Troy-Bilt 12210 Super Bronco, 12209 Bronco, 12227 Tuffy Owner's Manual

0 TRtIII BILT

OWNER'SMANUAL

Rear-TineTillers

• Safety

• Assembly

Before © read this

Models

• Controls

• Operation

• Maintenance

• PartsList

12227 - 3.75HP TUFFY®

12209 - 5.5HPBRONCOTM

12210 - 6.5HPSuper BRONCO'M

Model

12210

GARDEN WAYINCORPORATED

DearOwner:

Table of Contents

You now own one of the finest standard-rotating-tine tillers

available.Your new tiller allows you to till and cultivate your

garden with ease,and accomplish other property manage-

ment projects aswell. Your tiller is famous for its rugged-

ness,performance and high-quality engineering. We know

you'll enjoy using it.

Pleasecarefully readthis Manual. It tells you how to safely

and easily assemble,operate and maintain your machine

(four tiller models arecovered in this Manual--be sure to

useonly the information that applies to your model). Be

sure thatyou andany other operatorscarefully follow the

recommendedsafetypractices atall times. Failureto do so

could result in personal injury or property damage.

Of course, if you should ever haveany problems or ques-

tions, pleasecontact your local authorized dealeror callthe

Factory(seeback cover of this Manual).We want to be sure

that you are completelysatisfied at all times.

NOTE: Besureto fill out and return the Warranty Registra-

tion Cardthat was suppliedwith this Manual.

See Back Cover for

Customer Service information

SafetyAlertSymbol

This is a safetyalertsymbol. It is used in this

manualand on the unit to alert you to potential

hazards. Whenyou seethis symbol, readand

obeythe messagethat follows it. Failureto obey

safety messagescould result inpersonal injury or

property damage.

This machine meets voluntary safety standard

B71.8 - 1996, which is sponsored by the Outdoor

Power Equipment Institute, Inc., and is published

by the American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

SECTION1: SAFETY........................................... 3

SafetyDecals ............................................................. 5

OperatingSymbols ..................................................... 5

SECTION2: ASSEMBLY....................................... 6

Attach Handlebar........................................................ 6

Move Tiller Off Shipping Platform .............................. 6

Install ForwardClutch Cable....................................... 7

Install ReverseClutch Cable(Models 12209/12210).. 8

CheckLevel of TransmissionGearOil ........................ 9

Add Motor Oilto Engine............................................. 9

CheckHardwarefor Tightness.................................... 9

CheckAir Pressurein Tires ........................................ 9

SECTION3: FEATURES& CONTROLS........................ 10

EngineControls .......................................................... 10

WheelDrive Pins ........................................................ 10

ForwardClutch Bail .................................................... 11

ReverseClutch Control............................................... 11

DepthRegulator Lever................................................ 11

HandlebarHeightAdjustment ..................................... 11

SECTION4: OPERATION...................................... 12

Break-InOperation..................................................... 12

Starting and Stoppingthe Engine............................... 12

Operatingthe Tiller ..................................................... 13

Tilling Tips & Techniques........................................... 14

Loadingand Unloadingthe Tiller ................................ 16

SECTION5: MAINTENANCE.................................. 17

MaintenanceSchedule................................................ 17

Tiller Lubrication......................................................... 17

Checkfor Oil Leaks..................................................... 17

CheckHardware......................................................... 17

CheckTire Pressure.................................................... 17

Transmission GearOil Service.................................... 17

BoloTines................................................................... 18

CheckingandAdjusting Forward DriveBelt Tension .. 19

ForwardClutch BailAdjustment ................................. 20

CheckingandAdjusting ReverseDrive BeltTension... 20

EngineCleaning.......................................................... 20

Air CleanerService..................................................... 20

EngineOil Service....................................................... 20

Spark Plug Service..................................................... 21

SparkArrester ScreenService.................................... 21

Throttle LeverAdjustment .......................................... 21

Carburetor/GovernorControl Adjustments ................. 21

Off SeasonStorage..................................................... 21

Troubleshooting ............................................... 22

PartsList........................................................ 23

CustomerService Information .................... BackCover

SPARKARRESTERWARNINGTO RESIDENTS

OF CALIFORNIAAND SEVERALOTHERSTATES

UnderCalifornia law, and under the laws of several

other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels

on any forest, brush,hay, grain, or grass covered land;

or land covered by any flammable agricultural crop

without an engine spark arrester in continuous effec-

tive working order.

The engine on the unit is an internal combustion

engine which burns gasoline, a hydrocarbon fuel, and

must be equippedwith a spark arrester muffler in con-

tinuous effective working order. The spark arrester

must be attachedto the engineexhaust system in such

a manner that flames or heat from the system will not

ignite flammable material. Failureof the owner/oper-

ator of the unit to comply with this regulation is a mis-

demeanor under California law (and other states) and

may also be a violation of other state and/or federal

regulations, laws, ordinances or codes. Contact your

localfire marshalor forest servicefor specificinforma-

tion about whichregulations apply in your area.

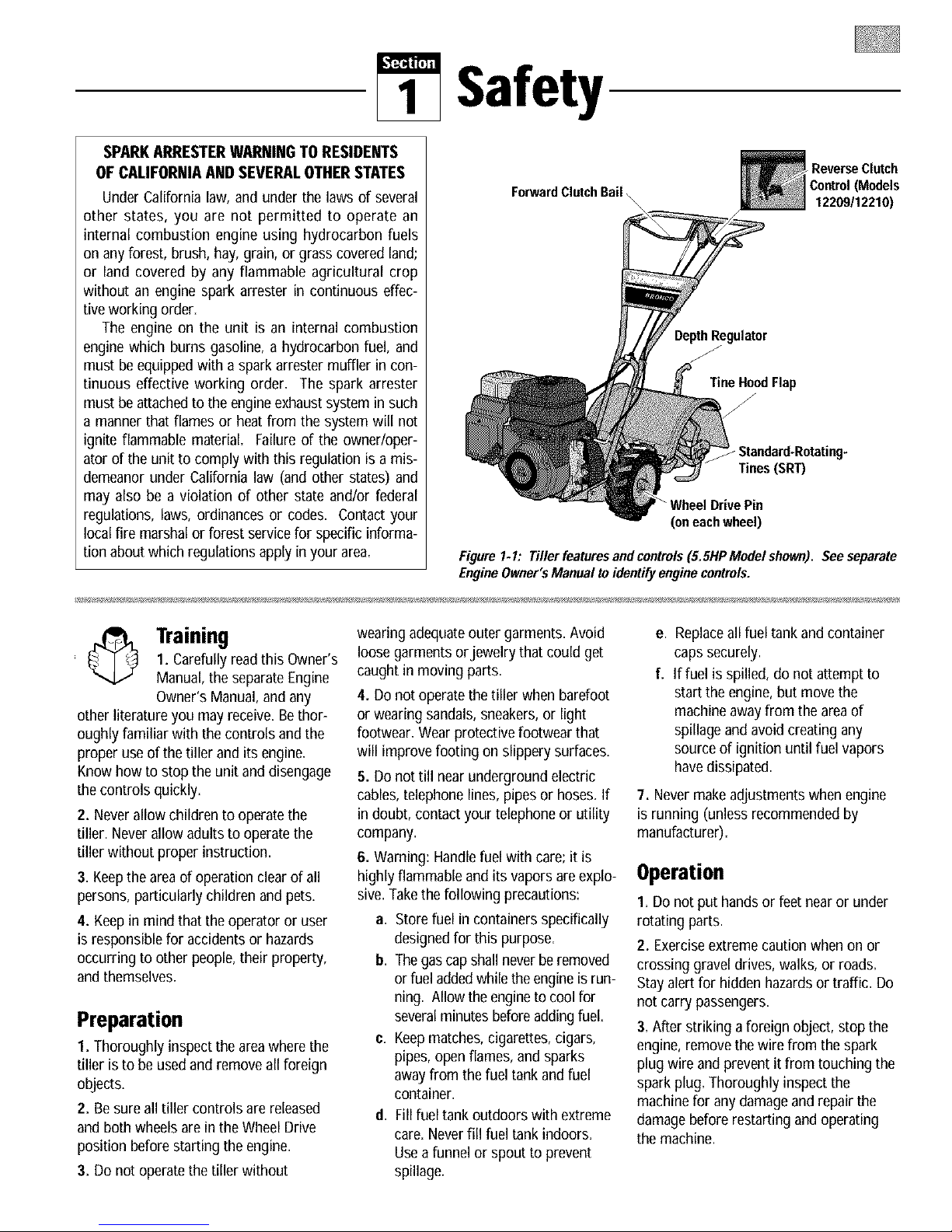

Safety

ReverseClutch

ForwardClutch Bail

DepthRegulator

TineHood Flap

f

_Standard-Rotating-

Tines (SRT)

"WheelDrivePin

(oneachwheel)

Figure1. I: Tiller featuresand controls(5.5HP Model shown). See separate

EngineOwner'sManual toidentify engine controls.

Control (Models

12209112210)

1. Carefullyreadthis Owner's

Training

Manual, the separateEngine

Owner's Manual, and any

other literatureyou may receive.Bethor-

oughly familiar with the controls and the

proper useof the tiller andits engine.

Knowhow to stop the unit and disengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operate the

tiller without proper instruction.

3. Keepthe areaof operationclearof all

persons,particularly children andpets.

4. Keepin mind that the operator or user

is responsiblefor accidentsor hazards

occurring to other people,their property,

and themselves.

Preparation

1. Thoroughlyinspectthe areawhere the

tiller is to be usedand remove all foreign

objects.

2. Be sureall tiller controls are released

and both wheels are in the Wheel Drive

position before starting the engine.

3. Do not operatethe tiller without

wearing adequateouter garments. Avoid

loosegarments orjewelry that could get

caught in moving parts.

4. Do not operate thetiller whenbarefoot

or wearing sandals, sneakers,or light

footwear. Wear protective footwear that

will improve footing on slippery surfaces.

5. Do not till nearunderground electric

cables,telephone lines, pipesor hoses. If

in doubt, contactyour telephone or utility

company.

6. Warning: Handlefuel with care;it is

highlyflammable and its vapors are explo-

sive.Takethe following precautions:

a. Storefuel incontainers specifically

designedfor this purpose.

b. Thegascapshallnever be removed

or fuel addedwhilethe engineis run-

ning. Allowthe engineto coolfor

severalminutesbefore addingfuel.

c. Keepmatches,cigarettes, cigars,

pipes, open flames, and sparks

away from the fuel tank and fuel

container.

d, Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Useafunnel or spout to prevent

spillage.

e. Replaceall fuel tank andcontainer

caps securely.

f. If fuel is spilled, do not attemptto

start the engine,but movethe

machine awayfrom the areaof

spillage and avoidcreating any

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustmentswhen engine

is running (unless recommendedby

manufacturer).

Operation

I. Do not put handsor feet nearor under

rotating parts.

2. Exerciseextremecaution when on or

crossing graveldrives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3. After striking aforeign object,stop the

engine, removethe wirefrom the spark

plug wire and preventit from touching the

spark plug. Thoroughly inspect the

machine for anydamage andrepair the

damagebefore restarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor-

mally, stop the engine,disconnect the

spark plug wire and prevent it from

touching the spark plug, and checkimme-

diatelyfor the cause. Vibration isgener-

allya warning of trouble.

6. Stopthe engine,disconnect the spark

plug wire and prevent it from touching the

spark plug, wheneveryou leavethe oper-

ating position, before unclogging the tines,

or when making any repairs, adjustments

or inspections.

7. Takeall possible precautionswhen

leavingthe machineunattended. Stopthe

engine. Disconnectthe spark plugwire

and move it awayfrom the spark plug. Be

surethat both wheels are in the Wheel

Drive position.

8. Beforecleaning,repairing, or

inspecting, stop the engineand make cer-

tain allmoving parts havestopped. Dis-

connectthe spark plug wire and prevent it

from touching thespark plug to prevent

accidentalstarting.

9. Theflap on thetine hoodmust be down

when operating thetiller.

10. Neverusethe tiller unless proper

guards, plates,or other safety protective

devicesare inplace.

11. Donot run the engine in an enclosed

area. Engineexhaustcontains carbon

monoxide gas, a deadlypoison that is

odorless,colorless, andtasteless.

12. Keepchildren and petsaway.

13. Neveroperatethetiller underengine

powerif thewheels are in theFreewheel

position. Inthe Freewheelposition, the

wheels will not holdthe tiller backandthe

revolving tines could propel the tiller

rapidly, possibly causing lossof control.

AIways engagethewheels with the wheel

drive pins in the WheelDrive position

beforestarting the engine orengaging the

tineslwheels with the Forward ClutchBail

(all models) orthe ReverseClutchcontrol

(Models 12209112210only).

14. Beawarethatthe tiller mayunex-

pectedly bounceupwardorjump forward

ifthe tinesshouldstrike extremelyhard

packedsoil, frozen ground,or buried

obstacleslike largestones,roots,or

stumps.If in doubtaboutthe tilling con-

ditions, alwaysusethe following

operatingprecautionsto assistyou in

maintainingcontrolofthe tiller:

a. Walk behindandtoone side ofthe

tiller, usingone handon thehan-

dlebars. Relaxyourarm, butusea

secure handgrip.

b. Use shallower depthregulatorset-

tings, workinggraduallydeeper

with each pass.

c. Useslower enginespeeds.

d. Clear the tilling area ofall large

stones, rootsandotherdebris.

e. Avoidusingdownwardpressureon

the handlebars.If need be, use

slight upwardpressureto keepthe

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lift the handlebarsto

raise the tines outof the soil.

g. In an emergency,stop the tines and

wheels byreleasingwhichever

clutchcontrolis engaged.Donot

attemptto restrainthe tiller.

15. Donot overloadthe tiller's capacity by

attempting to till too deeplyattoo fast a

rate.

16. Neveroperatethetiller at high trans-

port speedson hard or slippery surfaces.

Look behind and use carewhen backing

up.

17. Donot operatethe tiller ona slope

that is too steepfor safety.Whenon

slopes,slow down and make sureyou

havegood footing. Neverpermit the tiller

to freewheeldown slopes=

18. Neverallow bystanders nearthe unit.

19. Onlyuseattachments and accessories

that are approvedby the manufacturer of

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller if you aretired;

or underthe influenceof alcohol, drugs or

medication.

23. Operatorsshall not tamper withthe

engine-governorsettings onthe machine;

the governor controls the maximum safe

operatingspeed to protect theengine and

all moving partsfrom damagecaused by

overspeed. Authorized serviceshallbe

sought if a problem exists.

24. Donot touch engine parts which may

be hot from operation. Letparts cool down

sufficiently.

25. Pleaseremember:You can always

stop the tines andwheelsby releasing the

ForwardClutch Bail or onModels 12209

and 12210 the ReverseClutchcontrol,

(whichever control is engaged),or by

moving the ignition switch andlor throttle

control lever on the engineto "OFF"or

"STOP".

26. To loador unload the tiller, see the

instructions in Section 4 of this Manual.

27. Useextremecaution whenreversing

or pulling the machinetowards you.

28. Startthe enginecarefully according to

instructions andwith feet well awayfrom

thetines.

29. Neverpick upor carry a machine

while theengine is running.

Maintenance and Storage

I. Keepthe tiller, attachments and acces-

sories in safeworking condition.

2. Checkall nuts, bolts, and screws at

frequent intervalsfor proper tightness to

be surethe equipment is in safeworking

condition.

3. Neverstorethe tiller with fuel in the fuel

tank inside a building where ignition

sourcesare present such as hot water and

spaceheaters,furnaces, clothesdryers,

stoves,electric motors, etc.). Allow the

engineto cool before storing the unit in

anyenclosure.

4. To reducethe chancesof a fire hazard,

keepthe engine freeof grass, leaves,or

excessivegrease.

5. Storegasoline in a cool, well-ventilated

area,safely awayfrom anyspark- or

flame-producing equipment. Storegaso-

line in anapproved container, safelyaway

from the reachof children.

6. Referto the Maintenance sections of

this Manual and the separateEngine

Owner'sManual for instructions if the unit

is to be stored for an extendedperiod.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire is

connected,exceptwhen specifically

instructed to do so.

8. If thefuel tank hasto be drained, do

this outdoors.

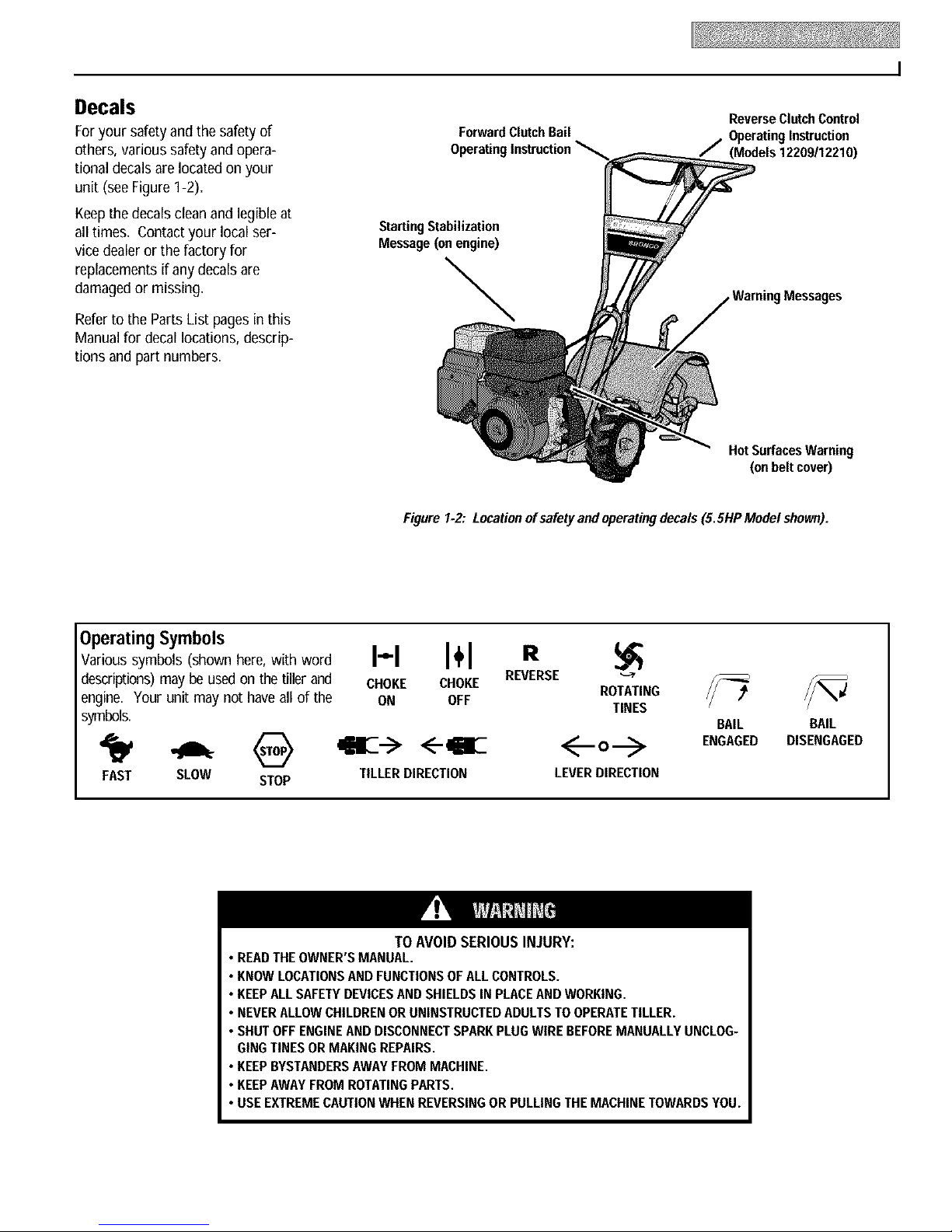

Decals

Foryour safety andthe safety of

others, various safety and opera-

tional decalsare located on your

unit (seeFigureI-2).

Keepthedecals cleanand legibleat

all times. Contactyour local ser-

vice dealeror the factory for

replacements ifany decalsare

damagedor missing.

Referto the Parts List pages in this

Manualfor decallocations, descrip-

tions and part numbers.

ForwardClutchBail

ReverseClutchControl

OperatingInstruction

Starting Stabilization

Message (on engine)

\

Hot Surfaces Warning

(on belt cover)

Figure 1.2: Locationof safety and operatingdecals(5.5HP Modelshown).

Instruction

1220911221O)

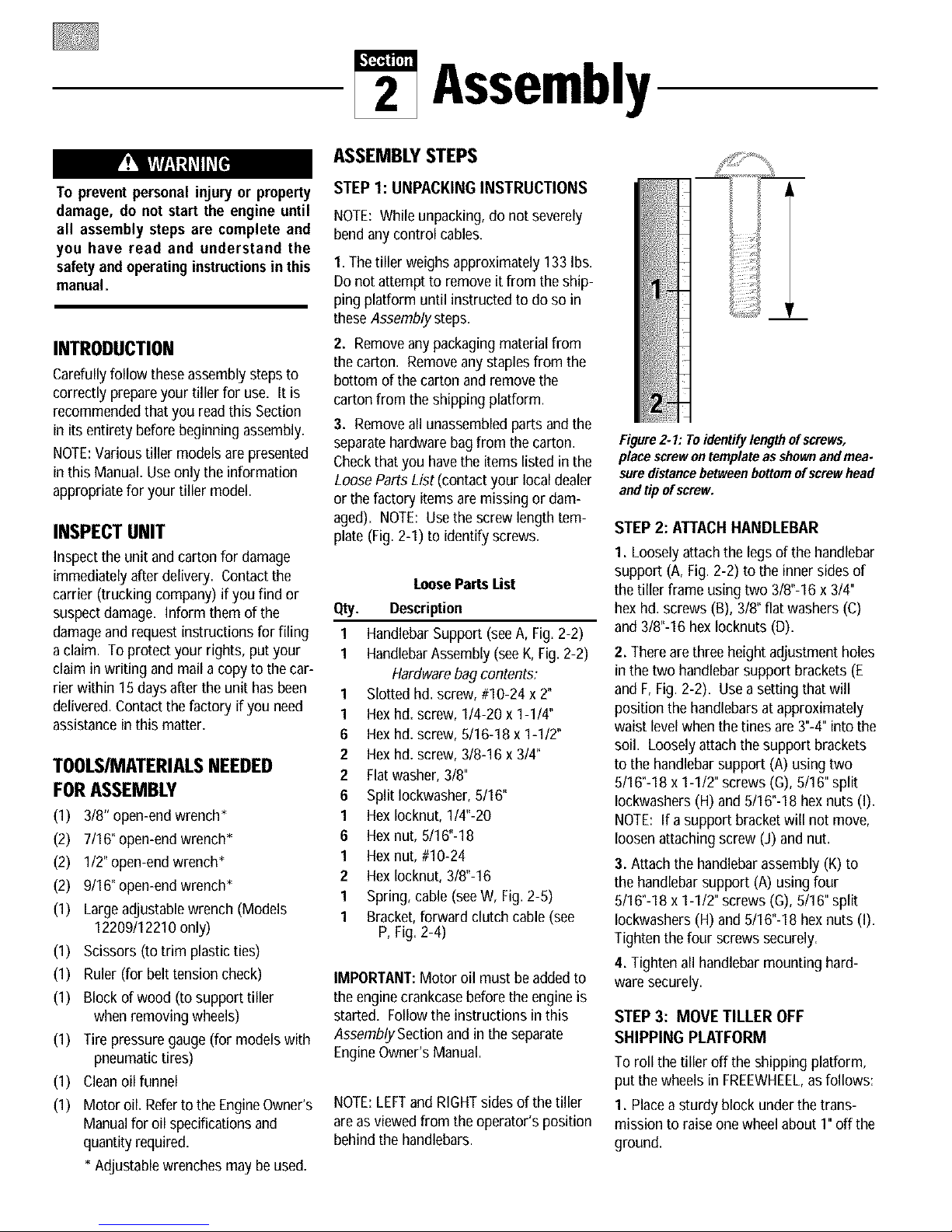

OperatingSymbols

Various symbols (shown here, with word

descriptions) may be used on the tiller and

engine. Your unit may not have all of the

symbols.

FAST SLOW STOP

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUT OFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUNCLOG-

GINGTINES ORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USE EXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDSYOU.

H I÷1 R

CHOKE CHOKE

ON OFF

<--qiE

TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

REVERSE

ROTATING

TINES

BAIL BAIL

ENGAGED DISENGAGED

Assembly

ASSEMBLYSTEPS

To prevent personal injury or property

damage, do not start the engine until

all assembly steps are complete and

you have read and understand the

safety and operatinginstructionsinthis

manual.

INTRODUCTION

Carefullyfollow theseassembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in its entirety before beginning assembly.

NOTE:Varioustiller modelsare presented

in this Manual. Useonly the information

appropriatefor your tiller model.

INSPECTUNIT

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspectdamage. Inform them of the

damageand request instructions for filing

a claim. To protectyour rights, put your

claim in writing andmail a copy to the car-

rier within 15 days after the unit hasbeen

delivered.Contactthe factory if you need

assistancein this matter.

TOOLS/MATERIALSNEEDED

FORASSEMBLY

(1) 3/8"open-end wrench*

(2) 7/16"open-end wrench*

(2) 1/2"open-end wrench*

(2) 9/16"open-end wrench*

(1) Largeadjustablewrench (Models

12209/12210 only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tension check)

(1) Block of wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatic tires)

(1) Cleanoilfunnel

(1) Motor oil. Referto the EngineOwner's

Manualfor oil specificationsand

quantity required.

* Adjustablewrenches may be used.

STEP 1: UNPACKINGINSTRUCTIONS

NOTE: While unpacking,do not severely

bend any control cables,

I. The tiller weighsapproximately133 Ibs.

Do not attemptto remove it from the ship-

ping platform until instructed to do so in

theseAssembly steps.

2. Removeanypackaging materialfrom

the carton. Removeany staples from the

bottom of the carton andremovethe

carton from the shipping platform.

3. Removeall unassembledparts andthe

separatehardwarebag from the carton.

Checkthat you havethe items listed in the

LooseParts List (contact your localdealer

or the factory items aremissing or dam-

aged). NOTE: Usethe screw lengthtem-

plate (Fig. 2-I) to identify screws.

LoosePartsList

Qty. Description

1 HandlebarSupport (seeA, Fig.2-2)

I HandlebarAssembly(seeK, Fig.2-2)

Hardwarebag contents:

1 Slotted hd. screw, #10-24 x 2"

1 Hexhd. screw, 1/4-20 x 1-1/4"

6 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

6 Split Iockwasher,8/16"

1 HexIocknut, 1/4"-20

6 Hexnut, 5/16"-18

1 Hexnut, #10-24

2 HexIocknut, 3/8"-16

1 Spring, cable(seeW, Fig. 2-5)

1 Bracket,forward clutch cable (see

P, Fig.2-4)

IMPORTANT:Motor oil must be added to

the enginecrankcasebefore the engineis

started. Follow the instructions inthis

Assembly Section and in the separate

EngineOwner's Manual.

NOTE:LEFTand RIGHTsides of the tiller

are asviewed from the operator's position

behind the handlebars.

Figure2. I: To identifylengthof screws,

place screwontemplate as shownand mea-

suredistancebetween bottomof screw head

and tipof screw.

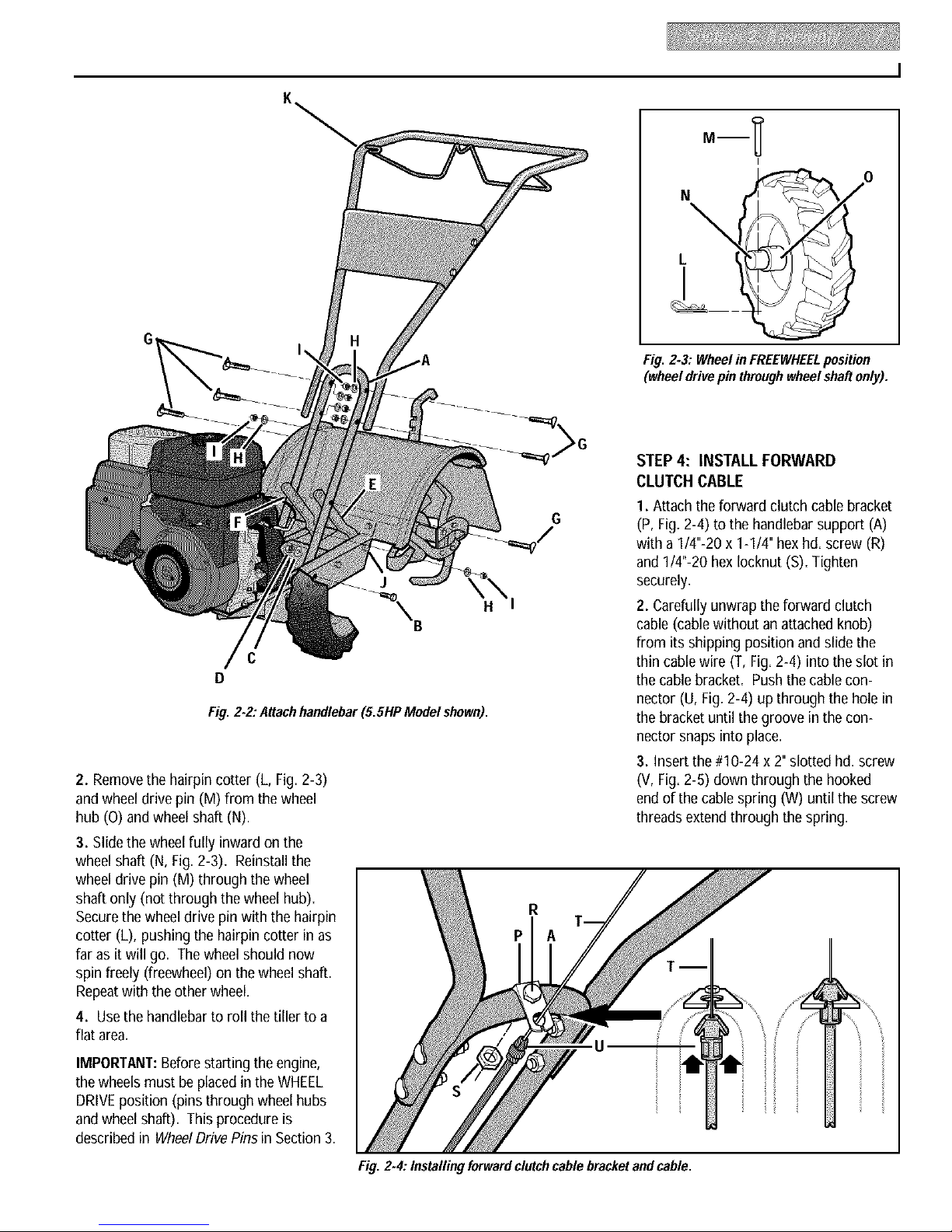

STEP 2: ATTACHHANDLEBAR

I. Loosely attachthe legsof the handlebar

support (A, Fig. 2-2)to the innersides of

the tiller frame usingtwo 318"-16x 314"

hexhd. screws (B), 318"flat washers (C)

and 318"-16hex locknuts (D).

2. Thereare three height adjustment holes

in the two handlebarsupport brackets(E

and F,Fig. 2-2). Usea setting that will

position the handlebarsat approximately

waist levelwhenthe tines are 3"-4"into the

soil. Loosely attachthe support brackets

to the handlebarsupport (A) using two

8116"-18x 1-112"screws (G),5116"split

lockwashers (H)and 5116"-18hexnuts (I).

NOTE: If asupport bracket will not move,

loosenattaching screw (J) and nut.

3. Attach the handlebarassembly(K) to

the handlebarsupport (A) using four

5116"-18x 1-112"screws (G),5116"split

lockwashers (H)and 5116"-18hexnuts (I).

Tighten the four screws securely.

4. Tighten all handlebarmounting hard-

ware securely.

STEP 3: MOVE TILLER OFF

SHIPPING PLATFORM

To roll the tiller off the shipping platform,

put the wheelsin FREEWHEEL,as follows:

I. Placea sturdy blockunder the trans-

mission to raiseone wheelabout I" off the

ground.

C

D

Fig. 2-2,"Attachhandlebar (5.SHPModel shown).

2. Removethe hairpin cotter (L, Fig. 2-3)

and wheel drive pin (M) from the wheel

hub (O) andwheel shaft (N).

3. Slidethewheelfully inwardon the

wheel shaft (N,Fig. 2-3). Reinstallthe

wheel drive pin (M) throughthe wheel

shaft only (not through the wheel hub).

Securethe wheel drive pin with the hairpin

cotter (L), pushingthe hairpincotter inas

far as it will go. The wheel should now

spin freely(freewheel)on the wheel shaft.

Repeatwith the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

a m

Fig. 2-3: Wheelin FREEWHEELposition

(wheeldrivepin throughwheel shaft only).

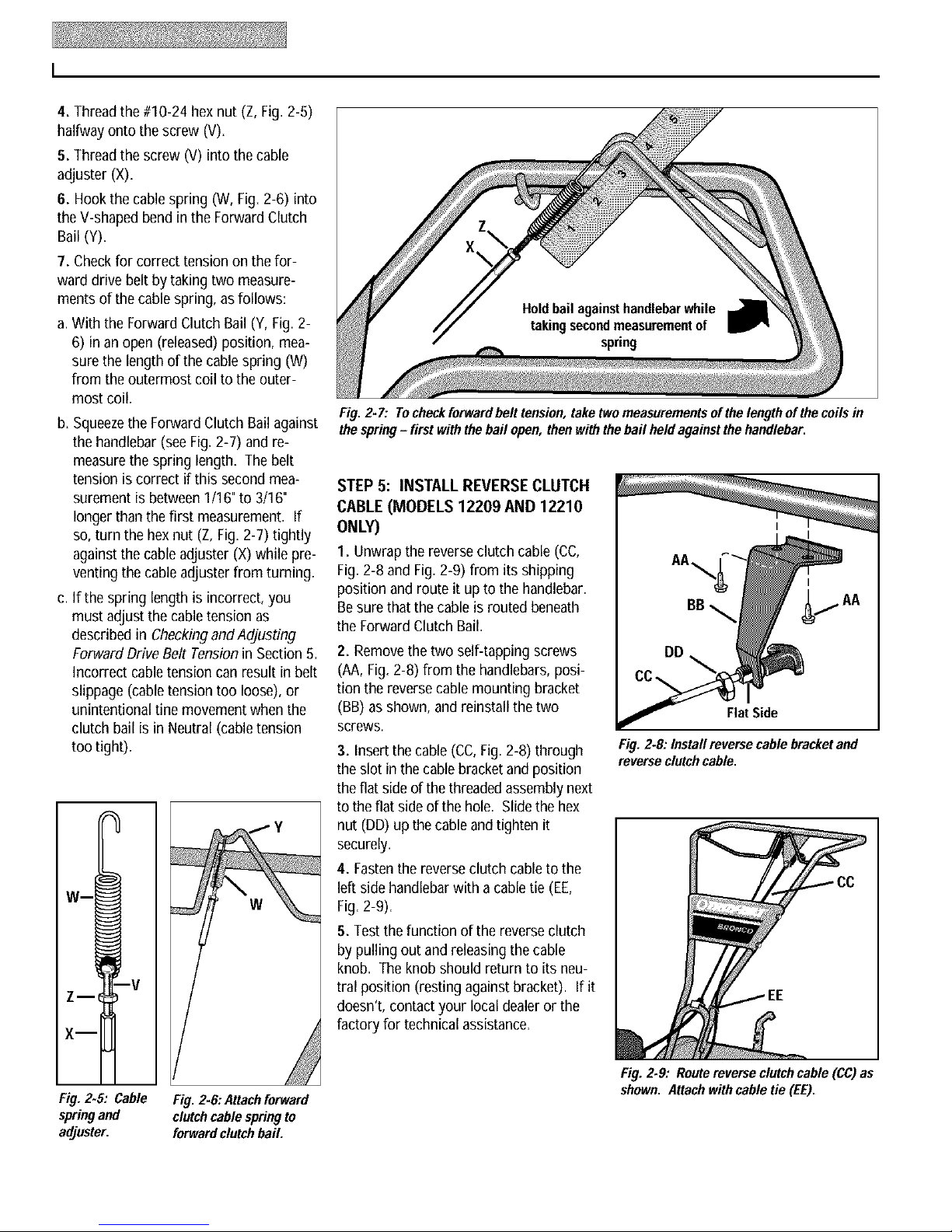

STEP 4: INSTALL FORWARD

CLUTCH CABLE

1. Attach the forward clutch cable bracket

(P, Fig.2-4) to the handlebarsupport (A)

with a 1/4"-20 x 1-1/4" hexhd. screw (R)

and 1/4"-20 hex Iocknut (S). Tighten

J

H

securely=

2. Carefullyunwrapthe forward clutch

cable(cable withoutan attached knob)

from its shipping position andslidethe

thincable wire (T, Fig.2-4) into the slot in

the cablebracket=Pushthe cable con-

nector (U, Fig.2-4) up through the hole in

the bracketuntil the groove in the con-

nector snapsinto place.

3. Insertthe #10-24 x 2" slotted hd. screw

(V, Fig.2-5) downthroughthe hooked

end of the cablespring (W) until the screw

threadsextendthroughthe spring.

IMPORTANT:Beforestarting theengine,

the wheelsmust beplacedin the WHEEL

DRIVEposition (pins through wheelhubs

and wheelshaft). This procedureis

described in WheelDrivePins in Section 3.

Fig. 2-4: Installing forwardclutchcable bracketand cable.

4. Threadthe #10-24 hexnut (Z,Fig. 2-5)

halfwayonto the screw (V).

5. Threadthe screw (V) into thecable

adjuster (X).

6. Hookthe cable spring (W, Fig.2-6) into

the V-shapedbend inthe ForwardClutch

Bail (Y).

7. Checkfor correct tension on the for-

ward drive belt by taking two measure-

ments of thecablespring, as follows:

a.With the ForwardClutch Bail (Y, Fig.2-

6) in an open (released)position, mea-

surethe lengthof the cablespring (W)

from the outermost coil to the outer-

most coil.

b. Squeezethe ForwardClutch Bail against

the handlebar (seeFig.2-7) and re-

measurethe spring length. Thebelt

tension is correct if this second mea-

surement is between1/16"to 3/16"

longer thanthe first measurement. If

so, turn the hexnut (Z, Fig.2-7) tightly

againstthe cableadjuster (X)while pre-

venting the cableadjuster from turning.

c. If the spring lengthis incorrect, you

must adjust the cabletension as

described in Checkingand Adjusting

Forward Drive Belt Tensionin Section5.

Incorrect cable tension can result inbelt

slippage (cabletension too loose),or

unintentional tine movementwhen the

clutch bailis in Neutral (cabletension

too tight).

W m

Fig. 2- 7: Tocheck forward belt tension, taketwomeasurementsof the length of thecoils in

thespring- first withthe bail open, then withthe bail heldagainst thehandlebar.

STEP 5: INSTALL REVERSE CLUTCH

CABLE (MODELS 12209 AND 12210

ONLY)

1. Unwrap the reverseclutch cable(CC,

Fig.2-8 and Fig.2-9) from its shipping

position and route it up to the handlebar.

Besurethat the cable is routed beneath

the Forward Clutch Bail.

2. Removethe two self-tapping screws

(AA,Fig. 2-8) from the handlebars,posi-

tion the reversecable mounting bracket

(BB) asshown, and reinstall the two

Flat Side

screws.

3. Insertthe cable(CC,Fig.2-8) through

the slot in the cablebracketand position

Fig. 2-8: Install reverse cable bracketand

reverseclutchcable,

the flat side ofthe threadedassemblynext

to the flatside of the hole. Slidethehex

nut (DD) up the cableand tighten it

securely.

4. Fastenthe reverseclutch cable to the

left side handlebarwith acable tie (EE,

Fig.2-9).

5. Testthe function of the reverseclutch

bypulling out andreleasingthe cable

knob. The knobshould return to its neu-

tral position (resting against bracket). If it

doesn't, contact your local dealeror the

factory for technical assistance.

Fig.2.5: Cable

springand

adjuster.

Fig. 2-8: Attachforward

clutchcable springto

forward clutchbail.

Fig. 2.9: Route reverse clutchcable (CC)as

shown. Attachwithcable tie (EE).

STEP 6: CHECKLEVELOF

TRANSMISSION GEAR OIL

STEP7: ADD MOTOR OIL

TO ENGINE

Thetransmission was filled with gearoil at

the factory. However,you should check

the gear oil levelatthis time to makecer-

tain it is correct.

IMPORTANT:Do not operatethe tillerif

the gear oil levelis low. Doingso will

result in severedamagetothe transmis-

sion components.

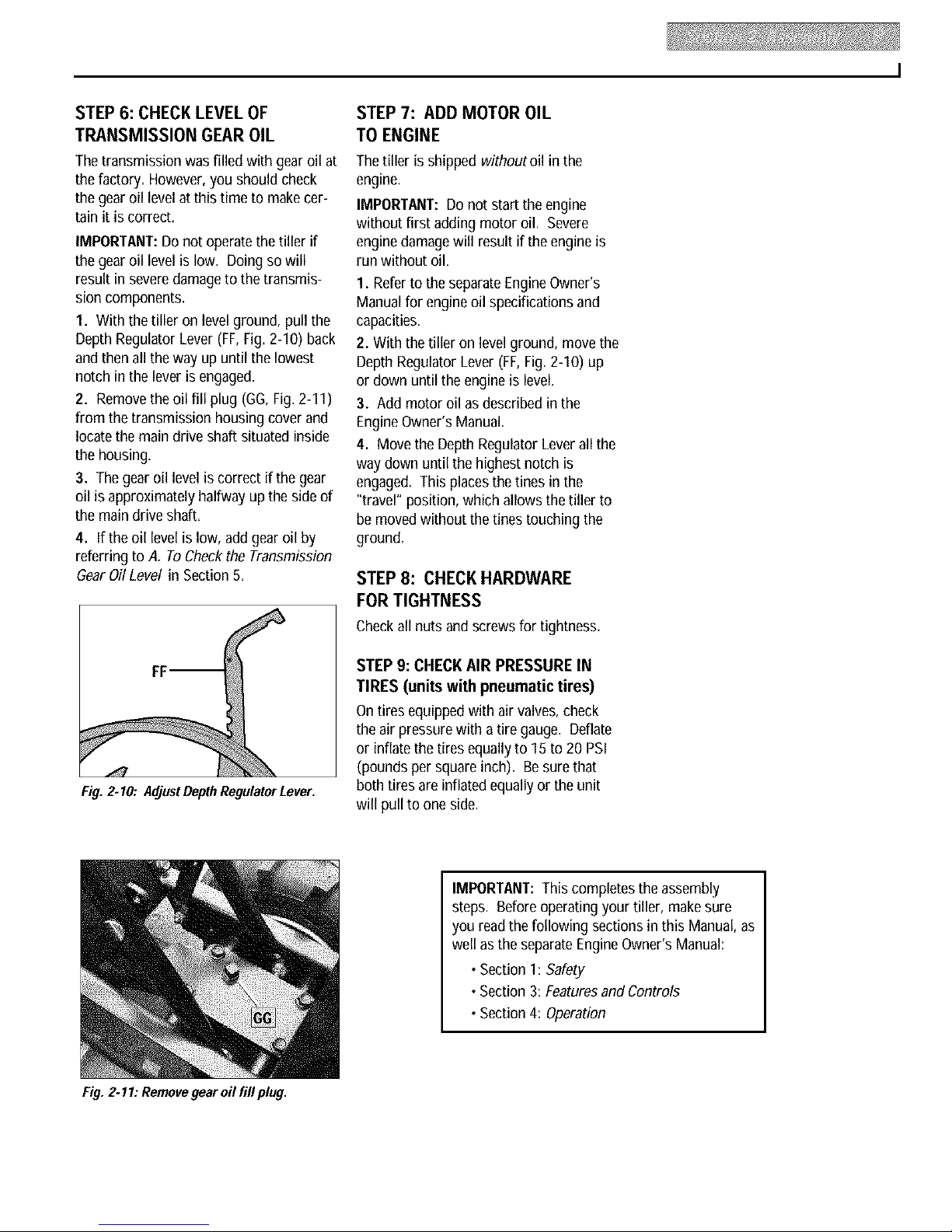

1. With the tilleron level ground, pull the

Depth Regulator Lever (FF,Fig. 2-10) back

and then all the way up until the lowest

notch in the leveris engaged.

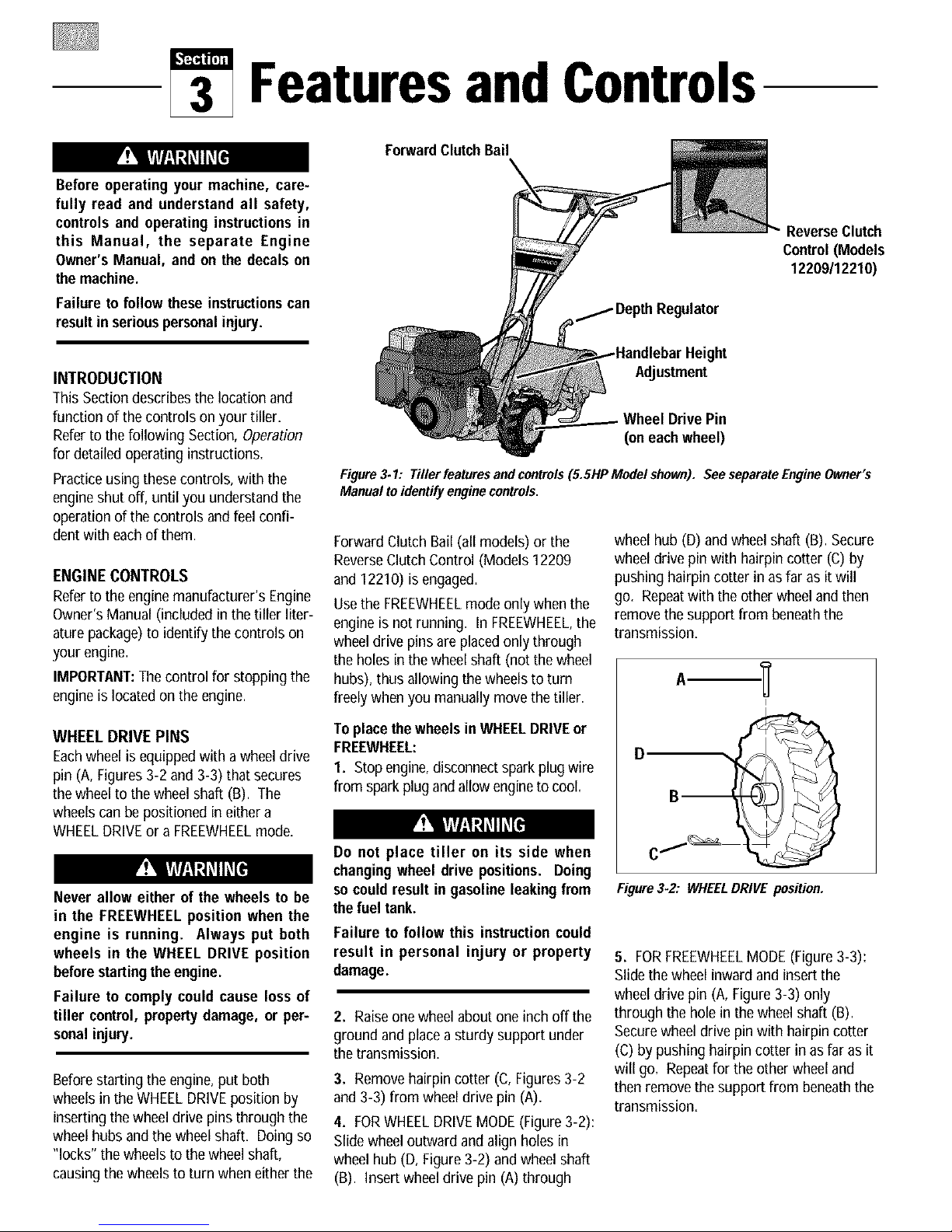

2. Removethe oil fill plug (GG, Fig.2-11)

from the transmission housing cover and

locate the main drive shaft situated inside

the housing.

3. Thegear oil level is correct if thegear

oil is approximately halfway up theside of

the main drive shaft.

4. If the oil levelis low, addgearoil by

referring to A. To Checkthe Transmission

GearOil Level in Section5.

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not startthe engine

without first addingmotor oil. Severe

enginedamagewill result if the engine is

run without oil.

1. Refertothe separateEngineOwner's

Manualfor engineoil specifications and

capacities.

2. Withthetilleron levelground, move the

Depth Regulator Lever (FF,Fig.2-10) up

or down until the engine is level.

3. Add motoroil asdescribed in the

EngineOwner's Manual.

4. Move the Depth Regulator Leverall the

way down until the highest notch is

engaged. Thisplacesthetines inthe

"travel" position, whichallows the tiller to

be moved without thetines touching the

ground.

STEP 8: CHECK HARDWARE

FOR TIGHTNESS

Checkall nutsand screws for tightness.

Fig. 2.10: AdjustDepthRegulatorLever.

Fig. 2.11: Removegear oil fill plug.

STEP 9: CHECK AIR PRESSURE IN

TIRES (units with pneumatic tires)

Ontires equippedwith air valves, check

the air pressure with atiregauge. Deflate

or inflate the tiresequallyto 15 to 20PSI

(pounds per squareinch). Besure that

both tires are inflatedequallyor the unit

will pull to one side.

IMPORTANT:This completes theassembly

steps. Before operating your tiller,make sure

you read the following sections inthis Manual, as

well as the separateEngineOwner's Manual:

• Section 1: Safety

•Section 3: FeaturesandControls

•Section 4: Operation

FeaturesandControls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, the separate Engine

Owner's Manual, and on the decals on

themachine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

INTRODUCTION

This Sectiondescribes the location and

function of the controls on your tiller=

Referto thefollowing Section, Operation

for detailedoperating instructions=

Practiceusing thesecontrols, withthe

engineshut off, until you understand the

operationof the controls and feel confi-

dentwith eachof them.

ENGINECONTROLS

Referto theengine manufacturer's Engine

Owner'sManual (included in the tillerliter-

aturepackage)to identify thecontrols on

your engine.

IMPORTANT:Thecontrol for stoppingthe

engine is locatedon the engine.

ForwardClutchBail

ReverseClutch

Control (Models

12209/12210)

Height

AdJustment

Wheel DrivePin

(oneachwheel)

Figure3.1: Tillerfeaturesandcontrols(5.SHPModelshown). SeeseparateEngineOwner's

Manual toidenti[y enginecontrols,

Forward Clutch Bail (all models) or the

ReverseClutch Control (Models12209

and 12210) is engaged.

Usethe FREEWHEELmode only whenthe

engine is not running. In FREEWHEEL,the

wheeldrive pinsare placedonly through

the holes inthe wheelshaft (not thewheel

hubs), thus allowing the wheels to turn

freely when you manually move the tiller.

wheel hub (D) and wheel shaft (B).Secure

wheel drive pinwith hairpin cotter (C) by

pushing hairpin cotter in as far as it will

go. Repeatwith the other wheeland then

removethe supportfrom beneaththe

transmission.

I

WHEEL DRIVE PINS

Eachwheel is equippedwitha wheeldrive

pin (A, Figures3-2 and 3-3) that secures

thewheelto the wheelshaft (B). The

wheelscan be positioned ineither a

WHEELDRIVEor a FREEWHEELmode=

Never allow either of the wheels to be

in the FREEWHEELposition when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

beforestartingthe engine.

Failure to comply could cause lossof

tiller control, property damage, or per-

sonalinjury.

Beforestarting the engine,put both

wheels in the WHEELDRIVEposition by

inserting the wheeldrive pinsthrough the

wheel hubs andthe wheel shaft. Doing so

"locks" the wheels to thewheel shaft,

causingthe wheels to turn wheneither the

To placethe wheels in WHEELDRIVEor

FREEWHEEL:

I. Stop engine,disconnectspark plug wire

from spark plugandallow engineto cool.

Do not place tiller on its side when

changingwheel drive positions. Doing

socould result in gasoline leakingfrom

the fuel tank.

Failure to follow this instruction could

result in personal injury or property

damage.

2. Raiseonewheel aboutone inch off the

ground and placea sturdy support under

the transmission=

3. Removehairpin cotter (C,Figures 3-2

and 3-3) from wheel drive pin (A)=

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheeloutward and align holes in

wheel hub (D, Figure3-2) and wheel shaft

(B). Insert wheeldrive pin (A)through

D

Figure3-2: WHEELDRIVE position.

5. FORFREEWHEELMODE(Figure 3-3):

Slidethe wheelinward andinsert the

wheel drive pin (A, Figure3-3) only

through the hole in the wheelshaft (B).

Securewheel drive pin with hairpin cotter

(C) bypushing hairpin cotter in as far asit

will go=Repeatfor the other wheel and

then removethe support from beneaththe

transmission=

Loading...

Loading...