Page 1

Important Safe Operation Practices • Assembly & Set-Up • Controls & Operation • Product Care

OperatOr’s Manual

Zero-Turn Tractor

Lapbar

Table of Contents

Important Safe Operation Practices ..................... 2

Assembly & Set-Up .................................................. 7

Controls & Operation .............................................11

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

NOTE: This Operator’s Manual covers several models. Features may vary by model. Not all features in this manual are applicable to all

models and the model depicted may differ from yours.

Product Care ...........................................................15

Parts/Warranty .............. See Separate Supplement

Form No. 769-11540

(October 5, 2016)

Page 2

Important Safe Operation Practices

WARNING

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this

manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. When you see this symbol. HEED ITS WARNING!

WARNING

California Proposition 65

Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

Batter y posts, term inals, and rela ted accessorie s contain lead an d lead compound s, chemicals k nown to the State of Ca lifornia to cau se cancer and re productiv e harm. Wash hands af ter

handling.

DANGER

This mac hine was built to be o perated accor ding to the safe op eration prac tices in this man ual. As with any ty pe of power equip ment, carele ssness or error o n the part of the o perator can

result in serious injury. This machine is capable of amputating hands and feet and throwing object s. Failure to observe the following safety instructions could result in serious injury or death.

2

General Operation

1. Read, understand, and follow all instructions

on the machine and in the manual(s) before

attempting to assemble and operate.

Keep this manual in a safe place for future

and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine

and disengage them quickly.

3. Never allow children under 14 years of

age to operate this machine. Children 14

and over should read and understand the

instructions and safe operation practices in

this manual and on the machine and should

be trained and supervised by an adult.

4. Never allow adults to operate this machine

without proper instruction.

5. To help avoid blade contact or a thrown

object injury, keep bystanders, helpers,

children and pets at least 75 feet from

the machine while it is in operation. Stop

machine if anyone enters the area.

6. Thoroughly inspect the area where the

equipment is to be used. Remove all stones,

sticks, wire, bones, toys, and other foreign

objects which could be picked up and

thrown by the blade(s). Thrown objects can

cause serious personal injury.

7. Plan your mowing pattern to avoid

discharge of material toward roads,

sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or

obstruction which may cause discharged

material to ricochet back toward the operator.

8. Always wear safety glasses or safety goggles

during operation and while performing an

adjustment or repair to protect your eyes.

Thrown objects which ricochet can cause

serious injury to the eyes.

9. Wear sturdy, rough-soled work shoes

and close-fitting slacks and shirts. Loose

fitting clothes and jewelry can be caught in

movable parts. Never operate this machine

in bare feet or sandals.

10. Be aware of the mower and attachment

discharge direction and do not point it at

anyone. Do not operate the mower without

the discharge cover or entire grass catcher

in its proper place.

11. Do not put hands or feet near rotating parts

or under the cutting deck. Contact with the

blade(s) can amputate hands and feet.

12. A missing or damaged discharge cover

can cause blade contact or thrown object

injuries.

13. Stop the blade(s) when crossing gravel

drives, walks, or roads and while not cutting

grass.

14. Watch for traffic when operating near or

crossing roadways. This machine is not

intended for use on any public roadway.

15. Do not operate the machine while under

the influence of alcohol or drugs.

16. Mow only in daylight or good artificial light.

17. Never carry passengers.

18. Do not use the machine for towing.

19. Back up slowly. Always look down and

behind before and while backing to avoid

a back-over accident. Be aware and pay

attention to the safety system function that

stops power to the blades when driving in

reverse. If not fuctioning properly, contact

an authorized dealer for safety system

inspection and repair.

20. Slow down before turning. Operate the

machine smoothly. Avoid erratic operation

and excessive speed.

21. Disengage blade(s), set parking brake, stop

engine and wait until the blade(s) come to a

complete stop before removing grass catcher,

emptying grass, unclogging chute, removing

any grass or debris, or making any adjustments.

22. Never leave a running machine unattended.

Always turn off blade(s), place drive control

levers in neutral, set parking brake, stop

engine and remove key before dismounting.

23. Use extra care when loading or unloading

the machine into a trailer or truck. This

machine should not be driven up or down

ramp(s), because the machine could tip

over, causing serious personal injury. The

machine must be pushed manually on

ramp(s) to load or unload properly.

24. Muffler and engine become hot and can

cause a burn. Do not touch.

25. Check overhead clearances carefully before

driving under low hanging tree branches,

wires, door openings etc., where the operator

may be struck or pulled from the machine,

which could result in serious injury.

26. Disengage all attachment clutches, set the

parking brake to the ‘ON’ position and move

the RH and LH drive control levers to the

neutral position before attempting to start

the engine.

27. Your machine is designed to cut normal

residential grass of a height no more than 10”.

Do not attempt to mow through unusually

tall, dry grass (e.g., pasture) or piles of dry

leaves. Dry grass or leaves may contact the

engine exhaust and/or build up on the mower

deck presenting a potential fire hazard.

28. Use only accessories and attachments

approved for this machine by the machine

manufacturer. Read, understand and follow

all instructions provided with the approved

accessory or attachment.

29. Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related injuries.

These operators should evaluate their

ability to operate the riding mower safely

enough to protect themselves and others

from serious injury.

30. If situations occur which are not covered

in this manual, use care and good

judgment. Contact your customer service

representative for assistance.

Slope Operation

Slopes are a major factor related to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy

on it, do not mow it.

For your safety, use the slope gauge included

as part of this manual to measure slopes before

operating this machine on a sloped or hilly area. If

the slope is greater than 15 degrees as shown on

the slope gauge, do not operate this machine on

that area or serious injury could result.

2

Page 3

Do:

1. Mow across slopes, not up and down.

Exercise extreme caution when changing

direction on slopes.

2. Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain could

overturn the machine. Tall grass can hide

obstacles.

3. Use slow speed. Choose a low enough

speed so that you will not have to stop while

on the slope. Avoid starting or stopping on

a slope. If the tires are unable to maintain

traction, disengage the blades and proceed

slowly and carefully straight down the slope.

4. Follow the manufacturer’s

recommendations for wheel weights or

counterweights to improve stability.

5. Use extra care with grass catchers or other

attachments. These can change the stability

of the machine.

6. Keep all movement on the slopes slow and

gradual. Do not make sudden changes

in speed or direction. Rapid acceleration

or deceleration could cause the front of

the machine to lift and rapidly roll over

backwards, which could cause serious injury.

Do Not:

1. Do not turn on slopes unless necessary;

then turn slowly uphill and use extra care

while turning.

2. Do not mow near drop-offs, ditches or

embankments. The mower could suddenly

turn over if a wheel is over the edge of a cliff,

ditch, or if an edge caves in.

3. Do not try to stabilize the machine by

putting your foot on the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction

could cause sliding.

Children

1. Tragic accidents can occur if the operator is

not alert to the presence of children. Children

are often attracted to the machine and the

mowing activity. They do not understand

the dangers. Never assume that children will

remain where you last saw them.

a. Keep children out of the mowing

area and in watchful care of a

responsible adult other than the

operator.

b. Be alert and turn machine off if a

child enters the area.

c. To avoid back-over accidents,

always look behind and down for

small children.

d. Never carry children, even with the

blade(s) shut off. They may fall off and

be seriously injured or interfere with

safe machine operation.

e. Use extreme care when approaching

blind corners, doorways, shrubs,

trees or other objects that may block

your vision of a child who may run

into the path of the machine.

f. Keep children away from hot or

running engines. They can suffer

burns from a hot muffler.

g. Remove key when machine is

unattended to prevent

unauthorized operation.

2. Never allow children under 14 years of

age to operate this machine. Children 14

and over should read and understand the

instructions and safe operation practices in

this manual and on the machine and should

be trained and supervised by an adult.

Service

Safe Handling of Gasoline:

1. To avoid personal injury or property damage

use extreme care in handling gasoline.

Gasoline is extremely flammable and

the vapors are explosive. Serious personal

injury can occur when gasoline is spilled

on yourself or your clothes which can

ignite. Wash your skin and change clothes

immediately.

a. Use only an approved gasoline

container.

b. Never fill containers inside a vehicle

or on a truck or trailer bed with a

plastic liner. Always place containers

on the ground away from your

vehicle before filling.

c. When practical, remove gas-

powered equipment from the truck

or trailer and refuel it on the ground.

If this is not possible, then refuel

such equipment on a trailer with a

portable container, rather than from

a gasoline dispenser nozzle.

d. Keep the nozzle in contact with the

rim of the fuel tank or container

opening at all times until fueling is

complete. Do not use a nozzle lockopen device.

e. Extinguish all cigarettes, cigars,

pipes and other sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel

while the engine is hot or running.

Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to

no more than ½” below bottom of

filler neck to allow space for fuel

expansion.

i. Replace gasoline cap and tighten

securely.

j. If gasoline is spilled, wipe it off

the engine and equipment. Move

machine to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine

free of grass, leaves, or other debris

build-up. Clean up oil or fuel spillage

and remove any fuel soaked debris.

l. Never store the machine or fuel

container inside where there is an

open flame, spark or pilot light as

on a water heater, space heater,

furnace, clothes dryer or other gas

appliances.

m. Allow a machine to cool at least five

minutes before storing.

General Service

1. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains

carbon monoxide, an odorless, and deadly gas.

2. Before cleaning, repairing, or inspecting,

make certain the blade(s) and all moving

parts have stopped. Disconnect the spark

plug wire and ground against the engine to

prevent unintended starting.

3. Periodically check to make sure the

blades come to complete stop within

approximately (5) five seconds after

operating the blade disengagement control.

If the blades do not stop within the this time

frame, your machine should be serviced

professionally by an authorized dealer.

4. Regularly check the safety interlock system

for proper function, as described later in this

manual. If the safety interlock system does not

function properly, have your machine serviced

professionally by an authorized dealer.

5. Check the blade(s) and engine mounting

bolts at frequent intervals for proper

tightness. Also, visually inspect blade(s) for

damage (e.g., excessive wear, bent, cracked).

Replace the blade(s) with the original

equipment manufacturer’s (O.E.M.) blade(s)

only, listed in this manual. “Use of parts

which do not meet the original equipment

specifications may lead to improper

performance and compromise safety!”

6. Mower blades are sharp. Wrap the blade or

wear gloves, and use extra caution when

servicing them.

7. Keep all nuts, bolts, and screws tight to be sure

the equipment is in safe working condition.

8. Never tamper with the safety interlock

system or other safety devices. Check their

proper operation regularly.

9. After striking a foreign object, stop the

engine, disconnect the spark plug wire(s)

and ground against the engine. Thoroughly

inspect the machine for any damage. Repair

the damage before starting and operating.

10. Never attempt to make adjustments or repairs

to the machine while the engine is running.

11. Grass catcher components and the

discharge cover are subject to wear and

damage which could expose moving parts

or allow objects to be thrown. For safety

protection, frequently check components

and replace immediately with original

equipment manufacturer’s (O.E.M.) parts

only, listed in this manual. “Use of parts

which do not meet the original equipment

specifications may lead to improper

performance and compromise safety!”

12. Do not change the engine governor settings

or over-speed the engine. The governor

controls the maximum safe operating speed

of the engine.

13. Maintain or replace safety and instruction

labels, as necessary.

14. Observe proper disposal laws and regulations

for gas, oil, etc. to protect the environment.

15. According to the Consumer Products Safety

Commission (CPSC) and the U.S. Environmental

Protection Agency (EPA), this product has an

Average Useful Life of seven (7) years, or 270

hours of operation. At the end of the Average

Useful Life have the machine inspected

annually by an authorized ser vice dealer to

ensure that all mechanical and safety systems

are working properly and not worn excessively.

Failure to do so can result in accidents, injuries

or death.

3Section 2 — important Safe operation practiceS

Page 4

Do not modify engine

To avoid serious injury or death, do not modify

engine in any way. Tampering with the governor

setting can lead to a runaway engine and cause it

to operate at unsafe speeds. Never tamper with

factory setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with

California and federal EPA emission regulations for

SORE (Small Off Road Equipment) are certified to

operate on regular unleaded gasoline, and may

include the following emission control systems:

Engine Modification (EM) and Three Way Catalyst

(TWC) if so equipped.

When required, models are equipped with

low permeation fuel lines and fuel tanks for

evaporative emission control. California models

may also include a carbon canister. Please contact

Customer Support for information regarding the

evaporative emission control configuration for

your model.

Spark Arrestor

WARNING! This machine is

equipped with an internal

combustion engine and should not

be used on or near any unimproved

forest-covered, brush-covered or

grass-covered land unless the

engine’s exhaust system is equipped

with a spark arrestor meeting applicable local or

state laws (if any).

If a spark arrestor is used, it should be maintained

in effective working order by the operator. In the

State of California the above is required by law

(Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal

laws apply on federal lands.

A spark arrestor for the muffler is available through

your nearest engine authorized service dealer or

contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before

attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and operate

DANGER — ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

DANGER — ROTATING BLADES

Mowing in reverse is not recommended.

WARNING — ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s) can amputate hands and feet.

DANGER — ROTATING BLADES

Look down and behind before and while backing to avoid a back-over accident.

WARNING — THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

DANGER — SAFETY DEVICES

Keep safety devices (guards, shields, switches, etc.) in place and working.

WARNING — BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING — SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees. Do not mow up and down slopes. Mow across slopes no greater

than 15 degrees. Avoid sudden turns. Use low speed. If machine stops going uphill, stop blades and back down slowly.

WARNING — HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and muffler to cool before touching.

DANGER — ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass catcher is in its proper place. If

damaged, replace immediately.

WARNING — FIRE HAZARD

Allow machine to cool before fueling or storing.

WARNING — FIRE HAZARD

max10"

Do not drive through piles of dry leaves or tall grass.

WARNING — FIRE HAZARD

Do not allow debris to accumulate. The build up of debris can lead to a fire.

WARNING! Your Responsibility—Restrict the use of this power machine to persons who read, understand and follow the warnings and

instructions in this manual and on the machine.

4 Section 2 — important Safe operation practiceS

SAVE THESE INSTRUCTIONS!

Page 5

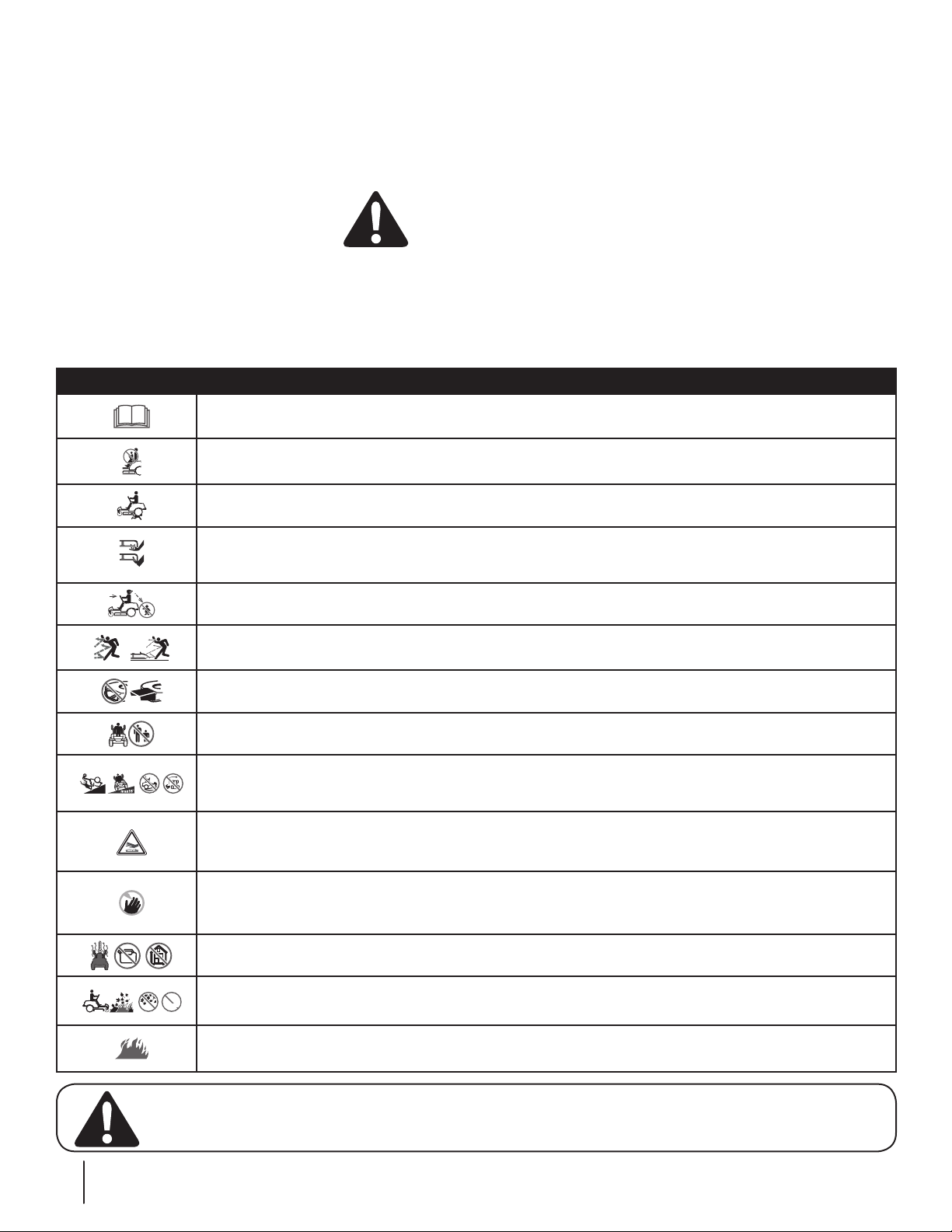

To check the slope, proceed as follows:

1. Remove this page and fold along the dashed line.

2. Locate a vertical object on or behind the slope (e.g. a pole, building, fence, tree, etc.)

3. Align either side of the slope gauge with the object (See Figure 1 and Figure 2 ).

4. Adjust gauge up or down until the left corner touches the slope (See Figure 1 and Figure 2).

5. If there is a gap below the gauge, the slope is too steep for safe operation (See Figure 2 above).

Do not operate machine on slopes in excess of 15 degrees. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it. Always mow up

and down slopes, never across the face of slopes.

WARNING! Slopes are a major factor related to tip-over and roll-over accidents which can result in severe injury or death.

(OK) (TOO STEEP)

IF A SLOPE IS TOO STEEP FOR SAFE OPERATION!

USE THIS SLOPE GAUGE TO DETERMINE

Slope Gauge

15° dashed line

Figure 2Figure 1

15° Slope

15° Slope

5Section 2 — important Safe operation practiceS

Page 6

Assembly & Set-Up

a

a

b

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

Thank You

2

Thank you for purchasing this product. It was carefully engineered to provide

excellent performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment. It instructs you

how to safely and easily set up, operate and maintain your machine. Please be

sure that you, and any other persons who will operate the machine, carefully

follow the recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent product information

available at the time. Review this manual frequently to familiarize yourself with

the machine, its features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various models.

Characteristics and features discussed and/or illustrated in this manual may

not be applicable to all models. We reserve the right to change product

specifications, designs and equipment without notice and without incurring

obligation.

If applicable, the power testing information used to establish the power rating of

the engine equipped on this machine can be found at www.opei.org or the engine

manufacturer’s web site.

If you have any problems or questions concerning the machine, phone your

local authorized service dealer or contact us directly. We want to ensure your

complete satisfaction at all times.

Throughout this manual, all references to right and lef t side of the machine are

observed from the operating position.

Contents of Crate

• Zero-Turn Tractor (1) • Operator’s Manual (1) • Engine Operator’s Manual (1)

• Oil Drain Tube (1) • Deck Wash Hose Coupler (1) • Hardware Pack (1)

Note: This Operator’s Manual covers several models. Tractor features may vary by model. Not all features in this manual are applicable to all tractor models and the

tractor depicted may differ from yours.

Note: All references in this manual to the left or right side and front or back of the tractor are from the operating position only. Exceptions, if any, will be specified.

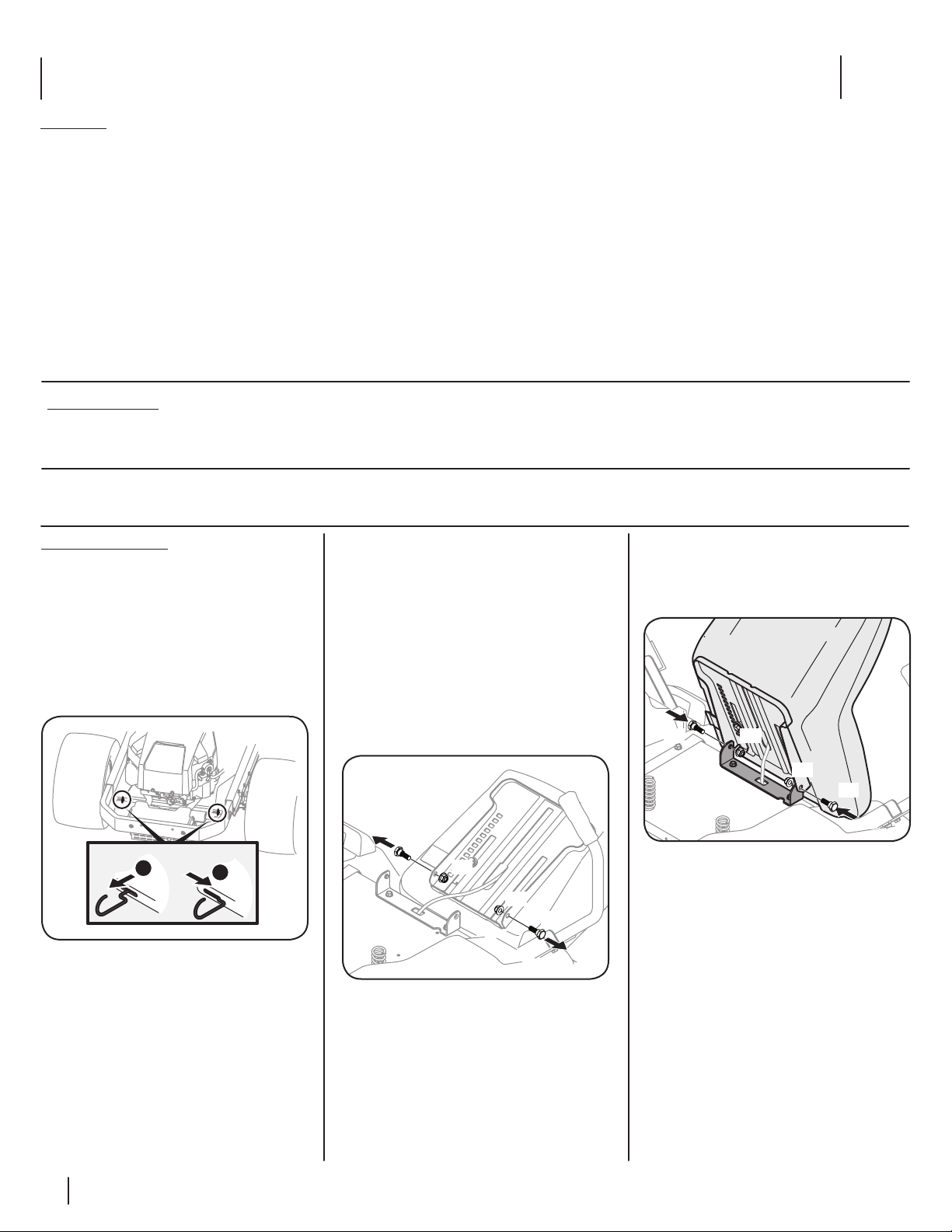

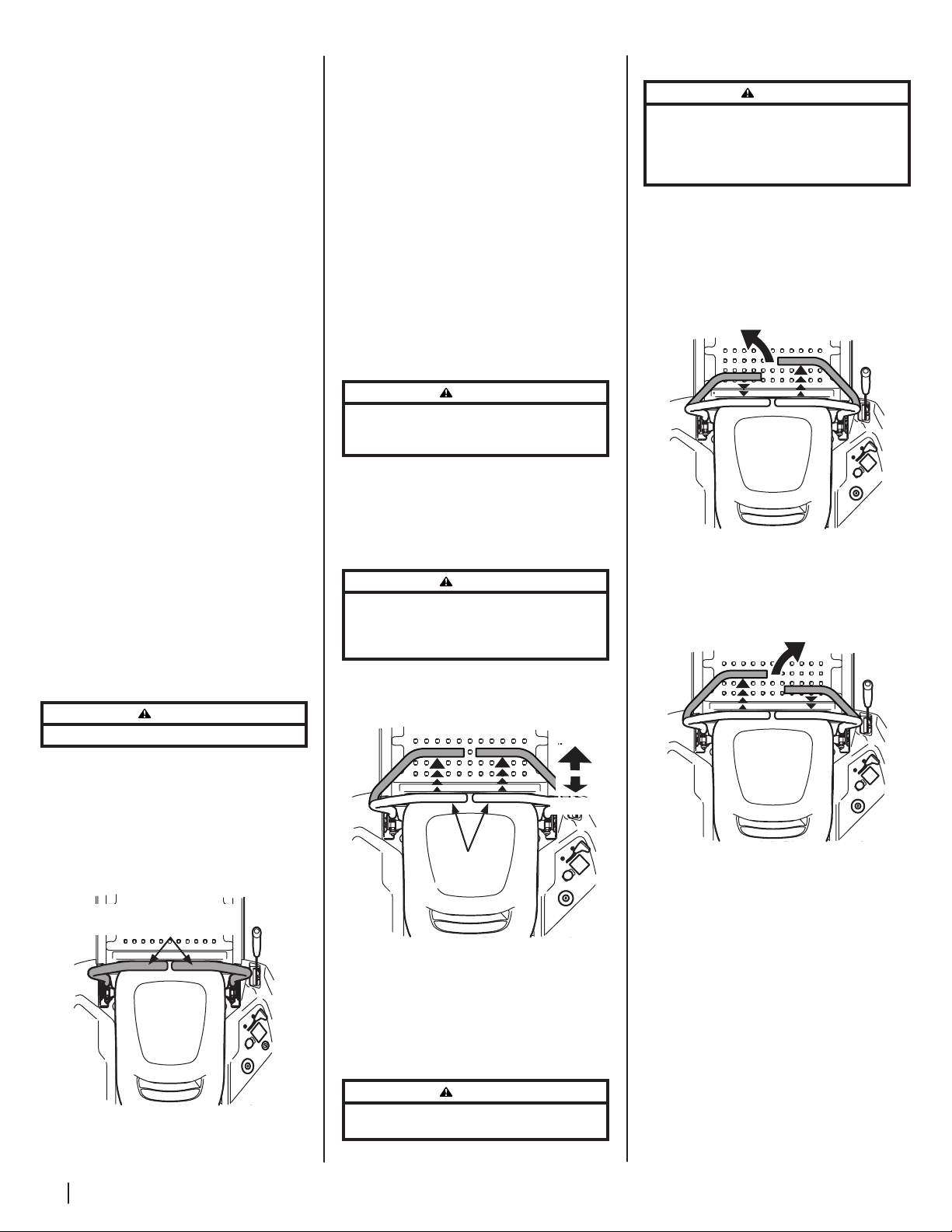

Tractor Preparation

Manually Moving the Tractor

1. Engage the transmission bypass rods, one

on each side of the tractor, to move the

tractor manually without starting it. The

transmission bypass rods are located on the

rear of the tractor, just inside each rear wheel.

Engage the bypass rods by pulling each one

out (a) and to the right (b) to lock it into place.

See Figure 2-1.

Install Operator’s Seat

To install the seat proceed as follows:

Note: The seat is shipped with the seat

switch and seat pan attached.

1. Cut any straps securing the seat assembly

and the drive control levers to the tractor.

Remove any packing material.

Note: Be careful not to cut the wiring harness

connecting the seat and the seat switch.

2. Remove the two shoulder screws (a) and

lock nuts (b) in the seat pan as shown in

Figure 2-2.

3. Rotate the seat into position and secure the

seat into place with the previously removed

shoulder screws (a) and lock nuts (b). Be careful

not to crimp or damage the wire harness while

installing the seat. See Figure 2-3.

Figure 2-1

2. Disengage the bypass rods by reversing the

steps after moving the tractor. See Figure 2-1.

3. Remove the deck wash system nozzle

adapter from the manual bag and store for

future use.

6

Figure 2-3

Note: Be sure to push the excess wire from

the wire harness into the seat box hole

before continuing.

Figure 2-2

Page 7

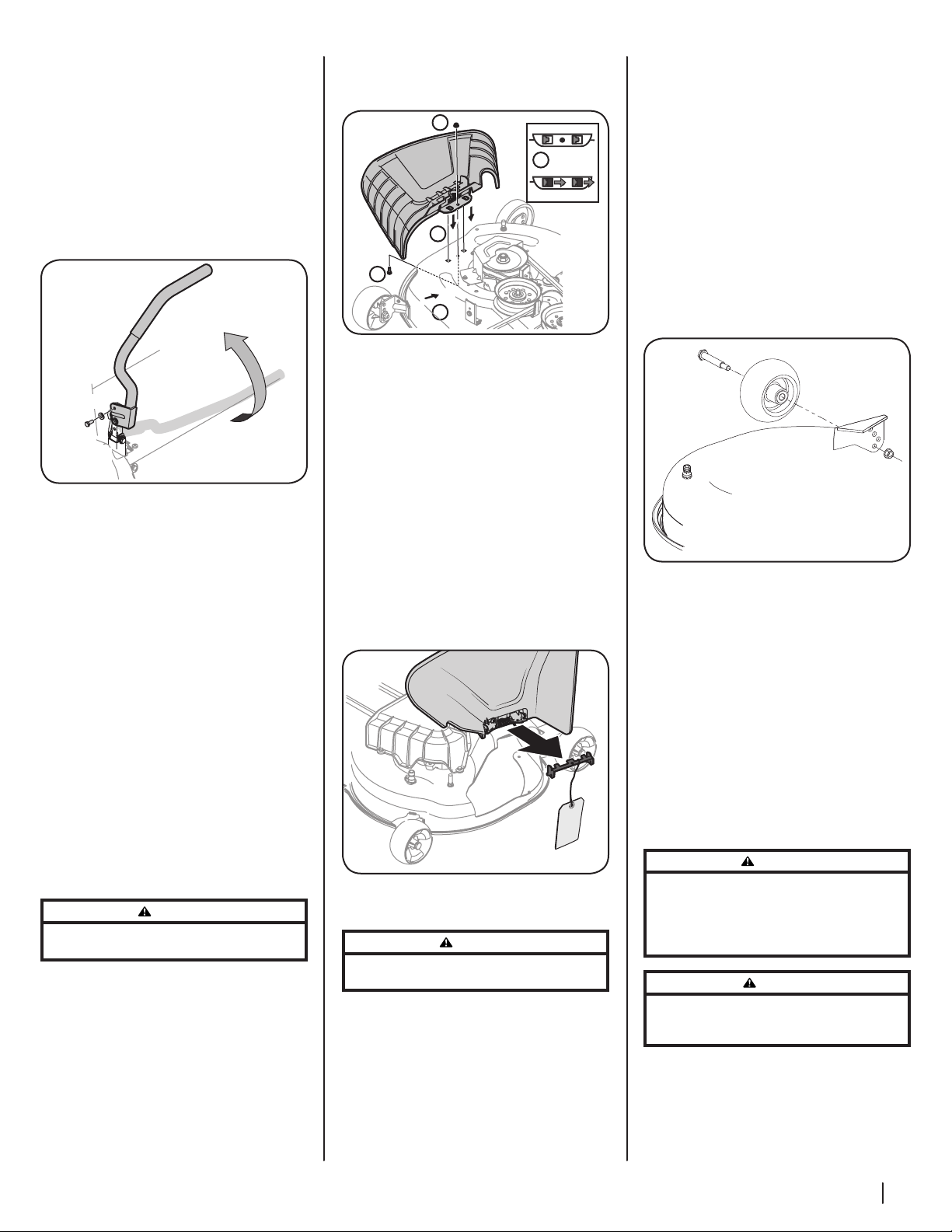

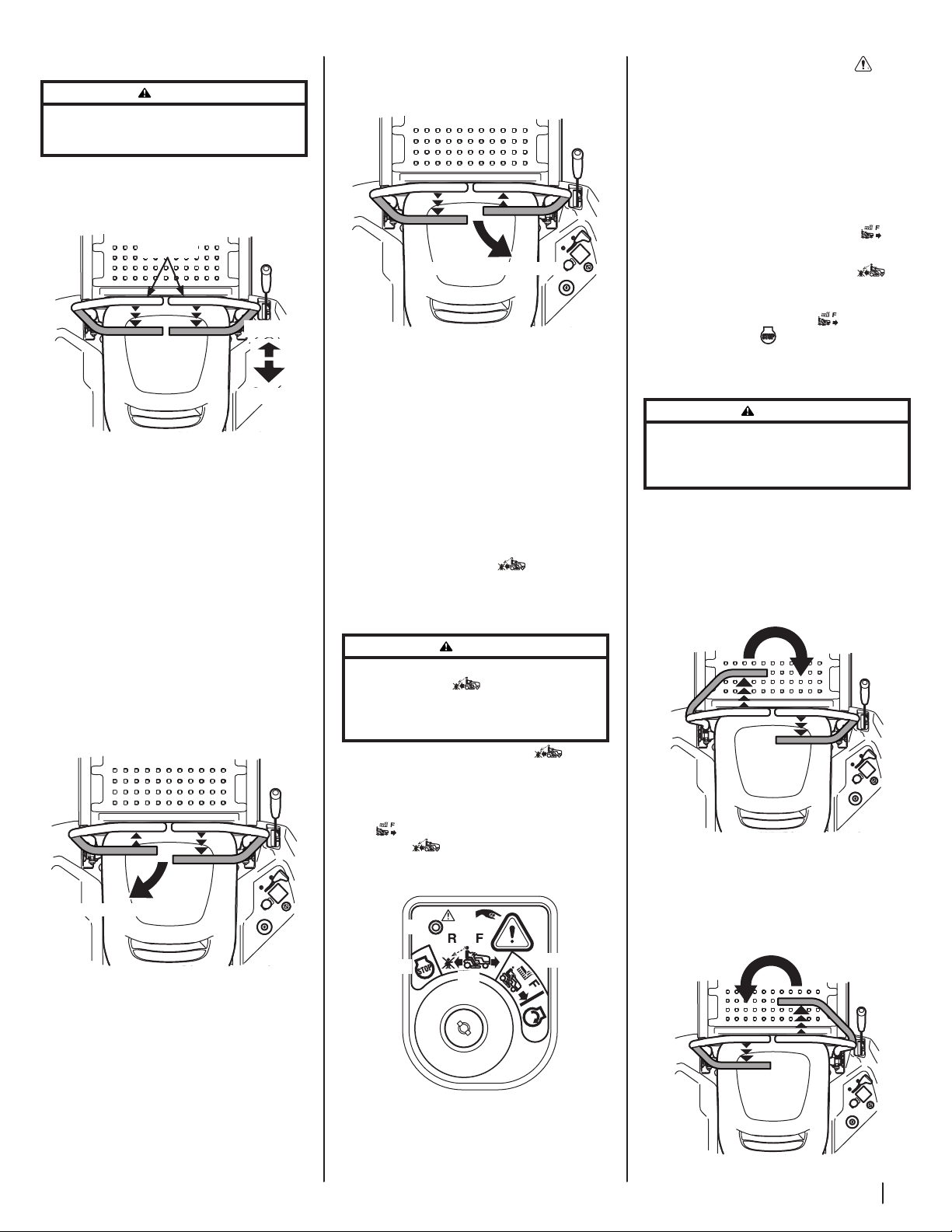

Position Drive Control Levers

(a)

(b)

(c)

(c)

(d)

34554

(a)

(b)

(c)

The drive control levers of the tractor are lowered

for shipping purposes. The hex screws and flat

washers that normally secure the control levers

in their operating position are in a hardware pack

inside your manual bag. The control levers must be

repositioned to operate the tractor. To reposition

the control levers for operation, proceed as

follows:

1. Remove the hex screws (a) and flat washers (b)

from the hardware pack in your manual bag.

See Figure 2-4.

Figure 2-4

2. Lift and swing that control lever (c) upward

until the slotted hole in the control lever (c)

bracket aligns with one of the holes in the

pivot bracket (d). See Figure 2-4.

3. Slide the flat washer (b) onto the hex screw

(a). From the outside, insert the hex screw

(a) with the flat washer (b) through the

control lever bracket (c) and the hole of the

pivot bracket (d). See Figure 2-4. Using a ⁄”

wrench snug the hex screw (a), but do not

fully tighten.

4. Note the relative position of the control

lever (c) to the pivot bracket (d), then repeat

the previous steps to reposition the other

control lever (c) in approximately the same

position.

Note: Torque the hex screws (a) down

tightly to prevent the control levers (c) from

slipping out of position.

5. Refer to “Adjusting the Drive Control Levers”

in the Product Care section for instructions

for the final adjustment of the levers.

Lower Deck Discharge Chute Deflector

WARNING

Never operate the mower deck without the chute deflector

installed and in the down position.

Note: For models with 34” Deck, skip ahead to

“Connecting the Battery Cables”. For models with a

46”, 50” and 54” Deck skip ahead to step 6.

1. Remove the keys that are attached with a

zip tie to the chute bracket.

2. Remove the flange lock nut and hex screw

from the deck.

3. Place the chute deflector on the deck, be

sure to insert the tabs on the chute deflector

into the holes on the deck. See Figure 2-5.

Figure 2-5

4. When the tabs are installed in the deck,

slide the chute deflector toward the rear of

the tractor until the bolt hole in the chute

deflector aligns with the hole in the deck.

See Figure 2-5.

5. Secure the chute def lector in place with the

flange lock nut and hex screw removed in step

2. Tighten to 102-124 in-lbs. See Figure 2-5.

6. On models with a 46”, 50” and 54” decks

the chute is shipped attached and with a

stop bracket holding the chute upright. The

stop brackets must be removed prior to

operating the tractor.

7. Holding the chute deflector fully upward,

remove the shipping brace. Lower the chute

deflector and discard the shipping brace.

See Figure 2-6.

Figure 2-6

Setting the Front Gauge Wheels

WARNING

Keep hand s and feet away fro m the discharge o pening of

the cutting deck.

Note: The deck wheels are an anti-scalp feature

of the deck and are not designed to support the

weight of the cutting deck.

Move the tractor on a firm and level surface,

preferably pavement, and proceed as follows:

1. Check the tire pressure, make sure the

pressure is correct and equal on all tires.

2. Make sure the deck is level, both front-toback and side-to-side. See the Maintenance

& Adjustments section for deck leveling

information and instructions.

3. Select the height position of the cutting deck

by placing the deck lift lever in the normally

desired mowing height setting.

4. Check the wheels for contact or excessive

clearance with the surface below. The deck

wheels should have between ¼” and ½”

clearance above the ground. Proceed as

follows to adjust the wheels:

a. Remove the lock nut (a) securing

one of the front gauge wheel (b)

shoulder screws (c) to the deck.

Remove the gauge wheel (b)and

shoulder screw (c). See Figure 2-7.

Figure 2-7

b. Insert the shoulder screw into the

one of four index holes in the front

gauge wheel bracket that will give

the gauge wheel a ⁄⁄” clearance

with the ground.

c. Note the index hole of the just

adjusted wheel, and adjust the

other front gauge wheel into the

respective index hole of the other

front gauge wheel bracket.

Note: Refer to Adjusting the Deck in the

Product Care section of this manual for

more detailed instructions regarding

various deck adjustments.

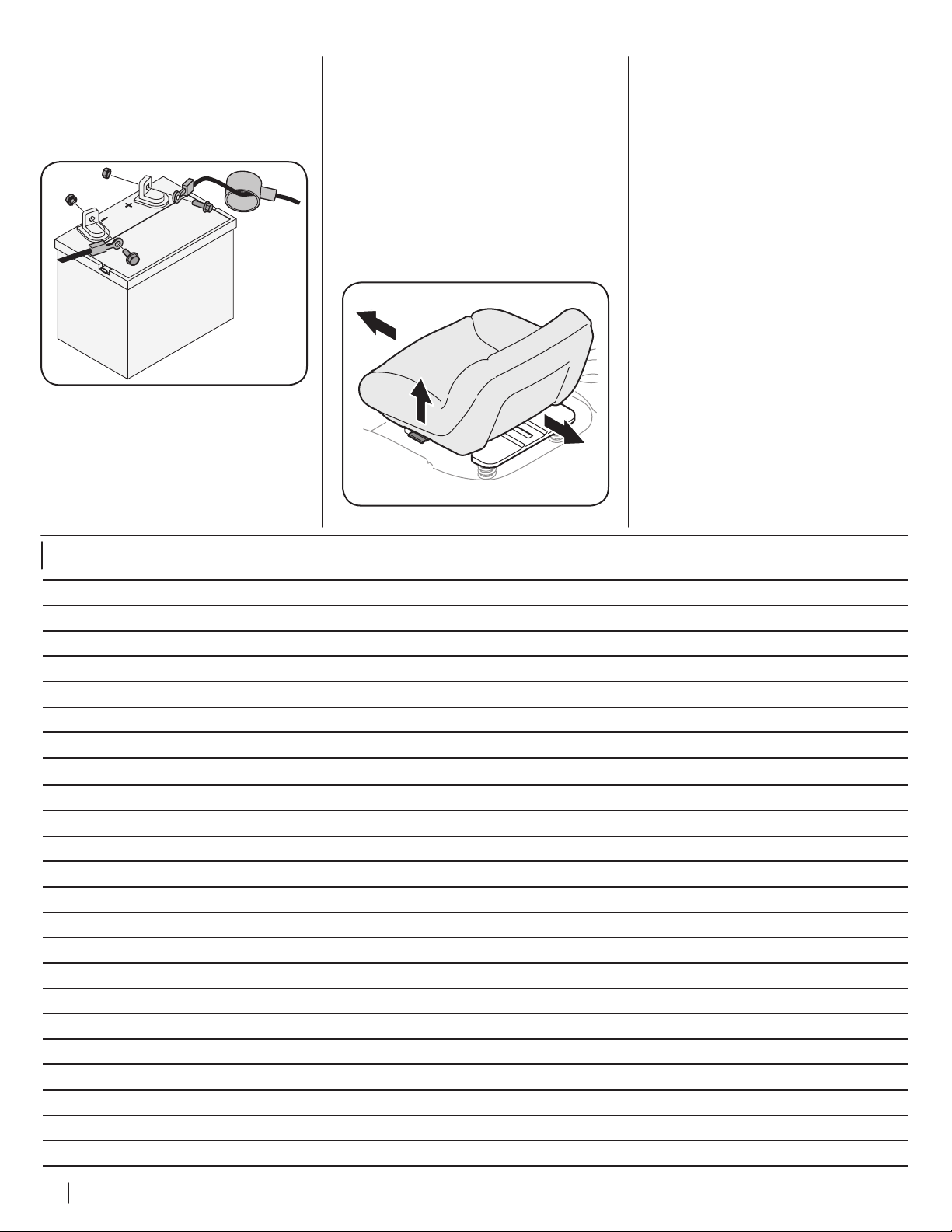

Connecting the Battery Cables

WARNING

California PROPOSITION 65 WARNING: Bat tery

posts, t erminals, and r elated accesso ries contain le ad and

lead comp ounds, chemi cals known to the St ate of Californ ia

to cause c ancer and repr oductive har m. Wash hands aft er

handling.

CAUTION

When att aching batte ry cables, al ways connect t he

POSITIVE (Red ) wire to its term inal first, f ollowed by the

NEGATIVE (Blac k) wire.

For shipping reasons, both battery cables on your

equipment may have been left disconnected from

the terminals at the factory. To connect the battery

cables, proceed as follows:

7Section 2 — ASSembly & Set-Up

Page 8

Note: The positive batter y terminal is marked Pos. (+).

(b)

(b)

(a)

(a)

(c)

The negative battery terminal is marked Neg. (–).

1. Remove the plastic cover, if present, from the

positive battery terminal and attach the red

cable to the positive batter y terminal (+) with

the bolt (a) and hex nut (b). See Figure 2-8.

Figure 2-8

2. Remove the plastic cover, if present, from the

negative battery terminal and attach the black

cable to the negative battery terminal (–) with

the bolt (a) and hex nut (b). See Figure 2-8.

3. Position the red rubber boot (c) over the

positive battery terminal to help protect it

from corrosion.

Note: If the battery is put into service after

the date shown on top/side of battery, charge

the batter y as instructed in the Produc t Care

section prior to operating the tractor.

Adjusting the Seat

To adjust the position of the seat, pull up and hold

the seat adjustment lever. Slide the seat forward

or rearward to the desired position; then release

the adjustment lever. Make sure seat is locked into

position before operating the tractor. See Figure 2-9.

Fuel Fill-Up

Using a good grade of unleaded regular gasoline,

fill the tank (beside the engine on the left side of

the mower). When the fuel tank reaches one inch

from the top of the tank, stop, DO NOT OVERFILL.

Space must be left for expansion.

Notes

Figure 2-9

8 Section 2 — ASSembly & Set-Up

Page 9

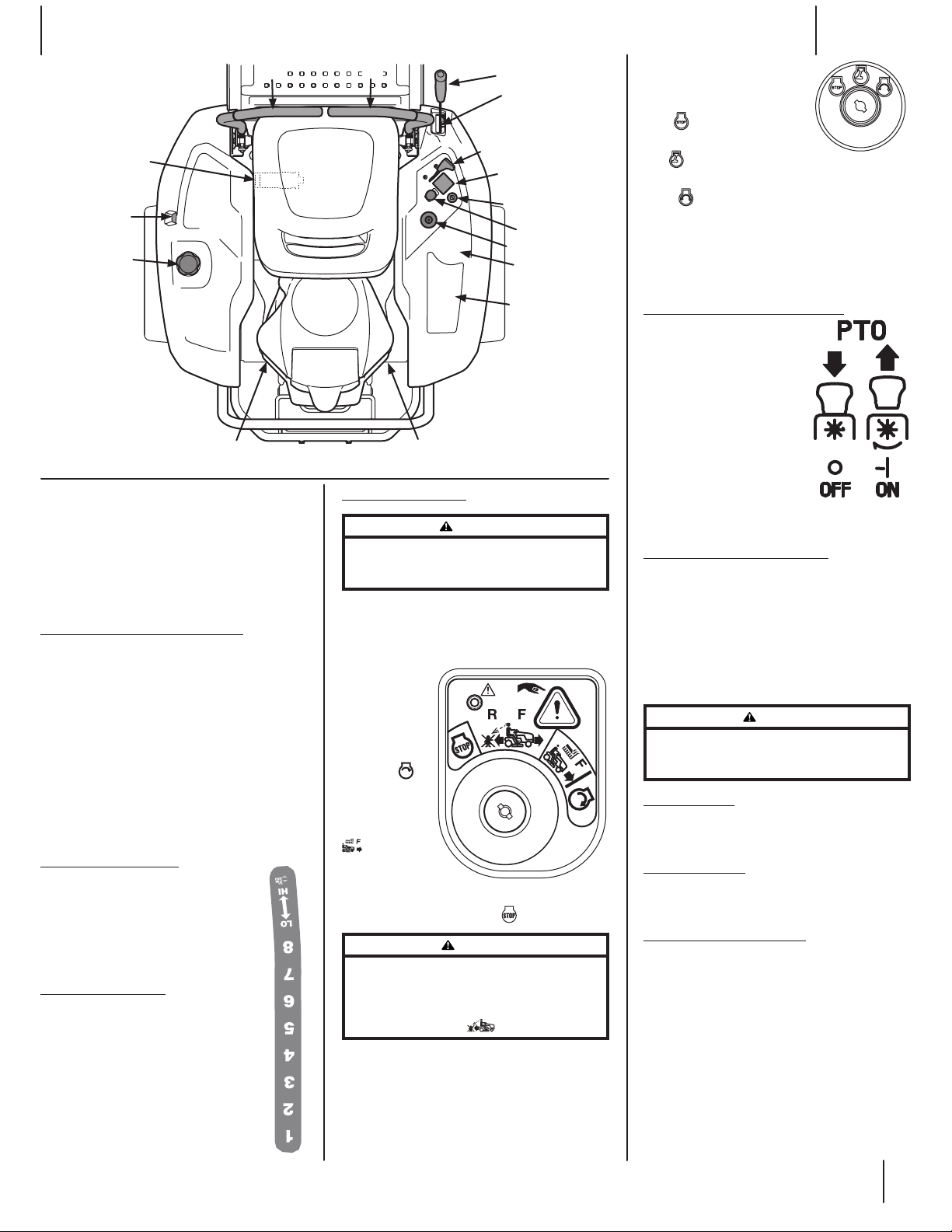

Controls & Operation

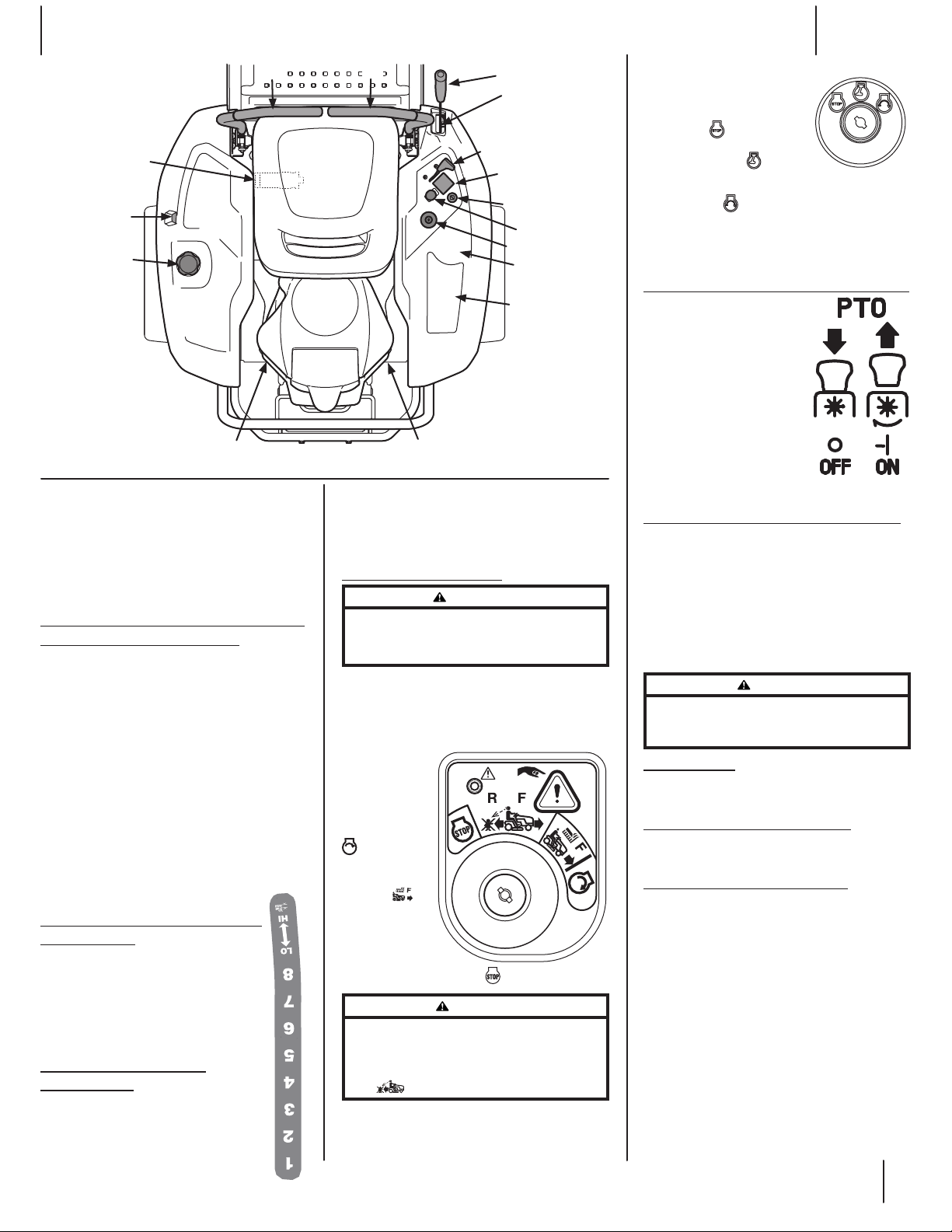

G

(B)

(L) †

(M) †

(D)

(H)

(E)

(N) †

(A)

(C)

(J)

(K)

(F)

(F)

(A)

(I)

† -- If Equipped

Figure 3-1

Note: This Operator’s Manual covers several

models. Tractor features may vary by model. Not

all features in this manual are applicable to all

tractor models and the tractor depicted may differ

from yours.

Note: References to LEFT, RIGHT, FRONT, and REAR

indicate that position on the tractor when facing

forward while seated in the operator’s seat.

RH & LH Drive Control Levers (A)

The RH and LH drive control levers are located on

each side of the operator’s seat. These hinged levers

pivot outward to open space to permit the operator

to either sit in the tractor seat, or to dismount

the tractor. The drive control levers must be fully

opened out and in the neutral position to start the

tractor engine. When the drive control levers are

fully outward, the parking brake is also engaged.

Each drive control lever controls the respective

transmission. Consequently, these levers control all of

the movements of the tractor. Driving and steering

utilizing these control levers is quite different from

conventional trac tors, and will take some prac tice to

master. Refer to Operation for instructions on using

the drive control levers.

Deck Height Index (B)

The deck height index consists of eight

index notches located on the front/right

of the console. Each notch corresponds to

a ⁄” change in the deck height position

ranging from 1-⁄” at the lowest notch to

4” at the highest notch.

Deck Lift Handle (C)

The deck lif t handle is located on the front /

right of the console, and is used to raise and

lower the mower deck.

Pull the deck lif t handle to the left out of the

index notch and push downward to lower

the deck, or pull upward to raise the deck.

When the desired height is attained, move

the deck lift handle to the right until fully in

the index notch.

Ignition Module (D)

WARNING

Never leave a running machine unattended. Always

diseng age PTO, set parkin g brake, stop engi ne and remove

key to prevent unintended star ting.

The ignition module is located on the RH console of

the riding mower seated in the operator’s position.

Ignition Module w/ Reverse Caution Mode (If

equipped)

To start the

engine, insert

the key into

the ignition

switch and turn

clockwise to

the STAR T

position. Release

the key into

the NORMAL

MOWING MODE

position

once the engine

has fired.

To stop the engine, turn the ignition key

counterclockwise to the STOP position.

Prior to operating the riding mower, refer to both Safety

Interlo ck Switches and St arting The Eng ine in the Operat ion

section of this manual for detailed instructions regarding

the Ignition Switch Module and operating the riding mower

in REV ERSE CAUTIO N MODE .

CAUTION

Ignition Module (If equipped)

3

The ignition switch has three

positions:

STOP — The engine and

electrical system is turned off.

RUN — The riding mower

electrical system is energized.

STA RT — The starter motor will turn over the

engine. Release the key immediately when the

engine starts

Note: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the riding mower is not in use.

Power Take-Off (PTO) Switch (E)

The PTO switch is located on

the RH console.

The PTO switch operates the

electric PTO clutch mounted

on the bottom of the engine

crankshaft. Pull the switch

knob upward to engage the

PTO clutch, or push the knob

downward to disengage the

clutch.

The PTO switch must be in the

“OFF” position when starting

the engine.

Transmission Bypass Rods (F)

The transmission bypass rods (one for each the RH

and LH transmission) are located on the rear of the

tractor, just inside each rear wheel.

When engaged, the two rods open a bypass within

the hydrostatic transmissions, which allows the

tractor to be pushed short distances by hand. Refer

to the Assembly & Set-Up section for instructions

on using the bypass feature.

CAUTION

Never tow you r tractor. Towing the tr actor with the r ear

wheels o n the ground may ca use severe damag e to the

transmissions.

Cup Holder (G)

The cup holder is located toward the middle of the

RH console.

Storage Tray (H)

The storage tray is located at the rear of the RH

console.

Seat Adjustment Lever (I)

The seat adjustment lever is located under

the seat. The seat adjustment lever allows for

adjustment forward or backward of the operator’s

seat. Refer to the Assembly & Set-Up section for

instructions on adjusting the seat position.

9

Page 10

Fuel Tank Cap (J)

FAST

SL

OW

FAST

SL

O

W

The fuel tank cap is located near the middle of

the LH console. Turn the fill cap approximately

⁄ turn and pull upward to remove. The fuel cap

is tethered to the tractor to prevent its loss. Do

not attempt to remove the cap from the tractor.

Fill tank to the bottom of the filler neck, allowing

some space in the tank for fuel expansion. Do not

overfill the tank.

Push the cap downward on the fuel tank fill neck

and turn approximately ⁄ turn clockwise to

tighten. Always re-install the fuel cap tightly onto

the fuel tank after removing.

WARNING

Never fi ll the fuel tank w hen the engine is r unning. If

the engi ne is hot from rec ently running, a llow to cool

for several minutes before refueling. Highly flammable

gasoli ne could splash o nto the engine and c ause a fire.

Fuel Level Window (K)

The fuel level window is located on the outer left

side of the LH console and shows the level of fuel

in the gas tank.

Throttle/Choke Control Lever or Throttle

Control (L)

Throttle/Choke Control (If equipped)

The throttle/choke control is located

on the RH console. When set in a given

position, a uniform engine speed will be

maintained.

• Push the throttle/choke control

handle forward to increase the

engine speed. The tractor is

designed to operate with the

throttle/choke control in the fast

position (full throttle) when the

tractor is being driven and the

mower deck is engaged.

• Pull the throttle/choke control

handle rearward to decrease the

engine speed.

• When starting the engine, push the control

handle fully forward into the “CHOKE” position.

• After starting and warming the engine,

move the control handle rearward until you

feel it move past the choke detent.

Throttle Control (If equipped)

The throttle control is located on the RH

console. When set in a given position, a

uniform engine speed will be maintained.

Push the throttle control handle forward

to increase the engine speed. The tractor

is designed to operate with the throttle

control in the fast position (full throttle)

when the tractor is being driven and the

tractor deck is engaged.

Pull the throttle control handle rearward to

decrease the engine speed.

Choke Control (If equipped) (M)

The choke control is located on

the RH console. The choke control

determines the position of the

engine choke. Pull the knob out to

choke the engine; push the knob

in to open the choke.

Hour Meter (N †)

LCD Service Minder & Hour Meter (If so equipped)

When the

key is rotated

out of the

STOP position

but not into

the START

position, the

LCD service

minder & hour

meter will

briefly display

the battery

voltage,

followed by

the tractor’s accumulated hours.

Note: Hours of tractor operation are recorded any

time the key is rotated out of the STOP position,

regardless of whether the engine is started.

The LCD service minder will remind the operator

of maintenance intervals for changing the engine

oil, air filter service, low engine and low battery

warnings.

Change Oil

The LCD will display the letters “CHG”, followed by

the letters “OIL”, followed by the letters “SOON”,

then finally followed by the meter’s accumulated

time. “CHG/OIL/SOON/TIME” will alternate on

the display for 7 minutes after the meter reaches

50 hours. This oil service minder interval will

occur every 50 hours. Before the interval expires,

change the engine oil as instructed in the Engine

Operator’s Manual

Low Oil

Note: The low oil pressure function only works if

the engine is equipped with an oil pressure switch.

The letters “LO” followed by the letters “OIL”, then

followed by the meter’s accumulated time will

indicate the engine has low oil pressure. This is

common when starting an engine. The indicator

will remain active until the engine sufficiently

builds pressure after starting. If it remains on with

the engine at full speed and after a few minutes

of operation, stop the tractor immediately and

check the engine oil level as instructed in the

Engine Operator’s Manual. If the oil is low, add

as instructed in the Engine Operator’s Manual. If

the oil level is correct and the indicator persists,

contact an authorized service dealer.

Low Battery

At startup, the battery voltage is briefly displayed

then changes to accumulated hours. The letters

“LO” will display followed by the letters “BATT” and

then followed by the meter’s accumulated time.

“LO/BATT/TIME” is displayed on the LCD when the

voltage drops below 11.5 volts. When this occurs,

the battery is in need of a charge or the engine’s

charging system is not generating sufficient

amperage. Charge the battery as instructed in the

Product Care section of this manual or have the

charging system checked by your local service

dealer.

Air Filter Service

The letters “CLN” will display, followed by the

letters “AIR”, followed by “FILT”, then followed

by the meter’s accumulated time. “CLN/AIR/FILT/

TIME” will alternate on the display for 7 minutes

after the meter reaches 25 hours. This air filter

service minder time interval will be every 25 hours.

On intervals that are common with oil service, the

oil message will be displayed first followed by the

air filter message.

LCD Service Minder & Hour Meter w/ Bluetooth®

(If equipped)

Connect your

Bluetooth®

enabled

LCD servi ce

minder & hour

meter to your

smartphone by

downloading

the App

for your

Bluetooth®

capable

Android or iOS

device.

The App’s automated maintenance dashboard

and log will help you keep your machine running

at peak performance and protect your investment

by tracking total hours across the lifetime of your

equipment.

Receive alert notifications when it’s time to perform

essential maintenance tasks. Your dashboard

provides real time monitoring and indicates when

it’s time for you to check or change the oil, air filter,

blades or battery. The App also enables you to

locate and contact service centers, access step-bystep instructions to perform routine maintenance

and purchase replacement parts directly from your

mobile device.

Simply download the app and follow the quick

step-by-step instructions on how to sync your

mobile device with your equipment.

Operation

General Safety

• RECEIVE INSTRUCTION — Entirely read

this operator’s manual. Learn to operate

this machine SAFELY. Do not risk INJURY or

DEATH. Allow only those who have become

competent in its usage to operate this

tractor.

• Before starting the engine or beginning

operation, be familiar with the controls. The

operator should be in the operator’s seat.

The PTO switch must be in the disengaged

position and the RH and LH drive control

levers moved fully outward in the neutral

position.

• Keep all shields in place. Keep away from

moving parts.

• NO RIDERS! Keep all people and pets a safe

distance away. Look behind and down to

both sides of the tractor before and while

backing up.

• DO NOT direct the mower discharge at

people.

10 Section 3 — controlS & operation

Page 11

• Avoid slopes where possible. Never operate

Control Levers Moved

Outward & in Neutral

on slopes greater than 15°. Slopes with a

greater incline present dangerous operating

conditions. Tractors can be rolled over.

• Before leaving the operator’s seat: Shut off

the PTO, move the RH and LH drive control

levers fully outward in the neutral position,

shut off the engine and remove the ignition

key. Wait for all movement to stop before

servicing or cleaning.

• Operate the drive control levers smoothly

and avoid any sudden movements of the

drive control levers when starting and

stopping. Keep a firm grip on the drive

control levers.

• Be careful when operating near roadways.

Stop the tractor motion and wait for

vehicles to pass before operating along the

road.

• Do not operate the tractor with the mower

deck removed. Removal of the deck will

change the balance of the tractor, and could

contribute to a tractor rollover.

• Avoid operation on traction surfaces that

are unstable; use extreme caution if the

surface is slippery.

• Slow down before turning and come to

a complete stop before any zero turn

maneuver.

• Do not stop the tractor or park the tractor

over combustible materials such as dry

grass, leaves, debris, etc.

• Do not fill the fuel tank when the engine is

running or while the engine is hot. Allow

the engine several minutes to cool before

refueling. Tighten the fuel cap securely.

Before Operating Your Tractor

• Before you operate the tractor, study this

manual carefully to familiarize yourself

with the operation of all the instruments

and controls. It has been prepared to help

you operate and maintain your tractor

efficiently.

• This engine is certified to operate only on

clean, fresh, unleaded regular gasoline.

For best results, fill the fuel tank with only

clean, fresh, unleaded gasoline with a pump

sticker octane rating of 87 or higher.

• Unleaded gasoline is recommended because

it leaves less combustion chamber deposits

and reduces harmful exhaust emissions.

Leaded gasoline is not recommended and

must not be used where exhaust emissions

are regulated.

Note: Purchase gasoline in small quantities.

Do not use gasoline left over from the

previous season, to minimize gum deposits

in the fuel system.

• Gasohol (up to 10% ethyl alcohol, 90%

unleaded gasoline by volume) is an

approved fuel. Other gasoline/alcohol

blends are not approved.

• Methyl Tertiar y Butyl Ether (MTBE) and

unleaded gasoline blends (up to a maximum

of 15% MTBE by volume) are approved fuels.

Other gasoline/ether blends are not approved.

• Check the engine oil level.

• Clean the air cleaner element if necessary.

• Check the tire inflation pressures.

• Adjust the seat for operator’s maximum

comfort, visibility and for maintaining

complete control of the tractor.

Safety Interlock System

This tractor is equipped with a safety interlock

system for the protection of the operator. If the

interlock system should ever malfunction, do not

operate the tractor. Contact an authorized service

dealer.

• The safety interlock system prevents the

engine from cranking or starting unless the

parking brake is engaged, and the PTO lever

is in the disengaged (OFF) position.

• The engine will automatically shut OFF if the

operator leaves the seat before engaging

the parking brake.

• The engine will automatically shut OFF if

the operator leaves the tractor’s seat with

the PTO lever in the engaged (ON) position,

regardless of whether the parking brake is

engaged.

• With the key in the NORMAL MOWING

MODE/RUN position, the PTO will

automatically shut OFF if the PTO lever

is moved into the engaged (ON) position

with the drive control levers in position for

reverse travel.

• The engine will automatically shut OFF if the

mulch plug, deck chute or bagger chute is

removed, regardless of whether the parking

brake is engaged or the PTO lever is in the

disengaged (OFF) position.

WARNING

Do not operate the riding mower if the safety interlock

system is malfunctioning. This system was designed for

your safety and protection.

Starting the Engine

WARNING

For personal safety, the operator must be sitting in the

tractor seat when starting the engine.

1. Operator must be sitting in the tractor seat

with the drive control levers fully outward in

neutral (parking brake on). See Figure 3-2.

Figure 3-2

2. Make certain the PTO switch is in the “OFF”

position. Move the choke control or throttle/

choke control into the full choke position.

Move the throttle control to midway between

its slow and fast positions on models with a

separate choke control.

Note: If the engine is warmed up, it may not

be necessary to choke the engine.

3. Turn the key clockwise to the START position.

After the engine starts, release the key. It

will return to the NORMAL MOWING/RUN

position.

CAUTION

Do NOT hold t he key in the START positio n for longer than

ten secon ds at a time. Doing so m ay cause damage to y our

engine’s electric starter.

4. As the engine warms up, gradually pull

the throttle/choke control lever rearward

past the choke detent position or slowly

disengage the choke on models with a

separate choke. Do not use the choke

position to enrich the fuel mixture, except

as necessary to start the engine.

5. Allow the engine to run for a few minutes

at mid-throttle before putting the engine

under load.

6. Observe the hour meter/indicator panel.

If the battery indicator light or oil pressure

light come on, immediately stop the

engine. Have the tractor inspected by your

authorized service dealer.

Cold Weather Starting

When starting the engine at temperatures near or

below freezing, ensure the correct viscosity motor

oil is used in the engine and the battery is fully

charged. Start the engine as follows:

1. Be sure the battery is in good condition.

A warm battery has much more starting

capacity than a cold battery.

2. Use fresh winter grade fuel. Winter grade

gasoline has higher volatility to improve

starting. Do not use gasoline left over from

summer.

3. Follow the previous instruction for Starting

the Engine.

Using Jumper Cables To Start Engine

WARNING

Batteries contain sulfuric acid and produce explosive gasses.

Make cer tain the area is we ll ventilated, we ar gloves and eye

protec tion, and avoid s parks or fla mes near the bat tery.

If the battery charge is not sufficient to crank the

engine, recharge the battery. If a battery charger

is unavailable and the tractor must be started, the

aid of a booster battery will be necessary. Connect

the booster battery as follows:

1. Connect the end of one cable to the

disabled tractor battery’s positive terminal;

then connect the other end of that cable to

the booster battery’s positive terminal.

2. Connect one end of the other cable to the

booster battery’s negative terminal; then

connect the other end of that cable to the

frame of the disabled tractor, as far from the

battery as possible.

3. Start the disabled tractor following the

normal star ting instructions previously

provided; then disconnect the jumper cables

in the exact reverse order of their connection.

11Section 3 — controlS & operation

Page 12

4. Have the tractor’s electrical system checked

Control Levers Moved

Inward & in Neutral

Driving Forward

Faster

Slower

Neutral

Position

Forward Left Turn

Forward Right Turn

and repaired as soon as possible to eliminate

the need for jump starting.

Stopping the Engine

1. Disengage the PTO.

2. Move the RH and LH drive control levers

fully outward in the neutral position.

3. Move the throttle control to midway

between the slow and fast positions.

4. Turn the key to the STOP position and remove

the key from the ignition module.

Note: Always remove the key from the ignition

module to prevent accidental starting or

battery discharge if the equipment is left

unattended.

Practice Operation (Initial Use)

Operating a zero-turn tractor is not like operating

a conventional type riding tractor. Although and

because a zero turn tractor is more maneuverable,

getting used to operating the drive control levers

takes some practice.

It is strongly recommended that you locate a

reasonably large, level and open “practice area”

where there are no obstructions, pedestrians, or

animals. You should practice operating the tractor

for a minimum of 30 minutes.

Carefully move (or have moved) the tractor to

the practice area. When performing the practice

session, the PTO should not be engaged. While

practicing, operate the tractor at approximately

⁄-⁄ throttle and at less than full speed in both

forward and reverse.

Carefully practice maneuvering the tractor using

the instructions in the following section “Driving

the Tractor.” Practice until you are confident that

you can safely operate the tractor.

Driving the Tractor

WARNING

Avoid sudden starts, excessive speed and sudden stops.

1. Adjust the operator’s seat to the most

comfortable position that allows you to

operate the controls. See seat adjustment in

the Assembly & Set-Up section.

2. Move the RH and LH drive control levers

inward in the neutral position which also

disengages the parking brake. Refer to

Figure 5 -2.

Note: Lap bars must be moved fully inward

before pushing forward or backward to

ensure brakes are fully disengaged. Parking

the tractor on uneven terrain or a hill may

cause the brakes to bind and not release fully.

In this case the tractor will not drive when the

lap bars are moved. If this happens, move the

lap bar in the opposite direction slightly to

take the load off the brakes and allow them

to release fully.

Note: If the control levers are not even in

the neutral position, refer to Maintenance

& Adjustments for instructions to adjust the

levers so that they are even.

3. Move the throttle to the full throttle position.

Note: Although the tractor’s engine is

designed to run at full throttle, when

performing a practice session the tractor

must be operated at less than full throttle.

This only applies to practice.

WARNING

Always mai ntain a firm g rip on the contro l levers. DO NOT

releas e the control leve rs to slow or stop th e tractor; move

levers to neutral position using your hands.

4. To drive the tractor, firmly grasp the

respective drive control levers with

your right and left hands and continue

with Driving the Tractor Forward on the

following page.

Driving the Tractor Forward

WARNING

Keep all move ment of the dri ve control leve rs slow and smoo th.

Abrupt m ovement of the co ntrol levers c an affec t the stabil ity

of the trac tor and coul d cause the tra ctor to fli p over, which

may result in serious injury or death to the operator.

1. Slowly and evenly move both drive control

levers forward. The tractor will start to move

forward. See Figure 3-4.

Figure 3-4

2. As the drive control levers are pushed farther

forward the speed of the tractor will increase.

3. To slow the tractor move the drive controls

lever rearward to attain the desired speed,

or move the drive control levers to the

neutral position to stop the tractor.

Turning the Tractor While Driving Forward

WARNING

When reversing the direction of travel, we recommend

performing gradual ‘U’ turns where possible. Sharper turns

increase the possibility of turf defacement, and could

affe ct control of th e tractor. ALWAYS slow the trac tor before

making sharp turns.

To turn the tractor while driving for ward, move the

drive control levers as necessar y so that one drive

control lever is rear ward of the other. The tractor will

turn in the direc tion of the rearward drive control lever.

1. To turn to the left, move the left drive

control lever rearward of the right drive

control lever. See Figure 3-5.

Figure 3-5

2. To turn to the right, move the right drive

control lever rearward of the left lever. See

Figure 3-6.

Figure 3-6

3. The greater the distance between the two

levers, the sharper the tractor will turn.

4. To execute a “pivot turn,” move the turn side

drive control lever to the neutral position,

while moving the other control lever

forward.

Note: Making a “pivot turn” on grass

will greatly increase the potential for

defacement of the turf.

Figure 3-3

12 Section 3 — controlS & operation

WARNING

Always mai ntain your gr asp on the drive c ontrol lever s. Do not

releas e the levers to sl ow the tractor o r to return to ne utral.

Page 13

Driving the Tractor In Reverse

Neutral

Position

Slower

Faster

Rearward Left Turn

Rearward Right Turn

(d)

(e)

(c)

(a)

(b)

Clockwise Zero Turn

Counterclockwise Zero Turn

WARNING

Always lo ok behind and dow n on both sides of th e tractor

before backing up. Always look behind while traveling in

the reverse direction.

1. Slowly and evenly move both drive control

levers rearward. The tractor will start to move in

the reverse direction. See Figure 3-7.

Figure 3-7

2. As the drive control levers are pushed

farther rearward the speed of the tractor

will increase.

3. To slow the tractor move the drive control

levers forward to attain the desired speed,

or move the drive control levers to the

neutral position to stop the tractor.

Turning While Driving Rearward

To turn the tractor while driving rearward, move

the drive control levers as necessary so that one

drive control lever is forward of the other. The

tractor will turn in the direction of the forward

drive control lever.

1. To turn to the left while traveling in reverse,

move the left drive control lever forward of

the right drive control lever. See Figure 3-8.

2. To turn to the right while traveling in reverse,

move the right drive control lever forward of

the left drive control lever. See Figure 3-9.

Figure 3-9

3. The greater the distance between the two

drive control levers, the sharper the tractor

will turn.

4. To execute a “pivot turn,” move the turn side

drive control lever to the neutral position,

while moving the other drive control lever

rearward.

Note: Making a “pivot turn” on grass

will greatly increase the potential for

defacement of the turf.

Reverse Caution Mode (If equipped)

The REVERSE CAUTION MODE position of the

ignition module allows the tractor to be operated in

reverse with the blades (PTO) engaged.

Note: Mowing in reverse is not recommended.

WARNING

Use extreme caution while operating the tractor in the

REVERSE C AUTION MODE . Always look dow n and

behind b efore and whil e backing. Do not o perate the

tractor when children or others are around. Stop the tractor

immediately if someone enters the area.

To use the REVERSE CAUTION MODE :

Note: The operator MUST be seate d in the tractor seat.

1. Start the engine as previously instructed.

2. Turn the key from the NORMAL MOWING

(a) position to the REVERSE CAUTION

MODE (b) position of the ignition

module. See Figure 3-10.

3. Press the REVERSE PUSH BUTTON (c) at

the top, right corner of the ignition module.

The red indicator light (d) at the top, left

corner of the ignition module will be ON

while activated. See Figure 3-10.

4. Once activated (indicator light ON), the

tractor can be driven in reverse with the

cutting blades (PTO) engaged.

5. Always look down and behind before and

while backing to make sure no children are

around. After resuming for ward motion,

return key to the NORMAL MOWING (a)

position.

6. The REVERSE CAUTION MODE B will

remain activated until:

a. The key is placed in either the

NORMAL MOWING (a) position

or STOP (e) position or

b. The operator leaves the seat.

Executing a Zero Turn

WARNING

When exec uting a zero t urn, the trac tor MUST BE STOPPED.

Executing a zero turn while the trac tor is moving can significantly

reduce your control of the tractor and will cause severe turf

defacement.

1. Stop the forward or reverse motion of the

tractor by moving the two drive control

levers to neutral.

2. To turn clockwise, move the left drive control

lever forward while simultaneously moving

the right drive control lever rearward. See

Figur e 3-11 .

Figure 3-11

3. To turn counterclockwise, move the

right drive control lever forward while

simultaneously moving the left drive control

lever rearward. See Figure 3-12.

Figure 3-8

Figure 3-10

Figure 3-12

13Section 3 — controlS & operation

Page 14

Stopping the Tractor

1. Move both drive control levers to the

neutral position to stop the motion of the

tractor.

2. Push the PTO switch downward to the OFF

position.

3. Use the deck lift handle to raise the deck to its

highest position.

4. If dismounting the tractor, move the

drive control levers fully outward in the

neutral position which also engages the

parking brake, move the throttle to the

FAST position, turn the key to STOP and

remove the from the ignition module.

WARNING

Do not leave the seat of the tractor without disengaging

the PTO and m oving drive con trol levers fu lly outward i n

the neutral/parking brake engaged position. If leaving the

tractor unattended, turn the ignition key off and remove key.

Driving On Slopes

Refer to the slope gauge in the Safe Operation

Practices section to help determine slopes where

you may not operate safely.

WARNING

Do not ope rate on inclines w ith a slope in exce ss of 15

degrees (a rise of approximately 2- ⁄ feet every 10 fe et). The

tractor could overturn and cause serious injury.

1. Always drive across slopes, never up and

down. Control the speed and direction of

the tractor using primarily the drive control

lever on the downhill side of the tractor,

with the uphill drive control lever remaining

essentially in a fixed position.

2. Avoid turning downhill if possible. Start at

the bottom of a slope and work upward.

Always slow down before turning.

3. Use extra care and go slowly when turning

downhill.

Operating the PTO

Operate the PTO clutch as follows:

1. Move the throttle to approximately the midthrottle position.

2. Pull the PTO switch upward to the “ON”

position.

3. Advance the throttle to the operating speed

(full engine speed).

4. The operator must remain in the tractor seat

at all times. If the operator should leave the

seat without turning off the PTO switch, the

tractor’s engine will shut off.

5. The PTO clutch cannot be operated

when the tractor is driving in the reverse

direction with the REVERSE CAUTION

MODE (if equipped) activated. The PTO

will disengage when both drive control

levers are moved to the reverse position. To

re-engage the PTO, the drive control levers

must be in the neutral or forward drive

position and the PTO switch must be placed

in the OFF (disengaged) position and then

returned to the ON (engaged) position.

Mowing

WARNING

To help avoid bla de contact or a th rown object i njury, keep

bystan ders, helper s, children an d pets at least 75 fee t from

the machine while it is in operation. Stop machine if anyone

enters the area.

WARNING

Make cer tain the area to be m owed is free of deb ris, sticks ,

stones, w ire or other obje cts that can b e thrown by the

rotating blades.

Note: Do not engage the mower deck when

lowered in grass. Premature wear and possible

failure of the ‘V” belt and PTO clutch will result.

Fully raise the deck or move to a non grassy area

before engaging the mower deck.

• Mow across slopes, not up and down. If

mowing a slope, start at bottom and work

upward to ensure turns are made uphill.

• Do not mow at high ground speed,

especially if a mulch kit or grass collector is

installed.

• Do not cut the grass too short. Short grass is

prone to weed growth and yellows quickly

in dry weather.

• Always operate the tractor with the throttle

in the FAST position while mowing.

• On the first pass pick a point on the

opposite side of the area to be mowed.

• Engage the PTO clutch using the PTO switch

and move the throttle control or throttle/

choke control to the FAST position.

• Lower the mower deck to the desired height

setting using the lift handle.

• For best results it is recommended that

the first two laps be cut with the discharge

thrown towards the center. After the first

two laps, reverse the direction to throw the

discharge to the outside for the balance of

cutting. This will give a better appearance

to the lawn.

• Slowly and evenly push the RH and LH drive

control levers forward to move the tractor

forward, and keep the tractor headed

directly toward the alignment point.

Note: The speed of the tractor will affect the

quality of the mower cut. Mowing at full speed

will adversely affect the cut quality. Control

the ground speed with the control levers.

• Do NOT attempt to mow heavy brush and

weeds or extremely tall grass. Your tractor is

designed to mow lawns, NOT clear brush.

• Keep the blades sharp and replace the

blades when worn.

• When approaching the other end of the

strip, slow down or stop before turning. A

U-turn is recommended unless a pivot or

zero turn is required.

• Align the mower with an edge of the

mowed strip and overlap approximately 3”.

• Direct the tractor on each subsequent strip

to align with a previously cut strip.

• To prevent rutting or grooving of the turf, if

possible, change the direction that the strips

are mowed by approximately 45° for the next

and each subsequent mowing.

WARNING

Be care ful when cross ing gravel paths o r driveways.

Diseng age the PTO and rais e the deck to the hig hest

position before crossing.

Note: When stopping the tractor for any

reason while on a grass surface, always:

• Place the drive control levers in the

neutral/parking brake engaged

position,

• Shut engine off and remove the key.

• Doing so will minimize the possibility

of having your lawn ‘‘browned’’ by hot

exhaust from your tractor’s running

engine.

Checking the Safety Interlock Circuits

Periodically check the safety interlock circuits

to ensure they are working properly. If a safety

circuit is not working as designed, contact you

Service dealer to have the tractor inspected. DO

NOT operate the tractor if any safety circuit is not

functioning properly. To check the safety circuits,

proceed as follows:

1. Pull the PTO switch upward to the engaged

position. Momentarily turn the ignition

switch to the START position; the engine

should not crank.

2. Move both control levers fully inward in the

neutral position; then lift upward from the

operator’s seat. The engine should stop.

3. With both control levers fully outward in the

neutral/parking brake engaged position,

engage the PTO. Lift upward from the

operator’s seat; the engine should stop.

4. Start the tractor and move the control levers

inward to the neutral operating position.

Engage the PTO and move both control lever

slowly into the slow reverse position with

the key in the NORMAL MOWING/RUN; the

PTO should disengage and the mower deck

should stop.

14 Section 3 — controlS & operation

Page 15

Product Care

Maintenance Schedule

4

Check & Clean Engine Cooling Fans for

Debris

Check Engine Oil Level

Check Air Filter for Dirty, Loose or Damaged

Parts

Clean Battery Terminals

Grease All Lubrication Points

Check Intake Screen/Clean as Needed

Check Blades/Sharpen or Replace as Needed

Check Tire Pressure

Check/Clean Underside of Deck

Inspect & Lube Deck Wheels

Before

Each use

After First

5 Hours

Every 10

Hours

Every 25

Hours

Every 50

Hours

Every 100

Hours

P P

P

P

P P

P P

P P

P P

P P

P

P P

Prior to

Storing

See Engine

Manual

Check Deck Level/Pitch

Check Belts & Pulleys for Damage/Wear

Check That All Hardware is in Place & Secure

Check Spark Plug Condition & Gap

Engine Break-In Oil Change

Change Engine Oil

Replace Oil Filter

Clean or Change Air Filter

Replace Fuel Filter

Have Valve Lash Checked & Adjusted *

* -- Have this item performed by an authorized service dealer

P P

P

P

P P P

P P

P P P

P P P

P P

P P

P

15

Page 16

Note: This Operator’s Manual covers several models.

(b)

(a)

(c)

(d)

(a)

(b)

(c)

Tractor features may vary by model. Not all features

in this manual are applicable to all tractor models

and the tractor depicted may differ from yours.

Troubleshooting

Excessive vibration

1. Cutting blade loose or unbalanced.

• Tighten blade and spindle.

2. Damaged or bent cutting blade.

• Replace blade.

Uneven cut

1. Deck not leveled properly.

• Perform side-to-side deck

adjustment.

2. Dull blade.

• Sharpen or replace blade.

3. Uneven tire pressure.

• Check tire pressure in all four tires.

Tractor will not mulch grass (If equipped w/

mulching kit)

1. Engine speed too low.

• Place throttle in FAST (rabbit)

position.

2. Wet grass.

• Do not mulch when grass is wet.

3. Excessively high grass.

• Mow once at a high cutting height,

then mow again at desired height or

make a narrower cutting swath.

4. Dull blade.

• Sharpen or replace blade.

Maintenance

WARNING

Before performing any maintenance or repairs, disengage

the PTO, move th e drive control le vers fully out ward in

the neutral position engaging the parking brake, stop the

engine a nd remove the key to pr event unintende d starting.

Engine

Refer to the engine operator’s manual for all

engine maintenance procedures and instructions.

Note: Maintenance, repair, or replacement of the

emission control devices and systems which are

being done at owner’s expense may be performed

by any engine repair establishment or individual.

Warranty repairs must be performed by an

authorized service dealer.

Changing the Engine Oil

2. Locate the oil drain hose (a) on the right side of

the engine. See Figure 4-1.

Figure 4-1

3. Route the free end of the oil drain hose

(a) toward an appropriate oil collection

container with at least a 2.5 quart capacity,

to collect the used oil. Remove the oil fill

cap/dipstick (b) from the oil fill tube.

4. While holding the free end of the oil drain

hose (a) over the oil collection container,

unscrew the square head hose plug (c) from

the end of the oil drain hose (a) . See Figure

4-1. Drain the engine oil into the collection

container.

5. After draining the oil, wipe any residual

oil from the oil drain hose (a). Thread the

square head hose plug (c) into the oil drain

hose (b) fitting and fully tighten the square

head hose plug (c).

6. Replace the oil filter (d), and refill the engine

with new oil as instructed in the Engine

Operator’s Manual.

Lubrication

WARNING

! Before lubricating, repairing, or inspecting, always

diseng age PTO, set parkin g brake, stop engi ne and remove

key to prevent unintended star ting.

• Using a pressure lubricating gun, lubricate

the front castor wheel axles with grease

after every 10 hours of service.

• Periodically lubricate all other pivot points

with a quality lubricating oil.

Cleaning & Lubricating the Spindle Pulleys

Once a month remove the belt covers to remove

any accumulation of grass clippings from around

the spindle pulleys and V-belt. Clean more often

when mowing tall, dry grass.

Every 25 hours, lubricate the deck spindles. Locate

the spindle lube fitting and using a grease gun,

lubricate the spindles. The spindle holds 2.3

ounces of grease. See Figure 4-2.