Page 1

0 TRtIII BILT

OWNER'SMANUAL

Rear-TineTillers

• Safety

• Assembly

Before © read this

Models

• Controls

• Operation

• Maintenance

• PartsList

12227 - 3.75HP TUFFY®

12209 - 5.5HPBRONCOTM

12210 - 6.5HPSuper BRONCO'M

Model

12210

GARDEN WAYINCORPORATED

Page 2

DearOwner:

Table of Contents

You now own one of the finest standard-rotating-tine tillers

available.Your new tiller allows you to till and cultivate your

garden with ease,and accomplish other property manage-

ment projects aswell. Your tiller is famous for its rugged-

ness,performance and high-quality engineering. We know

you'll enjoy using it.

Pleasecarefully readthis Manual. It tells you how to safely

and easily assemble,operate and maintain your machine

(four tiller models arecovered in this Manual--be sure to

useonly the information that applies to your model). Be

sure thatyou andany other operatorscarefully follow the

recommendedsafetypractices atall times. Failureto do so

could result in personal injury or property damage.

Of course, if you should ever haveany problems or ques-

tions, pleasecontact your local authorized dealeror callthe

Factory(seeback cover of this Manual).We want to be sure

that you are completelysatisfied at all times.

NOTE: Besureto fill out and return the Warranty Registra-

tion Cardthat was suppliedwith this Manual.

See Back Cover for

Customer Service information

SafetyAlertSymbol

This is a safetyalertsymbol. It is used in this

manualand on the unit to alert you to potential

hazards. Whenyou seethis symbol, readand

obeythe messagethat follows it. Failureto obey

safety messagescould result inpersonal injury or

property damage.

This machine meets voluntary safety standard

B71.8 - 1996, which is sponsored by the Outdoor

Power Equipment Institute, Inc., and is published

by the American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

SECTION1: SAFETY........................................... 3

SafetyDecals ............................................................. 5

OperatingSymbols ..................................................... 5

SECTION2: ASSEMBLY....................................... 6

Attach Handlebar........................................................ 6

Move Tiller Off Shipping Platform .............................. 6

Install ForwardClutch Cable....................................... 7

Install ReverseClutch Cable(Models 12209/12210).. 8

CheckLevel of TransmissionGearOil ........................ 9

Add Motor Oilto Engine............................................. 9

CheckHardwarefor Tightness.................................... 9

CheckAir Pressurein Tires ........................................ 9

SECTION3: FEATURES& CONTROLS........................ 10

EngineControls .......................................................... 10

WheelDrive Pins ........................................................ 10

ForwardClutch Bail .................................................... 11

ReverseClutch Control............................................... 11

DepthRegulator Lever................................................ 11

HandlebarHeightAdjustment ..................................... 11

SECTION4: OPERATION...................................... 12

Break-InOperation..................................................... 12

Starting and Stoppingthe Engine............................... 12

Operatingthe Tiller ..................................................... 13

Tilling Tips & Techniques........................................... 14

Loadingand Unloadingthe Tiller ................................ 16

SECTION5: MAINTENANCE.................................. 17

MaintenanceSchedule................................................ 17

Tiller Lubrication......................................................... 17

Checkfor Oil Leaks..................................................... 17

CheckHardware......................................................... 17

CheckTire Pressure.................................................... 17

Transmission GearOil Service.................................... 17

BoloTines................................................................... 18

CheckingandAdjusting Forward DriveBelt Tension .. 19

ForwardClutch BailAdjustment ................................. 20

CheckingandAdjusting ReverseDrive BeltTension... 20

EngineCleaning.......................................................... 20

Air CleanerService..................................................... 20

EngineOil Service....................................................... 20

Spark Plug Service..................................................... 21

SparkArrester ScreenService.................................... 21

Throttle LeverAdjustment .......................................... 21

Carburetor/GovernorControl Adjustments ................. 21

Off SeasonStorage..................................................... 21

Troubleshooting ............................................... 22

PartsList........................................................ 23

CustomerService Information .................... BackCover

Page 3

SPARKARRESTERWARNINGTO RESIDENTS

OF CALIFORNIAAND SEVERALOTHERSTATES

UnderCalifornia law, and under the laws of several

other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels

on any forest, brush,hay, grain, or grass covered land;

or land covered by any flammable agricultural crop

without an engine spark arrester in continuous effec-

tive working order.

The engine on the unit is an internal combustion

engine which burns gasoline, a hydrocarbon fuel, and

must be equippedwith a spark arrester muffler in con-

tinuous effective working order. The spark arrester

must be attachedto the engineexhaust system in such

a manner that flames or heat from the system will not

ignite flammable material. Failureof the owner/oper-

ator of the unit to comply with this regulation is a mis-

demeanor under California law (and other states) and

may also be a violation of other state and/or federal

regulations, laws, ordinances or codes. Contact your

localfire marshalor forest servicefor specificinforma-

tion about whichregulations apply in your area.

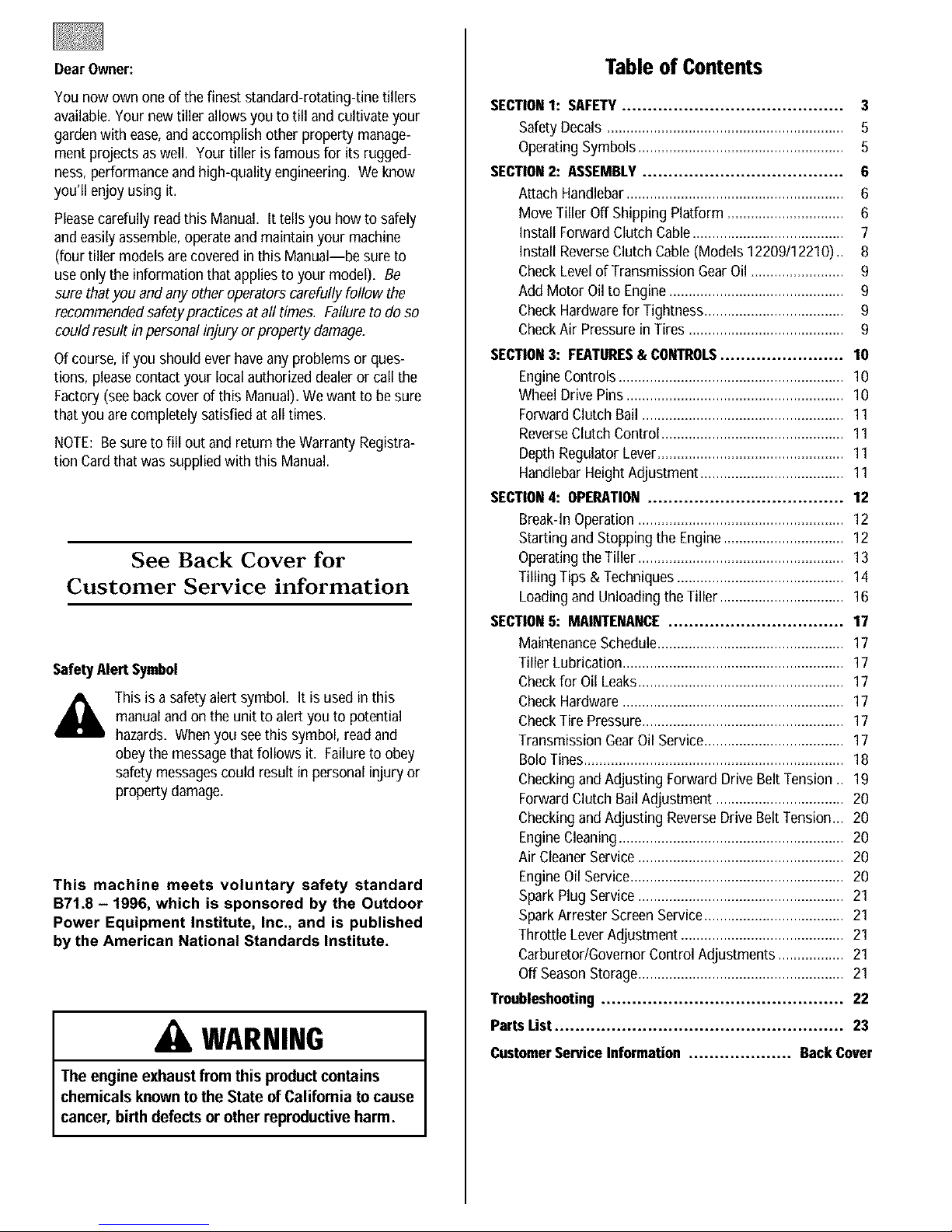

Safety

ReverseClutch

ForwardClutch Bail

DepthRegulator

TineHood Flap

f

_Standard-Rotating-

Tines (SRT)

"WheelDrivePin

(oneachwheel)

Figure1. I: Tiller featuresand controls(5.5HP Model shown). See separate

EngineOwner'sManual toidentify engine controls.

Control (Models

12209112210)

1. Carefullyreadthis Owner's

Training

Manual, the separateEngine

Owner's Manual, and any

other literatureyou may receive.Bethor-

oughly familiar with the controls and the

proper useof the tiller andits engine.

Knowhow to stop the unit and disengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operate the

tiller without proper instruction.

3. Keepthe areaof operationclearof all

persons,particularly children andpets.

4. Keepin mind that the operator or user

is responsiblefor accidentsor hazards

occurring to other people,their property,

and themselves.

Preparation

1. Thoroughlyinspectthe areawhere the

tiller is to be usedand remove all foreign

objects.

2. Be sureall tiller controls are released

and both wheels are in the Wheel Drive

position before starting the engine.

3. Do not operatethe tiller without

wearing adequateouter garments. Avoid

loosegarments orjewelry that could get

caught in moving parts.

4. Do not operate thetiller whenbarefoot

or wearing sandals, sneakers,or light

footwear. Wear protective footwear that

will improve footing on slippery surfaces.

5. Do not till nearunderground electric

cables,telephone lines, pipesor hoses. If

in doubt, contactyour telephone or utility

company.

6. Warning: Handlefuel with care;it is

highlyflammable and its vapors are explo-

sive.Takethe following precautions:

a. Storefuel incontainers specifically

designedfor this purpose.

b. Thegascapshallnever be removed

or fuel addedwhilethe engineis run-

ning. Allowthe engineto coolfor

severalminutesbefore addingfuel.

c. Keepmatches,cigarettes, cigars,

pipes, open flames, and sparks

away from the fuel tank and fuel

container.

d, Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Useafunnel or spout to prevent

spillage.

e. Replaceall fuel tank andcontainer

caps securely.

f. If fuel is spilled, do not attemptto

start the engine,but movethe

machine awayfrom the areaof

spillage and avoidcreating any

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustmentswhen engine

is running (unless recommendedby

manufacturer).

Operation

I. Do not put handsor feet nearor under

rotating parts.

2. Exerciseextremecaution when on or

crossing graveldrives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3. After striking aforeign object,stop the

engine, removethe wirefrom the spark

plug wire and preventit from touching the

spark plug. Thoroughly inspect the

machine for anydamage andrepair the

damagebefore restarting and operating

the machine.

Page 4

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor-

mally, stop the engine,disconnect the

spark plug wire and prevent it from

touching the spark plug, and checkimme-

diatelyfor the cause. Vibration isgener-

allya warning of trouble.

6. Stopthe engine,disconnect the spark

plug wire and prevent it from touching the

spark plug, wheneveryou leavethe oper-

ating position, before unclogging the tines,

or when making any repairs, adjustments

or inspections.

7. Takeall possible precautionswhen

leavingthe machineunattended. Stopthe

engine. Disconnectthe spark plugwire

and move it awayfrom the spark plug. Be

surethat both wheels are in the Wheel

Drive position.

8. Beforecleaning,repairing, or

inspecting, stop the engineand make cer-

tain allmoving parts havestopped. Dis-

connectthe spark plug wire and prevent it

from touching thespark plug to prevent

accidentalstarting.

9. Theflap on thetine hoodmust be down

when operating thetiller.

10. Neverusethe tiller unless proper

guards, plates,or other safety protective

devicesare inplace.

11. Donot run the engine in an enclosed

area. Engineexhaustcontains carbon

monoxide gas, a deadlypoison that is

odorless,colorless, andtasteless.

12. Keepchildren and petsaway.

13. Neveroperatethetiller underengine

powerif thewheels are in theFreewheel

position. Inthe Freewheelposition, the

wheels will not holdthe tiller backandthe

revolving tines could propel the tiller

rapidly, possibly causing lossof control.

AIways engagethewheels with the wheel

drive pins in the WheelDrive position

beforestarting the engine orengaging the

tineslwheels with the Forward ClutchBail

(all models) orthe ReverseClutchcontrol

(Models 12209112210only).

14. Beawarethatthe tiller mayunex-

pectedly bounceupwardorjump forward

ifthe tinesshouldstrike extremelyhard

packedsoil, frozen ground,or buried

obstacleslike largestones,roots,or

stumps.If in doubtaboutthe tilling con-

ditions, alwaysusethe following

operatingprecautionsto assistyou in

maintainingcontrolofthe tiller:

a. Walk behindandtoone side ofthe

tiller, usingone handon thehan-

dlebars. Relaxyourarm, butusea

secure handgrip.

b. Use shallower depthregulatorset-

tings, workinggraduallydeeper

with each pass.

c. Useslower enginespeeds.

d. Clear the tilling area ofall large

stones, rootsandotherdebris.

e. Avoidusingdownwardpressureon

the handlebars.If need be, use

slight upwardpressureto keepthe

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lift the handlebarsto

raise the tines outof the soil.

g. In an emergency,stop the tines and

wheels byreleasingwhichever

clutchcontrolis engaged.Donot

attemptto restrainthe tiller.

15. Donot overloadthe tiller's capacity by

attempting to till too deeplyattoo fast a

rate.

16. Neveroperatethetiller at high trans-

port speedson hard or slippery surfaces.

Look behind and use carewhen backing

up.

17. Donot operatethe tiller ona slope

that is too steepfor safety.Whenon

slopes,slow down and make sureyou

havegood footing. Neverpermit the tiller

to freewheeldown slopes=

18. Neverallow bystanders nearthe unit.

19. Onlyuseattachments and accessories

that are approvedby the manufacturer of

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller if you aretired;

or underthe influenceof alcohol, drugs or

medication.

23. Operatorsshall not tamper withthe

engine-governorsettings onthe machine;

the governor controls the maximum safe

operatingspeed to protect theengine and

all moving partsfrom damagecaused by

overspeed. Authorized serviceshallbe

sought if a problem exists.

24. Donot touch engine parts which may

be hot from operation. Letparts cool down

sufficiently.

25. Pleaseremember:You can always

stop the tines andwheelsby releasing the

ForwardClutch Bail or onModels 12209

and 12210 the ReverseClutchcontrol,

(whichever control is engaged),or by

moving the ignition switch andlor throttle

control lever on the engineto "OFF"or

"STOP".

26. To loador unload the tiller, see the

instructions in Section 4 of this Manual.

27. Useextremecaution whenreversing

or pulling the machinetowards you.

28. Startthe enginecarefully according to

instructions andwith feet well awayfrom

thetines.

29. Neverpick upor carry a machine

while theengine is running.

Maintenance and Storage

I. Keepthe tiller, attachments and acces-

sories in safeworking condition.

2. Checkall nuts, bolts, and screws at

frequent intervalsfor proper tightness to

be surethe equipment is in safeworking

condition.

3. Neverstorethe tiller with fuel in the fuel

tank inside a building where ignition

sourcesare present such as hot water and

spaceheaters,furnaces, clothesdryers,

stoves,electric motors, etc.). Allow the

engineto cool before storing the unit in

anyenclosure.

4. To reducethe chancesof a fire hazard,

keepthe engine freeof grass, leaves,or

excessivegrease.

5. Storegasoline in a cool, well-ventilated

area,safely awayfrom anyspark- or

flame-producing equipment. Storegaso-

line in anapproved container, safelyaway

from the reachof children.

6. Referto the Maintenance sections of

this Manual and the separateEngine

Owner'sManual for instructions if the unit

is to be stored for an extendedperiod.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire is

connected,exceptwhen specifically

instructed to do so.

8. If thefuel tank hasto be drained, do

this outdoors.

Page 5

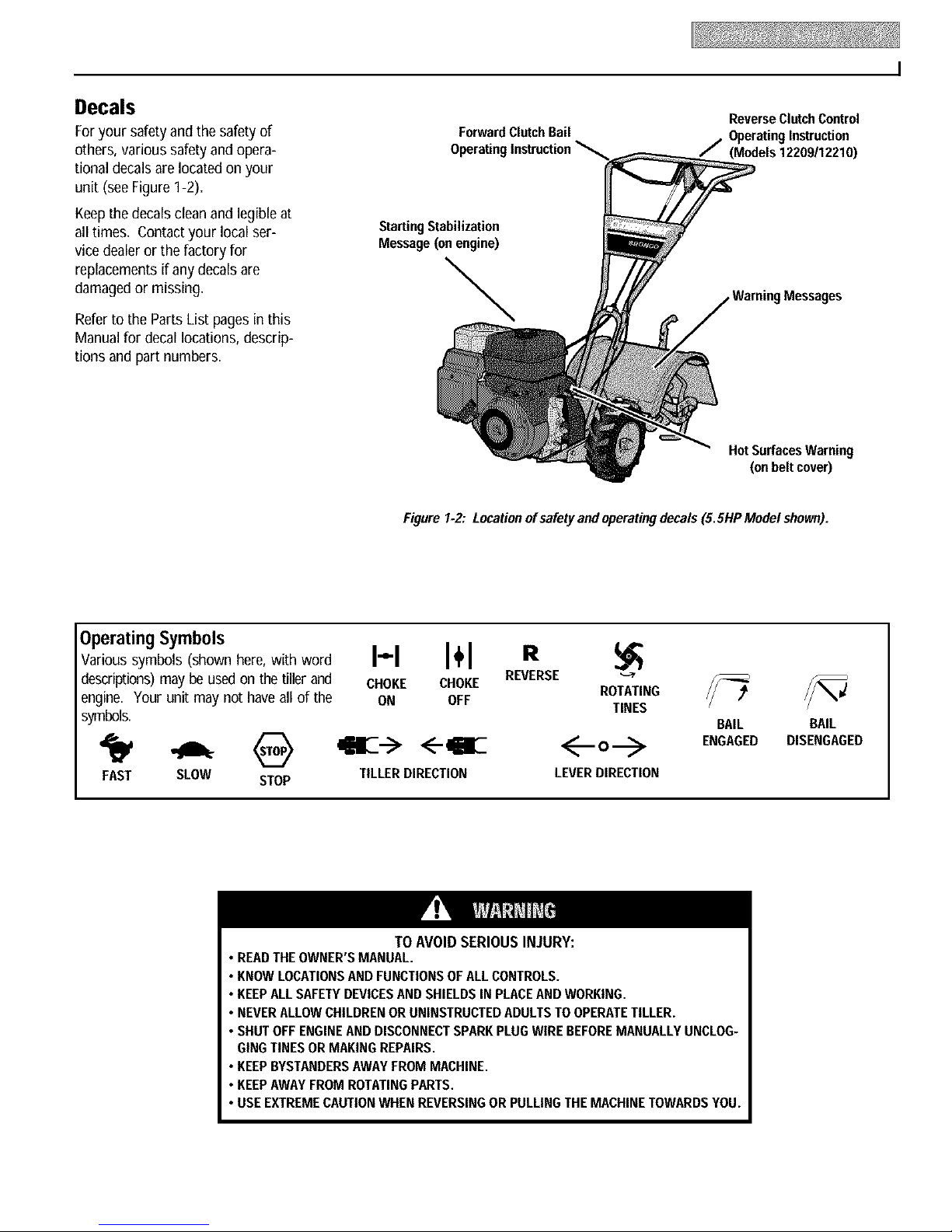

Decals

Foryour safety andthe safety of

others, various safety and opera-

tional decalsare located on your

unit (seeFigureI-2).

Keepthedecals cleanand legibleat

all times. Contactyour local ser-

vice dealeror the factory for

replacements ifany decalsare

damagedor missing.

Referto the Parts List pages in this

Manualfor decallocations, descrip-

tions and part numbers.

ForwardClutchBail

ReverseClutchControl

OperatingInstruction

Starting Stabilization

Message (on engine)

\

Hot Surfaces Warning

(on belt cover)

Figure 1.2: Locationof safety and operatingdecals(5.5HP Modelshown).

Instruction

1220911221O)

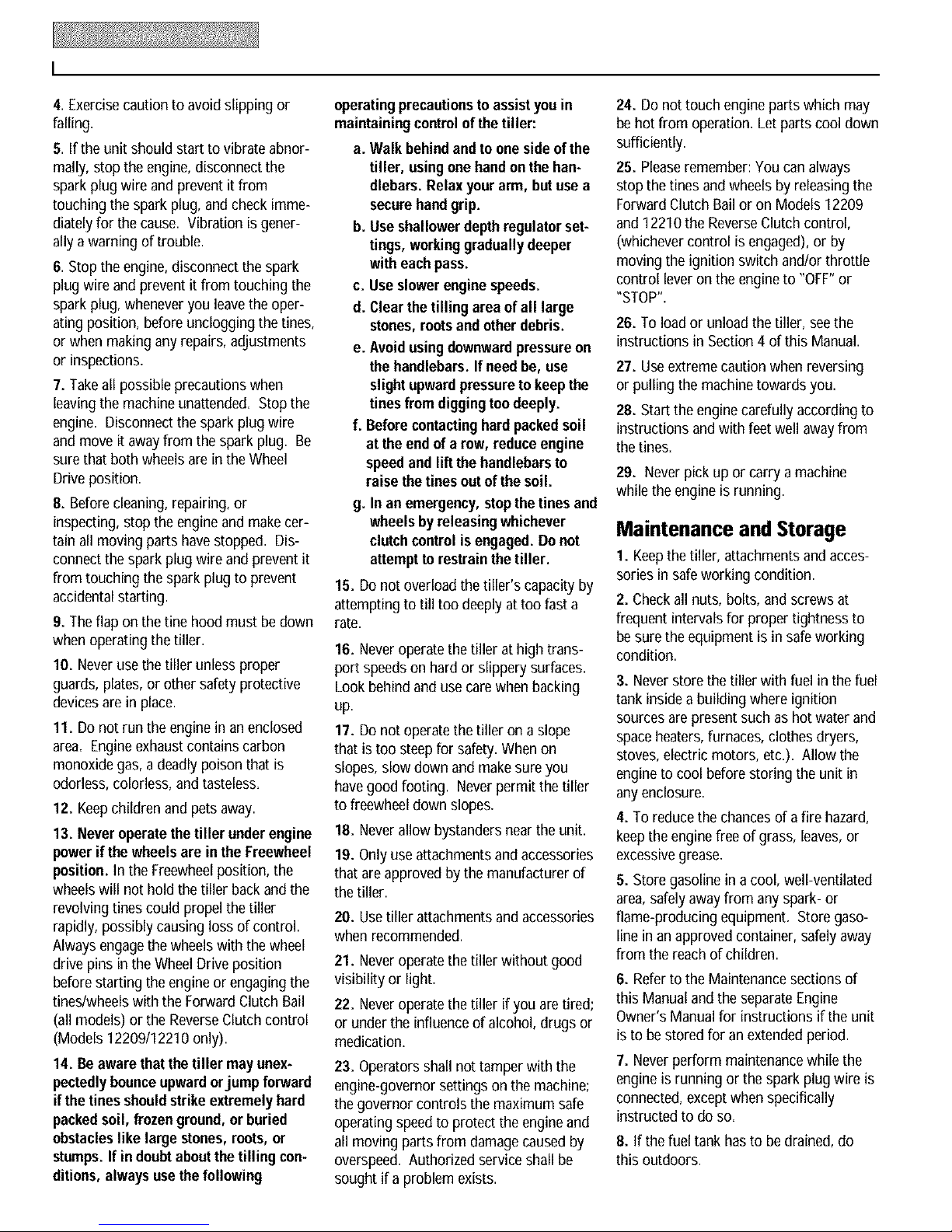

OperatingSymbols

Various symbols (shown here, with word

descriptions) may be used on the tiller and

engine. Your unit may not have all of the

symbols.

FAST SLOW STOP

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUT OFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUNCLOG-

GINGTINES ORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USE EXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDSYOU.

H I÷1 R

CHOKE CHOKE

ON OFF

<--qiE

TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

REVERSE

ROTATING

TINES

BAIL BAIL

ENGAGED DISENGAGED

Page 6

Assembly

ASSEMBLYSTEPS

To prevent personal injury or property

damage, do not start the engine until

all assembly steps are complete and

you have read and understand the

safety and operatinginstructionsinthis

manual.

INTRODUCTION

Carefullyfollow theseassembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in its entirety before beginning assembly.

NOTE:Varioustiller modelsare presented

in this Manual. Useonly the information

appropriatefor your tiller model.

INSPECTUNIT

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspectdamage. Inform them of the

damageand request instructions for filing

a claim. To protectyour rights, put your

claim in writing andmail a copy to the car-

rier within 15 days after the unit hasbeen

delivered.Contactthe factory if you need

assistancein this matter.

TOOLS/MATERIALSNEEDED

FORASSEMBLY

(1) 3/8"open-end wrench*

(2) 7/16"open-end wrench*

(2) 1/2"open-end wrench*

(2) 9/16"open-end wrench*

(1) Largeadjustablewrench (Models

12209/12210 only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tension check)

(1) Block of wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatic tires)

(1) Cleanoilfunnel

(1) Motor oil. Referto the EngineOwner's

Manualfor oil specificationsand

quantity required.

* Adjustablewrenches may be used.

STEP 1: UNPACKINGINSTRUCTIONS

NOTE: While unpacking,do not severely

bend any control cables,

I. The tiller weighsapproximately133 Ibs.

Do not attemptto remove it from the ship-

ping platform until instructed to do so in

theseAssembly steps.

2. Removeanypackaging materialfrom

the carton. Removeany staples from the

bottom of the carton andremovethe

carton from the shipping platform.

3. Removeall unassembledparts andthe

separatehardwarebag from the carton.

Checkthat you havethe items listed in the

LooseParts List (contact your localdealer

or the factory items aremissing or dam-

aged). NOTE: Usethe screw lengthtem-

plate (Fig. 2-I) to identify screws.

LoosePartsList

Qty. Description

1 HandlebarSupport (seeA, Fig.2-2)

I HandlebarAssembly(seeK, Fig.2-2)

Hardwarebag contents:

1 Slotted hd. screw, #10-24 x 2"

1 Hexhd. screw, 1/4-20 x 1-1/4"

6 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

6 Split Iockwasher,8/16"

1 HexIocknut, 1/4"-20

6 Hexnut, 5/16"-18

1 Hexnut, #10-24

2 HexIocknut, 3/8"-16

1 Spring, cable(seeW, Fig. 2-5)

1 Bracket,forward clutch cable (see

P, Fig.2-4)

IMPORTANT:Motor oil must be added to

the enginecrankcasebefore the engineis

started. Follow the instructions inthis

Assembly Section and in the separate

EngineOwner's Manual.

NOTE:LEFTand RIGHTsides of the tiller

are asviewed from the operator's position

behind the handlebars.

Figure2. I: To identifylengthof screws,

place screwontemplate as shownand mea-

suredistancebetween bottomof screw head

and tipof screw.

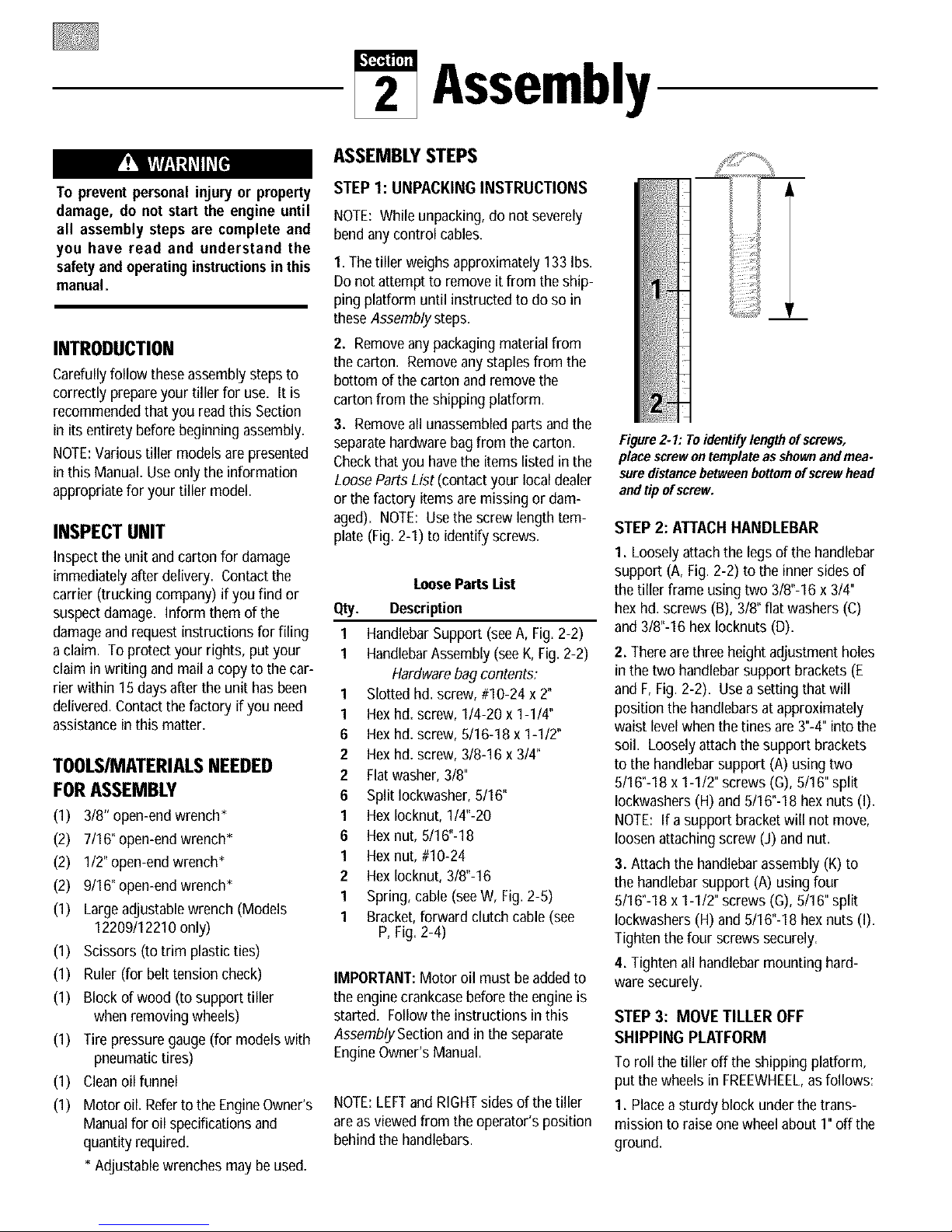

STEP 2: ATTACHHANDLEBAR

I. Loosely attachthe legsof the handlebar

support (A, Fig. 2-2)to the innersides of

the tiller frame usingtwo 318"-16x 314"

hexhd. screws (B), 318"flat washers (C)

and 318"-16hex locknuts (D).

2. Thereare three height adjustment holes

in the two handlebarsupport brackets(E

and F,Fig. 2-2). Usea setting that will

position the handlebarsat approximately

waist levelwhenthe tines are 3"-4"into the

soil. Loosely attachthe support brackets

to the handlebarsupport (A) using two

8116"-18x 1-112"screws (G),5116"split

lockwashers (H)and 5116"-18hexnuts (I).

NOTE: If asupport bracket will not move,

loosenattaching screw (J) and nut.

3. Attach the handlebarassembly(K) to

the handlebarsupport (A) using four

5116"-18x 1-112"screws (G),5116"split

lockwashers (H)and 5116"-18hexnuts (I).

Tighten the four screws securely.

4. Tighten all handlebarmounting hard-

ware securely.

STEP 3: MOVE TILLER OFF

SHIPPING PLATFORM

To roll the tiller off the shipping platform,

put the wheelsin FREEWHEEL,as follows:

I. Placea sturdy blockunder the trans-

mission to raiseone wheelabout I" off the

ground.

Page 7

C

D

Fig. 2-2,"Attachhandlebar (5.SHPModel shown).

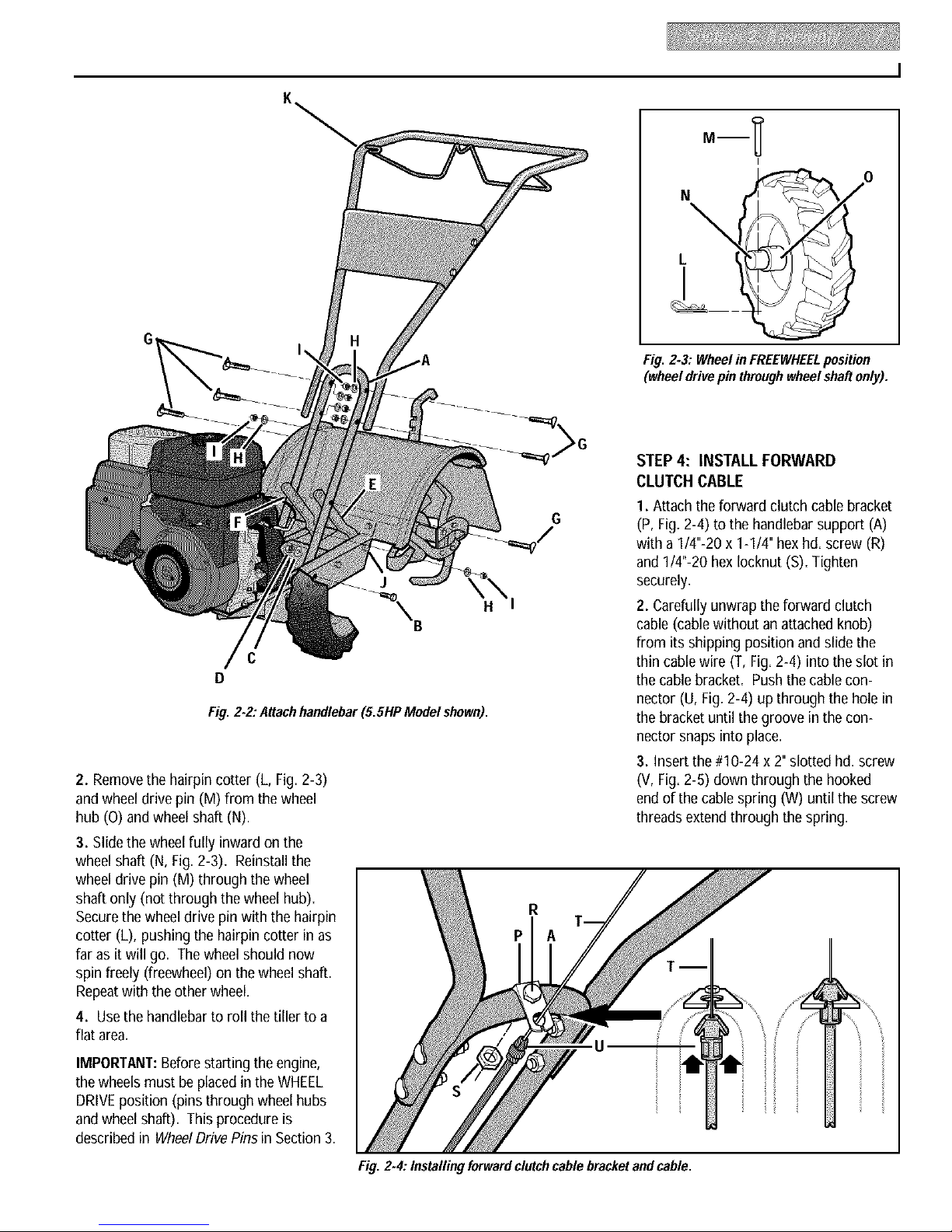

2. Removethe hairpin cotter (L, Fig. 2-3)

and wheel drive pin (M) from the wheel

hub (O) andwheel shaft (N).

3. Slidethewheelfully inwardon the

wheel shaft (N,Fig. 2-3). Reinstallthe

wheel drive pin (M) throughthe wheel

shaft only (not through the wheel hub).

Securethe wheel drive pin with the hairpin

cotter (L), pushingthe hairpincotter inas

far as it will go. The wheel should now

spin freely(freewheel)on the wheel shaft.

Repeatwith the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

a m

Fig. 2-3: Wheelin FREEWHEELposition

(wheeldrivepin throughwheel shaft only).

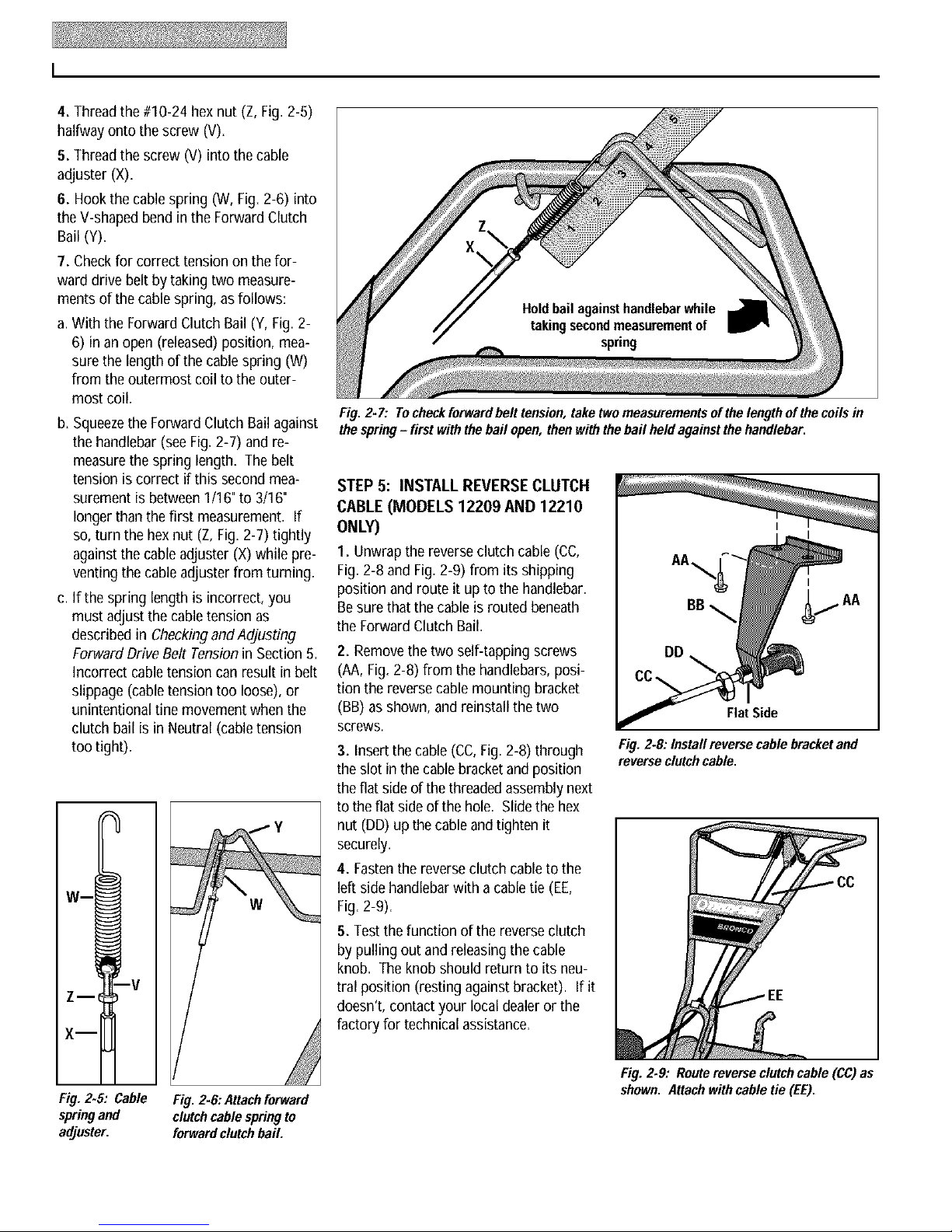

STEP 4: INSTALL FORWARD

CLUTCH CABLE

1. Attach the forward clutch cable bracket

(P, Fig.2-4) to the handlebarsupport (A)

with a 1/4"-20 x 1-1/4" hexhd. screw (R)

and 1/4"-20 hex Iocknut (S). Tighten

J

H

securely=

2. Carefullyunwrapthe forward clutch

cable(cable withoutan attached knob)

from its shipping position andslidethe

thincable wire (T, Fig.2-4) into the slot in

the cablebracket=Pushthe cable con-

nector (U, Fig.2-4) up through the hole in

the bracketuntil the groove in the con-

nector snapsinto place.

3. Insertthe #10-24 x 2" slotted hd. screw

(V, Fig.2-5) downthroughthe hooked

end of the cablespring (W) until the screw

threadsextendthroughthe spring.

IMPORTANT:Beforestarting theengine,

the wheelsmust beplacedin the WHEEL

DRIVEposition (pins through wheelhubs

and wheelshaft). This procedureis

described in WheelDrivePins in Section 3.

Fig. 2-4: Installing forwardclutchcable bracketand cable.

Page 8

4. Threadthe #10-24 hexnut (Z,Fig. 2-5)

halfwayonto the screw (V).

5. Threadthe screw (V) into thecable

adjuster (X).

6. Hookthe cable spring (W, Fig.2-6) into

the V-shapedbend inthe ForwardClutch

Bail (Y).

7. Checkfor correct tension on the for-

ward drive belt by taking two measure-

ments of thecablespring, as follows:

a.With the ForwardClutch Bail (Y, Fig.2-

6) in an open (released)position, mea-

surethe lengthof the cablespring (W)

from the outermost coil to the outer-

most coil.

b. Squeezethe ForwardClutch Bail against

the handlebar (seeFig.2-7) and re-

measurethe spring length. Thebelt

tension is correct if this second mea-

surement is between1/16"to 3/16"

longer thanthe first measurement. If

so, turn the hexnut (Z, Fig.2-7) tightly

againstthe cableadjuster (X)while pre-

venting the cableadjuster from turning.

c. If the spring lengthis incorrect, you

must adjust the cabletension as

described in Checkingand Adjusting

Forward Drive Belt Tensionin Section5.

Incorrect cable tension can result inbelt

slippage (cabletension too loose),or

unintentional tine movementwhen the

clutch bailis in Neutral (cabletension

too tight).

W m

Fig. 2- 7: Tocheck forward belt tension, taketwomeasurementsof the length of thecoils in

thespring- first withthe bail open, then withthe bail heldagainst thehandlebar.

STEP 5: INSTALL REVERSE CLUTCH

CABLE (MODELS 12209 AND 12210

ONLY)

1. Unwrap the reverseclutch cable(CC,

Fig.2-8 and Fig.2-9) from its shipping

position and route it up to the handlebar.

Besurethat the cable is routed beneath

the Forward Clutch Bail.

2. Removethe two self-tapping screws

(AA,Fig. 2-8) from the handlebars,posi-

tion the reversecable mounting bracket

(BB) asshown, and reinstall the two

Flat Side

screws.

3. Insertthe cable(CC,Fig.2-8) through

the slot in the cablebracketand position

Fig. 2-8: Install reverse cable bracketand

reverseclutchcable,

the flat side ofthe threadedassemblynext

to the flatside of the hole. Slidethehex

nut (DD) up the cableand tighten it

securely.

4. Fastenthe reverseclutch cable to the

left side handlebarwith acable tie (EE,

Fig.2-9).

5. Testthe function of the reverseclutch

bypulling out andreleasingthe cable

knob. The knobshould return to its neu-

tral position (resting against bracket). If it

doesn't, contact your local dealeror the

factory for technical assistance.

Fig.2.5: Cable

springand

adjuster.

Fig. 2-8: Attachforward

clutchcable springto

forward clutchbail.

Fig. 2.9: Route reverse clutchcable (CC)as

shown. Attachwithcable tie (EE).

Page 9

STEP 6: CHECKLEVELOF

TRANSMISSION GEAR OIL

STEP7: ADD MOTOR OIL

TO ENGINE

Thetransmission was filled with gearoil at

the factory. However,you should check

the gear oil levelatthis time to makecer-

tain it is correct.

IMPORTANT:Do not operatethe tillerif

the gear oil levelis low. Doingso will

result in severedamagetothe transmis-

sion components.

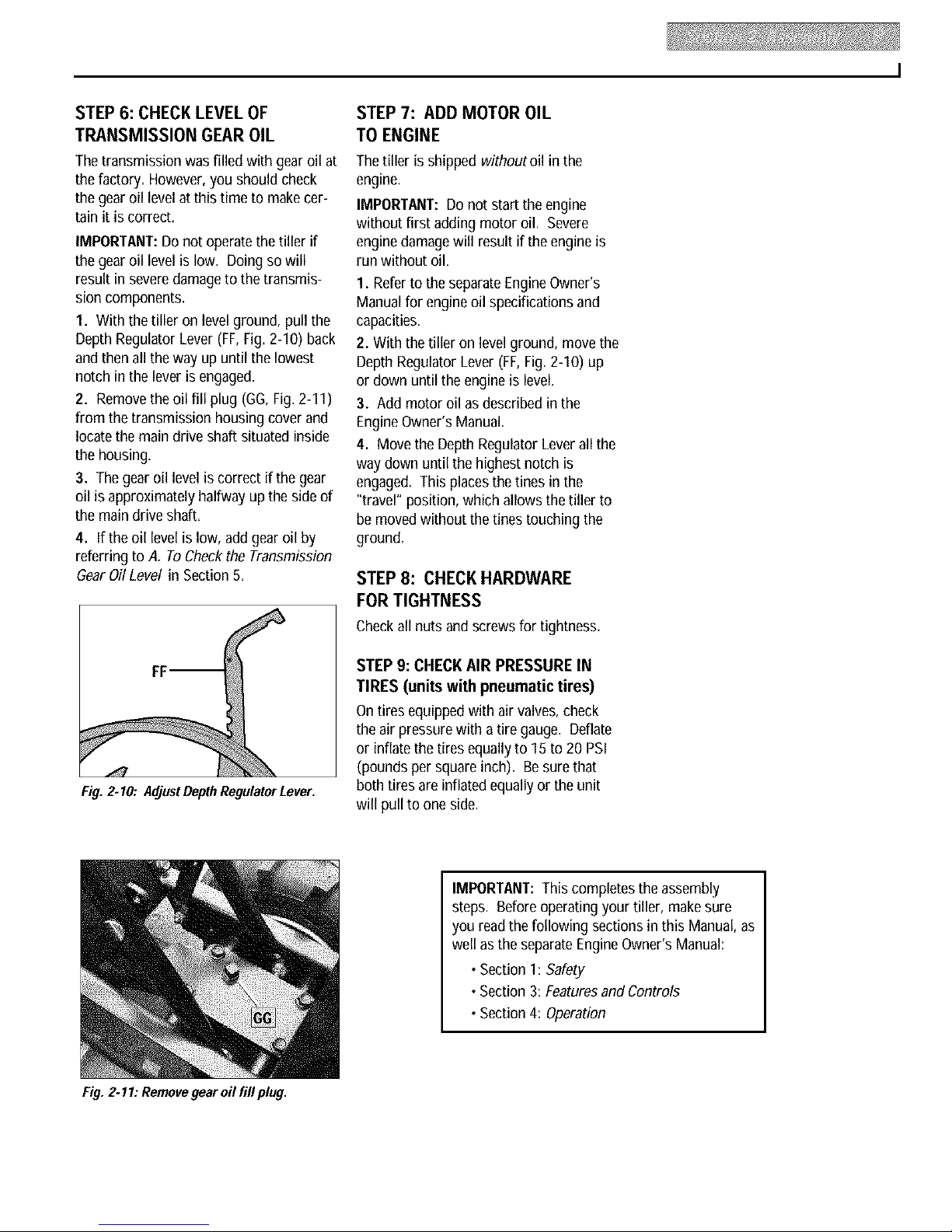

1. With the tilleron level ground, pull the

Depth Regulator Lever (FF,Fig. 2-10) back

and then all the way up until the lowest

notch in the leveris engaged.

2. Removethe oil fill plug (GG, Fig.2-11)

from the transmission housing cover and

locate the main drive shaft situated inside

the housing.

3. Thegear oil level is correct if thegear

oil is approximately halfway up theside of

the main drive shaft.

4. If the oil levelis low, addgearoil by

referring to A. To Checkthe Transmission

GearOil Level in Section5.

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not startthe engine

without first addingmotor oil. Severe

enginedamagewill result if the engine is

run without oil.

1. Refertothe separateEngineOwner's

Manualfor engineoil specifications and

capacities.

2. Withthetilleron levelground, move the

Depth Regulator Lever (FF,Fig.2-10) up

or down until the engine is level.

3. Add motoroil asdescribed in the

EngineOwner's Manual.

4. Move the Depth Regulator Leverall the

way down until the highest notch is

engaged. Thisplacesthetines inthe

"travel" position, whichallows the tiller to

be moved without thetines touching the

ground.

STEP 8: CHECK HARDWARE

FOR TIGHTNESS

Checkall nutsand screws for tightness.

Fig. 2.10: AdjustDepthRegulatorLever.

Fig. 2.11: Removegear oil fill plug.

STEP 9: CHECK AIR PRESSURE IN

TIRES (units with pneumatic tires)

Ontires equippedwith air valves, check

the air pressure with atiregauge. Deflate

or inflate the tiresequallyto 15 to 20PSI

(pounds per squareinch). Besure that

both tires are inflatedequallyor the unit

will pull to one side.

IMPORTANT:This completes theassembly

steps. Before operating your tiller,make sure

you read the following sections inthis Manual, as

well as the separateEngineOwner's Manual:

• Section 1: Safety

•Section 3: FeaturesandControls

•Section 4: Operation

Page 10

FeaturesandControls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, the separate Engine

Owner's Manual, and on the decals on

themachine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

INTRODUCTION

This Sectiondescribes the location and

function of the controls on your tiller=

Referto thefollowing Section, Operation

for detailedoperating instructions=

Practiceusing thesecontrols, withthe

engineshut off, until you understand the

operationof the controls and feel confi-

dentwith eachof them.

ENGINECONTROLS

Referto theengine manufacturer's Engine

Owner'sManual (included in the tillerliter-

aturepackage)to identify thecontrols on

your engine.

IMPORTANT:Thecontrol for stoppingthe

engine is locatedon the engine.

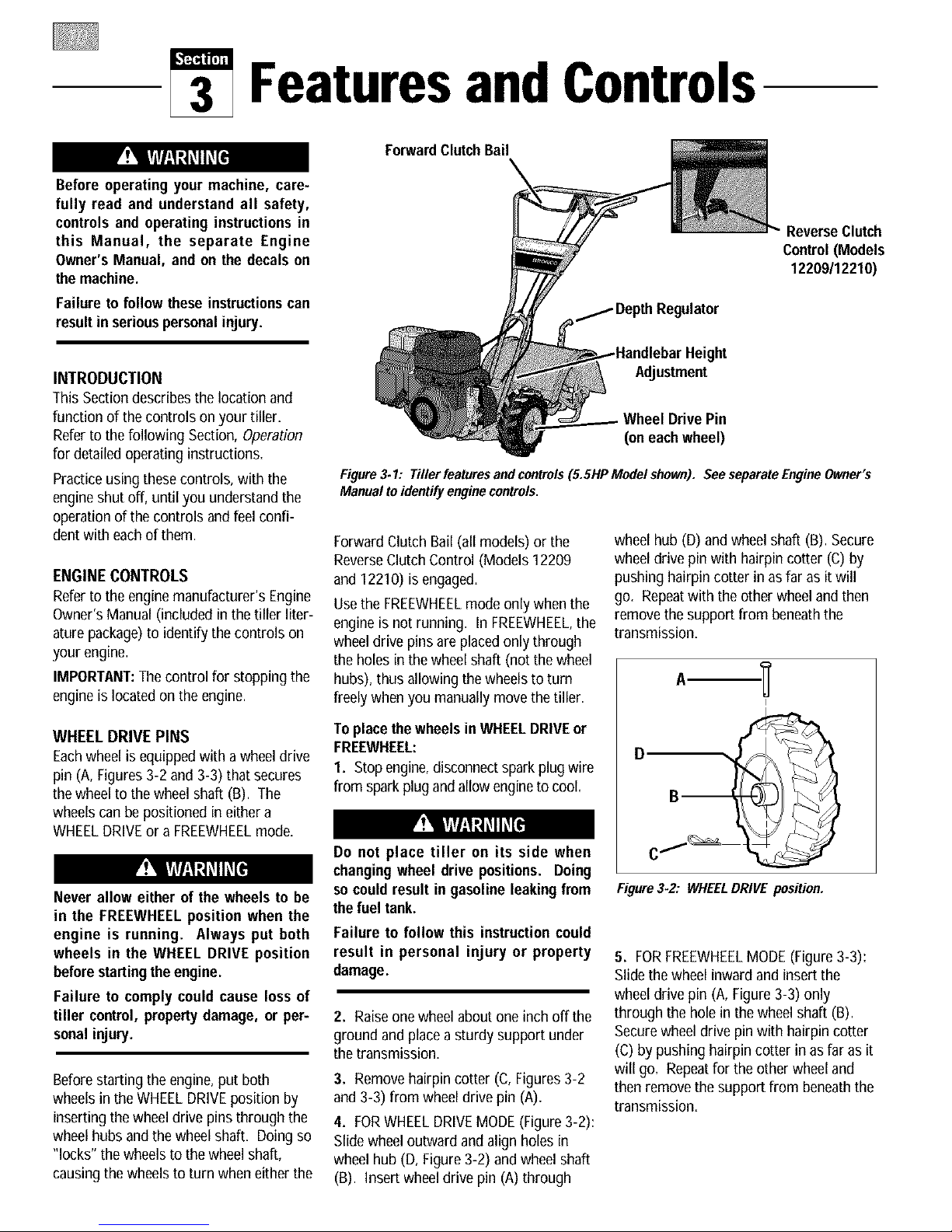

ForwardClutchBail

ReverseClutch

Control (Models

12209/12210)

Height

AdJustment

Wheel DrivePin

(oneachwheel)

Figure3.1: Tillerfeaturesandcontrols(5.SHPModelshown). SeeseparateEngineOwner's

Manual toidenti[y enginecontrols,

Forward Clutch Bail (all models) or the

ReverseClutch Control (Models12209

and 12210) is engaged.

Usethe FREEWHEELmode only whenthe

engine is not running. In FREEWHEEL,the

wheeldrive pinsare placedonly through

the holes inthe wheelshaft (not thewheel

hubs), thus allowing the wheels to turn

freely when you manually move the tiller.

wheel hub (D) and wheel shaft (B).Secure

wheel drive pinwith hairpin cotter (C) by

pushing hairpin cotter in as far as it will

go. Repeatwith the other wheeland then

removethe supportfrom beneaththe

transmission.

I

WHEEL DRIVE PINS

Eachwheel is equippedwitha wheeldrive

pin (A, Figures3-2 and 3-3) that secures

thewheelto the wheelshaft (B). The

wheelscan be positioned ineither a

WHEELDRIVEor a FREEWHEELmode=

Never allow either of the wheels to be

in the FREEWHEELposition when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

beforestartingthe engine.

Failure to comply could cause lossof

tiller control, property damage, or per-

sonalinjury.

Beforestarting the engine,put both

wheels in the WHEELDRIVEposition by

inserting the wheeldrive pinsthrough the

wheel hubs andthe wheel shaft. Doing so

"locks" the wheels to thewheel shaft,

causingthe wheels to turn wheneither the

To placethe wheels in WHEELDRIVEor

FREEWHEEL:

I. Stop engine,disconnectspark plug wire

from spark plugandallow engineto cool.

Do not place tiller on its side when

changingwheel drive positions. Doing

socould result in gasoline leakingfrom

the fuel tank.

Failure to follow this instruction could

result in personal injury or property

damage.

2. Raiseonewheel aboutone inch off the

ground and placea sturdy support under

the transmission=

3. Removehairpin cotter (C,Figures 3-2

and 3-3) from wheel drive pin (A)=

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheeloutward and align holes in

wheel hub (D, Figure3-2) and wheel shaft

(B). Insert wheeldrive pin (A)through

D

Figure3-2: WHEELDRIVE position.

5. FORFREEWHEELMODE(Figure 3-3):

Slidethe wheelinward andinsert the

wheel drive pin (A, Figure3-3) only

through the hole in the wheelshaft (B).

Securewheel drive pin with hairpin cotter

(C) bypushing hairpin cotter in as far asit

will go=Repeatfor the other wheel and

then removethe support from beneaththe

transmission=

Page 11

I

D,

B,

Figure3.3: FREEWHEELposition.

Before startingengine, besurethat both

wheels are in WHEEL DRIVE position.

See WheelDrivePins for instructions.

Engaging the Forward Clutch Bail or

Reverse Clutch Control (if equipped)

when the wheels are not in WHEEL

DRIVE could allow the tines to rapidly

propelthe tiller forward or backward.

Failure to comply could cause lossof

tiller control, propertydamage, or per-

sonalinjury.

• Use extreme caution when reversing

or pulling the machine towards you.

Lookbehind to avoidobstacles.

• Neverattempt to till in reverse.

Failure to follow this warning could

result in personal injury or property

damage.

To operatethe ReverseClutchControl:

I. Putwheels in WHEELDRIVEposition

(see"WARNING"statement at the left).

2. Stopall tiller motion by releasingthe

ForwardClutch Bail.

3. Liftthe handlebaruntil the tines clear

the ground, look behind you to avoid any

obstacles, and then pull the control knob

(F, Figure3-4) out. Thewheels and tines

will rotate in a reverse direction.

4. Releasethe control knob to disengage

(stop) the wheelsand tines (the engine

will continue to run).

results, alwaysbegin tilling at a very

shallow depth setting and gradually

increasethe tilling depth.

• Do not attempt to till too deeply too

quickly. Gradually work down to

deepertilling depths.

• Place the Depth Regulator Lever in

the "travel" position before starting

the engine. This position prevents

the tines from touching the ground

until youare ready to begintilling.

Failure to follow this warning could

result in personal injury or property

damage.

TravelPosition

Figure 3-5:Depth RegulatorLever(G).

FORWARD CLUTCH BAIL

TheForward ClutchBail (E, Figure3-4)

controls the engagementof forward drive

to the wheelsandtines.

To operate theForwardClutchBail:

1. Putwheels inWHEELDRIVEposition

(see"WARNING"statement above).

2. Lift and hold the clutch bail (E,Figure

3-4) againstthe handlebarto start the

wheels andtines rotating in aforward

direction.

3. Releasethe clutch bail to disengage

(stop) the wheels andtines (theengine

will continueto run).

REVERSE CLUTCH CONTROL

(Models 12209/12210 only)

TheReverseClutchControl (F,Figure3-4)

controls the engagementof reversedrive

to the wheelsandtines. The reversing

feature is used for maneuvering the tiller

only- neverengagethetines in the

groundwhile operatingin reverse.

F

E

Figure3.4: Allmodelshavea Forward

ClutchBail(E). OnlyModels12209/12210

havea ReverseClutchControl(F).

DEPTH REGULATOR LEVER

This lever (G, Figure3-5) controls the

tilling depthof thetines. Pull the lever

backand slide it up or down to engagethe

notched height settings.

The"travel position" (highestnotch) raises

the tines approximately 1-112"off the

ground, allowing the tiller to bemoved

without the tines contactingthe ground.

This setting should also be used when

starting the engine.

Moving the leverupward will increasethe

tilling depth. The lowestnotch allows a

tilling depthof approximately 6",

depending on soil conditions. Forbest

HANDLEBAR HEIGHT ADJUSTMENT

Thehandlebar height is adjustableto three

different settings (Figure3-6). Ingeneral,

adjust the handlebarsso they are atwaist

levelwhen the tines are3"-4"in the soil.

To adjustthe handlebars:

1. Stopengine, disconnect spark plug

wire from spark plug andallow engineto

cool.

2. Removehardware,reposition handle-

bars, andreinstall hardwaresecurely.

Figure 3-6:Handlebarheight adjustment.

Page 12

Operation

Before operating your machine, care-

fully read and understand all safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner's Manual, and on the decals on

themachine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

INTRODUCTION

Readthis OperationSectionand thesepa-

rateEngineOwner's Manualbeforeyou

start theengine. Then,take the time to

familiarize yourself with the basic opera-

tion of the tiller beforeusing it in the

garden. Findan open, levelareaand prac-

tice using the tiller controls without the

tines engagingthe soil (put tines in

"travel" setting). Onlyafter you've

becomecompletely familiar with the tiller

should you beginusing it inthegarden.

BREAK-INOPERATION

Perform the following maintenanceafter

the first two (2) hours of newoperation

(seeMaintenanceSection in this manual

and in the EngineOwner's Manual).

1. Changeengineoil.

2. Checkfor looseor missing hardware

on unit. Tighten or replaceas needed.

3. Checktension on forward drive belt.

4. Checktransmission gearoil level.

STARTINGANDSTOPPING

THEENGINE

Pre-StartChecklist

With the spark plug wire disconnected

from the spark plug, perform the following

checksand servicesbefore eachuse:

1. Readthe Safetyand Controls Sections

in this manual. Readthe separateEngine

Owner'sManual providedwith the unit.

2. Put thewheels in the WHEELDRIVE

position (wheel pins must be through

holesin wheelhubs and wheel shaft).

3. Checkunit for loose or missing hard-

ware. Serviceas required.

4. Checkengineoil level. SeeEngine

Owner'sManual.

ReverseClutchControl

(Models 12209/12210)

Fo_ardC

Depth

Regulator

Recoil Starter

•WheelDrivePin

(oneachwheel)

Fig. 4_I

5. Checkthat all safetyguardsand covers

are in place.

6. Checkair cleanerandengine cooling

system. SeeEngineOwner's Manual.

GASOLINEIS HIGHLYFLAMMABLEAND

ITSVAPORSAREEXPLOSIVE.

Follow gasoline safety rules in this

Manual (see Section1) and in the sepa-

rate EngineOwner'sManual.

Failure tofollow gasolinesafety instruc-

tions can result in serious personal

injuryandpropertydamage.

7. Fill the fuel tank withgasoline

according to the directions in the separate

EngineOwner's Manual. Follow all

instructions and safetyrules carefully.

8. Attach spark plug wire to sparkplug.

StartingtheEngine

Thefollowing stepsdescribe how to start

and stop the engine. Do not attempt to

engage the tines or wheels until you

have read all of the operating instruc-

tions in this Section. Also, review the

safety rules in Section 1: Safety, and the

tiller and engine controlsinformation in

Section 3: Features and Controls.

1. Completethe Pre-Start Checklist on

this page.

2. Putthe wheels in the WHEELDRIVE

position (see WheelDrivePinsin Section

3 of this manual).

To help preventserious personal injury

or damageto equipment:

• Before starting engine, put both

wheels in the WHEELDRIVE position.

Never have wheels in FREEWHEEL

position when engine is running.

When the wheels are in FREEWHEEL,

they donot holdback the tiller and the

tines could propel the tiller rapidly

forward or backward.

• Before starting engine, put Forward

Clutch Bail (all models) and Reverse

Clutch Control (Models 12209/12210

only) in neutral (disengaged)positions

byreleasing levers.

• Never run engine indoors or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide,anodorlessanddeadlygas.

•Avoid engine muffler and nearby

areas. Temperatures in these areas

mayexceed150°F.

3. Movethe Depth Regulator Lever all the

way down to the "travel" position, so that

the tines clearthe ground.

4. Releaseall controls on the tiller.

5. On engine's with afuel shut-offvalve,

turn valveto open position, as instructed

in the separateEngineOwner's Manual.

6. Put ignition switch andlor throttle con-

trol lever locatedon engine in the "ON",

"RUN", "FAST"or "START" position, as

instructed in the EngineOwner'sManual.

7. Chokeor prime engine,as instructed in

EngineOwner's Manual.

8. Put one hand on fuel tank to stabilize

unit when pulling starter rope handle.

Thenuse recoil starter to start engine,as

instructed in the EngineOwner'sManual.

Whenengine starts, gradually movechoke

lever(if soequipped) to "NO CHOKE",

"CHOKEOFF"or "RUN" position.

9. Usethe "FAST"throttle speedsetting

when tilling.

Page 13

Keepawayfrom rotatingtines. Rotating

tineswill causeinjury.

StoppingtheEngineand Tiller

1. To stop thewheels and tines, release

the ForwardClutch Bail (all models) or the

ReverseClutch Control (Models12209

and 12210) - whichever control is in use=

2. To stop the engine, put the ignition

switch and/or the throttle control leverin

the "OFF"or "STOP" position.

OPERATINGTHETILLER

Thefollowing operating instructions pro-

vide guidelinesto using your tiller effec-

tively and safely. Besureto read Tilling

Tips& Techniques inthisSection before

actually putting the tines into the soil

NOTE:This is atraditional "Standard-

Rotating-Tine" (SRT)tiller withforward

rotating tines. It operatescompletely dif-

ferently from "Counter-Rotating-Tine"

(CRT)tillers or from front-tine tillers.

1. Follow the Pre-StartChecklist atthe

beginning of this Section. Besure that the

wheels are in the WHEELDRIVEposition.

2. Move the DepthRegulator Leverall the

way down, so that the tines clearthe

ground. Usethis position whenpracticing

with the tiller and when traveling between

tilling sites. Beforeactually tilling, move

the leverto thedesired depthsetting (see

Tilling Tips& Techniques).

3. Start engineandallow it to warm up.

Thenput throttle in "FAST"setting.

4. Forforwardmotion of the wheels and

tines:

(a) Pull ForwardClutch Bail (Fig. 4-I) up

against handlebar. Releasebail to stop

forward motion of wheels and tines.

(b) Whentilling, relax and let the wheels

pull the unit while thetines dig. Walk

behindand a little to one side of the

unit. Use onehand, yetkeepa light--

but secure--grip onthe handlebar

(while keepingyour arm loose). See

Fig.4-2. Letthe unit move at its own

paceand do not push down on the

handlebarsto try andforce the tines to

dig deeper-- this takesweight off the

wheels, reducestraction, and causes

the tines to try and propelthe tiller.

Do not push downon the handlebarsto

try to make the tiller till more deeply.

This prevents the wheels from holding

the tiller back and can allow the tines

to rapidly propel the tiller forward,

which could result in loss of control,

property damage, orpersonal injury.

5. Forreversemotion of thewheels and

tines (Models 12209112210only):

(a) Look behind and exercisecaution when

operating in reverse. Donot till while

in reverse.

(b) Stop all forward motion. Lift handlebar

with one hand until tines areoff the

ground and then pull ReverseClutch

Control knob out (seeFig. 4-3). To

stop reversing, let go of ReverseClutch

Control knob.

(b) Swing the handlebarto the left so the

right wheeltakesa "step" backward.

Nextswing the handlebarto the right

so the leftwheel"steps" backward.

Repeatasneeded.

(c) If longer distancesneedto becovered

in reverse, shut off the engine, then

placethe two wheelsin FREEWHEEL.

7. To Turn the Tiller Around:

(a) Practiceturning the tiller in a level,

open area. Bevery careful to keep

your feetand legsaway from the tines.

(b) To begina turn, liftthe handlebarsuntil

thetines are outof the ground andthe

engineand tines arebalancedoverthe

wheels (Fig.4-4).

(c) With tiller balanced,push sideways on

handlebarto steerin direction of turn

(Fig. 4-5). After turning, slowly lower

tines into soil to resume tilling.

Fig. 4.4: Tobegin turn, lifthandlebars until

tinesare out of groundandunit is balanced.

Fig. 4.2: Useone handto guide tiller when

movingforward.

Fig. 4.3: Raise tinesoffgroundandlook

behindwhenmovingin reverse.

6. To move the Model 12227 inreverse

for short distances:

(a) ReleaseForwardClutchBail. Thenlift

handlebaruntil tines are off the ground.

Fig. 4.5: Withtinesout of ground,push

handlebarssidewaysto turntiller.

Stopping theTiller and Engine

1. To stop thewheels and tines, release

the Forward ClutchBail (all models) or the

ReverseClutch Control (Models 12209

and 12210) - whichever control is in use.

2. To stop the engine, put the ignition

switch and/or the throttle control lever in

the "OFF"or "STOP"position.

Page 14

TILLING TIPS & TECHNIQUES

• Avoidpushingdownon thehandlebarsin an attemptto force thetiller to dig deeper. Doing

so takes the weight off the poweredwheels, causing them to lose traction. Without the

wheels helping to hold the tiller back, the tines will attempt to propel the tiller - often

causingthe tillerto skip rapidlyacrossthe ground. (Sometimes,slight downwardpressure

Before tilling, contact your tele-

)hone or utilities company and

inquire if undergroundequipment

or lines are usedon your property.

Do not till near buried electric

cables, telephone lines, pipes or

hoses.

Whencultivating (breakingup surfacesoil around plants to destroyweeds,see Fig.4-9), adjustthe tines to dig only I" to 2"deep.

Usingshallowtilling depthshelpspreventinjury to plantswhoserootsoften grow closeto thesurface. If needed,lift uponthe handle-

barsslightly to preventthetinesfrom diggingtoo deeply. (Cultivatingon a regularbasisnotonly eliminatesweeds,it alsoloosensand

aeratesthe soil for bettermoistureabsorptionandfasterplantgrowth.)

With experience,youwill find the 'just right" tilling depthand tilling speedcombinationthat is best

for yourgarden.

Setthe enginethrottle leverat a speedto give theengine adequatepowerandyet allow it to operateat the slowest possiblespeed...at

least until you haveachievedthe maximumtilling depth you desire.Fasterenginespeedsmay be desirablewhen making final passes

through the seedbedor whencultivating. Selectionof the correct engine speed,in relation to the tilling depth,will ensurea sufficient

powerlevelto dothejob without causingthe engineto labor.

on the handlebarswill help get through a particularly tough sectionof sod or unbroken

ground,but in mostcasesthiswon't be necessary.)

•Avoidtrying to digtoo deeply too quickly, especiallywhen busting sodor when tilling soil

that hasn't beentilled for sometime. Useshallowdepthregulatorsettings (only an inch or

two deep)for thefirst passesthrough thesoil. With eachsucceedingpass,dig anotherinch

or two deeper. (Wateringthe areaa fewdays prior to tilling will maketilling easier,aswill

lettingthenewlyworkedsoil set for aday or two beforemakingafinal, deeptilling pass.)

Whiletilling, relaxand letthe wheelspull

the tiller alongwhile the tinesdo the dig-

ging. Walk on the side that is not yet fin-

ished (to avoid making footprints in the

freshly tilled soil) and lightly,but securely

gripthe handlebarwithjust onehand.

•Whenpreparinga seedbed,go overthe samepathtwice inthe first row,then

overlap one-half the tiller width on the rest of the passes (see Fig.

4-6). Whenfinishedin onedirection,makea secondpassat a right angle,as

shown in Fig.4-7. Overlapeachpassfor bestresults (in very hardground, it

maytakethreeor four passestothoroughlypulverizethe soil.)

If the garden size will not permit

lengthwise and then crosswise

tilling, then overlapthe first passes

by one-half atiller width, followed l_mi_

by successive passes at one-

quarterwidth (seeFig.4-8).

Wheneverpossible, walk on the untilled

sideof the unit to avoidmakingfootprints

in your freshly tilled or cultivated soil.

Footprintscausesoil compactionthat can

hamperroot penetrationandcontributeto

soil erosion. They can also "plant"

unwanted weed seeds back into the

freshlytilled ground.

Fig. 4-8

Tilling wetsoil often resultsin large, hard

clumps of soil that can interfere with

planting. If time permits,waita day or two

after heavy rains to allow the soil to dry

beforetilling. Testsoilby squeezingit into

a ball. If it compressestoo easily,it is too

wetto till.

Fig.4.6

With planning,youcanallow

enough room between _1,_.. ___1,,_.

rows to cultivate (see Fig. 1_1_31 _ I

4-9). Leave room for the

Fig. 4.7

hoodw dth,plusenough1 : 101

extra room for future _ "*_l,_

plantgrowth. Fig.4-9

Page 15

TILLING TIPS & TECHNIQUES (cont.)

Powercompostingsimply meanstilling underandburying inthesoil all mannerof

organicmattersuchascrop residues,leaves,grassclippingsandcovercrops. This

materialwill decomposeduringthenon-growing seasonandadd importantnaturalnutri-

entsto the soil.

Thefirst placeto begin iswith cropresiduessuchas leftovervines,stalks,stemsand

roots. Powercompostthesecrop residuesassoonastheyfinish bearing. Thesooner

this is done,thebetter,astender greenmatteriseasierto till under. Usethedeepest

depthregulatorsettingpossiblewithout causingtheengineto laboror thetiller to jump

ahead.

Standingcornstalksof reasonableheightcanbepowercomposted. Pushingover (but

not uprooting)cornstalkswill oftenmakeiteasierto chop upthestalks. Keepthe tines

clearof excessivetanglingby"fishtailing" or frequentlyusingreverse. Makeseveral

passes,thenreturn afew dayslaterto finish off any remainingstubble.

After tilling undercrop residues,addmoreorganicmattersuchas leaves,grassclippingsandevenkitchenscraps. Whentilled intothe

soil, this organic matterwill decomposeandaddevenmore importantnutrientsto the soil.

After powercomposting,you maywant to planta "greenmanure"covercropto protectthe soil during the off-season.Yousimply

grow acrop ofclover, alfalfa,buckwheat,peas,beans,ryegrass,grain, or kaleandthentill it intothe soilprior to the plantingseason.

When power composting,do not keep

the Depth Regulator Lever at a deep

setting if the tiller jumps or bucks.

Ifjumping or buckingoccurs,movethe

Depth Regulator Lever down to a

shallow setting and then slowly

increase the tilling depth on later

lasses.

Failure to follow this warning could

resultin personalinjury.

Read the following recommendationsbeforetilling on slopes:

If you must garden on a moderate slope, please follow two very important

guidelines:

I. Till only on moderate slopes, never on steep ground where footing is difficult

(reviewsafetyrulesin SectionI: Safetyof this manual).

2. Werecommendtilling upanddown slopesratherthan terracing. Tillingvertically

on a slopeallowsmaximumplantingareaandalso leavesroomfor cultivating.

IMPORTANT:When tilling on slopes, be sure the correct oil level is maintainedin

the engine(checkevery one-halfhour of operation). The incline of the slopewill

causetheoil to slantawayfrom its normal levelandthis can starveenginepartsof

requiredlubrication. Keepthe motor oil levelatthefull pointatall times!

Tilling UpandDownSlopes(VerticalTilling)

• To keepsoil erosion to a minimum, besure to add enoughorganicmatter to the

soil sothat it hasgood moisture-holdingtextureandtry to avoidleavingfootprints

or wheelmarks.

•When tilling vertically, try to makethe first pass uphill as the tiller digs more

deeplygoing uphillthan it doesdownhill. In soft soil or weeds,you may haveto

lift the handlebarsslightlywhile going uphill. Whengoing downhill, overlapthe

first passbyaboutone-halfthe width of thetiller.

TerraceGardening

• Whena slopeis too steepor too short for vertical tilling, it maybe necessaryto till acrosstheslopeand createterracedrows. Ter-

racesarerows that arecut intothe sideof aslope,creatinga narrow,butflat areaon whichto plant.

• Ona longslope,you canmakeseveralterraces,one belowthe other.

• Terracesshouldbe only 240-3 feetwide. Diggingtoo far intothe side of theslope will exposepoor subsoilthat is unproductivefor

plants.

Do not operate tiller on a slope too

steep for safe operation. Till slowly

and be sure you have good footing.

Never permit tiller to freewheel down

slopes. Failure to follow this warning

couldresultin personalinjury.

Tilling AcrossSlopesWithoutUsing

Terraces(HorizontalTilling)

• If vertical or terracing gardening aren't

practicalfor you, then you can till laterally

acrossa slope. Wedon't recommendthis

methodasit cancreateunsurefooting and

invitessoil erosion.

•As interrace gardening,start at the top of

the slopeand overlapthe first passby half

the width of the tiller. For addedstability of

thetiller, alwayskeepthe uphillwheelinthe

soft,newlytilled soil.

Page 16

TILLING TIPS & TECHNIQUES (cont.)

TerraceGardening(continued)

•To createa terrace,start at the top of the slope and workdown. Go backand forth O_!'_

acrossthe first row asshownin Fig.4-10. _,I_0

• Each succeeding lower terrace is started by walking below the terrace you're _]_l'll,

preparing. Foraddedstability of the tiller, alwayskeepthe uphill wheel in the soft, __iL_

newlytilled soil. Do not till the last12" or more of the downhill outside edgeof each _]_ II_"EPEAT

terrace. This untilled strip helps prevents the terraces from breaking apart and

washingdownhill. It alsoprovidesawalkingpath betweenrows. Fig.4.10

Thetines havea self-clearingactionwhich eliminatesmost tanglingof debris in

the tines. However,occasionallydry grass,stringy stalksor tough vines may

becometangled. Followtheseproceduresto help avoid tanglingand to clean

thetines, if necessary.

•To reducetangling, set the depth regulator deep enough to get maximum

"chopping" action asthe tines chop the materialagainsttheground. Also, try

to till under crop residues or cover crops while they are green, moist and

tender.

•Whilepowercomposting,try swaying thehandlebarsfrom sideto side (about

6"to 12"). This"fishtailing" actionoftenclearsthetinesof debris.

• If tanglingoccurs, lift the tines out of the soil and runthe tiller in reverse(if

unit is equippedwith poweredreverse)for a fewfeet. This reversingaction

shouldunwind agood dealof debris.

LOADINGAND UNLOADING

THETILLER

Loading and unloading the tiller into a

vehicle is potentiallyhazardousand we

don't recommenddoing so unless abso-

lutely necessary,as this could result in

personalinjury or propertydamage.

However, if you must load or unloadthe

tiller, follow the guidelinesgiven next.

• Beforeloading or unloading, stop the

engine,wait for allparts to stop moving,

disconnect thespark plug wire and let

the engine and muffler cool.

•Thetiller is too heavyand bulky to lift

safelyby one person.Two or more

peopleshould sharethe load.

• Usesturdy ramps andmanually (engine

shut off) roll the tiller into andout of the

vehicle. Two or more people areneeded

to do this.

•Theramps must bestrong enough to

support the combined weight of the tiller

and any handlers.The ramps should pro-

vide good traction to prevent slipping;

they should haveside rails to guide the

tiller alongthe ramps; andthey should

havea locking deviceto securethem to

the vehicle.

•Thehandlersshould wearsturdy footwear

that will helpto preventslipping.

• Position the loading vehicle sothat the

ramp angle is asflat as possible (the less

inclineto the ramp, the better). Turn the

vehicle's engineoff andapply its parking

brake.

•Whengoing up ramps, stand in the

normal operatingposition and pushthe

•It maybe necessaryto remove the debris by

hand (a pocket knife will help you to cut away

the material). Besure to stop the engineand

disconnectthe spark plug wire beforeclearing

thetinesby hand.

Beforeclearing thetines by hand, stop the

engine, allow all movingpartsto stop and

disconnectthe spark plugwire. Removethe

ignitionkeyonelectricstart models.

Failureto follow thiswarningcouldresultin

_ersonalinjury.

tiller aheadof you. Havea personat

eachside to turn the wheels.

•Whengoing down ramps, walk backward

with the tiller following you. Keepalert

for anyobstacles behind you. Position a

person ateach wheelto control the

speedof the tiller. Nevergo down ramps

tiller-first, asthe tiller could tip forward.

•Placewooden blocks on thedownhill

side of the wheelsif you needto stopthe

tiller from rolling down the ramp. Also,

usethe blocks to temporarily keepthe

tiller in placeon the ramps (if neces-

sary), and to chock the wheels in place

after the tiller is in the vehicle.

•After loading thetiller, prevent it from

rolling byengaging the wheels in the

WHEELDRIVEposition. Chockthe

wheels with blocks and securely tie the

tiller down.

Page 17

Maintenance

Before inspecting, cleaning or

servicing the machine, shut off engine,

wait for all moving parts to come to a

complete stop, disconnect spark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failure to follow these instructionscan

resultin serious personalinjuryor prop-

ertydamage.

MAINTENANCESCHEDULE

PROCEDURE NOTES

Checkmotor oil level 2, 3

Cleanengine 2, 7

Checkdrive belt tension 1,4

Checknuts and bolts 1,4

Change motor oil 4, 6, 9

Lubricatetiller 4

Serviceengine air cleaner system 7

Checkgear oil levelin transmission 1,5

Checktines for wear 5

Checkair pressure in tires (if unit

has pneumatic tires) 5

Servicesparkplug 7

NOTES

I - Checkat_erfirst 2hours ofbreak4n operation.

2 - Beforeeach use.

3 - Every 5 operating hours.

4- Every 10operating hours.

5 - Every 30 operating hours.

6 - Changemore frequently in dusty or dirty

conditions.

7 - SeeEngine Owner's Manual for service

recommendations.

B - Whichevertime interval occurs first.

g - Changeafter first 2 hours of break4n

operation.

TILLER LUBRICATION

After every 10operating hours, oil or

greasethe lubrication points shown in

Figure5-1 and described below.

Usecleanlubricating oil (#30 weight

motor oil is suitable) and cleangeneral

purposegrease (greasecontaining a metal

lubricant is preferred, if available).

•Removethe wheels, cleanthe wheel

shaft (A,Fig. 5-I) and applya thin

coating of greaseto the wheel shaft,

•Greasethe back, front andsides of the

depth regulator lever (B,Fig, 5-I),

•Removethe tines andcleanthe tine shaft

(C,Fig. 5-I). Usea file or sandpaperto

gently removeany rust, burrs or rough

spots (especiallyaround holesin shaft),

Apply greaseto endsof shaft before

installing tines.

•Oil the threads onthe handlebarheight

adjustment screws andthe handlebar

attachingscrews (D, Fig,5-I).

D

A

Figure5-1

CHECKFOROILLEAKS

Beforeeach use, check the tiller for signs

of anoil leak- usually a dirty, oily accu-

mulation either on the unit or onthe floor.

A little seepagearound a cover or an oil

sealis usually not acausefor alarm. How-

ever, if the oil drips overnight,then imme-

diate attention is needed. Ignoringanoil

leakcan result insevere transmission

damage!

If acover is leaking, checkfor loose

screws. If the screws are tight, anew

gasketor oil sealmay be required,

If the leakisfrom around a shaft and oil

seal,the oil sealprobably needsto be

replaced. Seeyour authorized dealeror

contact the factory for service or advice.

IMPORTANT:Neveroperate thetiller if the

transmission is lowon oil. Checkthe oil

levelafter every 30 hours of operationand

whenever there isany oil leakage.

CHECK HARDWARE

Checkfor looseor missing hardware after

every 10 operating hours and tighten or

replace(as needed)before reusingtiller

Besureto check the screws underneath

the tiller hoodthat securethe transmission

cover and the DepthRegulator Leverto the

transmission.

CHECKTIRE PRESSURE

(Models with pneumatic tires)

Checkthe air pressure in both tires= The

air pressure should bebetween 15-20 PSi

(pounds per square inch).

Keepbothtires equally inflated to help

prevent machinefrom pulling to oneside.

TRANSMISSIONGEAR

OILSERVICE

Checkthe transmission gear oil levelafter

every 30 hours of operation or whenever

you noticeanyoil leak. Operatingthe tiller

when thetransmission is low on oil can

result in severedamage.

A. ToCheckthe Transmission

GearOil Level:

1. Checkthe gear oil levelwhen thetrans-

mission is cool. Gearoil will expand in

warm operating temperaturesand this

expansion will provide an incorrect oil

levelreading.

2. With the tiller on level ground, pull the

Depth RegulatorLeverall the way up,

3. Removethe oil fill plug (A, Fig,5-2)

from thetransmission housing and look

insidethe oil fill holeto locatethe main

drive shaftsituated below the hole.

Page 18

I

cometo a complete stop,disconnectspark plug wire and move wire away from spark plug.

_ efore inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

4. Thegearoil levelis correctif the gear B. To Drainthe TransmissionGear Oil: BO/OTINES

oil isapproximately halfwayupthe side of

the maindriveshaft=

5. If the gearoil level is low, addgearoil

as described next. If the gearoil level is

okay, securelyreplace theoil fill plug.

IMPORTANT:Do not operatethetillerif

the gear oil levelis low. Doing sowill

result in severedamageto thetransmis-

sion components.

Figure 5.2: Removeoil fill plug (A) to check

gear oil level and to add gear oil. Remove

fourcoverscrews (B)to drain gear oil.

6. If addingonly a few ouncesof gear oil,

useAPI rated GL-4 or GL-5gearoil having

a viscosity of SAE140, SAEB5W-140or

SAE80W-90. If refilling an empty trans-

mission, use only GL-4 gear oil havinga

viscosity of SAE85W-140 or SAE140.

IMPORTANT: Donot useautomatic trans-

mission fluid or motor oil inthe transmis-

sion.

7. While checkingfrequently to avoid

overfilling, slowly addgearoil into the oil

fill hole until it reachesthe halfwaypoint

on the drive shaft.

8. Securelyreplace the oil fill plug.

Failure to follow these instructionscan result in serious personal injury or property damage.

Thetransmissiongear oil does not needto

be changedunless it hasbeencontami-

natedwith dirt, sandor metalparticles.

1. Drain gasolinefrom thefuel tankor run

theengine until the fueltank is empty. See

"DANGER"statementbelow.

Thebolo tines willwearwith use and

should be inspectedat the beginningof

eachtilling seasonand after every 30

operatinghours. Thetines can be

replacedeither individually or asa com-

pleteset. Seethe PartsList pagesfor fine

identification and part numbers.

A. Tine Inspection:

Gasoline is highly flammable and its

vapors are explosive. Follow these

safety practices to prevent personal

injury or propertydamage from fire or

explosion.

• Allow the engine and muffler to cool

for at least two minutes before

drainingthe tiller's gasolinetank.

• Do not allow open flames, sparks,

matchesor smokingin the area.

• Wipe away spills and pushtiller away

from spilledfuel.

• Use only an approved fuel container

and store it safely out of the reach of

children.

• Do not storegasolinein an area where

With use,the tines will becomeshorter,

narrower and pointed. Badlyworn tines

will result in a loss of tilling depth,and

reducedeffectivenesswhen chopping up

andturning under organic matter.

B. Removing/Installinga Single Tine:

1. With theengine shut off and the spark

plug wire disconnected,remove thetwo

screws (A, Figure5-3) and Iocknuts (B)

that attacha single tine to afine holder. If

needed,use penetratingoil onthe nuts.

2. When installing a single tine, be sure to

position it so that its cutting edge(sharp)

will enterthe soil first as the tiller moves

forward.

its vaporscould reachan open flame

or spark,or where ignitionsourcesare

present (suchas hot water and space

heaters, furnaces, clothes dryers,

stoves,electricmotors,etc.)

C. Removing/InstallingaTineAssembly:

I. A tine assembly consists of eight tines

mounted on afine holder.

2. If removing both fine assemblies,mark

them "left" and "right" before removal.

Removethe screw (C, Figure5-3) and

2. Drainthe oil from the engine.

3. Removefour screws (B, Figure5-2) and

removetransmission coverand gasket.

4. Removethe left-sidewheel.

5. Tiltthe left-sidewheel shaft into a drain

pan and allow the gear oil to drain through

the top of the transmission.

6. Reinstallthe wheel.

7. Installa new gasket (donot reuseold

gasket)and reinstallthe transmission

cover.

8. Refill the transmission usingGL-4 gear

oil (SAE85W-140 or SAE140).

9. Refill the enginewith motor oil and

locknut (D)that securethe tine assembly

to the fine shaft. If necessary,usea

rubber mallet to tapthe fine assembly out-

ward off the shaft.

3. Beforereinstalling the fine assembly,

inspectthe fine shaft for rust, rough spots

or burrs. Lightly file or sand,as needed.

Applya thin coatof greaseto the shaft.

4. Install eachtine assemblyso that the

cutting (sharp) edge of the tineswill enter

the soil first whenthe tiller moves

forward Securethe tine assemblyto the

fine shaft using the screw and Iocknut

previously removed.

replenish thefuel tank with gasoline.

Page 19

come to acomplete stop, disconnect spark plugwire and move wire away from spark plug.

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

Failure to follow these instructionscan result in serious personal injury or property damage.

c=Unhook the top of the spring from

the ForwardClutch Bail.

d. Usepliers to prevent the adjuster(B)

from turning and turn the slotted

ENGINE

screwlocated inside thespring

clockwise (viewedfrom operator's

position) to increasetension onthe

spring. Turn the screw counter-

clockwise to decreasetension. Once

TINE

SHAFT

D

adjusted, reattachthe spring to the

ForwardClutch Bail.

e. RepeatSteps2 and 3 to re-measure

C

the lengthof the spring. When the

secondmeasurementis between

1116"-to- 3116"longerthanthe first

A

measurement,retightenthe hexnut

(C)againstthe top of theadjuster (B).

I

Figure5.3: Install tinesso that cuttingedge of tines enter soil first whentiller movesforward.

CHECKINGAND ADJUSTING

FORWARDDRIVEBELTTENSION

It is important to maintain correct tension

on the forward drive belt. A loosebelt will

causethetines andwheelsto slow down -

or stop completely - even though the

engine is running atfull speed. A too tight

belt canresult in unintentional tine move-

ment when the clutch bail is in the Neutral

(released)position.

• Checkbelt tension after the first two

measurementis between 1116_-to- 3116"

longer than thefirst measurement.

4. If thespring is too short (less than

I116"),the tension is too loose. If the

spring istoo long (more than 3116"),the

tension is too tight.

5. Toadjust the length of thespring:

a=Releasethe Forward ClutchBail.

b. Unthreadthe hexnut (C, Figure5-4)

about halfway upthe adjustment

screw (D).

hours of break-in operationand after

every 10 operating hours.

•At the end of each tilling season,check

thebelt for cracks,cuts orfrayed edges

and replaceit assoon as possible.

ToCheckForwardBeltTension:

I. Stop engine,wait for all partsto stop

moving and disconnectspark plug wire.

2. With the ForwardClutch Bail in an

open (released)position, measureand

notethe overall length of the cablespring

(A, Figure5-4) by measuring from the out-

ermost coil to theoutermost coil.

3. Squeezethe Forward Clutch Bail

againstthe handlebar (seeFigure5-4) and

re-measurethe length of the coils= The

belt tension is correct if this second

Figure5.4: Tocheckforwardbelt tension, take two measurementsof

theoverall lengthof thecoils in the spring- first with theclutch bail

open, thenwith theclutch bail closedagainst the handlebar.

ReplacementBelt Information

If the drive belt needsto be replaced,see

your localauthorized dealeror refer to the

Parts List for ordering information. Use

only a factory-authorized belt asan "over-

the-counter" belt may not perform satis-

factorily. The procedurerequiresaverage

mechanicalability andcommonly available

tools.

Page 20

I

cometo a complete stop,disconnectspark plug wire and move wire away from spark plug.

_ efore inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

Failure to follow these instructionscan result in serious personal injury or property damage.

FORWARD CLUTCH

BAIL ADJUSTMENT

If the ForwardClutch Bail doesnot func-

tion properly, first checkthat the forward

drive belt is adjustedproperly (see

Checkingand Adjusting Forward Drive

Belt Tension). If this fails to correct the

problem, contact the factory Technical

ServiceDepartment or your authorized

dealerfor serviceadvice.

CHECKINGANDADJUSTING

REVERSEDRIVE BELTTENSION

(Models 12209112210 only)

It is important to maintaincorrect tension

on the reversedrive belt. A loosebeltwill

causethetines and wheelsto slow down -

or stop completely- eventhough the

engine is running at full speed.

Whenchecking belt tension, also check

the belt for cracks,cuts or frayed edges

and replaceit assoon as possible.

•Checkbelt tension afterthe first two

hours of break-in operation and after

every 10 operating hours.

To CheckReverseBeltTension:

I. Stop engine,waitfor allparts to stop

moving and disconnect sparkplug wire.

2. Removescrew in plastic belt cover and

slide beltcover (which is attachedto for-

ward clutch cable)out of the way.

3. Havean assistant pull the Reverse

ClutchControl knoball theway out and

hold it in that position. Measurethe

lengthof the cablewire betweenthe end

of thethreaded cableadjuster (A, Figure 5-

5) andthe end of the z-fitting (B) to which

the cablewire is attached.

4. Thebelttension is ideal if the cablewire

lengthmeasures betweenI18"to I/4". If it

is lessthan 118"(andifthere is no reverse

actionwhen thetiller is running), then

makethefollowing adjustments.

NOTE:Ifthe length is morethan I14",no

adjustment isneeded--as long asthe

reverseactionfunctions properly.

5. Releasethe ReverseClutch Control

knob.and then unthreadthe innerjam nut

(C,Figure5-6) oneto two turns. Pull the

threadedcable adjuster (A, Figure5-6) to

the leftuntil the innerjam nut (C) touches

the bracket.

6. Preventthe innerjam nut (C) from

turning andtighten the outerjam nut (D)

against the bracket. Preventtheouter jam

nut (D) from turning andtighten the inner

jam nut (C)against the bracket,

7. Measurethe gap by repeating Step3.

Readjustas neededby repeatingSteps5

and 6.

8. Reinstall the belt cover.

Figure5.5: Measure cable wire length to

checkfor correctreverse belt tension,

Figure5-6: Move threaded

adjuster (A) to left to increase

belt tension.

ReplacementBeltInformation

If the drive belt needsto be replaced,see

your localauthorized dealeror refer to the

Parts List for ordering information. Use

only a factory-authorized beltas an "over-

the-counter" belt may not perform satis-

factorily. Theprocedure requiresaverage

mechanicalability andcommonly available

tools.

ENGINECLEANING

Keepingthe engine cleanwill help to

ensuresmooth operationand prevent

damagefrom overheating. Referto the

EngineOwner's Manual for engine

cleaningservice intervals and instructions.

Besurethat the muffler is cool before ser-

vicing the engine.

AIR CLEANER SERVICE

Theair cleanerfilters dirt and dust out of

the air beforeit enters the carburetor.

Operatingthe enginewith adirty, clogged

air filter can cause poor performanceand

damageto the engine. Neveroperatethe

engine without the air cleaner installed.

Inspectand servicethe air cleaner more

often if operating in very dusty or dirty

conditions. Referto the EngineOwner's

Manualfor air cleaner service intervals

and instructions.

ENGINEOILSERVICE

Checkthe engine oil levelbeforeeach use

and after every 5 hours of continuous

operation. Running the enginewhen it is

lowon oil will quickly ruin the engine.

It is recommendedthat you change the

motor oil afterevery I0 hours of operation

and evensoonerwhen operating in

extremely dirty or dusty conditions. Refer

to the EngineOwner's Manual for detailed

service instructions.

A. To Checkthe EngineOil Level:

I. Parkthe tiller on a levelareaand shut

off the engine.

2. Levelthe engine(usethe DepthRegu-

lator Leverto adjust the engineangle).

Page 21