Page 1

0 TRtlV:BILT_

OWNER'SMANUAL

Tiller/Edger

• Safety

• Assembly

• Features and Controls

• Operation

• Maintenance

• Parts List

Model

12216

Serial Numbers:

122161100101-122161199999

GARDEN WAY INCORPORATED

Page 2

DearOwner:

Congratulationson your purchaseof a Tiller/Edgerwith

EdgerAttachment. It has beendesigned, engineeredand

manufactured to giveyou the best possible dependabilityand

performance.

Pleasecarefully readthis Manualwhich provides information

on howto safelyandeasily set-up, operateandmaintain your

machine. Besure thatyou and any other operatorscarefully

follow the recommended safety practices at all times. Failure

todo so could result in personal injury or property damage.

If you should everhaveanyproblems or questions, please

contact your local authorized servicedealer or call the Factory.

Seethe backcover of this Manualfor Customer Serviceinfor-

mation.

Wewant to be surethat you arecompletely satisfied at all

times.

See Back Cover for

Customer Service Information

SafetyAlert Symbol

_ his is a safety alertsymbol. It is used in this

sagescould result in personalinjury or propertydamage.

manualand on the unit to alert you to potential haz-

ards. When you seethis symbol, readand obeythe

messagethat follows it. Failureto obeysafety mes-

Table of Contents

SECTION1: SAFETY........................................... 3

Training......................................................................... 3

Preparation................................................................... 3

Operation...................................................................... 4

Maintenance/Storage.................................................... 4

SECTION2: ASSEMBLY........................................ 5

UnpackingInstructions ............................................... 5

Assembly Steps.......................................................... 5

SECTION3: FEATURESANDCONTROLS..................... 6

SECTION4: OPERATION...................................... 7

Pre-start Preparation.................................................. 7

Stopping and Starting the Engine............................... 7

Tilling and Cultivating ................................................. 8

Installing and Using the EdgerAttachment ................. 9

Attachments ............................................................... 9

SECTION5: MAINTENANCE.................................. 10

RequiredMaintenanceSchedule ................................ 10

EquipmentMaintenance............................................. 10

EngineMaintenance................................................... 11

TineRemovaland Installation..................................... 11

Storage....................................................................... 12

Troubleshooting.......................................................... 12

PARTSLIST ..................................................... 13

Safetyand Operating Decals....................................... 15

CUSTOMERSERVICEINFORMATION.............. BACKCOVER

This machine meets voluntary safety standard

B71.8 - 1996, which is sponsored by the Outdoor

Power Equipment Institute, Inc., and is published by

the American National Standards Institute.

WARNING

The engine exhaust from this productcontains chemi-

cals known to the State of California to cause cancer,

birth defects or other reproductive harm.

2

TOAVOIDINJURY:

• READTHEOPERATOR'SMANUAL.

• KNOWLOCATIONANDFUNCTIONOFALLCONTROLS.

• KEEPALL SAFETYDEVICESAND SHIELDS IN PLACEAND

WORKING,

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTO

OPERATEMACHINE.

• SHUT OFF ENGINEAND DISCONNECTSPARKPLUG WIRE

BEFORE MANUALLY UNCLOGGING TINES OR MAKING

REPAIRS,

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHEN REVERSINGOR PULLING

THEMACHINETOWARDSYOU.

Page 3

Safety

SPARKARRESTERWARNINGTO RESIDENTSOFCALIFORNIAAND SEVERALOTHERSTATES

UnderCalifornia law, and under the lawsof severalother states, you arenot permitted to operatean internalcombustion engine

using hydrocarbon fuels onanyforest, brush, hay,grain, or grass covered land;or land covered byanyflammable agricultural crop

without an enginespark arrester in continuous effectiveworking order.

Theengineon the unit isan internalcombustion enginewhich burns gasoline,a hydrocarbon fuel, and must be equippedwith a

spark arrester muffler in continuous effectiveworking order. The spark arrester must be attachedto the engineexhaustsystem in

such a mannerthat flames or heatfrom the system will not ignite flammable material. Failureof the owner/operator of the unit to

comply with this regulation is a misdemeanorunder California law (and other states)andmay also bea violation of other state

and/or federalregulations, laws, ordinances or codes. Contactyour local fire marshal or forest servicefor specific information

about which regulations apply in your area.

TRAINING

• Readthis Owner's Manualand the sep-

arateEngineOwner'sManualvery care-

fully beforeoperating this equipment. Be

completely familiar with the controls and

the proper useof the equipment. Know

how to stop the unit and disengagethe

controls quickly. A replacementManual

is availableby contacting your authorized

dealeror the Factory.

• Neverallow children or untrained

adults to usethis equipment. Let adults

operatethe unit only if instructed

properly.

• Keepthe areaof operationclearof all

persons, particularly small children and

pets. Keepbystanders at least25 feet

from the areaof operation.

• Keepin mind that the operator or user

is responsible for accidents or hazards

occurring to other people,their property

andthemselves.

• Familiarizeyourself with all of the

safety and operatingdecals on this equip-

ment and on anyof its attachments or

accessories.

• Do not run engine in an enclosedarea.

Engineexhaustcontains carbon

monoxide gas, a deadlypoison that is

odorless, colorless, and tasteless. Do not

operatethis equipmentnear buildings,

windows, or air conditioning equipment.

• Do not allow handsor anyother part of

the bodyor clothing nearthe rotating

tines or near any other moving part. The

tines begin to rotate forward oncethe

engine is startedand the Throttle/Tines

Control Leverissqueezed. Thetines con-

tinueto rotate until the operator releases

the Throttle/TinesControl Lever.

• Before inspectingor servicing any part

of the equipment, shut off engine,make

sure all moving parts havecome to a

completestop, then disconnect spark

plug wire from spark plug and move wire

awayfrom the plug.

• Do not operatethis equipmentifyou are

underthe influenceof alcohol,medication,

or whenyou aretired or ill.

PREPARATION

• Thoroughly inspectthe areawherethe

equipment is to beusedand remove all

foreign objects.

• Make sure that theThrottle/Tines Con-

trol Leveris disengagedand is in the neu-

tral position before you beginto start the

engine.

• Donot operate the machinewithout

wearingadequateouter garments. Avoid

loosegarments orjewelry that could get

caught in moving partsof the machine or

its engine.

• Donot operate the equipment when

barefoot or whenwearing sandals,

sneakers,or similar lightweight footwear.

Wearprotective footwear thatwill protect

your feet and improve footing on all

surfaces.

• Wearapprovedsafety glasses when op-

eratingthis equipment. The operationof

anypowered machinecan result in for-

eign objects beingthrown by high-speed

rotating parts.

• Donot till near underground electric

cables,telephone lines,pipes, or hoses.

If indoubt, contact your utility or tele-

phone company to locate underground

services.

• Handlefuel with care. Itis highly

flammable and has explosivevapors.

Takethese precautions:

a. Usean approvedfuel container.

b. Addfuel beforestarting the engine.

Neverremovethe cap of the fuel

tank or addfuel while the engineis

running orwhen the engine is hot.

Operatorsshall not smoke.

c. Keepmatches,cigarettes,cigars,

pipes, open flames, and sparks

awayfrom thefuel tank andfuel

container.

d. Fillfuel tank outdoors andwith ex-

treme caution. Neverfill fuel tank

when indoors. Usea funnel or

spout to prevent spillage.

e. Replaceall fuel tankand fuel con-

tainer caps securely.

f. If fuel is spilled, do not attempt to

start the engine, but move the ma-

chine awayfrom the areaof spillage

and avoid creatinganysource of ig-

nition until fuel vapors have

dissipated.

• Nevermake adjustmentsto your equip-

ment when the engine is running or spark

plug wire is connected(unless specifically

recommendedin Owner'sManual).

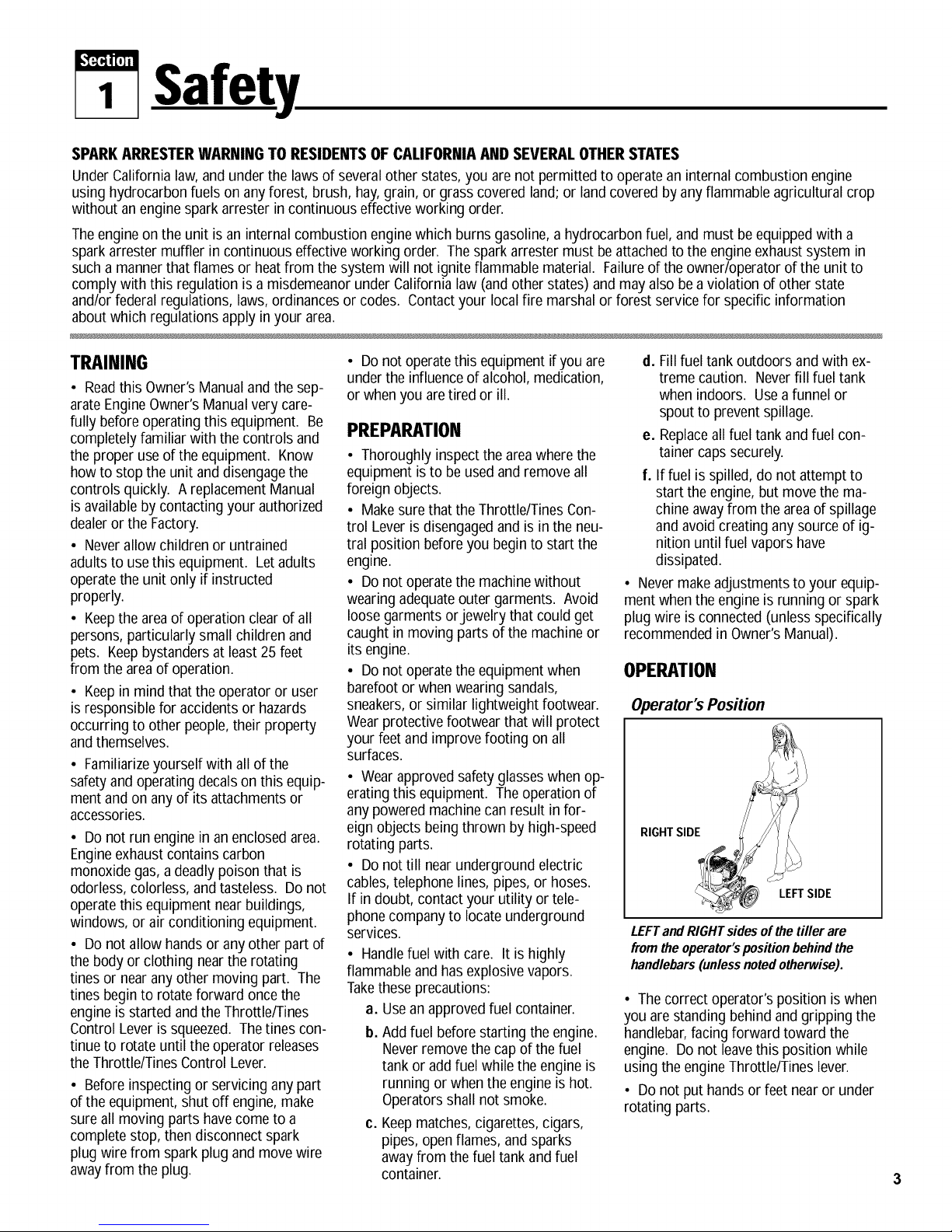

OPERATION

Operator's Position

RIGHTSIDE

LEFTSIDE

LEFTand RIGHTsidesof thetiller are

from the operator'spositionbehindthe

handlebars(unless notedotherwise).

• Thecorrect operator's position iswhen

you arestanding behind and gripping the

handlebar,facing forward toward the

engine. Donot leavethis position while

using the engineThrottle/Tines lever.

• Do not puthandsor feet nearor under

rotating parts.

Page 4

Section1: Safety

• Exerciseextreme caution when on or

crossing gravel drives, walks or roads.

Stay alert for hidden hazardsor traffic.

Do not carry passengers.

• After striking a foreign object,stop the

engine,let all moving parts come to a

completestop, disconnectthe spark plug

wire and prevent it from touching the

spark plug, then carefully inspectthe ma-

chinefor damage. Repairthe damage

beforerestarting andoperating the

machine.

• Exercisecaution to avoidslipping or

falling.

• If the machine should start to vibrate

abnormally,stop theengine. Disconnect

the spark plug wire and prevent it from

touching the plug. Checkimmediately for

the cause. Vibration is generallya

warning of trouble. Fixthe problem

beforeusing the equipment again.

• Stop the engine,disconnect the spark

plug wire and prevent it from touching the

spark plug wheneveryou leavethe equip-

ment, beforeunclogging the tines, or

when making anyrepairs, adjustments or

inspections.

• Takeall possibleprecautionswhen

leavingthe machine unattended. Always

stop the engine. Disconnect the spark

plug wire and prevent it from touching the

plug.

• Beforecleaning, repairing, or

inspecting, stop the engineand make

certain all moving parts have stopped.

Disconnectthe spark plug wire and

prevent it from touching the spark plugto

avoidaccidentalstarting.

• Neveroperateequipment without

proper guards, plates,or other protective

safety devices in place.

• Do not runthe engine inan enclosed

area. Theexhaustfumes from the engine

contain extremely dangerouscarbon

monoxide gas. Thisgas is colorless,

odorless,tastelessand deadlypoisonous.

• Keepchildren andpetsaway.

• Beawarethat theequipment mayunex-

pectedlybounce upwardorjump forward

if the tines should strike extremely hard

packedsoil, frozenground, or buried ob-

staclessuch as largestones, roots or

stumps. If you arein doubt about the

tilling conditions, always use the fol-

lowing operating precautions to assist

you in maintainingcontrol of the

equipment:

a. Standbehind the equipment, using

both handson the handlebars.

Relaxyour arms, but usea secure

hand grip.

b. Start tilling at shallowdepths,

working graduallydeeperwith each

pass.

c. Clearthe tilling areaof all large

stones, roots, andother debris.

d,

In an emergency,stop the tines by

releasingthe engineThrottle/Tines

leveron the handlebar. Tostop the

engine,movethe engineOn/Off

switch to OFE

• Donot overload the machine'scapacity

by attempting to till too deeplyattoo fast

a rate.

• Neveroperatethe equipment on slip-

pery surfaces. Look behind and use care

when backing up.

• Donot operate the equipment on a

slopethat is too steepfor safety. When

on slopes, slow down and makesure you

havegood footing.

• Neverallow bystandersnear the unit.

• Onlyuse attachmentsandaccessories

that arefactory-approved.

• Neveroperatethe equipment without

good visibility or good light.

• Neveroperatethe unit if you aretired,

or underthe influence of alcohol, drugs,

or medication.

• Donot tamper with the engine gov-

ernor settings on the machine;the gov-

ernor controls the maximum safeoper-

ating speedand protectsthe engine and

all other moving parts from damage

causedby engine overspeed. Authorized

serviceshall be sought if a problem

exists.

• Do not touch engineparts which may

be hot from operation. Allow partsto

cool before inspecting, cleaningor

repairing.

• Remember:you canstop the tines by

releasingthe engineThrottle/Tines lever.

Move the engineOn/Off switch to OFFto

shut the engineoff.

• Nevertransport this machinewhen the

engine is running.

• Terminalsand non-insulated electrical

parts shall beprotected against shorting

during normal servicing, refueling or

lubrication.

• Useextreme cautionwhen reversing or

pulling the machinetoward you.

• Start the enginecarefullyaccording to

instructions and with feet well awayfrom

thetines.

MAINTENANCE/STORAGE

• Keepthetiller, attachmentsand acces-

sories insafeworking condition.

• Checkall nuts, bolts, andscrews atfre-

quent intervalsfor proper tightnessto be

sureequipment is in safeworking

condition.

• Neverstore equipmentwith fuel infuel

tank inside abuilding wherefumes may

reachan open flame or spark(hot water

and spaceheaters,furnaces, clothes

dryers, stoves, electric motors, etc.).

• Allow the engineto cool beforestoring

theequipment.

• Keep the engine freeof grass, leaves,

or greaseto reducethe chanceof afire

hazard.

• Store gasolinein acool, well-ventilated

area,safely awayfrom anyspark- or

flame-producing equipment. Storegaso-

line inan approved container, safely away

from the reach of children.

• Neverperform maintenancewhen

engine is running or spark plugwire is

connectedunless instructed to do so.

• If fuel tank must be drained,do so out-

doors.

• Follow manufacturer's recommenda-

tions for safe loading, unloading, trans-

port and storage of machine.

4

Page 5

!,'£4"4!1T_

2 Assembly

Topreventpersonalinjuryor propertydamage, do notstart

the engine until all assembly stepsare completeand you

haveread andunderstandthe safetyand operatinginstruc-

tionsin this manual.

INTRODUCTION

Carefullyreadthese instructions in their entirety beforeyou

attempt to assembleor operateyour new equipment.

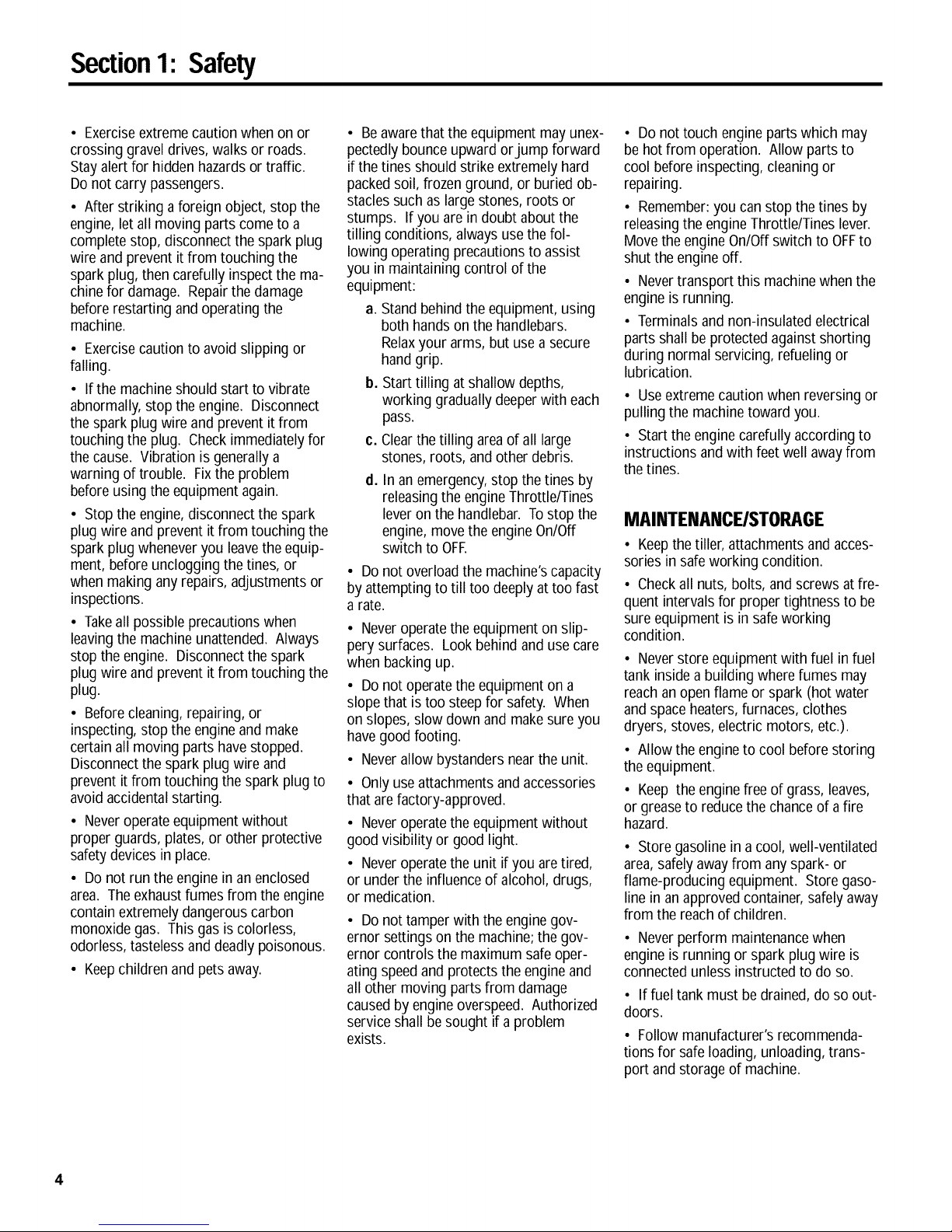

TheBorder EdgerAttachment (D, Figure1) doesnot needto

be installed until you are readyto do edging projects (referto

instructions in Section4).

UNPACKINGINSTRUCTIONS

1. Inspect your machine immediately. If you find or suspect

damageto the carton or contents,contact your localautho-

rizeddealeror the Factoryfor assistance.

2. Removeany packingmaterial. Checkfor loose parts

beforediscarding the packing material or carton. Loose parts

includethe following:

(1) Wheel(for edging)

(1) EdgerTine

(2) *Long Bushings

(1) *Short Bushing

*Packedin a separateplastic bag.

3. Perform the assemblyon a clean, levelsurface. Becareful

not to severely bend anyof the control cables on the unit.

STEP2: Inspect and Tighten Hardware

Checkall nuts, bolts andscrews on your unit andtighten as

needed.

ToolsNeededto Checkfor LooseHardware:

• Adjustable wrench

• Slotted-headscrewdriver

• Phillips-headscrewdriver

• 7/16"socket and extension

(to checkhardwareat ends of handlebar)

STEP3: Add Motor Oil to Engine

IMPORTANT:Theengine is shippedwithout oil inthe

crankcase. Donot start theengine without first adding motor

oil. Severeenginedamage will result if the engine is run

without motor oil.

1. Referto the separateEngineOwner'sManual for motor oil

specifications and capacities.

2. Add oil asdescribed in the EngineOwner's Manual(the

engine is a vertical type, GX31 model).

ASSEMBLYSTEPS

STEP 1: Unfold and AdJustHandlebars

IMPORTANT: Becareful not to pinch anycontrol cables.

Pushthe cablesout and awaybefore swivelingthe handle-

bars.

1. Loosenthe two handlebarknobs (A,Figure 1) and unfold

the handlebarsinto the operatingposition. Donot useforce

-- if there is binding, continue to loosenthe knobs.

2. Thereare two height setting holes in the upperhandlebar.

Theunit isshipped with the handlebar knobs in the lowest

height setting holes. Ifthis height is correct for you, simply

tighten the two handlebar knobs. Ifdesired, reposition the

handlebarknobs, mounting screws andwashersin the other

set of holes.

3. Checkthe six (6) plasticties (C, Figure 1). Ties must be

positioned as shown.

NOTE:Thereis only onehandlebarstorage position- folded

over anddown as originally shipped.

C

Figure 1

Page 6

I,'£4"41t_

3 FeaturesandControls

KNOW YOUR EQUIPMENT

READTHISOWNER'SMANUALANDALL SAFETYRULESBEFOREOPERATINGYOUREQUIPMENT.Knowthe location and function

of all features and controls on the equipment. Savethis manualfor future reference.

HandlebarHeightAdJustmentKnob(B, Figure2)

Twoheight settings, plus a storage position areavailable.

Before operating your machine, carefully read and under-

stand all safety, control, and operating instructionsin this

Manual, the separate Engine Owner's Manual and on the

decalson themachine.

Failure to follow theseinstructions can result inseriousper-

sonalinjury.

Referto Assembly Steps,STEP7in Section2 for adjustment

instructions.

TillingDepthAdjustmentKnob(C, Figure2)

Looseningthe knob enablesyou to move thewheelbracket (K)

up or down on the heightadjustment bar(L). Thiscontrols the

tilling depth.

IMPORTANT:Do not movethe wheel bracket any higherthan

thetop of the adjustment bar.

AdJustableTine Patterns(D, Figure2)

Thefour tine sections arearrangedfrom thefactory for max-

imum performance under a wide varietyof conditions. If

needed,the tinescan bearranged for narrowertilling or close

cultivating. Thetines canalso be arrangedto till verystony

soil. SeeAdjusting TinePositions in Section 4 for details.

CarryingHandle(E, Figure2)

j G

Whenthe handlebarisfolded in the storageposition the unit

canbe carried bythe carrying handle. Thecarrying handle

alsoserves asa tie-down anchor point.

EdgerAttachment (H, Figure2)

Usethis separateattachmentto createborders or edgesalong

walks,driveways,flower beds,etc. SeeSection 4 for details on

installing andusing this attachment.

Engine Controls

FuelPrimer Bulb(Section4, Figure4)

Usethe Fuel Primer Bulbto help start theengine under certain

conditions. SeeStoppingandStartingthe Enginein Section 4

and the EngineOwner'sManualfor details.

EngineChoke(Section4, Figure5)

Usethe EngineChoke leverto help start the engine. The posi-

tion of the lever is dependenton whetherthe engine is cold or

warm. SeeStoppingand Startingthe Enginein Section 4 and

the EngineOwner'sManualfor details.

EngineOn/OffSwitch (A, Figure2)

Usethe ON/OFFSwitchto start or stop theengine. SeeStop-

ping andStarting theEnginein Section 4 for details.

EngineRecoil Start Rope(F, Figure2)

Usethe recoil start ropeto start the engine. SeeStopping and

D

Starting theEngine in Section 4 for details.

Figure2: Featuresandcontrols.

Throttle/TinesControl Lever(G, Figure2)

Usethe Throttle/Tines Control Leverto start and stop tine rota-

tion. This leveralso varies tine speed. Releasethe leverto

stop all tine motion. SeeSection 4 for more detailson this

control.

Page 7

1,'£4"4U;_

4 Operation

Beforeoperatingthe unit, carefullyread

and understandall safety, control and

operating instructions in this Manual,

the separate Engine Owner's Manual

andthedecals onthe machine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

PRE-START PREPARATION

Beforestarting the engine, perform the

following checksand services:

1. Disconnectthe spark plug wire from

the spark plug.

2. Movethe engineOn/Off switch to the

OFFposition.

3. Checkthat all wiresand cables are

properly and securelyconnected.

4. Checkthe sixplastic cableties (J,

Figure2). Besure that cables andties are

positioned as shown. Cablesmust not be

kinked orjammed in the handlebar.

5. Adjust handlebar heightto desiredpo-

sition (seeSection 2).

6. Checkhardware for tightness.

7. Checkengine oil level(see Engine

Owner'sManual).

8. Checkthe airfilter (see EngineOwner's

Manual).

9. Adjust the tilling depth as follows:

a. Loosentilling depth adjustment

knob (A,Figure3).

Figure3

b.

Move wheel bracket(B, Figure 3) up

in relationto height adjustment bar

(C). Moving bracketupward results

in shallowertilling, which is recom-

mendedfor initial use.

IMPORTANT:Do not movethe wheel

bracket anyhigher than the top of

the adjustment bar.

c. Retightenthe depth adjustment

knob.

10. Reconnectthe spark plugwire.

GASOLINEIS HIGHLYFLAMMABLEAND

ITSVAPORSAREEXPLOSIVE.

Follow the gasoline safetyrules in this

Manual (Section 1) and in the separate

EngineOwner'sManual.

Failuretofollow gasolinesafety instruc-

tions can result in serious personal

injuryandpropertydamage.

11. Add gasoline to the fuel tank.

IMPORTANT:Readthe separate Engine

Owner'sManual before starting the

engine. Neverusestale or contaminated

gasolineor oil/gas mix. Theengine must

be stopped and cool beforeadding gas.

Fillthe fuel tank with unleadedgasoline

(with apump octane rating of 86 or

higher) accordingto the directions in the

separateEngineOwner'sManual. The

engine is a vertical type, GX31 model.

STOPPING AND

STARTING THE ENGINE

Stoppingthe Engine

Do notsqueezethe Throttle/Tines Con-

trol Leverwhile startingengine.

Tines maypropel the machineforward if

the engine speed is advancedfrom idle.

Failure to complycan result inpersonal

injuryor propertydamage.

Tostop the engine,move the On/Off

Switch (A, Figure 2) to the OFFposition.

NOTE:The On/Offswitch wire must be

securelyconnectedat both ends. Check

regularlyto ensurethat the switch wire is

securelyconnectedto the switch and the

engine.

Starting the Engine

NOTE: Donot squeezeEngine

Throttle/Tines Control Lever (G, Figure 2)

whenstarting engine.

Figure4:Primerbulb(A)andfuel-return

tube(B).

Figure5:Chokelever.

1. Move the On/Off Switch (A, Figure2)

to the ON position.

2. Tostart acold engine,move the choke

lever (C,Figure 5) to the CLOSEDposi-

tion. Torestart a warm engine,leavethe

choke lever in the OPENposition.

3. Tostart acold engine,or afterrefueling

an enginethat hasrun out of fuel, press

the priming bulb (A,Figure4) repeatedly

until fuel canbe seenin the clear-plastic

fuel-return tube (B). Torestart a warm

engine,it is not necessaryto press the

priming bulb.

4. Move to the starting position (Figure

6), keepingyour feet positioned safely

awayfrom the tines.

5. Placeone hand on the upper handlebar

to stabilizethe machine. Usethe other

handto pull the recoil start rope lightly

until you feel resistance,then pull briskly.

Letthe rope rewind slowly after eachpull.

NOTE:Analternatestabiliza-

tion method is to stand in

thestarting position

(Figure6), but placeone

hand on the carrying

handlewhile pulling the

starter rope with the

other hand.

6. If thechoke lever

was moved to the

CLOSEDposition to

start the engine, grad-

ually move it to the

OPENposition asthe

enginewarms up.

Figure6

Page 8

Section4: Operation

A

Figure7: Tinepatterns.

TILLING AND CULTIVATING

Keepawayfrom rotating tines. Rotating

tineswill causeseriouspersonalinjury.

Useyour machinefor busting sod,

preparing seedbedsandfor cultivating in

gardensand flower beds. It iseasyto op-

erate,but it is important thatyou start out

slowly and readthis Sectionthoroughly

beforeputting it to use. Letthe machine

do most of thework. Thetines will pull

the machineforward, letting you adjust

forward speedby pressing down or lifting

the handlebars.

1. Rollthe machineto the work area.

2. AdJustthetilling depthto the desired

position (see Pre-Start Preparationon the

previous page).

3. Start the engine(seeStopping and

Starting the Engineon the previous

page). Standbehind the handlebarand

push down on the bar to raise the tines

off theground. Squeezethe

Throttle/Tines Lever - the engineshould

speedup and thetines start rotating. Re-

leasethe Throttle/TinesLeverto return to

idle,the tines should stop rotating or they

may rotate very slowly. Loweringthem

backto theground should stop any rota-

tion.

NOTE: If tines continueto rotate when

engine is idling, either the idle speedis

too high orthe centrifugal clutch is mal-

functioning. If this occurs, contact the

Factoryor your localauthorized dealer.

4. Squeezethe Throttle/Tines Leverto

start thetines rotating. Lower the tines to

begin tilling. Firmly hold the handlebarto

prevent the machinefrom movingfor-

wardtoo quickly and to allow enough

time for the tinesto dig deeply enough.

AdJustenginespeedto suit the tilling

conditions. Rememberthat the rotating

tines helpto pull the machineforward.

Useslower speedsand a shallow depth

setting when learning to use the unit and

wheneveryou are tilling on hard,rough or

unevenground.

5. Do not try to till too deeply inthe first

pass through sod or very hardground. If

the machinejumps or bucks, use a shal-

lower depth setting andreducethe engine

speed. With eachsucceeding pass, till

more deeply.

6. Applydownward pressureon the han-

dlebarsfor shallower tilling. Lift the han-

dlebarsto dig moredeeply. If the ma-

chinestays andtills in one spot, try

swinging the handlebarsfrom sideto side

to start it moving forward again.

7. Foreasiertilling, water very hard soil a

few days before tilling. Avoidworking the

soil when soggy or wet. Wait aday or

two afterheavy rain for the ground to dry.

Cultivating

1. Cultivating is shallowtilling that dis-

rupts weedsandaeratesthe uppercrust

of soil.

2. Do not till deeperthan 1"-2"to avoid

injuring nearby plant roots. Cultivate

often, so that weeds do not grow large

and causeneedlesstangling in thetines.

3. With carefulplanning,you canspace

the seedrows far enoughapart to allow

sufficient room for the machineto culti-

vate after the plants havegrown.

AdJustingTine Positions

Dependingupon the tilling project, you

havea choice of three tine patterns:

Wide (Standard) Tine Positions- As

shippedfrom the factory, the unit is set

up for generaltilling andcultivating. This

10"widetine pattern (the maximum tilling

width) usesall four tine sections

(A, Figure7). See TineRemovaland In-

stallation in Section 5 for detailed informa-

tion on howto set up this tine position.

C

Narrow Tine Positions- Fora narrow,

4-1/2"tilling width, removethe outside

tine sectionon the left- and right-sides

(B,Figure7). SeeTineRemovaland In-

stallationin Section5 for detailedinforma-

tion on how to set up this tine position.

StonySoil TinePositions- When tilling

deeply in stony soil, stones may become

jammed betweenthe inner tines and the

machinehood. This setupswapsthe two

innertines to minimizejamming (c,

Figure7). See TineRemovaland/nstalla-

tion in Section 5 for detailed information

on howto set up this tine position.

Tilling Patterns

1. Tomakeseedbeds, go over the same

pathtwice in the first row, then overlap

one-half the machinewidth on eachsuc-

cessive pass until all rows are tilled twice

(D, Figure 8).

D E

Figure8:RecommendedTillingPattern.

2. Make a second passat a right angle

across theoriginal passes. Again,

overlapeach pass (E,Figure8). Hard

ground maytakethree to four passes

beforethe desired depth is achieved.

NOTE:Forsmall gardens,overlap by

one-half (1/2) the machinewidth, fol-

lowedby successivepasses at one-

quarter (1/4) machine width. Thisover-

lapping method assuresthorough tilling.

Making Border Edges

Usethe EdgerAttachmentto makeclean,

sharp edgesnext to walkways, driveways,

paths,plantedareas, patios, etc. SeeIn-

stalling and Using the EdgerAttachment,

in this Section,for detailed information.

Page 9

INSTALLINGANDUSING

THEEDGERATTACHMENT

Contact with rotating tines or other

moving parts can cause serious per-

sonalinjury.

Before installing or removing attach-

ments,or adjustingor servicingthe ma-

chine, stop the engine, let all moving

parts come to a complete stop, discon-

nect the spark plug wire and move the

wire away from the sparkplug.

Tocreate borders or edgesnearwalks,

driveways,flower beds,etc., you must

remove the four tine sectionsand install

the EdgerAttachment (thisattachment

was supplied with the unit - see

Section 3).

Installing the EdgerAttachment

1. Gathertogether the following parts:

Border/EdgerTine (A,Figure 10); Long

Bushing (B); Border/EdgerWheel (C); and

Short Bushing (D).

2. Prop the machinecarefully onto the

front of the tubular carrying handle. The

work surfaceshould befirm andflat.

NOTE:Typically,the Border/EdgerTine is

mounted on the right side of the unit for

right-handed people,and on the left-side

of the unit for left-handedpeople.

3. Flipopen and remove thetwo ring lock

pins (E, Figures9 and 10) oneachtine

shaft.

Figure9: Ringlockpin andtines.

Keepleft and right-side tines separateand

markedfor easierreinstallation.

IMPORTANT:Thering lockpin is under

spring tension - usecarewhen removing

or replacingthe ring lock pin.

4. It is important for propertilling perfor-

mancethat thetine sections be later rein-

stalled in their original positions. There-

fore, markthe positionof eachtine section

(Left-Outer,Left-Inner,etc.)beforere-

moving them. Referto Figure7 for tine

position information.

5. Install the short bushing (D, Figure10)

onto the tine shaft. Thenplacethe

Border/Edgerwheel (C) onto the same

shaft - the wheel hub should facetoward

the tiller. Insert the ring lock pin through

the rounded side of the tine shaft and

snapthe ring down over the shaft (see

"DETAIL",Figure10).

6. Slidethe long bushing (B, Figure 10)

onto the opposite side shaft. Theninstall

the Border/Edgertine (A) and secure it

with the ring lock pin.

Section4: Operation

_This side out

Figure 10:Border/Edgertine assembly.

Using the Edger Attachment

TheEdgerAttachment makesclean, sharp

edgesnextto walkways, driveways,

paths, plantedareas,patios, etc.

Takeyour time when

edging. Decidehow far

awayto edge thewalk or

drive, then slowly pro-

ceedusingthe walk or

drive asyour sight line.

Attachments

Thefollowing Tiller/Edgerattachmentsare availablewhere the Tiller/Edgerwas purchased. Seeyour localauthorized dealeror con-

tactthe Factoryfor details.

Power Lawn Rake Attachment - Model 12575

ThePower LawnRakehelps to keep

your lawnhealthy and vigorous.

Mattedgrass anddebris looks

unattractiveand stifles lawn

growth andoverall health.

This attachment mounts

without tools andfeatures

dozensof tempered steel

"fingers" that penetrate

and loosen matted grass

without disturbing root

growth. An 18"-wideswath

coversa largelawnareaquickly.

Lawn Aerator Attachment - Model 12574

TheLawnAerator Attachmenthelpsto

promote healthy,dense lawns by

loosening andaerating the soil

for better root growth. Four

temperedsteel tines punc-

ture the surface of the

lawnthus allowing nutri-

ents to reachthe roots

more easily. This attach-

ment assembleswithout

tools.

Page 10

s Maintenance

Beforeinspecting,cleaningor servicing

the machine, shut off engine, let all

moving parts cometo a completestop,

disconnectthe sparkplugwire and move

thewire away fromthe sparkplug.

Failure to follow these instructionscan

result in personal injury or property

damage.

EQUIPMENT MAINTENANCE

Transmission Maintenance

Thetransmission was lubricatedatthe

factory andshould not require any further

lubrication.

However,you should checkthe lubricant

levelafter the first five (5) hours of opera-

tion and every twenty-five (25) operating

hours thereafter. If needed,usea high-

quality,automotive-grade petroleum-

basedgrease.

Before tipping engine or equipment to

service transmission, drain fuel from

tankby runningengine until fuel tank is

empty. Allowenginetocool.

Tocheckthetransmission:

1. Stopthe engine, let it cool anddiscon-

nect the sparkplug wire.

2. Placethe machinedown on its left side

so the right endof the tine shaft faces up.

3. Removethe right-side tines (see Tine

Removaland Installation inthis Section).

4. Cleanthe transmission housing.

5. Removethe threethreaded plugs (A, B

and C, Figure11) from the transmission.

0

0 ABACI L _I

I I :

, ,

I I/"_"-,_ _lil_/f:.J,.,_l

I I

I _- H

Figure 11:Transmission lubricantcheck and

fill locations.

Perform at every indicated month or Each

operating hour interval, whichever Use

comes first.* See Engine Owner's Manual

for engine related maintenance.

CheckTightness of Bolts and Nuts x

CheckTransmission Lubricant Level x (1) x

Clean Machine x

CleanTine Shaft x

EngineOil Level x

Air Cleaner

Spark Plug

Cooling Fins Check x

Spark Arrester Clean x

FuelTank Clean x

FuelFilter Check x

Clutch Shoes Check x (3)

Idle Speed Check-AdJust x (3)

Valve Clearance Check-AdJust x (3)

FuelTubes Check Every2 years (Replace if necessary)(3)

* Forcommercial use, log hours of operation to determine proper maintenance intervals.

(1) Checkafter first 5 hours of use.

(2) Service more frequently when used in dusty areas.

(3) Item should beserviced by your servicing dealer,unless you havethe proper tools and

are mechanically proficient.

Lubricant should be visible inthetop two

holes (B and C). Ifso, replaceall three

plugs. If lubricant is needed,proceed as

follows.

Tolubricatethetransmission:

1. Placethe nozzle(D, Figure11) of a

standard greasegun firmly againstthe

rim of the middle hole(B) andadd grease

until it beginsto seepfrom the bottom

hole (A). Reinstall the plug in the bottom

hole (A). Next apply grease to the top fill

hole (C)until it begins to seepfrom the

middle hole (B). Reinstallthe plugs in the

middle (B) andtop (C) holes.

2. Beforereinstalling the tines, use afine

grade sandpaperto clean any rust off the

tine shaft. Apply afew drops of oil to the

tine shaft to makefuture tine removal

easier.

REQUIREDMAINTENANCESCHEDULE

REQUIRED MAINTENANCE Before

Check

Change x x

Check x

Change x (2)

Check/Clean x

Replace x

First Every3 Every6

month months months

or 10 Hrs. or 25 Hrs. or 50 Hrs.

Yearly Every

2 years

Other Lubrication Points

• HandlebarAdjustment Knobs: Spray

occasionally with asilicone type lubri-

cant.

• Throttle/Tines Control LeverCable:

Squeezethe lever closed and spray a lu-

bricant into the cable area.

• Tine Shaft: After eachuse,removethe

tines, cleanthetine shaftwith sandpaper

and apply a light coatof oil to thetine

shaft.

Hardware/Electrical Connections

Beforeeachuse, check that all hardware

is tight andthat theOn/Off Switchwire

connections are secure. Also check that

the switch wiring is in goodcondition.

10

Page 11

Section5: Maintenance

! !_W.'lq_q hqe]l Beforeinspecting,cleaning orservicingthe machine, shutoff engine, wait formovingpartsto stop, dis-

t _ connectsparkplugwire and movewire awayfromsparkplug.

Failuretofollow these instructionscanresult in seriouspersonal injuryor propertydamage.

ENGINEMAINTENANCE

Avoid contactwith the cutting edges on

Thetemperatureof the muffler and adja-

cent engine areas may exceed 150°F

(65°C). Contact maycauseburns. Avoid

these areas. Remove the spark plug

lead andgroundthelead to the engineto

preventaccidentalstarts andfires.

Failure to do this couldcause personal

injury.

• Maintain the correct engineoil leveland

changethe oil as recommended(more

often in dusty conditions).

• Keepthe airfilter clean. Operatingthe

engine with a dirty, clogged air filter can

cause poor performanceand damageto

the engine. Neveroperateengine

without airfilter installed.

• Keepthe spark plug cleanand properly

gapped. Replaceevery2 years.

•Theengine cooling fins must bekept

cleanto prevent overheatingof the

engine.

the tines.

To avoid personal injurywhen removing

or installing tines, wear heavy work

gloves. The engine must be off, all

moving parts stopped, and the spark

plug wire disconnectedfrom the spark

plugand movedaway from the plug.

ArrangingTines

for Narrow Tilling

1. Prop the machineforward so it rests

on the front of thetubular carrying

handle. Thework surface should beflat

and firm.

2. Flipopen the ring (A, Figure12) on the

left sidering lockpin and removethe ring

lock pin.

IMPORTANT:The ring lockpin (A,Figure

12) is under spring tension - usecare

when removing or replacingthe ring lock

pin.

Figure13:Narrowtillingtineconfiguration.

Arranging Tines for Stony Soil

1. Prop the machineforward so it rests

on the front of the tubular carrying

handle. Thework surface should beflat

andfirm.

2. Removethe ring lock pin (A, Figure12)

from both sides of the unit. Removeboth

outer tine sections. Besure to markeach

section asa left or right side tine and

whether it is aninner or outer section.

3. Removethe innertine sections and

swap their positions (the inner right-side

section goesonto the left sideof the ma-

chine, and the inner left-side goes onto

the right side of the machine).

Do not tamper with the engine governor

screwwhich isfactory-setfor the proper

enginespeed. Overspeedingthe engine

beyond the factory high speed setting

can be dangerous and will void the

engine warranty. Authorized service

shallbe soughtif a problem exists.

• If the engineis equippedwith aspark

arrester,clean it everyyear.

•Clean,check or adjust the following

items according to the instructions in

the EngineOwner's Manual:fuel tank,

fuel filter, clutch shoes, idlespeed,valve

clearanceand fuel tubes.

TINE REMOVAL

AND INSTALLATION

Thetines wearwith use and should be re-

placedif tilling takes longer than usual or

if the soil does not mix thoroughly. In ad-

dition to the standard 10"tilling width tine

pattern,the tines canbe arranged in a

narrow, 41/2" tilling width pattern for

smaller areas,and a special pattern for

stony soil conditions.

Figure 12: Standardwide tinepattern and

ring lockpin location.

3. Removethe outer tine section (do not

remove inner tine section) andmark it as

to which side it is from (left or right) and

whether it'san outer or inner tine section.

4. Slide oneof the long bushings(B,

Figure13), provided with the unit, onto

the shaft. Insertthe ring lockpin through

the rounded side of the tine shaft and

snapthe ring down over the shaft (see

DETAIL- RingLock Pin,Figure10, in

Section 4).

5. Repeatthis procedure on the opposite

side.

Figure 14: Stonysoiltine pattern.

4. Reinstallthetwo outer tine sections

onto the sides from which they were re-

moved (Figure 14).

5. Insert the ring lock pins through the

rounded side of the tine shafts and snap

the rings down over the shafts(see

DETAIL- RingLock Pin,Figure10, in

Section 4).

11

Page 12

Section5: Maintenance

IW!_W.'!:_II_q_ Beforeinspecting,cleaning orservicingthe machine, shutoffengine, wait formovingpartsto stop,dis-

_, _ connectsparkplugwire and movewire awayfromsparkplug.

Failuretofollow theseinstructionscan result in seriouspersonalinjuryor propertydamage.

Replacing Worn Tine Sections

Thetines are excessivelyworniftilling

takesmuch longerthan beforeand soil is

not being mixed thoroughly enough.

1. Prop the machineforward so it rests

on the front of the tubular carrying

handle. Thework surface should beflat

andfirm.

2. Removethe ring lock pin (A,Figure 12)

from both sides of the unit. Removethe

old tine sections and replacethem with

newtine sections. Referto Figure12 and

thetine position shown in the Parts List

for tine positioning details. Insert the ring

lock pinsthrough the rounded side of the

tine shafts and snap the ring over the

shaft (seeDETAIL- RingLock Pin,Figure

10, in Section4).

STORAGE

• Never storeyourequipmentwhenthere

isfuel inthefuel tank.

• Never place yourequipment near any

sourceof sparks or open flame (such

as from a hot water heater, a space

heateror clothesdryer).

Failure to comply can result in serious

personalinjury or propertydamage.

IMPORTANT:It is important to prevent

gum depositsfrom forming in essential

fuel systemparts such ascarburetor,fuel

filter, fuel hose, or tank during storage.

Also, experienceindicatesthat alcohol-

blendedfuels (calledgasoholor using

ethanolor methanol)can attractmoisture

which leadsto separationand formation

of acids during storage. Acidic gascan

damagethe fuel system of anenginewhile

in storage.

Off-SeasonStorageProcedure

• Protect the engineand perform recom-

mendedenginemaintenanceby fol-

lowing the engine storage instructions

found in the separateEngineOwner's

Manual.

NOTE:Besure to protectthe fuel lines,

carburetor and fuel tank from gum de-

posits by removing the fuel or by

treating the fuel with a stabilizer. See

EngineOwner'sManualfor more infor-

mation.

Removetines. Cleanall soil anddebris

from dust coversand tine shaft. Lubri-

catetine shaft with light oil. Replace

tines.

• Coverengineand store equipmentin a

dry, sheltered location.

TROUBLESHOOTING

Beforeperforming any of the corrections in this TroubleshootingChart, referto the appropriate information contained in this Manual

andthe EngineOwner'sManualfor thecorrect safety precautionsand servicing procedures. Contactyour local authorized Engine

Service Dealerfor engine service. Contactyour localauthorized dealerfor service problems with the machine.

Engine does not start.

Engine runs poorly or

has low power under

tilling conditions.

Engine overheats. 1. Engine cooling system clogged. 1. Remove debris.

Tines stop rotating. 1. Object wedged between tines and hood. 1. Remove wedged object.

1. Spark plug wire disconnected.

2. Out of gas.

3. Stale gas.

4. Priming/Choking procedure not correct.

5. Dirty air filter(s).

6. Worn, corroded or broken spark plug.

7. On/Off Switch in OFF position.

1. Fouled spark plug.

2. Dirty air filter(s).

3. Stale gas.

4. Carburetor malfunction/fuel filter

clogged/ignition malfunction/valves stuck, etc.

2. Carburetor out of adjustment. 2. See an authorized engine dealer.

2. Internal transmission problem. 2. See an authorized engine dealer.

1. Reconnect wire to spark plug.

2. Check fuel tank.

3. Drain old gas. Replace with fresh gas.

4. Refer to Priming/Choking procedure

and starting instructions in manual.

5. Clean or replace air filters.

6. Replace spark plug.

7. Move On/Off Switch to ON.

1. Remove, inspect, clean spark plug.

2. Clean or replace dirty air filters.

3. Drain old fuel and replace with fresh fuel.

4. See authorized engine service dealer.

12

Page 13

Model 12216 PartsList

20

Ref. # Part#

1 1915039

1915040

3

1983632

4

1918308

5

1983731

6

1983636

7

1983637

8

1904416

9 1909923

10 1185741

11 1111600

12 1100069

Transmission Assembly

Description Qty.

TransmissionCase- left-side.

(Incl. pressed-in bushing) ............ 1

TransmissionCase- right-side.

(Incl. pressed-in bushing) ............ 1

Oil Seal ............................. 2

Worm Input ShaftAssembly ............ 1

Input Bearing ........................ 2

Thrust Bearing ....................... 1

BallBearing ......................... 1

ShaftAssembly. (Incl. pressed-on worm

gear and two ring lock pins) ........... 1

Oil Seal,Input ........................ 1

Plug, 1/8 ............................ 3

Hex Screw, 1/4-20 x 7/8 (five locations,

identified as "A" on transmission case) ... 5

Hex Screw, 1/4-20 x 1 (three locations,

identified as "B" on transmission case) ... 3

Ref.

13

14

15

16

17

18

19

20

21

22

23

24

14, 15

Part #

1817146

1983635

1983640

1983641

1983642

1983638

1107381

1983663

1747166

1915055

1918052

1983713

22

\

21

Description Qty.

Locknut,Nyloc, 1/4-20 ................. 8

Thrust Washer,Output (.050") ........... AIR

Thrust Washer,Output (.040") ........... AIR

Thrust Washer,Input (.020") ............ AIR

Thrust Washer,Input (.035") ............ AIR

Thrust Washer ....................... 2

FlatWasher, 1/4 ...................... 2

Hex Hd. Screw, 1/4-20 x 5 .............. 2

SetScrew, 1/4-28 x 3/8 ................ 4

DustCover .......................... 2

Oil Seal,Input ........................ 1

FeltWasher ......................... 2

A/R- AsRequired

13

Page 14

PartsList Model 12216

55

42

/

SEEPREVIOUSPAGE

42

53

13

31

32

23

22

_o I

14

28

42

41

'o 9 41

40

Page 15

Model 12216 PartsList

Ref. # Part#

1

1918087

2

1909936

3

1909939

4

1918221

5 1917451

6 1917755

7 1750608

8 1731025

9 1909775

10 1983718

10A 1981012001

11 1766503

12 1918051

13 1763682

14 1917576001

15 1917575001

16 1909720

17 1983663

18 1107381

19 1817146

20 *

21 1917531

22 1918124

23 1917773

24 1904553

25 1904549

26 1904552

27 1186292

28 1186387

29 1100241

30 1100807

31 1909540

Description Qty.

HandlebarAssy. (Incl. Refs. 2, 3, 4 & 5)....... 1

Decal-On/Off Ignition Switch....................... 1

Decal- Starting Stabilization......................... 1

Decal- Throttle/TinesControl

Lever Operation .......................................... 1

HandlebarGrip, PVC..................................... 2

Throttle Leverand Cable............................... 1

Pan Hd. Screw, #10-16 x 1-1/2 ..................... 1

Saddle Hd. Screw, 5/16-18 x 2 ..................... 2

Spacer,Throttle Lever................................... 1

On/Off Ignition Switch................................... 1

Bracket- On/Off Ignition Switch .................. 1

Phillips Hd. Screw, #12-24 ........................... 1

Wire Assy. - On/Off Ignition Switch ............... 1

PlasticWire Tie............................................. 6

Lower Handlebar- Left-Side......................... 1

Lower Handlebar- Right-Side....................... 1

FoamSleeve.................................................. 1

Hex Hd. Screw, 1/4-20 x 5............................ 2

FlatWasher,1/4-20 ....................................... 2

Hex Locknut, 1/4-20 ..................................... 5

Engine........................................................... 1

Clutch Drum and Hub................................... 1

TineShield (Incl. Refs.23, 24, 25 & 26) ....... 1

Decal- Logo ................................................. 1

Decal-Warning, RotatingTines................... 1

Decal- Warning, Hot Surfaces...................... 1

Decal- Caution,Operation Hazards.............. 1

Hex Hd. Screw, #10-24 x 1/2 ........................ 2

FlangeLocknut, #10-24 ............................... 2

LockWasher, 1/4-20 ..................................... 8

HexCapScrew, 1/4-20 x 2............................ 4

Outer Tine - Right-Hand Side........................ 1

Ref. # Part#

32 1909539

33 1909712

34 1909711

35 1909680001

36 90077

37 1909835

38 1100069

39 1909517001

40 1909853

41 9532

42 1904321

43 1981022010

44 1763767

45 1177038

46 90041

47 1186332

48 1917530

49 1917529

50 1918365

51 **

52 **

Description Qty.

InnerTine- Right-Hand Side ........................ 1

OuterTine- Left-HandSide .......................... 1

InnerTine- Left-HandSide........................... 1

WheelBracket............................................... 1

CarriageBolt................................................. 1

Knob ............................................................. 1

Hex Hd. Screw, 1/4-20 x 1............................ 3

Axle............................................................... 1

Wheel............................................................ 2

E-Ring........................................................... 4

RingLock Pin ............................................... 2

TineHood Cover ........................................... 1

Knob ............................................................. 2

Lock Washer, 5/16 ........................................ 2

Hex.Hd. Screw, M6 x 20 .............................. 4

Hex FlangeScrew,5/16-18 x 1-1/4 ............... 4

Adapter Plate - Engine.................................. 1

Adapter Plate - Transmission........................ 1

Clutch Assy.(Incl. Refs.55 and56).............. 1

Hex Hd. Screw, M8....................................... 2

FlatWasher,M8 x M17................................. 2

EDGERATTACHMENT

53 1903777 EdgerWheel.................................................. 1

54 1903778 Bushing-Short ............................................ 1

55 1983648 Bushing-Long ............................................ 2

56 1915054 EdgerTine ..................................................... 1

OPTIONAL ATTACHMENTS

.... 12575 Power Lawn RakeAttachment ...................... 1

.... 12574 Lawn Aerator Attachment ............................. 1

* Order parts from your local authorizedengine dealer.Referto engine nameplatefor model/type number.

** Not availableseparately.

SAFETYANDOPERATINGDECALS

Decals are not shown at full size. See above Parts List for reordering information.

On top of handlebar

On top, left-side On rear, right-side On right-side handlebar

tine shield tine shield 15

On rear, left-

side tine shield

On right-side

handlebar

Page 16

CUSTOMERSERVICEINFORMATION

OwnerRegistrationCard

Pleasefill out andmailthe enclosed owner

registration card. The purposeof this card is

to register each unit at the Factoryso that we

can provideyou with warranty benefitsand

informational bulletins.

WarrantyService

Thewarranty statement is includedinthe unit's literature

package.

Model/Serial Numbers

A Model/SerialNumbersdecalis locatedon the handlebar.

For readyreference,recordthese numbers inthe spaces

below.

Dateof Purchase:

Model Number:

Serial Number:

AuthorizedDealerInformation

If you purchasedyour unit from an authorizeddealer,record

the dealer's addressand phone number below for ready

reference:

DealerName:

Address:.

Phone:

IMPORTANT:

Leftandright sidesof the unit are determinedbystanding

behindthe unit, inthe operator'sposition,andfacing in

the directionof forwardtravel.

CustomerServiceandTechnical Service

If you havequestions or problems with the

unit, contactyour localdealer or the Factory.

(Whencalling or writing, providethe

Model/Serial Numbers of the unit.)

ReplacementParts

Factoryspecified replacement parts are

availablefrom your authorizeddealer or di-

rectly from the Factory. Whenordering

parts, besure to providethe following:

• Model/Serial Numbers of theunit.

• Part number of the part needed.

• Part Description.

• Quantity needed.

NOTE:All replacementparts must conform to our rigid quality

specifications. Althoughsome replacementparts we provide

may vary slightly in shape,color or texture from the original

parts, anyvariations will not affectthefit or performance of

these parts on your unit.

EngineServiceand Repair

Forengineservice or repair,contact your

nearestauthorized enginedealer (look in

theYellow Pagesunder "Engines-Gaso-

line"). The engine is warranted by the

engine manufacturer.Any unauthorized

work performedon the engineduring the

warranty period may void this warranty.

Forcomplete details on the enginewar-

ranty,refer to the engineowner manual.

NOTICE:

We reservethe righttochangespecifications,add im-

provementsor discontinuethe manufactureofanyofour

equipmentwithout notice or obligationto purchasersof

ourequipment.

Forcustomerassistance,contactyour nearestauthorizeddealer or:

GARDEN WAY INCORPORATED • 1 GardenWay • Troy,NewYork 12180

CustomerService:1-800-437-8686 • TechnicalService:1-800-520-5520 • PartsService:1-800-648-6776

CustomerService:(518) 391-7007 • TechnicalService:(518)391-7008 • PartsService:(518) 391-7006 • FAX(518) 391-7332

1905532 (5/00) Printed in U.S.A. © 2000 Garden Way Incorporated

We urge using only genuine replacement parts, which

meet all the latest requirements. Replacement parts

manufacturedby otherscouldpresentsafetyhazards,even

thoughtheymayfit on the unit.

• FAX:(518)391-7332 • WEBSITE:www.troybilt.com

Outsidethe United Statesand Canada:

Loading...

Loading...