MaintenanceandStorage

'ng, stopthe engine and make certain all g. Inanemergency,stop the tines and 1. Keepthe tiller, attachmentsand acces-

mowng parts havestopped. Disconnect wheelsby releasing whichever sories in safe working condition.

the spark plug wire and prevent it from

touching the spark plug to preventacci- clutchcontrolis engaged. Do not 2. Checkall nuts, bolts, and screws at

dentalstarting.

9. The flap onthe tine hood must bedown

when operating the tiller.

10. Neveruse the tiller unlessproper

guards, plates,or other safety protective

devicesare in place.

11. Do not run the engine in an enclosed

area. Engineexhaust contains carbon

monoxide gas, a deadlypoison that is

odorless, colorless, and tasteless, is too steepfor safety. Whenon slopes,

12. Keepchildren and pets away.

13. Never operatethe tiller underengine

powerif the wheels are in the Freewheel

position.In the Freewheelposition, the

wheelswill not holdthe tiller backandthe

revolving tinescould propelthe tiller rapid- that are approved by the manufacturerof

ly, possiblycausing loss of control. Always the tiller.

engagethe wheels with the wheeldrive

pins nthe Wheel Drive position before

starting the engineor engagingthe

tines/wheelswith the Forward Clutch Bail

(all models) or the ReverseClutchcontrol

(Models 634F/634Aonly).

14. Be aware that the tiller mayunex-

pectedlybounceupwardorjumpforward

if the tinesshouldstrikeextremely hard

packedsoil, frozenground, or buried ob-

stacleslike large stones,roots,or

stumps.

If indoubtaboutthetilling conditions,al- 24. Do not touch engine parts which may

ways usethe followingoperatingprecau- be hotfrom operation.Let partscool down

tionsto assistyouinmaintaining control sufficiently.

ofthe tiller: 25. Pleaseremember:Youcan alwaysstop

a. Walk behindandto oneside of the thetines and wheels by releasingthe For-

tiller, usingonehandonthehandle ward Clutch Bailor on Models 634F and

634A the ReverseClutchcontrol, (which-

evercontrol is engaged),or by movingthe

b. Useshallowerdepthregulator

with eachpass.

e. Avoidusingdownwardpressureon

tines fromdiggingtoo deeply.

f. Beforecontactinghardpackedsoil 29. Neverpickuporcarryamachinewhile

at the endof a row,reduce engine theengine _srunning.

speedand lift thehandlebarsto

attemptto restrainthe tiller, ervalsfor proper tightness to besure the

15. Do not overloadthe tiller's capacityby equipment is insafeworking condition.

attempting to till too deeplyattoo fast a 3. Neverstorethetiller withfuel in thefuel

rate. tankinsidea building whereignition sourc-

18. Neveroperatethe tiller at high trans- esare presentsuchas hot waterandspace

port speedson hard or slippery surfaces, heaters,furnaces, clothesdryers, stoves,

Look behind and use carewhen backing electric motors,etc.). Allow the engineto

up cool before storing the unit in anyenclo-

17. Do notoperatethetiller onaslopethat sure.

slow down and makesure you have good

footing. Never permit the tiller to free-

wheeldown slopes.

18. Neverallow bystanders nearthe unit.

19. Only useattachmentsand accessories

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethe tiller without good

visibility or light.

22. Neveroperatethe tiller ifyou aretired;

or underthe influence of alcohol, drugsor

medication.

23. Operatorsshall nottamper with the en-

gine-governor settings on the machine

the governor controls the maximum safe

operatingspeed to protect the engine and

all moving parts from damagecaused by

overspeed. Authorized service shall be

sought if a problem exists.

ignition switch and/orthrottle control lever

on the engineto "OFF"or "STOP".

26. To load or unload the tiller, seethe in-

structions in Section4 of this Manua.

27. Useextreme caution when reversing

or pulling the machinetowards you.

28. Startthe enginecarefully accordingto

thetines.

4. To reducethe chancesof a fire hazard,

keepthe enginefreeof grass, leaves,orex-

cessivegrease.

5. Store gasolinein acool, well-ventilated

area,safely awayfrom anyspark- or

flame-producing equipment. Store gaso-

line nanapproved container,safely away

from the reachof children.

8. Refedto the Maintenancesections of

this Manualand the separateEngineOwn-

er'sManualfor instructions ifthe unit isto

be stored for an extendedperiod.

7. Neverperform maintenancewhilethe

engine isrunning orthe sparkplug wire is

connected,exceptwhen specifically n-

structed to do so.

8. Ifthe fueltank hasto bedrained,dothis

outdoors

Page 5

Decals

For your safety and the safety of others, vari-

ous safetyand operationaldecals are located

on your unit (see Figure 1,2).

ForwardClutchBail

ReverseClutchControl

OperatingInstruction

(Models 634F/634A)

Keep the decals clean and legible at all times.

Contact your local service dealer or the factory

for replacements if any decals are damaged or

missing.

Refer to the Parts List pages in this Manual for

decal locations, descriptions and part num-

bers.

StartingStabilization

Message (on engine)

WarningMessages

HotSurfacesWarning

Figure 1-2: Locationof safetyand operatingdecals.

OperatingSymbols

Varioussymbols(shownhere,withworddescriplions)

rr_ beusedonlhe_llerandengine.

NOTE:Yourunitm_ notha_ allof_esymbols.

FAST SLOW STOP TILLER DIRECTION LEVERDIRECTION

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALL CONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEAND WORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAYFROM ROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHEMACHINETOWARDS

YOU.

I-'-I I*1 R

CHOKE CHOKE REVERSE

ON OFF ROTATINGTINES

TO AVOID SERIOUS INJURY:

BAIL

ENGAGED

BAIL

DISENGAGED

Page 6

SECTION2: ASSEMBLY

WARNING: Toprevent ASSEMBLYSTEPS

personalinjuryor property

damage,do notstarttheengine STEP 1: UNPACKING INSTRUCTIONS

until all assemblysteps are NOTE:While unpacking,do notseverely

completeandyou haveread bendanycontrol cables.

and understandthesafety and 1.Thetiller weighs approximately 133 Ibs.

operatinginstructions inthis Do notattemptto remove it from the ship-

manual ping platform until instructedto do so in

INTRODUCTION

Carefullyfollow these assemblysteps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginning assembly.

NOTE: Various tiller models are

presented in this Manual Use only the

information appropriate for your tiller LoosePartsList(contactyour localdealer

model Engine styles vary by model Your or the factory itemsare missing or dam-

engine may appear differently than those aged).

illustrated in this manual,

INSPECTUNIT (Fig.2-1) toidentify screws.

Inspectthe unit and carton for damageim- LooseParts List

mediatelyafter delivery. Contactthe carri-

er (trucking company) if you find or

suspect damage. Inform them of the dam- 1

ageand request instructions for filing a

claim. To protect your rights, put your

claim in writing and mail a copyto the car-

rierwithin 15 daysafterthe unit has been

delivered.ContactTroy-Bilt LLC if you

needassistancein this matter.

TOOLS/ MATERIALSNEEDED

(2) 1/2" open-end wrench*

(2) 9/16" open-endwrench*

(1)

3/8" open-endwrench* started. Followthe instructions inthis IMPORTANT:The support brackets must

(1) Largeadjustable wrench

(Models634F/634A only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belttension check)

(1) Block of wood (to support tiller when

removing wheels)

(1) Tire pressure gauge (for modelswith

pneumatictires)

(1) Cleanoilfunnel

(1)

MotoroiI. Refertothe EngineOwner's thetillerframeusing wo3/8- 6 3/4 hex

Manualfor oil specificationsand hd. screws (B), 3/8" flat washers (C),and

quantityrequired. 3/8"-16 hexIocknuts (D).

* Adjustable wrenches maybeused.

these Assembly steps.

2. Removeanypackaging materialfrom

the carton. Removeanystaples from the

bottom of the carton and removethe car-

ton from the shipping platform.

3. Removeall unassembledparts andthe _

separatehardwarebagfrom the carton. -.........

Checkthat you havethe items listed in the Figure2-1:Toidentifylengthofscrews,place

NOTE: Use the screw length template

0tv.

HandlebarSupport (seeA, Fig.2-2)

1

HandlebarAssembly(seeK, Fig.2-2)

4 Hex hd. screw. 5/16-18 x 1-1/2....... levelwhen thetines are3"-4" intothe

2 Hex hd. screw. 3/8-16 x 3/4'

2 FlatWasher,3/8"

4 Split Iockwasher,5/16"

4 Hex nut, 5/16"-18

2 Hex Iocknut, 343"-16

*Model 634F& 634A only

IMPORTANT: Motor oil must beaddedto

the enginecrankcasebefore theengine is

Sectionand in theseparateEngine

Owner's Manual.

NOTE: LEFTandRIGHTsidesof thetiller

are as viewedfrom the operator's position

behind thehandlebars,

STEP 2: ATTACHHANDLEBAR

1. Looselyattachthe legs of the handlebar

support (A, Fig.2-2) to the inner sides of

Description 3. Therearethree heightadjustment holes

Hardware bagcontents: sition the handlebarsat approximately

t "lx "

screwontemplateasshownandmeasuredis-

tancebetweenbottomofscrewheadandtipof

screw.

2. Usingtwo 5/16"-18 x 1-1/2"screws (G),

5/16" split Iockwashers (H)and5/16"-18

hex nuts (I), looselyattach the handlebar

support (A) usingthe upperholes. Tighten

thetwo screws securely.

....................... brackets(E

and F,Fig. 2-2). Usea setting that will po-

soil. Looselyattachthe support brackets

tothe outsideofthe handlebarassembly

(K) usingtwo 5/16"-18 x 1-1/2" screws

(G),5/16" split Iockwashers(H) and 5/16"-

18 hexnuts (I). NOTE:Ifasupport bracket

will not move loosenattaching screw (J)

and nut.

beassembledto the outsideof the

handlebarassembly.

4. Tighten all handlebar mounting hard-

waresecurely.

STEP 3: MOVE TILLER OFF CRATE

Toroll the tiller off the shipping platform,

put the wheels in freewheel,as follows:

1. Placeasturdy block underthe transmis-

sion to raiseonewheel about 1"off the

ground.

2. Removethe hairpin cotter (L, Fig.2-3)

and wheeldrive pin (M) from the wheel

hub (0) and wheel shaft (N).

Page 7

K

G

Fig. 2.2: Attachhandlebar.

3. Slidethe wheelfully inward onthewheel

shaft (N, Fig.2-3). Reinstallthe wheel

drive pin (M) through the wheelshaft only

(not through the wheel hub). Securethe

wheeldrive pin with the hairpin cotter (L),

pushingthe hairpincotter in asfar as it will

go. Thewheelshould now spin freely

(freewheel) on the wheel shaft. Repeat

with the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

Fig. 2-3: Wheel in FREEWHEELposition

STEP 4: INSTALL FORWARD

CLUTCH CABLE

1. Carefully unwrapthe forward clutch ca-

ble (cablewithout anattachedknob)from

its shipping position and slide thethin ca-

ble wire (T, Fig.2-4) into the slot in theca-

ble bracket. Pushthe cableconnector (U,

Fig.2-4) upthrough the holein the bracket

until the groove in the connector snaps

into place.

2. Thread the #10-24 hex nut (Z, Fig. 2-5)

halfwayonto the screw (V)which runs

through the spring (W, Fig.2-5).

3. Thread the screw (V) into the cablead-

B

juster (X).

IMPORTANT:Before starting the engine,

the wheels must be placedin the WHEEL

DRIVEposition (pins through wheel hubs

andwheelshaft). This procedureis

describedin WheelDrivePinsinSection3.

Fig. 2-4:Installing forward clutchcable bracketand cable.

Page 8

4. Checkfor correct tension ontheforward

drive belt bytaking two measurementsof

the cable spring, asfollows

a. With the ForwardClutch Bail (Y,Fig.2-

6) in an open(released) position, measure

the length ofthe cablespring (W)from the

outermost coil to the outermost coil.

b. Squeezethe ForwardClutchBailagainst

the handlebar(see Fig. 2-7) and re-mea-

surethe spring length. The belttension is

correct if this secondmeasurementis be-

tween 1/16"to 3/16"longerthanthe first

measurement. If so, turn the hexnut (Z,

Fig.2-7) tightly against the cableadjuster

(X) while preventingthe cableadjuster

from turning.

c. If thespring length is incorrect, you

must adjustthe cabletension as described

"nCheckingand Adjusting Forward Drive

Belt Tensionin Section 5. Incorrect cable

tension can result in belt slippage (cable

tension too loose), or unintentional tine

movement whenthe clutch bail is inNeu-

tral (cable tension too tight).

Y

Fig. 2-7: Tocheckforwardbelttension, take twomeasurementsof thelengthofthecoils inthe

spring_ first with thebail open, thenwith thebail held against thehandlebar.

STEP 5: INSTALL REVERSE CLUTCH

CABLE(MODELS 634F & 634A ONLY)

1. Unwrapthe reverseclutch cable (CC,

Fig.2-8 and Fig.2-9) from itsshipping po- BB

sition and route it up to the handlebar. Be

surethat the cableis routed beneaththe

Forward Clutch Bail.

2. Insertthecable(CC,Fig.2-8)through the DD

slot inthecablebracketand positionthe flat

sideof thethreadedassembly nextto the

flat sideof the hole. Slidethe hexnut(DD)

up thecable andtighten itsecurely. Flat Side

3. Fastenthe reverseclutch cableto the

left side handlebarwith a cabletie (EE,Fig.

2-9). Fig.2-8:Installreversecablebracketand

4. Testthefunction ofthe reverseclutch by reverseclutchcable.

pulling out and releasingthecable knob.

The knob should return to its neutral posi-

tion (resting against bracket). If it doesn't,

contact your local dealer or Troy-Bilt LLC

for technical assistance.

Fig. 2-5: Cable Fig. 2-6: Attachforward

springand clutchcable springto

adjuster, forwardclutchbail.

Fig. 2-9: Route reverseclutchcable(CC)as

shown. Attachwith cable tie (EE).

Page 9

:sI=-P6: CHECKTRANSMISSION

OILLEVEL

Thetransmissionwasfilled withgearoil at

thefactory. However,you shouldcheck the

gear oil levelat this time to makecertain it

is correct.

IMPORTANT:Donot operatethe tiller if the

gearoil levelis low. Doingso will result in

severedamageto the transmission com-

ponents.

1. With the tiller on levelground, pullthe

Depth RegulatorLever(FF,Fig.2-10) back

andthen all the wayupuntil the lowest

notch in the lever isengaged.

2. Removethe oil fill plug (GG, Fig.2-11)

from the transmission housingcover and

locatethe main driveshaft situated inside

the housing.

3. Thegear oil level is correct ifthe gear

oil is approximately halfway up theside of

the main driveshaft.

4. Ifthe oil levelis low,addgearoilby re-

ferring to A. ToCheckthe Transmission

GearOil Level in Section 5.

_SI I::P1: ADD IVlUI UH UIL

The tilleris shipped withoutoil inthe en-

gine.

IMPORTANT:Do notstart the enginewith-

out first adding motor oil. Severeengine

damagewill resultifthe engineis run with-

out oil.

1. Referto the separateEngineOwner's

Manualfor engineoilspecifications and

capacities.

2. With the tiller on levelground, movethe

DepthRegulator Lever(FF,Fig.2-10) up or

down until the engine is level.

3. Add motor oil asdescribed inthe En-

gine Owner'sManual.

4. Movethe Depth RegulatorLeverall the

way down until the highest notch is en-

gaged. This placesthe tines in the "travel"

position, which allows the tiller to be

moved without the tines touching the

ground.

:si 8: CHECKHARDWARE

Checkall nuts and screws for tightness.

STEP 9: CHECKAIR PRESSURE IN

TIRES (units with pneumatic tires)

Checkthe air pressurewith a tire gauge.

Deflateor inflatethe tires equallyto be-

tween 15 PSI and 20 PSI (pounds per

squareinch). Besurethat bothtires are in-

flated equally or the unit will pullto one

side.

FF--

Fig. 2-10: AdjustDepthRegulatorLever.

Fig. 2-11: Removegear oil fillplug.

llVlt'UNIAP]l: Jn_scompletesmeassembly steps.

Beforeoperating your tiller, makesureyou readthe

following sections in this Manual,aswell as the

separateEngineOwner'sManual:

• Section1: Safety

• Section3: Featuresand Controls

• Section4: Operation

Page 10

SECTION3: FEATURESANDCONTROLS

WARNING: Before

operatingyour machine,

carefully readandunderstand

all safety,controls and

operatinginstructions inthis

Manual,the separateEngine

Owner'sManual, andon the

decalson the machine.

Failureto follow these

instructions can result in

serious personalinjury.

INTRODUCTION

This Section describesthe location and

function of thecontrols onyour tiller. Re-

fer to the following Section,Operationfor

detailedoperating instructions.

Practiceusing thesecontrols, with the en-

gine shut off, until you understandthe op-

eration of the controls andfeelconfident

with eachof them.

ForwardClutchBail

ReverseClutchControl

(Models634F/634A)

DepthRegulator

Handlebar HeightAdjustment

Wheel Drive Pin

(oneachwheel)

ENGINE CONTROLS

Referto the engine manufacturer'sEngine

Owner'sManual(included in the tiller liter-

ature package)to identify the controls on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is located on the engine.

WHEEL DRIVE PINS

Eachwheel is equippedwith a wheel drive

pin (A, Figures3-2 and 3-3) that secures

the wheelto the wheelshaft (B). The

wheelscan be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

WARNING: Neverallow

eitherof thewheelsto beinthe

FREEWHEELposition when the

engineis running. Always put

both wheelsin the WHEEL

DRIVEposition beforestarting

the engine.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

Beforestarting theengine,put both wheels

in the WHEELDRIVEposition byinserting

the wheel drive pins through the wheel

hubs andthe wheel shaft. Doingso

"locks" the wheels to the wheel shaft,

causingthe wheelsto turn when eitherthe

Figure3-1: Tillerfeaturesand controls.See sepereteEngineOwner'sManual to identify

enginecontrols.

Forward ClutchBail (all models) or the Re-

verse ClutchControl (Models 634F and

634A) isengaged.

Usethe FREEWHEELmode only whenthe

engineis not running. In FREEWHEEL,the

wheeldrive pins are placed only through

the holes in thewheel shaft (not the wheel

hubs), thus allowing the wheels to turn

freely whenyou manuallymovethe tiller.

To placethewheels in WHEELDRIVEor

FREEWHEEL:

1. Stopengine,disconnectspark plugwire

from spark plugandallowengineto cool.

WARNING: Do not place

tiller on its side whenchanging

wheeldrive positions. Doingso

could result in gasoline leaking

from thefuel tank.

Failureto follow this instruction

could result in personal injury

or property damage.

2. Raiseonewheelabout one inch off the

ground and placeasturdy support under

the transmission.

3. Removehairpincotter (C, Figures3-2

and 3-3) from wheel drive pin(A).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheeloutward and align holes in

10

Figure3.2: WHEELDRIVE position.

wheelhub (D, Figure 3-2) and wheel

shaft (B). Insert wheeldrive pin (A)

through wheel hub (D)and wheel

shaft (B). Securewheel drive pin with hair-

pin cotter (C) by pushing hairpin cotter in

asfar as it will go. Repeatwith the other

wheeland then removethe support from

beneaththe transmission.

5. FORFREEWHEELMODE( Figure3-3):

Slidethewheel inwardand insertthe wheel

drive pin (A, Figure3-3) onlythrough the

hole in the wheel shaft (B). Securewheel

drivepin with hairpincotter (C)by pushing

hairpin cotter in as far as it will go. Repeat

for the other wheel and then removethe

support from beneaththetransmission.

A

Page 11

B

oD

\

C

Figure3,3" FREEWHEELposition.

WARNING: Beforestarting

engine,besure that both

wheelsare in WHEELDRIVE

position. SeeWheelsDrive

Pins for instructions.

Engagingthe ForwardClutch

Bail or ReverseClutchControl

(if equipped) when thewheels

are notin WHEELDRIVEcould

allowthe tinesto rapidly propel

thetiller forward or backward.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

FORWARDCLUTCHBAIL

TheForward Clutch Bail(E, Figure3-4)

controls the engagementof forward drive

to the wheelsand tines.

Tooperatethe ForwardClutchBail:

1. Put wheels in WHEELDRIVEposition

(see"WARNING"statement above).

2. Lift and hold the clutch bail (E, Figure3-

4) againstthe handlebarto startthe wheels

andtines rotating inaforward direction.

3. Releasetheclutch bailto disengage

(stop) thewheels andtines (the enginewill

continue to run).

REVERSECLUTCHCONTROL

(Models634F/634A only)

TheReverseClutchControl (F,Figure3-4)

controls the engagementof reversedrive

to the wheelsand tines. The reversing

featureisusedfor maneuveringthetiller

only-- neverengagethe tines inthe

groundwhile operatingin reverse.

WARNING: Useextreme

caution whenreversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.

Neverattemptto till inreverse.

Failureto follow this warning

could result in personal injury

or property damage.

To operatethe ReverseClutchControl:

1. Put wheels in WHEELDRIVEposition

(see"WARNING"statement at the left).

2. Stop all tiller motion by releasingthe

Forward Clutch Bail.

3. Lift the handlebar untilthe tines clear

the ground, look behind you to avoid any

obstacles,and then pull the control knob

(F,Figure3-4) out. Thewheels andtines

will rotate in a reversedirection.

4. Releasethecontrol knob to disengage

(stop) the wheelsandtines (the enginewill

continue to run).

Figure3-4: All modelshave aForwardClutch

Bail (E). OnlyModels 634F/634Ahavea Re.

verseClutchControl(F).

DEPTH REGULATORLEVER

This lever (G, Figure3-5) controls the till-

ing depth of the tines. Pull the lever back

and slide it upor downto engagethe

notched heightsettings.

The"travel position" (highestnotch) raises

the tines approximately1-1/2"offthe

ground,allowing the tiller to be moved

without the tines contacting the ground.

This setting should also be used when

starting the engine.

Moving the lever upward will increasethe

tilling depth. Thelowestnotch allows atill-

ing depth of approximately 6", depending

onsoil conditions. Forbestresults,always

begintilling at avery shallow depthsetting

and gradually increasethe tilling depth.

WARNING: Do notattempt

totill too deeplytoo quickly.

Graduallywork down to deeper

tilling depths.

Placethe DepthRegulator

Leverin the "travel" position

beforestarting the engine. This

position preventsthetines from

touching the ground until you

are readyto begintilling.

Failureto follow this warning

could result in personal injury

or property damage.

TravelPosition !G

Settings

Figure3-5: Depth RegulatorLever (G).

HANDLEBAR HEIGHT ADJUSTMENT

Thehandlebarheight isadjustableto three

different settings (Figure 3-6). In general,

adjust the handlebars sothey areat waist

levelwhen the tines are3"-4" in the soil.

Toadjust the handlebars:

1. Stop engine, disconnect spark plug

wire from spark plug and allow engineto

cool.

2. Removehardware,reposition handle-

bars, and reinstall hardwaresecurely.

High

Figure3.6: Handlebarheightadjustment.

11

Page 12

SECTION4: OPERATION

WARNING: Before

operatingyour machine,

carefully readandunderstand

all safety (Section 1),controls

(Section 3) and operating

instructions (Section 4) inthis

Manual,the separateEngine

Owner'sManual, andon the

decalson the machine.

Failureto follow these

instructions can result in

serious personalinjury.

INTRODUCTION

Readthis OperationSectionandthe sepa-

rate EngineOwner'sManualbeforeyou

start the engine. Then,take thetime to fa-

miliarize yourself with the basic operation

of the tiller before using it in the garden.

Findanopen, levelareaandpractice using

thetiller controls without thetines engag-

ing the soil (put tines in "travel" setting).

0nly after you've becomecompletely fa-

miliar with thetiller shouldyou beginusing

it in the garden.

BREAK-INOPERATION

Perform thefollowing maintenanceafter

thefirst two (2) hours of new operation

(seeMaintenance Section in this manual

and in the EngineOwner's Manual).

1. Changeengine oil.

2. Checkfor looseormissing hardwareon

unit. Tightenor replaceas needed.

3. Checktension on forward drive belt.

4. Checktransmission gear oil level.

STARTINGANDSTOPPING

Pre-StartChecklist

With thespark plug wire disconnected

from the spark plug, perform thefollowing

checksand services beforeeach use:

1. Readthe Safetyand Controls Sections

in this manual. Readthe separateEngine

Owner'sManual providedwith the unit.

2. Putthe wheels in the WHEELDRIVE

position (wheel pins must bethrough

holes in wheel hubsand wheel shaft).

3. Checkunit for loose or missing hard-

ware. Serviceasrequired.

4. Checkengineoil level. See Engine

Owner'sManual.

ReverseClutchControl

(Models634F/634A)

)epthRegulator

Drive Pin

Fig. 4-1

5. Checkthatall safety guards andcovers

are in place.

6. Checkair cleaner and enginecooling

system. SeeEngineOwner's Manual.

WARNING: GASOLINEIS

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Follow gasolinesafety rules in

this Manual(seeSection1)and

in theseparateEngineOwner's

Manual.

Failureto follow gasolinesafety

instructions can result in

serious personalinjury and

property damage.

7. Fillthefueltankwith gasolineaccording

to the directions in the separate Engine

Owner's Manual. Followall instructions

and safety rules carefully.

8. Attach spark plug wire to spark plug.

Startingthe Engine

The following steps describe how to start

and stop the engine.

WARNING: Donotattempt

to engagethe tines or wheels

until you havereadall of the

operating instructions in this

Section. Also, reviewthe safety

rules in Section 1: Safety,and

the tiller andenginecontrols

information in Section3:

Featuresand Controls.

1. Completethe Pre-Start Checklist on

this page.

2. Putthe wheels inthe WHEELDRIVEpo-

sition (seeWheelDrive PinsinSection3 of

this manual).

,_ WARNING: To help

• Before starting engine, put both

wheels in the WHEEL DRIVEposition.

Never havewheels in FREEWHEELpo-

sition when engine is running. When

thewheelsare in FREEWHEEL,theydo

not hold backthe tiller and the tines

couldpropelthe tiller rapidly

forwardor backward.

• Before starting engine, put Forward

Clutch Bail (all models) and Reverse

Clutch Control (Models 634F/634A

only)in neutral(disengaged)positions

byreleasing levers.

• Never run engine indoors or in en-

closed,poorlyventilatedareas. Engine

exhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

• Avoidenginemufflerandnearbyareas.

Temperaturesin these areas may ex-

ceed150° F.

3. Movethe DepthRegulatorLeverall the

way down to the "travel" position, sothat

thetines clear the ground.

4. Releaseall controls on the tiller.

5. On engine'swith afuel shut-off valve,

turn valveto open position, as instructed

in the separate EngineOwner's Manual.

6. Put ignition switch and/or throttle con-

trol lever located on engine in the "ON",

"RUN", "FAST"or "START"position, as in-

structed in the EngineOwner's Manual.

7. Chokeor prime engine,as instructedin

EngineOwner'sManual.

8. Put one hand on fuel tank to stabilize

unit when pulling starter rope handle.

Thenuse recoilstarter to start engine,as

instructed in the EngineOwner'sManual.

Whenenginestarts, graduallymove choke

lever (if so equipped) to "NO CHOKE",

"CHOKEOFF"or "RUN" position.

9. Usethe "FAST"throttle speedsetting

whentilling.

preventserious personalinjury

or damageto equipment:

12

Page 13

KEEPAWAYFROMROTATINGTINES.

ROTATINGTINESWiLL CAUSEiNJURY.

Stoppingthe EngineandTiller

1.To stop thewheelsandtines, releasethe

Forward ClutchBail (all models) or the Re-

verse ClutchControl (Models 634F and

634A) --whichever control is in use.

2. Tostopthe engine, put the ignition

switch and/or the throttle control leverin

the "OFF"or "STOP"position.

OPERATINGTHE TILLER

Thefollowing operatinginstructions pro-

videguidelines to using your tiller effec-

tively and safely. Besureto read Tilling

Tips & Techniques in this Section before

actually putting the tines into the soil.

NOTE:Thisis a traditional "Standard-Ro-

tating-Tine" (SRT)tiller with forward ro-

tating tines. It operatescompletely

differently from "Counter-Rotating-Tine"

(CRT)tillers or from front-tine tillers.

1. Followthe Pre-StartChecklist at the

beginning ofthis Section. Besurethat the

wheelsare in the WHEELDRIVEposition.

2. Movethe DepthRegulator Leverall the

way down, sothat the tines clearthe

ground. Usethis position whenpracticing

with thetiller andwhentraveling between

tilling sites. Beforeactually tilling, move

the lever to the desireddepth setting (see

Tilling Tips& Techniques).

3. Start engine and allow it to warm up.

Then put throttle in "FAST"setting.

4. Forforward motion of the wheelsand

tines:

(a) Pull ForwardClutch Bail (Fig. 4-1) up

againsthandlebar. Releasebailto stop for-

ward motion of wheels and tines.

(b) Whentilling, relaxand let the wheels

pull the unit while the tines dig. Walk be-

hind anda little to oneside ofthe unit. Use

one hand,yet keepa light--but secure--

grip on the handlebar (while keepingyour

arm loose). SeeFig.4-2. Let the unit

move at its own paceand do not push

down on the handlebarsto try andforce

the tines to dig deeper-- this takes weight

off the wheels, reducestraction, and caus-

esthe tines to try and propel the tiller.

WARNING: Do not push

down onthe handlebarsto try

to makethe tiller till more

deeply. This preventsthe

wheelsfrom holdingthe tiller

backand canallow thetines to

rapidly propelthe tiller forward,

which could result in loss of

control, property damage,or

personalinjury.

5. Forreversemotion of the wheelsand

tines (Models634F/634Aonly):

(a) Lookbehindandexercisecaution when

operating in reverse. Donottill while in

reverse.

(b) Stopall forward motion. Lift handle-

bar with onehanduntil tines are off the

ground and then pull ReverseClutchCon-

trol knobout (seeFig.4-3). Tostoprevers-

ing, let go of ReverseClutch Control knob.

(b) Swingthe handlebarto the left so the

right wheeltakesa "step" backward.Next

swing the handlebarto the right sothe left

wheel"steps" backward.Repeatasneeded.

(c) If longer distancesneedto be covered

in reverse,shut off the engine,then place

thetwo wheels in FREEWHEEL.

7. ToTurntheTiller Around:

(a) Practiceturning thetiller in a level,

open area. Bevery careful to keepyour

feet and legsawayfrom the tines.

(b) Tobegina turn, lift the handlebarsuntil

thetinesareout ofthe groundandtheengine

andtines are balancedoverthe wheels(Fig.

4-4).

(c) With tiller balanced,push sidewayson

handlebarto steer in direction of turn (Fig.

4-5). After turning, slowly lowertines into

soil to resumetilling.

Fig.4,4: Tobeginturn,lift handlebarsuntil

tinesareoutofgroundandunitisbalanced.

Fig. 4-2: Use onehand to guidetiller when

movingforward.

Fig. 4,3: Raisetines offgroundand look

behind whenmoving in reverse.

6. Tomovethe Model630Cin reversefor

short distances:

(a) Releaseforward ClutchBail. Thenlift

handlebaruntiltines are off the ground.

13

Fig. 4.5: Withtinesout ofground,push han-

dlebarssidewaystoturn tiller.

StoppingtheTillerandEngine

1. Tostopthe wheels and tines, release

the ForwardClutch Bail (all models) or the

ReverseClutch Control (Models 634Fand

634A) -- whichevercontrol is in use.

2. Tostopthe engine, put the ignition

switch and/orthe throttle control leverin

the "OFF"or "STOP" position.

Page 14

TILLING TIPS&TECHNIQUES

Tilling Depths

WARNING: Before

tilling,contactyour

telephoneor utilities

companyand inquire if

underground equipment or

lines areused on your

property. Do nottill near

buried electric cables,

telephone lines,pipes or

hoses.

• Whencultivating(breakingupsurfacesoilaroundplantsto destroyweeds,seeFig.4,9), adjustthe tinestodig only 1"to 2,deep. Using

shallowtilling depthshelpspreventinjuryto plantswhoserootsoftengrowclosetothesurface. If needed,lift uponthehandlebarsslightly

to preventthetines from diggingtoo deeply.(Cultivating ona regularbasisnotonlyeliminatesweeds,it alsoloosensandaeratesthe soil

for bettermoistureabsorptionandfaster plantgrowth.)

• Avoid pushingdown onthe handlebarsin anattemptto forcethe tiller to dig deeper.Doing

sotakestheweightoff the poweredwheels,causingthemto losetraction.Without thewheels

helpingto holdthe tiller back,thetineswill attemptto propelthetil!er- oftencausingthetiller

to skip rapidlyacrossthe ground. (Sometimes,slightdownwardpressureonthehandlebars

will helpgetthrougha particularlytough sectionof sodor unbrokenground,butinmostcases

this won,t benecessary.)

• Avoidtrying to dig too deeplytoo quickly,especiallywhenbustingsodor when tilling soi!

that hasn,tbeentilledfor sometime. Useshallowdepthregulatorsettings(on!yaninchortwo

deep)for thefirst passesthrough thesoil,With eachsucceedingpass,diganotherinchortwo

deeper.(Wateringthe areaafew dayspriorto tilling will maketilling easier,as will lettingthe

newlyworkedsoil setfor aday or two beforemakinga final, deeptilling pass.)

ChoosingCorrectWheel&Tine Speeds With experience,you will find the "just right',tilling depthandtillingspeedcombination

that is I_estfor your garden.

Settheenginethrottleleverataspeedto give theengineadequatepowerandyet allowitto operateattheslowestpossib!espeed.,at least

untilyou haveachievedthe maximumtilling depthyou desire.Fasterenginespeedsmaybedesirablewhenmakingfinal passesthrough

theseedbedor whencultivating, Selectionof thecorrect enginespeed,inrelationtothetilling depth,will ensureasufficientpowerlevelto

dothejob without causingtheengineto labor.

LettheTiller DotheWork

Whiletilling, relaxandletthe wheelspullthe

tiller along while the tines do thedigging,

Walkon thesidethat is not yet finished(to

avoidmakingfootprints in the freshlytilled

soil) and lightly,but securelygrip thehan-

dlebarwith just onehand.

AvoidMakingFootprints

Whenever possible,wa!k on the untilled

sideof the unitto avoid makingfootprintsin

your freshly til!ed or cultivatedsoil. Foot-

printscausesoil compactionthat can ham-

per root penetrationand contribute to soil

erosion.They can also ',plant,,unwanted

weed seeds back into the freshly tilled

ground.

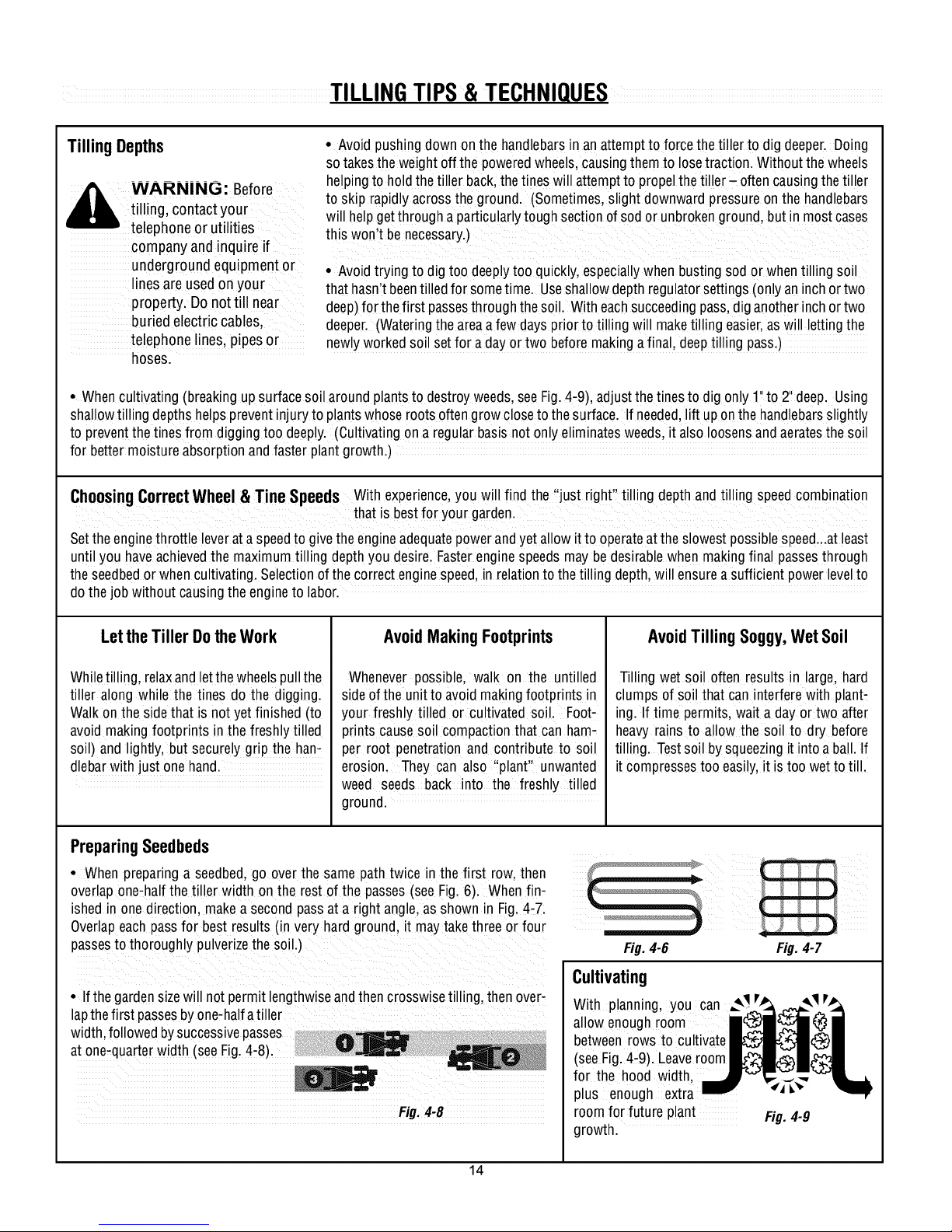

PreparingSeedbeds

• When preparing a seedbed,go overthe samepathtwice in thefirst row,then

ishedin onedirection,make a secondpassat aright angle,asshownin Fig,4,7:

overlapone,halfthe tiller width on the rest ofthe passes(see Fig,6). Whenfin-

Overlapeachpassfor best results(in veryhard ground,it maytakethreeor four

passesto thoroughlypulverizethesoil.)

• Ifthe gardensizewill not permitlengthwiseandthencrosswisetilling, thenover-

lapthefirst passesbyone,halfatiller

width,followedbysuccessivepasses

at one-quarterwidth (seeFig,4-8)

Fig. 4,8

AvoidTillingSoggy,WetSoil

Tilling wet soil oftenresultsin large,hard

clumps of soil that can interferewith plant-

ing.If time permits, wait a dayortwo after

heavyrains to allow the soil to dry before

tilling. Testsoil by squeezingit intoa ball.If

itcompressestooeasily,it is too wetto till,

Fig.4-6

Fig. 4-7

Cultivating

With planning, you can ..,_,_vj_, _,_ v_,_

allowenoughroom i_i _i(_i

betweenrows tocultivate__)_

(seeFig.4,9). Leaveroom_J_-')_¢"_

for the hood width, J""_,-%._"_lt_

plus enough extra _ "4A-_-

roomfor future plant Fig. 4-9

growth.

14

Page 15

TILLING TIPS&TECHNIQUES(CON'T)

PowerComposting

Powercompostingsimply meanstilling underand burying inthesoil allmanneroforganic WARNING: Whenpower

mattersuchas cropresidues,leaves,grassclippingsandcovercrops.This materialwill de- composting, do not keepthe

composeduringthe non,growingseasonandaddimportantnaturalnutrientstothesoil. Depth Regulator Leverat a

Thefirst placeto beginiswith crop residuessuchasleftovervines,stalks,stemsandroots, deepsetting ifthe tiller jumps

Powercompostthesecrop residuesas soonastheyfinish bearing.Thesoonerthis isdone, or bucks,

thebetter,astendergreenmatteris easiertotillunder. Usethedeepestdepthregulatorset- If jumping or bucking occurs,

ting possiblewithout causingtheengineto laboror thetillerto jump ahead, movethe DepthRegulator

Leverdown to a shallow

Standingcornstalksof reasonableheightcan bepowercomposted.Pushing over(but not ._e.ftnnand the.n._nw V

uprooting)cornstalkswill oftenmakeit easierto chopupthestalks.Keepthetinesclearof incieasethetiilinc]deoth on

excessivetanglingby fishtailing orfrequentlyusingreverse.Makeseveralpasses,thenre, ........._.._....

turna fewdays latertofinish off any remainingstubble. Failureto followthis warning

Aftertilling undercrop residues,addmoreorganicmattersuchas leaves,grassclippingsand could resultinpersonalinjury.

evenkitchenscraps. Whentilled intothe soil,this organicmatterwill decomposeandadd

evenmore importantnutrientstothe soil.

Afterpowercomposting,you maywantto planta !'greenmanure"covercrop to protectthesoil duringthe off-season.Yousimplygrowa

cropof clover,alfalfa,buckwheat,peas,beans,ryegrass,grain, orkaleandthentill it intothesoilprior to the plantingseason.

TillingOnSlopes

dtg/ pdbb_b.

Readthe followingrecommendationsbeforetilling onslopes: _ WARNING: Donot

Ifyou must gardenon a moderateslope,pleasefollow twoveryimportantguidelines: A operatetiller on aslopetoo

1. Till onlyon moderateslopes,neveronsteepgroundwherefootingis difficult(reviewsafe- _ steepfor safeoperation. Till

ty rulesin Section1: Safetyof this manual), slowly and besure you have

2. Werecommendtilling upanddown slopesratherthanterracing. Tillingvertically on a

slopeallows maximumplantingareaandalsoleavesroomfor cultivating.

IMPORTANT:Whentilling on slopes,besurethecorrect oil levelis maintainedintheengine

(checkeveryone-halfhour of operation). The inclineoftheslopewill causethe oilto slant

awayfrom its normallevelandthis canstarveenginepartsof requiredlubrication. Keepthe

motor oil evelatthefull pointatall times!

TillingUp and DownSlopes(Vertical Tilling)

• Tokeepsoilerosionto a minimum, besureto addenoughorganicmattertothe soil so that it hasgood moisture-holdingtextureandtry

toavoid leavingfootprintsor wheelmarks.

• Whentillingvertically,try to makethefirst passuphillas thetiller digs moredeeplygoing uphillthan it doesdownhill. Insoftsoil or

weeds,you mayhaveto iftthe handlebarsslightly while going uphill. Whengoingdownhill, overlapthefirst passbyaboutone-halfthe

width ofthe tiller.

TillingAcrossSlopesWithout UsingTerraces(HorizontalTilling)

• Ifvertical or terracinggardeningaren'tpracticalfor you,then you cantill laterallyacrossa slope. Wedon't recommendthis methodas

it cancreateunsurefootingand invitessoil erosion.

• As interracegardening,startat thetop ofthe slopeandoverlapthe first passby halfthewidth ofthetiller. Foraddedstabilityof thetiller,

alwayskeepthe uphillwheelinthe soft, newlytilled soil.

TerraceGardening

• Whena slopeis too steepor too short for verticaltilling, it may benecessaryto till acrosstheslopeandcreateterracedrows.Terraces

arerowsthat arecut intothe sideof a slope,creatinga narrow,butflat areaonwhich to plant.

• Ona longslope,you canmakeseveralterraces,onebelowtheother.

• Terracesshould beonly24o-3 feetwide. Diggingtoofar intothe sideoftheslopewill exposepoorsubsoilthat is unproductivefor plants.

goodfooting. Neverpermit

tiller to freewheeldown

slopes.Failureto follow this

warning could result in

personalinjury.

15

Page 16

TILLING TIPS&TECHNIQUES(CON'T)

• Eachsucceedinglowerterraceis startedbywalkingbelowtheterraceyou'repre- !1_

paring. Foraddedstabilityofthetiller,alwayskeepthe uphillwheelinthe soft,new- ___

ly tilled soil. Donot till the last12"or more of the downhilloutside edgeof each

terrace. This untilled strip helpspreventsthe terracesfrom breaking apartand

washingdownhill.It also providesawalking pathbetweenrows. 0 _RePeAT

Fig. 4-10

Clearingthe Tines

Thetines haveaself,clearingaction whicheliminatesmost tanglingof debrisin

thetines. However,occasionallydry grass,stringy stalksor toughvinesmaybe,

cometangled.Follow theseProceduresto helpavoid tanglingandto cleanthe

tines,if necessary.

• To reducetangling,set the depth regulatordeep enoughto get maximum

"chopping"actionasthetines chopthe materialagainsttheground. Also,tryto

till undercrop residuesor covercropswhile theyaregreen,moist andtender.

• While powercomposting,try swayingthe handlebarsfrom sidetOside(about

6"to 12"). This ,,fishtailing',action oftenclearsthetinesofdebris.

• Iftangling occurs,liftthetines out ofthesoil andrunthe tiller in reverse(if unit

is equippedwith poweredreverse)for a few feet. This reversingactionshould

unwindagooddealof debris,

• It maybenecessaryto removethedebrisby hand

(apocketknifewill helpyouto cut awaythemate-

rial).Besureto stopthe engineanddisconnectthe

spark plugwirebeforeclearingthetines byhand.

WARNING: Beforeclearingthe

A tines byhand,stopthe engine,allow

all movingpartsto stop and

disconnect thespark plugwire.

Removethe ignition keyon electric

start models.

Failureto follow this warning could

result in personal injury.

LOADINGANDUNLOADING • Usesturdy rampsand manually(engne tilleraheadof you. Havea personat each

THETILLER shut off) roll thetiller into and out of the sideto turn the wheels

vehicle. Twoor more peopleareneededto • When going down ramps, walk back-

_, WARNING: Loadingand dothis. ward with thetiller following you. Keep

• Beforeloading or unloading,stopthe en- ' ' ' •

gine,wait for all partsto stop moving, • Positionthe loadingvehicle so that the in the vehicle.

disconnect the spark plug wire and letthe ramp angleis asflat as possible (the less • After loadingthetiller, preventit from

engineand muffler cool. incline to the ramp, thebetter). Turnthe rolling byengaging thewheels in the

• The tiller is too heavyand bulky to lift vehicle'sengine off and apply its parking WHEELDRIVEposition. Chockthe wheels

safelyby one person.Two or more people brake, with blocksandsecurely tiethe tiller down.

should share the load. • When going upramps, stand in the

unloadingthe tiller into a • Theramps must be strong enough to alertfor any obstaclesbehindyou. Posi-

vehicle is potentially hazardous support thecombined weight ofthe tiller tion a person at eachwheelto control the

andwedon't recommenddoing and any handlers.Theramps should pro- speedof thetiller. Nevergo down ramps

sounlessabsolutely necessary, vide goodtraction to preventslipping;they tiller-first, as thetiller could tip forward.

asthis could result in personal should haveside railsto guidethetiller

injury or property damage, along the ramps; andthey should havea

However,if you must load or locking deviceto secure them to the

unloadthe tiller, follow the vehicle.

guidelinesgiven next. • The handlersshouldwearsturdy footwear

that wdl helpto preventshppmg

normal operating position and push the

• Placewooden blocks on the downhill

side of the wheels if you needto stop the

tiller from rolling downthe ramp. Also,

usethe blocksto ternporarily keepthetiller

in placeonthe ramps(if necessary),andto

chockthe wheels in placeafter the tiller is

16

Page 17

SECTION5: MAINTENANCE

WARNING: Before

inspecting, cleaningorservicing

the machine,shut off engine,

wait for all moving partsto come

to a completestop, disconnect

spark plug wire and movewire

awayfrom spark plug. Remove

ignition keyon electric start

models.

Failureto follow these

instructions can result in serious

personalinjury or property

damage.

MAINTENANCE SCHEDULE

PROCEDURE NOTES

Check motor oil level 2, 3

Clean engine 2, 7

Check drive belt tension

Check nuts and bolts 1,4

Change motor oil 4, 6, 9

Lubricate tiller 4

Service engine air cleaner system

Check gear oil level in transmission 1,5

Check tines for wear 5

Check air pressure in tires 5

(if unt has pneumat Ct res)

Service spark plug 7

1,4

1- Checkafter first 2 hours of break,in operation.

2 _ Beforeeach use.

3 ' Every 5 operating hours.

4 - Every 10 operating hours.

5 - Every 30 operating hours.

6 - Change more frequentlyin dustyconditions.

7, See EngineOwner'sManual for service

recommedations.

8 - Whichevertime interval occurs first.

9 - Changeafterfirst 2 hours of break-in

TILLERLUBRICATION

After every 10 operating hours, oil or

greasethe lubrication points shown in

Figure5-1 and described below,

Usecleanlubricating oil (#30weight motor

oil issuitable) and cleangeneralpurpose

grease(greasecontaining a metallubricant

is preferred, if available).

• Removethewheels,cleanthe wheelshaft

(A,Fig. 5-1) andapply a thin coating of

greaseto the wheel shaft.

• Greasethe back, front andsides of the

depth regulator lever (g, Fig.5-1).

• Removethe tines andclean thetine shaft

(C, Fig.5.1). Usea file or sandpaperto

gently remove anyrust, burrs or rough

spots (especially around holesin shaft).

Applygreaseto ends of shaft beforeinstall-

ing tines.

• Oilthe threads on the handlebarheight

adjustment screws and thehandlebar

attaching screws(D, Fig.5,1).

Figure5-1

CHECKFOROILLEAKS

Beforeeachuse,checkthetil!er for signs of

an oil leak--usually a dirty, oily accumu-

lationeither on the unit oron thefloor.

A little seepagearounda cover oran oil

sealis usuallynot a causefor alarm,How-

ever, ifthe o!l drips overnight, then imme-

diateattention is needed. Ignoring an oil

leakcan result in severe transmission

damage!

17

If a cover is leaking, checkfor loose

screws.If the screwsaretight, a new

gasket or oilseal may be required.

If the leak isfrom around a shaft andoil

seal, theoil sealprobably needsto be

replaced. Seeyour authorizeddealer or

contact thefacto ryfor serviceor advice.

IMPORTANT:Neveroperatethe tiller if

the transmission is low on oil. Check

the oil levelafter every30 hours of

operationand wheneverthere is any oil

leakage.

CHECKHARDWARE

Checkfor looseor missing hardwareaf.

ter every 10operating hours andtighten

or replace(as needed)beforereusing

tiller

Besureto checkthe screws underneath

the tillerhoodthat securethe transmis-

sioncoverandthe DepthRegulatorLever

to the transmission.

CHECKTIRE PRESSURE

(Modelswithpneumatictires)

Checktheair pressure in bothtires. The

air pressure should be between 15 PSI

and 20 PSI (pounds per squareinch).

Keepbothtires equally inflatedto help

prevent machinefrom pullingto one

side.

TRANSMISSION

GEAROILSERVICE

Checkthe transmission gear oil level

after every30 hours of operationor

wheneveryou notice any oil leak, Oper-

ating the tiller when thetransmissionis

low on oil can result in severedamage.

A. ToCheckthe Transmission

GearOil Level:

1, Checkthe gear oil level when the

transmission is cool. Gear oil will

expandin warm operatingtemperatures

and this expansionwill provide an incor,

rect oil levelreading.

2. With the tilleron levelground, pull the

Depth RegulatorLeverall the way up.

3, Removethe oil fill plug (A, Fig.5,2)

from thetransmission housingand look

insidethe oil fill hole to locatethe main

driveshaft situated below the hole.

Page 18

WARNING: Beforeinspecting,cleaningor servicing themachine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

4. Thegear oil level is correct ifthe gear B.ToDrainthe Transmission Gear0il:

oil is approximately halfway up theside of Thetransmission gear oil doesnot needto

the main driveshaft.

5. If the gearoil levelis low,addgearoil

asdescribed next. If the gear oil levelis

okay,securely replacethe oil fill plug.

IMPORTANT:Donot operatethetiller if the

gear oil levelis low. Doingso will result in

severedamageto the transmission com-

ponents.

Figure5-2: Removeoil fill plug (A) to check

gearoillevelandtoaddgearoil. Remove its vaporscouldreachan openflame forward.

fourcoverscrews(B)todraingearoil. orspark, orwhere ignitionsourcesare C. Removing/Installinga TineAssembly:

6. If adding onlya few ouncesof gear oil heaters, furnaces, clothes dryers, mounted on atine holder.

useAPI ratedGL-4or GL-5gearoil having stoves,electric motors,etc.)

aviscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an empty trans-

mission, useonly GL-4gearoil havinga 2. Drainthe oil from the engine

viscosity of SAE85W-140 or SAE140. 3. Removefour screws(B, Figure5-2) and

IMPORTANT:Do not use automatic trans- removetransmissioncoverandgasket.

missionfluid or motor oil inthe transmis- 4. Removethe left-side wheel.

sign.

7. While checkingfrequently to avoid

overfilling, slowly add gear oil into the oil

fill hole until itreachesthe halfwaypoint on

the drive shaft.

8. Securely replacethe oil fill plug

bechangedunless it hasbeencontaminat- should be inspectedat the beginning of

ed with dirt. sand or metal particles, eachtilling seasonand afterevery 30 oper-

1. Drain gasolinefrom the fuel tank or run ating hours. Thetines can be replacedel-

the engine until thefuel tank is empty.See ther individually or as acomplete set. See

"DANGER"statement below, the Parts List pagesfor tine identification

,_ WARNING: Gasoline is and part numbers.

• Allowthe engine and muffler to cool

for at least two minutesbefore drain- B. Removing/Installinga SingleTine:

ingthe tiller's gasolinetank. 1. With the engineshut off and the spark

• Do not allow open flames, sparks, plug wire disconnected,removethetwo

matchesor smokingin the area. screws (A, Figure5-3), Iockwahers(E)and

• Wipeaway spills and pushtiller away nuts (B) that attach a single tine to a tine

from spilledfuel. holder. If needed,use penetratingoil on

• Use only an approved fuel container the nuts.

and store it safely out of the reach of 2. When installing a singletine, besure to

children, position it so that its cutting edge(sharp)

• Do notstoregasoline in an area where will enter thesoil first as the tiller moves

present(suchas hot water and space 1. A tineassemblyconsists ofeighttines

5. Tilt the left-sidewheelshaft into adrain sembly outward offthe shaft.

panand allowthe gearoil to drainthrough

the top of thetransmission

6. Reinstall the wheel.

7. Install a newgasket (do not reuse old

gasket)and reinstall the transmission cov-

er.

8. Refillthetransmission usingGL-4 gear thesofl first whenthe tillermoves forward.

oil (SAE85W-140 or SAE140). Securethe tine assemblyto the tine shaft

9. Refillthe enginewith motor oiland re- using the screw and Iocknut

plenishthe fuel tank with gasoline.

highlyflammableanditsvapors A. Tine Inspection:

areexplosive. Followthese With use,the tines will becomeshorter

safety practicesto prevent

personalinjury or property

damagefrom fire or explosion.

BOLOTINES

Thebolo tines will wearwith useand

narrower and pointed. Badlyworn tines

will result in a loss of tilling depth, and re-

ducedeffectiveness whenchopping up

and turning under organic matter.

2. If removing bothtine assemblies,mark

them "left" and "right" beforeremoval.

Removethe screw (C, Figure 5-3), lock

washer (E)and Iocknut (D)that securethe

tine assemblyto the tine shaft. If neces-

sary,use a rubber mallet to tap the tineas-

3. Beforereinstalling thetine assembly,in-

spectthe tineshaft for rust, roughspots or

burrs. Lightlyfile or sand as needed.Ap-

ply a thin coat of greaseto the shaft.

4. Install eachtine assemblyso that the

cutting (sharp)edgeof thetines will enter

18

Page 19

WARNING: Beforeinspecting,cleaningor servicing themachine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

FORWARD

n

___ FRONT/

Figure5-3: Install tinessothat cuttingedgeoftines entersoil firstwhen tiller movesforward.

CHECKINGANDADJUSTING

FORWARDDRIVEBELTTENSION

It is important to maintain correct tension

on the forward drive belt. A loosebeltwill

causethe tinesandwheelsto slow down

or stop completely even though the en-

gine B running atfull speed. A too tight

belt can result in unintentional tine move- 5. Toadjust the length of the spring:

ment whenthe clutch bail is inthe Neutral a. Releasethe Forward Clutch Bail.

(released)position.

• Check belttension after the first two

hours of break-inoperation andafter every

10 operatinghours.

• At the end of eachtilling season,check

the belt for cracks, cuts or frayed edges

and replaceit assoon as possible

ToCheckForwardBeltTension:

1. Stop engine, wait for all parts to stop

mowng and disconnect spark plug wire.

2. With the ForwardClutch Bailinan open

(released)position, measureand notethe

overalllength ofthe cablespring (A,Figure

5-4) bymeasuringfrom the outermost coil

to the outermost coil.

3. Squeezethe Forward Clutch Bail

againstthe handlebar(see Figure5-4) and

re-measurethe length of the coils. The

belt tensionB correct ifthis second mea- your local authorizeddealeror referto the

surement is between1/6"-to- 3/16" longer Parts List for ordering information. Use

than the first measurement, only afactory-authorized belt asan "over-

4. If the spring istoo short (less than the-counter" belt may not perform satis-

1/16"),the tension istoo loose. If the mechanicalability andcommonly available

spring is too long (more than 3/ 6 ), he tools.

tension istoo tight.

Figure5-4: Tocheckforwardbelt tension, take twomeasurementsofthe

overalllengthof the coilsin thespring_ firstwiththe clutchbail open,

thenwith theclutchbail closedagainstthe handlebar.

19

1" t

b Unthreadthe hex nut (C, Figure5-4)

halfway upthe adjustment screw (D).

c. Unhookthe top of the spring from

the Forward Clutch Bail.

d. Usepliers to preventthe adjuster (B)

from turning and turn the slotted screw lo-

cated insidethe spring clockwise (viewed

from operator's position) to increaseten-

sion on the spring. Turnthe screw coun-

terclockwise to decreasetension. Once

adjusted,reattach the spring to the For-

ward Clutch Bail.

e. RepeatSteps2 and3to re-measure

thelengthof the spring. Whenthe second

measurementis between1/16"-to-3/16"

longerthanthefirst measurement,retighten

thehexnut(C)againstthetop ofthe adjuster

(B).

ReplacementBelt Information

Ifthe drive belt needsto be replaced,see

factorily. The procedurerequires average

Page 20

WARNING: Beforeinspecting,cleaningor servicing themachine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

FORWARDCLUTCH

BAILADJUSTMENT

If the ForwardClutch Bail doesnot func-

tion properly,first check that the forward

drive belt is adjusted properly (see Check-

ing andAdjusting ForwardDriveBelt Ten-

sion). Ifthis failsto correct the problem,

contact Troy-Bilt LLC or your authorized

dealerfor service advice.

CHECKINGANDADJUSTINGRE-

VERSEDRIVEBELTTENSION

(Models634F/634A only)

It is important to maintain correct tension

on the reversedrive belt. A loosebeltwill

causethetines andwheelsto slow down-

or stop completely - eventhough the en-

gine is running at full speed.

Whenchecking belttension, alsocheckthe

beltfor cracks, cuts or frayededgesand

replaceit as soon as possible.

• Check belttension after the first two

hours of break-inoperation andafter every

10 operatinghours.

ToCheckReverseBeltTension:

1. Stopengine, wait for allparts to stop

moving and disconnect spark plug wire.

2. Removescrewin plasticbeltcover and

slide belt cover (which is attachedto for-

ward clutch cable) out of the way.

3. Havean assistant pullthe Reverse

ClutchControl knob all the way out and

hold it in that position. Measurethe length

of the cablewire betweenthe end of the

threadedcableadjuster (A,Figure5-5) and

the end of the Z-fitting (B) to which theca-

ble wire is attached.

4. Thebelttension is idealifthecablewire

length measuresbetween1/8"to 1/4". If it

is lessthan 1/8"(and ifthere is noreverse

actionwhenthe tiller is running),then make

the following adjustments

NOTE:Ifthe lengthis morethan 1/4",noad-

justment isneeded--as longasthe reverse

actionfunctions properly.

5. ReleasetheReverseClutch Control

knob.andthen unthreadthe inner jam nut

(C, Figure5-6) one to two turns. Pull the

threaded cable adjuster (A, Figure 5-6) to

the left until the innerjam nut (C)touches

the bracket.

6. Preventthe innerjam nut (C)from turn-

ing andtighten the outer jam nut (D)

againstthe bracket. Preventthe outerjam

nut (D) from turning and tighten the inner

jam nut (C) againstthe bracket.

7. Measurethe gap by repeatingStep3.

Readjustas neededby repeating Steps5

and 6.

8. Reinstallthebeltcover.

ReplacementBelt Information

If thedrive belt needsto be replaced,see

your local authorized dealeror referto the

Parts List for ordering information. Use

only a factory-authorized belt asan "over-

the-counter" belt maynot perform satis-

factorily. The procedurerequires average

mechanicalability andcommonly available

tools.

ENGINECLEANING

Keepingthe engineclean will help to en-

suresmooth operation and prevent dam-

agefrom overheating. Referto the Engine

Owner'sManualfor enginecleaning ser-

vice intervals and instructions. Besure

thatthe muffler iscool beforeservicing the

engine.

AIRCLEANERSERVICE

Theair cleaner filters dirt anddustout of

theair before it enters the carburetor. Op-

eratingthe enginewith a dirty, clogged air

filter can causepoor performance and

damageto the engine. Neveroperate the

enginewithout the air cleanerinstalled. In-

spectand service theair cleaner more of-

ten if operating in very dusty or dirty

conditions. Referto the engine Owner's

Manualfor air cleanerservice intervalsand

Figure5-5: Measurecablewirelengthto instructions.

checkforcorrectreversebelttension.

ENGINEOILSERVICE

Checkthe engineoil levelbeforeeachuse

and after every five hours of continuous

operation. Runningthe engine when it is

low on oil will quickly ruin the engine.

It is recommendedthat you change the

motor oil after every 10 hoursof operation

and evensooner when operating in ex-

tremelydirty or dusty conditions. Referto

the EngineOwner'sManualfor detailed

service instructions.

A. ToCheckthe EngineOil Level:

1. Parkthe tiller on a level areaand shut

off the engine.

2. Levelthe engine (usethe Depth Regu-

Figure5-6:Movethreadedadjuster(A)toleft

toincreasebelttension.

lator Lever to adjust the engineangle).

20

Page 21

WARNING: Beforeinspecting,cleaningor servicing themachine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

3. Cleanaround the oil dipstick or oil fill

tube (whichever applies) to prevent dirt

from falling into the crankcase.

4. Onengineswith an oil fill tube, remove

thefill capand add oil (if required) until it

reachesthetop of thefill tube. Reinstall

thefill cap.

5. Onengineswith adipstick, remove it

and wipe it clean. Reinsertthe dipstick,

tighten it securely,and removeit. Add oil

asneededto bring the level upto the FULL

mark. Wipe dipstick cleaneachtime oil

level is checked. Do not overfill. Tighten

dipstick securely.

B. ToChangetheEngineOil:

Changethe engine oil as instructed in the

EngineOwner'sManual.

SPARKPLUGSERVICE

Inspectand cleanor replacethespark plug

after every 100 operating hours or annual-

ly. Referto the EngineOwner'sManualfor

spark plug service instructions.

Insome areas,local law requires using re-

sistor spark plugs to suppress ignition sig-

nals. Iftheenginewas originally equipped

with a resistor spark plug, usethe same

type for replacement.

SPARKARRESTERSCREEN

SERVICE

If theengine muffler is equipped with a

spark arrester screen,removeand clean it

according to the service intervals and in-

structions in the EngineOwner's Manual.

THROTTLELEVERADJUSTMENT

If the enginedoes not respond to various

throttle leversettings, referto the Engine

Owner'sManualfor serviceinformation or

contact your local authorized engine deal-

er.

WARNING: Operators

shallnot tamper with theengine

governorsettings on the

machine;the governorcontrols

the maximum safeoperating

speedto protect the engineand

all moving partsfrom damage

causedbyoverspeed.

Authorizedserviceshall be

sought if a problem exists.

CARBURETOR/GOVERNOR

CONTROLADJUSTMENTS

Thecarburetor was adjusted at thefactory

for best operatingspeed. Referto the En-

gine Owner'sManualfor anyadjustment

information or see your authorizedengine

dealer.

The governor controls the maximumsafe

operatingspeed and protects theengine

and all moving partsfrom damagecaused

by overspeeding. Do not tamperwith the

enginegovernor settings.

OFF-SEASONSTORAGE

Whenthe tiller won't beused for anex-

tendedperiod, prepareitfor storageasfol-

lows:

1. Cleanthe tillerand engine.

2. Doroutine tiller lubrication and check

for loose parts and hardware.

3. Protectthe engineand perform recom-

mendedengine maintenanceby following

thestorage instructions found in the En-

gine Owner's Manual. Besureto protect

thefuel lines,carburetorandfuel tank

from gum deposits byremoving fuel or by

treating fuel with a fuel stabilizer (follow

enginemanufacturer'srecommendations).

4. Store unit in a clean, dry area.

5. Neverstorethetiller with fuel inthefuel

tank in an enclosed areawheregas fumes

could reachan open flame or spark, or

whereignition sourcesare present (space

heaters,hot water heaters,furnaces, etc.).

21

Page 22

WARNING: Beforeinspecting,cleaningor servicing themachine,shut offengine,wait for all

moving partsto come to a completestop, disconnect spark plug wireand move wireawayfrom

spark plug. Failureto follow these instructions can result in serious personalinjury or property

damage.

TROUBLESHOOTING

PROBLEM

Enginedoes not start

Engineruns poorly.

Engineoverheats.

Enginedoes not shut off

Wheels and Tineswill not turn

Tines turn, butwheels don't.

Wheels Turn, butTines Don't.

Poortilling performance.

POSSIBLECAUSE

1. Spark plug wire disconnected.

2, EngineThrottle Control Lever incorrectly set,

3. Fueltank empty.

4. Chokecontrol (if so equipped) in incorrect position.

5, Stale gasoline.

6. Dirty air filter.

7. Defective or incorrectly gappedspark plug.

8, Carburetor out of adjustment,

9. Misadjusted throttle control

10. Dirt or water infuel tank.

1, Defective or incorrectly gappedspark plug.

2. Dirty air filter(s).

3. Carburetor out of adjustment.

4, Stale gasoline.

5. Dirt or water infuel tank.

6. Enginecooling system clogged.

1, Enginecooling system clogged.

2. Carburetor out of adjustment.

3. Oil level is low,

1, Misadjusted throttle control or ignition switch.

1, Improper useof controls.

2. Worn, broken, or misadjusted drive belt(s).

3. Internal transmission wear or damage.

4. Bolt loosein transmission pulley.

1. Wheel Drive Pins not inWHEEL DRIVE.

2, Bolt loosein transmission pulley.

3. Internal transmission wear or damage.