Page 1

$4'

Owner/Operator

Manual

PTO HORSE

Tiller

• Safety

• Assembly

50

Models

12087 (7HP Standard)

12088 (7HP Electric)

12089 (8HP Standard)

12090 (8HP Electric)

12204 (10HP Electric)

• Features and Controls

• Operation

• Maintenance

GARDEN WAY INCORPORATED

Page 2

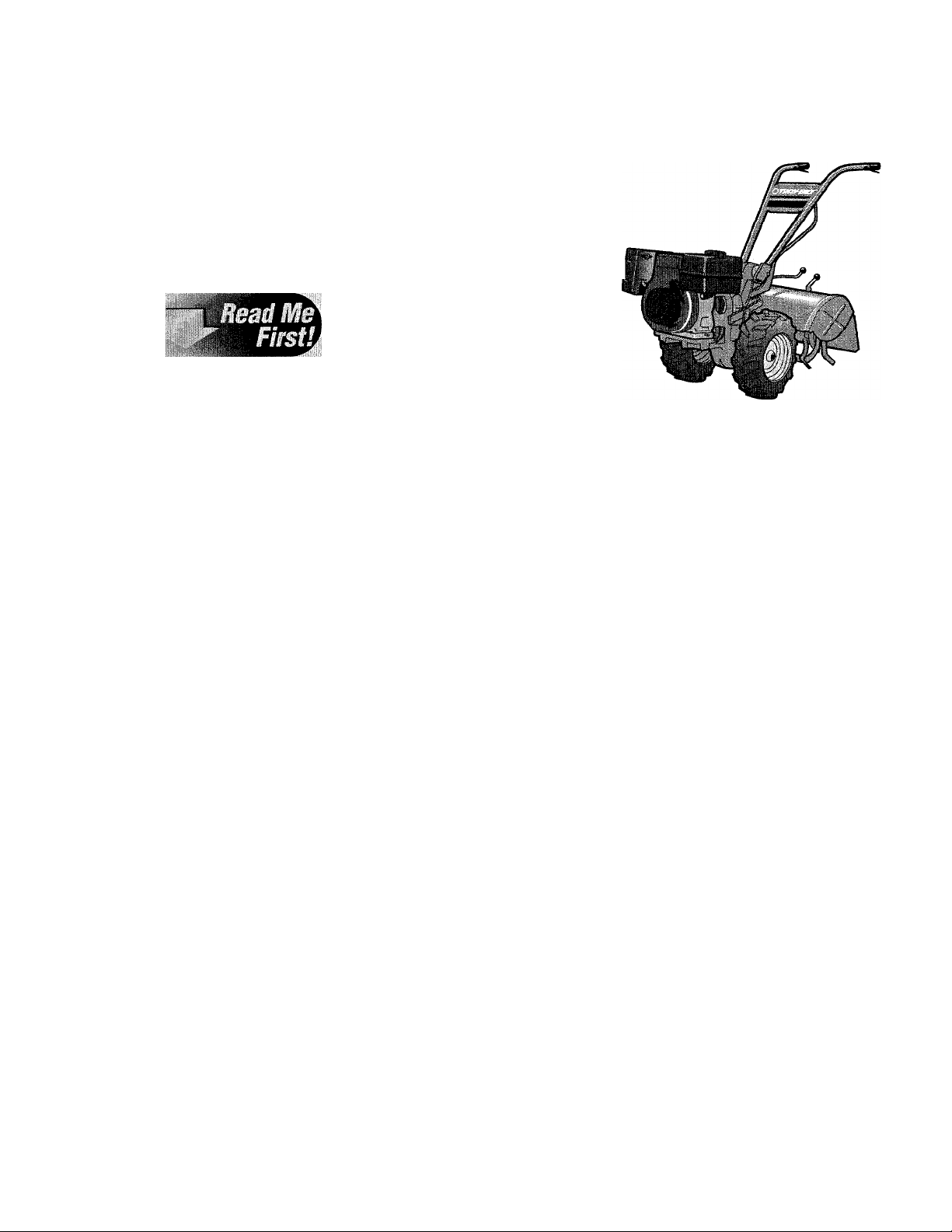

Dear Owner,

You now own one of the finest reartine rototillers available. Your new PTO

Horse Model tiller allows you to till and

cultivate your garden with ease, and ac

complish dozens of other property man

agement projects as well. Its PTO capa

bility allows it to power a variety of at

tachments, including a chipper/shredder

and a log splitter. Your tiller is famous

for its ruggedness, performance and

high-quality engineering. We know

you’ll enjoy using it.

Please carefully read this Manual. It

tells you how to safely and easily assem

ble, operate and maintain your machine.

Be sure that you and any other operators

carefully follow the recommended safety

practices at all times. Failure to do so

could result in personal injury or prop

erty damage.

Of course, if you should ever have any

problems or questions, please contact

your local authorized service dealer or

call us Toll-Free. Our telephone num

bers and mailing addresses are listed on

Page 4 and on the back cover of this

Manual.

We want to be sure that you are com

pletely satisfied at all times.

This is a safety alert

^

this symbol, read and obey the

safety message that follows it.

Failure to obey tfie safety message

could result in personal injury or

property damage.

symbol. It is used in

this Owner/Operator

Manual to alert you

to potential hazards.

Whenever you see

Be Sure To Return Your Owner Registration Card

Be sure to fill

out and return

your Owner

Registration

Card, which is

located in your

literature pack

age. The infor

mation con

tained on this card wiil register

your machine with us and entitle

you to full coverage under our

Warranty.

i'jI; ■ ...

This machine meets voluntary safety stan

dard B71.8 - 1996, which is sponsored by

the Outdoor Power Equipment Institute, Inc.,

and is published by the American National

Standards Institute.

WARNING:

The engine exhaust from

this product contains

chemicals known to the

State of California to

cause cancer, birth de

fects, or other reproduc

tive harm.

Page 3

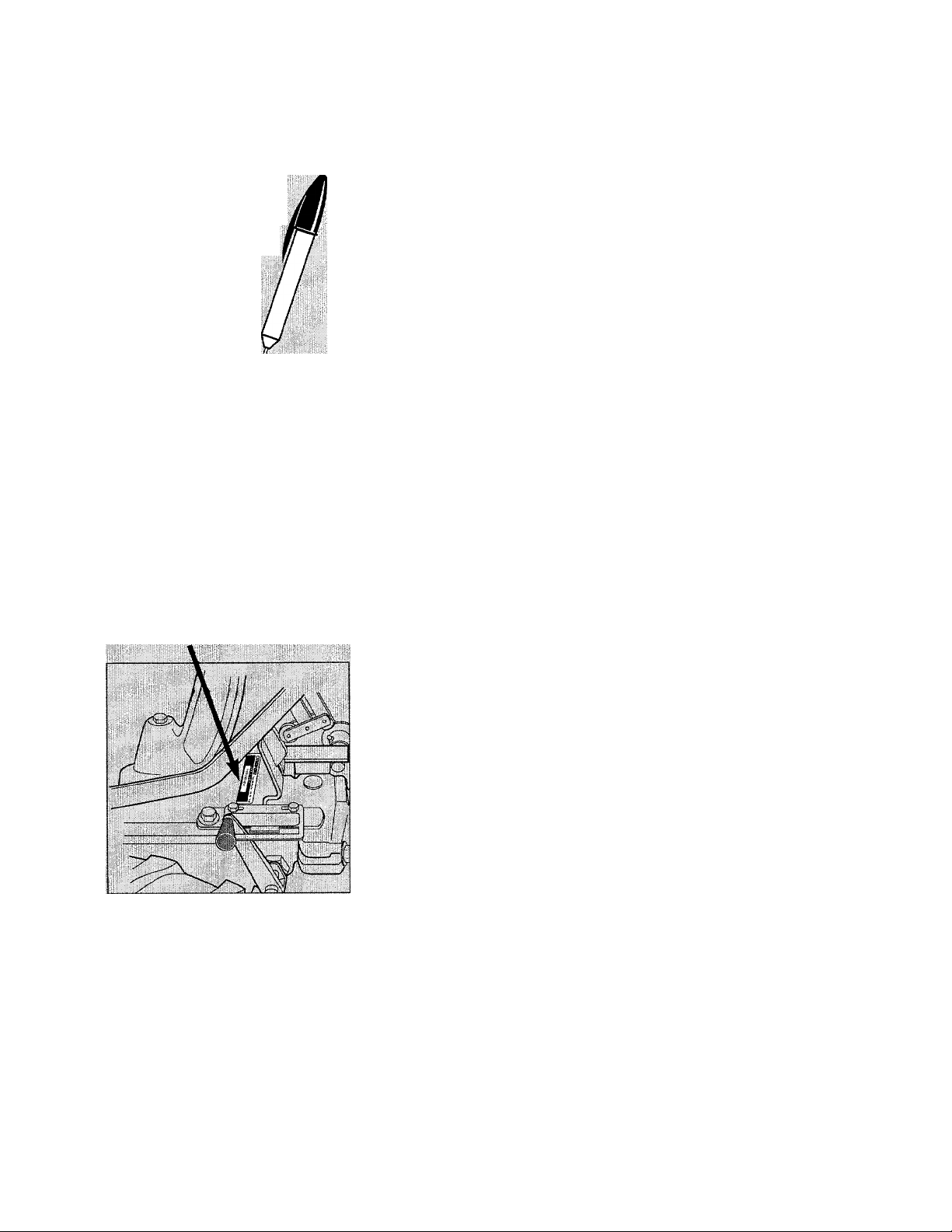

Owner’s Record

Please write the Model and Serial

numbers of your machine in

the spaces provided. You

can find the location of

these numbers by refer

ring to the illustration

below.

Model Number:

Serial Number;

Model and Serial Number location

SERVICE INFORMATION.................................................4

SECTION 1: SAFETY.....................................................5

Training..................................................................................................5

Preparation............................................................................................6

Operation...............................................................................................6

Maintenance and Storage......................................................................8

Decals....................................................................................................8

SECTION 2: ASSEMBLY...................................................9

SECTION 3: FEATURES AND CONTROLS

Tiller Features and Controls Identification

Engine Features and Controls Identification........................................23

SECTION 4: OPERATION

Break-In Operation

Test Forward Interlock Safety System

Starting and Stopping the Engine

Cold Weather Operation......................................................................28

To Operate Tiller..................................................................................29

Turning Around

Transporting Your Tiller.......................................................................31

To Change Belt Speeds.......................................................................32

Tilling in the Garden.............................................................................34

The PTO Power Unit............................................................................40

..............................................

..............................................................................

....................................................................................

SECTION 5: MAINTENANCE & REPAIRS

Required Maintenance Schedule.........................................................44

Tighten Bolts and Nuts.........................................................................45

Tiller Lubrication...................................................................................46

Transmission Gear Oil Maintenance....................................................46

Drive Belt Maintenance........................................................................49

Reverse Drive Maintenance

Bolo Tine Maintenance........................................................................54

Tine Shaft Maintenance.......................................................................56

Tire and Wheel Maintenance

Engine Oil Maintenance.......................................................................56

Air Cleaner, Throttle Cable, Ignition System, Spark Plug

Battery Care.........................................................................................58

Storing the Tiller...................................................................................60

Inspect Forward Interlock Wiring System

Troubleshooting Forward Interlock Safety System

................................................................

...............................................................

.............................

...........................................

.................................................

........................................................

.............................

....................

............................................

..............................

20

20

24

25

26

27

30

44

52

56

57

60

60

TROUBLESHOOTING PROCEDURES..................................61

ATTACHMENTS & ACCESSORIES..

TILLER SPECIFICATIONS....

...................................

..........................................

64

65

INDEX.................................................................. 66

Page 4

t

If you have any

HOWTO

REACH

US

GARDEN WAY

INCORPORATED

1 Garden Way

Troy. NY 12180

USA and

Canada:

Customer

Service:

1-800-437-8686

Technical

Service-

1-800-520-5520

Parts Service:

1-800-648-6776

FAX:

(518) 391-7332

Outside the

USA and

Canada:

Customer

Service:

(518) 391-7007

Technical

Service:

(518) 391-7008

Parts Service:

(518) 391-7006

FAX:

(518) 391-7332

Questions or

Problems...

...Please contact your local TROY-BILT® Tiller

authorized dealer or call or write the Factory. When calling

or writing, please be sure to provide the Model and Serial

Numbers of your machine (refer to Page 3).

If You Need Engine

Service:

If your engine should ever require

service or re

pair, contact

your nearest

authorized

engine service

dealer.

To find the name and address of

your nearest authorized engine

service dealer, look in the Yellow

Pages of the telephone book under

If You Need Parts:

Factory specified replacement

parts for your machine are avail

able from either your TROYBILT® Tiller authorized

dealer or directly from the

Factory.

To order a part from the

Factory, refer to your

separate Parts Catalog to

find the part number.

“Engines-Gasoline” (call us if you

need assistance in obtaining en

gine service or parts).

Please remember that your engine

is covered by the engine manufac

turer’s Limited Warranty. Any

unauthorized work performed on

the engine during the warranty pe

riod may void the warranty. For

full details on the engine manufac

turer’s Limited Warranty, refer to

the separate Engine Owner’s

Manual.

description, and quantity of the

part you need. Then, call or write

our Parts Department, being

sure to provide the Model

and Serial Numbers of your

machine.

Our trained parts special

ists will gladly assist you

if you have any difficulty

in identifying the part that

you need.

Page 5

Section

Please read and follow all of fhs

safety rules in this Safety Section

Failure to comply could result in

serious personal injury or prop

erty damage.

If you should lend this equipment

to another person, make sure that

he or she reads, understands, and

always follows these safety in

structions.

If you are not completely sure

about any of the information

found here or elsewhere in the

Manual, please contact either

your local authorised dealer or the

factory for assistance.

WARNING TO ALL CALIFORNIA

AND OTHER POWER EQUIPMENT OPERATORS

Under California law, and under the laws of several other states,

you are not permitted to operate an internal combustion engine

using hydrocarbon fuels on any forest-covered, brush-cov-

^ ered, or grass-covered land, or on land covered with grain,

^ \ hay, or other flammable agricultural crop, without an en

gine spark arrester in continuous effective working order.

The engine on your power equipment, like most outdoor power equipment, is an

internal combustion engine that burns gasoline, a hydrocarbon fuel. Therefore,

your power equipment must be equipped with a spark arrester muffler in continu

ous effective working order. The spark arrester must be attached to the engine

exhaust system in such a manner that flames or heat from the system will not ig

nite flammable material. Failure of the owner/operator of the equipment to com

ply with this regulation is a misdemeanor under California law, and may also be a

violation of other state and/or federal regulations, laws, ordinances, or codes.

Contact your local fire marshal or forest service for specific information about

what regulations apply in your area. Contact your authorized engine dealer for in

formation about obtaining a spark arrester.

TRAINING

4. Keep in mind that the operator

or user is responsible for accidents

or hazards occurring to other peo

ple, their property, and themselves.

A

This is a safety alert

symbol. It is used

in this Owner/ Oper

ator Manual and on

your equipment to

alert you to poten

tial hazards.

Whenever you see

this symbol, read

and obey the safety

message that fol

lows it. Failure to

obey those safety

messages could re

sult in serious per

sonal injury or cause

property damage.

1. Read this Owner/Operator

Manual and the separate Engine

Owner’s Manual carefully before

operating this equipment. Be com

pletely familiar with the controls

and the proper use of this equip

ment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children or un

trained adults to operate this equip

ment.

3. Keep the area of operation clear

of all persons, particularly small

children and pets. Keep by

standers at least 25 feet away from

5. Familiarize yourself with all of

the safety and operating decals on

this equipment and on any of its

attachments or accessories.

6. Do not mn engine in an en

closed area. Engine exhaust con

tains carbon monoxide gas, a

deadly poison that is odorless, col

orless, and tasteless.

7. Do not allow hands or any

other part of the body or clothing

near the rotating tines or near any

other moving part. The tines

begin to rotate

forward once

WARNING

the engine

starts, the

Tines/PTO

Clutch Lever is

&

i

in the ENGAGE

position, the Forward Interlock

Levers are squeezed closed and

the Wheels/Tines/PTO Drive Lever

Page 6

Safet^

is shifted to FORWARD. The tines

rotate in Reverse whether the In

terlock Levers are closed or open.

8. Before inspecting or servicing

any part of the equipment, shut off

PREPARATION

1. Thoroughly inspect the area

where the tiller will be used. Re

move foreign objects before tilling.

2. Put the Wheels/Tines/PTO

Drive Lever in NEUTRAL before

starting the engine.

3. Do not operate the tiller without

wearing suitable clothing. Avoid

loose garments or jewelry that

could get caught in moving parts

of the tiller or its engine.

4. Do not operate the tiller when

you are barefoot, in sandals, sneak

ers or other light footwear. Wear

the engine, wait for all moving

parts to come to a complete stop,

disconnect spark plug wire from

spark plug and move wire away

from the spark plug.

protective footwear that grips well

on slippery surfaces.

5. Do not till near underground

electric cables, telephone lines,

pipes, or hoses. Contact your tele

phone or utility to verify locations

of underground cables or lines.

6. Handle gasoline with care; it is

flammable, the vapors explosive.

Take the following precautions;

a. Use an approved gas container.

b. Gas cap shall never be re

moved or fuel added with en

gine running. Engine shall be

allowed to cool before refuel

ing. Operators shall not smoke.

c. Keep matches, cigarettes,

cigars, pipes, open flames, or

9. Do not operate this equipment

if you are under the influence of

alcohol, medication, or when you

are tired or ill.

sparks away from the fuel

tank and fuel container.

d. Fill fuel tank outdoors using

extreme caution. Never add

fuel indoors. Use a funnel or

spout to prevent spillage.

e. Replace all fuel tank and con

tainer caps securely.

f. If fuel is spilled, do not at

tempt to start engine, but move

the machine away from the

area of spillage and avoid cre

ating any source of ignition

until fuel vapors dissipate.

7. Never attempt to make any ad

justments while the engine is run

ning or the spark plug wire is con

nected, except when so instructed.

OPERATION

»

1. Do not put hands or feet near or

under rotating parts.

2. Use extreme caution when on or

crossing gravel driveways, walks or

roads. Be alert for hidden hazards

or traffic. Do not carry passengers.

3. If you hit a foreign object, stop

the engine (remove key on electric

start models), let all moving parts

come to a complete stop, discon

nect spark plug wire and move

wire away from the spark plug, and

inspect for damage. Repair dam

age before restarting.

iS

■

4. Exercise caution to avoid slip

ping or falling.

5. If abnormal tiller vibration oc

curs, stop engine immediately, dis

connect the spark plug wire and

move wire away from spark plug.

Check for the cause. Carefully in

spect for any damage. Fix the prob

lem before using the tiller again.

Vibration is generally a warning

sign of trouble.

6. Stop the engine, remove the key

on electric start models, and dis

connect the spark plug wire and

move wire away from spark plug

before leaving the operating posi

tion, unclogging tines, or making

repairs, adjustments or inspections.

7. Take all possible precautions

when leaving the machine unat

tended. Shift into neutral, stop en

gine (remove key on electric start

models), and disconnect spark plug

wire and move wire away from

plug to prevent accidental starting.

8. Before cleaning, repairing or in

specting, stop the engine (remove

key on electric start models), let all

moving parts stop,

and disconnect

spark plug

wire and

move wire

away from spark plug to prevent

accidental starting. For electrical

safety on electric start models, al

ways disconnect the negative (-)

cable from the battery post.

9. Flap on tine hood must be down

when running tiller, unless using

the hiller/furrower attachment.

10. Never operate the tiller unless

safety guards or other protective

safety devices are in place.

11. Do not run the engine in an

enclosed area. Engine exhaust

contains carbon monoxide gas, a

deadly poison that is odorless, col

orless, and tasteless.

12. Keep children and pets away.

Page 7

13. Never operate the tiller under

engine power if the Wheel Speed

Lever is in the FREEWHEEL posi

tion. In EREEWHEEL, the wheels

will not hold the tiller back and the

revolving tines could propel the

tiller rapidly, possibly causing loss

of control. Always engage the

Wheel Speed Lever in either EAST

or SLOW position before starting

the engine or engaging the tines

with the Wheel s/Tines/PTO Drive

Lever.

14. The tiller could unexpectedly

bounce upward or jump forward

and be propelled away from you if

the tines strike or catch very hardpacked soil, sod, frozen ground, or

any buried obstacle such as large

stones or roots. Let go of the han

dlebars and all controls. Do not try

to restrain it. If in doubt about till

ing conditions, use the following

precautions to assist you in main

taining tiller control:

a. Walk behind and on either

side of the tiller, using one

hand on the handlebars.

Relax your arm, but use a se

cure hand grip.

b. Use shallow depth regulator

settings, gradually working

deeper with each tilling pass.

c. Use slower wheel, tine and en

gine throttle speeds.

d. Clear the tilling area of big

stones, roots and other debris.

e. Avoid putting downward pres

sure on the handlebars. If

necessary, apply slight upward

pressure to prevent the tines

from digging too deeply.

f. Avoid contacting hard-packed

soil or sod at the end of a row

by reducing engine speed and

lifting handlebars up to raise

tines out of the soil.

g. In an emergency, stop the

tines and wheels by shifting

the Wheels/Tines/PTO Drive

Lever to NEUTRAL. If you

can not reach the lever or have

lost control of the tiller, let go

of the handlebars and all con

trols. Do not try to restrain it.

15. Do not overload the machine

capacity by trying to till too deeply

at too fast a rate.

16. Never use the tiller at high

ground speeds on hard or slippery

surfaces. Look behind and use care

when backing up.

17. Do not operate tiller on a slope

too steep for safety. On slopes,

slow down and be sure you have

good footing. Don’t let the tiller

“free-wheel” down slopes.

18. Clear the area of bystanders be

fore tilling.

19. Use only attachments and acces

sories approved by Garden Way Inc.

20. Use tiller attachments and ac

cessories when recommended.

21. Never operate the tiller without

good visibility or light.

22. Never operate the tiller if you

are fatigued, or under the influence

of alcohol, drugs or medication.

23. Operators shall not tamper with

the engine-governor settings on the

machine; the governor controls the

maximum safe operating speed and

protects the engine and all moving

parts from damage caused by over

speed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine parts that

may be hot from operation (muffler,

fins, etc.). Make certain all parts

have cooled down before inspect

ing, cleaning or repairing.

25. POISON/DANGER—

CAUSES SEVERE BURNS. The

battery on electric start models con

tains sulfuric acid. Avoid contact

with skin, eyes or clothing. Keep

out of reach of children.

Antidotes: External- Elush imme

diately with lots of water.

Internal- Drink large quantities of

water or milk. Eollow with milk of

magnesia, beaten eggs or vegetable

oil. Call a doctor immediately.

Eyes- Flush with water for 15 min

utes. Get prompt medical attention.

26. DANGER-BATTERIES

PRODUCE EXPLOSIVE

GASES. Keep sparks, flame or

smoking materials away. Ventilate

when charging battery or using in an

enclosed space. Always wear safety

goggles when working near battery.

27. Remember—To stop tines and

wheels, either put Wheels/

Tines/PTO Drive Lever in NEU

TRAL, or move Throttle Lever to

STOP position. If you lose control

of the tiller and can not reach the

levers, let go of the handlebars and

controls and do not try to restrain

the tiller. The Forward Interlock

Safety System will stop the engine.

28. Look behind and exercise cau

tion when backing up. For added

safety, put Wheel Speed Lever in

SLOW position before reversing.

29. When loading or unloading the

tiller, always disengage tines and

use slower wheel and engine throt

tle speeds. Use sturdy ramps wide

and strong enough to easily support

the tiller (280-to-325 lbs., depend

ing on model) and operator. Never

go down ramps in FORWARD

drive—the tiller could tip forward,

exposing you to the tines (which

should be disengaged). Always

use REVERSE drive and back down

ramps. To go up ramps, use FOR

WARD drive and follow the tiller.

30. The Forward Interlock Safety

System should be tested for correct

functioning every time the tiller or

pro power unit is used. See

Section 4 in this Manual.

31. If using the optional Dozer

Blade, either remove the tine attach

ment, or disengage the tines with

the Tines/PTO Clutch Lever.

Revolving tines are dangerous.

32. Use extreme caution when re

versing or pulling machine towards

you.

33. Start the engine carefully ac

cording to instructions and with feet

well away from the tines.

34. Never pick up or carry a ma

chine while the engine is running.

7

Page 8

MAINTENANCE AND

STORAGE

3. Check all nuts, bolts, and screws

frequently for proper tightness.

Always verify your equipment is in

safe working condition.

4. Never store the machine with

fuel in the fuel tank inside a build

ing where fumes may reach an

open flame or spark, or where igni

tion sources are present (such as

1. Never perform maintenance

when engine is running or spark

plug wire is connected except

when specifically directed to do so.

2. Keep tiller, attachments and ac

cessories in safe working condition.

hot water and space heaters, fur

naces, clothes dryers, etc.).

5. Let the engine cool down before

storing it in an enclosure.

6. To reduce fire hazard possibili

ties, keep the engine free of grass,

leaves or grease.

SAFETY DECALS

Make certain that all safety decals on this equipment

are kept clean and in good condition. The safety

decal locations are shown (at a reduced size) below.

There are other decals located on your equipment for

7. Store gasoline in a cool, wellventilated area, safely away from

any spark- or flame-producing

equipment. Store gasoline in an

approved container, safely out of

the reach of children.

8. Refer to the Maintenance sec

tion in this Manual for storage in

formation if your tiller is to be

stored for an extended period.

9. If the fuel tank has to be drained,

do so outdoors.

10. Follow manufacturer’s recom

mendations for safe loading, unload

ing, transport, and machine storage.

operation and controls identification. They are shown

in your Parts Catalog. If you need a replacement

decal, please refer to the Parts Catalog that accompa

nied this Manual.

A) WARNING: Hot Surfaces decal.

On Briggs & Stratton engines, located

on top of the air cleaner housing.

F) Engine Stabilization

decal. On Briggs & Stratton

engines, located on the fuel

tank.

Decal Locations

C) WARNING: Operating and

Safety Instructions decal.

B) WARNING: Engine Ignition. On elec

tric start models only.

E) Forward

Interlock Lever

decals (2).

D) Power Unit Operating

Instructions decal.

Page 9

Section

Please carefully follow the steps in

this Section to propeily assemble

your new machine. These steps

will not take vciy long and they

will assure you of having assem

bled your machine correctly.

WARNING

To prevent personal injury or

property damage, do not start the

engine until all assembly steps

are complete and you have read

and understand the safety and

operating instructions in this

Manual.

Tools Needed:

One 3./8 Open End or

Adjustable Wrench

One 9./16' Open End or

Adjustable Wrench

One 3/4' Open End or

Adjustable Wrench

Two 7/16 Open End or

Adjustable Wrenches

Two 1/2' Open End or

Adjustable Wrenches

One Flat Blade Screwdriver

Scissors ito trim plastic ties)

Quality Motor Oil (refer to the

Engine Owner Manual

provided with your unit

for motor oil specifica

tions and capacities).

Tire Pressure Gauge

A strong 4 /7 high prop (a

w'ood box. a brick, or

boards)

Subjects covered

in this Section:

• Inspection After Delivery

• Unpacking and Checking

Contents

• Attach the Handlebars

• Remove Tiller from Shipping Platform

• Connect Forward Interlock Wire Harness

• Attach Wheels/Tines/PTO Drive Lever

• Check Gear Oil Levels in Power Unit and Tine

Attachment Transmissions

• Add Motor Oil to Tiller Engine

• Attach Engine Throttle Lever to Handlebar

• Adjust the Air Pressure in the Tires

• Assembling the Electric Start System

Inspection After Delivery

Inspect your machine immediately

after it has been delivered. Make

sure that neither the carton nor the

contents have been damaged.

If you find or suspect any damage,

contact the carrier (trucking com

pany) right away. Inform them of

the specific damage and that you

wish to file a claim. To protect

your rights, be sure to put this in

writing to the carrier within 15

days after your machine arrives.

The carrier will let you know how

to proceed with your claim.

Please let us know if you need any

assistance with this matter.

IMPORTANT: Motor oil must

be added to the engine before it

is started. The procedure for

adding oil is explained later on

in these assembly instructions.

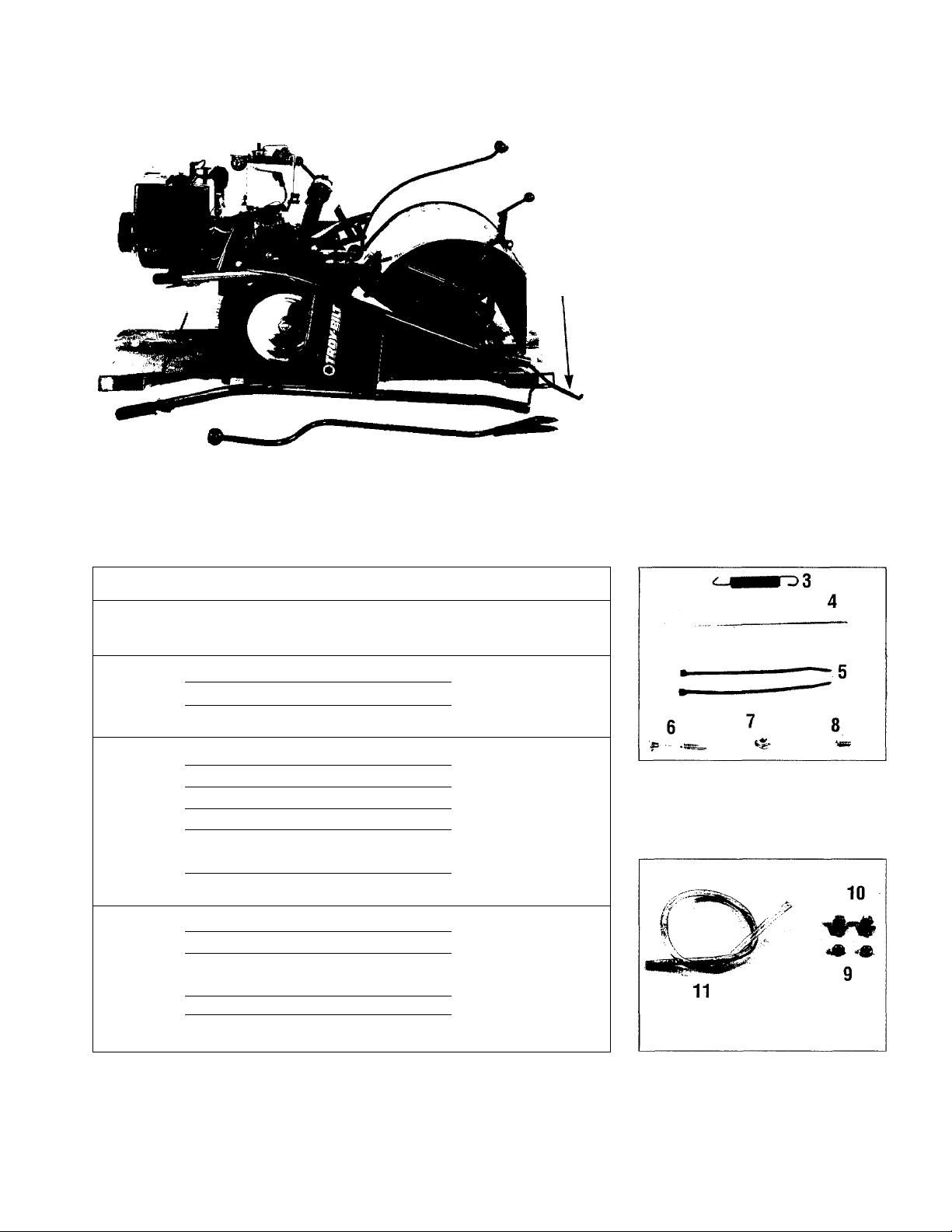

STEP1; Unpacking Contents

If you haven’t done so, unpack

and check the loose parts as listed

in the table on page 10. Contact

us if any parts are missing.

A. Remove the handlebars and the

Wheels/Tines/PTO Drive Lever

(Items 1 and 2 in Photo 2-1). You

may need to cut a plastic tie to free

the handlebars from its shipping

location. Set them on a clean sur

face. Do not get dirt on the wire

harness plug located at the bottom

of the handlebars!

B. Remove the loose parts from

the plastic envelope that contained

these instructions (Items 3 through

8 in Photo 2-2).

C. If you ordered an Electric Start

Tiller, take out the items from a

sealed plastic hardware package

under the battery clamp (Items 9

through 11 in Photo 2-3). Your ig

nition keys are in the keyswitch.

Page 10

.sseiii

wmmmiimmiiimmMmsmmmin

Wire

Harness

Plug

1-

2-

1- Handlebars

2- Wheels/Tines/

PTO Drive Lever

Photo 2-1. Put Handlebars (Item #1) and Wheels/Tines/PTO Lever (Item #2)

aside.

Table 1 - Carton Contents Parts List

KEY

QTY

DESCRIPTION FOR MODEL:

7HP 7HP 8HP 8HP

Elec. Std. Elec.

Std.

Photo 2-1:

1 1

2 1

Handlebars

..................................................

Wheels/Tines/PTO Drive Lever

...................

Photo 2-2:

3 1 Clutch Pa\A/l Spring.....................................

4

1 Belt Adjusting Tool.......................................

5

2

6 1

7 1

8 1

Plastic Cable Ties

Curved Head Bolt, 1/4“-20 x 2" (Grade 5)..

Flanged Lock Nut, 1/4"-20

Panhead Screw, #20 -24 x 1/2"

........................................

...........................

...................

•

•

• • •

•

• • •

• • • •

• • •

•

•

• • • •

• • •

•

•

•

o

o

•

•

Use This Ruler

to Check the

Hardware

Lengths

Photo 2-2. Parts inside the litera

ture envelope.

Photo 2-3:

9

2 Nuts, 1/4"-20, for battery terminals

10 2

11

Bolts, 1/4"-20 X 5/8“, for battery terminals

1 Battery Vent Tube........................................

2

Keys for Electric Start Models......................

(located in ignition keyswitch)

..............

•

•

• •

• •

10

•

•

Photo 2-3. Parts for Electric Start

Tiller models. (Ignition keys are

not shown.)

Page 11

STEP 2: Attach the Handlebars

Do not move tiller off shipping

platform unless handlebars are at

tached. This makes moving the

tiller easier and more controllable.

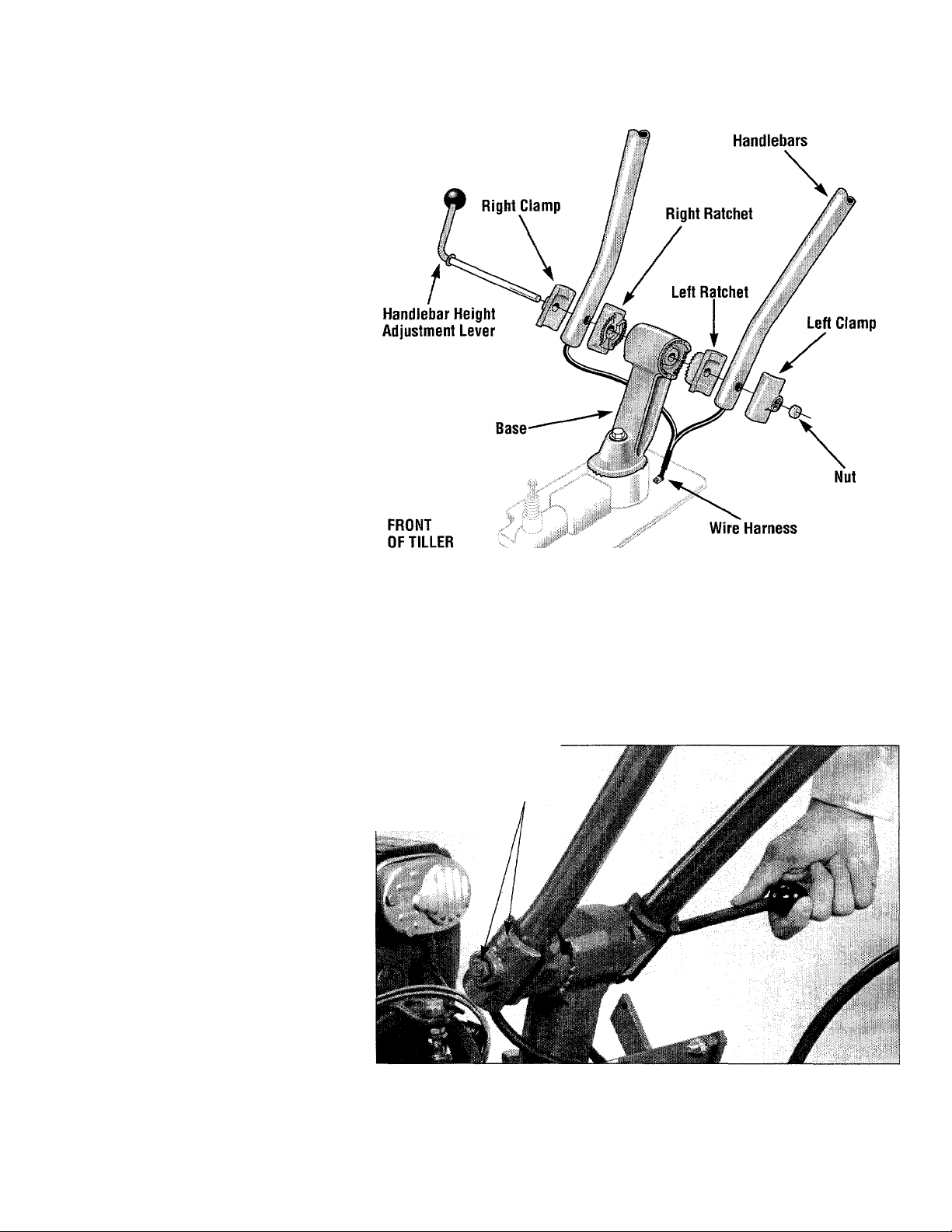

All the parts shown in Figure 2-4

(except the handlebars) are shipped

assembled. You must disassemble

these parts in order to attach the

handlebars.

A. Unwind the Handlebar Height

Adjustment Lever (Figure 2-4)

counterclockwise. Be prepared to

catch the nut, left clamp and left

ratchet as you remove the lever.

Completely withdraw the lever,

taking with it the right clamp and

right ratchet. Keep mating clamps

and ratchets grouped together.

Asseiiiblv

B. Place the handlebar ends on ei

ther side of the handlebar base and

the wire harness at the bottom of

the handlebars at the rear of the

base (Fig. 2-4).

C. Hold the right-side ratchet and

right-side clamp in position next to

right handlebar arm. Insert adjust

ment lever through the clamp, han

dlebar, ratchet and the base. Let

the adjustment lever protrude from

the other side of the base.

Note: The lever should pass freely

through the holes in the handlebar

ends. If it won’t- do not force it.

The wires to the Forward Interlock

Safety System may be blocking the

lever. Push a pencil through the

holes to gently move the wires

aside.

D. Position the left-side ratchet

and left-side clamp next to the left

handlebar arm (see Fig. 2-4). Move

the adjustment lever all the way

through these parts. Hold the nut

in place and screw the lever into it.

Don’t fully tighten the lever yet.

E. Raise the handlebars (jiggling

them on the ratchets helps) to one

of two pre-set height settings.

Then tighten the lever (Photo 2-5).

Figure 2-4. Unwind the Handlebar Height Adjustment Lever to separate the

handiebar assembly parts. Keep the mating ieft-side ratchet and damp

grouped together, and the right-side ratchet and damp grouped. Place the

handlebars so the ends are on either side of the handlebar base. Reas

semble ail parts securely.

Left Side

Clamp With

Nut

Photo 2-5. When handlebars are in position, reassemble all the compo

nents. Insert the Handlebar Adjustment Lever from right to left through all

the parts. As shown above, securely tighten the lever.

11

Page 12

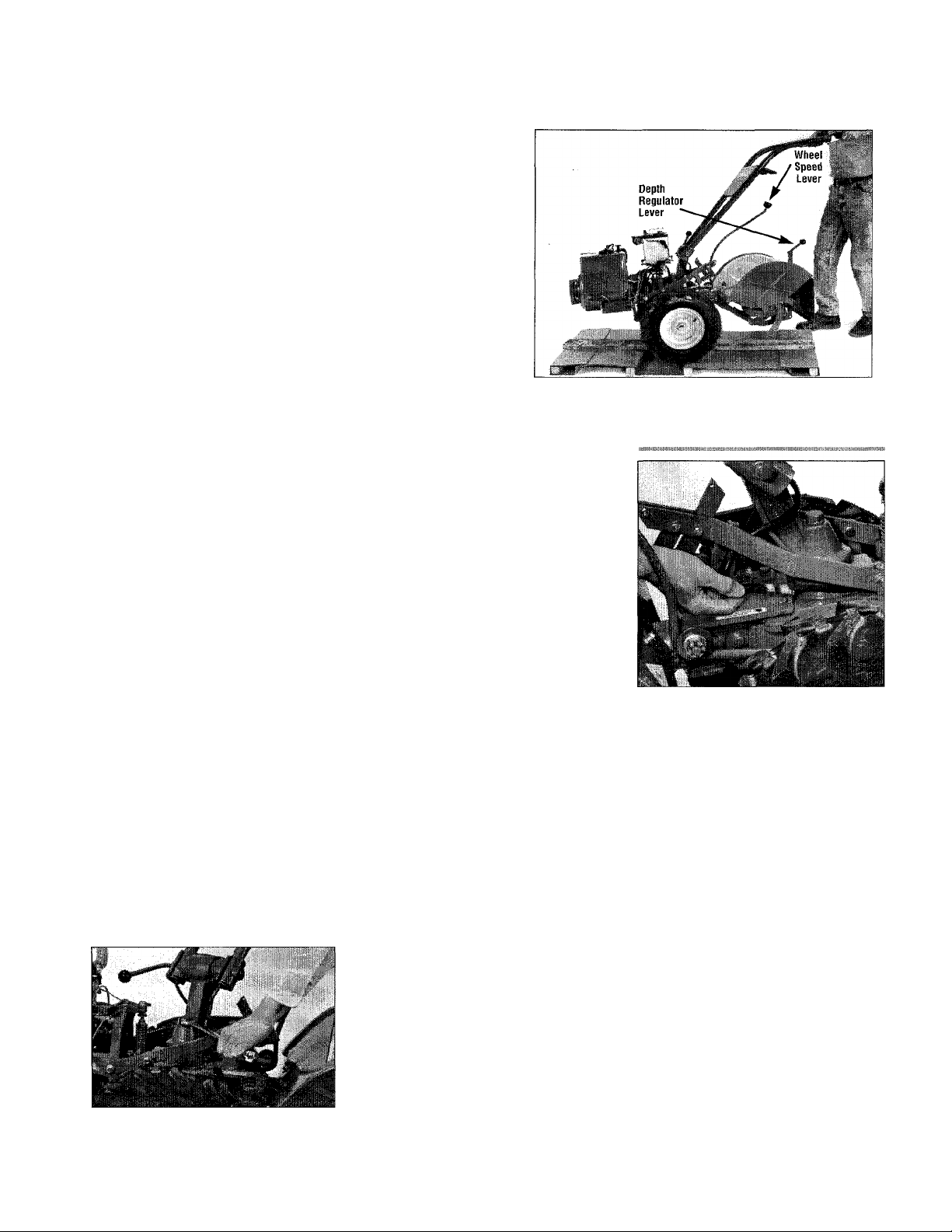

STEP 3; Remove Tiller from

Shipping Platform

A. The Depth Regulator Lever

(Photo 2-6) may be secured to its

own mounting bracket with a plas

tic tie strap. Removing the tie

strap lets you move the Depth

Regulator Lever up or down. To

check, lift the hinged flap at the

end of the hood and look for a tie

strap around the lever. Use a scis

sors to cut it loose.

B. Move the Wheel Speed Lever

(Photo 2-6) to FREEWHEEL posi

tion which lets the wheels turn

freely. FREEWHEEL

position is midway be

tween SLOW and

EAST positions. Then

lift the handlebars up

to clear the tines from

the platform. Pull the

handlebars firmly back

to roll the wheels out

of the platform wheel

wells.

C. Roll the tiller to a

level area where you

can complete the as

sembly steps.

Photo 2-6. Move tiller off shipping platform. Move

Wheel Speed Lever up or down to take wheels out

of gear.

STEP 4: Connect Forward Interlock Wire Harness

B. Before connecting the plug, be

sure that it and the receptacle it’s

going into are clean.

A. Connect the plug on the wire

harness that leads from the lower

ends of the handlebars into the

wire harness receptacle on the top,

right side of the transmission

(Photo 2-7). This connection com

pletes the wiring circuit for the

Forward Interlock Safety System.

It must be connected or the engine

will not start.

^ WARNING

To avoid personal injury, test

the Forward Interlock Satety

System prior to each use of

the tiller to be sure it is func

tioning properly. See Section

4 in this Manual for the test

ing procedure to use.

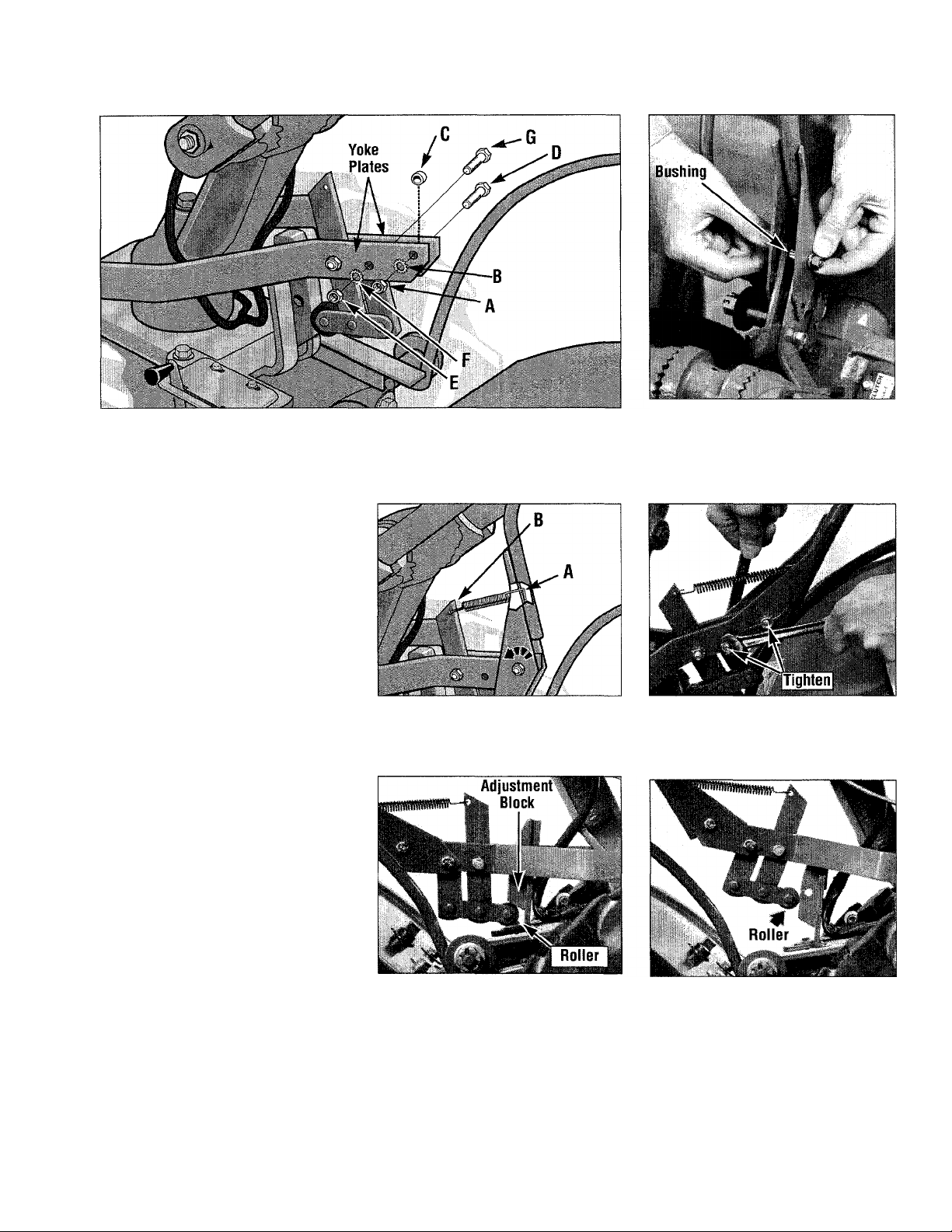

STEP 5: Attach the Wheels/Tines/PTO Drive Lever

This control lever is shown in Photo 2-1. To attach

it, you’ll need the clutch pawl spring (see Photo 2-2).

A. Loosen the large bolt at the top

of the handlebar base (Photo 2-8)

with a 3/4" wrench. Don’t remove

it. Swing the handlebars out of the

way to the right side of the tiller.

B. With two 1/2" wrenches, re

move and save the nut, star washer,

bushing and bolt from the hole at

the rear of the clutch yoke assem

bly plates (see Fig. 2-9, items A,

B, C, D).

C. Using two 1/2" wrenches, re

move (and save) the nut, star

washer and bolt (items E, E, and G,

Eigure 2-9) attaching the short ver

tical link to the center of the yoke.

Keep the short link (with a bushing

inside it) upright after the bolt

Photo 2-8. Loosen the large bolt

securing the handlebar base.

Swing handlebars to right side.

comes out. If it swings down,

reposition it upright again.

Photo 2-7. Connect forward inter

lock wire harness plug to recepta

cle.

Tools required: one 3/4" and two 1/2" wrenches.

D. Slide the plates located at the

end of the PTO drive lever over the

yoke and align the upper hole in

the plates with the hole at the rear

of the yoke (refer to Photo 2-10).

Insert the bushing (C, Figure 2-9)

inside the yoke and install the bolt

through the lever’s plates, bushing

and yoke. (Tap the bolt if neces

sary.) Add the star washer and nut

and tighten the nut finger-tight.

12

Page 13

Figure 2-9. First remove hardware from rear of yoke plates (hardware items

A, B, C, and D); then remove hardware securing short, upright steel link to

yoke plates (hardware items E, F, and G).

E. Look at both ends on the clutch

pawl spring. One hook end has a

wider opening. Insert the end with

the wider opening fully into the

small hole in the lever (hook point

ing down). See A, Figure 2-11.

F. Tilt the lever fully up and insert

the other end of the spring in the

hole in the top of the long steel

link (B, Figure 2-11). A pliers

may help. Do not overstretch the

spring. (Note: push handlebars to

Figure 2-11. Install clutch pawl

spring.

the right for extra clearance.)

G. Pull the lever back down. See

Photo 2-12. Insert bolt removed

earher (per paragraph C) back in the

remaining holes in the lever, yoke

and short vertical link. Add star

washer and nut.

H. Securely tighten both bolts.

I. Swing handlebars to the

straight-ahead position and tighten

the bolt in the handlebar base.

J. Test the operation of the lever.

Push it down until it’s engaged in

the FORWARD position. See

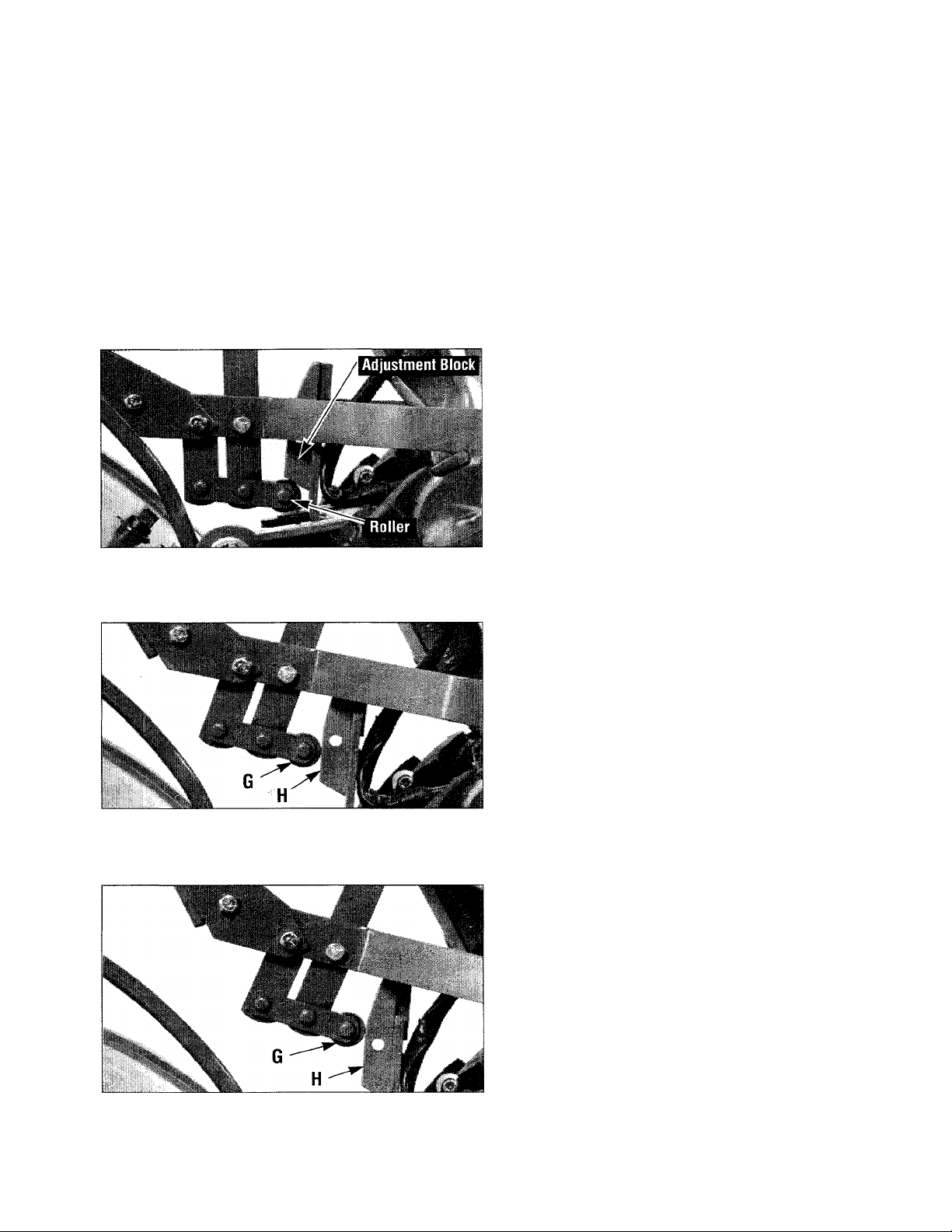

Photo 2-13 (the roller at the end of

Photo 2-13. Push lever down into

FORWARD position. The roller

must go under the adjustment

block.

the shift linkage must be engaged

beneath the belt adjustment block).

Next, move the lever up to the

NEUTRAL position- lift or tap it

up and let it go. The roller should

be resting on the face of the belt

adjustment block (Photo 2-14).

Last, lift and hold the lever all the

way up in REVERSE positionthen let it go. It should automati

cally return to the NEUTRAL po-

Photo 2-10. Insert bushing, then in

stall bolt through upper hole in

lever and yoke plates. Loosely add

the star washer and the hex nut.

Photo 2-12. Pull lever back down.

Reinstall last bolt, star washer and

nut as shown above.

Photo 2-14. When lever is in NEU

TRAL, roller rests against the face

of the adjustment block.

sition. If not, do not use the tiller.

See your local authorized Dealer

or call our Technical Service

Department for instmctions.

13

Page 14

Asseiniii?

STEP 6: Check Gear Oil Levels in Power Unit Transmission and Tine Attachment Transmission

Your tiller has two separate

transmissions: one for the Power

Unit; the other for the Tine Attach

ment. Both were filled with SAE

#85W-140 weight gear oil (with

an A.P.I rating of GL-4) at the

Factory. Please check level in both

transmissions to verify that levels

are still correct.

To Check Power Unit

Transmission:

A. Put the tiller on level ground.

B. Pull Depth Regulator Lever

back and then up so tines are rest

ing on the ground (Photo 2-15).

C. Use a 3/8" wrench to remove

oil level check plug on left side of

the transmission (just above the

wheel shaft). See Photo 2-16. You

may need to break the grip of any

dried paint on the check plug.

D. Oil should seep out hole if

level is correct (in cold weather, it

will seep out slowly). Reinstall

plug securely if gear oil level is

correct.

E. If no oil seeped out, see if tilt

ing tiller slightly toward check

hole (roll right wheel on a 1" thick

board) causes oil to seep out. If oil

starts to seep, only a, small amount

should be added. But - if there is

still no oil seeping out, the oil level

may be seriously low. In either

case, add the correct amount of

gear oil before using the tiller —

see “Adding or Changing Gear

Oil” in Section 5 of this Manual.

To Check Tine Attachment

Transmission:

Two different gear oil level

checking procedures for the tine

attachment transmission follow.

Use the procedure described first

for Tine Attachment dipsticks

with a ‘Check Cold’ marking.

Use the second procedure if dip

stick has both ‘cold’ and ‘hot’

markings at end. First remove

dipstick from tine transmission

(Photo 2-17) to see which type

dipstick you have. Then replace

dipstick.

For Dipsticks With ‘Check Cold’ IVIarkina:

A. Put the tiller on level ground.

B. Pull Depth Regulator Lever

back, then push it down all the way

to engage its top notch. This raises

tines off ground and lets tiller rest

on drag bar.

C. Place a support under engine to

prevent tiller from tilting too far.

Now slide three pieces of 2" x 4"

lumber under drag bar - raising

drag bar about 4-1/2" above

ground. This elevation is needed

to take an accurate “cold” gear oil

reading (“cold” means tiller was

never operated, or 2 hours have

passed since it was used last).

D. Wait two hours with tiller ele

vated (allow more time if tempera

ture is below 40°F).

E. Loosen and remove transmis

sion dipstick. (Photo 2-17). Wipe

with a clean rag.

F. Holding dipstick so markings

face rear of tiller, lower it straight

down into sump hole until it

touches driveshaft inside (Photo 2-

17). Don’t force or try to thread it

back in - or reading won’t be cor

rect.

G. Remove dipstick and check oil

level. It should be within crosshatched area or even slightly above

the ‘Max’ marking. If correct, re

place dipstick and remove boards.

H. If no oil showed on dipstick,

correct amount of oil must be

added to tine transmission. For

complete instructions, see “Adding

or Changing Gear Oil” in Section 5

of this Manual.

For Dipsticks With Hot/Cold Markings:

A. Follow Steps A and B given for

other type of dipstick.

B. Put one 2"x4" board under drag

bar- raising tiller and drag bar

about 3-1/2” above ground. This

elevation is for a ‘cold’ gear oil

reading (tiller never used or 2

hours since used last).

C. Follow Steps D, E, and F given

for other dipstick type.

Photo 2-15: Pull Depth Regulator

Lever back and then up to lower

the tines to the ground.

Photo 2-16: Gear oil should seep

out from oil level check hole in

power unit transmission.

14

Photo 2-17: Remove dipstick to

check gear oil in tine attachment

transmission. Insert dipstick so

markings face rear of tiller.

Page 15

D. Remove dipstick and check

that gear oil level is within or

above ‘Cold’ range marking (use

of ‘Hot’ marking is explained in

Section 5). If correct, replace dip

stick and remove the board.

E. If the level is incorrect, see

“Adding or Changing Gear Oil” in

Section 5 of this Manual.

IMPORTANT

Recheck gear oil level in both trans

missions after the first two hours of

new tiller operation, then every 30

operating hours thereafter. See

Section 5 for instructions.

STEP 7: Add Motor Oil to Engine

Add high-quality API-rated

“SF” or “SG” motor oil to engine

before starting. Refer to the Engine

Owner Manual provided with your

unit for motor oil specifications and

capacities.

To Add Oil:

A. Park the tiller on level ground.

Place a sturdy block under the drag

bar at the rear of the tiller to level

the base of the engine.

B. An oil fill tube is located on

each side of the engine. Either can

be used. See Photo 2-18.

C. Clean around the oil fill tube and

remove the oil fill plug. Use a clean

funnel and slowly pour motor oil

into the tube until the oil reaches the

top of the fill hole.

D. Reinstall the oil fill plug and re

move the block under the drag bar.

IMPORTANT:

> Always maintain oil level at the

overflow point in the oil fill tube.

' Check engine oil level every 5

hours of operation or daily.

' Change engine oil after first 5

hours of new operation.

Photo 2-18: Add

oil until it reaches

top of oil fill tube.

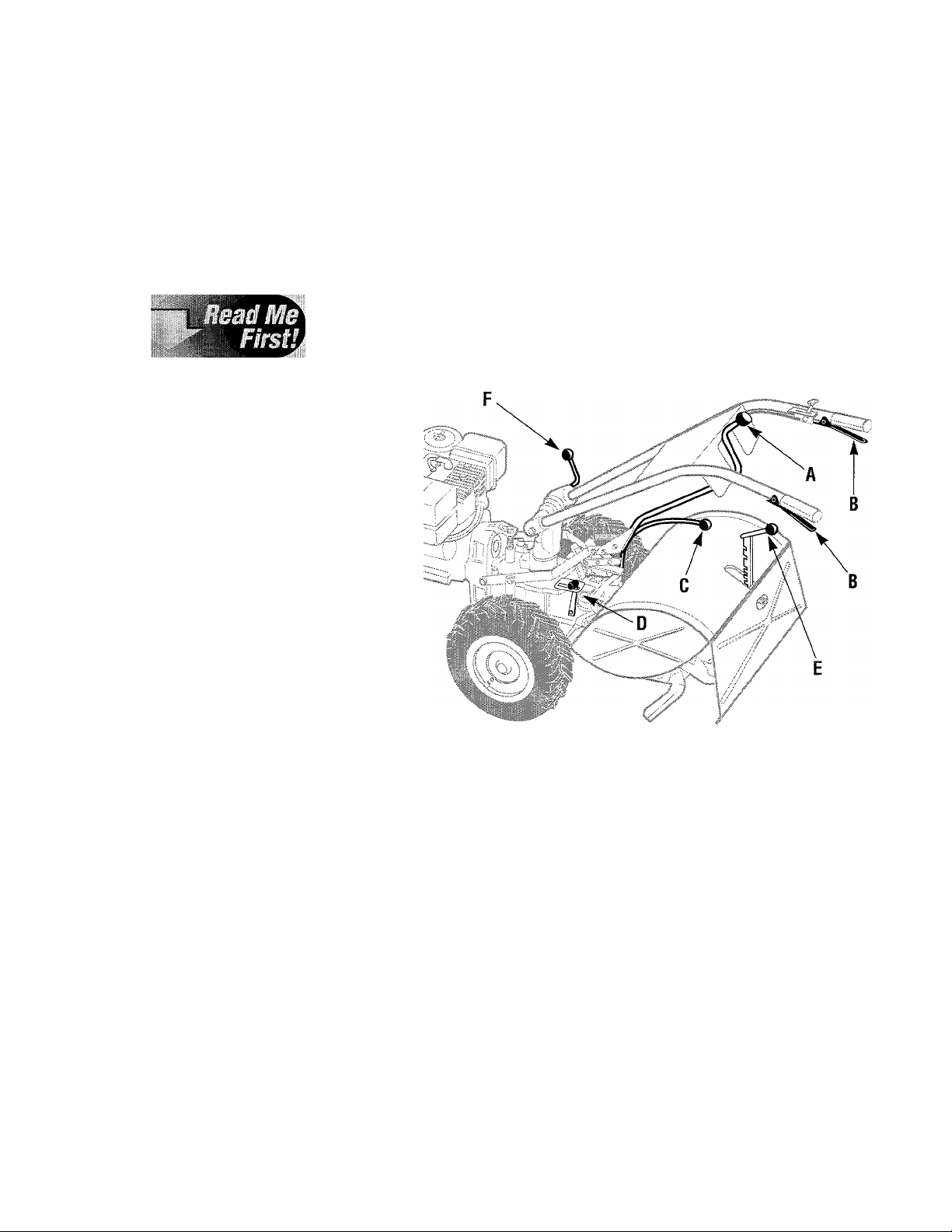

STEP 8: Attach Engine Throttle

Lever to Right Handlebar

The throttle cable (with throttle

lever) is wound around the engine

for shipping purposes. Carefully

unwind the cable. If the throttle

control decal is covered with a pro

tective coating, peel it off. Attach

the lever as follows.

A. You will need the curved head

bolt, flange locknut, panhead

screw and two plastic ties which

are shown in Photo 2-2, Page 10.

B. Run the throttle cable up the in

side edge of the right handlebar

and position the lever as shown in

Photo 2-19.

C. From the outside of the handle

bar, insert the curved head bolt

through the handlebar and the cen

ter hole in the throttle lever mount

ing bracket.

D. Loosely install the locknut.

E. Move the throttle lever to the

STOP position.

F. From the lever side of the

bracket, thread the panhead screw

into the small hole in the throttle

lever bracket and into the handle

bar. See Photo 2-19. Tighten the

screw securely.

G. Use a 7/16" wrench to securely

tighten the locknut and the curved

head bolt.

15

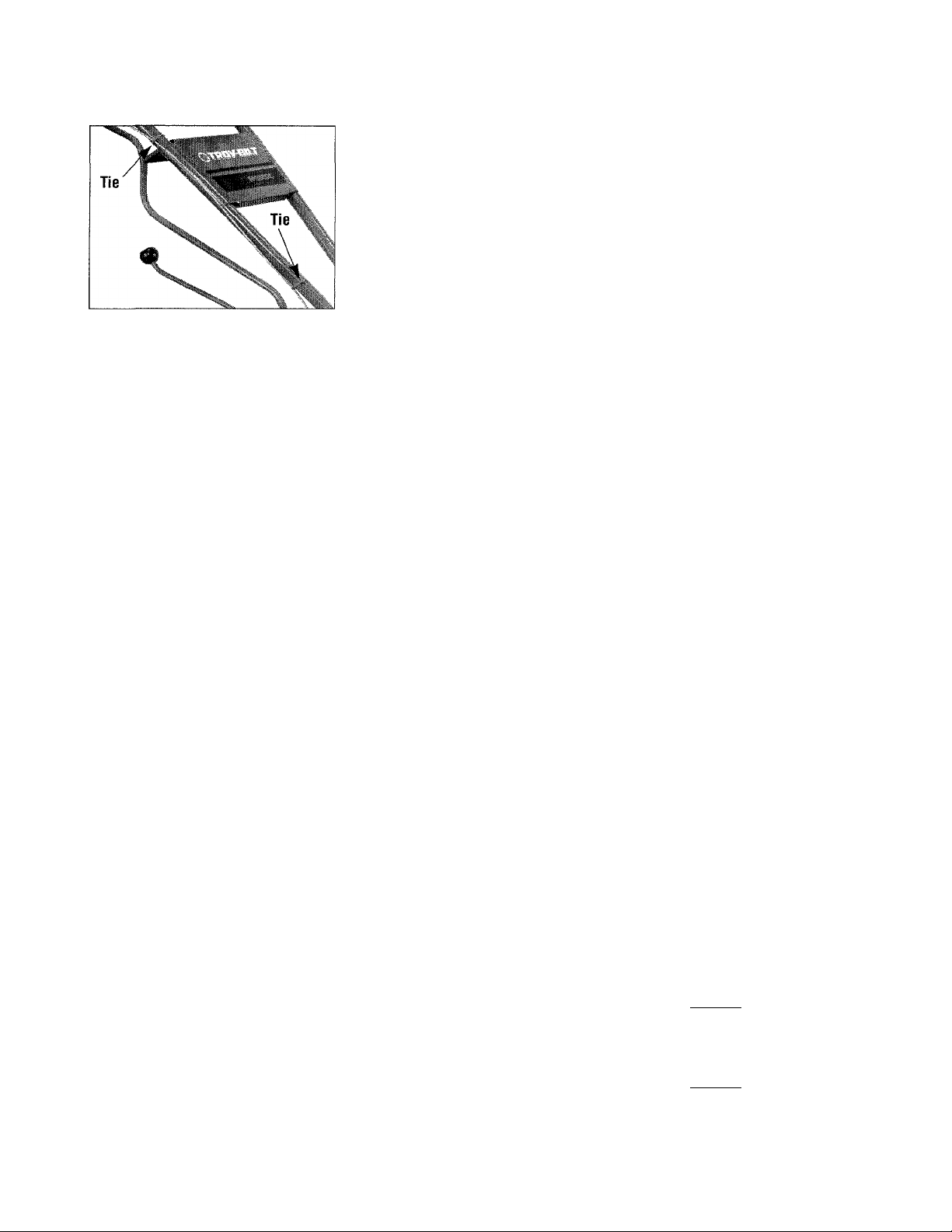

H. Using two plastic ties, secure

the throttle cable to the right han

dlebar in two places, as shown in

Photo 2-20. Loop each tie around

the handlebar and cable (serrated

side faces in) and pull the ties

tight. Trim the ends.

Photo 2-19: Attach engine throttle

lever to handlebar.

Page 16

¿4 Cl

I

Photo 2-20: Use plastic ties in two

places to hold cable to handlebars.

WARNING

On electric start tillers, to

avoid electric shock from a

short circuit, never allow

throttle cable to touch the

battery. Route cable below

the battery, on the outside of

the battery holder.

STEP 9; Adjust the Air Pressure in the Tires

A. For shipping purposes only, the

tires are overinflated.

B. Before using the tiller, check

the air pressure and adjust it to betiveen 10-to-20 psi (pounds per

square inch). Each tire should be

inflated to the same pressure.

Important

If you have a recoil start tiller,

it is now completely assem

bled. If you have an electric

start tiller, please continue

with the few remaining steps.

ASSEMBLING THE ELECTRIC START SYSTEM

The following steps explain battery activation, battery charging and installation. For your safety, follow

all steps and observe all accompanying safety messages. Section 5 has further general battery maintenance and

recharging instructions you will find helpful.

STEP 1: Activating and Charging the Battery

Important

The battery was shipped

“dry.” It needs battery elec

trolyte fluid (battery-grade

sulfuric acid) added to it. It

must then be fully charged

with a battery charger before

being used.

Adding electrolyte fluid to the

battery and battery charging can be

dangerous work. The electrolyte

contains acid that can burn or blind

you. Battery charging also pro

duces explosive gases.

To ensure that the battery is

properly activated and charged,

you should review these instruc

tions with your battery technician.

It is strongly recommended

that you have the battery acti

vated and charged by a trained

professional (Troy-Bilt Dealer,

service station, farm equipment

dealer, etc.) if you are not experi

enced with these procedures.

A

DANGER

Battery produces explosive

gases.

• Keep sparks, flames, and

cigarettes away.

• Ventilate area when charg

ing or using battery in an en

closed space.

• Make sure venting path of

battery is always open once

battery is filled with acid.

DANGER

Battery electrolyte fluid is

poisonous and burns severely.

Electrolyte is a sulfuric acid

solution. Avoid spills or con

tact with skin, eyes, clothing.

• To prevent accidents, wear

protective clothes, rubber

gloves and shield eyes with

safety goggles when working

on or near the battery.

• Neutralize acid spills with a

baking soda and water solu

tion. Neutralize electrolyte

container with same solution.

Then rinse with clear water.

Antidote: External- Flush with

water; Eyes- Flush with water

for 15 minutes and get imme

diate medical attention.

Antidote: Internal- Drink large

quantity of water or milk.

Follow with milk of magnesia,

beaten eggs, or vegetable oil.

Call a doctor immediately.

16

Page 17

To Activate the Battery:

A

WARNIHG

Remove metal jewelry before

working near the battery or

near the electrical system.

Failure to comply may cause

a short circuit, resulting in

electrical burns, a shock, or

explosion of battery gases.

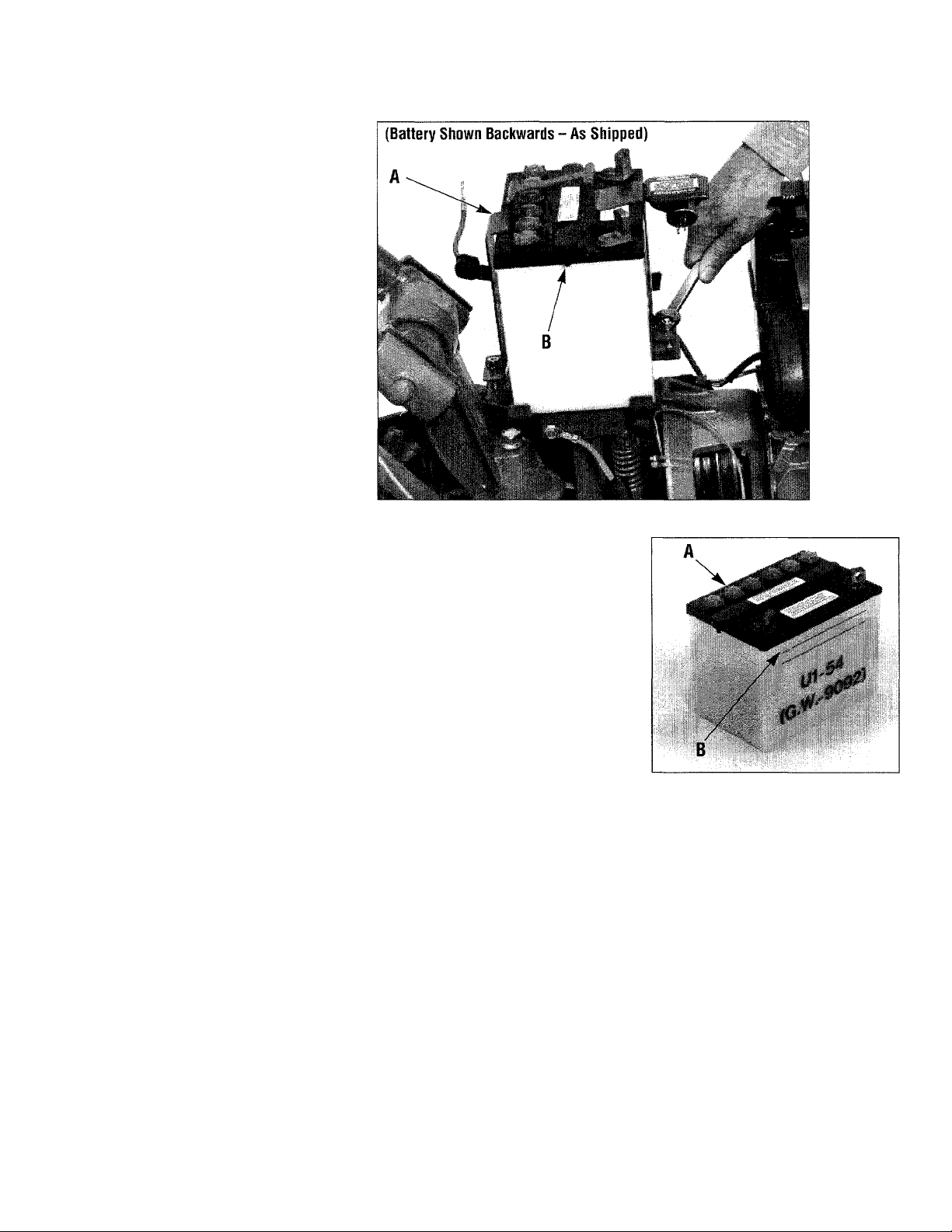

For shipping purposes only, the

unserviced battery and its hold

down clamp were installed back

wards at the factory. When rein

stalling the battery and hold-down

clamp, be sure to turn them around

so they face in the opposite direc

tion from which they were shipped.

A. Use a 7/16" wrench to remove

the two WA” long bolts and the two

1/4" whiz nuts securing the front

and rear hold-down clamp legs to

the battery bracket (Photo 2-23).

Lift off the clamp. Remove battery.

Save the hardware.

B. If there is a short piece of

sealed plastic tubing covering the

vent fitting on the negative side of

the battery (see Photo 2-23), re

move and discard it.

C. Put the battery on a level work

surface, far away from heat- or

flame-producing sources like

stoves, water heaters, dryers, fur

naces, etc.

D. Take off the six filler caps on

top of the battery. Put them aside.

Refer to Photo 2-24.

E. Be sure you are wearing pro

tective clothes, rubber gloves and

eye protection. Fill each cell to the

“Upper Level” line printed on the

battery case using battery-grade

electrolyte solution. (This is 1.265

specific gravity sulfuric acid.)

Temperature of battery and elec

trolyte is ideal when between

bO^^F-to-SO^F. Do not add water or

any other liquid to the battery dur

ing this initial activation.

F. Let battery stand for 30 min

utes. Check electrolyte level in

each cell. Add more electrolyte

solution if needed. Don’t overfill

battery-this could lead to flooding

from the cells during charging.

Photo 2-23:

Remove

hold-down

damp (A).

Remove

the piece

of clear

plastic tub

ing (B)if

so supplied.

Photo 2-24: Remove all six filler

caps (A). Fill each cell up to the

“Upper” level line (B).

To Charge the Battery:

A. Follow one of the three charg

ing methods described next for

maximum starting capacity and

longest battery life.

Note: The electrolyte solution

within the cells is gassing freely

when the surface of the electrolyte

is covered with small bubbles.

When checking for bubbles, al

ways wear safety goggles to pro

tect eyes. A flashlight makes the

inspection easier. Inspect all cells.

17

Our Recommended Method:

Charge the battery at a rate of 1-to2 amperes until all cells gas freely.

Do not exceed 24 hours charging.

First Alternative Chai^g Method:

Charge the battery at a rate of 4-to6 amperes until all cells gas freely.

Do not exceed 8 hours charging.

Page 18

Second Alternative Charging Mdhod:

Charge the battery at a rate from

6-to-12 amperes until all cells gas

freely. Do not exceed 4 hours

charging time.

B. Turn off the charging equip

ment and disconnect the charger

cables from the battery terminals.

C. Recheck electrolyte level in

each cell. Top off any low cells

with electrolyte solution up to the

“Upper” level line.

D. Securely replace all six filler

caps. Use a baking soda and water

mixture to rinse off electrolyte that

may have spilled on the battery.

A DANGER

Never jump start the battery

with a vehicle battery or charg

ing system. This may produce

a battery explosion, causing

acid or electrical burns.

DANGER

To Avoid Personal Injury or

Property Damage;

• Batteries produce explosive

gases - always keep sparks

and flame away from battery.

• Ventilate area when charg

ing or using the battery.

• During charging, don’t

leave battery unattended.

Charging time need not be

continuous.

• Follow safety rules and in

structions supplied by battery

and charger manufacturers.

• Do not charge battery at a

rate higher than 12 amperes

to avoid generating excessive

heat and gassing which could

damage the battery.

DANGER

To Avoid Personal Injury or

Property Damage:

• Do not touch positive bat

tery terminal and any sur

rounding metal objects with

tools, jewelry or other metal

items. Failure to comply

could cause a short circuit

leading to electrical burns or

explosion of battery gases.

• Never bring a gas can near

the positive (+) battery termi

nal. A short circuit could

occur leading to an explosion

of the gasoline or the battery

gases. Always fill the engine

fuel tank from the front or

side of the engine.

STEP 2: Connect the Wire Harness Receptacle

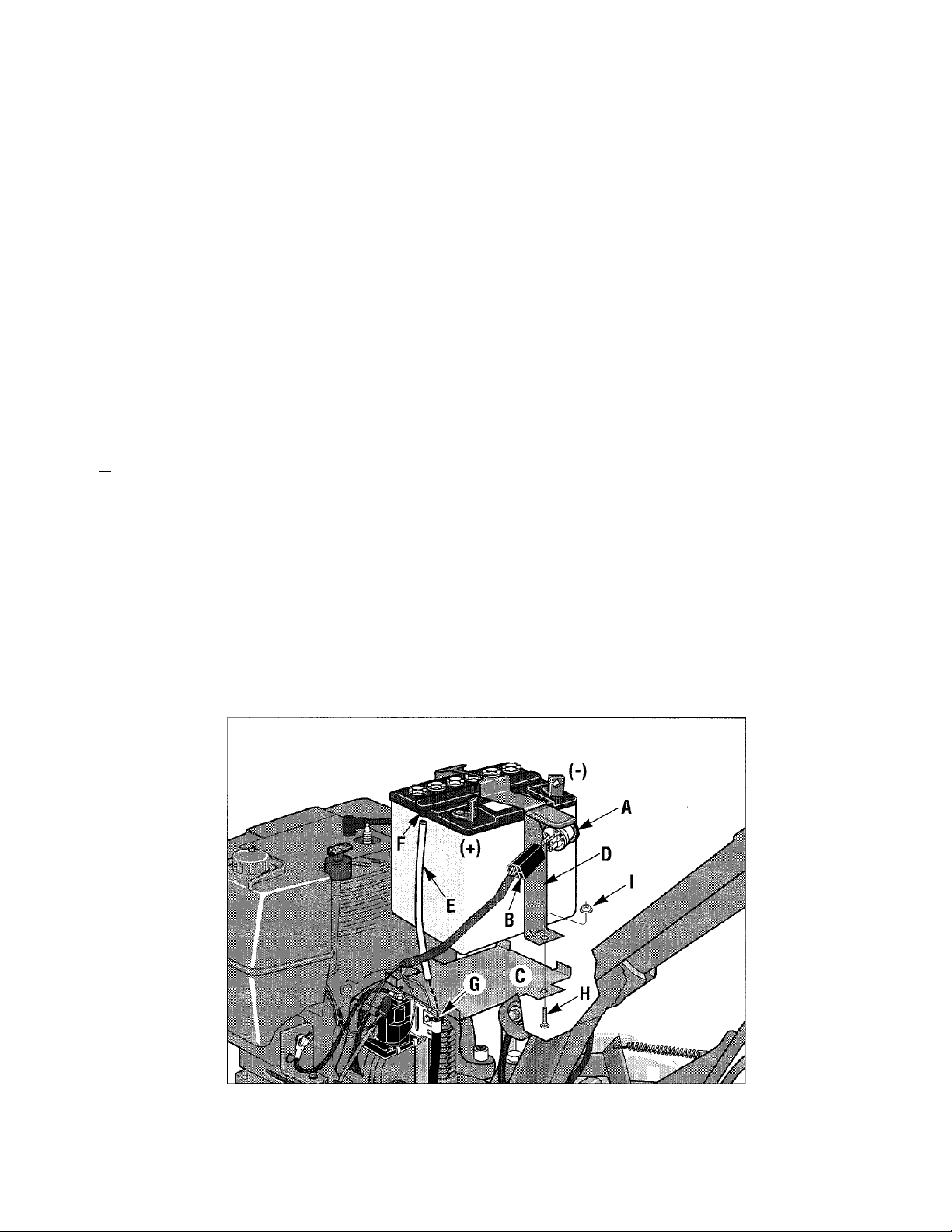

A. The keyswitch (A, Figure 2-25)

is part of the hold-down clamp as

sembly (D). The prongs at the

back of the keyswitch must be se

curely inserted into the plastic wire

harness receptacle (B).

B. Remove the pair of ignition

keys from the keyswitch. Store

them safely away. Do not put a

key in the keyswitch until you have

read the sections in this

Owner/Operator Manual covering

features, controls and operation.

Figure 2-25: First connect Keyswitch (A) to wire harness (B). Then, the acti

vated battery must be secured to mounting platform (C) using the hold

down clamp (D) with its mounting hardware (H, I). Last, install plastic vent

tube (E) over the vent fitting (F), and down into vent tube shield (G).

18

Page 19

STEP 3: Installing the Battery

A. Carefully place the activated

battery back on the battery mount

ing platform as seen in Fig. 2-25,

The side of the battery with the

terminals (the posts) and the fill

lines on it must face the rear of

the tiller. [Another way to verify

the correct placement of the bat

tery is when the positive (-I-) bat

tery post is on the left side of the

tiller as you face forward when

standing behind the handlebars.]

A

B. Place the battery hold-down

CAUTION

Incorrect installation of the

battery can resuit in eiectrical system damage.

Follow these installation in

structions carefully to avoid

damage to your tiller.

clamp (D, Figure 2-25) over the

battery, and secure the two legs of

the clamp to the platform (C) using

the two bolts and whiz nuts (FI, I)

removed previously. Insert the

bolts up from the bottom. Tighten

the hardware to make the battery

secure, but don’t overtighten the

nuts or the clamp tabs will bend.

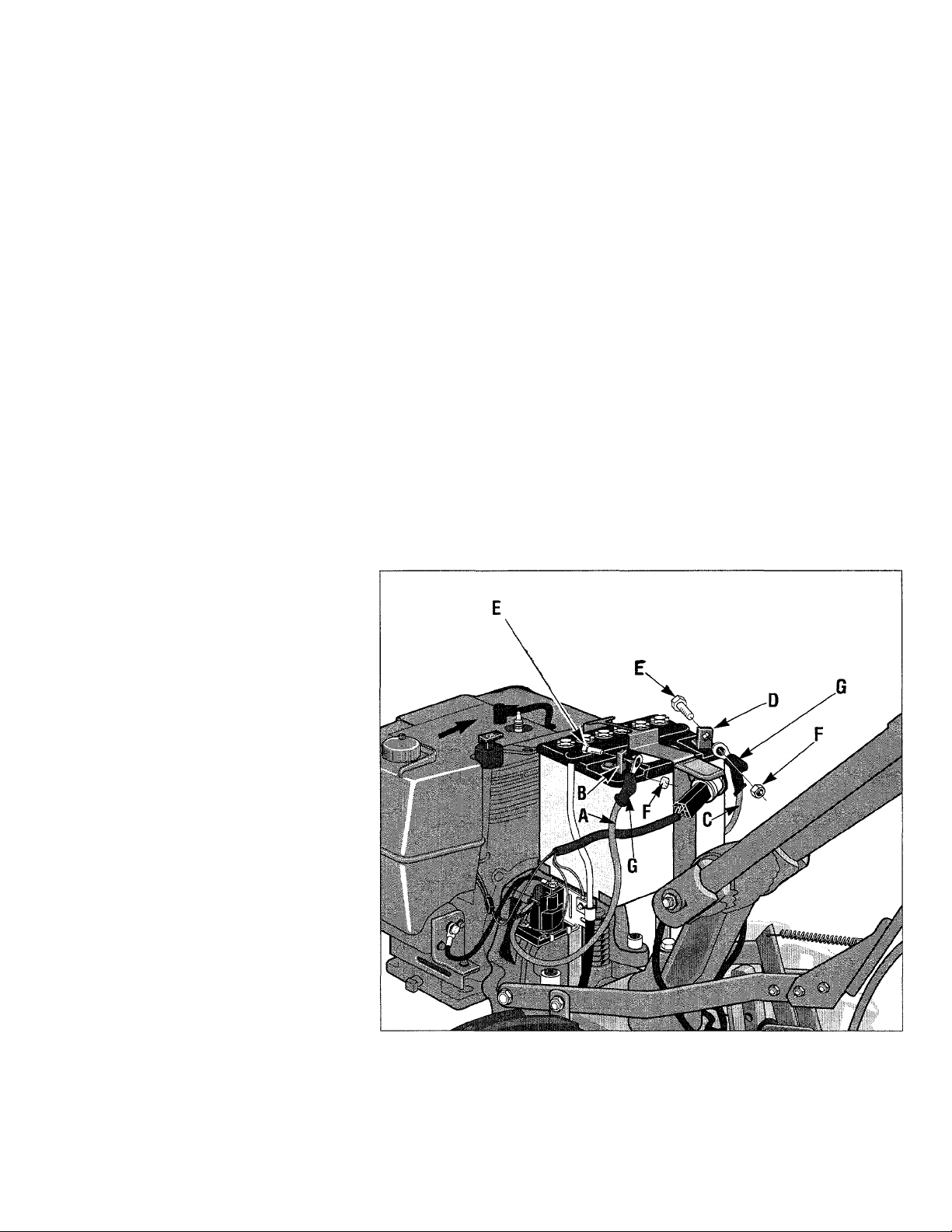

STEP 4: Installing the

Battery Cables

A. Locate the two (2) 5/8" long

bolts and l/4"-20 hex nuts shown

in Photo 2-3 on page 10. Use them

to connect the loose ends of the

two battery cables to the two bat

tery terminals (posts).

B. On the left side of the tiller (as

viewed from behind the handle

bars), connect the loose end of the

positive (+) battery cable (A,

Figure 2-26 - this is the red cable

already attached at the other end to

the solenoid) to the positive (+)

battery post (B). Flold the cable

terminal against the side of the

post facing the keyswitch. Install

and tighten a bolt (E) and nut (F)

with two wrenches.

C. Slide the pre-installed black

rubber boot (G) completely over

the battery post and hardware.

D. Repeat this procedure on the

right side of the battery. Position

the end of the negative cable (C)

against the negative battery post

(D) as shown, and secure it with

the remaining bolt (E) and nut (F).

Again, slide the black rubber boot

completely over the battery post.

E. Check the lower end of the vent

tube shield into which you inserted

the clear plastic vent tube. The

lower end of the black shield must

be located in front of the wheel

shaft axle. Move it there if neces

sary. Your electric start tiller is

now fully assembled.

C. The clear plastic vent tubing

must be installed next. If coiled

up, straighten it out. Slide one end

of the tube (E, Figure 2-25) over

the vent fitting (F) at the top of the

battery. Slide the other end down

into the black vent tube shield (G).

WARNING

Improper battery venting can

cause a battery to explode,

resulting in severe personal

injury.

Be sure the vent tube is not

crimped, pinched or folded.

Figure 2-26: Connect positive (+) cable (A) to positive battery post (B).

Connect negative (-) cable (C) to negative battery post (D). Be sure to posi

tion bolts (E) and nuts (F) as shown. After the connections are secure, slide

black rubber boots (G) completely over battery posts.

19

Page 20

Section

Learn the locations of the features

and controls on your machine

before slatting the engine, laking

the time now to understand the lo

cation. tunction and opeiation of

these controls Vi/ill greatly add to

the productive use, safe operation,

and enjoyment of your machine,

for detailed step-by-step operating

instructions, please refer to

“Section 4: Operation."

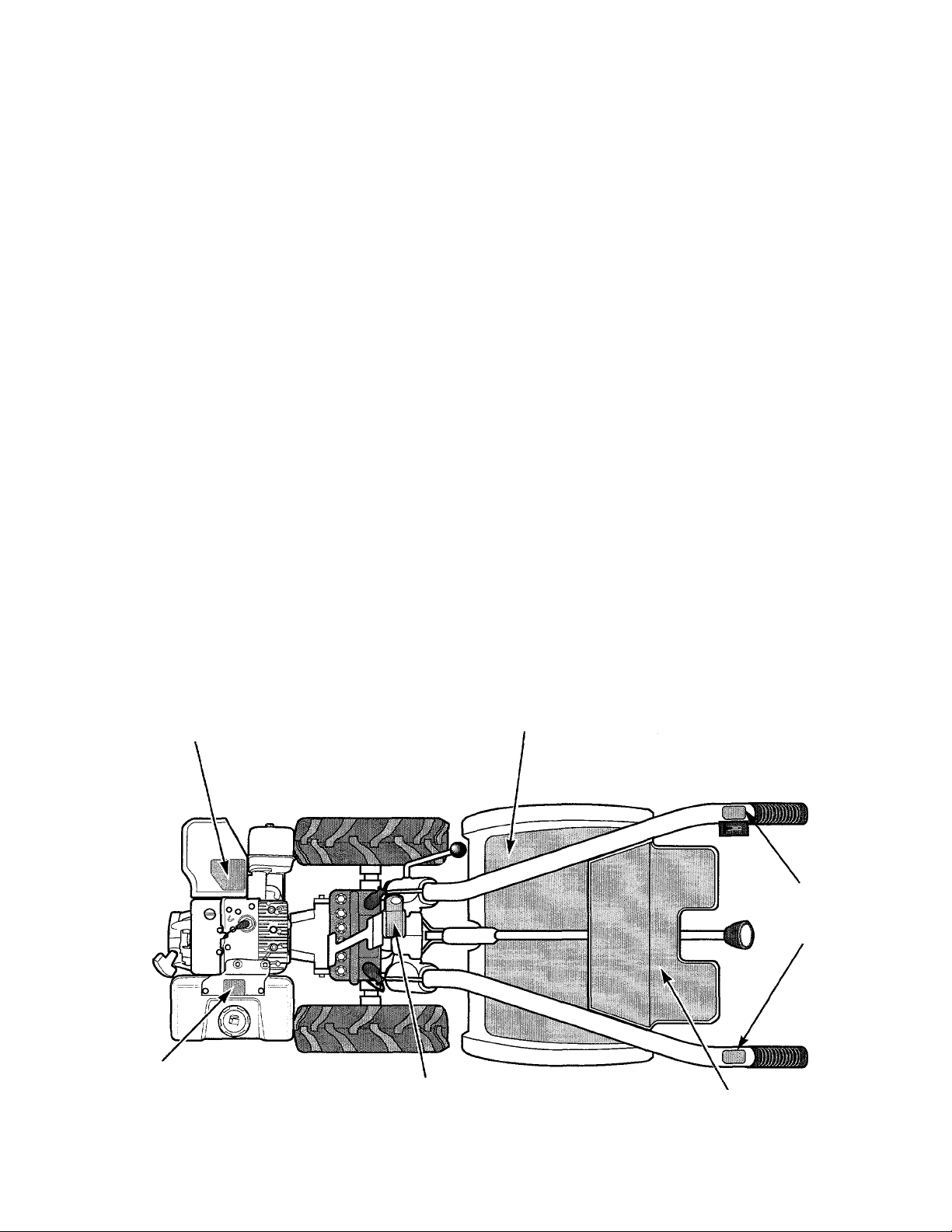

TILLER FEATURES AND CONTROLS IDENTIFICATION

The major tiller controls and features are identified and illustrated on the

next few pages. The use and operation of each control and feature is cov

ered in detail in Section 4 “Operating Instructions.”

A WARNING

TO AVOID PERSONAL INJURY OR

DAMAGE TO EQUIPMENT:

Before using your tiller or PTO

Power Unit for the first time, be

come thoroughly familiar with the

operation of the controls by mov

ing them to their various posi

tions while the engine is not run

ning. The proper operation of

each control is discussed in detail

in Section 4.

NOTE: All references to left, right,

front and rear of the machine are

determined by standing behind the

handlebars and facing the direction

of forward travel

Figure 3-1; A- Wheels/Tines/PTO Drive Lever; B- Forward Interlock

Levers; C- Wheel Speed Lever; D- Tines/PTO Clutch Lever; E~ Depth

Regulator Lever; F- Handlebar Height Adjustment Lever.

Wheels/Tines/PTO Drive Lever

This lever (A, Figure 3-1)

engages and disengages power

from the engine to the transmis

sion. It has three operating posi

tions: FORWARD, NEUTRAL and

REVERSE.

To stop the wheels, tines or any

PTO attachment, move the lever to

NEUTRAL by lifting or tapping

the lever upwards and letting it go

(in NEUTRAL the clutch roller

will be located on the face of the

adjustment block, as shown in

Photo 3-lB).

FORWARD - Lever moved down

until it engages in drive position

(clutch roller at end of lever is en

gaged below adjustment block, as

shown in Photo 3-1 A). Use this

setting for forward motion of the

wheels and tines, or to apply power

to any optional PTO (Power Take

Off) attachment.

REVERSE - Lever moved all the

way up and held in that position

(clutch roller will be located higher

on the face of the adjustment

block, as shown in Photo 3-lC).

Use this setting for moving the

machine in reverse. To stop mov

ing in reverse, let go of the lever

and it will automatically return to

the NEUTRAL position.

20

Page 21

Check Position of Clutch Rolier

• Do not operate the tines or any PTO attachment

when in REVERSE.

A'^ you shill hoiwoL'ii i'ORWARI). NI A.' I RAI.

;inJ Kl A'liRSt'. iho diildi rolli.-r the hoUtuii of

iho Icwr should Iv fK'sitioiiod as shown in Pholos

1 \. Ò-1 f5 and A-IC. Chix’k iho posilion of ilio

diitoh rollor as you shill the le\er. IT ii is noi po-

siiioncd eonvelly. eontael the I’aclory or see \i'iir

loeal aulhoii/od dealer.

Photo 3-1 A: When the Wheels/Tines/PTO Drive Lever is in

the FORWARD position, the clutch roller will be engaged

b^ow the adjustment block.

NEUTRAL - Lever moved in between FORWARD

and REVERSE positions. Use this setting to stop the

wheels, tines or any PTO attachment.

• Always shift to NEUTRAL before starting the

engine or before engaging the wheels, tines or any

PTO attachment.

Forward Interlock Levers

A Forward Interlock Lever (B, Figure 3-1) is

located below each handlebar grip.

At least one of these interlock levers must be kept

squeezed against a handlebar grip whenever the

'N^eels/Tines/PTO Drive Lever is engaged in FOR

WARD. (The levers do not affect operation when the

Wheels/Tines/PTO Drive Lever is in REVERSE.)

If both interlock levers are released before first

returning the Wheels/Tines/PTO Drive Lever to

NEUTRAL, the engine will stop.

Important - This is a safety feature should you lose

control of your tiller and cannot stop forward mo

tion by moving the Wheels/Tines/PTO Drive Lever

into NEUTRAL.

Photo 3-1B: When the Wheels/Tines/PTO Drive Lever is in

the NEUTRAL position, the clutch roller (G) must be located

approximately as shown on the face of toe adjustment block

Photo 3-1C: When the Wheeis/Tines/PTO Drive Lever is held

up in the REVERSE position, the clutch roller (G) must be

located higher on the face of the adjustment block (H).

Wheel Speed Lever

Use this lever (C, Fig. 3-1) to select a wheel speed

or the freewheel position. There are three operating

positions; SLOW, FAST and FREEWHEEL.

SLOW - Lever moved all the way down. Use for nor

mal tilling or for low-speed transporting.

FAST - Lever moved all the way up. Use for cultivat

ing or for fast-speed transporting.

FREEWHEEL - Lever in between SLOW and FAST

positions (wheels will roll freely). Use for transporting

the machine on level ground without engine power and

when using stationary PTO attachments.

• To avoid transmission damage, always put the

Wheels/Tines/PTO Drive Lever in NEUTRAL

before shifting the Wheel Speed Lever.

• When shifting into SLOW or FAST, gently roll the

machine to help fully engage the wheel gears. When

engaged, the wheels will not turn unless the engine

is running and the Wheels/Tines/PTO Drive Lever is

engaged in FORWARD or REVERSE.

21

Page 22

Figure 3-2: A- Wheels/Tines/PTO Drive Lever; B- Forward Interiock

Levers; C- Wheel Speed Lever; D- Tines/PTO Clutch Lever; E- Depth

Regulator Lever; F- Handlebar Height Adjustment Lever.

Tines/PTO Clutch Lever

Use this lever (D, Figure 3-2) to

engage or disengage power from

the transmission PTO clutch to the

tines or any PTO attachment. It has

two operating positions: ENGAGE

and DISENGAGE.

ENGAGE - Lever moved into de

tent slot furthest from engine. Use

to operate tines or other PTO attach

ments. After shifting to ENGAGE,

briefly operate machine in

FORWARD to help fully engage the

PTO clutch.

DISENGAGE - Lever moved into

Depth Regulator Lever

Use this lever (E, Figure 3-2) to

regulate the tilling depth of the

tines. It also has a TRAVEL posi

tion, which places the tines out of

the ground.

To operate the lever, pull it

straight back and then slide it up or

down to any of the eight notched

settings.

The highest notch is the

TRAVEL setting. For shallow till

ing and cultivating, use the second

or third notch from the top. The

other notches are for deeper tilling

and for power composting.

detent slot nearest engine. Use to

disengage power to tines or other

PTO attachments before transport

ing, loading, turning, or backing up.

• To avoid transmission damage,

always put the Wheels/Tines/

PTO Drive Lever in NEUTRAL

before shifting the Tines/PTO

Clutch Lever.

WARNING

To avoid personal injury,

always place the tines in the

TRAVEL position before start

ing the engine. This prevents

the tines from touching the

ground until you are ready to

begin tilling.

22

Handlebar Height Adjustment Lever

Use this lever (F, Figure 3-2) to

adjust the handlebars at one of the

two preset height settings.

To change the height, hold the

handlebars with one hand and

loosen the lever in a counterclock

wise direction. Move the handle

bars to one of the two preset height

settings and retighten the lever.

• Swapping the positions of the in

side handlebar ratchets (see Page

11) will change the preset set

tings by a few inches.

WARNING

For use with the PTO Chipper/

Shredder attachment only,

the handlebars can be swung

30° to tbe right side by loos

ening the mounting bolt at

the bottom of the handlebar

base. Never operate your

tiller or other attachments

with the handlebars swung

out to the right side. This

could result in unsafe han

dling and personal injury.

ENGINE FEATURES AND

CONTROLS IDENTIFICATION

The following are descriptions

of the controls on your engine.

Additional engine information is

provided in Section 4 “Operation”

and in the engine manufacturer’s

Owner’s Manual which was in

cluded in your literature package.

Be sure to read the engine Owner’s

Manual carefully and save it for fu

ture reference.

WARNING

To avoid serious personal in

jury or damage to equipment,

do not start your engine at

this time. Complete starting

instructions are described in

Section 4 “Operation.”

Page 23

Figure 3-4: 7HP Briggs & Strattori engine. H- Choke

controi, i- Recoii starter.

Figure 3-5:8HP and 10HP Briggs & Stratton engines.

H- Choke controi; i- Recoii starter; L- ON/OFF Switch;

M- Secondary engine throttie control lever.

Engine Throttle Lever

The throttle lever on the right

handlebar (G, Figure 3-3) is used

to adjust the

engine speed

as well as

start and stop

the engine (a

„ secondary

Figure 3-3 throttle lever

is located on the front of the 8HP

and lOHP engines—see M, Fig. 3-5.)

Move the lever away from the

STOP position before starting the

engine. Engine speeds can be var

ied between the FAST and SLOW

settings. Use the STOP position to

turn the engine off.

Engine Choke Control

The choke control lever (H,

Figures 3-4 or 3-5) makes starting

a cold engine easier. The choke in

creases or decreases the amount of

air in the carburetor’s fuel-air mix

ture. Use the CHOKE position

when starting a cold engine. After

starting, gradually return the lever

to the RUN position.

Engine Recoil Starter

The recoil starter (I, Eigures 3-4

or 3-5) is used to manually start

the engine. Before pulling the

starter rope, the Wheels/Tines/PTO

Drive Lever must be in NEUTRAL

and your free hand must be on top

of the fuel tank to stabilize the

tiller.

Keyswitch Starter

The keyswitch starter on electric

start models (J, Eigure 3-6) has

three posi

tions: OEE,

RUN and

START. Turn

the key to

START to

start the en

Figure 3-6

gine. Release

the key and it

will return to the RUN position.

Turn the key to OFF to stop the en

gine. (A second way to stop the

engine is to move the engine throt

tle lever to the STOP position.)

Fuel Shut-Off Valve

The shut-off valve (K, Fig. 3-7)

is located under the fuel tank. The

valve must be in the ON position

(1/4 turn counterclockwise) to

operate the engine. Close the shut

off valve when the tiller is trans

ported or not in operation to pre

vent fuel leakage.

On/Off Switch

The 8 HP and lOHP Briggs &

Stratton engines have an On/Off

Switch (L, Figure 3-5) which must

be switched to ON before operat

ing the engine.

23

Page 24

Section

This Section explains how to:

• Perform Pre-Starting Break-In and Preparation

• Test the Forward Interlock Safety System

As v.ilh any other piece of outdoor

powered equipment, getting the

"feel" for how your machine oper

ates and getting to know tlie best

techniques for particular jobs are

very important to overall good per

formance.

Read this Section very thoroughly

before you start the engine. The

instructions given here will help you

familiarize yourself with the

tiller and have you operating it effi

ciently in a short time.

A WARNING

Before operating your machine,

be sure you read and understand

all safety, controls, and all

operating instructions in this

Owner/Operator Manual and on

the decals on your machine.

• Start and Stop the Engine

• Operate and Turn the Tiller Around

• Transport the Tiller

• Change Belt Range Speed (from High to Low and back)

• Till in the Garden

• Till Up and Down Slopes

• Use Special Tilling Techniques

• Remove and Replace the Tine Attachment

• Use the PTO Power Unit with Other Attachments

Failure to follow these instructions

can result in serious injury or

property damage.

NOTE: All references to left, right,

front and real of the machine are de

termiried by standing behind the

handlebars and facing the direction

of forward travel.

24

Page 25

Before operating the tiller, be

sure you have first read and under

stood all Safety Instructions in

Section 1 and Controls information

in Section 3. First practice using

the tiller in an open, level area.

Practice without the tines revolving

- disengage the tines with the

Tines/PTO Clutch Lever. After a

thorough practice session, the tiller

can then be moved to the garden.

WARNING

Your tiller and its optional

PTO attachments are capable

ot causing serious injury to

untrained or careless opera

tors.

To avoid serious personal in

jury or property damage,

read the Owner/Operator

Manual provided with any op

tional accessories or attach

ments before using the tiller

or PTO power unit.

Break-In Operation

During the first few hours of

new tiller operation, the following

maintenance steps are required.

For subsequent maintenance proce

dures, refer to Section 5 —

Maintenance.

1. Change Engine Oil. Change

the oil after the first 5 hours of new

operation. Thereafter, change oil

after every 10 operating hours.

Increase the frequency of oil

changes under very dirty or dusty

conditions.

2. Check Transmission Gear Oil

Level. After the first 2 hours of

new operation, check the gear oil

levels in the PTO power unit and

the tine attachment transmissions.

Thereafter, check them every 30

hours.

3. Check Drive Belt Tension.

Due to belt seating, a tension ad

justment may be needed after the

first 2-to-3 hours of new operation.

Thereafter, check belt tension

every 10 operating hours.

4. Check Hardware, After 2

hours of new operation, check for

loose bolts and nuts. Thereafter,

do this every 10 operating hours.

Preparation Before Starting

Make the following checks and

perform the following services be

fore starting the engine.

1. Check Engine Oil Level.

2. Check the Air Cleaner. It must

be securely assembled and clean.

3. Check Safety Guards. All

guards and covers must be securely

in place.

4. Attach Spark Plug Wire,

5. Check Engine Cooling System.

The cooling fins and air intake

screen must be clear of debris.

6. Adjust Handlebar Height.

7. Check Battery Fluid Level.

Cells must be filled to proper level,

cell caps must be tight, and all

electric wire connections secure.

8. Add Gasoline to Fuel Tank.

Use fresh, clean, lead-free automo

tive gasoline. A minimum of 77

octane is recommended. DO NOT

MIX OIL WITH GASOLINE!

DANGER

Gasoline is highly flammable and its vapors are explosive. Follow

these safety practices to prevent injury from fire or explosion:

• Never fill tank if engine is running or hot from use. Let engine and

muffler cool down before refueling.

• Do not permit open flames, sparks, matches or smoking in the fueling

area.

• Fill fuel tank outdoors in a well-ventilated area. Wipe up any fuel

spills and move tiller away from fumes before starting the engine.

• Use only an approved fuel container and lock it safely away from

children.

• Store fuel and the tiller in a well-ventilated area. Do not store fuel or

tiller where fuel vapors may reach an open flame or spark, or an igni

tion source (a hot water heater, furnace, clothes dryer, electric motor,

or the like).

• Let engine cool before storing.

• Never bring a metal fuel can near battery post on electric start model

tillers. An electrical short circuit could result, causing an explosion of

the gasoline or of battery gases.

Refer to the separate Engine

Owner’s Manual for detailed fuel

recommendation s.

Note: The use of gasoline which

contains alcohol, such as gasohol,

is not recommended. However, if

gasoline with alcohol is used, it

must contain less than 10%

Ethanol and must be removed from

the engine during storage. Do not

use gasoline which contains

Methanol.

Purchase fuel in a quantity that can