Page 1

GARDEN WAY INCORPORATED

OWNER’S MANUAL

Trimmer/Mower

• Safety

• Assembly

• Features/Controls

• Operation

• Maintenance

• Parts List

Models

52057 – 5HP Recoil Start

52058 – 6HP Electric Start

(Electric Start Model Shown)

$4.

50

Page 2

SECTION 1: SAFETY ...........................................1

General Operation ......................................................1

Slope Operation .........................................................2

Children......................................................................2

Service.......................................................................2

Safety Decals .............................................................3

SECTION 2: ASSEMBLY.......................................4

Inspection After Delivery............................................4

Step 1: Unpacking Unit ..............................................4

Step 2: Install Handlebars..........................................4

Step 3: Attach Throttle Control Lever.........................5

Step 4: Add Motor Oil.................................................5

Step 5: Check Trimmer Head Hardware .....................5

Step 6: Connect and Charge Battery...........................6

SECTION 3: FEATURES AND CONTROLS ...................7

SECTION 4: OPERATION ......................................8

Pre-Start Checklist.....................................................8

Fill Fuel Tank..............................................................8

Adjust Handlebar Height ............................................8

Adjust Line Cutting Height .........................................8

Use the Correct Diameter Trimmer Line.....................9

Using the Trimmer Head Control Bail.........................9

Operating the Trimmer/Mower...................................9

Additional Operating Tips and Techniques...............10

SECTION 5: MAINTENANCE.................................11

Required Maintenance Schedule..............................11

Adjusting Trimmer Head Engagement......................11

Removing and Replacing the Trimmer Head............12

Inspecting/Replacing the Drive Belt..........................12

Cleaning and Debris Removal ..................................14

Cleaning the Engine Debris Guard............................14

Lubrication...............................................................14

Compact Storage .....................................................14

General Engine Maintenance....................................14

Engine Oil Service....................................................14

Air Cleaner Service...................................................14

Spark Plug Service...................................................14

Spark Arrester Screen Service..................................14

Engine Cleaning .......................................................14

Carburetor/Governor Adjustments...........................14

Throttle Control Adjustment.....................................15

Off-Season Storage..................................................15

Battery Recharging/Replacement.............................15

Changing Trimming Lines........................................16

Troubleshooting.......................................................17

PARTS LIST ...................................................18

CUSTOMER SERVICE INFORMATION...........Back Cover

Table of Contents

Dear Owner:

You now own one of the finest trimmer/mowers available. It was designed to easily handle a wide variety of

trimming, mowing and clearing chores. You will find

the machine to be an invaluable tool in caring for your

property.

Please carefully read this Manual which tells you how

to safely and easily assemble, operate, and maintain

your machine. Be sure that you and any other operators

carefully follow the recommended safety practices at all

times. Failure to do so could result in personal injury or

property damage.

Of course, if you should ever have any problems or

questions, please contact your local authorized service

dealer or call the Factory.

We want to be sure that you are completely satisfied

at all times.

Note: Be sure to fill out and return the Owner

Registration Card that was supplied with this Manual.

See Back Cover for

Customer Service Information

WARNING

The engine exhaust from this product contains

chemicals known to the state of California to

cause cancer, birth defects, or other reproductive harm.

Safety Alert Symbol

This is a safety alert symbol. It is used in this

manual and on the unit to alert you to potential

hazards. When you see this symbol, read and

obey the message that follows it. Failure to

obey safety messages could result in personal injury or

property damage.

Page 3

1

Under California law, and under the laws of several other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels on any forest covered, brush covered, or grass

covered land, or on land covered with grain, hay, or other flammable agricultural crop, without an engine spark arrestor in continuous effective working order.

The engine on your power equipment, like most outdoor power equipment, is an internal combustion engine that burns

gasoline, a hydrocarbon fuel. Therefore, your power equipment must be equipped with a spark arrestor muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in such a manner that flames

or heat from the system will not ignite flammable material. Failure of the owner/operator of the equipment to comply with

this regulation is a misdemeanor under California law, and may also be a violation of other state and/or federal regulations,

laws, ordinances, or codes. Contact your local fire marshal or forest service for specific information about what regulations

apply in your area.

SPARK ARRESTER WARNING TO RESIDENTS OF CALIFORNIA AND SEVERAL OTHER STATES

General Operation

IMPORTANT

Safe Operation Practices for Walk-Behind Mowers

This cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

1. Read, understand, and follow all

instructions on the machine and in the

manuals. Be thoroughly familiar with

the controls and the proper use of the

equipment before starting.

2. Do not put

hands or feet near or

under rotating parts.

Keep clear of the rotating trimmer head

and line at all times.

3. Only allow responsible adults,

who are familiar with the instructions,

to operate the trimmer/mower. Never

let children or untrained adults operate this equipment.

4. Inspect the area where the machine is to be used. The machine can

propel small objects at high speed,

causing personal injury or property

damage. Clear the area of objects

such as rocks, toys, wire, bones,

sticks, etc., which could be picked up

and thrown by the trimmer line.

5. Be sure the area is clear of other

people (particularly small children and

pets) before mowing. Stop machine if

anyone enters the area. Keep bystanders at least 50 feet from the area

of operation.

6. Do not operate the machine when

barefoot or wearing open sandals.

Always wear substantial footwear.

7. Wear appropriate clothing such as

a long-sleeved shirt or jacket. Also

wear long trousers or slacks. Do not

wear shorts.

8. Do not wear loose clothing– it

could catch in the equipment.

9. Do not mow in reverse unless

absolutely necessary. Always look

down and behind before and while

moving backwards.

10. Do not operate the trimmer/mower

without proper guards, plates, or other

protective safety devices in place.

11. Refer to provided instructions for

proper operation and installation of accessories. Only use factory-approved

accessories.

12. Stop trimmer head when crossing

gravel drives, walks, or roads. Wait for

trimmer lines to stop.

13. Stop engine and disconnect spark plug wire from

spark plug whenever you

leave the unit, clean

the equipment, or

replace trimmer line.

Remove key on electric start model.

14. Wait until the trimmer head comes

to a complete stop, shut the engine off,

and disconnect the spark plug wire

before installing or removing trimmer

line. Be sure trimmer head is securely

attached before operating equipment.

15. Mow only during daylight hours or

when good artificial light is available.

16. Do not operate the machine while

under the influence of alcohol or drugs,

or when tired or ill.

17. Never operate this equipment in

wet grass. Be sure of your footing; keep

a firm hold on the handlebar and walk;

never run.

18. Release the Trimmer Head Control

Bail before starting the engine.

19. If the unit starts to vibrate abnormally, stop the engine and disconnect

the spark plug wire. Check immediately for the cause. Vibration is generally a warning of trouble.

Safety

1

Section

Page 4

2

Section 1: Safety

20. Always wear approved safety gog-

gles or safety glasses with side shields

when operating equipment. The use of

any powered machine can result in foreign objects being thrown by highspeed rotating parts which can cause

personal injury or property damage.

Stay away from glass and other easily

thrown or breakable objects.

21. Wear work gloves and sturdy

footwear when using this equipment.

Leather work shoes or short boots are

ideal. They protect ankles and shins

from rocks, pebbles, splinters, etc.

22. It is advisable to wear protective

headgear to prevent the possibility of

being hit by small flying particles, etc.

23. Before each use, inspect the Throttle Control Lever and cable. Make sure

the cable is free and the lever functions

properly.

24. Watch for traffic when near or

when crossing roadways.

25. Never attempt to carry children or

other passengers on the equipment.

They could fall off and be seriously injured, or they could interfere with safe

operation of the equipment.

26. The machine is equipped with a

plastic debris shield in front of the

engine and a rubber debris flap under

the frame. They must be in place and

working properly. Never remove or

cause the debris shield or debris flap to

cease working. If either of these parts

is missing or not working properly, do

not use the equipment until this situation is corrected.

27. Be aware of where the machine is

discharging materials and do not point

the discharge at anyone.

28. Never run the engine in an enclosed area. Engine exhaust contains

carbon monoxide, a deadly gas that is

odorless, colorless and tasteless.

Always run the engine outdoors where

there is adequate ventilation.

29. Slow down before turning.

30. Shut off engine when not trimming

or mowing.

31. Use extra care when loading or unloading machine into a trailer or truck.

32. Use this equipment for its intended

purpose only.

33. Always make sure the handlebars

are tight and comfortably positioned.

They should never be in an awkward

position for the operator.

Slope Operation

Slopes are a major factor related to

loss of control and tip-over accidents

which can result in severe injury or

death. All slopes require extra caution.

If you can not back up the slope or you

feel uneasy on a slope, do not mow it.

DO:

Mow across the face of slopes; never

up and down. Exercise extreme caution when changing direction on

slopes. Avoid slopes greater than

15o.

Remove objects such as rocks, tree

limbs, etc.

Uneven terrain could overturn the

machine. Watch for holes, ruts, or

bumps. Tall grass can hide obstacles.

Use slow speed.

Use extra care with grass catchers or

other attachments. These can

change the stability of the machine.

Keep all movement on the slopes

slow and gradual.

Avoid starting or stopping on a

slope.

DO NOT:

Do not mow near drop-offs, ditches,

or embankments. You could lose

footing or balance.

Do not mow on very steep slopes.

Do not mow on wet grass. Slippery

footing can be hazardous.

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

machine and the mowing activity.

Never assume that children will remain

where you last saw them.

1. Keep children out of the mowing

area and under the watchful care of a

responsible adult.

2. Be alert and turn machine off if children enter the area.

3. Before and while moving backwards, look behind and down for small

children.

4. Never allow children to operate the

machine.

5. Use extra care near blind corners,

shrubs, trees, or other objects that

may obscure vision.

6. Never carry children, even with the

trimmer head stopped. Children may

fall off and be seriously injured or interfere with safe machine operation.

7. Do not allow children nearby if you

are working.

Service

1. Use extra care in handling gasoline

and other fuels. They are flammable

and their vapors are explosive. To

help prevent a fire or explosion:

a) Use only an approved container.

b) Never remove gas cap or add

fuel when the engine is running.

Let engine cool before refueling.

Do not smoke.

c) Never refuel the machine in-

doors. Fill the fuel tank outdoors

and with extreme care.

d) Never store the machine or fuel

container inside where there is

an open flame, such as a water

heater, etc.

e) Replace caps on the fuel tank

and fuel container and clean up

spilled fuel before starting engine. Move machine away from

any gasoline fumes before starting the engine.

f) Keep matches, smoking materi-

als, open flames, and sparks

away from the fuel tank and fuel

container.

g) Leave 1/2" air space at the top of

the fuel tank to allow for fuel expansion.

Page 5

3

Section 1: Safety

and debris shield. Make sure they are

not bent, damaged, or loose.

10. Only use eighteen-inch long .130"

or .155" diameter trimmer line. Never

use other lengths, diameters or material

as trimmer line.

11. Trimmer line moves

at high speed and can

cut. Always stop the

engine and let all moving parts stop before

replacing the trimmer lines. Let the

engine cool.

12. Do not change the engine governor setting or overspeed the engine.

The governor controls maximum safe

operating speed and protects the engine and all moving parts from damage caused by overspeed. Authorized

service shall be sought if a problem

exists.

13. Do not touch engine parts which

may be hot from operation. Allow

parts to cool completely before inspecting, cleaning or repairing the unit.

14. Maintain or replace safety and instructional decals. Refer to the Parts

List for replacement decal information.

15. Use only original-equipment

replacement parts. Parts manufactured by others could present safety

hazards and affect performance even

though they may fit on this machine.

2. Never run the engine inside a

closed area.

3. Never clean, or make adjustments

or repairs with the engine running.

Disconnect the spark plug wire and

keep the wire away from the plug to

prevent accidental starting. Remove

key on electric start models.

4. Keep all nuts and bolts tight, especially the trimmer head attachment

bolts, and keep equipment in good

condition. Check mounting hardware

on trimmer head every time you

change trimmer line and prior to each

use.

5. Never tamper with safety devices.

Check their proper operation regularly.

6. To reduce fire hazard, keep mower

free of grass, leaves or other debris

build-up. Clean up oil or fuel spills. Let

machine cool before storing.

7. After striking an object, stop the

engine and disconnect the spark plug

wire. Inspect the machine and repair, if

necessary, before restarting.

8. Never make adjustments or repairs

while engine is running.

9. Components subject to wear,

damage and deterioration could expose moving parts or allow objects to

be thrown. Frequently check components and replace with factory recommended parts, when necessary.

Regularly inspect the trimmer head

16. Remember – the end of the sea-

son is a good time to inspect equipment prior to storage.

17. To guard against engine overheating, always keep the engine debris

guard mounted and clean.

18. For units equipped with electric

start:

a) Batteries produce explosive

gases. Keep sparks, flame,

cigarettes, etc., away. Ventilate

area when charging battery. Do

not charge battery in an airtight

space.

b) Do not use a battery charger

other than the one provided with

the unit.

c) The battery contains toxic mate-

rials. Do not damage the battery

case. If the case is broken or

damaged, avoid contact with the

battery contents.

d) Properly dispose of a damaged

or worn out battery. Check with

local authorities for proper disposal methods.

e) Do not short circuit the battery.

Severe burns and fire can

result.

Safety Decals

Make certain that all safety decals on this equipment are

kept clean and in good condition. The decals are shown (at

reduced sizes) below. If you need a replacement decal,

refer to the Parts List in this Manual.

WARNING

THROWN OBJECT HAZARD

Objects will be thrown violently by the

cutting head, resulting in significant hazard!

Keep children, pets and bystanders 50 feet

away from machine while operating.

Be alert to hidden obstacles.

ROTATING CUTTING HEAD

Do not service or adjust cutting head or other

moving parts unless engine is stopped and

spark plug wire is disconnected.

•

•

•

READ OWNERS MANUAL

If you need a replacement manual, write to the

address listed on the serial number decal on

this unit.

1918115 (12/99)

At front of deck

On engine, above muffler

On left

handlebar

Page 6

4

Introduction

Carefully follow these assembly steps

to correctly prepare your machine for

use. It is recommended that you read

this Section in its entirety before beginning assembly.

NOTE: If an assembly step applies only

to certain models, those models are

noted at the beginning of that step.

Otherwise, a step applies to all models.

Inspection After Delivery

Inspect your machine immediately after

it has been delivered. Make sure that

neither the carton nor the contents

have been damaged.

If you find or suspect any damage,

contact the carrier (trucking company)

right away. Inform them of the specific

damage and that you wish to file a

claim. To protect your rights, be sure

to put this in writing to the carrier

within 15 days after your machine arrives. Please let us know if you need

assistance with this matter.

IMPORTANT: The engine is shipped

without motor oil in its crankcase.

Motor oil must be added to the engine

before starting.

NOTE: LEFT and RIGHT sides of unit

are as viewed from operator’s position

behind the handlebars.

Tools/Supplies Needed:

• (1) Utility Knife or Scissors

• (2) 1/2" (or adjustable) Wrenches

• (2) 7/16" Wrenches (one with a boxed

end)

• Motor Oil (see Engine Owner’s

Manual for oil specifications and

quantity required)

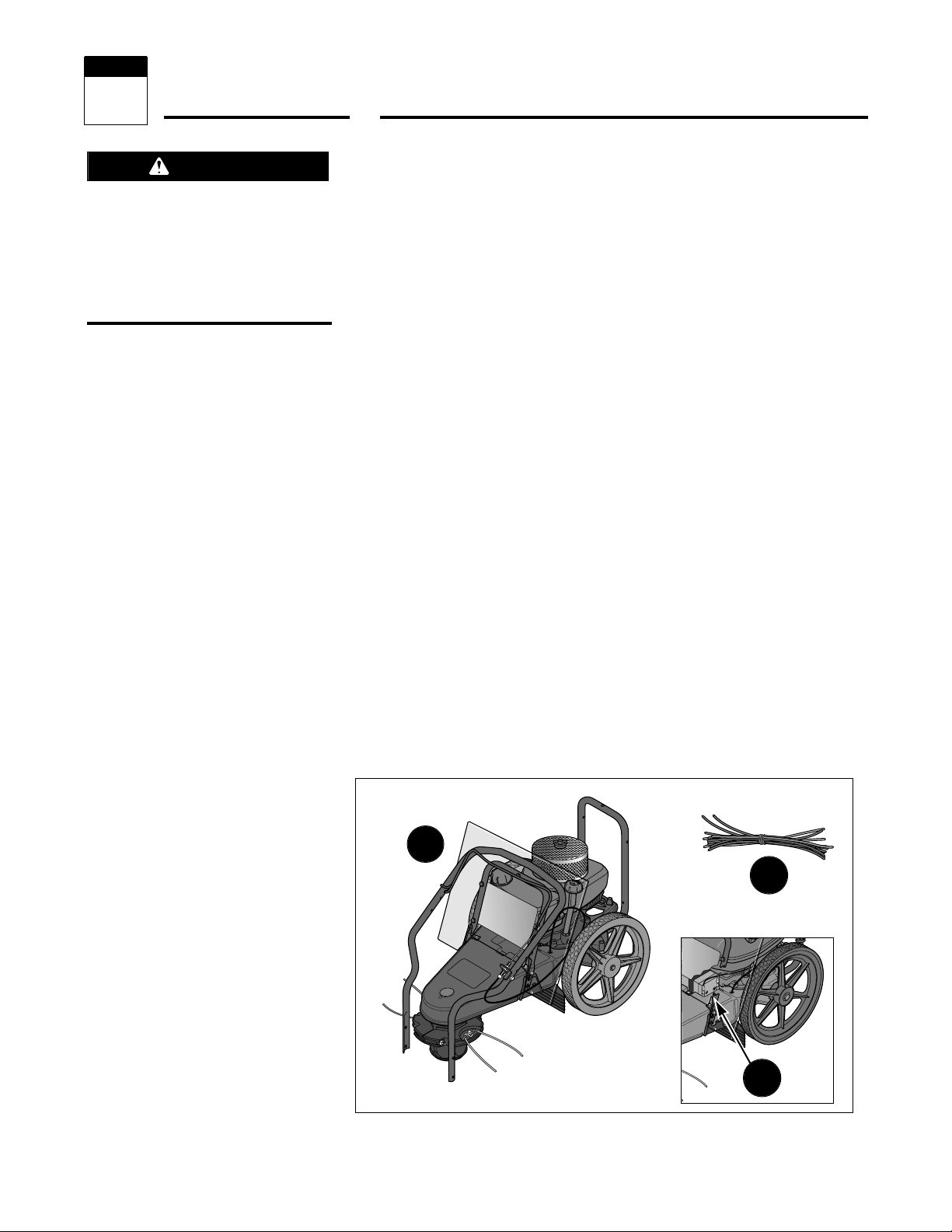

STEP 1: Unpacking Unit

1. Remove the protective packaging

material (plastic film and cardboard)

from the handlebars and the unit.

2. Remove the handlebars from the

insert and carefully (do not pinch or

kink the attached cables) put them

aside before removing the unit from

the shipping carton.

3. Compare the parts inside the carton

with the following list:

• Trimmer/Mower Assembly (A, Figure

2-1)

• Extra Trimmer Line (B, Figure 2-1):

six pieces of heavy-duty gauge .130"

dia. line and six pieces of extra-heavyduty gauge .155" dia. line.

• The following items are in a separate

package:

(1) Safety goggles

(3) Plastic cable ties

(1) Hex Hd. Screw, 1/4-20 x 2

(1) Hex Locknut, 1/4-20

(2) Hex Hd. Screw, 5/16-18 x 2

(2) Hex Locknut, 5/16-18

• Electric Start Model Only:

(1) Battery (installed on unit – see

C, Figure 2-1)

(2) Ignition Keys and (1) Battery

Recharger (in separate electric

start package)

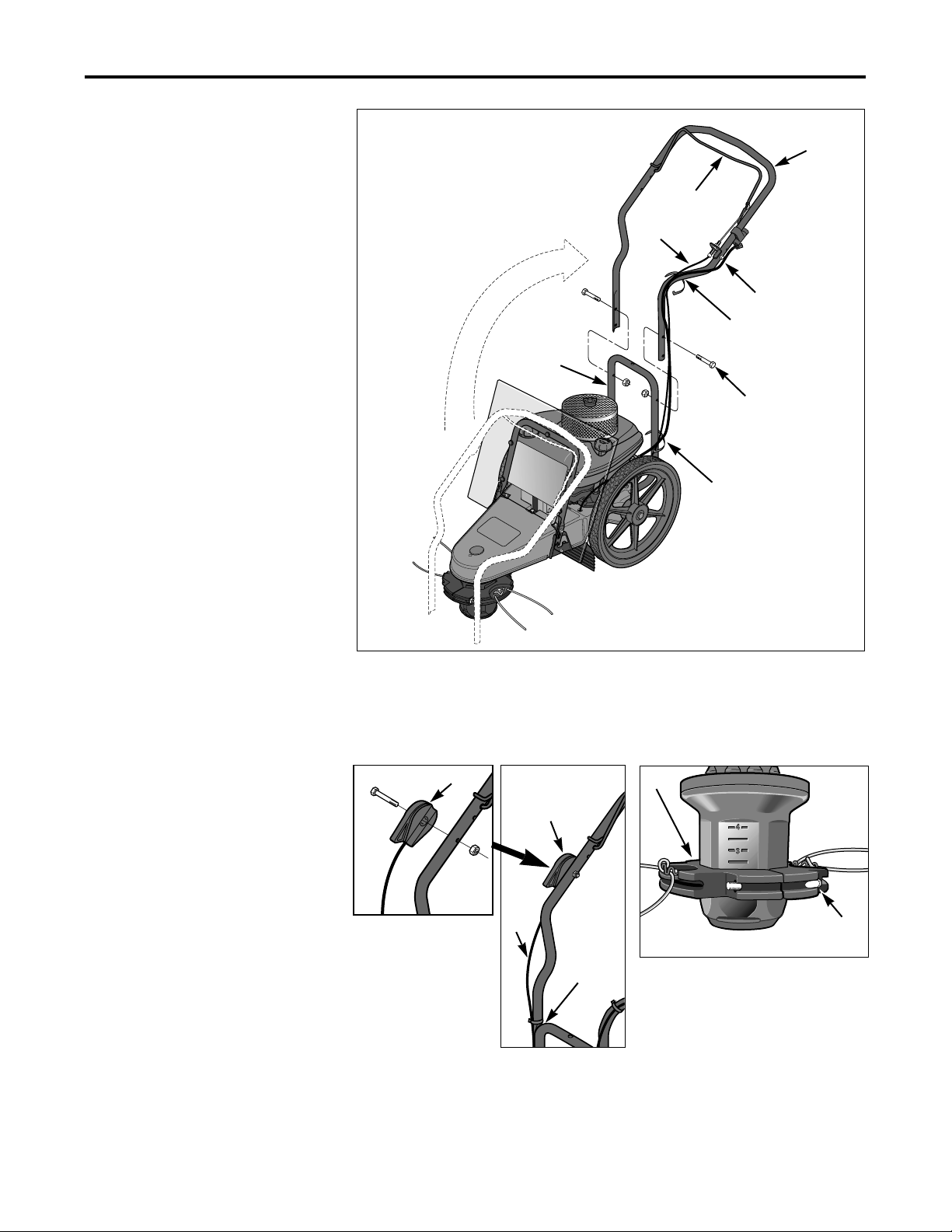

STEP 2: Install Handlebars

1. Cut the plastic tie and remove the

tape that secures the control bail (G,

Figure 2-2) to the handlebar (A).

NOTE: Do not pinch or kink the attached cable(s) while unfolding and

securing the handlebars.

2. Carefully lift the handlebars (A,

Figure 2-2) to rear of the unit and align

the handlebar legs with the handlebar

support bracket (B).

3. Route the trimmer head control

cable (C, Figure 2-2) to the outside of

the handlebar. On electric start models,

also route the electrical wire harness

(O) to the outside of the handlebar.

4. Select the low or high height setting

holes in the handlebar legs and attach

the legs with the two 5/16-18 x 2 hex

hd. screws (D) and 5/16-18 locknuts

(E) from the hardware bag.

IMPORTANT: Adjust the handlebars as

close as possible to waist level so that

your arms are at a comfortable height.

This position will result in less pressure on the mower wear cup, making

the unit easier to roll and reducing wear

to the wear cup.

A

Figure 2-1: Unit as shipped (recoil start model shown). Battery for electric start

model is shown in inset.

B

Assembly

2

Section

To prevent personal injury or property

damage, do not attempt to start the

engine until all assembly steps are

complete and you have read and understand all of the safety and

the operating instructions in this

Manual.

WARNING

C

Page 7

5

Section 2: Assembly

Figure 2-2: Handlebar installation (electric start model shown).

A

C

D

F

E

B

G

F

O

M

M

Figure 2-4: Check trimmer head hardware for tightness.

5. Use two cable ties (F, Figure 2-2)

to secure the trimmer head control

cable (C) and the electrical wiring harness (O) to the handlebar at the locations shown.

STEP 3: Attach Throttle

Control Lever

1. One end of the Throttle Control

Cable (H, Figure 2-3) is attached to

the engine. Gently unwind the cable

from its shipping position and position the Throttle Control Lever (I) on

the outside of the right handlebar,

next to the throttle control decal.

2. Secure the Throttle Control Lever

to the handlebar with a 1/4-20 x 2 hex

hd. screw (J, Figure 2-3) and 1/4-20

hex locknut (K).

3. Use a cable tie (L, Figure 2-3) to

secure the throttle cable (H) to the

handlebar at the location shown.

STEP 4: Add Motor Oil

1. The engine is shipped without

motor oil which MUST BE ADDED

before the engine is started.

2. See the separate Engine Owner’s

Manual for filling instructions and for

the correct oil specifications. Engine

must be level when checking oil level.

In ambient temperatures above 320 F,

use a high-quality, SAE 30 weight

detergent oil classified for Service SF SJ. Use no special additives. Do not

mix oil with fuel.

STEP 5: Check Trimmer

Head Hardware

Check that the two bolts (M, Figure

2-4) on the trimmer head are tightened securely. The trimmer head can

be rotated to make access to the hardware easier.

IMPORTANT: The trimmer head hardware is designed to be permanently

installed and is not removable. Do not

attempt to replace it with non-factory

specified hardware.

NOTE: The two holes (one is covered

with a plastic plug) on the top, front

end of the mower deck are access

holes that allow certain parts to be

serviced.

Figure 2-3: Attach throttle lever to right-side

handlebar.

I

J

K

L

I

H

Page 8

6

Section 2: Assembly

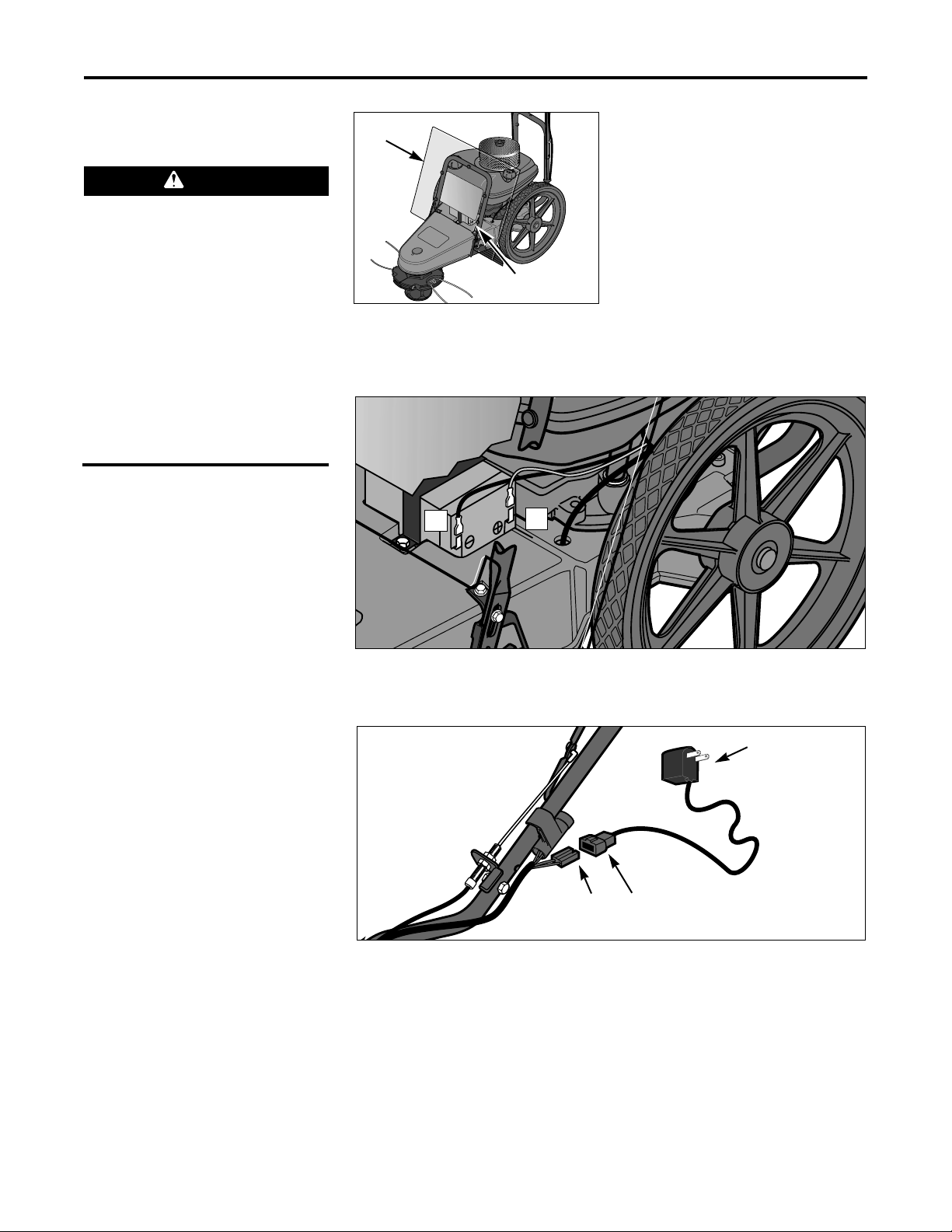

STEP 6: Connect and Charge

Battery (Electric Start Models)

1. Lift and tilt debris shield (X, Figure

2-5) forward to view battery (P).

Connect the red wire (R, Figure 2-6) to

the positive (+) red-coded terminal on

the battery. Then, connect the black

wire (S) to the negative (–) blackcoded terminal on the battery. Close

the debris shield (X, Figure 2-5).

2. Connect the small plug (U, Figure

2-7) on the battery recharger cord to

the wire harness plug (V) located near

the keyswitch. Then, plug the charger

box (W) into a grounded, 120V wall

outlet.

3. Charge the battery for 24 hours.

After charging, first unplug the charger

box (W) from the wall outlet, then disconnect the recharging line plugs (U

and V).

• Wet conditions can cause an electric shock hazard during battery

recharging. Avoid wet conditions

when charging battery.

• Recharging the battery with improper equipment could cause a

battery explosion. Use only the battery charger shipped with the unit.

The engine must be shut off and the

spark plug wire disconnected and

moved away from the spark plug.

Failure to comply could result in

personal injury or property damage.

DANGER

S

R

Figure 2-6

V

W

U

Figure 2-7

X

P

Figure 2-5: Lift and tilt debris shield

forward to access battery.

Page 9

7

Features and Controls

3

Section

Operating Symbols

Various symbols (shown

here, with word descriptions) are used on the

unit.

STOP

FEATURES AND CONTROLS

This Section describes the location and

function of the features and controls on

your machine. Refer to the following

Operation Section for detailed operating instructions.

Do not start the engine until you read

and understand all safety, controls and

operating instructions in this Manual,

the separate Engine Owner’s Manual,

and on the decals on the machine.

IMPORTANT: Refer to the separate

Engine Owner’s Manual for detailed

information about the controls on the

engine.

Trimmer Head Control Bail

Pull the control bail (A, Figure 3-1) up

against the handlebar (engage bail) to

start rotation of the trimmer head. Let

go of the control bail (disengage bail)

to stop the trimmer head.

Cutting Height Settings

The trimmer head (B, Figure 3-1) is

adjustable to an infinite number of

height settings from 1-1/2" -to- 4-1/2".

Trimmer Line Holders

The trimmer lines are secured to line

holders (C, Figure 3-1). Replacing the

trimmer lines is a simple procedure (see

Changing Trimming Lines in Section 5).

Handlebar Height Adjustment

The handlebar (D, Figure 3-1) has two

height settings (see Adjust Handlebar

Height in the Operation Section).

Plastic Debris Shield

The plastic debris shield (E, Figure 3-1)

protects the engine from all manner of

debris. The shield tilts forward for access to the engine.

ENGINE

STOP

TRIMMER

HEAD

ENGAGE

BAIL

DISENGAGE

BAIL

SLOW

FAST

STOP

Engine Throttle Control Lever

Use this lever (F, Figure 3-1) to regulate engine speed and to stop the engine. The throttle settings are shown

on the decal next to the lever.

Engine Recoil Starter

The recoil starter (G, Figure 3-1) is

located at the rear of the engine and is

used to pull start the engine.

Engine Debris Guard

The engine debris guard (H, Figure

3-1) protects the engine from accumulations of cut materials that can clog

the engine cooling passages. See the

Maintenance Section for information

on servicing this important guard.

Fuel Primer Button

The fuel primer button (I, Figure 3-2)

allows a cold engine to be primed for

faster, easier starting.

Keyswitch (Electric Start Model)

On electric start models, the keyswitch

(J, Figure 3-1) is used to start the

engine. The keyswitch does not have

an engine stop position. Use the

Engine Throttle Control Lever (F) to

stop the engine.

IMPORTANT: Remove key from

keyswitch when leaving unit unattended to help prevent unauthorized or

unintentional starting.

Battery (Electric Start Model)

On electric start models, the battery (K,

Figure 3-1) will crank the engine starter

motor when the keyswitch is turned to

the start position. Do not crank engine

longer than five (5) seconds per each

starting attempt.

Figure 3-1: Features and controls (electric start model shown).

J

D

C

B

H

G

K

F

A

E

I

Figure 3-2: Engine primer.

Page 10

8

PRE-START CHECKLIST

1. Review Section 1: Safety and also

Section 3: Features and Controls.

2. Check for loose or missing hardware. Tighten or replace as needed.

3. Check the engine oil level*. It must

be up to the “FULL” mark on the oil

dipstick. (See the Engine Owner’s

Manual for instructions.)

4. Check the fuel level* in the fuel

tank. (See the Engine Owner’s Manual

and this page for instructions.)

5. Check the Trimmer Head Control

Bail and the Engine Throttle Control

Lever for freedom of movement.

6. Select the cutting height (see Adjust

Line Cutting Height in this Section).

7. Check handlebar height position.

8. On electric start models, check the

wire harness connections.

9. Carefully check the area to be

trimmed and remove any debris.

10. Install the correct diameter trimmer line (see Use the Correct Diameter

Trimmer Line in this Section).

11. Check that the spark plug wire is

securely attached to the spark plug.

* Clean debris from around fuel cap,

oil dipstick, and engine debris guard

before checking oil level or adding

gasoline, in order to keep dirt out of

engine.

FILL FUEL TANK

1. Lift and tilt plastic debris shield (E,

Figure 3-1) forward.

2. Clean fuel fill area and engine debris

guard each time before fuel is added.

3. Fill the fuel tank with gasoline according to the directions in the separate Engine Owner’s Manual. Follow all

instructions and safety rules carefully.

4. Securely replace the fuel tank cap

and the fuel container cap. Promptly

wipe up any fuel spills.

5. Lift and tilt the debris shield back,

then push it down to secure it.

ADJUST HANDLEBAR HEIGHT

To adjust handlebar height, refer to

Install Handlebars in the Assembly

Section of this Manual.

ADJUST LINE CUTTING HEIGHT

The cutting height of the trimmer line

adjusts from 1-1/2"-to-4-1/2" high in

infinite increments. The cutting height

has been factory-set at one of the

higher settings – we recommend that

you start at this higher setting and

make adjustments as needed.

In general, use higher height settings

to handle taller material and to cope

with tougher cutting conditions. For

less demanding situations, use any

trimming height desired. To adjust the

cutting height:

1. The cutting line height can be

changed when the wear cup is in contact with the ground. If necessary, you

may tip the unit back slightly for a

better view (do not tip unit all the way

back or motor oil may flow to the exhaust area and the engine may smoke

for several seconds when started).

2. Use a 1/2" wrench to loosen both

bolts (A, Figure 4-1) securing the trimmer head.

3. The cutting heights are marked on

the side of the spindle head (Figure

4-2). Move the top of the trimmer

head to the desired setting.

4. Tighten both trimmer head bolts

securely (to 75 in/lbs.) and evenly.

INTRODUCTION

Read this Section thoroughly before

you start the engine. As with any piece

of outdoor power equipment, getting

the “feel” for how your machine operates and knowing the best techniques

for particular jobs are important to

overall good performance.

NOTE: All references to LEFT, RIGHT,

FRONT and REAR of the machine are

determined by standing in the operator’s position.

Before adjusting handlebar height,

stop engine and wait for all moving

parts to stop, disconnect spark plug

wire and prevent it from touching

spark plug.

Failure to comply could result in

personal injury or property damage.

CAUTION

Before adjusting the cutting height,

shut off the engine, wait for all moving parts to stop, allow the engine to

cool, disconnect the spark plug wire

and prevent it from touching the

spark plug.

Failure to comply could result in personal injury or property damage.

CAUTION

GASOLINE IS HIGHLY FLAMMABLE

AND ITS VAPORS ARE EXPLOSIVE.

Follow gasoline safety rules in this

Manual (see Section 1) and in the

separate Engine Owner’s Manual.

Failure to follow gasoline safety rules

and instructions can result in serious

personal injury and property damage.

DANGER

Before operating your machine, carefully read and understand all safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner’s Manual, and on the decals

on the machine.

Failure to follow these instructions

can result in serious personal injury.

WARNING

Operation

4

Section

Figure 4-1

A

A

Page 11

9

Section 4: Operation

USE THE CORRECT DIAMETER

TRIMMER LINE

Before starting a project, examine the

grass or material you will be cutting

and trimming.

For tougher conditions, use two (or

four) sections of the thicker gauge,

.155" diameter extra-heavy duty line.

For less demanding conditions, use

two sections of the thinner gauge,

.130" diameter heavy-duty line. The

thicker line has the heft to chop

through tougher materials, while the

thinner line provides a more precise

cut. To change trimmer lines, refer to

Changing Trimmer Lines in Section 5.

NOTE: The thinner gauge line is also

recommended for use near trees or ornamentals to help prevent girdling

(cutting the bark).

USING THE TRIMMER HEAD

CONTROL BAIL

Before starting the engine, it is essential to know how to use the Trimmer

Head Control Bail.

1. The Trimmer Head Control Bail (A,

Figure 4-3) is used to start and stop

trimmer head motion.

2. Leave the control bail in the disengaged (released) position when starting the engine to prevent the trimmer

head from turning when the engine

starts. See Figure 4-3.

3. When the engine is running, pull up

and hold the control bail against the

handlebar (Figure 4-4) to start rotation

of the trimmer head.

4. Let go of the control bail to stop the

trimmer head. The control bail should

spring forward to the disengaged position. If it doesn’t, do not use the machine until the control bail has been

repaired.

OPERATING THE

TRIMMER/MOWER

Once you have read and understood

the sections in this Manual on Safety,

Assembly, Features and Controls, and

Operation, you are ready to start and

operate your trimmer/mower.

Checklist Before Starting

1. Complete the Pre-Start Checklist in

this Section of the Manual. You must

wear safety glasses or goggles.

2. Check that the line cutting height is

adjusted according to the instructions.

Starting the Engine

1. Move the unit to the work area.

2. Connect the spark plug wire to the

spark plug.

3. Put on safety-approved eye

protection.

4. Release (disengage) the Trimmer

Head Control Bail (A, Figure 4-3).

5. Put the Engine Throttle Control

Lever in the FAST (rabbit symbol)

position.

6. Push in the fuel primer button as

instructed in the Engine Owner’s

Manual. NOTE: Do not use primer to

restart a warm engine after a short

shutdown.

7. Recoil Starting: Pull recoil start rope

slowly until resistance is felt. Then

pull rope out rapidly to start engine.

Let rope back in slowly. NOTE: If

engine fails to start after three pulls,

repeat step 6.

Electric Starting: Stand behind handlebars and turn ignition key clockwise to crank engine. If engine

does not start after five seconds of

cranking, stop and repeat step 6.

When engine starts, release key.

To Start the Trimmer Head

1. Stand in the operator’s position

directly behind the handlebars.

2. Slowly close the Trimmer Head

Control Bail (Figure 4-4) against the

handlebars to activate the trimmer

head. Use the Engine Throttle Lever to

adjust the turning speed of the trimmer

head.

3. Once the trimmer head is revolving,

push the trimmer/mower along the

path to be cut.

To Stop the Trimmer Head

Let go of the Trimmer Head Control Bail.

It will return to its open position and

the trimmer head will stop turning.

To Stop the Engine

Put the Engine Throttle Control Lever in

the STOP position. (If time allows, first

move throttle lever to SLOW setting

before stopping engine.)

Figure 4-2

Height

Guide

Figure 4-3: Control bail disengaged.

A

Figure 4-4: Control bail engaged.

If the trimmer head control bail is not

operating properly, shut off the

engine, disconnect the spark plug

wire and move wire away from plug.

Adjust or repair the control bail

before using the trimmer/mower.

Failure to follow this instruction could

result in personal injury or property

damage.

WARNING

Page 12

10

Tips for Precision Cutting

For the most precise cutting possible,

be sure to select the appropriate line

cutting height and trimmer line size

(thickness) for the conditions at hand.

When mowing, let the cutting head rest

lightly on the ground and do not lift up

on the handlebars. This allows the cutting head to follow the ground contour

closely, resulting in the most even cut

possible. Also, be sure to ease into

heavy growth to prevent overwhelming

the machine.

Trim When Wet or Dry

Grass and most other materials are

most efficiently trimmed when dry.

But, the trimmer/mower will do a fine

job even with damp or wet materials.

When conditions are moist or damp, be

sure to clean debris off the machine

regularly to keep cutting efficiency

high. And watch your footing!

Clean the Trimmer/Mower

On a Regular Basis

Clean under the mower deck frequently

to remove any grass buildup. Also

clean around the muffler and on top of

engine. See the cleaning instructions

in Section 5: Maintenance.

Do Not Let the Trimmer

Lines Become Too Short

Once the trimmer lines are worn to less

than 1/2 their original length, trimming

jobs begin to take far longer than they

should.

As a general guideline, once the line

length becomes half of its original

length, it’s time to change to new lines.

Use Extreme Caution on Slopes

When operating on sloping ground,

use extreme caution and common

sense to avoid possible injury or property damage.

Do not mow on excessively steep

slopes! Avoid slopes if greater than

150or wherever footing is unsure. If a

slope is difficult to stand on, it is probably too steep to trim or mow. In this

case, it may be wiser to establish a permanent ground cover on this area.

Do not trim on slopes when the ground

is slippery. Trim across the face of a

slope, not up and down. Slow down

and exercise caution when changing

direction on slopes.

Use Correct Walking Speed

Use a walking speed that is suitable for

the conditions at hand. For example,

you’ll get better trimming and mowing

results at slower walking speeds if the

grass is tall or lush. Shorter grass or

less dense growth can be cut at faster

travel speeds.

Vary the Throttle Setting

According to Conditions

The majority of trimming and mowing

jobs will yield the best results if the

Engine Throttle Control is set at the

fastest engine speed.

Less demanding jobs that require very

precise cutting will yield better results

if the engine throttle is backed off

somewhat to reduce engine speed.

(For example, damage to trees and ornamentals can be avoided by reducing

the engine speed; using the lighter

.130" diameter line; and by keeping a

safe distance away.)

Again, once you begin a particular job

and get a “feel” for the conditions, you

will be able to make adjustments for

the best possible results.

Keep the Mowed Side to Your

Right as You Move Ahead

The trimmer/mower feeds cut materials

to the right side. Stay on the right side

of unmowed growth as you move

along.

THROWN OBJECT HAZARD

• Objects such as rocks, pebbles,

and small debris will be thrown

violently by the cutting head,

resulting in significant hazard to

eyes and exposed body parts.

• Always wear safety-approved eye

protection and suitable clothing

and footwear.

• Keep children, pets and bystanders

50 feet away from machine while

operating.

• Be alert to hidden obstacles.

Failure to comply could result in

injury or property damage.

WARNING

ADDITIONAL OPERATING TIPS

AND TECHNIQUES

NOTE: If the trimmer is operated in

a stationary position with the wear

cup in contact with dry vegetation,

significant heat will result that may

deform the plastic spindle or scorch

vegetation.

Section 4: Operation

Page 13

11

ADJUSTING TRIMMER

HEAD ENGAGEMENT

The tension on the drive belt must be

correct for proper operation of the

trimmer head. If the tension is correct,

the trimmer head will rotate when the

Trimmer Head Control Bail is pulled

back against the handlebar (another indication of correct tension is if the

engine stalls when the trimmer head

becomes bound up in very tough

material.)

A worn or loose drive belt will slip on

its pulleys, causing the trimmer head

to move slowly, or not at all, when the

control bail is engaged (belt squealing

may also be noticeable).

If the tension is too tight, the trimmer

head may rotate before the control bail

is engaged, or when there is no free

play in the control bail.

To Adjust Belt Tension

1. Stop the engine and wait for all

parts to stop moving. Adjust the position of the two nuts on the control

cable adjustment stud (see Figure 5-2)

as described next:

a. To tighten belt tension, move the

upper nut (A, Figure 5-2) upward,

then move the lower nut (B) upward.

Tighten both nuts securely.

b. To loosen belt tension, move the

lower nut (B, Figure 5-2) down and

then the upper nut (A) down.

Tighten both nuts securely.

REQUIRED MAINTENANCE SCHEDULE

BEFORE EVERY EVERY EVERY AS

REQUIRED MAINTENANCE EACH 5 25 100 NOTED

USE HOURS HOURS HOURS

CHECK ENGINE OIL LEVEL ••

CHECK TRIMMER/MOWER LINES • 1

CHECK TRIMMER HEAD ENGAGEMENT •

ENGINE/MACHINE CLEANING • 3

CHECK NUTS AND BOLTS •

CHANGE ENGINE OIL • 2, 5

SERVICE AIR FILTER SYSTEM • 5

CLEAN UNDER DECK •

GENERAL LUBRICATION •

INSPECT DRIVE BELT •

CLEAN ENGINE DEBRIS GUARD • 4

CHECK WEAR CUP • 6

NOTE 1 – New line replacement is suggested when old line is 50% or less of original length.

NOTE 2 – Change oil after first two hours of new operation; thereafter every 25 hours.

NOTE 3 – Clean daily if used in extremely dusty/dirty conditions (see Engine Owner’s Manual).

NOTE 4 – Clean before using machine and at each fuel refill.

NOTE 5 – Service more often if used in extremely dusty or dirty conditions (see Engine

Owner’s Manual).

NOTE 6 – Replace when severe gouges exist on bottom surface.

Chart 5-1

Maintenance

5

Section

Before inspecting, cleaning or servicing the machine, shut off engine, disconnect spark plug wire, and make sure that all moving parts have come to a complete stop. Remove ignition key on electric start models.

Failure to follow these instructions can result in personal injury or property

damage.

WARNING

NOTE: LEFT and RIGHT sides of unit are as viewed

from operator’s position behind the handlebars.

Figure 5-2: Belt tension adjustment.

B

A

Page 14

REMOVING AND REPLACING

THE TRIMMER HEAD

1. Stop the engine and wait for all

moving parts to stop. Disconnect

spark plug wire and move it away from

the spark plug. Remove the ignition

key on electric start models.

2. Two bolts (A, Figure 5-3) secure the

trimmer head (B) to the spindle head

(C). Loosen both bolts (not the nuts)

just enough to open up the trimmer

head and allow it to slide down the

spindle head and past the two stops.

Do not attempt to remove the bolts

completely – they are permanently

attached.

3. Install the new trimmer head on the

spindle head. Tighten the hardware

securely (to 75 in/lbs.) and evenly.

4. If the wear cup (D, Figure 5-3) is

worn, replace it. Use a 1/2" socket

wrench to remove the screw (E, Figure

5-3) and washer (F). Install the new

wear cup and reinstall the washer and

screw. Tighten the screw securely.

INSPECTING / REPLACING

THE DRIVE BELT

The drive belt can be inspected or replaced from beneath the machine deck.

The belt should not require inspection

for many hours of operation. If replacement becomes necessary, follow

the instructions given here.

Belt Inspection

Stop the engine and let all moving parts

stop. Allow the engine to cool.

Disconnect the spark plug wire and

move it away from the spark plug.

Remove the ignition key on electric

start models.

1. For convenience, we recommend

that you place the unit on a raised platform to make access to the underside

of the deck as easy as possible.

2. Examine the belt. Feed it around

the rear (engine) pulley so the entire

belt can be examined. If cracks or

other damage are noted, a new belt is

needed.

Belt Removal

1. Stop the engine and wait for engine

to cool. Disconnect the spark plug wire

and move it away from the spark plug.

Remove the ignition key on electric

start models.

2. Remove gasoline from fuel tank.

3. Carefully tip unit on its left side and

secure it in place.

4. Remove the plastic plug (A, Figure

5-4) from the top of the mower deck.

5. Using a 3/4" socket wrench, remove

nut (B, Figure 5-4), belleville washer

(C) and flat washer (D) from spindle

shaft (E).

6. Thread nut (B, Figure 5-4) a few

turns back onto spindle shaft (E) to

protect threads on spindle shaft during

the next step.

7. Loosen the spindle shaft by placing

a wood block against the top of the nut

(B, Figure 5-4) and firmly striking the

wood block with a hammer.

8. Remove the nut from the spindle

shaft and then remove the spindle shaft

(E, Figure 5-5) and entire spindle head

assembly (F) from the bottom of the

deck. Slip the belt off the spindle head

pulley (P).

9. Disconnect the idler arm spring (R,

Figure 5-6) from the hole in the idler

arm (T).

10. Using a 1/2" wrench, loosen the

idler arm mounting screw (S, Figure 5-

6) two full turns.

12

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove ignition key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

Figure 5-3

GASOLINE IS HIGHLY FLAMMABLE

AND ITS VAPORS ARE EXPLOSIVE.

• Drain fuel into approved container

outdoors, away from open flame.

• Be sure engine and muffler are cool

before draining gasoline.

• Do not smoke.

Failure to comply can result in serious personal injury and property

damage.

DANGER

Figure 5-4

A

B

C

D

E

A

B

D

F

E

C

Section 5: Maintenance

WARNING

Page 15

13

Section 5: Maintenance

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove ignition key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

11. Using a 9/16" wrench and a 7/32"

hex (Allen) wrench, loosen the mounting nut (G, Figure 5-6) and screw on

the idler pulley (I) a few turns, or until

belt is free to slip out between pulley

and belt guide (J). Remove belt.

12. Loosen rear belt guide screw (K,

Figure 5-6) enough to allow belt to be

removed from engine pulley (L).

Remove belt from unit.

Belt Replacement

1. Install belt on engine pulley (L,

Figure 5-6) and retighten rear belt

guide screw (K) securely.

2. Route belt between idler pulley (I,

Figure 5-6) and belt guide (J), to inside

of brake arm (M), and next to die-cast

belt guides (N).

3. Securely tighten the mounting nut

(G, Figure 5-6) and screw in the idler

pulley (I).

4. Securely tighten the idler arm

mounting screw (S, Figure 5-6). After

tightening, check that idler arm is free

to rotate. If not, remove idler arm and

check for debris that may be interfering

with freedom of movement.

5. Look at the spindle head mounting

hole (O, Figure 5-6) and note the

grooves that are cut into the inner

sides of the hole. These grooves were

formed by the splines on the spindle

shaft (E, Figure 5-5).

6. Install the belt on the spindle head

pulley (P, Figure 5-5) and insert the

spindle shaft (E) (with attached spindle

head assembly) into the spindle head

mounting hole (O, Figure 5-6). Rotate

the spindle head assembly to align the

splines on the spindle shaft with the

grooves in the mounting hole. Check

that the belt is still in the pulley groove

and is to the inside of the die-cast belt

guides (N, Figure 5-6).

7. Using a firm push on the spindle

head assembly (Figure 5-6A), seat the

spindle head assembly into the hole.

Check that the threaded end of the

spindle shaft is protruding through the

bottom of the hole.

8. Reinstall the flat washer (D, Figure

5-4), belleville washer (C) and nut (B)

on the spindle shaft. Note that the

dished-in side of the belleville washer

must face the flat washer. Tighten the

nut securely (torque to 50 ft./lbs.),

while checking frequently to ensure

that the spindle head rotates freely. If

the spindle head binds, it could be due

to the belt being pinched between the

spindle head and the belt guides. If so,

remove the spindle head assembly and

repeat steps 5-7.

9. Replace plastic plug (A, Figure 5-4).

10. Reattach the idler arm spring (R,

Figure 5-6) in the hole in the idler arm

(T).

11. A new belt may need to be ad-

justed by following the Adjusting

Trimmer Head Engagement instruc-

tions in this Section.

Figure 5-5

Figure 5-6

E

F

P

R

T

K

N

N

O

M

G

I

S

J

L

Figure 5-6A

WARNING

Page 16

14

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove ignition key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

Section 5: Maintenance

TRIMMER/MOWER CLEANING

AND DEBRIS REMOVAL

Thorough and regular cleaning of debris from around the engine and on the

machine is required for maximum

engine efficiency and good overall

performance. Inspect and clean the

following areas regularly, making sure

the engine is stopped, and cool, before

proceeding:

• Brush and wipe off all engine surfaces, especially before checking oil

or adding fuel. Do not let oil or

grease accumulate. For access to the

front of the engine, the debris shield

can be lifted up and tilted forward.

• Wipe the deck clean, particularly near

the engine muffler.

• Clean the underside of the deck.

• Keep safety and operating decals

clean and legible.

• Keep all operating control levers

debris-free so they work properly.

CLEANING THE ENGINE

DEBRIS GUARD

It is extremely important to keep the

engine debris guard (A, Figure 5-7)

free of dirt and debris so the engine

can run as efficiently and as cool as

possible.

Brush the debris guard clean before

using the unit each time and whenever

you see a build-up of dirt and debris.

NOTE: The separate engine air cleaner

must also be serviced according to the

instructions in the Engine Owner’s

Manual.

LUBRICATION

Applying light oil or a silicone-based

lubricant to your machine allows parts

to work more smoothly and protects

them from the elements. The following

are general guidelines:

Silicone-base Spray Lubricant

(or light oil):

• Throttle control cable

• Control bail cable

• Nuts, bolts and other hardware

NOTE: The spindle head is permanently lubricated at the factory. There

is no need for additional lubrication.

COMPACT STORAGE

For compact storage of the unit, remove the two screws and locknuts securing the handlebar and carefully (to

avoid kinking the cables) rotate the

handlebar so that the upper portion

rests on the engine and the handlebar

legs face to the rear of the unit.

GENERAL ENGINE

MAINTENANCE

Perform the following engine maintenance for your engine according to the

engine maintenance schedule and instructions in the separate Engine

Owner’s Manual:

Engine Oil Service

Check the engine oil level before starting the engine each day and check it

after each 5 hours of continuous oper-

ation. Running the engine when it is

low on oil will quickly ruin the engine.

Change the oil after every 25 hours of

operation and even sooner when

operating in extremely dirty or dusty

conditions.

Air Cleaner Service

The engine air cleaner filters dirt and

dust out of the air before it enters the

carburetor. Operating the engine with a

dirty, clogged air filter can cause poor

performance and damage to the engine. Never operate the engine without

the air cleaner installed. Inspect and

service the air cleaner after every 25

operating hours, more often if operating in very dusty or dirty conditions.

Refer to the Engine Owner’s Manual for

cleaning or replacement instructions.

Spark Plug Service

Inspect and clean or replace the spark

plug after every 100 operating hours or

annually. Refer to the Engine Owner’s

Manual for cleaning or replacement

instructions.

Spark Arrester Screen Service

If the engine is equipped with a spark

arrester screen, remove and clean it

according to the time intervals and

instructions in the Engine Owner’s

Manual.

Engine Cleaning

The engine must be kept clean to assure smooth operation and to prevent

damage from overheating. Refer to the

Engine Owner’s Manual for specific

cleaning instructions.

Carburetor/Governor Control

Adjustments

The carburetor was adjusted at the factory for best operating speed. Refer to

the Engine Owner’s Manual for any adjustment information.

The governor controls the maximum

safe operating speed and protects the

engine and other moving parts from

Figure 5-7

A

Never run engine without debris

guard properly installed. If debris

guard is not properly installed, grass

clippings may be drawn into engine,

causing heat buildup and, in some

cases, a fire.

Failure to comply can cause injury or

property damage.

WARNING

WARNING

Page 17

15

Section 5: Maintenance

damage caused by overspeeding. Do not

tamper with the governor settings. Seek

authorized service if you think an adjustment is required.

Throttle Control Adjustment

If the engine does not shut off when the

throttle lever is moved to the stop position, or if the engine does not respond

to various throttle settings, refer to the

Engine Owner’s Manual for service information.

OFF-SEASON STORAGE

When storing the trimmer/mower for

extended periods, follow these procedures to ensure that the unit will be in

good condition for future use.

• Store machine on a level surface.

• Thoroughly inspect the machine for

any loose, broken or missing parts.

Repair or replace parts as necessary.

• Perform recommended engine mainte-

nance by following the engine

storage instructions found in the

Engine Owner’s Manual. Be sure to

protect the fuel lines, carburetor and

fuel tank from gum deposits by removing fuel or by treating fuel with a fuel

stabilizer (follow engine manufacturer’s

recommendations).

• Change engine oil.

• Clean any dirt, grass or chaff from the

air cooling system intake area and

other parts of the engine.

• Check nuts, bolts, other hardware for

tightness. Replace missing hardware.

• On an electric start model, remove key

from keyswitch. Charge battery for 24

hours before and after storage.

• Disconnect spark plug wire from spark

plug. Prevent wire from touching

spark plug by placing wire away from

spark plug.

BATTERY RECHARGING (Models

with electric start feature)

Recharge the battery before and after

storing the unit for more than three

weeks.

The engine must be stopped and the

area in which recharging will take place

must be dry.

1. Connect the small plug on the bat-

tery charger cord (A, Figure 5-8) to the

wire harness plug (B) located near the

keyswitch.

2. Plug the recharger box (C, Figure 5-

8) into a grounded 120-Volt wall

outlet.

3. Charge the battery for 24 hours.

After charging, unplug the recharger box

(C, Figure 5-8) from the wall outlet first,

then disconnect the recharging line

plugs (A and B, Figure 5-8).

BATTERY REPLACEMENT

If the battery no longer takes a charge,

or if it is leaking or otherwise damaged,

it must be replaced.

1. Tilt the debris shield forward.

2. Disconnect the negative (–) black

wire first; then the positive (+) red wire.

3. A clamp secured with two screws

holds the battery to the deck. Remove

screw (D, Figure 5-9), then lift the battery from under the battery clamp.

4. Position the new battery under the

clamp and replace screw (D).

5. Connect the red wire to the positive

(+) red-coded battery terminal. Then,

connect the black wire to the negative

(–) black-coded battery terminal.

NOTE: Discard battery properly, as

required by regulations in your area.

6. Close the debris shield.

• Never perform maintenance when

engine is running or spark plug wire

is connected, except when

instructed to do so.

• Never store mower with fuel in fuel

tank inside a building where fumes

can reach an open flame or spark,

or where ignition sources are present such as hot water and space

heaters, furnaces, clothes dryers,

stoves, electric motors, etc. Make

sure engine is cool before storing.

• Drain gasoline outdoors into an

approved container.Do not smoke

and keep fuel away from open

flame.

Failure to follow these instructions

will result in serious personal injury

or property damage.

WARNING

• Wet conditions can cause an electric shock hazard during battery

charging. Avoid wet conditions

when charging.

• Recharging the battery with

improper equipment could cause a

battery explosion. Use only the battery charger shipped to you. All

parts must be fully stopped and the

spark plug wire disconnected and

moved away from the spark plug.

Failure to comply could result in personal injury or property damage.

DANGER

Figure 5-8: Use recharger supplied with

unit.

A

C

B

Figure 5-9: Battery replacement.

D

Page 18

16

Section 5: Maintenance

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Remove ignition key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

CHANGING TRIMMER LINES

The trimmer lines will wear with use

and eventually require replacement.

Also, you may wish to switch between

the thinner and thicker gauge lines to

handle different mowing conditions.

Replace the trimmer lines when they

wear to the point that trimming and

mowing projects take too long and

require too much maneuvering of the

machine. A good rule of thumb is to

change the lines when they reach half

their original length.

Use the extra-heavy duty gauge (.155"

diameter) line when cutting thick,

tough growth. The thinner gauge

(.130" diameter) line is for use in less

demanding conditions, and is also recommended for use near trees or ornamentals to help prevent girdling (cutting of bark).

To Change Trimmer Lines:

1. Stop engine, allow all parts to stop

moving and then disconnect the spark

plug wire. Remove the ignition key on

electric start models. DO NOT tip the

machine. DO NOT touch the metal

wear cup on the bottom of the spindle

head. This surface may be hot.

NOTE: The two line holders on the

trimmer head are permanently secured

by a screw and a nut. Do not attempt

to remove the line holders as it is not

necessary to remove them in order to

change the trimmer lines.

2. The trimmer lines can be changed

when the trimmer head is in contact

with the ground. If necessary, you

may tip the unit back slightly for a better view. However, do not tip the unit

all the way back or motor oil may flow

to the exhaust area and the engine may

smoke for several seconds when

started.

3. Three different line installation patterns are available, as shown in Figures

5-10, 5-11 and 5-12.

4. Simply feed the line through the

loops of the line holder as shown. An

equal amount of line should project out

from each side of the line holder, creating an overall 22" wide cutting swath.

You may offset both trimmer lines

somewhat to increase the cutting

swath up to 25" wide. However, DO

NOT offset the line so that the overall

cutting swath is greater than 25". See

Warning statement at right.

IMPORTANT: Whether replacing one

or both lines, they must both be .130"

or .155" in diameter.

5. Repeat steps 2 through 4 to replace

the second trimmer line.

Figure 5-10: Use this single line, easy-loop pattern

for all but the more difficult

cutting conditions.

Figure 5-12: For more difficult cutting conditions, use

two of the thicker gauge

(.155" diameter) lines in

each line holder. Follow

the installation pattern

shown in Figure 5-10.

Figure 5-11: If the lines

should loosen while trimming (especially in more

difficult conditions), add a

simple reverse loop. Note

that this pattern will result

in a slightly narrower overall cutting swath.

Offsetting the trimmer lines causes

the lines to rotate faster than when

they project an equal length on each

side. This increases the chance of

loose materials being dislodged and

propelled at high speeds.

Failure of the operator to wear safety

goggles and appropriate clothing and

to keep bystanders away can result in

severe personal injury or property

damage.

WARNING

Reverse Loop

WARNING

Page 19

17

Section 5: Maintenance

PROBLEM POSSIBLE CAUSE CORRECTION

Engine does not start. 1. Spark plug wire disconnected. 1. Reconnect wire.

2. Defective or incorrectly gapped spark plug. 2. Inspect/replace spark plug.

3. Fuel tank empty. 3. Add fuel.

4. Dirty carburetor or fuel line. 4. Clean carburetor or fuel line.

5. Dirty air cleaner. 5. Clean or replace.

6. Carburetor out of adjustment. 6. Adjust carburetor. See Engine Service Dealer.

7. Engine flooded. 7. Wait several minutes before starting.

8. Engine Throttle Lever in incorrect position. 8. Move Throttle Lever to FAST position.

9. Stale gasoline. 9. Drain old fuel and add fresh fuel.

10. Defective Engine Throttle Lever. 10. See Engine Service Dealer.

11. Dirt or water in fuel tank. 11. See Engine Service Dealer.

Engine runs poorly. 1. Bad spark plug. 1. Inspect/replace spark plug.

2. Dirty air filter. 2. Clean or replace.

3. Carburetor out of adjustment. 3. Adjust carburetor. See Engine Service Dealer.

4. Stale fuel. 4. Drain and replace fuel mixture.

5. Dirt or water in fuel tank. 5. See Engine Service Dealer.

6. Engine cooling system clogged. 6. Clean fins.

Engine overheats. 1. Engine cooling system clogged. 1. Clean air cooling areas and behind debris shield.

2. Carburetor out of adjustment. 2. Adjust Carburetor. See Engine Service Dealer.

Engine does not shut off. 1. Throttle control misadjusted. 1. See Engine Service Dealer.

.

Poor mowing performance. 1. Line length is too short or too long. 1. Adjust line length to 18" long. When less

than 1/2 this length, replace the line.

2. Cutting height is too high or low for height 2. Adjust cutting height to approximately 1/3

of grass being cut. of the length of the grass.

3. Engine not set at FAST speed. 3. Move Engine Throttle Lever to FAST (Rabbit).

Trimmer/Mower vibrates. 1. Trimming head mounting bolt loose. 1. Tighten bolt.

2. Line lengths are substantially different. 2. Adjust lines to approximately equal lengths.

3. Loose nuts or bolts. 3. Check all bolts and nuts, including engine bolts.

4. Broken spindle head or trimmer head. 4. Replace broken part.

Trimmer head does not 1. Incorrect line installation for mowing conditions. 1. See Changing Trimmer Lines in Section 5.

retain line.

Trimmer Head does not 1. Head bolts may be loose. 1. Tighten head bolts to 75 in/lbs.

retain height setting. 2. Head is worn. 2. Replace head assembly.

Electric Starter does not 1. Wires to battery unconnected. 1. Reconnect wires.

start engine (electric start 2. Battery not charged. 2. Charge battery.

models only). 3. Broken wire in wiring harness. 3. Replace wiring harness.

4. Malfunctioning starter motor. 4. Contact local engine dealer.

Battery does not charge 1. Broken wire in engine recharging circuit. 1. See Engine Service Dealer.

during engine operation 2. Malfunctioning engine recharging system. 2. See Engine Service Dealer.

(electric start models). 3. Dead battery. 3. Replace battery.

Battery charger does not 1. Broken battery lead. 1. Replace battery lead.

charge battery (electric 2. Broken battery charger wire. 2. Replace battery charger.

start models). 3. Dead battery. 3. Replace battery.

TROUBLESHOOTING

Before performing any of the corrections in this Troubleshooting Chart, refer to the appropriate information contained in this

Manual or the Engine Owner’s Manual for the correct safety precautions and servicing procedures. Contact your local authorized Engine Service Dealer for engine service. Contact your local authorized dealer for service problems with the machine.

Page 20

18

Parts List Models 52057 & 52058

DRAWING NO. 1

1

2

3

4

5

5

5

5

5

5

7

8

9

10

11

12

13

17

17

17

16

20

21

22

23

24

25

15

18

19

14

14

6

6

Page 21

19

Models 52057 and 52058 Parts List

1 1917765 Debris Guard............................................ 1

2 1918082 Decal-Logo (B)......................................... 1

1904401 Decal-Logo (A) ......................................... 1

3 1915290 Push-in Fastener....................................... 5

4 1917407001 Debris Guard Support............................... 1

5 1754128 Hex Flange Screw, 1/4-20 x 3/4................ 8

6 1915320 Spacer ...................................................... 2

7 * Engine....................................................... 1

8 1904511 Decal-Hot Surface Warning ...................... 1

9 1917727 Engine Pulley............................................ 1

10 1100243 Spring Lock Washer................................. 1

11 1100009 Hex Hd. Screw, 3/8-24 x 1, Grade 5 ......... 1

12 1918228 Deck (Incl. Ref. 13)................................... 1

Ref. # Part # Description Qty.

*

Order parts from your local authorized engine dealer. Refer to engine

for model/type number.

13 1918115 Decal-Warning.......................................... 1

14 1917144001 Hood Bracket............................................ 2

15 1186389 Flange Lock Nut, 1/4-20 ........................... 2

16 1917574 Belt Guide................................................. 1

17 1768194 Hex Hd. Screw, 3/8-16 x 1-1/2 ................. 3

18 1917154 Deflector Flap............................................ 1

19 1917155 Rod........................................................... 1

20 1909647 Battery (A)................................................ 1

21 1915268 Battery Pad (A)......................................... 1

22 1915204001 Battery Clamp (A)..................................... 1

23 90063 Hex Flange Screw (A), 5/16-18 x 1........... 2

24 1918055 Wire Harness (A)...................................... 1

25 96520 Ignition Key (A)......................................... 2

Ref. # Part # Description Qty.

PARTS LIST – DRAWING NO. 1

(A) Model 52058

(B) Model 52057

Page 22

20

Parts List Models 52057 & 52058

DRAWING NO. 2

See DRAWING

NO. 1

See DRAWING

NO. 3

See ACCESSORIES

AND KITS

2

2

1

1

3

3

4

7

8

9

10

11

12

13

14

15

16

27

17

18

22

23

24

25

26

18

18

19

20

21

6

1 1917778 Wheel/Tire Assembly.............................. 2

2 1917593 Locking Retaining Ring.......................... 2

3 1917775 Flat Washer ............................................ 2

4 1917258 Axle........................................................ 1

6 1918069 Self-Tap Screw, 5/16-18 x 2................... 2

7 1917588 Cap Plug................................................. 1

8 1734514 Hex Lock Nut, 1/2-13 ............................. 1

9 9928 Belleville Washer.................................... 1

10 1917745 Hardened Washer................................... 1

11 1917579 V-Belt ..................................................... 1

12 1918246 Spindle Head Adapter (Incl. Bearing) ..... 1

13 1917581 Spindle Shaft.......................................... 1

14 1918329 Spindle Head Assembly (Incl. Bearing,

Insert, and Refs. 16, 17, 18)............... 1

15 1918393 Trimmer Head Assembly (Incl. Ref. 27). 1

16 1915220001 Wear Cup ............................................... 1

17 1917599 Square Washer....................................... 1

18 1724491 Self-Tap Screw, 5/16-18 x 3/4................ 3

19 1917573 Cable Bracket ......................................... 1

20 1910849 Idler Spring ............................................ 1

21 1917746 Flat Washer ............................................ 1

22 1917589 Control Cable - Trimmer Head ............... 1

23 1910857 Button Hd. Screw, 3/8-16 x 1-1/2........... 1

24 1917572 Idler Arm................................................ 1

25 1910855 Idler Pulley............................................. 1

26 1186393 Flange Lock Nut, 3/8-16......................... 1

27 1918332 Rubber Shim Kit (2 shims per kit).......... 1

Ref. # Part # Description Qty.

PARTS LIST – DRAWING NO. 2

Page 23

21

DRAWING NO. 3

1

4

5

2

3

6

6

8

7

9

12

13

13

13

14

15

16

14

10

11

1 1918283 Upper Handlebar (Incl. Refs. 2 & 3)....... 1

2 1915889 Decal–Bail Engage/Disengage ................ 1

3 1918304 Decal–Throttle ....................................... 1

4 1918070001 Control Bail–Trimmer Head ................... 1

5 1917589 Cable Assembly–Trimmer Head ............. 1

6 1908677 Bushing.................................................. 2

7 1749977001 Cable Bracket ......................................... 1