Page 1

$7.a>

Owner/Operator

Manual

TROY-Blir

Suburban

TRACTORS

Hydrostatic-Drive Models

13027

13028

Serial Numbers:

130270100101 and up

130280100101 and up

• Safety

• Assembly

• Controls

• Operation

• Maintenance

GARDEN WAY INC.

1763973 (11/91)

Page 2

hank you for purchasing

this Troy-Bilt® Tractor.

T

of the finest tractors available

anywhere.

sembly, operation and general

maintenance manual which does

We feel you now own one

This manual is a safety, as

not attempt to cover major re

pairs. Our equipment is care

fully designed, engineered, and

manufactured to provide excel

lent performance if properly

maintained. Review this manual

to familiarize yourself with your

tractor, its features and its

proper operation.

Your tractor meets the safety standards of the American National

Standards Institute for Lawn Tractors—as a result, this tractor is

entitled to bear the official OPEI safety seal.

Please complete and return the

enclosed Owner Warranty Regis

tration Card. The purpose of the

card is to register each owner at

the factory so informational bul

letins or safety literature may be

sent to you.

SERVICE INFORMATION

Engine Service:

If your tractor engine ever needs

service or repair, contact your

nearest Authorized Engine Dealer.

To locate the nearest Dealer, refer

to the “Yellow Pages” in your tele

phone book under either

“Engines- Gasoline” or “Gasoline

Engines.”

If you have problems getting

engine service or parts locally, let

us know so we crm provide you

with the name of the nearest

Dealer. A servicing engine dealer

will require Engine Model and

Serial Number information found

on the engine to assist you prop

erly. Record the engine identifica

tion numbers in the area provided

below for this purpose.

Tractor Service and Repair:

To obtain tractor service or

parts, please contact your local

Authorized Troy-Bilt Dealer, a

Troy-Bilt Factory Store, or the

Troy-Bilt Manufacturing Company

(for Factory telephone numbers

ENTER YOUR PRODUCT IDENTIFICATION NUMBERS BELOW

ENGINE IDENTIFICATION:

Manufacturer Name

Model

___________________________________

Serial Number_____________________________

________________________

and addresses, refer to the back

cover of this Manual).

You will need to provide the

Model and Serial Numbers of your

tractor, plus as complete a descrip

tion as you can provide of specific

service and parts needs.

Warranty Service:

To obtain warranty service,

please read the information about

the Limited Warranty printed on

the back cover of this Manual.

TRACTOR IDENTIFICATION

Model Name & Number

Serial Number

____________

____

The Serial Number decal with information

specific to your tractor is foimd under the

operator’s seat.

Page 3

TABLE OF CONTENTS

Safety ..................................................................................................................................................................4

Attachments and Kits.......................................................................................................................................... 8

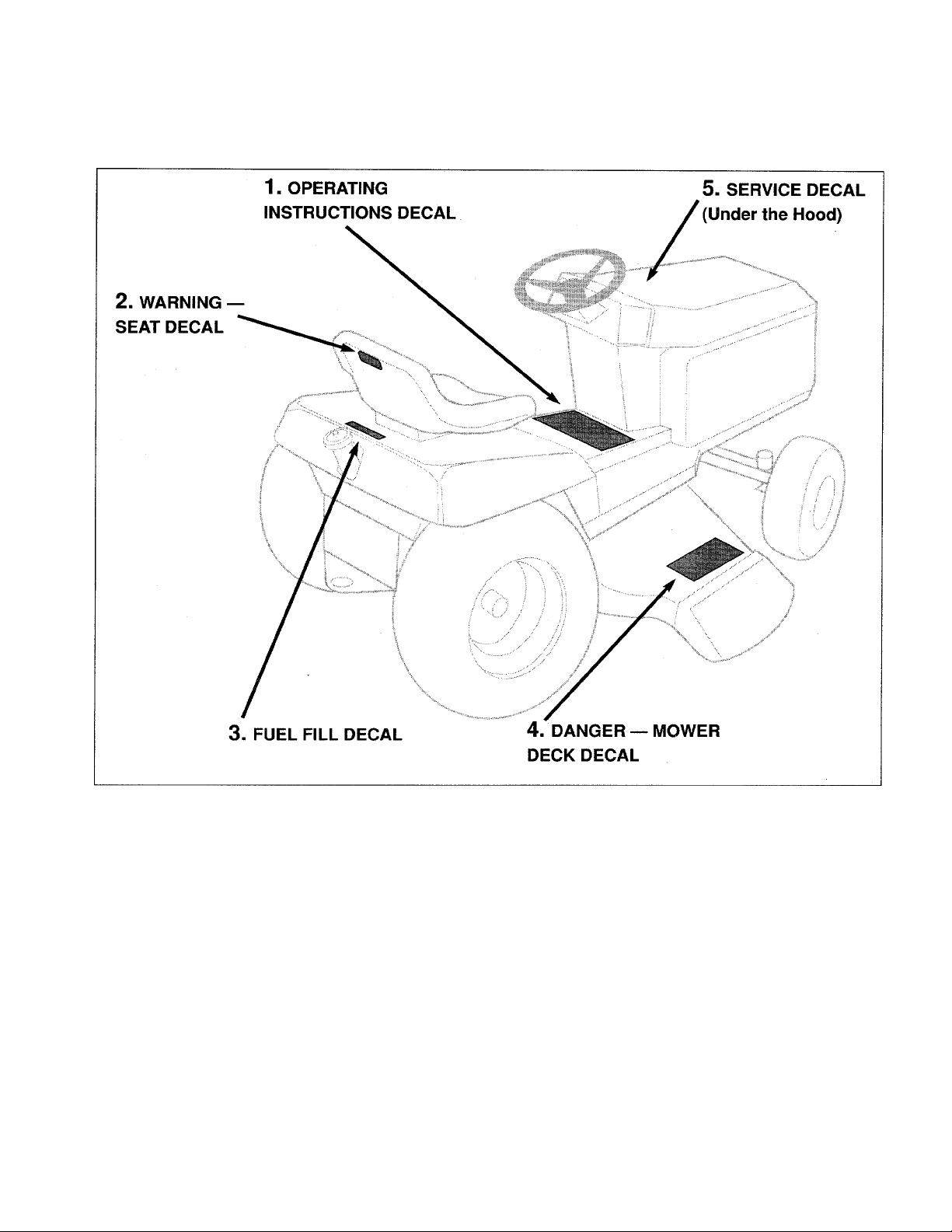

Product Decals.....................................................................................................................................................8

Specifications...................................................................................................................................................... 9

Assembly.............................................................................................................................................................10

Controls........................................................................................................................................................... 16

Operation

Pre-Starting Instructions............................................................................................................................... 18

Engine Starting Instructions..........................................................................................................................19

Tractor Operation......................................................................................................................................... 20

Using Hydrostatic Travel Pedal....................................................................................................................20

Tips and Techniques for Lawn Mowing..................................................................................................... 21

Techniques for Snow Throwing....................................................................................................................22

Maintenance

Engine Maintenance......................................................................................................................................23

Checking And Changing Motor Oil......................................................................................................... 23

Fuel Filter............................................................................................................................................... 25

Carburetor.................................................................................................................................................25

Air Cooling System................................................................................................................................. 25

Ignition System........................................................................................................................................ 25

Spark Plug............................................................................................................................................ 25

Battery Care............................................................................................................................................ 25

Diode Rectifier......................................................................................................................................... 25

Fuse...........................................................................................................................................................25

Air Cleaner Maintenance..........................................................................................................................26

Tractor Maintenance

Transmission.............................................................................................................................................27

Tires..........................................................................................................................................................27

Hardware............................................................................................................................................. 27

Interlock Safety Switch System.............................................................................................................. 28

Brake Adjustment.....................................................................................................................................29

Brake Pedal Adjustment...........................................................................................................................29

Drive Belt Removal..................................................................................................................................29

Lubrication Chart......................................................................................................................................30

Tractor Storage......................................................................................................................................... 30

Troubleshooting................................................................................................................................................ 31

Warranty...............................................................................................................................................Back Cover

A

RECOGNIZE IMPORTANT

SAFETY INFORMATION.

The triangular-shape symbol at left is

the international “Safety Alert

LEFT AND RIGHT SIDES

Whenever “Left” and “Right” sides of your equipment are mentioned

in this Manual, the orientation is from the operator’s seated position.

Symbol.” It is used on your tractor

and throughout this Manual to call

your attention to important safety

messages which, if not followed, can

result in serious personal injury.

Page 4

Section

This is a safety aiert

symbol, it Is used in

A

this Owner/Operator

Manual and on your

tractor to alert you

to potential hazards.

Whenever you see

this symbol, read

and obey the safety

message that fol

lows it. Failure to

obey these safety

messages could re

sult in serious per

sonal injury or prop

erty damage.

A CAUTION TRAINING

To Avoid Injury:

• Read Owner/Operator Manual.

• Know location and function of

ail controls.

• Keep aii safety devices and

shields in place.

• Never let children or un

trained adults operate tractor.

• Shut off engine and remove

the ignition key before leav

ing your equipment.

• Keep bystanders away from

the tractor.

• Keep away from rotating

parts.

• This cutting machine is capa

ble of amputating hands and

feet and throwing objects.

Failure to observe the follow

ing safety instructions could

result in serious injury or

death.

WARNING TO ALL OPERATORS IN CALIFORNIA

A

Under California law, and under the laws of several other states,

you are not permitted to operate an internal combustion engine

gine spark arrester in continuous effective working order.

The engine on your power equipment, like most outdoor power equipment, is an

internal combustion engine that burns gasoline, a hydrocarbon fuel. Therefore,

your power equipment must be equipped with a spark arrester muffler in continu

ous effective working order. The spark arrester must be attached to the engine

exhaust system in such a manner that flames or heat from the system will not ig

nite flammable material. Failure of the owner/operator of the equipment to com

ply with this regulation is a misdemeanor under California law, and may also be a

violation of other state and/or federal regulations, laws, ordinances, or codes.

Contact your local fire marshal or forest service for specific information about

what regulations apply in your area.

1. Thoroughly read and be sure

you understand the contents of this

Owner/Operator Manual. A free

replacement Manual is available

by sending your tractor model

name and serial number to the

Factory. Our address is on the

back cover of this Manual, and on

the Parts Catalog you received.

2. Also thoroughly read and un

derstand any Attachment

Manuals and engine manufac

turer literature you received.

3. Know the location and the func

tion of all operating controls on

your tractor before using your

equipment.

AND ALL OTHER APPLICABLE STATES

using hydrocarbon fuels on any forest covered, brush cov

ered, or grass covered land, or on land covered with grain,

hay, or other flammable agricultural crop, without an en

4. Familiarize yourself with all of

the safety and operating decals on

the tractor and any attachments.

5. Never allow children or un

trained adults to operate the trac

tor. They are not qualified to use

this equipment safely. Only re

sponsible, trained adults who have

received full instructions should

use the tractor.

6. Do not carry passengers

under any circumstances. Do

not mow when children and oth

ers are nearhy. Operator must

remain on the tractor seat while

using the tractor.

7. Gasoline and its vapors are

volatile and dangerous. Never

allow gasoline or a gas container

near the hot engine exhaust.

Never allow flame, sparks, smok

ers’ materials or intense heat near

gasoline fumes or gtisoline itself.

8. The muffler exhaust gas is very

hot. To avoid a fire—^keep dry

Page 5

Saft

grass, mowed grass, oil, fuel and

other combustible materials far

away from the engine exhaust.

9. To reduce fire hazard risks, keep

the engine free of grass, leaves, oil

and grease.

10. Always wear sturdy footwear

and hearing protection while using

your tractor. Do not wear

loose-fitting clothing, jewelry,

scarves, ties, etc. that can get

caught in moving parts.

11. Check brake operation fre

quently. Adjust and service as re

quired.

12. Do not operate this tractor or

any other implement attached to it

if you are under the influence of

alcohol, medication, or are tired or

ill. Normal awareness and re

sponse time are required to use this

equipment safely.

13. All safety shields and other

safety devices must be in place, se

curely attached and operating

properly. Do not use your tractor

otherwise.

14. Use only attachments that are

approved for use with your tractor.

Contact us if you are not certain as

to whether an attachment is appro

priate for your tractor.

15. Take all possible precautions

before leaving the tractor unat

tended— a) disengage the power

take-off; b) lower any attachment;

c) set the parking brake; d) stop

the engine; e) remove the ignition

key.

PREPARATION

1. Clear the work area of objects

which could be picked up and

thrown at high speed by rotating

equipment parts. Remove objects

like rocks, branches, wire, cans,

and all other foreign materials.

2. Be sure machine and attach

ments are in safe operating condi

tion by checking all hardware for

tightness. Check the blade mount

ing hardware frequently to be cer

tain tightening specifications are

met. Check brakes, steering, and

other major controls for proper op

eration. Correct any malfunctions

before using the tractor or its at

tachments.

3. Fill fuel tank with gasoline be

fore starting the engine. Do not

spill fuel. Wipe up spills immedi

ately. Gasoline is flammable—

handle it very carefully.

• Use an approved gas container.

• Do not pour gasoline when

equipment is indoors, when en

gine is running, or when engine

is still hot from use.

• Never smoke when

space at top of fuel tank fill tube

when filling tank with gasoline.

Fuel needs room to expand.

® When moving equipment out

side from a building or enclo

sure, only run the engine to

transport the machine outside.

Do not run the engine in an

enclosed area. Engine exhaust

contains carbon monoxide gas,

a deadly poison that is odor

less, colorless, and tasteless.

4. Operator must be fully seated

before the starting procedure is

begun. Before starting the engine.

move all controls to their neutral or

off positions. The pro

Attachment Drive Switch must be

OFF. Only the Parking Brake

should be ON (it is engaged by de

pressing the Brake Pedal and then

moving the Parking Brake knob

backward and up).

5. Always disengage power to at

tachments, apply the Parking

Brake, and stop the engine before

leaving the operator’s position.

6. Be sure that safety and operating

decals are in place and legible.

Please order replacement decals if

they are needed.

Page 6

Cl¥

OPERATION

1. Disengage power to attachments

when transporting tractor, or when

attachments are not being utilized.

2. When using the tractor with a

mower deck, proceed as follows:

a. Mow only in daylight or in

good artificial light.

b. Never make a cutting height

adjustment while,the engine is

running if the operator must dis

mount in order to do so.

c. Shut the engine off when re

moving the grass catcher or un

clogging the discharge chute.

d. Check the blade mounting

bolts for proper tightness at fre

quent intervals.

3. Do not use your tractor on

slopes when there is a risk of turn

ing over the machine. Do not

mow on hills steeper than a 15° in

cline—see the slope gauge in the

Operation Section of this Manual.

Never mow across slopes. Stay

away from holes, ditches, soft or

steep embankments or other poten

tially dangerous terrain. Tall grass

can hide obstacles. Wet surfaces

reduce traction and stability.

4. Keep observers far away from

the area where you are using your

tractor and attachments. Rotating

blades can hurl objects at high

speed, causing injury to bystanders.

5. Reduce speed and exercise cau

tion on slopes and when making

turns. Be especially careful when

changing direction on slopes. Do

not start or stop suddenly when

going uphill or downhill. Always

mow up and down the face of ter

rain that has an incline. Do not

mow on an incline greater than

15°. Never mow across slopes.

6. If the tractor is unable to con

tinue moving uphill, move the

PTO Attachment Drive Switch to

OFF and back slowly downward.

7. Always be observant. Watch for

and avoid obstacles.

8. Do not direct the discharge of

mowed materials toward others.

9. Watch out for traffic when you

are crossing or near roadways.

10. The tractor and attachments

should be stopped and inspected

for damage after striking a foreign

object. Repair any damage before

using the equipment again.

11. Use caution when pulling loads

• Use only approved drawbar

hitch points.

• Limit loads to those that can

be safety controlled.

• Do not turn sharply. Use extra

caution when backing up.

• Use counterweights or wheel

weights for extra traction.

12. Disengage power to the mower

attachment before backing up. As

a general rule, do not mow in re

verse. When absolutely necessary

to mow a small area using reverse,

go very slowly and carefully watch

the area behind the mower.

13. Keep your hands, feet, face

and clothing away from rotating

attachment and tractor parts at all

times. Never leave the operator’s

seat while the tractor is moving or

the mower attachment is in use. A

safety interlock switch will shut

off the engine if the operator

leaves the seat when an attachment

is on or the parking brake is not

engaged. If not working properly,

the safety interlock switch must be

repaired before using the tractor.

14. Before crossing a roadway or

driveway, disengage power to the

mower deck and raise the mower

housing to its highest level. This

prevents loose materials from

being blown around.

15. Do not leave the operator’s po

sition if the tractor has not come to

a full stop. Before dismounting:

• Disengage power to mower

deck by moving PTO Attach

ment Drive Switch to OFF.

• Lower all attachments.

• Place all other control levers

in their Neutral positions.

• Depress the Brake Pedal and

apply the Parking Brake.

• Turn off the engine and re

move the ignition key.

16. Avoid contact with the engine

or muffler while the engine is run

ning and for several minutes after

the engine is shut off. Hot sur

faces can cause a severe bum.

17. Under normal use, the grass

catcher bag material (on the op

tional Power Packer) is subject to

deterioration and wear. It should

be checked frequently for bag re

placement. Replacement bags

must comply with the original

manufacturer’s recommendations

or specifications.

18. Always engage the Parking

Brake when parking the tractor on

a hill.

Page 7

SERVICE

engine to prevent any possibility

of accidental engine starting.

“To Charge The Battery” in

Section 2 in this Manual.

1. Before performing service or

maintenance, disengage power to

the attachment, lower the attach

ment, move all control levers to

Neutral, apply the Parking Brake,

then shut off the engine and re

move the ignition key. Park the

tractor on a firm, level surface.

2. If the tractor engine must be

running to perform a specific ad

justment, keep hands, feet, face,

and clothing away from the mower

deck blades and any parts that are

moving.

3. Do not change the engine’s gov

ernor setting. Over-speeding the

engine may cause engine damage.

Have your Authorized Dealer

check and adjust engine speed

with an accurate tachometer.

4. Disconnect the battery ground

(negative) cable, then the positive

cable, before working near or with

electrical wires or components. To

avoid sparks from an accidental

short circuit, the battery ground

cable must be disconnected first

and reconnected last.

5. Disconnect the spark plug wire

before servicing or adjusting the

6. After tipping the tractor up at an

angle to perform any maintenance

or an adjustment, be certain there

is no leakage of fuel from the gas

tank or oil from the engine crank

case. Use a very strong block or

jack to prop up the tractor.

7. Never store the tractor with fuel

in the gas tank inside a building

where fumes may reach an open

flame or spark. Always let the en

gine cool down before moving the

tractor inside an enclosure.

8. Be prepared for an emergency.

Have a fire extinguisher nearby to

put out a fire. Keep a first aid kit

on hand. Emergency telephone

numbers should be kept right next

to your telephone.

9. Wheel attachment hardware

must be checked regularly for se

cure attachment.

10. Do not try either to remove or

mount a tire on a wheel rim unless

you are experienced in doing so,

you follow proper safety precau

tions, and you have the appropriate

tools for this service procedure.

Mounting a wheel improperly can

produce an explosion, resulting in

serious injury or death.

11. Before trying to “charge” a

dead battery, familiarize yourself

with the correct procedure. See

12. Always protect your hearing if

the engine will be running while

you do a service or maintenance

procedure. Use quality ear protec

tion devices to minimize noise.

13. Use extra care when loading or

unloading the machine into a

trailer, truck, or other transport ve

hicle.

14. Mower blades are sharp and

can cut. Wrap blade, or wear

gloves, and use extra caution when

servicing them.

STORAGE

1. Do not store the tractor with fuel

in its gas tank inside a building

where gasoline fumes could be ig

nited by flame, sparks, or other ig

nition sources. Proper ventilation

is important for safe storage.

Always let the engine cool down

before bringing the tractor inside.

2. Keep tractor and fuel supplies

securely locked away to prevent

children from having access.

3. Remove the ignition key.

4. Disconnect battery cables or re

move the battery if tractor will be

stored for an extended period.

Remove the negative cable first

and reinstall it last.

Page 8

SAFETY AND OPERATING INSTRUCTIONS PRODUCT DECALS

ATTACHMENTS AND KITS

Not All Attachments and Kits are Available for All Tractor Models. Your Authorized Dealer

Can Supply You With Up-To-The-Minute Attachment Information For Your Tractor.

42" Rear Dischaige Rotaiy Mower (14HP/16HP only)

36" Side Discharge Rotary Mower

42" Side Discharge Rotary Mower (14HP/16HP only)

48" Side Discharge Rotary Mower (14HP/16HP only)

Grass Reduction System (“GRS”)

38" Two-Stage Snowthrower (Requires Rear Wheel

Weight Kit and an Installation Kit)

38" Single-Stage Snowthrower (Requires Rear Wheel

Weight Kit)

26" Rotary Tiller (14HP/16HP only)—^Requires Rear

Wheel Weight Kit

PowerPacker for 36" Mower Deck

PowerPacker Plus for 42" and 48" Mower

Decks (Requires either the Cart Grass Collector or

the Two-Bag Grass Collector)

Electric Lift Kit

Rear Wheel Weight Kit

Installation Kit for the 38" Two-Stage SnowthrowerCart Grass Collector (used with PowerPacker Plus)

Two-Bag Grass Collector (used with PowerPacker Plus)

42" Blade (Rear Wheel Weight Kit recommended)

Cab

Protective Storage Cover

Page 9

SPECIFICATIONS

TRACTOR

MODEL

ENGINE

TYPE

IGNITION

OIL CAPACITY 4 Pints (1.9 Liters)

OIL FILTER

AIR CLEANER

FUEL CAPACITY

DRIVE TYPE

DRIVE SPEEDS

POWER TO

ATTACHMENTS

13024— 12.5HP

13027— 14HP

13028— 14HP

Kohler 12.5HP & 14HP

Single-Cylinder

4-Cycle OHV

Air-Cooled

Full-Pressure Lube

Electronic

Full-flow auto type N/A

Cartridge w/Pre-Cleaner Cartridge w/Pre-Cleaner

EATON HYDROSTATIC TRANSMISSION (Model 751-047)

Infinitely Variable Speed

Forward: O-to-5.2 MPH (O-to-8.4 km/hr)

Reverse: O-to-2.1 MPH (O-to-3.4 km/hr)

ELECTRIC CLUTCH WITH BELT

13014— 14HP

13015— 14HP

13013— 12HP

Briggs & Stratton

12 HP Single Cylinder

4-Cycle, I/C

Air-Cooled

Magnetron Electronic Magnetron Electronic

3 Pints (1.4 Liters)

5 Gallons (19 Liters)

13016— 16HP

Briggs & Stratton

14 HP & 16HP

Twin Cylinder

4-Cycle OHV Air-Cooled

Full-Pressure Lube

3.5 Pints (1.65 Liters)

Full-flow auto type

Cartridge w/Pre-Cleaner

BATTERY

TIRES-REAR 20x8.00-8

TIRES-FRONT

LENGTH

WIDTH 34-1/2" (88 cm)

HEIGHT

WHEEL BASE

TURNING RADIUS

GROUND CLEARANCE Front— 8" (20.3 cm) Rear— 6.5" (16.5 cm)

22" (56 cm) Inside Rear Wheel / 155" (394 cm) Curb to Curb

45 AMP / 12 Volt (280 CCA / 40 min Reserve)

15 X 6.00- 6

69" (175 cm)

42" (106 cm)

45" (114 cm)

Page 10

A

This is a safety aiert

symbol. It is used in

this Owner/Operator

Manual and on your

tractor to alert you

to potential hazards.

Whenever you see

this symbol, read

and obey the safety

message that fol

lows it. Failure to

obey these safety

messages could re

sult in serious per

sonal injury or prop

erty damage.

TRACTOR ASSEMBLY STEPS

If your tractor has not been as

sembled and prepared by an

Authorized Dealer, use the in

structions that follow to complete

the assembly and preparation

steps that must be taken prior to

starting and using your new

Suburban tractor.

mal tools and mechanical skills.

We urge you to have an assistant

present during the assembly to

make the assembly steps safer

and easier for you. Of course, if

your tractor has already been as

sembled and prepared, you can

ignore the steps in Section 2 and

proceed directly to Section 3

The assembly procedure is

straightforward and requires mini

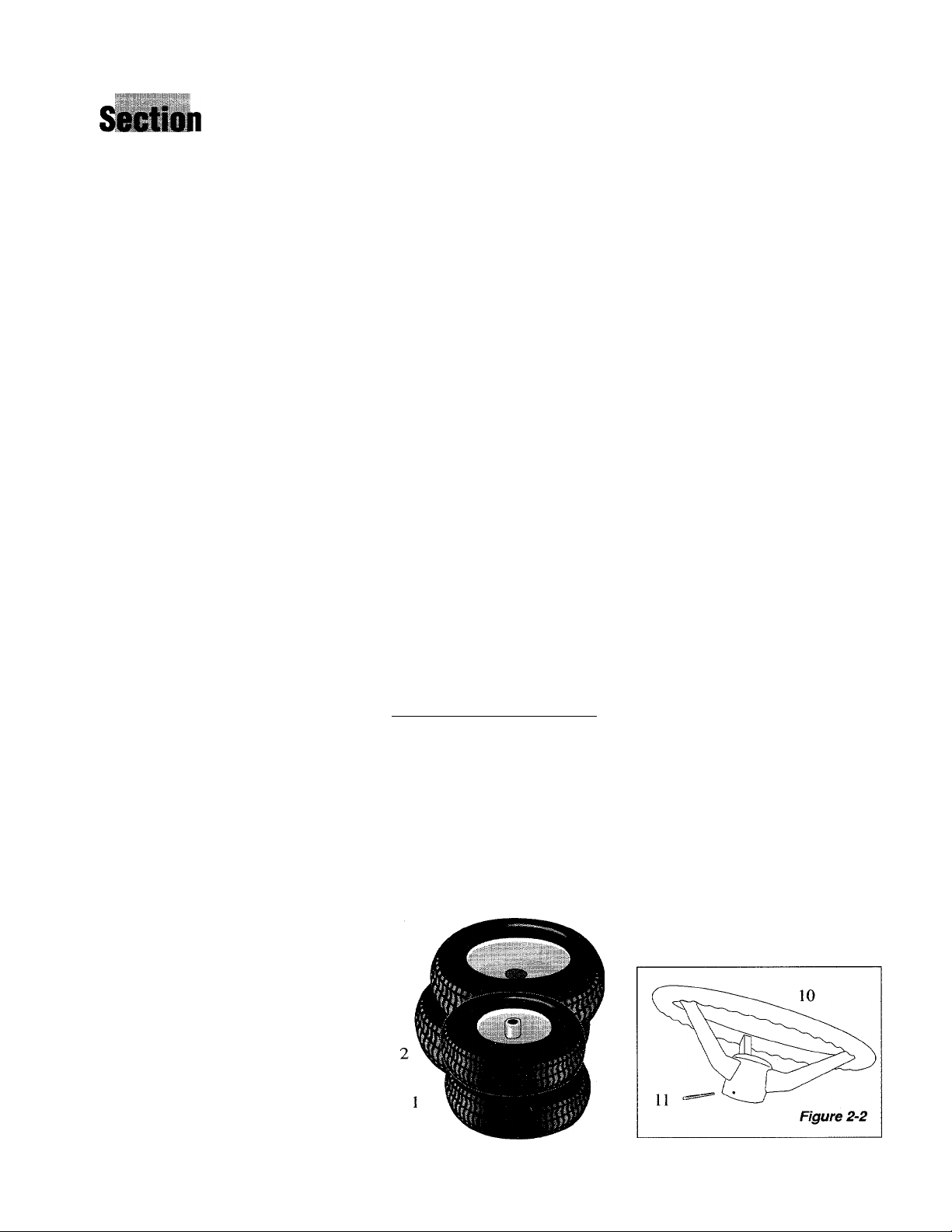

Step 1: Check Shipping Carton Contents for Assembly Parts

Numbers below cross-reference

with parts shown in Figure 2-1,

Figure 2-2 and Figure 2-3.

Wheels and Wheel Hardware:

3

5

ii

4 QIO

which gives you important infor

mation about Controls.

1. Two Front Wheels (15 x 6.00-6).

2. Two Rear Wheels (20 x 8.00-

8).

3. Two long Hub Caps.

4. Two short Hub Caps.

5. Ten Flat Washers-1" x 2".

6. Four Flat Washers-3/4" x 1-3/8".

7. Two Square Keys.

8. Four Retaining Rings— two 1"

and two 3/4".

9. Two Flat Washers— 1" x 1-1/4".

11#’^^

„ oo

^ oo

Figure 2-1

©@@@

@@

9

10

Not Shown is the Ignition Key.

Steering Wheel and Hardware:

10. One Steering Wheel.

11. One Roll Pin (for steering wheel).

Page 11

A «i. f-

Seat and Seat Hardware:

12. One Operator’s Seat.

13. Two Knobs with flat washers.

14. Two Bolts, two flat washers, two

nylon washers, two wave washers.

Step 2: Tools You Will Need

For Assembly

• One 3/8" wrench.

• One 7/16" wrench.*

• One 1/2" wrench.*

• One 9/16" wrench.*

• One Hammer.

• One long flat Punch (to drive the

roll pin through the steering column).

• Snap Ring Pliers (external type).

• Sturdy wood props (2).

• Low-pressure Tire Gauge.

• Two quarts of high-quality engine

oil (see your Engine Manufacturer’s

Manual for oil recommendations).

• High-quality grease.

*An adjustable wrench may be sub

stituted.

Step 3: Check Tire Pressure

Before mounting the wheels,

use your tire gauge to

check, and adjust if

necessary, the air

pressure in all four

tires. The tires

were overinflated

for shipping purposes only. Be

sure that you adjust the pressures

as follows;

Front Tires—14 PSI

Rear Tires—12 PSI

Step 4: Install the Wheels

It’s easiest to install the wheels

first on one side of the tractor, and

then on the other side.

1. To begin, first tip up the tractor

far enough (on either side) to slide

strong wood props under the

frame. The props must be high

enough so the front and rear axles

have clearance for the wheels to go

on. The tractor is heavy, so be

sure you have an assistant to help.

2. Apply grease to the front and

rear axle shafts. An anti-seize lu

bricant or a similar type of coating

is satisfactory.

3. On the rear axle, slide on a 1" x

1-1/4" flat washer. Also insert a

square key into the axle.

4. Slide a large rear wheel on the

axle—valve stem facing inward.

Snug the wheel up against the

washer. Now slide on as many 1"

X 2" flat washers as will fit be

tween the wheel and the snap ring

groove on the axle shaft. You

must minimize the amount of

wheel end play by adding as many

washers as will fit. Then install a

1" retaining ring in the axle shaft

snap ring groove using the snap

ring pliers. See Figure 2-4.

5. Tap on a short hub cap. Repeat

this rear wheel installation proce

dure (steps 1-5) when the other

side of the tractor is propped up.

stall one of the front wheels as fol

lows:

6. Slide a small front wheel on the

front axle with the valve stem fac

ing inward. (Lubricate the axle

with grease prior to installing the

wheel.)

7. Slide one (or two) 3/4" x 1-3/8"

flat washers up against the wheel.

Add a second washer to remove

any wheel end play. Install a 3/4"

retaining ring in the axle shaft

groove with the snap ring pliers.

8. Tap on one of the long hub caps.

9. Now remove the props from this

side. Chock the wheels to prevent

the tractor from rolling. Then prop

up the other side of the tractor.

Repeat the rear wheel and front

wheel installation steps as above.

Refer to Figure 2-4.

WARNING

it is essentiai that the assembiy steps be foiiowed accu

rately and completely. Failure

to comply can result in a haz

ardous operating condition

which could lead to serious

personal injury or property

damage. Please read and fol

low these assembly and prepa

ration instructions.

Now go to the front axle to in

Figure 2-4. Prop tractor up to mount wheels. Install rear (“A ”) and front

(“B”) wheels on one side of tractor first, then the other side. Use washers

(“C”) as shims to take the free play out of the wheels before the retaining

rings (“D”) are installed.

11

Page 12

WARNING

It is essential that the assem

bly steps be followed accu

rately and completely. Failure

to comply can result in a haz

ardous operating condition

which could lead to serious

personal injury or property

damage. Please read and fol

low these assembly and prepa

ration instructions.

Step 5: Install Steering Wheel

You will need the steering

wheel and the roll pin. Tools

needed are a hammer and a long

flat punch. (NOTE: The roll pin

may already be started in the steer

ing wheel hub.)

1. Remove tape from steering col

umn, lubricate the column with

grease, then place the steering

wheel (roll pin may already be

partially in the hole in the side of

the steering wheel hub) down on

the steering column.

Step 6: Install Tractor Seat

The seat must be attached using

the hardware that comes already

mounted on the seat bottom.

Remove this hardware from the

seat first. You should then have

the following loose hardware: 2

knobs and the 2 flat washers mated

with the knobs; 2 screws, 2 steel

washers, 2 nylon washers, and 2

wave washers.

1. Attach the electrical connector

at the bottom of the seat to the

wire harness connector coming out

of the middle of the rear fender as

sembly. See Figure 2-7. These

two connectors must be securely

plugged together for safety rea

sons— they allow the automatic

engine shutoff feature to work if

you leave the operator’s seat with

out turning off the engine or en

gaging the parking brake. The

wire harness must also move

freely when the seat is moved for

ward or backward.

2. Place the seat on the seat sup

port. Very loosely secure the rear

of the seat to the seat support with

the two knobs and the two flat

washers that accompanied them.

Refer to Figure 2-6.

3. At the front of the seat, slide a

metal washer between the seat and

the seat support (see Fig.’ 2-6).

Next slide a wave washer and then

a nylon washer on each of the two

screws and insert the screws from

underneath the seat support. The

screws must pass up through the

seat support, the metal washer and

the seat frame. See Figure 2-6.

Securely tighten the screws.

4. If the seat is propped up, lower

it. Adjust the seat forward and

backward until comfortable for

you. Tighten the two knobs at the

rear of the seat.

Figure 2-5: Slide the steering wheel

over the steering column. Align the

holes and tap the roll pin through

the holes to secure the wheel.

2. Turn the wheel slowly until the

holes in the wheel hub are aligned

with the holes in the steering col

umn. See Figure 2-5. When

aligned, tap the roll pin through

the hub and the column. Use the

punch to tap the roll pin in until it

is flush with the hub.

Figure 2-6: Remove hardware from seat first. Place seat on seat support.

Mount knobs and washers at rear. Mount screws and washers at front.

Figure 2-7:

Connect the

wire coming

up from the

fender to the

electrical

switch under

neath the seat.

Page 13

Assemblf

DANGER

• Battery electrolyte solution

contains sulfuric acid which

can burn your skin, eyes and

clothes.

• Wear protective ciothing,

rubber gloves and shield eyes

with safety goggles when you

work near battery.

• Keep sparks, flame and all

smokers’ materials away.

• Ventilate area when charg

ing battery in an enclosed

space.

• The venting path of the bat

tery must always be open.

Step 7: Remove Tractor Battery For Servicing, Then Reinstall

If your battery has not been

dealer serviced or charged, it will

be necessary to remove the battery

from the tractor, activate it with

electrolyte solution and charge it

correctly, then reinstall the battery.

We urge you, however, to have a

professional battery technician

do this job for you if you are not

experienced in doing this work.

Tools Required: one 7/16"

wrench; one 3/8" wrench; two

quarts of battery-grade electrolyte

solution; battery charger; flash

light; safety glasses and gloves;

baking soda.

Remove Battery from Tractor:

1. Unlatch the two black, rubber

hold-down straps securing the rear

of the tractor hood. One strap is

located on each side of the trac

tor’s control panel. Tip the hood

upward and forward.

2. The battery is located at the

back of the engine compartment.

Use a 7/16" wrench to remove the

two nuts securing the hold-down

bracket over the battery. Put the

hold-down bracket aside along

with its hardware. See Figure 2-8.

3. If connected, use a 3/8" wrench

to disconnect the black battery

cable from the negative (-) battery

terminal. Bend the cable away.

4. Discoimect the red battery cable

from the positive (-I-) battery termi

nal. Use a 3/8" wrench.

5. Remove battery from tractor.

Take the battery to a qualified ser

vice technician, or place it on a

wood or plastic surface to service

the battery.

To Activate the Battery;

6. Make sure all switches are in the

‘Off’ position (on battery charger).

Before opening the electrolyte,

read instructions on its container.

Also read operating instructions

for the battery Charger.

7. Put on safety goggles and rub

ber gloves. Remove filler caps

from top of battery. Fill battery

cells to proper level with elec

trolyte. LET BATTERY SIT FOR

20 MINUTES BEFORE CON

TINUING.

To Charge the Battery:

8. With filler caps removed, con

nect battery to charger and charge

at 2 Amperes until specific gravity

reading is 1.265-to-1.275. This

may take several hours. When

charged, the electrolyte in the cells

will be gassing freely—^the surface

will be bubbling. Wearing your

safety goggles, examine the cells

with your flashlight. Turn the

charger OFF. Disconnect it from

the battery.

9. If electrolyte level has fallen, re

fill cells to proper level with dis

tilled water only.

10. Reinstall the battery caps.

Wash any acid spillage off the bat

tery with water and baking soda.

Reinstall Battery

11. If the ignition key is in the

keyswitch, remove the key.

12. Place the battery back on the

tractor battery support—the posi

tive terminal must be on the lefthand side as viewed from the oper

ator’s position.

13. Reconnect red positive cable to

the positive battery terminal.

Securely attach with the original

screw and nut.

14. Reconnect black negative

cable to negative battery terminal.

15. Re-attach the hold-down

bracket over the battery.

Figure 2-8: Remove battery hold

down bracket so battery can be re

moved for servicing.

Figure 2-9: Fill cells with elec

trolyte solution, then charge battery

at 2 amperes until specific gravity

reads between 1.265 -1.275.

13

Page 14

step 8: Add Motor Oil to the Tractor Engine

1. The tractor must be on a level

surface.

2. Unhook the two rubber latches

securing the tractor hood. Lift the

tractor hood up.

3. Remove the engine oil dipstick

from the oil fill tube. The dipstick

is located near the top of the en

gine (all engine makes are similar

in this regard — see your engine

manufacturer literature for spe

cifics regarding your engine).

Refer to Figure 2-10. Place a clean

oil funnel into the oil fill tube.

4. Refer to the Engine Owner’s

Manual for all-important informa

tion about motor oil type, viscos

ity, and quantity of motor oil re

quired. Be certain to follow the

engine manufacturer’s literature

so you do not risk having your

engine warranty coverage voided

due to using incorrect motor oil.

5. Very slowly add oil to the en

gine through the oil fill tube.

Check the level frequently as you

add oil. Replace the oil dipstick

completely. Remove the dipstick

to check the level. Allow enough

time for the oil to settle. Oil

doesn’t flow quickly and may give

a false reading if checked too soon.

Figure 2-10: Remove dipstick at top

of engine to add motor oii. See en

gine manufacturer literature for im

portant motor oil specifications.

When the level is up to the full

mark on the dipstick, replace the

dipstick securely for the last time.

Step 9: PTO Attachment Drive Clutch— Break-In Procedure

After you install either a mower

deck or a snowthrower attachment

to your tractor (by following sepa

rate installation instructions pro

vided with that attachment), you

will need to perform a simple, but

important, break-in procedure so

the PTO attachment clutch mecha

nism operates smoothly. Do the

following:

a. Adjust the attachment’s level

ing or lift (as applicable).

Step 10; Check Hydrostatic

Transmission Fluid Level

The tractor transmission is filled

at the factory with transmission

fluid. Please re-check the fluid

level before using your tractor.

1. Roll the tractor to level ground

(please see “Free-Wheeling” on

next page before proceeding).

2. Look beneath the left-hand rear

fender to see the white opaque

reservoir for the transmission fluid.

Fluid level must be up to the “Full

Cold” line. If not, add the correct

amount of SAE 20W20 transmis

b. Start the tractor engine.

Allow it to warm up and run at the

idle speed.

c. Engage and disengage the

tractor’s PTO Attachment Drive

Switch 10 or 15 times. Refer to

Figure 2-11. Be certain the attach

ment is neither cutting grass nor

blowing snow while you perform

this break-in procedure.

sion fluid to the reservoir per Step

3 next.

3. From under the rear fender, push

the black plastic plug upward until

it pops out of the fender.

Unscrew the cover from the top

of the reservoir. See Figure 2-12.

Insert a clean funnel down through

the fender hole and into the reser

voir. Slowly add the correct

amount of transmission fluid (up to

“Full Cold” line).

4. Reinstall the reservoir cover.

Last, push the black plastic plug

back into the hole in the fender.

Figure 2-11: After an attachment is

installed, turn the PTO Attachment

Drive Switch ON and OFF about a

dozen times to complete the “breakin” procedure.

Figure 2-12: Check transmission

fluid level in reservoir under fender.

Add SAE 20W20 oil to reservoir if

needed. Remove plastic plug in

fender for access to reservoir.

14

Page 15

‘Free-Wheeling’ Your Tractor

When your tractor must be

moved without the engine running,

be sure to first push UP the Lock

Lever underneath the transmission

housing (see Figure 2-13, “A”).

This disengages the transmis

sion and allows the tractor to be

‘free-wheeled’ easily to another lo

cation. Remember to re-engage

the Lock Lever by pulling it

DOWN after you’ve rolled the

tractor to its new location.

Figure 2-13: To free-wheel tractor,

locate the Lock Lever (“A”) under

the transmission and move it UP.

Final Assembly Review

Please take the time to make

sure you performed all the assem

bly steps as described. The perfor

mance of your tractor, not to men

tion your personal safety, are good

reasons to do so.

Check all electrical connections.

Is the spark plug wire(s) on the en

gine securely attached (raise the

hood to verify)? Go around your

tractor and be sure hardware is se

curely tightened. Does the steering

wheel turn the wheels positively

from left to right and back? Is the

seat hardware secure? Inspect

your tractor carefully and com

pletely. If you are unsure of any

thing, please contact your

Authorized Dealer before you start

and operate your tractor.

15

Page 16

Sectio

I

"

Figure 3-1

IDENTtFICATION AND FUNC

TIONS OF CONTROLS AND

FEATURES

Prior to the actual operation of

your tractor, it is very important

that you know where all the con

trols are and what they do. The

major operating controls and their

functions are described here.

12 13 14

1. Engine Choke Lever

Located on the left-hand side of

the instrument panel. When

moved upward to the “ON” posi

tion, helps to start a cold engine.

Move to “ON” before starting.

Once engine starts, move slowly

downward to “OFF” position.

Choke may not be needed to start a

warm engine.

16

2. Engine Throttle Lever

Located on the right-hand side

of the instrument panel. Provides

infinite engine speed selection

from “Slow” to “Fast.” Prior to

starting the engine, move lever

three-quarters of the way to “Fast.”

Always move it fully to “Fast”

position when operating attach

ments.

Page 17

Controls

WARNING

Before operating your tractor,

be sure you read and under

stand all safety, controls, and

operation instructions in this

Owner/Operator Manual and

on the decals on your tractor.

Failure to follow these in

structions can result in seri

ous personal injury or prop

erty damage.

3. ignition Keyswitch

Located on the right-hand side

of the instrument panel. Accepts

your ignition key which is used to

start the engine. The keyswitch

has three key positions— “OFF”,

“RUN”, and “START.” When the

key is turned to the “Off ’ position,

the engine will be shut off. Turn

the key to “Start” to start the en

gine. Release the key after starting

and it will move automatically to

the “Run” position.

4. Brake Pedal

Located near the operator’s left

foot when the operator is seated in

the tractor seat. This pedal is used

to stop the tractor. When fully de

pressed, it also allows the parking

brake knob to be engaged.

tractor to go in forward or reverse

direction when pressed down.

Press the top of the pedal to go for

ward. Press the bottom of the

pedal to go in reverse. Remove

your foot from the pedal for neu

tral position.

7. Light Switch

This rocker switch is on the lefthand side of the instrument panel.

It controls the headlights at the

front of the tractor. It has “On”

and “Off’ positions.

8. PTO Attachment Drive Switch

Located on the right-hand side of

the instrument panel. It electrically

engages and disengages power to

your attachments. It has two posi

tions-“On” and “Off.” Always

move this switch to Off before leav

ing the operator’s seat. If you leave

the seat while the switch is “On”,

the engine will stop automatically.

If left in the “On” position, the en

gine will not restart.

9. Attachment Lift Lever

The long lever located alongside

the operator’s right leg. To raise an

attachment, pull the lever back to

the rear; lower the attachment by

pushing the lever forward.

12. PTO Indicator Light

Located on the bottom of the in

strument panel. Lights up when the

PTO Attachment Drive Switch is

moved to “On.”

13. Voltage Indicator Light (Optional)

Located on the bottom of the in

strument panel. This light comes

on if the battery voltage is low.

Identify the electrical problem be

fore using your tractor further.

Available only on certain models.

14. Safety Start Switch Indicator Light

Located on the bottom of the in

strument panel. This light comes

on to indicate that the safety inter

lock switches are not properly acti

vated to start the engine.

15. Steering Wheel

The steering wheel controls a

helical gear and sector steering de

sign. The turning radius is 22".

16. Fuel Cap and Gauge

The fuel tank is located at the

rear of the tractor. Its fuel cap

(with built-in gauge) is mounted

on top of the tank.

5. Parking Brake

Near the operator’s left foot, the

Parking Brake knob should be en

gaged before you leave the tractor.

To engage it, push Brake Pedal

down fully, then lift the knob

which will latch the pedal in the

“park” position. To release the

Parking Brake, push the Brake

Pedal down again.

6. Travel Pedal

Positioned to the right of the op

erator’s seat, this pedal allows the

10. Hour Meter (Optional)

A graphic display, in the pod on

the left-hand side of the instrument

panel, that registers hours of tractor

use. Optional on some models,

standard on other models.

11. Electric Lift Switch (Optional)

If ordered as an optional kit on

your tractor, this rocker switch is lo

cated on the right side of the instru

ment panel and electrically controls

the raising and lowering of attach

ments. It is used instead of the

Attachment Lift Lever (#9).

17

17. Cruise Switch (Optional)

Located on left-hand side of in

strument panel. Activates cruise

control feature. To deactivate

cruise control, either move switch

to off or press down on Brake

Pedal. Available on 14HP and

16HP models.

18. Cruise Indicator Light (Opt.)

Lights up when cruise control

feature is activated. Available on

14HP and 16HP models.

Page 18

Section

Brake Pedal

Choke Lever / //) Fuel

Cap

Steering Wheel

Throttle Lever

Light

Switch

Cruise Control

Switch (Optional)

Figure 4-1

WARNING

Before operating your tractor,

be sure you read and under

stand all safety, controls, and

operation instructions in this

Owner/Operator Manual and

on the decals on your tractor.

Failure to follow these in

structions can result in seri

ous personal injury or prop

erty damage.

Hour Meter (Optional)

Choke ■ FTO Indicator volt Light

Leygj Light ^ Light Indicator Light Lever

PRE-STARTING

Keyswitch

Any leaks must be attended to be

fore starting your equipment. See

INSTRUCTIONS

Please read and carry out the

following pre-starting instructions

and procedures before starting the

tractor engine and using your

your Authorized Dealer for assis

tance if needed.

3. Check the battery electrolyte

level. Fill any cells that are below

the full mark with distilled water.

equipment.

4. Fill the fuel tank with fresh,

1. Be sure the engine has been

filled with the proper type and

amount of motor oil. Check the

oil level by removing the engine

dipstick on top of the engine (see

Assembly Step 8 in Section 2).

2. Check for any oil or fluid leaks

clean unleaded gasoline. Automotive-grade Unleaded Regular

gasoline with an octane rating of

87 minimum is highly recom

mended. Clean up any spills. DO

NOT MIX MOTOR OIL WITH

THE GASOLINE!

on the tractor or on the ground.

18

Electric Lift

(Optional)

Page 19

Operation

5. Adjust the operator’s seat to the

position most suitable for you. To

move the seat forward or back

ward, loosen the two knobs under

neath the seat at the rear, slide the

seat ahead or back, and securely

retighten the two knobs.

Figure 4-2: Be sure the seat is ad

justed so you can reach aii controis

quickiy and convenientiy.

ENGINE OPERATION INSTRUCTIONS

To Start the Engine:

1. Take your position in the opera

tor’s seat. Have the ignition key

ready to install.

2. Move the PTO Attachment

Drive Switch to “Off’ if not al

ready in the Off position.

3. Engage the Parking Brake if not

already engaged. To do so, de

press the Brake Pedal fully, and lift

up the Parking Brake knob. This

locks the Brake Pedal down, ap

plying the brakes. The tractor can

not roll now.

4. Keep your foot away from the

Travel Pedal so the tractor remains

in Neutral.

5. Move the Attachment Lift Lever

forward to lower the attachment to

the ground.

6. Insert the key into the ignition

keyswitch.

7. Move the Engine Choke Lever

all the way up to “On” position.

6. The attachment you will be

using (mower deck, snowthrower,

etc.) must be properly and securely

attached according to the separate

instructions provided with that at

tachment.

7. Move the Attachment Lift Lever

forward and backward to lower

and raise the attachment. Verify

that it’s working properly.

8. Check the operation of the

Parking Brake. Do so by depress

ing the Brake Pedal and lifting the

Parking Brake knob— this locks

the Brake Pedal down. To release

the Parking Brake, step down on

the Brake Pedal.

Note: Always engage the

Parking Brake before you leave

8. Move the Engine Throttle Lever

about three-quarters of the way to

ward the “Fast” position. This po

sition is for starting only.

Important-You will be starting

the engine next. The electrical

starter wilt operate only if the

PTO Attachment Drive Switch is

“OIT”, the Brake Pedal is de

pressed (with Parking Brake

preferably engaged), and the op

erator is fully seated.

9. To start the engine, turn the igni

tion key to the right to the “Start”

position. Release key when the

engine starts.

Important- In case of a “false

start” (where engine attains

enough speed to disengage the

starter, then fails to keep run

ning), allow engine to stop com

pletely before another starting

attempt is made. Failure to com

ply can damage the starting

mechanism and the engine.

Limit continuous cranking to 30

seconds maximum to avoid over

heating the starter and causing

starter damage.

10. Slowly move Engine Choke

Lever down to “Off’ and let en

the tractor or before starting the

engine.

9. Clear the area in which you will

be working of any debris. Remove

branches, rocks, cans, bottles and

any other foreign objects which

could be picked up and thrown by

rotating blades or other moving

parts on your tractor.

10. Check to see that the air

cleaner element and the entire en

gine compartment are free of any

debris.

gine warm up for a minute or so.

In normal operation, it must be in

the “Off’ position.

II. Move the Engine Throttle

Lever to the “Fast” position.

Engine is designed to operate most

efficiently at “Fast” throttle.

You are now ready to operate

the tractor and any attachment you

may have mounted. If you wish to

stop the engine and leave the trac

tor at anytime, do as follows:

To Stop the Engine:

1. Be sure the PTO Attachment

Drive Switch is “Off.”

2. Depress the Brake Pedal and

move the Parking Brake Knob up

to engage the Parking Brake.

3. Move Engine Throttle Lever to

“Slow” so engine is idling.

4. Turn ignition key to “Off.”

Remove the ignition key.

See “Tractor Operation” instruc

tions next to operate the tractor.

19

Page 20

TRACTOR OPERATION

To operate your tractor, first

start the tractor engine using the

engine starting instructions (steps

1 through 11) given previously.

Remember- the starter motor will

not turn the engine over unless the

PTO Attachment Drive Switch is

“Off’, the Brake Pedal is de

pressed, and the operator is in the

operator’s seat.

A

WARNING

Do not permit any person

other than the operator to

ride on the tractor.

Do not drive close to edges of

banks which could collapse

under the tractor’s weight.

While turning, reduce your

operating speed.

Failure to comply could result

in serious personal injury.

To Start the Tractor:

1, After starting, let the engine

warm up. Slowly move the Choke

Lever to “Off.” Then move the

Engine Throttle Lever to “Fast.”

Figure 4-3: Depress Brake Pedal

(“B”) fully to disengage the parking

brake (“C”).

Switch to “On” to power your at

tachment.

3. Release Parking Brake (“C”,

Fig. 4-3), by fully depressing the

Brake Pedal (“B”). Position both

hands securely on steering wheel.

4. Place your right foot on the

Travel Pedal. See Figure 4-4

below. The Travel Pedal provides

infinitely variable speed. To go

forward, slowly press the top of

the Travel Pedal down. To go in

reverse, press the bottom of the

Travel Pedal. Top speed in for

ward is 5.2 MPH (8.4 km/hr); in

reverse, top speed is 2.1 MPH (3.4

km/hr). Be very careful not to ex

ceed the speed at which you are in

total control of the tractor.

To Stop the Tractor:

1. Take your right foot off the

Travel Pedal and apply the brakes

with your left foot using the Brake

Pedal.

2. Move the PTO Attachment

Drive Switch to “Off.”

3. Engage the Parking Brake.

You may now leave the operator’s

seat temporarily, if desired, and the

engine will not shut off providing

the PTO Attachment switch is Off

and the Parking Brake is engaged.

Never leave the tractor unattended

while the engine is running. If you

are stopping work, also shut the

engine off and take the ignition

key with you.

IMPORTANT: When parked on

a hill, always engage the tractor

Parking Brake.

Note: Always operate unit at

Fast engine throttle setting

whenever using attachments.

2. Move the Attachment Lift Lever

forward to lower the attachment.

Move the PTO Attachment Drive

WHICH GROUND SPEED?

Knowing how quickly or slowly

you should travel on your tractor

has much to do with your specific

job site and the nature of the job it

self, as well as your own experi

ence, but here are some very gen

eral guidelines that you may find

helpful.

Figure 4-4: The Travel Pedal pro

vides infinitely variable forward and

reverse tractor speeds.

Ground Speed Guidelines

Slow

Slow/Moderate

Moderate

Moderate/Quick

Going up or down moderate hills, traveling on slippery

surfaces, high grass, deep snow, towing heavier loads,

moving out of storage site, maneuvering in tight areas.

Level terrain to mild slopes, normal grass and snow

depths, towing light loads.

Level terrain, light mowing and snowthrowing.

Travel on level terrain from storage site to work loca

tions.

20

Page 21

GENERAL OPERATING TIPS AND TECHNIQUES FOR LAWN MOWING

Figure 4-5:

Your tractor excels at lawn

care maintenance. For best

results, cut no more than

one-third (1/3) the height of

the grass at a time. Proceed

at a moderate speed. Set en

gine throttle to “Fast. ”

Always be alert for the pres

ence of children and small

animals, changes in terrain,

foreign objects, and slippery

surfaces. You have a power

ful piece of outdoor equip

ment at your command—

please operate it with safety

foremost in mind.

Regardless of the engine

horsepower rating of your trac

tor or the width of the mower

deck attached to the tractor,

there are some general mowing

procedures and guidelines you’ll

want to practice so you obtain

the best mowing results and the

best performance from your

equipment. Please be sure to read

the specific mower deck operating

instructions in your Attachment

Owner!Operator Manual.

• It is always preferable to mow

a lawn in natural daylight. If

you need to mow in the

evening, be sure the area is

very well lighted and level.

• Only engage the PTO

Attachment Drive Switch

under a no-load condition.

For example, on previously

cut grass it is OK to lower the

mower deck, then to engage

the PTO Switch. But in high

grass, engage the PTO

Switch first, then lower the

deck.

• As a general rule, do not oper

ate your tractor across the

face of a slope. There is too

much risk of the equipment

tipping over and seriously in

juring the operator.

• On sloped terrain, always

travel up and down the slope.

Do not attempt to go on

slopes that have an incline

steeper than 15°. See Figure

4-6 for reference.

' Mowing the grass when it is

dry is far preferable to mow

ing it when wet or damp.

The quality of the job will be

superior and your equipment

will not have to work as hard.

Traction will also be better.

I If the grass is high, make two

separate passes at gradually

lower cutting heights to cut it

to the correct final height.

This will put less stress on

both the grass and your

equipment.

Page 22

Operation

GENERAL TECHNIQUES FOR SNOW THROWING

Figure 4-7: There are

Two-Stage and Single-

Stage Snow Thrower

models- your particu

lar tractor model will de

termine which snow

throwers you will be

able to choose from.

See your Authorized

Dealer for complete

product specifications

and recommendations.

...

By purchasing an optional

snow thrower attachment for

your tractor, you expand the

property-management capability

of your equipment substantially.

Please be sure to read the as

sembly, operating and safety in

structions for the specific snow

thrower model you purchase in

that attachment’s Owner /

Operator Manual.

WARNING

Before operating your tractor

with an attachment, be sure

you read and understand ail

safety, controls, and opera

tion instructions in this Owner

/Operator Manuai and in the

Attachment Manual.

Failure to follow these in

structions can result in seri

ous personal injury or prop

erty damage.

Each property is unique, but

here are some general tips to make

snow throwing more effective.

• If possible, perform snow

throwing operations during

the daylight hours for maxi

mum visibility.

• In deep snow, it is recom

mended that you reduce the

width of the cuts to lessen the

strain on the equipment.

• Under normal snow condi

tions, keep the Engine

Throttle Lever at “Fast” posi

tion and proceed at a suitable

ground speed.

• When blowing light snow or

cleaning up scattered patches,

set the tractor at a higher

ground speed to maintain a

stream of snow coming out

of the chute.

• Check wind direction. For

maximum performance,

throw the snow in the direc

tion in which the wind blows.

With the wind blowing

across the area to be cleared,

begin on the windward side

and cast snow downwind.

• When turning around, turn

with the wind. Adjust the

chute as you turn to keep the

discharge downwind.

• Before putting the snow

thrower away, clean all the

excess snow and slush off the

unit to prevent the controls

and chute from freezing.

22

Page 23

Section

MAINTENANCE

There are several maintenance

procedures which you as the

owner can confidently perform to

keep your tractor in good operat

ing condition. Changing the motor

oil and the oil filter (if equipped

with one), are very important. As

is servicing the air cleaner. You

can do other checks and adjust

ments as well.

Major service procedures such

as engine and transmission repairs,

bearing replacement and other

moderate to heavy-duty jobs

should probably best be done by

your Authorized Dealer or, in the

case of the engine, by the engine

manufacturer’s local representative.

There is a Troubleshooting

Chart and a Maintenance Chart in

this section which you should refer

to regularly. Please refer to the

Operator Manual supplied with an

Attachment should it need service.

WARNING

Before performing any main

tenance on the tractor or the

engine, the tractor must be

stopped, the PTO switch shut

Off, the Parking Brake en

gaged, the engine stopped

and the key removed, and the

spark plug wire must be dis

connected and kept away

from the plug. Always let en

gine and muffler cool down.

Failure to comply can result

in serious personal injury.

Engine Maintenance

Checking & Changing Motor Oil

It is vitally important to main

tain the correct motor oil level in

your engine in order to prevent

premature wear or failure. You

should check the oil level before

using your tractor every time. And

you should change your motor oil

(and oil filter if so equipped) per

the service information following.

Kohler 12.5HP/14HP Engines

Checking Oil Level: Refer to

Figure 5-1 for the Oil Dipstick/Oil

Fill Tube location. Simply unlatch

the tractor hood, and raise the

hood for access to the engine.

Unthread and remove the dipstick.

Wipe oil off. Reinsert dipstick and

rest it on the fill tube (do not re

thread). Remove dipstick and

check oil level. Add oil up to

“Full” mark if needed. Securely

re-install the dipstick.

Changing Oil: After the first 5

hours of operation on a new

Kohler engine, change the oil.

Thereafter, change the oil every

100 operating hours. Change the

oil filter every 200 operating

hours. Refer to Figure 5-2 for lo

cation of engine oil drain plug, oil

filter, and oil filter drain plug.

See your engine manufacturer

literature for complete motor oil

and oil filter changing instruc

tions and requirements.

23

Figure 5-1: Kohler 12.5 HP/ 14HP

erìgine Oil Fill Dipstick/OII Fill Tube.

Figure 5-2: The Kohler engine oil fil

ter (“A”) is a spin-off automotive

type. Note engine oil filter drain

plug (“B”) location. Oil crankcase

drain plug (“C”) is on opposite side.

Kohler Recommended Motor Oil

Viscosity Grades:

Use API Service Class SF oil.

High-quality detergent oil is recom

mended.

0° F to 100“F: SAE lOW-30, lOW-40.

-20“ F to 32“ F: SAE 5W-20, 5W-30.

Page 24

WARNING

Before performing any main

tenance on the tractor or the

engine, the tractor must be

stopped, the PTO switch shut

Off, the Parking Brake en

gaged, the engine stopped

and the key removed, and the

spark piug wire must be dis

connected and kept away

from the piug. Always let en

gine and muffler cool down.

Failure to comply can result

in serious personal injury or

property damage.

Briggs & Stratton 12HP , 14 HP,

and 16 HP Engines

Checking Oil Level: Refer to

Figures 5-3 and 5-4 for Oil Dip

stick / Oil Fill Tube locations on

the 12HP and 14HP/16HP Briggs

engines. The oil level should be

checked before every use.

oil every 50 operating hours, or

every 25 hours if used under heavy

loads or at high temperatures. The

spin-off automotive-type oil filter

needs changing every 100 hours of

operation. See Figure 5-6 for loca

tion of oil filter and oil drain plug.

To change the oil, use the same

procedure described previously

with the 12HP Briggs engine.

See your engine manufacturer

literature for complete motor oil

and oil filter changing instruc

tions and requirements.

Briggs & Stratton Recommended

Motor Oil Viscosity Grades:

Use API Service Class SE,SF, or

SG oil. High quality detergent oil

is recommended. No special addi

tives should be used. DO NOT

MIX OIL WITH GASOLINE.

40°F to 100° F: SAE 30 weight oil.

0° F to 40° F: SAE 5W-30 or

SAE lOW-30; or synthetic 5W-

20 or 5W-30.

-20° F to 40° F: synthetic 5W-20 or

5W-30.

To check properly—Place en

gine so it is level. Unscrew the

dipstick and wipe it clean. Screw

the dipstick firmly back into place.

Remove it again to check the level.

Add oil as necessary to bring it up

to the “Full” mark on the dipstick.

Changing OU-12HP Briggs:

Change oil after the first 5 hours of

operation. Thereafter, change oil

every 50 hours, or every 25 hours

if operated under heavy load or in

high temperatures. This engine

does not have a removable oil fil

ter. See Figure 5-5 for oil drain

plug location at bottom of engine.

Remove the drain plug. Drain oil

while it is still warm to promote

more complete drainage. Securely

replace drain plug, then add fresh

motor oil through oil fill tube at

top of engine. Fill to “Full” mark

on the dipstick.

Changing Oil-14HP And

16HP Briggs Engines:

Change oil after the first 8 hours of

operation. Thereafter, change the

Figure 5-3: Briggs 12 HP engine Oii

Fiii Dipstick/ Oii Fiii Tube (“A”).

Figure 5-4: Briggs 14 HP/ 16HPen

gines—iocation of Oii Fiii Dipstick/

Oil Fiii Tube.

Figure 5-5: Briggs 12 HP engine—

removai of oii drain piug is shown.

Figure 5-6: Briggs 14 HP/ 16HP en

gines. Spin-off oii filter (“A”) and

oil drain plug (“B”) are shown.

24

Page 25

Fuel Filter Service

Your engine may be equipped

with an in-line fuel filter placed in

the fuel line between the gas tank

and the carburetor. Visually in

spect the fuel filter periodically

(every 100 hours or once a year)

and replace when dirty. The filter

is a throw-away type.

Carburetor

The carburetor is adjusted at the

factory and should not have to be

readjusted. If any black exhaust is

noticed, check the air cleaner com

ponents first. An overly “rich”

mixture is usually caused by a

poorly serviced, clogged air

cleaner element, not by an improp

erly adjusted carburetor.

Clean the Air Cooling System

Grass, chaff, and dirt may clog

the rotating screen in the blower

housing, and work underneath the

blower housing, especially after

prolonged service cutting dry

grasses. It is recommended that

the screen (see Figure 5-7) be

cleaned off regularly, and the

blower housing be removed every

100 operating hours (or each sea

son) to clean out any debris that

has collected around the cooling

fins and flywheel. Your engine is

air cooled only, so keeping it free

of debris allows it to run at lower

temperatures.

ignition System

Your engine has a dependable,

electronic ignition system.

Beyond periodically checking/replacing the spark plug, there are

no other maintenance, timing or

other types of adjustments needed.

Spark Plug

Every 100 hours of operation,

remove the spark plug, check its

condition, and either reset the gap

WARNING

Before performing any main

tenance on the tractor or the

engine, the tractor must be

stopped, the PTO switch shut

Off, the Parking Brake en

gaged, the engine stopped

and the key removed, and the

spark plug wire must be dis

connected and kept away

from the plug. Always let en

gine and muffler cool down.

Failure to comply can result

in serious personal injury or

property damage.

Figure 5-7: The rotating screen on

top of your engine must be kept

free of ait debris. Ctean it off regu-

tariy so the engine runs cooter.

or replace the plug as necessary.

See your engine manufacturer

literature for spark plug gap set

tings and recommended spark

plugs. Good operating conditions

are present when the plug has a

light coating of a gray or tan de

posit. A black coating may indi

cate an over-rich fuel mixture

(caused by either a clogged air

cleaner or improper carburetor ad

justment.) A badly worn plug

should be replaced with a new one.

NOTE: Do Not Sandblast Spark

Plugs to clean them. Remaining

grit on the plug could enter the

engine causing extensive wear

and damage.

Battery Care

When servicing the battery, be

sure the battery cables are discon

nected before you remove the bat

tery from the tractor. Always dis

connect the negative (-) cable first.

When installing the battery, always

check the polarity of the battery

terminals to be sure you will be

connecting the positive cable to

the positive terminal, and the nega

tive cable to the negative terminal.

Apply a light coating of

petroleum jelly or oil to the inside

of the clamp terminals and over

the bolt studs before connecting

the cables. Always re-connect the

negative cable last.

WARNING

Electric storage batteries

give off highly flammable gas

while charging, and continue

to do so for some time after

receiving a steady charge.

Do not permit any electric

spark or an open flame near

the battery. Do not set tools

across the battery terminals

as this may result in a spark

or short circuit and cause an

explosion. Be very careful to

avoid contact with battery

electrolyte—it can burn skin

and clothing.

Diode Rectifier or Voltage Regulator

The 12HP Briggs engine has a

diode assembly in the wiring har

ness at the dash console. The

diode changes alternating current

(AC) from the alternator to direct

current (DC ) to charge the battery.

See the wiring diagram in the Parts