Page 1

Owner’s Manual

REAR-TINE TILLERS

• Safety

• Assembly

• Controls

• Operation

• Maintenance

$4.50

Models

12217-3.5HPTUFFY®

• Parts List

12208- 4.5 HP Super TUFFY®

12209- 5.5 HP BRONCO™

12210- 6.5 HP Super BRONCO™

GARDEN WAY INCORPORATED

Page 2

Dear Owner:

Table of Contents

You now own one of the finest standard-rotating-tine tillers

available. Your new tiller allows you to till and cultivate your

garden with ease, and accomplish dozens of other property

management projects as well. Your tiller is famous for its

ruggedness, performance and high-quality engineering. We

know you’ll enjoy using it.

Please carefully read this Manual. It tells you how to safely

and easily assemble, operate and maintain your machine

(four tiller models are covered in this Manual... be sure to

use only the information appropriate to your tiller model).

Be sure that you and any other operators carefully follow

the recommended safety practices at all times. Failure to

do so could result In personal Injury or property damage.

Of course, if you should ever have any problems or

questions, please contact your local authorized dealer or

call the Factory (see back cover of this Manual). We want to

be sure that you are completely satisfied at all times.

NOTE; Be sure to fill out and return the Warranty Registra

tion Card that was supplied with this Manual.

See Back Cover for

Customer Service Information

SECTION 1: SAFETY..................................................................... 3

Safety Decals.............................................................................. 5

SECTION 2: ASSEMBLY................................................................ 6

Attach Flandlebar........................................................................ 7

Move Tiller Off Shipping Platform............................................... 7

Install Forward Clutch Cable....................................................... 8

Install Reverse Clutch Cable (Models 12209/12210)

Check Level of Transmission Gear Oil

Add Motor Oil to Engine.............................................................. 9

Check Hardware for Tightness.................................................. 9

Check Air Pressure in Tires

SECTION 3: FEATURES & CONTROLS

Wheel Drive Pins....................................................................... 10

Forward Clutch Bail

Reverse Clutch Control (Models 12209/12210)

Depth Regulator........................................................................ 12

Handlebar Height Adjustment................................................... 12

SECTION 4: OPERATION

Break-In Operation.................................................................... 13

Starting and Stopping the Engine

Operating the Tiller.................................................................... 14

Tilling Tips & Techniques.......................................................... 16

Power Composting.................................................................... 18

Loading and Unloading the Tiller

........................................................

..................................................................

.....

......................................................

.......................................

........................................

.............................................

..............................................

.................

.......................

10

11

11

13

13

18

9

9

9

Safety Alert Symbol

This is a safety alert symbol, it is used in this

manual and on the unit to alert you to

A

Failure to obey safety messages could result in personal

injury or property damage.

potential hazards. When you see this symbol,

read and obey the message that follows it.

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

A WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

SECTION 5: MAINTENANCE

Required Maintenance Schedule.............................................. 19

Tiller Lubrication........................................................................ 20

Check for Oil Leaks................................................................... 20

Check Hardware

Check Tire Pressure

Transmission Gear Oil Service

Bolo Tines................................................................................. 21

Checking and Adjusting Forward Drive Beit Tension

Forward Clutch Bail Adjustment................................................ 22

Checking and Adjusting Reverse Drive Belt

Tension (Models 12209/12210)

Engine Cleaning....................................................................... 23

Air Cleaner Service

Engine Oil Service

Spark Plug Service.................................................................... 24

Spark Arrester Screen Service.................................................. 24

Carburetor/Governor Control Adjustments

Off Season Storage

Troubleshooting......................................................................... 25

Tiller Attachments

PARTS LIST

CUSTOMER SERVICE INFORMATION............... Back Cover

......................................................................

...................................................................

..................................................................... 25

...

........................................................................... 26

.......................................................

.................................................................

.................................................

..............

.............................................

...................................................................

...............................

................................................................. 24

19

20

20

20

22

23

23

24

24

Page 3

Section

il Safety

SPARK ARRESTER WARNING TO RESIDENTS OF CALIFORNIA AND SEVERAL OTHER STATES

Under California law, and under the laws of several other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels on any forest, brush, hay, grain, or grass

covered land; or land covered by any flammable agricultural crop without an engine spark arrester in

continuous effective working order.

The engine on the unit is an internal combustion engine which burns gasoline, a hydrocarbon fuel, and must be equipped with a

spark arrester muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in

such a manner that flames or heat from the system will not ignite flammable material. Failure of the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may also be a violation of other state

and/or federal regulations, laws, ordinances or codes. Contact your local fire marshal or forest service for specific information

about which regulations apply in your area.

Training

1. Carefully read this

Owner’s Manual, the

separate Engine Owner’s

Manual, and any other literature you may

receive. Be thoroughly familiar with the

controls and the proper use of the tiller

and its engine. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the

tiller. Never allow adults to operate the

tiller without proper instruction.

3. Keep the area of operation clear of all

persons, particularly children and pets.

4. Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people, their property,

and themselves.

Preparation

1. Thoroughly inspect the area where the

tiller is to be used and remove all foreign

objects.

2. Be sure all tiller controls are released

and both wheels are in the Wheel Drive

position before starting the engine.

3. Do not operate the tiller without

wearing adequate outer garments. Avoid

loose garments or jewelry that could get

caught in moving parts.

4. Do not operate the tiller when barefoot

or wearing sandals, sneakers, or light

footwear. Wear protective footwear that

will improve footing on slippery surfaces.

5. Do not till near underground electric

cables, telephone lines, pipes or hoses. If

in doubt, contact your telephone or utility

company.

6. Warning: Handle fuel with care; it is

highly flammable and its vapors are

explosive. Be sure to take the following

precautions:

a. Store fuel in containers specifically

designed for this purpose.

b. The gas cap shall never be removed

or fuel added while the engine is

running. Allow the engine to cool

for several minutes before adding

fuel.

c. Keep matches, cigarettes, cigars,

pipes, open flames, and sparks

away from the fuel tank and fuel

container.

d. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

Use a funnel or spout to prevent

spillage.

e. Replace all fuel tank and container

caps securely.

f. If fuel is spilled, do not attempt to

start the engine, but move the

machine away from the area of

spillage and avoid creating any

source of ignition until fuel vapors

have dissipated.

7. Never make adjustments when engine

is running (unless recommended by

manufacturer).

Operation

1. Do not put hands or feet near or under

rotating parts.

2. Exercise extreme caution when on or

crossing gravel drives, walks, or roads.

Stay alert for hidden hazards or traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine, remove the wire from the spark

plug wire and prevent it from touching

the spark plug. Thoroughly inspect the

machine for any damage and repair the

damage before restarting and operating

the machine.

4. Exercise caution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor

mally, stop the engine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and check

immediately for the cause. Vibration is

generally a warning of trouble.

6. Stop the engine, disconnect the spark

plug wire and prevent it from touching

the spark plug whenever you leave the

operating position, before unclogging the

tines, or when making any repairs, adjust

ments or inspections.

Page 4

Section 1: Safety

7. Take all possible precautions when

leaving the nnachine unattended. Stop the

engine. Disconnect spark plug wire and

move it away from the spark plug. Be

sure both wheels are in the Wheel Drive

position.

8. Before cleaning, repairing, or inspect

ing, stop the engine and make certain all

moving parts have stopped. Disconnect

the spark plug wire and prevent it from

touching the spark plug to prevent acci

dental starting.

9. The flap on the tine hood must be

down when operating the tiller.

10. Never use the tiller unless proper

guards, plates, or other safety protective

devices are in place.

11. Do not run engine in an enclosed

area. Engine exhaust contains carbon

monoxide gas, a deadly poison that is

odorless, colorless, and tasteless.

12. Keep children and pets away.

13. Never operate the tiller under

engine power if the wheels are in the

Freewheel position. In the Freewheel

position, the wheels will not hold the tiller

back and the revolving tines could propel

the tiller rapidly, possibly causing loss of

control. Always engage the wheels with

the wheel drive pins in the Wheel Drive

position before starting the engine or

engaging the tines/wheels with the

Forward Clutch Ball (all Models) or the

Reverse Clutch control (Models

12209/12210 only).

14. Be aware that the tiller may unex

pectedly bounce upward or jump

forward if the tines should strike

extremely hard packed soil, frozen

ground, or buried obstacles like large

stones, roots, or stumps. If in doubt

about the tilling conditions, always use

the tollowing operating precautions to

assist you in maintaining control of the

tiller:

a. Walk behind and to one side of the

tiller, using one hand on the han

dlebars. Relax your arm, but use a

secure hand grip.

b. Use shallower depth regulator

settings, working gradually

deeper with each pass.

c. Use slower engine speeds.

d. Clear the tilling area of all large

stones, roots and other debris.

e. Avoid using downward pressure

on handlebars. If need be, use

slight upward pressure to keep the

tines from digging too deeply.

f. Before contacting hard packed soil

at the end of a row, reduce engine

speed and lift handlebars to raise

tines out of the soil.

g. In an emergency, stop tines and

wheels by releasing whichever

clutch control is engaged. Do not

attempt to restrain the tiller.

15. Do not overload the tiller’s capacity

by attempting to till too deeply at too fast

a rate.

16. Never operate the tiller at high

transport speeds on hard or slippery

surfaces. Look behind and use care when

backing up.

17. Do not operate the tiller on a slope

that is too steep for safety. When on

slopes, slow down and make sure you

have good footing. Never permit the tiller

to freewheel down slopes.

18. Never allow bystanders near the unit.

19. Only use attachments and acces

sories that are approved by the manufac

turer of the tiller.

20. Use tiller attachments and acces

sories when recommended.

21. Never operate the tiller without good

visibility or light.

22. Never operate the tiller if you are

tired, or under the influence of alcohol,

drugs or medication.

23. Operators shall not tamper with the

engine-governor settings on the machine;

the governor controls the maximum safe

operating speed to protect the engine and

all moving parts from damage caused by

overspeed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine parts which may

be hot from operation. Let parts cool

down sufficiently.

25. Please remember: You can always

stop the tines and wheeis by releasing the

Forward Clutch Bail or on Models 12209

and 12210 the Reverse Clutch control,

(whichever control is engaged), or by

moving the ignition switch and/or throttie

control lever on the engine to “OFF” or

“STOP”.

26. To load or unload the tiller, see the

instructions in Section 4 of this Manual.

27. Use extreme caution when reversing

or pulling the machine towards you.

28. Start the engine carefully according to

instructions and with feet well away from

the tines.

29. Never pick up or carry a machine

while the engine is running.

Maintenance and Storage

1. Keep the tiller, attachments and acces

sories in safe working condition.

2. Check all nuts, bolts, and screws at

frequent intervals for proper tightness to

be sure the equipment is in safe working

condition.

3. Never store the tiller with fuel in the

fuel tank inside a building where ignition

sources are present such as hot water

and space heaters, furnaces, clothes

dryers, stoves, electric motors, etc.).

Allow engine to cool before storing in any

enclosure.

4. To reduce the chances of a fire hazard,

keep the engine free of grass, leaves, or

excessive grease.

5. Store gasoline in a cool, well-ventilated

area, safely away from any spark- or

flame-producing equipment. Store

gasoline in an approved container, safely

away from the reach of children.

6. Refer to the Maintenance sections of

this Manual and the separate Engine

Owner’s Manual for instructions if the

tiller is to be stored for an extended

period.

7. Never perform maintenance while the

engine is running or the spark plug wire

is connected, except when specifically

instructed to do so.

8. If the fuel tank has to be drained, do

this outdoors.

Page 5

Decals

For your safety and the safety of

others, various safety and opera

tional decals are located on your

unit (see Figure 1).

Keep the decals clean and legible at

all times. Contact your local

service dealer or the factory for

replacements if any decals are

damaged or missing.

Refer to the Parts List pages in this

Manual for decal locations, descrip

tions and part numbers.

Forward Clutch Bail

Operating Instruction

Starting Stabilization

Message (on engine)

Section 1: Safety

Reverse Clutch Control

Operating Instruction

(Models 12209/12210)

Warning Messages

Operating Symbols

Various symbols (shown here, with word

descriptions) are used on the tiller and engine.

Your unit m^ not have all of the symbols.

^oy

FAST

SLOW

STOP

• READ THE OWNER’S MANUAL.

• KNOW LOCATIONS AND FUNCTIONS OF ALL CONTROLS.

• KEEP ALL SAFETY DEVICES AND SHIELDS IN PLACE AND WORKING.

• NEVER ALLOW CHILDREN OR UNINSTRUCTED ADULTS TO OPERATE TILLER.

• SHUT OFF ENGINE AND DISCONNECT SPARK PLUG WIRE BEFORE MANUALLY UNCLOG

GING TINES OR MAKING REPAIRS.

• KEEP BYSTANDERS AWAY FROM MACHINE.

• KEEP AWAY FROM ROTATING PARTS.

• USE EXTREME CAUTION WHEN REVERSING OR PULLING THE MACHINE TOWARDS YOU.

Hot Surtaces/Moving Beits

Warning (on belt cover)

Figure 1: Location of Safety and Operating Decals (5.5HP Model shown).

H M

CHOKEONCHOKE

OFF

TILLER DIRECTION

R

REVERSE

—T

ROTATING

TINES

O ^

LEVER DIRECTION

f l ^

BAIL BAIL

ENGAGED DISENGAGED

WARNING

TO AVOID SERIOUS INJURY:

Page 6

Section

2 Assembly

A WARNING

To prevent personal injury or property

damage, do not start the engine until

all assembly steps are complete and

you have read and understand the

safety and operating instructions in this

manual.

Introduction

Carefully follow these assembly steps to

correctly prepare your tiller for use. It is

recommended that you read this Section

in its entirety before beginning assembly.

MOTE: Various tiller models are presented

in this Manual. Use only the information

appropriate for your tiller model.

Inspect unit

Inspect the unit and carton for damage

immediately after delivery. Contact the

carrier (trucking company) if you find or

suspect damage, inform them of the

damage and request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 days after the unit has

been delivered. Contact us at the factory if

you need assistance in this matter.

STEP 1: Unpacking Instructions

NOTE: Be careful not to severely bend any

of the control cables on the unit.

listed below (contact your local dealer or

the factory if any items are missing or

damaged). NOTE: Use the screw length

template (Fig. 2-1) to identify screws.

Loose Parts List

Qty.

1 Handlebar Support (see A, Fig. 2-2,

1 Handlebar Assembly (see K, Fig. 2-2)

1 Slotted hd. screw, #10-24 x 2”

1 Hex hd. screw, 1/4-20 X1-1/4”

6 Hex hd. screw, 5/16-18 X1-1/2"

2 Hex hd. screw, 3/8-16 x 3/4"

2 Flat washer, 3/8”

6 Split lockwasher, 5/16"

1 Hex locknut, 1/4”-20

6 Hexnut, 5/16"-18

1 Hex nut, #10-24

2 Hex locknut, 3/8”-16

1 Spring, cable (see W, Fig. 2-5,

1 Bracket, forward clutch cable (see

IMPORTANT: Motor oil must be added to

the engine crankcase before the engine is

started. Follow the instructions in this

“Assembly” Section and in the separate

Engine Owner’s Manual.

Description

page 7)

The following items

are in the hardware bag:

page 8)

P, Fig. 2-4, page 8)

Tools/Materials Needed for Assembly

(1) 3/8” open-end wrench*

(2) 7/16" open-end wrench*

(2) 1/2" open-end wrench*

(2) 9/16” open-end wrench*

(1) Large adjustable wrench (Models

12209/12210 only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tension check)

(1) Biockof wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatic tires)

(1) Clean oil funnel

(1) Clean, high-quality motor oil. Refer

to the Engine Owner’s Manual for

motor oil specifications and quantity

required.

* Adjustable wrenches may be used.

1

1. Remove any cardboard inserts and

packaging material from the carton.

Remove any staples from the bottom of

the carton and remove the carton.

2. The tiller is heavy (approximately 133

lbs.). Do not attempt to remove it from

the shipping platform until instructed to

do so in these “Assembly” steps.

3. Remove all unassembled parts and

the separate hardware bag from the

carton. Check that you have the items

NOTE: LEFT and RIGHT sides of the tiller

are as viewed from the operator’s

position behind the handlebars.

2-

Figure 2-1: To identify length of screw,

place screw on template as shown and

measure distance between bottom of screw

head and Up of screw.

Page 7

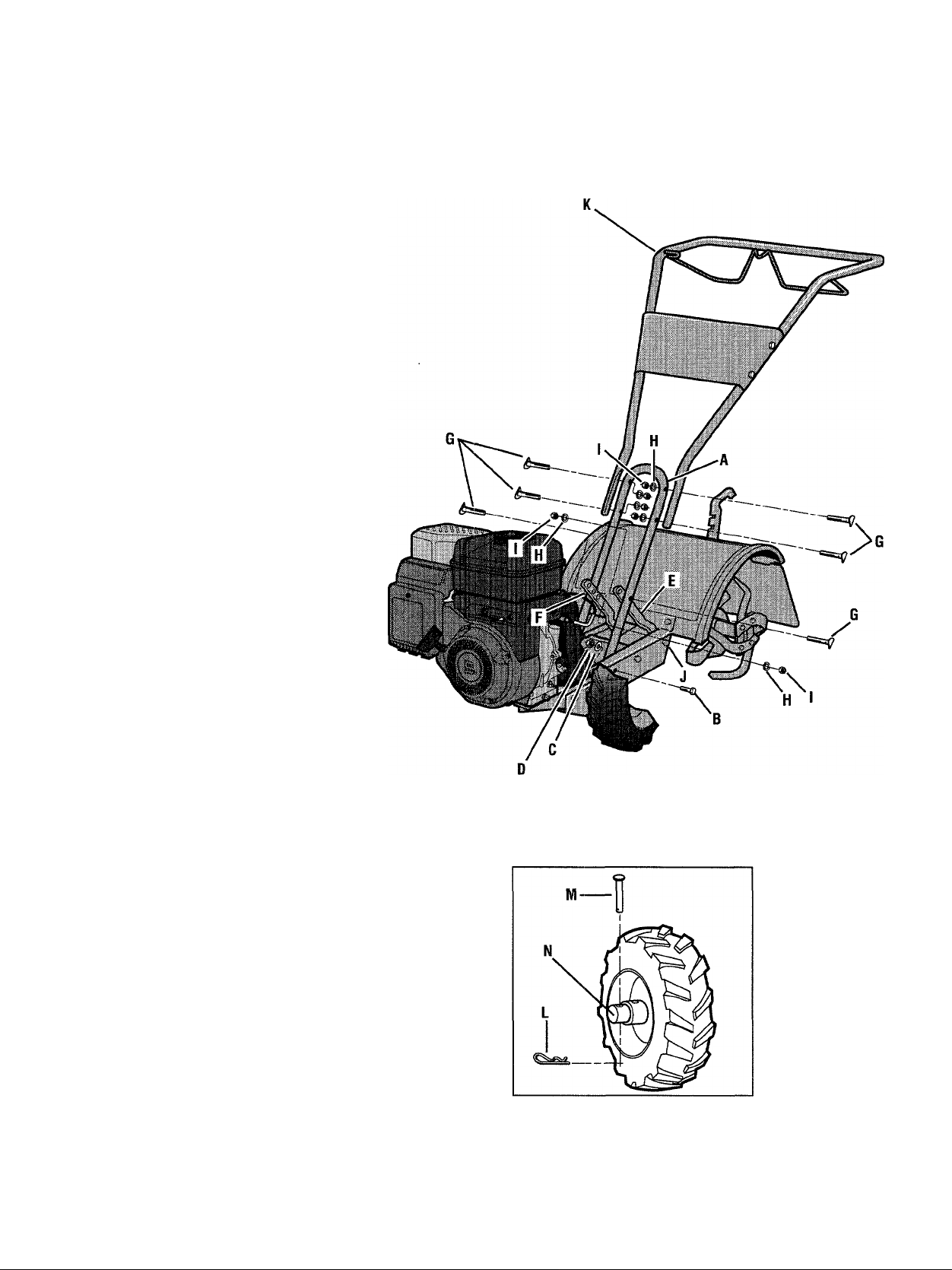

STEP 2: Attach Handlebar

1. Loosely attach the two legs of the

handlebar support (A, Fig. 2-2) to the

inner sides of the tiller frame using two

3/8"-16 X 3/4" hex hd. screws (B), 3/8" flat

washers (C) and 3/8”-16 hex locknuts (D).

2. There are three height adjustment holes

in the two handlebar support brackets (E

and F, Fig. 2-2). Choose a setting that will

position the handlebars at approximately

waist level when the tines are 3“-4" into

the soil. Loosely attach the support

brackets to the handlebar support (A)

using two 5/16"-18 X1-1/2" screws (G),

5/16“ split lockwashers (H) and 5/16“-18

hex nuts (I). NOTE; If a support bracket

will not move, loosen attaching screw (J)

and nut.

3. Attach the handlebar assembly (K) to

the handlebar support (A) using four

5/16"-18 x 1-1/2" screws (G), 5/16" split

lockwashers (FI) and 5/16"-18 hex nuts (I).

Tighten the four screws securely.

4. Tighten all handlebar mounting

hardware securely.

Section 2: Assembly

STEP 3: Move Tiller Off Shipping Platform

To move the tiller without the engine

running, put the wheels in the

FREEWFiEEL position, as described below.

1. Use a sturdy block under the transmis

sion to raise one wheel about 1” off the

ground.

2. Remove the hairpin cotter (L, Fig. 2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheel shaft (N). Reinstall

the wheel drive pin through the wheel

shaft only (not through the wheel hub)

and secure it with the hairpin cotter (push

hairpin cotter in as far as it will go).

Repeat with the other wheel.

3. Using the handlebar as a lever, roil the

tiller to a flat area.

IMPORTANT: Before starting the engine,

the wheels must be placed in the WHEEL

DRIVE position (pins through wheel hubs

and wheel shaft). This procedure is

described in “Wheel Drive Pins” in

Section 3.

Fig. 2-2: Attach handlebar (5.5HP Model shown).

Fig. 2-3: Wheel in FREEWHEEL position

(wheel drive pin through wheel shaft

only).

Page 8

Section 2: Assembly

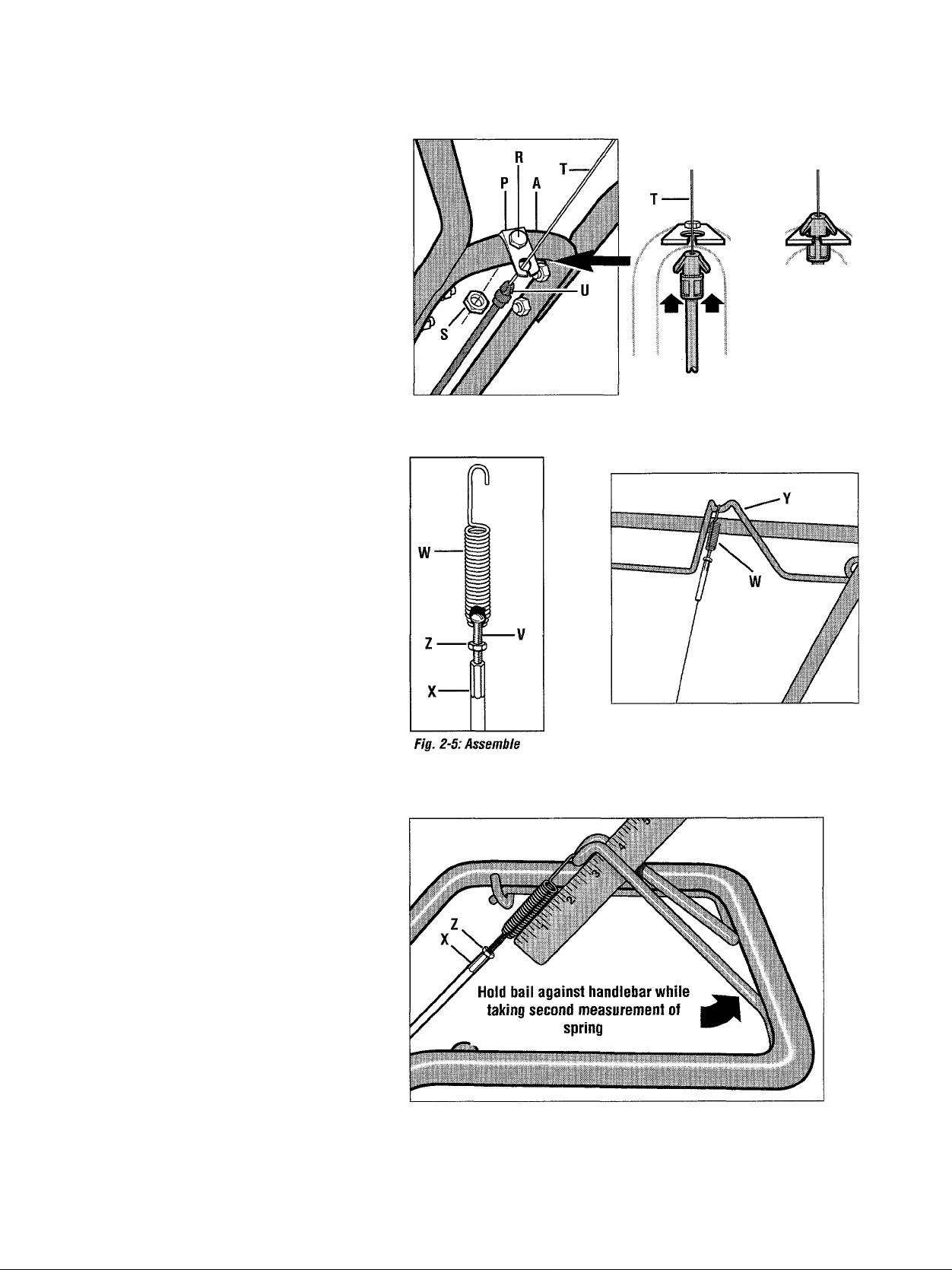

STEP 4: install Forward Clutch Cable

1. Attach the forward clutch cable bracket (P,

Fig. 2-4) to the handlebar support (A) with a

1/4"-20 X 1-1/4" hex hd. screw (R, Fig. 2-4) and

1/4“-20 hex locknut (S). Tighten securely.

2. Carefully unwrap the forward clutch cable

(cable without a knob) from its shipping

position and slide the thin cable wire (T, Fig. 2-

4) into the slot in the cable bracket. Push the

cable connector (U, Fig. 2-4) up through the

hole in the bracket until the groove in the

connector snaps into place.

3. Insert the #10-24 x 2" slotted hd. screw (V,

Fig. 2-5) into the cable spring (W) until the

screw threads extend through the spring.

4. Thread the #10-24 hex nut (Z, Fig. 2-5)

halfway onto the screw (V).

5. Thread the screw into the cable adjuster (X).

6. Hook the cable spring (W, Fig. 2-6) into the

“V”-shaped bend in the Forward Clutch Bail (Y).

7. Check for correct tension on the forward

drive belt by taking two measurements of the

cable spring, as follows:

a. With the Forward Clutch Bail (Y, Fig. 2-6) in

an open (released) position, measure the

length of the cable spring (W) from fhe

outermost coil to the outermost coil.

b. Lift and hold the Forward Clutch Bail against

the handlebar (see Fig. 2-7) and re-measure

the length of the coils while the spring is

under tension. The belt tension is correct if

this second measurement is between 1/16" to- 3/16" longer than the first measurement.

If so, turn the hex nut (Z, Fig. 2-7) tightly

against the cable adjuster (X) while prevent

ing the adjuster from turning.

c. If the spring length is incorrect, you must

adjust the cable tension as described in

“Checking and Adjusting Forward Drive Belt

Tension” in Section 5. Incorrect tension on

the forward drive belt can result in belt

slippage (tension too loose) or unintentional

tine movement when the clutch ball is in

Neutral (tension too tight).

Fig. 2-4: Installing forward dutch cable bracket and cable.

Fig. 2-6: Install forward clutch cable.

spring and adjuster.

Fig. 2-7: To check forward belt tension, lake two measurements of the

overall length ot the colls in the spring - first with the clutch bail open,

then with the dutch bail dosed against the handlebar.

Page 9

Section 2: Assembly

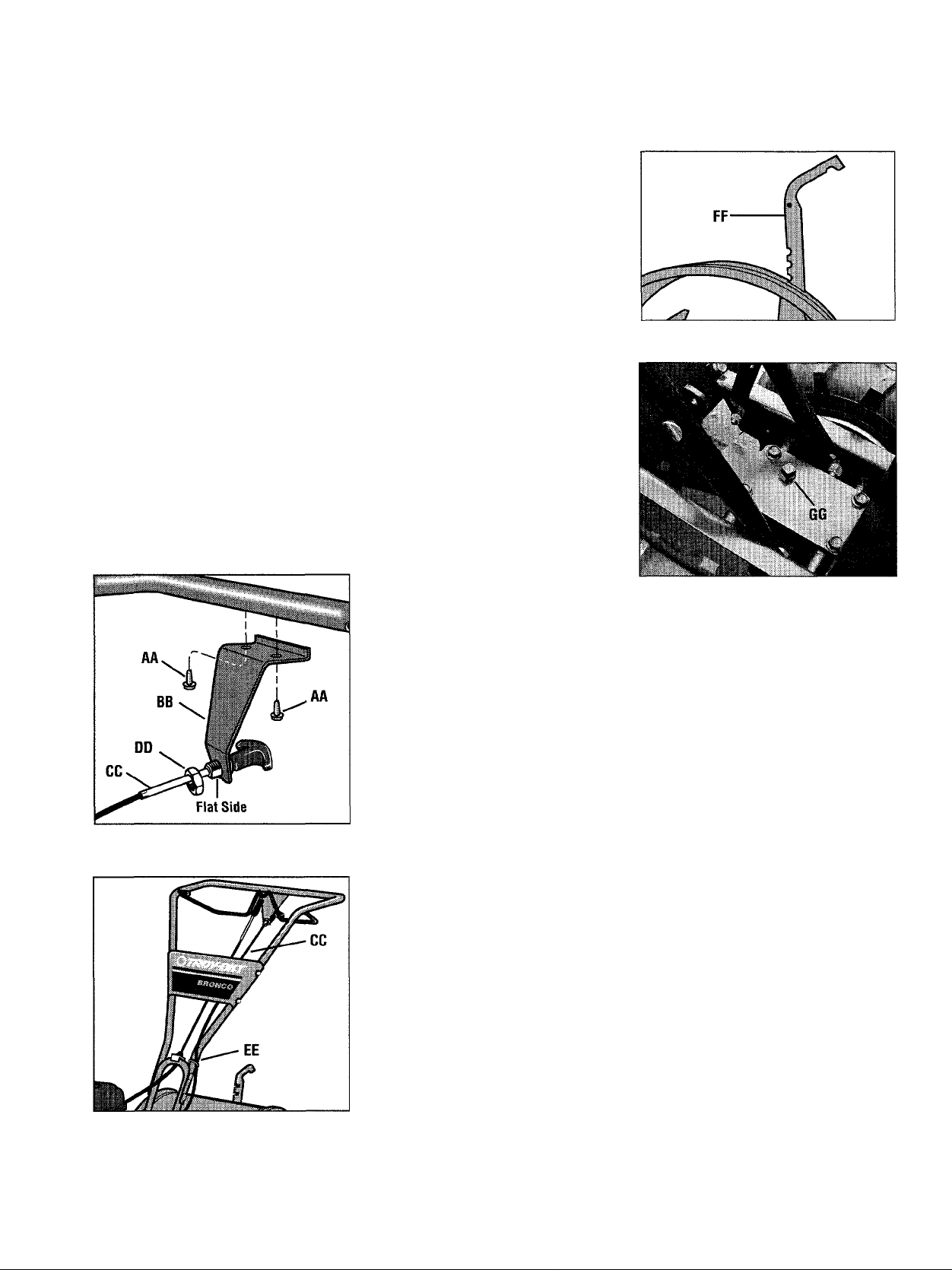

STEP 5: Install Reverse Clutch Cable (Models 12209/12210)

1. Unwrap the reverse clutch cable (cable

with a knob, a large hex nut and a bracket

attached to it) from its shipping position

and route the cabie (CC, Fig. 2-8 and Fig.

2-9) up to the handlebar. Be sure that the

cable is routed beneath the Forward

Clutch Bail.

2. Remove the two self-tapping screws

(AA, Fig. 2-8) from the handlebars,

position the reverse cable mounting

bracket (BB, Fig. 2-8) as shown, and

reinstail the two self-tapping screws.

3. Insert the cable (CC) through the slot in

the cable bracket and position the threaded

assembly so that the flat side is aligned

with the flat side of the mounting hole.

Slide the large hex nut (DD) up the cable

and tighten it securely.

Fig. 2-8: Install reverse cable bracket and

reverse clutch cable.

Fig. 2-9: Route reverse clutch cable (CC) as

shown. Attach with cable tie (EE).

4. Fasten the reverse clutch cable to the

left side handlebar with a cable tie (EE,

Fig. 2-9).

5. Test the function of the reverse clutch

cable by pulling the knob out and

releasing it. The knob should return to its

neutral position (resting against bracket).

If it doesn’t, contact your local dealer or

the factory for technical assistance.

STEP 6: Check Level of Transmission Gear Oil

The transmission was filled with gear oil

at the factory. However, you should check

the gear oil level to make certain it is

correct.

IMPORTANT: Do not operate the tiller if

the gear oil level is low. Doing so will

result in severe damage to the transmis

sion components.

1. With the tiller on level ground, pull the

Depth Regulator Lever (FF, Fig. 2-10)

back and then all the way up until the

lowest notch in the lever is engaged.

2. Remove the oil fill plug (GG, Fig. 2-11)

from the transmission housing cover and

locate the main drive shaft situated inside

the housing.

3. The gear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

4. If the gear oil level is low, add gear oil

by referring to “A. To Check the Transmis

sion Gear Oil Level” in Section 5.

STEP 7: Add Motor Oil to Engine

The tiller is shipped without oW in the

engine.

IMPORTANT: Do not start the engine

without first adding motor oil. Severe

engine damage will result if the engine is

run without oil.

1. Refer to the separate Engine Owner’s

Manual for engine oil specifications and

capacities.

2. With the tiller on level ground, move

the Depth Regulator Lever (FF, Fig. 2-10)

up or down until the engine is level.

3. Add motor oil as described in the

Engine Owner’s Manual.

Fig. 2-10: Adjust Depth Regulator Lever.

Fig. 2-11: Remove gear oil fill plug.

4. Move the Depth Regulator Lever all

the way down until the highest notch is

engaged. This places the tines in the

“travel” position.

STEP 8: Check Hardware for Tightness

Check all nuts and screws for tightness.

STEP 9: Check Air Pressure in Tires (units with pneumatic tires)

If the tires are equipped with air valves,

check the air pressure with a tire gauge.

Deflate or inflate the tires equally to 15-

to-20 PSI (pounds per square inch). Be

sure that both tires are inflated equally or

the unit will pull to one side.

IMPORTANT: This completes the

assembly steps. Before operating your

tiller, make sure you read the following

Sections in this Manual, as well as the

separate Engine Owner’s Manual:

• Section 1; “Safety”

• Section 3: “Features and Controls”

• Section 4; “Operation”

Page 10

Section

3 Features and Controls

A WARNING

Before operating your machine,

carefully read and understand all

safety, controls and operating instruc

tions in this Manual, the separate

Engine Owner’s Manual, and on the

decals on the machine.

Failure to follow these instructions can

result in serious personal injury.

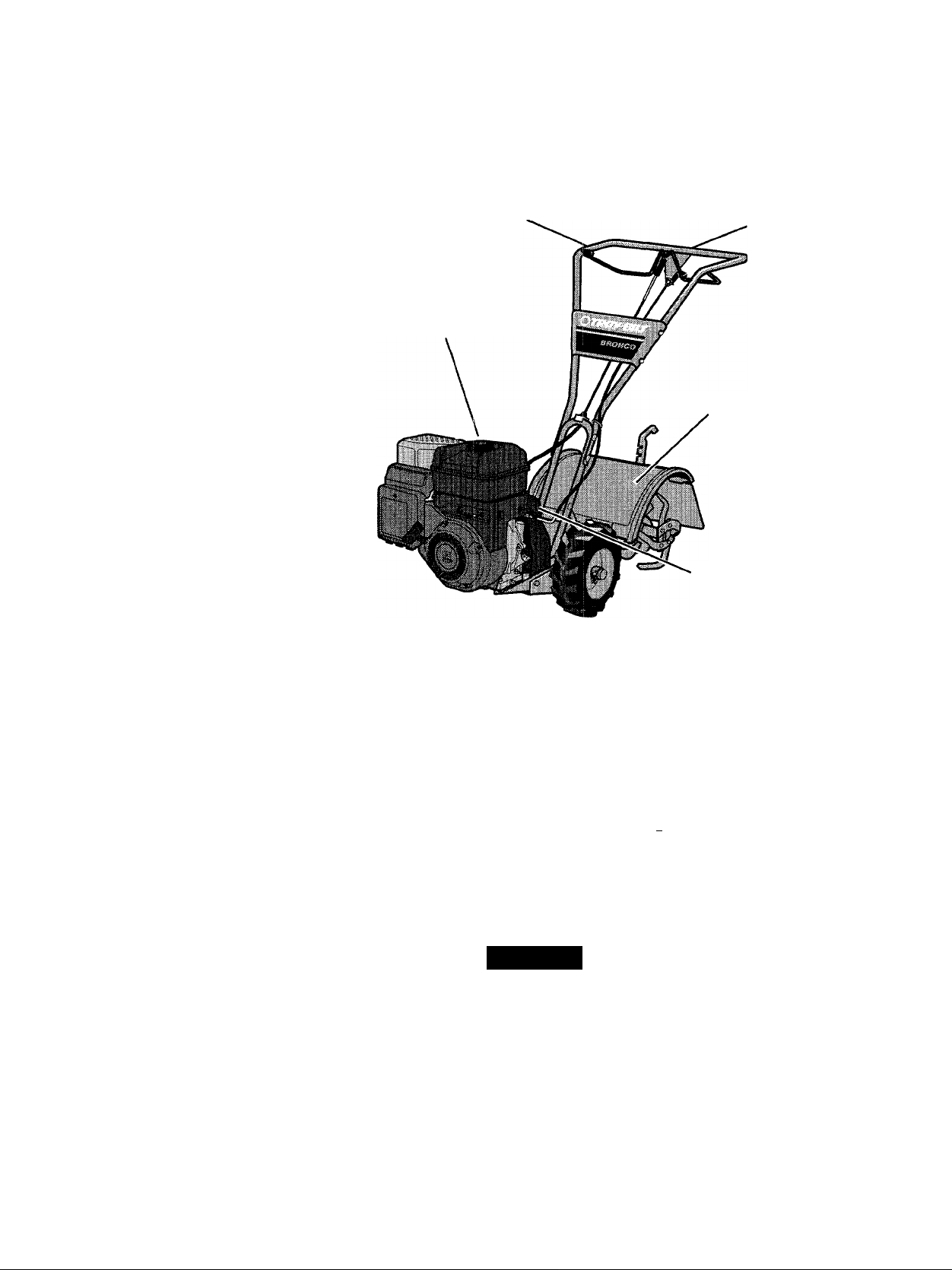

Forward

Clutch Bail

Depth Regulator

Reverse Clutch

Control (Models

12209/12210)

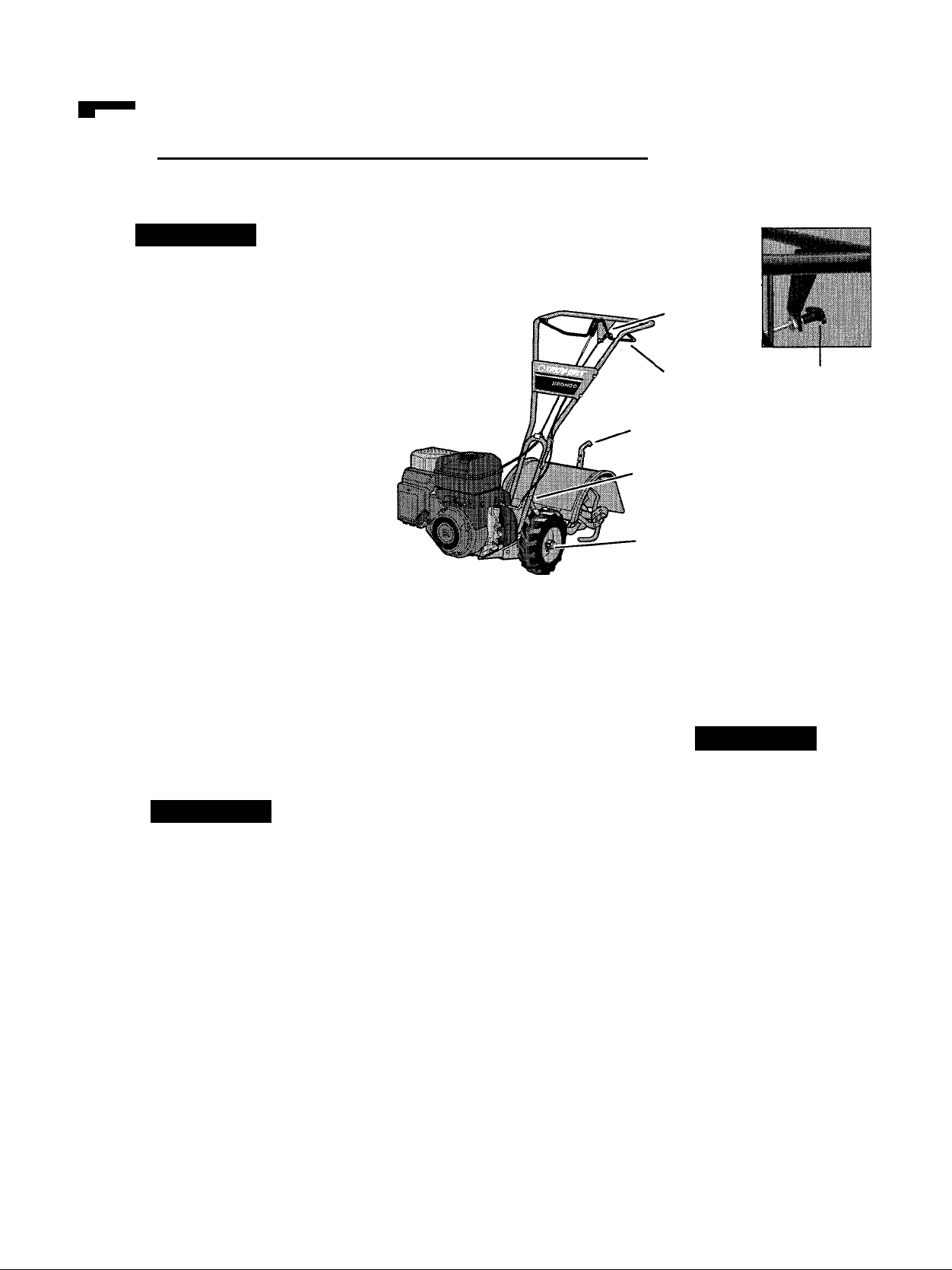

Introduction

This section describes the location and

function of the controls on your tiller.

Refer to the following section

“Operation” for detailed operating

instructions.

Practice using these controls, with the

engine shut off, until you understand the

operation of the controls and feel

confident with each of them.

IMPORTANT: Refer to the separate

engine manufacturer’s Engine Owner’s

Manual for information about the

controls on the engine.

Wheel Drive Pins

A WARNING

Never allow either of the wheels to be

in the FREEWHEEL position when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

before starting the engine.

Failure to comply could cause loss of

tiller control, property damage, or

personal injury.

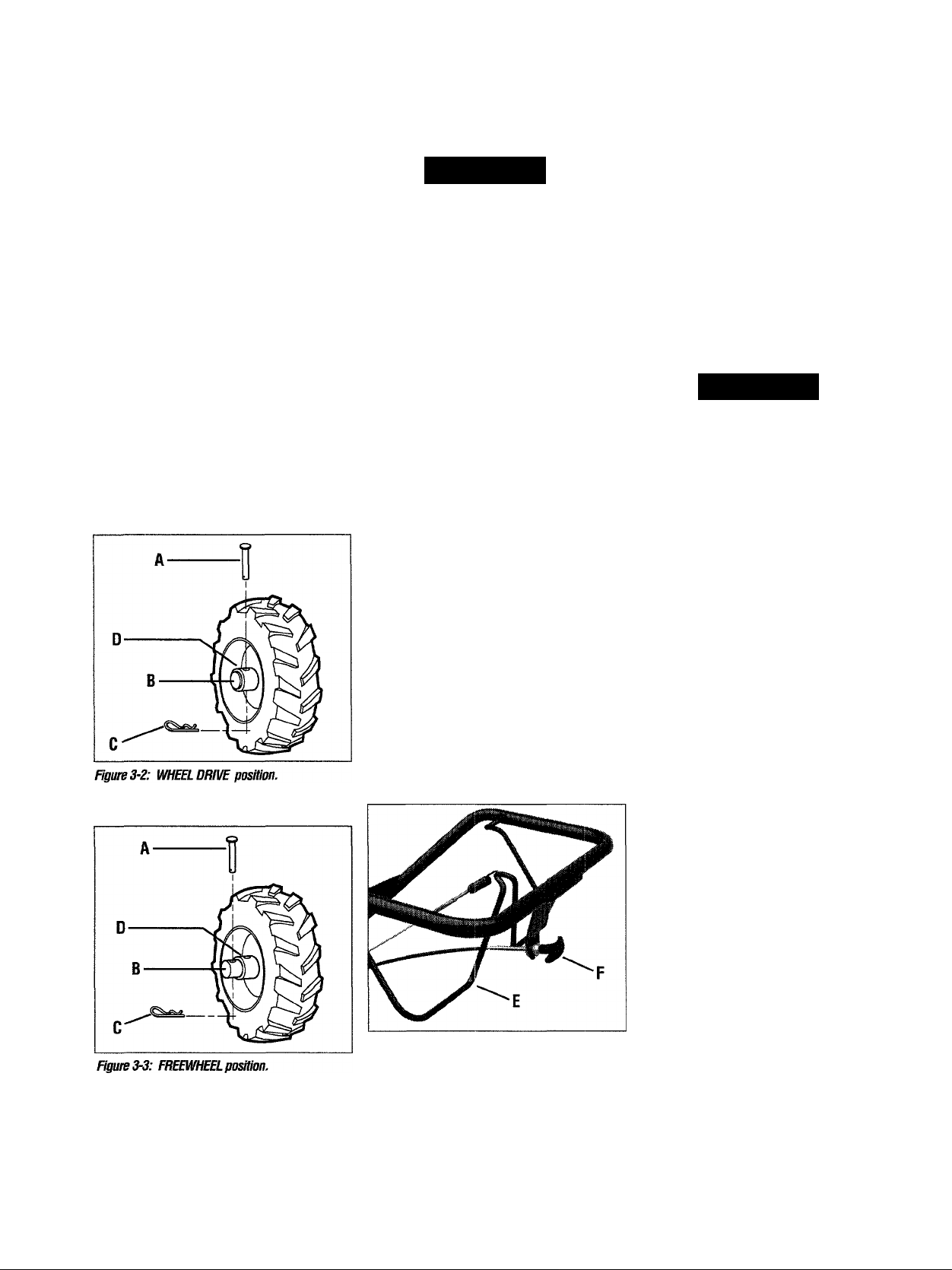

Each wheel is equipped with a Wheel

Drive Pin (A, Figures 3-2 and 3-3) that

secures the wheel to the wheel shaft (B).

The wheels can be positioned in either a

WHEEL DRIVE or a FREEWHEEL mode.

Figure 3-1: Features and controls (5.5HP Model shown)

Before starting the engine, put both

wheels in the WHEEL DRIVE position by

inserting the Wheel Drive Pins through

the wheel hubs and the wheel shaft. This

“locks” the wheels to the wheel shaft,

causing the wheels to turn when either

the Forward Clutch Bail or the Reverse

Clutch Control (Models 12209/12210) is

engaged.

Use the FREEWHEEL mode only when the

engine is not running. In FREEWHEEL,

the Wheel Drive Pins are placed only

through the holes in the wheel shaft (not

the wheel hubs), thus allowing the wheels

to turn freely when the tiller is pushed or

pulled by hand.

Handlebar Height

Adjustment

Wheel Drive Pin

(on each wheel)

To Place the Wheels in WHEEL DRIVE or

FREEWHEEL:

A WARNING

Do not place the tiller on its side when

changing the wheel drive positions as

doing so could result in gasoline

leaking from the fuel tank.

Failure to follow this instruction could

result in personal injury or property

damage.

1. Stop the engine, disconnect the spark

plug wire from the spark plug and allow

the engine to cool.

2. Raise one wheel off the ground and

place a sturdy support under the

transmission.

3. Remove the hairpin cotter (C, Figures

3-2 and 3-3) from the wheel drive pin (A).

10

Page 11

Section 3; Features and Controls

4. FOR WHEEL DRIVE mode (Figure 3-2):

Slide the wheel outward and align the

holes in the wheel hub (D, Figure 3-2) and

the wheel shaft (B). insert the wheel drive

pin (A) through the wheel hub and the

wheel shaft. Secure the wheel drive pin

with the hairpin cotter (C) by pushing the

hairpin cotter in as far as it will go. Repeat

for the other wheel and then remove the

support from beneath the transmission.

5. FOR FREEWHEEL mode (Figure 3-3):

Slide the wheel inward and insert the

wheel drive pin (A, Figure 3-3) only

through the hole in the wheel shaft (B).

Secure the wheel drive pin with the

hairpin cotter (C) by pushing the hairpin

cotter in as far as it will go. Repeat for the

other wheel and then remove the support

from beneath the transmission.

A WARNING

Before starting the engine, be sure that

both wheels are in the WHEEL DRIVE

position. See “Wheel Drive Pins” for

instructions.

Engaging the Forward Clutch Bail or the

Reverse Clutch Control (if so equipped)

when the wheels are not in the WHEEL

DRIVE position could allow the tines to

rapidly propel the tiller forward or

backward.

Failure to comply could cause loss of

tiller control, property damage, or

personal injury.

Forward Clutch Bail

The Forward Clutch Bail (E, Figure 3-4)

controls the engagement of forward drive

to the wheels and tines.

To Operate the Forward Clutch Bail:

1. Put the wheels In the WHEEL DRIVE

position (see the “WARNING” statement

above).

2. Lift and hold the bail against the

handlebar. The wheels and tines will

rotate in a forward direction.

3. Release the bail to disengage (stop)

the wheels and tines. All forward motion

will stop (the engine will continue to run).

Reverse Clutch Control (Models 12209/12210 only)

The Reverse Clutch Control (F, Figure 3-4)

controls the engagement of reverse drive

to the wheels and tines. This reversing

feature is used for maneuvering the

tiller only - never engage the tines in

the ground whiie going in the reverse

direction.

To Operate the Reverse Clutch Control:

A WARNING

• Use extreme caution when reversing

or pulling the machine towards you.

Look behind to avoid obstacles.

• Never attempt to till in reverse.

Failure to follow this warning could

result in personal injury or property

damage.

1. Put the wheels in the WHEEL DRIVE

position (see the “WARNING” statement

at the left).

2. Stop all tiller motion by releasing the

Forward Clutch Ball.

3. Lift up the handlebar until the tines

clear the ground, look behind you to avoid

any obstacles, and then pull the reverse

clutch control knob out. The wheels and

tines will rotate in a reverse direction.

4. Release the reverse clutch control

knob to disengage (stop) the wheels and

tines. All reverse motion will stop (the

engine will continue to run).

Figure 3~4: All models have a Forward Clulch

Bail (E). Only Models 12209/12210 have the

Reverse Clutch Control (F).

11

Page 12

Section 3: Features and Controls

Depth Regulator Lever

This lever (G, Figure 3-5) controls the

tilling depth of the tines. Pull the lever

straight back and slide it up or down to

engage the notched height settings.

The highest notch (lever all the way down)

raises the tines approximately 1-1/2" off

the ground. This “travel” setting allows

the tiller to be moved without the tines

digging into the ground. Also use this

setting when starting the engine.

Move the lever upward to increase the

tilling depth. The lowest notch allows a

tilling depth of approximately 6",

depending on soil conditions.

For best results, always begin tilling at

a very shallow depth setting and

gradually increase the tilling depth.

Handlebar Height Adjustment

The handlebar height is adjustable to

three different settings (see Figure 3-6).

As a general rule, adjust the handlebars

so they are at waist level when the tines

are 3"-4” into the soil.

To Adjust the Handlebars:

1. Stop the engine, disconnect the spark

plug wire from the spark plug and allow

the engine to cool.

Z. Remove the screws, lockwashers and

nuts, reposition the handlebars, and

reinstall the hardware.

ENGINE CONTROLS

Refer to the engine manufacturer’s Engine

Owner’s Manual (included in the tiller lit

erature package) to identify the controls

on your engine.

IMPORTANT: The control for stopping the

engine is located on the engine.

Figure 3-5: Depth Regutator Lever (G).

A WARNING

• Do not attempt to till too deeply too

quickly. Gradually work down to

deeper tilling depths.

• Place the Depth Regulator Lever in

the “travel” position before starting

the engine. This position prevents

the tines from touching the ground

until you are ready to begin tilling.

Failure to follow this warning could

result in personal injury or property

damage.

Figure 3-6: Hanillebar height adjustment.

12

Page 13

Section

4 Operation

A WARNING

Before operating your machine,

carefuiiy read and understand ail safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner’s Manual, and on the decals on

the machine.

Failure to follow these instructions can

result in serious personal injury.

INTRODUCTION

Read this Section of the manual thor

oughly before you start the engine. Then,

take the time to familiarize yourself with

the basic operation of the tiller before

using it in the garden. Find an open, level

area and practice using the tiller controls

without the tines engaging the soil (put

tines in “travel” setting). Oniy after

you’ve become completely familiar with

the tiller should you begin using it in the

garden.

BREAK-IN OPERATION

Perform the following maintenance

during the first hours of new operation

(see “Maintenance” Section in this

Manual and in the Engine Owner’s

Manual).

1. Change engine oii after first 2 hours of

new engine operation.

2. Check for loose or missing hardware

on unit. Tighten or replace as needed.

3. Check tension on forward drive belt

after first 2 hours of operation.

4. Check transmission gear oil level after

first 2 hours of operation.

STARTING AND STOPPING THE ENGINE

Pre-Start Checklist

Make the following checks and perform

the following services before starting the

engine.

1. Read the “Safety” and “Controls”

Sections in this Manual. Read the

separate Engine Owner’s Manual provided

by the engine manufacturer.

2. Check that the wheels are in the

WHEEL DRIVE position (wheel pins must

be through the wheel hubs and the wheel

shaft holes).

3. Check unit for loose or missing

hardware. Service as required.

4. Check engine oil level. See Engine

Owner’s Manual,

5. Check that all safety guards and

covers are in place.

6. Check air cleaner and engine cooling

system. See Engine Owner’s Manual.

7. Attach spark plug wire to spark plug.

A DANGER

GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE.

Follow gasoline safety rules in this

Manual (see Section 1) and in the

separate Engine Owner’s Manual.

Failure to follow gasoline safety

instructions can result in serious

personal injury and property damage.

8. Fill the fuel tank with gasoline

according to the directions in the separate

Engine Owner’s Manual. Follow all

instructions and safety rules carefully.

13

Page 14

Section 4: Operation

Starting the Engine

The following steps describe how to start

and stop the engine. Do not attempt to

engage the tines or wheeis untii you

have read all of the operating instruc

tions in this Section. Also review

the safety rules in Section 1: “Safety”

and the tiller and engine controls

information in Section 3: “Features and

Controls.”

A CAUTION

To help prevent serious

personal injury or damage to

equipment:

• Before starting engine, put both

wheeis in the WHEEL DRIVE position.

Never have the wheels in the

FREEWHEEL position when the

engine is running. When the wheels

are in FREEWHEEL, they do not hold

back the tiller and the tines could

propel the tiller rapidly forward or

backward.

• Before starting engine, put Forward

Clutch Bail (all Models) and Reverse

Clutch Control (Models 12209/12210

only) in neutral (disengaged)

positions by releasing levers.

• Never run engine indoors or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas.

• Avoid engine muffler and nearby

areas. Temperatures in these areas

may exceed150°F.

1. Complete the “Pre-Start Checklist” on

the previous page.

2. Put the wheels in the WHEEL DRIVE

position (see “Wheel Drive Pins” in

Section 3).

3. Put the Depth Regulator Lever in the

“travel” position (lever all the way down)

so that the tines are clear of the ground.

4. Release all controls on the tiller.

5. If engine is equipped with a fuel valve,

turn valve to open position as instructed

in the separate Engine Owner’s Manual.

6. Put ignition switch and/or throttle

control lever on engine in “ON”, “RUN”,

“FAST” or “START” position as instructed

in the separate Engine Owner’s Manual.

7. Choke or prime engine as instructed in

the separate Engine Owner’s Manual.

8. Place one hand on the fuel tank to

stabilize the unit when you pull the starter

handle. Use the recoil starter rope to start

the engine as instructed in the separate

Engine Owner’s Manual. When engine

starts, gradually move choke lever (on

engines so equipped) to “NO CHOKE”,

“CHOKE OFF” or “RUN” position.

9. Use the “FAST” throttle speed setting

when tilling.

A WARNING

i

Keep away from rotating tines. Rotating

tines will cause injury.

Stopping the Engine and Tiller

1. To stop the wheels and tines, release

the Forward Clutch Bail or the Reverse

Clutch Control (on Models 12209/12210)

-whichevercontrol is in use.

2. To stop the engine, put the ignition

switch and/or the throttle control lever on

the engine in the “OFF” or “STOP”

position.

OPERATING THE TILLER

The following pages provide guidelines to

using your tiller effectively and safely in

various gardening applications. Be sure

to read “Tilling Tips & Techniques” in this

Section before you actually put the tines

into the soil.

This is a traditional “standard-rotatingtine” (SRT) tiller with forward rotating

tines. It operates completely differently

from “counter-rotating-tine” (CRT) tillers

or from front-tine tillers.

1. Follow the “Pre-Start Checklist” on the

previous page. Be sure that the wheels

are in the WHEEL DRIVE position.

2. Put the Depth Regulator Lever in the

“travel” position (lever all the way down)

so that the tines are clear of the ground.

Use this position when practicing with

your tiller or when moving to or from the

garden. When you are ready to begin

tilling, you must move the Depth

Regulator Lever to the desired depth

setting (see “Tilling Tips & Techniques”).

3. Start the engine and allow it to warm

up. When warm, put throttle control in

fast speed setting.

Figure 4-2: Use one hand to guide tilier

when moving forward.

4. For forward motion of the wheels and

tines:

(a) Pull the Forward Clutch Bail up and

hold it against the handlebar. Release

the bail to stop forward motion of the

wheels and tines.

(b) As the tiller moves forward, relax and

let the wheels pull the unit along while

the tines dig. Walk behind and a little

to one side of the tiller. Use a light

but secure grip with one hand on the

handlebars, but keep your arm loose.

See Figure 4-2. Let the tiller move

ahead at its own pace and do not push

down on the handlebars to try and

force the tiller to dig deeper - this

takes weight off the wheels, reduces

traction, and causes the tines to try

and propel the tiller.

14

Page 15

Section 4: Operation

A WARNING

Do not push down on the handlebars to

try to make the tiller till more deeply.

This prevents the wheels trom holding

the tiller back and can allow the tines

to rapidly propel the tiller forward,

which could result in loss of control,

property damage, or personal injury.

5. For reverse motion of the wheels and

tines (Models 12209/12210 only):

(a) Look behind and exercise caution

when operating in reverse. Do not till

while in reverse.

(b) Stop all forward motion before

reversing. Lift the handlebars with one

hand until the tines are off the ground

and then pull the Reverse Clutch

Control knob out to engage reverse

motion (see Figure 4-3). To stop

reverse motion, let go of the Reverse

Clutch Control knob.

NOTE: To move the Models 12208/12217

in reverse for short distances, use the

following procedure:

(a) Release the Forward Clutch Bail.

(b) Tilt the handlebar slightly upward until

the tines are out of the soil.

(c) Swing the handlebar to the left so the

right wheel takes a “step” backward.

Next move the handlebar to the right so

the left wheel takes a “step” backward.

(d) Repeat to “walk” the tiller rearward. If

longer distances need to be covered in

reverse, shut off the engine, then place

the two wheels in FREEWHEEL.

6. To Turn the Tiller Around:

(a) Practice turning the tiller in a level,

open area. Be very careful to keep

your feet and legs away from the tines.

(b) To make a turn, lift the handlebars

until the engine and tines are balanced

over the wheels (Figure 4-4). The

tines must be out of the ground while

turning the tiller.

Figure 4-3: Raise tines off ground and iook

behind when moving in reverse. (Modeis

12209 and 12210 have powered reverse.

Models 12208 and 12217 can be “fishtailed’’ backward manuaiiy for a short

distance, or rolled backward when wheels

are in FREEWHEEL)

(c) With the tiller balanced, push sideways

on the handlebar to move the tiller in

the direction of the turn (Figure 4-5).

After completing the turn, slowly lower

the tines into the soil to resume tilling.

Stopping the Tiller and Engine

1. To stop the wheels and tines, release

the Forward Clutch Bail or the Reverse

Clutch Control (on Models 12209/12210)

-whichevercontrol is in use.

2. To stop the engine, put the ignition

switch and/or the throttle control lever on

the engine in the “OFF” or “STOP”

position.

A WARNING

Before tilling, contact your telephone or

utilities company and inquire if under

ground equipment or lines are used in

your area. Their representative will be

glad to answer your questions and tell

you if any of their equipment or lines

are buried underground on your

property.

Turning the Tiller Around

Figure 4-4: To begin turn, lift handlebars

until engine and tines are balanced over

wheels. Be sure tines are out of ground.

Figure 4-5: With tiller balanced over

wheels (and tines out of the ground),

push handlebars sideways to turn tiller.

15

Page 16

Section 4: Operation

Tilling Tips & Techniques

Let the tiller do the work

• While tilling, relax and let the wheels

pull the tiller along while the tines do

the digging. Walk on the side that is

not yet finished (to avoid making foot

prints in the freshly tilled soil) and

lightly, but securely grip the handlebar

with just one hand. See Figure 4-2.

•Avoid pushing down on the handlebars

in an attempt to force the tiller to dig

deeper. Doing so takes the weight off

the powered wheels, causing them to

lose traction. Without the wheels

helping to hold the tiller back, the tines

will attempt to propel the tiller - often

causing the tiller to skip rapidly across

the ground. (Sometimes, slight

downward pressure on the handlebars

will help get through a particularly

tough section of sod or unbroken

ground, but in most cases this won’t be

necessary at all.)

Tilling depths

• Avoid trying to dig too deeply too

quickly, especially when busting sod or

tilling soil that hasn’t been tilled for

some time. Use shallow depth settings

(only an inch or two deep) for the first

passes through the garden area. With

each succeeding pass, adjust the depth

regulator to dig another inch or two

deeper. (Watering the garden area a

few days prior to tilling will make tilling

easier, as will letting the newly worked

soil set for a day or two before making

a final, deep tilling pass.)

• When cultivating (breaking up the

surface soil around plants to help

destroy weeds), use very shallow depth

settings to prevent injury to plants whose

roots often grow close to the surface. If

needed, lift up on the handlebars slightly

to prevent the tines from digging too

deeply. Cultivating on a regular basis not

only eliminates weeds, it also loosens

and aerates the soil for better moisture

absorption and faster plant growth.)

Avoid tilling wet, soggy soil

Tilling wet soil often results in large,

hard clumps of soil that can interfere

with planting. If time permits, wait a day

or two after heavy rains to allow the soil

to dry before tilling. Test the soil by

squeezing it into a ball. If it compresses

too easily. It is too wet to till.

Avoid making footprints

When possible, walk on the untilled side

of the unit to avoid making footprints in

the freshly tilled soil. Footprints cause

soil compaction that can hamper root

penetration and contribute to soil erosion.

They can also “plant” unwanted weed

seeds back Into the newly tilled soil.

Choosing correct wheel and tine speeds

With experience, you will find the “just

right” tilling depth and tilling speed com

bination that is best for your garden.

Set the engine throttle lever at a speed to

give the engine adequate power and yet

allow it to operate at the slowest possible

speed...at least until you have achieved

the maximum tilling depth you desire.

Faster engine speeds may be desirable

when making final passes through the

seedbed or when cultivating. Selection of

the correct engine speed, in relation to

the tilling depth, will ensure a sufficient

power level to do the job without causing

the engine to labor.

Suggested tilling patterns

• When preparing a seedbed, go over the

same path twice in the first row, then

overlap one-half the tiller width on the

rest of the passes (see Figure 4-6).

When finished in one direction, make a

second pass at a right angle as shown

in Figure 4-7. Overlap each pass for

best results (in very hard ground it

may take three or four passes to thor

oughly pulverize the soil).

’ If the garden size will not permit

lengthwise and then crosswise tilling,

then overlap the first passes by one-

half a tiller width, followed by succes

sive passes at one-quarter width (see

Figure 4-8).

• With planning, you can allow enough

room between rows to cultivate (see

Figure 4-9). Leave room for the hood

width, plus enough extra room for

future plant growth.

Figure 4-7

Figure 4-8

Figure 4-1

16

Page 17

Tilling Tips & Techniques

Section 4: Operation

Clearing the tines

The tines have a self-clearing action

which helps to eliminate most tangling

of debris. However, occasionally dry

grass, stringy stalks or tough vines may

become tangled. Follow these proce

dures to help avoid tangling and to clear

the tines, if necessary.

• To reduce tangling, set the depth

regulator deep enough to get maximum

“chopping” action as the tines chop the

material against the ground. Also, try

to till under crop residues or cover

crops while they are green, moist and

tender.

• While power composting, try swaying

the handlebars from side to side (about

6" to 12"). This “fishtailing” action

often clears the tines of debris.

• If tangling occurs on models equipped

with a powered reverse, lift the tines

out of the soil and run the tiller in

reverse for a few feet. This reversing

action should unwind a good deal of

debris.

• It may be necessary to remove the

debris by hand (a pocket knife will help

you to cut away the material).

A WARNING

Before clearing the tines by hand, stop

the engine, allow all moving parts to

stop and disconnect the spark piug

wire.

Failure to follow this warning could

result in personal injury.

Tilling on slopes

if you must garden on sloping ground,

please follow two very important guide

lines:

1. Tiil oniy on moderate siopes, never on

steep inclines where footing is difficult

(review safety rules in the “Safety”

Section of this Manual).

2. We recommend tilling up and down

slopes rather than terracing. Tilling

verticaiiy on a slope allows maximum

planting area and also leaves room for

cultivating.

IMPORTANT: When tilling on slopes, be

sure the correct oil level is maintained in

the engine (check every one-half hour of

operation). The incline of the slope will

cause the oil to slant away from its

normal level and this can starve engine

parts of required lubrication. Keep the

engine oil level at the full point at all

times!

A. Tilling up and down slopes:

• To keep soil erosion to a minimum, be

sure to add enough organic matter to

the soil so that it has good moisture

holding texture and try to avoid leaving

footprints or wheel marks.

• When tilling vertically, try to make the

first pass uphill as the tiller digs more

deeply going uphill than it does

downhill. In soft soil or weeds, you

may have to lift the handlebars slightly

while going uphill. When going

downhill, overlap the first pass by

about one-half the width of the tiller.

B. Terrace Gardening:

• When a slope is too steep or too short

for vertical tilling, it may be necessary

to till across the slope and create

terraced rows. Terraces are rows that

are cut into the side of a slope, creating

a narrow, but flat area on which to

plant.

• On a long slope, you can make several

terraces, one below the other.

> Terraces should be only 2-to-3 feet

wide. Digging too far into the side of

the siope wiii expose poor subsoil that

is unproductive for plants.

• To create a terrace, start at the top of

the slope and work down. Go back and

forth across the first row as shown in

Figure 4-10.

• Each succeeding lower terrace is

started by walking below the terrace

you’re preparing. For added stability of

the tiller, always keep the uphill wheel

in the soft, newly tilled soil. Do not till

the last 12” or more of the downhill

outside edge of each terrace. This

untilled strip helps prevents the

terraces from breaking apart and

washing downhill. It also provides a

walking path between rows.

i: UNTILLID

REPEAT

Figure 4-10

C. Tilling across slopes without using

terraces:

• If vertical or terracing gardening aren’t

practical for you, then you can till

laterally across a slope. We don’t

really recommend this method as it can

create unsure footing and invites soil

erosion.

• As in terrace gardening, start at the top

of the slope and overlap the first pass

by half the width of the tiller. For added

stability of the tiller, always keep the

uphill wheel In the soft, newly tilled soil.

17

Page 18

Section 4: Operation

POWER COMPOSTING

Power composting simply means tiiiing

under and burying in the soil all manner

of organic matter such as crop residues,

leaves, grass clippings and cover crops.

This material will decompose during the

non-growing season and add important

natural nutrients to the soil.

A WARNING

When power composting, do not keep

the Depth Regulator Lever at a deep

setting if the tiller jumps or bucks.

If jumping or bucking occurs, move the

Depth Regulator Lever down to one ot

the shallower settings and then slowly

increase the tilling depth on later

passes.

Failure to comply could result in loss

of tiller control, property damage or

personal injury.

After power composting, you may want to

plant a “green manure” cover crop to

protect the soil during the off-season.

You simply grow a crop of clover, alfalfa,

buckwheat, peas, beans, rye grass, grain,

or kale and then till it into the soil prior to

the planting season.

LOADING AND UNLOADING THE

TILLER

A WARNING

Loading and unloading the tiller into a

vehicle is potentially hazardous and

we don’t recommend doing so unless

absolutely necessary, as this could

result in personal injury or property

damage.

However, it you must load or unload

the tiller, follow the guidelines given

* •

next.

' Position the loading vehicle so that the

ramp angle is as flat as possible (the

less incline to the ramp, the better).

Turn the vehicle’s engine off and apply

its parking brake.

• When going up ramps, stand in the

normal operating position and push the

tiller ahead of you. Have a person at

each side to turn the wheels.

• When going down ramps, walk

backward with the tiller following you.

Keep alert for any obstacles behind you.

Position a person at each wheel to

control the speed of the tiller. Never go

down ramps tiller-first, as the tiller could

tip forward.

• Use wooden blocks to place on the

downhill side of the wheels if you need

to stop the tiller from rolling down the

ramp. Also, use the blocks to temporar

ily keep the tiller in place on the ramps

(if necessary), and to chock the wheels

in place after the tiller is in the vehicle.

The first place to begin is with crop

residues such as leftover vines, stalks,

stems and roots. Power compost these

crop residues as soon as they finish

bearing. The sooner this is done, the

better, as tender green matter is easier to

till under. Use the deepest depth

regulator setting possible without causing

the engine to labor or the tiller to jump

ahead.

Standing cornstalks of reasonable height

can be power composted. Pushing over

(but not uprooting) cornstalks will often

make it easier for your tiller to chop up

the stalks. Keep the tines clear of

excessive tangling by “fishtailing” or fre

quently using reverse. Make several

passes, then return a few days later to

finish off any remaining stubble.

After tilling under crop residues, add more

organic matter such as leaves, grass

clippings and even kitchen scraps. When

tilled into the soil, this organic matter will

decompose and add even more important

nutrients to the soil.

’ Before loading or unloading, stop the

engine, wait for all parts to stop moving,

disconnect the spark plug wire and let

the engine and muffler cool.

> The tiller is too heavy and bulky to lift

safely by one person. Two or more

people should share the load.

• Use sturdy ramps and manually (engine

shut off) roll the tiller into and out of the

vehicle. Two or more people are needed

to do this.

' Ramps must be strong enough to

support the combined weight of the tiller

and any handlers. The ramps should

provide good traction to prevent

slipping: they should have side rails to

guide the tiller along the ramps; and they

should have a locking device to secure

them to the vehicle.

• The handlers should wear sturdy

footwear that will help to prevent

slipping.

> When the tiller is in the vehicle, prevent

it from rolling by engaging the wheels in

the WHEEL DRIVE position. Chock the

wheels with blocks and securely tie the

tiller down.

18

Page 19

Section

vuuui mm ■ ■

5 Maintenance

A WARNING

Before inspecting, cleaning or

servicing the machine, shut off engine,

wait for all moving parts to come to a

complete stop, disconnect spark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failure to follow these instructions can

result in serious personal injury or

property damage.

REQUIRED MAINTENANCE SCHEDULE

PROCEDURE Each 10 30 Noted

Check engine oil level

Clean engine

Check drive belt tension

Check nuts and bolts

Change engine oil

Lubricate tiller

Service engine air cleaner system

Check gear oil level in

transmission

Check tines for wear

Check tire pressure

(pneumatic tires only)

Before Every Every As

Use Hours Hours

•

•

•

•

•

•

•

•

•

And every 5

operating hours

A

t

t

*

A

t

Service spark plug

* Change more frequently in dusty or dirty conditions. Change after first 2 hours of

break-in operation.

t Check after first 2 hours of break-in operation.

A See Engine Owner’s Manual for service intervals and instructions.

A

19

Page 20

Sections: Maintenance

A WARNING

Before inspecting, cieaning or servicing the machine, shut off engine, wait for all moving parts to come

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

♦ n

key on electric start models.

Failure to tollow these instructions can result in serious personal injury or property damage.

TILLER LUBRICATION

Proper lubrication of the tiller is an

essential part of your maintenance

program. After every 10 operating

hours, oil or grease the lubrication points

shown in Figure 5-1 and described

below.

Use a good quality lubricating oil (#30

weight engine oil is suitable) and a good

quality general purpose grease (grease

that has a metal lubricant is preferred, if

available).

• Remove wheels, clean wheel shaft (A,

Fig. 5-1) and apply thin coating of

grease to shaft.

• Grease back, front and sides of depth

regulator lever (B, Fig. 5-1).

• Remove tines, clean tine shafts (C, Fig.

5-1) and inspect for rust, rough spots

or burrs (especially around holes). File

or sand smooth and coat ends of shaft

with grease.

• Oil the threads on the handlebar height

adjustment screws and the handlebar

attaching screws (D, Fig. 5-1).

Figure 5-1

20

CHECK FOR OIL LEAKS

Before each use, check your tiller for

signs of an oil leak - usually a dirty, oily

accumulation either on the unit or on the

floor where it has been parked.

A little seepage around a cover or oil seal

is usually not a cause for alarm. However,

if the oil drips overnight then immediate

attention is needed as ignoring a leak can

result In severe transmission damage.

If a cover is leaking, check for loose

screws. If the screws are tight, a new

gasket or oil seal may be required. If the

leak is from around a shaft and oil seal,

the oil seal probably needs to be replaced.

See your authorized dealer or contact the

factory for service or advice.

IMPORTANT: Never operate the tiller if the

transmission is low on oil. Check the oil

level after every 30 hours of operation and

whenever there is any oil leakage.

CHECK HARDWARE

Check for loose or missing hardware after

every 10 operating hours. Tighten or

replace hardware before using the tiller.

Be sure to check the screws underneath

the tiller hood (lift the hood flap) that

secure the transmission cover and the

Depth Regulator Lever to the transmis

sion.

CHECK TIRE PRESSURE (Models with pneumatic tires)

Check the air pressure in both tires.

Deflate or inflate both tires evenly from

15-to-20 PSI (pounds per square inch).

Be sure that both tires have the same air

pressure or the unit will tend to pull to

one side.

TRANSMISSION GEAR OIL SERVICE

Check the transmission gear oil level after

every 30 hours of operation or whenever

you notice any oil leak. Operating the

tiller when the transmission is low on oil

can result in severe damage.

A. To Check the Transmission

Gear Oil Level:

1. Check the gear oil level when the trans

mission is cool. Gear oil will expand in

warm operating temperatures and this

expansion will provide an incorrect oil

level reading.

2. With the tiller on level ground, pull the

Depth Regulator Lever all the way up.

3. Remove the oil fill plug (A, Fig. 5-2)

from the transmission housing and locate

the main drive shaft situated inside the

housing.

4. The gear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

5. If the gear oil level Is low, add gear oil

as described next. If the gear oil level is

okay, securely replace the oil fill plug.

IMPORTANT: Do not operate the tiller If

the gear oil level is low. Doing so will

result in severe damage to the transmis

sion components.

6. If adding only a few ounces of gear

oil, use API rated GL-4 or GL-5 gear oil

having a viscosity of SAE 140, SAE 85W140 or SAE 80W-90. If refilling an empty

transmission, use only GL-4 gear oil

having a viscosity of SAE 85W-140 or

SAE 140.

IMPORTANT: Do not use automatic

transmission fluid or motor oil in the

transmission.

7. While checking frequently to avoid

overfilling, slowly add gear oil into the oil

fill hole until it reaches the halfway point

on the drive shaft.

8. Securely replace the oil fill plug.

B. To Drain the Transmission Gear Oil:

The transmission gear oil does not need

to be changed unless it has been contam

inated with dirt, sand or metal particles.

1. Drain gasoline from the fuel tank or

run the engine until the fuel tank is

empty. See “DANGER” statement that

follows.

Page 21

Sections: Maintenance

A WARNING

A|nv||^l

♦ r?

n’

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

A DANGER

Gasoline is highly flammable and its

vapors are explosive. Follow these

satety practices to prevent personal

injury or property damage from fire or

explosion.

• Allow the engine and muffler to cool

for at least two minutes before draining

the tiller’s gasoline tank.

• Do not allow open tiames, sparks,

matches or smoking in the area.

• Wipe away spills and push tiller away

from spilled fuel.

• Use only an approved fuel container

and store it safely out of the reach of

children.

• Do not store gasoline in an area

where its vapors could reach an open

flame or spark, or where ignition

sources are present (such as hot water

and space heaters, turnaces, clothes

dryers, stoves, electric motors, etc.)

2. Drain the oil from the engine.

3. Remove four scre\ws (B, Figure 5-2) and

remove transmission cover and gasket.

4. Remove the left-side wheel.

5. Tilt the left-side wheel shaft into a

drain pan and allow the gear oil to drain

through the top of the transmission.

6. Reinstall the wheel, install a new

gasket cover (do not reuse old gasket)

and reinstall the transmission cover.

7. Refill the transmission using GL-4

gear oil (SAE 85W-140 or SAE 140).

8. Refill the engine with motor oil and

replenish the fuel tank with gasoline.

Figure 5-2: Remove oil fill plug (A) to check

gear oil level and to add gear oil. Remove

four cover screws (B) to drain gear oii.

A. Tine Inspection:

With use, the tines will become shorter,

narrower and pointed. Badly worn tines

will result in a loss of tilling depth and

reduced effectiveness when chopping up

and turning under organic matter.

B. Removing a Single Tine:

1. With the engine shut off and the spark

plug wire disconnected, remove the two

screws (A, Figure 5-3) and locknuts (B)

that attach a single tine to the tine holder.

If needed, use penetrating oil on the nuts.

2. When installing a single tine, be sure to

position it so that its cutting edge will

enter the soil first as the tiller moves

forward.

C. Removing a Tine Assembly:

1. A tine assembly consists of eight tines

mounted on a tine holder.

2. If removing both tine assemblies, mark

them “left” and “right” before removal.

Remove the screw (C, Figure 5-3) and

locknut (D) that secure the tine assembly

to the tine shaft. If necessary, use a

rubber mallet to tap the tine assembly

outward off the shaft.

3. Before reinstalling the tine assembly,

inspect the tine shaft for rust, rough

spots or burrs and file or sand as needed.

Apply a thin coat of grease to the shaft.

4. Install each tine assembly so that the

cutting edge of the tines will enter the

soil first when the tiller moves forward.

Secure the tine assembly to the tine shaft

using the screw and locknut previously

removed.

BOLD TINES

The bolo tines will wear with use and they

should be inspected at the beginning of

each tilling season and after every 30

operating hours. The tines can be

replaced individually or as a complete set.

See the Parts List for tine identification

and part numbers.

Figure 5-3: Install lines so that cutting edge of tines enter soil first when tiller moves forward.

21

Page 22

Sections; Maintenance

A WARNING

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

* n

n'

key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

CHECKING AND ADJUSTING FORWARD DRIVE BELT TENSION

Maintaining correct tension on the

forward drive beit is important to good

tilling performance and long belt life.

A loose belt will slip on the engine and

transmission pulleys and cause the tines

and wheels to slow down - or stop com

pletely - even though the engine is

running at full speed. A belt that is too

tight can result in unintentional tine

movement when the clutch bail is in the

Neutral (released) position.

Also check the belt for cracks, cuts or

frayed edges and replace it as soon as

possible.

• Check belt tension after the first two

hours of break-in operation (new beit).

• Check belt tension after every 10

operating hours.

To Check Forward Belt Tension:

1. Stop the engine, wait for all parts to

stop moving and disconnect the spark

plug wire.

2. With the forward ciutch bail in an open

(released) position, measure and carefully

note the overall length of the cable spring

(A, Figure 5-4) by measuring from the

outermost coil to the outermost coil.

3. Lift and hold the forward clutch bail

against the handlebar (see Figure 5-4) and

re-measure the overall length of the coils

while the spring is under tension. The belt

tension is correct if this second measure

ment is between 1/16" -to- 3/16” longer

than the first measurement.

4. If the spring is too short (less than

1/16“ greater than the first measurement),

the tension is too loose. If the spring is

too long (more than 3/16" greater than the

first measurement), the tension is too

tight.

To adjust the length of the spring:

a. Release the Forward Clutch Bail.