Page 1

Form 1905103 (3/98)

Owner’s Manual

5 H.P.

• Safety

• Assembly

• Controls

• Operation

• Maintenance

Model

12168

®

© 1998 GARDEN WAY INCORPORATED

TM

Page 2

2

Dear Owner:

Thank you for purchasing the TROY-BILT

®

VersaTiller™. This unique piece of outdoor

power equipment gives you the deep tilling

power that rear-mounted counter-rotating tines

provide, and provides the outstanding convenience of a front tine cultivator and tiller as well.

The optional edger attachment and optional aerator

attachment install easily and work very effectively

to add even more versatility to your machine.

Please read this manual. It tells you how to

safely and easily assemble, operate and

maintain your machine. Be sure that you and

any other operator carefully follow the

recommended safety practices at all times.

Failure to do so could result in personal injury

or property damage. This manual is considered

a permanent part of the unit and it must stay

with the unit if it is resold. A replacement

manual can be obtained from the factory or

your local authorized dealer.

All information in this manual is based on the

latest product information available at the time

of printing. Review this manual frequently to

familiarize yourself with its features and operation.

If you have any problems or questions concerning the unit, contact your local authorized dealer

or the factory. Our telephone numbers and

mailing addresses are listed on Page 3.

We want to ensure your complete satisfaction at

all times.

Safety Alert Symbol

This is a safety alert symbol.

It is used in this manual and

on the unit to alert you to

potential hazards. When you see this

symbol, read and obey the message

that follows it. Failure to obey safety

messages could result in personal

injury or property damage.

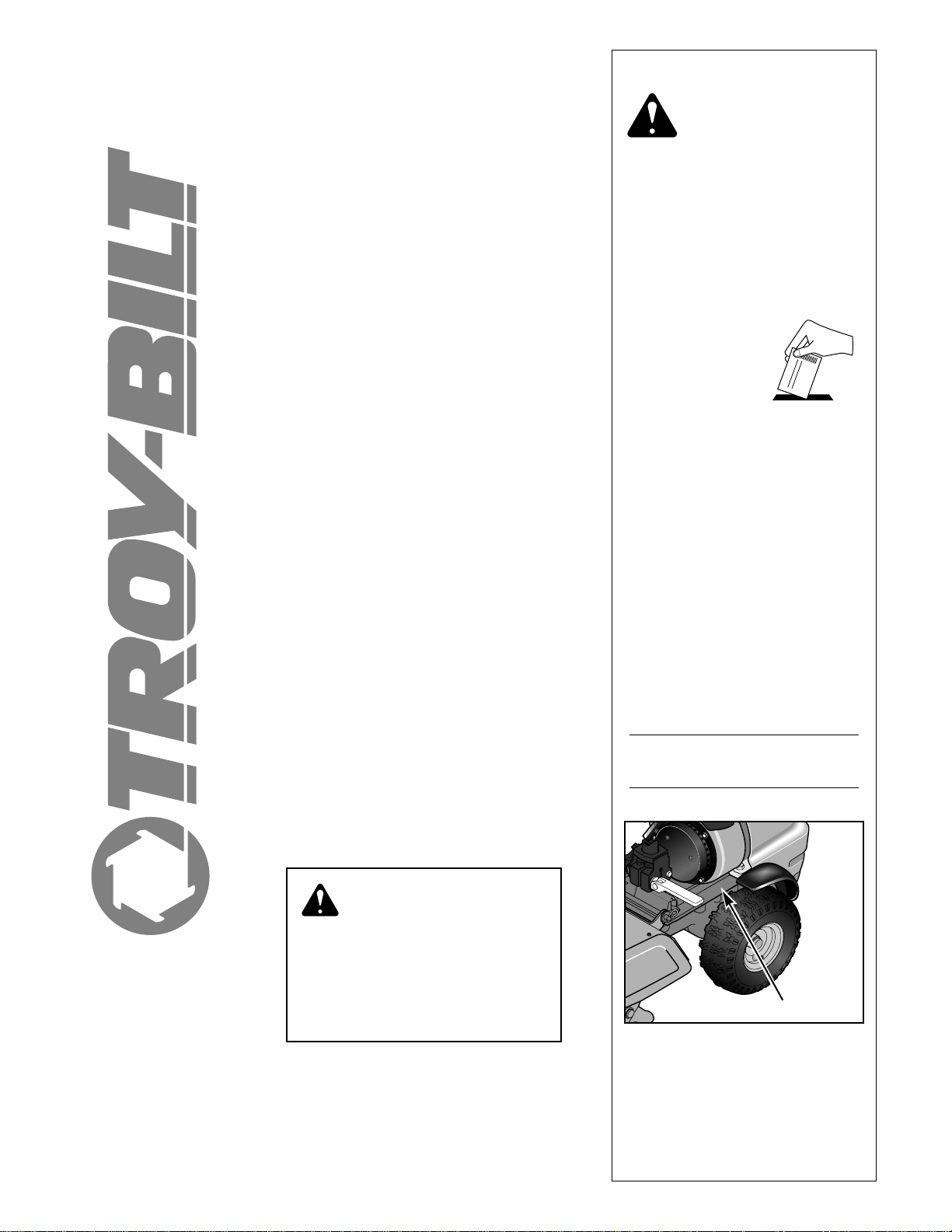

Owner Registration Card

Please fill out and mail the enclosed

owner registration

card. The purpose of

this card is to register

each unit at the

factory in order to

keep the owner

informed with informational bulletins

and safety literature.

Warranty Service

The warranty statement is included in

the unit’s literature package.

Model/Serial Numbers

The Model/Serial Numbers are located

on the engine mounting bracket (see

figure below). For ready reference,

record these numbers in the spaces

below.

Date of purchase:

Model/Serial Numbers:

Left and Right Sides

Left and right sides of the unit are

determined from the operator’s

position behind the handlebar.

®

M

I

A

L

M

I

A

L

Model/Serial Numbers

The engine exhaust from this

product contains chemicals

known to the State of

California to cause cancer,

birth defects or other

reproductive harm.

WARNING:

Page 3

3

Table of Contents

Owner Registration card ............................................................ 2

Warranty Service .................................................................... 2

Model/Serial Numbers .............................................................. 2

Customer Service and Technical Service ........................................ 3

Replacement Parts .................................................................. 3

Engine Service and Repair ......................................................... 3

SECTION 1: SAFETY ................................................................. 4

Safety Decals .................................................................................................. 6

SECTION 2: ASSEMBLY ............................................................. 7

Handlebar Assembly ....................................................................................... 7

Add Motor Oil to Engine .................................................................................. 8

Check/Adjust Tire Pressure.............................................................................. 8

Check Hardware Tightness.............................................................................. 8

How to Transport Machine in “Freewheel”....................................................... 8

SECTION 3: FEATURES & CONTROLS............................................... 9

Drive Bail......................................................................................................... 9

Swivel Handlebars........................................................................................... 9

Handlebar Locking Lever................................................................................. 9

Hood Release Pin............................................................................................. 9

Tines................................................................................................................ 9

Operational Interlock System........................................................................... 9

Engine Throttle Lever....................................................................................... 10

Fuel Primer Bulb.............................................................................................. 10

Recoil Starter................................................................................................... 10

Oil Fill Tube and Dipstick ................................................................................. 10

Fuel Tank......................................................................................................... 10

Spark Plug....................................................................................................... 10

Air Cleaner....................................................................................................... 10

Muffler............................................................................................................. 10

SECTION 4: OPERATION ............................................................. 11

Preparation Before Starting ............................................................................. 12

Break-In Operation........................................................................................... 12

The Operational Interlock System.................................................................... 13

Convert From Rear Tine Tiller to Front Tine Tiller/Cultivator............................ 14

Start and Stop the Engine................................................................................ 15

How to Operate Your Machine As A Rear Tine Tiller........................................ 15

Clearing Debris from Tines.............................................................................. 16

How to Operate Your Machine As A Front Tine Tiller/Cultivator....................... 16

Cultivating in Flower Beds/Shrubbery Areas.................................................... 16

Optional Attachments ...................................................................................... 17

Loading and Unloading the Tiller..................................................................... 18

SECTION 5: MAINTENANCE ......................................................... 19

Required Maintenance Schedule...................................................................... 19

Tiller/Cultivator Maintenance........................................................................... 20

Engine Maintenance......................................................................................... 23

Off Season storage.......................................................................................... 23

Troubleshooting.................................................................................. Back Cover

Customer Service and

Technical Service

If you have questions or

problems with the unit,

contact your local dealer

or call or write to the

factory. (When calling or

writing the factory,

provide the model/serial

number of the unit.)

Replacement Parts

Factory specified

replacement parts are

available from your

authorized dealer or

directly from the

factory. For parts ordering information,

refer to the parts catalog.

Engine Service and

Repair

For engine service or

repair, contact your

nearest authorized

engine dealer (look in

the Yellow Pages

under “Engines–Gasoline”). The engine

is warranted by the engine manufacturer.

Any unauthorized work performed on the

engine during the warranty period may

void this warranty. For complete details

on the engine warranty, refer to the

engine owner manual.

To Contact the Factory:

GARDEN WAY INCORPORATED

1 Garden Way

Troy, New York 12180

FAX: (518) 391-7332

Telephone Numbers:

Customer Service: 1-800-437-8686

Technical Service: 1-800-520-5520

Parts Service: 1-800-648-6776

Outside the United States and Canada:

Customer Service: (518) 391-7007

Technical Service: (518) 391-7008

Parts Service: (518) 391-7006

TO AVOID SERIOUS INJURY:

• READ THE OWNER’S MANUAL.

• KNOW LOCATIONS AND FUNCTIONS OF ALL CONTROLS.

• KEEP ALL SAFETY DEVICES AND SHIELDS IN PLACE AND WORKING.

• NEVER ALLOW CHILDREN OR UNINSTRUCTED ADULTS TO OPERATE TILLER.

• SHUT OFF ENGINE AND DISCONNECT SPARK PLUG WIRE BEFORE MANUALLY

UNCLOGGING TINES OR MAKING REPAIRS.

• KEEP BYSTANDERS AWAY FROM MACHINE.

• KEEP AWAY FROM ROTATING PARTS.

• USE EXTREME CAUTION WHEN REVERSING OR PULLING THE MACHINE TOWARDS

YOU.

CAUTION

Page 4

Training

Read this Owner’s Manual and the

separate engine owner manual

carefully before operating this

equipment. Be completely familiar

with the controls and the proper use

of the unit. Know how to stop the

unit and disengage the controls

quickly. A replacement manual is

available by contacting us.

2. Never allow children to operate the

equipment. Never allow adults to

operate the equipment without

proper instruction.

3. Keep the area of operation clear of all

persons, particularly small children

and pets. Keep bystanders at least

25 feet away from the area of

operation.

4. Keep in mind that the operator or

user is responsible for accidents or

hazards occurring to other people,

their property, and themselves.

5. Familiarize yourself with all safety

and operating decals on the unit and

on any attachments or accessories.

6. Do not run the engine in an enclosed

area. Engine exhaust contains

carbon monoxide gas, a deadly

poison that is odorless, colorless,

and tasteless. Do not operate the

unit near buildings, windows, or air

conditioners.

7. Do not allow hands or any other part

of the body or clothing near the

rotating tines or near any other

moving part. Once the engine is

started and the unit is in rear tine

tiller mode, the tines and wheels

begin to rotate when the Drive Bail is

closed against the handlebar. If in

front tine cultivator mode, only the

tines rotate when the Drive Bail is

closed.

8. Before inspecting, servicing or

adjusting any part of the unit, shut

the engine off, wait for all moving

parts to stop, disconnect the spark

plug wire from the spark plug. Move

the wire away from the spark plug.

9. Do not operate the unit if you are

under the influence of alcohol,

medication, or when tired or ill.

Preparation

1. Thoroughly inspect the area where

the equipment will be used. Remove

foreign objects before tilling or

cultivating.

2. Let go of the Drive Bail before starting

the engine.

3. Do not operate this equipment without wearing suitable clothing. Avoid

loose garments or jewelry that could

get caught in moving parts of the

tiller or its engine.

4. Do not operate the tiller when you

are barefoot, in sandals, sneakers or

other light footwear. Wear protective

footwear that grips well on slippery

surfaces.

5. Do not till or cultivate near underground electric cables, telephone

lines, pipes or hoses. Contact your

telephone company or utility to verify

locations of cables or lines.

6. Handle gasoline with care; it is

flammable, the vapors explosive.

Take the following precautions:

a.) Use an approved gas container.

b.) Gas cap shall never be removed

or fuel added with engine running.

Engine shall be allowed to cool

before refueling. Operators shall not

smoke.

c.) Keep matches, cigarettes, cigars,

pipes, open flames, or sparks away

from the fuel tank and fuel container.

Section

1

Safety

SPARK ARRESTER WARNING TO RESIDENTS OF CALIFORNIA AND SEVERAL OTHER STATES

Under California law, and under the laws of several other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels on any forest, brush, hay, grain, or grass

covered land; or land covered by any flammable agricultural crop without an engine spark arrester in

continuous effective working order.

The engine on the unit is an internal combustion engine which burns gasoline, a hydrocarbon fuel, and must be equipped with a

spark arrester muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in

such a manner that flames or heat from the system will not ignite flammable material. Failure of the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may also be a violation of other state

and/or federal regulations, laws, ordinances or codes. Contact your local fire marshal or forest service for specific information

about which regulations apply in your area.

4

Rear

Tine

Tiller

Mode

Front Tine

Cultivator

Mode

Drive

Bail

Page 5

Section 1: Safety

Operation

1. Do not put hands or feet near or

under rotating parts.

2. Use extreme caution when on or

crossing gravel driveways, walks or

roadways. Be alert for hidden

hazards or traffic. Do not carry

passengers.

3. If you hit a foreign object, stop the

engine, let all moving parts come to

a complete stop, disconnect spark

plug wire and move wire away from

the spark plug, and inspect for damage. Repair damage before restarting.

4. Exercise caution to avoid slipping or

falling.

5. If abnormal tiller vibration occurs,

stop engine immediately, disconnect

the spark plug wire, and move wire

away from spark plug. Check for the

cause. Carefully inspect for any damage. Fix the problem before using

the tiller again. Vibration is generally

a warning sign of trouble.

6. Stop the engine, let all moving parts

stop completely, disconnect the

spark plug wire and move the wire

away from the plug before leaving

the operating position, unclogging

tines, or making repairs, adjustments

or inspections.

7. Take all possible precautions when

leaving the machine unattended. Let

go of all controls. Stop engine, allow

all moving parts to stop completely,

disconnect spark plug wire and move

wire away from plug to prevent the

possibility of accidental starting.

8. Before cleaning, repairing or

inspecting, stop the engine, let all

moving parts stop completely,

disconnect the spark plug wire and

move wire away from spark plug to

prevent the possibility of accidental

starting.

9. The Operational Interlock System

should be tested for correct function

every time prior to using this equipment. See Section 4 in this Manual.

10. Never use equipment unless safety

guards and safety devices are in

place and working properly.

11. Do not remove the hood flap or in

any way alter its performance. Doing

so may allow stones to be thrown in

the operator’s direction, increase the

risk of accidentally coming into contact with the tines, or increasing the

possibility that the unit may unexpectedly be propelled backward.

12. Do not run the engine in an enclosed

area. Engine exhaust contains carbon

monoxide gas, a deadly poison that

is odorless, colorless and tasteless.

13. Keep children and pets away.

14. Never operate the equipment in the

rear tine tiller mode (operator

standing behind the tines) unless the

tine hood is properly installed over

the tines. Refer to illustrations on

Page 4. The tine hood may only be

removed after the handlebar is

swung around 180oto the front tine

tiller/cultivator mode (handlebar is

positioned over the engine). Never

till or cultivate in front tine tiller/

cultivator mode with the tine hood

installed— in this mode the tine

hood should always be off. Failure to

comply with these requirements

could result in serious personal

injury or damage to the tine hood. A

special safety interlock switch prevents the engine from running if the

tine hood is removed when the handlebaris in the rear tine tiller mode

(handlebars over hood and tines).

See illustration on Page 4.

15. When in rear tine tiller mode, the

tiller could unexpectedly jump

backward if the tines dig in too

deeply and the wheels lose traction.

To minimize the possibility of the

machine jumping backwards, do not

push down on the handlebar when in

rear tine tilling mode.

16. If in doubt about tilling conditions,

use the following precautions to help

you in maintaining tiller control:

a.) Walk on the left side of the

handlebar when in the rear tine tilling

mode. When front tine tilling or

cultivating, walk behind the handlebar.

b.) Use slower engine throttle speeds.

c.) When tilling, work gradually

deeper with each tilling pass.

d.) Clear the tilling area of big

stones, roots and other debris.

e.) When in rear tine tilling mode,

avoid putting downward pressure on

the handlebar which would cause the

wheels to lose traction. If necessary,

apply upward pressure to increase

wheel traction and to prevent the

tines from digging too deeply. When

in the cultivating mode, do the

opposite—apply downward

handlebar pressure to prevent the

tines from digging too deeply.

f.) In an emergency, release the control lever to stop tines and wheels.

17. Do not overload the capacity of the

machine by trying to till or cultivate

too deeply at too fast a rate.

18. Never use the tiller at high speed on

hard or slippery surfaces. Look

behind and use care when backing

up (there is no powered “reverse”).

19. Do not use this unit on steep slopes.

On modest slopes, slow down.

Obtain good footing. Don’t let unit

“freewheel” down slopes. When

possible, operate unit under power

with wheels engaged.

20. Clear the area of bystanders before

tilling or cultivating.

21. Use only attachments and accessories approved by Garden Way Inc.

22. Use tiller attachments and accessories when recommended.

23. Never operate this equipment without good visibility or light.

5

d.) Fill fuel tank outdoors using

extreme caution. Never add fuel

indoors. Use a funnel or spout to

prevent spillage.

e.) Replace all fuel tank and

container caps securely.

f.) If fuel is spilled, do not attempt to

start the engine, but move the

machine away from the area of

spillage and avoid creating any

source of ignition until fuel vapors

dissipate.

7. Never attempt to make any

adjustments while the engine is

running or the spark plug wire is

connected, except when so

instructed.

Page 6

6

24. Never operate this equipment if

you are fatigued, or under the influence of alcohol, drugs or medicine.

25. Operators shall not tamper with

the engine-governor settings; the

governor controls the maximum

safe operating speed and protects

the engine and all moving parts

from damage caused by

overspeed. Authorized service

shall be sought if a problem exists.

26. Do not touch engine parts that

may be hot from operation

(muffler, fins, etc.). Be certain all

parts have cooled down before

inspecting, cleaning or repairing.

27. Remember—to stop tines and

wheels, let go of the Drive Bail.

Do not try to restrain the tiller. Let

go of the handlebar if necessary.

28. Use extreme caution when moving

backward or pulling unit toward you.

29. Start the engine carefully

according to instructions and with

feet well away from the tines.

30 Never pick up or carry equipment

while the engine is operating.

Section 1: Safety

1. Never perform maintenance when

engine is running or spark plug wire is

connected except when specifically

directed to do so.

2. Keep tiller, attachments and

accessories in safe working condition.

3. Check all nuts, bolts and screws frequently for proper tightness. Always

verify the equipment is in safe working

condition.

4. Never store the machine with fuel in

the fuel tank inside a building where

fumes may reach an open flame or

spark, or where ignition sources are

present (such as hot water and space

heaters, furnaces, clothes dryers, etc.).

5. Let the engine cool down before

storing it in an enclosure.

6. To reduce fire hazard possibilities, keep

the engine free of grass, leaves or

grease.

7. Store gasoline in a cool, well-ventilated

area, safely away from any spark- or

flame-producing equipment. Store

gasoline in an approved container,

safely out of the reach of children.

8. Refer to the Maintenance Section in

this Manual for storage information if

your equipment is to be stored for an

extended period.

9. If the fuel tank has to be drained, do

this outdoors.

10.Follow manufacturer’s recommendations for safe loading, unloading,

transport and machine storage.

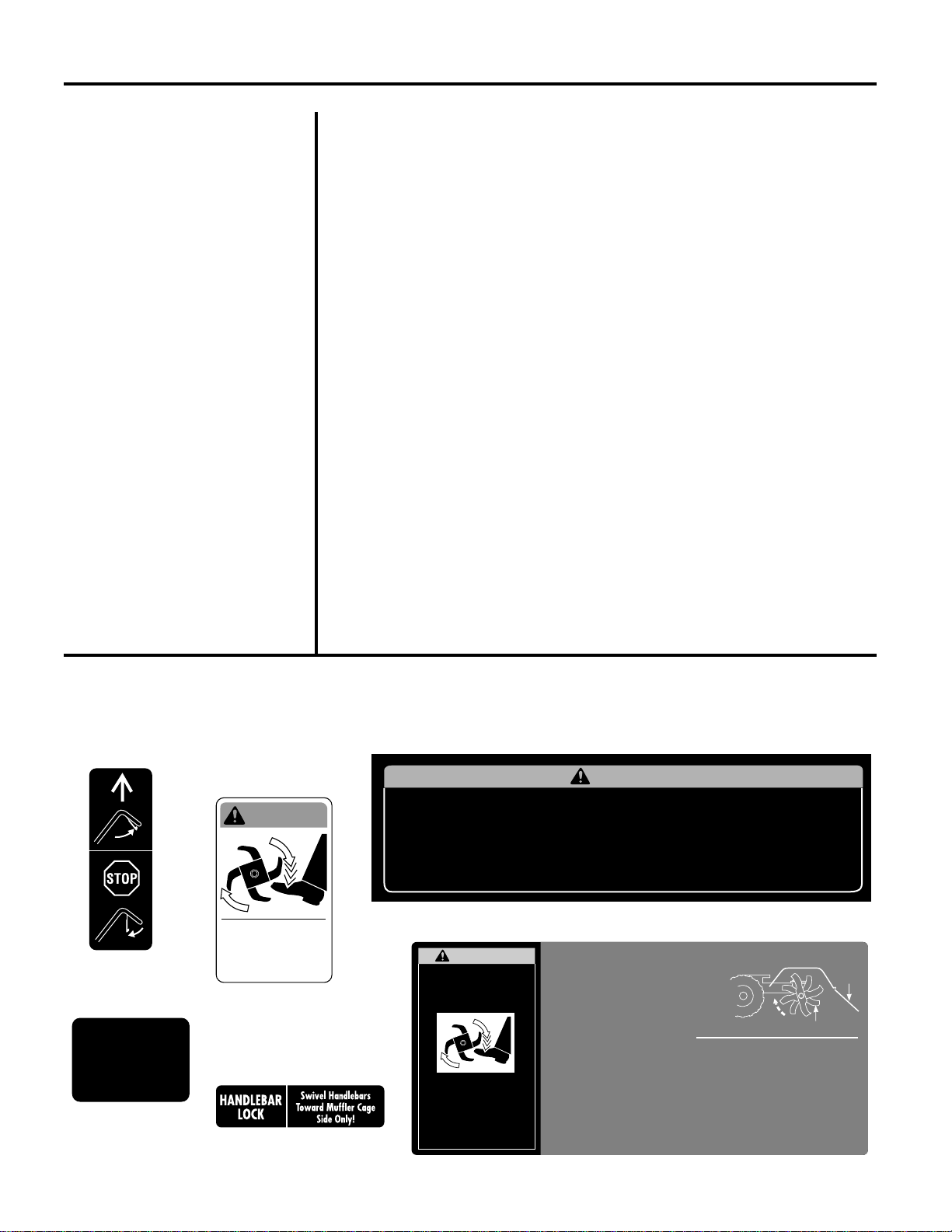

Decals For your personal safety and the safety of

others, safety message decals have been affixed to your unit.

Keep them clean and legible . Contact your local service

dealer or the factory for replacements if any decals are

damaged or missing. Refer to the separate parts catalog for

decal locations, part numbers, and ordering instructions.

The safety and operational decals on your equipment are

shown below (not actual size).

Maintenance and Storage

1911359.A (1/98)

WARNING

1911362.B (3/98)

To Avoid Serious Injury:

• Read the Operator’s Manual.

• Know the location and functions

of all controls.

• Keep all safety devices and

shields in place and working.

• Keep away from rotating parts.

•

Never allow children or uninstructed

adults to operate machine.

• Shut off engine and disconnect spark

plug wire before manually unclogging

tines or making repairs.

• Use extreme caution when reversing

or pulling the machine towards you.

• Keep bystanders away from

machine.

• Do not operate tiller in rear

tine tilling mode without tine

hood in place, or in front tine

tilling mode with tine hood

installed.

PLACE FREE HAND

HERE

WHEN MANUALLY

STARTING ENGINE.

1915810 (12/97)

W ARNING

Keep away from

rotating tines.

Rotating tines will

cause injury.

1911361.A (1/98)

Decal located on front plate of handlebar.

Decal located on top

of handlebar– left side.

Decal located on bottom

of handlebar and on

hood flap.

Decal located on

fuel tank.

Decal located on

handlebar locking lever.

WARNING

Tines could propel tiller backwards

when rear-tine tilling!

Contact with tines will cause injury.

To avoid injury:

Let go of control lever.

Stand to left rear side of handlebar

when first setting down tines onto

sod or hard ground.

Follow these safe operating procedures before starting the engine:

1. When in rear-tine mode, check that the wheels are properly

engaged (NOT in Freewheel). When properly engaged, wheels

will not roll more than 10 inches before locking up.

2. Check that flap on tine hood is in place, freely hanging down and

trailing behind tiller (see illustration at right).

3. Check that tines are properly installed so that curved cutting

edges will enter the soil first.

4. Check the engine for fuel and oil. Check the tiller's safety items.

Curved Cutting Edge

Freely

Trailing

Flap

TILLING/CULTIVATING INSTRUCTIONS

See your Owner's Manual for complete operating and safety instructions before operating this machine; the following are just some key

reminders. (A replacement manual is available from your dealer or at the factory.)

1. For front-tine cultivating, remove the tine hood. Loosen

the Handlebar Locking Lever and swing the handlebar

around over the engine. Swing only toward the muffler

cage side of engine. Rotating the handlebar in the wrong

direction will damage the safety electrical interlock switch.

Tighten the locking lever.

2. For rear-tine tilling, attach the tine hood. Loosen the

Handlebar Locking Lever and swing the handlebars to the

rear position over the hood. Swing only toward the muffler

cage side of engine. Tighten the locking lever.

3. Squeeze the Drive Bail lever to operate. Release this

lever at any time to immediately stop the tiller.

4. For rear-tine mode, walk to one side (the left is easiest);

lift slightly on the handlebar for better wheel traction.

Wheels are automatically engaged.

5. For front-tine mode, walk right behind the handlebar;

wheels are automatically in Freewheel.

6. Use front-tine mode to roll machine across lawns or

driveways.

IMPORTANT: Check that safety interlock switch is clean and free of debris at all times. See "Maintenance" Section in

Owner's Manual.

1911507.A (5/98)

Decal located on top of tine hood.

Page 7

7

WARNING

TO PREVENT PERSONAL INJURY

OR PROPERTY DAMAGE, DO

NOT START THE ENGINE UNTIL

ALL ASSEMBLY STEPS ARE

COMPLETE AND YOU HAVE READ

AND UNDERSTAND THE SAFETY

AND OPERATING INSTRUCTIONS

IN THIS MANUAL.

Inspect unit

Inspect the unit and carton for damage

immediately after delivery. Contact the

carrier (trucking company) if you find or

suspect damage. Inform them of the

damage and request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 days after the unit has

been delivered. Contact the factory if you

need assistance in this matter.

Tools/Materials Needed for

Assembly

(One) 1/2" wrench*

(Two) 9/16" wrenches*

(One) Automotive-type air pressure gauge

(One) Clean oil funnel

(One) Quart clean, high-quality engine oil.

Refer to the Engine Owner Manual

for engine oil specifications and

quantity required. Do not overfill.

* Adjustable wrenches may be

substituted.

IMPORTANT: Motor oil must be added to

the engine before starting. Follow the

instructions in this “Assembly” section

and in the Engine Owner’s Manual.

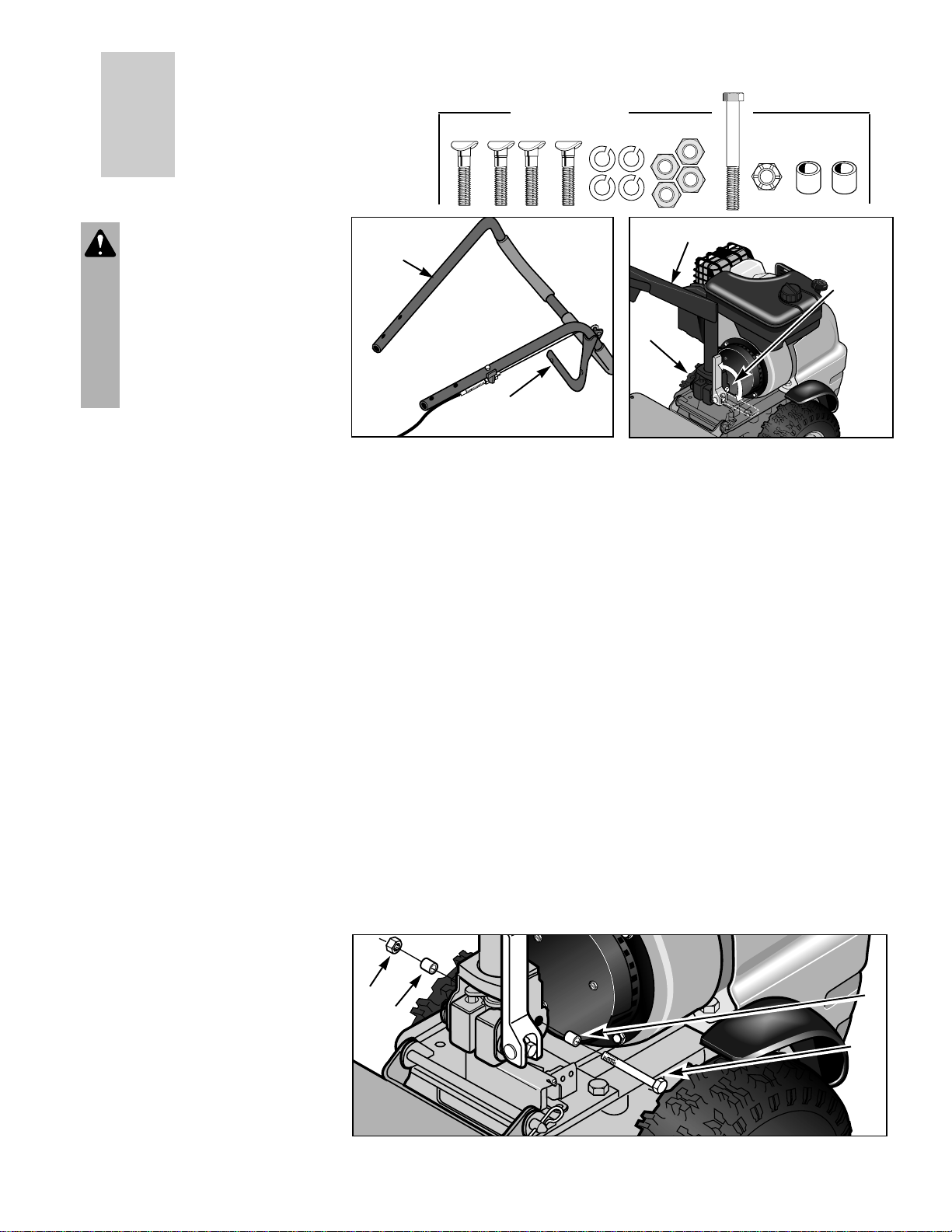

Unpacking Instructions

1. After opening the carton, remove cardboard support materials and packaging

material around handlebar and engine.

2. Lift up the carton to remove it.

3. Carefully put aside the upper section

of the handlebar (it is connected to the

machine by a control cable) and the hardware bag. See Fig. 2-1. Do not kink the

control cable connected to the uper handlebar section. Also cut the plastic tie on the

handlebar to free the drive bail (Fig. 2-1).

4. The assembly is easiest by leaving the

tiller on the wood shipping pallet until the

handlebar has been completely assembled.

If the unit must be moved off the pallet

and rolled to another location for assembly, see “Freewheel” message on Pg. 8.

5. Open the hardware bag and group the

hardware. Check the contents against the

following list and Fig. 2-1A above (hardware shown at a reduced size):

• four 5/16"-18 x 1-1/2" curved head screws

• four 5/16" lockwashers

• four 5/16"-18 hex nuts

• one 3/8"-16 x 3-1/4" screw

• one 3/8"-16 locknut

• two steel bushings (for handlebar)

STEP 1: Adjust Handlebar Height

1. Move the handlebar locking lever up

(A, Fig. 2-2), then tilt the lower handlebar

section upward to align the holes in the

base and the lower handlebar section (B).

2. Hold the lower handlebar section in

this position with the holes in the base

aligned. Move the handlebar locking

lever down to “freeze” the hole alignment.

STEP 2: Install Hardware in Base

and Lower Handlebar Section

1. Insert one bushing (C, Fig. 2-3) on the

end of the 3-1/4" long screw (D), and

slide the screw through the base of the

lower handlebar section. Put the other

bushing (C) on the screw on the other

side, sliding it on all the way.

2. Use 9/16" wrenches to install the 3/8"

locknut (E) on the screw (D). Tighten hardware securely. NOTE: Do not tighten the

other long screw next to this hardware – it

is factory tightened. See Fig. 2-3.

Section

2

Assembly

Fig. 2-1

Fig. 2-2

Upper

Handlebar

Section

Cut plastic tie to

free the drive bail

Fig. 2-3: Install hardware to secure lower handlebar section to the base.

C

C

D

B

Hardware Shipped

Fig. 2-1A

A

Lower Handlebar

Section

E

Page 8

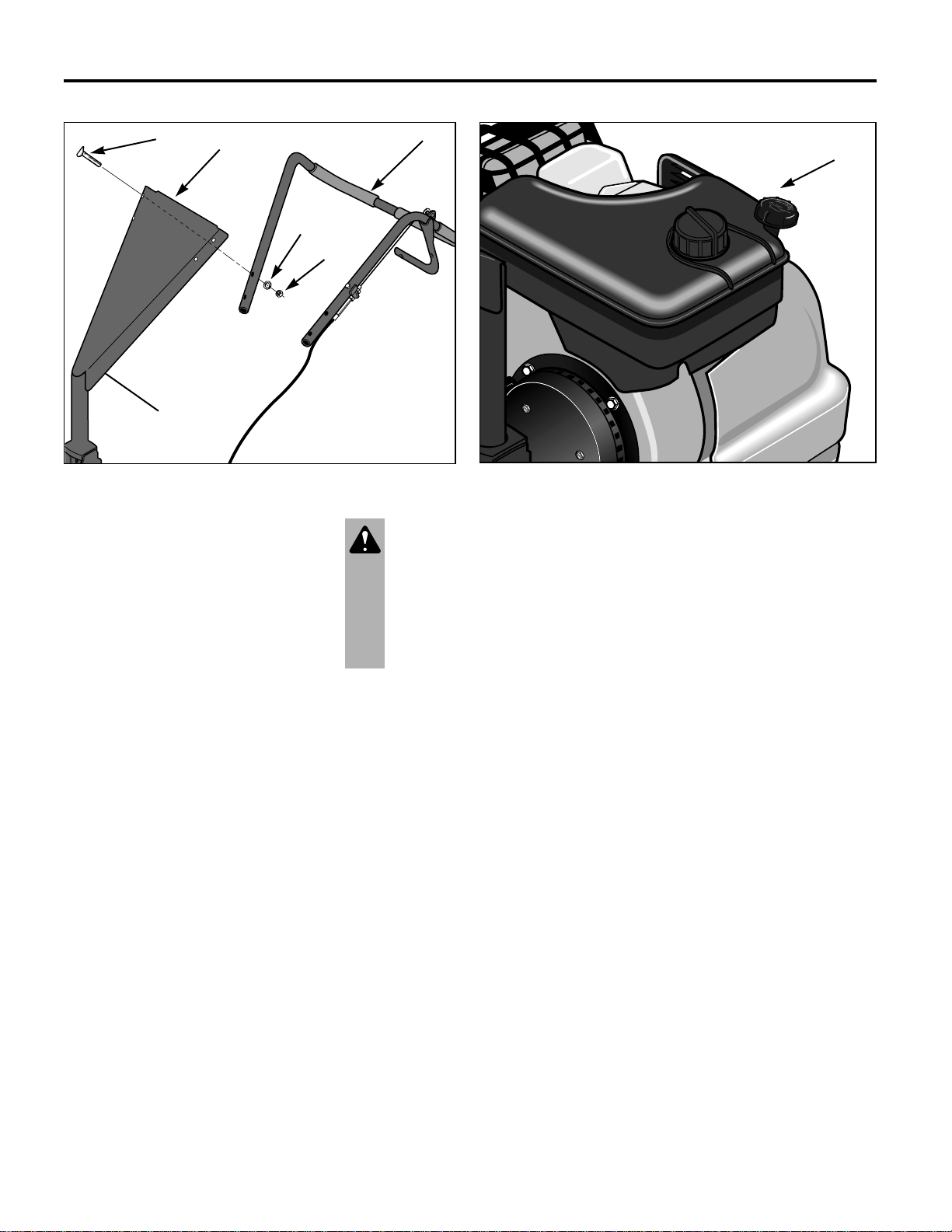

STEP 3: Attach Upper Handlebar

Section to Lower Handlebar Section

1. Align the mounting holes in the upper

handlebar section (F, Fig. 2-4) with the

corresponding mounting holes in the

lower handlebar section (G).

2. Insert four 5/16"-18 x 1-1/2" curved

head screws (H, Fig. 2-4) DOWN through

the holes in the two handlebar sections.

Install the top screws first for easiest

installation. Secure the screws with four

5/16" lockwashers (I), and four 5/16"-18

hex nuts (J). Tighten with a 1/2" wrench.

3. Press the handlebar control cable into

the plastic clip (K, Fig. 2-4) underneath

the left side of the control panel.

4. Lift up the handlebar locking lever and

swivel the handlebar toward the engine

starter rope to test hardware tightness at

the base of the handlebar. If the handlebar

seems secure and swivels smoothly, the

hardware is tightened properly. Tighten

the front bolt (D, Fig. 2-3) more if the

handlebar doesn’t seem secure enough.

Loosen the front bolt (D) a little if the

handlebar is hard to swivel. IMPORTANT:

This bolt must be tightened properly for

the handlebar to swivel properly. The

other long bolt next to it should not be

tightened now, but may at some time in

the future require tightening which is

explained in the Maintenance Section.

WARNING

DO NOT START THE ENGINE

UNTIL ENGINE CRANKCASE HAS

BEEN FILLED WITH OIL.

FAILURE TO FOLLOW THIS

INSTRUCTION WILL RESULT

IN SERIOUS ENGINE DAMAGE.

STEP 4: Add Motor Oil to Engine

1. Refer to the separate Engine Owner’s

Manual for the recommended type and

viscosity motor oil to use.

2. With the tiller on level ground,

unscrew and remove the oil fill dipstick

(L, Fig. 2-5). Using a funnel, pour fresh

motor oil into the dipstick opening. Add

oil gradually and check the level with the

dipstick several times to be sure not to

overfill the engine. Add oil until the level

is up to the “FULL” mark on the dipstick.

3. The oil level on the dipstick should

always be between the “ADD” and “FULL”

marks. Wait a few minutes after filling the

crankcase for the oil to settle. Re-check

the oil level and adjust as needed.

4. Wipe up any oil spillage and replace

the oil fill dipstick securely.

STEP 5: Check and Adjust

Tire Air Pressure

Use an automotive-type tire pressure

gauge to check the air pressure in both

pneumatic tires. Inflate both tires evenly

between 15-to-20 PSI.

STEP 6: Check External

Hardware for Tightness

Inspect the screws, bolts and nuts on the

tiller and make sure they are securely

tightened.

How To Move the

Machine in “Freewheel”

IMPORTANT: To “freewheel” (wheels

turn freely due to disengagement from

transmission gears) the machine off the

pallet to another location, unlock the

handlebar locking lever (see Pg. 9),

then swivel the lower section of the

handlebar (stand on the engine muffler

cage side only) 1800to position it over

the engine. Relock the lever. Using the

lower handlebar section for leverage,

roll the equipment to the desired

location. Swivel the handlebar back to

its original position over the tine hood to

return to the rear tine tiller mode. Do

not pick up the machine by the fenders

to avoid damage to the fenders.

8

Section 2: Assembly

Fig. 2-4

Fig. 2-5

F

G

H

I

J

K

L

Lower

Handlebar

Section

Upper

Handlebar

Section

Page 9

Section

3

Features and Controls

This section describes the various

features and controls on the unit. Refer

to the next section, “Operation,” for an

explanation of the use of these controls.

TILLER FEATURES/CONTROLS

Drive Bail

Holding the Drive Bail (A, Fig. 3-1)

closed against the handlebar engages the

tines and wheels (when handlebar is in

the rear tine tiller mode) or engages

power to just the tines (when handlebar is

turned to front tine tiller/cultivator mode).

Swivel Handlebar

The handlebar (B, Fig. 3-1) swivels 180

o

to convert the equipment into either a rear

tine tiller or a front tine tiller/cultivator.

The handlebar also offers infinite height

adjustments for operator comfort.

IMPORTANT: Only swivel the handlebar

180o on the muffler cage side of the equipment, or damage to the unit can occur!

Handlebar Locking Lever

Lift up the lever (C, Fig. 3-1) to unlock

the handlebar. This allows the handlebar

height to be raised or lowered, and the

handlebar to be swiveled 180o. See Inset

Figures above for rear tine tiller and front

tine tiller/cultivator modes.

Hood Release Pin

This pin (D, Fig. 3-1) locks the hood to

the tiller chassis. When the pin is taken out

the hood can be removed and then the

handlebar swiveled around and positioned

over the engine for cultivating. NOTE: The

hood must always be in place and locked

with the hood release pin when the

machine is used for rear tine tilling or else

the engine will not run.

Tines

Four tine sets (E, Fig. 3-1) (each set has

four tines) rotate at high speed and

do the tilling and cultivating in the soil.

When you are rear tine tilling and standing in the operator’s position behind the

hood, the tines rotate counterclockwise

(CRT) in a direction opposite from forward

travel. When you are front tine tilling or

cultivating (hood is removed; handlebar is

swung 180oover the engine), the tines

rotate clockwise in the direction of

forward travel.

IMPORTANT: In rear tine tiller mode,

both the tines and wheels are powered.

In front tine tiller/cultivator mode, only

the tines are powered.

Operational Interlock System

Located at the base of the handlebar (F,

Fig. 3-1). This safety switch shuts the

engine off or prevents it from starting if

the operator attempts rear tine tilling with

the tine hood off, or attempts front tine

tilling/cultivating with the handlebar in

any position other than pointing back

over the engine.

IMPORTANT: Do not attempt to operate

machine in front tine tiller/cultivator

mode with the tine hood installed as

damage to the tine hood could occur.

Fig. 3-1

A

B

C

D

E

F

Rear Tine

Tiller Mode

(tine hood

must be on)

Swivel

Handlebar

on this side

ONLY

Front Tine

Tiller/

Cultivator Mode

(tine hood must

be removed)

1

2

3

9

MUFFLER

CAGE

Page 10

10

Section 3: Features and Controls

ENGINE FEATURES/CONTROLS

The following are descriptions of the

features and controls on your engine.

Additional engine information is

provided in Section 4 “Operation” in this

manual and in the engine manufacturer’s

Operator’s Manual which is included in

your literature package. Be sure to read

the Engine Operator’s Manual carefully

and save it for future reference.

Engine Throttle Lever

The throttle lever (G, Fig. 3-2) is used to

adjust engine speed as well as start and

stop the engine.

Move the throttle lever all the way up

from the STOP position to the START/RUN

position before pulling out the recoil

starter. There is an IDLE position between

the STOP and START/RUN positions.

Move the throttle lever down to the STOP

position to turn the engine off.

Fuel Primer Bulb

This bulb (H, Fig. 3-2) pumps a small

amount of gasoline into the carburetor to

aid in starting the engine. Refer to the

following section, “Operation,” for

specific primer bulb operating

information under various starting

conditions.

Recoil Starter

The recoil starter (I, Fig. 3-2) is used to

manually start the engine.

Oil Fill Tube and Dipstick

Turn and lift up to remove the oil

dipstick (J, Fig. 3-2) from the top of the

engine. Always keep the oil level between

the “ADD” and “FULL” marks at the end of

the dipstick. Refer to your Engine

Operator’s Manual for specific motor oil

recommendations.

Fuel Tank

The fuel tank and cap are on top of the

engine (K, Fig. 3-2).

Spark Plug

The spark plug wire (L, Fig. 3-2) must

be securely attached to the spark plug in

order for the engine to start and run

properly. Always disconnect the spark

plug wire and move it away from the plug

before performing any repairs or

maintenance.

Air Cleaner

Your engine has a dual element air

cleaner system for maximum filtration

efficiency (see M, Fig. 3-2). Never run

the engine without the complete air

cleaner installed. Service the air filter

system regularly as specified in your

Engine Operator’s Manual.

Muffler

The engine muffler (N, Fig. 3-2) has a

steel cage surrounding it to keep objects

away from its hot surface. Do not touch

the engine muffler while the engine is

running or cooling down.

Fig. 3-2: Engine features and controls.

J

K

M

N

WARNING

Before operating your machine,

be sure you read and understand

all safety, controls, and operating instructions in this Owner’s

Manual and on the decals on

your machine.

Failure to follow these instructions can result in serious injury

or property damage.

L

I

H

G

Page 11

This section explains how to:

• Transport the Machine

• Prepare for Starting and

Break-In Operation

• Check Operational Interlock System

• Convert the Equipment From a

Rear Tine Tiller to a Front Tine

Tiller/Cultivator...Then Back to a

Rear Tine Tiller

• Start and Stop the Engine

• Operate the Rear Tine Tiller

• Clear Debris from the Tines

• Operate the Front Tine

Tiller/Cultivator

• Cultivate in Flower Beds and

in Confined Shrub Areas

• Optional Attachments

• Load and Unload the Tiller

Before operating your unit, be sure you

have read and understand all Safety

Instructions in Section 1 and Controls

information in Section 3. First practice

using the unit (as a tiller and a cultivator)

in an open, level area. After a thorough

practice session, you can then “freewheel”

the unit to the work area.

How To Transport the

Machine in “Freewheel”

To “freewheel” the machine to another

location, unlock the handlebar locking

lever (see Pg. 9), then swivel the

handlebar (do this on the engine muffler

side only) 1800to position it over the

engine. Relock the lever. Roll the

equipment to the desired location.

Swivel the handlebar back to its original

position over the tine hood to return to

the rear tine tiller mode.

IMPORTANT: Always swivel

handlebar around on muffler

cage side of engine. To avoid

damage to engine recoil cover

and control cable, never swivel

handlebar on fuel tank side of

engine!

Fig. 4-1A

Fig. 4-1B

Fig. 4-2A

Fig. 4-2B

WARNING

Before operating your machine,

be sure you read and understand

all safety, controls, and operating instructions in this Owner’s

Manual and on the decals on

your machine.

Failure to comply can result in

injury or property damage.

Section

4

Operation

WARNING

• To avoid injury, keep hands,

feet, legs and clothing away

from revolving tines.

• Do not operate tiller in

rear tine tilling mode without tine hood in place, or in

front tine tilling/cultivating

mode with tine hood on.

11

MAXIMUM RECOMMENDED HANDLEBAR OFFSET IS 200LEFT OR 200RIGHT IN

EITHER REAR TINE TILLER MODE OR FRONT TINE TILLER/CULTIVATOR MODE.

Rear

Tine

Tiller

Mode

Front Tine

Tiller/

Cultivator

Mode

(Swinging handlebar 200in either

direction equals about 1/2 the

handlebar width)

(Swinging handlebar 200in

either direction equals about

1/2 the handlebar width)

Page 12

12

Section 4: Operation

Preparation For Starting

Make the following checks and

adjustments before starting the engine.

1. Check Engine Oil Level.

2. Check the Air Cleaner. It must be

securely assembled and clean.

3. Check Safety Guards. All guards and

covers must be securely in place.

4. Attach Spark Plug Wire.

5. Check Engine Cooling System. Cool-

ing fins and air intake must be clean.

6. Adjust Handlebar Height.

7. Test Operational Interlock System.

Perform this test in both front tine cultivator mode and in rear tine tiller mode.

Refer to Pg. 13 for full instructions.

8. Select Rear Tine Tiller Mode or

Front Tine Tiller/Cultivator Mode. If you

select rear tine tiller mode, check to see

that the wheels do not

“Freewheel.” Roll

the tiller forward several inches to verify

that the wheels are fully engaged.

If you

select front tine tiller/cultivator mode,

check to see that the wheels do

“Freewheel.” See Pg. 14 for instructions.

8. Add Gasoline to Fuel Tank. Use

fresh, clean unleaded automotive gasoline.

Either regular or premium grades are

acceptable. DO NOT MIX OIL WITH GASOLINE. See the separate Engine Operator’s

Manual for all fuel recommendations.

NOTE: Do not use fuel containing

methanol (wood alcohol). Fuel containing

up to 10% ethanol or “Gasohol” may be

used but requires special care when the

engine is not used for extended periods.

Use clean fuel and store in an approved,

covered container. Use a clean fill funnel.

Never use “stale” gasoline left over from

last season or if stored for long periods.

To Add Gasoline:

1. Clean the fuel cap area before removing

the fuel cap.

2. Using a clean funnel, fill tank to within

1/2" of the top to prevent spills and to

allow for fuel expansion. Replace the fuel

cap securely before starting the engine.

WARNING

Gasoline is highly flammable and its vapors are explosive. Follow these

safety practices to help prevent injury from fire or explosion:

• Never fill tank if engine is running or hot from use. Let engine and

muffler cool down before refueling.

• Do not permit open flames, sparks, matches or any smoking materials in

the refueling area.

• Fill fuel tank outdoors in a well-ventilated area. Wipe away any fuel

spills and move tiller away from fumes before starting the engine.

• Use only an approved fuel container and lock it safely away from children.

• Store fuel and the equipment in a well-ventilated area. Do not store fuel

or the tiller where fuel vapors may reach an open flame or spark, or an

ignition source (a hot water heater, furnace, clothes dryer, electric motor,

or the like).

• Let engine cool down before storing equipment.

Fig. 4-3

Break-In Operation

During the first few hours of new

operation, the following maintenance

steps are required. For detailed informa-

tion on these procedures, refer to Section

5— “Maintenance.”

1. Change Engine Oil. Change oil after

the first two (2) hours of new operation.

Thereafter, every fifty (50) operating hours.

2. Check Drive Belt Tension. Due to the

new belt “seating in,” a tension adjustment

may be needed after the first 2-to-3 hours

of new operation.

IMPORT ANT: TO AVOID DAMAGE

TO THE ENGINE RECOIL COVER,

CONTROL CABLE AND THE

INTERLOCK SYSTEM, NEVER

SWIVEL HANDLEBAR ON FUEL

TANK SIDE OF ENGINE.

Page 13

Section 4: Operation

13

DANGER

The Operational Interlock

System is designed for the

operator’s safety. Do not

disconnect or attempt to defeat

the purpose of the system. If

the system malfunctions,

immediately contact your local

authorized dealer or the TROYBILT Technical Service

Department for assistance. Do

not use the equipment unless the

Operational Interlock System is

functioning properly.

Fig. 4-4A: Handlebar positioned over the engine. Hood is off. Start

the engine. Swing the handlebar from over the engine halfway around

toward the tines. The engine should stop.

Fig. 4-4B: The handlebar is positioned over the tines; the tine hood is

installed. Start the engine. Remove the tine hood– the engine should

stop and fail to restart. Replace tine hood– the engine should start.

Check the Operational Interlock System by

performing the test below in

Front Tine Tiller/Cultivator Mode :

Check the Operational Interlock System by

performing the test below In

Rear Tine Tiller Mode :

The Operational Interlock System

The Operational Interlock System is a

micro-switch designed to shut the engine

off immediately (or prevent it from

starting) if an attempt is made to use the

equipment in either of two unsafe conditions.

The system is active all the time and will

shut the engine off or prevent it from

starting if: A) you attempt to operate the

equipment in the rear tine tiller mode with

the hood removed, or B) if the equipment

is in the front tine tiller/cultivator mode

(hood is removed) and an attempt is made

to swivel the handlebar more than halfway

around from the cultivating position at the

front of the engine. If either of these

situations occurs, the engine will shut off

if running, or the engine will not start.

Rear Tine Tiller Mode – In this mode, the

handlebar is positioned directly over the

tine hood (or within 200of this position)

and the operator stands alongside or behind the hood. The hood must be properly installed and securely locked. If the

tine hood were to be removed, the

engine would stop immediately or, if it

had not been running, it would not start.

Front Tine Tiller/Cultivator Mode – In this

mode, the handlebar is swiveled around

so it is over the engine (or is within 20

0

of this position) and the tine hood is

removed. If the handlebar were

swiveled more than halfway around in the

direction of the tines, the engine would

stop or, if it had not been running, it

would not start.

TOP VIEW

TOP VIEW

1) When the equipment is in “Front Tine Tiller /

Cultivator Mode,” the handlebar is positioned over the

engine and the tine hood is removed. See Pg. 14 for

detailed instructions.

2) Start the engine.

3) Swivel handlebar halfway around toward the tines

(one muffler cage side of engine). See Fig. 4-4A.

4) The engine should shut off and should not be able

to be restarted with the handlebar in this position.

This means the Interlock System is operating properly.

5) Swivel handlebar around over the engine again.

Now the engine should be able to be started.

1) When in “Rear Tine Tiller Mode,” the handlebar is

positioned over the tine hood. The hood must be

properly and securely installed. Engine must be off.

2) Start the engine.

3) Be very careful not to engage the Drive Bail when

performing this step. Remove the tine hood (see Fig 44B). The engine should stop. If it does, the Interlock

System is operating properly. Do not use the tiller if

the engine continues to run– a repair is needed.

4) Replace the tine hood securely. The engine will

now be able to be started again.

Engine

Muffler

Cage

Page 14

Section 4: Operation

To Change from rear tine tiller mode

to front tine tiller/cultivator mode:

1. Move the equipment to a level, firm

surface.

2. Stop the engine and disconnect the

spark plug wire.

3. Lift up the handlebar locking lever (A,

Fig. 4-5) to unlock the handlebar.

4. Grasp the handlebar and walk it

around the muffler cage side of the

engine a full 180ountil the handlebar is

positioned over the top of the engine.

Refer to Fig. 4-6.

5. Push the handlebar locking lever

down.

6. Remove the hair pin clip (B, Fig. 4-7)

from the hood release pin (C, Fig. 4-7).

Slide the hood release pin out of the hood

bracket (D, Fig. 4-7).

7. Lift up the hood flap and tilt the tine

hood backward so the bracket at the rear

of the hood disengages from the

transmission. Lift the hood assembly off

and put it aside. Refer to Fig. 4-7. Keep

the hair pin clip and hood release pin

installed on the hood at all times to

prevent their loss. Reconnect the spark

plug wire securely.

8. The equipment is now ready for front

tine tilling and cultivating! See Fig. 4-8.

T o Change from front tine tiller/

cultivator mode to rear tine tiller mode:

1. Stop the engine and disconnect the

spark plug wire. The equipment must be

on a level, firm surface.

2. Replace the hood by first engaging the

rear hood bracket on the pin at the endof

the transmission (see Fig. 4-7). Connect

the front of the hood to the handlebar base

by aligning the two brackets (offset the

hood brackets to the left of the base

brackets), then insert the hood release pin

and hair pin clip (see Fig. 4-7).

3. Lift up the handlebar locking lever (A,

Fig. 4-5) to unlock the handlebar.

4. Swivel the handlebar around on the

engine muffler cage side of the equipment 180o to position it over the tine

hood. Push the locking lever down. This

is the rear tine tiller mode. See Fig. 4-9.

5. Reconnect the spark plug wire.

Use this procedure to convert your equipment from rear tine tiller mode...

to front tine tiller/cultivator mode..then back to a rear tine tiller again.

WARNING

To avoid serious personal

injury or property damage,

stop the engine, let all

moving parts stop

completely, disconnect the

spark plug wire, move the

wire away from the spark

plug, and let the engine and

muffler cool down before

changing from one tiller

mode to another or performing any adjustments or service on your equipment.

Fig. 4-5

Fig. 4-6

A

14

Fig. 4-7

B

C

D

Fig. 4-8

Fig. 4-9

Page 15

To Start and Stop the Engine

IMPORTANT: Use the following steps to

practice starting and stopping the

engine ONLY. Do not attempt to use the

equipment as a tiller or cultivator until

you have read all operating instructions

in this Owner’s Manual.

To Start the Engine:

1. The spark plug wire must be connected

to the spark plug and the fuel tank must

have fresh, unleaded gasoline.

2. Let go of all controls.

3. Move engine throttle lever (E, Fig. 4-10)

all the way up to RUN/START position.

4. Push fuel primer bulb (F, Fig. 4-10) two

or three times. Allow two seconds or so

between pushes. In cold weather (below

50oF) push primer five times. NOTE:

Primer use may be needed to restart a

warm engine after a short shutdown.

5. Grasp starter handle (G, Fig. 4-10) and

pull rope out slowly until it pulls slightly

harder. Let rope rewind slowly. Then pull

rope with a rapid full arm stroke. Let rope

return slowly. NOTE: If engine fails to

start after three (3) pulls, push fuel primer

two times and pull starter rope again.

To Stop the Engine:

1. Move the engine throttle lever (E, Fig. 4-

10) down to the STOP position.

2. Let all moving parts come to a

complete stop, then disconnect the spark

plug wire and move the wire away from the

spark plug to prevent the possibility of

accidental starting.

Fig. 4-10

E

F

G

Section 4: Operation

How to Operate Your Machine

as a Rear Tine Tiller

You will find that general tilling, and

sodbusting in particular, are real delights

with the VersaTiller. This is largely due to

the machine’s counter-rotating tines

which handle tough ground-breaking jobs

easily. Be sure the equipment is in rear

tine tiller mode (see Fig. 4-11).

When breaking new sod (especially

when it is wet or very hard), the wheels

could lose traction and cause the tines to

unexpectedly propel the tiller backward.

This condition is most likely to occur during initial tine engagement with the sod,

such as when starting a new tilling pass.

If this condition occurs, simply release

the drive bail to quickly stop the tines and

wheels. Do not exert any downward

pressure on the handlebar or attempt to

restrain the tiller.

To minimize the possibility of the tiller

moving unexpectedly backwards, always

avoid pushing down on the handlebar

when in the rear tine tilling mode. If

necessary, apply upward pressure to

increase wheel traction and to prevent

the tines from digging too deeply. This

is a very important technique! See Fig.

4-11. Also, check that the tine hood flap

is back in the trailing position and not

pointing straight down or toward the tines.

1. Start the engine and let it warm up.

2. Stand behind and on the left-side of

the handlebar and close the Drive Bail by

moving the bail up against the handlebar.

The tines and wheels will rotate. You may

walk on the left side of the machine and

slightly behind the handlebar, guiding the

tiller as it moves along, keeping its path

straight. Using one

hand on the handlebar

prevents footprints in

the freshly tilled soil

3. As you approach

the end of the first

row, raise the

handlebar to lift the

tines out of the soil.

As you swing the

handlebar to make

your turn for the next

row, let the powered

wheels assist you in

making the turn.

4. Lower the handlebar to let the tines

contact the soil again and complete the

next row. Continue tilling back and forth.

5. Till the complete garden area once

again, but at a right-angle to the original

direction.

6. To stop the tiller, let go of the Drive

Bail. To stop the engine, move the engine

throttle lever all the way down to STOP.

IMPORTANT: The wheels will not “freewheel” when the equipment is in rear

tine tiller mode (they only “freewheel”

when in front tine cultivator mode).

Fig. 4-11

WARNING

Engine throttle lever speed

should not be adjusted while

the tines are engaged either

for tilling or cultivating.

Failure to comply could

result in severe personal

injury or property damage.

15

Page 16

16

Section 4: Operation

Clearing Debris from the Tines

Long grass, string, or tough vines may

become tangled in the tines. It’s not

necessary to remove all of the tangled

material for best tilling results, but the

bulk of the material should be removed

for effective tilling. The tine hood may be

removed for the most complete tine

cleaning.

To avoid tangled materials:

• Till under crop residues or cover crops

while they are still green.

• Using the handlebar, swing the tiller

from side-to-side (6" to 12" each way)

occasionally– this can clear up tangles.

• If tangled material begins to build up,

stop the engine, let all moving parts

stop completely, disconnect the spark

plug wire, move the wire away from the

plug, then use a pocket knife or

linoleum knife to cut the material away.

WARNING

To help avoid personal injury,

shut off the engine, let all

moving parts stop completely,

disconnect the spark plug wire

and move the wire away from

the plug before attempting to

clean the tiller tines.

How to Operate Your Machine as

a Front Tine Tiller/Cultivator

The VersaTiller is not only a very

capable, high-performance rear tine tiller,

but a wonderful front tine tiller/cultivator

as well. Its cultivating capabilities will help

your garden, flower beds, and shrubbery

areas flourish the entire growing season.

If you plan carefully before planting,

you can leave enough room between plant

rows for later cultivating. That will

eliminate most hand-weeding or hoeing

chores during the growing season. Allow

for the overall wheel width (16") between

rows plus some additional room for plant

growth (particularly for bushy crops like

beans, tomatoes, peas, etc.) See Fig. 4-12.

Tine Width (all four tine gangs): 12"

Tine Width (inner tine gangs only): 71⁄4"

Wheel-to-Wheel Width: 16"

1. Be sure the equipment is in front tine

tiller/cultivator mode (see Fig.4-8 and 4-

12). The handlebar must be positioned

over the engine and the tine hood

removed. (See Page 14 for instructions.)

2. Start the engine and let it warm up.

Adjust the throttle lever to a medium

engine speed.

3. Stand behind the handlebar and at the

front of the engine (Fig. 4-12). Close the

DRIVE BAIL against the handlebar and the

tines will revolve.

IMPORTANT: When in front tine tiller/

cultivator mode, only the tines are

powered when the Drive Bail is closed–

NOT THE WHEELS. In this mode, the

wheels are always in “freewheel” and the

equipment can be easily moved.

4. The rotating tines will pull the machine

along as it tills or cultivates. You can

push down on the handlebar to raise the

tines if they stay in one location too long.

5. To stop the tines, let go of the drive bail.

To stop the engine, move the engine

throttle lever all the way down to STOP.

Cultivating Tips:

• Shallow cultivating is most effective.

Don’t let the tines dig in too deeply as

you proceed through a row. To prevent

this from happening, push down on the

handlebar to raise the tines up. Also use

the handlebar as a depth control so the

tines do not till up vegetable plant roots

which are deeper than weed roots.

• Sweep the tines from side to side by

moving the handlebar. This action imitates hand-weeding and prevents the tines

from staying in one location too long.

• You may remove both outer tine gangs

if a narrower overall tine width will help

cultivate between individual plants.

Simply take off the hardware that secures

both outer tine gangs and slide the outer

gangs off the tine shaft.

Cultivating in Flower Beds and

in Confined Shrubbery Areas

The VersaTiller is designed to help you

cultivate easily in and around congested

flower beds and shrub areas. If

necessary, simply remove the two outer

tine gangs. The remaining inner tine

gangs measure just 71⁄

4" overall. You can

“poke” these tines into very compact

areas without damaging flowers, leaves

and stems.

Fig. 4-12: Cultivating in the garden.

Page 17

17

OPTIONAL A TTACHMENTS

The Edger Attachment

The Edger Attachment allows you to

make clean, sharp edges wherever grass

meets a walkway, driveway, terrace, patio,

or other such surface. It’s an extremely

handy landscaping and yard care tool that

attaches quickly to your equipment.

Simply set up in front tine tiller/cultivator

mode (the tine hood must be off, and

handlebar positioned over the engine),

remove the tines, and install the edger

blade and wheel on the tine shaft. Refer

to Fig. 4-13.

The Aerator Attachment

The aerator is an extremely effective way

to open up the “pores” in your lawn’s

sod, thereby allowing sprinkler water,

commercial nutrients, rain, and air to

enter the earth and nourish the lawn

roots. It is especially beneficial when

reseeding areas of grass, as lawn growth

occurs much more quickly after you use

the aerator tines.

This attachment is used when your

equipment is in the rear tine tiller mode—

the tine hood is securely mounted and the

handlebar extends back over the tine

hood. Simply remove the four tine gangs

from the tine shaft, and in their place

install the four aerator blades supplied

with their own mounting hardware. See

Fig. 4-14.

Section 4: Operation

Fig. 4-13: The edger

attachment leaves sharp,

clean edges between grassy

areas and walkways,

driveways, patio areas, etc.

Fig. 4-14: The aerator

attachment uses four aerator

tines (installed in place of the

regular tiller tines) to open

up airways in the soil for

better absorption of

moisture, air, and lawn

fertilizer applications.

Page 18

18

Section 4: Operation

Loading and Unloading the Tiller

• Shut off the tiller engine before loading

or unloading. Let the engine cool. Disconnect the spark plug wire and prevent the

wire from touching the spark plug.

• The tiller is too heavy (over 120 lbs.)

and bulky to be safely lifted by one

person. If you do lift the tiller, two or

more people should share the load. With

one person on one side of the equipment

and another person on the other side,

each should grip the machine at the front

shield (use the slot in the shield) and at

the tine hood.

• However, the preferred method that we

recommend is that you use sturdy ramps

and manually roll the tiller (in front-tine

cultivator mode so the wheels freewheel)

in or out of the vehicle with another

person’s assistance.

• Ramps should be strong enough to

easily support the tiller and those moving

it. The ramps should also have good

traction, side rails to direct the tiller, and a

locking device to secure them to the

vehicle bed.

• The operator and assistants should

wear sturdy footwear with good traction.

• Position the vehicle so the ramp angle

is as flat as possible. Turn off the vehicle

engine and apply its parking brake.

• When going up the ramps, stand behind

the handlebar and push the equipment

ahead of you.

• When going down ramps, walk backward down the ramps with the equipment

following you.

• Have wood blocks handy to chock the

wheels if necessary. Use the chocks, for

example, if repositioning the equipment

on the ramps is required. Also chock the

wheels when transporting the equipment

in the vehicle.

• Once in the vehicle, securely tie the

equipment for stability during travel.

WARNING

Loading and unloading a

tiller in or from a vehicle is

potentially hazardous and

we don’t recommend that

you do so unless absolutely

necessary, as this could

result in personal injury or

property damage. However,

if you must load or unload

the tiller, follow the directions below.

Page 19

Section

5

Maintenance

NOTE: All references to left, right,

front and rear of the machine are

determined by standing behind the

handlebar and facing the direction of

forward travel.

Subjects covered in this section

include:

• Tiller/Cultivator Maintenance

• Engine Maintenance

• Storing your Equipment

REQUIRED MAINTENANCE SCHEDULE

Before Every Every As

PROCEDURE Each 10 25 Noted

Use Hours Hours

Check engine oil level • And every 5

operating hours

Test Operational Interlock • See Section 4

Safety System

Check drive belt tension • After initial

2 hours

Check nuts and bolts • After initial

2 hours

Clean tiller tine shaft •

Lubricate tiller •

Change engine oil* Every 50 oper-

ating hours

***

Clean foam element air filter • More often in

Check paper element air filter • dusty, dirty areas

Check for oil leaks • After initial

2 hours

Check gear oil level in • **

the transmission

Check tines for wear •

Check air pressure in tires • Annually, at

start of season

Lubricate eccentric pivot bushings • And at end of

tilling season

* During engine break-in period, change engine oil after first 2 hours of operation.

** Check transmission gear oil level every 25 hours and at beginning of tilling season

if any leakage is observed.

*** More often under dirty or dusty conditions.

WARNING

Before inspecting, cleaning

or servicing the machine,

shut off engine, wait for all

moving parts to come to a

complete stop, disconnect

spark plug wire and move

wire away from spark plug.

Failure to follow these

instructions can result in

serious personal injury or

property damage.

19

Page 20

20

TILLER/CULTIVA TOR

MAINTENANCE

Tighten Bolts and Nuts

Check for loose or missing hardware

every ten (10) operating hours. Failure to

tighten or replace missing fasteners can

cause poor performance, equipment

damage or oil leakage. See your Parts

Catalog for fastener descriptions.

Most hardware on your equipment is

visible. Pay particular attention to the

hardware shown in Fig. 5-1 at right.

1. Check the mounting screws (A) securing the protective high-impact cover on

the engine.

2. Check hardware (B) securing Drive

Bail to the handlebar.

3. Check the two screws (C) securing the

bearing cap to the end of the transmission housing. Do not overtighten them or

the aluminum threads could be stripped.

4. Check the four screws (D) securing

the handlebar mounting plate to the two

chassis side rails.

5. Check the mounting hardware

securing the tine sets (E) to the tine shaft.

The locknuts do not need to be overtightened. Just tighten them securely.

6. Check that the interlock switch (F) is

securely connected to the interlock housing.

7. The cable jam nuts (G) on the left side

of the handlebar securing the Drive Bail

cable to the cable bracket must be tight.

8. Also, if the handlebar feels loose (the

handlebar locking lever must be DOWN)

when force is exerted on the handlebar

either up and down or from side to side,

check the tightness of the two screws (H

and I in the Inset Figure above) that

secure the handlebar and the handlebar

locking lever to the base. Over time, the

“seating” of parts can cause some looseness to occur. Tighten both nuts that

secure the screws approximately onesixth (1/6th) of a turn. Check to see if the

loose handlebar feeling has been

eliminated. Alternate between modest

tightening and checking for handlebar

looseness until the handlebars feel as

secure as when new.

Section 5: Maintenance

WARNING

Before inspecting, cleaning

or servicing the machine,

shut off engine, wait for all

moving parts to come to a

complete stop, disconnect

spark plug wire and move

wire away from spark plug.

Failure to follow these

instructions can result in

serious personal injury or

property damage.

Fig. 5-1: Hardware locations to check for tightness.

Tiller/Cultivator Lubrication

Proper lubrication of the tiller’s mechanical parts is an essential part of good

maintenance. Lubrication should be done

after every ten (10) hours of operation.

Use #30 weight motor oil wherever oil is

specified. Use a quality grease with a

metal lubricant where grease is

recommended (grease without a metal

lubricant is acceptable). The

transmission requires special gear oil

which is described on the next page.

IMPORTANT– Do not allow oil or

grease, or other lubricant to come into

contact with pulleys or drive belt. This

can cause the belt to slip on the pulleys.

1. After removing the wheels (one at a

time), lightly lubricate the wheel shaft on

the areas which the wheels ride. Use a

quality metal lubricant.

2. After removing the tine gangs from the

tine shaft, very lightly grease all exposed

areas of the tine shaft (both ends).

3. The base of the handlebar locking

lever has several rotating parts. Use a

spray lubricant such as WD-40 to keep

these parts lubricated.

A

B

C

D

E

F

G

H

I

Page 21

Section 5: Maintenance

21

T ransmission Gear Oil Maintenance

A. Check for Transmission Oil Leaks

After the first two (2) hours of brandnew operation, check the transmission for

oil leaks. Thereafter, check for leaks

every 25 operating hours. Specifically,

inspect the following areas for signs of

leaks or seepage:

1. There are oil seals on each side of the

transmission housing where the tine shaft

passes through the housing. Examine

those areas for seepage or for leaks on

the ground. An oil seal leak can lead to

internal damage, so the seal should be

replaced immediately.

2. There are oil seals on each side of the

transmission housing where the wheel

shaft passes through the housing. Leaks

from either of these seals also means seal

replacement should be done right away.

3. The end of the transmission housing

has a bolted on end cap. It should be

examined for leaks. Tighten the bolts if

they seem loose. If a gear oil leak continues, remove the end cap, clean its

surfaces, and apply a new coating of

rubberized silicone sealant behind the end

cap. Reinstall the end cap by tightening

the bolts securely, but do not overtighten

them.

B. Check Transmission Gear Oil Level

Every 25 hours of operation (and at the

beginning of the tilling season), check the

gear oil level in the transmission housing

(see Fig. 5-2).

1. Shut off the engine, let all moving

parts stop completely, disconnect the

spark plug wire and move the wire away

from the plug to prevent the possibility of

accidental starting.

2. Disconnect the tine hood from the

hood bracket and put the hood aside

(refer to Figs. 4-6 and 4-7). Tilt tine end

of tiller up to allow gear oil to move to

front cavity in the transmission. Then

lower tine end of tiller down.

3. Clean around the top cover (H, Fig. 5-

2) before removing the four cover screws

(I, Fig. 5-2). Loosen the cover by gently

tapping it sideways with a hammer (do

not pry it up with a screwdriver which

could damage the gasket underneath the

cover). The gear oil level should be 1-3/4"

below the topmost surface of the chassis

(this surface is machined) when level.

Add or remove gear oil as needed (use a

dipper or suction).

Small Top-0ffs: use SAE 140 or SAE

85W-140. Use API rating of GL-4 .

Full Replacement: SAE 140 or SAE 85W-

140 with an API rating of GL-4 only.

4. Replace the top cover securely with

the four screws (I) removed previously.

Tighten them firmly, but do not overtighten to avoid thread damage.

5. Replace the tine hood.

6. Reconnect the spark plug wire.

Drive Belt Maintenance

A. Checking Cable Tension

Applied to the Drive Belt

After the first two hours of operation,

the amount of tension that the bail lever

cable applies to the drive belt should be

checked and, if necessary, adjusted.

Thereafter, perform this check every

twenty-five (25) operating hours.

1. Move the machine to firm, level

ground. The equipment must be in the

front tine cultivator mode (the handlebar

is swung around over the engine and the

tine hood is removed).

2. Start the engine. Move the throttle

lever to between idle and full-speed.

Position yourself behind the handlebar.

3. Slowly pull the Drive Bail back toward

the handlebar and note when the tines

begin to rotate. The bail lever should

have traveled anywhere between one-third

(1/3) to one-half (1/2) the distance toward

the handlebar. Cable tension on the belt

must be increased if the bail traveled

more than one-half the distance. Reduce

cable tension if the tines “creep” with the

bail fully open or if they rotate when the

bail is less than one-third closed.

B. Adjusting Cable Tension

Applied to the Drive Belt

4. To increase cable tension, loosen the

upper nut (J, Fig. 5-3) securing the

threaded cable adjuster (K) to the handlebar mounting bracket. Turn the lower nut