Troybilt 12213 Owner’s Manual

GARDEN WAY

_ TRD_J_!LT"

Owner'sManual

REAR-TINETILLER

• Safety

• Assembly

• Controls

• Operation

• Maintenance

• Parts List

Model

12213- 4.5HP

GARDEN WAYINCORPORATED

DearOwner:

Tableof Contents

You now own one of the finest standard-rotating-tine tillers

available.Your new tiJJerallows you to tiJland cultivateyour

gardenwith ease,andaccomplish dozensof other property

managementprojects aswell. Your tiller is famous for its

ruggedness,performance and high-quality engineering. We

know you'll enjoyusing it.

Pleasecarefully readthis Manual. Ittells you howto safely

and easily assemble, operateand maintain your machine.

Besure that you and anyother operators carefully follow

the recommended safety practices atall times. Failureto

do so could result in personal injury or property damage.

Of course, if you should ever haveany problems or

questions, pleasecontact your local authorized dealeror

call the Factory (seehack cover of this Manual). We want to

be sore that you are completely satisfied at arttimes.

NOTE:Be sure to fill out and return the Warranty Registra-

tion Cardthat was supplied with this Manual.

See Back Cover for

Customer Service Information

SECTION1: SAFETY........................................... 3

SafetyDecals .................................................................... 5

SECTION2: ASSEMBLY....................................... 6

Attach Handlebar............................................................... 7

Move Tiller Off Shipping Platform ...................................... 7

Install Forward Clutch Cable.............................................. 8

CheckLevel ofTransmission GearOil................................ 9

Add Motor Oil to Engine..................................................... 9

CheckHardwarefor Tightness........................................... 9

CheckAir Pressure in Tires................................................ 9

SECTION3: FEATURES& CONTROLS........................ 10

Wheel Drive Pins ............................................................... 10

Forward ClutchBail............................................................ 11

Depth Regulator................................................................. 11

HandlebarHeightAdjustment ............................................ 11

SECTION4: OPERATION...................................... 12

Break-in Operation.......................................................... 12

Starting and Stoppingthe Engine...................................... 12

Operatingthe Tifler ............................................................ 13

Tilling Tips & Techniques .................................................. 15

PowerComposting ............................................................ 17

Loadingand Unloading the Tiller ....................................... 17

Safety AlertSymbol

,_ This isa safety alert symbol. It is used in this

Failureto obeysafety messagescould result in personal

injury or property damage.

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

manualand on the unit to alertyou to

potential hazards. When you see this symbol,

readand obeythe messagethat follows it.

WARNING

SECTION5: MAINTENANCE.................................. 18

RequiredMaintenance Schedule........................................ 18

Tiller Lubdcation................................................................ 19

Checkfor Oil Leaks............................................................ 19

CheckHardware................................................................. 19

CheckTire Pressure........................................................... 19

Transmission GearOil Service........................................... 19

Bold Tines.......................................................................... 20

Checkingand Adjusting Forward Drive Belt Tension.......... 21

Forward ClutchBailAdjustment ......................................... 21

EngineCleaning................................................................. 22

Air CleanerService............................................................ 22

EngineOil Service.............................................................. 22

Spark Plug Service............................................................ 22

SparkArrestor Screen Service........................................... 22

CarburetodGovernor Control Adjustments ........................ 22

Off SeasonStorage............................................................ 22

Troubleshooting................................................................. 23

PARTSLIST ..................................................... 24

CUSTOMERSERVICEINFORMATION.............. BackCover

The engine exhaust from this product contains

chemicals known te the State of California to cause

cancer, birth defects or other reproductive harm.

2

I1

Safety

SPARKARRESTERWARNINGTO RESIDENTSOFCALIFORNIA ANDSEVERAL OTHERSTATES

UnderCalifornialaw, and under the laws of severalother states, you are not permitted to operate an

internalcombustion engine using hydrocarbon fuels on any forest, brush, hay, grain, or grass

covered land; or land covered by anyflammable agricultural crop without anengine spark arrester in

continuous effective working order.

Theengine on the unit is an internal combustion engine which burns gasoline, a hydrocarbon fuel, and must be equipped with a

spark arrester muffler in continuous effectiveworking order. The spark arrester must beattached to the engine exhaustsystem in

such a mannerthat flames or heatfrom the system will not ignite flammable material. Failureof the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may alsobe a violation of other state

and/or federal regulations, laws, ordinances or codes. Contactyour local fire marshal or forest servicefor specific information

about which regulations apply in your area.

Training

1. Carefully readthis

Owner'sManual, the

separateEngineOwner's

Manual,and any other literature you may

receive.Bethoroughly familiar with the

controls and the proper useof the tiller

and its engine,Know how to stop the unit

and disengagethe controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe area of operation clearof all

persons,particularly children and pets.

4. Keepin mind that the operator or user

isresponsible for accidents or hazards

occurring to other people,their property,

andthemselves.

Preparation

1. Thoroughly inspect the areawhere the

tiller is to be used and remove all foreign

objects.

2. Be sure all tiller controls arereleased

and both wheels are in the Wheel Drive

position before starting the engine.

3. Do not operate the tiller without

wearingadequate outer garments, Avoid

loose garments or jewelry that could get

caught in moving parts.

4. Do not operate the tiller when barefoot

or wearing sandals, sneakers,or light

footwear. Wear protective footwear that

will improve footing on slippery surfaces,

5. Do nottill nearunderground electric

cables, telephone lines, pipes or hoses. If

in doubt, contact your telephone or utility

company.

6. Warning: Handlefuel with care; it is

highly flammable and its vapors are

explosive. Besure to take the following

precautions:

a. Storefuel in containers specifically

designedfor this purpose.

b. The gas cap shall never be removed

or fuel added while the engine is

running. Allow the engine to cool

for several minutes beforeadding

fuel.

c. Keepmatches, cigarettes, cigars,

pipes, openflames, and sparks

away from the fuel tank and fuel

container.

d. Fillfuel tank outdoors with extreme

care.Neverfill fuel tank indoors.

Usea funnel or spout to prevent

spillage.

e. Replaceall fuel tank and container

caps securely.

f. Iffuel is spilled, do not attempt to

start the engine, but move the

machine awayfrom the area of

spillageand avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Nevermake adjustments when engine

is running (unless recommended by

manufacturer).

Operation

1. Do not put handsor feet near or under

rotating parts.

2. Exerciseextreme caution when on or

crossing gravel drives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3, After striking a foreign object, stop the

engine, removethe wire from the spark

plug wire and prevent it from touching

the spark plug. Thoroughly inspectthe

machinefor any damageand repairthe

damagebefore restarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor-

mally,stop the engine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and check

immediately for the cause.Vibration is

generallya warning of trouble.

6. Stop the engine, disconnect the spark

plug wire and prevent it from touching

the spark plug whenever you leavethe

operating position, beforeunclogging the

tines, or when making any repairs, adjust-

ments or inspections.

Section1: Safety

7. Take all possible precautions when

leavingthe machine unattended.Stop the

engine. Disconnectspark plugwire and

move it awayfrom the spark plug. Be

sure both wheels are in the Wheel Drive

position.

8. Before cleaning, repairing, or inspect-

ing, stop the engineand make certain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching the spark plug to prevent acci-

dental starting.

9. The flap on the tine hood must be

down when operating the tiller.

10. Never usethe tiller unless proper

guards, plates,or other safety protective

devicesare in place.

11. Do not run engine in an enclosed

area. Engineexhaust contains carbon

monoxide gas, a deadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren and pets away.

13. Never operatethe tiller under

engine powerif the wheels are in the

Freewheel position.In the Freewheel

position, the wheels will not hold the tiller

back and the revolving tines could propel

the tiller rapidly, possibly causing loss of

control. Always engagethe wheels with

the wheel drive pins in theWheel Drive

position beforestarting the engine or

engaging the tines/wheels with the

Forward Clutch Bail.

14. Be aware that the tiller may unex-

pectedlybounceupwardor jump

forwardif the tines shouldstrike

extremely hardpackedsoil, frozen

ground,or buried obstacleslike large

stones,roots, or stomps. If in doubt

aboutthe tilling conditions,alwaysuse

the following operatingprecautionsto

assistyouin maintaining controlof the

tiller:

a. Walk behindand to oneside ol the

tiller, usingone hand onthe han-

dlebars. Relaxyour arm, butusea

securehandgrip.

b. Use shallowerdepth regulator

settings,workinggradually

deeperwith each pass.

c. Useslower enginespeeds.

d. Clear thetilling area ofall large

stones,rootsand otherdebris.

e. Avoidusingdownwardpressure

on handlebars.If need be, use

slight upwardpressureto keep the

tines lrom diggingtoodeeply.

f. Beforecontactinghardpackedsoil

atthe end of a row, reduceengine

speedand lift handlebarsto raise

tines outofthe soil.

go In an emergency, stoptines and

wheels byreleasing whichever

clutchcontrol isengaged. Donot

attemptto restrainthetiller.

15. Do not overload the tiger's capacity

by attempting to till too deeplyat too fast

a rate.

16. Never operate thetiller at high

transport speeds on hard or slippery

surfaces. Look behind and usecare when

backing up.

17. Do not operate the tiller on a slope

that is too steepfor safety. When on

slopes, slow down and makesure you

havegood footing. Neverpermit the tiller

to freewheel down slopes.

18. Never allow bystanders nearthe unit.

19. Only useattachments and acces-

sories that are approvedby the manufac-

turer of the tiller.

20. Usetiller attachments and acces-

sories when recommended.

21. Neveroperate the tiller without good

visibility or lighL

22. Neveroperate the tiller ifyou are

tired, or under the influence of alcohol,

drugs or medication.

23. Operatorsshall not tamper with the

engine-governor settings on the machine;

the governor controls the maximum safe

operating speed to protect the engineand

all moving parts from damagecausedby

overspeed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine partswhich may

behot from operation, Let parts cool

down sufficiently,

25. Pleaseremember: You can always

stop the tines and wheels by releasingthe

Forward Clutch Bail or by moving the

Throttle Control Lever on theengine to

"OFF"or "STOP".

26. To load or unload the tiller, see the

instructions in Section 4 of this Manual.

27. Use extreme caution when reversing

or pulling the machine towards you.

28. Start the engine carefully according to

instructions and with feet well away from

thetines.

29. Neverpick upor carry amachine

while the engine is running.

Maintenance and Storage

1. Keepthe tiller, attachments and acces-

sories in safe working condition.

2. Checkall nuts, bolts, and screws at

frequent intervals for proper tightness to

besure the equipment is in safeworking

condition.

3. Neverstore the tiller with fuel in the

fuel tank inside a building where ignition

sources are present such as hot water

and spaceheaters,furnaces, clothes

dryers, stoves, electric motors, etc.).

Allow engineto cool before storing in any

enclosure.

4. To reducethe chances of afire hazard,

keepthe engine free ofgrass, leaves,or

excessivegrease.

5. Store gasolinein a cool, welI-ventilated

area,safely away from anyspark- or

flame-producing equipment. Store

gasoline in an approved container, safely

awayfrom the reach of children.

6. Referto the Maintenance sections of

this Manual and the separateEngine

Owner's Manual for instructions if the

tiller is to be stored for an extended

period.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire

is connected, except when specifically

instructed to do so.

8. If the fuel tank has to be drained, do

this outdoors,

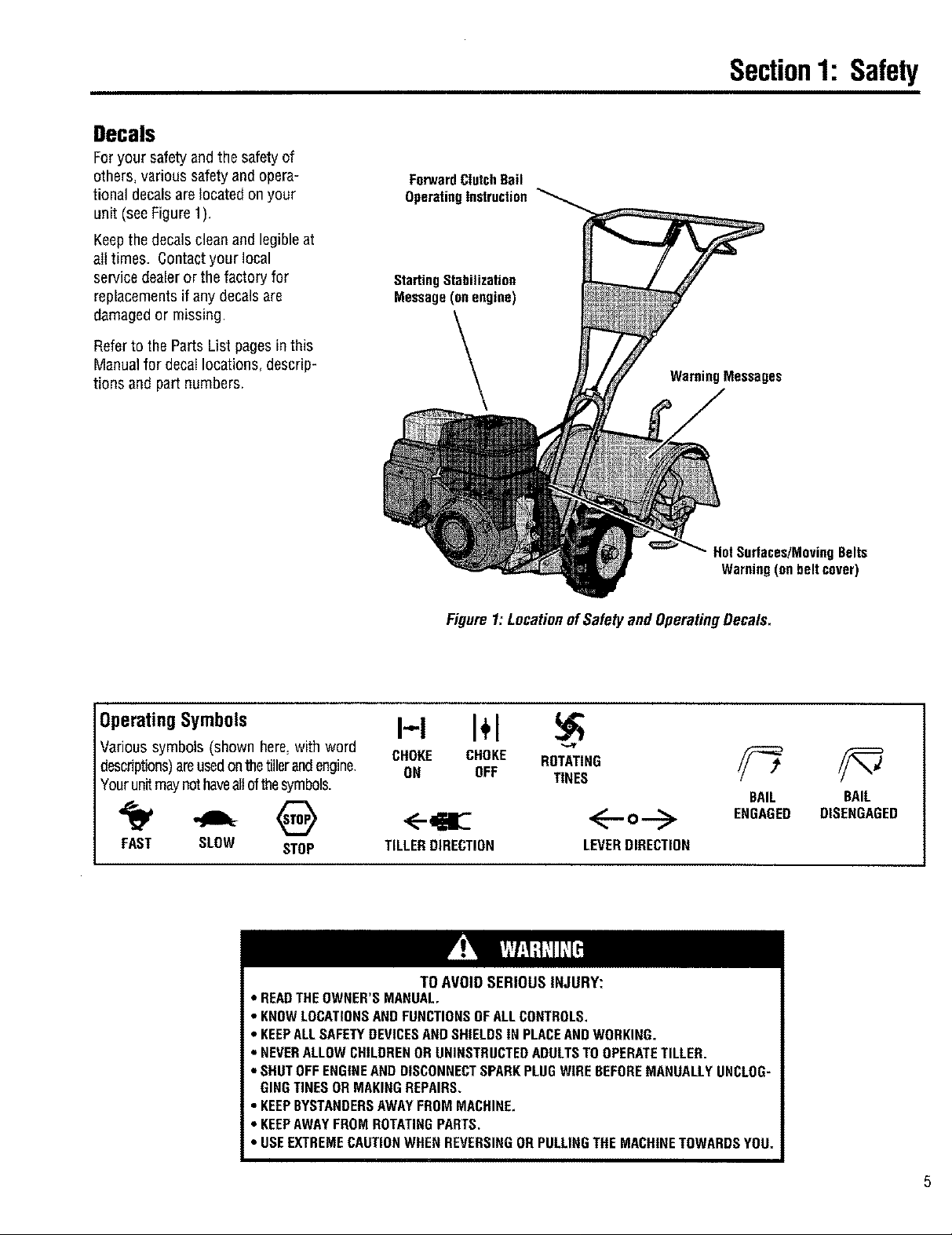

Decals

Foryour safety and the safety of

others, various safetyand opera-

tional decalsare located on your

unit (see Figure 1).

Keepthe decals clean and legible at

al!times. Contactyour local

service dealer or the factory for

replacementsif any decalsare

damaged or missing.

Referto the Parts List pagesin this

Manualfor decallocations, descrip-

tions and part numbers.

Section1: Safety

ForwardClutchBail

OperatingInstruction

Starting Stabilization

Message(on engine)

WarningMessages

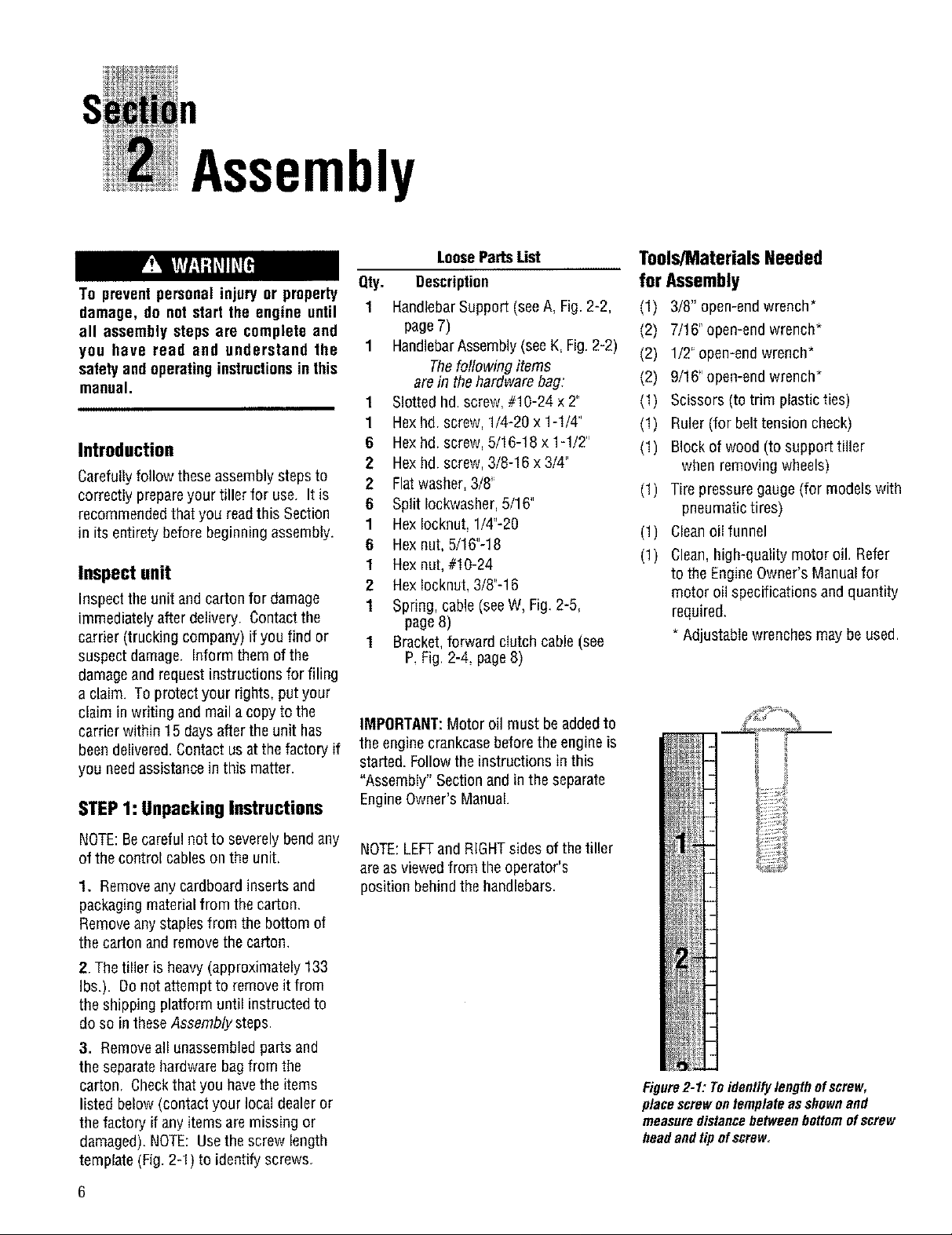

OperatingSymbols

Various symbols (shown here, with word

desndptions)areused onthe tiller and engine.

Your unit may not haveall of the symbols.

FAST SLOW STOP

• READTHEOWNER'S MANUAL,

• KNOWLOCATIONSANDFUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESAND SHIELDSIN PLACEANDWORKING.

• NEVERALLOW CHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINES OR MAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE,

• KEEPAWAYFROMROTATINGPARTS,

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHE MACHINETOWARDSYOU.

Figure1: LocationofSafetyand OperatingDecals.

I-,,-I I+1

CHOKE CHOKE ROTATING

ON OFF TINES

TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

HotSurfaces/MovingBelts

Warning(onbeltcover)

BAIL

ENGAGED

BAIL

DISENGAGED

I1

Assembly

To preventpersonal injury or property

damage, do net start fhe engine until

all assembly steps are complete and

you have read and understand the

safety and operatinginstructionsinthis

manual.

Introduction

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginning assembly.

Inspectunit

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail acopy to the

carrier within 15 days after the unit has

been delivered.Contact us at the factory if

you needassistance in this matter.

STEP1: UnpackingInstructions

LooseParts List

Qty. Description

1 HandlebarSupport (seeA, Fig. 2-2,

page 7)

1 HandlebarAssembly(see K,Fig.2-2)

Thefollowing items

are in the hardware bag:

1 Slotted hd. screw, #10-24 x 2"

1 Hexhd. screw, 1/4-20 x 1-1/4"

6 Hexhd. screw, 5/16-t8 x 1-1/2"

2 Hexhd screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

6 Split Iockwasher,5/16"

1 Hex Iocknut, 1/4'-20

6 Hex nut, 5/16"-18

1 Hex nut,#10-24

2 Hexlocknut, 3/8"-16

1 Spring, cable (seeW, Fig. 2-5,

page8)

1 Bracket,forward clutch cable (see

P,Fig. 2-4, page8)

IMPORTANT:Motor oil must be addedto

the enginecrankcase before the engine is

started. Follow the instructions in this

"Assembiy" Section and in the separate

EngineOwner's Manual.

Tools/MaterialsNeeded

for Assembly

(1) 3/8" open-endwrench*

(2) 7/16"open-end wrench*

(2) 1/2" open-endwrench*

(2) 9/16" open-endwrench*

(1) Scissors (to trim plasticties)

(1) Ruler(for belt tension check)

(1) Blockof wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatic tires)

(1) Cleanoil funnel

(1) Clean,high-quality motor oil. Refer

to the EngineOwner's Manual for

motor oil specifications and quantity

required.

* Adjustable wrenches may be used,

NOTE:Becareful not to severely bend any

of the control cableson the unit.

1. Removeanycardboard inserts and

packagingmaterial from the carton.

Removeany staples from the bottom of

the carton and remove the carton.

2. The tiller is heavy (approximately 133

]bs.). Oonot attempt to remove it from

the shipping platform until instructed to

do so in these Assembly steps.

3. Removeall unassembledparts and

the separatehardware bagfrom the

carton, Checkthat you havethe items

listed below(contact your local dealeror

the factory if anyitems are missing or

damaged). NOTE: Usethe screw length

template (Fig. 2-1) to identify screws.

NOTE:LEFTandRIGHTsides of thetiller

are asviewed from the operator's

position behind the handlebars,

Figure2-1: Toidentifylengthofscrew,

placescrewontemplateasshownand

measuredistancebetweenbottomofscrew

headandtipofscrew

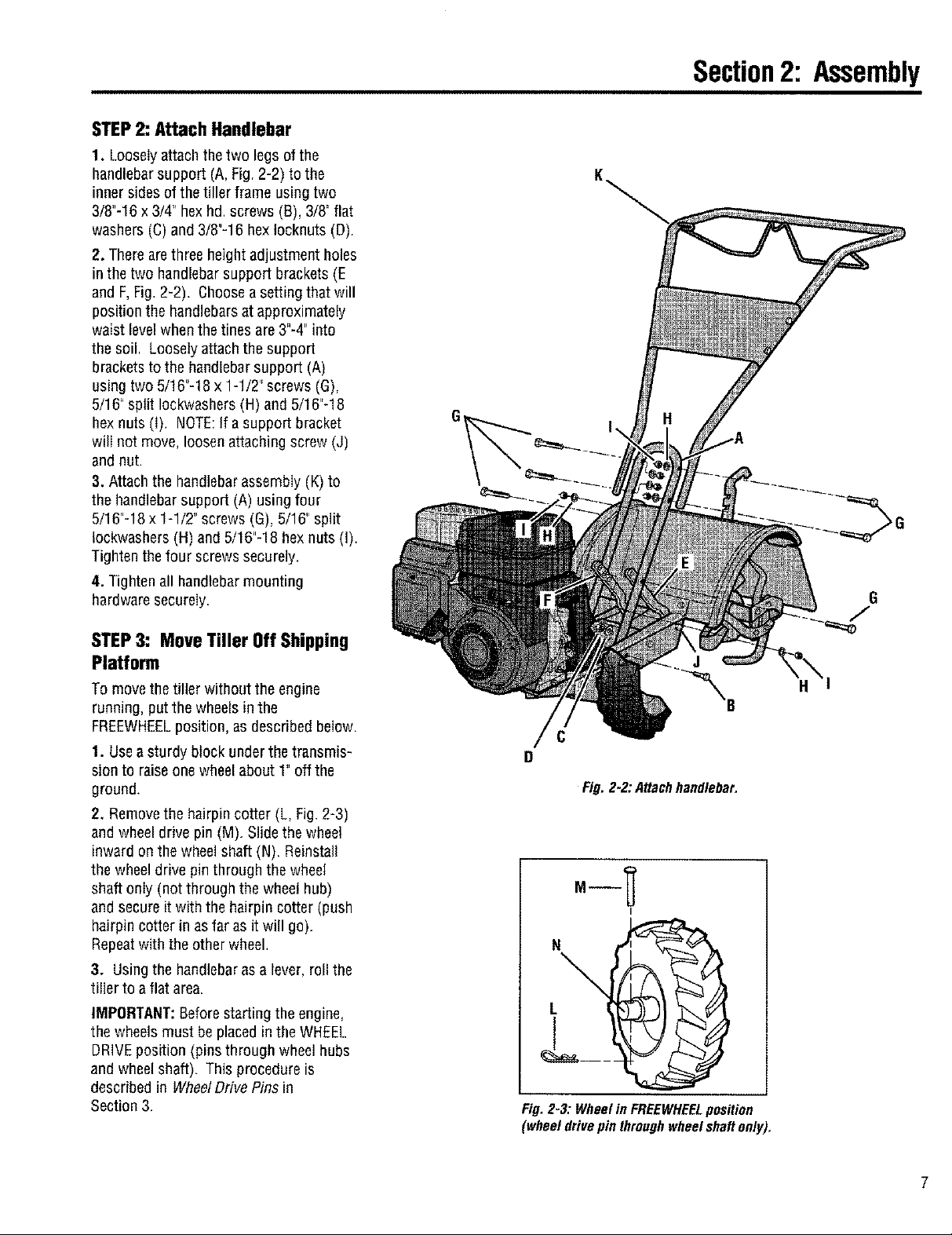

STEP2: Attach Handlebar

1. Looselyattach the two legs of the

handlebarsupport (A,Fig. 2-2) to the

inner sides of the tiller frame using two

3/8"-16 x3/4" hexhd, screws (B), 3/8' flat

washers (C) and 3/8"-16 hexIocknuts (D)

2. There are three height adjustment holes

in the two handlebar support brackets (E

and F,Fig. 2-2). Choosea setting that will

position the handlebars at approximately

waist level when the tines are 3"-4" into

the soil, Looselyattachthe support

bracketsto the handlebar support (A)

using two 5/16"-18 x 1-1/2' screws (G),

5/16" split Iockwashers (H) and5/16"-18

hexnuts (I) NOTE:If a support bracket

will not move, loosen attaching screw (J)

and nut.

3. Attach the handlebarassembly (K) to

the handlebar support (A) using four

5/16"-18 x 1-1/2' screws (G), 5/16" split

Iockwashers (H) and 5/16"-18 hexnuts (I).

Tighten the four screws securely

4. Tighten all handlebar mounting

hardware securely.

Section2: Assembly

K

STEP3: MoveTiller OffShipping

Platform

To move the tiller without the engine

running, put the wheels inthe

FREEWHEELposition, as described below.

1. Use asturdy block under the transmis-

sion to raiseone wheel about 1' off the

ground.

2. Remove the hairpin cotter (L, Fig.2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheel shaft (N). Reinstall

the wheel drive pin through the wheel

shaft only (not through the wheel hub)

and secure it with the hairpin cotter (push

hairpin cotter in as far as it will go).

Repeatwith the other wheel.

3. Usingthe handlebaras a lever, roll the

tiller to a flat area.

IMPORTANT:Beforestarting the engine,

the wheels must be placedin the WHEEL

DRIVEposition (pins through wheel hubs

and wheelshaft). Thisprocedure is

described in WheelDrive Pins in

Section 3.

J

H

Fig. 2-2:A_achhnndleba_

L

Fig.2-3: WheelinFREEWHEELposition

(wheeldrivepinthroughwheelshaftonly).

7

Section2: Assembly

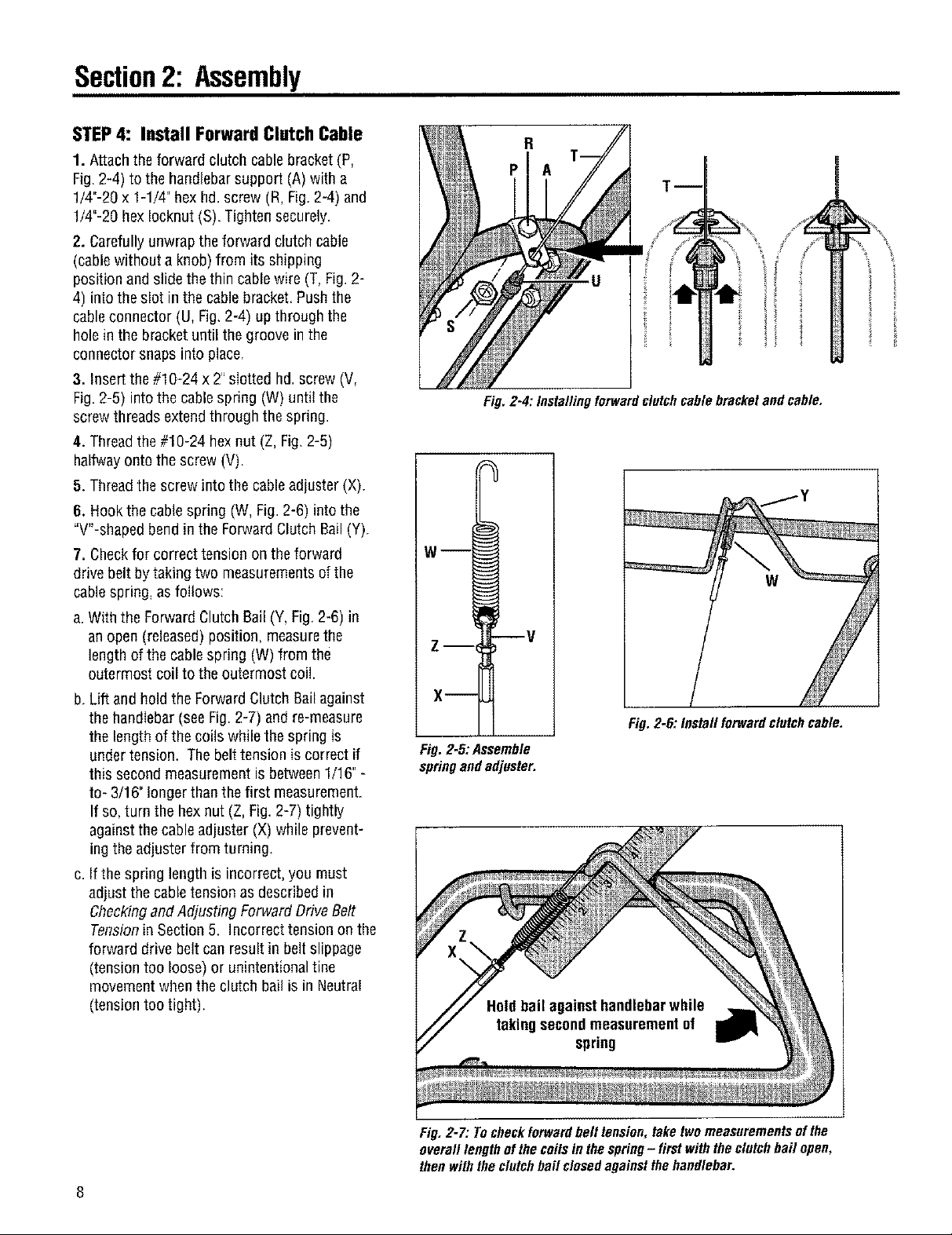

STEP4: Install ForwardClutchCable

1. Attach the forward clutch cablebracket (P,

Fig. 2-4) to the handlebarsupport (A) with a

1/4"-20 x 1-1/4" hex hd. screw (R, Fig. 2-4) and

1/4"-20 hexIocknut (S). Tighten securely.

2. Carefully unwrap the forward clutch cable

(cablewithout a knob) from its shipping

position and slide the thin cable wire (T, Fig.2-

4) into the slot in the cable bracket. Pushthe

cableconnector (U, Fig,2-4) up through the

hole in the bracket until the groove in the

connector snaps into place,

3. Insert the #10-24 x 2"slotted hd.screw (V,

Fig. 2-5) intothe cablespring (W) until the

screw threads extend through the spring.

4. Thread the #10-24 hex nut (Z, Fig.2-5)

halfwayonto the screw (V).

5. Thread the screw into the cableadjuster (X).

6. Hook the cable spring (W, Fig. 2-6) into the

"W-shaped bend inthe Forward Clutch Bail(Y).

7. Checkfor correct tension on the forward

drive belt bytaking two measurements ofthe

cable spring, as follows:

a. With the Forward Clutch Sail (Y, Fig.2-6) in

an open (released) position, measurethe

length of the cable spring (W) from the

outermost coil to the outermost coi!.

b. Lift and hold the Forward Clutch Bail against

the handlebar (see Fig. 2-7) and re-measure

the length of the coils while the spring is

under tension. Thebelt tension is correct if

this second measurement is between 1/16"-

to- 3/16" longer than thefirst measurement.

If so, turn the hex nut (Z, Fig. 2-7) tightly

against thecable adjuster (X) while prevent-

ing theadjuster from turning.

c. If the spring length is incorrect, you must

adjust the cable tension asdescribed in

Checkingand Adjusting Forward Drive Belt

Tension in Section 5. Incorrect tension on the

forward drive belt can result in belt slippage

(tension too loose) or unintentional tine

movement whenthe clutch bail is in Neutral

(tension too tight),

ii

Fig, 2-4: Installingforward clutchcable bracketand cable.

w--I

w

Z-- V

X--

Fig, 2-6: Install forwardclutchcable,

Fig. 2-5:Assemble

springand adjuster.

Fig. 2-7: Tocheckforwardbelt tension, take twomeasurements ofthe

overall length of the coilsin the spring- first with the clutch bail open,

then withthe clutch bail closedagainstthe handlebar.

Section2: Assembly

STEP5: Check Level of

Transmission Gear Oil

Thetransmissionwasfilledwithgearoil

atthefactory.However,youshouldcheck

thegearoillevelto makecertainit is

correct,

IMPORTANT:Do not operate the tiller if

thegear oil level is low. Doingso will

result in severe damageto the transmis-

sion components,

1. With the tiller on levelground, pull the

Depth Regulator Lever (FF,Fig. 2-8) back

and thenall the way up until the lowest

notch in the lever is engaged.

2. Removethe oil fill plug (GG,Fig.2-9)

from the transmission housing coverand

locate the main drive shaft situated inside

the housing.

3. Thegear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

4. If the gear oil levelis low, add gear oil

by referring to A. ToCheckthe Transmis-

sion Gear Oil Level in Section 5,

STEP6: Add Motor Oil to Engine

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not start the engine

without first adding motor oil Severe

engine damagewill result if the engineis

run without oil.

1. Referto the separate EngineOwner's

Manual for engine oil specifications and

capacities,

2. With the tiller on level ground, move

the Depth Regulator Lever (FF,Fig, 2-8)

up or down until the engine is level.

3. Add motor eli as described in the

EngineOwner's Manual.

4. Movethe Depth Regulator Leverall

the way down until the highest notch is

engaged. This placesthe tines in the

"travel" position.

Fig. 2-8: Adjust DepthRegulator Lever.

Fig,Z-9:Removegearoilfill plug.

STEP7: Check Hardware far

Tightness

Checkall nutsandscrewsfortightness,

STEP 8: Check Air Pressure in

Tires(unitswith pneumatictires)

If the tires areequipped with air valves,

checkthe air pressurewith a tire gauge.

Deflateor inflate the tires equallyto 15-

to-2g PSI (pounds per square inch), Be

surethat both tires are inflated equallyor

the unit will pull to oneside.

IMPORTANT: This completes the

assembly steps, Beforeoperatingyour

tiller, make sure you readthe following

Sections in this Manual, as well as the

separate Engine Owner'sManual:

• Section 1:Safety

• Section3: FeaturesandControls

• Section4: Operation

9

FeaturesandControls

Before operating your machine,

carefully read end understand all

safety, controls and operating instruc-

tions in this Manual, the separate

Engine Owner's Manual, and on the

decalson the machine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

Introduction

This section describes the location and

function of the controls on your tiller.

Referto the following section

"Operation" for detailed operating

instructions.

Practiceusing these controls, with the

engine shut off, until you understand the

operation of the controls and feel

confident with each of them.

IMPORTANT:Refer to the separate

enginemanufacturer's EngineOwner's

Manualfor informationabout the

controls on the engine.

Wheel Drive Pins

Never allow either of the wheels to be

in the FREEWHEELposition when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

beforestartingthe engine.

Failure to comply could cause loss of

tiller control, property damage, or

personalinjury.

Eachwheel is equipped with aWheel

Drive Pin (A, Figures3-2 and 3-3) that

securesthe wheelto thewheel shaft (B),

Thewheels can be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

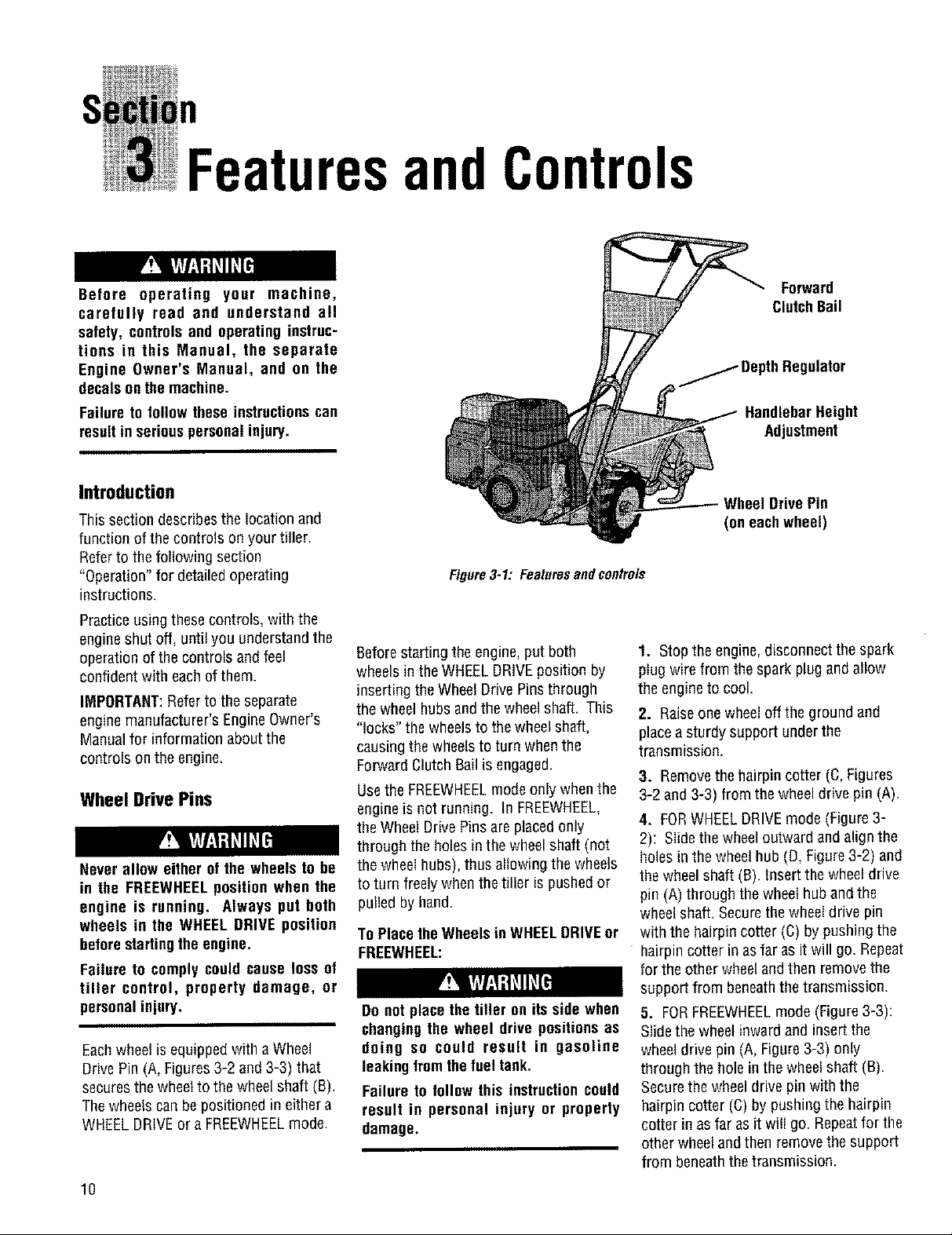

Figure3-1: Featuresandcontrols

Beforestarting the engine, putboth

wheels in the WHEELDRIVEposition by

inserting the Wheel Drive Pinsthrough

the wheel hubsand the wheel shaft. This

"locks" the wheelsto thewheel shaft,

causing the wheels to turn when the

Forward ClutchBail is engaged.

Use the FREEWHEELmodeonly when the

engine is not running. In FREEWHEEL,

the Wheel Drive Pinsare placed only

through the holes in the wheel shaft (not

the wheel hubs), thus allowing the wheels

to turn freely whenthe tiller is pushedor

pulled by hand.

To Place the Wheels in WHEELDRIVEor

FREEWHEEL:

Do not placethe tiller on its side when

changing the wheel drive positions as

doing so could result in gasoline

leaking fromfhefueltanko

Failure to follow this instructioncould

result in personal injury or property

damage.

Forward

ClutchBail

_ DepthRegulator

HandlebarHeight

Adjustment

Wheel Drive Pin

(on eachwheel)

1. Stop the engine,disconnect the spark

plug wire from the spark plug and allow

the engine to cool.

2. Raiseone wheel off the ground and

placea sturdy support under the

transmission,

3. Removethe hairpin cotter (C, Figures

3-2 and 3-3) from the wheel drive pin (A).

4. FORWHEELDRIVEmode (Figure 3-

2): Slide the wheel outward and align the

holes in the wheelhub (D, Figure3-2) and

thewheel shaft (B), Insert the wheel drive

pin (A) through the wheelhub and the

wheel shaft, Securethe wheel drive pin

with the hairpin cotter (C) by pushing the

hairpin cotter in as far as it will go. Repeat

for the other wheel and then removethe

support from beneaththe transmission.

5. FORFREEWHEELmode (Figure3-3):

Slide the wheel inward and insert the

wheeldrive pin (A, Figure 3-3) only

through the hole in the wheel shaft (B),

Securethe wheeldrive pin with the

hairpin cotter (C) by pushing the hairpin

cotter in as far as it will go. Repeatfor the

other wheel and then removethe support

from beneaththe transmission.

10

Loading...

Loading...