Page 1

$4.50

OWNER’S MANUAL Chipper/Shredder

• Safeh

SAFI^ FIRST!

Before operating t№ egnlitoient, read this

Owner’s Manntlwt^M№a!e manual

supplied Iqr tin tngli^iwMfacturer.

• As

• Featur^/Cdntrnls

• Operation

• M^ntenance

• p«f»V

Models

47329

47330

GARDEN WAY INCORPORATED

/

Page 2

Dear Owner;

Thank you for purchasing this Chipper/Shredder. This unit has

been designed, engineered and manufactured to give you the

best possible dependability and performance.

Please carefully read this Manual. It tells you how to safely

and easily assemble, operate and maintain your machine. Be

sure that you and any other operators carefully follow the rec

ommended safety practices at all times. Failure to do so

could result in personal injury or property damage.

Please complete and return the Owner Registration Card that

is included in the literature package. Returning this card will

register your name at the Factory so that we can provide you

with warranty benefits and special informational bulletins.

If you should ever have any problems or questions, please

contact your local authorized service dealer or the Factory

(see back cover).

We want to be sure that you are completely satisfied at all

times.

See Back Cover for

Customer Service information

Safety Alert Symbol

This is a safety alert symbol. It is used in this manual

and on the unit to alert you to potential hazards.

A

When you see this symbol, read and obey the mes

sage that follows it. Failure to obey safety messages

could result in personal injury or property damage.

This machine has met the rigid safety standards of

the Outdoor Power Equipment Institute and an inde

pendent testing laboratory.

A DANGER

Contact with rotating cutting blades inside discharge

opening will cause serious personal injury! Cutting blades

are rotating while unit is running, and continue to rotate

until the cylinder assembly comes to a complete stop.

Keep hands, teet, face and clothing out of shredder hopper

inlet and chipper chute inlet, and away from discharge

area and moving parts at all times to avoid serious per

sonal injury. Before doing maintenance or service, shut

off engine, aliow ail moving parts to come to a complete

stop, disconnect spark plug wire and keep it away from

spark plug.

Table of Contents

SECTION 1: SAFETY

Safety Decals.......................................................................... 5

SECTION 2: ASSEMBLY

Introduction

Step 1: Unpacking Instructions

Step 2; Check Carton Contents............................................... 6

Step 3; Attach Chipper Chute.................................................. 6

Step 4: Attach Handle

Step 5; Install Clutch Lever

Step 6: Add Motor Oil to Engine.............................................. 7

Step 7; Check Hardware for Tightness

SECTIONS: FEATURES & CONTROLS................................... 8

Introduction.............................................................................. 8

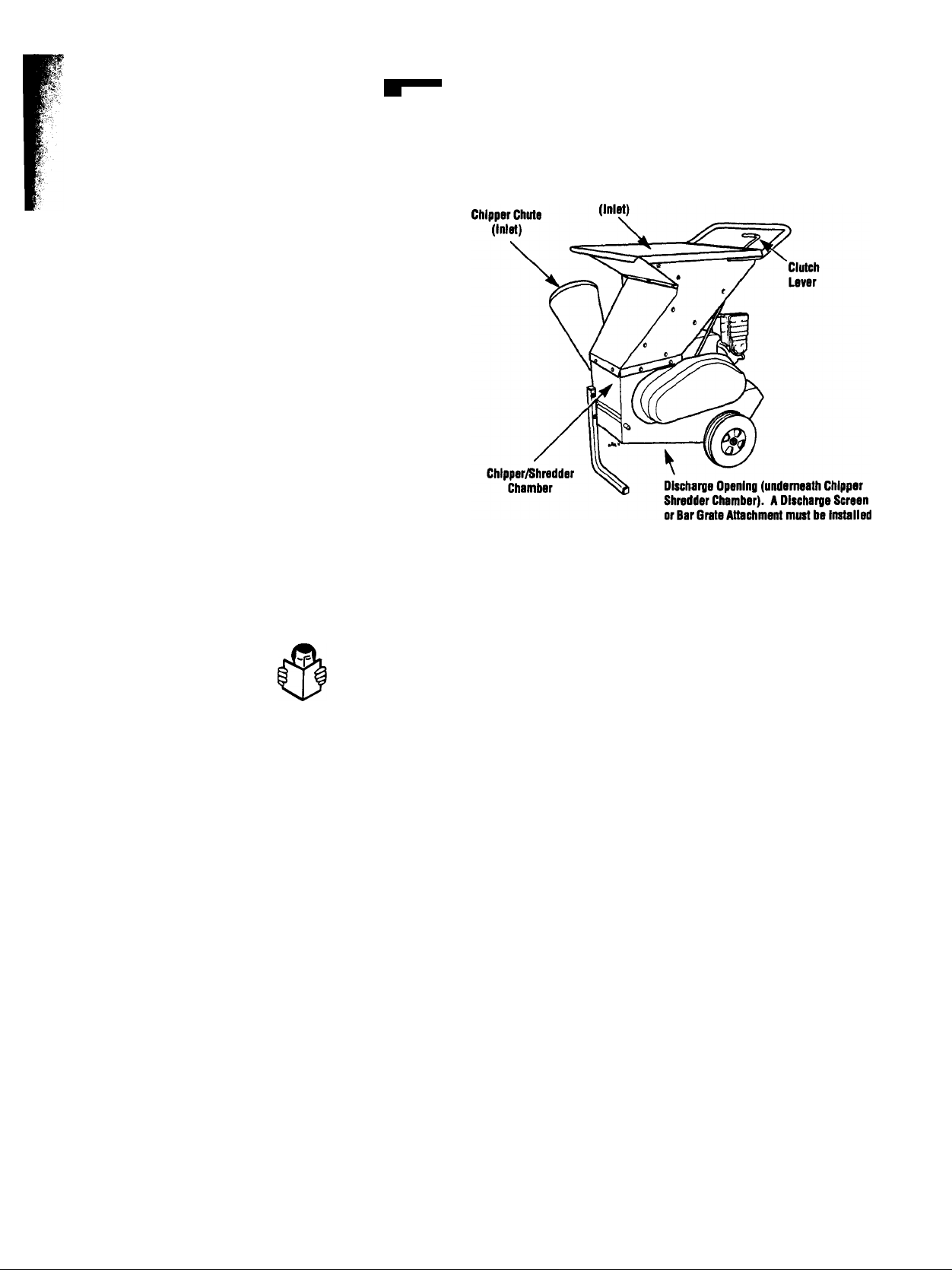

Chipper/Shredder Features and Controls

Shredder Hopper (Inlet)........................................................... 8

Chipper Chute (Inlet)............................................................... 9

Chipper/Shredder Chamber

Discharge Opening and Discharge Screen............................. 9

Bar Grate Attachment.............................................................. 9

Clutch Lever

Leaf Tamper.......................................................................... 10

Engine Controls..................................................................... 10

Engine ON/OFF Rocker Switch............................................ 10

Fuel Shut-Off Valve

Choke Control........................................................................ 10

Rope Starter.......................................................................... 10

SECTION 4: OPERATION

Moving the Unit..................................................................... 11

Pre-Start Checklist................................................................ 11

Motor Oil and Gasoline......................................................... 11

Starting and Stopping the Unit.............................................. 11

Using the Chipper/Shredder

Materials................................................................................ 12

Using the Chipper.................................................................. 13

Using the Shredder................................................................ 14

Shredding Wet, Soggy, or Green Materials

Removing/lnstalling Discharge Screen or Bar Grate

Optional Discharge Screens.................................................. 16

SECTIONS: MAINTENANCE

Maintenance Schedule.......................................................... 17

Lubrication............................................................................. 17

Drive Belt Service.................................................................. 17

Cylinder Assembly Service and Repair

Chipper Blade Removal/lnstallation

Hopper Flap Replacement

Engine Maintenance.............................................................. 22

Off-Season Storage............................................................... 22

Troubleshooting....................................................... 23

Parts List............................................................... 24

Customer Service Information

....................................................

.................................................

.............................................................................

...............................................

.............................................................

.....................................................

...................................

...............................

....................................................

............................................................................

.........

...................................................... 10

.............................................

.................................................

..........................

............

...........................................

................................

......................................

....................................................

............................

Back Cover

11

12

14

15

17

18

20

21

A WARNING

The engine exhaust from this product contains

chemicais known to the State of Caiifomia to cause

cancer, hirth defects or other reproductive harm.

3

6

6

6

7

7

7

8

9

9

Page 3

Section

n Safety

SPARK ARRESTER WARNING TO RESIDENTS OF

CALIFORNIA AND SEVERAL OTHER STATES

Under California law, and under the laws of several

other states, you are not permitted to operate an inter

nal combustion engine using hydrocarbon fuels on any

forest, brush, hay, grain, or grass covered land; or

land covered by any flammable agricultural crop with

out an engine spark arrester in continuous effective

working order.

The engine on the unit is an internal combustion

engine which burns gasoline, a hydrocarbon fuel, and

must be equipped with a spark arrester muffler in con

tinuous effective working order. The spark arrester

must be attached to the engine exhaust system in such

a manner that flames or heat from the system will not

ignite flammable material. Failure of the owner/operator of the unit to comply with this regulation is a mis

demeanor under California law (and other states) and

may also be a violation of other state and/or federal

regulations, laws, ordinances or codes. Contact your

local fire marshal or forest service for specific informa

tion about which regulations apply in your area.

Shredder Hopper

Inside Dlscherge Opening.

Training

1. Read this Owner’s

Manual and the separate

Engine Owner’s Manual very carefully

before operating this equipment. Be com

pletely familiar with the controls and the

proper use of the equipment. Know how

to stop the unit and disengage the con

trols quickly. A replacement Manual is

available by contacting your authorized

dealer or the Factory.

2. Know where the engine shut-off con

trol is and know how to use it (refer to

Section 3 in this Manual).

3. Never allow children or untrained

adults to use this equipment. Allow adults

to operate the equipment only if instructed

properly.

4. Keep the area of operation clear of all

persons, particularly small children and

pets. Keep bystanders at least 25 feet

from the area of operation.

5. Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people, their property

and themselves.

6. Familiarize yourself with all safety and

operating decals on this equipment and on

any of its attachments or accessories.

7. Do not run engine in an enclosed area.

Engine exhaust contains carbon monoxide

gas, a deadly poison that is odorless, col

orless, and tasteless. Do not operate this

equipment near buildings, windows, or air

conditioning equipment.

8. Do not put hands, feet, face, or any

other part of your body or clothing near

the chipper chute, shredder hopper, or

discharge area. The cutting blades begin

to rotate and build up speed once the

engine is running and continue to rotate

for some time after the engine is stopped.

Serious personal injury will occur if con

tact with the blades is made while they are

rotating. Wait for all moving parts to stop

completely.

9. Before inspecting or servicing any part

of the equipment, shut off engine, make

sure all moving parts have come to a

complete stop, then disconnect spark plug

wire from spark plug and move wire away

from the plug.

Preparation

1. The operation of the unit can result in

foreign objects being thrown by high

speed rotating parts. Wear safety approved

eye protection (with side shields) when

using the unit.

2. Do not wear loose-fitting clothing, such

as scarves, which could be caught by

moving parts. Tie up or restrain long hair.

3. Make sure the unit is level and stable

before starting the engine. Operate unit

only on level ground.

4. Do not operate unit on a paved, hard,

or gravel surface. Discharged material

may bounce from a hard surface and

cause injury. Always operate unit on a

level, earthen surface.

5. Each time before starting the unit,

make a visual check to see that all screws,

nuts, bolts and other fasteners are prop

erly secured. The discharge screen (or

the optional bar grate), chipper chute

and all safety covers must be correctly

and securely installed. Disconnect

spark plug wire and move it away from

spark plug before performing this check.

Replace any damaged or unreadable

warning and operating decals.

Page 4

4 Section 1: Safety

6. Handle fuel with саге. It is highly

flammable and has explosive vapors. Take

these precautions;

a. Use an approved fuel container.

b. Add fuel before starting engine. Never

remove fuel tank cap or add fuel while

engine is running or when engine is

hot. Operators shall not smoke.

c. Keep matches, cigarettes, cigars,

pipes, open fiâmes, and sparks away

from the fuei tank and fuei container.

d. Fiii fuel tank outdoors and with

extreme caution. Never fill fuel tank

when indoors. Use a funnel or spout

to prevent spillage.

e. Replace all fuel tank and fuel con

tainer caps securely.

f. If fuel is spilled, do not attempt to

start engine, but move machine away

from area of spillage and avoid creat

ing any source of ignition until fuel

vapors have dissipated.

7. Never make adjustments to your equip

ment when the engine is running or spark

plug wire is connected (unless specifically

recommended in Owner’s Manual).

blades is made while they are rotating.

Wait for all moving parts to stop

completely.

7. Do not use hands or feet to clear mate

rial from discharge area or discharge

opening.

8. Do not stand in front of discharge area

when operating unit. Material exits quickly

from discharge screen and discharge

opening and can cause serious personal

injury.

9. Do not allow chipped or shredded

material to build up in, or clog the dis

charge area — clogging prevents proper

discharge of materials and can result in

kickback of material up through the shred

der hopper or chipper chute. To remove

material from discharge area, first shut off

engine, allow all moving parts to stop

completely, and disconnect spark plug

wire and keep it from touching the plug.

long stick. NEVER USE HANDS OR FEET

TO CLEAR MATERIAL FROM DISCHARGE

AREA OR DISCHARGE OPENINGI ROTAT

ING BLADES CUT 1/4-INCH FROM DIS

CHARGE SCREEN (OR BAR GRATE).

KEEP AWAYI NEVER PUT HANDS OR

Operation

1. Secure the spark plug wire away from

the spark plug and remove any unpro

cessed material from inside the unit before

starting the unit.

2. Do not feed metal, rocks, bottles, nails,

cans, or any other foreign objects into the

chipper chute or shredder hopper. Pro

cess organic materials only!

3. Keep your face and body away from

shredder hopper and chipper chute.

FEET IN DISCHARGE AREA OR DISCHARGE

OPENINGI

10. Shut engine off immediately if unit

strikes a foreign object or develops an

unusual noise or vibration. When engine

is off and all moving parts have come to a

complete stop, disconnect spark plug wire

and keep it away from plug. Then proceed

as follows;

• V«*

4. Keep hands, feet, face and clothing

away from shredder hopper inlet, chip

per chute inlet, and discharge area to

avoid serious personal injury.

5. Keep hands and feet out of discharge

opening when machine is running.

Rotating cutting blades inside opening

will cause serious personal injury.

6. Do not put hands, feet, face or any

other part of your body or clothing near

chipper chute, shredder hopper or dis

charge area. The cutting blades begin to

rotate and build up speed once the engine

is running and continue to rotate for some

time after engine is stopped. Serious per

sonal injury will occur if contact with

11. Keep engine surfaces clean and free

of leaves, grass, oil, grease, or any other

combustible material to avoid fires and/or

engine damage.

12. If the unit jams or becomes clogged,

shut the engine off. jlKail U1ÜÍ1 all moving

parts have come lo a complelo stop.

(The bearing collar on the chipper chute

side of the unit has a white line painted

on It. When this whits line is stationary,

the cylinder assembly has stopped rotat

ing.) Disconnect spark plug wire and

Then USB a long-handled shovel or a

a. Inspect for damage.

b. Remove all foreign objects.

c. Check for loose parts or hardware

and tighten if loose.

d. Replace or repair damaged parts

before starting engine.

prevent it from touching spark plug before

inspecting shredder hopper inlet, chipper

chute inlet, internal cutting chamber, dis

charge screen (or the optional bar grate)

and discharge area. Use a long wooden

stick (or a long-handled shovel) to clear

jammed material.

13. Keep all safety shields, guards,

screens, and deflectors properly secured

and in good condition. Do not operate

unit unless shredder hopper and chipper

chute are securely bolted in place and a

discharge screen (or optional bar grate)

is correctiy instailed in unit.

14. Processed material exits at high

speed from discharge opening. Keep

away from discharge opening and dis

charge area while operating unit.

15. Do not over-reach when feeding mate

rial into shredder hopper or chipper chute.

Always keep arms parallel to ground

while feeding material into shredder

hopper. Use the leaf tamper (supplied)

to push leaves down into shredder

hopper. When chipping, keep arms per

pendicular (at a 90° angle) to chipper

chute. Keep proper footing and good bai-

ance at all times.

16. Do not tamper with engine governor

settings on machine. The governor con

trols the maximum safe operating speed

and protects engine and all moving parts

from damage caused by overspeed. Con

tact your nearest authorized dealer if an

engine governor problem exists.

17. Do not transport or move unit while

engine is running.

18. Rotating cutting blades do not stop

for 20 - 30 seconds after engine has

been shut off. You can tell when the

rotating cylinder stops by watching the

white line on the cylinder bearing collar.

When this white line is stationary, the

cylinder has stopped rotating.

19. Take all possible precautions when

leaving machine unattended. Always stop

the engine. Disconnect the spark plug

wire and prevent it from touching the plug.

20. Never operate unit if you are tired or

under the influence of alcohol, drugs or

medication.

21. Do not touch hot muffler, cylinder,

fins or other engine parts which can causa

burns.

Page 5

Section 1: Safety

Maintenance and Storage

1. Before performing any maintenance or

adjustments, shut the engine off, wait for

all moving parts to come to a complete

stop, and disconnect and secure the spark

plug wire away from the spark plug. Allow

unit to cool before working near it or plac

ing a storage cover over it.

2. Store unit where children will not have

access to it. Always disconnect the spark

Safety Decals

For your safety and the safety of others,

various safety and operational decals are

located on your unit (see below).

plug wire and prevent it from touching the

spark plug before storing unit.

3. Be sure unit is stored in an area where

gasoline vapors (fumes) from unit cannot

reach an open flame or spark.

4. Keep the chipper blade sharp.

5. For seasonal storage; Disconnect

spark plug wire and move wire away from

spark plug. Let engine cool before storing.

Keep the decals clean and legible at all

times. Contact your local service dealer or

the factory for replacements if any decals

are damaged or missing.

Refer to the Engine Owner’s Manual for

proper engine storage information.

6. Check all nuts, bolts and screws at fre

quent intervals for proper tightness to be

sure equipment is in safe working

condition.

Refer to the Parts List in this Manual for

decal locations, part numbers and order

ing instructions.

NOTE; Ail decals are shown at a reduced

size.

A

DANGER

ROTATING CHIPPER

BLADE WILL CAUSE

SERIOUS PERSONAL

INJURY. DO NOT

OPERATE UNLESS

CHIPPER CHUTE IS

BOLTED IN PLACE.

i4 DANGER

ROTATING currma BLADES.

MAOES CUT IN MCH PROM

OtSCHARQE SCREENI

TO AVOID SERIOUS PERSONAL INJURY WHILE

MACHINE »RUNNING:

• KEEP HANDS AND FEET OUT OF

DISCHARGE opening;

• K^ AWAY FROM OBCHAROE AREAI

NO HANDS 8EL0W TMS LINE

BLADES CUT

1/4 MCH FROM

DI8CHARGE 8CR8ENI

^—1

Ref. Description and Location

A Operating Instructions Decal — Located on forward portion of hopper

B Danger Decal — Located on forward portion of machine, above discharge area

C Danger Decal — Located on left side of mainframe, in front of belt cover

D Danger Decal — Located on right side of mainframe

E Danger Decal — Located on right side of mainframe, at bottom of chute

F Fire Hazard Decal — Located on the handlebars

G Danger Decal — Located on the inside of the chipper chute

H Warning Decal — Located under belt cover

\

TO AVOID A FIRE HAZARD. KEEP LEAVES, GRASS AND OTHER COMBUSTABLE MATERIALS AWAY FROM HOT ENGINE AND MUFFLERI

A DANGER

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF INLET AND DISCHARGE

OPENINGS WHILE MACHINE

IS RUNNING TO AVOID

SERIOUS PERSONAL INJURY.

NO HANDS BELOW THIS LINE

V

________________________

ii WARNING

^

DO NOT START ENGINE UNLESS BELT

COVER IS ATTACHED. FMIurs to Comply

Could Rosult In PoroonM Injury From Moving

Boh And Pulloys. Boo Ownor^s Manual For

Full Safaty And Maintonanea Instructions.

ik WARNiNG

Page 6

Section

21 Assembly

A WARNING

To prevent personal injury or property

damage, do not start the engine until all

assembly steps are complete and you

have read and understand the safety and

operating instructions in this Manual.

INTRODUCTION

For best results, read these instructions in

their entirety before you attempt to assem

ble your new equipment.

STEP 1: UNPACKING INSTRUCTIONS

1. inspect the unit immediately. If you find

or suspect damage, contact the carrier

(trucking company) right away and tell the

carrier you wish to file a claim.

2. Remove any packing materiai from

around the unit. Remove the chipper

chute (item 2, Figure 2-1) and clutch lever

(item 7, Figure 2-1) from the top of the

machine. Remove the package containing

loose parts. Be sure to check thoroughly

for any parts before disposing of the

carton or any of the packing materials.

3. Use a pry bar to remove any wooden

blocks from the front stand assembly.

Have an assistant help you move the unit

off the wood pallet.

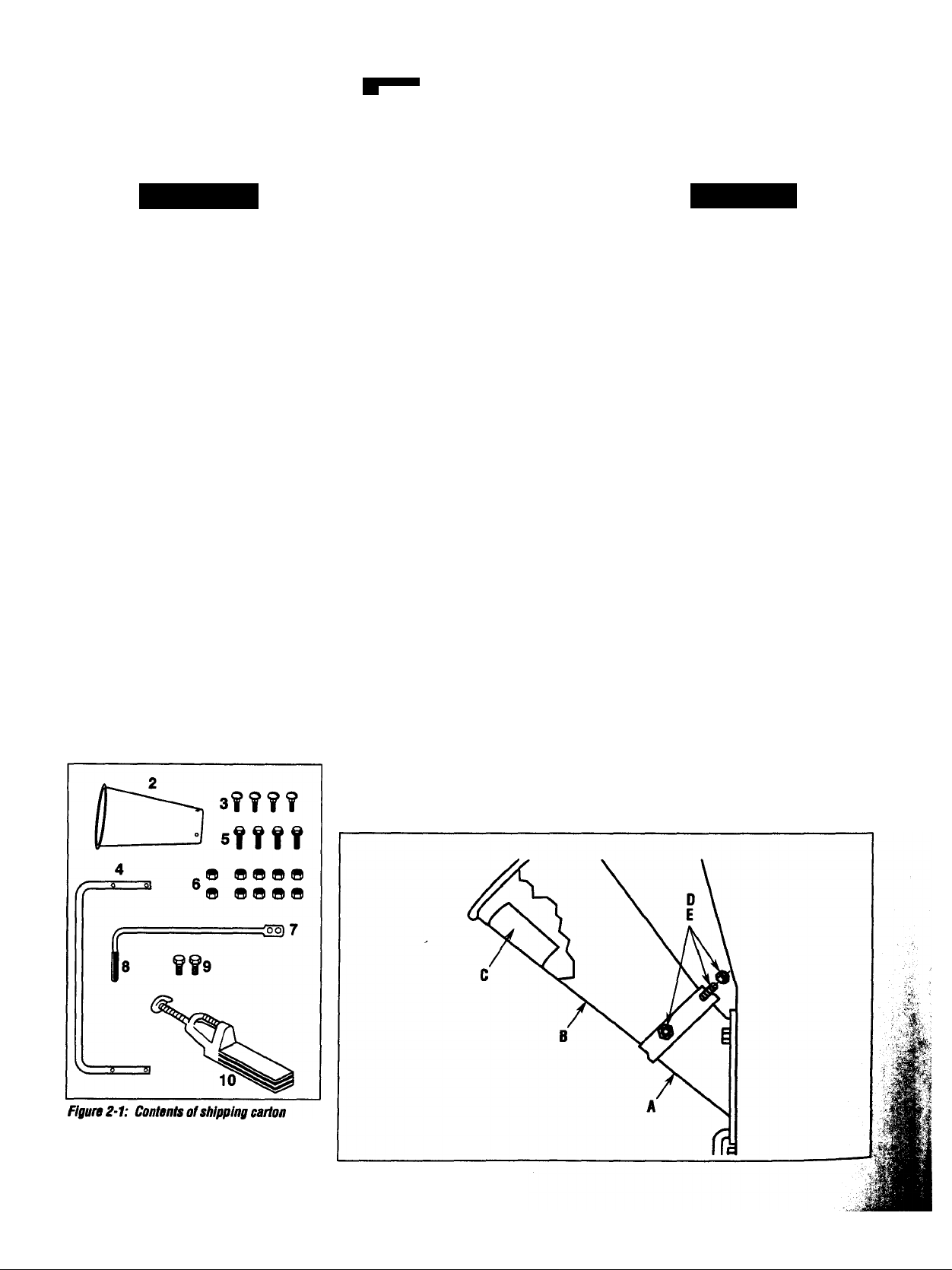

STEP 2: CHECK CARTON CONTENTS

Check that you have the items listed below

and shown in Figure 2-1. Contact your

authorized dealer or the factory if any

items are missing or damaged.

(1) Engine/mainframe assembly (not

(1)

(4)

(1)

(4)

(10) 1/4'-20 toplock nuts (No. 6,

(1)

(1)

(2)

(1)

Tools needed for assembly;

(2) 7/16" wrenches*

(1) 3/8" wrench*

(1) 1/2" wrench*

(1) Flat blade screwdriver

illustrated).

Chipper chute (No. 2, Figure 2-1).

1/4"-20x 5/8' round hd. carriage bolts

(No. 3, Figure 2-1).

Handle (No. 4, Figure 2-1) - shipped

upside down on shredder hopper.

1/4“-20 X1-1/4' flange hd. cap

screws (No. 5, Figure 2-1).

Figure 2-1).

Top section of clutch lever (No. 7,

Figure 2-1).

Vinyl grip for clutch lever (No. 8,

Figure 2-1).

1/4'-20 X 3/4" hex hd. cap screws

(No. 9, Figure 2-1).

Leaf tamper (No. 10, Figure 2-1).

* You may substitute an adjustable

wrench.

A DANGER

The chipper blade is extremely sharp —

do not touch the blade while installing

the chipper chute. When the engine is

running, the chipper blade revolves at

high speed. The chipper chute must be

securely attached before operating the

unit.

STEP 3: AHACH CHIPPER CHUTE

1. Find the safety message decal (C,

Figure 2-2) located inside the large open

ing of the chipper chute (B).

iMPORTANT: The chute must be instailed

so that the safety message decal (C) can

be read when the operator looks down into

the chute.

2. Insert the small end of the chipper

chute (B, Figure 2-2) into the chipper

chute mounting base (A) and align the

four square holes in the chipper chute with

the four round holes in the mounting base.

Check that the safety message decal (C) is

positioned as shown in Figure 2-2.

3. Reach inside the chipper chute and

insert four 1/4"-20 x 5/8" round head car

riage bolts (D, Figure 2-2) out through the

four holes. Add 1/4"-20 toplock nuts (E)

and tighten securely.

(shown al reduced sizes).

Figure 2-2: Install chipper chute.

Page 7

Section 2: Assembly

J

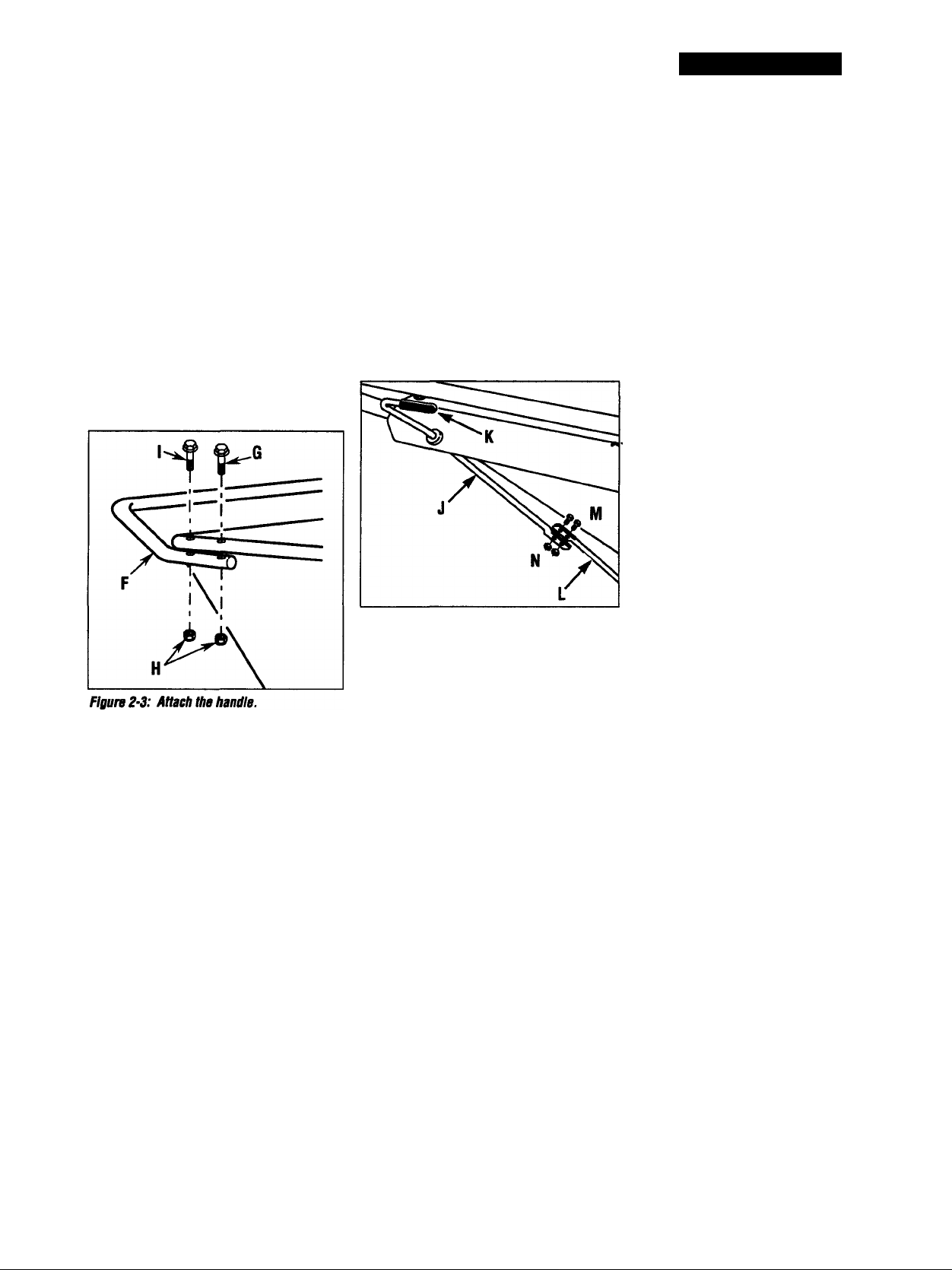

STEP 4: AHACH HANDLE

1. Using two 7/16" wrenches, remove the

handle (F, Figure 2-3) and discard the

screv№ and nuts. Turn the handle over

and position it as shown in Figure 2-3.

The bend in the handle must face upward

as shown.

2. Insert one 1/4“-20 x 1-1/4" flange head

screw (G, Figure 2-3) down through the

forward holes in the shredder hopper and

handlebar. Loosely add one 1/4“-20

toplock nut (H). Repeat on the other side.

3. Install the remaining two screws (I)

and nuts (H). Tighten all four screws and

nuts with 3/8" and 7/16’ wrenches.

STEP 5: INSTALL CLUTCH LEVER

1. Insert the angled end of the upper

clutch lever section (J, Figure 2-4) up

through the hole in the lip of the shredder

hopper. Slide the vinyl grip (K) onto the

handle.

2. Turn the lever so that the handle faces

inward, as shown in Figure 2-4. Attach

the lever top section (J) to the lever

bottom section (L) using two 1/4'-20 x

3/4" screws (M) and 1/4"-20 toplock nuts

(N). Tighten securely.

Figure 2-4: Cottuect top section (J) of clutch

lever to bottom section (L).

STEP 6: ADD MOTDR OIL TO ENGINE

Refer to the separate Engine Owner’s

Manual (included in the unit’s literature

package) for correct oil specifications and

capacities.

IMPORTANT: The unit is shipped without

oil in the engine crankcase. Do not start

the unit without first adding oil to the

engine. Severe damage will result if the

engine is run without oil.

1. Make sure the engine is level.

2. Add motor oil according to the instruc

tions provided in the engine manufac

turer’s Engine Owner’s Manual.

STEP?: CHECK HARDWARE FOR

TIGHTNESS

Inspect the screws, nuts and bolts on the

unit and tighten any loose hardware.

IMPORTANT: This completes the assem

bly steps. Be sure to read the rest of this

Manual, and the separate Engine Owner’s

Manual, before you attempt to operate

your chipper/shredder.

Page 8

Section

3I Features and Controls

A WARNING

Before operating your machine, carefully read and undersfand all safety, controls, and operating Instructions In this

Manual, In the separate Engine Owner’s Manual, and on the

decals on the machine.

Failure to follow these Instructions can result in serious per

sonal injury.

INTRODUCTION

This Section describes the location and function of the main fea

tures and controls on your chipper/shredder. Refer to Section 4;

Operation ior detailed operating instructions.

IMPORTANT: Refer to the separate Engine Owner’s Manual for

detailed information about the controls on the engine.

A DANGER

The cutting blades inside the chipper/shrodder chamber

rotate when the engine is started. Contact with rotating

blades will cause severe personal injury.

Keep hands, face, feet and clothing away from chipper chute

inlet, shredder hopper inlet, discharge opening and dis

charge area at all times.

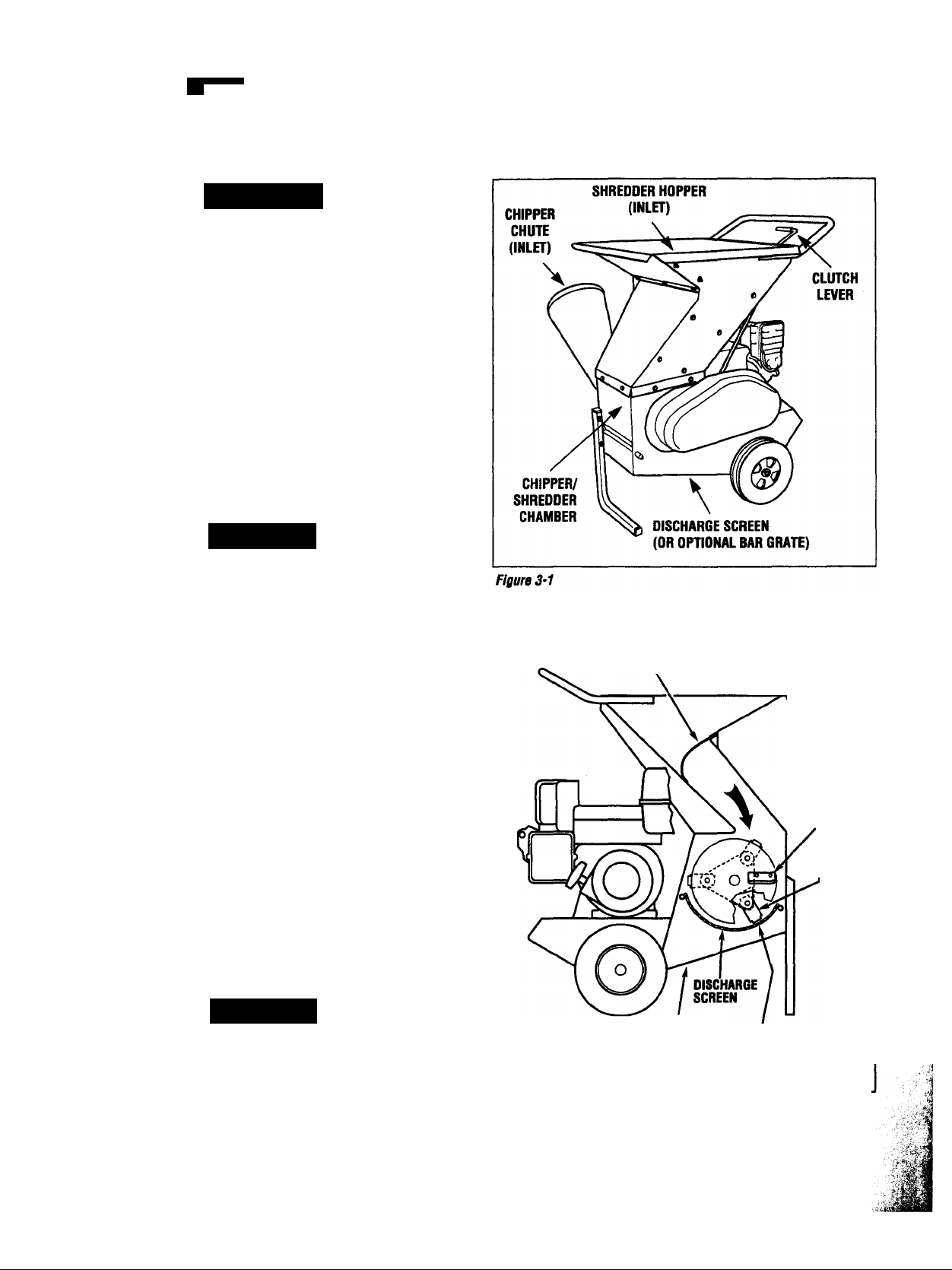

CHIPPER/SHREDDER FEATURES AND CDNTRDLS

SHREDDER HOPPER (INLET)

The shredder hopper (see Figures 3-1 and 3-1 A) is the opening at

the top of the unit for material to be shredded. Material up to 1/2'

in diameter can be processed through the shredder hopper. In the

shredder chamber, rotating cutting blades shreS the material.

A rubber retainer flap (Figure 3-1 A) is installed at the shredder

hopper opening. Material is pushed past this retainer flap (using

only the leaf tamper supplied with unit) and enters the shredder

chamber. The retainer flap prevents kickback of materialsl Do

not use the unit unless the retainer flap is securely fastened

and is hanging freely inside the hopper opening. Immediately

replace the retainer flap if it is torn or damaged.

RETAINER

FLAPv

SHREDDER HDPPER

/

CHIPPER

BLADE

SHREDDER

BLADE

A DANGER

Shredded particles can kick back up through the shredder

hopper inlet. The retainer flap is designed to reduce kickback of particles and must be in place and securely fastened.

Before using the chipper/shredder, be sure the retainer flap

is securely fastened. Failure to do so can result in serious

personal injury. Also make sure you are wearing protective

and approved safety goggles or g lasses.

Figure 3-1A: Rotating shredder cutting btades cut 1/4"away from

discharge screen—KEEP HANDS AND FEET AWAY from diseharga

area at all times to avoid serious personal Injury.

DISCHARGE

OPENING

1/4" BETWEEN

SHREDDER BLADES

AND DISCHARGE

SCREEN

Page 9

Section 3: Features and Controls 9

A DANGER

Contact with rotating cutting blados will

cause serious personal injury. Do not

put hands, face, feet or clothing into the

directed between the blade and anvil,

where it is sheared off by the blade. The

chips are processed inside the chamber

and then discharged through the dis

charge screen or the optional bar grate.

shredder hopper inlet, chipper chute

inlet, discharge opening, or near the

discharge area at any time.

Perform maintenance and service only

after the engine is off, the spark plug

wire is disconnected and moved away

from the spark plug, and all moving

parts have come to a complete stop.

Then use only a long wooden stick or a

long handled shovel to clear away dis

charged materials or blockages.

CHIPPER CHUTE (INLET)

Material up to 3" in diameter (such as

small branches and vines) can be pro

cessed through the side-mounted chipper

chute (Figure 3-1). Material fed into the

chipper chute is turned into chips by a

chipper blade mounted on a revolving fly

wheel (Figure 3-1A).

A WARNING

Do not oporate unit unless chipper chute

is properly bolted to side of unit. Seri

ous personal injury can result if chipper

chute is not securely attached.

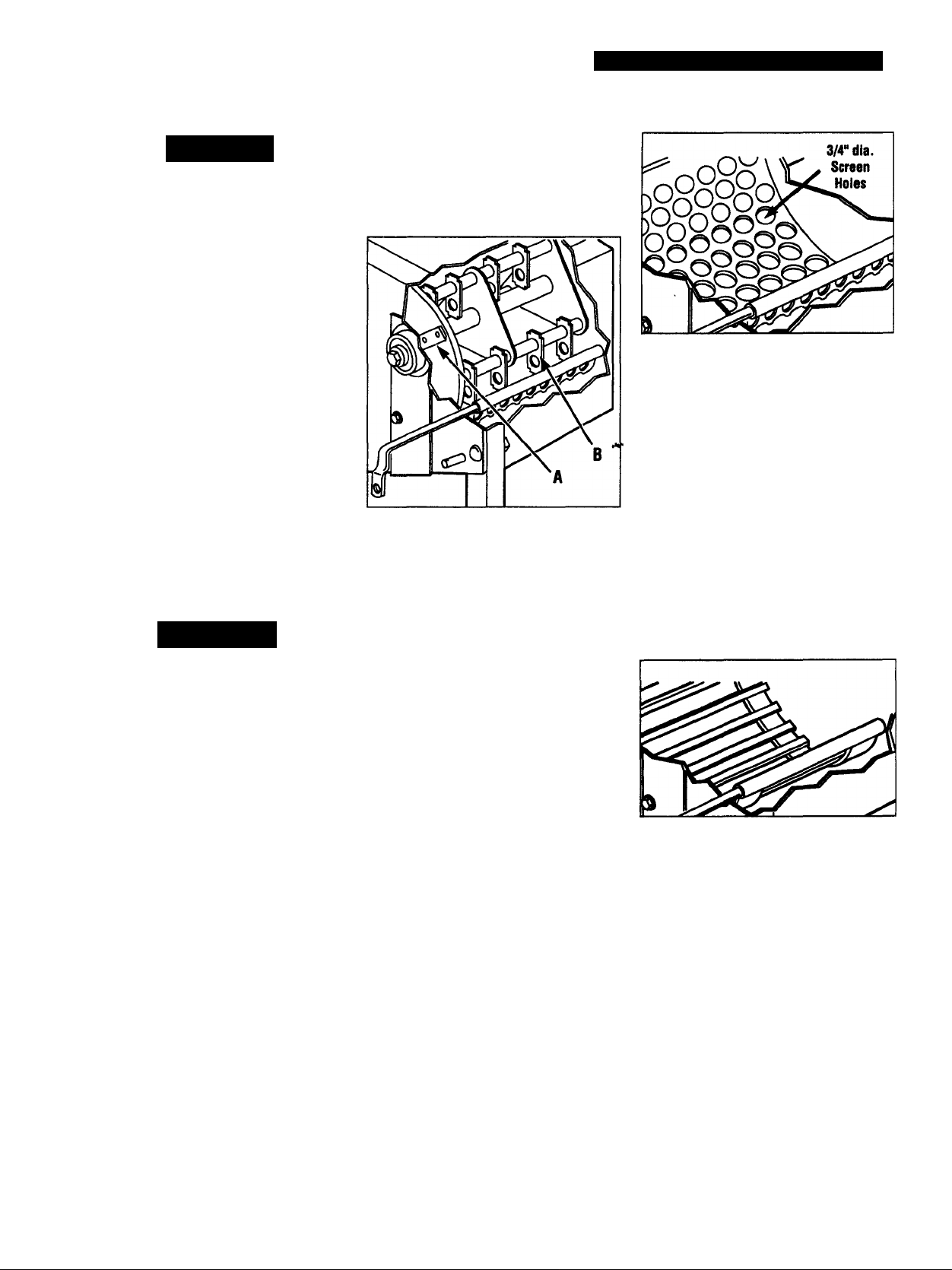

CHIPPER/SHREDDER CHAMBER

Inside the chipper/shredder chamber is a

flywheei/cylinder assembly that is beltdriven by the engine drive shaft.

The flywheel has a chipper blade (A, Figure

3-2) attached to one side. The cylinder

assembly holds 12 shredder cutting blades

(B). During operation, the chipper blade

and shredder blades revolve at the same

time, allowing you to either chip or shred.

Material fed into the shredder hopper is

shredded and ground when the shredder

cutting blades force material against the

chamber baffles and the discharge dis

charge screen. When shredded finely

enough, the material is forced out through

the holes in the discharge screen (or

between the bars of the optional bar grate).

The chipper cutting blade is separated

from a stationary anvil by a gap of 1/16' to

1/8". Material fed into the chipper chute is

Figure 3-2: View Inside cMpper/shredder

chamber shows chipper blade “A ” and a

shredder cutting blade “B".

DISCHARGE OPENING

AND DISCHARGE SCREEN

At the bottom of the unit, under the chip

per/shredder chamber, is a discharge

screen (Figure 3-3) through which pro

cessed materials must pass before being

discharged from the unit. The diameter of

the holes in the screen determines how

finely the materials are shredded.

The unit comes equipped with a screen

that has 3/4" holes. Optional screens

having 3/8", 1" or 1-3/4" holes are avail

able. The smaller holes produce more

finely shredded particles. The larger holes

produce more coarsely processed material

and may not clog as readily when wet,

soggy or green materials are processed.

(A bar grate for processing very wet,

heavy materials is also available). To

remove and install a discharge screen,

refer to Removal/lnstallation Discharge

Screen or Bar Grate in Section 4.

IMPORTANT: Rotating shredder cutting

blades pass within 1/4" of the discharge

screen or bar grate. Keep hands and feet

away at all timesi Never operate

machine unless a discharge screen or

bar grate is secureiy installed.

Figure 3-3: Standard discharge screen has

3/4" diameter holes.

BAR GRATE AHACHMENT (OPTION)

The bar grate attachment (Figure 3-4) has

slotted openings that are wide enough to

efficiently process wet or soggy materials

such as matted leaves, spoiled or leftover

vegetables, manure, etc. If desired, this

coarsely shredded material can then be

dried and later run through the shredder

when a discharge screen is installed. To

remove and install a bar grate, refer to

Removal/lnstallation Discharge Screen or

Bar Grate in Section 4.

Figure 3-4: Optional bar grate.

CLUTCH LEVER

Use the clutch lever (Figure 3-5) when

starting the engine. Engaging the lever

releases tension on the cylinder assembly

drive belt (Figure 3-6) to make engine

starting easier.

When starting the engine, squeeze the

clutch lever against the handlebar while

pulling the recoil rope starter. Release the

clutch lever slowly when the engine starts

and is running smoothly. This action puts

tension on the drive belt to rotate the

shredder cylinder assembly.

Page 10

10 Section 3: Features and Controls

Figure 3-S: Squeeze clutch lever against

handlebar when starting engine. Release

clutch lever slowly after engine starts.

Figure 3-7: The leaf tamper (protected by

U.S. Patents to 329,737and 35,082,329).

ENGINE CONTROLS

ON position. To stop the engine, push the

switch to the OFF position.

FUEL SHUT-OFF VALVE (IF EQUIPPED)

Before starting the engine, turn the fuel

shut-off valve (Figure 3-8) 1/4 turn from

the OFF position to the OPEN position.

After stopping engine, return valve to OFF

position.

A DANGER

Close fuel shut-off valve, when trans

porting engine, to prevent fuel leakage.

• The following information describing

• Additional information on operating and

Figure 3-6: Squeezing the clutch lever

against the handlebar causes the Idler

pulley to move away from fhe belt, taking

tension off the heft while starling the engine.

• The engine does not have a throttle

LEAF TAMPER

Use the supplied leaf tamper (Figure 3-7)

to push light, loose, bulky materials (dry

leaves, straw, and twigs) down past the

retainer flap and Into the shredder hopper

inlet.

The leaf tamper has a “stop” that prevents

the tamper end from being struck by the

rotating cutting blades. Do not force the

tamper beyond this point. Always hold it

by the handles with the “stop” facing up.

When using the leaf tamper, use either

one hand or both hands positioned on the

built-in handle grips and be sure that the

“stop” is facing up. Always position your

ENGINE ON/OFF ROCKER SWITCH

Before starting the engine, push the

.(JN/OFF rocker switch (Figure 3-8) to the

arms so they do not point down into the

shredder hopper opening.

IMPORTANT;

controls on the engine should NOT be

used as engine starting instructions.

Complete engine starting and stopping

instructions are given in Section 4.

caring for the engine is given in the sepa

rate Engine Owner’s Manual. Please read

the Engine Owner’s Manual carefully and

save it for future reference.

speed control as the engine operating

speed has been pre-set at the factory.

Do not attempt to alter the pre-set engine

speed. Engine speed adjustments

should be performed only by an autho

rized engine dealer.

Choke Control ON/OFF Rocker Switch

CHOKE CONTROL

Before starting the engine, move the

engine choke control (Figure 3-8) to the

CHOKE position. A warm engine requires

less choking than a cold engine.

When engine starts, first open choke

(toward RUN) until engine just begins to

run smoothly. Then open choke in small

steps, allowing engine to accept small

changes in speed and load, until choke is

fully open (in RUN).

ROPE STARTER

The engine is started by pulling out the

recoil starter handle (Figure 3-8). Detailed

instructions for operating the recoil starter

are given in Section 4.

Do not attempt to start the engine until

you have carefully read and followed all

of the instructions in this Manual and in

the separate Engine Owner’s Manual.

'’'Fuel Shut-Off Valve

Use the hook on the end of the leaf tamper

to hang the tamper on the side of the unit.

Rope Starter

Figure 3-8: Engine controls.

Page 11

Section

4I Operation

A WARNING

Before operating the unit, carefuiiy read

and understand all safety, controls and

operating instructions in this Manual, in

the separate Engine Owner’s Manual,

and the decals on the machine.

Failure to follow these instructions can

easier to push the unit. Pulling is easier if

the wheels must go over ruts or obstacles.

S. When you reach your destination, put

your foot back on the engine deck and let

the unit tilt forward slowly until the front

stand is on the ground. The unit must be

level and stable. Operate the unit only on

a level, earthen surface.

result in serious personal injury.

A DANGER

Contact with rotating cutting blades

inside the discharge opening will cause

serious personal injury.

The cutting blades inside the discharge

opening cut 1/4-inch from the discharge

screen or optional bar grate. Keep

hands and feet out of discharge opening

and away from discharge area while

machine is running, and while blades

are coming to a stop.

MOVING THE UNIT

The unit can be pushed or pulled by the

handlebar. Before moving the unit, the

engine and all moving parts must be com

pletely stopped.

The unit weighs over 250 ibs. Use cau

tion when rolling the unit and carefully

balance the weight of the unit over the

wheel axle. Improper handling can lead

to injuryl Follow the instructions below.

1. STOP THE ENGINE and wait for all

parts to stop completely. Disconnect

spark plug wire from spark plug and pre

vent it from touching spark plug.

2. Grasp the handlebar with both hands

and put one toot on the rear of the engine

deck (Figure 4-1). Place the other foot

firmly on the ground.

3. Steady the unit with your foot and

slowly pull the handlebar backward until

you find the balance point (center of grav

ity). Use caution when tilting the unit to

make sure it doesn’t fall on you. Maintain

the balance point as you carefully remove

your toot from the engine deck.

4. Watch tor obstacles. Keep a firm grip

on the handlebar and slowly pull or push

the unit. On smooth, level ground it is

PRE-START CHECKLIST

Before starting the engine, perform this

Pre-Start Checklist and read this Section

completeiy.

• Check engine oil level (see Motor Oil and

Gasoline in this Section).

• Fill the fuel tank (see Motor Oil and

Gasoline in this Section).

• Make sure all bystanders and pets are at

least 25 feet away from the area of

operation.

• Put on safety goggles, hearing protec

tion, sturdy work gloves and sturdy

footwear. Do not wear loose-fitting

clothing that can get caught in moving

parts.

• Check for foreign objects in the chipper

chute and the shredder hopper.

• Check that the chipper chute is correctly

and securely attached.

• Check that the discharge screen (or the

optional bar grate, if installed) is cor-

rectiy and securely installed. (See

Removing/lnstalling Discharge Screen or

Bar Grate in this Section.) Check for

clogged holes in the discharge screen

and clean them, if needed, with a stick.

• Be sure that all hardware is securely

fastened.

• Reconnect spark plug wire to spark plug.

IMPORTANT: Use unit only on an earthen,

level surface. Do not use unit on hard sur

faces like concrete, asphalt, brick, gravel

or rocks, where discharged materials can

rebound off a hard surface and cause seri

ous personal injury or property damage.

MOTOR OIL AND GASOLINE

Before starting the engine, check the

motor oil level and the gasoline level.

1. Check motor oil level before starting

engine and after every 8 hours of opera

tion. Refer to Engine Owner’s Manual for

how to check, add and change oil.

A DANGER

GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE.

Follow the gasoline safety rules in this

Manual (Section 1) and in the separate

Engine Owner’s Manual.

Failure to follow gasoline safety instruc

tions can result in serious personal

injury and property damage.

2. Add Gasoline. Refer to the Engine

Owner's Manual for correct gasoline spec

ifications. Fill the gasoline tank slowly and

carefully. Allow space inside the gasoline

tank to allow for fuel expansion. Clean up

all fuel spills before starting the engine.

STARTING AND STOPPING THE UNIT

TO START

1. Follow the Pre-Start Checklist (at left)

and read this Section of the Manual com

pletely. Make sure you are wearing safety

glasses, hearing protection and sturdy

footwear.

2. Turn fuel shut-off valve (if equipped)

1/4 turn to OPEN position. See Figure 3-8.

3. Move the engine choke control (Figure

3-8) to the CHOKE position. A warm

engine requires less choking than a cold

engine.

Page 12

Section 4: Operation

4. Push the rocker ON/OFF switch (Figure

3-8) to the ON position.

5. Squeeze the clutch lever (Figure 3-5)

up against the handle. Grasp the engine

starter rope handle and pull slowly until

resistance is felt. Then pull cord rapidly to

overcome compression, prevent kickback

and start engine. Let the rope rewind

gradually. Repeat if necessary with choke

off.

6. After the engine starts, first open the

choke (toward RUN position) until the

engine just begins to run smoothly. Then,

open the choke in small steps, allowing

the engine to accept small changes in

speed and load, until the choke is fully

open (in RUN).

NOTE; The cutting blades may begin to

turn slowly even if the clutch lever is held

in the up position.

7. SLOWLY release the clutch lever. If

the engine stalls, restart it and allow It to

warm up for a longer period before releas

ing the clutch lever.

8. When the engine is running, the cut

ting biades inside the unit wiii rotate at a

fast speed. As the biades begin to

rotate, you wiii hear the biades “ciattering” untii they buiid up speed.

to a complete stop. Allow 20-to-30 sec

onds after the engine is shut off for the

parts to stop moving.

LOOK — The bearing collar on the chipper

chute side of the unit has a white line

painted on it (Figure 4-2). When this

white line is stationary, the cylinder

assembly has stopped rotating.

2. Turn fuel shut-off valve (if equipped) to

OFF position.

EMERGENCY ENGINE STOPPING

If the engine rocker ON/OFF switch does

not stop the engine, move the engine

choke lever to the CHOKE position.

After stopping the engine with the choke

controi lever, be sure that the shut-off

problem is diagnosed and repaired before

starting the engine. Regularly using the

choke control lever to shut the engine off

could damage the engine.

Rotating cutting biades siow down graduaiiy after engine is shut off. Biades

normaiiy require 20-30 seconds to stop.

Contact with rotating cutting biades wiii

cause serious personai injury.

Keep hands, feet, face, and ciothing out

of chipper chute iniet, shredder hopper

A DANGER

Rotating cutting blades inside

chipper^hredder chamber are in motion

iniet and discharge opening. Aiso keep

a safe distance away from discharge

area and aii moving parts when unit is

running.

once engine is started. Contact with

cutting blades will cause severe per

sonal injury.

Keep hands, feet, face and ciothing out

of chipper chute iniet, shredder hopper

iniet and discharge opening. Also keep

a safe distance away from discharge

area and aii moving parts when unit is

running.

TO STOP

1. Push rocker ON/OFF switch (Rgure 3-8)

to OFF position.

LISTEN — Remove any hearing protection

and listen to the sound of the unit as it

slows down. There is a definite audible

tone that changes as the cylinder assem

bly slows down—the shredder blades will

begin “clattering” as they slow, then will

become silent. Wait for all parts to come

Figure 4-2: Check white line on bearing

collar (Chipper Chute removed for clarity).

A DANGER

USING THE CHIPPER/SHREDDER

SOME MATERIALS SHOULD BE

SHREDDED, OTHERS SHOULD BE

CHIPPED. HERE’S HOW TO DECIDE

WHICH METHOD TO USE:

To enjoy the greatest benefits from the

unit, it is important to know which materi

als are best fed into the shredder hopper

and which ones are best fed into the chip

per chute. Use the following information

as a guide. iMPORTANT: Refer to Using

the Shredder and Using the Chipper m this

Section of the Manual for detailed operat

ing instructions.

Do not food the following materials

Into the shredder hopper or the chipper

chute:

• Metal • Glass • Bottles

• Plastic • Cans • Rocks/Stones

• Other Non-organic Foreign Objects

IMPORTANT: Do not allow processed

material to build up beneath or beside

the unit to the point where it contacts

the discharge screen. If material

cannot freely exit the discharge screen,

it will continue to circulate within the

processing chamber. This leads to

clogs and the possibility of some of the

material being “blown” back up

through the hopper.

If shredded material builds up beneath

the unit, do not attempt to remove it

until the engine is stopped, the spark

plug wire is disconnected and moved

away from the spark plug, and all

moving parts have come to a complete

stop. Use a long stick or long-handled

shovel to remove the material. Never

use your hands or feet to remove

material!

* •

Page 13

Listed below are materials suitable for

shredding, along with any special pro

cessing conditions. NOTE: If the mate

rial is wet or green, refer to the special

processing instructions Shredding Wet,

Soggy, or Green Materials in this

Section.

Material

Branches, TwigsUp to 1/2• * in diameter.

Leaves, Grass

Clippings, Brush,

Hay, Straw and

other light, loose

Organic Material

Vines, Stalks Up to 1/2* in diameter

Paper, Cardboard

(corrugated)

Newspaper

Organic Waste

Materiais and

Organic Garbage

Wood Chips Use chips previousiy

Manure Use of Bar Grate Attach

Conditions

Severai may be shredded

at once if diameter of

bundie is less than 1/2*.

Cut to 3-5 foot lengths.

No special conditions.

and 2-3 feet long.

No special conditions.

Feed one or two sec

tions at a time.

Remove all metal, bot

tles, cans, rocks, plastic,

etc. before processing.

processed by chipper, if

finer chips are desired.

ment recommended.

Listed below are materials suitable for

chipping, along with any special pro

cessing conditions.

Material Conditions

Branches

Short, thick

Branches (left

over when a long

branch is pro

cessed)

Lumber Up to 3* in diameter.

Staiks, Vines

Up to 3* in diameter,

depending on hardness.

Wood with extremely

hard knots wili not pro

cess weli.

Short, thick branches up

to 3* in diameter can be

chipped by pushing

them into chute using

another iong branch.

Remove nails, metal

parts before chipping.

From 1* to 3* in diame

ter. Cut to 2-3 foots

iengths before chipping.

USING THE CHIPPER

IMPORTANT: Always wear safety goggles

(with side shields), appropriate gloves,

and hearing protection. Review and follow

the safety rules in this Manual.

A DANGER

Do not put hands inside chipper chute.

The rotating cutting blade inside chute

will cause serious personal Injury.

Section 4: Operation

• Evenly rotate the branch to help prevent

the bark from turning into long strips that

can get tangled around the internal cylin

der shaft. Rotating the branch also

improves the cutting action of the chipper

blade.

• Feed the branch slowly into the chipper

chute until just a few inches of the branch

stick out from the top of the chipper chute.

NEVER put your hands inside the chipper

chute — serious personal injury can

resultl Short stubs of branches may be

pushed through the chipper with the next

branch.

• If the engine slows down under load,

reduce feed pressure and allow the engine

to regain full speed before continuing.

Overloading the chipper could result in

damage to the belt or engine.

NOTE; If the chipper is not cutting

branches efficiently, the chipper blade

could be dull, or the wood could be partic

ularly hard. Try processing another type

of wood to see if it cuts more easily. If

not, check the condition of the chipper

blade. Refer to Chipper Blade Removal

and Installation in Section 5.

A DANGER

Rotating cutting biades cut within 1/4incli from the discharge screen. Never

put hands or feet near discharge open

ing or discharge area whiie unit is oper

ating! Contact with cutting biades wiil

cause serious personal injury.

if shredded material builds up under the

unit during operation, do not attempt to

remove it until the engine is stopped,

the spark plug wire is disconnected and

moved away from the plug, and all

moving parts have come to a complete

stop. Then use a long stick or long-han

dled shovel to move the material out of

• After the engine is started and has built

up speed, the unit is ready to use.

• Position yourself on either side of the

chipper chute. Grip one end of a branch

(maximum 3' diameter) with both hands

and feed the other end of the branch into

the chipper chute. Do not feed the branch

into the chipper chute with your arms

pointing into the chipper chute — keep

your arms perpendicular (at a 90° angle)

to the chute. See Figure 4-3. Keep the

branch away from your body to avoid any

bounce-back and do not over-reach.

Hold the branch firmly to control the rate

of feed at all times.

the way. Never use your hands or feet

to remove discharged material.

Figure 4-3: Feeding a branch Into the chip

per chute. Always position your body and

arms so your arms are holding the material

at a 90* angle to the chipper chute.

Page 14

14 Section 4: Operation

USING THE SHREDDER

IMPORTANT: Always wear safety goggles

(with side shields), appropriate gloves,

and hearing protection. Read and follow

the safety rules in this Manual.

A DANGER

Contact with rotating cutting blades will

cause serious personal injury. The

blades rotate when engine is on and

slow gradually after engine is shut off.

Keep hands, feet and clothing out of

The rotating shredder blades can tug

suddenly at material being fed into the

shredder hopper. Contact with cutting

blades will cause severe personal injury.

Do not hold on too tightly to branches

and vines. Do not feed material straight

down into the hopper with your arm

pointing downward toward the opening,

instead, keep your arms parallel to the

ground and several inches above the top

edge of the hopper.

chipper inlet, shredder feed inlet and

discharge opening when unit is running.

• When the engine starts, the cutting

blades inside the chipper/shredder cham

ber will begin to revolve at a high rate of

speed. The shredder is then ready to use.

• Do not feed materiai into the shredder

hopper from the engine side of the unit.

Always avoid the hot muffler on the

engine.

• When feeding material into the shred

der, stand a foot or two away from the

hopper opening and keep your arms and

hands parallel to and several inches above

the top edge of the hopper. See Figure 4-

4. Do not point hands or arms downward

toward the hopper opening or put hands

or arms inside the hopper.

• Feed materials Into the shredder slowly,

and in limited quantities, until you become

familiar with its operation. Bulk and

lengths can be increased gradually if the

material is being processed easily. Do not

overload the shredder as doing so will

cause the engine speed to decrease

significantly.

• A steady flow of materials into the

shredder hopper provides the most effec

tive results. The rate of feed for small

branches, vines (2-3 foot lengths only),

and brush can be controlled by lightly

pushing and guiding the free end of the

material until it extends above the top of

the hopper. At this point, LET GO OF THE

MATERIAL. The cutting blades can tug

suddenly at material being fed into the

hopper. Do not hold onto the material I

Always hold material loosely and be

ready to let go of it quickly.

NOTE; It is best to cut long branches into

3-5 foot lengths and vines to 2-3 foot

lengths before feeding them into the

shredder hopper. When shredding wet

material, mix dry material in with it. Alter

nating wet and dry materiai helps prevent

material from sticking inside the shredder

chamber. Very wet materials should be

processed using the optional Bar Grate at

tachment. Refer to Shredding Wet,

Soggy, or Green Materials in this Section

for other methods of processing wet or

green materials.

Also:

• Do not put any part of your body or

• Stand clear of the discharge area.

• Keep face and body away from the dis

• Use the leaf tamper (Figure 4-4)

• When feeding loose material, such as

leaves, straw or grass clippings, just drop

the material into the shredder opening and

push it into the shredder hopper using the

leaf tamper (supplied). Do not allow com

bustible materials to contact the hot

engine.

• If the engine slows down under load,

stop feeding material and allow the engine

to regain full speed before continuing.

Overloading the shredder could result in

damage to the belt or engine.

• All shredded material will be forced

through the discharge screen at the

bottom of the unit. Always keep clear of

the discharge to avoid injury from materi

als exiting the unit at high speed. The

A DANGER

•

standard discharge screen supplied with

the unit has 3/4-inch holes. This screen is

best for processing most dry materials

such as brush and dry leaves. To install a

different size screen, refer to

Removing/lnstalling Discharge Screen or

Bar Grate in this Section.

Figure 4-4: Using the leaf tamper to process

material into Iho shroddor hoppor.

To avoid a fire hazard, keep leaves,

grass and other combustible materials

away from the engine and mufflerl

clothing Inside the shredder hopper or

near the discharge area.

The discharge opening and discharge

area are dangerous. Rotating cutting

blades inside the discharge opening cut

charge area.

1/4-inch from the discharge screen.

To avoid serious personal injury, keep

supplied with the unit to push bulky

material into the shredder hopper. DD

NDT USE YDUR HANDS!

hands, feet, and clothing out of the dis

charge opening and away from the dis

charge area. Follow all safety rules.

SHREDDING WET, SOGGY,

OR GREEN MATERIALS

Wet or “green” materials (such as wet,

matted leaves, vegetables, “green” vegeta

tion like squash vines, etc.) can clog the

3/4” holes in the standard discharge

screen, depending on the moisture con

tent of the material.

To help avoid clogging, try shredding this

material with the optional 1-3/4' discharge

screen. If clogging persists, install the

optional Bar Grate attachment. See

Removing/lnstalling Discharge Screen or

Bar Grate in this Section for detailed

instructions.

A DANGER

A DANGER

Page 15

Section 4: Operation 15

J

Wet, soggy, or “green” materials will be

shredded to a medium consistency when

using the Bar Grate. However, to shred

these materials to an even finer consis

tency, you may wish to process the mate

rial a second time.

If you do not have the optional Bar Grate

attachment, try alternating small wet and

small dry batches of material to help pre

vent clogging the discharge screen.

A DANGER

Do not shred brush, branches, or other

dry materials when the Bar Grate Is

Installed. Materials will exit the

discharge opening at high speed and

wiil not be properly processed.

A DANGER

Before removing jammed or clogged

material, shut the engine off, wait for

all moving parts to come to a stop and

disconnect the spark plug wire and

move it away from the spark plug.

Use only a long wooden stick or a long-

handled shovel to clear away dis

charged materials or blockages.

REMOVING/INSTALLING DISCHARGE

SCREEN OR BAR GRATE

It may be necessary to remove the stan

dard discharge screen for any of these

reasons:

1. The screen may need cleaning. The

hoies in the screen may be ciogged,

preventing materiais from being properiy discharged.

2. To process wet or green materials.

This is best accompiished by removing

the screen and installing the optional

bar grate attachment.

3. To change the size of the discharged

materiai. Remove the standard screen

and replace it with one of the optional

screens (with different size holes).

A DANGER

Rotating cutting blades inside discharge

opening will cause serious personal

injury. Biades cut 1/4-inch from dis

charge screen or bar grate attachment.

Before removing or installing the dis

charge screen or bar grate, be certain

the engine is off, all moving parts have

stopped completely, and the spark plug

wire is disconnected and kept away

from the sparkplug.

Discharge Screen or Bar Grate Removal

1. Stop the engine and wait for ail moving

parts to come to a complete stop. Discon

nect the spark plug wire and secure it

away from the spark plug.

2. Move the unit away from any dis

charged material that could block access

to the screen or bar grate.

3. Remove two hair pin cotters (A, Figure

4-5) from two small studs (C) securing

ends of the two discharge screen rods (B).

4. Pull out the two discharge screen rods

(B). Support the screen or bar grate so

that It doesn’t fall on you.

5. If the screen doesn’t drop out, hook

the end of a discharge screen rod into a

hole in the screen (Figure 4-6). Pry the

screen downward until it drops free.

NOTE: The holes in the 3/8" screen are

too small for the screen retainer rod —

use a screwdriver to pry that screen loose.

6. Make certain that you install either a

discharge screen or optional bar grate

attachment before using the unit again.

Figure 4-5: Remove both hair pin cotters (A)

and slide out two discharge screen rods (B).

Discharge Screen or Bar Grate Installation

1. Stop the engine and wait for all moving

parts to come to a complete stop. Discon

nect the spark plug wire and secure it

away from the spark plug.

2. Move the unit away from any dis

charged material that could block access

to the screen.

3. Remove the discharge screen or bar

grate (see Discharge Screen or Bar Grate

Removal on this page).

4. Position the discharge screen or bar

grate up into the bottom of the unit. Make

sure that the tube holes at each end of the

screen align with the holes in the wall of

the unit (see Figures 4-7 or 4-8).

5. Hold the discharge screen or bar grate

in position and slide the two screen rods

(B, Figure 4-5) all the way through the

screen tubes and out the other side of

unit. Insert the rear rod first, followed by

the front rod. NOTE: The holes in the

ends of the screen rods (B, Figure 4-5)

must go over the two stud pins (C) on the

machine wall.

6. Replace the two hair pin cotters (A,

Figure 4-5) through the stud pins (C). The

discharge screen or bar grate is now

securely installed. If the hair pin cotters

become lost, call for replacements imme

diately. DO NOT OPERATE UNIT WITH

OUT ORIGINAL EQUIPMENT PINS

INSTALLED PROPERLY.

A DANGER

Do not operate the unit unless a

discharge screen or bar grate is

securely installed.

Figure 4-6: If screen Is stuck, pry It loose

using one of the screen retainer rods.

Page 16

Section 4: Operation

Figure 4-7: The illseharge screen must be positioned as shown above. The holes In the tubes

at tbe screen ends must align with the holes In the machine wall. Reinstall discharge screen

rods and then hairpin cotters.

A DANGER

Do not shred brush, branches or other

material when bar grate is installed.

Materials will exit discharge opening at

high speeds and will not be properly

processed.

OPTIONAL OISCHARGE SCREENS

in addition to the standard discharge

screen with 3/4' diameter hoies and the

bar grate attachment, there are three other

screens to choose from with 3/8‘, 1', and

1-3/4“ diameter hoies.

The smaiier the hoie size in the screen, the

more fineiy shredded materiais can be

processed. Consider the screens with the

iarge hole sizes if you are working with

coarser materiais or wish to minimize

clogging. See the Parts List in this Manual

for part numbers.

Figure 4-8: The bar grata must be positioned as shown above. The holes la the tubes at the

grate ends must align with the holes In the machine wall. Reinstall discharge screen rods

and then hairpin cotters.

Page 17

Section

51 Maintenance

A WARNING

il Maintenaiice

Moving parts on the unit can cause seri

ous personai injury.

Shut off the engine, iet aii moving parts

stop completeiy, disconnect the spark

piug wire and prevent it from touching

the spark piug before performing any

maintenance or service procedures.

Check engine oil level /

Check hardware for tightness ✓

Check that engine is free

of flammable debris

Change engine oil ✓ (1)

Service engine air cleaner /(2)

Replace spark plug

Clean unit ✓ ✓ ✓

Inspect engine spark

Check belt condition.

Clean engine cooling system

Clean engine fuel filter

(1) Change after the first 5 hours of operation.

(2) Service more often under dusty conditions or when airborne debris is present.

(3) Every 50 hours of operation if engine is equipped with this item.

(4) See Engine Owner’s Manual for instructions.

(5) Every 100 hours or every season.

arrester

Schedule

Before

Each

Use

/

Every 25

Hrs. of

Operation

Annually

At End

of

Season

Prior to

storing

Comments

Every 8 hrs.

✓

/

/

/

/(5) (4)

(4)

(4)

(4)

(4)

(3)(4)

(3)(4)

EQUIPMENT MAINTENANCE

Follow the Maintenance Schedule above to

keep your equipment properly maintained.

See the separate Engine Owner’s Manual

for specific engine maintenance informa

tion and instructions.

LUBRICATION

There are no parts or assemblies on the

unit (other than the engine) that require

periodic lubrication.

DRIVE BELT SERVICE

After every 25 operating hours, examine

the drive belt for cuts, cracks, fraying or

other damage. See Figure 5-1. Examine

the clutch lever operation to see that it

moves the idler pulley property. The idler

pulley is spring-loaded and maintains ten

sion on the belt until the clutch lever is

squeezed to take tension off the belt for

easier engine starting.

BELT INSPECTION

1. Stop engine and wait for all parts to

come to a complete stop. Disconnect

spark plug wire and secure it away from

spark plug.

2. Remove the four screws securing the

belt cover. Remove the belt cover.

3. Replace the belt if it is worn or dam

aged (refer to Belt Removal/lnstallation

below). Replace belt cover and reconnect

spark plug wire.

BELT REMOVAL/INSTALLATION

Belt Removal

1. Stop engine and wait for ali parts to

come to a complete stop. Disconnect

spark piug wire and secure it away from

spark plug.

2. Remove the four screws securing the

belt cover. Remove the belt cover.

3. Loosen (do not remove) nut securing

wire belt guide (A, Figure 5-2). Move belt

guide away from idler pulley (B).

4. Push idler pulley (B, Figure 5-2) down

ward and remove belt from pulleys.

Belt Installation

1. Place the belt in the grooves of the two

main pulleys.

2. Push idler pulley (B, Figure 5-2) down

and route belt into groove of idler pulley.

3. Position the wire belt guide 1/16"-1/8“

away from the belt. Tighten the nut to

secure the belt guide in place.

4. Reinstall belt cover and reconnect

spark plug wire.

Figure 5-2: To remove belt, loosen belt

guide (A) and push Idler pulley (B) down.

Page 18

18 Section 5: Maintenance

A WARNING

Before inspecting, cieaning or servicing the machine, shut off engine, wait for ait moving parts to

come to a comptete stop, disconnect spark ptug wire and move wire away from spark ptug.

Faiture to foitow these instructions can resutt in serious personat injury or property damage.

CYLINDER ASSEMBLY SERVICE AND REPAIR

A WARNING

Before performing any maintenance on

the unit, stop the engine, wait for ait

moving parts to stop and disconnect

spark ptug wire. Wear gioves when

working with the cyiinder assembty to

protect against cuts.

Cylinder Assembly Removal

1. Remove the upper clutch lever section

from the lower section by removing the

two screws and nuts.

2. Remove the eight flange screws secur

ing the shredder hopper to the unit.

Remove the hopper.

3. Remove the discharge screen or bar

grate (see Removing/lnstalling Discharge

Screen or Bar Grate in Section 4).

Remove the belt cover as described in

Belt Removal/lnstallation in this Section.

BEARING

SET SCREW-

Figure 5-3 BEARING COLLAR

HOLE FOR PUNCH

• Tighten In direction of

shott rotetlon (counter

clockwise)

• Loosen egelnst direc

tion of shaft rotation

(clockwise)

A WARNING

Wear sturdy work gioves and bo careful

handling the cylinder assembly. Many

cutting edges on the assembly can

cause severe cuts. Be especially caretul near the chipper blade.

______

4. Remove the snap ring that secures the

cylinder pulley to the cylinder assembly.

Carefully note (for later reassembly) the

location of all hardware securing cylinder

pulley to cylinder. Remove the cylinder

pulley.

5. Loosen set screw that secures bearing

locking collar on cylinder shaft (located

under cylinder pulley). Remove the lock

ing collar from the cylinder shaft by turn

ing the collar against the direction of the

shaft rotation. Use a hammer and a punch

to loosen the collar (Figure 5-3).

6. Place a long wooden stick down the

shredder hopper to prevent the cylinder

assembly from rotating. Remove the cap

screw securing the other end of the cylin

der shaft. Remove the remaining washers

.Jiopper.

and spacers from the cylinder shaft. Note

that there is a felt washer at each end of

the shaft to protect the bearings. Also

note the location of all hardware for

reassembly. Remove the stick from the

A WARNING

Take special care to note the exact or

NOTE; An assistant will be needed for the

next step.

7. Put on sturdy work gloves and safety

glasses. Hold the cylinder assembly

through the hopper opening. Remove the

six flange screws (keep any washers with

screws) retaining the cylinder shaft bear

ings and the closure plate to the main

frame. The cylinder assembly can now be

lowered out of the unit.

der and placement of all parts on the

cylinder assembly for reassembly. It is

recommended that the cyiinder pins and

all components be marked before disas

sembly to aid In correct reassembly. If

there are any questions about correct

placement and order of cylinder assem

bly parts, refer to the cylinder assembly

parts breakdown (located in the parts

list). Failure to follow these instruc

tions could result in severe personal

injury or property damage.

The shredder blades (flails) on the cylinder

assembly can be rotated or flipped if dull

(Figure 5-4). The shredder blades use

only one cutting edge at a time.

Cylinder Assembly Disassembly

NOTE; Roll pins (see Figures 5-5 and

5-5A) secure the three cylinder pins in the

cylinder assembly. The roll pins must be

driven from the assembly with a 5/32*

punch and hammer. The pins will come

out in only one direction through the outer

sleeves (Figure 5-5).

1. Securely clamp the cylinder assembly

by the chipper flywheel in a vise. Position

Page 19

Section 5: Maintenance 19

Before Inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

the assembly so one of the roll pins can be

driven out with a punch and a hammer.

2. Carefully Inspect the holes in the outer

sleeve. One hole is larger than the other.

Position the sleeve so the roll pin will be

pushed out of the cylinder assembiy

through the LARGER hole (it wili not pass

through smaller hole). Use penetrating oii

to loosen sleeve if it does not spin easily.

3. Tap the roll pin out of the cylinder pin,

the spacer, and the LARGER hole in the

sleeve with a 5/32“ punch and a hammer.

4. Discard the used roll pin. Disassembie

the cyiinder pin, spacers and shredder

blades located on the cylinder pin.

5. Rotate the cyiinder assembly to access

the remaining cylinder pin assemblies and

repeat the disassembly procedure.

Cylinder Assembly Component Repair

NOTE: Refer to the Parts List pages for

part numbers when ordering cylinder

assembly components.

A WARNING

Before performing any maintenance on

the unit, stop the engine, wait for ail

moving parts to stop and disconnect

spark plug wire. Wear gloves when

working with the cylinder assembly to

protect against cuts.

1. Flip or rotate the shredder biades as

needed to expose fresh cutting surfaces

(Figure 5-4). Replace the blade if all cut

ting surfaces are dull.

2. Replace any spacers or sleeves that are

worn or damaged. Use original equipment

replacements only! See the Parts List for

part numbers when ordering.

3. Thoroughly clean and inspect all parts.

Remove any burrs that could prevent the

parts from fitting properly.

Cylinder Assembly Reassembly

1. Securely clamp the cylinder assembiy

by the chipper flywheel in a vise. Position

the assembiy to allow reassembly of the

cylinder pins.

2. Slide the correct locking spacer inside

the correct sieeve (refer to the Parts List, if

necessary). Line up the roii pin hole in the

sleeve and the spacer.

3. Carefully inspect the holes in the sleeve

and note that one hole is iarger. Use a

pliers to hoid a new roll pin (never reuse a

roli pin) and tap it through the LARGE hoie

in the sieeve, and into the top hole in the

spacer (Figure 5-5). Tap the roli pin into

the spacer only until it is flush with the

bottom surface of the top hole.

Л WARNING

The cylinder pin rows must be properly

assembled and then secured with new

roll pins before unit is operated.

Failure to follow these instructions

could result in severe injury or property

damage.

4. Feed one cylinder pin into the cylinder

assembly with the correct spacers and

shredder blades in the proper order and

placement. Refer to the Parts List, or to

Figure 5-5A, if you are unsure about the

proper order and placement of the cylinder

assembly parts. Slide the pre-assembled

spacer/sleeve/roli pin assembly onto the

end of the cylinder pin.

5. Rotate the pre-assembled

spacer/sleeve/roll pin assembly until the

hole in the cylinder pin is aligned with the

holes in a spacer and sleeve.

6. Coat the exposed surface of the roll pin

with Loctite® 242 (or equivalent) remov

able thread sealant. Allow the sealant to

cure for 24 hours before using the unit.

7. Use a hammer and 5/32“ punch to tap

the roli pin into the holes in the cylinder

pin and spacer. Stop when the ends of the

roll pin are flush with the outside edges of

the spacer.

8. The sleeve must spin freely. If it

doesn’t spin, check to make sure the roil

pin is not protruding beyond the outside

edges of the spacer.