Troybilt 12212 Owner’s Manual

0 TRtlI BILT°

Before ( , read this

manual

OWNER'SMANUAL

,®

REAR-TINETILLER

• Safety

• Assembly

• FeaturesandControls

• Operation

• Maintenance

• Parts List

Model

12211- RecoilStart

12212- ElectricStart

(Recoil Start Model Shown)

GARDEN WAYINCORPORATED

DearOwner:

You now own one of the finest standard-rotating-tine tillers

available.Yournew PONY® Model tiller allows you to till

and cultivate your garden with ease,andaccomplish

dozensof other property managementprojects aswell.

Your tiller is famous for its ruggedness,performanceand

high-quality engineering. We know you'll enjoy using it.

Pleasecarefully readthis Manual. It tells you how to safely

and easilyassemble, operate andmaintain your machine.

Be sure that you and any other operators carefully follow

the recommendedsafetypractices atall times. Failureto

do so could result in personal injury or property damage.

Ofcourse, if you should ever haveany problems or ques-

tions, pleasecontact your local authorized servicedealeror

callthe factory (see back cover of this Manual).

Wewant to be surethat you arecompletely satisfied at all

times.

NOTE:Besureto fill out and return the Warranty Registra-

tion Cardthat was suppliedwith this Manual.

See Back Cover for

Customer Service information

SafetyAlert Symbol

This is a safetyalert symbol. It is usedin this

manualand on the unit to alertyou to potential

hazards. Whenyou seethis symbol, readand

obey the messagethat follows it. Failureto

obey safety messagescould result in personal

injury or property damage.

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Table of Contents

SECTION1: SAFETY........................................... 3

SafetyDecals .................................................................... 5

SECTION2: ASSEMBLY....................................... 6

Attach Handlebars.............................................................. 6

Attach ReverseClutch Control ........................................... 7

Attach ForwardClutch Control Cable................................. 7

CheckTransmission GearOil Level.................................... 8

Add Motor Oil to Engine..................................................... 8

AttachWheelGearLever.................................................... 8

CheckAir Pressure in Tires................................................ 8

CheckHardwarefor Tightness........................................... 8

ElectricStart Assembly Steps............................................ 9

SECTION3: FEATURES& CONTROLS........................ 11

WheelGearLever............................................................... 11

ForwardClutch Control...................................................... 11

ReverseClutch Control ...................................................... 12

Depth Regulator................................................................. 12

HandlebarHeightAdjustment............................................ 12

EngineControls ................................................................. 13

SECTION4: OPERATION...................................... 14

Starting and Stoppingthe Engine...................................... 14

OperatingtheTiller ............................................................ 15

Tilling Tips & Techniques.................................................. 17

PowerComposting ............................................................ 19

Loading and Unloadingthe Tiller ....................................... 19

SECTION5: MAINTENANCE.................................. 20

MaintenanceSchedule....................................................... 20

Tiller Lubrication ................................................................ 20

CheckHardware................................................................. 20

CheckTire Pressure........................................................... 20

Checkfor Oil Leaks............................................................ 21

Transmission GearOilService........................................... 21

EngineOilService.............................................................. 22

Air CleanerService............................................................. 22

SparkPlug Service............................................................. 22

SparkArrester Screen Service........................................... 22

EngineCleaning................................................................. 22

Carburetor/GovernorControlAdjustments ........................ 22

Throttle Control Adjustment............................................... 22

WheelGearCableAdjustment............................................ 23

Off Season Storage............................................................ 23

Bolo Tines.......................................................................... 23

Checkingand Adjusting Tension on the Clutch Belts......... 24

ForwardClutch Belt Removal/Replacement....................... 25

ReverseClutch Belt Removal/Replacement....................... 27

BatteryMaintenance.......................................................... 28

TILLERATTACHMENTS........................................ 28

TROUBLESHOOTING.......................................... 29

PARTSLIST..................................................... 30

CUSTOMERSERVICEINFORMATION ............ BACKCOVER

Safety

SPARKARRESTERWARNINGTORESIDENTSOF

CALIFORNIAAND SEVERALOTHERSTATES

UnderCalifornia law,and under the lawsof severalother

states,you are not permitted to operate an internalcom-

bustion engineusing hydrocarbon fuels on any forest,

brush, hay,grain, or grass covered land;or landcovered

by anyflammable agricultural crop without an engine

spark arrester in continuous effective working order.

The engineon the unit isan internal combustion engine

which burns gasoline, a hydrocarbon fuel, and must be

equippedwith a spark arrester muffler in continuous

effectiveworking order. The spark arrester must be

attachedto the engineexhaustsystem in such a manner

that flames or heatfrom the system will not ignite

flammable material. Failureof the owner/operator of the

unit to comply with this regulation is a misdemeanor

under California law (and other states) and may also be a

violation of other state and/or federal regulations, laws,

ordinances or codes. Contactyour local fire marshal or

forest servicefor specific information about which regu-

lations apply in your area.

improvefooting onslippery surfaces.

1. Carefullyreadthis

TRAINING

Owner's Manual,the sepa-

rateEngineOwner's Manual,

and any other literature you may receive.

Bethoroughly familiar with thecontrols

andthe proper use of thetiller and its

engine.Know how to stop the unit and

disengagethe controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthearea of operation clear of all

persons, particularly children and pets.

4. Keepin mind thatthe operator or user

is responsible for accidents or hazards

occurring to other people,their property

andthemselves.

PREPARATION

1. Thoroughly inspect the areawherethe

tiller is to be used and remove all foreign

objects.

2. Besure all controls arereleasedand

the Wheel GearLever is in ENGAGE

beforestarting theengine.

3. Donot operatethe tiller without

wearing adequateouter garments. Avoid

loosegarments orjewelry that could get

caught in moving parts.

4. Donotoperatethe tiller when barefoot

or wearing sandals,sneakers,or light

footwear. Wearprotectivefootwearthat will

5. Donottill nearundergroundelectric

cables,telephonelines,pipesor hoses. If in

doubt, contactyour telephoneor utility

company.

6. Warning:Handlefuelwith care;it is

highlyflammableandits vaporsareexplo-

sive. Takethefollowingprecautions:

a.

Storefuel in containers specifically

designedfor this purpose.

b.

Thegascap shall neverbe removed

or fuel addedwhile the engine is

running. Allow the engine to cool

for severalminutes beforeadding

fuel.

C,

Keepmatches, cigarettes,cigars,

pipes, openflames, and sparks

away from the fuel tank and fuel

container.

d. Fill fuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Usea funnel or spout to prevent

spillage.

e. Replaceall fuel tankand container

caps securely.

f. Iffuel is spilled, do not attempt to

start theengine, but move the

machineawayfrom the areaof

spillageand avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Never makeadjustments when engine

is running (unless recommendedby

manufacturer).

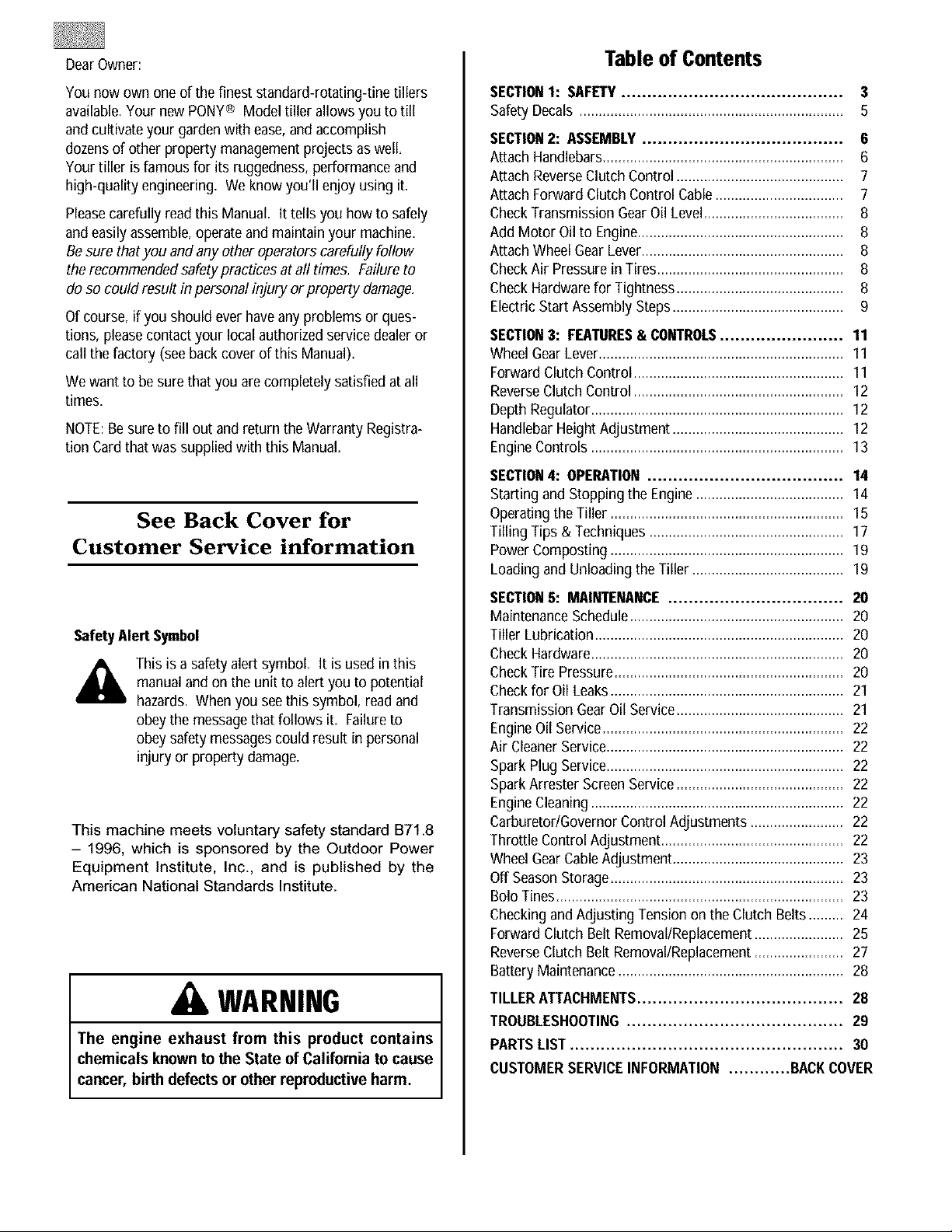

Figure I

ForwardClutch

Control

Handlebar

HeightAdJuster

Wheel Gear

Lever

ForwardClutch

Contml Lever

Lever

_Standard

RotatingTines

OPERATION

1. Donot put handsor feet nearor under

rotating parts.

2. Exerciseextreme caution when on or

crossing graveldrives, walks, or roads.

Stay alert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking aforeign object,stop the

engine (and remove the ignition keyon

electric start models), disconnect the

spark plug wire and prevent it from

touching the spark plug, carefully inspect

the tiller for any damage,and repairthe

damagebeforerestarting and operating

thetiller.

4. Exercisecautionto avoid slipping or

falling.

5. If the unit should start to vibrateabnor-

mally,stop the engine(and removethe

ignition key on electricstart models). Dis-

connectthe sparkplug wire and preventit

from touchingthespark plug, andcheck

immediatelyfor the cause.Vibration is

generallya warning of trouble.

6. Stop theengine (and removethe igni-

tion keyon electric start models), discon-

nect the spark plug wire and prevent it

from touching the spark plug whenever

you leavethe operating position, before

unclogging the tines,or when making any

repairs, adjustments or inspections.

7. Takeall possible precautionswhen

leavingthe machine unattended. Stop the

engine.Removeignition keyon electric

start models. Disconnectspark plug wire

and move it away from the spark plug.

Move Wheel GearLeverto ENGAGE.

8. Beforecleaning, repairing, or inspect-

ing, stop the engine, removethe ignition

key on electricstart models,and make

certain all moving parts havestopped.

Disconnectthe spark plug wire and

prevent it from touching the spark plug to

prevent accidental starting. On electric

start models, alwaysremove the cable

from the negativeside (-) of the battery.

9. Alwayskeepthetiller tine hood flap

down, unless using the hiller/furrower

attachment.

10. Neverusethe tiller unless proper

guards, plates,or othersafetyprotective

devicesarein place.

11. Donot run engine in an enclosed

area.Engineexhaust contains carbon

monoxide gas, a deadly poison that is

odorless, colorless, and tasteless.

12. Keepchildren and petsaway.

13. Never operatethe tiller under

enginepowerif the Wheel GearLever is

in DISENGAGE(FREEWHEEL).In this

position,the wheels will notboldthe

tiller backand therevolvingtinescould

propelthe tiller rapidly, possibly

causinglossofcontrol.Always move the

WheelGearLeverto ENGAGEbefore

starting the engine or engaging the

tines/wheelswith the Forward Clutch

Control or the ReverseClutch Control.

14. Beaware thatthetiller may unex-

pectedlybounceupwardorjump

forward if the tinesshouldstrike

extremelyhardpackedsoil, frozen

ground,or buriedobstacleslike large

stones,roots,or stumps.If in doubt

aboutthe tilling conditions,alwaysuse

thefollowing operatingprecautionsto

assistyou in maintainingcontrolof the

tiller:

a. Walk behindand toone sideofthe

tiller, usingonehandonthe han-

dlebars. Relax yourarm, butusea

securehandgrip.

b. Use shallower depthregulatorset-

tings, workinggraduallydeeper

with each pass.

c. Useslowerengine speeds.

d. Clear the tilling area of all large

stones,rootsandotherdebris.

e. Avoidusingdownwardpressure

on handlebars. If need be, use

slight upwardpressureto keepthe

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lift handlebarstoraise

tines outofthe soil.

Inan emergency,stoptinesand

g_

wheels by releasing whichever

ClutchLeveris engaged. Do not

attempttorestrainthe tiller.

15. Donot overloadthetiller'scapacity

byattempting to till too deeplyattoo fast

arate.

16. Neveroperatethe tiller at high trans-

port speedson hardor slippery surfaces.

Look behind and usecarewhen backing

up.

17. Donot operatethe tiller on a slope

that is too steepfor safety.Whenon

slopes,slow down and makesure you

havegood footing. Neverpermit thetiller

to freewheeldown slopes.

18. Neverallow bystanders nearthe unit.

19. Only useattachments and acces-

soriesthat areapprovedby the tiller

manufacturer.

20. Usetiller attachments andacces-

sorieswhen recommended.

21. Neveroperatethe tiller without good

visibility or light.

22. Neveroperatethetillerif youaretired,

or underthe influenceof alcohol,drugs or

medication.

23.Operatorsshallnottamperwith the

engine-governorsettingsonthe machine;

thegovernorcontrolsthe maximumsafe

operatingspeedto protecttheengineand

allmoving partsfrom damagecausedby

overspeed.Authorizedserviceshallbe

soughtif aproblem exists.

24. Donottouchenginepartswhich may

behotfrom operation.Letpartscooldown

sufficiently.

25. Thebatteryon electricstart modeltillers

containssulfuric acid.Avoidcontactwith

skin,eyes,or clothing.Keepout of the

reachof children.

Antidote-ExternalContact:Flushimme-

diatelywith lotsofwater.

Antidote-lntemal: Drinklargequantities

of wateror milk. Followwithmilk of

magnesia,beateneggs or vegetableoil.

Calla doctor immediately.

Antidote-EyeContact: Flushwith water

for 15 minutes.Getprompt medical

attention.

26. Batteriesproduceexplosivegases.Keep

sparks,flame,andsmokingmaterialsaway.

Ventilatewhen charging batteriesorwhen

usinga batteryin anenclosedspace.

ALWAYSwearsafetygoggleswhen

working nearbatteries.

27. Pleaseremember:Youcanalwaysstop

thetinesandwheelsbyreleasingthe

ForwardClutchControlLeveror the

ReverseClutchControlknob(whichever

controlyou haveengaged),or bymoving

theEngineThrottleControlLever(located

on engine)to STOPon recoil start models

or by turning the ignition keyto OFFon

electricstart models.

28. Toloador unloadthetiller, seethe

instructionsin Section4 of this Manual.

29. Useextremecautionwhen reversingor

pullingthe machinetowardsyou.

30. Starttheenginecarefullyaccordingto

instructionsandwith feetwellawayfrom

thetines.

31. Neverpickup orcarry amachinewhile

theengineis running.

MAINTENANCEANDSTORAGE

1. Keepthe tiller, attachmentsand acces-

sories in safe working condition.

2. Checkall nuts, bolts, and screws at

frequent intervals for proper tightness to

be sure the equipment is in safeworking

condition.

3. Neverstorethe tillerwith fuel in thefuel

tank insideabuildingwhereignition

sourcesarepresentsuch as hot waterand

spaceheaters,furnaces,clothesdryers,

stoves,electricmotors, etc. Allowengineto

coolbeforestoringin anyenclosure.

4. To reducethechancesof afire

hazard,keepthe enginefree of grass,

leaves,orexcessivegrease.

5. Storegasolinein a cool, well-venti-

latedarea,safely awayfrom any spark-

or flame-producing equipment. Store

gasolinein an approvedcontainer,

safelyawayfrom the reachof children.

6. Referto the Maintenancesection of

this Manualand intheseparateEngine

Owner'sManual for instructions if the

tiller isto be stored for anextended

period.

7. Neverperform maintenancewhile

the engine is running or the spark plug

wire is connected,exceptwhen specifi-

cally instructed to do so.

8. If the fuel tank hasto bedrained, do

this outdoors.

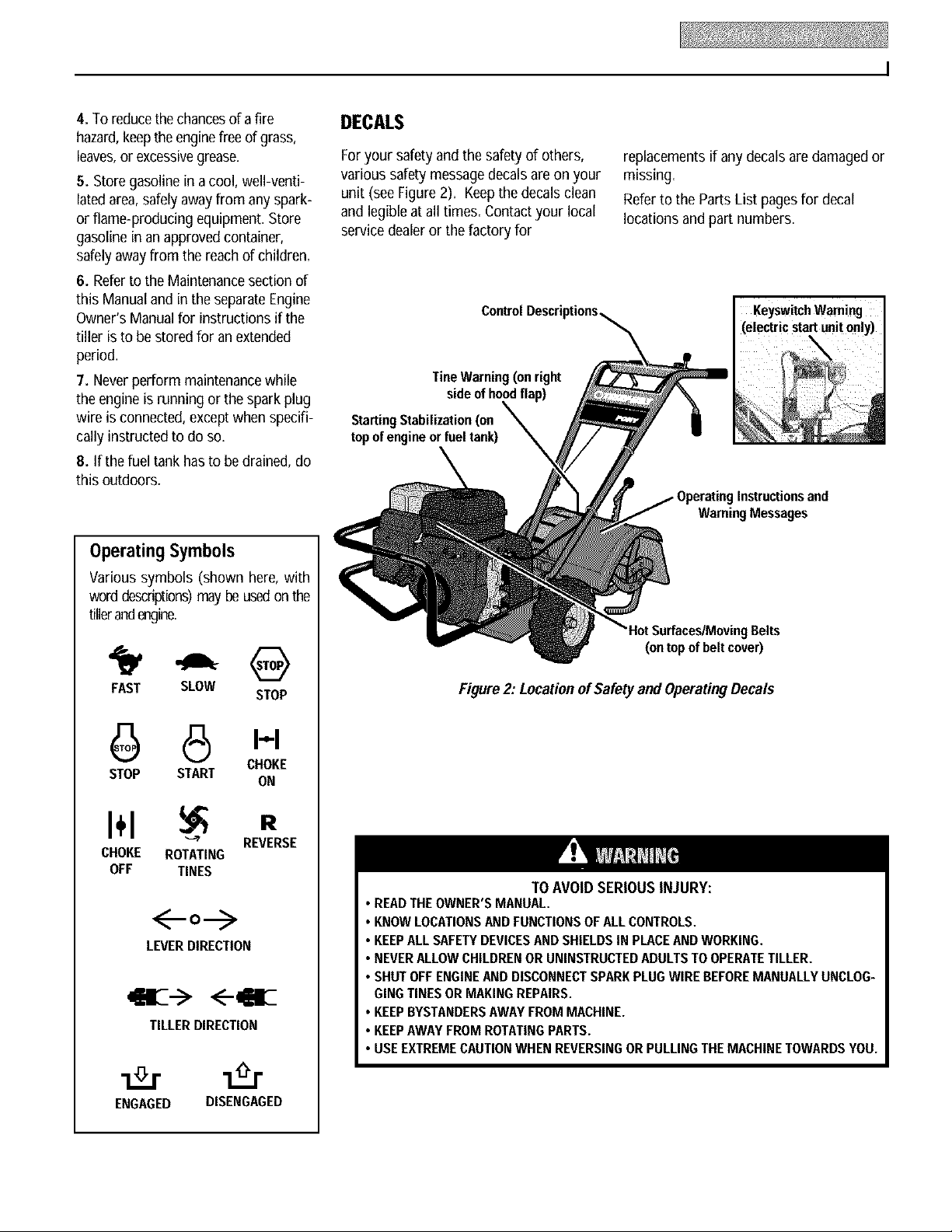

OperatingSymbols

Various symbols (shown here,with

worddescriptions)may beusedonthe

tillerandengine.

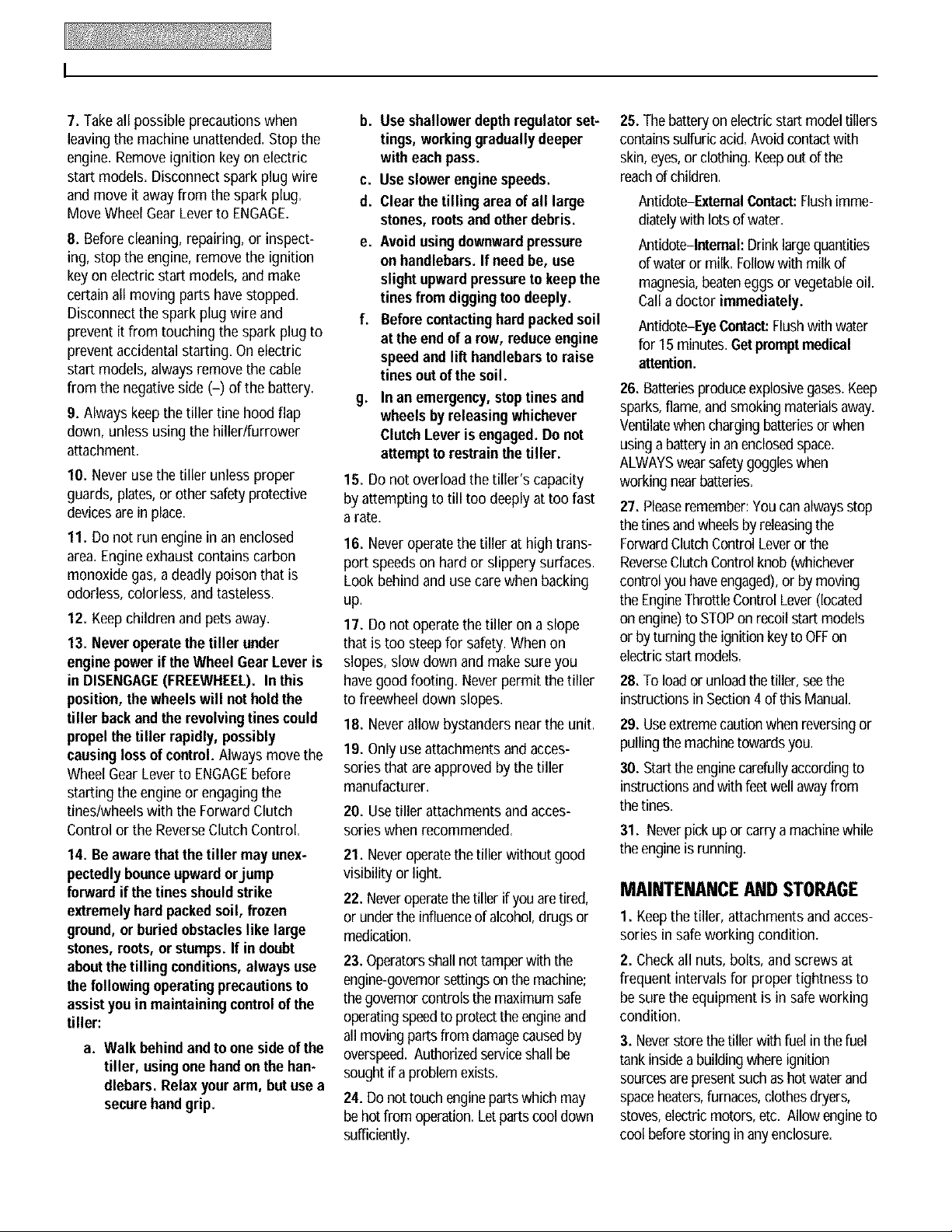

DECALS

Foryour safety and the safety of others,

various safety messagedecals are on your

unit (seeFigure2). Keepthe decalsclean

and legible atall times. Contactyour local

servicedealeror the factoryfor

TineWarning (on right

sideof hoodflap)

StartingStabilization(on

topofengine orfuel tank)

replacementsif anydecals aredamagedor

missing,

Referto the Parts List pagesfor decal

locationsand part numbers.

I KeyswitchWarning

(electrc start unton y)

Instructions and

Warning Messages

Surfaces/MovingBelts

(ontopofbeltcover)

FAST SLOW

STOP

6 8 I-'-I

STOP START

CHOKE

ON

I÷1 R

CHOKE ROTATING

OFF TINES

41BE--><--411

ENGAGED DISENGAGED

"_ REVERSE

o--->

LEVERDIRECTION

TILLERDIRECTION

Figure2: Locationof Safetyand OperatingDecals

TO AVOID SERIOUS INJURY:

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALL CONTROLS.

• KEEPALL SAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINES ORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROM ROTATINGPARTS.

• USEEXTREMECAUTIONWHEN REVERSINGORPULLINGTHEMACHINETOWARDSYOU.

Assembly

HARDWARE BAG PARTS LIST

To prevent personal injury or property

damage, do notstartthe engineuntil all

assembly steps are complete and you

haveread and understandthe safetyand

operatinginstructionsin thisManual.

INTRODUCTION

Carefullyfollow these assembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety beforebeginning assembly.

INSPECTUNIT

Inspect the unit and carton for damage

immediately after delivery. Contact the

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 daysafter the unit has

beendelivered. Contactus at thefactory if

you needassistancein this matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeanycardboardinserts and

packagingmaterial from thecarton.

Removeanystaplesfrom the bottom of

thecarton and remove the carton.

2. Cutthe large,plastictie strap that

securesthe transmission tube to the ship-

ping pallet. Leavethe handlebarson top

of thetiller to avoiddamaginganycables.

3. A bagwith loose hardware is inside

the literature envelope. Checkthecon-

tents againstthe following list and Figure

2-1. Contactyour localdealer orthe

factory if any items are missing or

damaged.

NOTE: Forelectric start units, a second

hardwarebag is locatednearthe battery.

4. Thetiller is heavy. You should not

attempt to remove it from the shipping

platform until instructed to doso in these

"Assembly" steps.

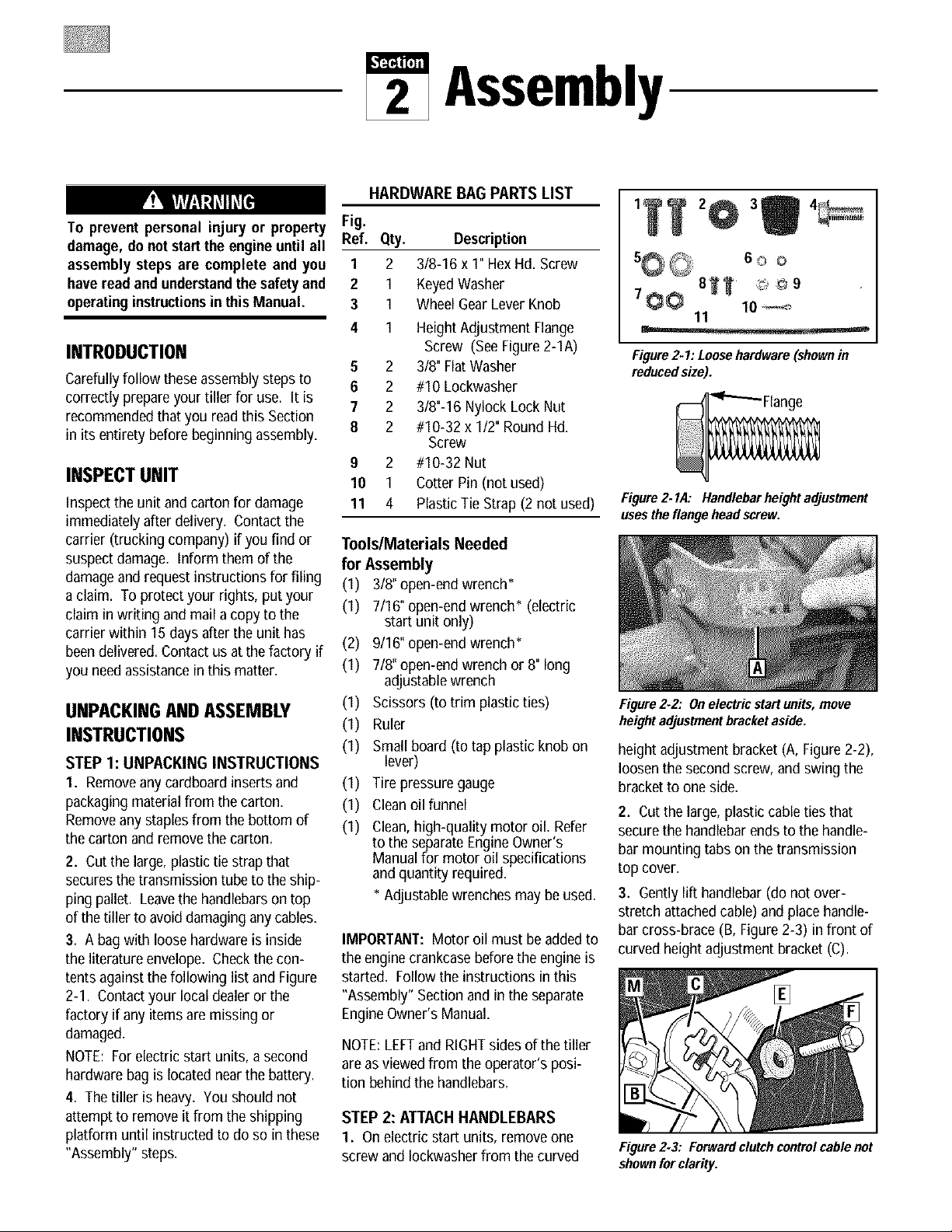

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1"Hex Hd. Screw

2 1 KeyedWasher

3 1 WheelGear LeverKnob

4 1 HeightAdjustment Flange

Screw (SeeFigure2-1A)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" RoundHd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 Plastic Tie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8"open-end wrench*

(1) 7/16" open-end wrench* (electric

start unit only)

(2) 9/16" open-end wrench*

(1) 7/8" open-end wrenchor 8"long

adjustablewrench

(1) Scissors (to trim plastic ties)

(1) Ruler

(1) Small board (to tap plastic knobon

lever)

(1) Tire pressure gauge

(1) Cleanoil funnel

(1) Clean,high-quality motor oil. Refer

to the separateEngineOwner's

Manualfor motor oil specifications

and quantity required.

* Adjustable wrenches may be used.

IMPORTANT:Motor oil must be addedto

the engine crankcasebeforethe engine is

started. Follow the instructions in this

"Assembly" Section andin the separate

EngineOwner's Manual.

NOTE:LEFTand RIGHTsides of the tiller

are as viewed from the operator's posi-

tion behind the handlebars.

STEP 2: ATTACHHANDLEBARS

1. Onelectric start units, remove one

screw and Iockwasherfrom the curved

60o

81 T

700 lo

11

Figure2-I: Loosehardware(shownin

reducedsize).

Figure2.1,4: Handlebarheightadjustment

usestheflangeheadscrew,

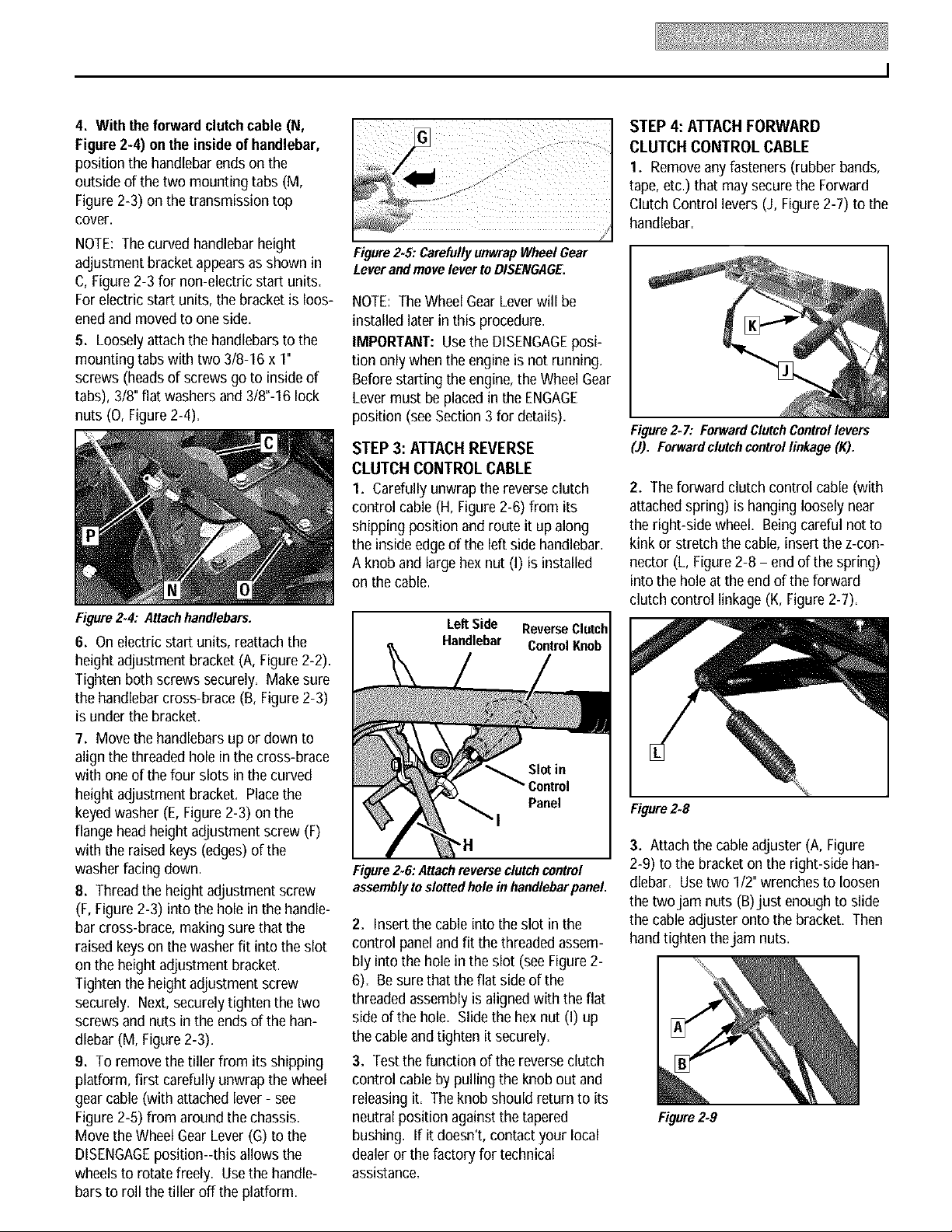

Figure2.2," Onelectricstart units, move

heightadjustmentbracketaside.

height adjustment bracket (A, Figure 2-2),

loosenthe secondscrew, andswing the

bracketto one side.

2. Cutthe large, plastic cable ties that

securethe handlebarends to the handle-

bar mounting tabs on the transmission

top cover.

3. Gentlylift handlebar(do not over-

stretch attachedcable) and placehandle-

bar cross-brace (B, Figure2-3) in front of

curved height adjustment bracket (C).

Figure 2.3: Forwardclutch controlcable not

shownfor clarity.

4. With theforward clutchcable (N,

Figure2-4) onthe insideof handlebar,

position the handlebarends on the

outside of the two mounting tabs (M,

Figure2-3) on the transmission top

cover.

NOTE: Thecurved handlebarheight

adjustment bracket appearsas shown in

C, Figure 2-3 for non-electric start units.

Forelectric start units, the bracketis loos-

enedand movedto one side.

5. Loosely attachthe handlebarsto the

mounting tabs with two 3/8-16 x 1"

screws (heads of screws go to inside of

tabs),3/8" flat washers and 3/8"-16 lock

nuts (O, Figure2-4).

Figure2.4: Attachhandlebars.

6. On electric start units, reattach the

height adjustment bracket (A, Figure 2-2).

Tighten both screws securely. Makesure

the handlebarcross-brace (B, Figure2-3)

is under the bracket.

7. Move the handlebars up or down to

align the threaded hole in the cross-brace

with one of the four slots in the curved

height adjustment bracket. Placethe

keyedwasher (E,Figure 2-3) on the

flange headheight adjustment screw (F)

with the raised keys (edges) of the

washer facing down.

8. Threadthe height adjustment screw

(F, Figure2-3) into the hole in the handle-

bar cross-brace, making sure that the

raised keyson the washer fit into the slot

on the height adjustment bracket.

Tighten the height adjustment screw

securely. Next,securelytighten the two

screws and nuts in the endsof the han-

dlebar (M, Figure2-3)=

9. To remove the tiller from its shipping

platform, first carefully unwrap the wheel

gear cable (with attached lever- see

Figure2-5) from around the chassis.

Move the Wheel GearLever(G) to the

DISENGAGEposition--this allows the

wheelsto rotate freely. Usethe handle-

barsto roll the tiller off the platform.

Figure2.5: CarefullyunwrapWheelGear

LeverandmovelevertoDISENGAGE.

NOTE: TheWheelGearLeverwill be

installed later in this procedure.

IMPORTANT: UsetheDISENGAGEposi-

tion only whentheengine is not running.

Beforestarting the engine,theWheelGear

Levermust be placed in the ENGAGE

position (see Section 3 for details).

STEP 3: ATTACH REVERSE

CLUTCH CONTROL CABLE

1. Carefully unwrapthe reverseclutch

control cable (H, Figure2-6) from its

shipping position and route it up along

the inside edgeof theleft side handlebar.

A knob and large hex nut (I) is installed

on the cable.

Left Side ReverseClutch

Handlebar Control Knob

"H

Figure2.6:Attachreverseclutchcontrol

assemblytoslottedholeinhandlebarpanel.

2. Insertthe cableinto the slot inthe

control paneland fit the threadedassem-

bly into the hole in the slot (see Figure2-

6)= Besure thatthe flat side of the

threadedassembly is aligned with theflat

side of thehole=Slide the hexnut (I) up

the cableand tighten it securely=

3. Testthe function of the reverse clutch

control cable by pulling the knob out and

releasingit. The knob should return to its

neutral position against thetapered

bushing. If it doesn't, contact your local

dealer or the factory for technical

assistance.

STEP4: ATTACHFORWARD

CLUTCH CONTROL CABLE

1. Removeany fasteners (rubber bands,

tape, etc.) that may securethe Forward

ClutchControl levers (J, Figure 2-7) to the

handlebar.

Figure2- 7: ForwardClutchControllevers

(J). Forwardclutch controllinkage (K).

2. Theforward clutch control cable (with

attachedspring) is hanging loosely near

the right-side wheel. Beingcareful not to

kink or stretch the cable, insert the z-con-

nector (L, Figure2-8 - end of the spring)

into the hole at the end of the forward

clutch control linkage (K, Figure2-7).

Figure2-8

3. Attach the cableadjuster (A, Figure

2-9) to the bracket on the right-side han-

dlebar. Usetwo 1/2"wrenches to loosen

the two jam nuts (B)just enoughto slide

the cableadjuster onto the bracket. Then

handtighten thejam nuts.

Figure2.9

Incorrectcable adjustment could cause

thewheels and tines to rotate unexpect-

edly. Follow adjustment procedures

carefully. Failure to do so could result

in personal injuryor propertydamage.

4. Checkfor correct spring/cabletension

as instructed in Section 5, Checkingand

Adjusting Forward Clutch Belt Tension.

5. Whentension is correct, tighten the

two jam nuts (B) securely.

STEP 5: CHECK TRANSMISSION

GEAR OIL LEVEL

Thetransmission wasfilled withgear oil

at thefactory. However,besure to check

the oil level at this time to makecertain it

iscorrect.

IMPORTANT:Donot operatethe tiller if

the gearoil levelis low=Doing sowill

result in severedamageto the transmis-

sion components.

I. With the tiller on levelground, pull the

DepthRegulator Lever(R, Figure2-13)

back and then slide it to the second notch

from the top. NOTE:If the leverdoesnot

move, lift the fine hood flap and look for a

plastic tie securing the lever in place. Cut

and remove the tie.

2. Removethe oil level check plug (M,

Figure2-I0) on the left-side of thetrans-

mission= (Dueto dried paint on the plug

threads, it may require some force to

remove the plug the first time.) Thegear

oil level is correct if oil starts to flow out

of the hole as the plug is removed. If so,

securely reinstall the plug.

Figure 2-11: Addinggear oil.

(b) If adding only a few ounces of gear

oil, useAPI ratedGL-4 or GL-5 gearoil

having aviscosity of SAE140, SAE85W-

140 or SAE80W-90. If refilling anempty

transmission, use only GL-4 gearoil

having aviscosity of SAE85W-140 or

SAE140.

(c) Using a clean funnel, slowly add gear

oil until it flows from the gear oil level

check hole (N, Figure2-11).

(d) Reinstall andtighten securely the gear

oil fill plug (M, Figure 2-10).

STEP 6: ADD MOTOR OIL TO ENGINE

Thetiller is shipped withoutoil in the

engine crankcase.

IMPORTANT:Do not start the engine

without first adding motor oil. Severe

engine damagewill result if the engineis

run without oil=

1. Referto the separateEngineOwner's

Manualfor motor oil specifications and

capacities.

2. With the unit on levelground, move

the Depth Regulator Lever(R, Figure 2-

13) up or down until the engine is level.

3. Add motor oil as described in the

EngineOwner's Manual.

4. Move the DepthRegulatorLever all

the way down until the highest notch is

engaged. This placesthe tines in the

"travel" position.

Figure2.12: Attach Wheel Gear Lever.

Figure2.13: Attachwheelgear cable and

reverse clutchcable withcable ties ($).

3. Usea small board to tap the Wheel

Gear Lever knob securely onto the lever.

4. Securethe wheelgear cable and the

reverseclutch control cableto the left-

sidehandlebarwith two plastic ties (S,

Figure2-I 3) locatedabout two feet apart.

Snip off anyexcesstie lengthwith

scissors.

STEP 8: CHECK AIR

PRESSURE IN TIRES

Usea tire pressuregaugeto check the air

pressure in both tires. Deflateor inflate

bothtires equally to 154o-20 PSI

(pounds per square inch). Besure that

bothtires are inflated equally or the unit

will pull to oneside=

Figure2-10: Gearoil level checkplug.

3. If oildoes not flow from the check

hole, addoil asfollows:

NOTE:Do not use automatic transmission

fluid or motor oil in the transmission.

(a) Cleanareaaround the fill hole (N,

Figure2-11) and unscrew gearoil fill

plug.

STEP 7: ATTACHWHEEL GEAR

LEVER

I. Insert theWheelGear Lever (P, Figure

2-I 2) upthrough the slot in thecontrol

panel that is labeled"WHEELGEAR."

2. Insert two #10-32 x I12"round head

screws down through the "+"marks on

the control panel decaland securely

attachthe wheelgear mounting bracket

using two #10 lockwashersand #10-32

nuts.

STEP 9: CHECK HARDWARE

FOR TIGHTNESS

Inspect the hardware on the unit and

tighten any loose screws, bolts and nuts=

IMPORTANT:

• This completesassembly for recoil start

tillers. Readthe rest of this Manual, and

the separateEngineOwner's Manual,

before operatingthe tiller.

•Electric start models--continue with the

Assembly Steps.

Electric Start

AssemblySteps

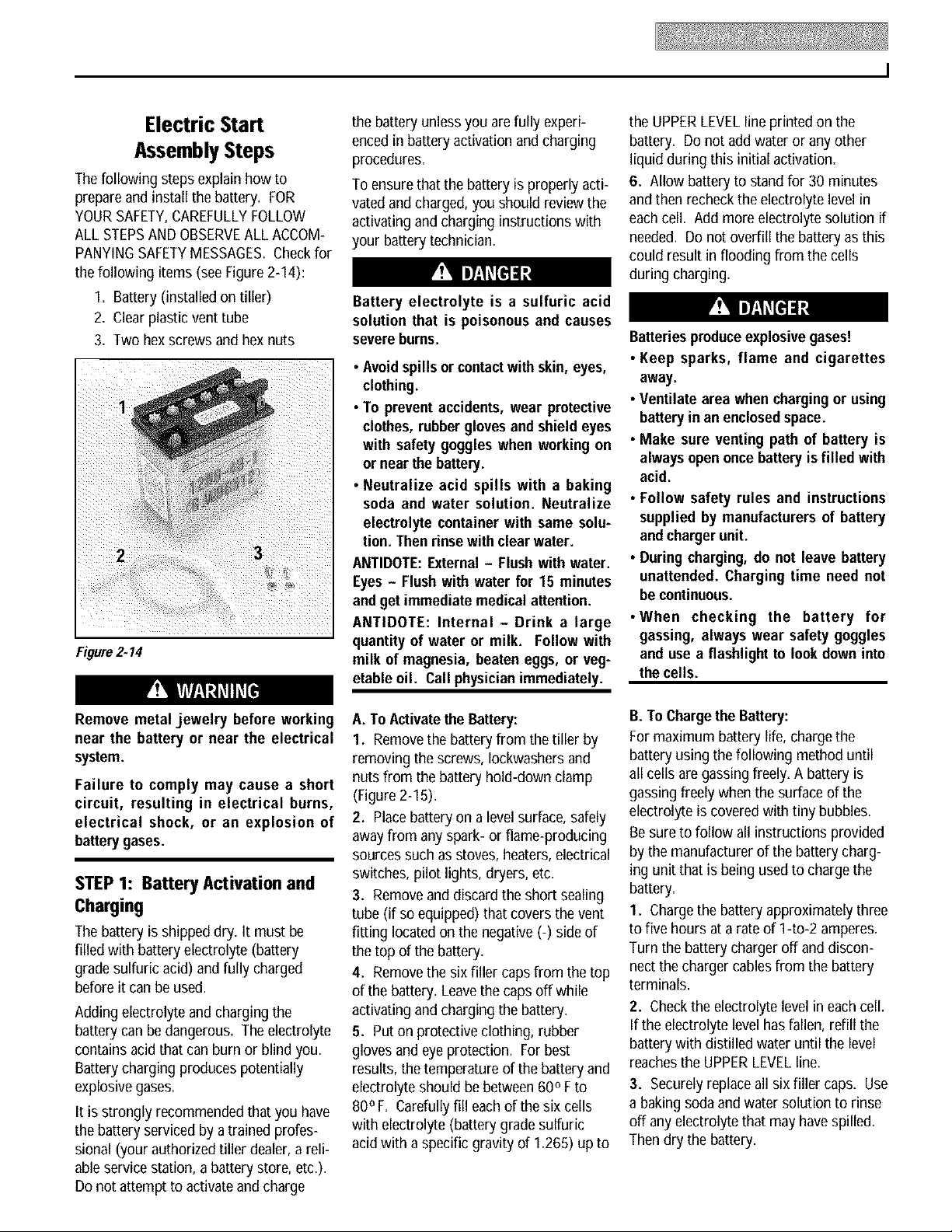

Thefollowing steps explain how to

prepareand install the battery. FOR

YOURSAFETY,CAREFULLYFOLLOW

ALL STEPSANDOBSERVEALL ACCOM-

PANYINGSAFETYMESSAGES.Checkfor

the following items (see Figure 2-14):

I. Battery (installed on tiller)

2. Clearplastic vent tube

3. Two hex screws and hex nuts

2 3

Figure2.14

the battery unlessyou arefully experi-

encedin battery activation and charging

procedures.

To ensurethat the battery is properly acti-

vated and charged,you should review the

activating and charging instructions with

your battery technician.

Battery electrolyte is a sulfuric acid

solution that is poisonous and causes

severeburns.

• Avoidspills or contactwithskin, eyes,

clothing.

• To preventaccidents, wear protective

clothes, rubberglovesandshield eyes

with safety goggles when working on

or nearthe battery.

• Neutralize acid spills with a baking

soda and water solution. Neutralize

electrolyte container with same solu-

tion. Then rinse with clear water.

ANTIDOTE:External- Flushwith water.

Eyes- Flush with water for 15 minutes

and get immediate medical attention.

ANTIDOTE: Internal - Drink a large

quantity of water or milk. Follow with

milk of magnesia, beaten eggs, or veg-

etable oil. Call physicianimmediately.

the UPPERLEVELline printed on the

battery. Do not add water or anyother

liquid during this initial activation.

6. Allow batteryto stand for 30minutes

and then recheck the electrolyte levelin

eachcell. Add more electrolyte solution if

needed. Donot overfill the battery as this

could result in flooding from the cells

during charging.

Batteriesproduceexplosivegases!

• Keep sparks, flame and cigarettes

away.

• Ventilate area when chargingor using

batteryin an enclosedspace.

• Make sure venting path of battery is

alwaysopenoncebatteryis filled with

acid.

• Follow safety rules and instructions

supplied by manufacturers of battery

andchargerunit.

• During charging,do not leave battery

unattended. Charging time need not

becontinuous.

• When checking the battery for

gassing, always wear safety goggles

and use a flashlight to look down into

thecells.

Remove metal jewelry before working

near the battery or near the electrical

system.

Failure to comply may cause a short

circuit, resulting in electrical burns,

electrical shock, or an explosion of

batterygases.

STEP 1: Battery Activation and

Charging

Thebattery is shippeddry=It must be

filled with battery electrolyte (battery

grade sulfuric acid) and fully charged

beforeit canbe used.

Adding electrolyte and charging the

battery canbe dangerous. Theelectrolyte

contains acidthat can burn or blind you.

Batterycharging produces potentially

explosivegases.

It is strongly recommended that you have

the batteryserviced by atrained profes-

sional (your authorized tiller dealer, a reli-

ableservice station, abattery store, etc.).

Donot attempt to activate and charge

A. To Activatethe Battery:

I. Removethe batteryfrom thetiller by

removing the screws, lockwashers and

nuts from the battery hold-down clamp

(Figure2-15).

2. Placebattery on a levelsurface, safely

away from any spark- or flame-producing

sources such as stoves, heaters, electrical

switches, pilot lights, dryers, etc.

3. Removeand discard the short sealing

tube (if soequipped) that coversthe vent

fitting locatedon the negative(-) side of

the top of the battery.

4. Removethe six filler caps from the top

of the battery. Leavethe caps off while

activating and charging the battery.

5. Puton protectiveclothing, rubber

gloves and eyeprotection. For best

results, the temperature of the battery and

electrolyte should be between600 Fto

80° F. Carefully fill eachof the six cells

with electrolyte (batterygrade sulfuric

acidwith a specific gravity of 1.265) up to

B. To Chargethe Battery:

Formaximum battery life, charge the

batteryusing the following method until

all cells are gassingfreely. A battery is

gassing freely when the surfaceof the

electrolyte is covered with tiny bubbles.

Besureto follow all instructions provided

bythe manufacturer of the battery charg-

ing unit that is being used to charge the

battery.

1. Chargethe batteryapproximately three

to five hours at a rateof 1-to-2 amperes.

Turn the battery chargeroff and discon-

nectthe charger cablesfrom the battery

terminals.

2. Checkthe electrolyte level in eachcell.

If the electrolyte level hasfallen, refill the

batterywith distilled water until the level

reachesthe UPPERLEVELline.

3. Securelyreplaceall six filler caps. Use

a baking soda and water solution to rinse

off any electrolyte that may havespilled.

Thendry the battery.

• Do not touch positive (+) battery

terminal and any surrounding metal

with tools, jewelry or other metal

objects. Failure to complycouldcause

a shortcircuitthat couldcauseelectri-

cal burns or an explosion of battery

gases.

• Incorrectinstallationofthe batterycan

result in electrical system damage.

Follow installation instructions care-

fully to avoid damage.

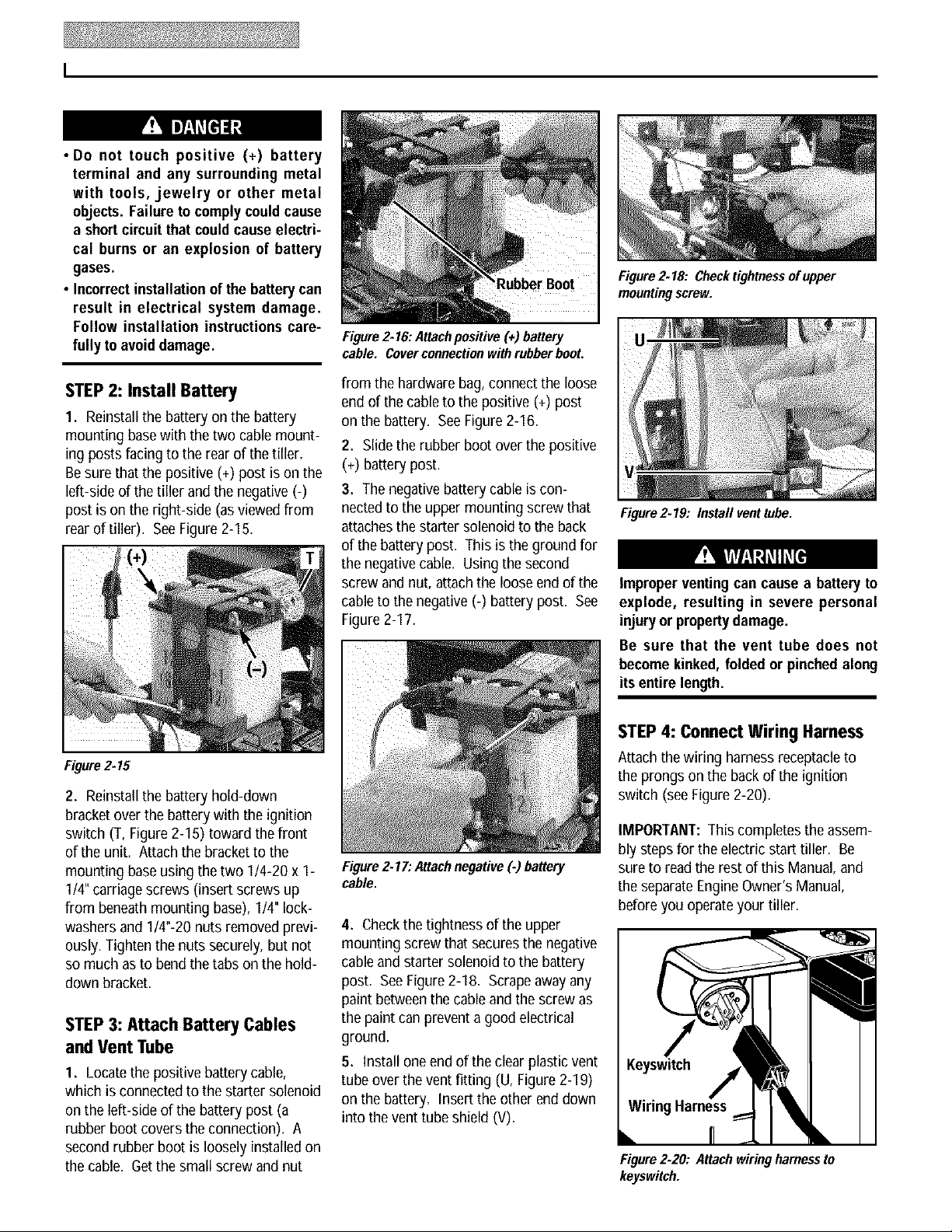

Figure2.18: Checktightness of upper

mountingscrew.

Figure2.16: Attachpositive (+) battery

cable. Coverconnectionwithrubber boot.

STEP2: Install Battery

1. Reinstallthebattery on the battery

mounting basewith thetwo cablemount-

ingposts facing to the rear of the tiller=

Besure that thepositive (+) post ison the

left-sideof the tillerand the negative (-)

post is on theright-side (as viewedfrom

rear of tiller). SeeFigure 2-15.

Figure2.15

2. Reinstallthe battery hold-down

bracketoverthe batterywiththe ignition

switch (T, Figure2-15) toward thefront

of the unit. Attach the bracket to the

mounting base using the two 1/4-20 x 1-

1/4"carriage screws (insert screws up

from beneath mounting base), 1/4" lock-

washers and 1/4"-20 nuts removedprevi-

ously. Tightenthe nuts securely,but not

so much as to bend thetabs on the hold-

down bracket.

STEP3: Attach Battery Cables

and Vent Tube

1. Locatethe positivebattery cable,

which is connectedto the starter solenoid

on the left-side of the battery post (a

rubber boot covers the connection). A

second rubber boot is loosely installed on

the cable. Get the small screw and nut

from the hardware bag, connect the loose

end of the cable to the positive (+) post

on the battery. See Figure2-16.

2. Slidethe rubber boot over thepositive

(+) batterypost.

3. The negativebattery cableis con-

nected to the upper mounting screw that

attachesthe starter solenoidto the back

of thebattery post. This is the ground for

the negativecable. Usingthe second

screw and nut, attachthe looseend of the

cableto thenegative (-) battery post. See

Figure2-17.

Figure2.17: Attachnegative (.) battery

cable.

4. Checkthetightnessof the upper

mounting screw that securesthe negative

cableand starter solenoid to the battery

post. SeeFigure2-18, Scrapeaway any

paint betweenthe cableand the screw as

the paint canprevent a good electrical

ground.

5. Install one endof the clearplastic vent

tube overthe vent fitting (U, Figure2-19)

on the battery= Insertthe other end down

into thevent tube shield (V)=

Figure2.19: Instafl vent tube.

Improper ventingcan causea battery to

explode, resulting in severe personal

injuryor propertydamage.

Be sure that the vent tube does not

becomekinked, folded or pinchedalong

itsentire length.

STEP 4: Connect Wiring Harness

Attachthe wiring harness receptacleto

the prongs on the back of the ignition

switch (seeFigure2-20).

IMPORTANT: This completes the assem-

bly steps for the electric start tiller. Be

sureto read the rest of this Manual, and

the separateEngineOwner'sManual,

beforeyou operateyour tiller.

Figure2.20: Attachwiringharnessto

keyswitch.

FeaturesandControls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, the separate Engine

Owner's Manual, and on the decals on

the machine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

INTRODUCTION

This Section describesthe location and

function of the controls on your tiller.

Referto thefollowing section "Opera-

tion" for detailedoperating instructions,

Practiceusing these controls, withthe

engine shut off, until you understandthe

operationof the controls and feel confi-

dentwith them.

IMPORTANT:Referto theseparate

engine manufacturer's EngineOwner's

Manualfor information aboutthe con-

trois on theengine.

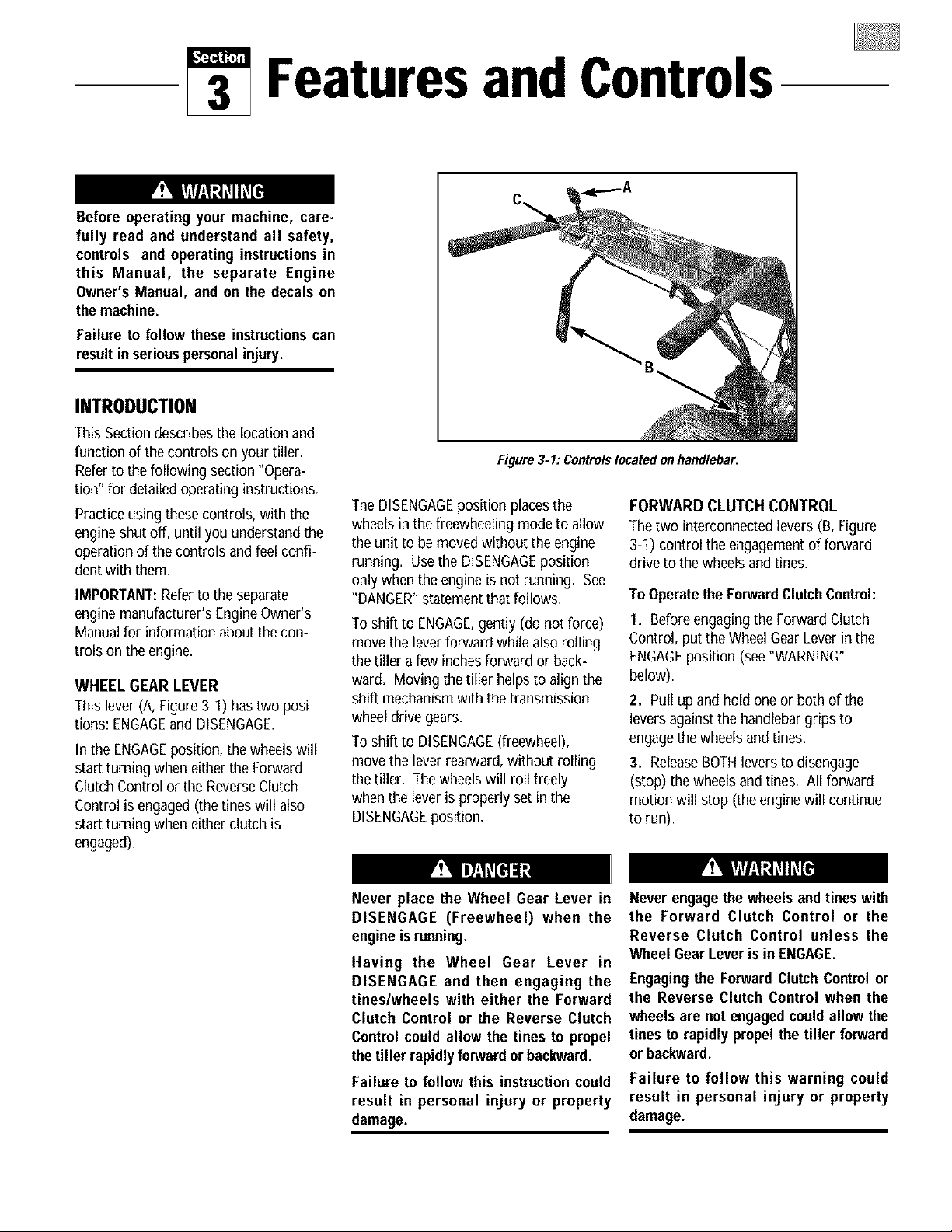

WHEEL GEAR LEVER

Thislever (A, Figure 3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, the wheels will

start turning when eitherthe Forward

ClutchControl or the ReverseClutch

Control is engaged (thetines will also

start turning when eitherclutch is

engaged).

Figure3. I: Controlslocated onhandlebar.

TheDISENGAGEposition placesthe

wheels in the freewheeling mode to allow

the unit to be moved without the engine

running. Usethe DISENGAGEposition

only whenthe engine is not running. See

"DANGER"statementthat follows.

To shift to ENGAGE,gently (do not force)

move the lever forward whilealso rolling

thetiller a few inchesforward or back-

ward. Moving thetiller helps to align the

shift mechanismwith the transmission

wheeldrive gears.

To shift to DISENGAGE(freewheel),

move the lever rearward, without rolling

thetiller. The wheels will roll freely

whenthe lever is properly set in the

DISENGAGEposition.

FORWARD CLUTCH CONTROL

Thetwo interconnectedlevers (B, Figure

3-1) control the engagementof forward

drive to the wheels and tines.

To Operate the ForwardClutch Control:

1. Beforeengagingthe Forward Clutch

Control, put the WheelGearLeverin the

ENGAGEposition (see"WARNING"

below).

2. Pull up and hold one or both of the

leversagainst the handlebargrips to

engagethe wheelsand tines.

3. ReleaseBOTHlevers to disengage

(stop) the wheels and tines. All forward

motion will stop (theenginewill continue

to run).

Never place the Wheel Gear Lever in

DISENGAGE (Freewheel) when the

engine is running.

Having the Wheel Gear Lever in

DISENGAGE and then engaging the

tines/wheels with either the Forward

Clutch Control or the Reverse Clutch

Control could allow the tines to propel

thetiller rapidly forward or backward.

Failure to follow this instructioncould

result in personal injury or property

damage.

Never engage the wheels andtines with

the Forward Clutch Control or the

Reverse Clutch Control unless the

Wheel GearLever is in ENGAGE.

Engagingthe ForwardClutchControl or

the Reverse Clutch Control when the

wheels are not engagedcould allow the

tines to rapidly propel the tiller forward

or backward.

Failure to follow this warning could

result in personal injury or property

damage.

REVERSECLUTCHCONTROL

TheReverseClutch Control (C,Figure

3-1) controls the engagementof reverse

drive to the wheels and tines. The revers-

ingfeature is usedfor maneuveringthe

tiller only - neverengagethetines in

thegroundwhile goinginthe reverse

direction.

• Use extreme caution when reversing

or pulling the machine towards you.

Look behindto avoid obstacles.

• Never attemptto till inreverse.

Failure to follow this warning could

result in personal injury or property

damage.

To Operatethe ReverseClutch Control:

1. Put the WheelGearLeverinthe

ENGAGEposition (seethe "WARNING"

statementon previous page).

2. Stop all tiller motion by releasingthe

ForwardClutchControl levers=

3. Lift up the handlebarsuntil thetines

cleartheground, look behind you to avoid

any obstacles,andthen pullthe Reverse

Clutch Control knob out. Thetines and

wheels will rotate in a reversedirection=

4. Releasethe ReverseClutchControl

knobto disengage(stop) thewheelsand

tines=All reversemotion will stop (the

engine will continue to run).

• Do not attempt to till too deeply too

quickly. Gradually work down to

deepertilling depths.

• Place the Depth RegulatorLever in the

"travel" position before starting the

engine. This position prevents the

tines from touching the ground until

youare readyto begintilling.

Failure to follow this warning could

result in personal injury or property

damage.

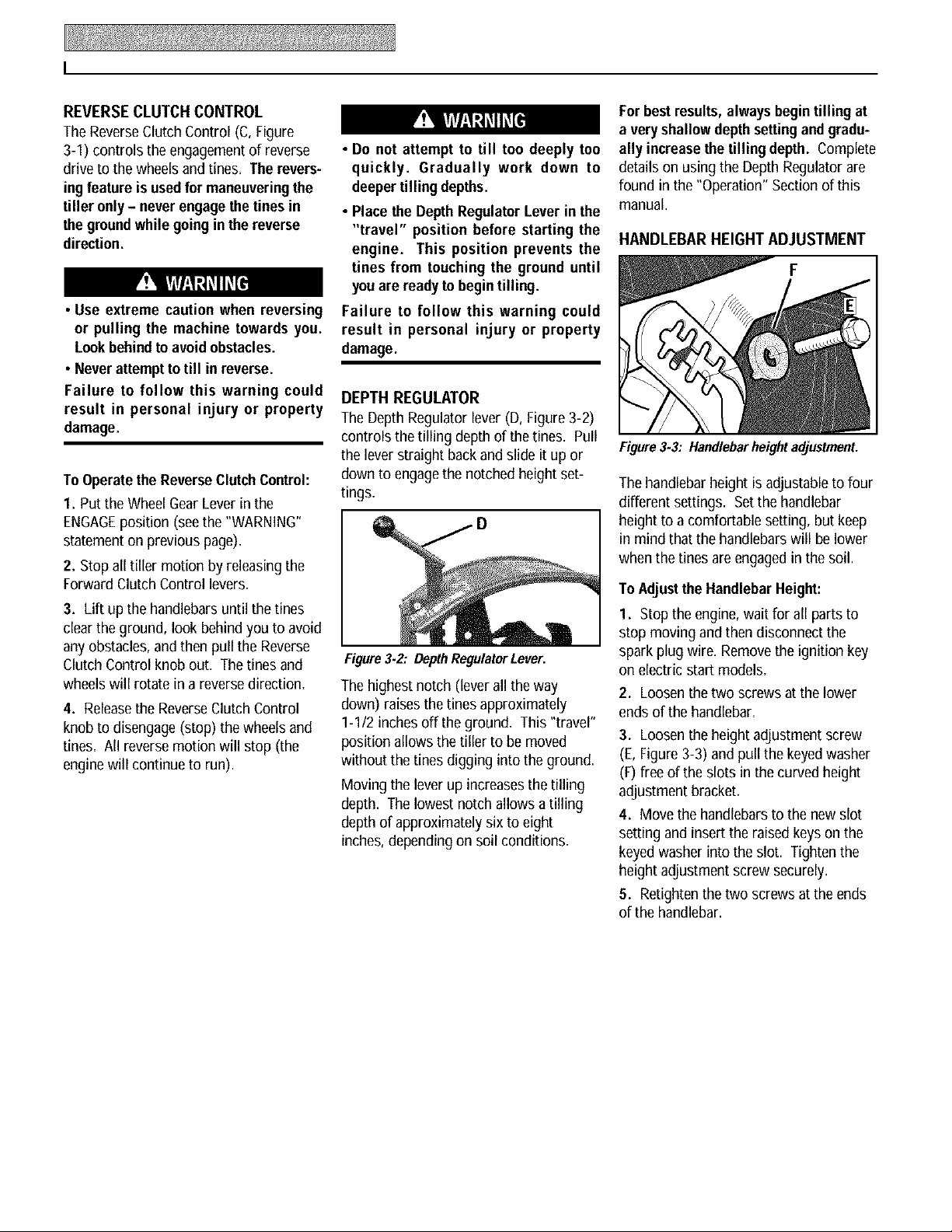

DEPTH REGULATOR

TheDepth Regulator lever (D, Figure 3-2)

controls thetillingdepthof the tines. Pull

theleverstraight backand slide it upor

down toengagethenotched height set-

tings.

Figure3.2: DepthRegulatorLever.

Thehighest notch (leverall the way

down) raises the tines approximately

1-1/2 inches offthe ground= This"travel"

position allows the tiller to be moved

without the tines digging into theground.

Moving the lever up increasesthe tilling

depth. The lowest notch allows a tilling

depth of approximately six to eight

inches,depending on soil conditions.

Forbestresults, alwaysbegintilling at

a very shallowdepthsetting andgradu-

ally increasethe tilling depth. Complete

details on using the Depth Regulator are

found in the "Operation" Section of this

manual.

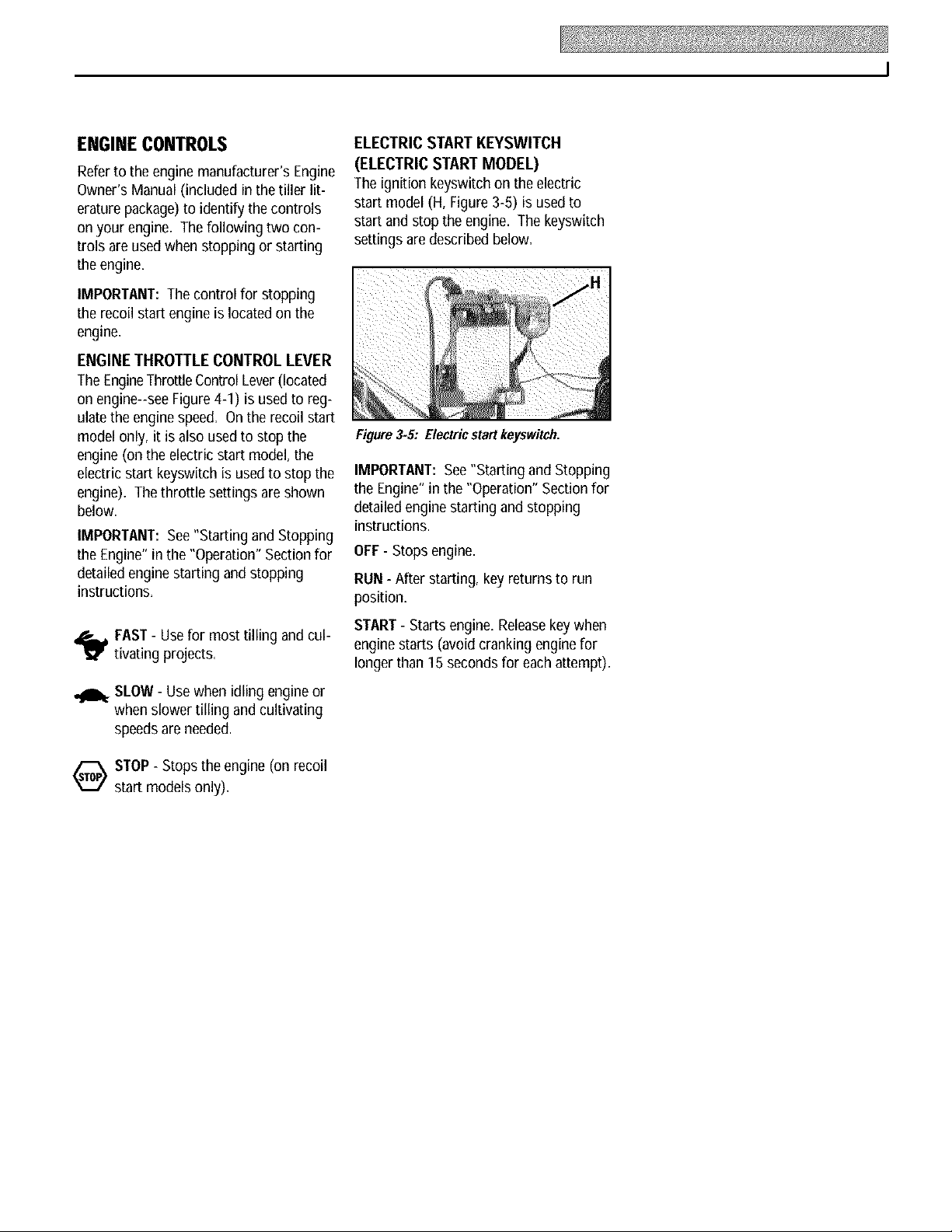

HANDLEBAR HEIGHT ADJUSTMENT

Figure3.3: Handlebar heightadjustment.

The handlebarheight is adjustableto four

different settings. Setthe handlebar

heightto a comfortable setting, but keep

in mind that the handlebarswill be lower

when the tines are engagedin thesoil.

To Adjust the HandlebarHeight:

I. Stop the engine, wait for all partsto

stop moving and then disconnect the

spark plug wire. Removethe ignition key

on electric start models.

2. Loosenthe two screws at the lower

endsof the handlebar=

3. Loosenthe height adjustment screw

(E,Figure3-3) and pull the keyedwasher

(F)free of theslots in the curved height

adjustment bracket.

4. Move the handlebars to the new slot

setting and insert the raised keyson the

keyedwasher into the slot. Tightenthe

height adjustment screw securely.

5. Retightenthetwoscrews at the ends

of the handlebar.

ENGINECONTROLS

Referto the engine manufacturer's Engine

Owner's Manual (included inthe tiller lit-

erature package)to identify the controls

on your engine. The following two con-

trols areusedwhen stopping or starting

the engine.

IMPORTANT:Thecontrol for stopping

the recoil start engine is located on the

engine.

ENGINE THROTTLE CONTROL LEVER

TheEngineThrottleControlLever(located

on engine--see Figure4-1) is usedto reg-

ulatethe engine speed. Onthe recoil start

modelonly, it is also used to stop the

engine (on the electricstart model, the

electric start keyswitch is used to stop the

engine). Thethrottle settings areshown

below.

IMPORTANT: See"Starting andStopping

the Engine"in the "Operation" Section for

detailedengine starting andstopping

instructions.

ELECTRIC START KEYSWITCH

(ELECTRIC START MODEL)

The ignition keyswitch on the electric

start model (H, Figure 3-5) is usedto

start and stop the engine. The keyswitch

settings are described below.

Figure3.5: Electricstartkeyswitch.

IMPORTANT: See"Starting and Stopping

the Engine"in the "Operation" Section for

detailedengine starting and stopping

instructions.

OFF-Stops engine.

RUN - After starting, keyreturns to run

position.

,_ FAST- Usefor most tilling and cul-

tivating projects.

SLOW- Usewhen idling engineor

when slower tilling and cultivating

speeds areneeded.

O STOP- Stops the engine (onrecoil

start models only).

START- Starts engine. Releasekey when

engine starts (avoid cranking enginefor

longer than 15 secondsfor eachattempt).

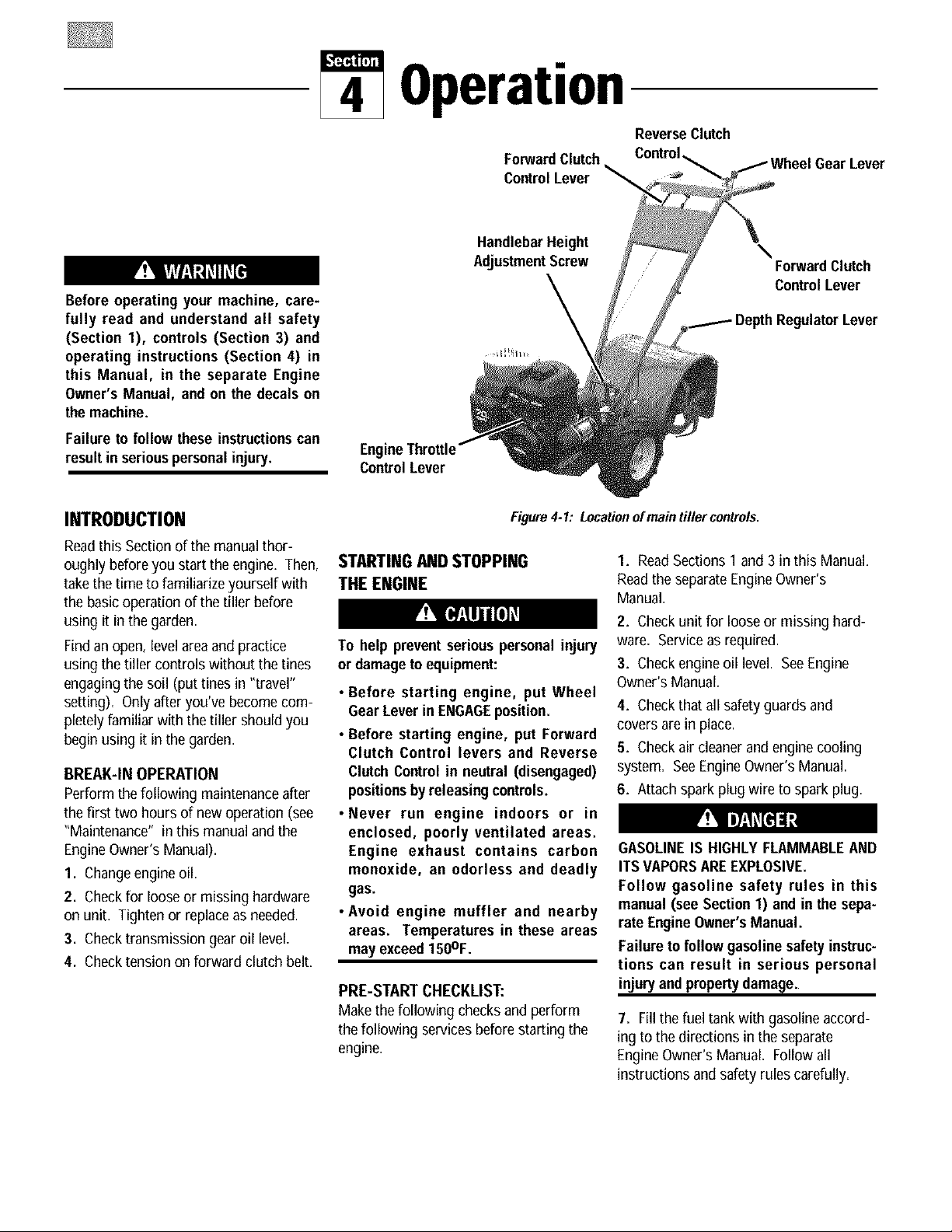

Operation

ForwardClutch

ControlLever

ReverseClutch

GearLever

Before operating your machine, care-

fully read and understand all safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner's Manual, and on the decals on

themachine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

INTRODUCTION

Readthis Sectionof the manualthor-

oughly beforeyou start theengine, Then,

takethe time to familiarizeyourself with

the basicoperation of the tiller before

using it in the garden.

Findan open, level areaand practice

using thetillercontrols without the tines

engagingthe soil (put tines in"travel"

setting). Only after you've becomecom-

pletely familiar with the tiller should you

begin using it in the garden.

BREAK-IN OPERATION

Perform the following maintenanceafter

thefirst two hours of new operation (see

"Maintenance" in this manual andthe

EngineOwner's Manual).

1. Changeengine oil.

2. Checkfor loose or missing hardware

on unit. Tighten or replaceas needed.

3. Checktransmission gear oil level.

4. Checktension on forward clutch belt.

HandlebarHeight

AdjustmentScrew

EngJ

Control Lever

Figure 4- I: Locationof main tiller controls.

STARTINGANDSTOPPING

THE ENGINE

To help prevent serious personalinjury

or damagetoequipment:

• Before starting engine, put Wheel

GearLeverin ENGAGEposition.

• Before starting engine, put Forward

Clutch Control levers and Reverse

ClutchControlin neutral (disengaged)

positionsby releasing controls.

• Never run engine indoors or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas.

•Avoid engine muffler and nearby

areas. Temperatures in these areas

may exceed150OF.

PRE-START CHECKLIST:

Make the following checks and perform

the following services beforestarting the

engine.

\

ForwardClutch

Control Lever

1. ReadSections 1 and 3 in this Manual.

Readthe separateEngineOwner's

Manual.

2. Checkunit for loose or missing hard-

ware. Serviceas required.

3. Checkengine oil level. SeeEngine

Owner's Manual.

4. Checkthat all safety guards and

covers are in place.

5. Checkair cleanerand engine cooling

system. See EngineOwner's Manual.

6. Attachspark plug wire to spark plug.

GASOLINEIS HIGHLYFLAMMABLEAND

ITSVAPORSAREEXPLOSIVE.

Follow gasoline safety rules in this

manual (see Section1) and in the sepa-

rate EngineOwner'sManual.

Failure tofollow gasoline safety instruc-

tions can result in serious personal

injuryand propertydamage.

7. Fillthefuel tank with gasolineaccord-

ing to the directions in the separate

EngineOwner's Manual. Follow all

instructions andsafety rules carefully.

Loading...

Loading...