Page 1

$7.50

m

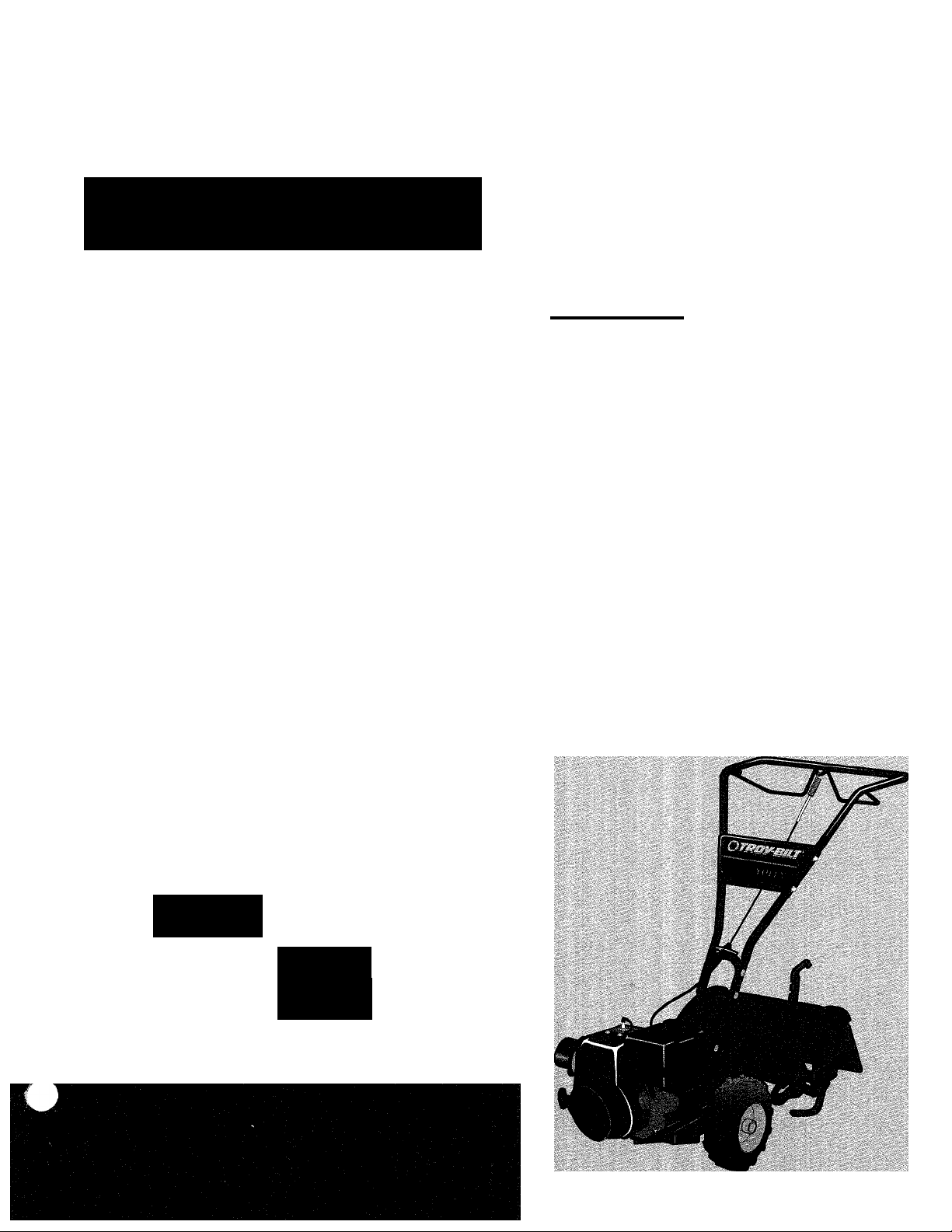

TRaV^-BILT

Owner/Operator

Manual

___ ___ _

TUFFY Tiller

• Safety

• Assembly

• Controls

• Operation

• Maintenance

Models

12060

12065

Page 2

Dear Owner,

You now own one of the finest reartine rototillers available. Your new

TUFFY® Model tiller allows you to till

and cultivate your garden with ease, and

accomplish dozens of other property

management projects as well. Your tiller

is famous for its ruggedness, perfor

mance and high-quality engineering. We

know you’ll enjoy using it.

Please carefully read this Manual. It

tells you how to safely and easily assem

ble, operate and maintain your machine.

Be sure that you and any other operators

carefully follow the recommended safety

practices at all times. Failure to do so

could result in personal injury or prop

erty damage.

Of course, if you should ever have any

problems or questions, or for a free re

placement copy of this Manual, please

contact your local authorized service

dealer or call us Toll-Free. Our tele

phone numbers and mailing addresses

are listed on Page 4 and on the back

cover of this Manual.

We want to be sure that you are com

pletely satisfied at all times.

This is a safety alert

symbol. It is used in

this Owner/Operator

Manual to alert you

A

this symbol, read and obey the

safety message that follows it.

Failure to obey the safety message

could result in personal injury or

property damage.

to potential hazards.

Whenever you see

Be Sure To Return Your Warrant)

Registration Card

Be sure to fill

out and mail

your Warranty

Registration

Card, which is

located in your

literature pack

age. The infor

mation contained

on this: card will register your ma

chine with us and entitle you to full

coverage under our Troy-Bilt Full

No-Time-Limit Warranty.

NOTE: An Ownership Transfer

Card is included in this Manual.

This card should be filled out and

returned to us ONLY if you trans

fer ownership of your machine to

someone else.

i'll;.

This machine meets voluntary safety stan

dard B71.8 - 1986, which is sponsored by

the Outdoor Power Equipment Institute, Inc.,

and is published by the American National

Standards Institute.

WARNING:

A

The engine exhaust from

this product contains

chemicals known to the

State of California to

cause cancer, birth de

fects, or other reproduc

tive harm.

Page 3

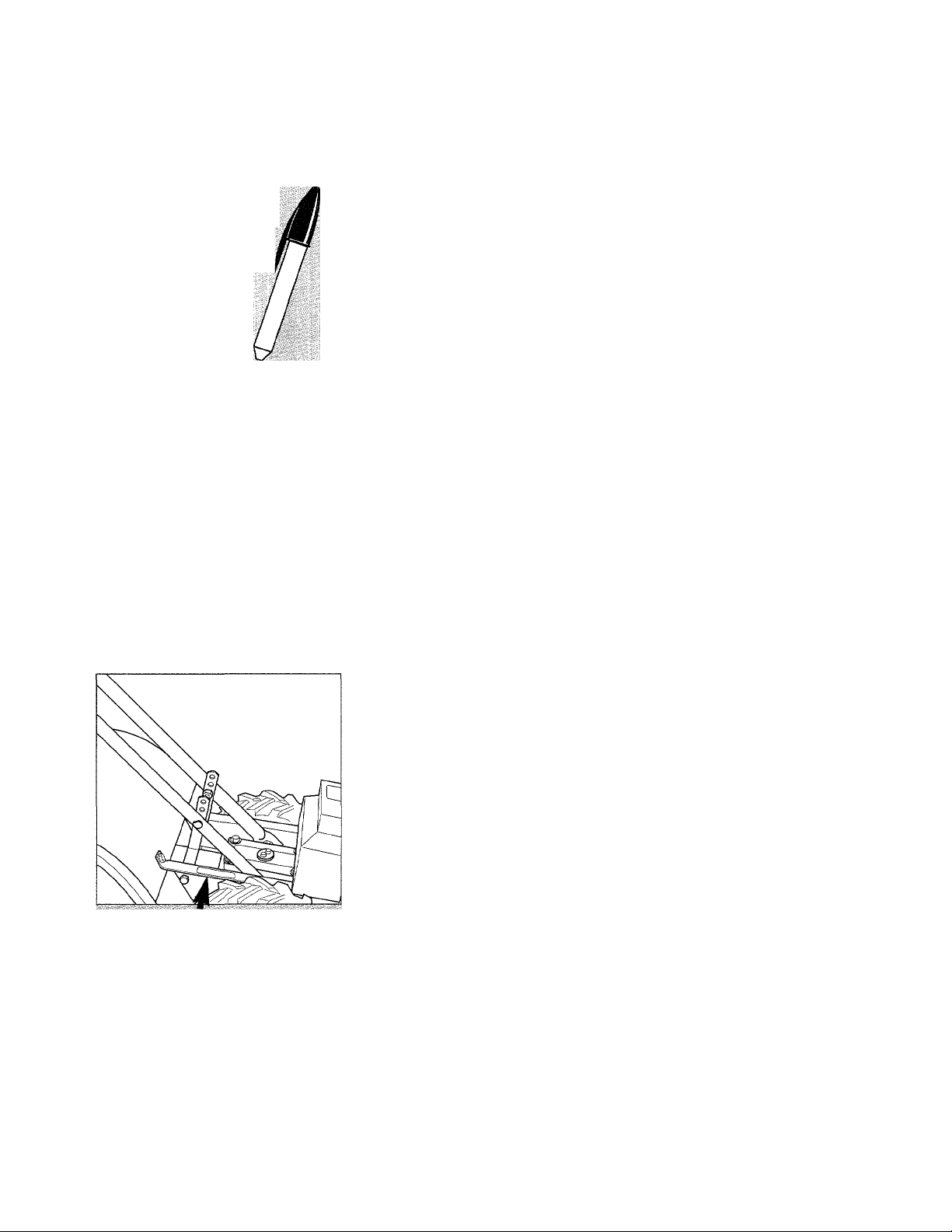

Owner’s Record

Please write tlie Model and Serial

numbers of your machine in

the spaces provided. You

can find the location of

these numbers by refer

ring to the illustration

below.

Model Number:

Serial Number:

Model and Serial Number location

SERVICE INFORMATION

...................................................................

SECTION 1: SAFETY........................................................................ 5

Training............................................................................ 5

Preparation ......................................................................

Operation

Maintenance and Storage

Decals.............................................................................. 7

.........................................................................6

......................................................

SECTION 2: ASSEMBLY.................................................................. 8

SECTION 3: FEATURES ANO CONTROLS

Tiller Features and Controls Identification

Engine Features and Controls Identification................................14

....................................

..................................

12

12

SECTION 4: OPERATION.................................................................15

Break-In Operation............................................................. 15

Pre-Start Checklist.............................................................. 16

Starting and Stopping the Engine.........................................16-17

Tilling Depths.................................................................... 17

Guiding the Tiller

Moving the Tiller Forward.....................................................17

Moving the Tiller Rearward

Turning the Tiller Around...................................................... 18

Tilling in the Garden............................................................18

Seedbed Preparation...........................................................18

Cultivating

Power Composting

Fligh-Traction Frame Weights

Preventing Tines from Becoming Tangled

Tilling on Slopes................................................................. 20

Terrace Gardening.............................................................. 20

Loading and Unloading the Tiller

...............................................................

...................................................

.......................................................................

.............................................................

................................................

..................................

............................................

17

17

19

19

19

20

21

SECTION 5: MAINTENANCE & REPAIRS.......................................22

Required Maintenance Schedule.............................................22

Regular Maintenance.......................................................... 23

Tiller Lubrication................................................................ 23

Checking and Adding Engine Oil..............................................23

Changing Engine Oil............................................................ 24

Checking and Topping Off Transmission Gear Oil

Changing Transmission Gear Oil..............................................25

Checking for Oil Leaks..........................................................26

Air Cleaner Maintenance

Engine Cooling System Maintenance

Engine ignition System Maintenance

Spark Plug Maintenance....................................................... 26

Carburetor Adjustments.......................................................26

Tightening Tiller Hardware

Bolo Tines........................................................................27

Removing and Installing Tine Assemblies

Removing and Installing Individual Tines....................................27

Checking and Adjusting Belt Tension

Belt Removal and Replacement

Forward Clutch Bail Replacement............................................29

Removing and Installing the Forward Clutch Cable........................29

Tiller Storage

....................................................................

......................................................

........................................

........................................

....................................................

........................................

..............................................

..........................

...................................

24

26

26

26

27

27

28

28

30

TROUBLESHOOTING.......................................................................31

TILLER & ENGINE SPECIFICATIONS

.............................................

32

INDEX.................................................................................................33

NO-TIME-LIMIT WARRANTY............................................Back Cover

4

6

7

Page 4

If you have any

HOWTO

REACH

US

U.S.A.

GARDEN V/VAY

INCORPORATED.

102tidSt.&

9th Ave..

Troy, N.Y.

12180

U.S.A.

Mon.-Fri.,

8 A.M.to 7 P.M.

Saturday

9 A.M. to 4 P.M.

..mumimm..........

Canada

GARDEN WAY

INCORPORATED.

320 Van Sickle Rd..

Unit 12,

St Catherines. Out.

L2R 6P/

Canada

Mon.-Fri..

8 A.M. to 4:30 P.M.

o

Questions or

Problems...

...Please contact your local TROY-BILT® Tiller

authorized dealer or call or write the Factory. When calling

or writing, please be sure to provide the Model and Serial

Numbers of your machine (refer to Page 3).

If You Need Engine

Service:

If your engine should ever require

service or re- ,==.===

pair, contact

your nearest

authorized

engine service

dealer.

To find the name and address of

your nearest authorized engine

service dealer, look in the Yellow

Pages of the telephone book under

:

............

.1!%.

“Engines-Gasoline” (call us if you

need assistance in obtaining en

gine service or parts).

Please remember that your engine

is covered by the engine manufac

turer’s Limited Warranty. Any

unauthorized work performed on

the engine during the warranty pe

riod may void the warranty. For

full details on the engine manufac

turer’s Limited Warranty, refer to

the separate Engine Owner’s

Manual.

U.S.A.

(Toll Free)

For Technical

Service;

1-800-520-5520

For Parts

Service:

1-800-648-6776

International

calls:

518-391-7000

Canada

(Toll Free)

For Technical

Service and Parts

Service:

1-800-225-3585

If You Need Parts:

Factory specified replacement

parts for your machine are

available from either your

TROY-BILT® Tiller autho

rized dealer or directly

from the Factory.

To order a part from

the Factory, refer to

your separate Parts

Catalog to find the part

number, description, and quantity

of the part you need. Then,

call or write our Parts

Department, being sure to

provide the Model and

Serial Numbers of your

machine.

Our trained parts special

ists will gladly assist you if

you have any difficulty in

identifying the part that you need.

Page 5

Sectio

"

Please read and follow all of the

safety rules in this Safety Seclion.

Failure to comply could result in

serious personal injury or prop

erty damage.

If you should lend this equipment

to another person, make sure that

he or she reads, understands, and

always follows these safety in

structions.

It you are not completely sure

about any of the information

found here or elsewhere in the

Manual, please contact either

your local authorized dealer or the

factory tor assistance.

WARNING TO ALL CALIFORNIA

AND OTHER POWER EQUIPMENT OPERATORS

Under California law, and under the laws of several other states,

you are not permitted to operate an internal combustion engine

using hydrocarbon fuels on any forest-covered, brush-cov

ered, or grass-covered land, or on land covered with grain,

hay, or other flammable agricultural crop, without an en

gine spark arrester in continuous effective working order.

The engine on your power equipment, like most outdoor power equipment, is an

internal combustion engine that burns gasoline, a hydrocarbon fuel. Therefore,

your power equipment must be equipped with a spark arrester muffler in continu

ous effective working order. The spark arrester must be attached to the engine

exhaust system in such a manner that flames or heat from the system will not ig

nite flammable material. Failure of the owner/operator of the equipment to com

ply with this regulation is a misdemeanor under California law, and may also be a

violation of other state and/or federal regulations, laws, ordinances, or codes.

Contact your local fire marshal or forest service for specific information about

what regulations apply in your area. Contact your authorized engine dealer for in

formation about obtaining a spark arrester.

TRAINING

A

This is a safety alert

symbol. It is used

in this Owner/ Oper

ator Manual and on

your equipment to

alert you to poten

tial hazards.

Whenever you see

this symboi. read

and obey the safety

message that fol

lows it. Failure to

obey those safety

messages could re

sult in serious per

sonal injury or cause

property damage.

1. Rc;ui llii.'' ()u iier/Operator

\huuMl ;iiul ilk' ^гparate Engine

Owner's Manua carefully before

operating this equipment. Be com

pletely familiar with the controls

ami ilie prnper Use of this equipmeni. Know how to stop the unit

and disengage the controls quickly.

2. \e\er allow children or un

named adults to operate this equip

ment.

3. Keep I lie aie; of operation clear

of all persons, particularly small

elnldivn and pels. Keep bystanders

at least 2.S feel -ovay from the area

of operai ion.

OPERATING AREi

4. Familiarize yourself with all of

the safety and operating decals on

this equipment and on any of its

attachments or accessories.

5. Do not run engine in an en

closed area. Engine exhaust con

tains carbon monoxide gas, a

deadly poison that is odorless, col

orless, and tasteless. Do not oper

ate this equipment near buildings,

windows, or air conditioners.

6. Do not allow hands or any

other part of the body or clothing

near the rotating tines or near any

other moving

part. The tines

begin to rotate

forward once

the engine starts

and the Forward

Clutch Bail is

engaged.

A WARNING

à

&

Page 6

7. Before inspecting or servicing

any part of the equipment, shut off

the engine, wait for all moving

parts to come to a complete stop,

disconnect the spark plug wire

from the spark plug and move wire

away from the spark plug.

8. Do not operate this equipment

if you are under the influence of

alcohol, medication, or when you

are tired or ill.

9. Keep in mind ihai ihe operator

or user is responsible for accidents

or hazards occurring to other peo

ple, their property, and themselves.

PREPARATION

1. Thoroughly inspect the area

where the tiller will be used. Re

move foreign objects before tilling.

2. Make sure that all control levers

are released and both wheels are in

Wheel Drive position before start

ing the engine.

3. Do not operate the tiller without

wearing suitable clothing. Avoid

loose garments or jewelry that

could get caught in moving parts

of the tiller or its engine.

OPERATION

1. Do not put hands or feet near or

under rotating parts.

2. Use extreme caution when on or

crossing driveways, walks or roads.

Be alert for hidden hazards or traf

fic. Do not carry passengers.

3. If you hit a foreign object, stop

the engine, let all moving parts

come to a complete stop, discon

nect spark plug wire, move wire

away from the spark plug, and in

spect for damage. Repair damage

before restarting.

4. Exercise caution to avoid slip

ping or falling.

4. Do not operate the tiller when

you are barefoot, in

sandals, sneakers or

other light footwear.

Wear shoes that grip

well on slippery surfaces.

5. Do not till near underground

electric cables, telephone lines,

pipes, or hoses. Contact your tele

phone or utility to verify locations

of underground cables or lines.

6. Handle gasoline with care; it is

highly flammable, and has explo

sive vapors.

a. Use an approved gas container.

b. Gas caps shall never be re

moved or fuel added with en

gine running. Engine shall be

5. If abnormal tiller vibration oc

curs, stop engine immediately, dis

connect the spark plug wire and

move wire away from spark plug.

Check for the cause. Carefully in

spect for any damage. Eix the prob

lem before using the

tiller again.

6. Stop the

engine, dis

connect the spark

plug wire and move wire away

from spark plug before leaving the

operating position, unclogging

tines, or making repairs, adjust

ments or inspections.

7. Before leaving tiller unattended,

make sure that all control levers are

released, stop engine, and disconnect

spark plug wire and move wire away

from plug to prevent accidental

starting. Be sure both wheels are

in the WHEEL DRIVE position.

8. Before cleaning, repairing or in

specting, stop the engine, let all

moving parts stop, and disconnect

allowed to cool before refuel

ing. Operators shall not smoke.

c. Keep matches, cigarettes,

cigars, pipes, open flames, or

sparks away from the fuel

tank and fuel container.

d. Eill fuel tank outdoors using

extreme caution. Never add

fuel indoors. Use a funnel or

spout to prevent spillage.

e. Replace fuel caps securely and

clean up fuel spills before

starting the engine.

7. Never attempt to make any ad

justments while the engine is run

ning or the spark plug wire is con

nected, except when so instructed.

spark plug wire and move wire

away from spark plug to prevent

accidental starting.

9. The flap on the tine hood must

be down when operating tiller.

10. Never operate the tiller unless

safety guards or other protective

devices are in place.

11. Do not run the engine in an en

closed area. Engine exhaust con

tains carbon monoxide gas, a

deadly poison that is odorless, col

orless, and tasteless.

12. Keep children and pets away.

13. Never operate the tiller under

engine power if the wheels are in

the FREEWHEEL position. In

FREEWHEEL, the wheels will not

hold the tiller back and the revolv

ing tines could propel the tiller

rapidly, possibly causing loss of

control. Always engage the

wheels with the Wheel Drive Pins

in WHEEL DRIVE position be

fore starting the engine or engag

Page 7

ing the tines with the Forward

Clutch Bail.

14. The tiller could unexpectedly

bounce upward or jump forward

and be propelled away from you if

the tines strike or catch very hardpacked soil, sod, frozen ground, or

any buried obstacle such as large

stones or roots. If in doubt about

tilling conditions, use the follow

ing precautions to assist you in

maintaining tiller control:

a. Walk behind and on either

side of the tiller, using one

hand on the handlebars.

Relax your arm, but use a se

cure hand grip.

b. Use shallow depth regulator

settings, gradually working

deeper with each tilling pass.

c. Use slower engine speeds.

d. Clear the tilling area of big

stones, roots and other debris.

e. Avoid putting downward pres

sure on the handlebars. If

necessary, apply slight upward

pressure to prevent the tines

from digging too deeply.

f. Avoid contacting hard-packed

soil or sod at the end of a row

by reducing engine speed and

lifting handlebars up to raise

tines out of the soil,

g. In an emergency, stop tines

and wheels by releasing the

Forward Clutch Bail. Do not

attempt to restrain the tiller.

15. Do not overload the machine

capacity by trying to till too deeply

at too fast a rate.

16. Never use the tiller at high

ground speeds on slippery surfaces.

17. Do not operate tiller on a slope

too steep for safety. On slopes,

slow down and be sure you have

good footing. Don’t let the tiller

“freewheel” down slopes.

18. Clear the area of bystanders be

fore tilling.

19. Use only attachments and ac

cessories approved by Garden Way

Incorporated.

20. Use tiller attachments and ac

cessories when recommended.

21. Never operate the tiller without

good visibility or light.

22. Never operate the tiller if you

are fatigued, or under the influence

of alcohol, drugs or medication.

23. Operators shall not tamper with

the engine-governor settings on the

machine; the governor controls the

maximum safe operating speed and

protects the engine and all moving

parts from damage caused by over

speed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine parts that

may be hot from operation (muffler,

fins, etc.). Make certain all parts

have cooled down before inspect

ing, cleaning or repairing.

25. Remember—^To stop the tines

and wheels, release the Forward

Clutch Bail.

26. Look behind and exercise cau

tion when backing up.

27. To load or unload the tiller

from a vehicle, see complete in

structions in Section 4.

MAINTENANCE AND

STORAGE

1. Never perform maintenance

when engine is running or spark

plug wire is connected except

when specifically directed to do so.

2. Keep tiller, attachments and ac

cessories in safe working condition.

3. Check all nuts, bolts, and screws

frequently for proper tightness.

Always verify your equipment is in

safe working condition.

4. Never store the machine with

fuel in the fuel tank inside a build

ing where fumes may reach an

open flame or spark, or where igni

tion sources are present (such as

hot water and space heaters, fur

naces, clothes dryers, etc.).

5. Let the engine cool down before

storing it in an enclosure.

SAFETY DECALS

Make certain that all safety decals on this equipment

are kept clean and in good condition. There are other

decals located on your equipment for operation and

6. To reduce fire hazard possibili

ties, keep the engine free of grass,

leaves or grease.

7. Store gasoline in a cool, wellventilated area, safely away from

any spark- or flame-producing

equipment. Store gasoline in an

approved container, safely out of

the reach of children.

8. Refer to the Maintenance sec

tion in this Manual for storage in

formation if your tiller is to be

stored for an extended period.

controls identification. If you need a replacement

decal, please refer to the Parts Catalog that accompa

nied this Manual.

Page 8

Section

Please carefully follo'-v the steps in

this Section to pioperiy assemble

your new machine. These steps wiil

not take very long and they wiii as

sure you of having assembled your

machine correctly.

WARNING

To prevent personal injury or prop

erty (lamacje. do not attempt to

start the engine until all assemlily

steps are complete and you have

read and understand the safety and

operating instructions in this

Manual.

Tools Needed:

One 3/8" Open End or

Adjustable Wrench

Two 7/16" Open End or

Adjustable Wrenches

Two 9/16" Open End or

Adjustable Wrenches

Funnel (to add oil)

Rag (to clean up any

spilled oil)

Block of Wood (to support

liller v.'hen removing wheei)

Ruler (for belt tension check)

1. Package Inspection

Inspect carton and its contents

upon delivery for evidence of

damage.

If you find or suspect any damage,

contact the carrier (trucking com

pany) immediately. Inform them

of the specific damage and that

you wish to file a claim. To pro

tect your rights, be sure to put this

in writing to the carrier within 15

days after your machine arrives.

The carrier will let you know how

to proceed with your claim.

Please let us know if you need any

assistance with this matter.

.»y £r^'

si

1

FIG. 2-1. Place screw on fop of tem

plate and measure distance between

bottom of screw head and tip of

screw.

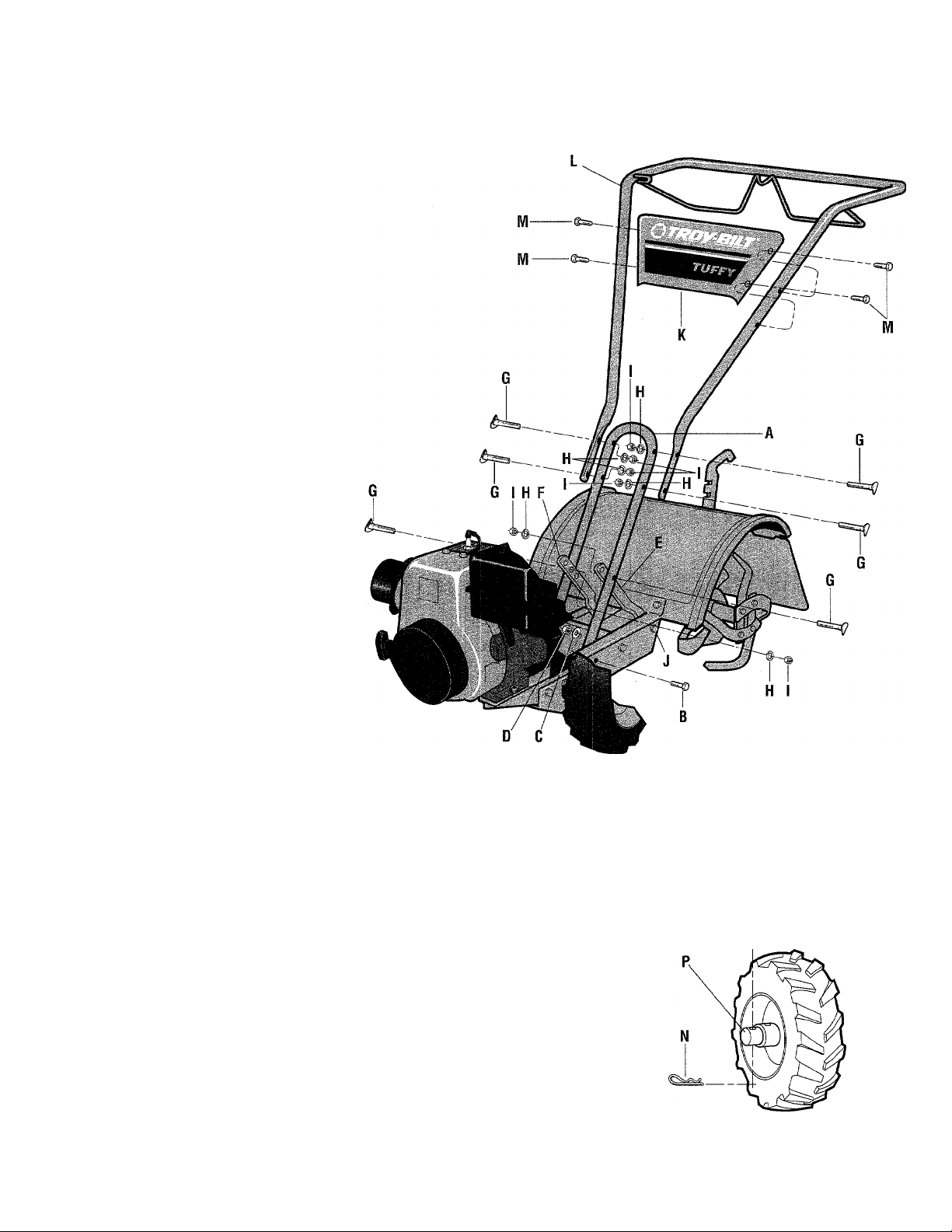

2. Package Contents

NOTE: Wait until you have as

sembled the handlebars before

moving the tiller off the shipping

platform.

Carefully unpack the carton and

check that you have received the

items listed below. If any items are

missing or damaged, please con

tact us for replacements.

• Tiller/Engine Assembly

• Handlebar Support (see A, Fig.

2-2).

• Handlebar Assembly (see L,

Fig. 2-2).

• Handlebar Panel (see K, Fig.

2-2).

• Hardware bag - includes:

NOTE: Use screw length tem

plate (Fig. 2-1) to identify screws.

• (1) Slotted hd. screw,

#10-24 X 2" long

• (6) Curved head screws,

5/16"-18x 1-1/2” long

• (1) Hex hd. screw,

l/4"-20x 1-1/4" long

• (2) Hex hd. screws,

3/8"-16x3/4" long

• (4) Hex hd. self-threading

screws, l/4"-20x 1/2" long

• (2) Flat washers, 3/8"

• (6) Split Lockwashers, 5/16"

• (1) Hex locknut, l/4"-20

• (6) Hex nuts, 5/16”-18

• (2) Hex locknuts, 3/8"-16

• (1) Cable spring

• (1) Cable bracket (see R,

Fig. 2-4).

IMPORTANT: Motor oil must

be added to the engine before it

is started! The oil fitting proce

dure is exptained in Step 7.

Page 9

NOTE: “LEFT” and “RIGHT”

sides of tiller are as viewed from

the operator’s position behind the

handlebars.

3. Attach the Handlebar

1. Attach the legs of the handlebar

support (A, Fig. 2-2) loosely to the

inner sides of the tiller frame using

two 3/8"-16 X 3/4" hex hd. screws

(B), 3/8" flat washers (C) and 3/8"-

16 hex locknuts (D).

2. Using the middle holes in the

handlebar support brackets (E and

F, Fig. 2-2), loosely attach the sup

port brackets to the handlebar sup

port (A) using two 5/16"-18 X 1-

1/2" curved hd. screws (G), 5/16"

split lockwashers (H) and 5/16"-

18 hex nuts (I). NOTE: If a sup

port bracket will not move, loosen

attaching screw (J) and nut.

3. Attach the handlebar panel (K,

Fig. 2-2) to the handlebar assem

bly (L) using four l/4"-20 X 1/2"

self-threading screws (M). Tighten

the four screws securely.

4. Attach the handlebar assembly

(L) to the handlebar support (A)

using four 5/16"-18x 1-1/2"

curved hd. screws (G), 5/16" split

lockwashers (H) and 5/16"-18 hex

nuts (I). Tighten the four screws

securely.

5. Tighten all handlebar mounting

hardware securely.

4. Move Tiller Off Shipping

Platform

To roll the tiller without the engine

running, the wheels must be

placed in their FREEWHEEL po

sition, as described below.

1. Use a sturdy block to raise one

wheel off the ground.

2. Remove the hair pin cotter (N,

Fig. 2-3) and clevis pin (O). Slide

the wheel inward on the axle (P)

and reinstall the clevis pin and hair

pin cotter through the axle only

Fig. 2-2: Assemble handlebar.

(not through the wheel hub).

Repeat with the other wheel.

3. Using the handlebar as a lever,

roll the tiller to a flat area.

IMPORTANT: Before starting

the tiller’s engine, the wheels must

be placed in their WHEEL DRIVE

position (pins through wheel hubs

and axle). This procedure is de

scribed in “Wheel Drive Pins” on

Pages 12-13 in Section 3.

Fig. 2-3: Wheel in FREEWHEELING

position.

Page 10

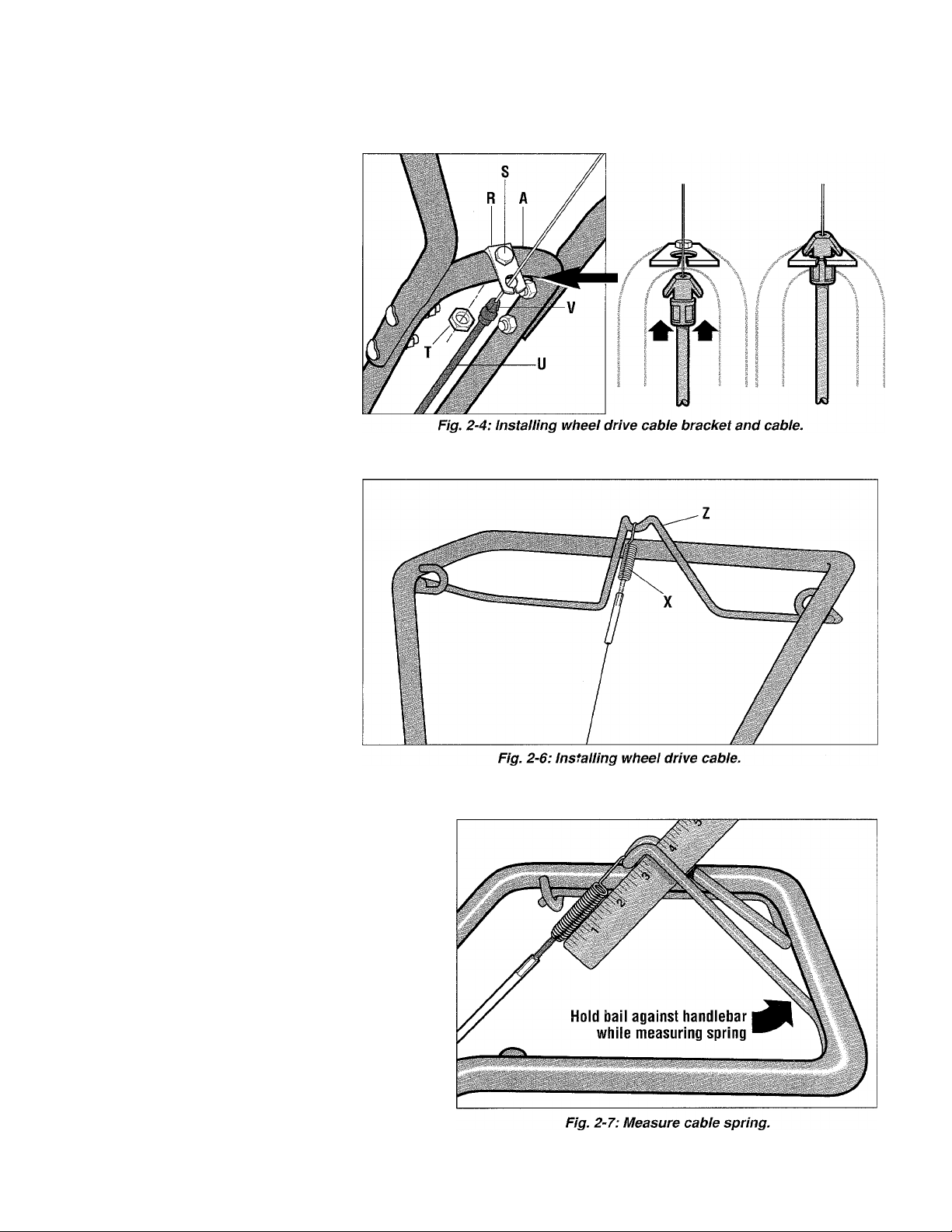

5. Install Wheel Drive Cable

1. Place the cable bracket (R, Fig.

2-4) on the handlebar support (A)

as shown.

2. Attach the cable bracket using a

1/4"-20 X 1-1/4" hex hd. screw (S,

Fig. 2-4) and l/4"-20 hex locknut

(T). Tighten securely.

3. Unwrap the forward clutch cable

(U, Fig. 2-4) from around the en

gine and slide the thin cable wire

into the slot in the cable bracket.

Push the cable connector (V, Fig.

2-4) up through the hole in the

bracket until the groove in the con

nector snaps into place on the

bracket.

4. Insert the #10-24 x 2" slotted hd.

screw (W, Fig. 2-5) into the cable

spring (X).

5. Thread the screw (W) into the

cable adjuster (Y).

6. Hook the cable spring (X) into

the “V”-shaped bend in the for

ward clutch bail (Z, Fig. 2-6).

7. Lift and hold the forward clutch bail

against the handlebar. See Fig. 2-7.

8. Measure the distance between

the coils of the cable spring (Fig.

2-7). The length should be approx

imately 1-7/8”. If the length is in

correct, you will have to make an

adjustment to the cable tension as

described in “Checking and Ad

justing Belt Tension” on Page 28.

Fig. 2-5:

Assemble spring

and adjuster.

W-

Y-

10

Page 11

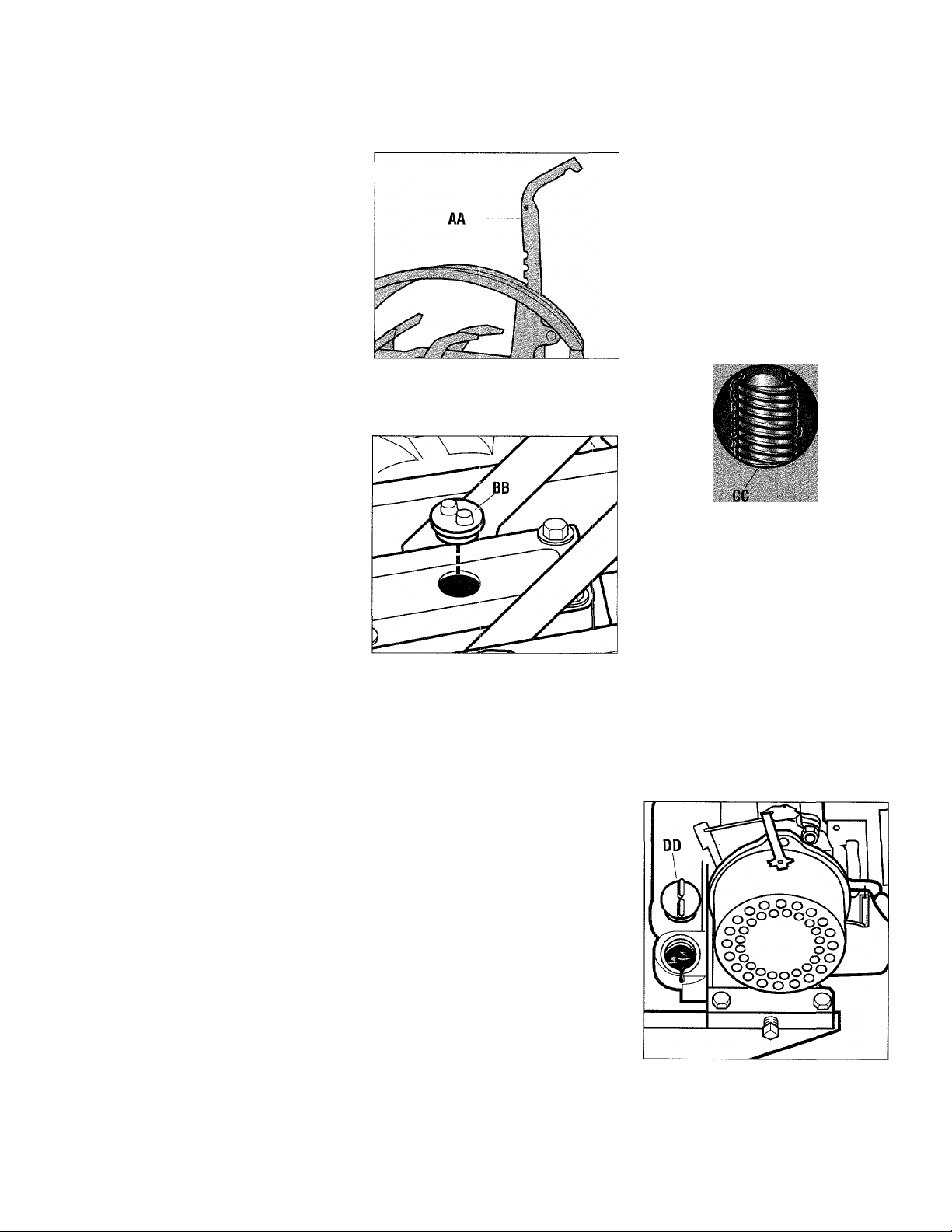

6. Check Level of

Transmission Gear Oil

The transmission was filled with

gear oil prior to being shipped.

However, you should check the

gear oil level to make certain it is

correct.

1. With the tiller on level ground,

pull the Depth Regulator Lever

(AA, Fig. 2-8) back and then all

the way up until the lowest notch

in the lever is engaged.

2. Remove the plastic fill plug

(BB, Fig. 2-9) from the transmis

sion housing and look into the

filler hole.

3. Inside the hole there is a

grooved worm (CC, Fig. 2-10) on

the drive shaft. If the gear oil level

is correct, the gear oil should be

approximately half way up the

sides of the worm.

4. If the gear oil level is low, add

gear oil by referring to “Checking

and Topping off Transmission

Gear Oil” on Page 24. DO NOT

OPERATE TILLER IF GEAR

OIL LEVEL IS LOW. SEVERE

DAMAGE TO TRANSMISSION

WIEL RESULT.

Fig. 2-8: Adjust Depth Regulator

Lever.

Fig. 2-9: Remove gear oil fill plug.

lO NÛ

c>—b

Fig. 2-10: Gear oil should be half

way up sides of worm.

7. Add Motor Oil to Engine

The tiller is shipped without oil in

the engine. PERMANENT EN

GINE DAMAGE WILL RESULT

IF THE ENGINE IS RUN WITH

OUT OIL.

1. Refer to the Engine Owner’s

Manual (supplied with tiller) for

engine oil specifications and

capacities.

2. With the tiller on level ground,

pull the Depth Regulator Lever

(AA, Eig. 2-8) back and then all

the way up until the lowest notch

in the lever is engaged.

3. Unscrew the engine oil fill plug

(DD, Fig. 2-11). Using a clean

funnel, slowly add oil until the oil

level reaches the overflow point in

the oil fill tube. ALWAYS

MAINTAIN THE OIL LEVEL AT

THE OVERFLOW POINT.

4. Securely replace the oil fill plug.

8. Check Hardware for

Tightness

Check all nuts and screws for

tightness.

IMPORTANT: Before operating

your tiller, make sure you read the

following Sections in this Manual,

as well as the separate Engine

Owner’s Manual;

• Section 1: “Safety”

• Section 3: “Tiller and Engine

Controls”

• Section 4; “Operation”

11

Fig. 2-11: Add motor oil to engine.

Page 12

Section

Learn the locations of the tealiires

and controls on your machine

before starting the engine. Taking

the time now to understand the lo

cation. function and operation of

these controls v.'lll greatly add to

the productive use. safe operation,

and enjoyment of your machine.

For detailed step-by-step operating

instructions, please refer to

"Section ■ 1; Operation."

TILLER FEATURES AND CONTROLS IDENTIFICATION

The major tiller controls and features are identified and illustrated on the

next few pages. The use and operation of each control and feature is cov

ered in detail in Section 4 “Operating Instructions.”

A WARNING

TO AVOID PERSONAL INJURY OR

DAMAGE TO EQUIPMENT:

Before using your tiller for the

first time, become thoioughiy fa

miliar with the operation of the

controls by moving them to their

various positions while the en

gine is not running. The proper

operation of each control is dis

cussed in detaii in Section 4.

NOTE:

All references to left, right,

front and rear of the machine are

determined by standing behind the

handlebars and facing the direction

of forv/ard travel.

Figure 3-1: A- Wheel Drive Pins; B- Forward dutch Baii; C- Depth

Regulator Lever; D- Handlebar Height Adjustment; E- Engine Throttie

Lever; F- Engine Choke Lever; G- Engine Recoii Starter.

A) Wheel Drive Pins

These two pins (one on each

side of the wheel shaft), secure the

wheels to the wheel shaft and can

be positioned by you to put the

wheels in either a WHEEL DRIVE

or a FREEWHEEL mode.

Before starting the engine, put

both wheels in the WHEEL

DRIVE position by inserting the

Wheel Drive Pins through the

holes in both the wheel shaft and

wheel hub on both sides of the

tiller. This “locks” the wheels to

the wheel shaft, causing the wheels

to turn when you engage the

Forward Clutch Bail.

Use the FREEWHEEL position

only when the engine is off. This

A

position lets you easily push or

pull the tiller. To use FREE

WHEEL, place the Wheel Drive

Pins only through the holes in the

wheel shaft. This keeps the wheels

on the shaft, but allows the wheels

to rotate when you push or pull the

tiller handlebar.

WARNING

Never let either of the wheels

be in FREEWHEEL position

when the engine is running.

Always put both wheels in the

WHEEL DRIVE position before

starting the engine.

Failure to comply could cause

loss of tiller control, property

damage, or personal injury.

12

Page 13

To Place Wheels in WHEEL DRIVE

Position:

1. The engine must be shut off

and cool. Disconnect spark plug

wire and move it away from the

spark plug.

2. Raise one wheel off the ground

and place a sturdy support under

the transmission.

A

WARNING

Do not place tiller on its side

when changing wheel drive

positions or gasoline could

leak from the fuel tank.

Failure to follow this instruc

tion could result in personal

injury or property damage.

3. Remove the hair pin cotter from

the wheel drive pin and pull out

the wheel drive pin.

4. Slide the wheel outward and

align the holes in the wheel hub

and wheel shaft. Insert the wheel

drive pin through these holes (see

Figure 3-2). Insert the straight leg

of the hair pin cotter into the hole

in the wheel drive pin as far as it

will go.

5. Repeat the above steps for the

other wheel, then remove the sup

port under the transmission.

To Place Wheels in FREEWHEEL

Position:

1. Follow steps l-through-3 of “To

Place Wheels in WHEEL DRIVE

Position.”

2. Slide wheel inward on wheel

shaft as far as possible.

3. Insert wheel drive pin only

through the hole in the wheel shaft.

Insert the straight leg of the hair

pin cotter into the wheel drive pin

as far as it will go. See Figure 3-3.

4. Repeat Steps l-through-3 for

the other wheel. Remove the sup

port beneath the transmission.

B) Forward Clutch Bail

The Forward Clutch Bail (Photo

3-4) is used to engage or disengage

(stop) the tiller wheels and tines.

WARNING

Before starting the engine, be

sure that both wheels are in

the WHEEL DRiVE position.

See “Wheel Drive Pins” for

instructions.

Failure to comply could result

in ioss of tiller control, personal

injury or property damage.

Operate the Forward Clutch Bail

as described below:

1. Put the wheels in the WHEEL

DRIVE position.

2. Rest one hand, palm down, on

top of the handlebar.

3. Use the other hand to lift up and

hold the Forward Clutch Bail. See

Photo 3-4. When the bail is in this

position, the wheels/tines will rotate.

4. To stop forward motion of

wheels/tines, release the Forward

Clutch Bail.

13

am

r

Photo 3-4: Operating the Forward

Clutch Bail.

Page 14

Features ani Controls

C) Depth Regulator Lever

A

WARNING

Do not attempt to till too

deeply too soon. Gradually

work down to deeper tilling

depths.

Failure to do so could result

in loss of tiller control, per

sonal injury or property damage.

This lever controls the depth

that the tines penetrate the soil (see

Figure 3-5). Adjust the lever to

change tilling depth by pulling

back on it and moving the lever up

(for deeper tilling) or down (for

shallower tilling).

To place the tines in the “travel”

position, move the lever down to

the highest notch. This raises the

tines above the ground and allows

the tiller to be moved without till

ing. Do not attempt to till too

deeply too soon. Begin tilling with

the lever adjusted down in one of

the shallower settings. Gradually

increase tilling depth by moving

the lever upward.

Figure 3-5: Depth Reguiator Lever.

D) Handlebar Height Adjustment

You can adjust the tiller handle

bar height to any one of three posi

tions. (See Figure 3-6.) As a gen

eral guide, adjust the handlebars so

they are at waist level when the

tines are 3"-to-4" into the soil.

WARNING

Before adjusting handlebar

height, shut off the engine,

let it cooi down, let all mov

ing parts stop completely,

then disconnect the spark

plug wire and move it away

from the spark plug.

Failure to do so can cause per

sonal injury or property damage.

Figure 3-6: Handiebar adjustment

offers three height settings.

ENGINE CONTROLS

WARNING

Release the Forward Clutch

Bail before adjusting the

Engine Throttie Lever.

Failure to comply could result

in personal injury or property

damage.

Figure 3-7: Engine Throttie Lever

(“A”) adjusts engine speed. Engine

Choke Lever (“B”) is used to assist

starting when engine is coid.

E) Engine Throttie Lever

Adjust this lever (see A, Figure

3-7) to start and stop the engine

and to regulate engine speed.

• To increase engine speed, move

the lever upward to FAST (Rabbit

symbol) position.

• To decrease engine speed, move

the lever down toward SLOW

(Turtle symbol) position.

• To stop the engine, move

the lever all the way down to

STOP position.

• To start the engine, move

the lever to the FAST

(Rabbit symbol) position.

F) Engine Choke Lever

The Choke Lever (B,

Figure 3-7) allows a richer

air/gasoline mixture (more

gasoline) to enter the engine

cylinder to make starting a

cold engine easier. The lever

has three settings: FULL

Photo 3-8: The Engine Recoii Starter rope is

used to start the engine.

CHOKE, PARTIAL CHOKE and

NO CHOKE.

Detailed instructions for using

the Choke Lever are provided in

the Operation Section (Section 4).

G) Engine Recoil Starter

The Engine Recoil Starter (refer

to Photo 3-8) is used to start the

engine. For full instructions on the

use of this control, see Section 4.

14

Page 15

Section

• Break-In Operation

• Pre-Start Checklist

As with any other piece of outdoor

powered equipment, getting the

• Starting the Engine

• Stopping the Engine

“feel” for how your machine oper

ates and getting to know the best

techniques for particular jobs are

very important to overall good per

formance.

Read this Section very thoroughly

before you start the engine. The

instructions given here will help you

familiarize yourself

wth

your ma

• Guiding The Tiller

• Tilling Depths

• Moving the Tiller Forward

• Moving the Tiller Rearward

• Turning the Tiller Around

chine and have you operating it ef

fectively in a short time.

A WARNING

Before operating your machine,

be sure you read and understand

ail safety, controls, and all

operating instructions in this

Owner/Operator Manual and on

the decals on your machine.

Failure to follow these instructions

can result in serious injury or

property damage.

NOTE: Ail references to left, right,

front and rear of the machine are de

termined by standing behind the

handiebars and facing the direction

of forward travel.

This Section

Break-In Operation

ing maintenance during the first

few hours of new tiller operation.

Refer to the Maintenance Section

for regularly scheduled mainte

nance procedures.

1. Change engine oil after the first

two hours of new tiller operation.

2. Check the transmission gear oil

level after the first two hours of

operation.

3. Check the tension on the for

ward drive belt after the first 2-to-3

hours of operation.

4. After the first two hours of op

eration, check all fasteners (nuts,

bolts, screws) for tightness.

explains:

Tilling in the Garden

Seedbed Preparation

Cultivating

Power Composting

“High Traction” Frame Weights

Preventing Tangling on Tines

Tilling on Slopes

Terrace Gardening

Loading/Unloading the Tiller

Be sure to perform the follow

15

Page 16

Pre-Start Checklist

Move the tiller to a level area,

then make the following checks

and perform the following services

before starting the engine.

1. Disconnect Spark Plug Wire.

Starting the Engine

1. Do not engage (hold) the

Forward Clutch Bail against the

handlebar.

2. Both wheels must be in the

WHEEL DRIVE position (see

Figure 3-2).

2. Check Engine Oil Level.

3. Check the Air Cleaner. It must

be securely assembled and clean.

4. Check Safety Guards. All

guards and covers must be fastened

securely in place.

5. Check Engine Cooling System.

The cooling fins and air intake

screen must be clear of debris.

6. Adjust Handlebar Height.

7. Check that the Wheels are in

the WHEEL DRIVE position.

8. Put Gasoline in the Fuel Tank.

Use fresh, clean, unleaded fuel.

Fuel goes stale if stored for more

than six months. Do Not Mix Oil

With Gasoline!

a. Clean the fuel cap area before

removing the fuel cap.

h. Use a clean funnel to add gas.

c. Fill tank to within 1/2” of the

top to prevent spills and allow

for fuel expansion.

3. Move the Choke Lever to the

FULL CHOKE position. (An en

gine which is warm from operation

may start without moving the

Choke Lever at all.)

4. Move the Engine Throttle Lev

er fully up to FAST (Rabbit) posi

tion which is used for starting.

9. Put Depth Regulator Lever in

the “travel” position.

WARNING

Always place both wheels in

the WHEEL DRIVE position

before starting the engine.

Never have the wheels in the

FREEWHEEL position when

the engine is running. When

the wheels are in FREE

WHEEL, they do not hold

hack the tiller, and the tines

could propel the tiller forward

rapidly.

Failure to comply could result

in serious personal injury or

property damage.

5. Place your left hand on the

gasoline tank to stabilize the tiller

when starting.

6. Use your right hand to slowly

pull the recoil starter rope until you

feel resistance. Then rapidly pull

the starter rope outward. (First

check for any obstacles behind you.)

Repeat until the engine starts.

?■ - '_______

■■■

■ 'W

'

>

■V.#

Photo 4-2: Pull Recoil Start Rope

out rapidly to start engine.

7. Once the engine is running, grad

ually move the Choke Lever to the

NO CHOKE position.

8. Move the Engine Throttle Lever

to the position that provides the de

sired engine speed.

10. Reconnect Spark Plug Wire.

^ DANGER

Do not run the engine in

doors. Engine exhaust con

tains carhon monoxide, a

deadly gas that is colorless,

odorless and tasteless.

Failure to follow this instruc

tion could result in serious

personal injury or property

damage.

A

DANGER

Gasoline is highly flammable and its vapors are explosive. Follow

these safety practices to prevent injury from fire or explosion:

• Never fill tank if engine is running or hot from use. Let engine and

muffler cool down before refueling.

• Do not permit open flames, sparks, matches or smoking in fueling area.

• Fill fuel tank outdoors in a well-ventilated area. Wipe up any fuel

spills and move tiller away from fumes before starting the engine.

• Use only an approved fuel container and lock it safely away from

children.

• Store fuel and the tiller in a well-ventilated area. Do not store fuel or

tiller where fuel vapors may reach an open flame or spark, or an igni

tion source (a hot water heater, furnace, clothes dryer, electric motor,

or the like).

• Let engine cool before storing.

16

Page 17

/i

Stopping the Engine

1. Release the Forward Clutch

Bail to stop the wheels and tines

from turning.

2. Move Engine Throttle Lever to

STOP position to stop the engine.

NOTE; If moving the Engine

Throttle Lever to STOP does not

shut off the engine, you can stop

the engine by moving the Choke

Lever to the FULL CHOKE posi

tion. However, do not continue to

stop the engine using the Choke

Lever because doing so may dam

age the engine. Repair the Engine

Throttle Lever as soon as possible.

Guiding the Tiller

When tilling, relax and let the

tiller move along at its own speed.

Do not push the tiller to make it

move faster. Do not push down on

the handlebars to make the tines

dig more deeply.

Walk beside the tiller on the un

tilled side. Use one hand, yet keep

a firm hand grip on the handlebar

(while keeping your arm loose) to

guide the tiller. Walking alongside

keeps you from disturbing the

newly tilled soil and replanting any

weed seeds which the tines might

have brought up to the surface. It

is also easier to control the tiller in

hard or rocky soil if you walk be

side it guiding it with one hand.

(Instead of walking behind it, con

trolling the tiller with two hands.)

Photo 4-3: Tilling With Just One

Hand is recommended.

Tilling Depths

WARNING

Always begin tilling at a shal

low Depth Regulator Lever

setting and gradually work

down to deeper settings.

Failure to comply could result

in loss of tiller control, prop

erty damage or personal injury.

Do not try to till too deeply at

first. Gradually raise the Depth

Regulator Lever (one notch at a

time) so the tiller digs slightly

deeper with each pass. This allows

thorough tilling and minimizes the

chance of the tiller jumping or

“bucking.”

When cultivating between rows,

use a shallow Depth Regulator

Lever setting. This will get rid of

in-row weeds, but prevent the tines

from digging deeply enough to

damage plant roots.

Moving the Tiller Forward

IMPORTANT: Before you begin

tilling, move the tiller to a safe,

level area and practice maneu

vering the tiller w ithout actually

tilling. Keep the Depth

Regulator Lever in the “travel”

position. After you become fa

miliar with the handling of your

tiller, you can move it into the

garden and begin tilling.

1. Put the wheels in the WHEEL

DRIVE position (wheel pins must

be through the wheel hubs and the

axle holes).

2. Start the engine.

3. Move the Depth Regulator

Lever to the desired position.

4. For forward motion of the

wheels and tines, lift and hold the

Forward Clutch Bail against the

handlebars. The wheels and tines

will rotate as long as the bail is

held in this position.

5. As the tiller moves forward, let

the wheels pull the tiller along. Do

not push the tiller to make it go

faster. Allow the tiller to move

along at its own speed.

A

6. To stop the wheels and tines, re

lease the Forward Clutch Bail. The

engine will continue to run until

stopped by moving the Engine

Throttle Lever to the STOP position.

WARNING

Do not push down on the han

dlebars to try to make the

tiller till more deeply. This

prevents the wheels from

holding the tiller back and

can allow the tines to rapidly

propel the tiller forward,

which could result in loss of

control, property damage, or

personal injury.

Moving the Tiller Rearward

The tiller weighs only 117

pounds, so it is quite easily maneu

vered rearward for short distances

by using the follow procedure:

1. Release the Forward Clutch

Bail.

2. Tilt the tiller slightly forward

until the tines are out of the soil.

3. Place both hands on the corners

of the handlebars. Tilt the tiller

slightly to raise the right wheel off

the ground.

4. Slowly swing the handlebars to

the left so the right wheel takes a

“step” toward the rear.

5. Set the right wheel back down.

6. Now tilt the tiller so the left

wheel is slightly off the ground

and slowly move the handlebars to

the right so the left wheel takes a

step backward.

7. Repeat to “walk” your tiller

rearward.

17

Page 18

Turning the Tider Around

Practice turning your tiller in an

open, level area until you feel

comfortable with the procedure.

1. As you near the end of a row,

lift the handlebars so the tines clear

the ground. Refer to Photo 4-4.

2. As you come out of a row,

swing the handlebars to the side,

pivoting the tiller 180°, so you can

line up with the next row. See

Photo 4-5.

3. As the tiller enters the next row,

lower the handlebars slowly until

the tines start to till.

Tilling in the Garden

The following pages provide

many ideas about using the tiller in

the garden. You can often design

your garden layout to obtain the

most beneficial use from your

tiller.

‘J'.-v;.

Photo 4-4: Exiting a row in the garden.

Seedbed Preparation

Prior to planting, be sure the soil

is as loose and finely textured as

possible due to proper tilling.

About two or three weeks before

planting, till the garden two or

three times. Then, till once more

before planting. This final tilling

helps plants get a head start on fu

ture weed growth.

When preparing the soil, go

over the same path twice in the

first row. Then overlap one-half

the tilling width on each succeed

ing pass. See Figure 4-6. After

going up and down the rows in one

direction, make a second pass at a

right angle across your earlier

rows. See Figure 4-7. Again,

overlap each pass to really pulver

ize the soil. (In very hard ground,

three or four passes may be

needed.)

If your garden isn’t long enough

to till lengthwise and then cross

wise, first overlap each pass by

Photo 4-5: Lining up the tiller to enter the next row.

c

Figure 4-6: Initial tilling pattern.

18

one-half a tilling width, followed

by successive passes of one-quar

ter a tilling width. See Figure 4-8.

Don't till when the soil is too wet.

This produces

large clumps

which later dry

out and become

hard. If the soil

compresses eas

ily into a ball, it

is still too wet to

be tilled.

Avoid Making Footprints

When tilling, al

ways try to walk

alongside the

tiller on the side

that is yet to be

tilled. This pre

vents replanting

weed seeds and

leaves a nice ap

pearance.

Figure 4-8:

Tilling narrow

strips.

Page 19

Cultivating

When planning your garden,

keep in mind that the tiller has a

tilling width of approximately 14”.

Allow at least this width between

rows in your garden— plus addi

tional width for plant growth.

Take into account that bushy plants

like beans and tomatoes need more

width. Refer to Photo 4-9.

When cultivating, use a shallow

Depth Regulator Lever setting. Do

not cultivate deeper than l"-or-2".

Shallow cultivating keeps weed

growth to a minimum and doesn’t

damage plant roots.

For best results, begin cultivat

ing as soon as seedlings appear,

and then cultivate as often as once

a week. The day after a light rain

is an excellent time to cultivate, as

long as the plants are dry. Avoid

working in the garden when plants

are wet. Diseases, blight, and rust

can be easily spread among wet

plants with your hands, clothing or

even the tiller.

helps replace any nutrients har

vested (as vegetables), and also

improves soil structure.

A simple method of power com

posting is to chop, blend and till

under leafy crop residues, leaves,

grass clippings and “green ma

nure” crops. This organic matter

will decompose and add important

nutrients back into garden soil.

When composting, put the

Depth Regulator Lever at the deep

est setting that does not allow the

tiller to jump or cause the engine

to labor.

CAUTION

When power composting, do

not keep the Depth Regulator

Lever at a deep setting if the

tiller jumps or bucks.

If jumping or bucking occurs,

move the Depth Regulator

Lever down to one of the

shallower settings and then

slowly increase the tilling

depth on later passes.

Failure to comply could result

in loss of tiller control, prop

erty damage or personal injury.

Till crop residues back into the

soil as soon as the vegetables are

harvested. Green, tender crops are

more easily tilled.

Since the tiller is a compara

tively lightweight machine, we

don’t recommend it for power

composting large standing crops

such as cornstalks. However, you

can uproot the leftover green corn

stalks, run them through a shred

der, or chop them into smaller

pieces and then scatter them on

your garden. This allows you to

power compost them back into the

soil.

After tilling under crop residues,

you can plant a cover crop such as

buckwheat, annual ryegrass, peas,

or beans to protect your garden

soil. This builds soil, adds nutri

ents to the garden and helps con

trol soil erosion.

High-Traction Frame Weights

The “High-Traction” Frame

Weight Kit is a handy accessory

for your tiller. This kit consists of

two 13-1/2 lb. cast iron weights

which attach to the tiller frame

right above each wheel axle.

V ■

Photo 4-9: Cultivating within rows.

Power Composting

To keep your garden productive,

regularly till organic matter back

into the soil (Photo 4-10). This

To till very heavy soil or im

prove tiller traction, the weights

are what you need. The weights

allow you to till under tougher

conditions and till deeper at a

somewhat faster rate.

V- i- ^

Photo 4-10: Power Composting

“feeds” your garden.

19

Page 20

Preventing Tines From Becoming Tangled

When power composting, you

may find that the tines become tan

gled with material (tall vegetation,

long grass, tough vines, etc.).

WARNING

Before removing any debris

from the tines, stop the en

gine, allow it to cool, discon

nect the spark plug wire and

move it away from the spark

piug.

Failure to do so could result

in personal injury or property

damage.

To help prevent tangling:

1. While tilling, swing the handle

bars from side-to-side about 6”-to-

12". This “fishtailing” action will

often dislodge any debris.

2. Always use the deepest Depth

Regulator Lever setting possible

(without making the tiller jump or

buck upward).

3. Till under cover crops and crop

residues while they are still green.

4. Shred or chop up any tall,

tough, or stringy organic matter

before tilling it into the soil.

5. You may have to mow or cut

vegetation before power composting.

6. If the tines are heavily tangled,

stop the engine and disconnect the

spark plug wire. Then, cut away

any debris.

Tilling on Siopes

Plant your garden preferably on

flat ground, but certainly on no

more than a moderate slope. Do

not operate the tiller on a slope that

is too steep for safe operation.

Plant garden rows vertically on

a slope (up and down the slope).

This lets you use the entire area for

a seedbed and leaves enough room

between the rows for cultivation.

You lose these valuable benefits

when you terrace garden (dis

cussed later).

If you put enough organic mate

rial into your garden’s soil to im

prove its water-holding capabili

ties, you should not have a prob

lem with soil erosion.

When you begin to till vertically

on a slope, start at the bottom and

go up. The tines dig in more

deeply when you go uphill than

when you go downhill. As you

turn around at the top to go back

down the hill, overlap the uphill

pass by about half the tilling width.

WARNING

A

Do not operate the tiller on a

slope that is too steep for

safe operation. Till slowly

and be sure that you have

good footing.

oil level is full to the point of over

flow from the oil check tube before

starting to till. Also check the oil

level every thirty minutes while

you’re tilling on a slope.

Terrace Gardening

If your garden is too steep or too

short for vertical tilling, you may

have to till across the slope. To

achieve best results, use your tiller

to create terraces for your garden.

Make the terrace 2-to-3 feet

wide. You can plant one or two

rows of plants in each terrace and

later till the plants under.

However, you may not have

enough room to use the tiller for

cultivating. If you make the ter

race too wide, you would have to

dig as much as a foot into the up

hill side of the terrace and would

end up trying to grow plants in

poor subsoil.

Start to terrace at the top of the

slope and work down. Always

keep the uphill wheel in soft,

newly tilled soil. Start each suc

ceeding terrace by walking below

the terrace you are preparing. In

three or four passes you can create

a terrace wide enough for planting.

Leave at least a 12" wide un

tilled space between terraces.

Keeping the soil unbroken here

will help prevent the terraces from

breaking apart. Refer to the next

page - see Figure 4-12 - for im

portant information on making ter

race gardens.

Photo 4-11: Cutting tangled tines.

Failure to do so could result

in personal injury or property

damage.

NOTE: When you till on a slope,

the oil level in the tiller engine

slants toward the downhill side of

the engine. Some internal parts

may not get enough oil. To pre

vent this, make sure that the engine

20

Page 21

UPHILL

12" UNTILLED

REPEAT

DOWNHILL

Figure 4-12: Creating a terrace in just three passes with the tiller.

Loading and Unloading

the Tiller

CAUTION

Loading and unloading a

tiller into or from a vehicle is

potentially hazardous. We do

not recommend that you do

so unless absolutely neces

sary because this could result

in personal injury or property

damage.

If loading or unloading must

be undertaken, use the fol

lowing guidelines to assist

you.

• Shut the tiller engine off before

loading or unloading. Allow the

tiller engine to cool, disconnect the

spark plug wire and prevent the

wire from touching the spark plug.

• The tiller is too heavy (over 115

lbs.) and bulky to be safely lifted

by one person. If you do lift the

tiller, two or more people should

share the load.

• We recommend that you use

sturdy ramps and that you manu

ally roll the tiller into or out of the

vehicle (tiller engine must be off).

This requires the assistance of an

other person.

• Ramps should be strong enough

to support the tiller and those mov

ing it. The ramps should provide

good traction; they should have

side rails to guide the tiller up and

down the ramps; and they should

have a locking device to secure

them to the vehicle bed.

• The operator and handlers

should wear sturdy footwear that

grips well to prevent slips.

• Position the vehicle so the ramp

angle is as flat as possible. Turn

the vehicle engine off and apply

the vehicle parking brake.

•

• When going UP ramps, stand in

the normal operating position and

push the tiller ahead of you.

Position a person at each wheel to

turn the wheels.

• When going DOWN ramps,

walk backward down the ramps

with the tiller following you. Keep

alert for and avoid any obstacles

which could cause you to fall.

Position a person at each wheel to

control the speed of the tiller.

Never go down ramps tiller-first,

because the tiller could tip for

ward.

• Have wood blocks handy to

place on the downhill sides of the

wheels if you need to stop the tiller

from rolling down the ramps while

loading or unloading. Use the

blocks to temporarily keep the

tiller in place on the ramps while

you get a firmer grip on the han

dlebars, reposition the tiller, etc.

Also use the block to keep the

wheels in place after tieing down

the tiller.

• After positioning the tiller in the

vehicle, be sure both wheels are

engaged in the WHEEL DRIVE

position to prevent the tiller from

moving. Then securely tie down

the tiller.

21

Page 22

Section

]

Carefully read this Section on en

gine and tiller maintenance and

service.

Performing the required mainte

nance according to schedule will

ensure the proper performance

and long life of your machine.

A CAUTION

Before inspecting, cleaning or

servicing the machine, shut off

engine, make sure that ail mov

ing parts have come to a com

plete stop, then disconnect

spark plug wire and move wire

away from spark plug.

Failure to follow these instruc

tions can result in personal in

jury or property damage.

NOTE:

All references to left, right,

front and rear of the machine are

determined by standing behind the

handlebars and facing the direction

of forward travel.

Subjects covered in this Section include:

Regular Maintenance

Tiller Lubrication

Checking and Adding Engine Oil

Changing Engine Oil

Checking Transmission Gear Oil

Changing Transmission Gear Oil

Checking for Oil Leaks

Air Cleaner Maintenance

Engine Cooling System Maintenance

Engine Ignition System Maintenance

Tightening Tiller Hardware

Removing and Installing Tine Assemblies

Removing and Installing Single Tines

Checking and Adjusting Belt Tension

Belt Removal and Replacement

Forward Clutcb Bail Adjustment

Tiller Storage

REQUIRED MAINTENANCE SCHEDULE

Before

REQUIRED MAINTENANCE

Each

Use Hours

Check Engine Oil Level

Clean Engine Cooling Fins

Check Bolts and Nuts

Change Engine Oil

Check Tension on Drive Belt

Lubricate Tiller

Check Transmission Gear Oil Level

Check Tines for Wear

Inspect Spark Plug

Replace Paper Air Filter Cartridge

Every Every Every As

10

30 50 Noted

Hours Hours

•

•

•

•

•

•

•

•

1

3

2

3

4

o

«

5

NOTE 1 - Check frequently during first 2 hours of new operation; thereafter every 5 hours.

NOTE 2 - Change after 2 initial operating hours; thereafter every 10 hours.

NOTE 3 - Check after 2 initial operating hours; thereafter every 10 hours.

NOTE 4 - Check after 2 initial operating hours; thereafter every 30 hours.

NOTE 5 - Replace more often if used in extremely dusty or dirty conditions

22

Page 23

Malriteiiaiice/Eepairs

Regular Maintenance

Because the tiller is operated in

the garden, frequently under hot

and dirty conditions, regular main

tenance is very important to ensure

that you are getting proper perfor

mance from your tiller. There are

several items of maintenance that

will help keep your tiller in good

operating condition:

• Change engine oil regularly.

• Lubricate the controls regularly.

• Keep the correct tension on the

forward drive belt.

• Replace the engine air cleaner

element when dirty.

• Keep engine cooling fins clean.

Tiller Lubrication

Refer to Photos 5-1 and 5-2 for

the lubrication points on your tiller.

5. Shifting Mechanism

Carefully oil all of the pivot points

on the shifting mechanism (“5”,

Photo 5-2.

NOTE: When you oil the pivot

points on the shifting mechanism,

be sure that you do not get any oil

on either the belt or the pulleys.

Otherwise, the belt could slip and

be unable to transfer engine power

to the transmission.

Checking and Adding Engine Oii

NOTE: Check the engine oil level

frequently during the first two hours

of engine break-in operation.

Always check the engine oil

level before starting the engine

(refer to Figure 5-3 below). When

operating the tiller, stop the engine

and check oil level every 5 operat

ing hours. Running the engine

when low on oil can cause expen

sive damage. Keep oil level at the

overflow point in the oil fill hole.

^ WARNING

stop the engine, allow it to

cool, disconnect the spark

plug wire from the spark plug

and move the wire away from

the plug before checking en

gine oil level.

Failure to do so could result

in personal injury or property

damage.

Use ordinary, clean motor oil

(#30 weight) when oil is called for.

When possible, use a good quality

grease with a metal lubricant addi

tive. However, regular automotive

grease is acceptable.

1. Wheel Shaft

Remove the wheels and use a clean

rag to wipe off old grease from the

wheel shaft (“1”, Photo 5-1).

Inspect the shaft and use fine sand

paper to remove any rust or burrs.

Apply new grease to the wheel

shaft. This makes future wheel re

moval easy.

2. Depth Regulator Lever

Clean and grease the back, front

and sides (refer to “2”, Photo 5-1).

3. Handlebar Support Bolts

Oil the threads on both handlebar

support bolts (“3”, Photo 5-1).

4. Tine Shaft

Remove the tine holder assemblies

and clean any rust or burrs from

the shaft (“4”, Photo 5-1) with a

fine sandpaper. Liberally apply

grease to the tine shaft.

Photo 5-1: Tiller lubrication points.

-•''V

Photo 5-2: Lubrication points on

shifting mechanism.

Figure 5-3: Oil Fill Plug location.

23

Page 24

Checking Engine Oii Levei:

1. Move the tiller to a level area.

2. Pull the Depth Regulator Lever

all the way up until it is in the bot

tom notch.

3. Unscrew the oil fill plug from

the right side of the engine (see

Figure 5-3).

4. If the oil level is correct, the

level will crest at the top of, or

begin to flow from, the oil fill

tube. Reinstall the oil fill plug.

5. If the level of the oil was below

the very top of the fill hole, oil

must be added as follows.

Adding Engine Oii:

1. Insert a clean funnel into the oil

fill hole.

2. Select the correct type and

weight of engine oil according to

the separate Engine Owner’s

Manual.

3. Slowly pour oil into the funnel.

Check the oil level frequently

while pouring. (Remove the fun

nel when checking.) When the oil

just begins to overflow, the level is

correct.

4. Replace the oil fill plug securely.

Changing Engine Oil

Change the engine oil after the

first two hours of initial tiller opera

tion. Thereafter, change the engine

oil every ten operating hours.

NOTE: The engine manufacturer

recommends that the engine oil be

changed after 25 hours of operation.

Because the tiller is constantly op

erated in a dusty, dirty environment,

we recommend that you change the

oil every 10 operating hours (or

even sooner if the environment is

extremely dirty or dusty).

Changing the engine oil removes

impurities and contaminants which

would otherwise increase wear on

internal engine parts. New oil as

sures that the various internal mov

ing parts of the engine receive

proper lubrication.

^ WARNING

stop the engine, allow it to

cool, disconnect the spark

plug wire and prevent it from

touching the spark plug be

fore changing the engine oil.

Do not touch any engine parts

which may be hot.

Failure to do so could result

in personal injury or property

damage.

1. Start the engine and allow it to

mn until it is warm. Then TURN

THE ENGINE OEF.

2. There are two engine oil drain

plugs on either side of the engine

base. Use whichever one is most

conveniently located for you.

3. Place a 2"x 4" wood board under

the wheel opposite the drain plug

you’ll be removing.

4. Place a drain pan with a mini

mum capacity of 1-quart beneath

the drain plug.

Photo 5-4: Draining engine oil.

5. Use a 3/8" open end wrench to

remove the drain plug. Put it aside.

Let all of the old engine oil drain

completely into the drain pan.

6. Reinstall the drain plug securely.

7. Remove the wood board from

beneath the wheel.

8. Refill the engine with the correct

type and weight of engine oil. See

your separate Engine Owner’s

Manual for specifications.

9. Check the oil level to be sure it

is correct before starting the engine.

WARNING

stop the engine, allow it to

cool, disconnect the spark

plug wire and prevent it from

touching the spark plug be

fore checking, adding or

changing the transmission

gear oil. Do not touch any

engine parts which may be

hot.

Failure to do so could result

in personal injury or property

damage.

Checking and Topping-Off Transmission Gear Oil

Checking Transmission Gear Oil:

1. Move the tiller to a level area.

2. Pull the Depth Regulator Lever

all the way up.

3. Unscrew the filler/check plug

from the top of the transmission (it

is located just behind the belt cover).

4. Use a flashlight to look down

into the filler/check plug hole. Note

the worm gear on the drive shaft

(refer to Figure 5-5 inset). Look on

either side of the worm gear to see

the surface of the gear oil. If the

gear oil level is correct, it should be

halfway up the sides of the worm

gear. If topping off is required, fol

low instructions given next.

24

Page 25

Photo 5-5: Checking the transmis

sion gear oil level. The Inset Figure

shows the worm gear.

Topping off Transmission

Gear Oil

1. Complete steps l-through-3 de

scribed in “Checking Transmission

Gear Oil.”

2. Insert a funnel into the

filler/check plug hole.

NOTE: When adding only a few

ounces of gear oil, use API rated

GL-3 or GL-5 transmission gear

oil with a viscosity of SAE 140,

SAE 85W-140, or SAE 80W-90.

(Straight SAE 140 with an API rat

ing of GL-3 is preferred). When

adding a complete refill of new

gear oil after having drained the

transmission, refill only with

SAE 140 or SAE 85W-140 with

an API of GL-3.

3. Slowly pour clean gear oil into

the transmission. Frequently

check the level so as not to overfill

the transmission. See Figure 5-6.

4. When the gear oil level is cor

rect, reinstall the filler/check plug

securely.

Figure 5-6: Gear oil fill hole.

Changing Transmission Gear Oil

The transmission gear oil does

not have to be changed unless you

know that it has been contaminated

by foreign materials such as sand,

dirt, or metal particles. Of course,

any internal repairs on the trans

mission would also require that the

gear oil be drained and changed.

1. Drain gasoline from the fuel

tank or run the engine until the fuel

tank is empty.

2. Drain the oil from the engine.

3. Remove the four bolts and

washers securing the transmission

cover to the front part of the trans

mission. Lift the cover and gasket

off the transmission. See Photo 5-7.

4. Remove the left wheel.

5. Lower the left axle down into a

drain pan and slowly tilt the tiller

to the left so the gear oil drains

from the top of the transmission

into the drain pan. See Photo 5-8.

6. Once gear oil has drained, tilt

tiller upright and reinstall wheel.

7. Reinstall the transmission cover

using a new cover gasket.

8. Add new gear oil—see specifi

cations in NOTE at left.

9. Add engine oil to the engine.

DANGER

Gasoline is highly flammable

and its vapors are explosive.

Follow these safety practices

to prevent personal injury or

property damage from fire or